Consumable electrode type gas shielded arc welding control apparatus and welding control method

A gas shielding and electrode consumption technology, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of small particle splashing, failure to fully prevent droplet detachment detection errors, etc., and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

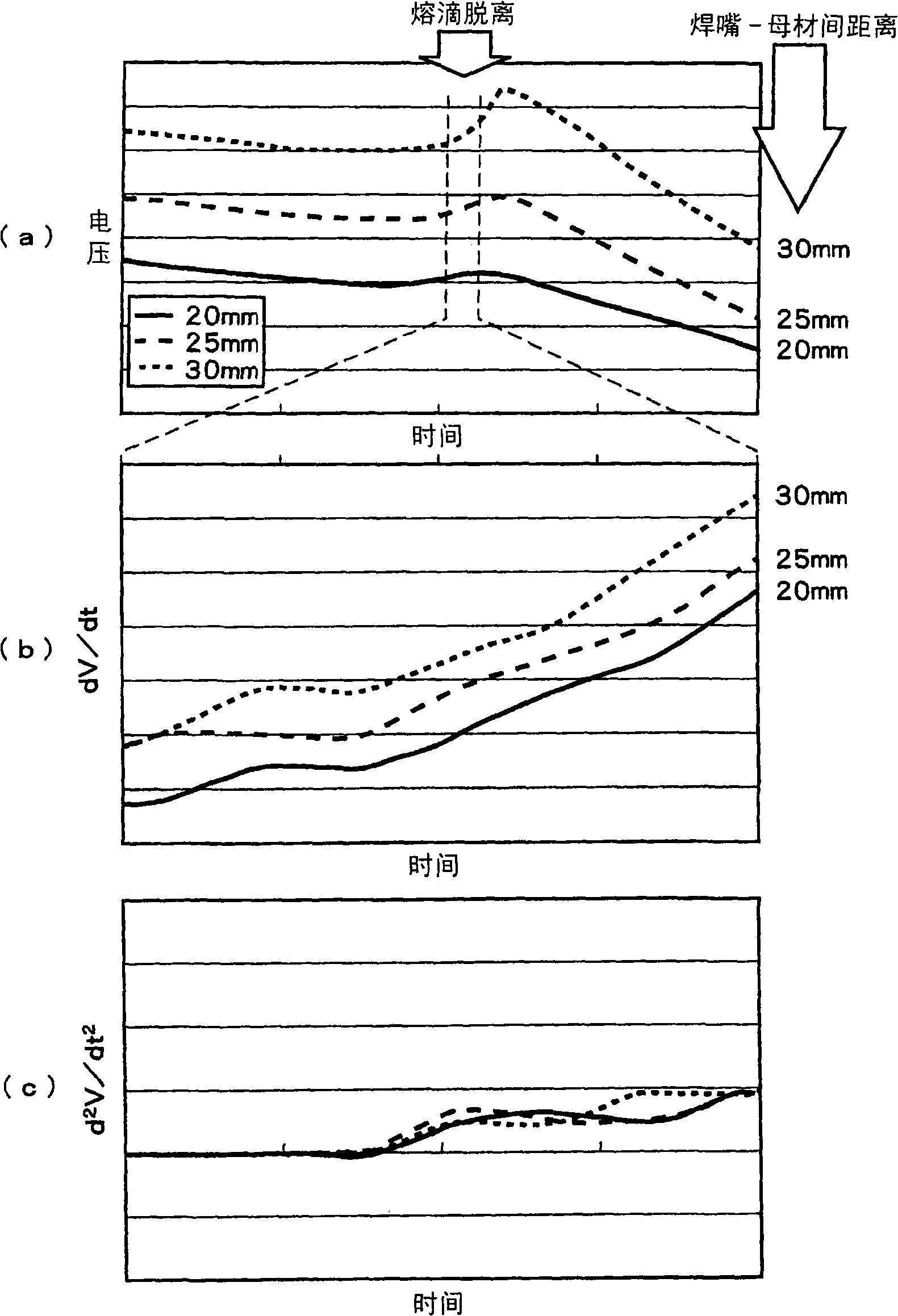

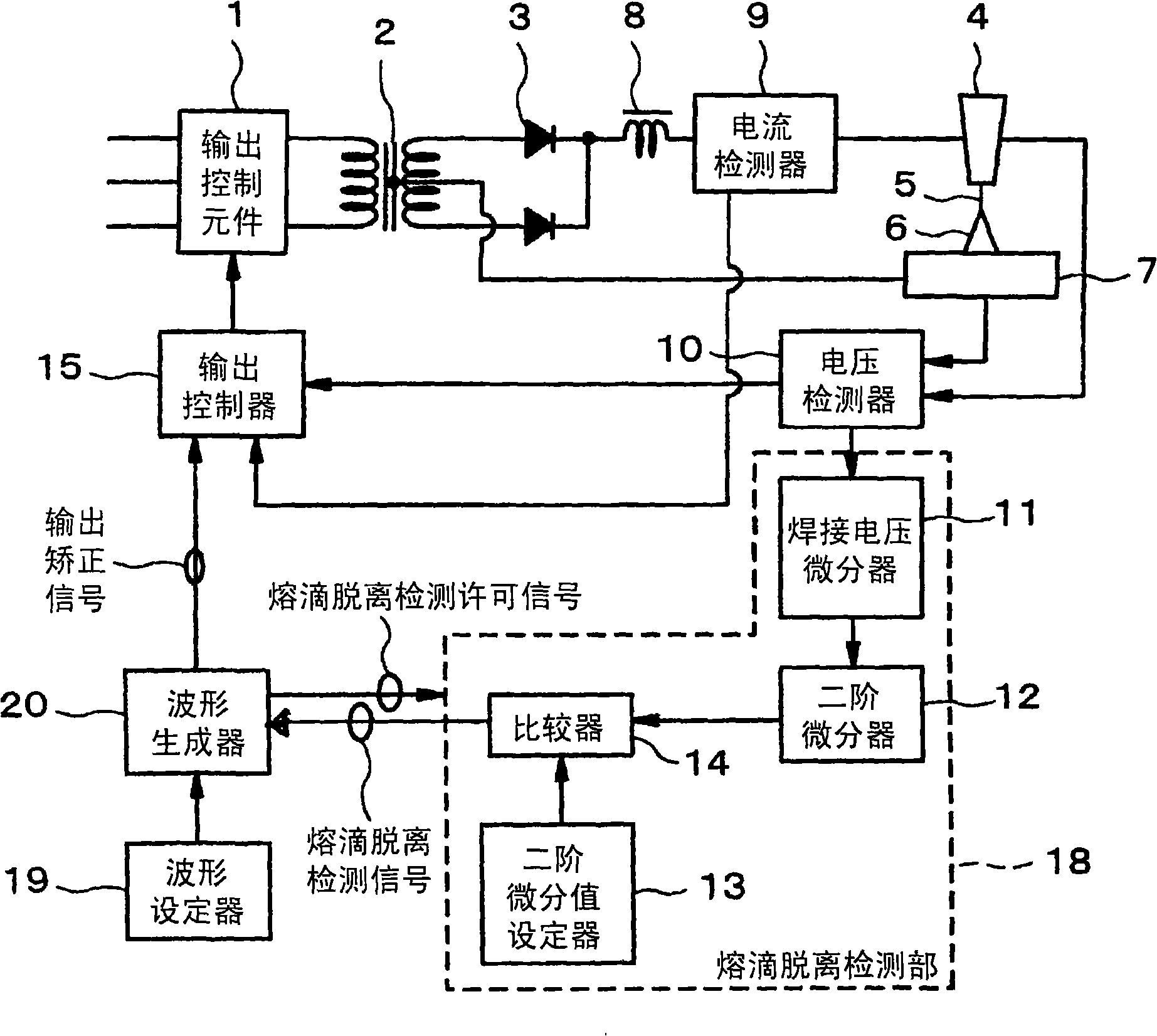

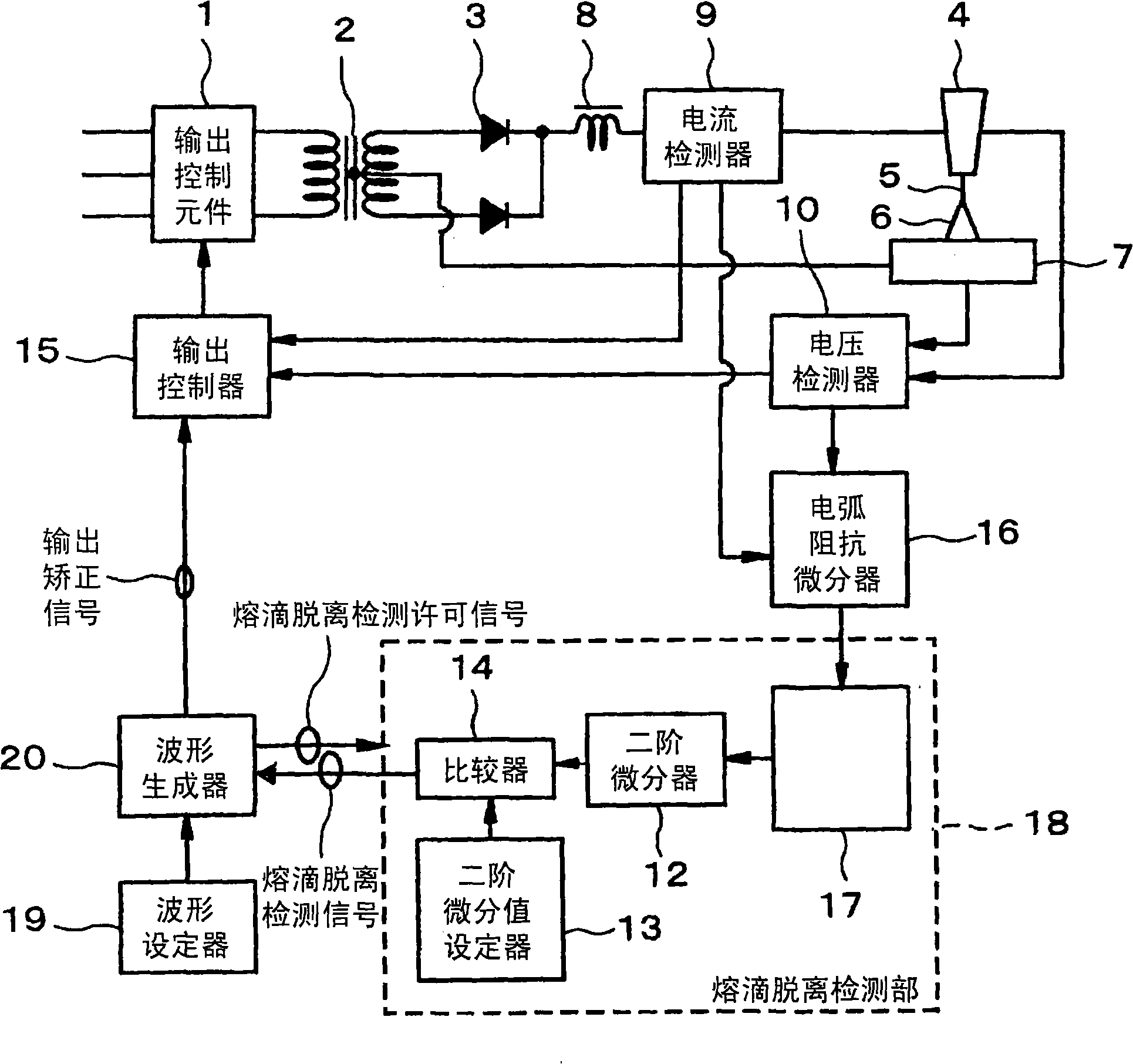

[0036] use figure 2 and image 3 The welding control devices of the first and second embodiments shown use a solid wire with a wire diameter of 1.2 mm as the consumable electrode wire, and use MAG (80% Ar+20% CO2) as the shielding gas. 2 ) gas for gas shielded arc welding. At this time, the welding current and voltage waveform and the time second order differential value of welding voltage d 2 V / dt 2 , The time second order differential value d of arc resistance 2 R / dt 2 , the detachment detection signal waveform is displayed on the Figure 4 (a), (b). Welding conditions were an average current of 240 A, an average voltage of 30 to 32 V, a welding speed of 30 cm / min, and a welding wire protrusion length of 25 mm.

[0037] exist Figure 4 Shown in (a), capture d 2 V / dt 2 or d 2 R / dt 2 The change of the welding current is switched to 120A immediately after the separation detection signal is output, and it returns to the original current (240A) state after 2.0ms. in...

Embodiment 2

[0039] Using the welding control devices of the first and second embodiments, a solid wire with a wire diameter of 1.2 mm is used as the consumable electrode wire, and CO is used as the shielding gas. 2 , for pulse arc welding. Welding current and voltage waveform in this welding, time second order differential value d of welding voltage 2 V / dt 2 , the detachment detection signal waveform is displayed on the Figure 5 (a), (b). in addition, figure 2 Indicates the pulse waveform. as it should Figure 6 As shown, the pulse peak current Ip1, Ip2 and pulse width Tp1, Tp2 are two different pulse waveforms, which will be output alternately. Figure 5 The first pulse (Ip1, Tp1) in makes the droplet detach, Figure 5 The second pulse ( Ip2 , Tp2 ) in , enables droplet formation, whereby one droplet transfer can be achieved per cycle. During the peak period or the falling slope period of the first pulse, the droplet detachment permission signal is output, and immediately after...

Embodiment 3

[0041] use figure 2 and image 3 The welding control device shown uses a solid wire with a wire diameter of 1.2 mm as the consumable electrode wire, and uses MAG (80% Ar+20% CO2) as the shielding gas. 2 ) gas shielding gas arc welding, and the use of 100% CO 2 Gas pulse arc welding. In downward surfacing welding, the welding is carried out under the conditions of swing width 6.0mm and swing frequency 2Hz. During welding, the protruding length of the welding wire changes at all times, compared with the existing technology (detected by the time differential value dV / dt of the voltage) ) and the present invention (time second order differential value d of the same voltage 2 V / dt 2 Detection) droplet detachment detection success rate. The average current was 300A, the voltage was set to an appropriate voltage according to each shielding gas, and the welding speed and wire protrusion length were the same as those in Example 1 and Example 2. Using a high-speed camera image, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com