Patents

Literature

241 results about "Arc resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arc resistance is a measure of the time required to make an insulating surface conductive under a high voltage / low current arc in carefully controlled laboratory conditions. Or in other terms, it is the ability of the plastic material to resist the action of a high voltage electrical arc.

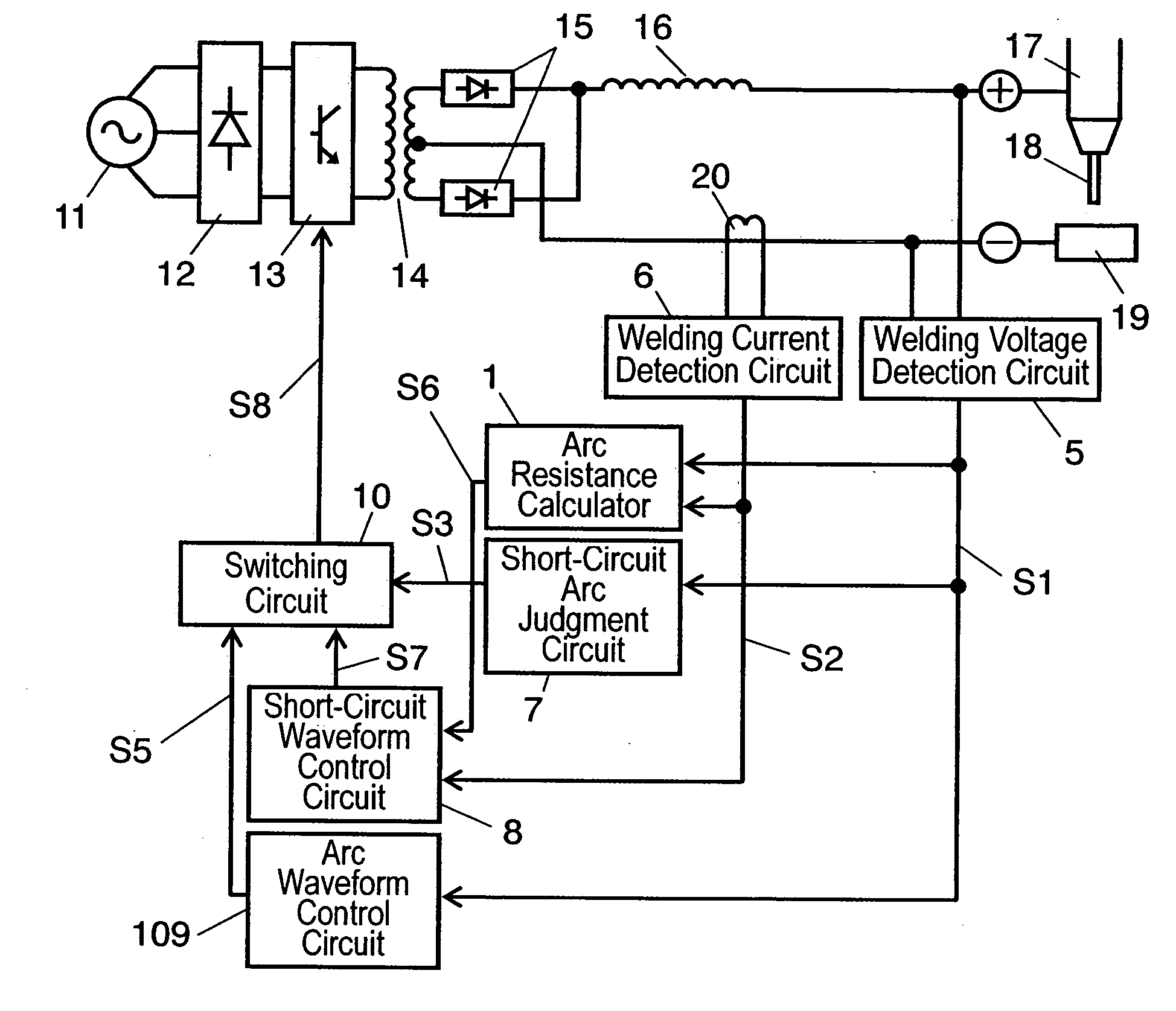

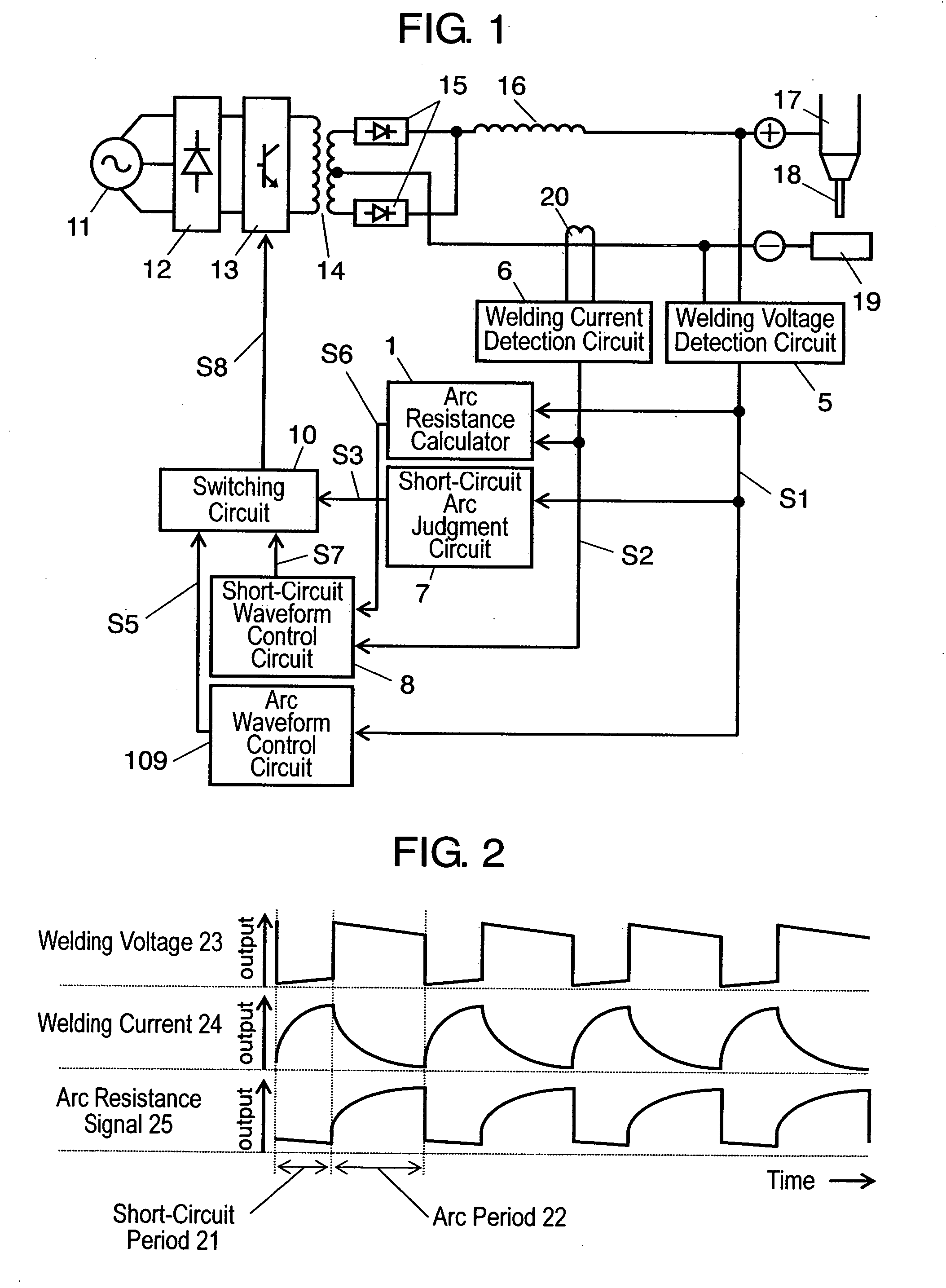

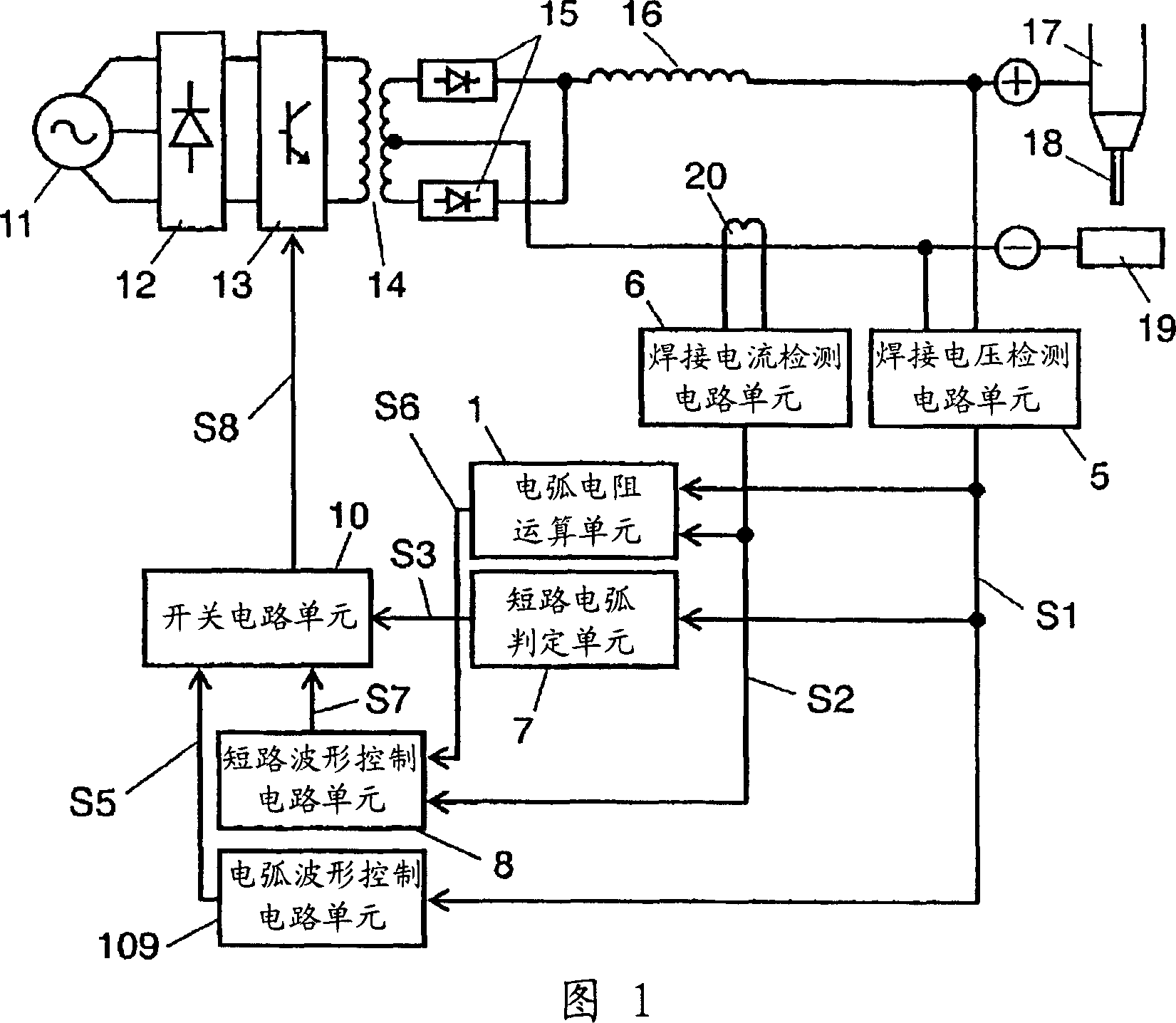

Consumable Electrode Type Arc Welding Machine

InactiveUS20080264916A1Dc-dc conversionElectrode supporting devicesElectrical resistance and conductanceArc stability

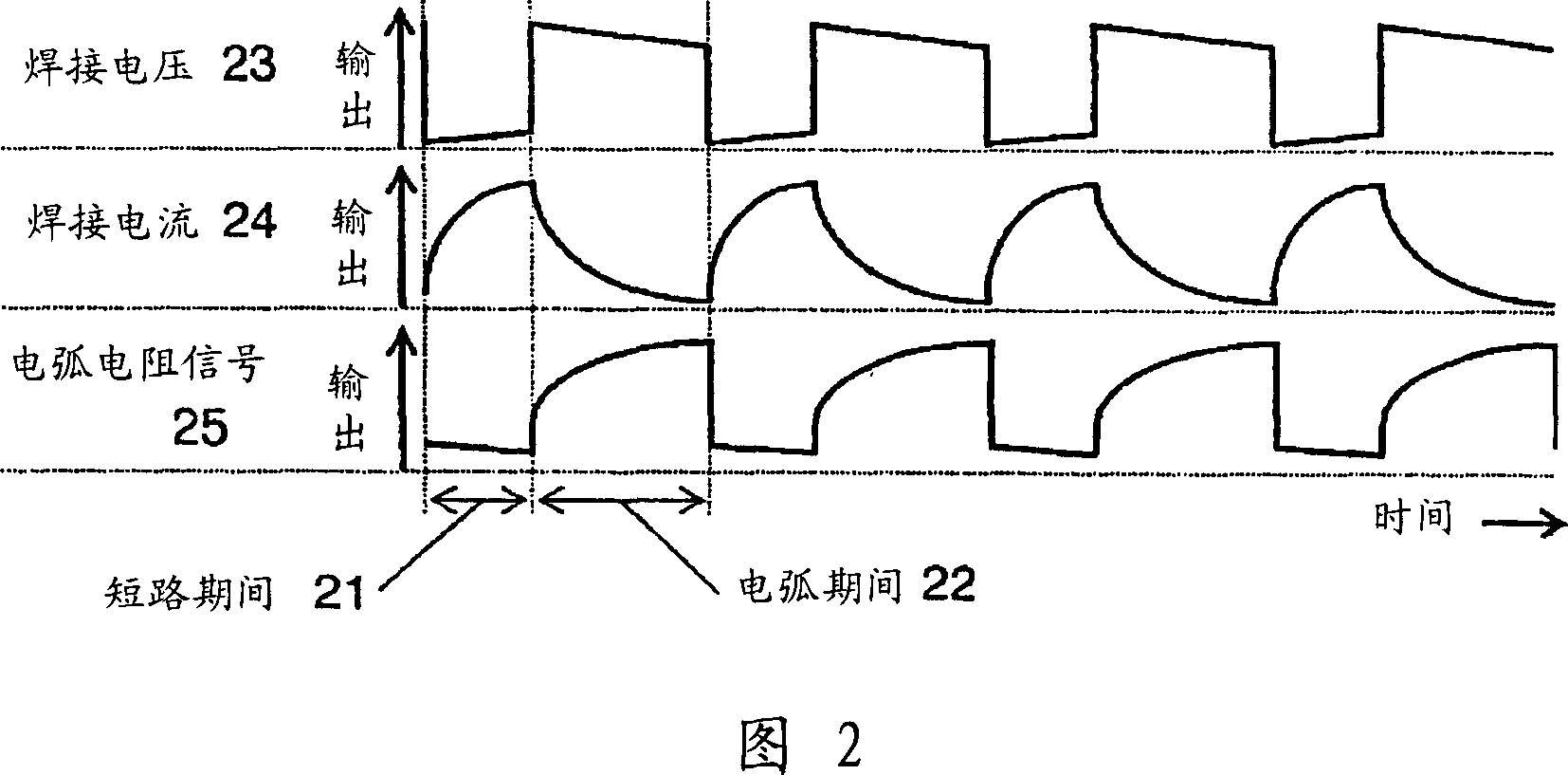

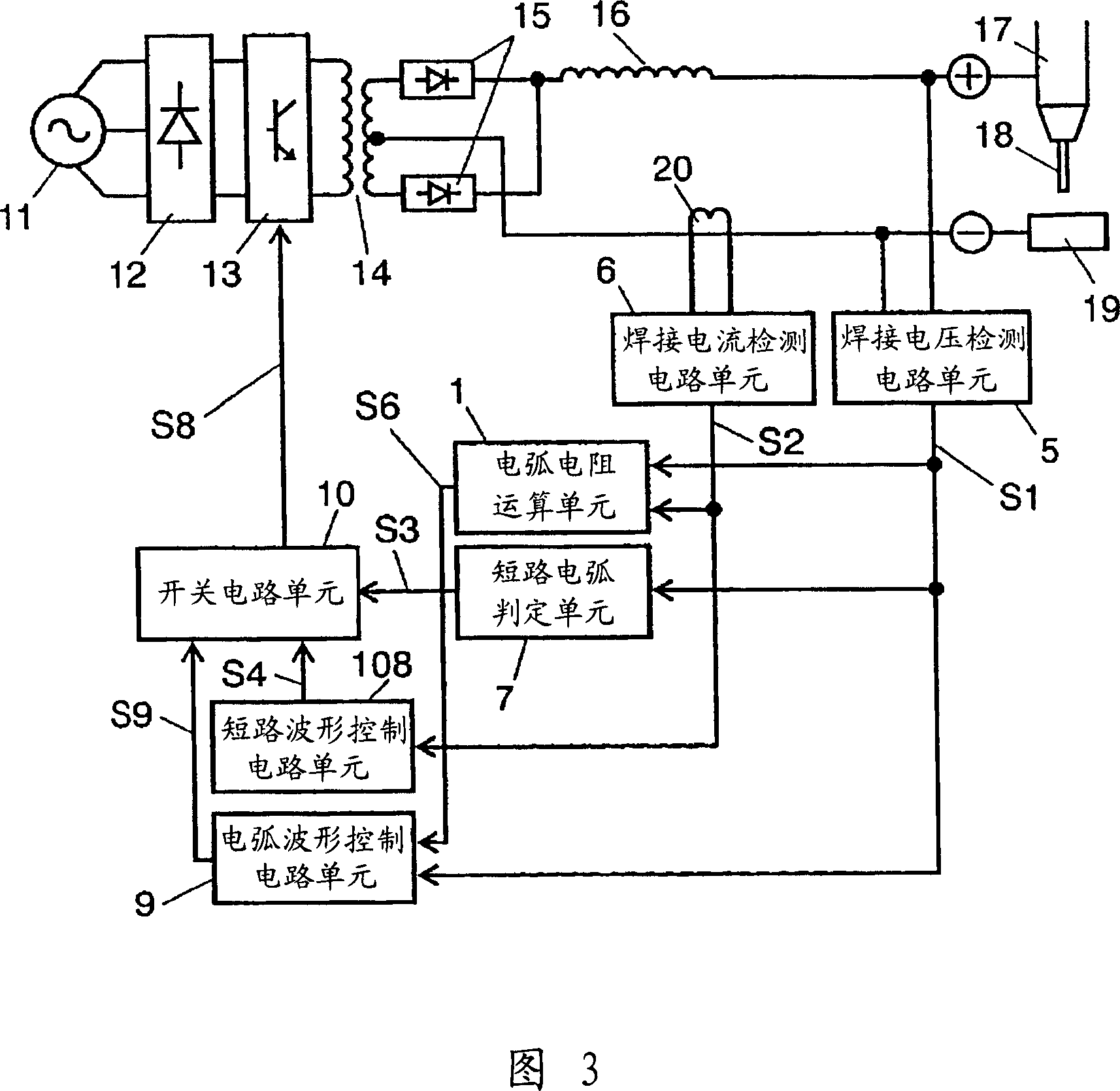

A consumable electrode arc-welding machine comprising an arc resistance calculating part that calculates an arc resistance from a welding current and a welding voltage to develop an arc resistance signal, wherein the welding current and welding voltage are controlled by a short-circuit waveform control signal and an arc waveform control signal that vary in accordance with the arc resistance signal. In this way, the spatter control and the arc stability can be achieved. During an arc period, if the arc resistance signal exhibits a level greater than a predetermined level for a predetermined period, a constant current control signal is developed to perform a constant current control of the welding current by use of a predetermined current value that is higher than the current value developed during the development of the arc waveform control signal, thereby preventing the arc from going off.

Owner:PANASONIC CORP

Manufacturing method for environment-friendly type insulator shell

InactiveCN101840757AImprove mechanical propertiesImprove insulation performanceInsulatorsEpoxyDark color

The invention relates to a manufacturing method for an environment-friendly type insulator shell, comprising the following steps: firstly mixing the following components uniformly in parts by weight: 100 parts of modified BPA epoxy resin, 280-310 parts of silica powder, 100 parts of curing agent, 40-45 parts of dark color paste and 40-60 parts of fire retardant, and degassing for 1.5-2 hours under the vacuum degree of 0-minus1 MPa; then injecting the degassed mixture into a mold to conduct the primary curing, and curing for 30-40 minutes under the condition of 140 plus or minus 5 DEG C; demolding, conducting the secondary curing, and curing for 8 hours plus or minus 10 minutes under the condition of 128-135 DEG C; and finally, conducting finish machining on the blank after being cured secondarily. The Epoxy resin insulating component manufactured by the method has the advantages of high mechanical strength, strong arc resistance, high compactness, bright and clean surface, better cold-resistant and heat-resistant properties, good electrical insulating property and the like, is widely applied in the power sector, and mainly plays a role in supporting and insulating.

Owner:YANGZHOU DONGYU ELECTRIC

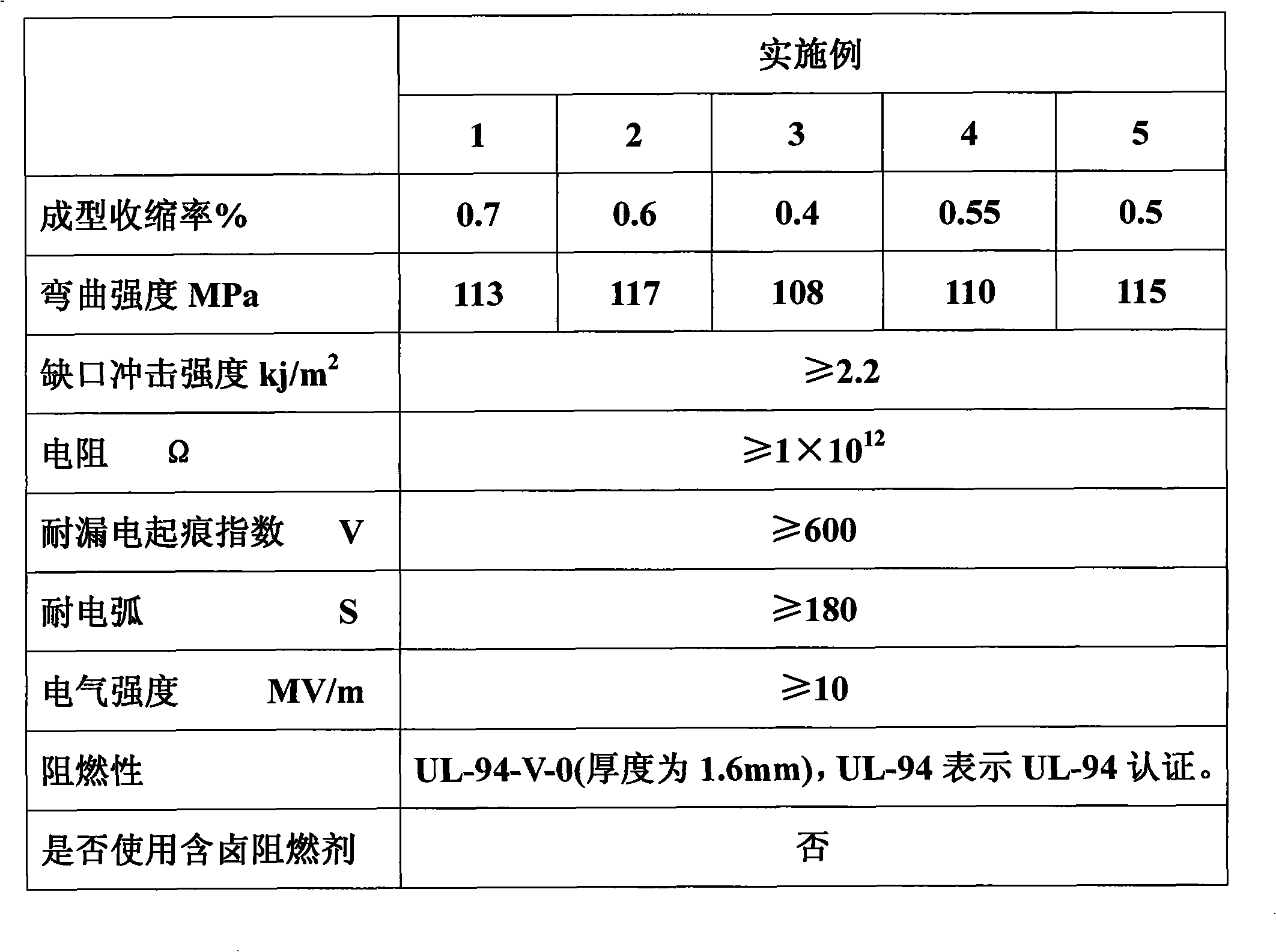

Halogen-free flame-proof glass fiber reinforcement epoxy molding compound

The invention relates to non-halogen flame-resistant glass fiber reinforced epoxy molding compound. According to the weight parts, the material of the non-halogen flame-resistant glass fiber reinforced epoxy molding compound comprises 20 parts to 25 parts of epoxy resin, 7 parts to 9 parts of phenolic resin, 1.4 parts to 3.4 parts of curing agent, 60 parts to 75 parts of mineral filler, 4 parts to 7.5 parts of phosphate, 0.8 parts to 2 parts of metal oxide, 1.8 parts to 2.5 parts of mould releasing agent and 15 parts to 20 parts of reinforced fiber. The non-halogen flame-resistant glass fiber reinforced epoxy molding compound has advantages that because halogen is not contained in the formulation, when being burnt, noxious gas and harmful gas can not be generated, and the physical safety and the environmental protection can be ensured; the shrinkage ratio is 0.4 percent to 0.7 percent, the bending strength is 105 to 120 MPa, the notched impact strength is greater than 2.2 KJ per m<2>, the resistance is 1X10<12> Omega, the proof tracking index is greater than 600 V, the arc resistance is greater than 180 s, the electrical strength is greater than 10 MV per m, the flame-resistant performance reaches grade UL-94-V-0 (1.6 mm), and the non-halogen flame-resistant glass fiber reinforced epoxy molding compound can be suitable for the sealing material for manufacturing automobile commutators and electronic products.

Owner:常熟东南塑料有限公司

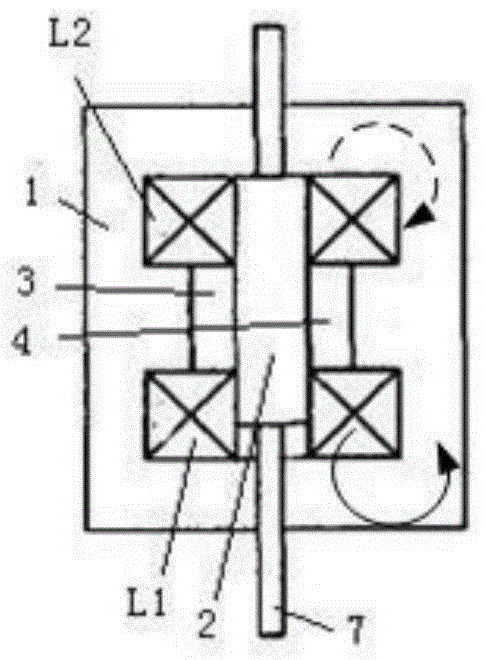

Method for measuring two-dimension displacement and two-dimension displacement sensor

ActiveCN101063621ASimple structureHigh measurement accuracyUsing electrical meansConverting sensor output electrically/magneticallyEngineeringRotation around a fixed axis

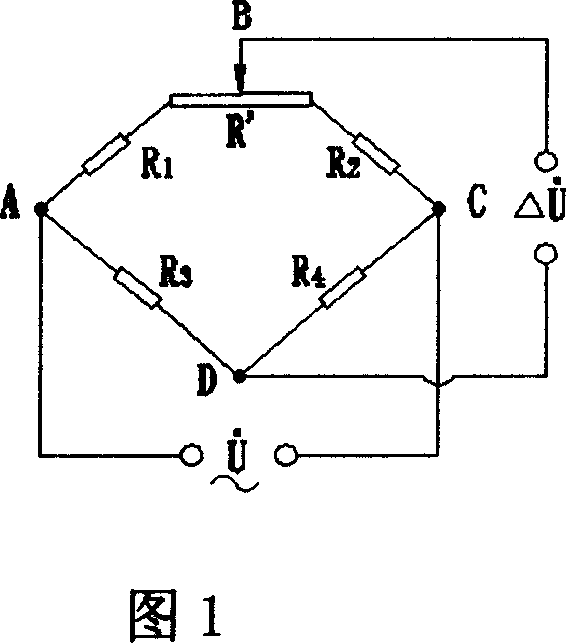

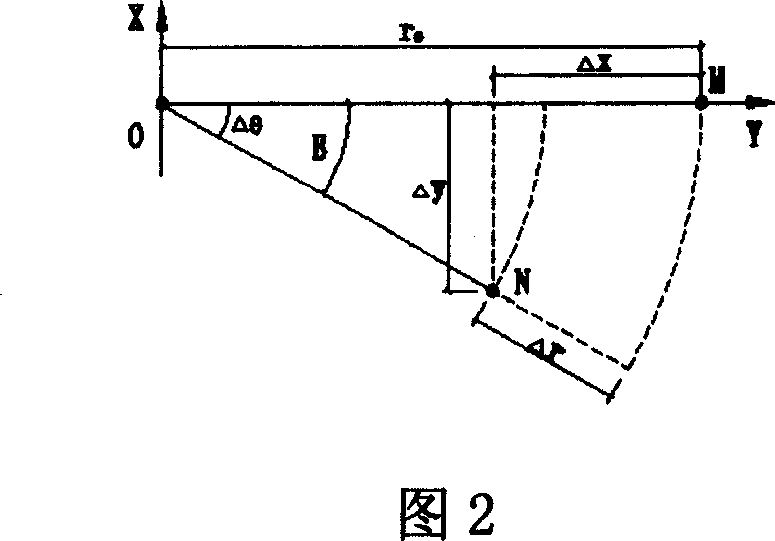

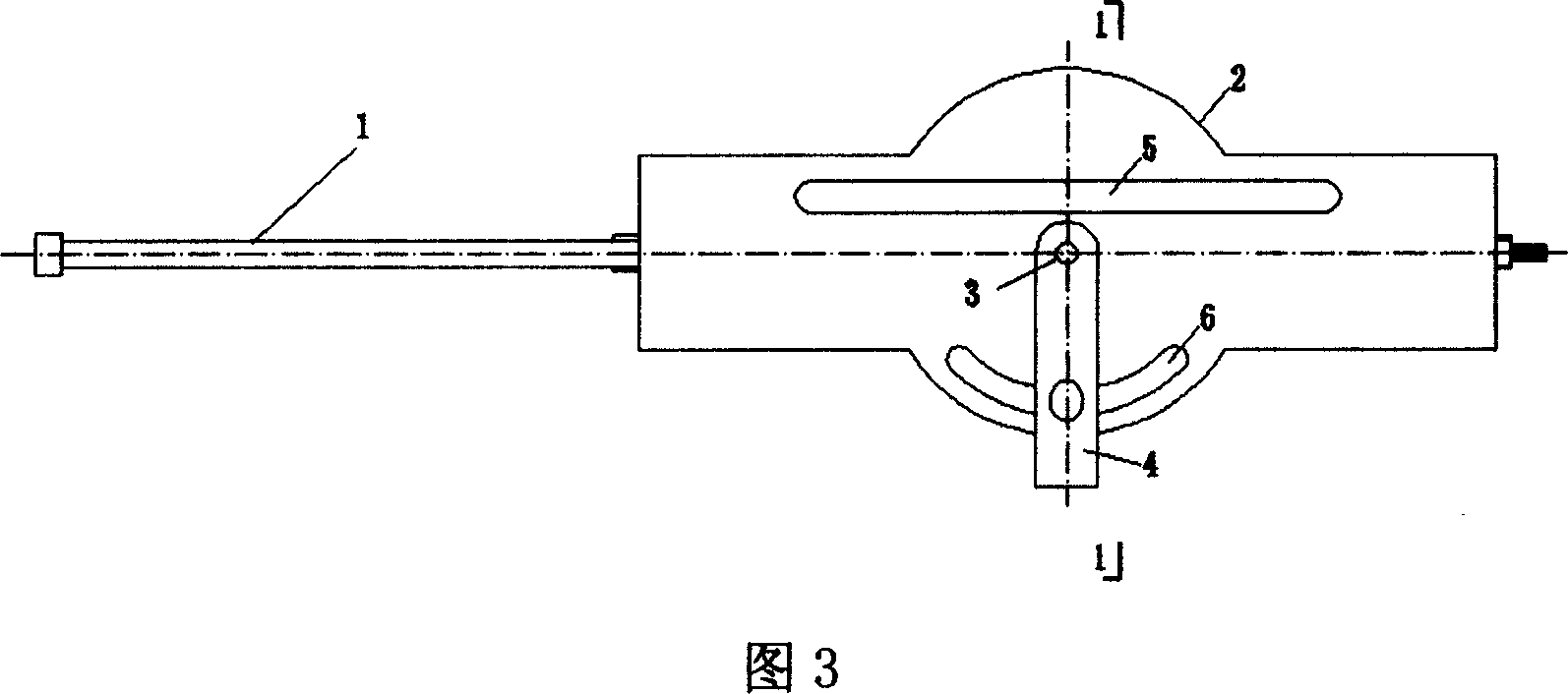

This invention relates to one 2D displacement measurement method, which comprises the following steps: according to Wheatstone bridge circuit test principle to distribute the bridge resistance wire into direct or arc shape and the direct resistance wire is to test line displacement; the arc resistance wire is to test arc length change volume and then according to the relationship between arc length and radium to get test point rotary angle; through testing points in electrode coordinate displacement change to realize 2D displacement. The 2D displacement sensor comprises the test bridge line resistance wire and arc resistance wire fixed onto one structure around axis and it also comprises data transmission line.

Owner:上海筑邦测控科技有限公司

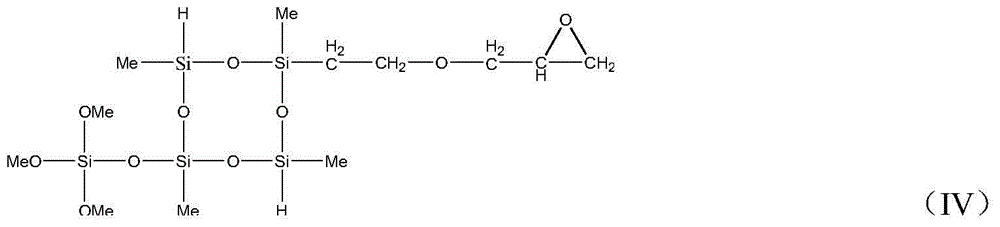

Solvent-free anti-pollution flashover organic silicon coating and preparation method thereof

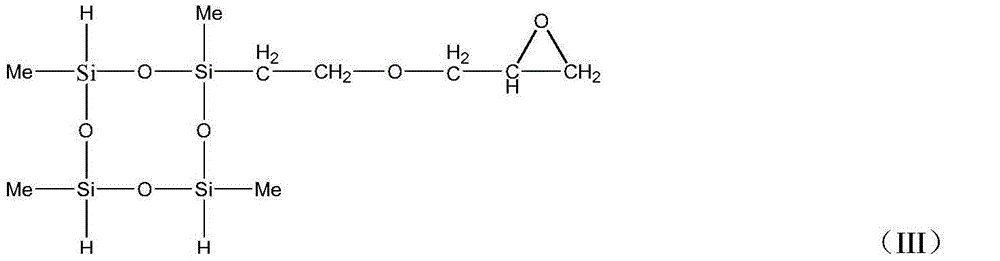

The invention discloses a solvent-free anti-pollution flashover organic silicon coating which comprises the following components in parts by weight: 100 parts of polysiloxane containing at least two silicon vinyl groups, 1-20 parts of polysiloxane containing at least two silicon oxygen groups, 5-25 parts of white carbon black, 10-40 parts of a flame-retardant filler, 10-35 parts of a vinyl-containing silicon resin, 2-8 parts of a water repellent, 0.1-10 parts of platinum catalyst and 1-5 parts of a tackifier, wherein the specific surface area of silica in the white carbon black is 150-250m<2> / g, and the average particle size does not exceed 20 microns. The invention also discloses a method for preparing the solvent-free anti-pollution flashover organic silicon coating. The method comprises the following steps: (a), preparing a basic sizing material and (b) mixing the glue; or (a) preparing a basic sizing material; (b), preparing a component A; (c) preparing a component B; and (d) mixing the glue. After being subjected to room temperature or medium temperature curing, the solvent-free anti-pollution flashover organic silicon coating is dried, fine, smooth and bright in surface and excellent in hydrophobic property and has excellent self-cleaning performance, and the surface rainwater and floating dust can be automatically flushed away. In addition, the solvent-free anti-pollution flashover organic silicon coating has excellent aging performance, mechanical properties, high / low-temperature resistance, arc resistance, electric insulation performance and the like.

Owner:眉山拓利科技有限公司

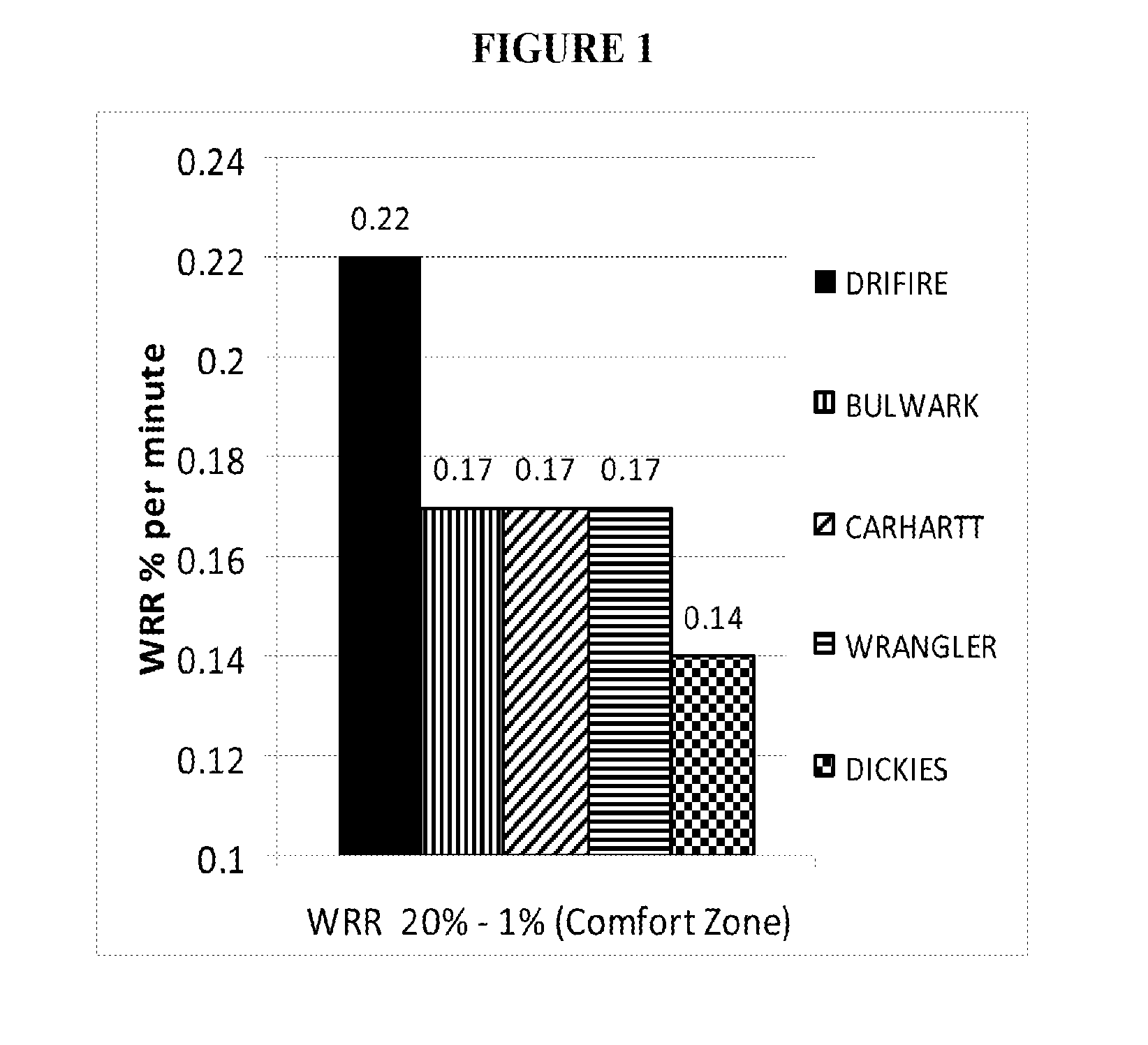

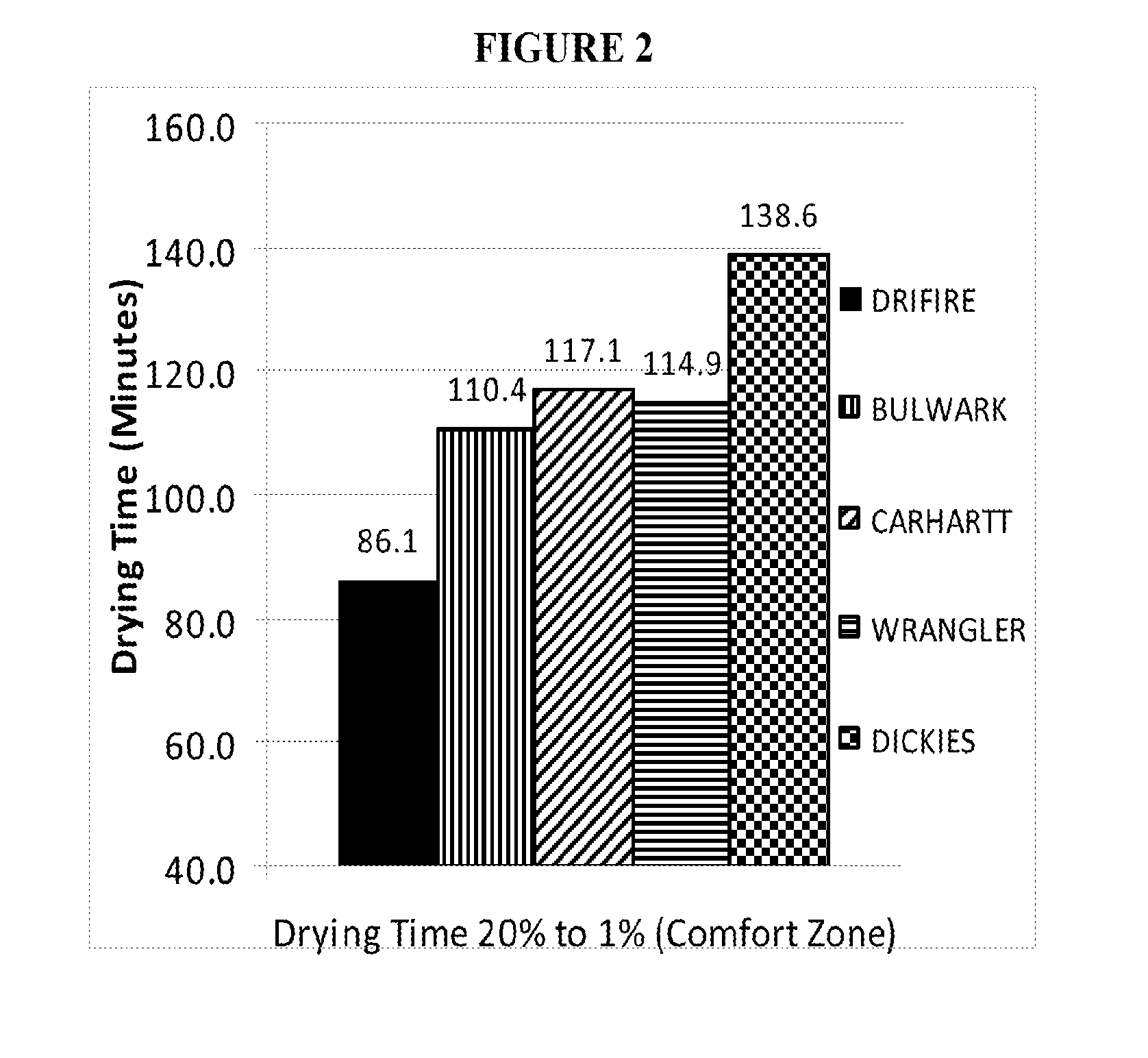

Fire resistant woven fabrics and garments

ActiveUS20130216810A1Superior moisture management propertyComfortable to wearTrousersJacketsFiberTopical treatment

Owner:DRIFIRE

Lightweight, arc-rated, dyeable fabrics

InactiveUS20160060809A1Improve thermal performanceImprove visibilityFibre treatmentAbsorbent padsVisibilityEngineering

Lightweight, dyeable fabrics with a balance of high thermal properties, especially arc resistance, on the one hand, and durability and comfort properties, on the other hand, are disclosed. Articles, such as garments and linen, made from the lightweight dyeable fabrics are also disclosed. The fabrics are particularly useful in garments for utility workers, industrial workers, military personnel, and firefighters, especially for use in environments requiring high visibility.

Owner:NAT SAFETY APPL INC

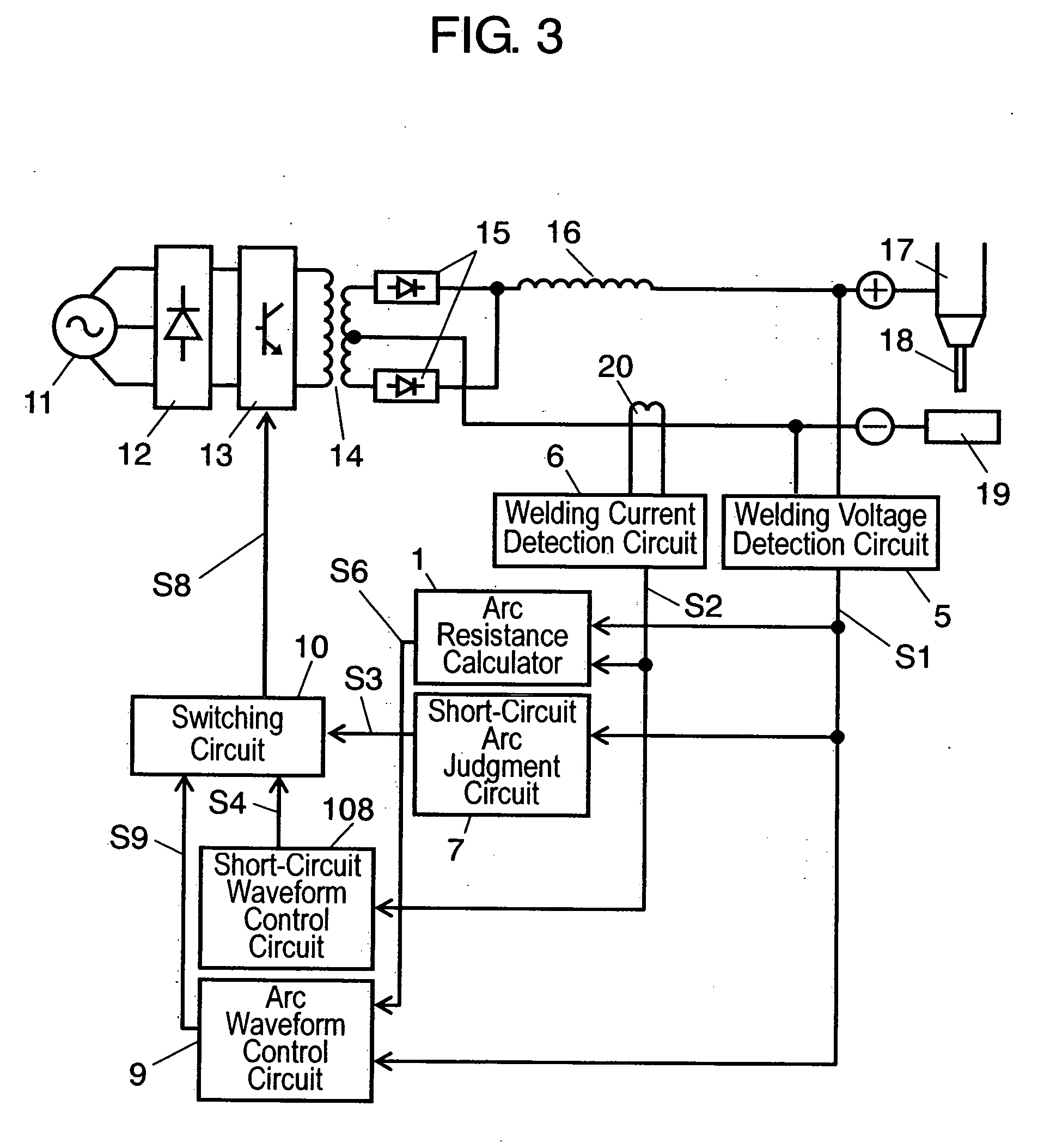

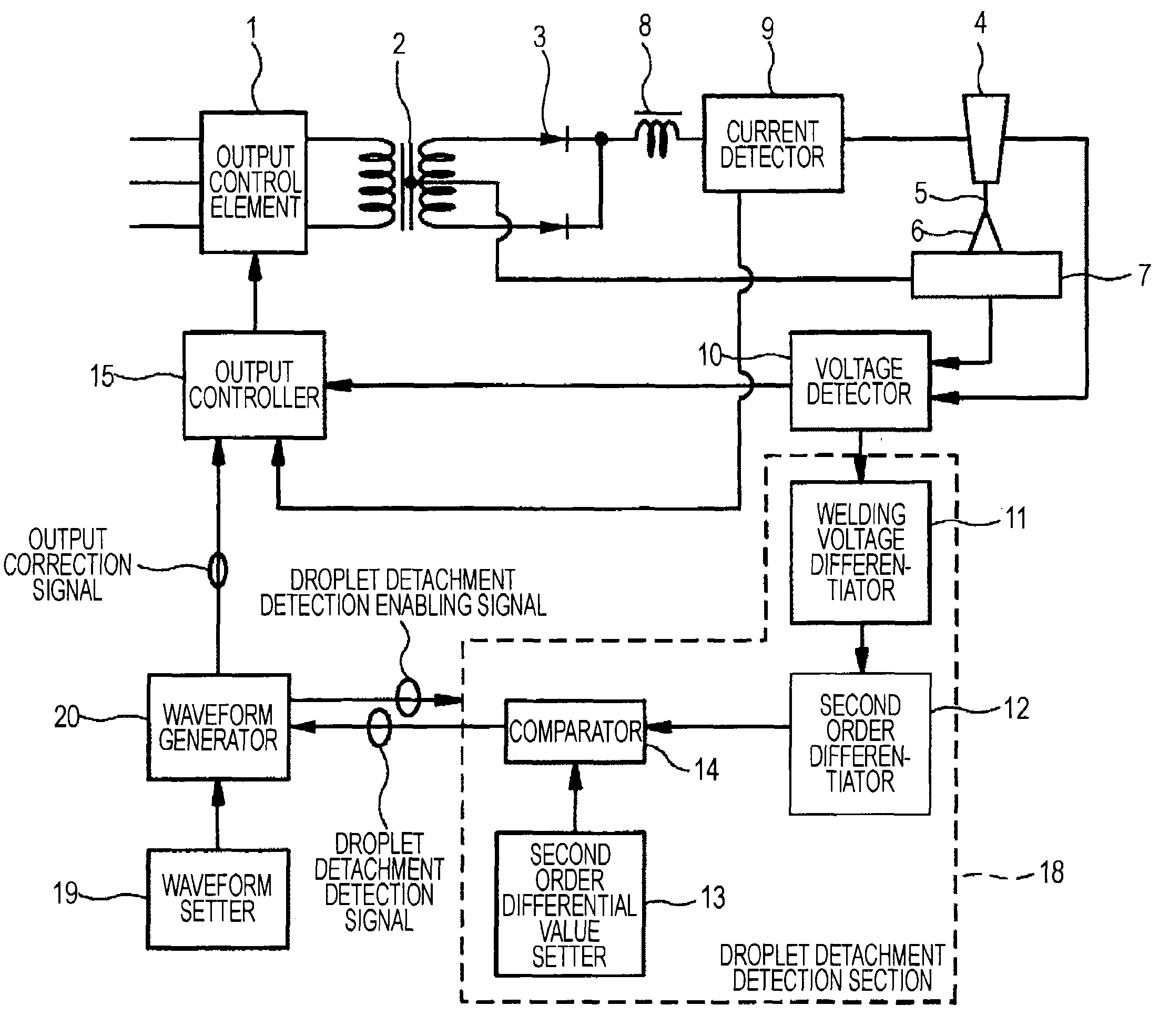

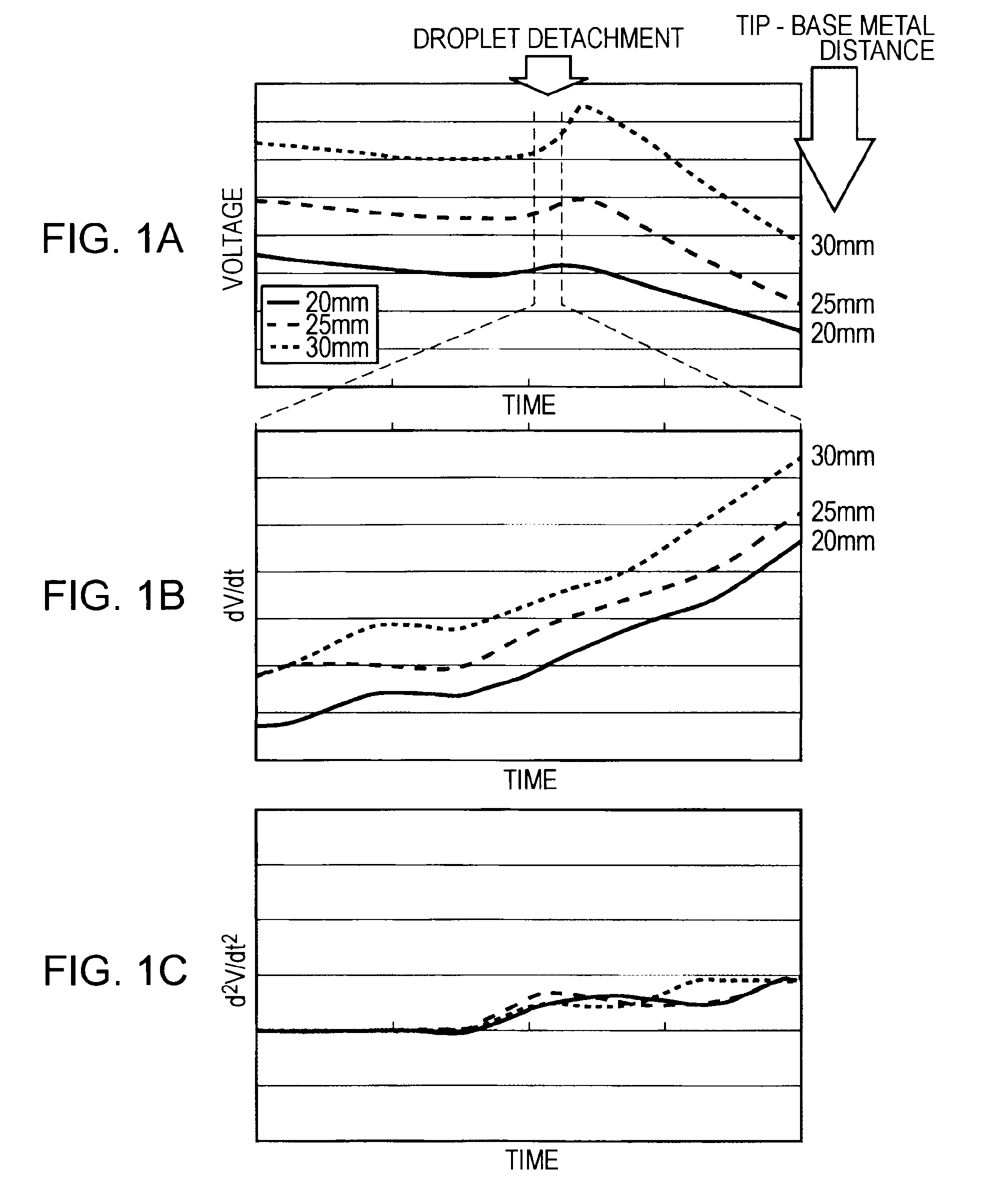

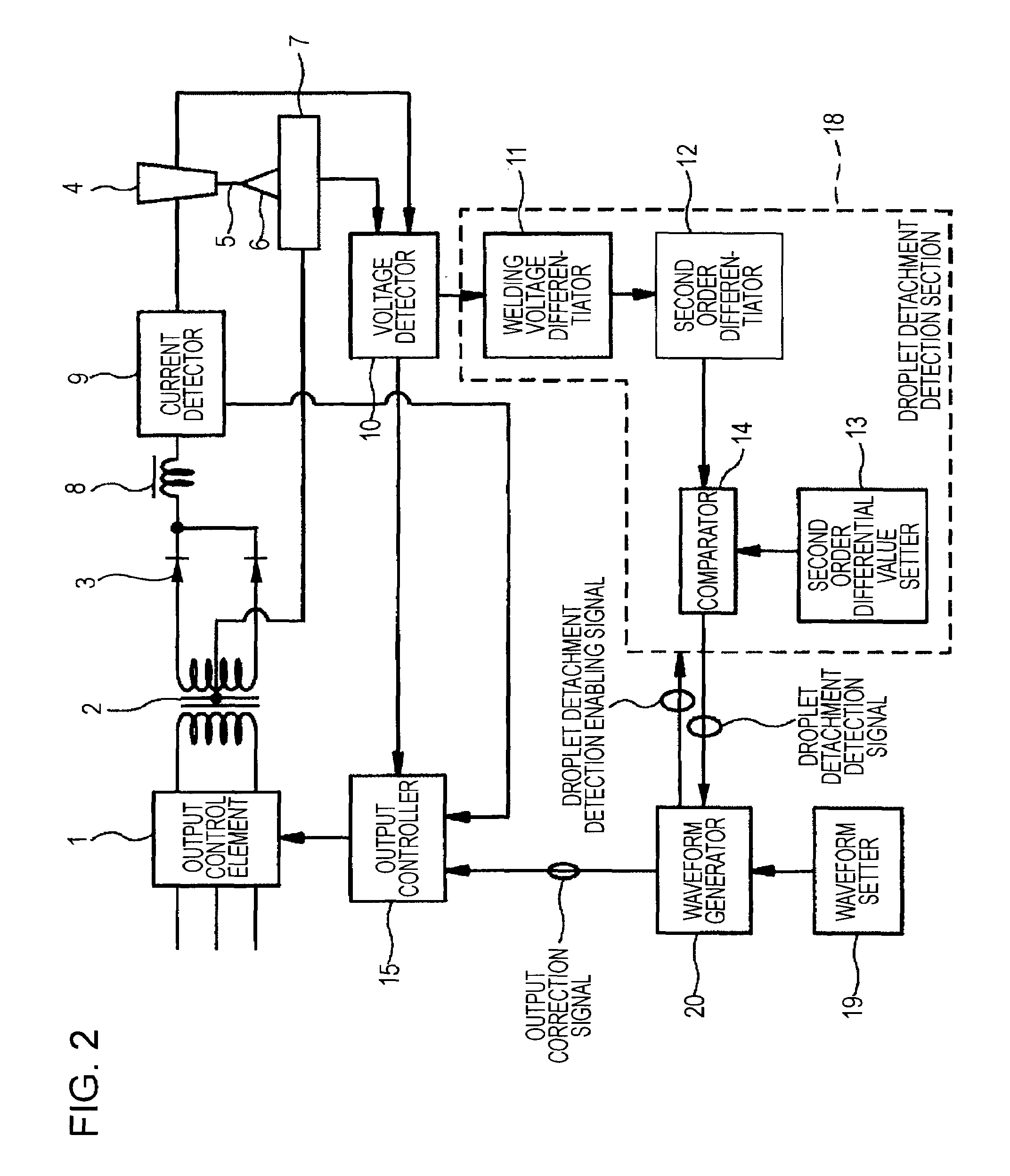

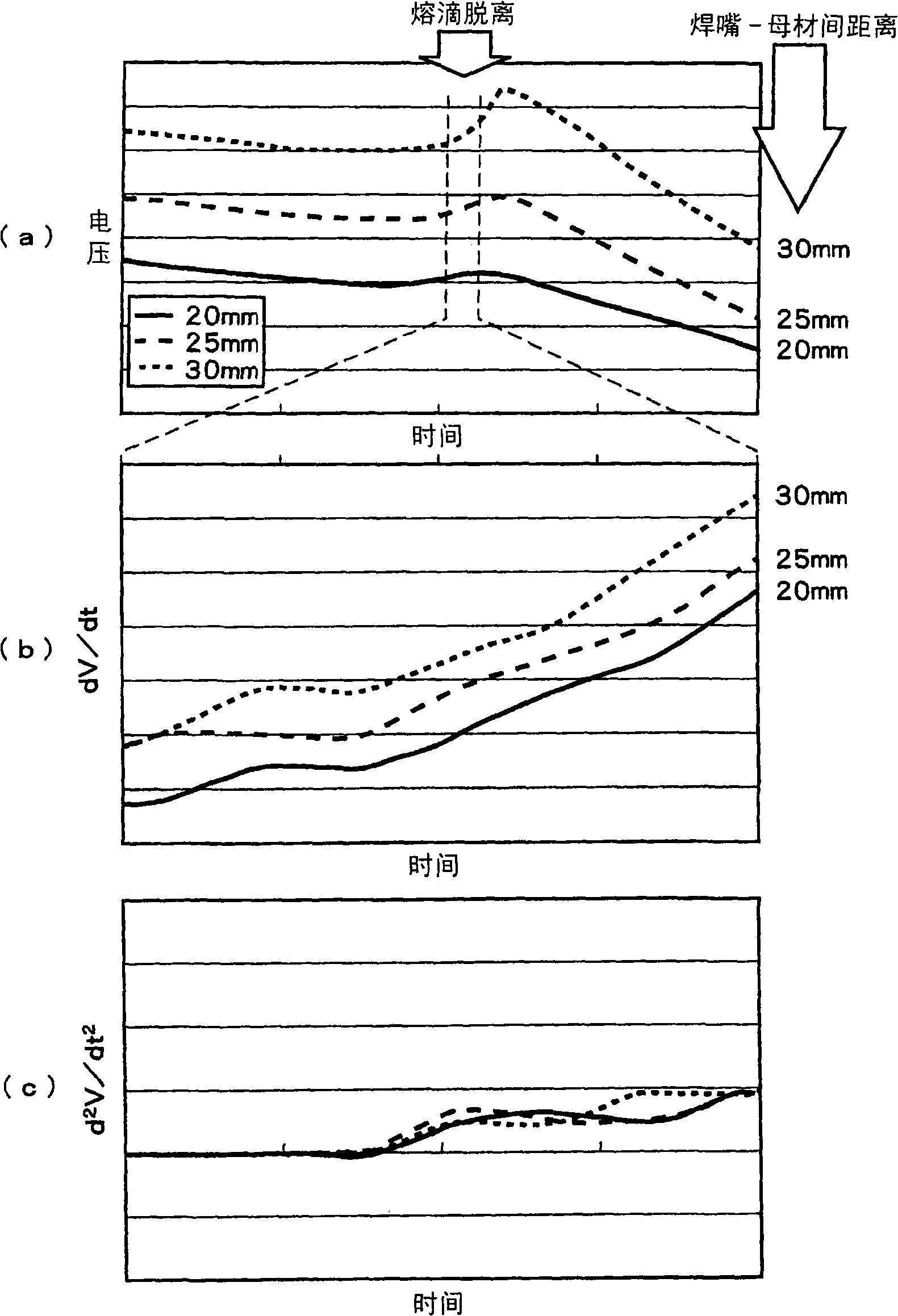

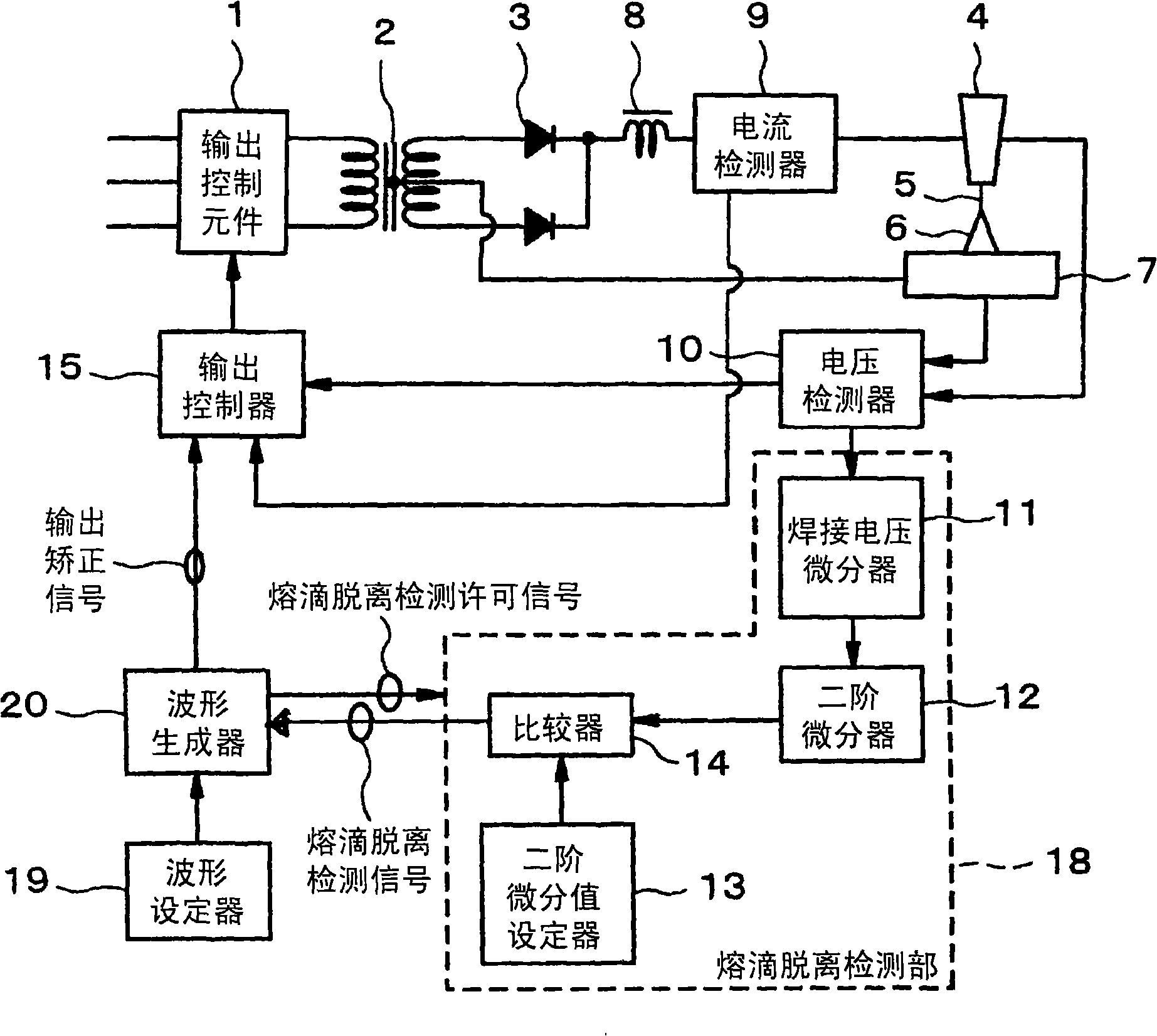

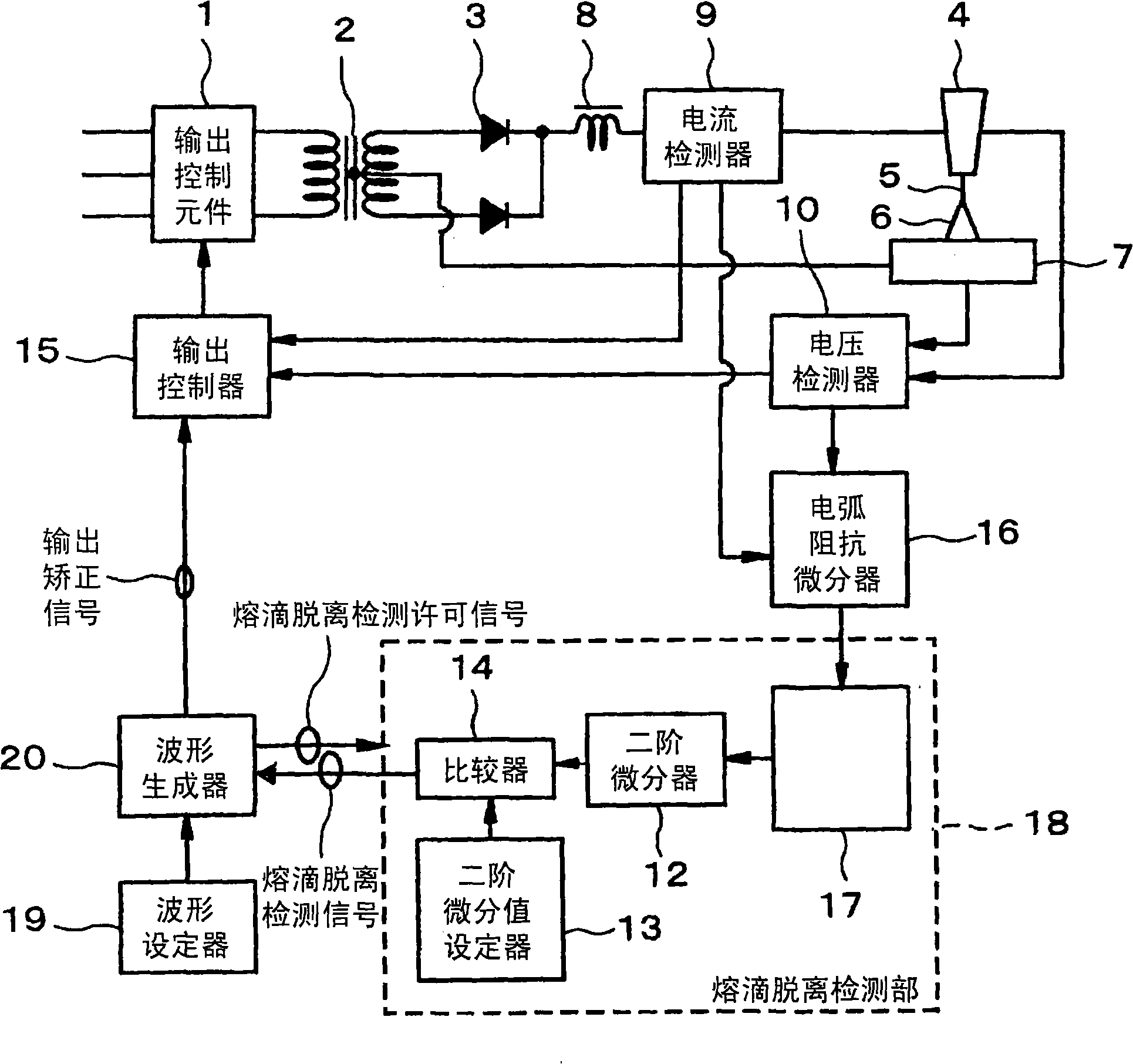

Consumable electrode type gas shielded arc welding control apparatus and welding control method

InactiveUS20080237196A1Accurate detectionTotal current dropArc welding apparatusWelding/cutting media/materialsElectrical resistance and conductanceControl theory

In consumable electrode type gas shielded arc welding, a time second order differential value of a welding voltage or an arc resistance is calculated. Based on the second order differential value, a detachment of a droplet or a timing just before the detachment is detected. After the droplet detachment or the timing just before the detachment is detected, a welding current value is immediately switched to a predetermined current value lower than that at the time of the detection. According to the control, even if welding conditions are changed or wire extension lengths are changed in the welding, the droplet detachment can be correctly detected.

Owner:KOBE STEEL LTD

Consumable electrode type gas shielded arc welding control apparatus and welding control method

ActiveCN101274384AOut of correctImprove qualityArc welding apparatusElectrical resistance and conductanceEngineering

In consumable electrode type gas shielded arc welding, a time second order differential value of a welding voltage or an arc resistance is calculated. Based on the second order differential value, a detachment of a droplet or a timing just before the detachment is detected. After the droplet detachment or the timing just before the detachment is detected, a welding current value is immediately switched to a predetermined current value lower than that at the time of the detection. According to the control, even if welding conditions are changed or wire extension lengths are changed in the welding, the droplet detachment can be correctly detected.

Owner:KOBE STEEL LTD

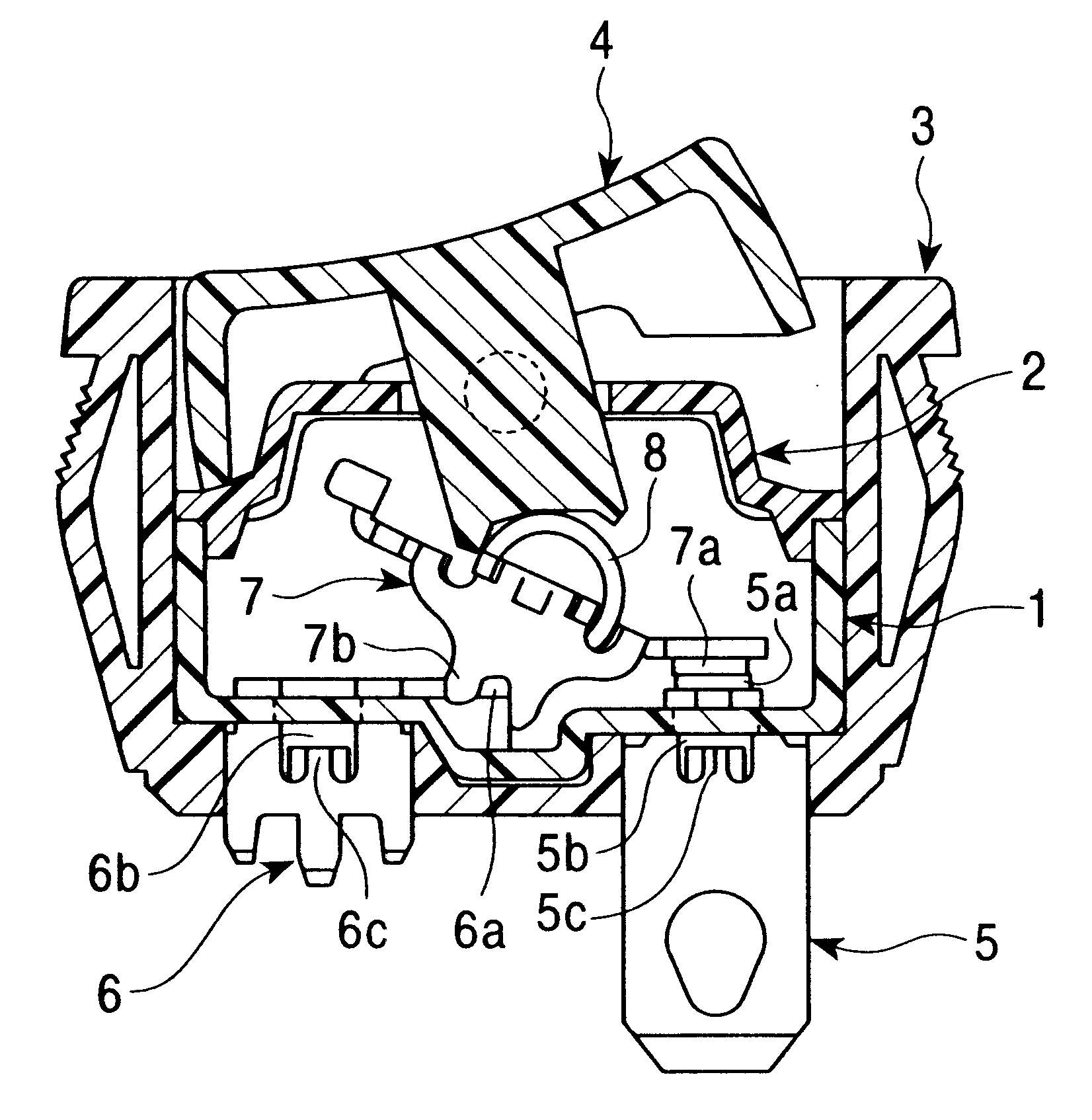

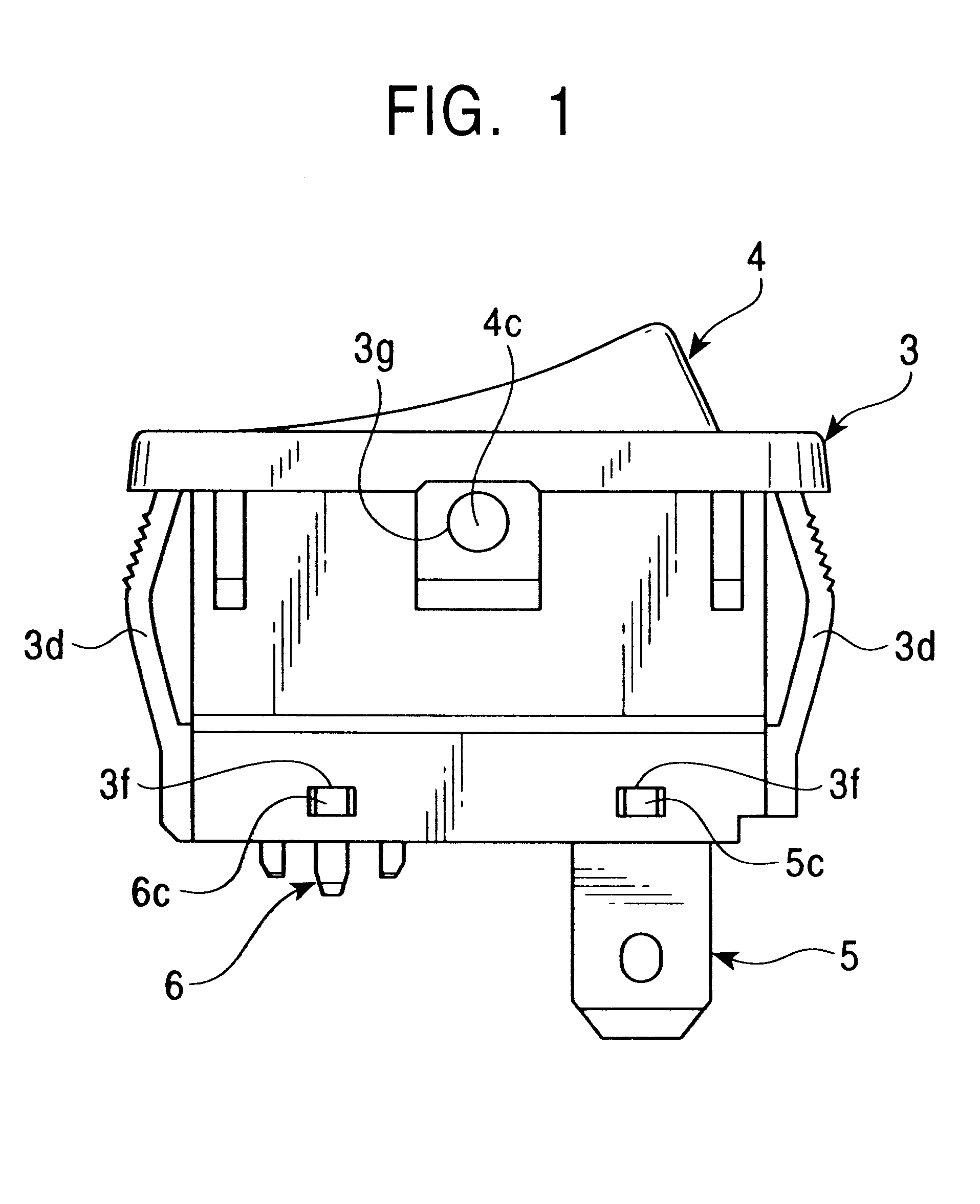

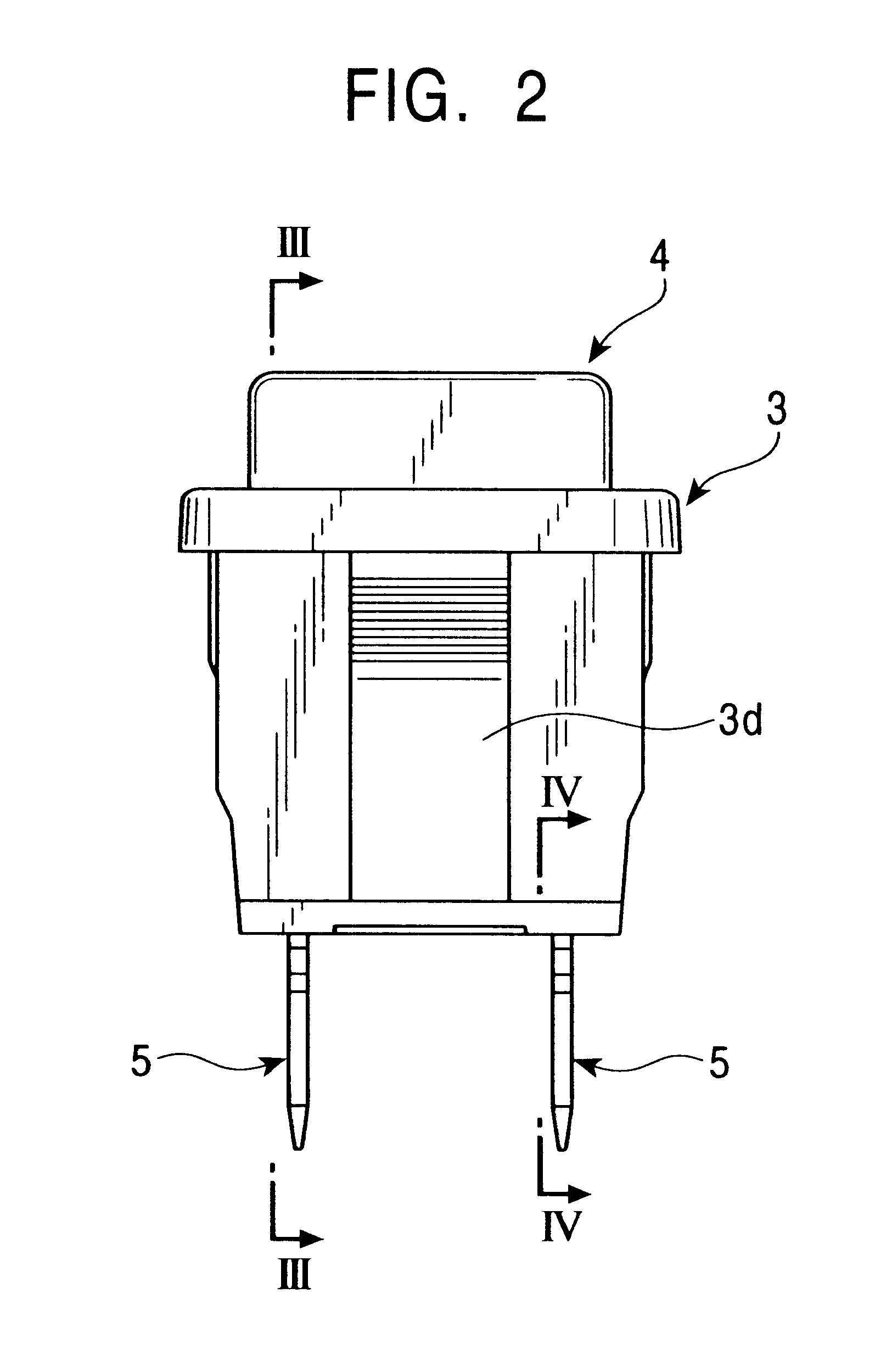

Rocker-type power-supply switch device

A switch device includes a first case and a second case. Stationary contacts are enclosed within the first case that is sealed by a cover. An operating lever configured to actuate a movable contact is partially received by a window hole within the cover. An engaging hook is unitary part of or is coupled to the outside surface of the second case. Stationary terminals project from the stationary contacts. The second case encloses the first case and the cover. The first case and the cover are made of resins having an arc resistance. The second case is made of a thermoplastic resin that is more flexible than the first case.

Owner:ALPS ALPINE CO LTD

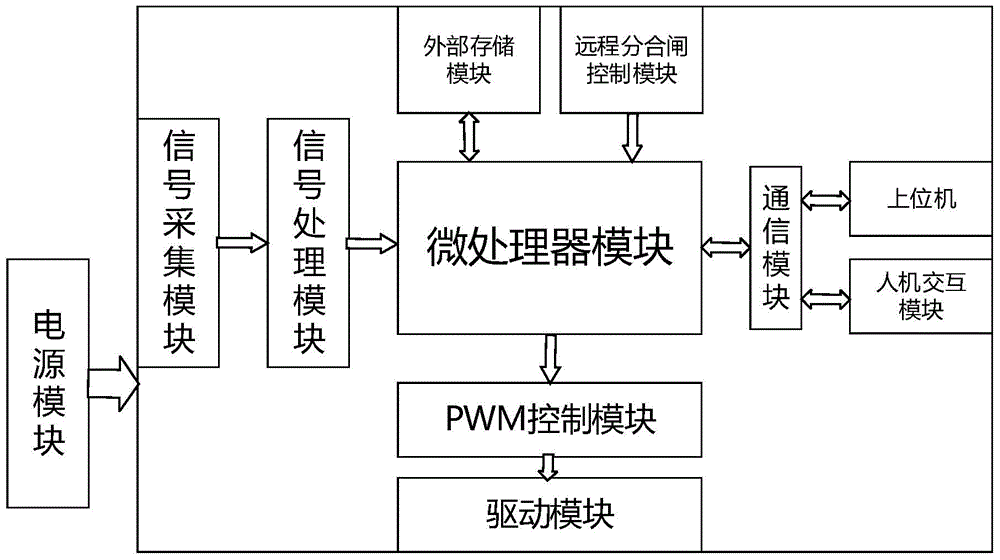

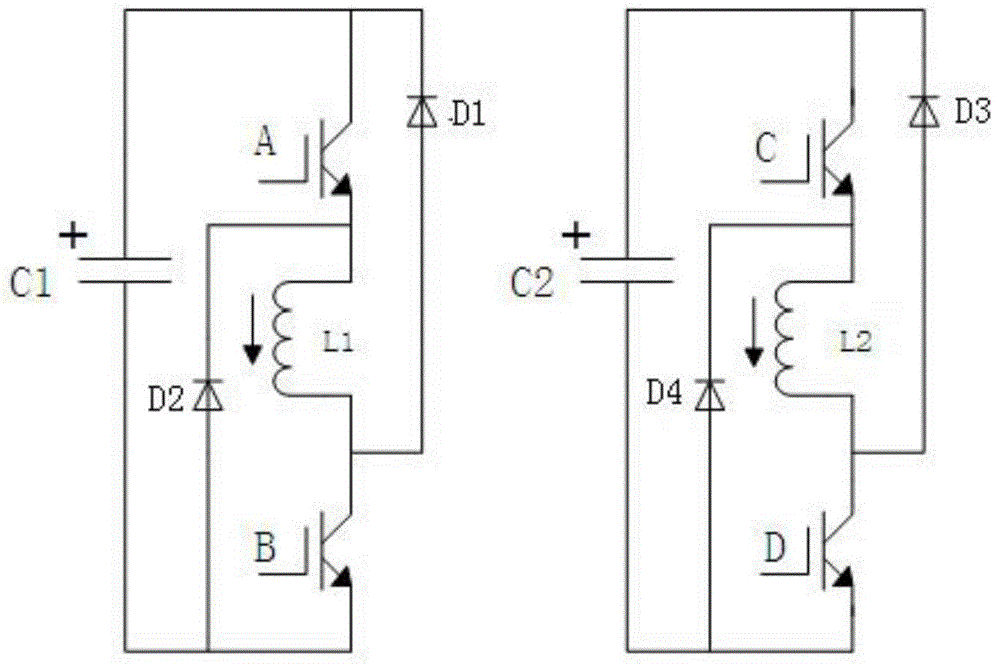

Control device and method of bistable permanent-magnet vacuum circuit breaker rapid divide-shut brake

InactiveCN104157509ASmall pressure dropAvoid generatingHigh-tension/heavy-dress switchesAir-break switchesCapacitancePeak current

The invention discloses a control device and method of a bistable permanent-magnet vacuum circuit breaker rapid divide-shut brake. The method comprises the following steps that a freewheeling diode is utilized for enabling the coils to be supplied with follow current, so that the coils can discharge to a corresponding discharge capacitor when switch tubes on the two sides of an opening coil or a closing coil are all turned off, and at the same time, the induced voltage generated by mutual inductance is counteracted with the negative voltage, namely, the voltage of a non-discharge voltage. According to the control device and method, the problem of the conventional bistable operating mechanism that the voltage drop of the capacitor is too big and the operation is influenced by the induced current is solved, the control voltage is reduced, the discharging peak current is reduced, the movement speed can be adjusted by the PWM drive control module according to requirements and the contact bounce is reduced, so that the operating characteristic is more in accordance with the arc resistance of the circuit breaker.

Owner:SOUTHEAST UNIV

Insulating wood laminating product and preparation method thereof

ActiveCN101941217AWith self-locking abilityHigh mechanical strengthPlywood pressesTransformers/inductances coils/windings/connectionsTransformerHigh resistivity

The invention relates to a wood laminating material, in particular to a wood laminating material used for manufacturing transformer connecting pieces and a preparation method thereof, and more particularly relates to a material which can be processed into woody bolt or woody nut with an insulating function. The raw materials of the product provided by the invention comprises broad leaf miscellaneous tree veneers the water content of which is less than 4%, wherein, the thickness of the veneer is 1-2mm; and the adjacent veneers are arranged according to a sequential fiber direction or a mutually vertical fiber direction, and are superposed one by one into an assembly after being soaked in the insulating rubber, and formed after being carried out hot-pressing. The wood laminating material of the invention has good mechanical strength, arc resistance, higher resistivity, lower dielectric loss and a certain self-locking performance after being soaking in the oil. The product of the invention can be further processed into bolt plates or nut plates; the bolts and the nuts manufactured by the invention have the following advantages that each layer of rubber plate is soaked with modified alcohol-soluble phenol aldehyde resin, thus leading that the bolts and nuts have higher mechanical strength and uniform inner structure compared with an electric laminating wood board, avoiding the property of partial discharge generated by bubbles, making up for the shortcomings of the bolts prepared by phenolic bakelite and nylon, and being used in the transformer with the voltage more than 220KV.

Owner:ZHALANTUN TONGDE WOOD

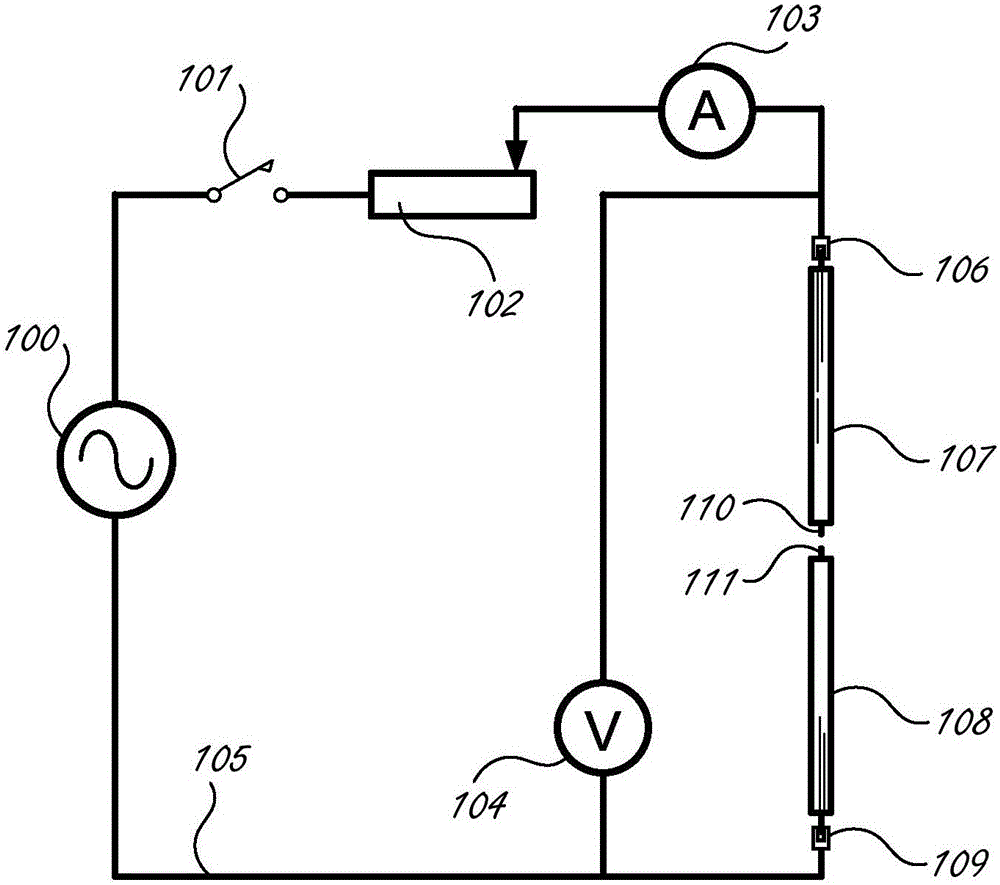

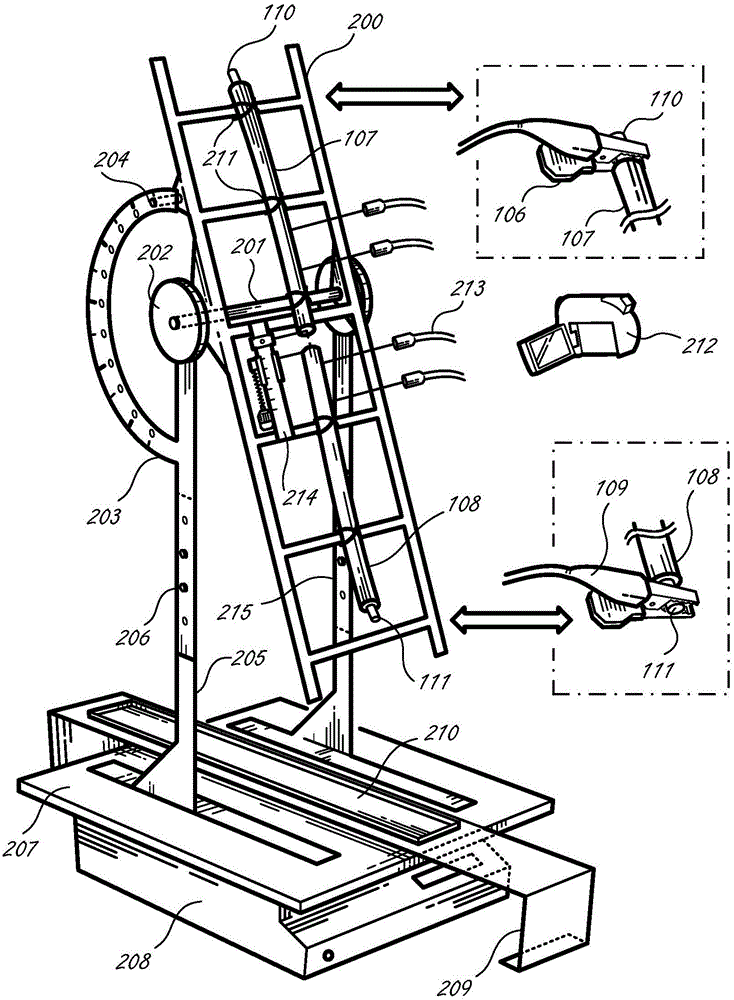

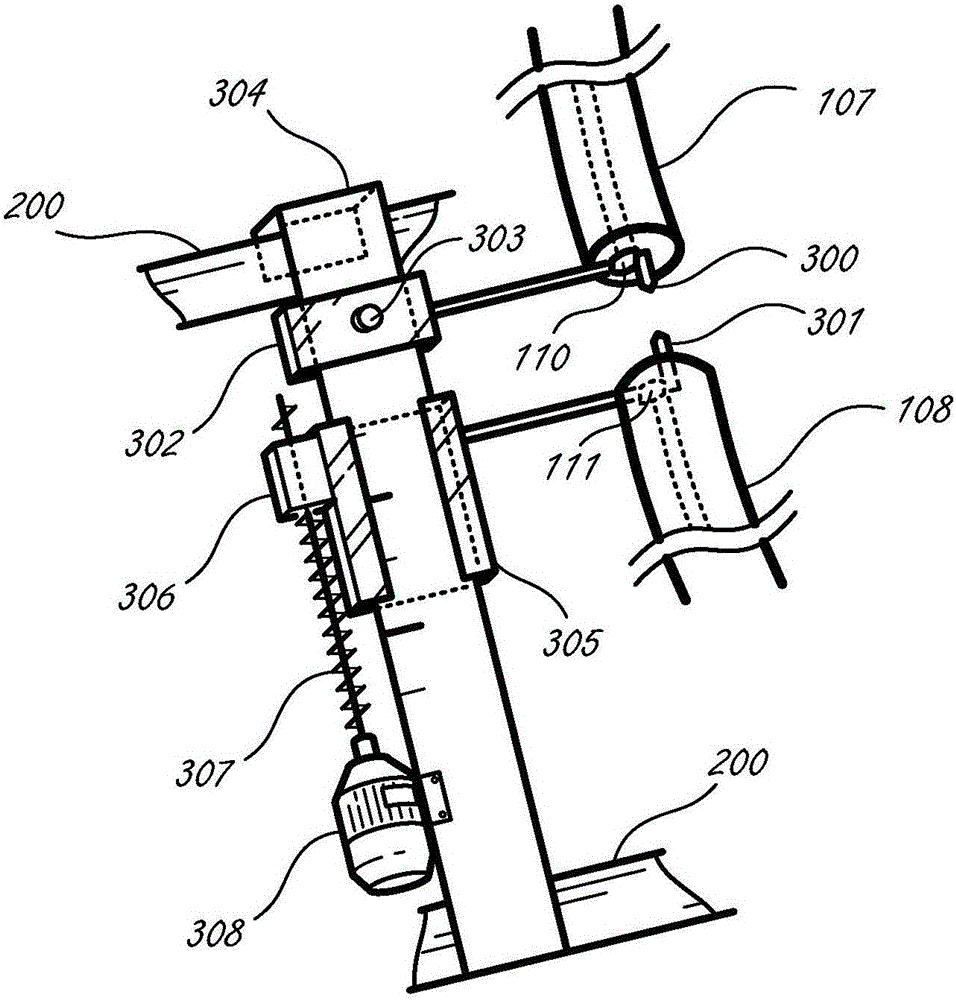

Apparatus for testing cable heating and combustion characteristics under effect of simulating fault arc

ActiveCN105021492ADetermining state critical transition conditionsAccurate adjustmentWeighing by removing componentCombustionCritical condition

The invention provides an apparatus for testing cable heating and combustion characteristics under effect of simulating fault arc. The apparatus mainly comprises a cable testing platform and a corresponding power supply loop; the cable testing platform comprises a to-be tested cable sample, a cable channel and an arc starting device; the cable channel is capable of adjusting the space included angle of a cable, and a mass measurement device is disposed below the cable channel; and the arc starting device is capable of precisely controlling the artificial fault arc state in the cable sample. Through the arc heat effect, the state developing mode of processes of being heated, combustion, fire propagating and the like of the cable sample with different space arrangement inclination angle and critical conditions are determined, and therefore the heating combustion behavior of various cables under fault arc effect is researched, and basis is provided for cable arc resistance testing and classification standard.

Owner:HUAQIAO UNIVERSITY

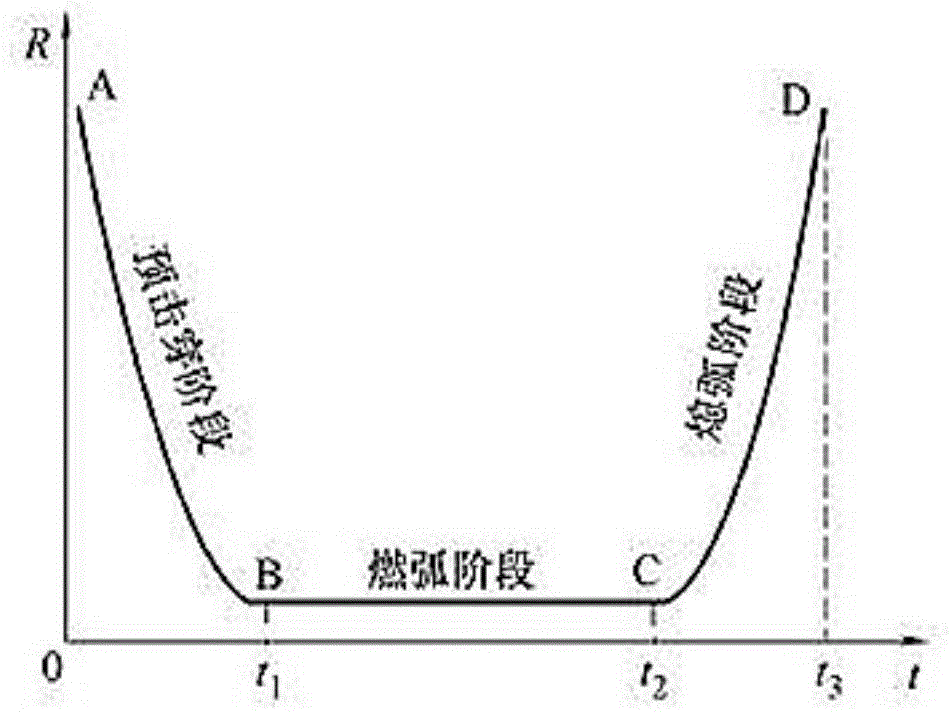

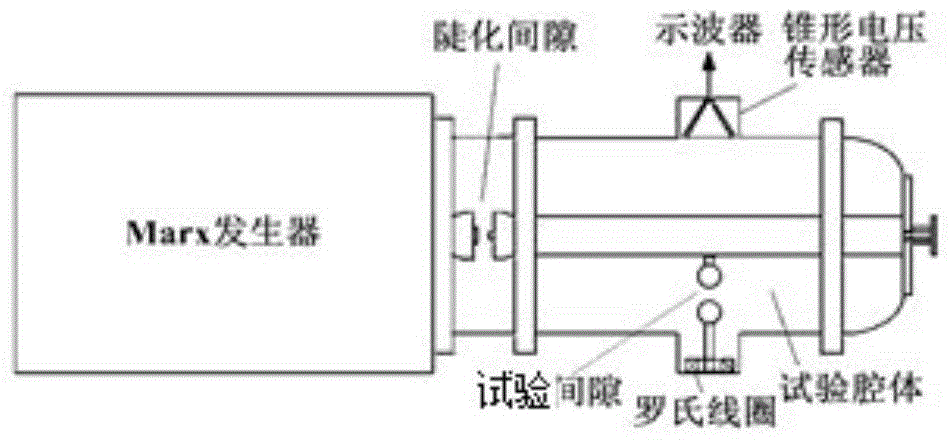

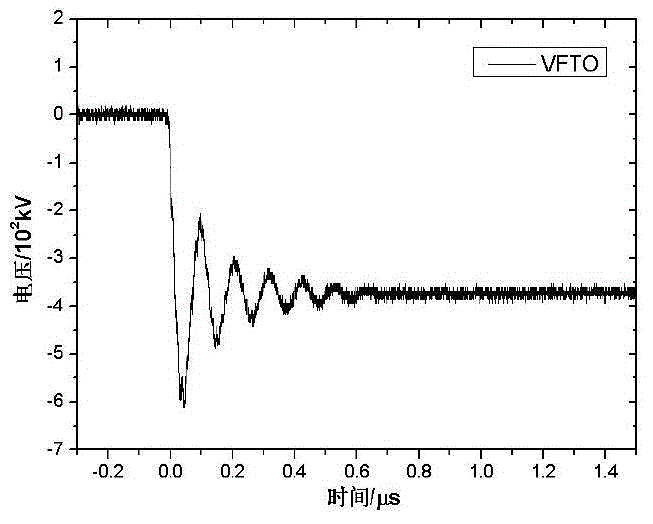

Modeling method for GIS disconnecting switch high frequency voltaic arc resistance model

ActiveCN104392049AVerify validityImprove scienceSpecial data processing applicationsOvervoltageMathematical model

The invention relates to a modeling method for a GIS disconnecting switch high frequency voltaic arc resistance model, the method holds that a high frequency voltaic arc consists of three stages, namely pre-breakdown, arcing and arc blowout; voltaic arc resistance decreases according to an exponential form in the pre-breakdown stage, is a stable value in the arcing stage, and increases according to the exponential law when entering the arc blowout stage. By SF6 gap high frequency arcing tests, the effect law of a stable arcing resistance, a current peak, air pressure and a voltaic arc length on the voltaic arc resistance is obtained so as to build a steady state arcing resistance math model; by GIS disconnecting switch hot-line operation tests, the time varying law and parameter of the voltaic arc resistance are obtained so as to build a double exponential time varying math model of the GIS disconnecting switch voltage arc resistance; and by carrying out emulation calculation on very fast transient overvoltage generated by GIS disconnecting switch hot-line operation, in comparison with a GIS disconnecting switch test result, the effectiveness of the GIS disconnecting switch high frequency voltaic arc resistance match model is verified, and the scientific nature and accuracy degree of the very fast transient overvoltage are obviously improved.

Owner:STATE GRID CORP OF CHINA +3

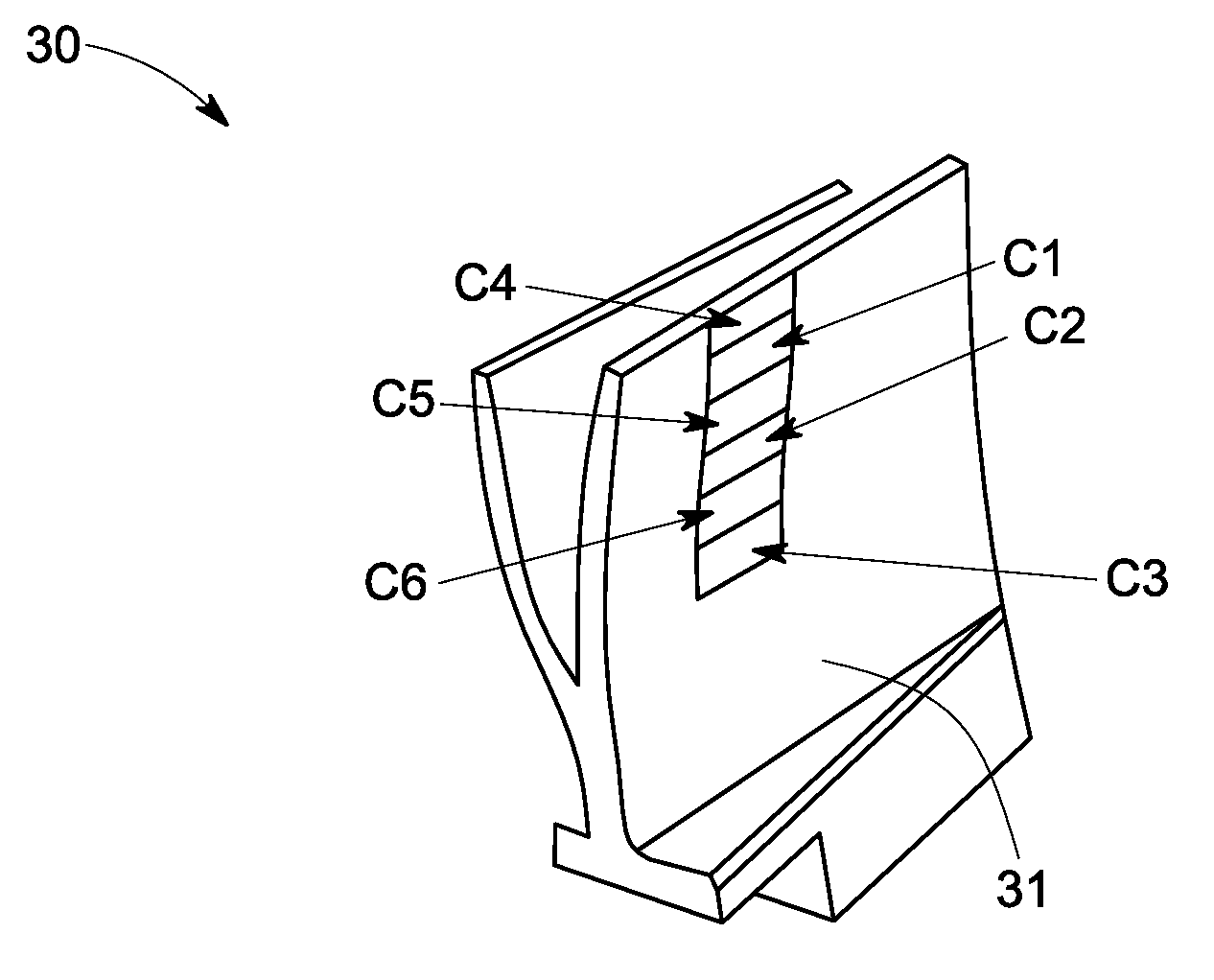

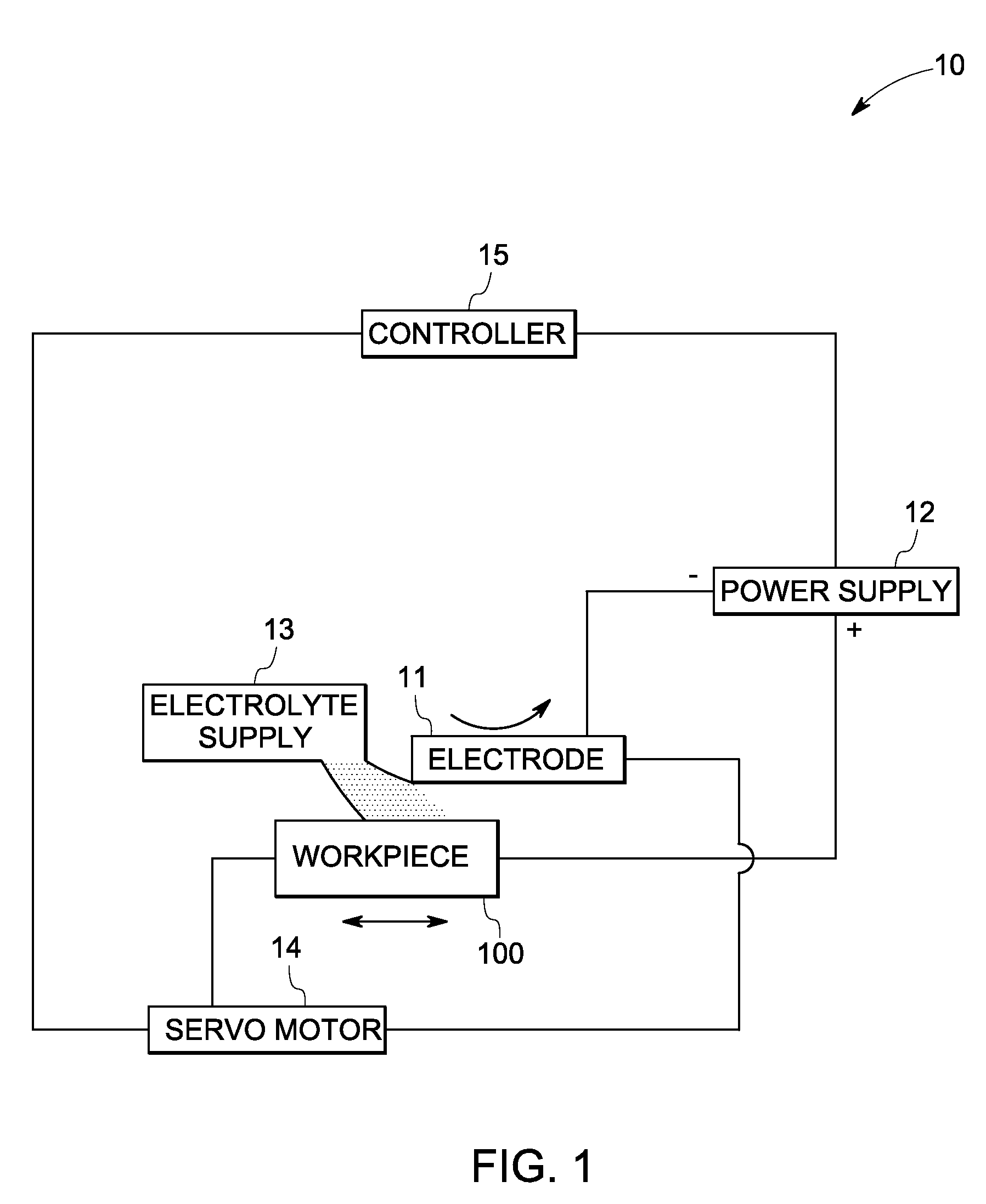

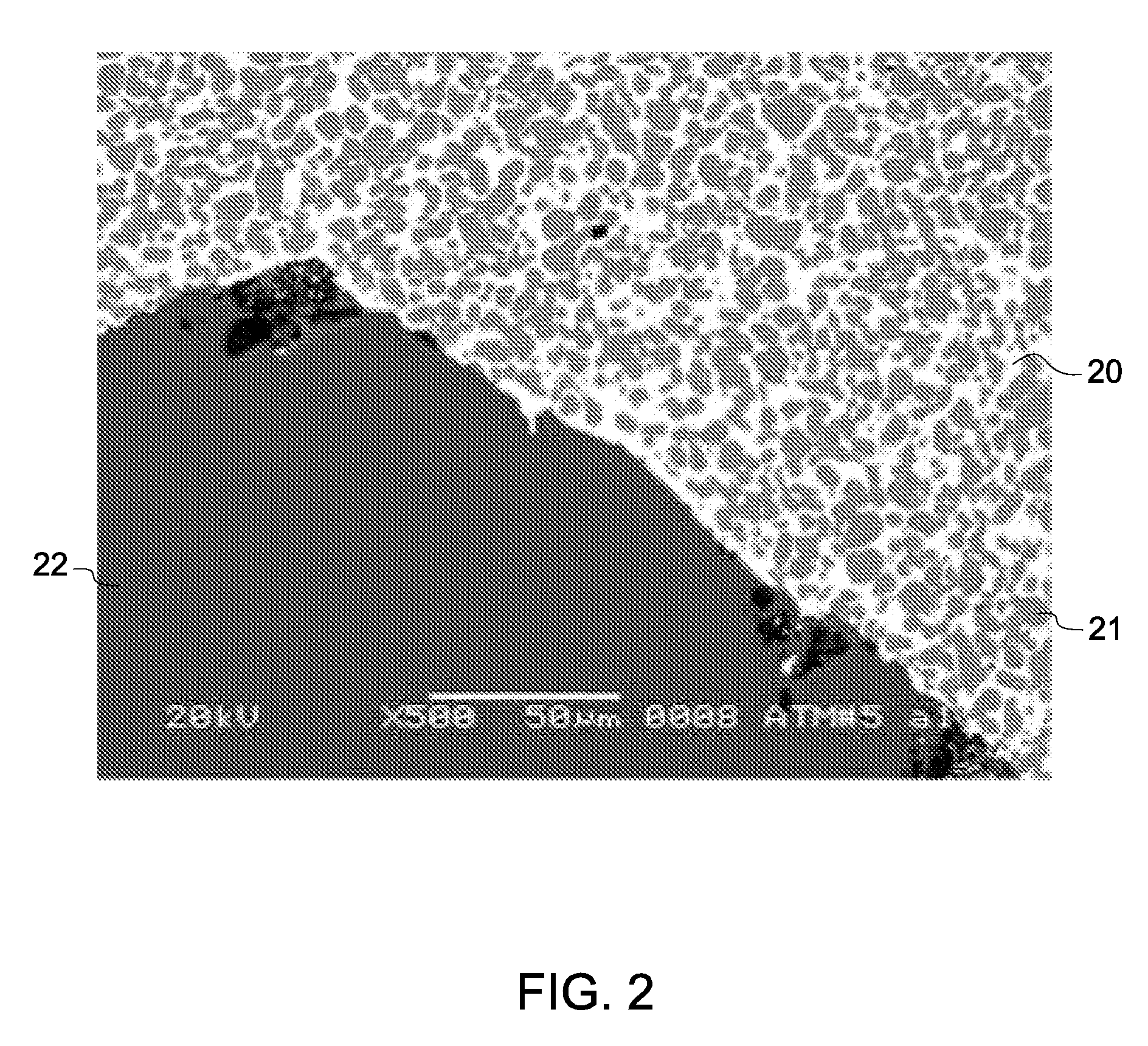

Electrochemical grinding electrode, and apparatus and method using the same

An electrochemical grinding electrode comprises an electrically conductive material; an arc resistance material; and an abrasive material different from the arc resistance material. An electrochemical grinding apparatus and a method are also presented.

Owner:GENERAL ELECTRIC CO

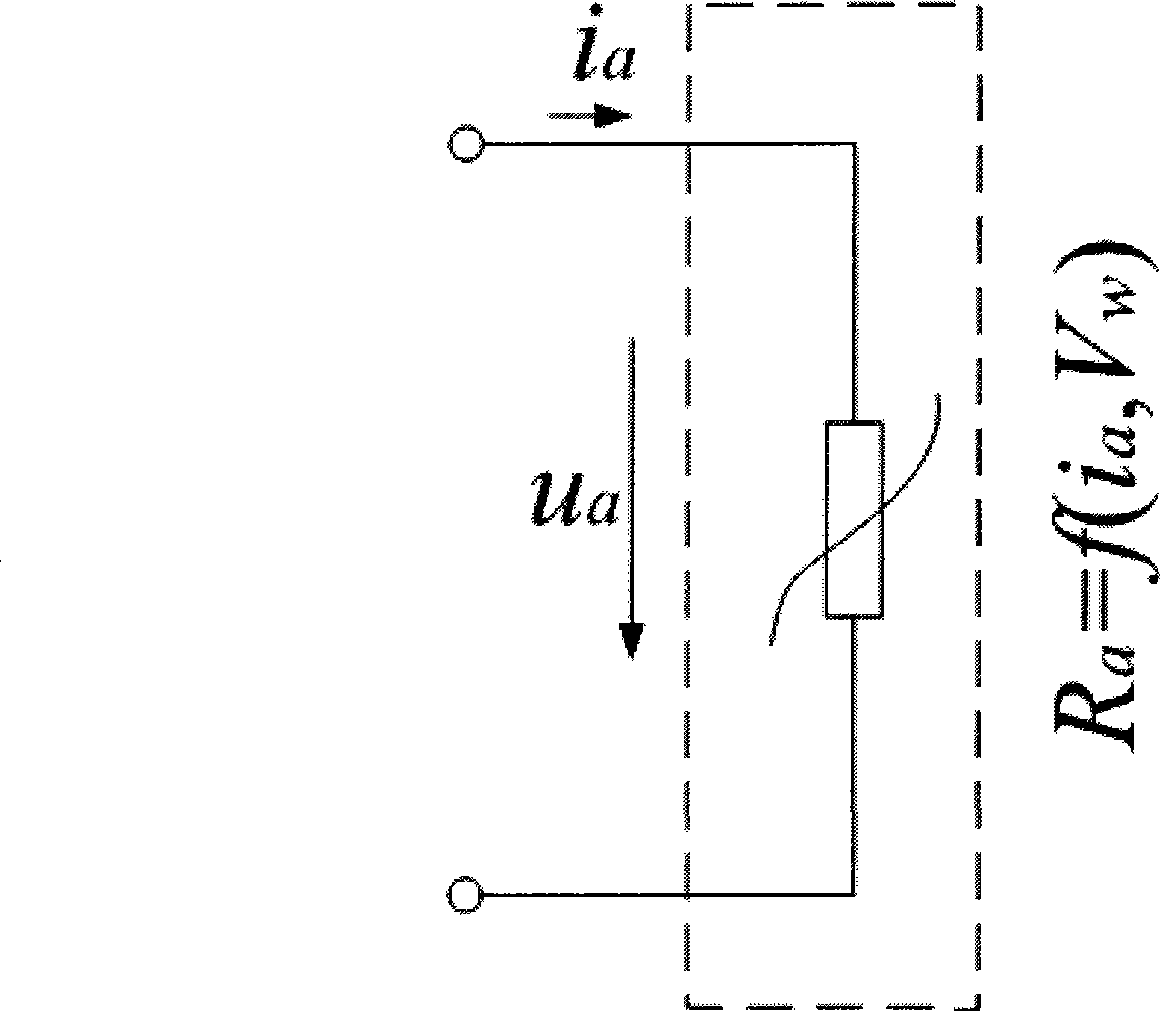

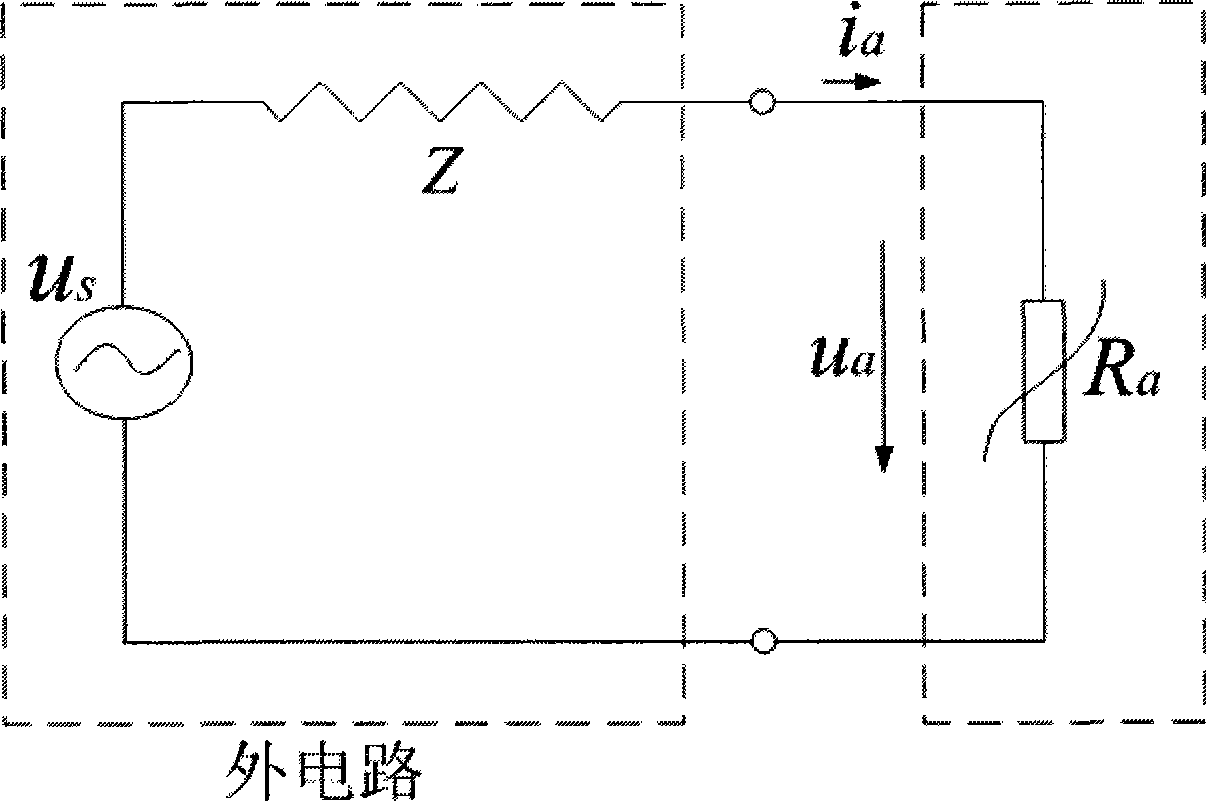

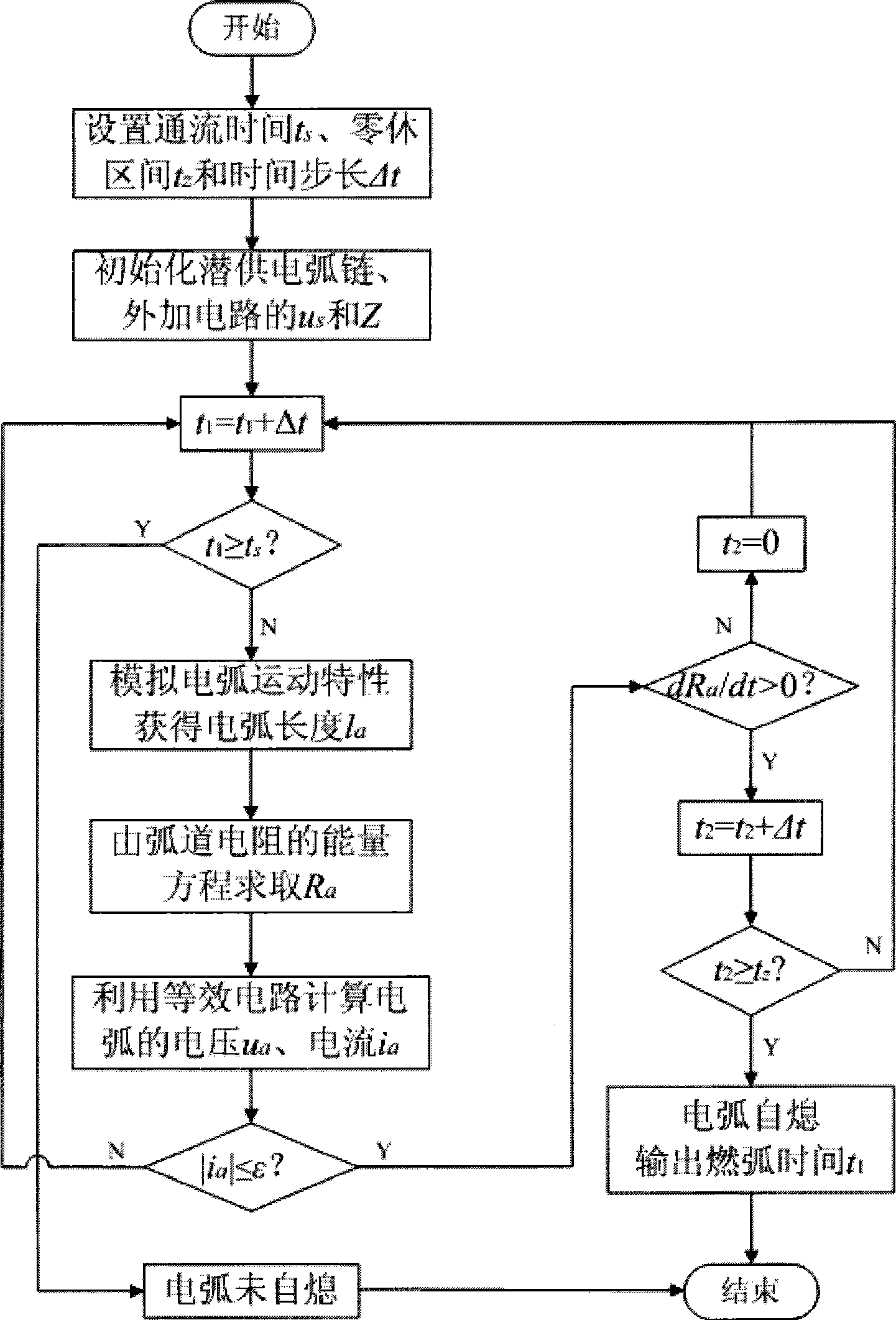

Secondary arc analogue simulation apparatus and method for transmission line

The invention provides a simulating analog device of a transmission line secondary arc and a method thereof, which adopt the following technical proposal: the arcing situation of an arc channel is simulated by adopting a nonlinear time-varying resistance, and the arc channel resistance satisfies a dynamic equation which is established according to arc conservation of energy; a real-time secondary arc length is obtained according to arc movement characteristics by analyzing electrodynamic power, wind load and air resistance of an arc in movement and is used for modifying an arc length in the arc resistance equation; and by combining the characteristics of secondary arc current, whether self-extinguishing of the arc can be achieved is judged according to a change rate of the arc channel resistance when the arc current runs through a zero zone. A nonlinear differential equation which applies mathematical methods to solve the arc resistance occurs the electromagnetic transient process of the secondary arc with a computing system connected with an external circuit, and an the self-extinguishing time of the secondary arc is obtained by the arc channel resistance criterion during the zero-rest period of the arc current.

Owner:CHINA ELECTRIC POWER RES INST +1

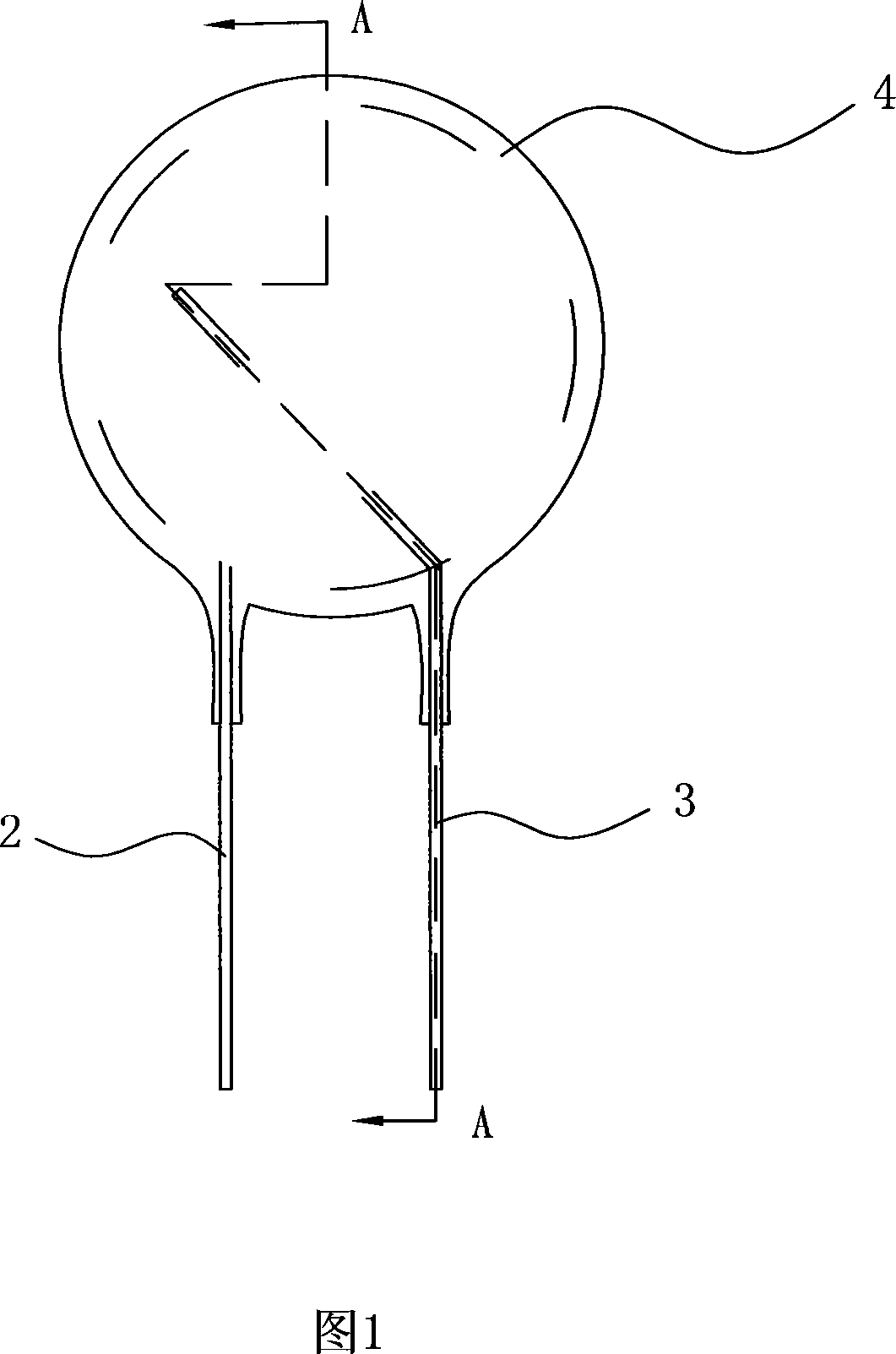

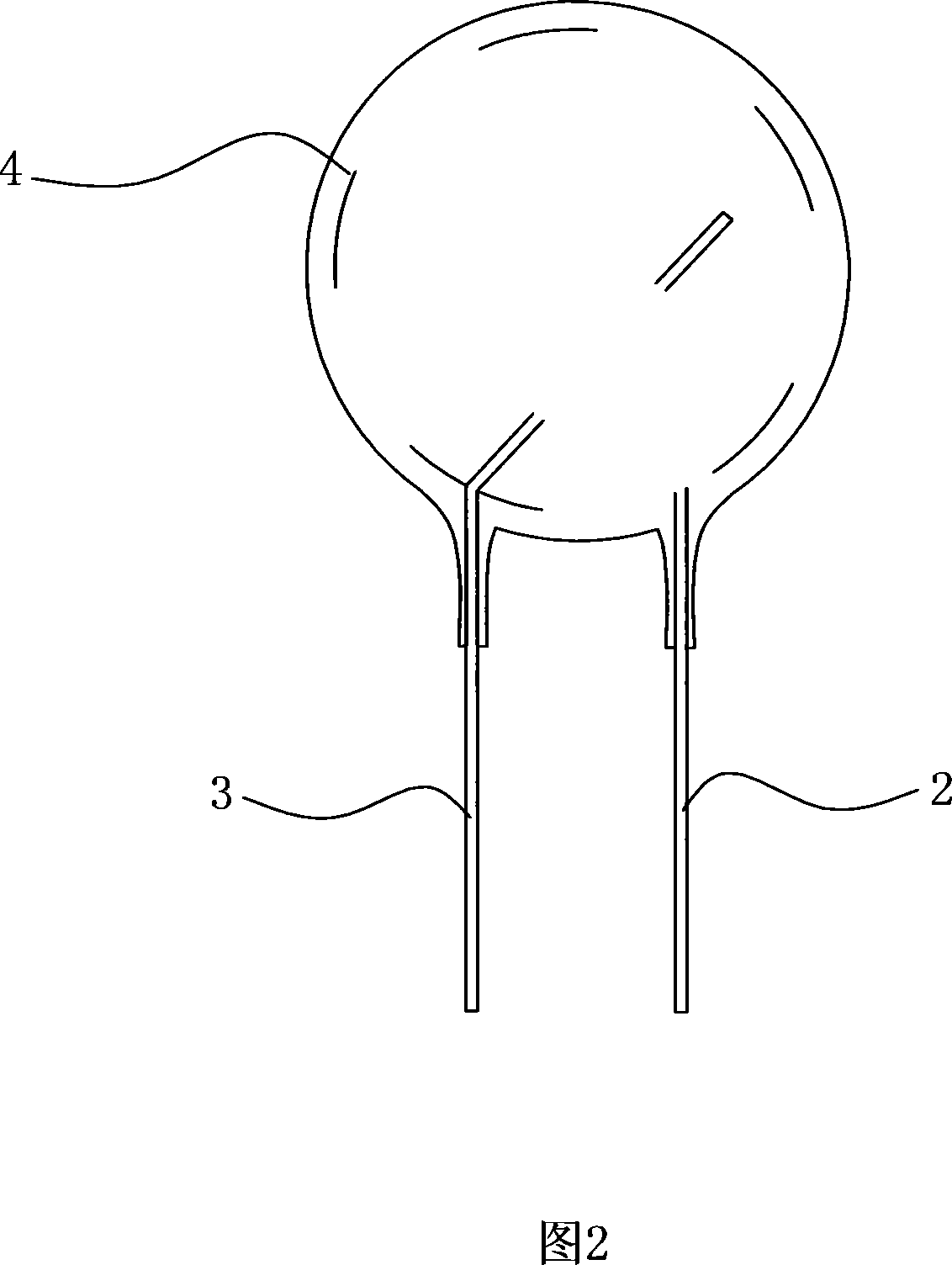

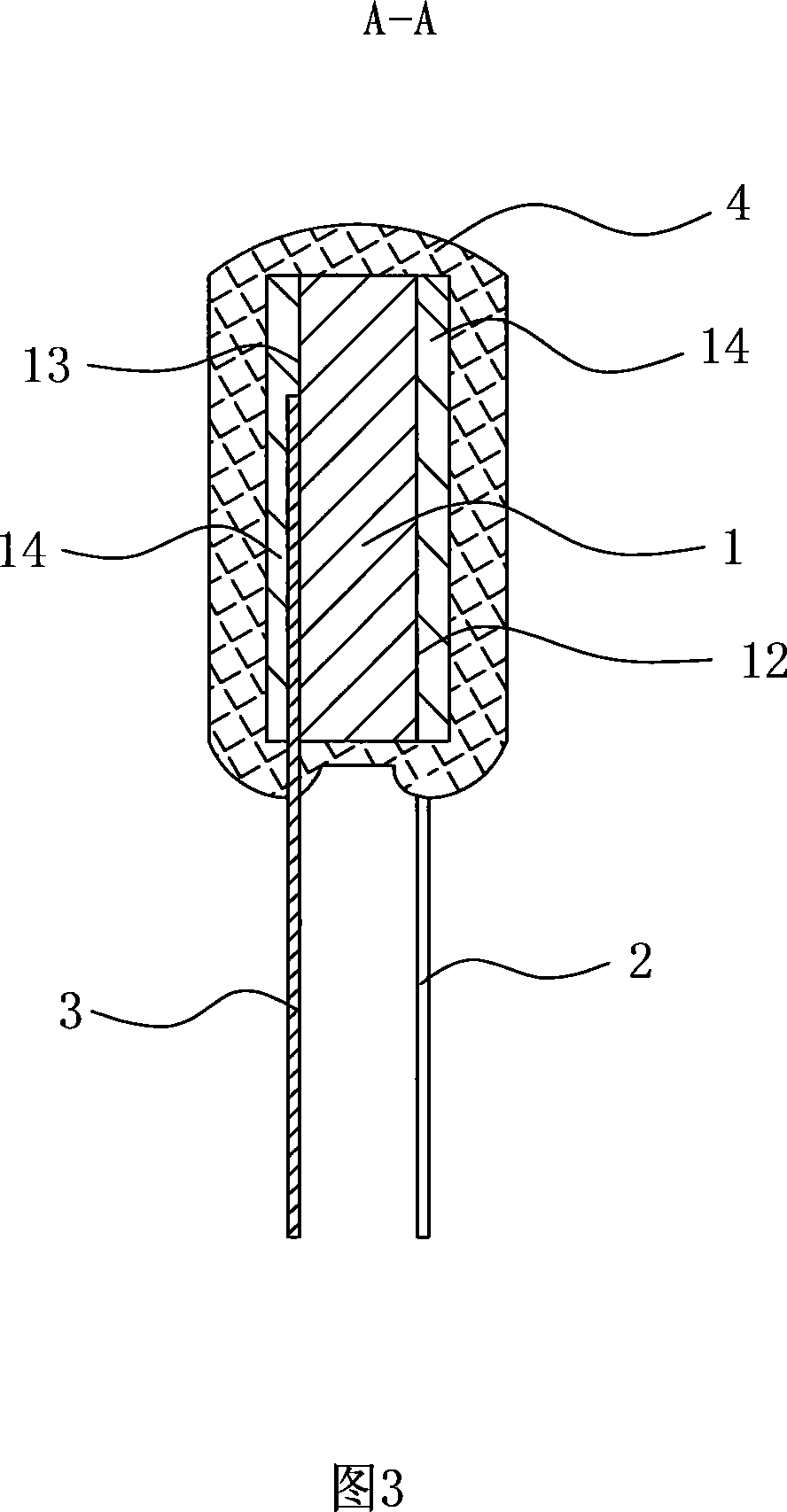

Highly secure and non-combustible voltage-dependent resistor

InactiveCN101079341AAvoid fireResistor manufactureResistor detailsElectrical resistance and conductanceElectricity

The invention disclose a high safe non-ignitable piezoresistor, which comprises the following parts: a piezoresistor chip with two corresponding surfaces, the first leading electrode electric connected with a surface of the piezoresistor chip, the second leading electrode electric connected with the other surface of the piezoresistor chip, wherein the outboards of two corresponding surfaces are provided with a low-melting point metal conductive layer which can melt at 155Deg.C-450Deg.C, the intermediate of two outboard low-melting point metal conductive layers doesn' t have electric connection of the good conductor. The invention guarantees that the current foldback fuse or the current foldback switch can break arc current quickly before the shell of the pieziresistor is on fire, which avoids the occurrence of fire.

Owner:苏州中普电子有限公司 +1

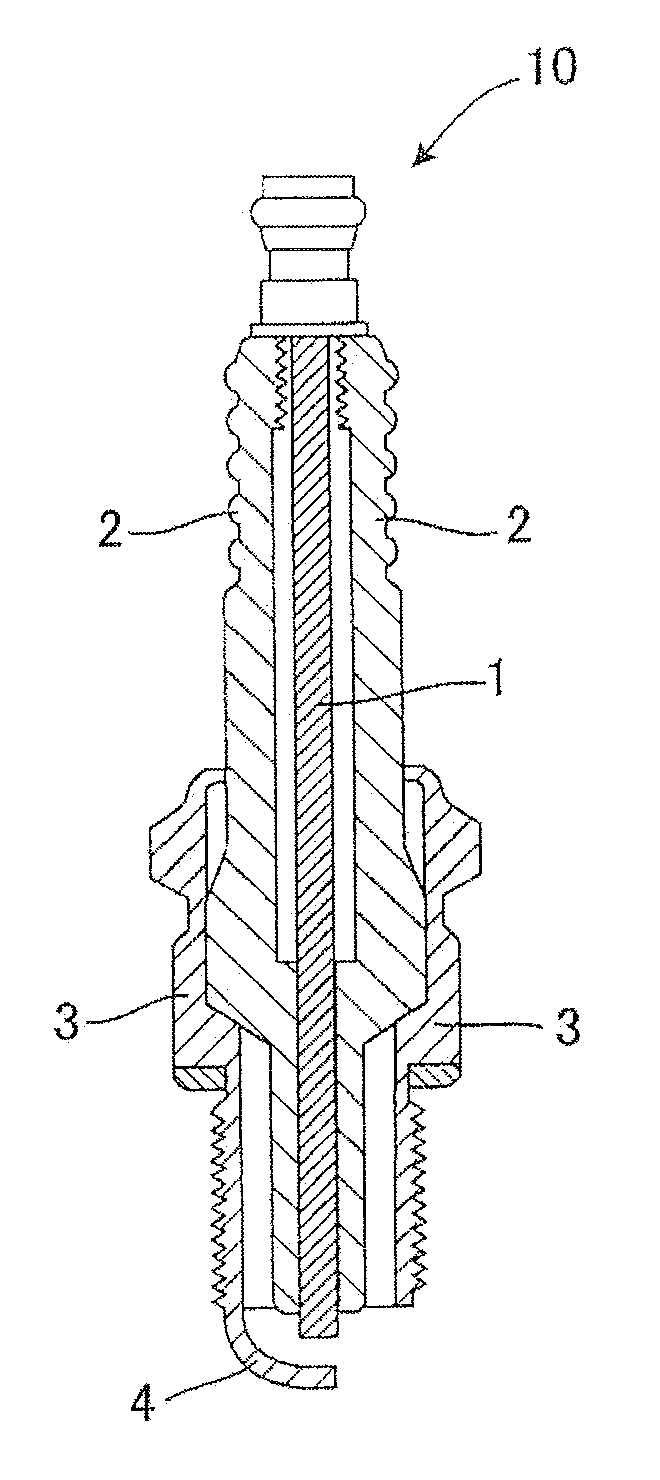

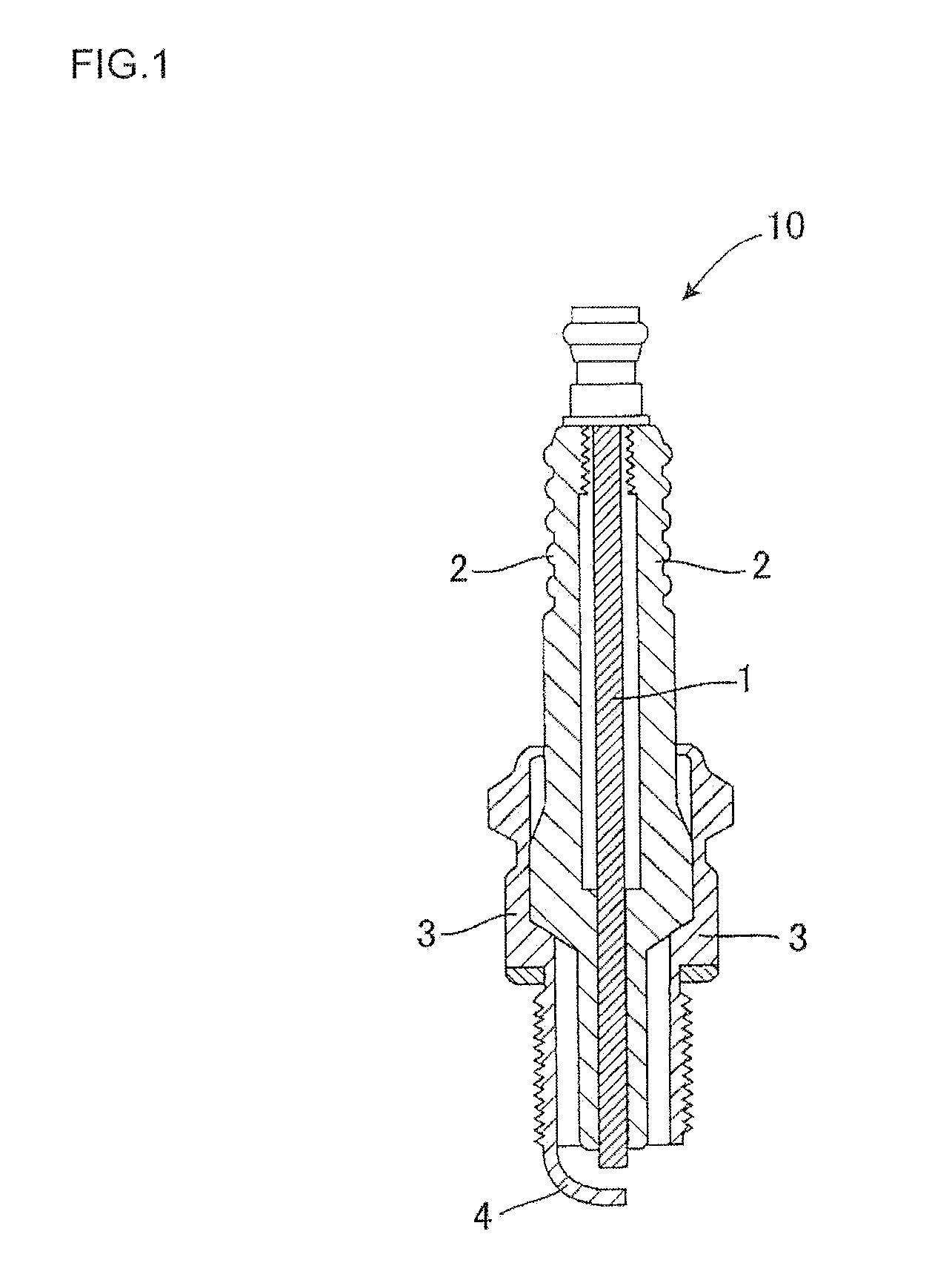

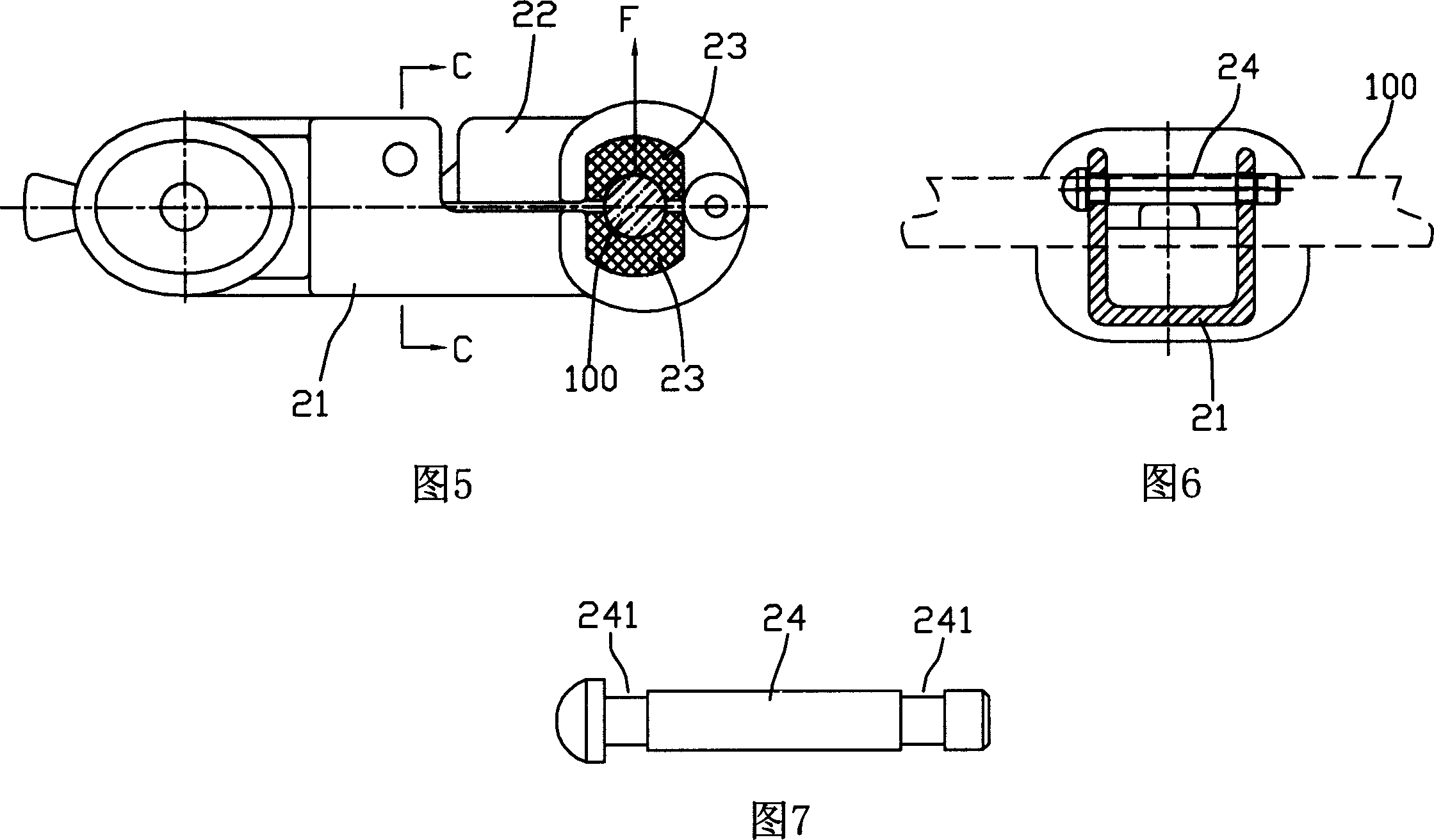

Ti3SiC2 BASED MATERIAL, ELECTRODE, SPARK PLUG AND MANUFACTURING METHOD THEREOF

ActiveUS20120186723A1Improve arc resistanceReducing TiC (heterophase) content and open porosityConductive materialCeramic shaping apparatusSpark plugPorosity

The present invention provides a Ti3SiC2 based material that exhibits excellent arc resistance, an electrode, a spark plug, and methods of manufacturing the same. A Ti3SiC2 based material according to the present invention includes Ti3SiC2 as a main phase, the Ti3SiC2 based material having a TiC content of 0.5 mass % or less and an open porosity of 0.5% or less. It may be preferable that 0 to 30 mol % of Si contained in the main phase Ti3SiC2 be substituted with Al. A spark plug according to the present invention includes an electrode formed using the Ti3SiC2 based material.

Owner:NGK INSULATORS LTD

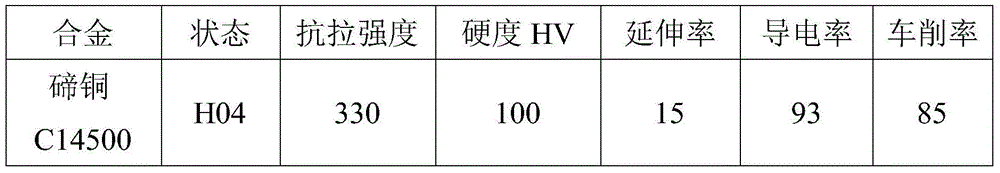

High-conductivity, arc-resistance and free-cutting leadfree tellurium copper alloy material

The invention relates to the technical field of preparation of alloy materials, in particular to a tellurium copper alloy material. The high-conductivity, arc-resistance and free-cutting leadfree tellurium copper alloy material is prepared by the following raw materials in percentage by weight: 0.4-0.7% of Te, 0.01-0.015% of P, and the balance of Cu. As the technical scheme is adopted, the prepared tellurium copper alloy gives consideration to excellent free-cutting performance, excellent electricity and heat conductivity and higher toughness, corrosion resistance and electric ablation resistance, has equivalent arc resistance with a silver-copper alloy, is better in cold and hot machinability, and can be forged, extruded, drawn, punched and molded.

Owner:SHANGHAI FANGYI ENTERPRISE DEV CO LTD

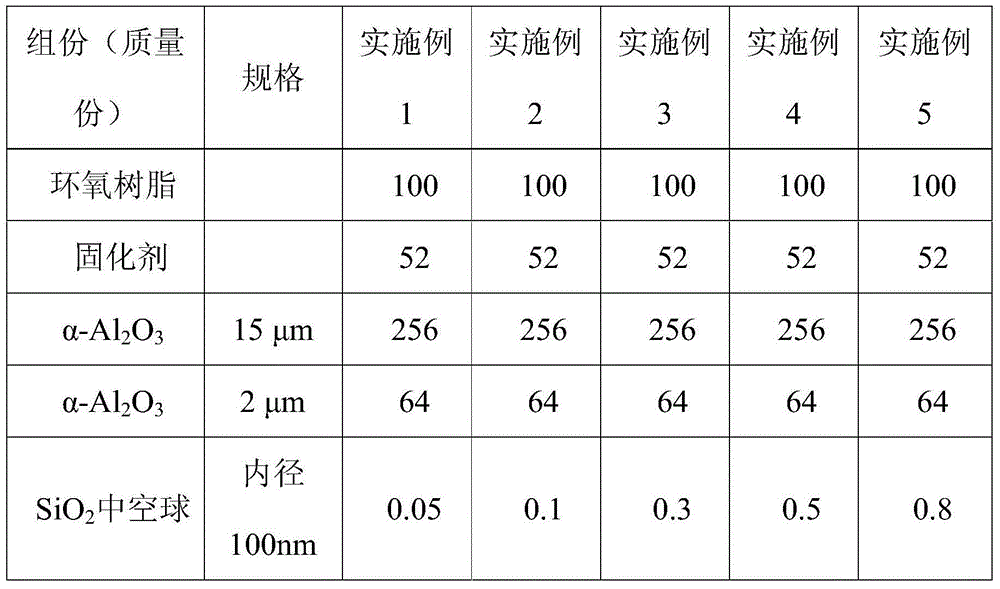

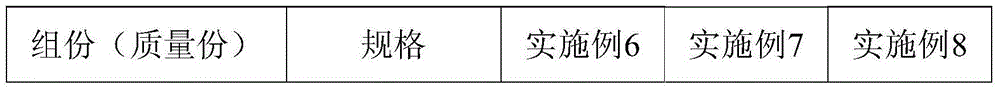

Electrical insulating epoxy resin composition and preparation method thereof

The invention discloses an electrical insulating epoxy resin composition which consists of the following components: (A) one or more than two epoxy resins; (B) one or more than two anhydride curing agents; (C) a micron inorganic particle composition which accounts for 60-75% of the mass of the electrical insulating epoxy resin composition; and (D) one or more than two inorganic hollow nanoparticles which account for 0.05-0.8% of the mass percentage of the component (A), and the component (C) includes two particles differing in size. The epoxy resin composition disclosed by the invention is low in dielectric constant, and is capable of improving such electrical properties as breakdown strength and arc-resistance time as well as mechanical properties.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

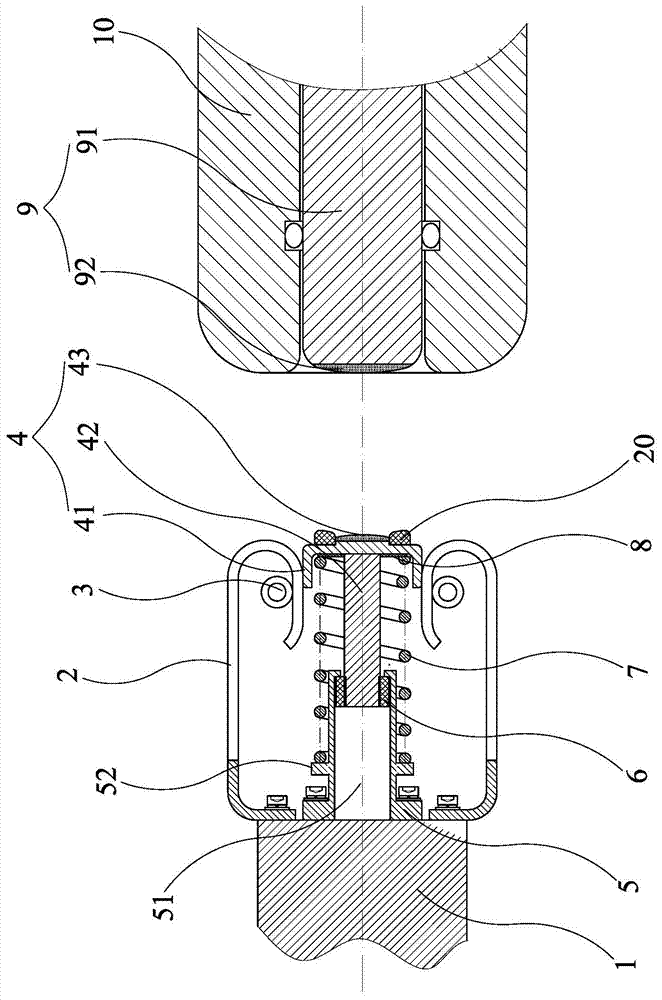

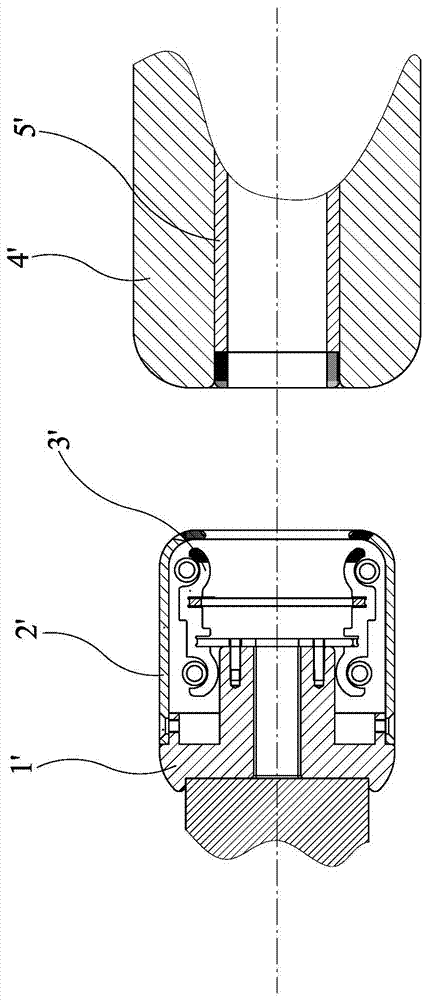

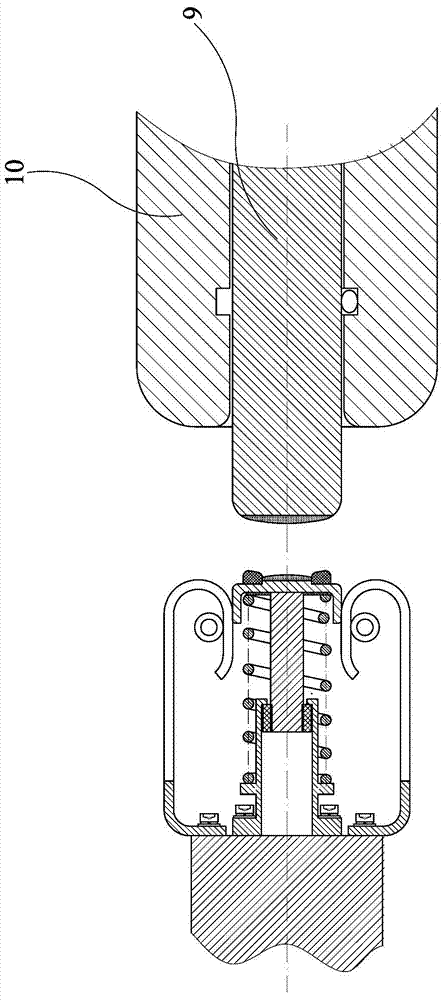

Grounding switch contact

PendingCN107887184ASlow downReduce impactContacts enclosures/screensAir-break switch detailsElectrical conductorGuide tube

The invention discloses a grounding switch contact, which comprises a static contact conductor, a shielded static contact, a contact spring, a static arcing contact, a guide cylinder, a guide block, a buffer spring, an insulating gasket, and a grounding switch moving contact. Head, moving contact seat. The contact spring is sleeved on the outer wall of the middle hole of the shielded static contact, the guide cylinder and the static arc contact are sleeved in the inner cavity of the shielded static contact, and the buffer spring sleeve Connected to the outer end of the guide rod, the two ends of the buffer spring respectively lean against the inner wall of the cup-shaped conductor and the spring stop steps of the guide cylinder, and an insulating gasket is provided between the buffer spring and the inner wall of the cup-shaped conductor; The conductive rod is movably nested in the movable contact seat, and the arc-resistant alloy of the movable contact on the conductive rod can abut against the arc-resistant alloy of the static arc-starting contact on the cup-shaped conductor to realize the closing of the switch. Because the electric contact of the present invention adopts the end face of the static arcing contact to contact with the front face of the moving contact of the earthing switch, the contact is more reliable.

Owner:XUJI XIAMEN INTELLIGENT SWITCHGEAR MFG +1

Copper-tungsten-carbon-titanium-rare earth alloy material and production thereof

An alloy material of Cu-tungsten carbide-C-Ti-RE is consists of Cu, WC, C, Ti, rare-earth. The material decrease the content of the 'WC' and increase the content of 'Cu' so improve the conductance, as a result, it can control the temperature of the material. The material which added proper C and Ti, RE can improve the non-fusibility, wearability, arc resistance, life of the electricity. The process can improve the fine structure of the histology so the material can be used from the high-current switch, circuit breaker to majority medium-current switch. Especially, it can save the silver and have good market future.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Environmentally-friendly underfill adhesive having low dielectric constant, and preparation method thereof

ActiveCN107828358ALow dielectric constantLow Halogen Environmental ProtectionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHalogen

The invention relates-an environmentally-friendly underfill adhesive having a low dielectric constant, and a preparation method thereof, and belongs to a one-component epoxy resin adhesive. The underfill adhesive comprises, by weight, 30-38 parts of epoxy resin, 8-20 parts of a curing agent, 33-46 parts of a filler, 2-5 parts of a diluent, 6-9 parts of a toughener, 0.3-0.5 part of a silane coupling agent, 0.3-0.5 part of an antifoaming agent and 0.2-0.8 part of a pigment. The underfill adhesive prepared in the invention has the advantages of low halogen content, low dielectric constant, high arc resistance, high weather resistance and the like, so packaging components have a high environmental protection property, a high electrical insulation property and a high reliability.

Owner:YANTAI DARBOND TECH

PRTV durability anti-pollution flashover paint

The invention relates to PRTV durability anti-pollution flashover paint, which comprises the following components by part by weight: 40 to 50 parts of dihydric polydimethylsiloxane, 2 to 6 parts of nano Si02, 2 to 6 parts of cross-linking agent, 0.02 to 1 part of catalyst, 20 to 30 parts of aluminum hydroxide, 5 to 8 parts of decabromodiphenyl, 40 to 50 parts of solvent and 1 to 2 parts of pigment. The paint uses dihydric polydimethylsiloxane as base rubber and has the good properties of ageing resistance, corrosion resistance, water resistance, moisture prevention, no toxin, insulation, shake resistance, excellent simulation, demolding, extremely low contractibility rate and the like. Because nano Si02 is added to the paint, the weather fastness, the ultraviolet resistance and the ageing resistance of a coating are improved. The aluminum hydroxide and the decabromodiphenyl are used as excellent composite fire retardants for the paint, thereby remarkably enhancing the arc resistance of the paint and helping to increase the thickness of the coating. Therefore, inflaming retarding and ageing resistance become more stable.

Owner:TIANJIN DINGXUANKE IND TRADE

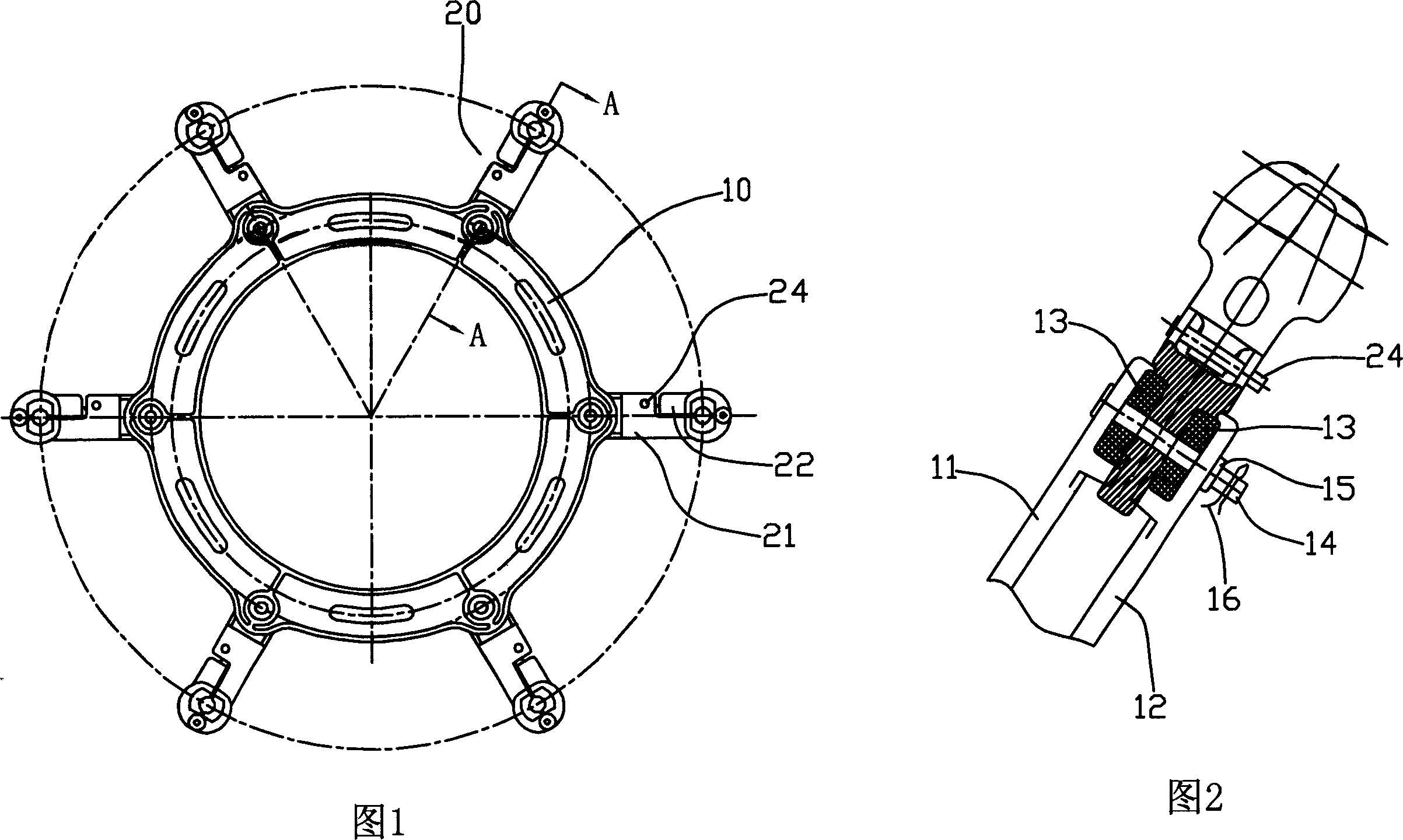

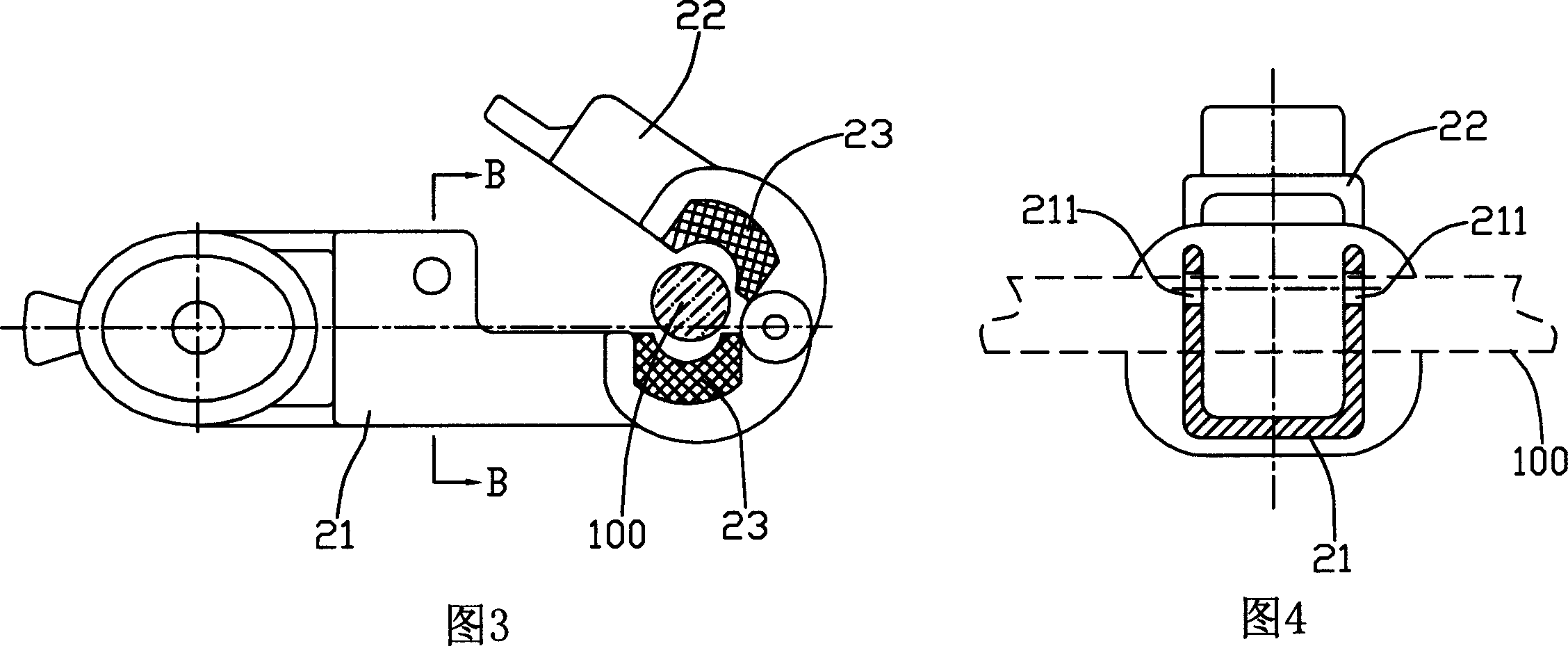

Six breaks spacer for +/- 800KV DC line

InactiveCN101013806AIncrease centripetal forceImprove interchangeabilityMaintaining distance between parallel conductorsEngineeringHigh pressure

The invention relates to transmission circuit fix wares and to one six crack isolation bar of+-800KV, which comprises central frame and six wire clamper round center, wherein, the wire clamper main part and pressure cover are hinged on front end; the wire clamper main part and pressure cover are set with rubber tilt, wherein, the central rack is composed of two symmetric frames; two frame inner side is set with arc resistance rubber; the clamper back end is between two rubber through bolt, bolt top and close bolt and central frame.

Owner:GUANGZHOU XYHY ELECTRIC POWER LINE EQUIP

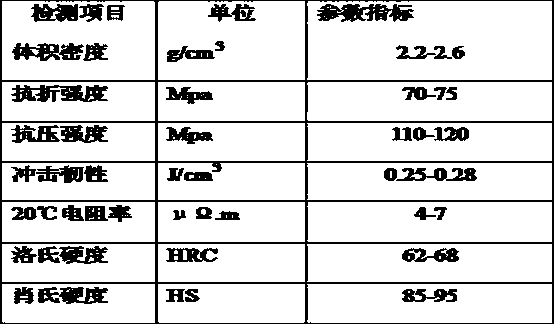

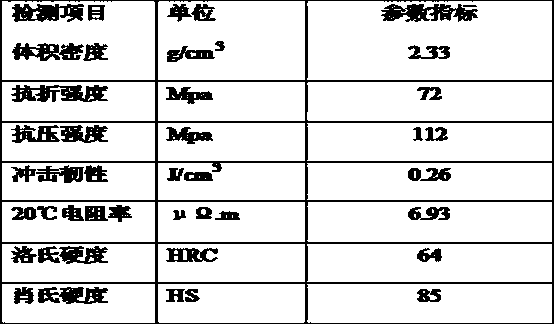

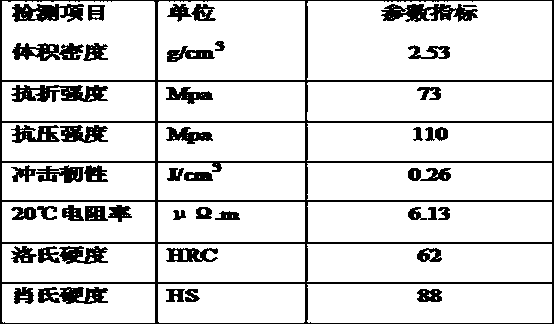

Preparation method of high-speed locomotive pantograph carbon slide plate material

The invention relates to the field of an electric locomotive, in particular to a preparation method of a high-speed locomotive pantograph carbon slide plate material. The preparation method of the material comprises the steps of graphite powder copper plating, mixing and kneading, shaping, roasting, soaking and secondary roasting. In the mixing and kneading process, aggregates are prepared from 30to 50 percent of graphite powder with the granularity being 65 to 71 mu m and 3 to 5 percent of carbon black with the particle diameter being 40 to 50 mu m; bonding agents are 15 to 20 percent of resin bonding agents; impregnating agents are impregnating asphalt; the copper plating graphite powder content is 20 to 30 percent. The graphite copper plating stable process is used; the graphite has good conductivity, arc resistance, friction resistance and anti-corrosion performance; the service life is long; the friction force on a conducting wire is small; the conducting wire can be well protected; the material can completely replace a conventional carbon slide plate to be used.

Owner:安徽锦美碳材科技发展有限公司

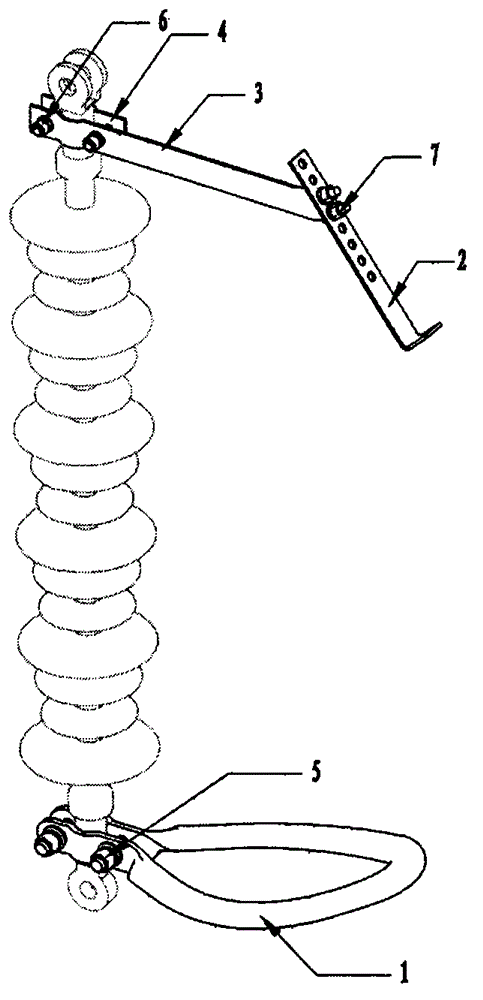

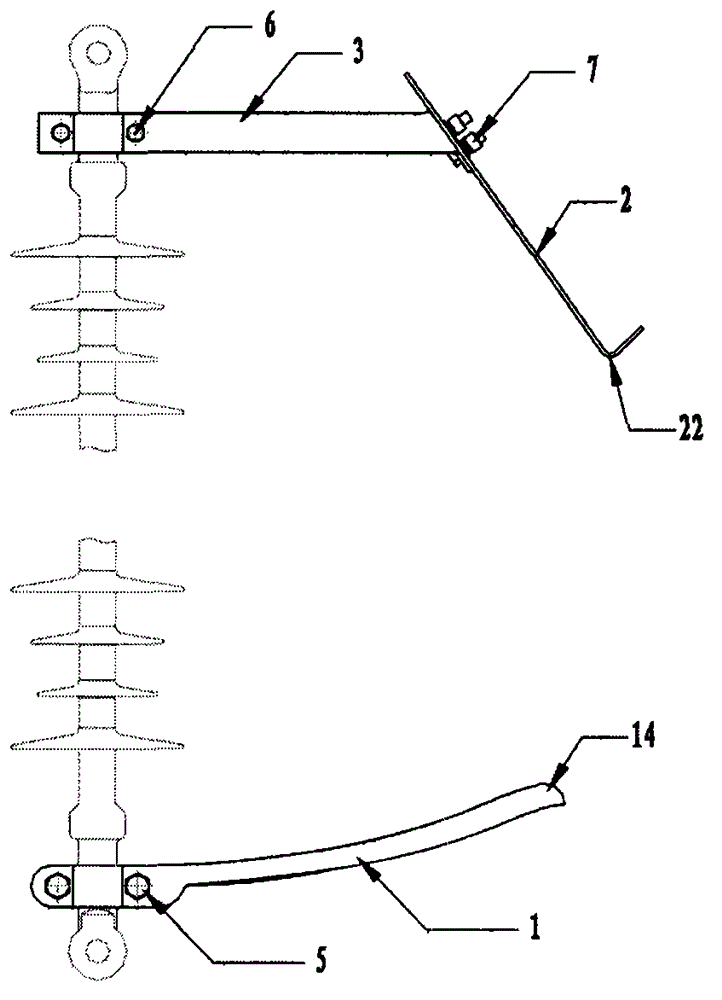

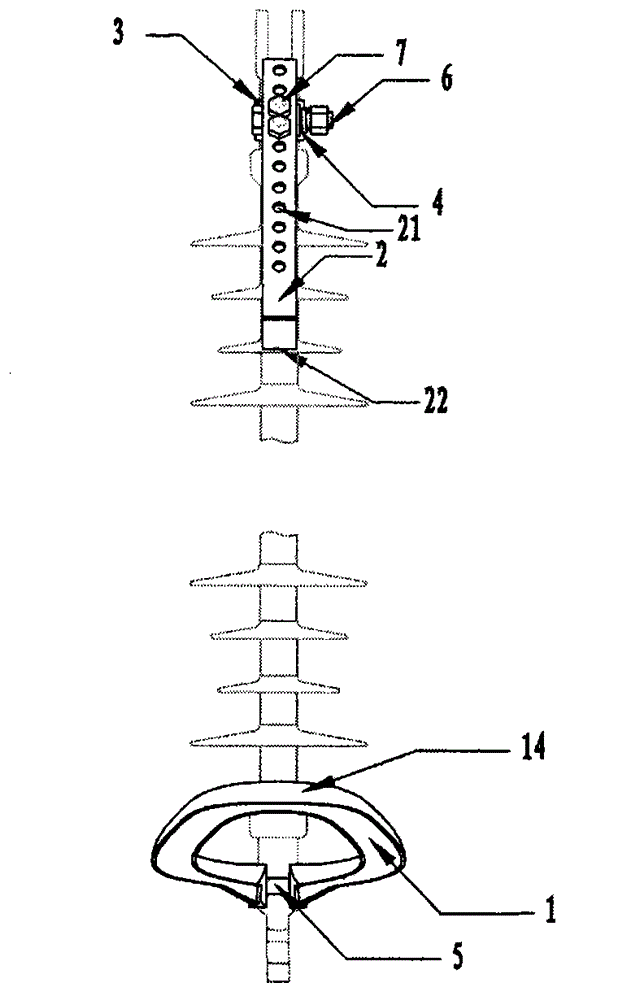

Discharge gap device

InactiveCN102751056AStable arc starting voltageKeep Dry Arc DistanceInsulatorsOvervoltageComposite insulators

The invention discloses a discharge gap device for preventing surface flashover of an insulator, which can solve the problem that the surface flashover of the insulator is cuased under the overvoltage to burn the insulator. The technical scheme of the invention is as follows: the discharge gap device comprises a high voltage arc initiating ring, an arcing horn, a pressing plate and a fastening piece; the high voltage arc initiating ring is arranged at a high voltage end of the insulator; a fixing plate and the pressing plate are arranged at a low voltage end of the insulator; and the arcing horn is connected with the fixing plate by the fastening piece, and the other end of the arcing horn bends downwards to form a discharge gap with the high voltage arc initiating ring. The discharge gap device not only can be directly fixed on fittings of two ends of a composite insulator, but also can be fixed on a cross yoke plate by installing holes to be connected with a ceramic insulator. The invention provides the novel discharge gap device adaptive to the composite insulator and the ceramic insulator and having rapidness in installation, adjustable gap, stable discharge voltage and good arc resistance and arc quenching performance.

Owner:GULIFA GRP CO LTD +1

Consumable electrode arc-welding machine

ActiveCN1942279ADc-dc conversionArc welding apparatusElectrical resistance and conductanceSputtering

In a consumable electrode type arc welding machine, an arc resistance calculator for calculating an arc resistance from the welding current and the welding voltage is provided. The welding current and the welding voltage are controlled by making use of a short-circuit waveform control signal and an arc waveform control signal which change in accordance with the arc resistance signal. This suppresses the sputtering phenomenon and ensures the stability of arc. Furthermore, if arc resistance signal goes higher than a certain specific level for a certain time in an arc period, a constant-current control signal is output so as to control the welding current to be a constant-current with a certain current value that is higher than that output at the moment when arc waveform control signal is output. This prevents the occurrence of an arc break.

Owner:PANASONIC CORP

High-arc resistance epoxy insulating material and preparation method thereof and insulator

ActiveCN105504685AGood arc resistanceIncrease the number of pressure operationsPlastic/resin/waxes insulatorsMetallic oxidesPolyethylene glycolGlass transition

The invention discloses a high-arc resistance epoxy insulating material and a preparation method thereof and an insulator. The epoxy insulating material is prepared from the following raw materials in parts by mass: 1 part of composite epoxy resin, 0.51-0.55 part of curing agent methyl tetrahydrophthalic anhydride and 3.25-3.45 parts of aluminum oxide, wherein the composite epoxy resin is a mixture of phenolic aldehyde modified bisphenol A epoxy resin, polyethylene glycol modified bisphenol A epoxy resin and diphenolic acid modified bisphenol A epoxy resin. The epoxy insulating material is equivalent to traditional materials in glass-transition temperature, tensile strength and electric strength, the arc resistance reaches 237s, and after a 252kV circuit breaker is switched on / off under voltage for over 3243 times, flashover appears behind; and the epoxy insulating material has excellent arc resistance, the operation times of a high-voltage circuit breaker under voltage is remarkably increased, the service lives of internal epoxy insulating components are prolonged and reliability of the internal epoxy insulating components is improved, and the maintenance and overhauling cost of a power station is reduced.

Owner:PINGGAO GRP +2

Lightweight, dual hazard fabrics

Lightweight fabrics with a balance of high thermal properties, especially arc resistance and flash fire resistance, on the one hand, and durability and comfort properties, on the other hand, are disclosed. Articles, such as garments and linen, made from the lightweight fabrics are also disclosed. Spun yarns made with an intimate blend of fibers including flame resistant fiber, fire-resistant hydrophilic fibers, and a low level of anti-static fibers are described. The lightweight fabrics are particularly useful in garments for utility workers, industrial workers, military personnel, and firefighters.

Owner:NAT SAFETY APPL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com