Assembling jig for antenna casing

A technology for assembling jigs and housings, which is applied to antennas, antenna supports/mounting devices, antenna components, etc. It can solve the problems of glue overflow on antenna housings, difficult assembly, uneven gaps, etc., and achieve simple assembly, Easy to operate, uniform gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

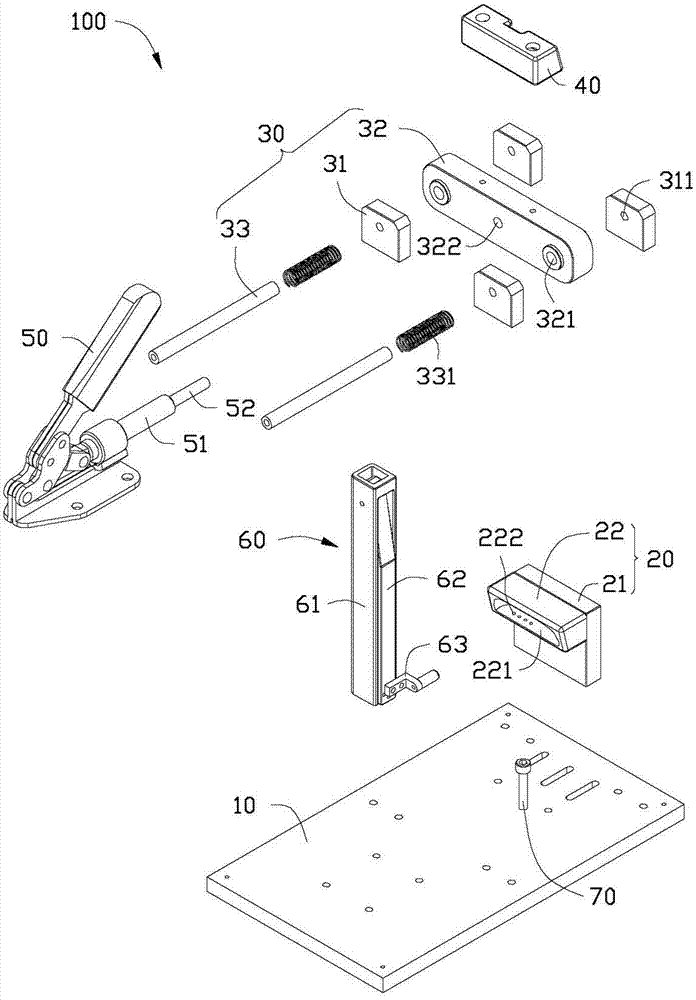

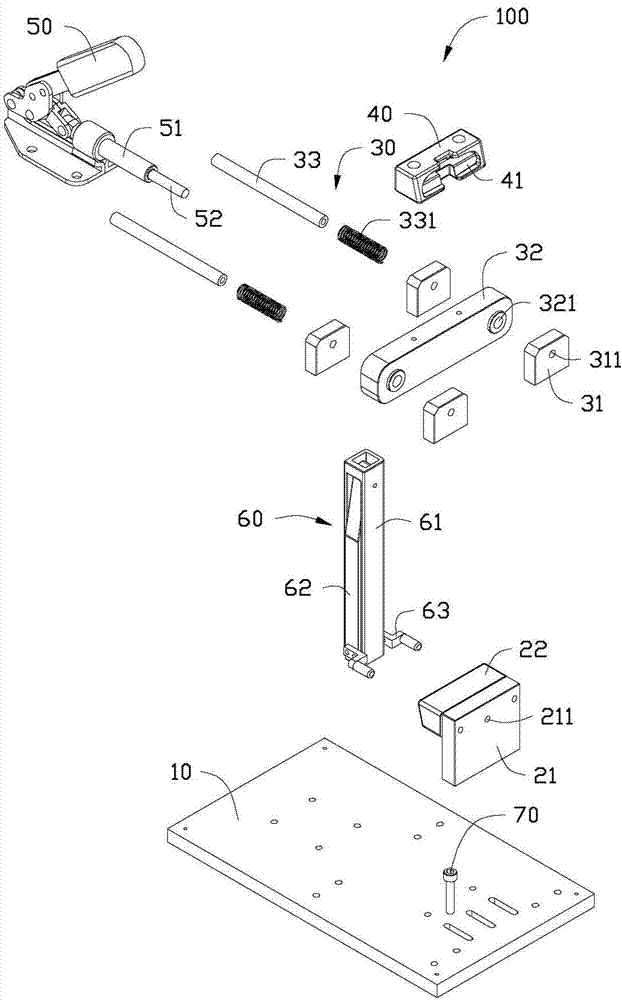

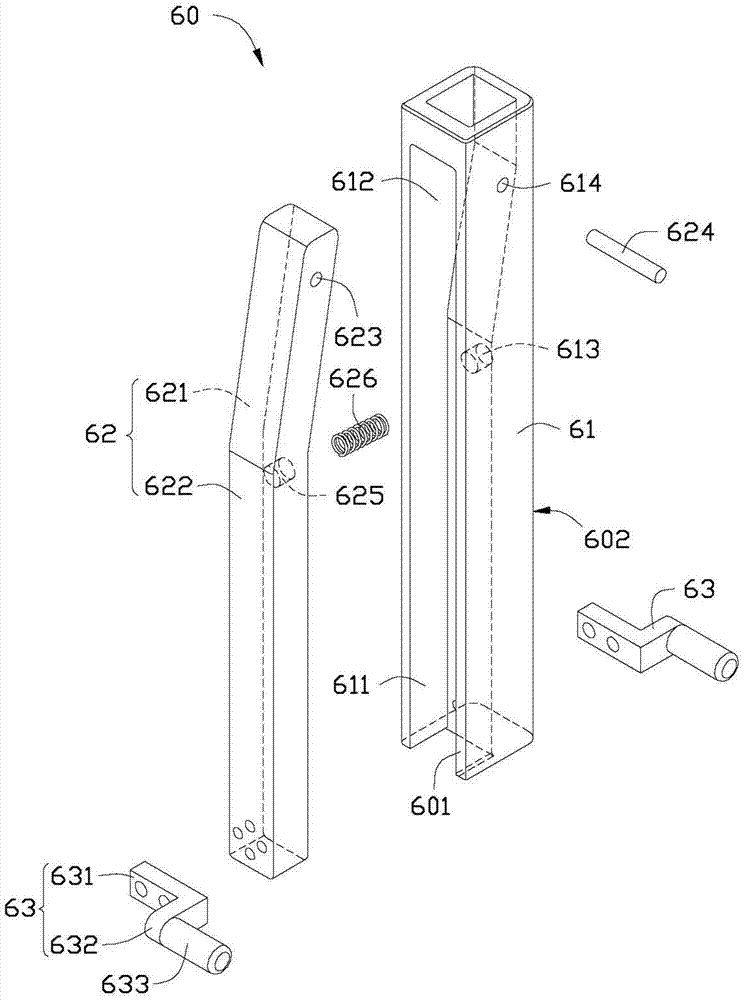

[0016] Please also refer to figure 1 and figure 2 , the preferred embodiment of the present invention provides a portable electronic device antenna housing assembly jig 100, including a base 10, a first mounting part 20, a sliding part 30, a second mounting part 40, an operating part 50 and a clamping part 60 .

[0017] The base 10 is a rectangular plate. The first mounting member 20 includes a fixing plate 21 and a mounting portion 22 . The fixing plate 21 is substantially in the shape of a rectangular plate, and is fixed on the base 10 . The mounting portion 22 is roughly block-shaped and fixed on one side of the fixing plate 21 . A first mounting slot 221 is defined on a side of the mounting portion 22 away from the fixing plate 21 . The shape and structure of the first installation groove 221 correspond to the shape and structure of the existing antenna housing, and are used for accommodating the antenna housing. An air suction hole 222 is defined in the first insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com