A light curable frame glue material composition

A material composition, light-curing technology, applied in the directions of adhesives, adhesive types, adhesive additives, etc., can solve the problems of easy overflow of liquid optical adhesives, damage to the function of laminating components, etc., and achieve proper fluidity and softness. , Improve the yield and avoid the effect of overflowing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1

[0068] The glue solution of the light-curable sealant composition of Examples 1 to 10 and Comparative Example 1 was prepared according to the manner described below, and its composition is listed in Table 1.

[0069] Firstly, each component is mixed with the weight (grams) listed in Table 1, and stirred at room temperature and in a dark room until completely mixed evenly to form a light-curable sealant material composition.

[0070] Table 1

[0071]

[0072]

[0073] (a): Polyurethane acrylate oligomer (produced by Changxing Company, EX-06)

[0074] (b1): Monofunctional monomer (tetrahydrofurfuryl acrylate; produced by Changxing Company, EM214)

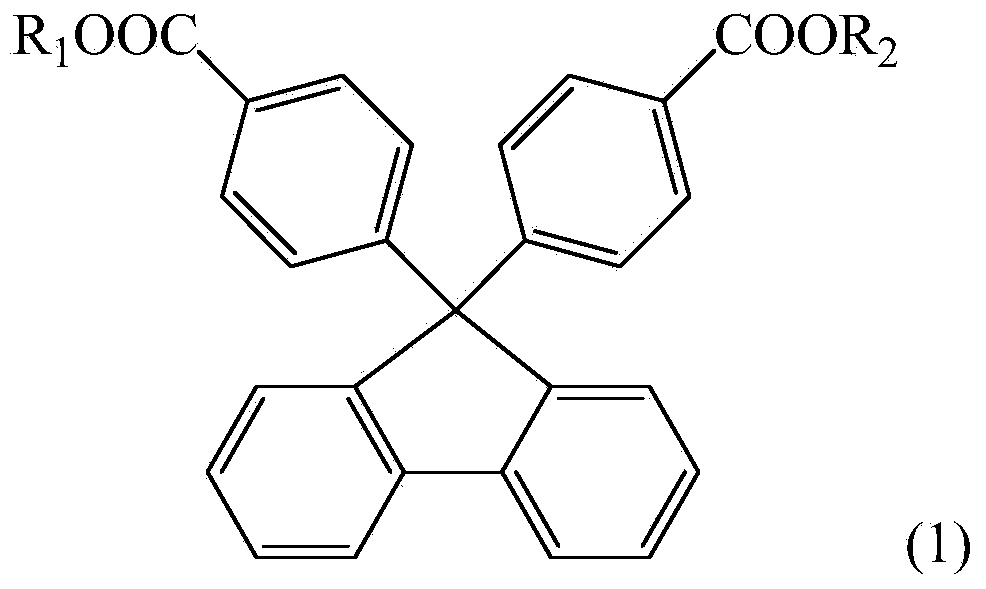

[0075] (b2): Multifunctional monomer (ethoxylated bisphenol A diacrylate; produced by Changxing Company, EM2261)

[0076] (c): Photoinitiator (1-hydroxycyclohexyl phenyl ketone; produced by BASF, Irgacure184)

[0077] (d1): plasticizer (bisphenol A bis(diphenyl phosphate) tetraphenyl4,4'-(propane-2,2-diyl)bis(4,1-phenylene)di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com