Radiation refrigeration metal plate as well as preparation method and application thereof

A radiation refrigeration and metal plate technology, applied in the direction of application, refrigerator, refrigeration and liquefaction, etc., can solve the problems affecting the radiation cooling effect and service life of the radiation cooling metal plate, the fracture and damage of the radiation cooling functional layer, and achieve the reduction of air conditioning. Cooling power consumption, simple and reliable preparation method, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

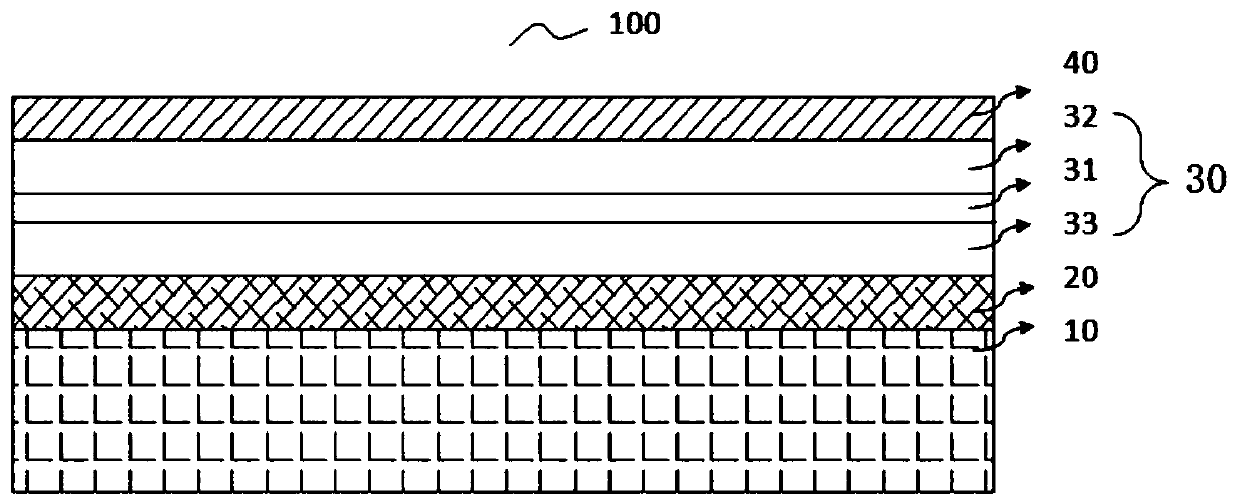

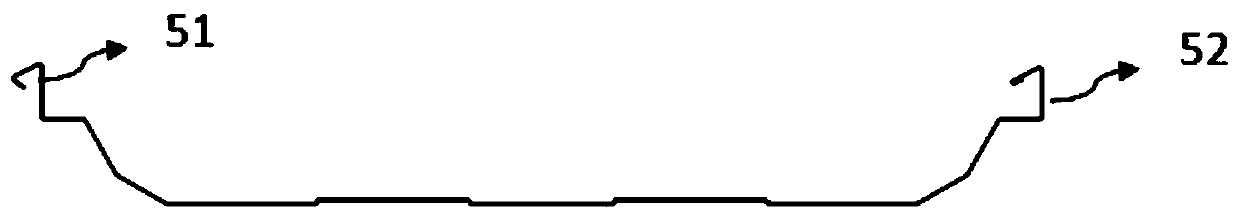

[0099] One of the preferred embodiments of the present invention provides a method for preparing a radiation cooling metal plate 100, the preparation method comprising the following steps:

[0100] (1) providing the metal substrate 10;

[0101] (2) The first adhesive layer 20 and the radiant cooling functional layer 30 are sequentially formed on the surface of the metal substrate 10 .

[0102] Further, the above steps also include:

[0103] (3) Before the step of sequentially forming the laminated first adhesive layer 20 and the radiative cooling function layer 30 on the surface of the metal substrate 10 , cleaning the metal substrate 10 is performed.

[0104] In this preferred embodiment, the step of cleaning the metal includes:

[0105] (3.1) providing a cleaning agent, and wetting the surface of the metal substrate 10 with the cleaning agent;

[0106] (3.2) brushing the surface of the metal substrate 10;

[0107] (3.3) Spray cleaning the surface of the metal substrate 1...

Embodiment 1

[0135] Radiatively cooled metal panels include:

[0136] Aluminum alloy metal substrate with a thickness of 100 μm;

[0137] Polyurethane solvent-based adhesive with a thickness of 3 μm;

[0138] The second protective layer of polyethylene terephthalate has a thickness of 30 μm.

[0139] Among them, the radiation cooling function layer includes:

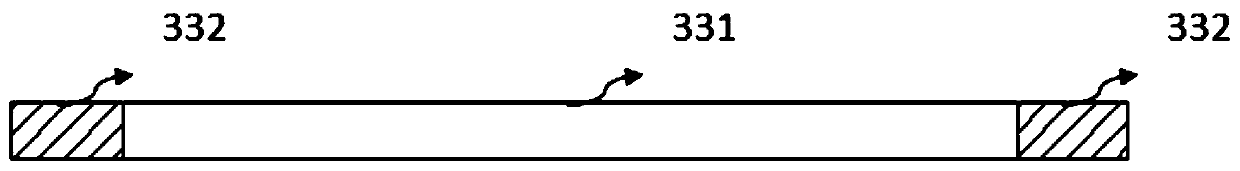

[0140] The reflective layer, including the middle area of pure silver and the alloy layer arranged at both ends of the middle area of pure silver, has a thickness of 0.05 μm;

[0141] For the emission layer, the first polymer includes poly-4-methyl-1-pentene, and the mass ratio of poly-4-methyl-1-pentene to the emission layer is 92%, the filler is silicon dioxide, and the particle size is 3 μm , the mass ratio of the filler to the emissive layer is 6%, the rest are additives, and the thickness is 50 μm;

[0142] The first protective layer is made of high weather-resistant polyester and polymethyl methacrylate, wherein the mas...

Embodiment 2

[0146] Radiatively cooled metal panels include:

[0147] Aluminum-magnesium-manganese metal substrate with a thickness of 400 μm;

[0148] Polyacrylate solvent-based adhesive with a thickness of 4 μm;

[0149] The second protective layer of polyethylene has a thickness of 50 μm.

[0150] Among them, the radiation cooling function layer includes:

[0151] The reflective layer, including the stainless steel middle area and the metal oxide layers arranged at both ends of the stainless steel middle area, has a thickness of 0.1 μm;

[0152] In the emission layer, the first polymer includes polyethylene terephthalate, and the mass ratio of polyethylene terephthalate to the emission layer is 88%, the filler is silicon nitride, and the particle size is 5 μm. The mass ratio of the emissive layer is 7%, the rest are additives, and the thickness is 100 μm;

[0153] The first protective layer is made of polyvinylidene fluoride and polymethyl methacrylate, wherein the mass ratio of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com