Glue overflow control method of laminar structure

A control method and technology of lamination structure, applied in the direction of multi-layer circuit manufacturing, etc., can solve problems such as adding processes, and achieve the effect of promoting glue curing and speeding up progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

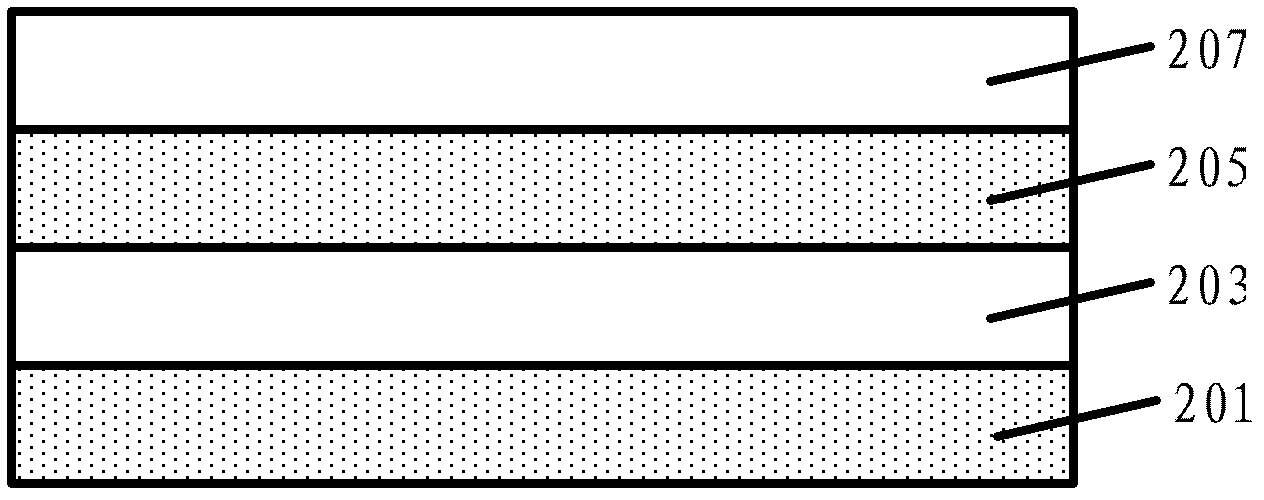

[0040] Please refer to Figure 3-Figure 6 , Figure 3-Figure 6 A schematic cross-sectional structure showing the glue overflow control process of the laminated structure according to the embodiment of the present invention.

[0041] Please refer to image 3 , at least two single-layer boards stacked in sequence are provided, and the single-layer boards include a prepreg for bonding two adjacent single-layer boards.

[0042] The stacked single-layer boards are used for subsequent pressing to form multi-layer boards. Take two stacked single-layer boards as an example for demonstration.

[0043] In the embodiment of the present invention, it includes: a first single-layer board (not marked), the first single-layer board includes a first prepreg 201, and the first circuit formed on the first prepreg 201 layer 203 ; a second single-layer board (not labeled), the second single-layer board includes a second prepreg 205 , and a second circuit layer 207 formed on the second prepreg...

no. 2 example

[0062] Different from the first embodiment of the present invention, in the second embodiment of the present invention, the adhesive resist layer 209 is a high temperature resistant polyimide (hereinafter referred to as "PI") tape (not shown). After the multiple single-layer boards are stacked and placed in sequence, a high-temperature-resistant adhesive tape is wound around the multiple single-layer boards to prevent glue overflow.

[0063] In order to facilitate the air discharge between two adjacent single-layer boards without affecting the effect of subsequent lamination, the surface of the high temperature resistant PI tape has multiple gaps, for example, 1-30 gaps with a width of 0.5-2.0 mm.

[0064] In the second embodiment of the present invention, high-temperature-resistant tape is used as the glue-resisting layer, which is easy to operate and effectively prevents overflowing glue from forming long glue edges. The plate is drilled, saving the milling process.

[0065...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com