Low cycle fatigue life prediction method based on asymmetrical cyclic stress control load

A technology of cyclic stress and low cycle fatigue, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, and can solve problems such as inability to accurately predict low cycle fatigue life estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The present invention is a method for predicting the low-cycle fatigue life of metal materials under the condition of asymmetric cyclic stress control. Taking the low-cycle fatigue life prediction of AZ91 magnesium alloy material as an example, the implementation details of the life prediction method involved in the present invention will be introduced in detail , whose methods include:

[0028] Step 1: A low cycle fatigue experiment based on asymmetric cyclic stress control is carried out on AZ91 magnesium alloy material (rolling direction sampling), and the step of obtaining its low cycle fatigue life;

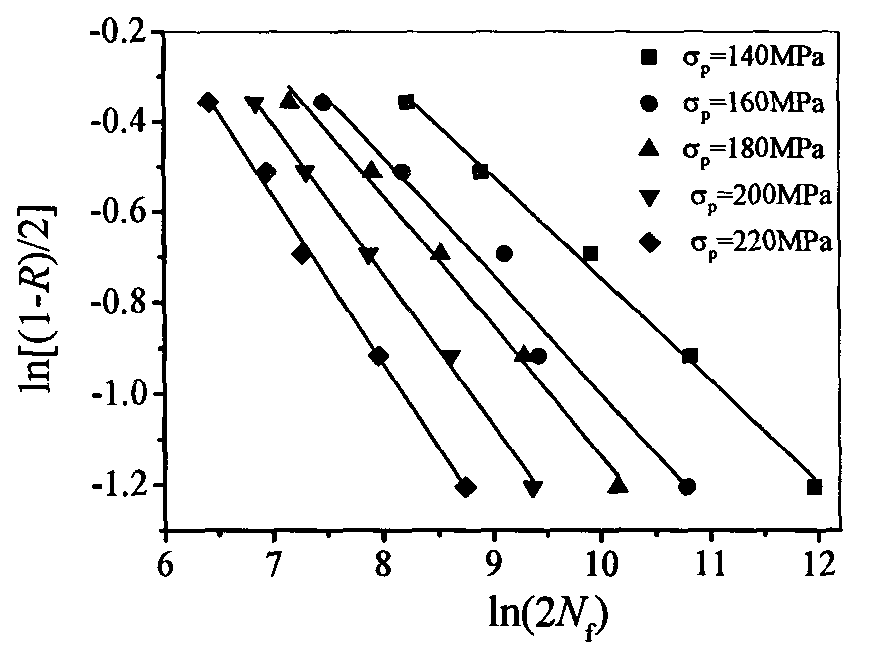

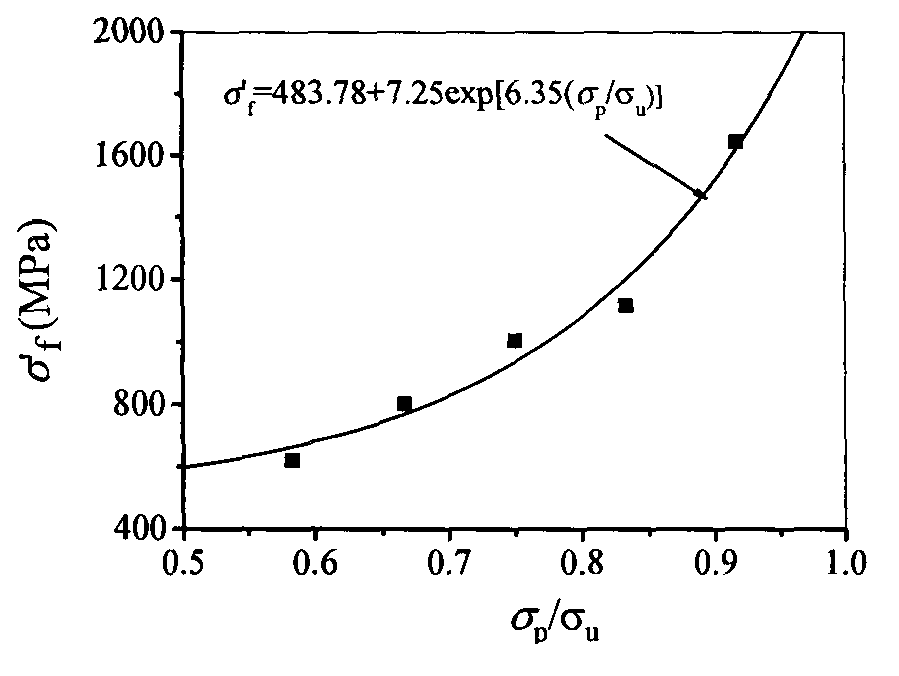

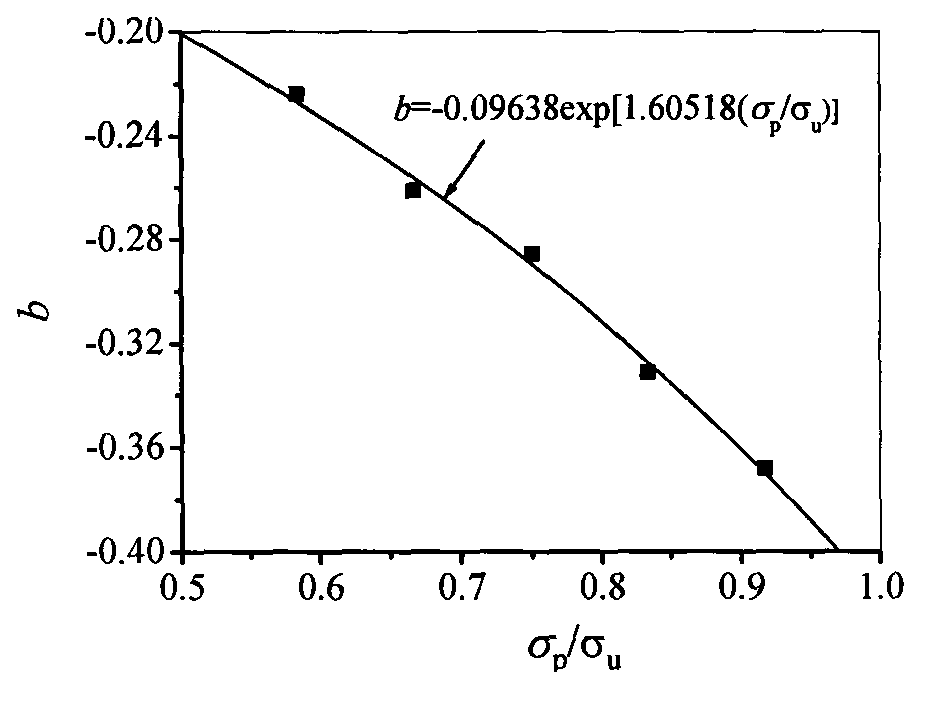

[0029] The parameters of cyclic loading conditions include peak stress and stress ratio. The peak stress ranges from 124.0MPa to 262.6MPa, and the stress ratio ranges from -0.4 to 0.4. The peak stresses are 140MPa, 160MPa, 180MPa, 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com