Method for preparing silicon carbide and precursor composite fibers

A composite fiber, precursor technology, applied in the direction of fiber chemical characteristics, dry spinning, conjugated synthetic polymer rayon, etc., can solve the problem of low fiber yield, achieve high yield, short production cycle, heat Excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

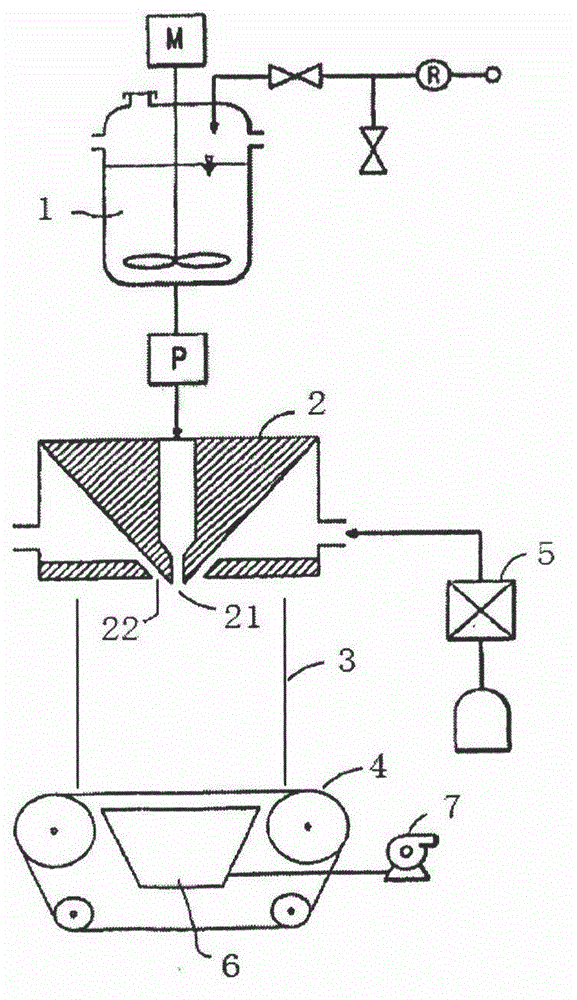

[0024] For the preparation device used in all embodiments of the present invention see figure 1 : the spinneret hole 21 and the spinneret air gap 22 are located on the spinneret die head 2, and are connected to the spinning liquid storage tank 1 through the infusion tube; the vacuum chamber 6 is connected to the exhaust fan 7, and the fibers in the drying chamber 3 are sucked in the collection Net curtain 4 on.

[0025] Embodiment 1.

[0026] (1) Preparation of oil-in-water (O / W) spinning emulsion: 12g polycarbosilane was dissolved in 10mL toluene to make a homogeneous oil phase solution with a mass fraction of 60%; 1.5g polyethylene oxide was dissolved in Add 0.07g sodium lauryl sulfate to 10mL of distilled water to form a homogeneous water phase solution with a mass fraction of 13%; then add the water phase solution dropwise to the oil phase solution, stir and mix to obtain a stable and uniform Oil-in-water (O / W) spinning emulsion;

[0027] (2) Precursor fibers prepared b...

Embodiment 5

[0048] (1) Preparation of oil-in-water (O / W) spinning emulsion: 10g of polycarbosilane and 5g of polyureasilane were dissolved in 10mL of toluene and carbon tetrachloride mixed solution (volume ratio of toluene and carbon tetrachloride 1: 1) to make a homogeneous oil phase solution with a mass fraction of 55%; 4g polyvinylpyrrolidone and 2g polyvinyl alcohol were dissolved in 10mL distilled water, and 0.02g alkyl betaine was added to form a mass fraction of 37.5%. A homogeneous water phase solution; then adding the water phase solution dropwise into the oil phase solution, stirring and mixing to obtain a stable and uniform oil-in-water (O / W) spinning emulsion;

[0049] (2) Precursor fibers prepared by solution jet spinning: the spinning emulsion is supplied to the spinneret die at a rate of 12mL / h / spinning hole, the jet air flow rate is 20000 times that of the spinning emulsion fine flow, and the jet air flow temperature The temperature is 100°C, the spray angle is 20°, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com