Patents

Literature

141results about How to "Avoid the problem of easy shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

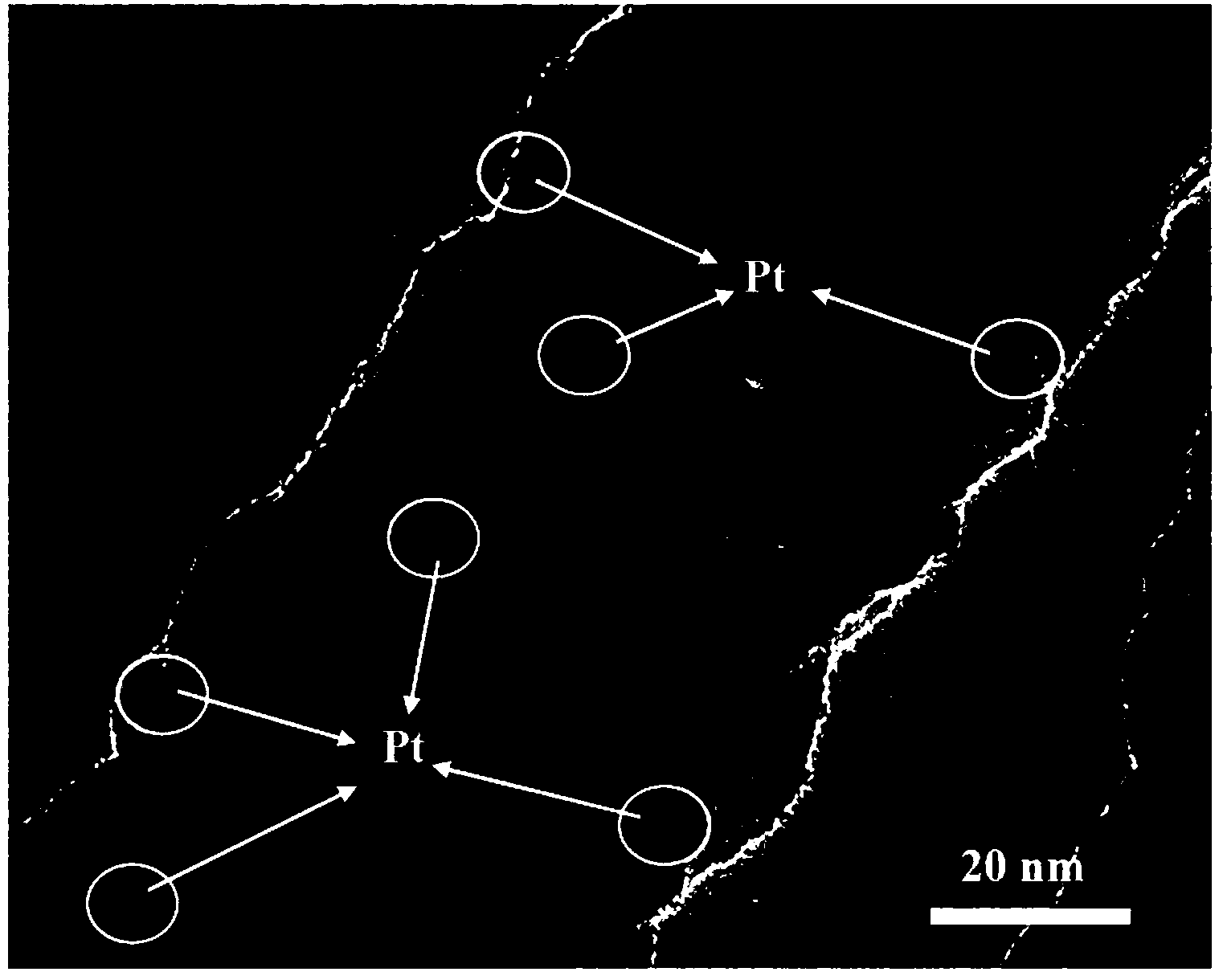

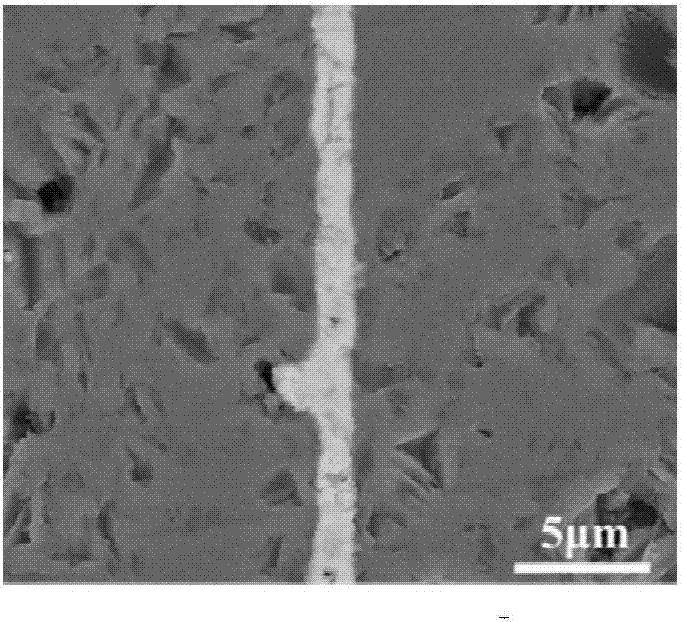

Porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst and preparation method thereof

ActiveCN103721705AHigh activityNot easy to fall offDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberActive component

The invention relates to a porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst and a preparation method thereof. The porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst comprises a porous TiO2 fiber carrier and noble metal active components which are dispersed in the carrier; the porous TiO2 fiber carrier is of a felt shape, and is formed by weaving the TiO2 fibers with the length of a plurality of microns; irregular pores with the pore diameter range of 2-1000nm are formed in the TiO2 fibers so as to form a graduation mesoporous-macroporous structure; and the noble metal exists in a zero valence form with the particle size range of 0.5-3nm. The porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst provided by the invention is of a graduation mesoporous-macroporous structure; the active component noble metal has good dispersibility in the carrier, has the particle size of 1-3nm, and is zero valence; and formaldehyde can be subjected to catalytic decomposition at room temperature, and the catalytic activity is good, and the using quantity is less.

Owner:WUHAN UNIV OF TECH

Method for preparing rice hull active carbon/silicon dioxide/titanium dioxide composite material

ActiveCN102145280AImprove adsorption capacityImprove photocatalytic performanceCatalyst activation/preparationCarbonizationSilicon oxide

The invention discloses a method for preparing a rice hull active carbon / silicon dioxide / titanium dioxide composite material in the technical field of preparation of nano titanium dioxide photocatalysts. The method comprises the following steps of: carrying out acid cleaning on rice hull powder; adding an NaOH solution into the rice hull powder which is subjected to acid cleaning and carrying out alkali cooking to obtain mixed size consisting of rice hulls and sodium silicate; preparing a rice hull / silicon dioxide / titanium dioxide precursor; and finally carrying out carbonization and activating treatment to prepare the rice hull active carbon / silicon dioxide / titanium dioxide composite material. The rice hulls and nano titanium dioxide are combined in a chemical bond mode by silicon dioxide. The rice hull active carbon / silicon dioxide / titanium dioxide composite material not only has excellent adsorption performance of rice hull active carbon, but also has excellent photocatalysis performance of the nano titanium dioxide. The problem that the nano titanium dioxide is easy to fall off on the surface of a vector is effectively avoided. The stability of the composite material is greatly improved. The method has the advantages of simple preparation process, low price of raw materials, low cost and low pollution.

Owner:溧阳常大技术转移中心有限公司

Supported advanced oxidation catalyst material and preparation method thereof

ActiveCN107029720APromote engineering applicationOvercoming the problem of weak bindingMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsChemical platingOrganic solvent

The invention belongs to the field of catalyst materials for waste water treatment, and provides a supported advanced oxidation catalyst material and a preparation method thereof. The method includes the steps: (1) pre-treating carrier materials; (2) placing the pretreated carrier materials into plating solution with a pH (potential of hydrogen) value of 3-13, stirring mixture for at least 5 minutes at the temperature ranging from 30 DEG C to 90 DEG C, performing solid-liquid separation, cleaning a solid phase by the aid of water and organic solvents, and drying the cleaned solid phase to chemically-plated carrier materials; (3) aerobically roasting the chemically-plated carrier materials for 1-8 hours at the temperature ranging from 200 DEG C to 1000 DEG C to obtain the catalyst material. According to the catalyst material, metal oxides are uniformly loaded on the surfaces of the carrier materials, binding force among the loaded metal oxides and the carrier materials can be effectively improved, loading capacity is improved, the service life of the catalyst material is prolonged, catalytic activity is improved, and secondary pollution caused by metal ion leaching is effectively relieved.

Owner:成都柏溪环境科技有限公司

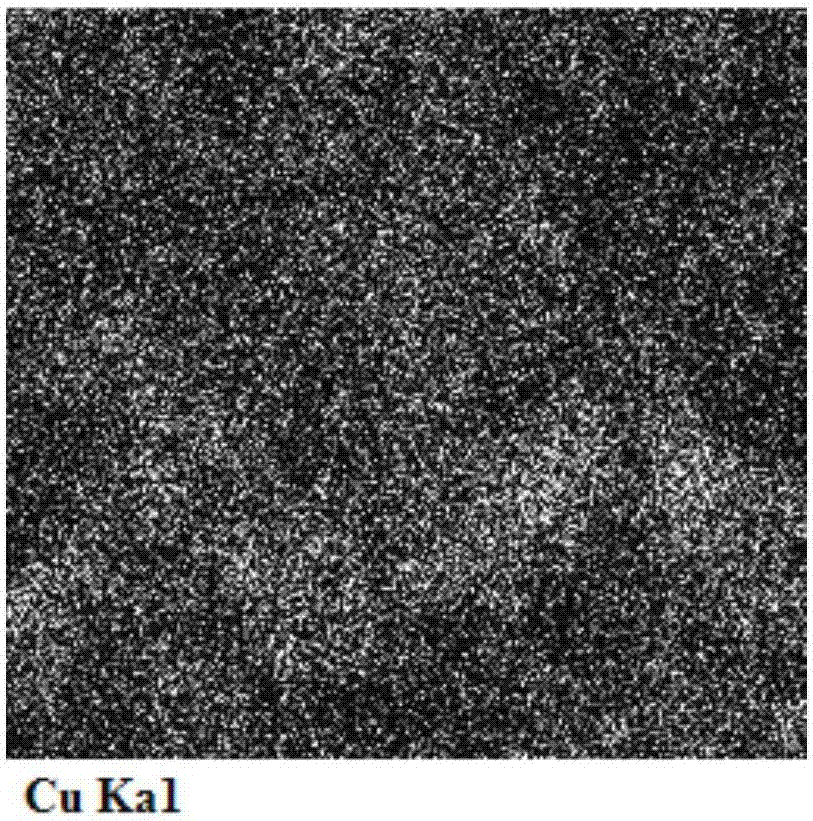

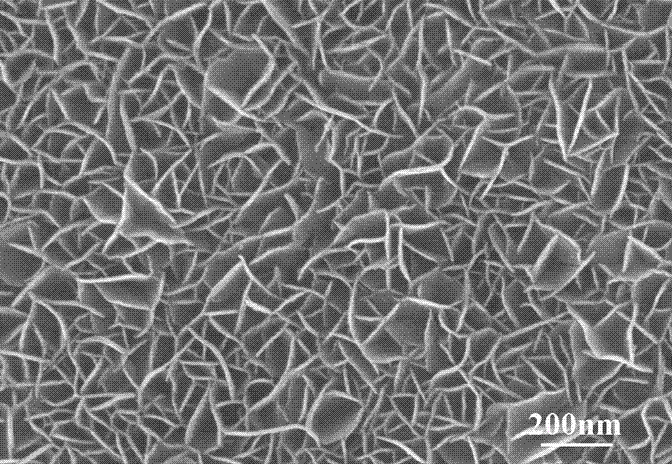

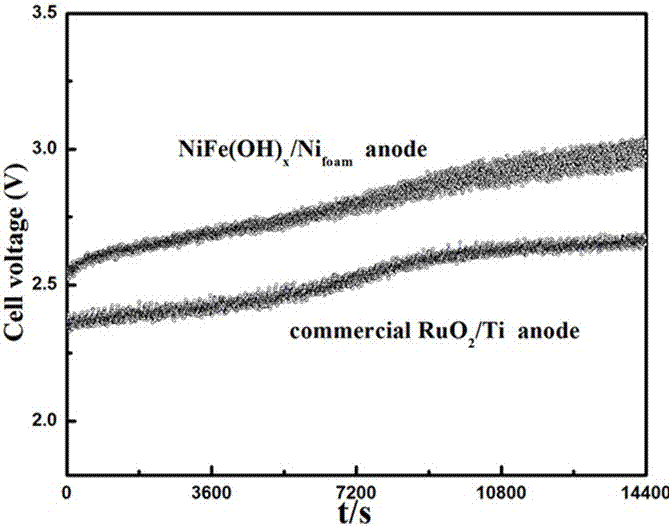

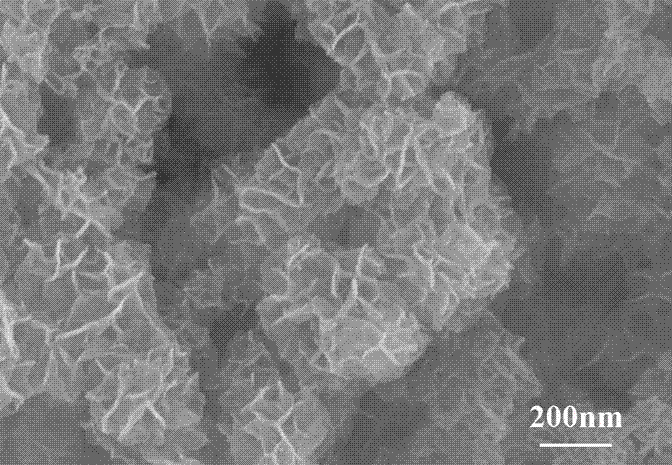

Three-dimensional nanoflower-like Ni-Fe composite hydroxide oxygen evolution anode used for carbonate electrolysis

ActiveCN107385489AReduce tank pressureReduce electrolysis energy consumptionElectrolytic inorganic material coatingNanotechnologyElectrolysisOxygen

The invention discloses a Ni-Fe composite hydroxide oxygen evolution anode material used for a sodium carbonate system and a preparation method of the Ni-Fe composite hydroxide oxygen evolution anode material. The oxygen evolution anode material is of a three-dimensional nanoflower-like structure assembled by ultrathin nanosheets. Because of the special three-dimensional structure, not only are oxygen evolution catalytic activity sites of an electrode surface increased, but also escape of precipitated oxygen is facilitated. The oxygen evolution anode material is applied to sodium carbonate electrolysis, oxygen evolution potentials are reduced, energy consumption is greatly reduced, and economic value and practical value are great. Meanwhile, a method of cathodic reductionelectro-deposition is adopted in a sulfate or chlorate system, hydrogen generated from cathodic reduction serves as a template to facilitate oriented growth of deposited composite hydroxides, and the three-dimensional nanoflower-like structure is obtained. The preparation method is simple, feasible, mild in condition and suitable for industrialized application.

Owner:内蒙古瑞达泰丰化工有限责任公司

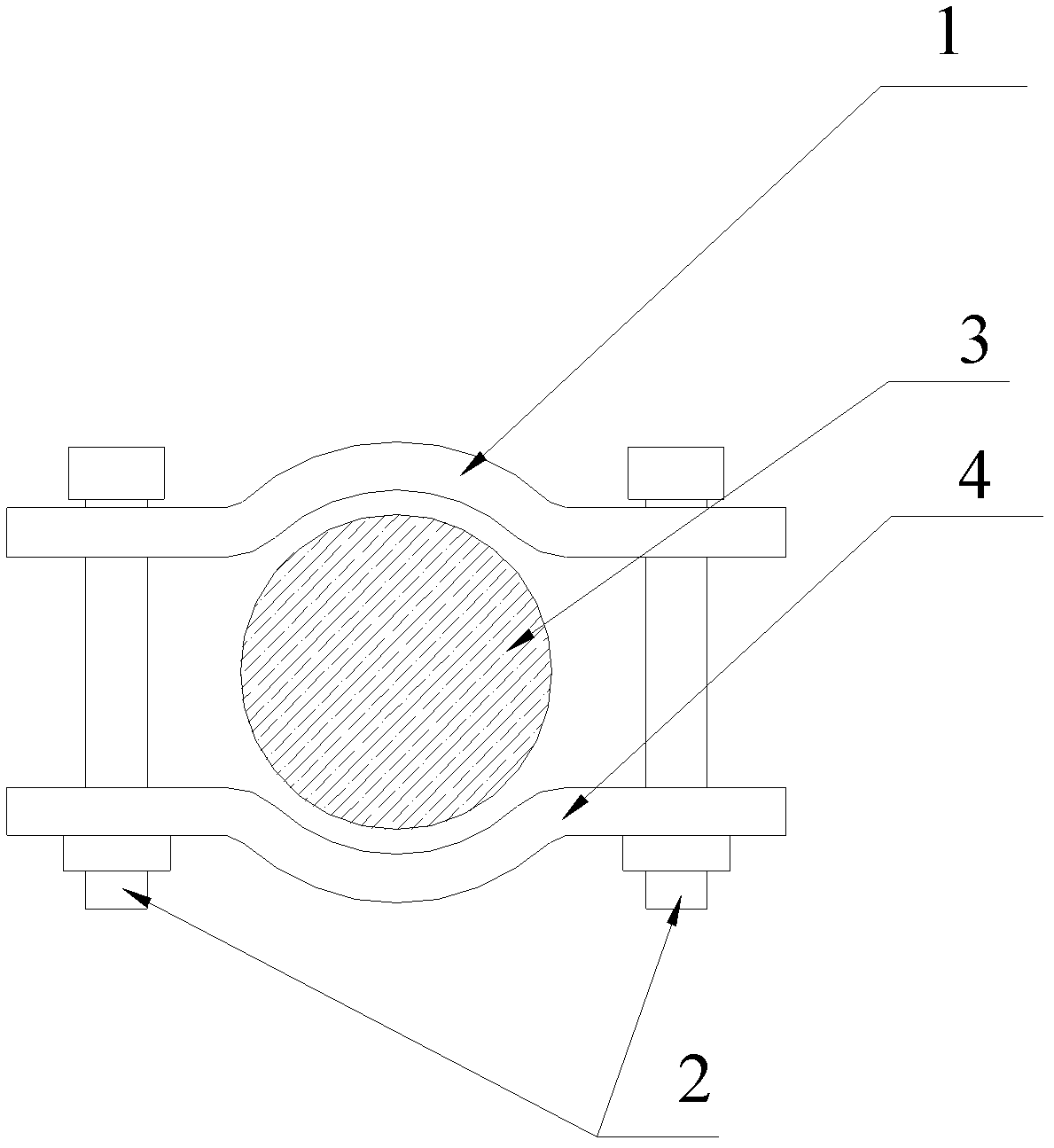

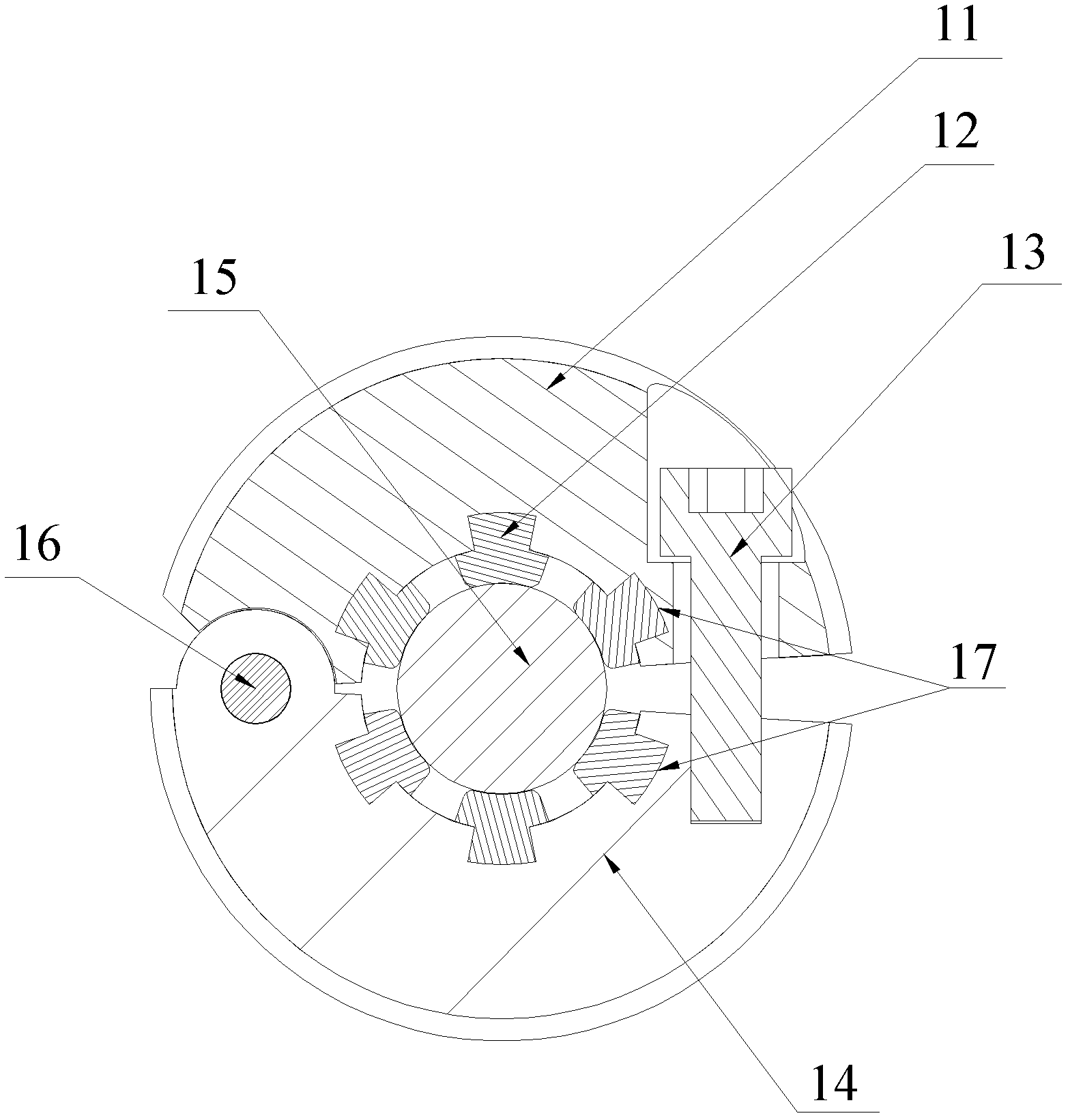

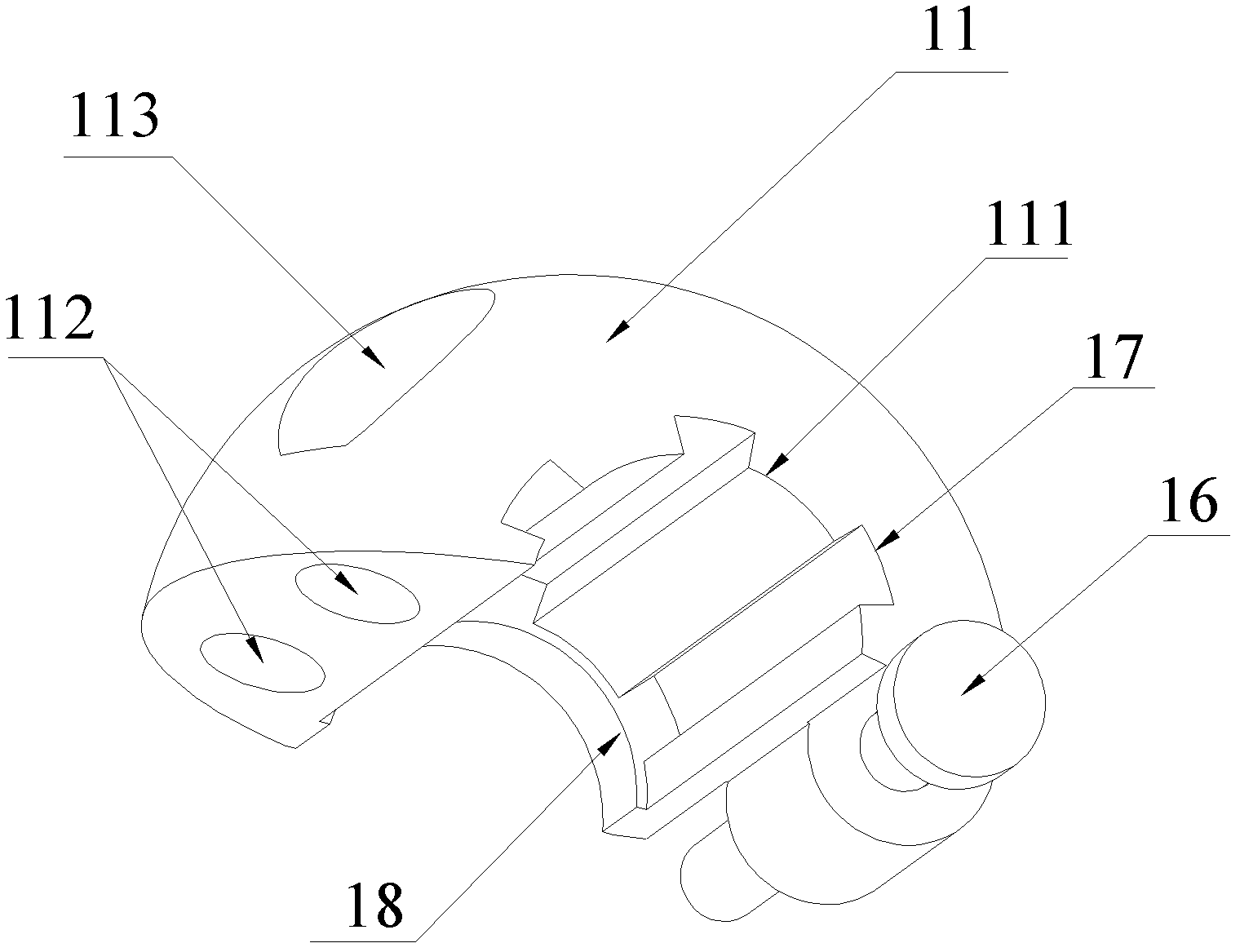

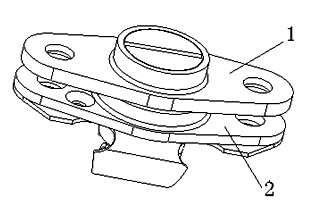

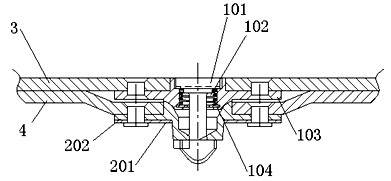

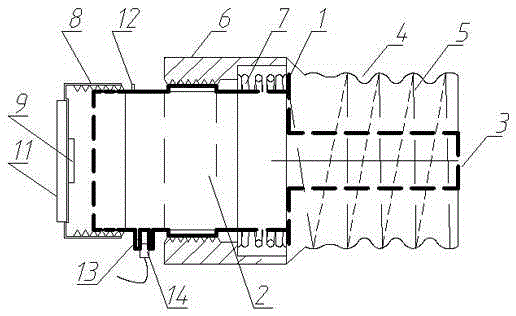

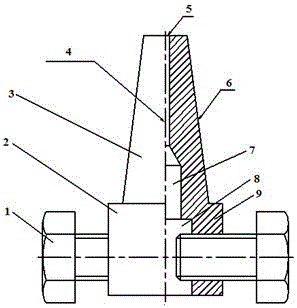

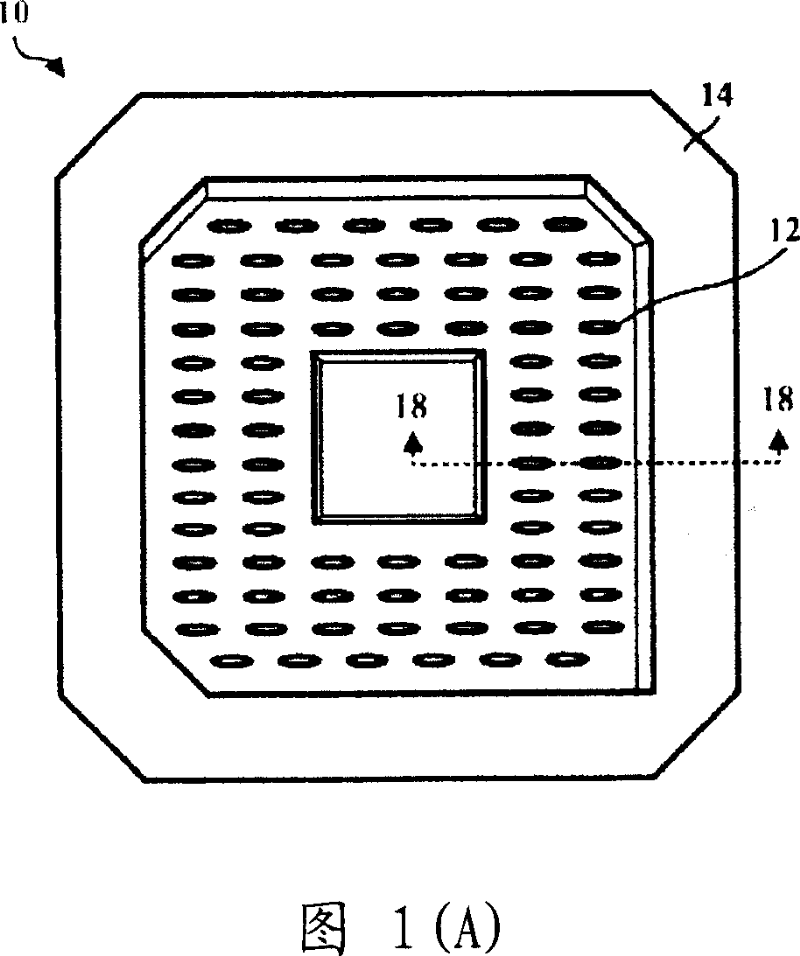

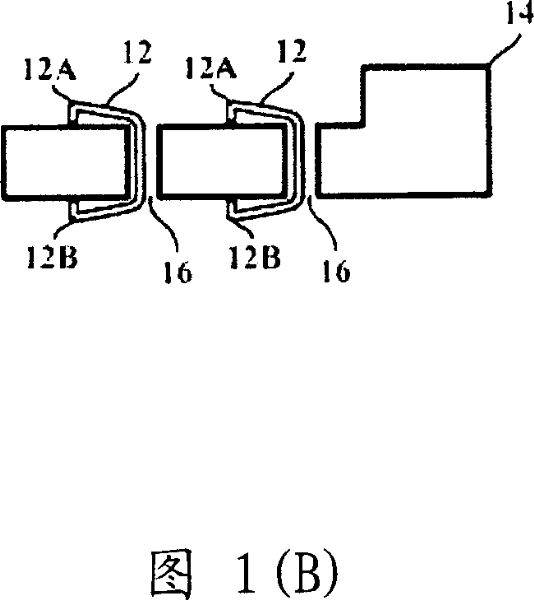

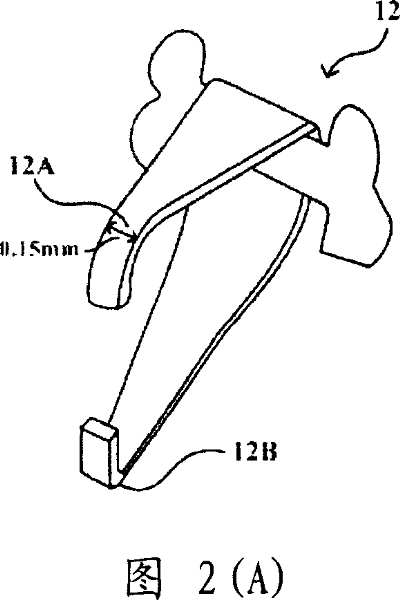

Lead clamping device

InactiveCN102611060AAvoid the problem of easy sheddingAvoid crackingSuspension arrangements for electric cablesMechanical engineering

Owner:AEROSPACE SCI & IND SHENZHEN GROUP

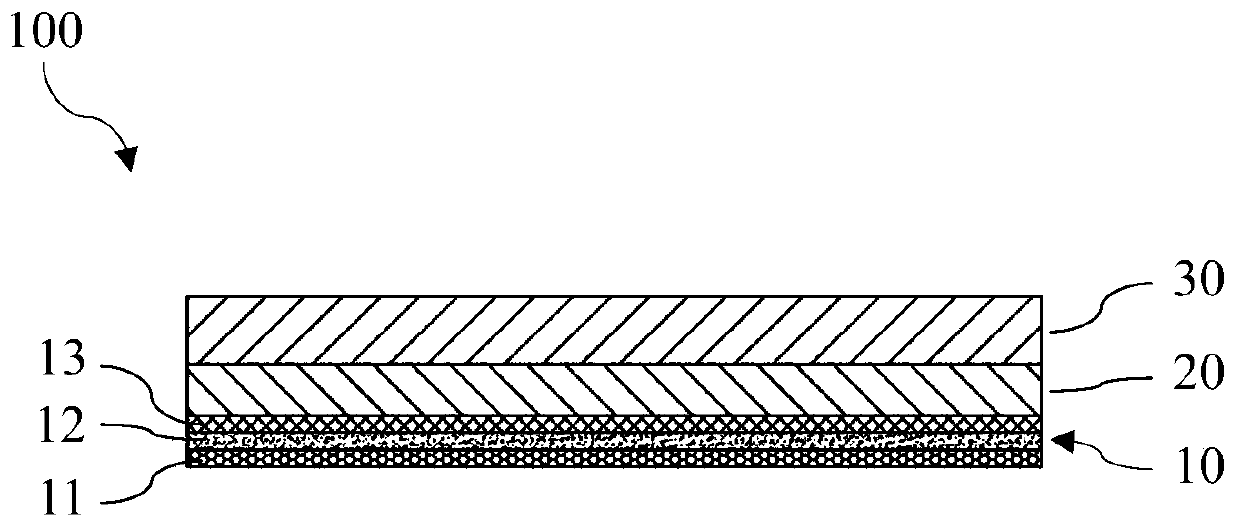

Skin-simulating function film and preparation method thereof

ActiveCN103251511AImprove comfortGood effectCosmetic preparationsToilet preparationsPressure sensitivePhysiological function

The invention relates to a skin-simulating function film and a preparation method thereof. The skin-simulating function film comprises a skin-simulating base material layer and a pressure-sensitive glue layer compounded on the surface of the skin-simulating base material layer, wherein release paper or a release film covers outside the pressure-sensitive glue layer, a backing layer is arranged outside the skin-simulating base material layer, the moisture permeation ratio of the skin-simulating function film is 500g / m<2>*24h-2,000g / m<2>*24h, and the air permeability of the skin-simulating function film is not less than 2,000mL / m<2>*24h.0.1MPa. Through using the skin-simulating base material layer with skin similar physiological function air permeability, moisture permeation and good biocompatibility and matching with the pressure-sensitive glue layer, the prepared skin-simulating function film is high in comfort and good in effect during using.

Owner:武汉华卫科技有限公司

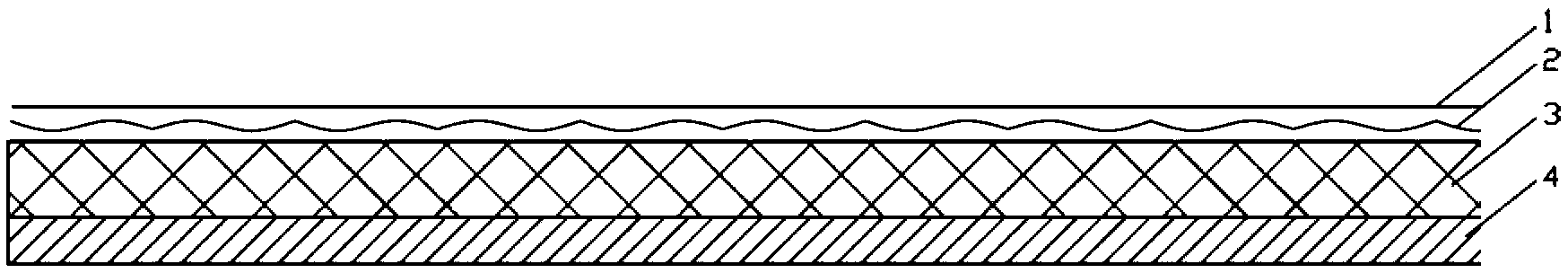

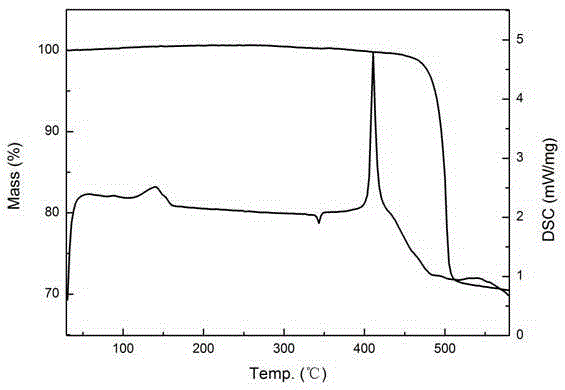

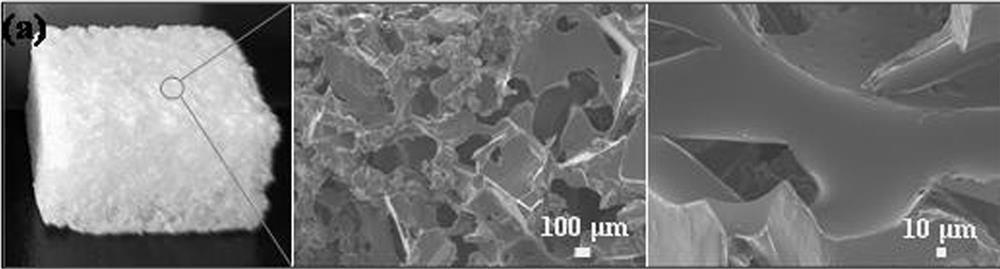

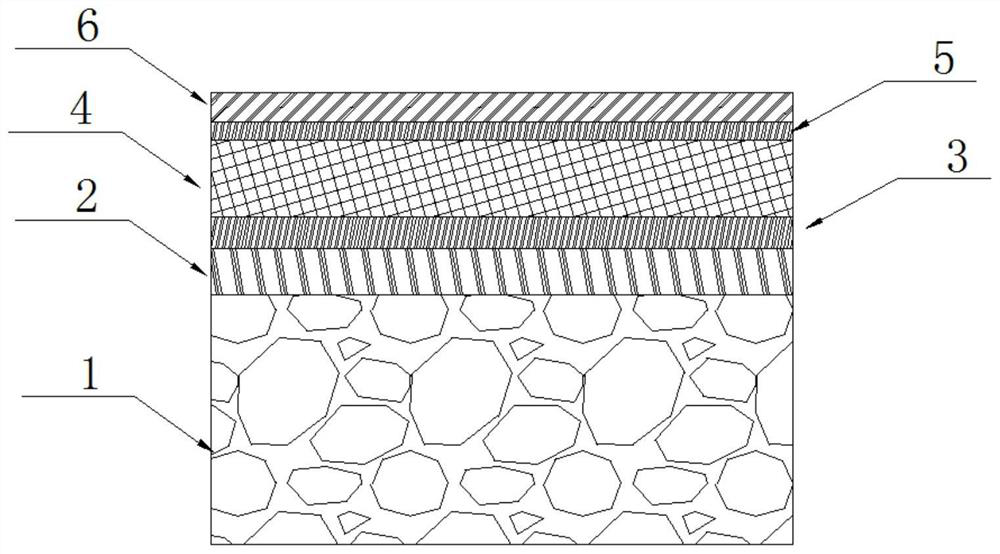

Aerogel phase change thermal insulation material and preparation method thereof

ActiveCN109927386AGuaranteed smart thermostat functionAvoid the problem of easy sheddingSynthetic resin layered productsLaminationInsulation layerThermal insulation

The invention provides an aerogel phase change thermal insulation material and a preparation method thereof. The invention provides an aerogel phase change thermal insulation material. The aerogel phase change thermal insulation material comprises a heat insulation layer and a heat preservation layer, the heat insulation layer is of an aerogel sponge structure; the heat preservation layer is compounded on one side face of the heat-insulation layer through a predetermined bonding mode, the heat preservation layer comprises a moisture-conducting fiber net layer, a heat storage fiber net layer and a heat insulation fiber net layer which are sequentially arranged and are connected with each other through a non-woven needling mode, the heat insulation fiber net layer is connected with the heatinsulation layer, the moisture-conducting fiber net layer is used for being in contact with a human body, the moisture-conducting fiber net layer is a fiber net layer made of common fibers, special-shaped hollow ultrafine fibers and curled fibers, the heat storage fiber net layer is a fiber net layer made of phase change cellulose fibers, and the heat insulation fiber net layer is a fiber net layer made of aerogel polyimide fibers. The aerogel phase change thermal insulation material further comprises a waterproof moisture permeable layer which is compounded on the other side surface of the heat insulation layer in a predetermined bonding mode.

Owner:北京中科海势科技有限公司

Preparation method of high-efficiency composite attapulgite/rice hull activated carbon purified water material

InactiveCN103301807ARich pore structureImprove specific surface area and adsorption capacityOther chemical processesWater/sewage treatment by sorptionActivated carbonChemistry

The invention relates to a preparation method of a high-efficiency composite attapulgite / rice hull activated carbon purified water material. The preparation method is characterized in that specifically, attapulgite and rice hulls are utilized as raw materials, the attapulgite and the rice hulls are simultaneously subjected to activation and counterbore through alkali treatment, and then a one-step method is adopted to prepare the high-efficiency composite attapulgite / rice hull activated carbon purified water material. The composite attapulgite / rice hull activated carbon purified water material prepared by using the method provided by the invention has the excellent adsorption property.

Owner:CHANGZHOU UNIV

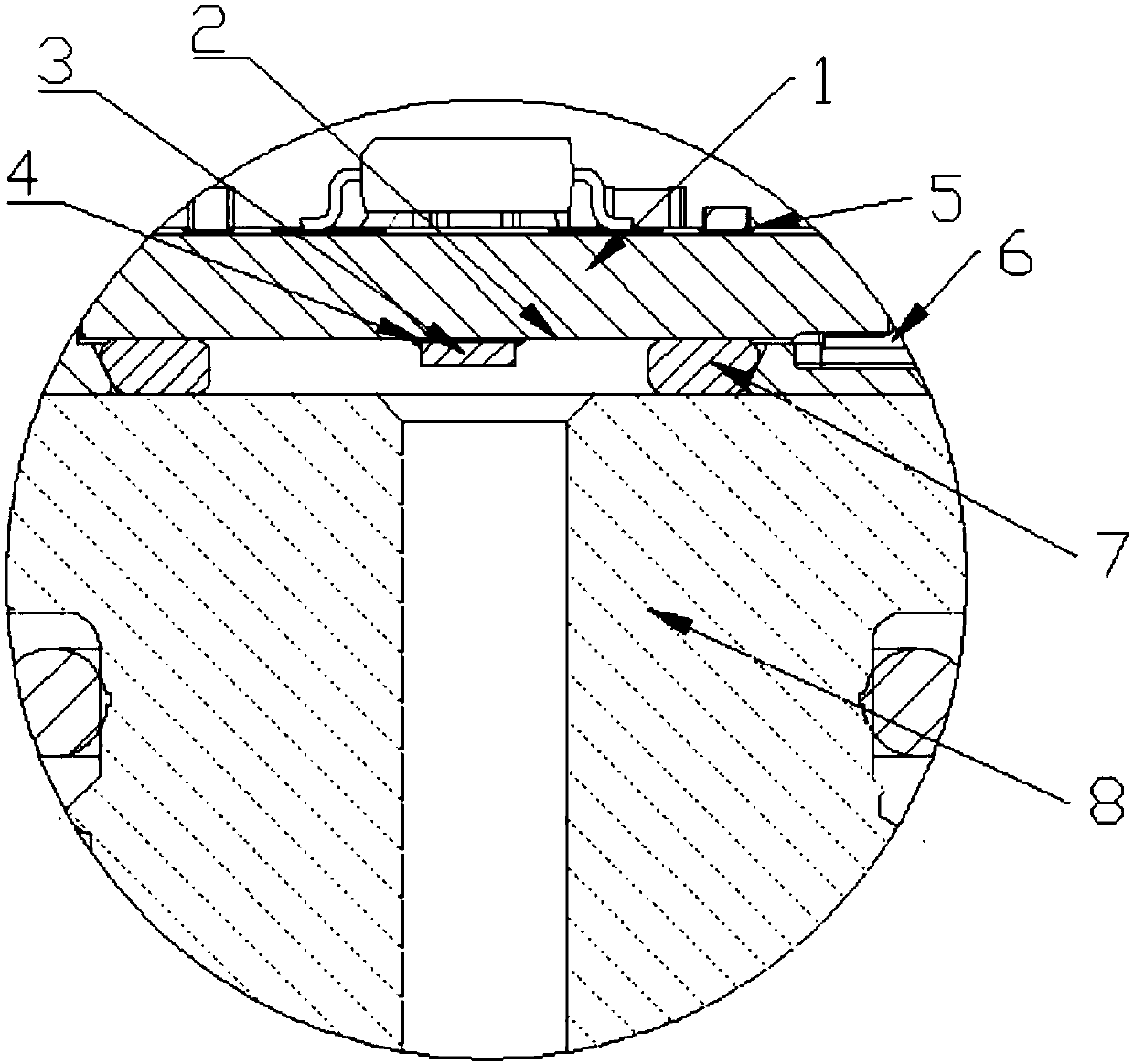

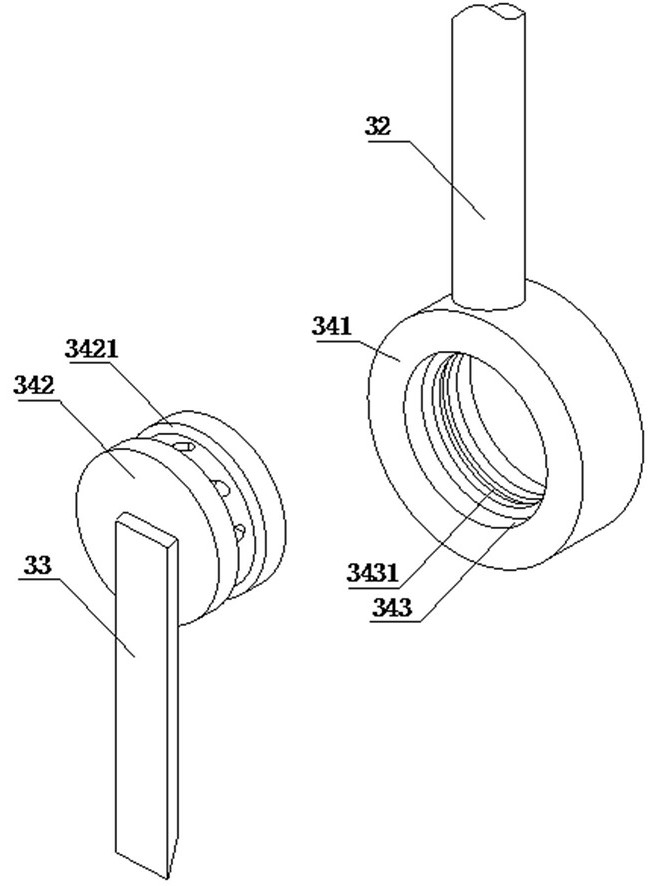

Quick release lock with spring device

ActiveCN102425591AEasy to disassembleQuick and easy disassemblySnap-action fastenersAircraft accessoriesAirplaneCircumferential rings

The invention discloses a quick release lock with a spring device. An upper lock body consists of a lock pin, a spring, a lock seat disk and a gasket; the lock seat disk and a lower lock seat are both provided with two side blades respectively and are also provided with installation holes; the lock seat disk is provided with a central through hole, a protruded circumferential ring surrounding thecentral through hole is arranged on two sides of the lock seat disk respectively, the spring is arranged and the lock pin is sleeved in the central through hole of the protruded circumferential ring;the spring is connected with a step of the lock pin; the other end of the spring is connected with a step in the central through hole; the gasket is arranged in a connection gap between the spring and the central through hole; the lower lock seat consists of a snap spring sheet and a lower lock body; the lower lock body is arranged in the snap spring sheet; and a through hole corresponding to theupper lock body is formed in the center of the snap spring sheet and the lower lock body respectively. The quick release lock can solve the problem that a large-curvature curved covering cap cannot be opened by a common quick release lock, and can also avoid the problem that the lock pin falls, and facilitates the daily using and maintenance of an airplane.

Owner:JIANGXI HONGDU AVIATION IND GRP

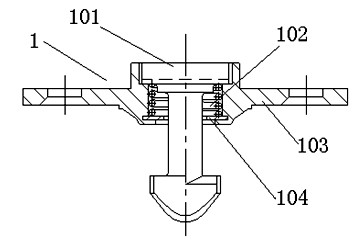

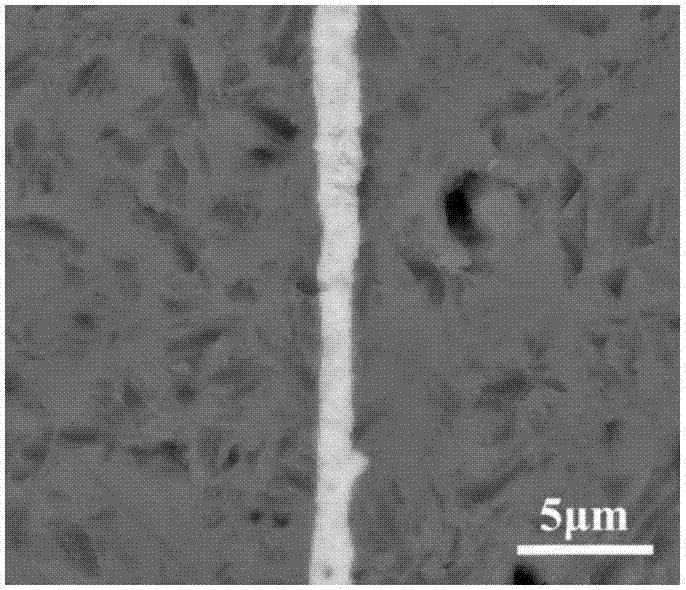

High-corrosion-resistance silicon carbide ceramic connecting material, and connecting method for silicon carbide ceramic

The invention provides a high-corrosion-resistance silicon carbide ceramic connecting material. The connecting material is a titanium membrane with a thickness of less than 1 [mu]m. The connecting material is clamped between to-be-connected silicon carbide ceramic materials, and the to-be-connected silicon carbide ceramic materials are connected together by heating a connection interface to a connection temperature of more than 1000 DEG C via an external heat source; and the connection position of the connected silicon carbide ceramic materials has high corrosion resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

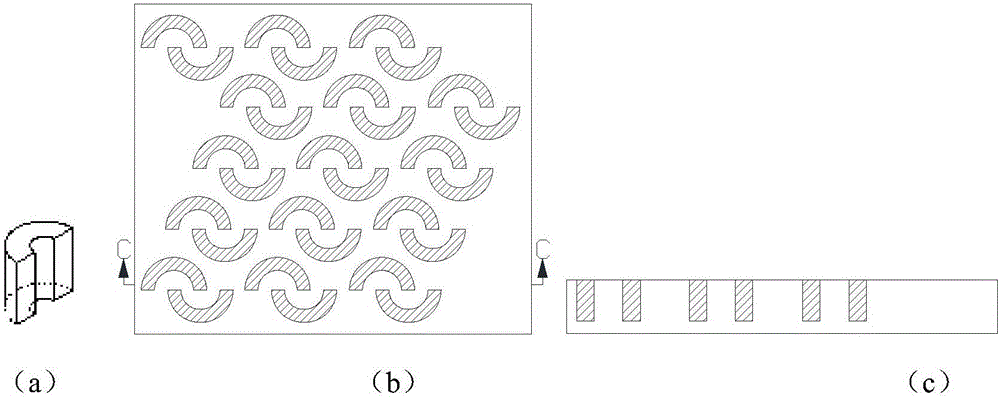

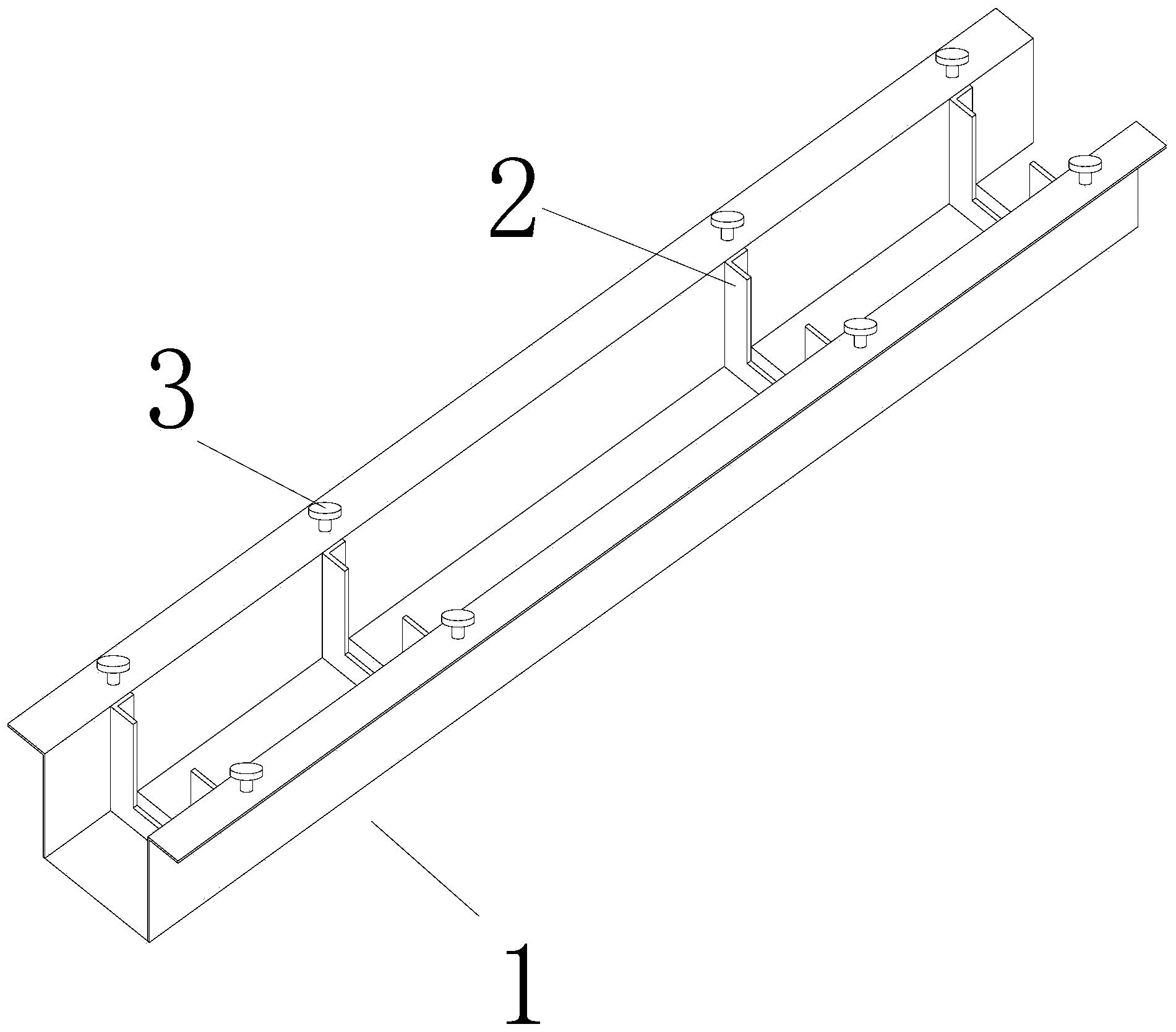

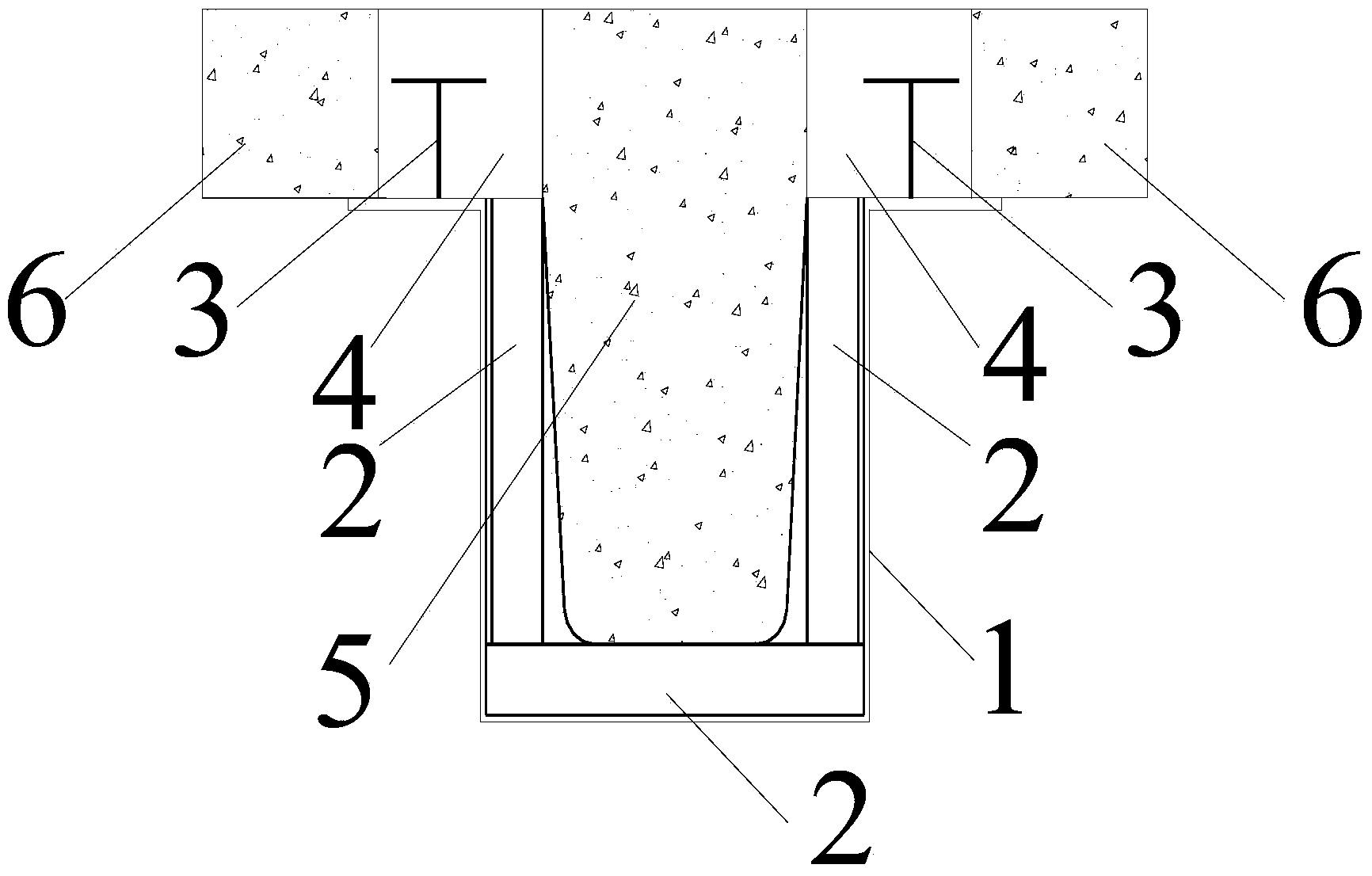

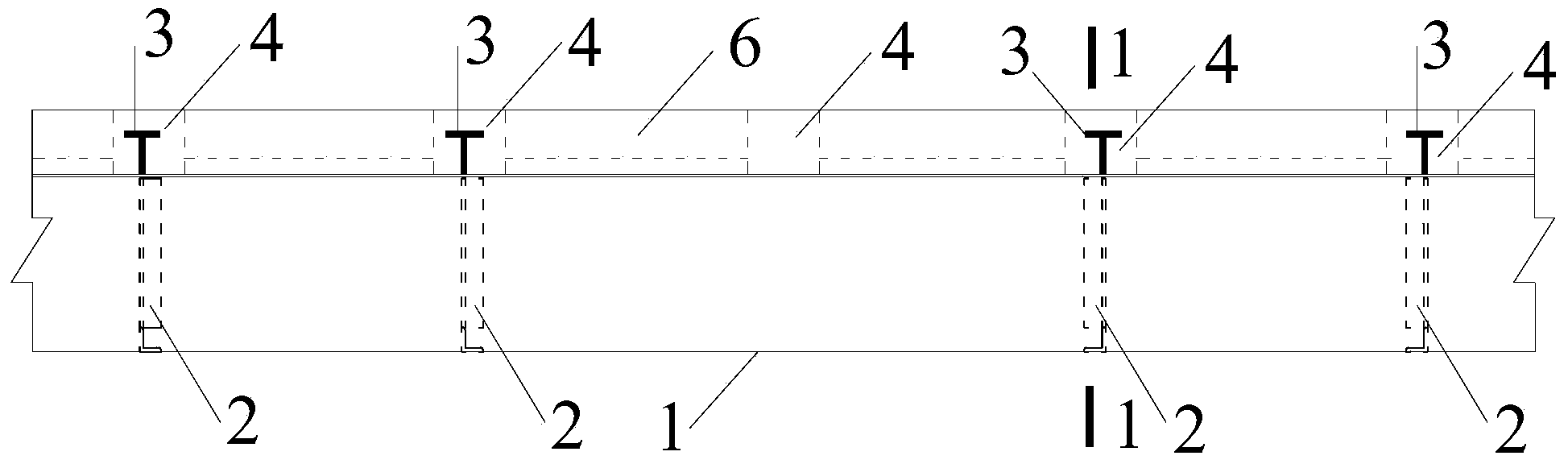

Reinforcing device of concrete beam and construction method thereof

ActiveCN103711328AImprove carrying capacityAvoid the problem of easy sheddingBuilding repairsConcrete beamsLong axis

The invention provides a reinforcing device of a concrete beam. The reinforcing device of the concrete beam comprises a steel groove body, inner distance rings and studs. The steel groove body is of the structure with the upper surface provided with an opening. The concrete beam can be sleeved with the steel groove body. An interlayer is arranged between the steel groove body and the concrete beam. The two sides of the long axis of the upper surface of the steel groove body respectively extend horizontally and outwards to form an upper wing platform. The studs are fixedly arranged on the upper wing platforms at intervals respectively. The inner distance rings are fixedly arranged on a groove defined by the side faces and the bottom face of the steel groove body at intervals. The steel groove body, the concrete beam and a grout blanket are fixedly connected together through the inner distance rings and the studs, so that the bending bearing performance and the shearing bearing performance of the concrete beam are improved, the grouting bracket is effectively prevented from shedding, and the long-term reinforcing effect is guaranteed. The invention further provides a construction method of the reinforcing device, and effective application of the reinforcing device is guaranteed.

Owner:HUAQIAO UNIVERSITY

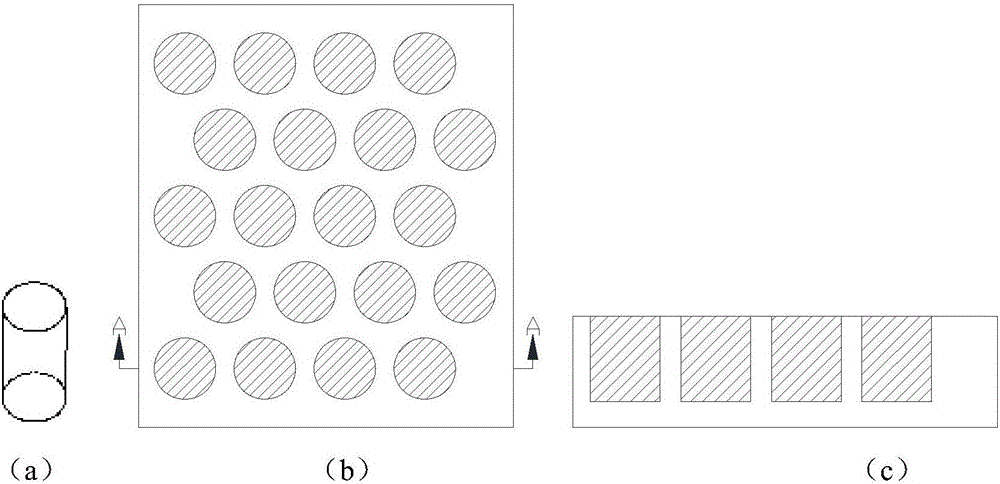

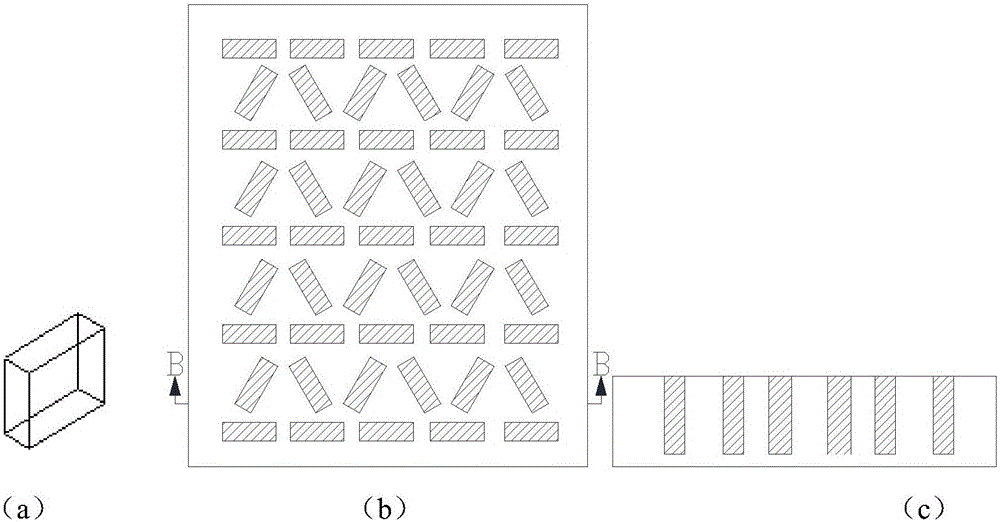

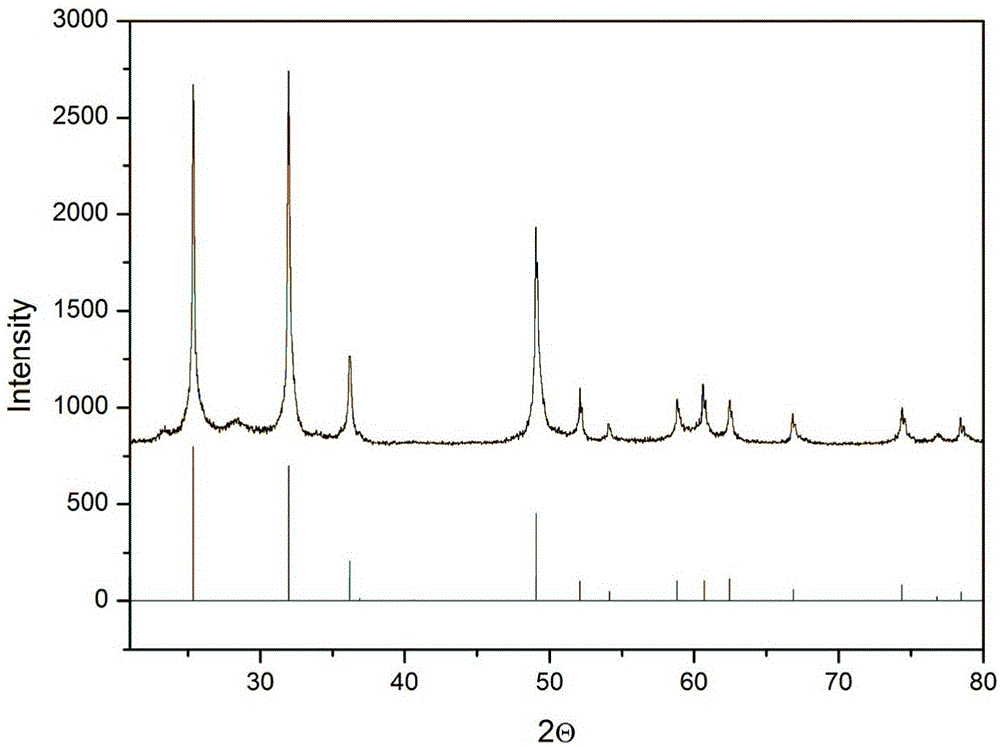

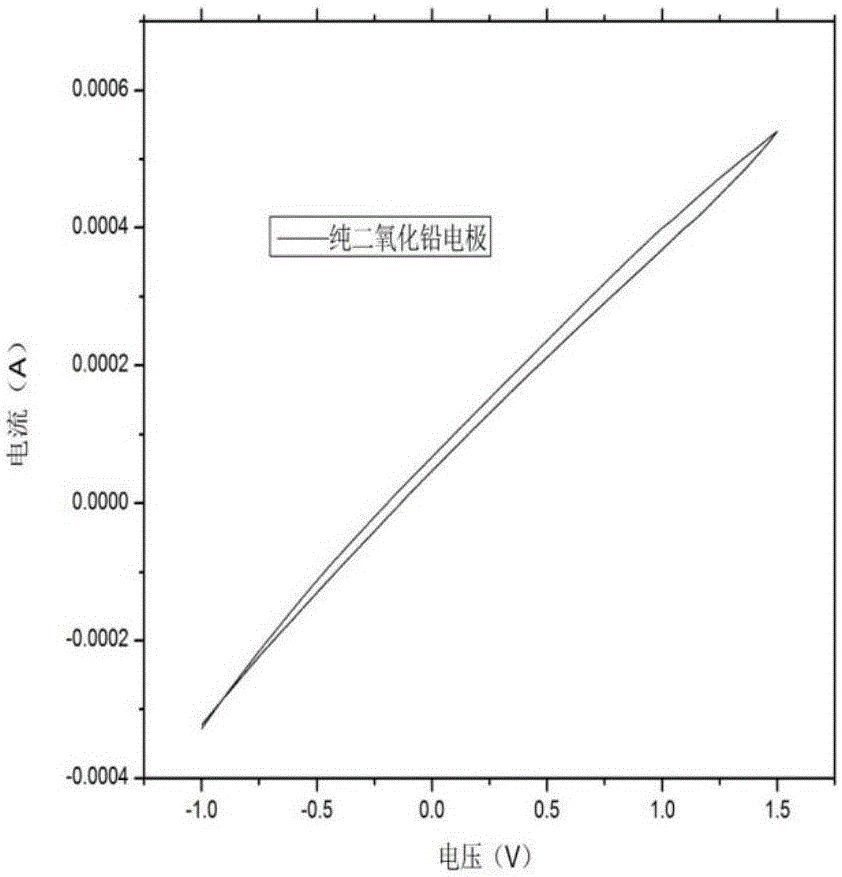

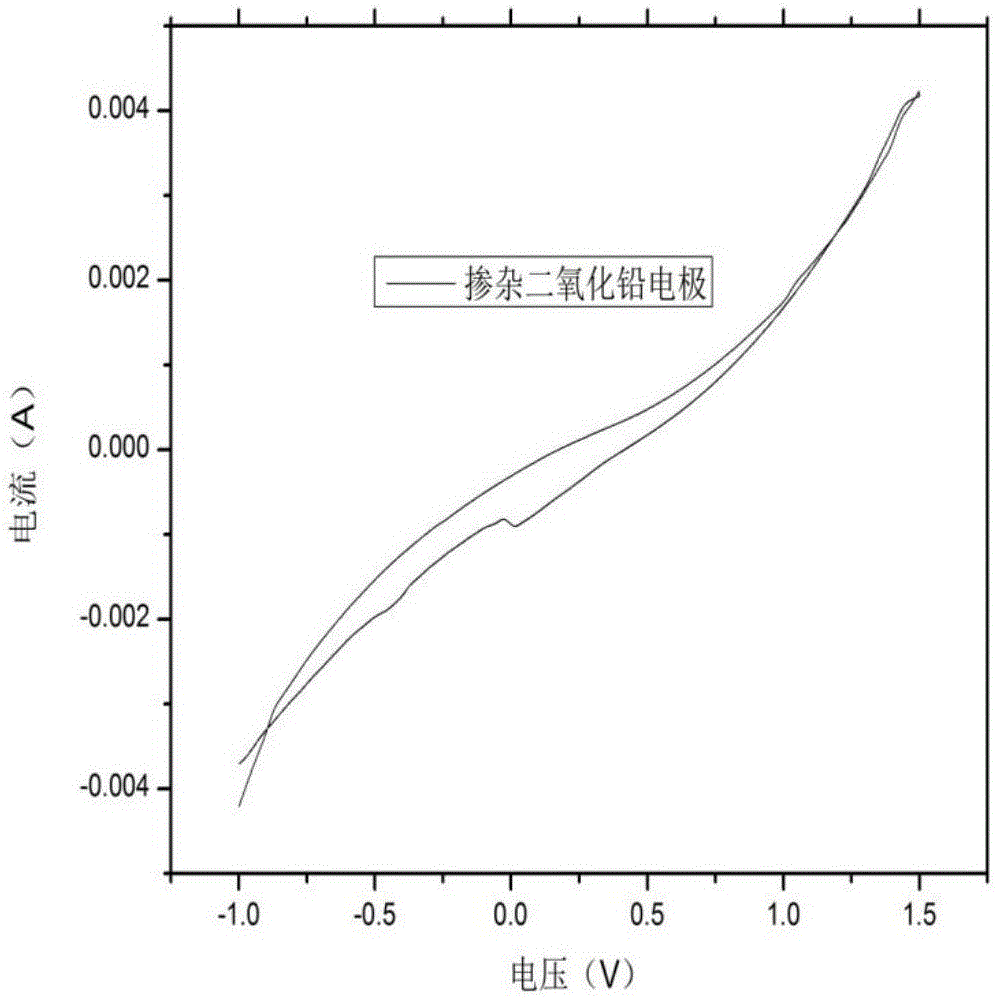

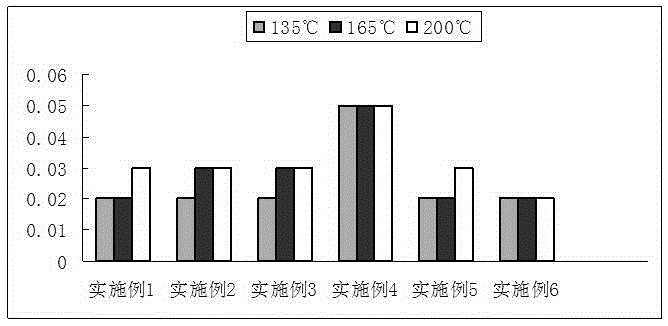

Cerium oxide-doped modified lead dioxide porous electrode and preparation method thereof

InactiveCN105000637AImprove conductivityImprove electrolysis efficiencyWater/sewage treatmentMetal/metal-oxides/metal-hydroxide catalystsTemperature controlEmulsion

The invention discloses a cerium oxide-doped modified lead dioxide porous electrode and a preparation method thereof. The preparation method comprises the following steps: dissolving lead acetate in water, adjusting the pH value of the obtained solution to 9.0 to 10.0 by using NaOH, adding NaOH, carrying out uniform mixing under stirring, carrying out a reaction at 90 DEG C for 6 h, successively subjecting the obtained reaction solution to filtering and washing until eluant is neutral, and carrying out drying at a temperature controlled to be 60 to 90 DEG C so as to obtain beta-PbO2 powder; and uniformly mixing the obtained beta-PbO2 powder with mixed powder composed of cerium oxide powder and carbon powder, adding a teflon emulsion with mass percent concentration of 60%, carrying out uniform mixing under stirring, then carrying out drying at a temperature controlled to be 60 to 90 DEG C for 30 to 60 min, filling a circular-sheet-shaped or long-strip-shaped die with the dried mixture, controlling a pressure to be 20 MPa for 2 min and carrying out high-pressure sheet molding so as to obtain the cerium oxide-doped modified lead dioxide porous electrode with good conductivity and electro-catalytic properties. The cerium oxide-doped modified lead dioxide porous electrode is applied to treatment of dyeing waste water.

Owner:SHANGHAI INST OF TECH

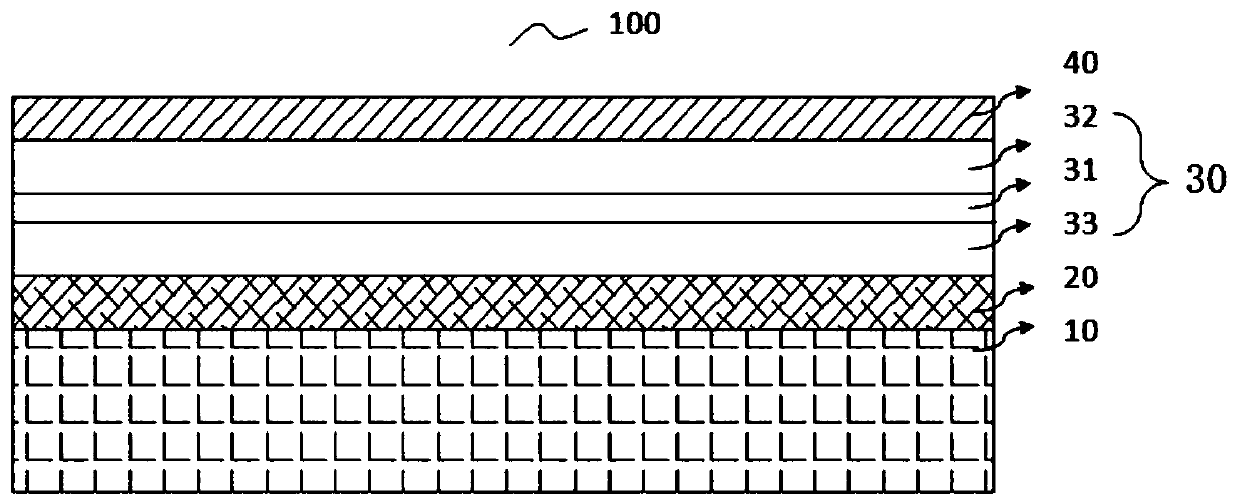

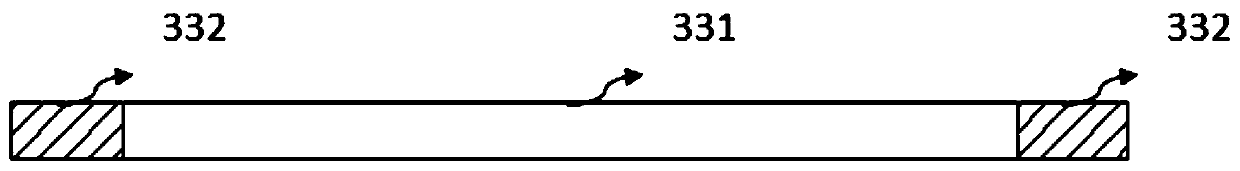

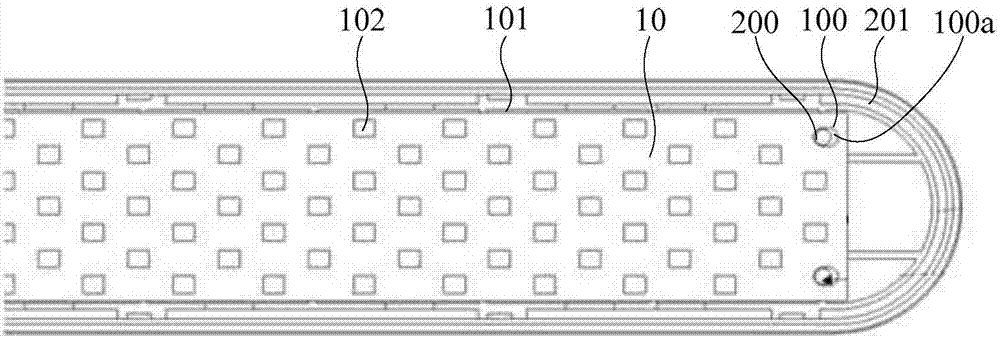

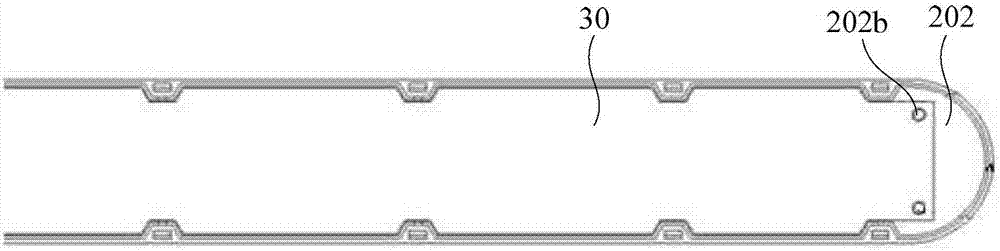

Preparation method for polyimide modified composite battery membrane and product prepared therethrough

InactiveCN108172742AAvoid the problem of easy sheddingLow costCell component detailsPolyamic acidChemistry

The invention relates to a preparation method for a polyimide modified composite battery membrane and a product prepared therethrough. The preparation method comprises the steps of dispersing a pore-forming agent in a solvent, and adding diamine and dianhydride successively to obtain a polyamic acid solution A containing the pore-forming agent, wherein based on the total mass of polyamic acid, thecontent of the pore-forming agent is 40-55% and the molar ratio of the dianhydride to the diamine is 0.96:1 to 1.02:1, and based on the total mass of the solvent and the polyamic acid, the mass solidcontent of the polyamic acid is 10-40%; dipping a non-woven fabric in the solution A to obtain a polyamic acid composite membrane B containing the non-woven fabric; dipping the composite membrane B in a solidification solution for performing chemical imidization to obtain a polyimide composite membrane C; and placing the polyimide composite membrane C in a drying oven for heating to enable the pore-forming agent to be gasified and decomposed to form pores, thereby obtaining the polyimide modified composite battery membrane. The polyimide modified composite battery membrane does not contain the bonder, so that the problem of easy falling of laminated membranes in the composite membranes prepared by using the bonder is avoided; and excess solvents do not need to be used for removing the pore-forming agent, so that the cost is reduced, and the production efficiency is improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Preparation method for poly-dopamine modified ceramic particle nonwoven diaphragm

InactiveCN105390642AAvoid the problem of easy sheddingImprove flame retardant performanceCell component detailsOrganic solventDopamine

The invention relates to a preparation method for a poly-dopamine modified ceramic particle nonwoven diaphragm. The method is characterized by comprising the following concrete steps of: a) soaking ceramic particles in a dopamine solution with the concentration of 0.5-2.0g / L for 10-24 hours, and performing suction filtration and evaporation to dryness to obtain poly-dopamine modified ceramic particle powder, wherein a mass ratio of poly-dopamine to ceramic particles is 0.05-0.2; meanwhile, b) treating a nonwoven diaphragm with a mixed solution containing an organic binder, an organic solvent, modified ceramic powder and a hole former; and c) performing grinding and vacuum drying on a diaphragm obtained in the step b) to obtain the poly-dopamine modified ceramic particle nonwoven diaphragm, wherein the vacuum drying temperature is 50-75 DEG C. The poly-dopamine modified ceramic particle nonwoven diaphragm has good flame resistance and heat resistance and high liquid absorption rate and mechanical performance. A lithium ion battery assembled by the diaphragm is greatly improved in safety performance.

Owner:CHINA FIRST AUTOMOBILE

Radiation refrigeration metal plate as well as preparation method and application thereof

InactiveCN111497378AStable structureExtended service lifeSynthetic resin layered productsCoatingsIndoor air temperatureMaterials science

The invention relates to a radiation refrigeration metal plate as well as a preparation method and application thereof. The radiation refrigeration metal plate comprises a metal substrate, a first bonding layer and a radiation refrigeration function layer which are sequentially arranged in a stacked mode; the radiation refrigeration function layer is laid on the surface of the metal substrate, thefirst bonding layer is arranged between the metal substrate and the radiation refrigeration function layer, and the elongation at break of the radiation refrigeration function layer is 1%-300%. The radiation refrigeration metal plate has enough ductility and can generate enough deformation to deal with bending of the radiation refrigeration function layer in the pressing process, so the radiationrefrigeration function layer cannot be damaged or broken, and therefore the structural integrity of the radiation refrigeration function layer and the radiation refrigeration effect of the metal substrate are guaranteed. When the radiation refrigeration metal plate is used, the indoor air temperature of a building is reduced by about 5-10 DEG C under the condition that energy is not consumed compared with the condition that the radiation refrigeration metal plate is not used.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD +1

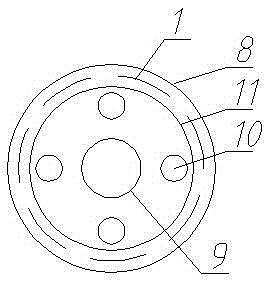

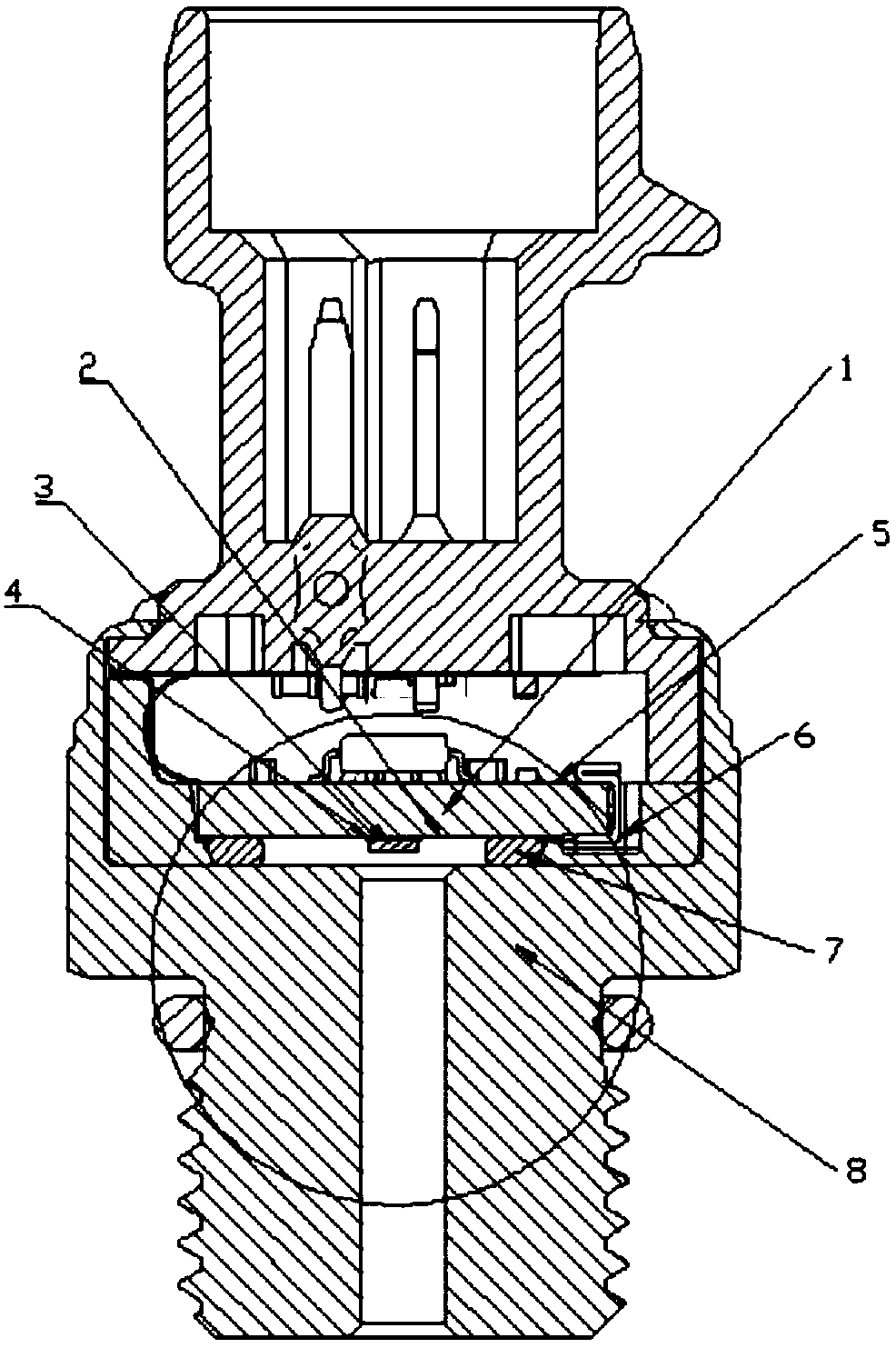

Earplug earphone with adjustable external auditory canal pressure elastic ring

The invention relates to an earplug earphone with an adjustable external auditory canal pressure elastic ring, which comprises an earphone base body and an inner core inside the earphone base body, and is characterized in that the front end of the earphone base body is provided with a sound outlet cylinder, the sound outlet cylinder is provided with a hose, a light and thin spring is arranged between the hose and the sound outlet cylinder, and the light and thin spring is connected with an inner hole surface of the hose; the middle section of the earphone base body is in threaded connection with an earphone outer sleeve, the tail end of the earphone outer sleeve is internally provided with a compression spring arranged on the earphone base body in a sleeved manner, and the earphone outer sleeve is connected with the hose; sound inlet holes in the tail end of the earphone base body are communicated with an inner hole of the hose, the tail end of the earphone base body is in threaded connection with a tail cover, the diameter of a central area of the end face of the tail cover is slightly greater than the diameter of the sound inlet holes, and the end face of the tail cover is provided with the small sound inlet holes which are uniformly distributed around the circumference of the central area; and when the earplug earphone is used, the light and thin spring rotating through the earphone outer sleeve can perform compression on the hose along the axial direction and the radial direction of the sound outlet cylinder, and the compression spring can perform compression on the earphone outer sleeve along the axial direction of the earphone base body. The earphone improves the comfort in use, and a user can also hear an external emergency sound warning while listening to the music.

Owner:陈梦飞

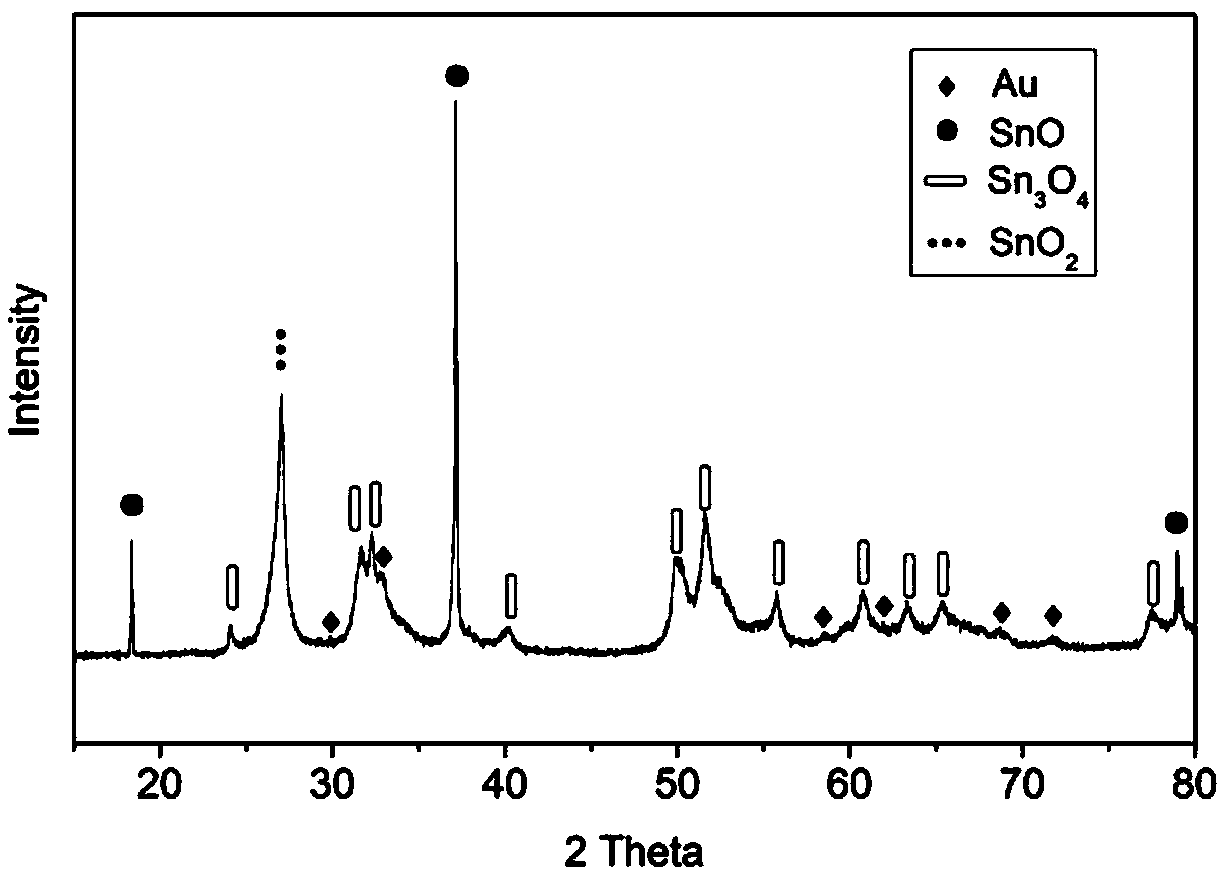

Preparation method of Au modified SnO/Sn3O4/SnO2 nano composite photocatalytic material

InactiveCN109092307AEnhanced light absorptionEasy to separateHydrogen productionHydrogen/synthetic gas productionHeterojunctionPhotocatalytic water splitting

The invention relates to a preparation method of an Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material. The nano composite material is obtained by placing chloroauric acid and a tin source into a solvent, a surfactant and a reducing agent and forming chemical bond complexing among composite ingredients of the materials according to an ice salt bath and solvent combined hot wet chemical in-situ synthesis method. The composite material prepared by the invention utilizes a plasma resonance effect of Au metal nanoparticles, an excellent energy level matching heterojunction structureamong composite components of a tin oxide material and excellent electron conduction of Au metal nanoparticles, and implements rapid electron-hole separation in the process of cooperating photocatalytic oxidation and reduction degradation of pollutants with photocatalytic water splitting hydrogen production, thereby improving efficiency of photocatalytic water splitting and photocatalytic rhodamine B degradation of the Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material.

Owner:PINGDINGSHAN UNIVERSITY

Medical dressing for treating large area wound and manufacturing method thereof

InactiveCN105662713APromote healingAnti-water intrusionPlastersAdhesive dressingsWound healingBurning Pain

The invention discloses a medical dressing for treating a large area wound and a manufacturing method thereof. The medical dressing is composed of from top to bottom: an isolation paper, a sodium alginate hydrogel, a non-woven fabric, a medical glue layer and a base cloth; or from top to bottom, an isolation paper, an alginate hydrogel, a medical glue layer and a base cloth. The sodium alginate hydrogel is a hydrogel mixed by 100 percent pure sodium alginate crystals and water. The alginate hydrogel is a hydrogel, which assumes a transparent gel shape formed by immersing a 100 percent pure calcium alginate non-woven fabric to a sodium alginate solution, automatically converts between a solid state and a liquid state based on changes of using state. The novelty of the invention lies in combining a material which promotes curing of the wound and a material which is secured to body surface. The medical dressing of the invention has the advantages of outside water resistance, extra-long adhering time, and simple operation and usage. The medical dressing of the invention faces towards the wound in humid environment, which promotes healing. The medical dressing can also reduce burning pain caused by the large area wound, prevent infection and wound adhesion, block bacteria from entering, and reduce times for changing medicine.

Owner:WUXI HENGCHENG MEDICAL TECH CO LTD

Fluorescence in-situ hybridization method for endosymbiotic bacteria in insect ovary

InactiveCN108179202AAvoid freezingAvoid the tedious process of slicingMicrobiological testing/measurementStainingFluorescence

The invention relates to a fluorescence in-situ hybridization method for endosymbiotic bacteria in an insect ovary. The method comprises following steps: the insect ovary is dissected under a microscope, the dissected insect ovary is transferred to a glass slide, an insect tissue stationary liquid is added for fixation, and a destaining solution is added for destaining; pre-hybridization and hybridization staining are performed on a specimen, and an eluant is added for elution after hybridization is completed; finally, a sample is sealed with glycerin, and observation and photographing are performed under a confocal microscope. By means of the method, a good cell staining effect can be kept, the operation can be simplified, time can be shortened, reagents can be saved and the cost can be reduced. Several endosymbiotic bacteria in the ovary can be subjected to multiple staining simultaneously, a good staining effect is obtained, and the method is simple, convenient, rapid and economical.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

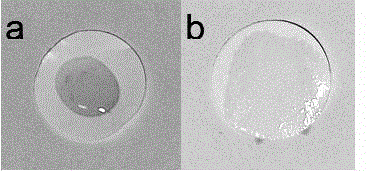

Intraocular lens coating with excellent biological antifouling performance and preparation method thereof

ActiveCN111729130AGood biocompatibilityImprove hydrophilicityPharmaceutical delivery mechanismTissue regenerationHydrophilic polymersMedicine

The invention discloses a preparation method of an intraocular lens coating with excellent biological antifouling performance. The preparation method includes the following steps that low-temperatureplasma surface treatment is performed on the surface of an intraocular lens material, then an adhesive is coated on the surface of the intraocular lens material, and drying is carried out to obtain atransition layer; and a functional layer coating solution with a concentration of 0.1-30wt% is prepared with a hydrophilic polymer and then coated on the transition layer, and drying is carried out toobtain the intraocular lens coating with excellent biological antifouling performance. The invention further includes the intraocular lens coating with excellent biological antifouling performance prepared by the preparation method. The surface characteristics of an intraocular lens are adjusted through the method of combining the transition layer and the functional layer, the hydrophilicity andbiofouling resistance of the material surface are improved, the biocompatibility of the intraocular lens is improved, the occurrence of adhesion of cells, proteins and bacteria on the surface of the lens and inflammatory reactions is effectively prevented or reduced, and therefore the probability of secondary cataract is reduced.

Owner:SICHUAN UNIV

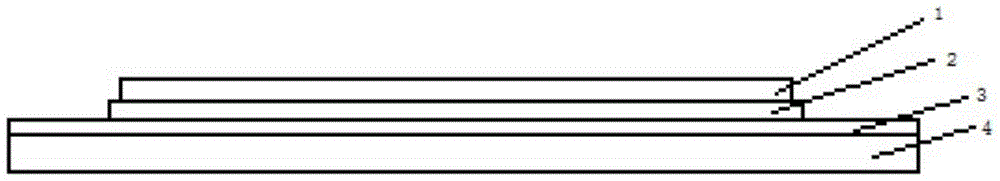

Production process of dielectric isolation type pressure sensor based on flip welding chip

ActiveCN109534282ASimple production processLess investmentDecorative surface effectsFluid pressure measurement by electric/magnetic elementsMems pressure sensorFlexible circuits

The invention discloses a production process of a dielectric isolation type pressure sensor based on a flip welding chip. The pressure sensor comprises a shell and a ceramic substrate arranged on theinner side of the shell. The production process of the dielectric isolation type pressure sensor comprises the following specific steps: printing a thick film circuit on the bottom of the ceramic substrate; brushing glass glaze on the thick film circuit, so that the glass glaze covers the thick film circuit to protect the thick film circuit on the ceramic substrate from being eroded when being applied to various media; flip welding an MEMS pressure sensitive chip on the bottom of the ceramic substrate; and welding a welding point of the thick film circuit on the bottom of the ceramic substratetogether with a flexible circuit board at the top of the ceramic substrate to realize an electrical connection of the MEMS pressure sensitive chip and the flexible circuit board. The purpose of the invention is to provide a pressure sensor with a simple process, to realize the application of the sensor in a harsh environment and a medium, and to realize the stable and reliable work of the MEMS pressure sensor in the harsh environment and the medium with high cost performance.

Owner:江西新力传感科技有限公司

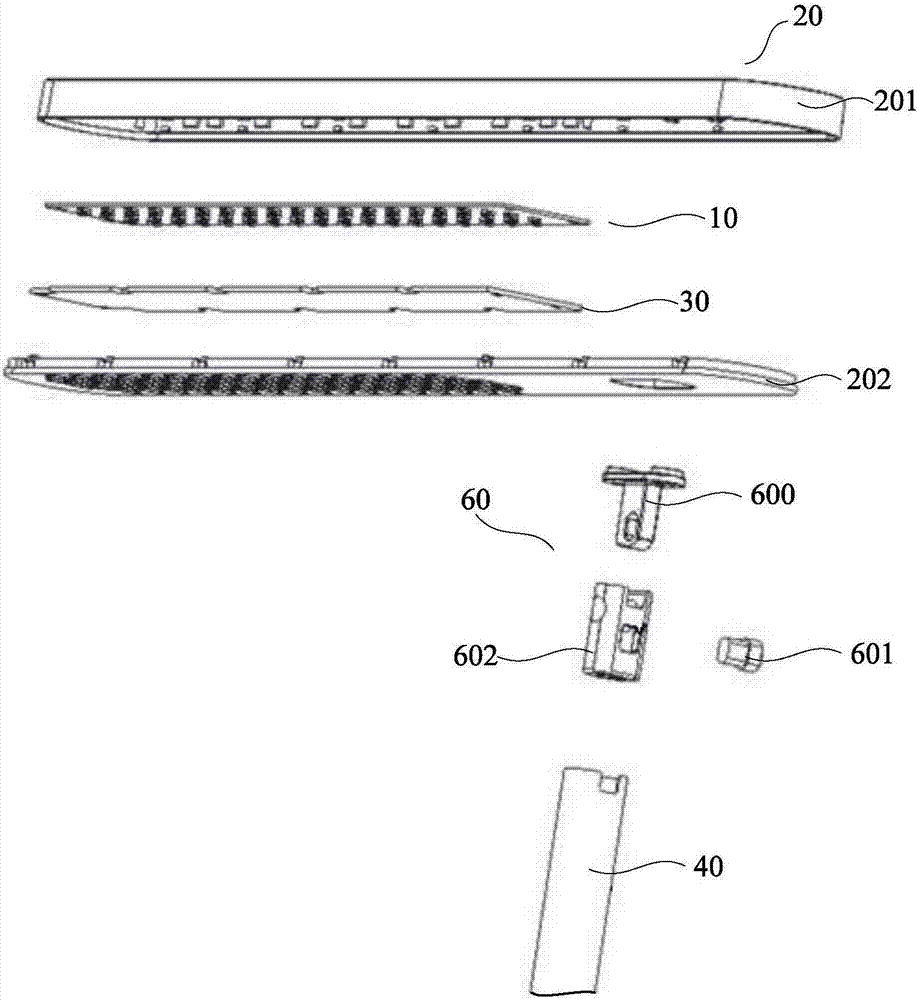

Table lamp

PendingCN107166219AGood anti-glareAvoid plating easy to fall offElectrical apparatusElectric light circuit arrangementPhysicsChemical plating

The invention discloses a table lamp which comprises a light emitting potion and a light emitting portion installation foundation. The light emitting portion installation foundation comprises a shell and a honeycomb light-transmitting plate arranged on the opening side of the shell. The honeycomb light-transmitting plate and the shell are connected to form a light source containing cavity which contains the light emitting portion. The light emitting portion comprises a light emitting body. The honeycomb light-transmitting plate is provided with a honeycomb through hole opposite to the light emitting body. In the table lamp, the honeycomb through hole in the honeycomb light-transmitting plate can achieve the effect of shielding part of light, and thus achieves the good ant-dazzle purpose, and meanwhile the problem that a plating layer is likely to fall off when a chemical plating layer is adopted for preventing dazzle can be avoided.

Owner:OPPLE LIGHTING

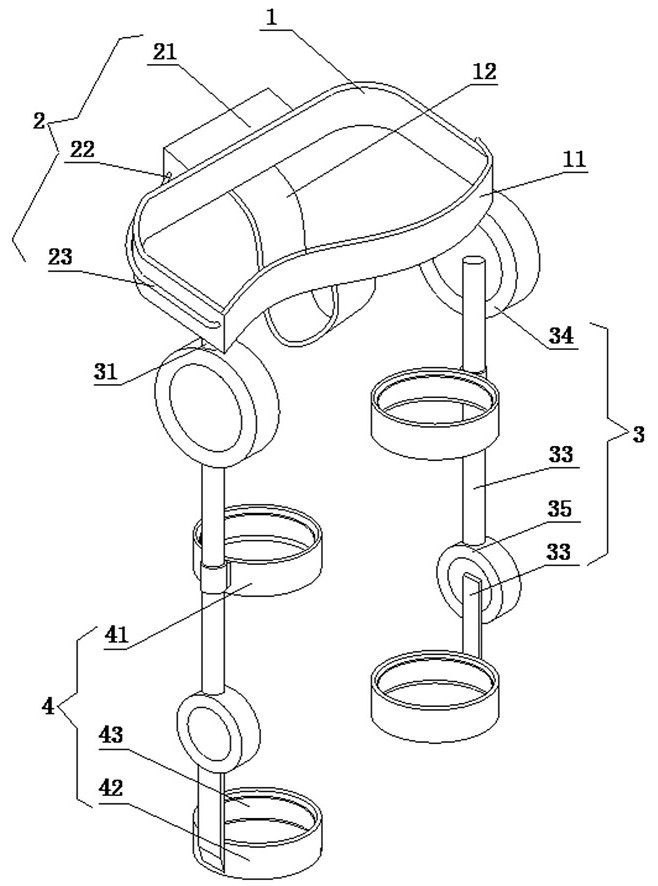

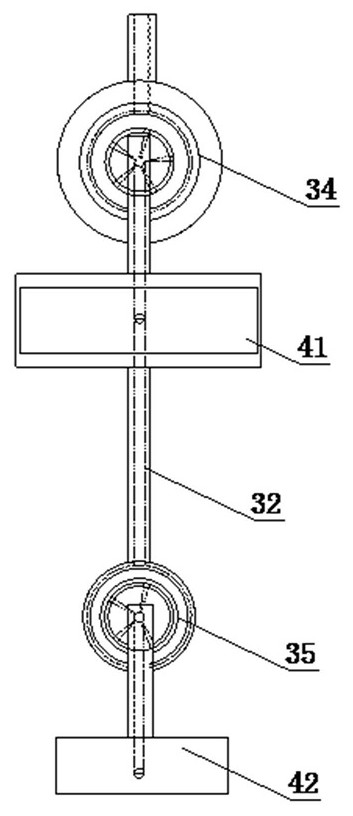

Hip joint assisting walking mechanism

The invention discloses a hip joint assisting walking mechanism. The hip joint assisting walking mechanism comprises a hip joint frame, inflation mechanisms, supporting arm mechanisms and lower limb limiting mechanisms, wherein the outer wall of the hip joint frame is connected with the inflation mechanism; the two ends of the hip joint frame are connected with the supporting arm mechanisms respectively; the lower limb limiting mechanisms are fixed to the two opposite supporting arm mechanisms; and the inflation mechanisms penetrate through the supporting arm mechanisms to be connected with the lower limb limiting mechanisms. According to the hip joint assisting walking mechanism, airflow of an air pump flows into an annular groove position through an upper arm, a part of air is inflated into an air bag of a thigh ring, the airflow of the air pump flows into the annular groove position through the upper arm, the other part of the air is inflated into an air bag of a shank ring through an annular groove of a middle arm, and expansion or contraction of the air bags is controlled, so the air bags can clamp the leg during expansion; and pressure sensors are matched for use, so the problems of insufficient blood supply caused by long-time clamping of the leg due to excessive pressure of the air bags or easiness in falling off due to relatively slight clamping force between the air bags and the leg are solved.

Owner:李红才

Clamping and positioning device for wire electrode of wire-cut electrical discharge machine capable of realizing rapid wire feeding

ActiveCN106312211AEffective clampingAvoid vulnerable handsElectrical-based machining electrodesEngineeringMachine tool

The invention discloses a clamping and positioning device for a wire electrode of a wire-cut electrical discharge machine capable of realizing rapid wire feeding. The device comprises a device body; the device body sequentially comprises a wire penetrating part and a clamping part from top to bottom; a wire penetrating hole is formed in the top of the wire penetrating part; a groove is formed in the bottom of the clamping part and communicates with the wire penetrating hole; bolts are symmetrically arranged on side walls on two opposite sides of the clamping part; and ends of the bolts penetrate through the side walls of the clamping part to extend into the groove. With the structure of the device, the wire electrode can be effectively clamped, and meanwhile, problems that hands are hurt easily and the wire electrode falls off easily when the wire electrode is directly held by hand are solved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

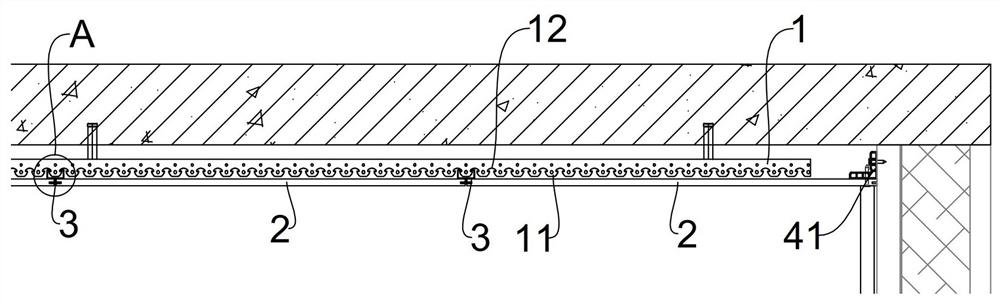

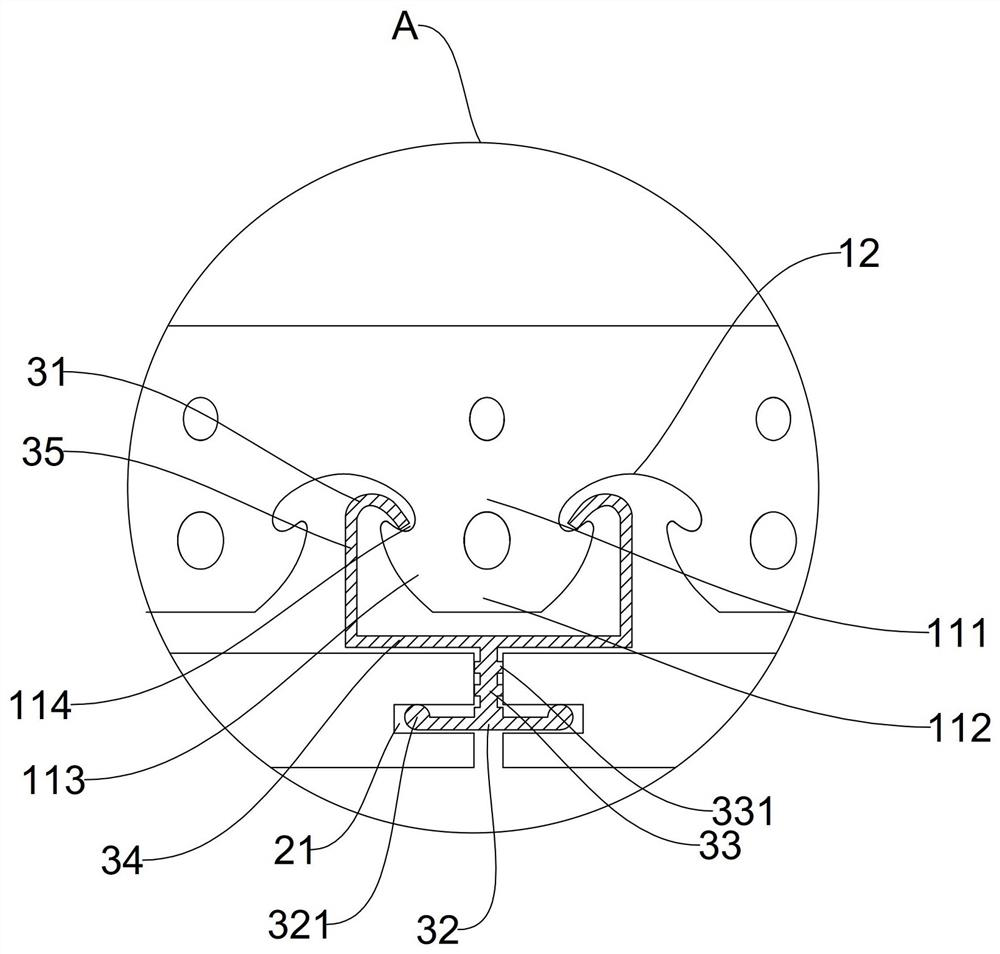

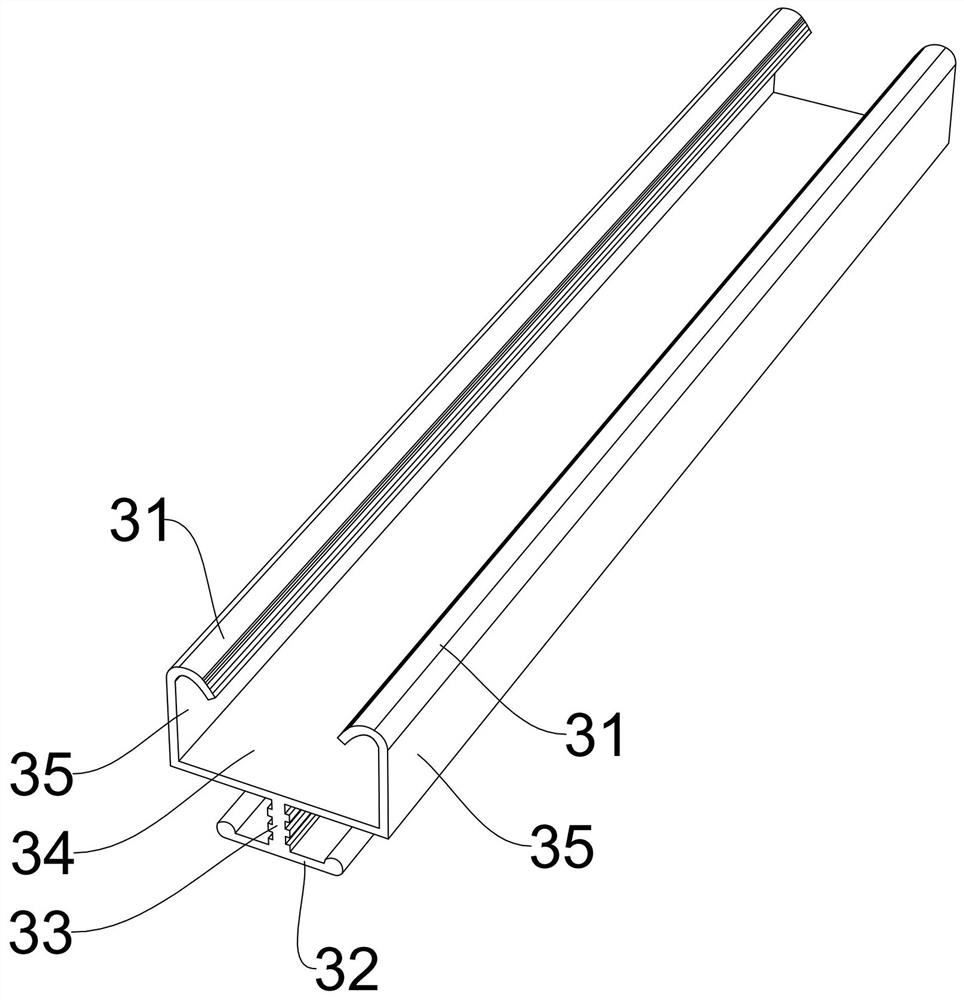

Integrated clamping keel suspended ceiling structure and installing method thereof

PendingCN112554430AAvoid the problem of easy sheddingOccupies less floor heightCeilingsAcute angleKeel

The invention relates to the technical field of suspended ceilings, in particular to an integrated clamping keel suspended ceiling structure and an installing method thereof. The integrated clamping keel suspended ceiling structure comprises a keel and a panel, wherein the keel is installed on a top wall, the panel is installed on the keel through a clamping bone, one side of the keel is arrangedon the top wall through a hanging piece, a plurality of anchor pieces are evenly arranged on the other side of the keel in the length direction of the keel, and each anchor piece comprises a main bodyperpendicularly connected to the keel, an anchor crown arranged at the free end of the main body and two anchor arms arranged on the anchor crown, the every two anchor arms are symmetrical with the respect of a main body, one ends of the anchor arms are connected to the anchor crowns, acute angle grooves are formed between the other ends of the anchor arms and the main body, the clamping bone isperpendicular to the keel and comprises a connecting plate connected to the panel and two hook plates with one ends arranged on the connecting plate and the other ends capable of being inserted into the acute angle grooves. According to the integrated clamping keel suspended ceiling structure and the installing method thereof, a keel body and the multiple anchor pieces are integrally formed, and then the panel is connected through the anchor pieces, so that the problem that in a traditional suspended ceiling structure, connecting pieces are prone to falling off is solved, and meanwhile, the installing steps are reduced, and the floor height occupied by the suspended ceiling is reduced.

Owner:ZHEJIANG YASHA DECORATION

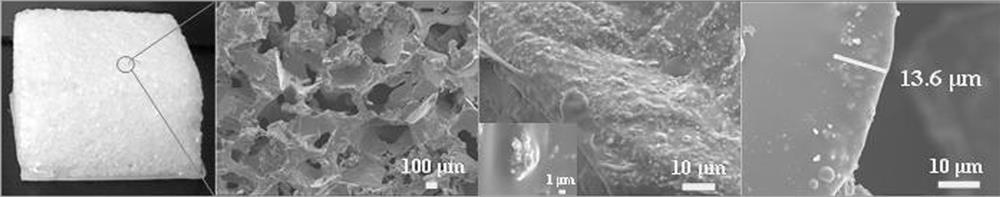

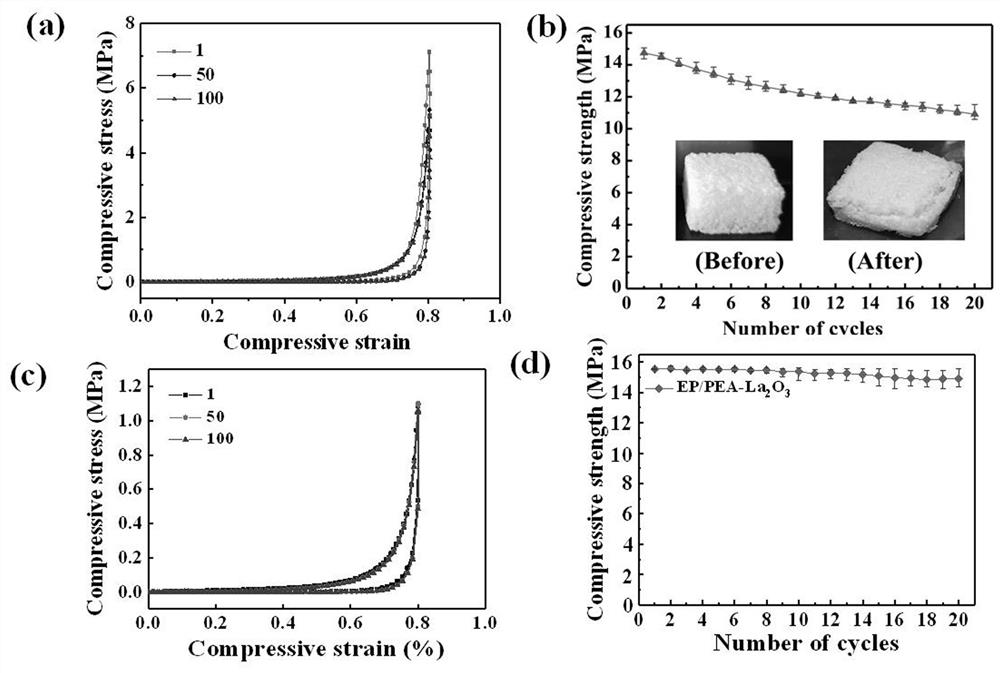

Oil-water separation sponge with high elasticity and mechanical durability and preparation method thereof

InactiveCN112480606AImprove brittlenessHigh hardnessNon-miscible liquid separationEpoxyPolymer science

The invention belongs to the technical field of functional material preparation, and provides a sponge with high elasticity and mechanical durability and a preparation method thereof so as to solve the problem that the elasticity and mechanical durability of an existing polymer sponge material cannot be compatible. The method comprises the steps: ultrasonically dispersing the oxide nano-material into a volatile solvent, uniformly coating the oxide nano-particles onto a 3D skeleton template material, and completely volatilizing the solvent at room temperature; pouring an epoxy resin precursor solution onto the 3D skeleton template material, and vacuumizing to remove bubbles; and performing curing, demolding and drying to obtain the oil-water separation epoxy resin sponge with high elasticity and mechanical durability. The method is simple and easy to implement and remarkable in effect, the sponge can be circularly compressed for 100 times under 80% strain, the sponge can still keep thestructural integrity after being circularly compressed for 15 times under the maximum pressure of 15.8 MPa, the problem that improvement of elasticity and mechanical durability cannot be compatible issolved, and the prepared sponge can be used for continuously and efficiently separating an oil-water mixture.

Owner:SHANXI UNIV

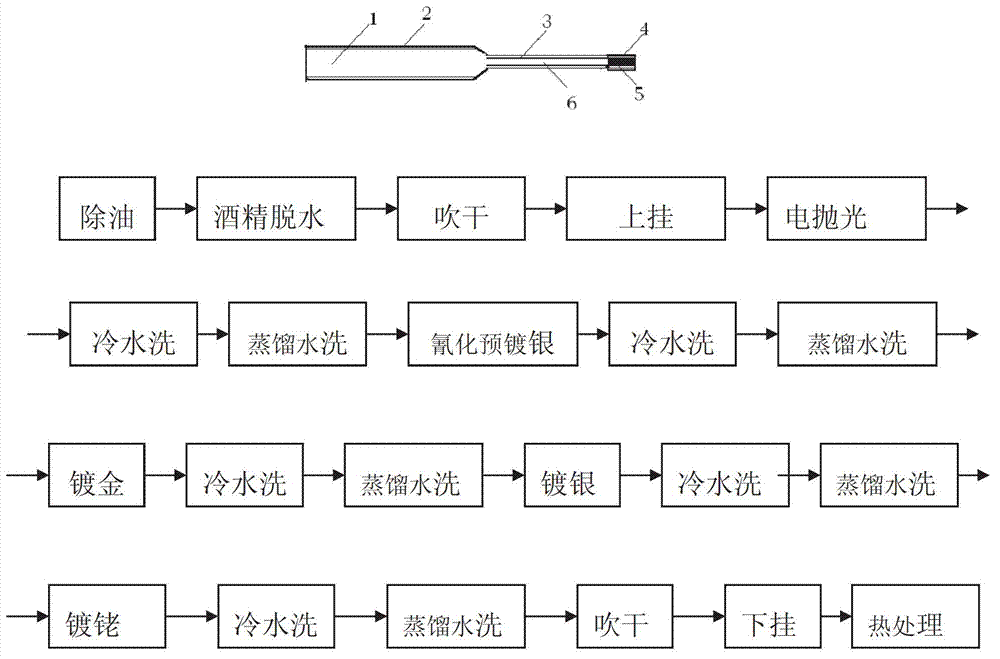

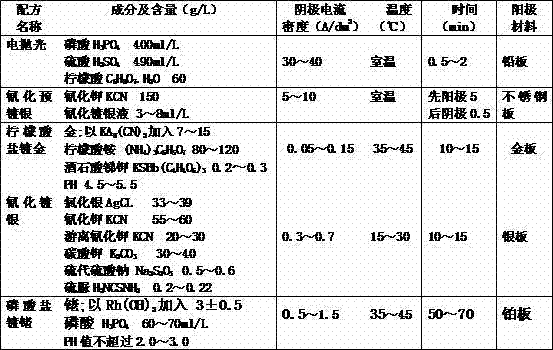

Gold-silver-rhodium multilayer composite plating process

The invention provides a gold-silver-rhodium multilayer composite plating process. According to the process, a rhodanizing coating does not crack, bubbling, peeling and falling off of each plating can be avoided, platings are well combined and do not discolor, the service life is high, and movement of a silver plating can be effectively constrained at a high temperature. According to the technical scheme, a cyaniding pre-silver-plating process is added before gold plating, a 3ml / L-8ml / L of cyaniding silver plating solution is added in a cyaniding tank, a reversing power supply is adopted after cyaniding, and a thin silver layer is plated reversely in the solution, after the cyaniding pre-silver-plating process, citrate is adopted for gold plating; after the gold plating, silver is plated through cyaniding, rhodium is plated through phosphate, after the rhodium plating, vacuum annealing heat treatment is performed at the temperature of 900-950 DEG C to evenly coat the three precious metal of the gold, the silver and the rhodium on the surface of a part. According to the process, under the condition that a rhodium plating of a contact type switching element such as a reed switch can not be welded, one end of a workpiece can be welded with a wire or sealed with glass, and bubbles, cracks and air tightness problems are not easy to cause.

Owner:四川泛华航空仪表电器有限公司

Socket for semiconductor apparatus

InactiveCN101039007AAvoid the problem of easy sheddingIncrease contact areaCoupling device connectionsElectric discharge tubesEngineeringSemiconductor

The invention provides a socket for electrical connecting a chip with a circuit board. The chip contains at least a conductive port, and the circuit board contains at least a contact point corresponding to the conductive port. The socket contains a substrate and at least a conductive pillar. The substrate contains a hole penetrating the substrate. The conductive pillar is configured to pass through the hole. When the socket is disposed between the chip and the circuit board, a first end of the pillar contacts with the conductive port, and a second end of the same contacts to the contact point.

Owner:BENQ CORP

Composite coating of printed circuit board drill point and preparation method thereof

PendingCN112267097AQuality improvementHigh hardnessVacuum evaporation coatingSputtering coatingInsulation layerGraphite

The invention provides a composite coating of a printed circuit board drill point and a preparation method thereof. The composite coating sequentially comprises a bottom layer, a carbonitriding layer,a diamond-like carbon coating and a heat insulation layer from the surface of the drill point to the outside; the bottom layer comprises any one of a metal layer, an alloy layer or a metal compound layer; and the heat insulation layer is a metal nitride ceramic layer. According to the composite coating, through the design of a multi-coating structure, the hardness and abrasion resistance of the drill point can be effectively improved through the arrangement of the diamond-like carbon coating, so that the service life of the drill point is prolonged; the adhesion strength of the diamond-like carbon coating can be effectively improved through the arrangement of the carbonitriding layer, and the problem that the diamond-like carbon coating is prone to falling off is avoided; the heat insulation layer can delay graphitization of the diamond-like carbon coating, so that the service life of the drill point is further prolonged; and through deposition of a composite coating, the drill pointis particularly suitable for drilling of a high-frequency and high-speed printed circuit board, and obtained drilled holes are high in quality and precision.

Owner:GUANGDONG DTECH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com