Halogen-free thermosetting epoxy adhesive and application thereof

A technology of thermosetting and epoxy adhesives, which is applied in the direction of epoxy resin adhesives, modified epoxy resin adhesives, adhesives, etc., can solve the problems of shortening the service life of E-PAPER, slow curing speed of epoxy adhesive at low temperature, and inability to use ultraviolet light. Complete penetration and other issues, to achieve the effect of improving storage stability, excellent crack resistance, and preventing glue overflow

Active Publication Date: 2016-03-09

深圳百丽春新材料科技有限公司

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the adhesion between UV-curable adhesive and PET substrate is average, and its moisture resistance and high temperature resistance are poor.

Chinese patent CN104619804A provides a UV-curable epoxy adhesive, which has good chemical resistance and high-temperature reliability; however, there may be black or other dark inks on the edge of the E-PAPER frame, which makes the UV light unable to penetrate completely. The glue in the shadow part cannot be cured or is not completely cured, thus shortening the service life of E-PAPER

However, the general epoxy adhesive has good adhesion, but it needs medium and high temperature curing, and the shrinkage rate is relatively large; while the low temperature curing speed of thermosetting epoxy adhesive is slow and the viscosity stability is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

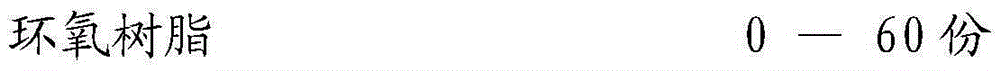

[0037] A halogen-free thermosetting epoxy adhesive, comprising the following raw materials by weight:

[0038]

[0039]

Embodiment 2

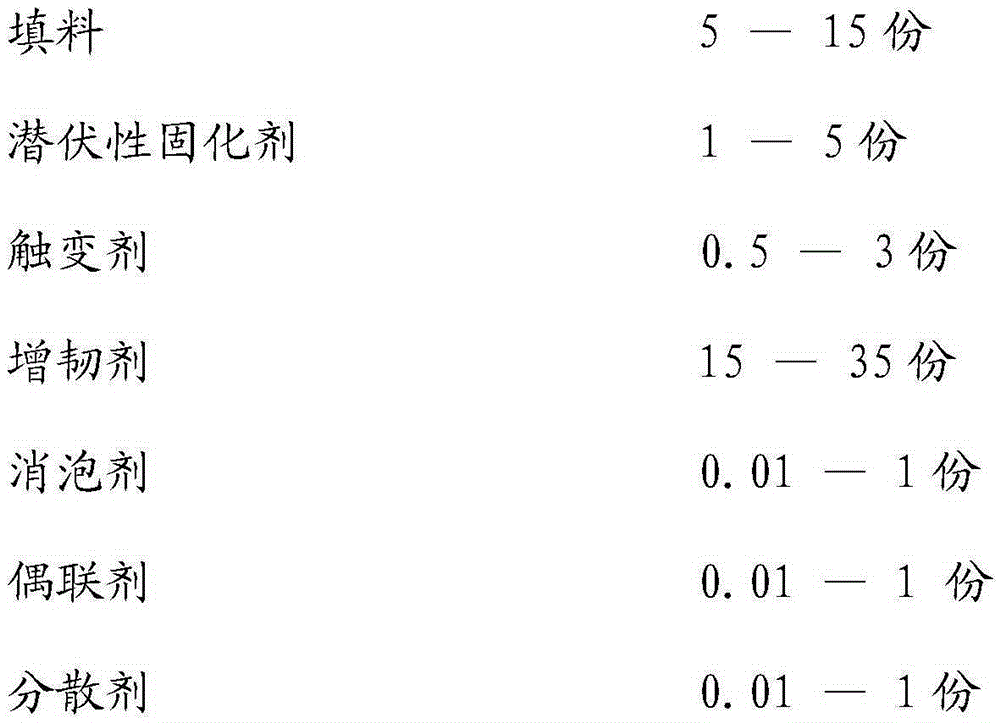

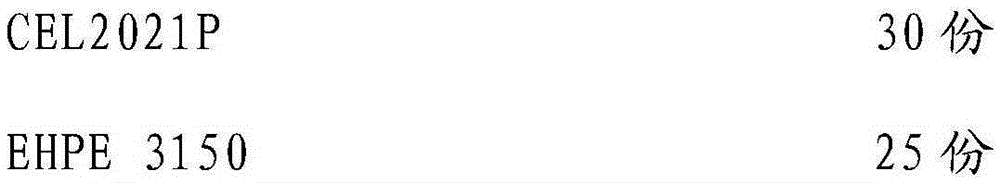

[0041] A halogen-free thermosetting epoxy adhesive, comprising the following raw materials by weight:

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a halogen-free thermosetting epoxy adhesive. The halogen-free thermosetting epoxy adhesive comprises, by weight, 0-60 parts of epoxy resin, 5-15 parts of a filler, 1-5 parts of a latent curing agent, 0.5-3 parts of a thixotropic agent, 15-35 parts of a flexibilizer, 0.01-1 part of an antifoaming agent, 0.01-1 part of a coupling agent and 0.01-1 part of a dispersant. The halogen-free thermosetting epoxy adhesive can be applied in E-Paper edge sealing. The epoxy adhesive provided by the invention has the advantages of no halogen, realization of low-temperature rapid solidification, excellent bonding strength and flexibility, high heat resistance, low heat expansion coefficient and high water resistance.

Description

Technical field [0001] The invention relates to the technical field of thermosetting epoxy adhesives, and in particular to a halogen-free thermosetting epoxy adhesive and its application. Background technique [0002] The scientific name of electronic paper is Electronic Paper (referred to as E-Paper), also known as digital paper (Digital Paper) and paper-like display (Paper-Like Display). It is an electronic display device with visual effects similar to paper. It is easy to read, portable and Low power consumption and other features. E-PAPER is generally made of flexible substrate materials. The flexible substrate materials are generally polyethylene terephthalate (PET) or polymethyl methacrylate (PMMA). These two flexible materials are relatively difficult to use among plastic substrates. attached. [0003] In the early days of development, E-PAPER used double-sided tape for edge sealing to achieve a sealing effect. The initial bonding strength of double-sided tape is s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J163/00C09J163/10C09J11/04C09J11/06C09J11/08

CPCC08K2201/014C08L2201/08C08L2201/22C08L2205/035C09J11/04C09J11/06C09J11/08C09J163/00C08L63/00C08L63/10C08K13/02C08K3/36C08K5/5435

Inventor 叶明浩潘自鼎

Owner 深圳百丽春新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com