Rubber textile wheel sizing material as well as preparation method and application thereof

A textile wheel and rubber technology, which is applied in the field of rubber textile wheel rubber materials and preparation, can solve the problems of easy heat generation, wear, and wear of contact objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

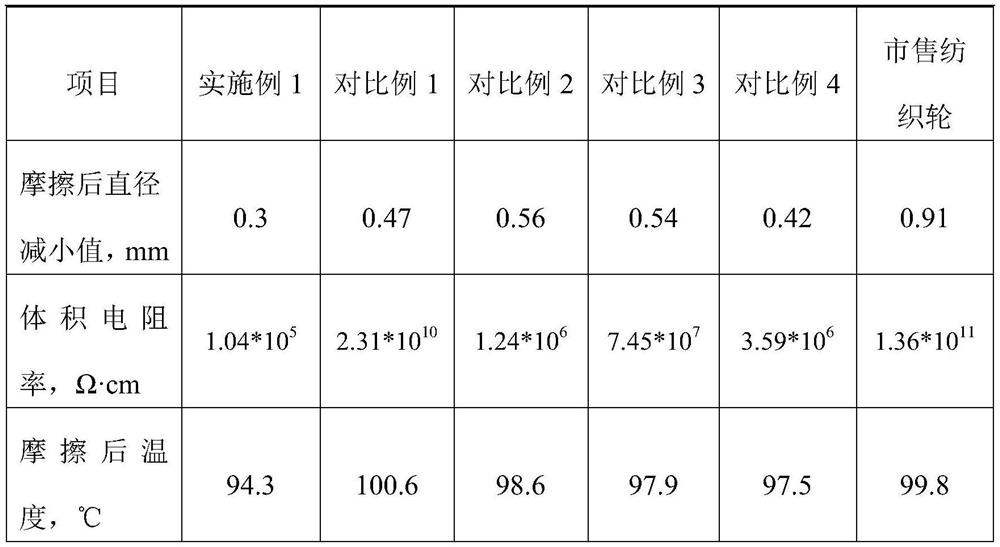

Examples

preparation example Construction

[0061] In some specific embodiments, the preparation method of rubber spinning wheel sizing material comprises the following steps:

[0062] 1) the natural rubber is masticated in a banbury mixer;

[0063] 2) Mix the masticated natural rubber and nitrile rubber in an internal mixer and add nano-zinc oxide, stearic acid, graphene and carbon nanotubes, fillers, coupling agents, plasticizers and mix Evenly, add a vulcanization accelerator in an open mill to obtain a rubber textile wheel compound.

Embodiment 1

[0065] The rubber spinning wheel sizing material of the present embodiment, raw material comprises following components by weight:

[0066] 80 parts of natural rubber, 20 parts of nitrile rubber with 35% acrylonitrile content, the specific surface area reaches 80m 2 5 parts of nano-zinc oxide / g above, 1.5 parts of stearic acid, 1 part of anti-aging agent RD, 1.5 parts of anti-aging agent 4010NA, 1.5 parts of microcrystalline wax, 1.5 parts of graphene, 4.5 parts of carbon nanotubes, 70 parts of calcined kaolin, white 40 parts of carbon black, 3 parts of Si69, 5 parts of paraffin oil, 1.5 parts of accelerator CZ, 10 parts of insoluble sulfur.

[0067]The preparation method of above-mentioned rubber spinning wheel sizing material comprises the following steps:

[0068] 1) The natural rubber is masticated in an internal mixer, the temperature should be below 155°C, and the masticating time is about 12 minutes;

[0069] 2) Mix the masticated natural rubber and nitrile rubber in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com