High-safety high-energy long-cycle lithium iron phosphate type 18650 lithium battery and preparation method thereof

A lithium iron phosphate, high-energy technology, applied in the direction of battery electrodes, secondary batteries, battery components, etc., can solve the problems of limited battery capacity, etc., and achieve the effects of material cost reduction, reasonable particle size composition, and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

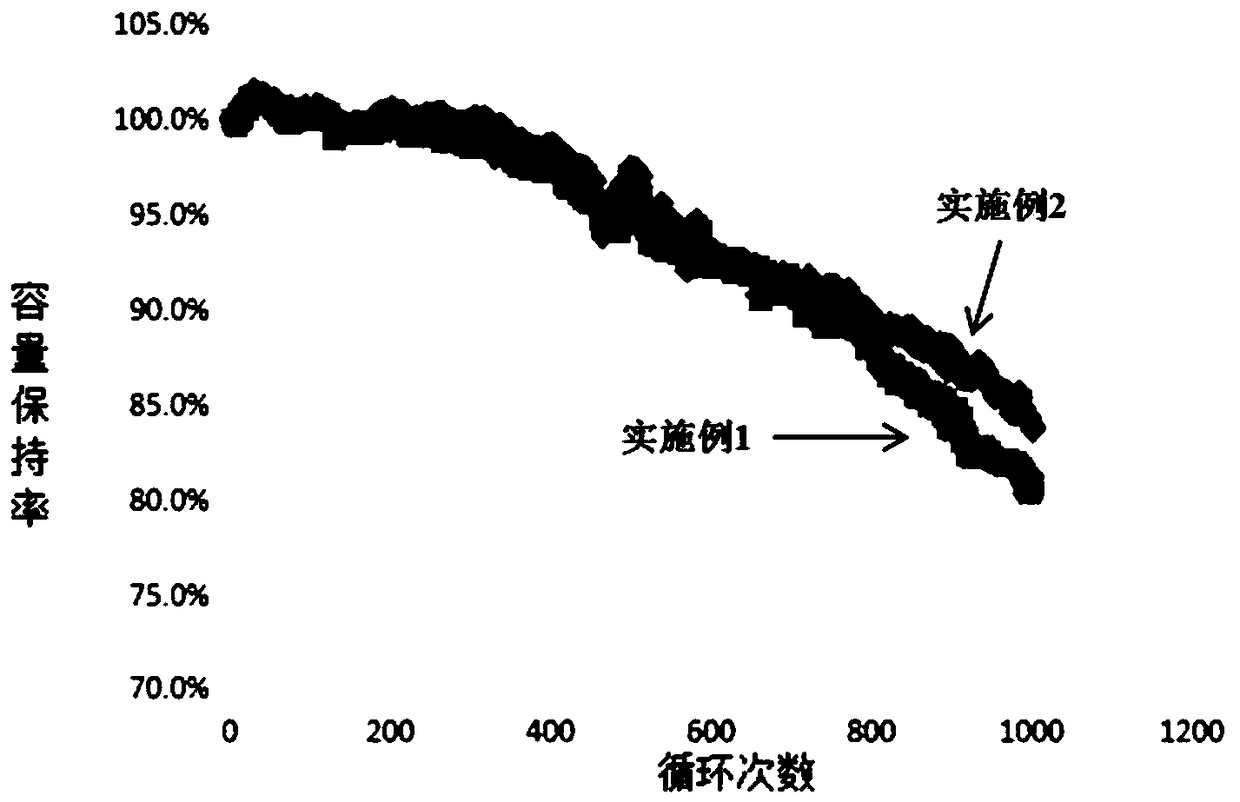

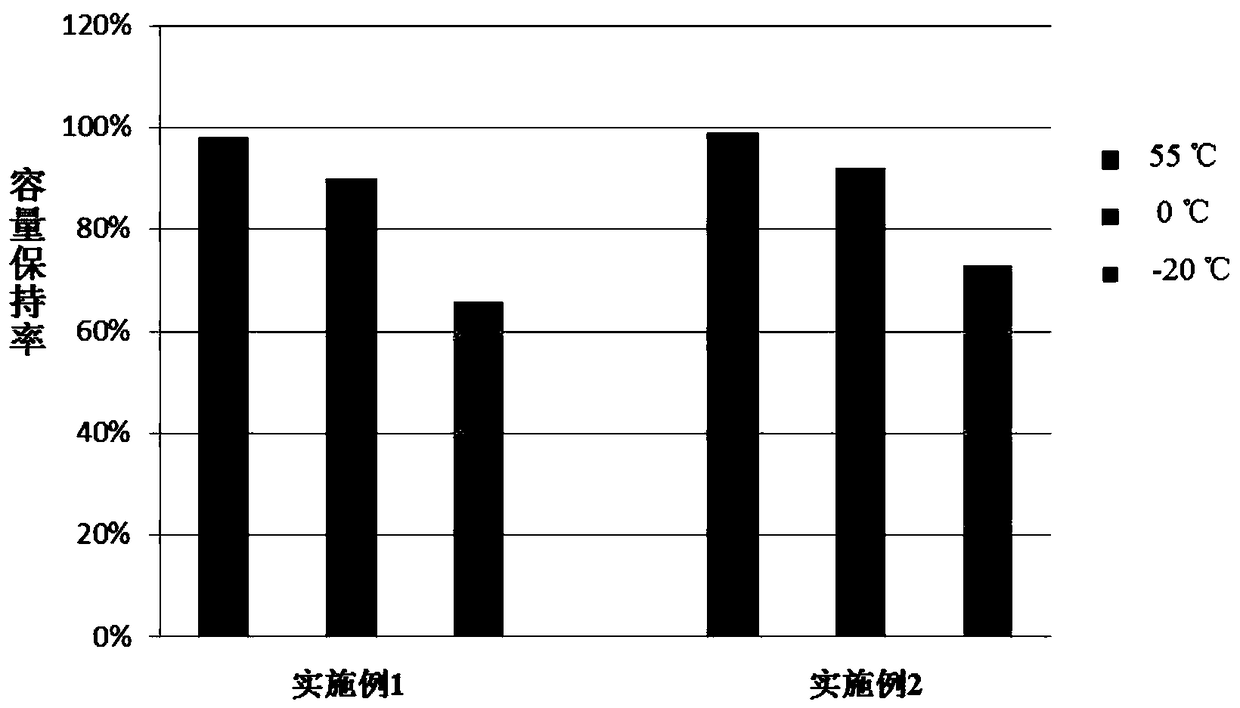

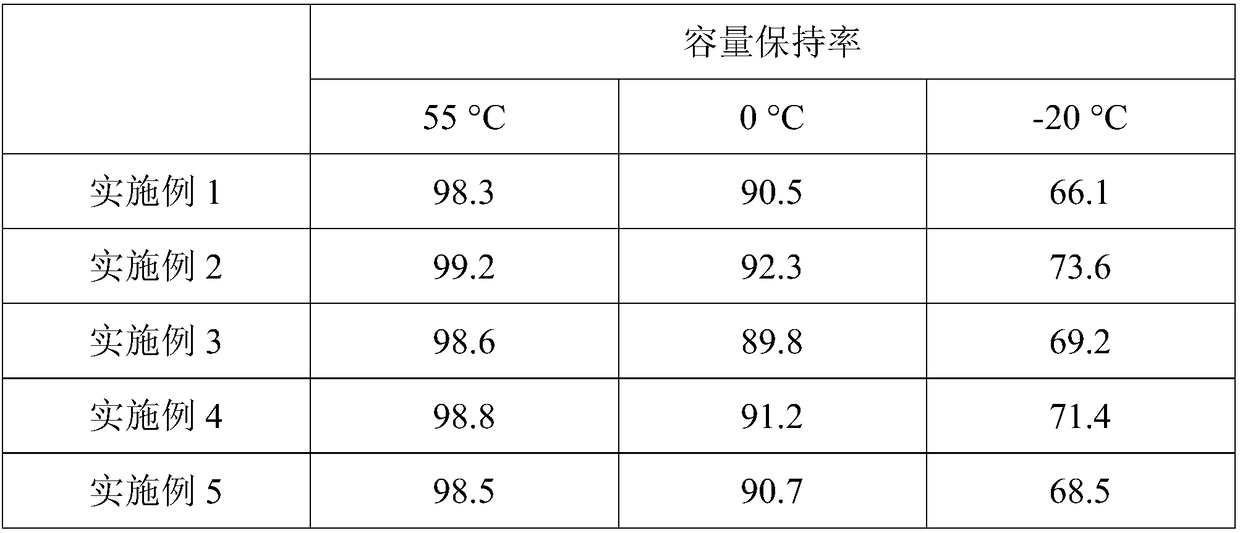

Embodiment 1

[0053] A high-safety, high-energy, long-cycle lithium iron phosphate 18650 lithium battery, including a positive electrode, a negative electrode, a separator, an electrolyte, and a casing. The positive electrode is a mixture of active material, conductive agent and binder uniformly coated on metal aluminum foil Made from two sides, areal density 280mg / cm 2 The negative electrode is made by uniformly coating the mixture of active material, conductive agent and binder on both sides of the metal copper foil, with an area density of 280mg / cm 2 Among them: the thickness of the metal aluminum foil is 11.5μm, the active material in the positive electrode coating mixture is carbon-doped lithium iron phosphate, the carbon content is 1.05wt%, the particle size D50 is 2.2μm, the D90 is 11μm, and the specific capacity is 155mAh / g , Compaction density 2.05g / cm 3 , The conductive agent is Super P composite CNT, the binder is PVDF; the diaphragm is a ceramic diaphragm, which is a PE base film c...

Embodiment 2

[0055] A high-safety, high-energy, long-cycle lithium iron phosphate 18650 lithium battery, including a positive electrode, a negative electrode, a separator, an electrolyte, and a casing. The positive electrode is a mixture of active material, conductive agent and binder uniformly coated on metal aluminum foil Made from two sides, areal density 340mg / cm 2 The negative electrode is made by uniformly coating the mixture of active material, conductive agent and binder on both sides of the metal copper foil, with an area density of 340mg / cm 2 Among them: the thickness of the metal aluminum foil is 12.8μm, the active material in the positive electrode coating mixture is carbon-doped lithium iron phosphate, the carbon content is 1.25wt%, the particle size D50 is 2.5μm, D90 is 10.5μm, and the specific capacity is 157mAh / g, compaction density 2.4g / cm 3 , The conductive agent is GR composite CNT, the binder is PVDF; the diaphragm is a ceramic diaphragm, which is a PE base film coated wi...

Embodiment 3

[0057] A high-safety, high-energy, long-cycle lithium iron phosphate 18650 lithium battery, including a positive electrode, a negative electrode, a separator, an electrolyte, and a casing. The positive electrode is a mixture of active material, conductive agent and binder uniformly coated on metal aluminum foil Made from two sides, surface density 320mg / cm 2 , The negative electrode is made by uniformly coating the mixture of active material, conductive agent and binder on both sides of the metal copper foil, with an area density of 320mg / cm 2 , Where: the thickness of the metal aluminum foil is 13μm, the active material in the positive electrode coating mixture is carbon-doped lithium iron phosphate, the carbon content is 1.38wt%, the particle size D50 is 3.5μm, the D90 is 9μm, the specific capacity is 165mAh / g, Compacted density 2.25g / cm 3 , The conductive agent is CF composite CNT, the binder is PVDF; the diaphragm is a ceramic diaphragm, which is a PE base film coated with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com