Supported advanced oxidation catalyst material and preparation method thereof

An oxidation catalytic material and supported technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Equal problem, to achieve the effect of alleviating secondary pollution, prolonging catalytic life, and avoiding easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

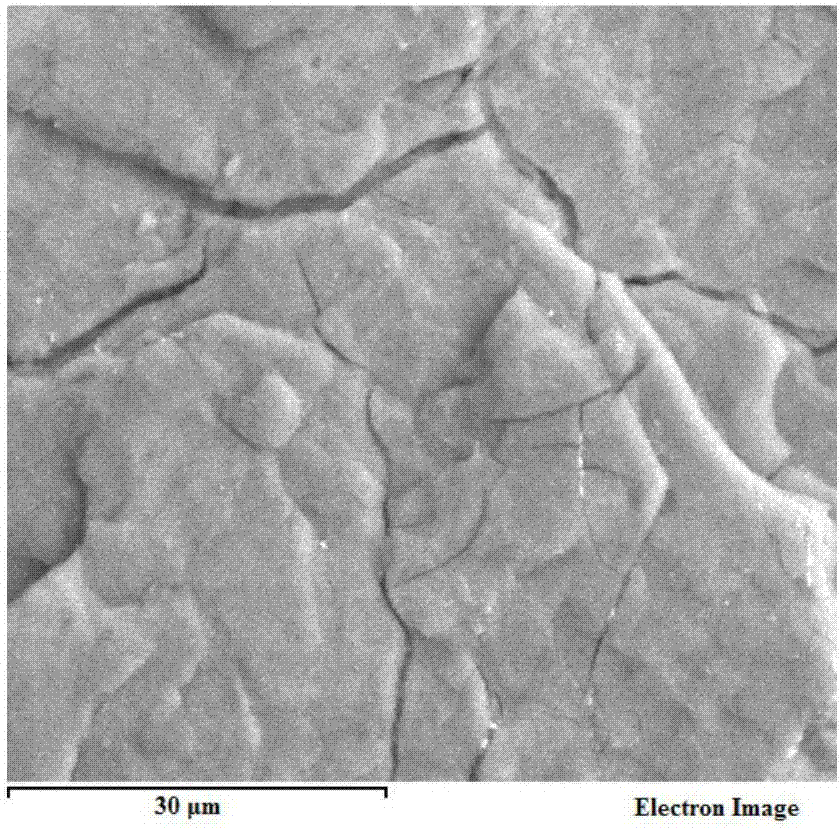

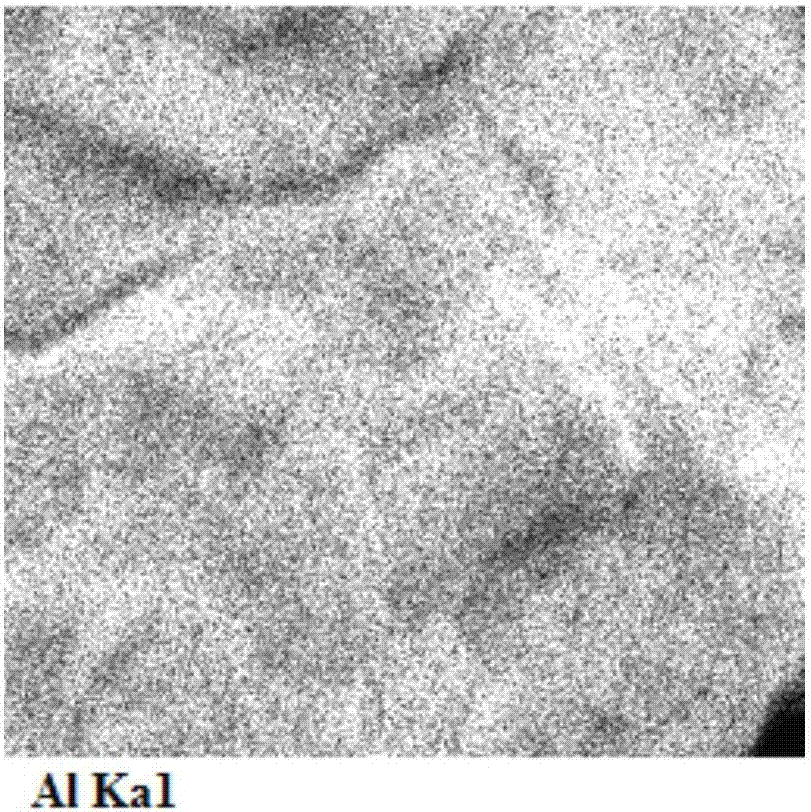

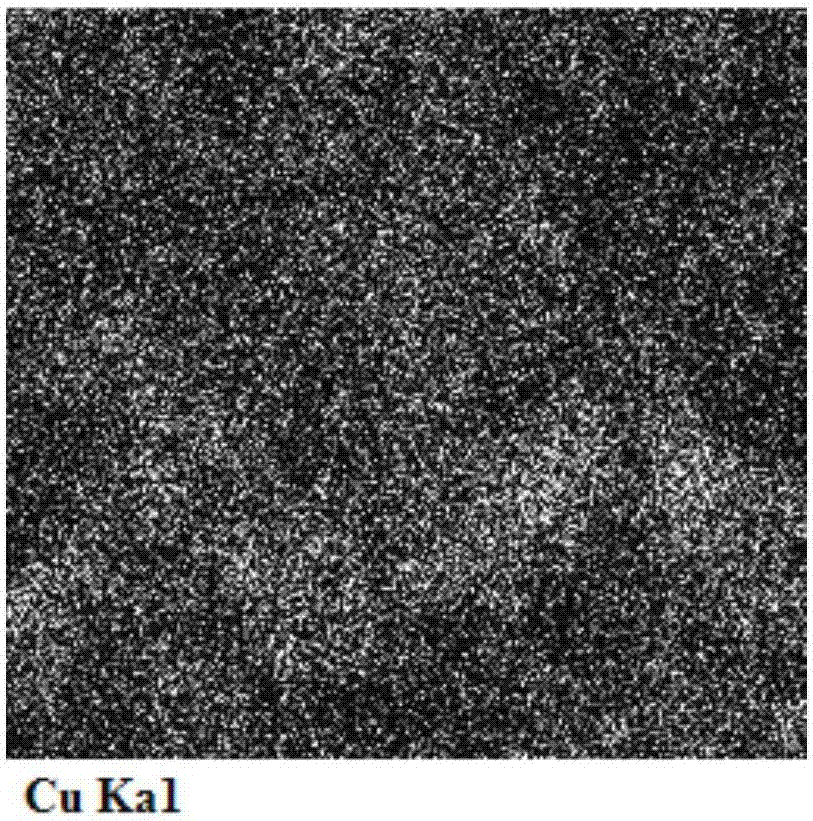

Image

Examples

Embodiment 1

[0046] In this example, the preparation of supported advanced oxidation catalytic material, the steps are as follows:

[0047] (1) Carrier material pretreatment

[0048] γ-Al with an average particle size of 50 microns 2 o 3 Particles are the carrier material, the carrier material is deionized water, and the cleaned carrier material is placed in SnCl 2 Concentration of 10g / L, HCl concentration of 1.8wt% SnCl 2 - In aqueous HCl solution, mechanically stir at 250rpm at room temperature for 10 minutes for sensitization treatment, filter, and wash the solid phase with deionized water to remove SnCl 2 and HCl followed by PdCl 2 Concentration of 0.02g / L, HCl concentration of 0.4wt% PdCl 2 - In aqueous HCl solution, mechanically stir at room temperature at 250 rpm for 10 min for activation treatment, filter, and wash the solid phase with deionized water to remove PdCl 2 and HCl to complete the pretreatment of the carrier material.

[0049] (2) Electroless plating

[0050] Pla...

Embodiment 2

[0070] In this example, the preparation of supported advanced oxidation catalytic material, the steps are as follows:

[0071] (1) Carrier material pretreatment

[0072] γ-Al with an average particle size of 50 microns 2 o 3 The particle is the carrier material, the carrier material is cleaned with deionized water, and the cleaned carrier material is placed in SnCl 2 Concentration of 10g / L, HCl concentration of 1.8wt% SnCl 2 - In aqueous HCl solution, mechanically stir at 250rpm at room temperature for 10 minutes for sensitization treatment, filter, and wash the solid phase with deionized water to remove SnCl 2 and HCl followed by AgNO 3 The concentration is 5g / L, NH 4 · AgNO with an OH concentration of 40g / L 3 -NH 4 In the aqueous solution of OH solution, mechanically stir at room temperature at a speed of 250rpm for 10 minutes for activation treatment, filter, and wash the solid phase with deionized water to remove AgNO 3 and NH 4 OH is to complete the pretreatment ...

Embodiment 3

[0080] In this example, the preparation of supported advanced oxidation catalytic material, the steps are as follows:

[0081] (1) Carrier material pretreatment

[0082] γ-Al with an average particle size of 50 microns 2 o 3 Particles are the carrier material, the carrier material is deionized water, and the cleaned carrier material is placed in SnCl 2 The concentration is 1g / L, AgNO 3 The concentration is 1g / L, NH 4 SnCl with an OH concentration of 15g / L and a pH value of 2.5 2 -AgNO 3 -NH 4 In OH aqueous solution, mechanically stir at room temperature at 250rpm for 30min for one-step sensitization-activation treatment, filter, and wash the solid phase with deionized water to remove SnCl 2 , AgNO 3 and NH 4 OH is to complete the pretreatment of the carrier material.

[0083] (2) Electroless plating

[0084] Place the pretreated carrier material in the plating solution, mechanically stir at 90°C at a speed of 250 rpm for 10 minutes, filter, wash the solid phase with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com