Patents

Literature

194results about How to "Uniform diameter distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

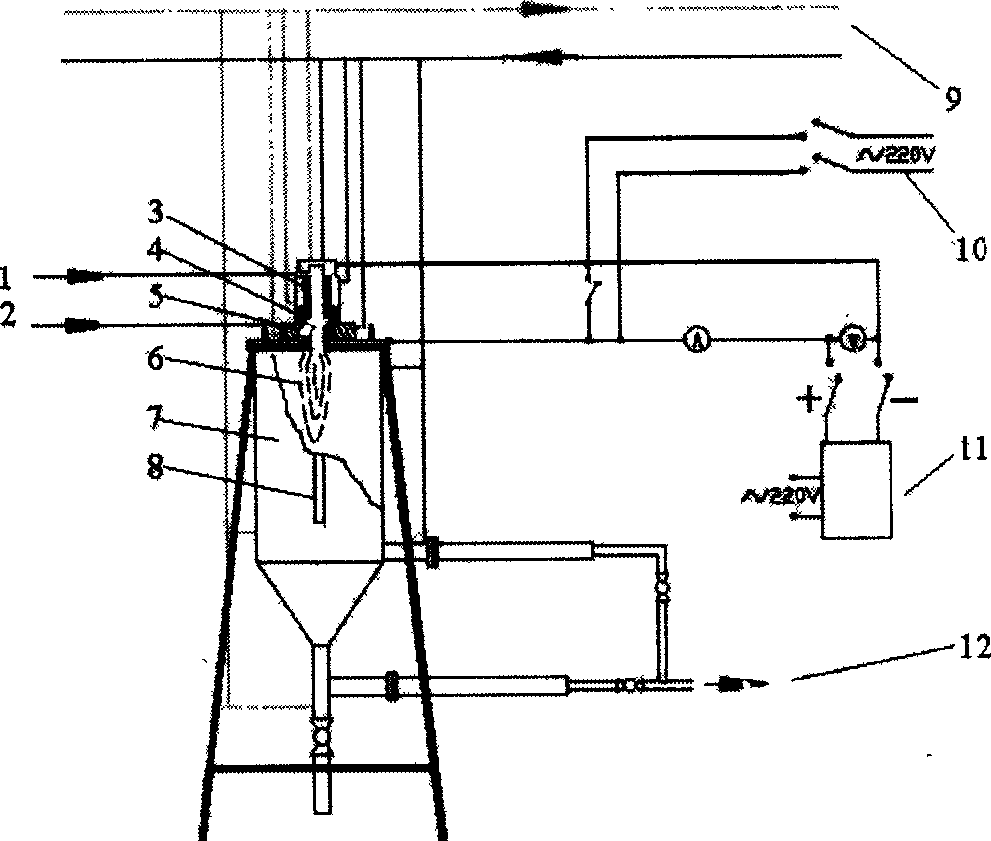

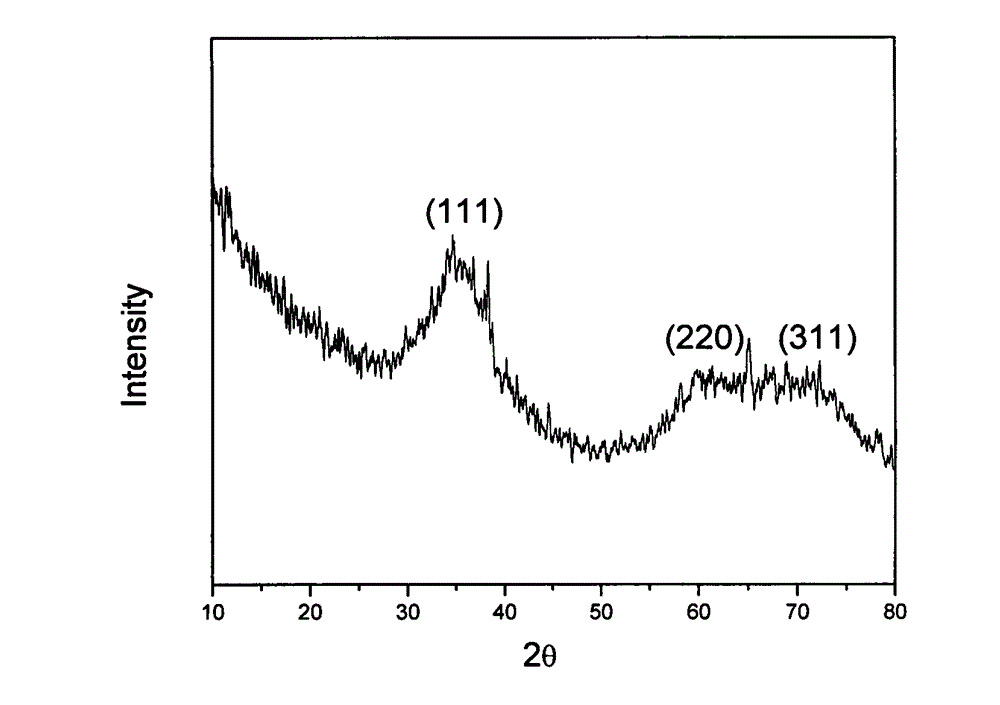

Plasma method for preparing nano carbon material using coal liquefied residue as raw material

The invention discloses an arc plasma torch preparing nanometer charcoal fibrous material method, which comprises the following steps: placing untreated leavings of liquefying coal directly in direct current arc plasma torch to carry on heat-treatment; using nitrogen for arc working gas under atmosphere pressure; getting nanometer charcoal fibrous material after 120-175 seconds, wherein there is no need to add in any activators in preparing process. The method is characterized by the following: the craft route is simple; the raw material is the waste of coal hydrogenant liquefaction craft; it's a good way to use coal liquification leavings to prepare high-added value, functional carbon material; the nanometer charcoal fibrous material can be used for accelerating agent, catalyst carrier, lithium ion secondary cell anode material, double-layer capacitor electrode, highly effective active solid, release agent and construction reinforced materials.

Owner:DALIAN UNIV OF TECH

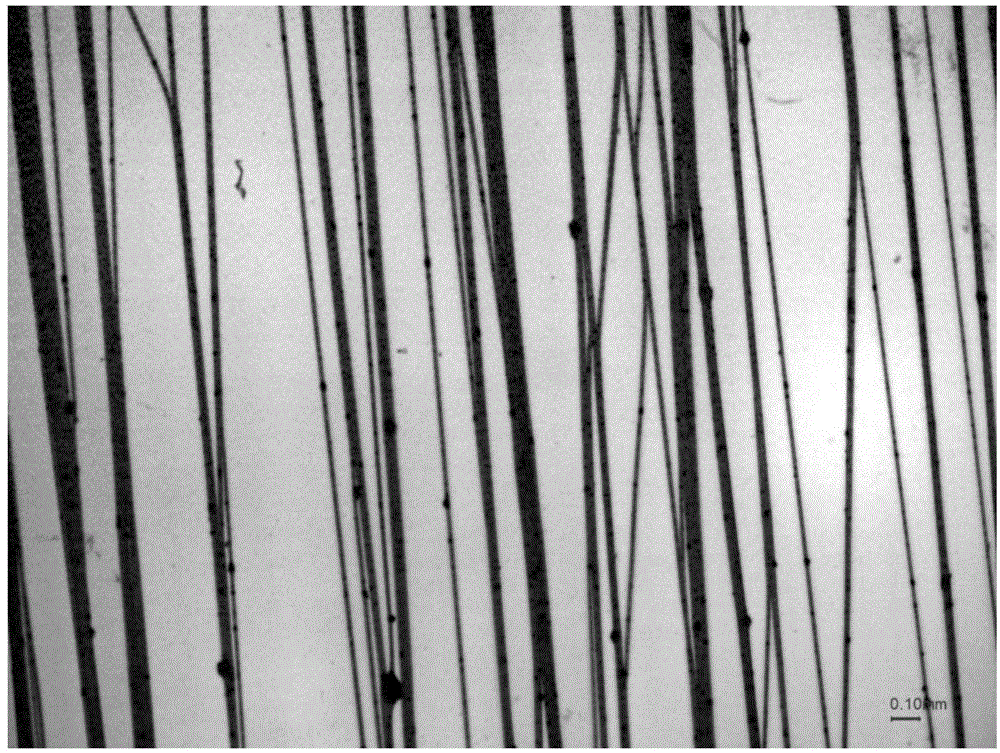

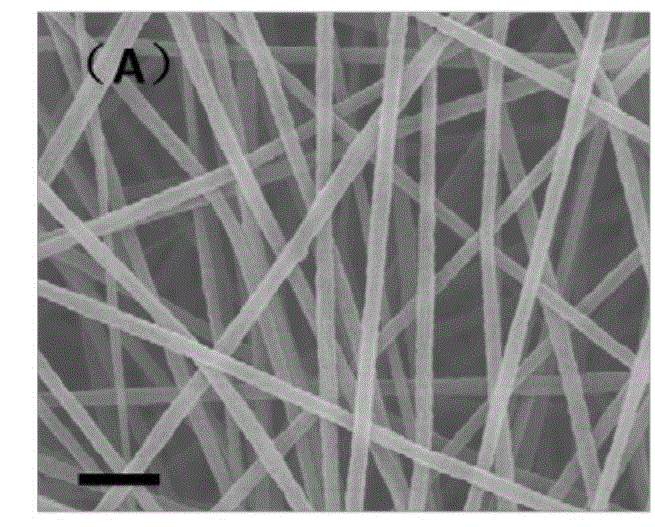

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

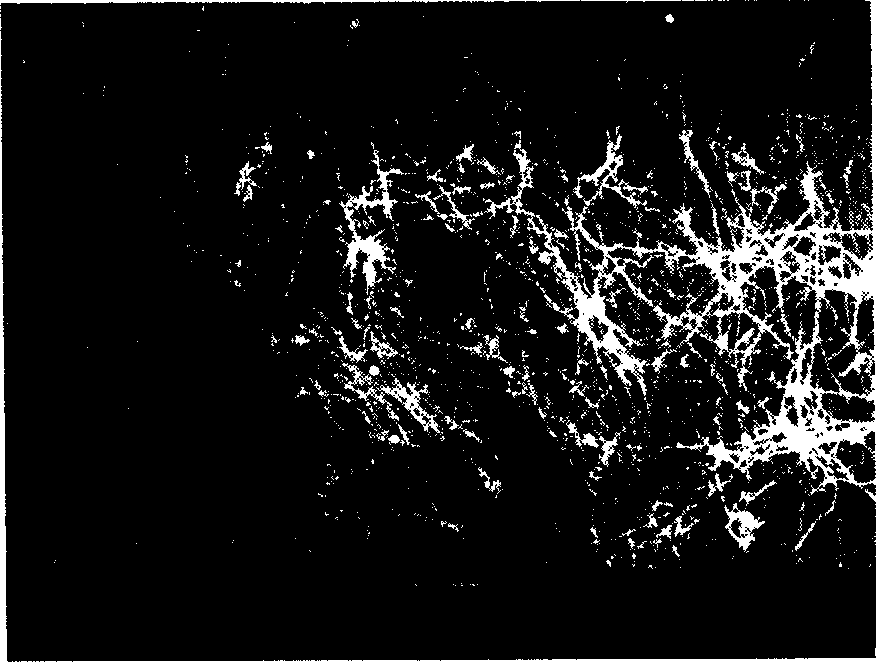

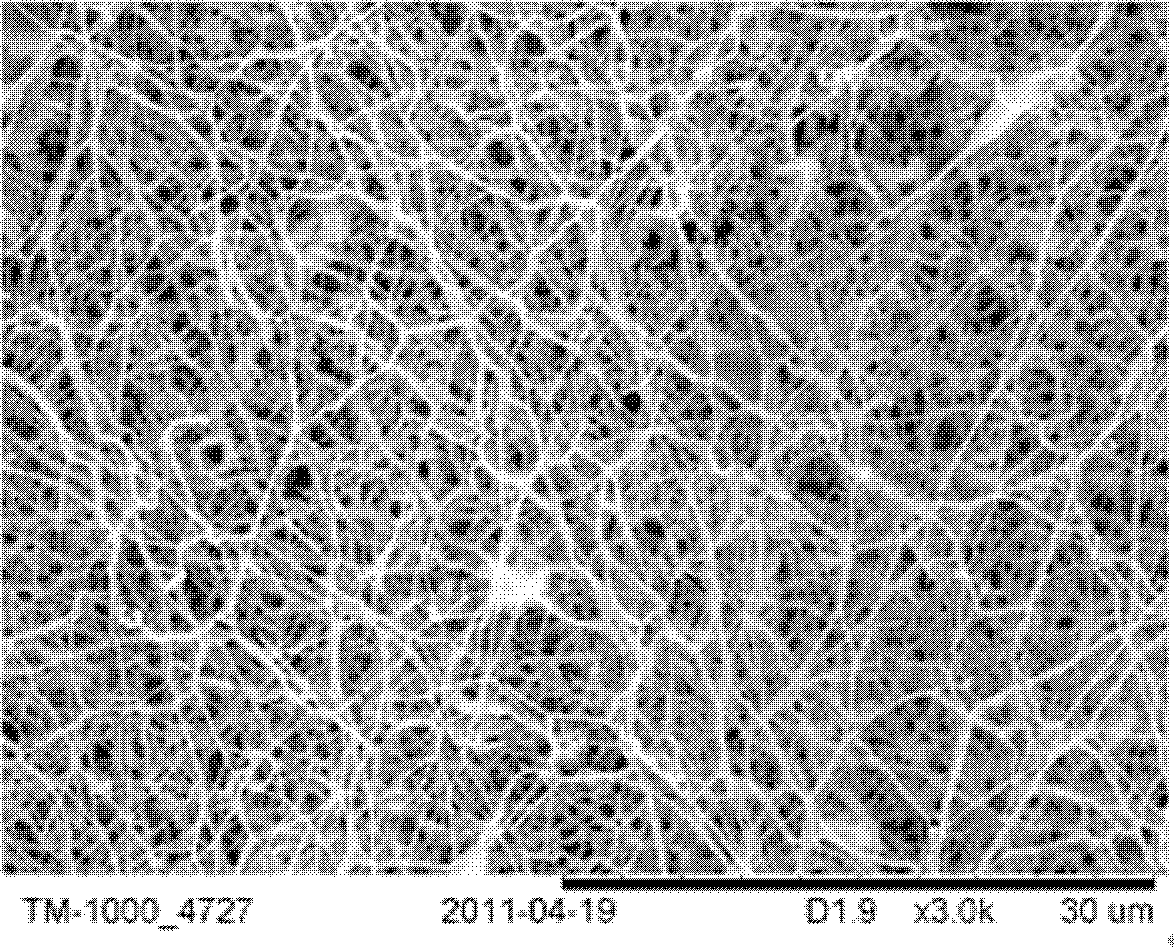

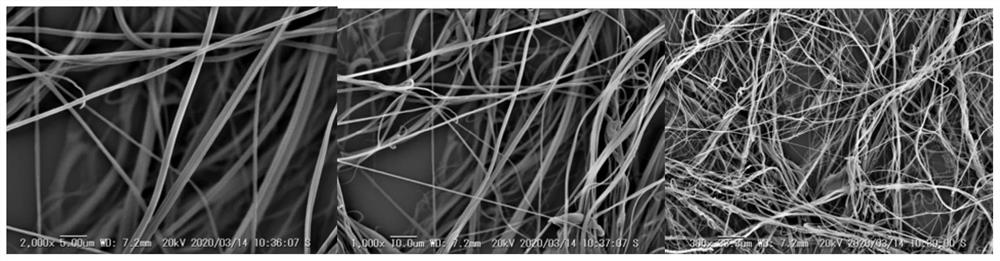

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

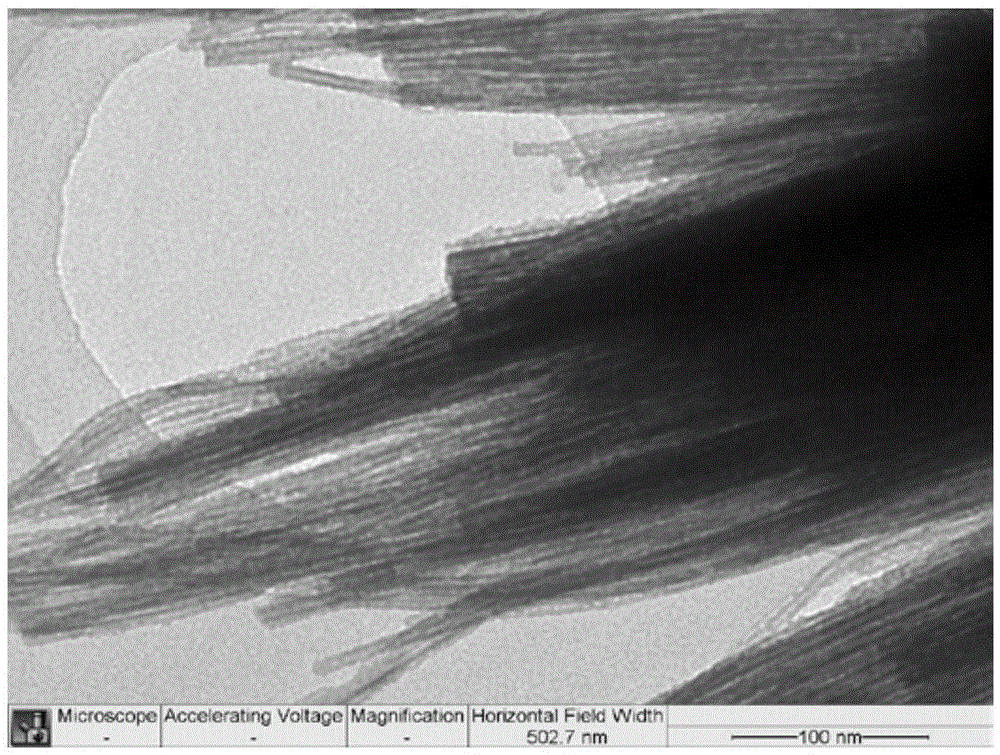

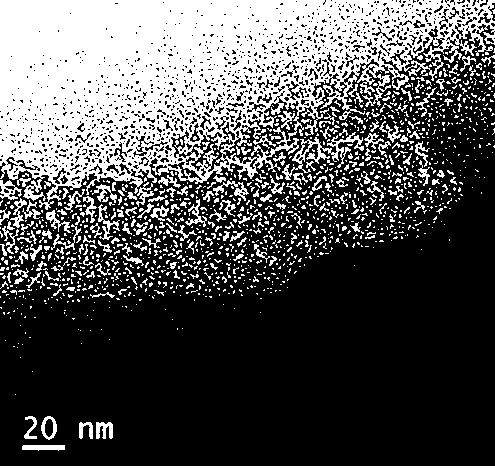

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

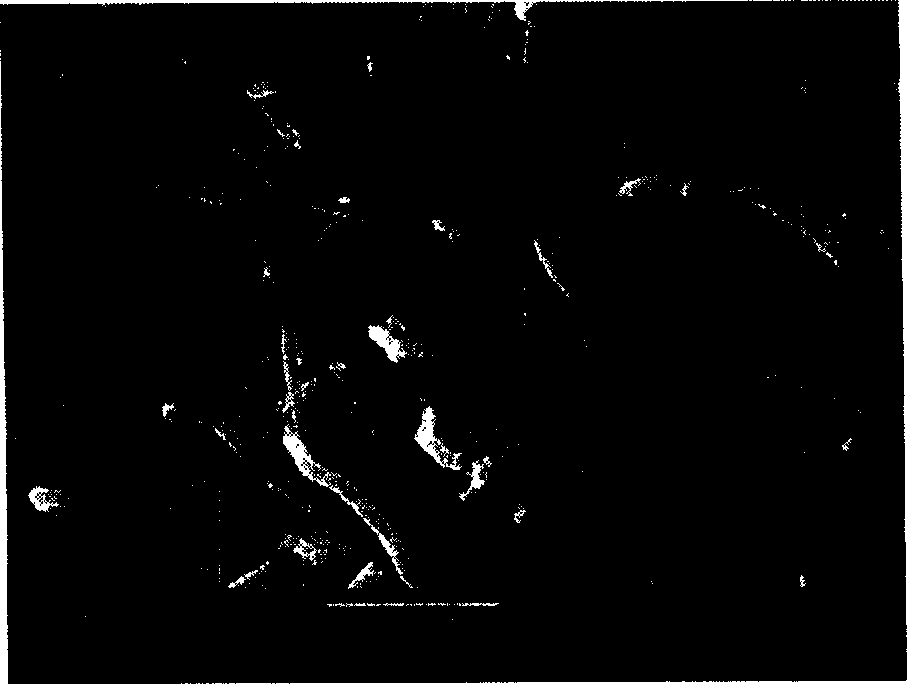

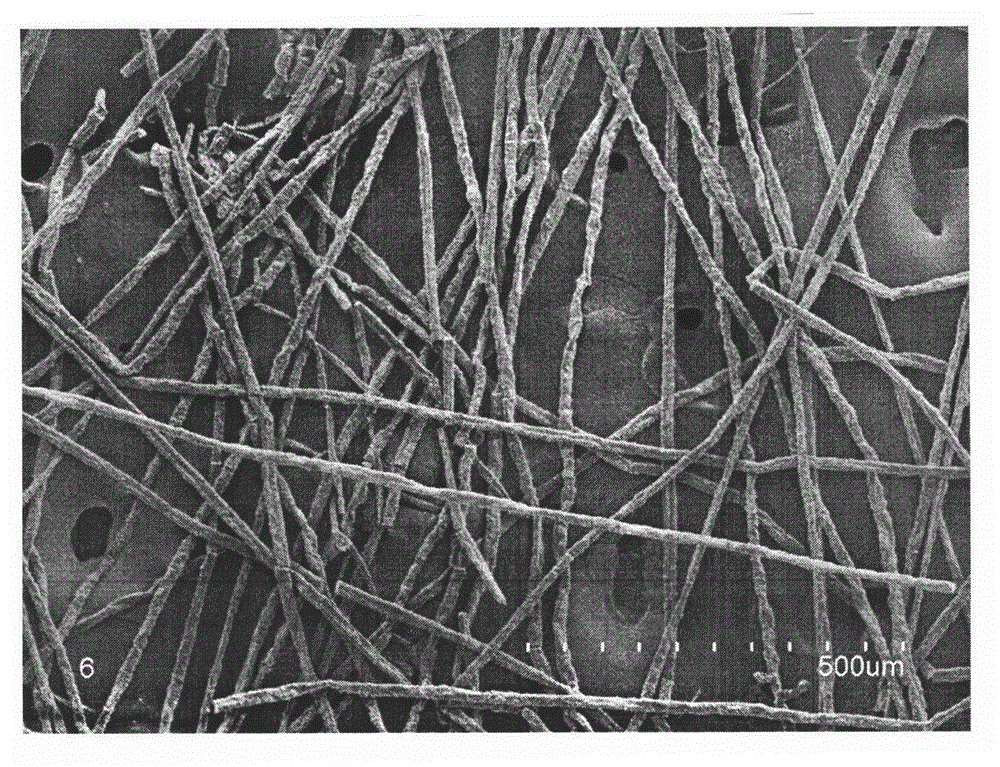

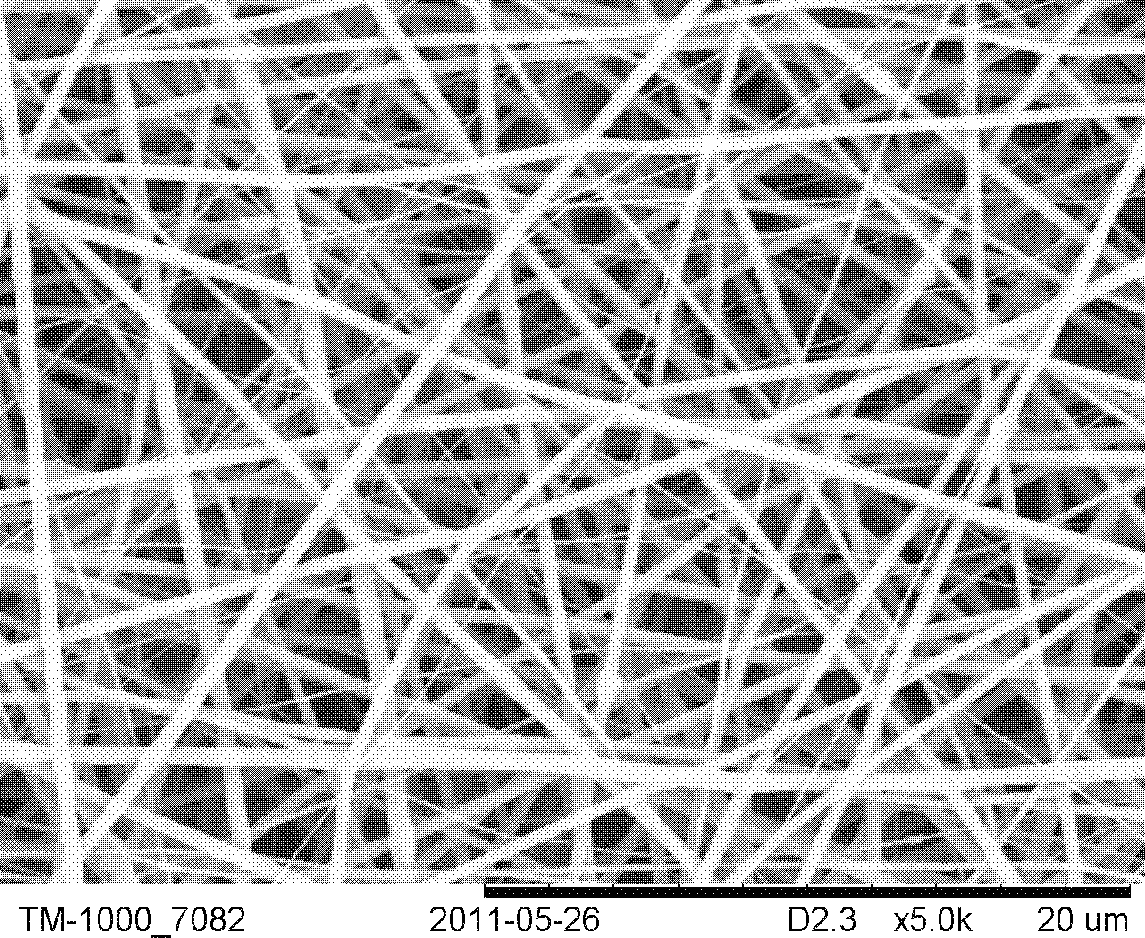

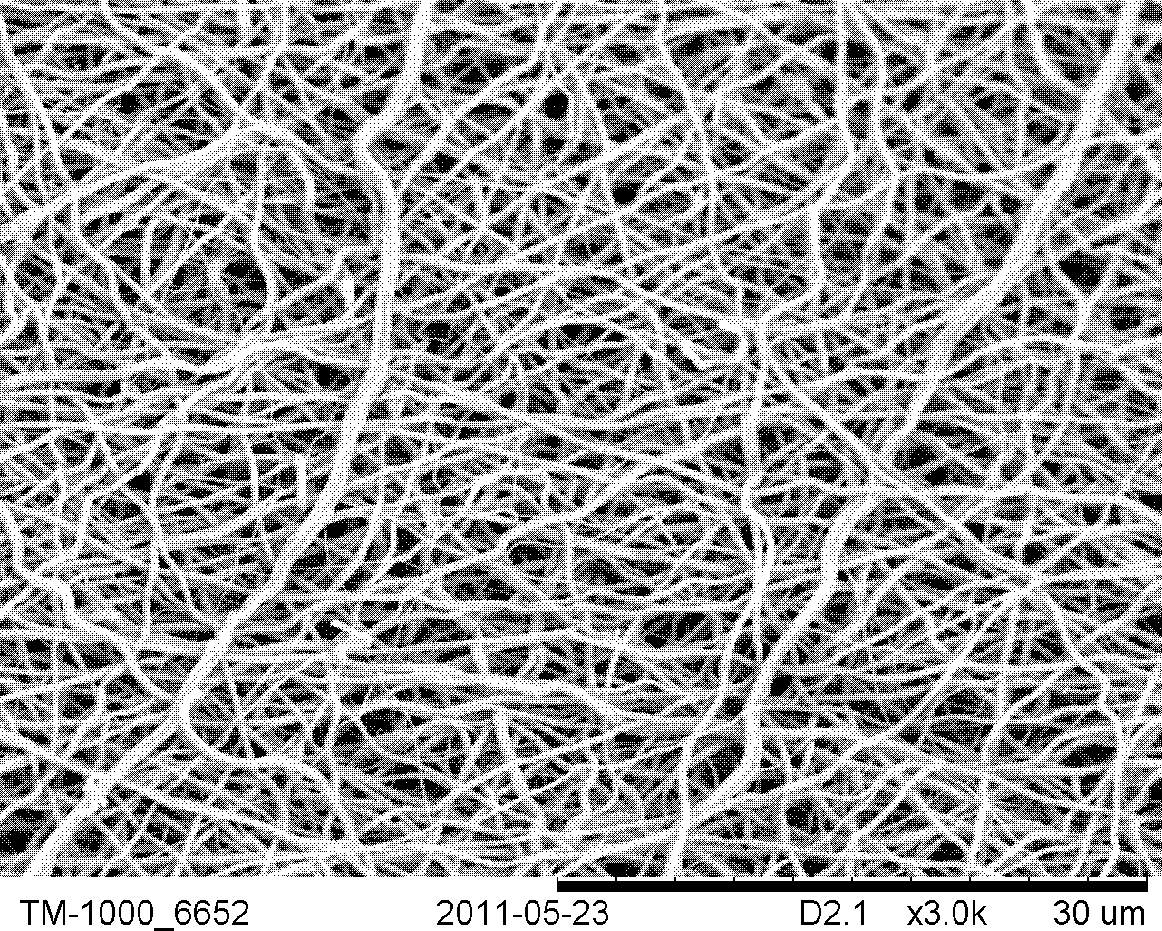

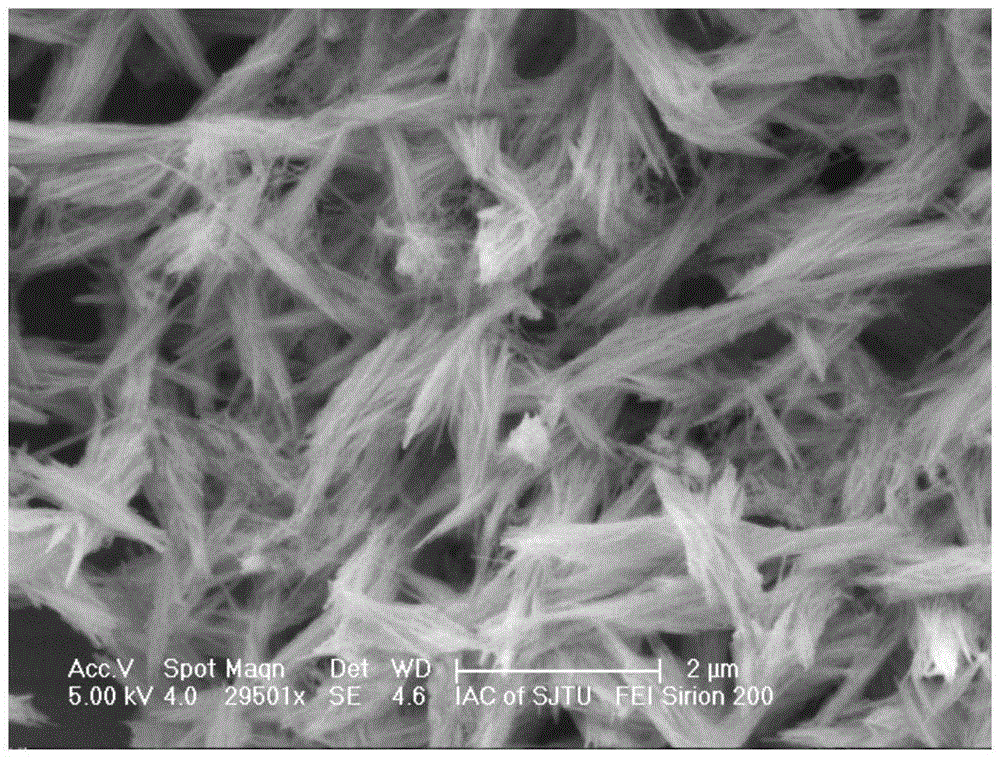

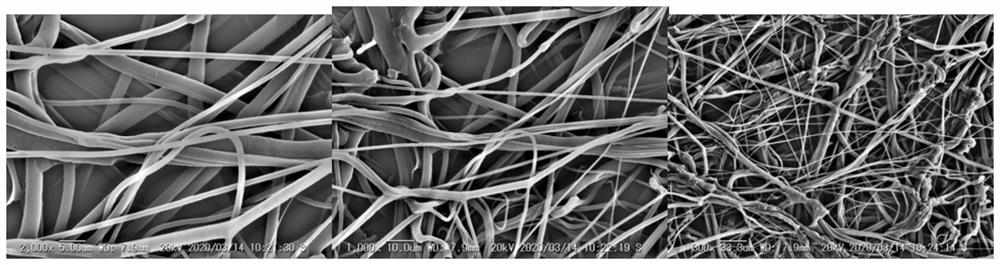

Silicon-dioxide aerogel heat insulation composite material and preparation method thereof

InactiveCN103011745AImprove mechanical propertiesChange the chemical state of the surfaceFiberSupercritical drying

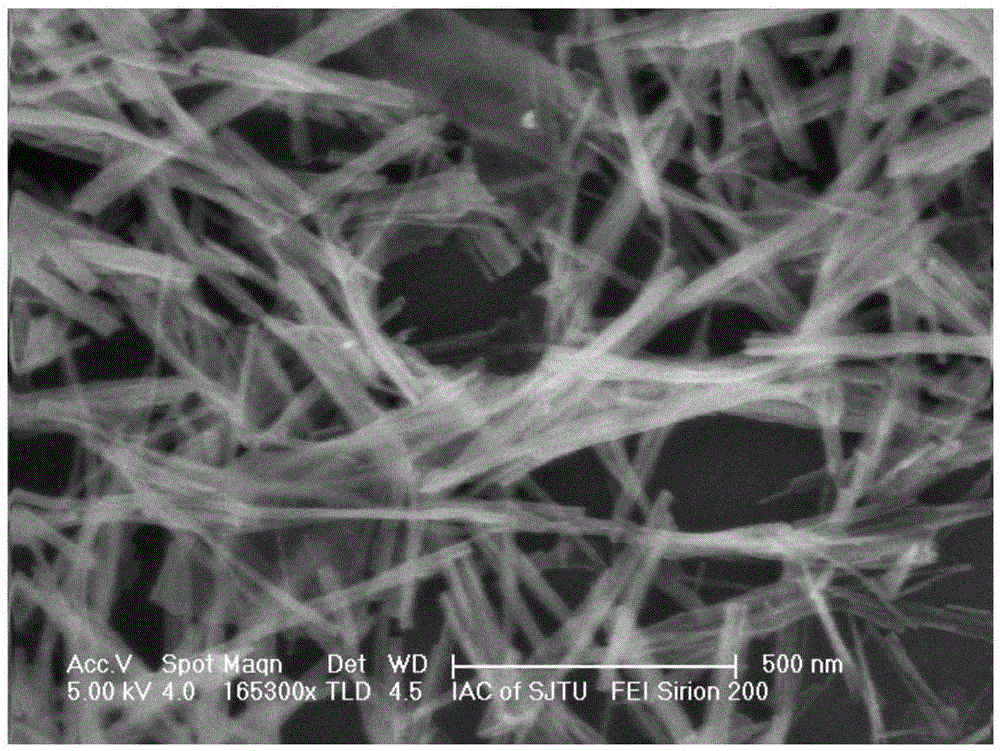

The invention provides a fiber-reinforced silicon-dioxide aerogel heat insulation composite material and a preparation method thereof. According to the preparation method, mineral fibers with high mechanical strength, low heat conductivity and good heat stability serve as a reinforcing phase, silicon alcoholate serves as a precursor, fiber-composite silicon-dioxide wet gel is prepared by adopting an acid-base two-step catalysis method, and the block-shaped fiber-reinforced silicon-dioxide aerogel heat insulation composite material is then obtained through aging, modification, solvent displacement and supercritical drying. The prepared aerogel heat insulation composite material has the advantages of excellent mechanical property, good heat-insulating property and higher heat resistance. The aerogel composite material has a three-dimensional porous network-like structure, the compatibility between fibers and an aerogel matrix is good, the interfacial bonding is firm, and no obvious interfaces exist; and according to the block-shaped aerogel composite material, the density is 0.15-0.25 g / cm<3>, the compressive strength is 10%, the strain energy reaches 0.4-2.0MPa, and the coefficient of heat conductivity is 0.016-0.027 W / mK.

Owner:TIANJIN UNIV

Biodegradable fluorourcacil polyester medicine-carried nanospheres and its preparation method

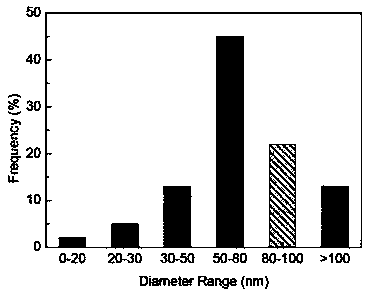

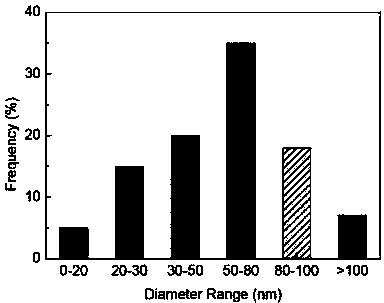

InactiveCN101053553AHigh drug loadingSmall particle sizeOrganic active ingredientsPowder deliveryPolyesterPolymer science

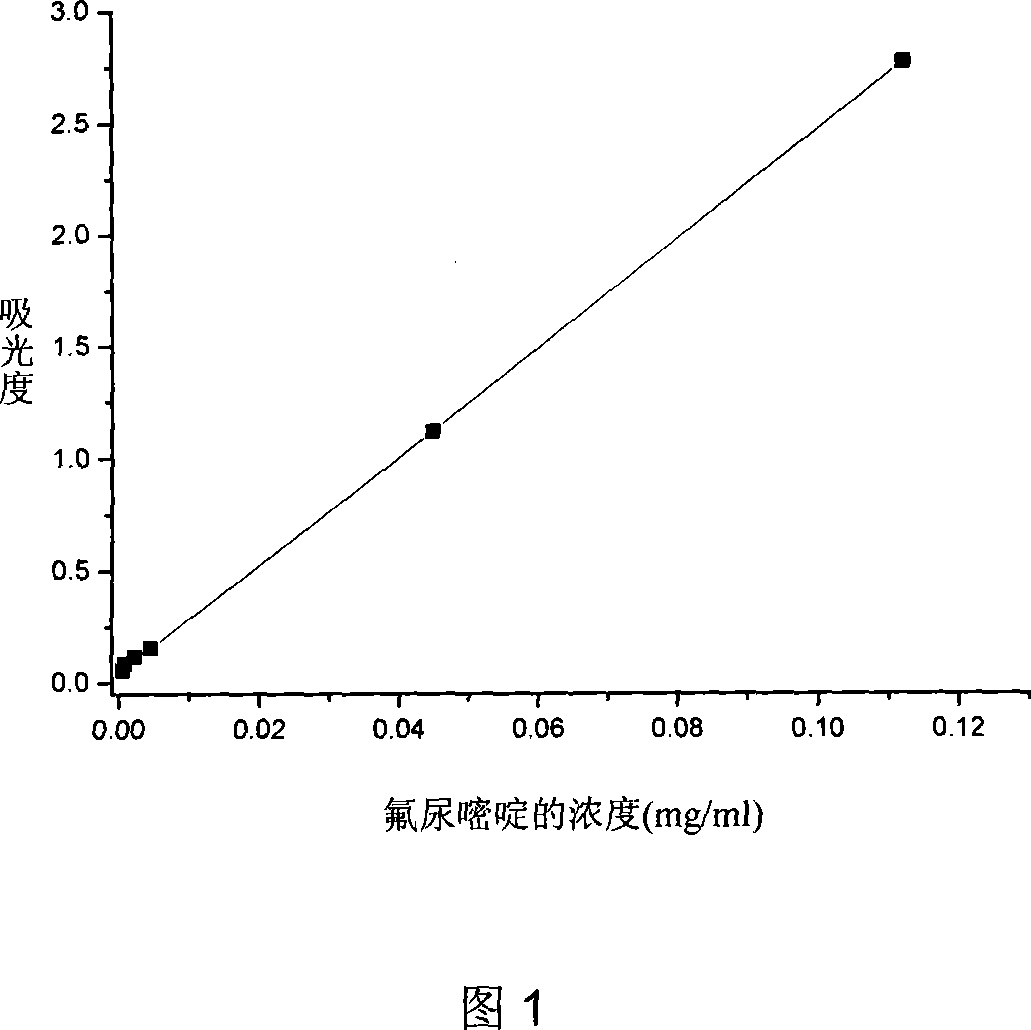

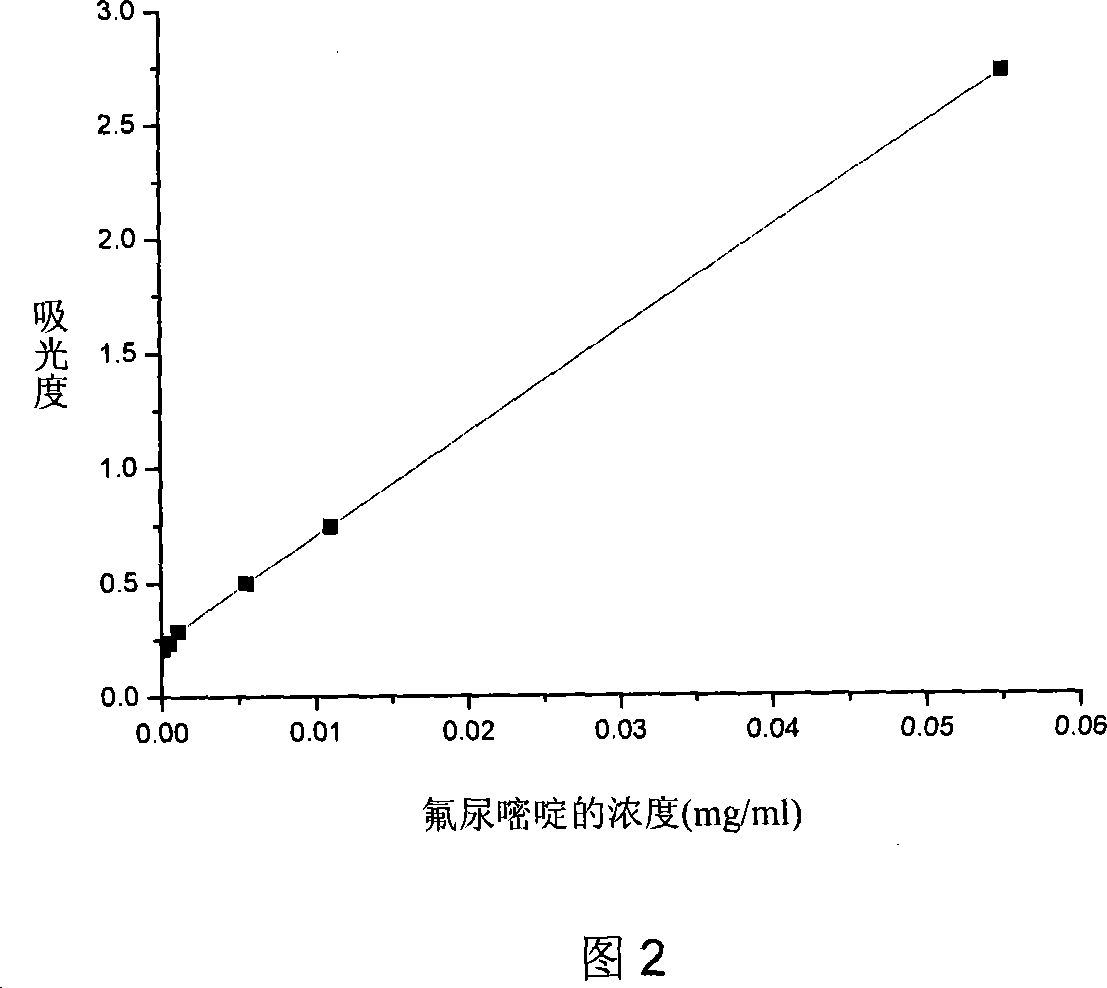

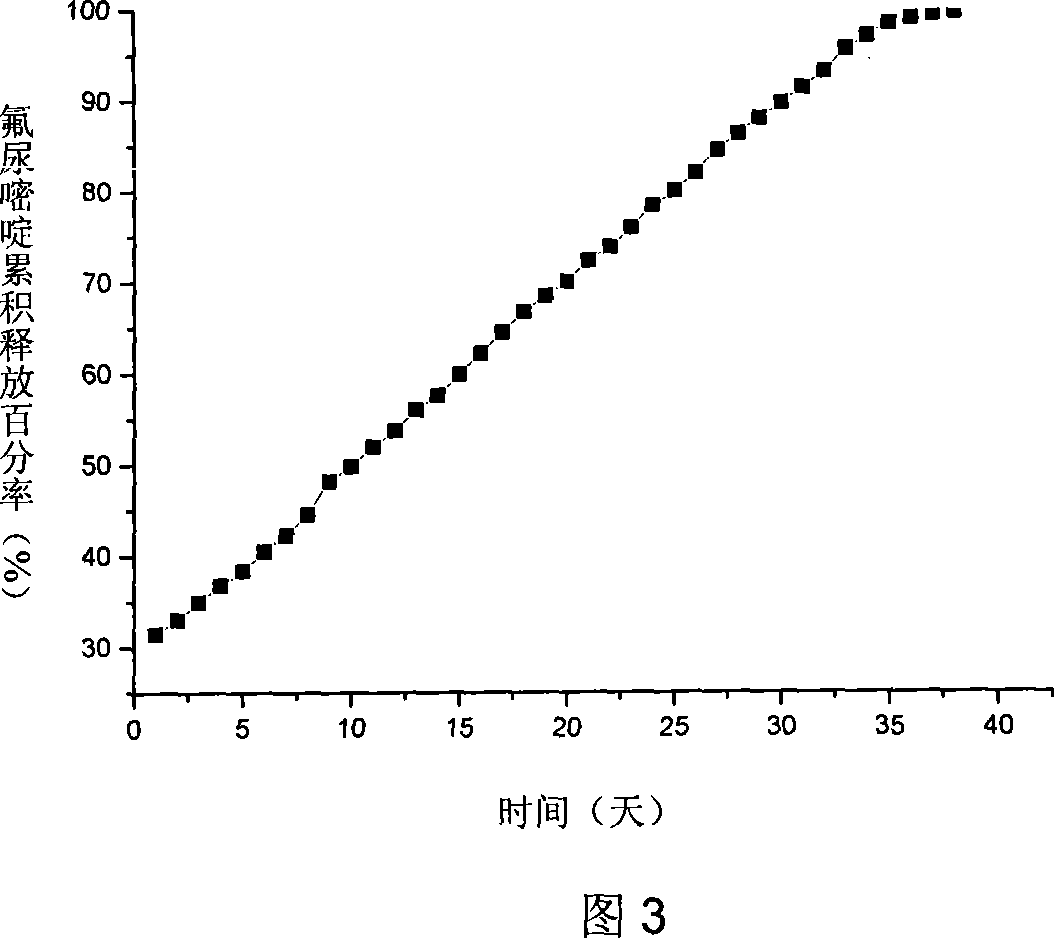

The invention relates to biodegradable fluorouracil(Fu) polyester drug-bearing manoparticles with a coating material of polylactic acid, polylactic acid-glycolic acid, polylactic acid-polyethylene glycol block copolymer or polylactic acid-glycolic acid-polyethylene glycol block copolymer and the producing method including: firstly, fully dissolving the copolymer in the dichloromethane, under the ultrasonic shock, injecting the fluorouracil NaOH solution in the dichloromethane solution, dispersing uniformly, forming W / O primary latex, and beating up the primary latex and injecting into the fluorouracil saturated water solution containing 5 wt% of polyvinylalcohol (PVA), and storing in the refrigeratory after freeze-dry. The drug-bearing manoparticle has a drug content which is 10-25% of the microparticle mass, and has a smooth surface, an even diameter distribution, a remarkable slow release function and not adhesive. The micropartical size is 100-1000nm.

Owner:JILIN UNIV +1

Preparation method for composite material of cellulose nanofiber and reinforced polyurethane

InactiveCN103436002AHigh strengthReduce forcePaper recyclingWaste paper working-upCelluloseChemical treatment

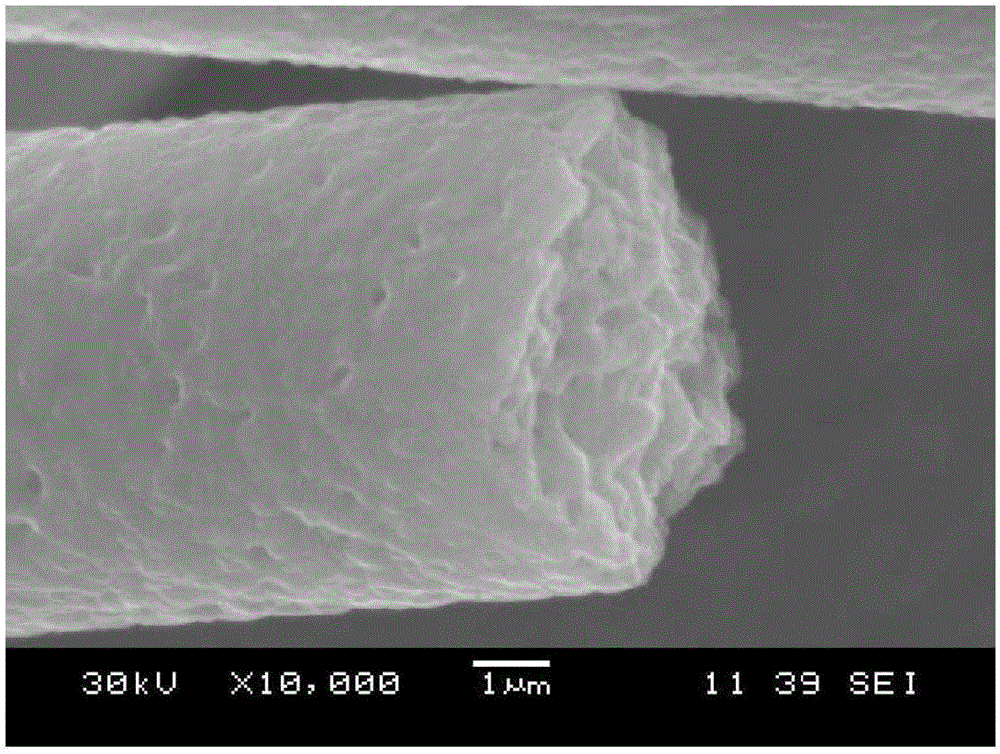

The invention discloses a preparation method for a composite material of cellulose nanofiber and reinforced polyurethane. The method comprises the following steps: 1) pretreating in a chemical method; 2) unfastening fibers in a mechanical method. According to the invention, chemical treatment and mechanical treatment are adopted to separate the cellulose nanofiber, which has a high length diameter ratio and is used for reinforced polyurethane, from newspaper; the transparent nano composite material with high-intensity is prepared; wood meal and newspaper are adopted as raw materials to prepare cellulose nanofiber through the chemical treatment combined with the mechanical treatment; the diameter range of the cellulose nanofiber is 30-100 nm, and the length diameter ratio is higher than 1000.

Owner:NANJING FORESTRY UNIV

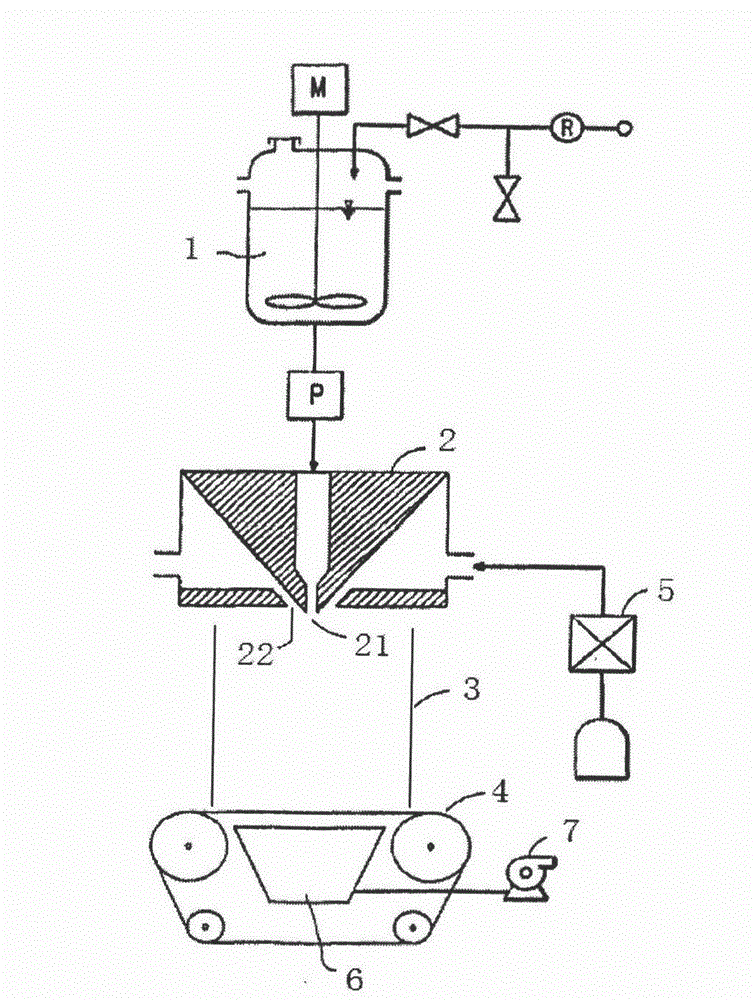

Method for preparing silicon carbide and precursor composite fibers

InactiveCN102943319AGood crystal formImprove thermal stabilitySpinning head liquid feederConjugated synthetic polymer artificial filamentsPolymer dissolutionOil phase

The invention relates to a method for preparing silicon carbide and precursor composite fibers. A silicon carbide precursor polymer is dissolved in at least one organic solvent to form uniform oil phase solution with the mass fraction of 10-70%; a water-soluble fiber-forming polymer is dissolved in water, surfactants are added, uniform water phase solution with the mass fraction of 1-50% is formed, and the quantity of the surfactants is 0.1-10% of the mass of the solution; the precursor solution and the water-soluble polymer solution are mixed according to the volume ratio of 1:10-1:1 to obtain stable oil-in-water (O / W) spinning solution; spinning precursor fibers with the spinning solution by a solution jet spinning method to obtain a precursor composite fiber with the diameter ranging from 50 nanometers to 50 micrometers; and the precursor fibers are not melted and calcined at high temperature to obtain silicon carbide fibers. The method has the advantages of high production efficiency, simple process, uniformity of fiber diameter distribution and the like, and is suitable for large-scale production.

Owner:TIANJIN POLYTECHNIC UNIV

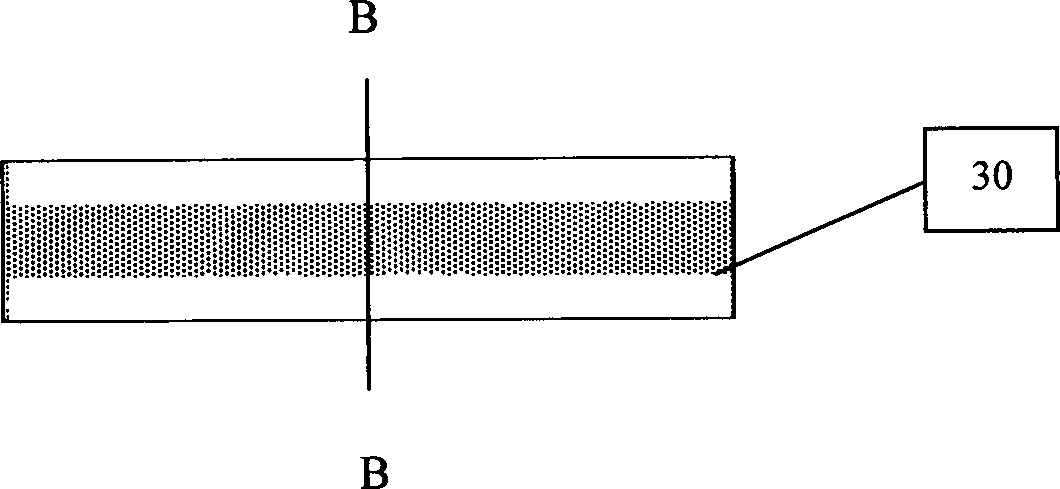

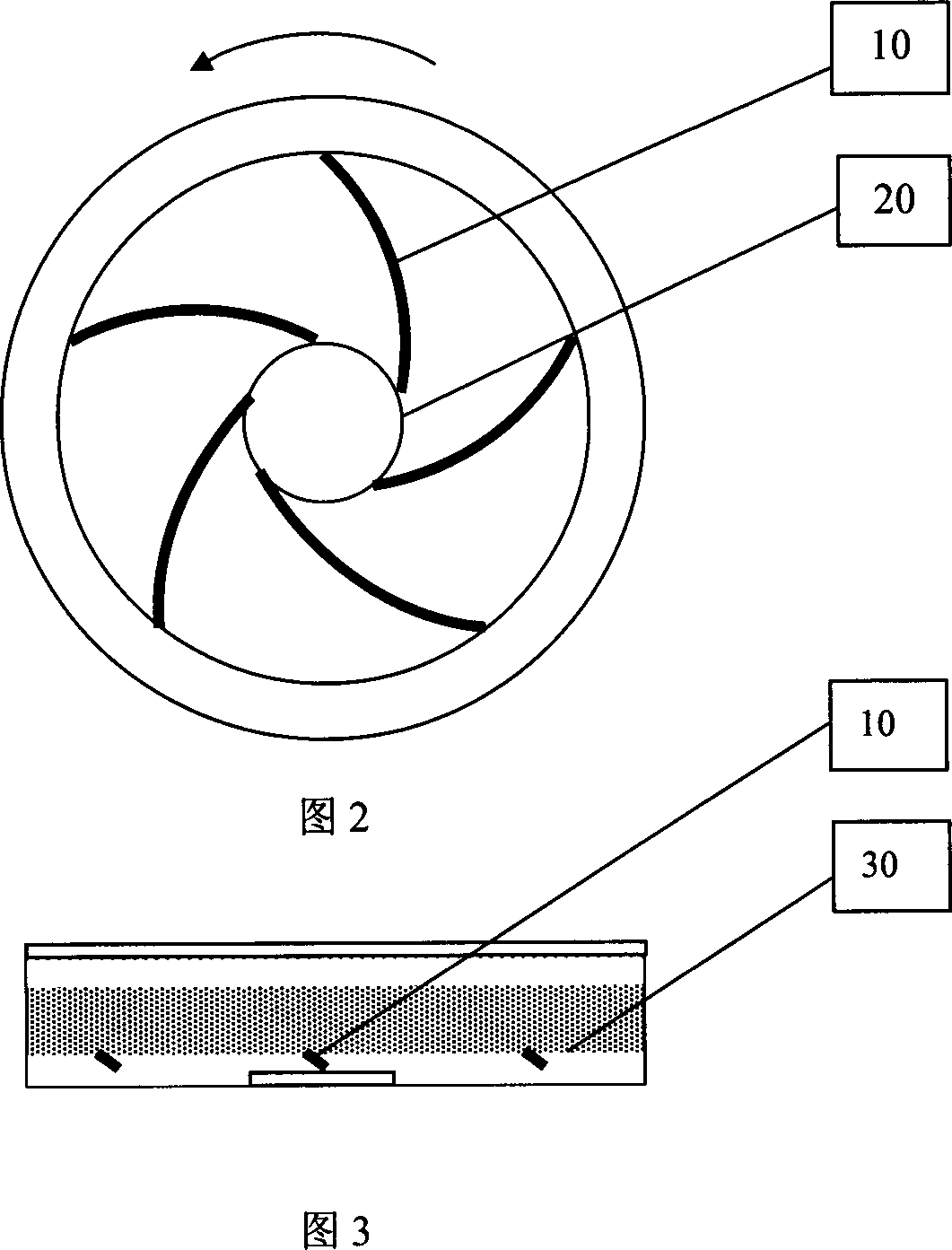

Centrifugal disc for producing glass wool

InactiveCN103723913AGood fibrillationUniform diameter distributionGlass making apparatusFiberEngineering

The invention relates to a centrifugal disc for producing glass wool. The centrifugal disc is characterized in that a curved slot for guiding the flowing direction of glass metal is formed in the bottom surface of the centrifugal disc, and the curve is in the shape of an Archimedean spiral; a main shaft installing hole in the bottom surface of the centrifugal disc is used as the starting end of the curved slot, a lower terminated line of a hole in the inner wall of the centrifugal disc is used as the ending end of the curved slot, and the curved slot is arranged in the same direction as the rotating direction of the centrifugal disc. The curved slot in the shape of the Archimedean spiral is formed in the bottom of the centrifugal disc, and is arranged in the same direction as the rotating direction of the centrifugal disc, therefore, the centrifugal disc has the characteristic of guiding the glass metal to adhere on the lateral wall of the centrifugal disc continuously and evenly so as to prevent the glass metal from generating turbulence in a centrifugal process; the centrifugal fiber-forming effect of the glass wool is significantly improved. The centrifugal disc can be widely applied to the field of preparing the glass wool in different levels, and can provide references for other fields of preparing materials in a centrifugal method.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

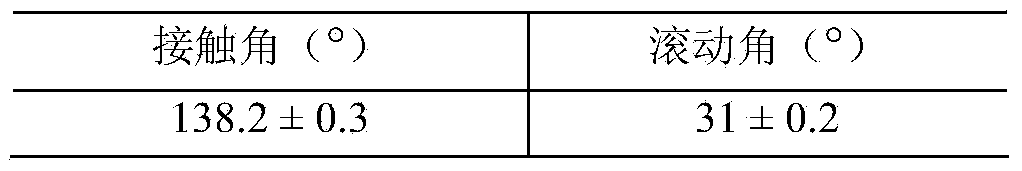

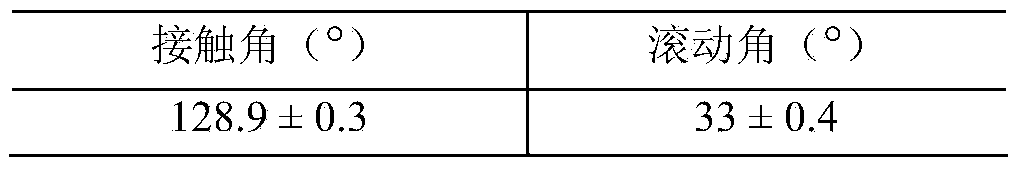

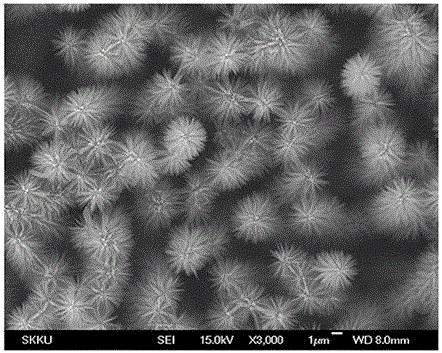

Preparation method of organic/inorganic hybridization nano super-hydrophobic fiber film

ActiveCN103820945AComprehensive collectionUniform diameter distributionNon-woven fabricsFiberPolymer science

The invention relates to a preparation method of an organic / inorganic hybridization nano super-hydrophobic fiber film. The method comprises the steps of dissolving a polymer carrier in water, and heating and stirring to obtain a polymer carrier solution; mixing tetraethoxysilane, water, zinc acetate and phosphoric acid, and stirring at the room temperature to obtain a mixing solution; uniformly mixing the mixed solution and the polymer carrier solution, then performing electrostatic spinning, drying in vacuum, forging, cooling and dipping in HCl solution, and drying to obtain a SiO2 porous nano fiber film; compositing and laminating the SiO2 porous nano fiber film, pouring a liquid, and drying in vacuum to obtain the organic / inorganic hybridization nano super-hydrophobic fiber film. The super-hydrophobic nano inorganic fibers have superhigh hydrophobic performance which can be maintained under the conditions of humidity, low temperature and the like without the FAS processing, is smooth and soft in hand feeling, gets rid of the limitation of the economic cost of an organic fluorocarbon and APEO and the environment-friendly limitation, and has the advantages of low price, no pollution, wide applicable range and the like.

Owner:DONGHUA UNIV +1

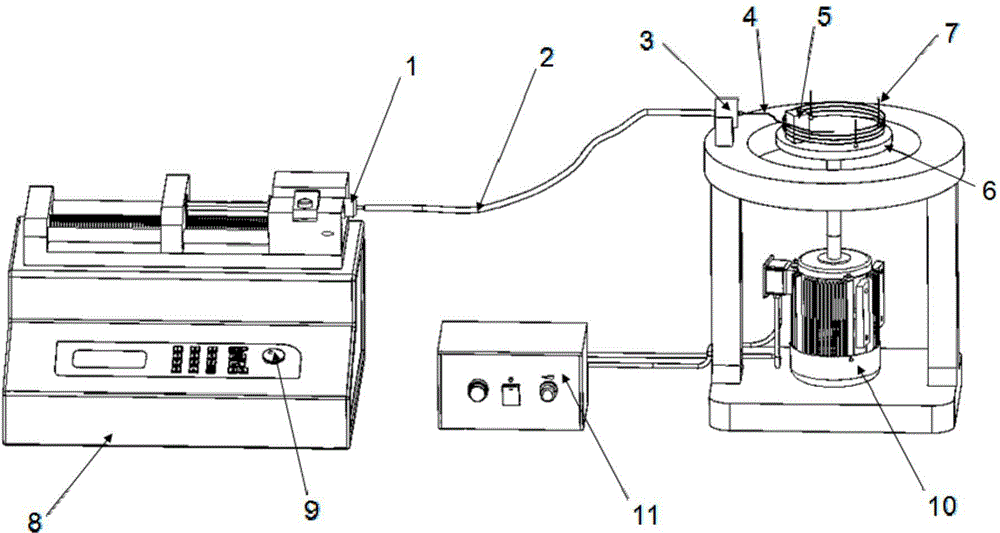

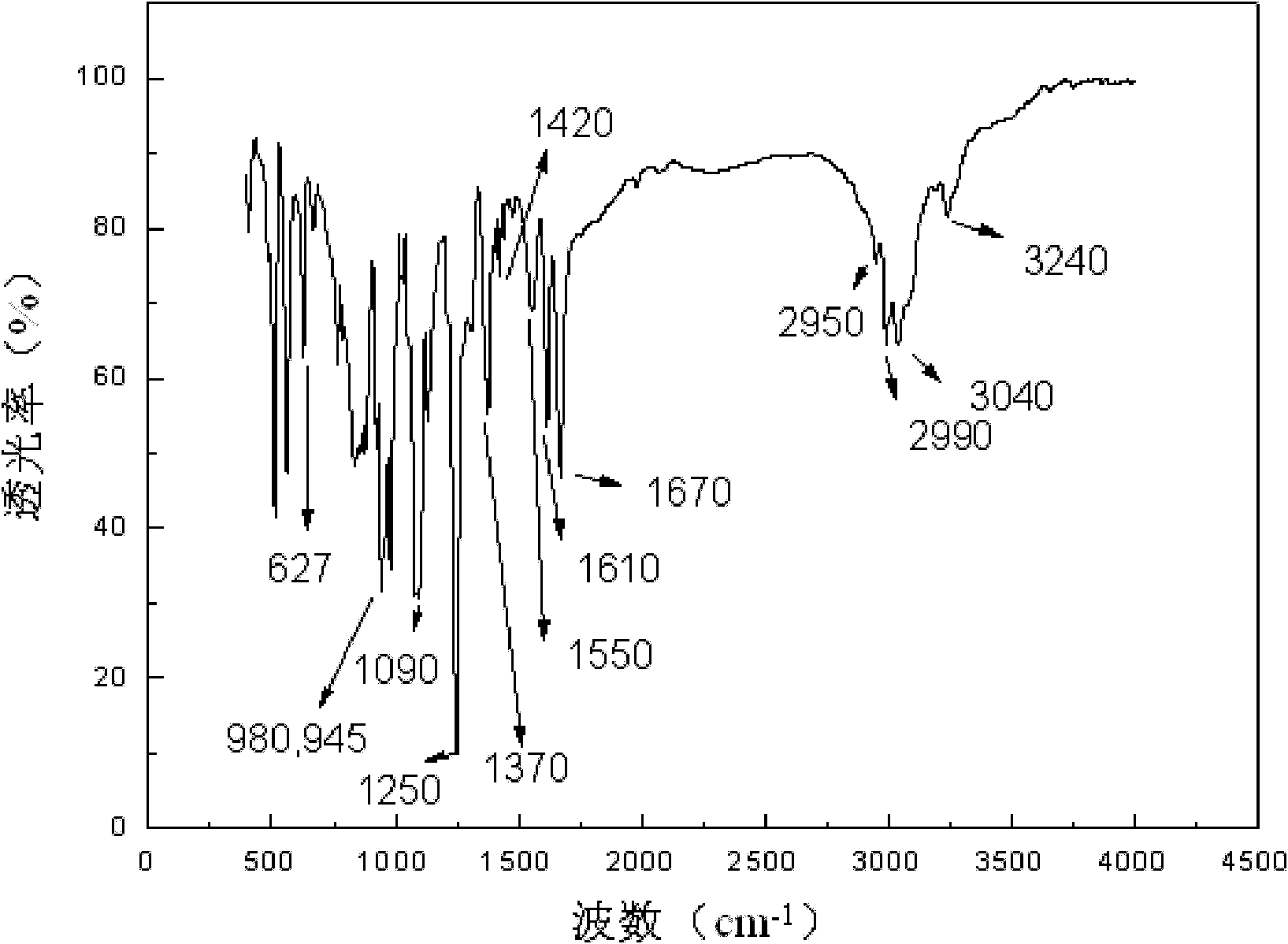

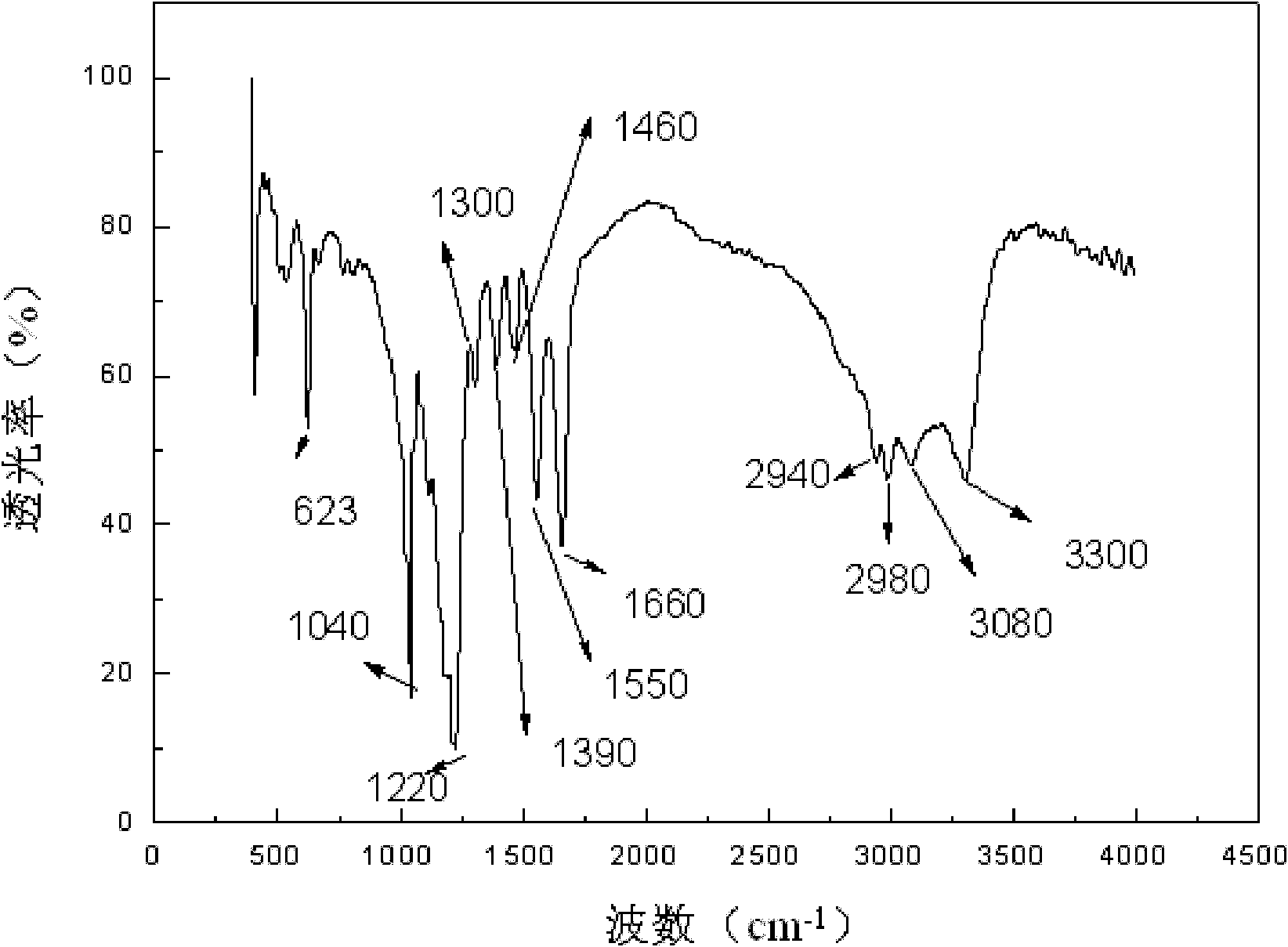

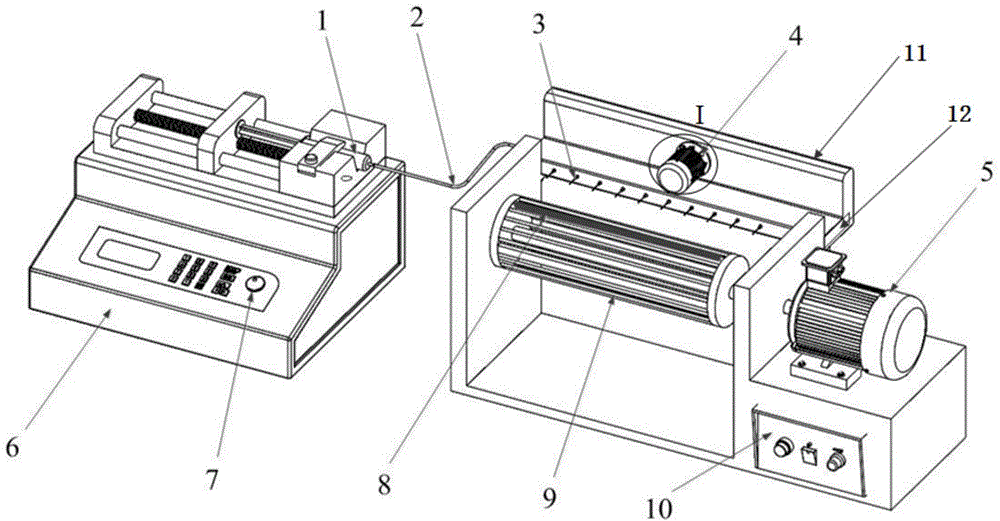

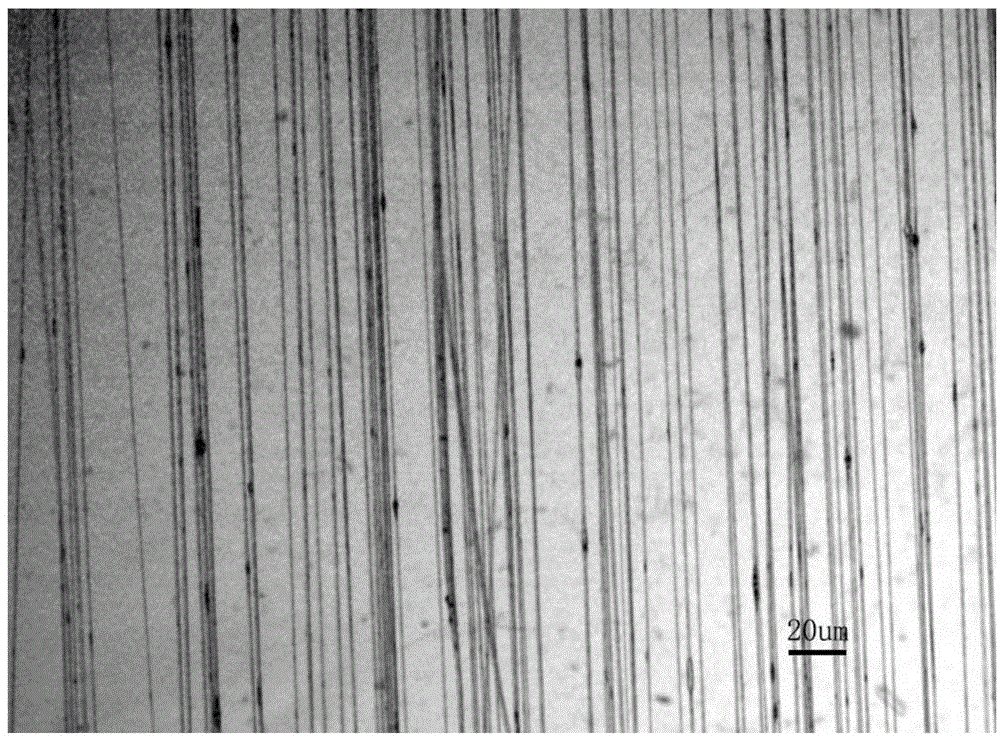

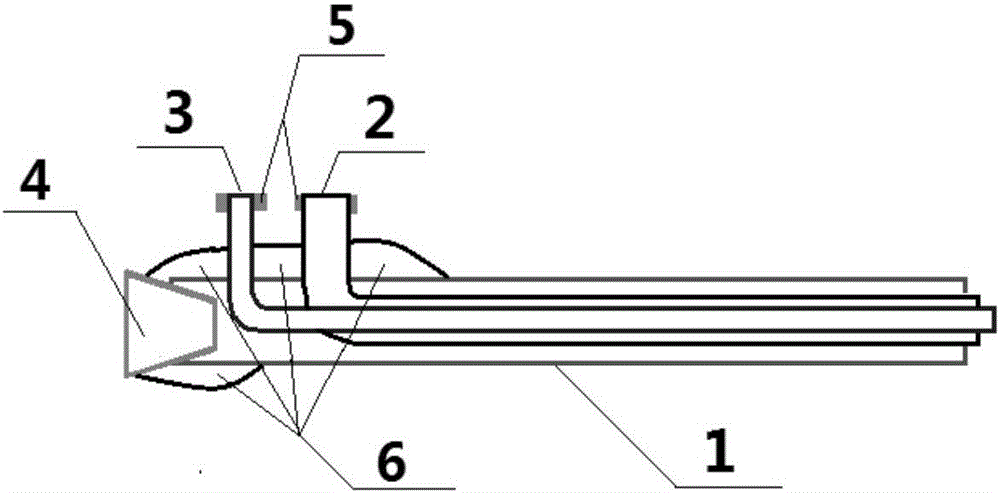

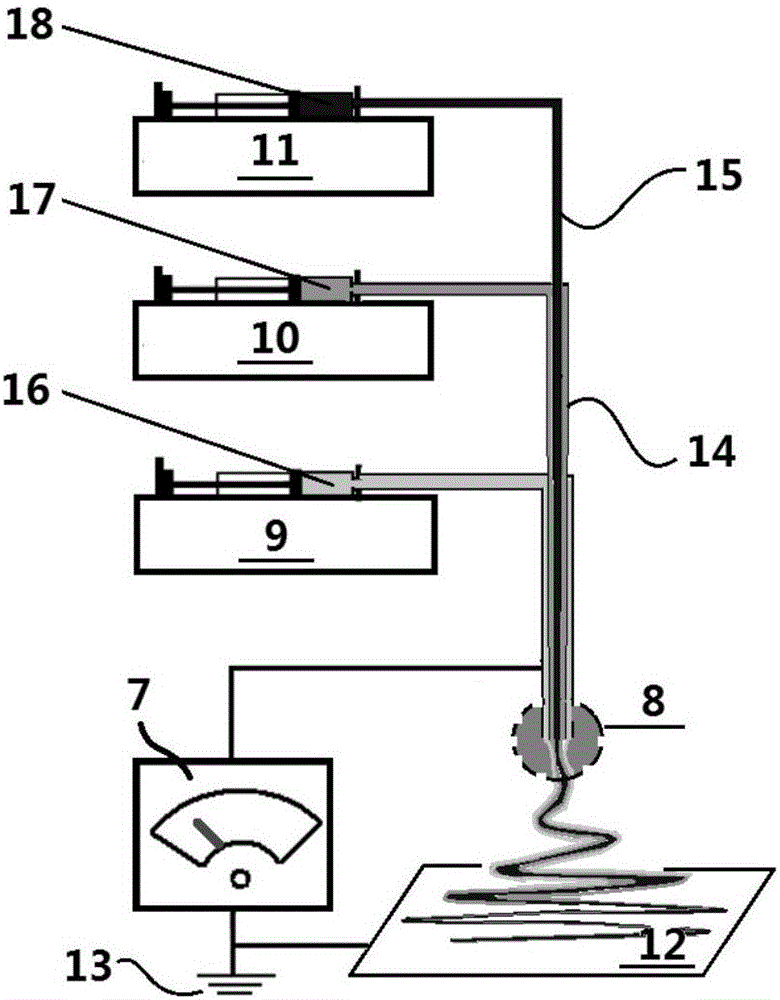

Method for preparing conducting polymer micro-nanofibers in magnetic spinning mode

ActiveCN104911719AArranged in an orderly mannerIncrease productionElectroconductive/antistatic filament manufactureFilament/thread formingMicro nanoFiber

The invention discloses a method for preparing conducting polymer micro-nanofibers in a magnetic spinning mode. The method comprises the steps that 1, a magnetic spinning device is built, wherein the magnetic spinning device comprises a rotary collection disc with a permanent magnet; 2, a spinning precursor solution is prepared, wherein magnetic nano particles, high-molecular polymer and conducting polymer are mixed and dissolved in an organic solvent solution; 3, the magnetic spinning device is utilized for preparing conducting polymer micro-nano complex fibers, wherein the spinning precursor solution is injected into a feeding device, the feeding device is started, liquid drops on an opening of a spinning nozzle forms a jet flow under the effect of magnetic field force to be connected with the permanent magnet to be a bridge, a brushless direct-current motor is started to drive the collection disc to rotate, the ferrofluid jet flow is continuously pulled out under the effect of magnetic field force, and conducting polymer micro-nanofibers are wound and formed among vertical supporting columns of the collection disc. The method does not need the high voltage effect, reduces the production cost and potential safety hazards, is suitable for large-scale production and has the good application prospect, and the fibers are distributed in order.

Owner:QINGDAO UNIV

Preparation method of NiO/gamma-Al2O3 composite ceramic nanofiber

The invention relates to a preparation method of an NiO / gamma-Al2O3 composite ceramic nanofiber, and the method comprises: (1) mixing and stirring an aluminum salt with a solvent so as to obtain an aluminum salt solution, adding a nickel salt into the aluminum salt solution, and stirring them fully so as to obtain an aluminum salt / nickel salt mixed solution; (2) first adding a spinnable polymer into the solvent, and adding the obtained solution into the aluminum salt / nickel salt mixed solution, thus obtaining an aluminum salt / nickel salt / spinnable polymer mixed spinning solution; (3) subjecting the mixed spinning solution to electrostatic spinning, thus obtaining a precursor composite nanofiber; and (4) calcinating the precursor composite nanofiber so as to obtain the NiO / gamma-Al2O3 composite ceramic nanofiber. The method of the invention utilizes the traditional electrostatic spinning technology for preparing an inorganic nanofiber indirectly, and the fiber has uniform diameter distribution, high length-diameter ratio, and good flexibility. And the method has simple and practicable process, as well as high success rate.

Owner:DONGHUA UNIV

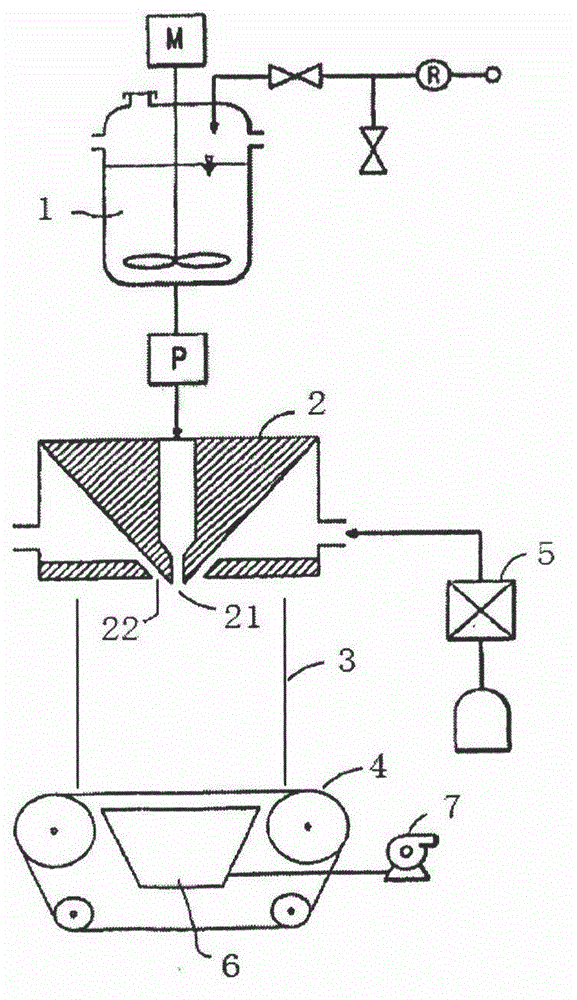

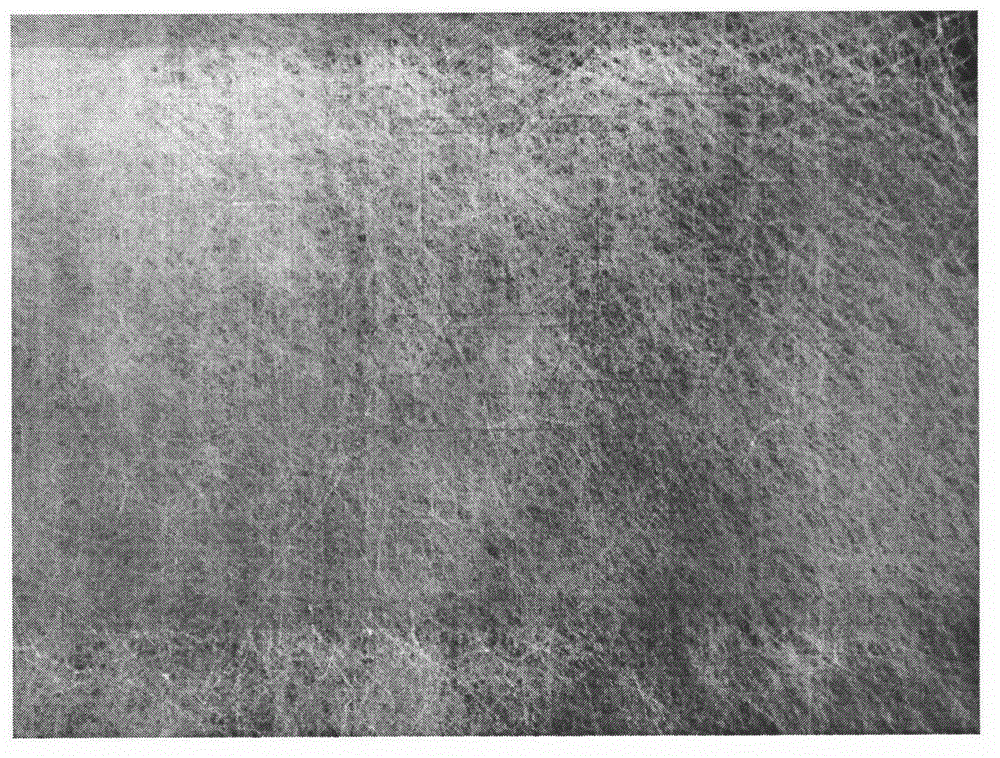

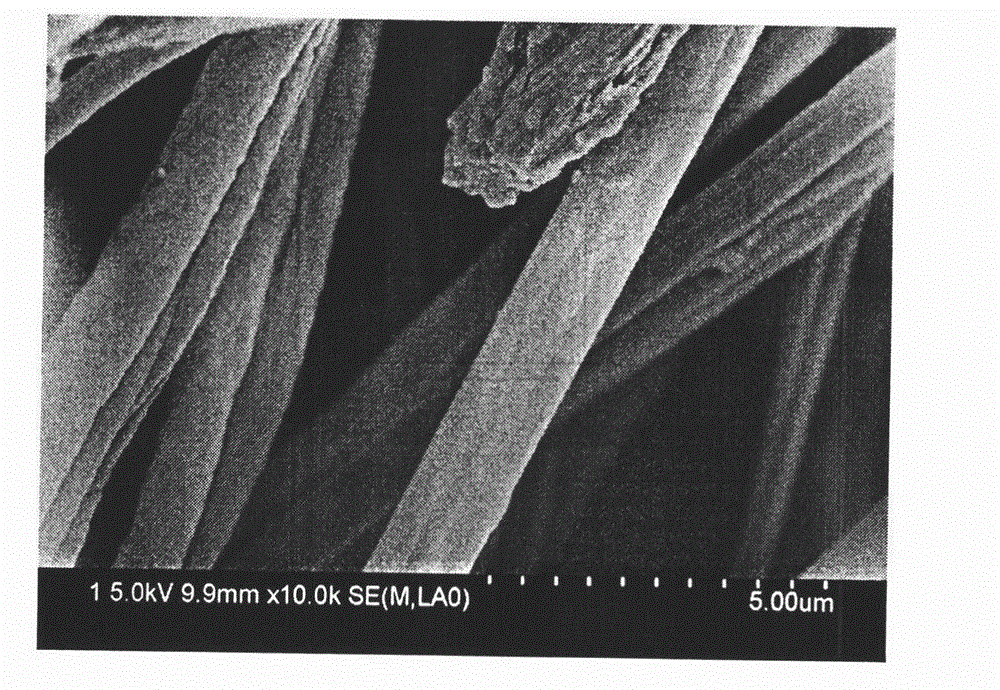

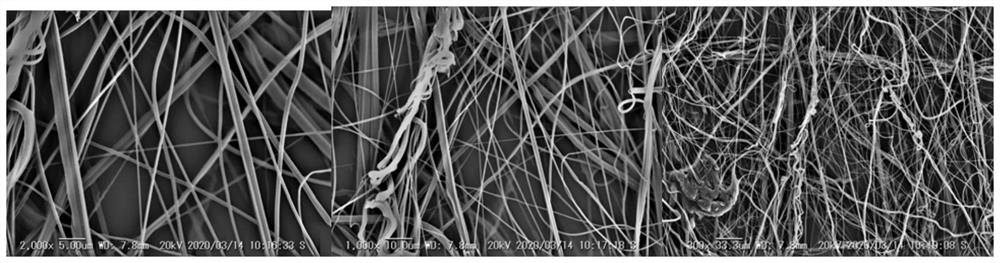

Preparation method of carbonized silicon (SiC) sub-micron fibers

InactiveCN102912476AHigh yieldFine fiber diameterFibre chemical featuresDry spinning methodsInjection pressurePolymer science

The invention relates to a preparation method of SiC sub-micron fibers. The method includes the steps that a precursor polymer is mixed with a fiber-forming polymer according to a mass ratio of (5:20)-(20:5) and dissolved in a solvent to produce an even and stable spinning solution; the spinning solution is supplied to a spinneret at a rate of 5-30mL / h for each spinneret orifice and extruded through the spinneret orifice to form solution trickles, and simultaneously, the spinning solution trickles are drafted and refined by high-speed injection airflow with an injection pressure of 0.1-1.5MPa to form precursor fibers with diameters of 50nm-10mum; the precursor fibers are subjected to oxidation treatment under an atmospheric condition of 160-250DEG C to obtain infusible fibers; and the infusible fibers are subjected to high-temperature calcinations under an inert gas atmosphere of 1000-1600DEG C to obtain the SiC sub-micron fibers with diameters of 10nm-5mum. The preparation method has the advantages of being high in production efficiency, simple in process, even in fiber diameter distribution, suitable for scale production and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Electrostatic spinning method for polyhydroxylated polymer

InactiveCN101275291AIncreased electrospinning speedImprove product qualityFilament/thread formingMonocomponent polyesters artificial filamentFiberSolvent

The invention discloses an electrostatic spinning method of polyhydroxylated polymer, comprising the following steps of dissolving polyhydroxylated polymer in a solvent to prepares polyhydroxylated polymer solution with mass percent 5% to 10%; adding water-soluble polyol including saponarin, flavonoid glycoside, alkaloid, sterol, diterpene or sesquiterpene compound, and arbutin, sophorolipid or vitamin with mass percent as 5% to 40% of total amount of polyhydroxylated polymer, after uniform agitation, undergoing deaeration treatment to prepare stock solution of electrostatic spinning. Under the condition of the same spinning technique, the speed for producing the stock solution of electrostatic spinning can be 3 to 6 times faster by the method; diameter of the produced fiber is nano-level to sub-micron level with smooth surface and uniform distributed diameter; the quality of product is improved obviously; the method has simple technique without special manufacturing device; therefore, the method is easy for popularization and application.

Owner:SUZHOU UNIV

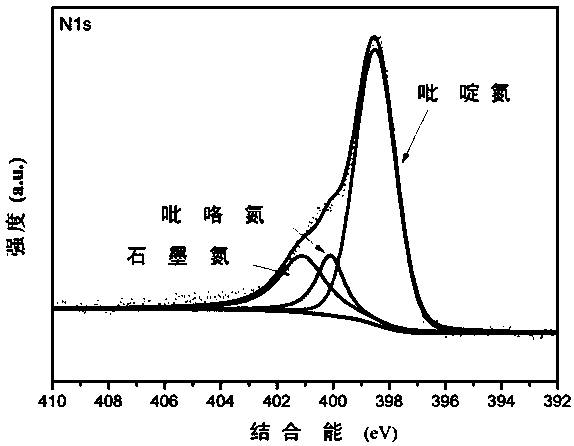

Nitrogen-doped carbon nanofiber electrocatalyst and preparation method and application thereof

ActiveCN108914153AEasy to prepareRaw materials are conventional and cheapElectrolytic organic productionElectrodesN dimethylformamideCarbonization

The invention discloses a nitrogen-doped carbon nanofiber electrocatalyst and a preparation method and application thereof. The method comprises: dissolving copper chloride dihydrate, polyvinylpyrrolidone and polyacrylonitrile in an N, N-dimethylformamide (DMF) solvent to obtain a spinning solution, then carrying out electrospinning through an electrospinning technique to obtain a copper chloride / polyvinylpyrrolidone / polyacrylonitrile nanofiber membrane, and orderly carrying out hydrothermal treatment, post-treatment, pre-oxidation treatment and carbonization treatment on the nanofiber membrane to obtain the porous nitrogen particle-loaded nitrogen-doped carbon nanofiber electrocatalyst with a certain mechanical strength. The preparation method is simple and is suitable for large-scale production. The nitrogen-doped carbon nanofiber electrocatalyst can be used for electric reduction of carbon dioxide.

Owner:SHENZHEN UNIV

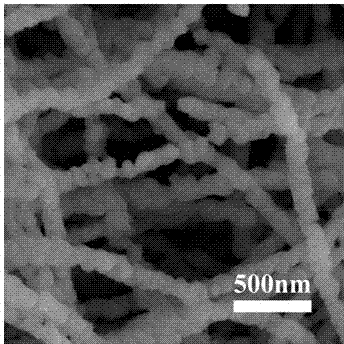

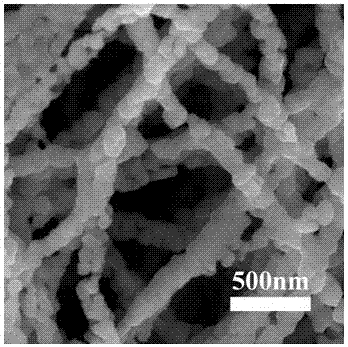

Cobaltosic oxide bead-chain-shaped fiber and preparation method thereof

InactiveCN104775185AHigh yieldEasy to produceInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberSpinning

The invention relates to a cobaltosic oxide bead-chain-shaped fiber and a preparation method thereof. The preparation method comprises the following steps: adding a cobalt source to N,N-dimethylformamide (DMF), and fully stirring till the cobalt source is completely solved; and adding polyvinylpyrrolidone (PVP) to the solution, stirring to obtain a spinning solution, spinning the spinning solution by utilizing an electrostatic spinning technique to obtain fibers, and forging fiber samples to obtain the cobaltosic oxide bead-chain-shaped fiber. According to the cobaltosic oxide bead-chain-shaped fiber and the preparation method thereof, the one-step electrostatic spinning technique is utilized; a bead-chain-shaped structure is formed by controlling the property of a precursor raw material; the process is simple; the bead-chain-shaped structure is a one-dimensional structure formed by connecting Co3O4 monocrystal grains of similar granularity, the diameter is distributed uniformly, the shape is regular, the grains are completely exposed and are connected closely, and the specific surface area is relatively large; the cobaltosic oxide bead-chain-shaped fiber and the preparation method thereof have the wide application prospect in the fields of battery electrode materials, chemical catalysts, gas sensing and the like.

Owner:UNIV OF JINAN

Material based on bismuth oxycarbonate or bismuth oxide nano tube and preparation method thereof

InactiveCN105271405AMild reaction conditionsEasy to operateMaterial nanotechnologyBismuth compoundsPhotocatalytic degradationAmmonia

The invention discloses a preparation method of a material based on a bismuth oxycarbonate or bismuth oxide nano tube. The preparation method of the material based on the bismuth oxycarbonate or bismuth oxide nano tube comprises the following steps: firstly dissolving bismuth nitrate in dilute nitric acid or dissolving bismuth nitrate into dilute nitric acid solution dispersed with oxidized graphene, and uniformly stirring, so as to obtain first reaction solution; secondly, dropwise adding ammonia water in the first reaction solution until pH value of a system generated by mixing the first reaction solution and the ammonia water to be alkaline, so as to obtain second mixed liquor; and thirdly, stirring the second mixed liquor in CO2-containing atmosphere or CO2-free atmosphere, so as to obtain the material based on the bismuth oxycarbonate or bismuth oxide nano tube. The obtained material is a bismuth oxycarbonate nano tube, a bismuth oxide nano tube, a graphene-based bismuth oxycarbonate nano tube or a graphene-based bismuth oxide nano tube and can be applied to the fields of photocatalysis degradation, sterilization, adsorption, gas sensing, energy storage and pharmacy.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of polycrystalline Al2O3-Y3Al5O12 complex-phase fibers or pure YAG fibers

InactiveCN105002601AUniform diameterShort preparation timeInorganic material artificial filamentsArtifical filament manufactureFiberPolymer science

The invention discloses a preparation method of polycrystalline Al2O3-Y3Al5O12 complex-phase fibers or pure YAG fibers. The preparation method comprises the following steps that (1) precursor colloids of the polycrystalline Al2O3-Y3Al5O12 complex-phase fibers and the pure YAG fibers are prepared; (2) centrifugal spinning is performed, namely a home-made centrifugal spinning machine is adopted to perform centrifugal spinning so as to obtain uniform-diameter gel fibers under the conditions of appropriate wind seed, appropriate rotation speed and relative humidity; (3) the polycrystalline Al2O3-Y3Al5O12 complex-phase fibers and the YAG fibers are prepared, namely the obtained gel fibers are dried at the temperature of 55-75 DEG C for 12 hours, then heat processing is performed at the temperature interval of 800-1400 DEG C for 2 hours to obtain the required polycrystalline Al2O3-YAG complex-phase fibers and continuous YAG fibers. The fibers prepared by means of the preparation method have good flexibility, higher in high-temperature-resistance degree and better in creep resistance performance, and industrial production can be considered.

Owner:南京理工宇龙新材料科技股份有限公司

High-safety high-energy long-cycle lithium iron phosphate type 18650 lithium battery and preparation method thereof

ActiveCN109088033ASignificant conjugation effectGood electrical conductivityMaterial nanotechnologyFinal product manufactureCarbon dopedSmall particle

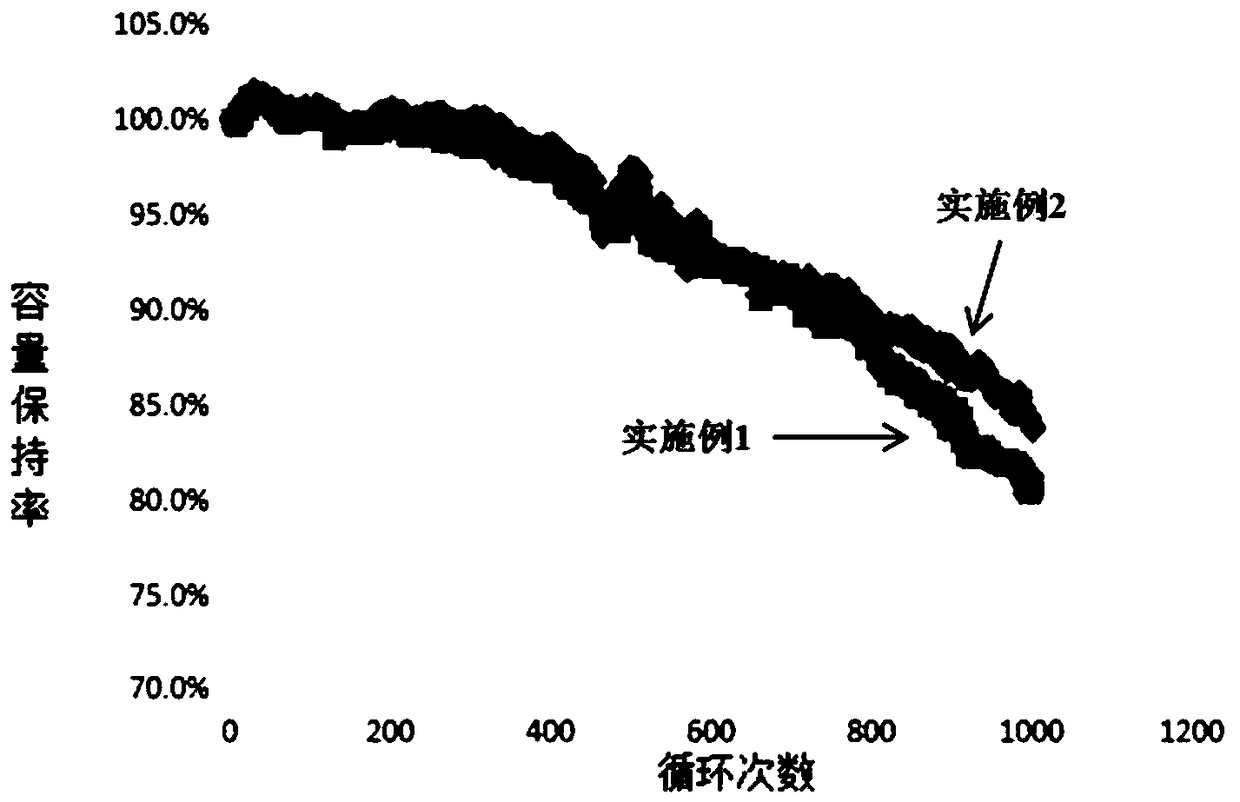

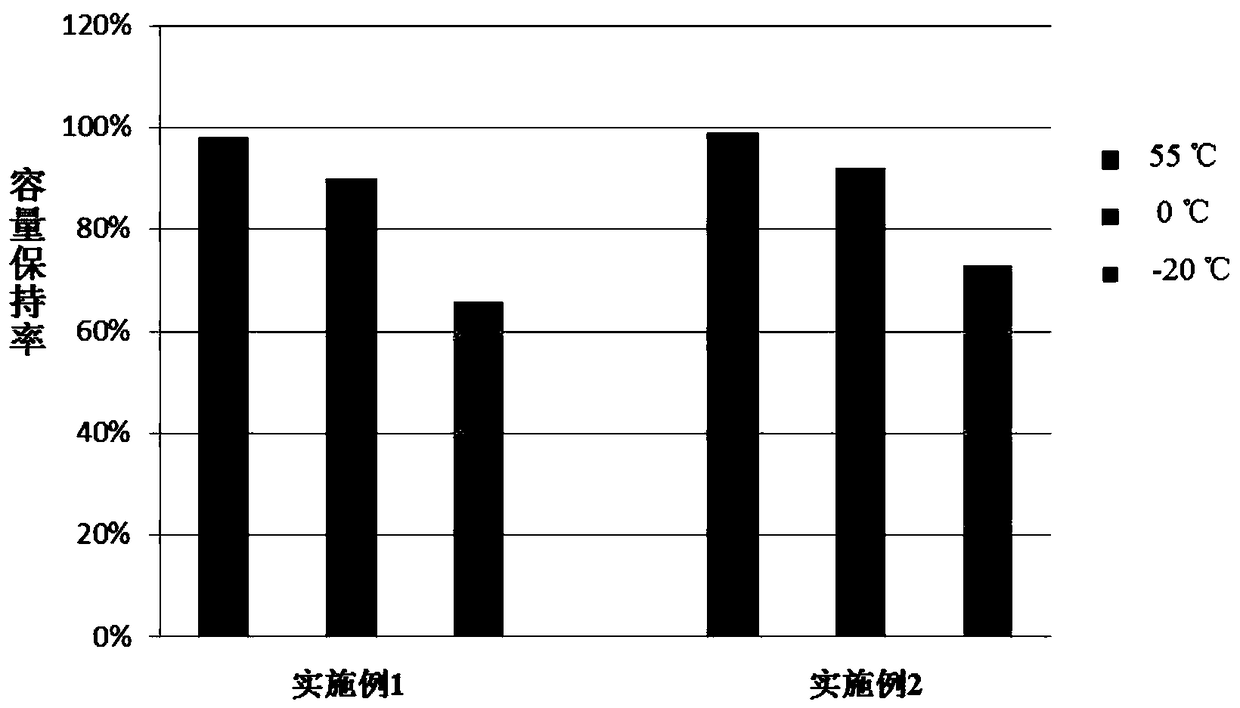

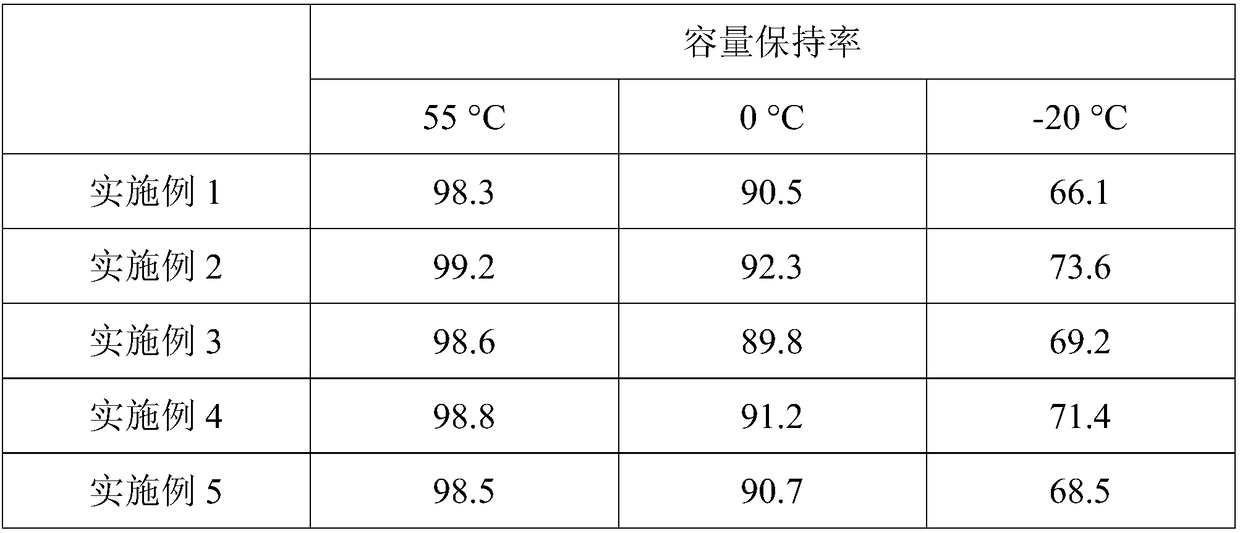

The invention provides a high-safety high-energy long-cycle lithium iron phosphate type 18650 lithium battery and a preparation method thereof. The cathode active material of the battery is carbon doped coated lithium iron phosphate with a small particle size and uniform particle size distribution, with the specific capacity being not less than 155 mAh / g and the compaction density being 2.0 - 2.8g / cm<3>; the anode active material is graphite with the specific capacity being 350 - 375 mAh / g and the compaction density being not less than 1. 7 g / cm<3>; a membrane is a PE base membrane coated with a nanometer Al2O3 ceramic membrane. The method comprises the steps of homogenizing, coating, rolling, cutting, winding, shelling, liquid injection, cleaning, oiling, forming and mixing. The batteryenergy density of the invention is as high as 390Wh / L, the discharge capacity of the monomer cell 0.2 C is not less than 2000 mAh, the cycle performance is excellent, the capacity retention rate of the cell 0.5 C / 0. 5C100% DOD after 1000 cycles is above 80%, the thermal stability is good, and the overcharge performance is good.

Owner:江西省汇亿新能源有限公司

Process for preparing titanium dioxide nano-tube

InactiveCN101239738AReduce the temperatureSave resourcesNanostructure manufactureTitanium dioxideGranularityAqueous sodium hydroxide

The present invention provides a titanium dioxide nanotube and its preparing method. The method is first dripping titanium tetrachloride in de-ionized water containing organic additive to form homogeneous solution; then mixing to homogeneous buffer alkaline solution according to a certian mol ratio of ammonia and urea, adding the solution in homogeneous solution containing titanium to proceed ultrasonical reaction after being mixed; the nano titanium dioxide powder obtained by preheating reactant which granularity is homogeneous; then mixing nano titanium dioxide powder and NaOH solution containing organic additive, placing in reactor, processing kaline ultrasonical reaction, then obtaining titanium dioxide nanotube after being dried. The titanium dioxide nanotube has a simple process, convenient operation, the diameter of the titanium dioxide nanotube is homogeneous.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing porous mullite fiber through coaxial electrostatic spinning

InactiveCN106868632AUniform diameter distributionSimple manufacturing processInorganic material artificial filamentsFiberN dimethylformamide

The invention relates to a method for preparing porous mullite fiber through coaxial electrostatic spinning and belongs to the science and technology technical field of materialsmaterial science. The fiber preparing method comprises the following steps: preparing anhydrous aluminum chloride, tetraethoxysilane, isopropyl ether and anhydrous dichloromethane into a reaction solution according to a certain molar ratio, then heating the reaction solution, triggering non-hydrolytic sol-gel reaction to synthesize mullite gel; mixing absolute ethyl alcohol and a certain amount of polyvinylpyrrolidone (PVP) according to a certain ratio to obtain a PVP ethanol solution, dissolving the synthesized mullite gel in the PVP ethanol solution, then adding N,N-dimethylformamide (DMF) to obtain a spinning precursor solution; taking liquid paraffin as an inner solution, taking the mullite precursor solution as an outer solution, preparing mullite gel / PVP composite fiber through a coaxial electrostatic spinning process, then calcining the mullite gel / PVP composite fiber under high temperature to obtain the porous mullite fiber. The preparation method of the porous mullite fiber is simple; the porous structure is easy to control; the porous mullite fiber has excellent heat insulation and heat preservation properties; a novel high-temperature heat insulation material is provided for the fields such as aviation and military industry and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

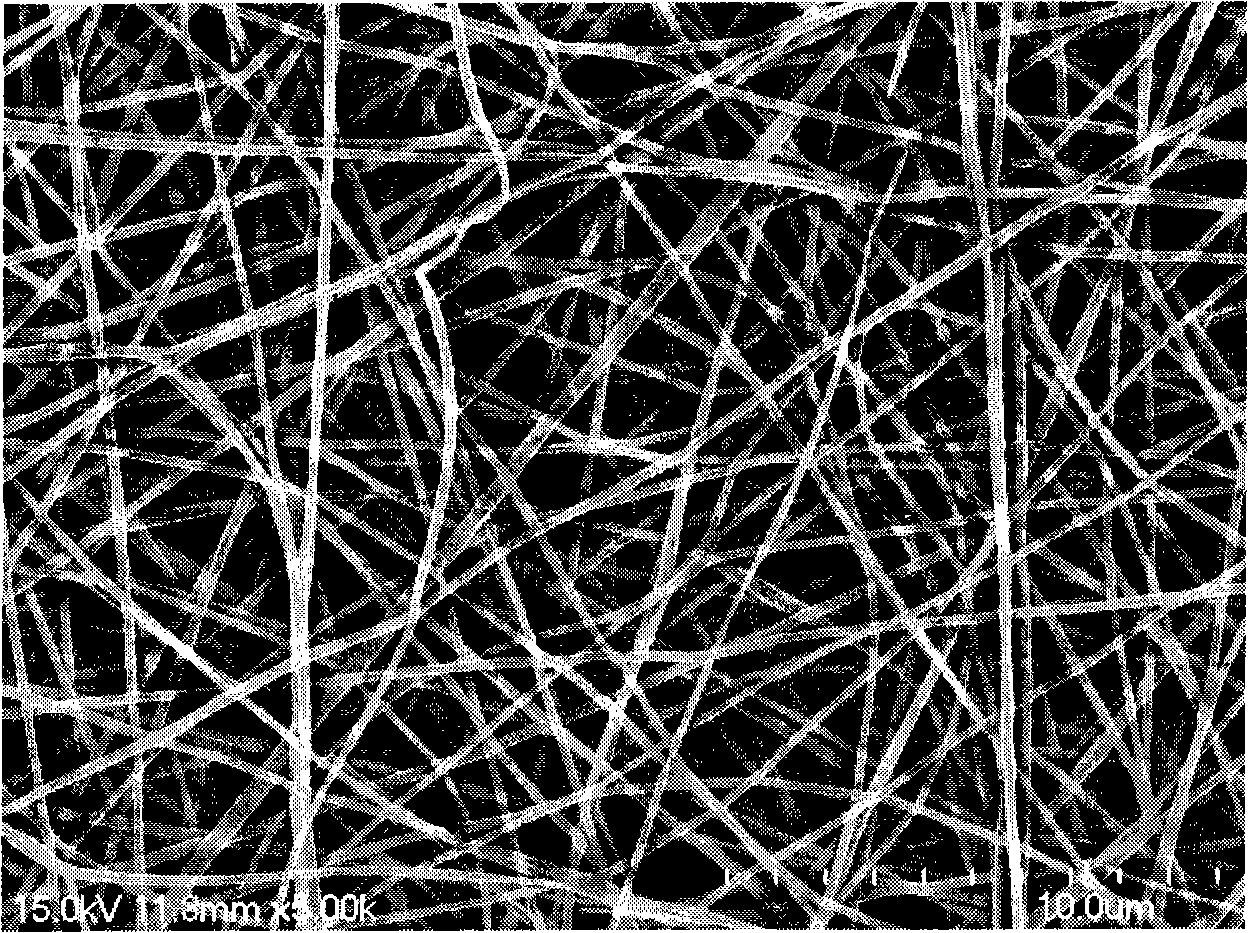

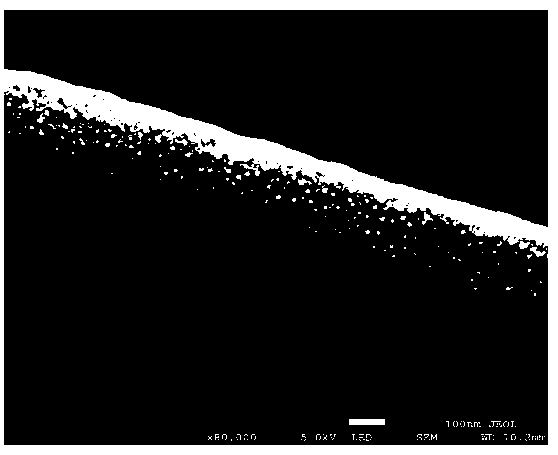

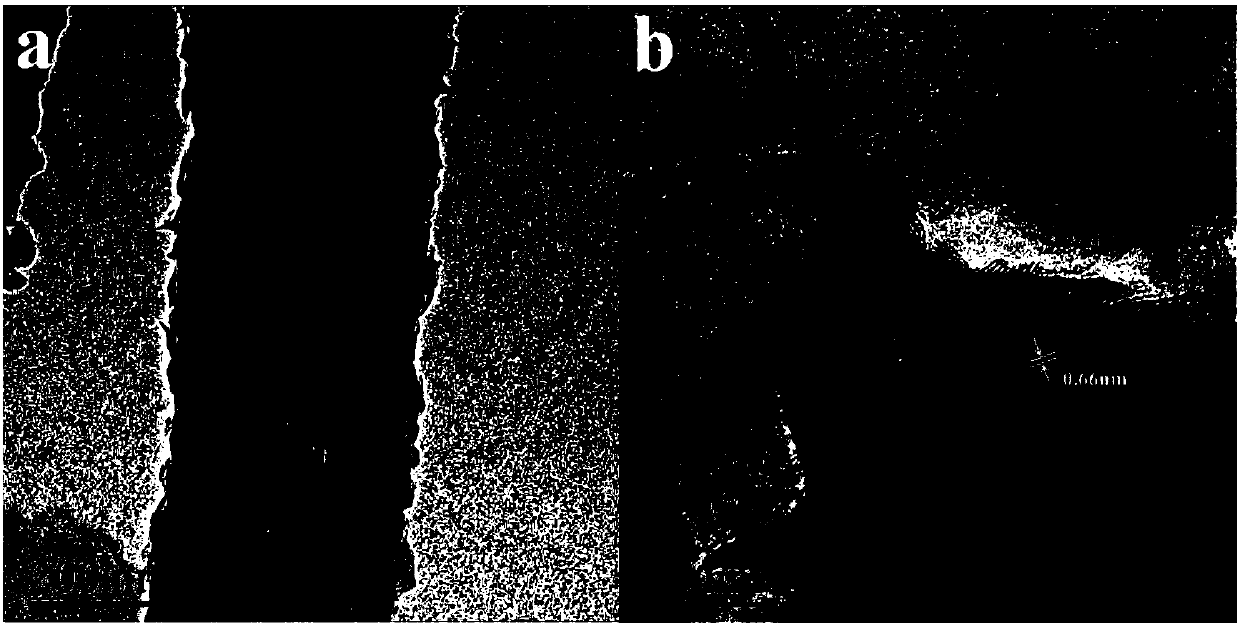

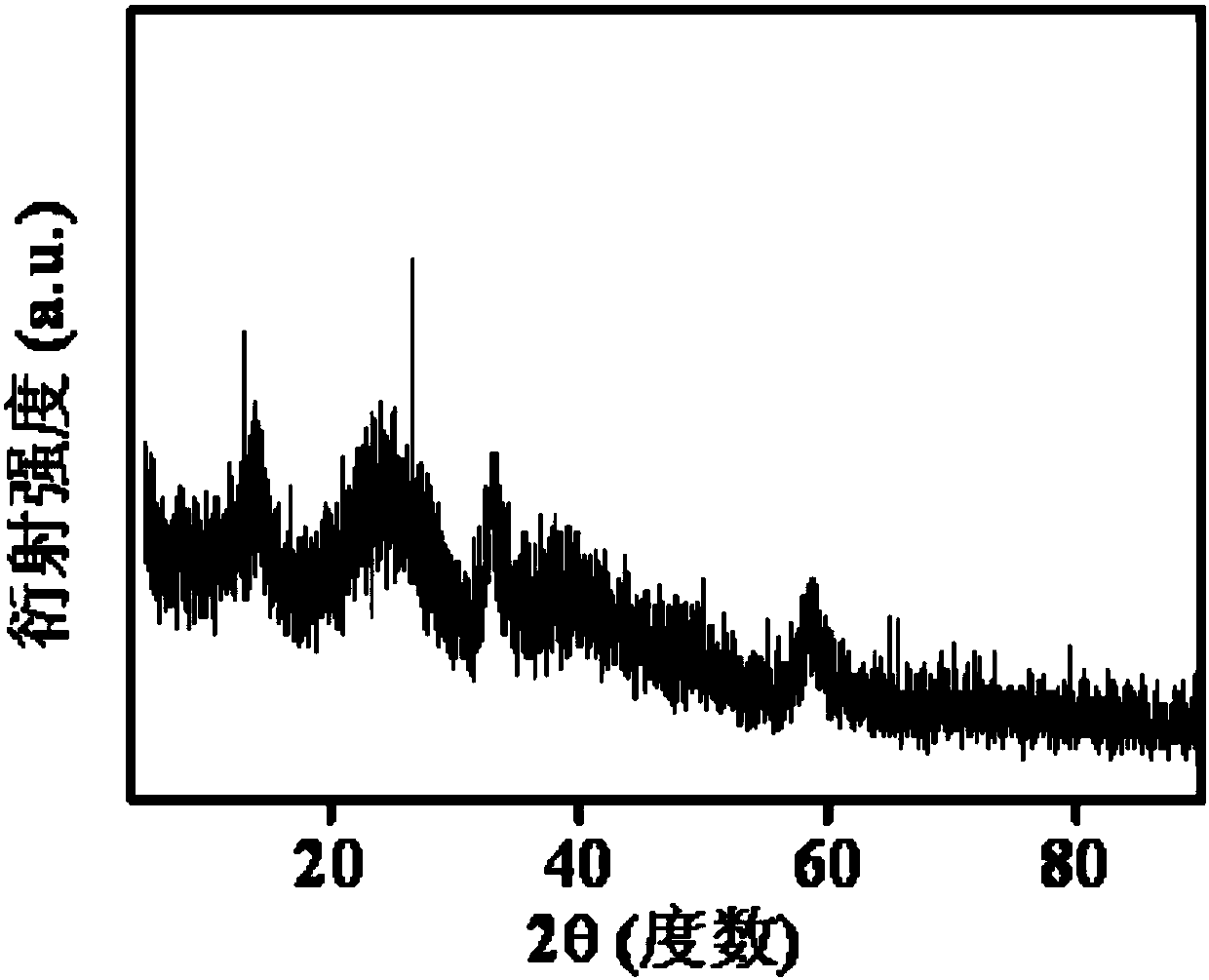

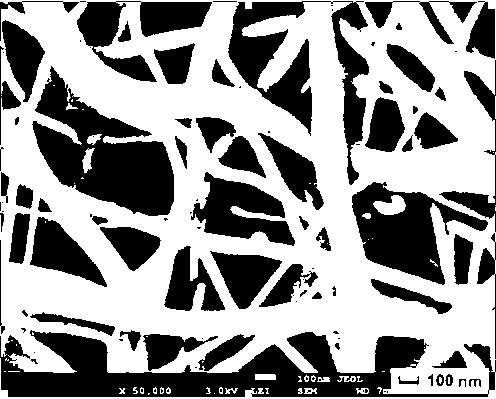

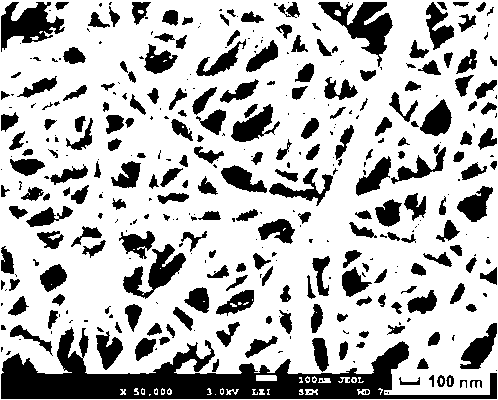

Nitrogen doped carbon nanofiber/molybdenum disulfide composite and preparation method and application thereof

ActiveCN107768622AUniform diameter distributionLarge specific surface areaCell electrodesSecondary cellsFiberHigh rate

The invention relates to a nitrogen doped carbon nanofiber / molybdenum disulfide composite. The nitrogen doped carbon nanofiber / molybdenum disulfide composite takes a polymethyl methacrylate nanofiberas a template, polypyrrole is polymerized on the surface of the nanofiber in situ, the molybdenum disulfide is then grown in situ, the composite has a hollow tubular structure, a molybdenum disulfidesheet is evenly distributed on the surface of the nitrogen doped carbon nanofiber, the size of the nitrogen doped carbon nanofiber is uniform, a preparation method comprises synthesis of a polymethylmethacrylate spinning solution, synthesis of a polymethyl methacrylate nanofiber membrane, synthesis of the polypyrrole / polymethyl methacrylate nanofiber membrane, synthesis of the nitrogen doped carbon nanofiber / molybdenum disulfide nanofiber membrane, and synthesis of the nitrogen doped carbon nanofiber / molybdenum disulfide composite. The method is simple, is easy to operate and is environmentally friendly; the prepared nitrogen doped carbon nanofiber / molybdenum disulfide composite has the advantages of high specific surface area, high cycle stability, high electric conductivity, high rate capability and high specific capacity, and is used as a negative electrode material for a lithium ion battery.

Owner:DONGHUA UNIV

Glass carbon nanometer fiber preparation method

InactiveCN102936763AAbundant productionLow costFilament/thread formingHeating/cooling textile fabricsFiberCellulose acetate

The present invention relates to the field of nanometer fibers, specifically to a glass carbon nanometer fiber preparation method, which is characterized by comprising: 1) adopting cellulose acetate as a precursor, adopting acetone and N,N-dimethylacetamide as a mixed solvent, carrying out magnetic stirring to prepare a spinning solution, and adopting an electrostatic spinning method to prepare cellulose acetate nanometer fibers; 2) carrying out hydrolysis on the cellulose acetate nanometer fibers for 24 h by using an ethanol solution containing 0.1 mol / L NaOH, washing with distilled water to achieve a neutral state, draining for 8 h under an atmospheric environment, and carrying out vacuum drying for 12 h at a temperature of 70 DEG C to obtain cellulose nanometer fibers; and 3) placing the cellulose nanometer fibers in a tube furnace to carry out a stabilization and carbonization treatment to obtain the glass carbon nanometer fibers. The preparation method has characteristics of low cost, low pollution and simple process. With the preparation method, diameter and morphology of the fibers can be controlled by adjusting composition of the spinning solution and electrospinning parameters, the prepared fibers have uniform diameter distribution, and the method is suitable for mass production.

Owner:FUJIAN NORMAL UNIV

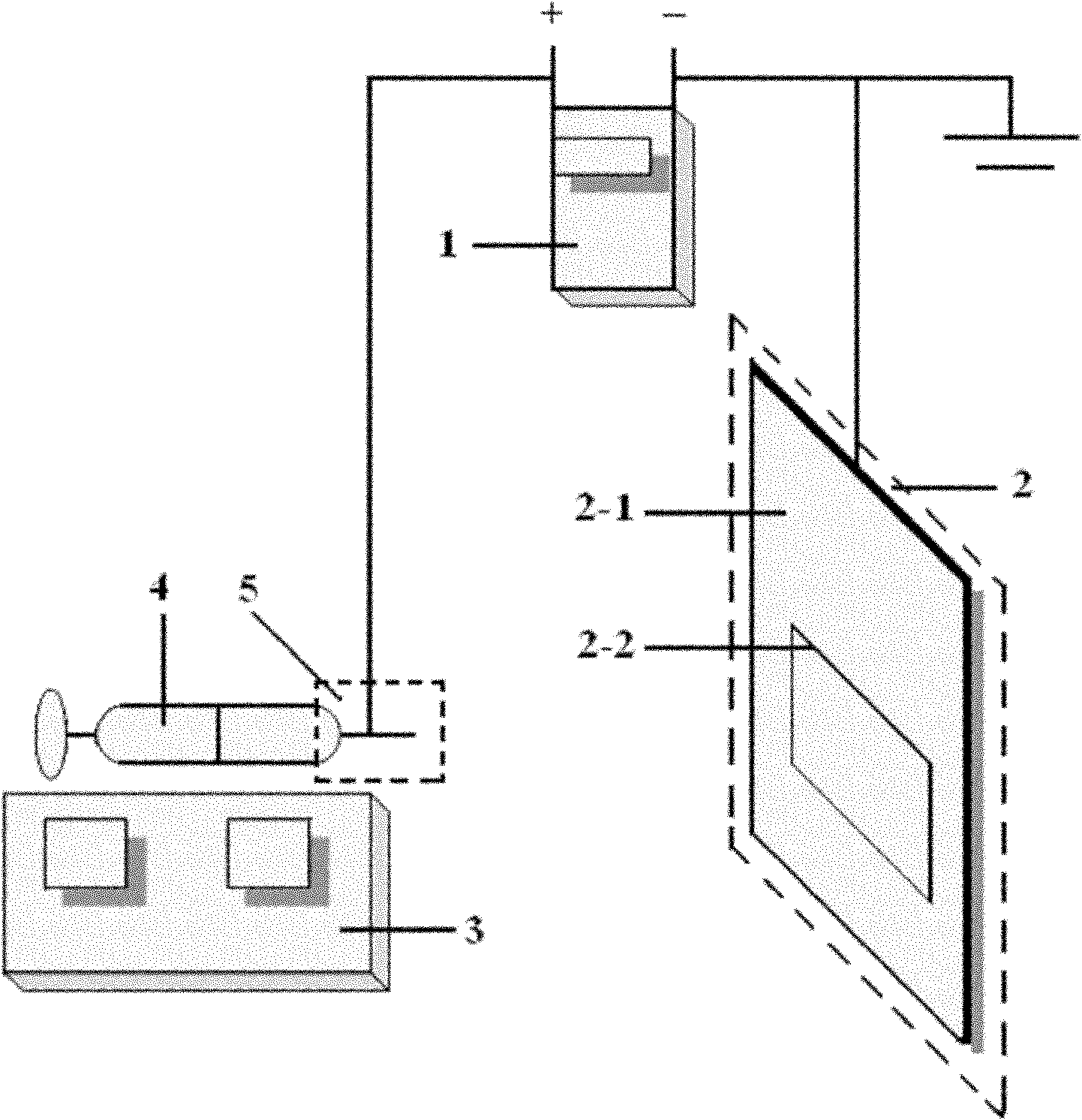

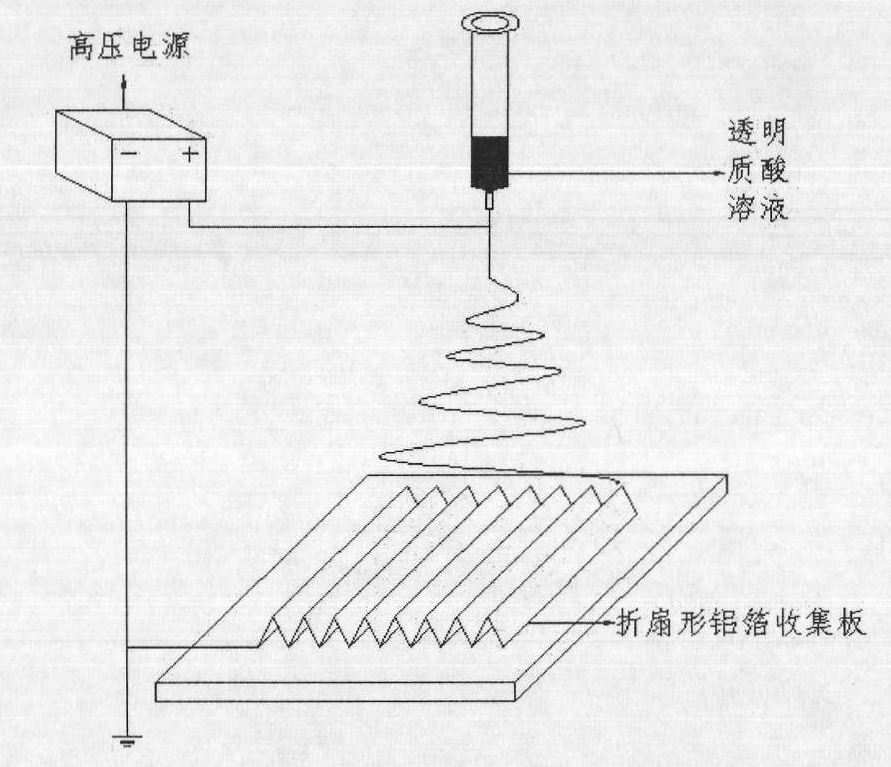

Electrostatic spinning equipment and method thereof for preparing one-dimensional ordered PAMPS (2-Acrylamide-2-methylpro panesulfonic acid)/PNIPAAm (Poly(N-Isoprolacrylamide)) micro-nanofibers

InactiveCN102031574AIncrease the areaImprove orderNew-spun product collectionArtificial thread manufacturing machinesFiberElectrospinning

The invention discloses electrostatic spinning equipment and a method thereof for preparing one-dimensional ordered PAMPS (2-Acrylamide-2-methylpro panesulfonic acid) / PNIPAAm (Poly(N-Isoprolacrylamide) micro-nanofibers, relating to electrostatic spinning equipment and a method thereof for preparing one-dimensional ordered micro-nanofibers. The invention solves the problem that the traditional electrostatic spinning equipment is unavailable for the production of large-area one-dimensional ordered micro-nanofibers. The electrostatic spinning equipment comprises a high voltage source, a receiving device, a boost pump, an injection syringe and a nozzle, wherein the receiving device is composed of an aluminum foil and a quartz glass receiving sheet arranged on an aluminum foil receiving surface in parallel, and the aluminum foil surface is vertical to the spinning direction of the nozzle. The method comprises the following steps of: preparing electrostatic spinning liquid of which the polymer mass concentration is 7-14%; injecting the electrostatic spinning liquid into the injection syringe; fixing the injection syringe on the boost pump; setting an electrostatic spinning parameter; and starting the equipment. In the equipment, the quartz glass sheet serves as the receiving sheet, the electric field distribution of an aluminum foil receiving plate is changed, and the large-area one-dimensional ordered micro-nanofibers are prepared. The one-dimensional ordered PAMPS / PNIPAAm micro-nanofibers are obtained by spinning, with diameters evenly distributed.

Owner:HARBIN INST OF TECH

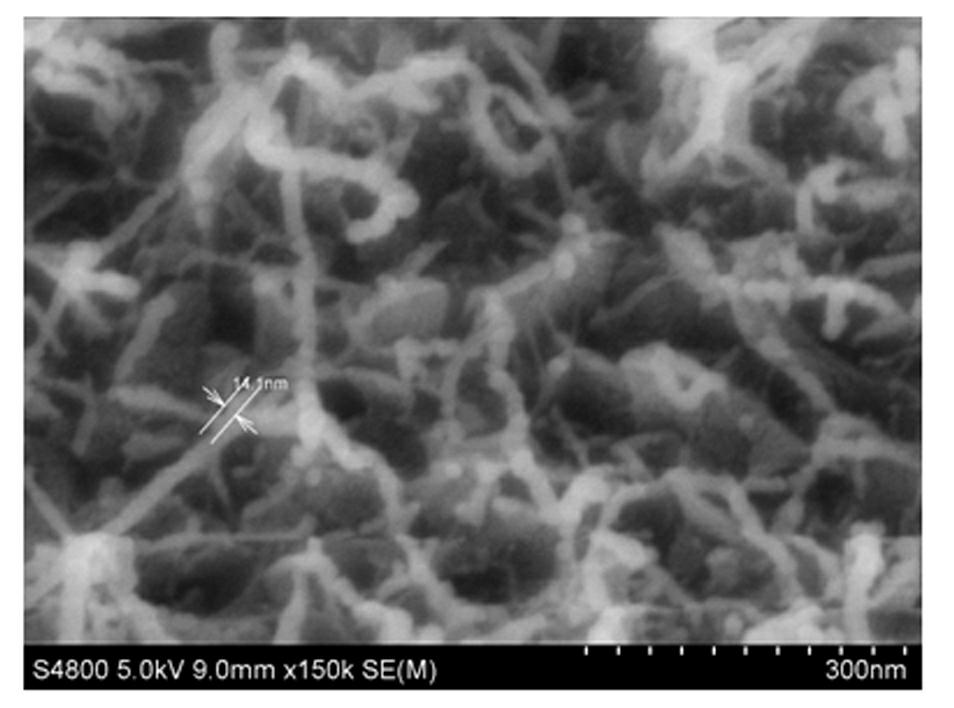

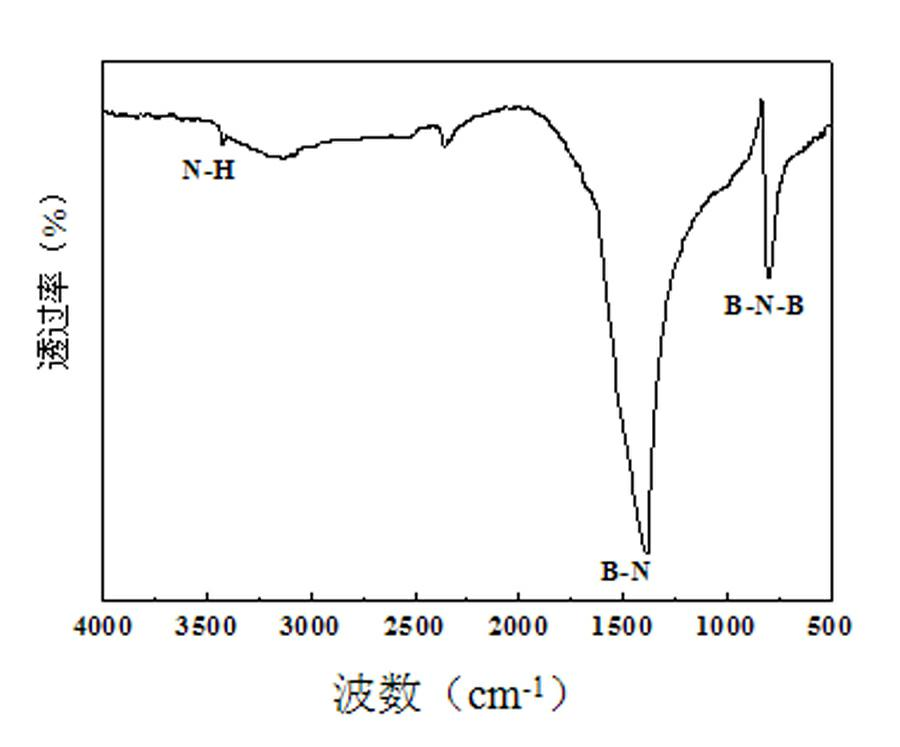

Method for preparing boron nitride nanowire by cracking of polymer

ActiveCN102126710AUniform diameter distributionIncrease contact areaNitrogen compoundsChemical industrySemiconductor materialsNanowire

The invention provides a method for preparing a boron nitride nanowire by cracking of a polymer. The method comprises the following steps: synthesizing a polyalkylamino borazine precursor according to the prior art: grinding the precursor under the protective condition of inert gas and screening the grinded precursor through a 1000-mesh sieve; placing the precursor powder in a graphite boat, rising the temperature to 100-200 DEG C at the speed of 3-10 DEG C / min in the presence of high-pure nitrogen in a tubular furnace, and then insulating for 1-3 hours; rising the temperature to 500-700 DEG C at the speed of 3-10 DEG / min, and then insulating for 1-3 hours; at the atmosphere of nitrogen, heating to 1000-1600 DEG C at the rising speed of 3-10 DEG C / min, then insulating for 0.5-5 hours, and then cooling along with the furnace so as to obtain the boron nitride nanowire. The diameter of the nanowire prepared by the method is about 13-18 nm and is evenly distributed, no catalyst is used, preparation temperature is low, and energy is saved, thereby reducing the cost; and the method is simple in process, is convenient for operation and is easy to achieve large scale; and as a structure reinforced material, a semiconductor material, a wave-transparent material and the like, the prepared boron nitride nanowire has a good prospect of application.

Owner:NAT UNIV OF DEFENSE TECH

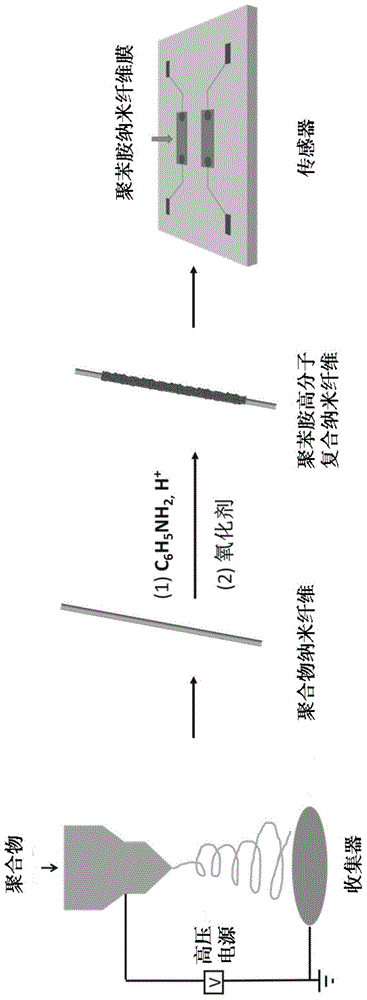

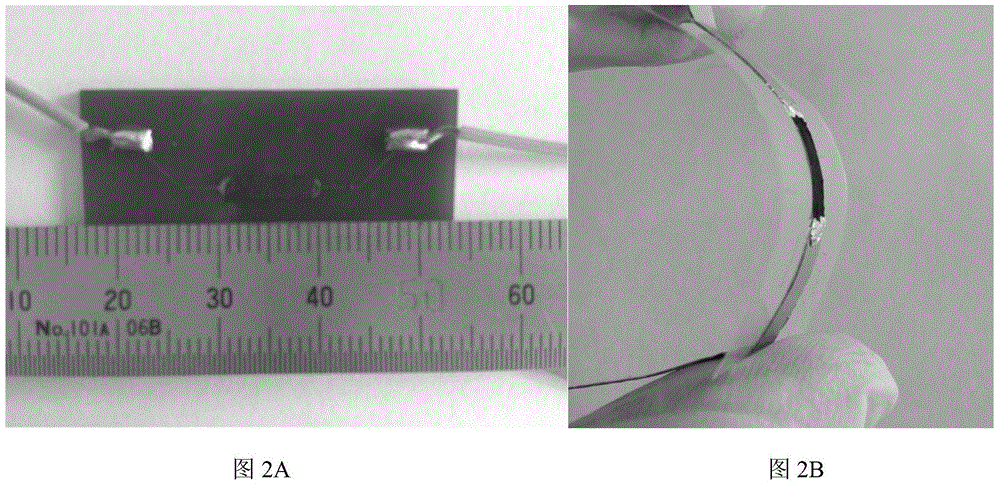

Flexible CO room temperature sensor and preparation method thereof

InactiveCN105987934AUniform diameter distributionRegular shapeMaterial resistanceFlexible fiberElectricity

The invention discloses a flexible CO room temperature sensor which includes a polyaniline fiber film which is mainly formed by coating a nano fiber thin film with polyaniline. The polyaniline fiber film is electrically connected to an electrode. The invention also discloses a preparation method of the flexible CO room temperature sensor. The method includes the steps of: soaking the nano fiber thin film in a solution containing aniline and an acid, adding an oxidizing agent to polymerize the aniline and coat the nano fiber thin film with polyaniline to obtain a flexible polyaniline fiber film; and electrically connecting the polyaniline fiber film to the electrode to form the flexible CO room temperature sensor. The flexible CO room temperature sensor has simple structure, high sensitivity, wide detection range and high detection speed. The flexible fiber film can be combined with substrates in different materials easily. The sensor is simple in preparation method, is low in cost and is suitable for large-scale production and application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

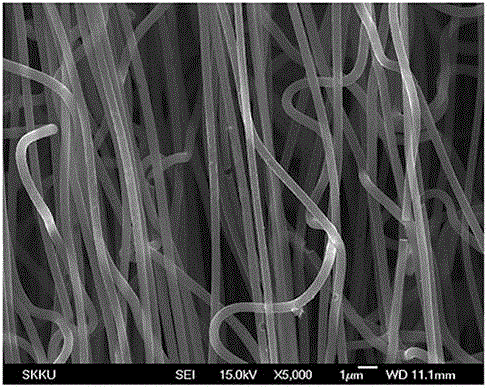

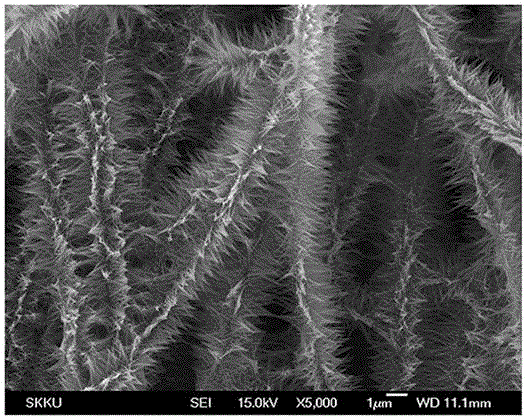

Preparation method of zinc oxide nanowire array/carbon nanofiber composite material

InactiveCN105712316AUniform diameter distributionSimple processMaterial nanotechnologyZinc oxides/hydroxidesElectrospinningCarbon nanofiber

The invention discloses a preparation method of zinc oxide nanowire array / carbon nanofiber composite material, relates to preparation methods of nano composite materials, and aims to solve the problems that existing carbon nanofibers are low in surface area, and the contact area of the carbon nanofibers with solution is limited during application. The preparation method includes the steps of firstly, using an electrospinning method; secondly, using a hydrothermal synthesizing method. The zinc oxide nanowire array / carbon nanofiber composite material is large in surface area, excellent in conductivity, and the like. The preparation method is mainly used for preparing the zinc oxide nanowire array / carbon nanofiber composite material.

Owner:HARBIN UNIV OF SCI & TECH

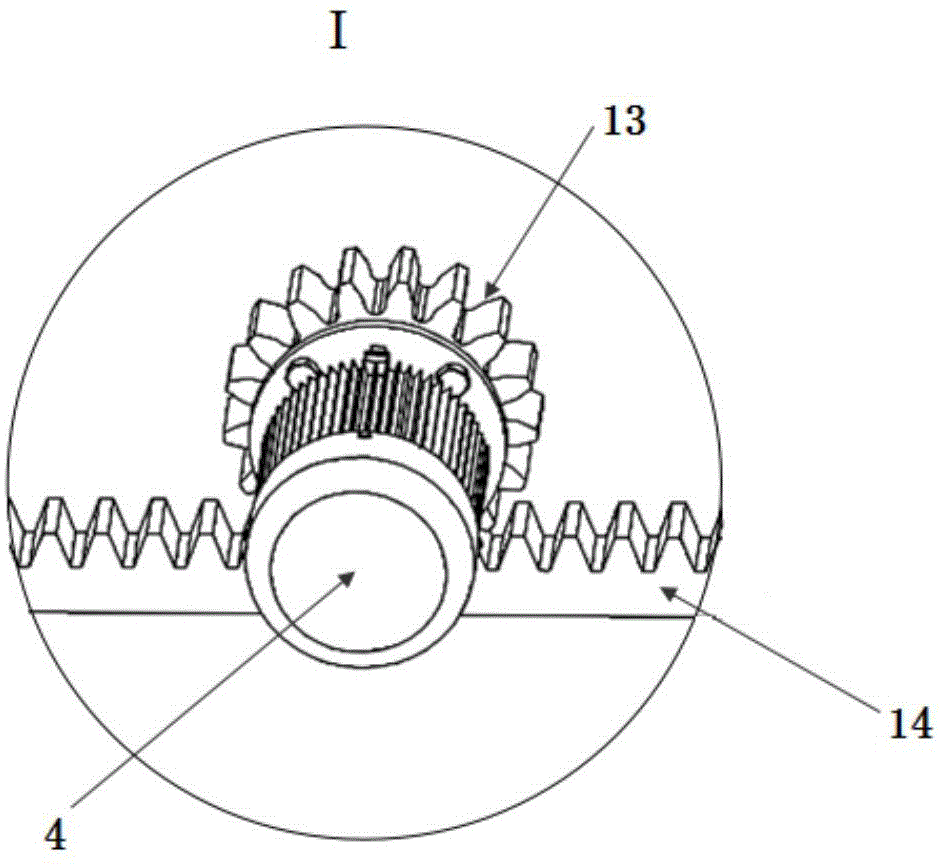

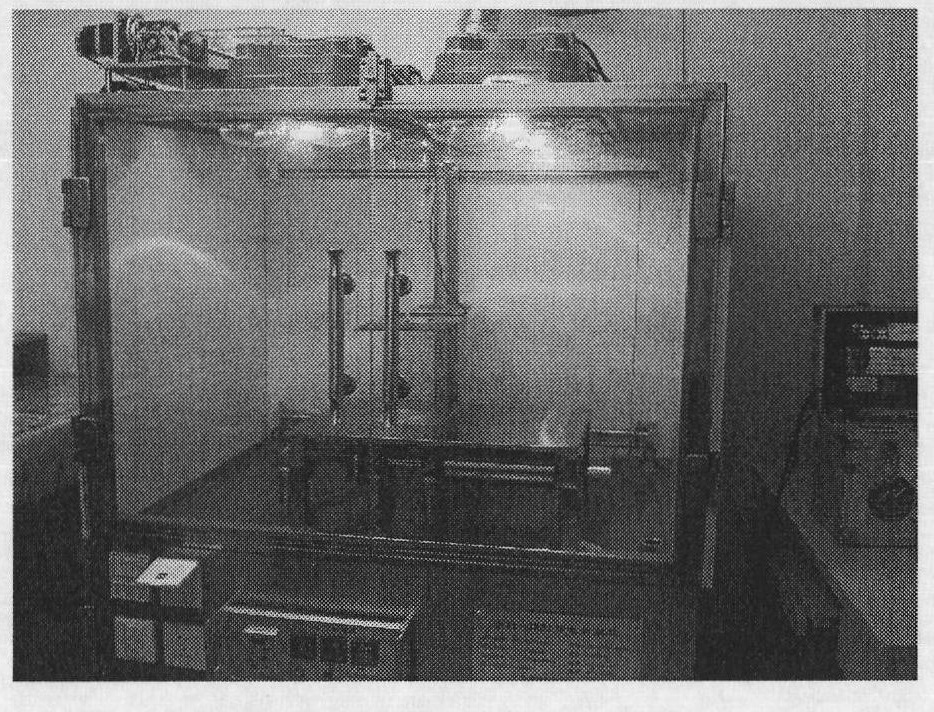

Large-scale magnetic spinning equipment and method using equipment for manufacturing micro-nano-meter fibers

ActiveCN104878461AArranged in an orderly mannerIncrease productionArtificial thread manufacturing machinesFilament/thread formingMicro nanoFiber

The invention discloses large-scale magnetic spinning equipment and a method using the equipment for manufacturing micro-nano-meter fibers. The equipment comprises a support, a feeding device, a spinning spraying device and a roller type collecting device horizontally arranged. Bar-shaped permanent magnets for providing a magnetic field are fixed to the surface of a collecting roller of the roller type collecting device. The spinning spraying device is provided with a plurality of spinning spraying heads which are uniformly arranged in a column. Injection orifices of the spinning spraying heads point to the bar-shaped permanents of the surface of the collecting roller. The spinning spraying device further comprises a spraying head drive mechanism which can drive the spinning spraying heads to do reciprocating motion in the center axis direction of the collecting roller. According to the equipment, magnetic field force replaces electric field force, under the effect of the alternating magnetic field, ferrofluid is stretched to manufacture the magnetic micro-nano-meter fibers, the high-voltage effect is not needed in the whole process, the production cost and the potential safety hazards are reduced effectively, the micro-nano-meter fibers can be produced continuously in batches, the manufactured fibers are arranged orderly, the yield is high, and the magnetic spinning equipment is suitable for mass production.

Owner:QINGDAO UNIV

Deep filter element with crude and fine fiber mixed structure and preparation method of deep filter element

PendingCN111603846AEnsure structural stabilityDoes not increase filter resistanceMembrane filtersMelt spinning methodsCrude fibreFiber diameter

The invention discloses a deep filter element with a crude and fine fiber mixed structure. The deep filter element at least comprises two filtering layers; each filtering layer comprises a crude fiberset and a fine fiber set which are interwoven with each other; the average diameter of the crude fiber set of each filtering layer is reduced from the outer side to the inner side; the average diameter of the fine fiber set of each filtering layer is reduced from the outer side to the inner side; the fiber diameter of the fine fiber set of the innermost filtering layer is not larger than 1 micrometer; the fiber diameter of the crude fiber set of the outermost filtering layer is not smaller than 5 micrometers. The invention further discloses a preparation method of the deep filter element withthe crude and fine fiber mixed structure. The preparation method comprises the following steps of: 1) melt spinning; and 2) receiving a finished screen. The crude coarse fiber sets play a role in bonding the fine fiber sets and play a role in supporting, and therefore, the filter element is prevented from being compressed in a using process, and a dirt containing amount is increased, the fine fiber sets play a role in filtering and intercepting, so that filtering precision is improved, and the filter element has the functions of high filtering precision, high dirt containing capacity and longservice life and is good in filtering effect.

Owner:HANGZHOU COBETTER TECH CO LTD

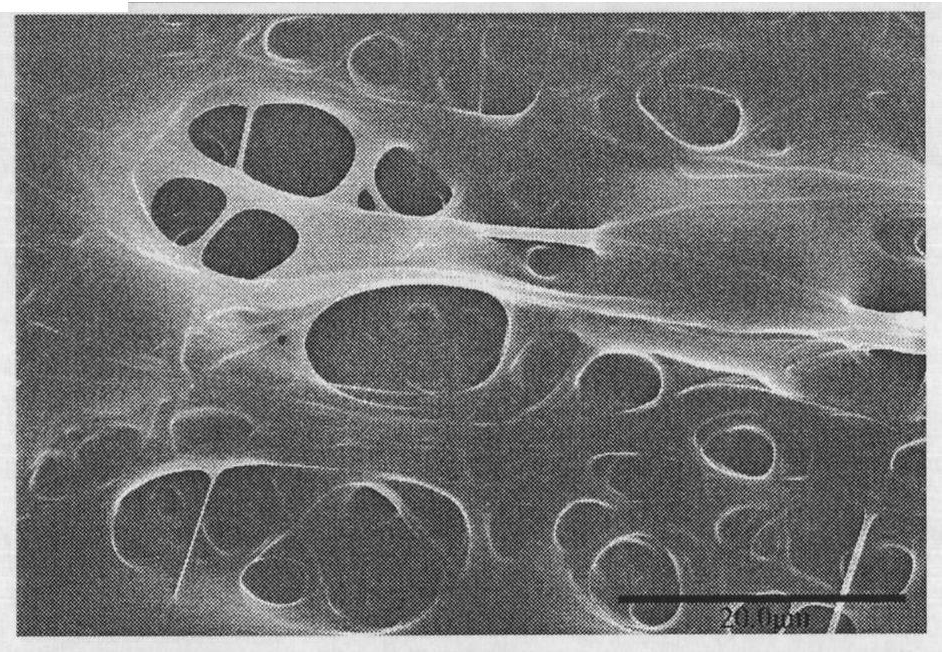

Method for preparing pure hyaluronic acid nano fiber non-woven fabric

InactiveCN101792955ASimple post-processingLow equipment requirementsFilament/thread formingFibre chemical featuresFiber diameterSolvent

The invention relates to a method for preparing a pure hyaluronic acid nano fiber membrane. The method is that hyaluronic acid powder is dissolved in mixed solvent formed by water, formic acid and DMF to prepare solution, the solution is statically placed in ultrasonic wave for one hour to enable all bubbles to be precipitated to obtain transparent hyaluronic acid solution; and the prepared hyaluronic acid electrostatic spinning solution is added into an injection pump, spinning voltage, distance between a spinning nozzle and a collecting plate and flow of the spinning solution sprayed by the spinning nozzle are properly adjusted, and electrostatic spinning is conducted within 5-60 DEG C to spin the solution on a folding fan-shaped aluminum foil to obtain the hyaluronic acid nano fiber non-woven fabric with average fiber diameter of 200-600nm. The preparation process and the post-treatment process are simple, the hyaluronic acid nano fiber non-woven fabric can be obtained within the wide temperature range and the diameter distribution of the obtained hyaluronic acid nano fiber is even.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

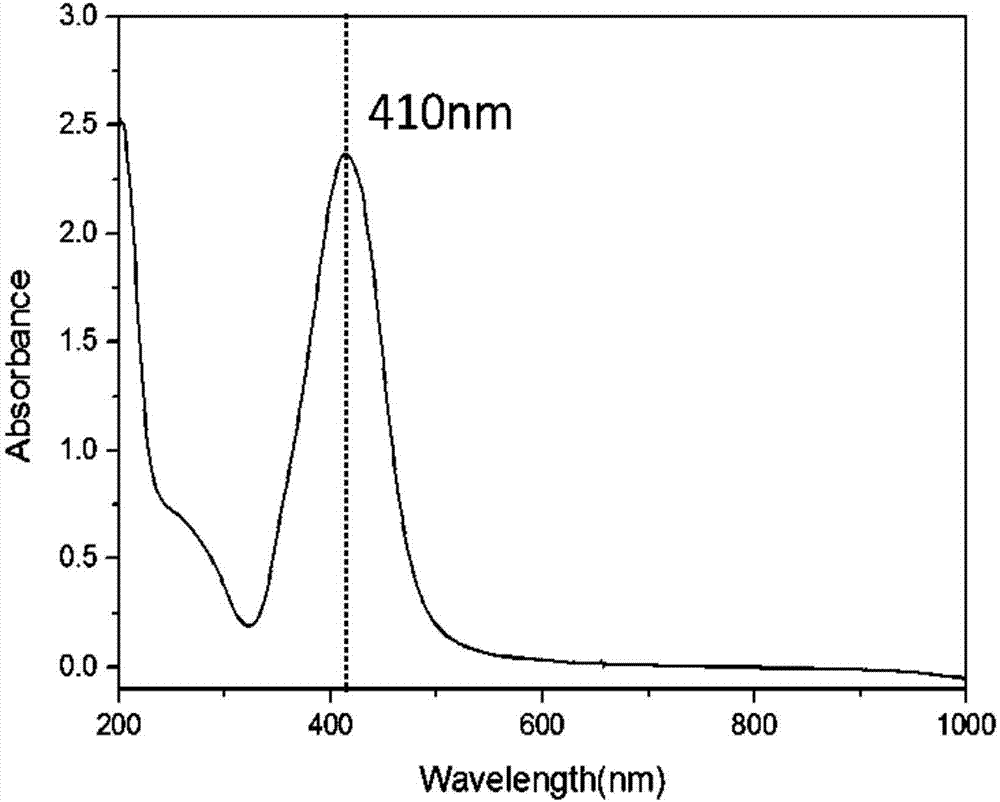

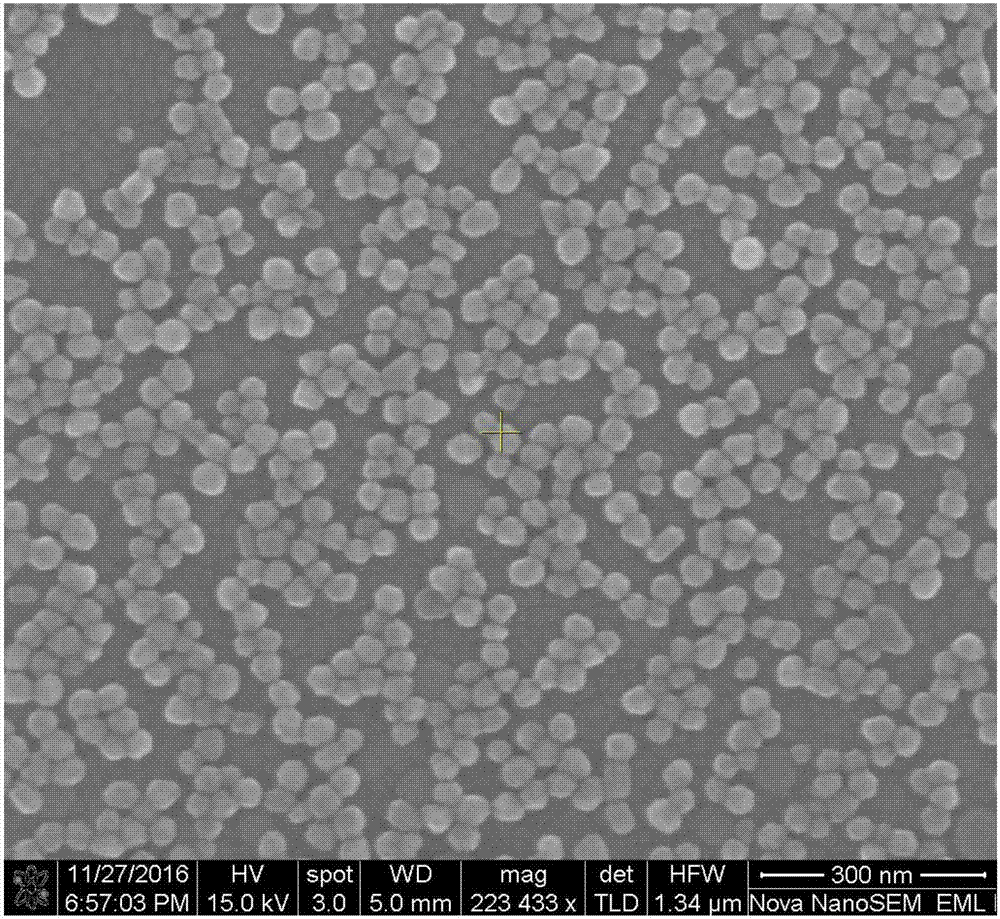

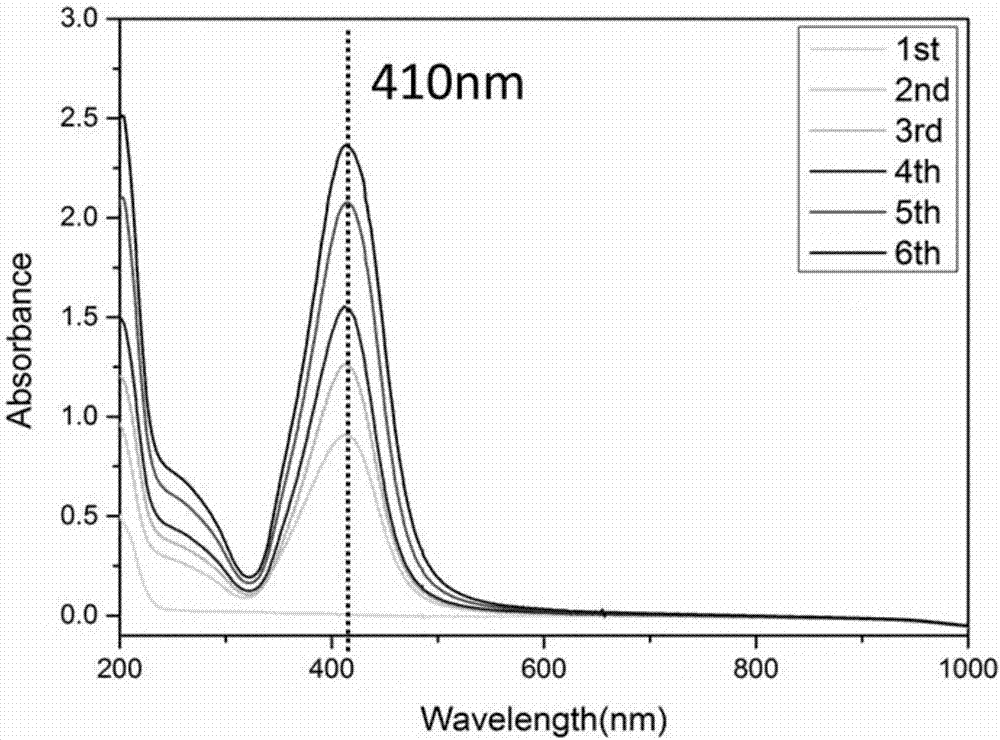

Preparation method for surface-enhanced raman scattering substrate based on nano-silver particles

ActiveCN107322005ASynthetic method is cheapUniform diameter distributionMaterial nanotechnologyRaman scatteringChemical synthesisSilver ion

The invention discloses a low-cost green chemical synthesis method for nano-silver particles and a preparation method for a surface raman-enhanced active substrate based on the nano-silver particles. By utilizing the principle that silver ions are reduced by aldehyde groups in a silver mirror reaction, a trace amount of a silver-ammino complex solution is added into an aldehyde-group-contained compound solution with a certain concentration at the room temperature, so that the silver ions are reacted fully and reduced into elemental silver and generate the nano-silver particles. The nano-silver particles obtained by adopting the chemical synthesis method are even in particle size (diameters are between 35 nm to 38 nm), and good in monodispersity. Then, a synthetic nano-silver particle solution is directly dropped on a glass sheet or other carrier such as a silicon slice and an organic polymer film, after the solution is evaporated to be dry completely, a coffee-ring effect after a liquid drop is evaporated to be dry is effectively inhibited because of existing of excess glucose, and moreover the excess glucose severs as a protective layer to prevent the nano-silver particles from being oxidized, and thus the surface raman-enhanced active substrate with the good stability is obtained.

Owner:PEKING UNIV

Three-level coaxial electro-spinning method for loading two sheath fluids without spinnability on core fluid

InactiveCN106676653AQuality improvementHigh quality core sheath structureConjugated cellulose/protein artificial filamentsFilament/thread formingThree levelNano structuring

The invention relates to a three-level coaxial electro-spinning method for loading two sheath fluids without spinnability on a core fluid. According to the method, spinnability of the polymer core fluid is used as support, functional fluids without spinnability are loaded in an external sheath fluid surrounding manner to serve as an interlayer, pure organic solvents serve as outermost fluids, and a three-level coaxial high-voltage electrostatic spinning process is implemented. The outermost organic solvents can effectively ensure stability and continuous implementation of the three-level coaxial electro-spinning process, and high-quality core sheath structure nano-fiber products can be prepared. The functional fluids without spinnability are effectively led into the three-level coaxial electro-spinning process, and the nano-structure preparation capacity of the process is greatly extended. Besides, the method is effective in single step, prepared nano-fiber core sheath structures are clear, small in nano-fiber diameter, good in linearity and uniform in diameter distribution, and fiber surfaces are smooth. By the method, numerous functional components can be loaded on the polymer nano-fiber surfaces to obtain novel functional nano-fiber products.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com