Toughening and modifying method for melamine formaldehyde resin

A technology of formaldehyde resin and melamine, which is applied in the field of toughening and modification of melamine formaldehyde resin, can solve the problems of high brittleness, complicated preparation process, easy to drop blocks, etc. of melamine formaldehyde resin, and achieves low production cost, simple production process, and improved brittleness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

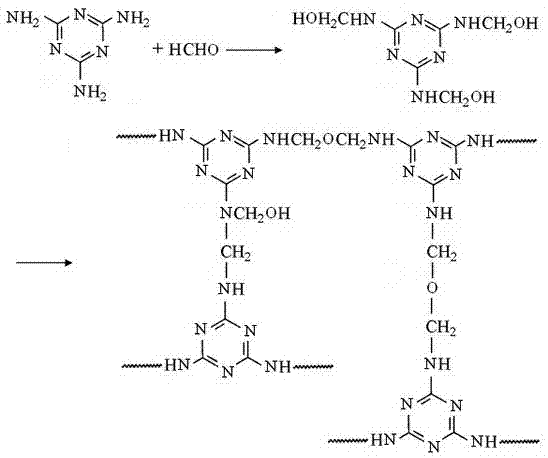

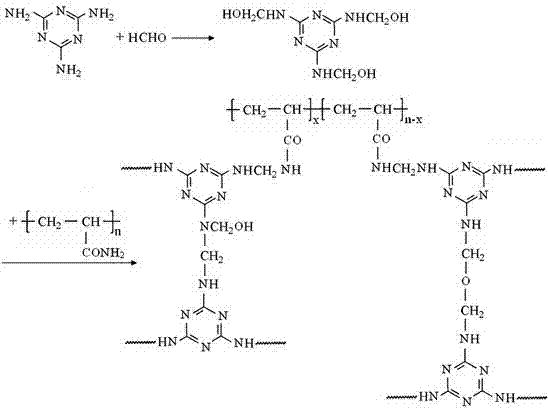

Method used

Image

Examples

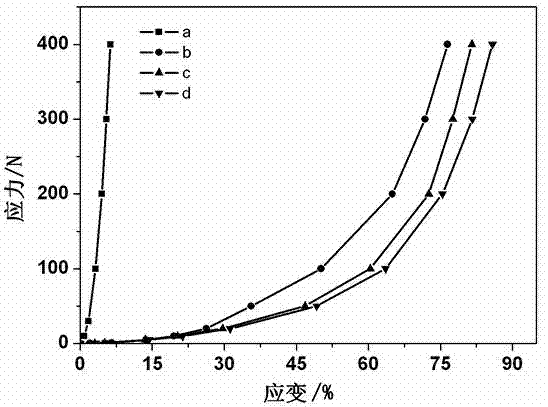

Embodiment 1

[0019] Add hydrochloric acid to 60 parts of methylolmelamine to adjust the pH value to 4, and react in a water bath at 35°C for 8 minutes to obtain a polymer solution with a certain viscosity. Add NaOH to the polymer solution to adjust the pH value to 9. React at 75°C for 8 hours, take it out and cool it down to obtain melamine formaldehyde resin.

Embodiment 2

[0021] Add hydrochloric acid to 48 parts of methylolmelamine to adjust the pH value to 4, then add 12 parts of toughening agent polyacrylamide, and react in a water bath at 35°C for 8 minutes to obtain a polymer solution with a certain viscosity. Add NaOH to the polymer solution to adjust the pH value to 9, react at 75°C for 8 hours, take it out and cool it, and obtain the toughened melamine formaldehyde resin.

Embodiment 3

[0023] Add hydrochloric acid to 42 parts of methylolmelamine to adjust the pH value to 4, then add 18 parts of toughening agent polyacrylamide, and react in a water bath at 35°C for 8 minutes to obtain a polymer solution with a certain viscosity. Add NaOH to the polymer solution to adjust the pH value to 9, react at 75°C for 8 hours, take it out and cool it, and obtain the toughened melamine formaldehyde resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com