Silicon-based composite negative electrode material, preparation method thereof and lithium-ion battery

A technology of negative electrode materials and composite materials, which is applied in the field of lithium ion batteries, silicon-based composite negative electrode materials and their preparation, can solve the problems of poor specific capacity and cycle performance of composite negative electrode materials, etc., and achieves significant conjugation effect and rapid improvement. The effect of charging performance and cycle life, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] This embodiment prepares the silicon-based composite negative electrode material according to the following method:

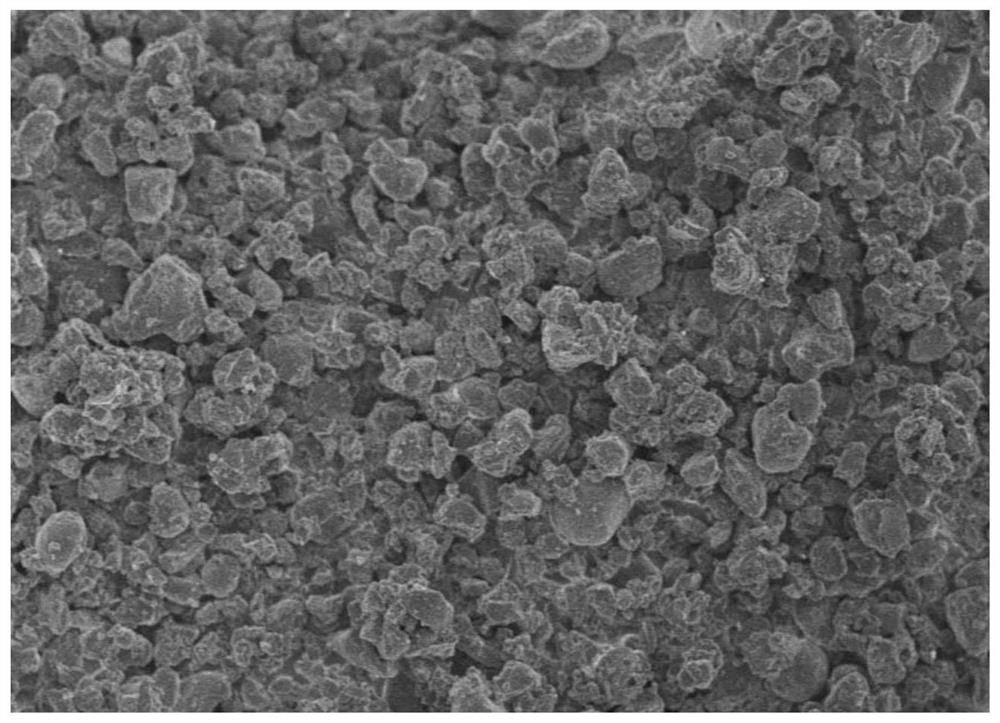

[0109] (1) Add 37.5g of natural graphite with a median diameter of 3μm, 4g of sodium dodecylbenzenesulfonate, and 20mL of ethanol into 200mL of water, accelerate stirring, and then add 60g of silicon particles with a median diameter of 50nm to the above liquid , spray drying after ultrasonication for 10 minutes to obtain the first composite material with a median particle size of 5 μm;

[0110] (2) The first composite material and epoxy resin (median particle size is 3 μm) are respectively added to the VC mixer according to the mass ratio of 1:0.8, mixed at a speed of 3000rpm / min for 1h, and then the mixture is placed in a high-temperature furnace , nitrogen gas was introduced, the temperature was raised to 1100°C at 2.0°C / min, kept for 5h, and cooled to room temperature naturally. The high-temperature product was pulverized and sieved to obtain a secon...

Embodiment 2

[0117] In this embodiment, except that the graphite used in step (1) is artificial graphite with a median particle size of 3 μm, other raw material types and operating conditions are the same as in Embodiment 1.

[0118] The silicon-based composite negative electrode material provided in this embodiment comprises an inner core and an outer shell positioned on the inner core surface, the inner core includes emulsified graphite and nano-silicon, the outer shell is composed of an inner layer positioned on the inner core surface and an outer layer positioned on the inner layer surface, the inner layer The layer is an amorphous carbon layer, and the outer layer is a polypyrrole-carbon nanotube composite material. The median particle size of artificial graphite is 3 μm, the median particle size of nano-silicon is 50 nm; the diameter of carbon nanotubes is 5 nm, and the length is 10 μm. Carbon nanotubes have sulfonic acid groups.

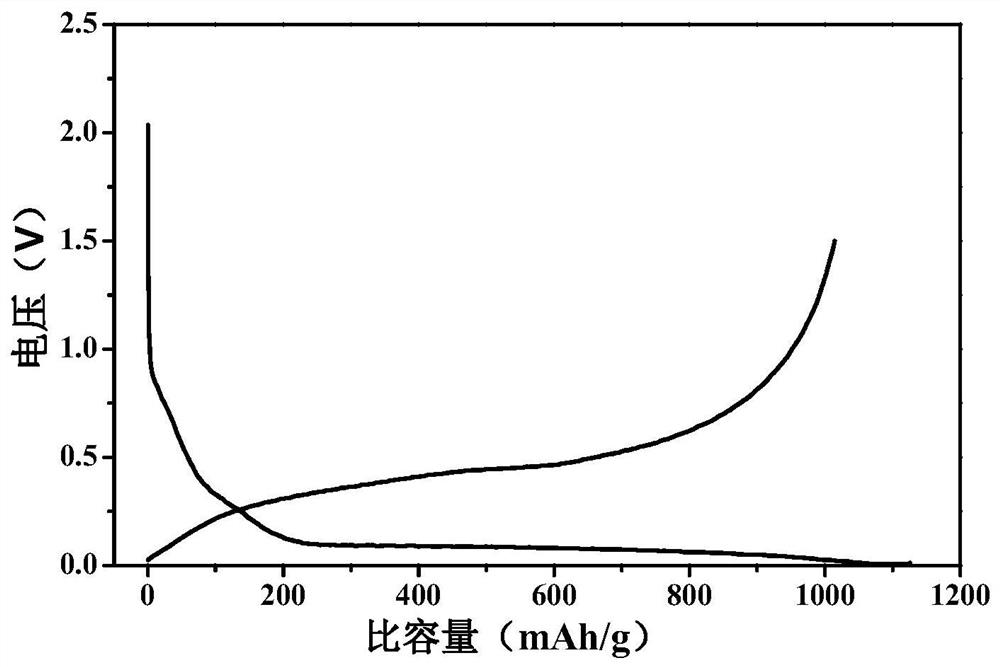

[0119] The silicon-based composite anode material p...

Embodiment 3

[0121] This embodiment prepares the silicon-based composite negative electrode material according to the following method:

[0122] (1) Add 37.5g of natural graphite with a median diameter of 2μm, 5g of fatty acid polyoxyethylene ester, and 20mL of ethanol into 200mL of water, accelerate stirring, then add 60g of silicon particles with a median diameter of 20nm to the above liquid, and ultrasonically Spray drying after 10 minutes to obtain the first composite material with a median particle size of 3.5 μm;

[0123] (2) The first composite material and epoxy resin (median particle size is 0.5 μm) are respectively added to the VC mixer according to the mass ratio of 1:0.8, mixed at 500rpm / min for 1.5h, and then the mixture is placed in In the high-temperature furnace, argon gas was introduced, the temperature was raised to 550°C at 1.0°C / min, kept for 8 hours, and naturally cooled to room temperature. The high-temperature product was pulverized and sieved to obtain a second com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com