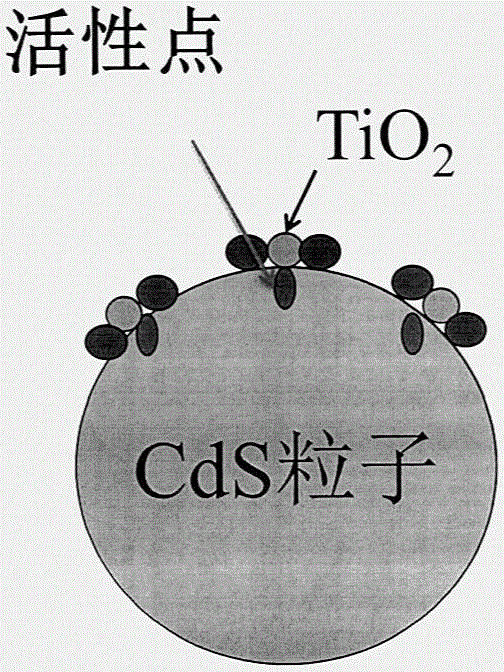

Method for prolonging service life of CdS nano photocatalyst

A nano-photocatalyst, life-span technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve problems such as easy photocorrosion and reduced photocatalytic lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

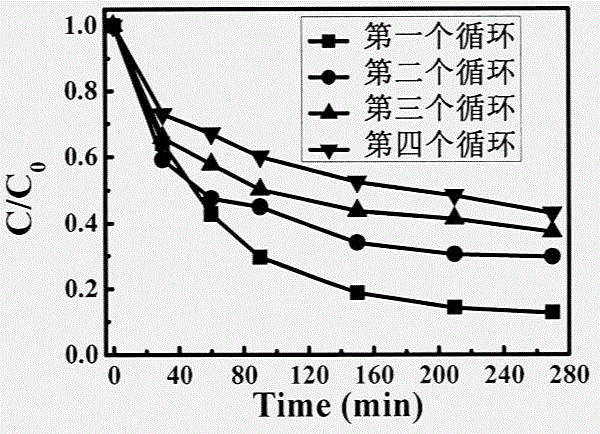

Embodiment 1

[0019] 1) Prepare 10 ml of aqueous solution with 0.025 mol of cadmium acetate, 0.075 mol of thiourea, 0.005 mol of sodium dodecylbenzenesulfonate and 0.2 mol of ammonia water. Prepare the precursor with 0.002mol CdS and 40ml deionized water. Pour the two into a 50mL polytetrafluoroethylene sleeve and mix thoroughly; put the mixed solution and the polytetrafluoroethylene sleeve into a 50ml stainless steel hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an oven and heat to 120°C. Keep for 2 hours, then cool naturally; centrifuge the suspension obtained after the reaction, and ultrasonically clean the solid substance obtained after centrifugation with deionized water, repeating 5 times; dry the solid substance obtained after cleaning at a temperature of 70°C After 12 hours, the nanometer cadmium sulfide powder was obtained; the cadmium sulfide powder obtained by hydrothermal synthesis was sent into the atomic layer deposition vacuum chamber, and the a...

Embodiment 2

[0021] 1) Prepare 10 ml of aqueous solution with 0.025 mol of cadmium acetate, 0.075 mol of thiourea, 0.005 mol of sodium dodecylbenzenesulfonate and 0.2 mol of ammonia water. Prepare the precursor with 0.002mol CdS and 40ml deionized water. Pour the two into a 50ml polytetrafluoroethylene sleeve and mix thoroughly; put the mixed solution and the polytetrafluoroethylene sleeve into a 50ml stainless steel hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an oven and heat to 120°C. Keep for 2 hours, then cool naturally; centrifuge the suspension obtained after the reaction, and ultrasonically clean the solid substance obtained after centrifugation with deionized water, repeating 5 times; dry the solid substance obtained after cleaning at a temperature of 70°C After 12 hours, the nanometer cadmium sulfide powder was obtained; the cadmium sulfide powder obtained by hydrothermal synthesis was sent into the atomic layer deposition vacuum chamber, and the a...

Embodiment 3

[0023]1) Prepare 10 ml of aqueous solution with 0.025 mol of cadmium acetate, 0.075 mol of thiourea, 0.005 mol of sodium dodecylbenzenesulfonate and 0.2 mol of ammonia water. Prepare the precursor with 0.002mol CdS and 40ml deionized water. Pour the two into a 50ml polytetrafluoroethylene sleeve and mix thoroughly; put the mixed solution and the polytetrafluoroethylene sleeve into a 50ml stainless steel hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an oven and heat to 120°C. Keep for 2 hours, then cool naturally; centrifuge the suspension obtained after the reaction, and ultrasonically clean the solid substance obtained after centrifugation with deionized water, repeating 5 times; dry the solid substance obtained after cleaning at a temperature of 70°C After 12 hours, the nanometer cadmium sulfide powder was obtained; the cadmium sulfide powder obtained by hydrothermal synthesis was sent into the atomic layer deposition vacuum chamber, and the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com