Automatic carton folding production line

A production line and carton technology, which is applied to the improvement of the structure of the automatic folding production line of the carton, can solve the problems of mutual interference of the raw cardboard on both sides, the glue contaminates the surface of the carton, and affects the product quality, etc. Guaranteed not to be contaminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

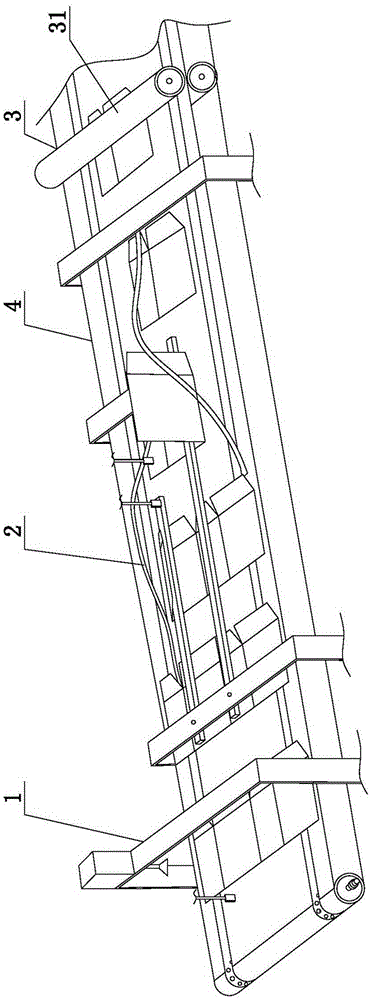

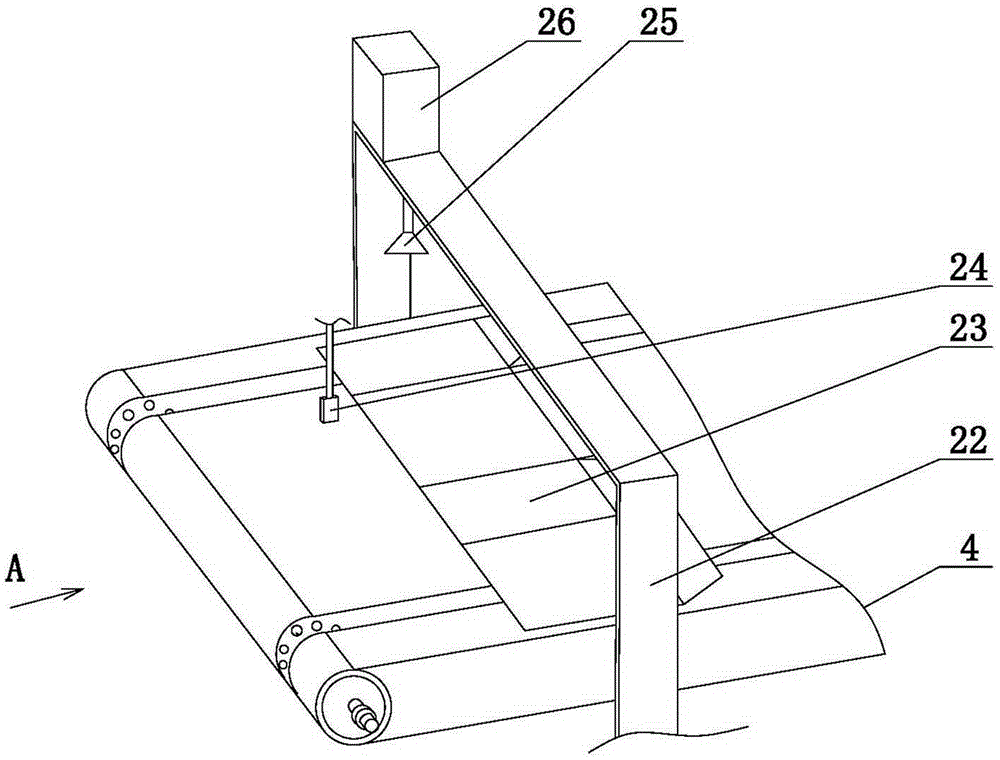

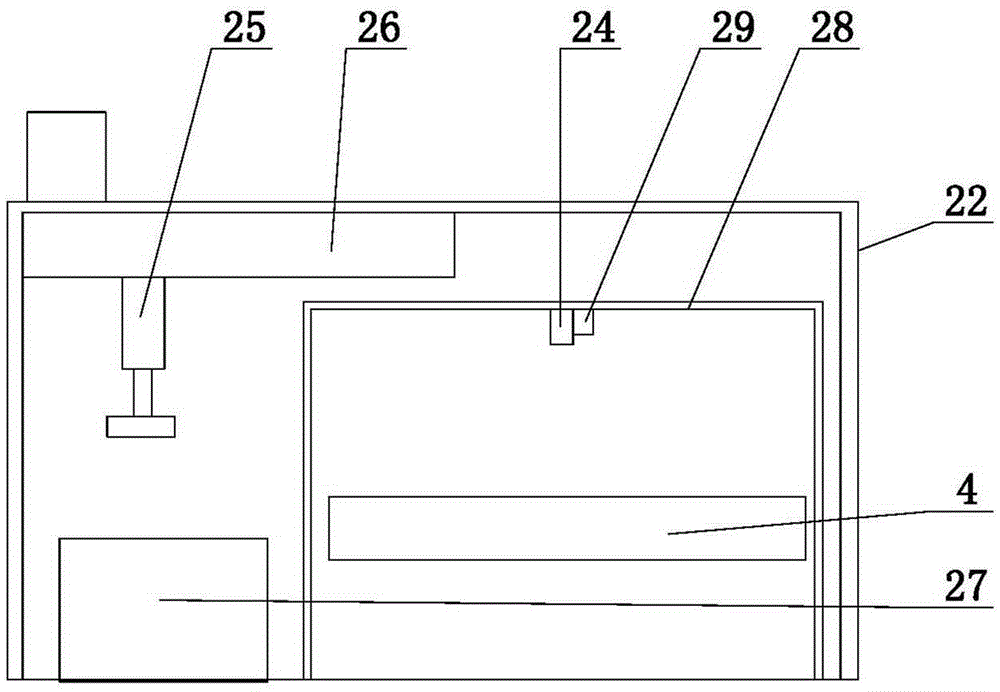

[0026] The invention includes a carton folding and forming mechanism 1, which is characterized in that: the front end of the carton folding and forming mechanism 1 is provided with a carton raw material cardboard automatic detection device 2, and the rear end of the carton folding and forming mechanism 1 is provided with a rolling mechanism 3; the carton folding and forming Mechanism 1 comprises transmission belt 4, and transmission belt 4 is provided with left folding belt 14 and right folding belt 110, is characterized in that: the top of transmission belt 4 is provided with front installation frame 11, middle bracket 19 and rear installation frame 111, described The end of the left folding belt 14 is arranged on the middle bracket 19, and the left pressing bar 12 corresponding to the left folding belt 14 is arranged on the said front mounting frame 11; Glue spray nozzle 16, the rear of glue spray nozzle 16 is provided with drying air duct 17; the rear mounting frame 111 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com