Oil-water separation sponge with high elasticity and mechanical durability and preparation method thereof

An oil-water separation and durability technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of mechanical durability and elasticity that are difficult to coordinate and unify, and achieve the effect of low price, efficient separation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

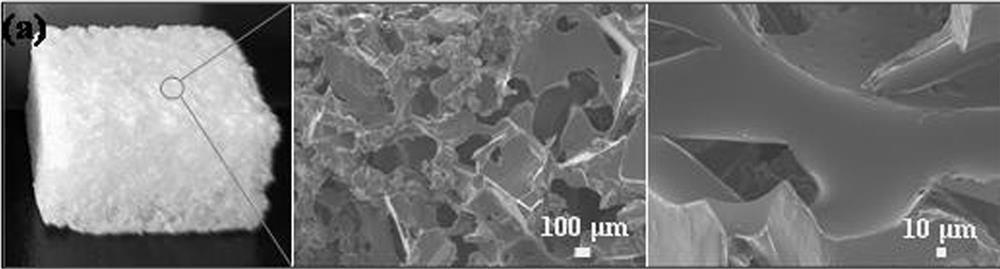

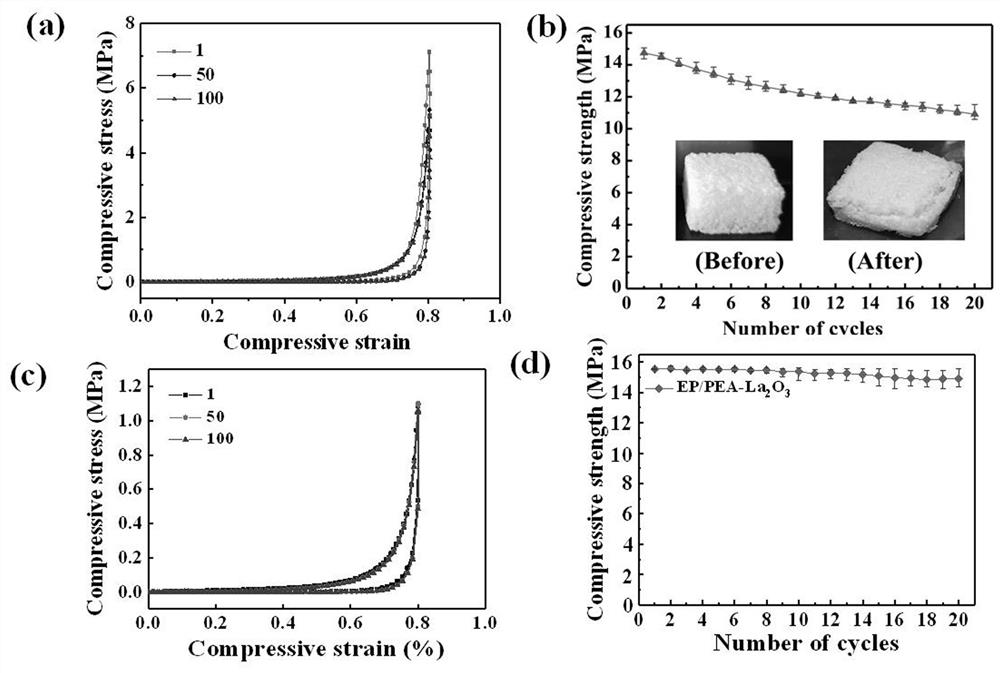

[0022] Embodiment 1: A kind of preparation method with high elasticity and mechanical durability oil-water separation sponge specifically comprises the steps:

[0023] 1) will La 2 o 3 Nanoparticles were dispersed into isopropanol solution to prepare a suspension with a mass fraction of 0.5 wt% (La 2 o 3 The mass fraction of nanoparticles relative to the epoxy resin is 0.16 wt%). After the ultrasonic dispersion is uniform, it is drip-coated on the six surfaces of the sugar cube, and placed at room temperature. After the solvent is completely evaporated, it is ready for use;

[0024] 2) Pouring the above precursor solution on the sugar cube, after the organic solvent is completely volatilized, pour the epoxy resin and polyetheramine precursor solution (epoxy resin: polyetheramine D400: polyetheramine D200=1:0.3:0.7) ;

[0025] 3) Vacuum with a 2 Pa vacuum pump to accelerate the precursor liquid to La 2 o 3 Wetting of nanoparticle-coated 3D porous framework templates to en...

Embodiment 2

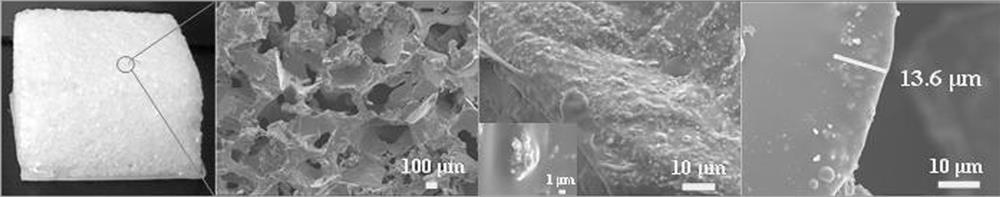

[0036] Embodiment 2: a kind of preparation method with high elasticity and mechanical durability oil-water separation sponge specifically comprises the steps:

[0037] 1) TiO 2 Nanoparticles were dispersed in isopropanol solution to prepare a suspension with a mass fraction of 0.5 wt% (TiO 2 The mass fraction of nanoparticles relative to the epoxy resin is 0.32 wt%), after the ultrasonic dispersion is uniform, it is drip-coated on the surface of the sugar particles, placed at room temperature, and used after the solvent is completely evaporated;

[0038] 2) Pouring the above precursor solution onto the sugar particles, and pouring the epoxy resin and polyetheramine precursor solution (epoxy resin: polyetheramine D400: polyetheramine D200=1:0.3:0.7) after the organic solvent has evaporated completely ;

[0039] 3) Vacuum with a 2 Pa vacuum pump to accelerate the precursor liquid to TiO 2 Wetting of nanoparticle-coated 3D porous framework templates to enhance TiO 2 The embed...

Embodiment 3

[0041] Embodiment 3: a kind of preparation method with high elasticity and mechanical durability oil-water separation sponge specifically comprises the following steps:

[0042] 1) SiO 2 Nanoparticles were dispersed in isopropanol solution to prepare a suspension with a mass fraction of 0.5 wt% (SiO 2 The mass fraction of nanoparticles relative to the epoxy resin is 0.50 wt%), after ultrasonic dispersion is uniform, drop-coated on the surface of salt particles, placed at room temperature, and ready for use after the solvent is completely volatilized;

[0043] 2) Pouring the above precursor solution on the salt particles, after the organic solvent is completely volatilized, pour the epoxy resin and polyetheramine precursor solution (epoxy resin: polyetheramine D400: polyetheramine D200=1:0.3:0.7) ;

[0044] 3) Vacuum with a 2 Pa vacuum pump to accelerate the precursor solution to SiO 2 Wetting of nanoparticle-coated 3D porous framework templates to enhance TiO 2 The embeddi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com