Resin matrix composite with super-hydrophobic bionic surface and preparation method of resin matrix composite

A composite material and resin-based technology, applied in the direction of coating, etc., can solve the problems of resin-based composite material damage, thermal damage, large thermal effect, etc., and achieve the effect of improving environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for manufacturing a superhydrophobic biomimetic surface for resin-based composite materials, which includes the following steps:

[0052] 1) Grinding and cleaning the resin-based composite material

[0053] Use 400-800# sandpaper to grind the surface of the resin-based composite material until the surface turns white, and then use ethanol to ultrasonically clean the resin-based composite material for 15-30 minutes.

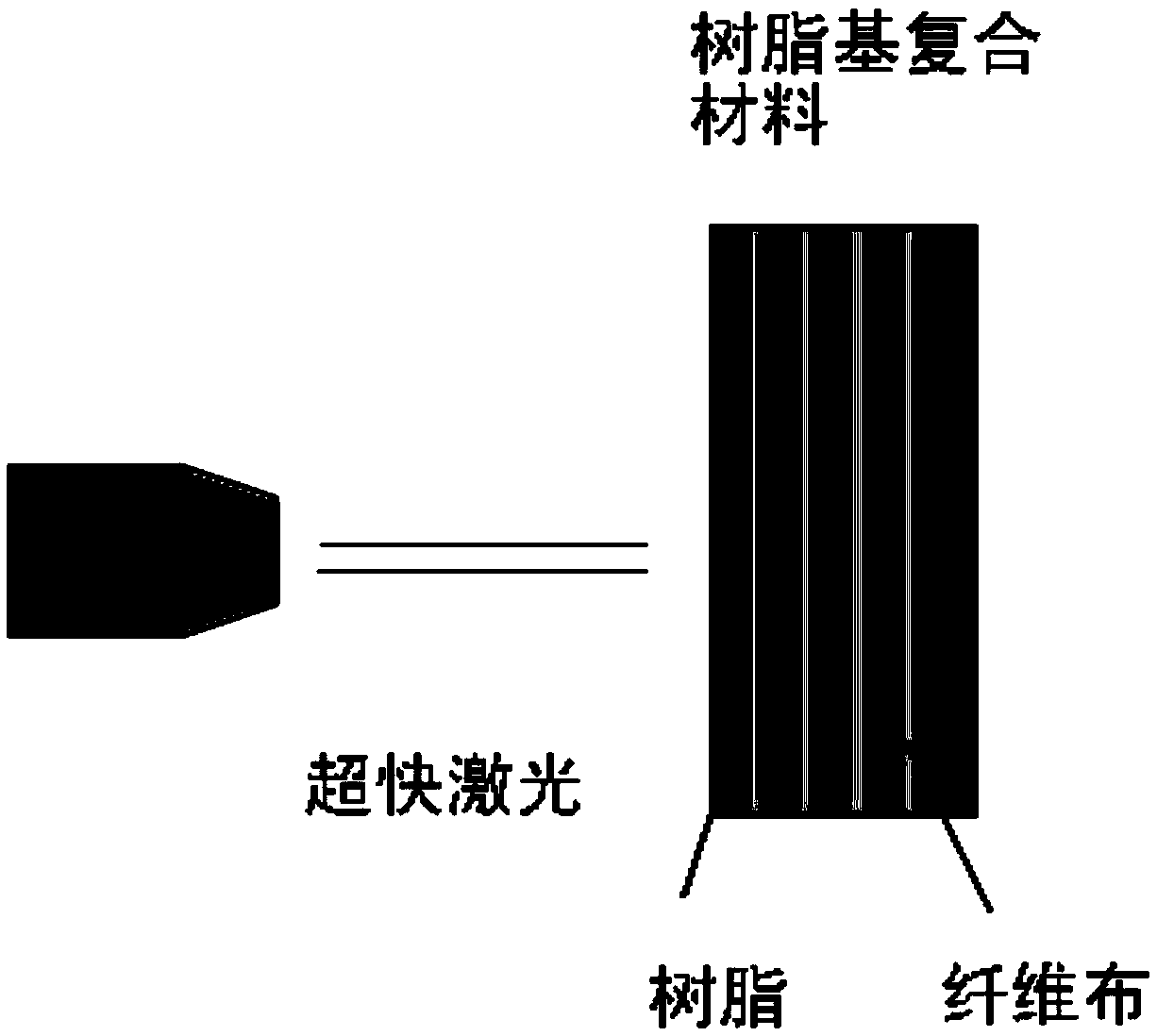

[0054] 2) Microstructure processing of resin matrix composites

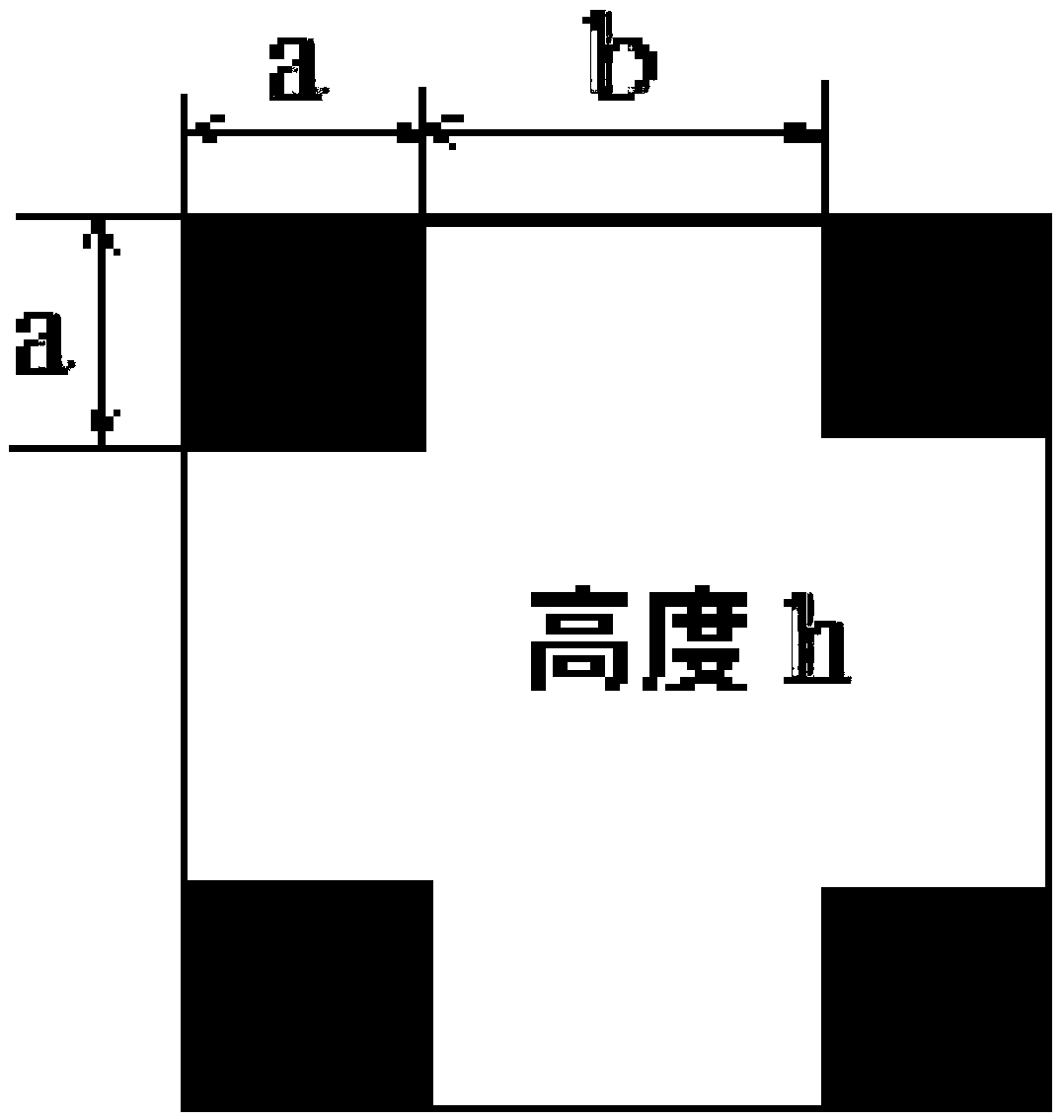

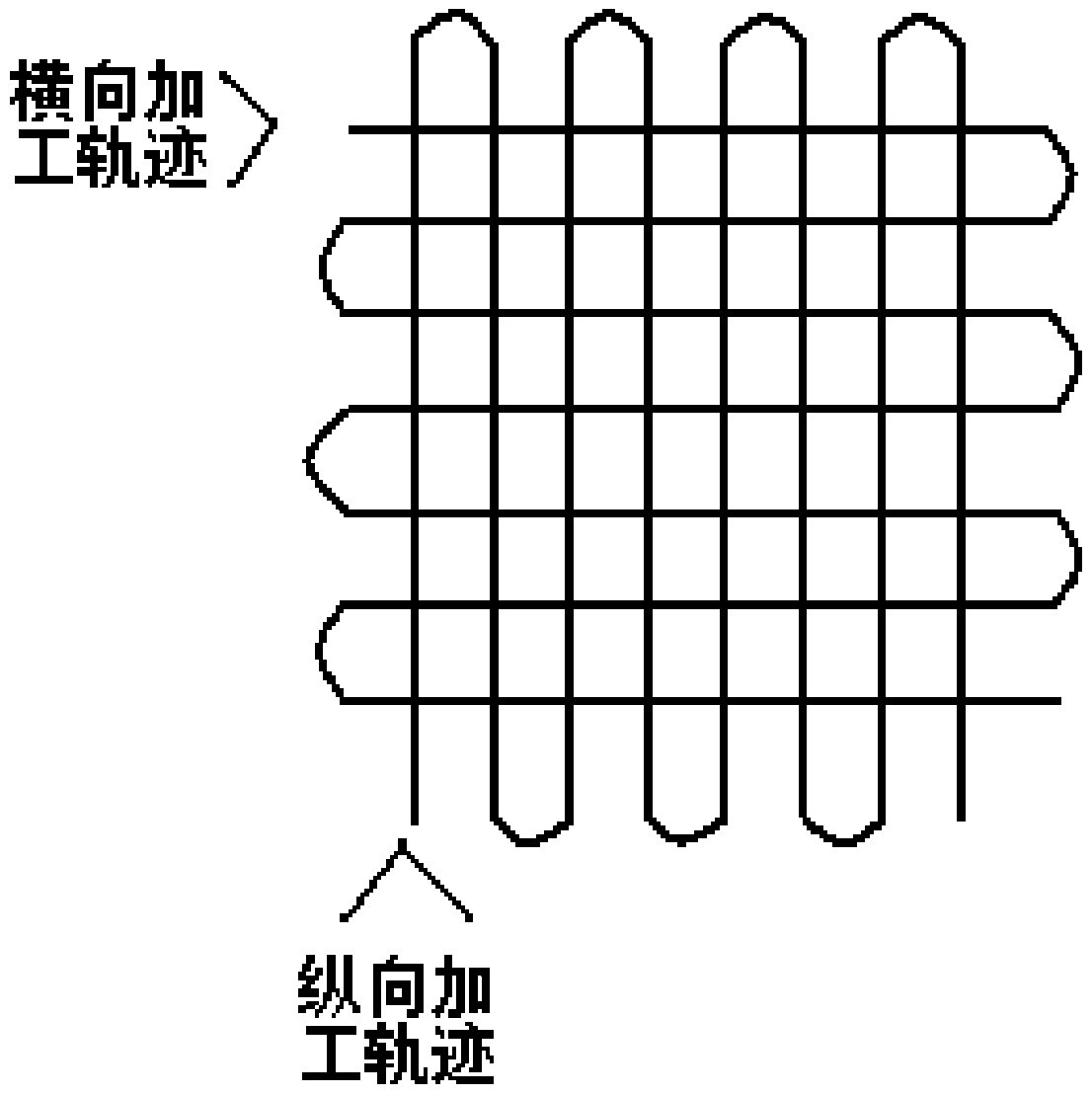

[0055] Femtosecond laser is used to process the microstructure of the resin matrix composite material to make it have a microstructure surface; the size design of the microstructure is carried out according to formula I, and the contact angle θ between the smooth surface of the resin matrix composite material and water is taken * (also referred to as intrinsic contact angle) is 100 °, the resin-based composite material with microstructure surface obtained aft...

Embodiment 2

[0063] This embodiment provides a method for manufacturing a superhydrophobic biomimetic surface for resin-based composite materials, which includes the following steps:

[0064] 1) Grinding and cleaning the resin-based composite material

[0065] Use 400-800# sandpaper to polish the surface of the resin-based composite material until the surface turns white, and then use ethanol to ultrasonically clean the resin-based composite material for 30 minutes.

[0066] 2) Microstructure processing of resin matrix composites

[0067] Adopt picosecond laser (picosecond laser system power is 40W, pulse width is 214ps, pulse frequency is 1000Hz) to carry out microstructure processing to resin-based composite material, make it have microstructure surface; The size design of microstructure is carried out according to formula I, Take the contact angle θ of the smooth surface of the resin matrix composite material with water *(also referred to as intrinsic contact angle) is 100 °, the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com