High-conductivity, arc-resistance and free-cutting leadfree tellurium copper alloy material

An alloy material and anti-arc technology, applied in the field of tellurium copper alloy materials, can solve the problems of high cost of bismuth brass, unfavorable processing and production, high price, and achieve the effects of good cold and hot processing performance, excellent electrical conductivity and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

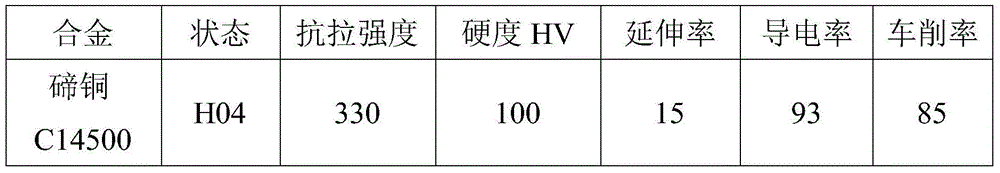

Image

Examples

Embodiment 1

[0048] The present invention is prepared according to the following steps:

[0049] 1) Melting in a power frequency induction furnace: After melting the melting channel of the electric furnace, gradually add industrial pure copper. After the solid copper is melted, raise the temperature of the molten copper to 1200°C, and cover it with 15cm thick charcoal for heat preservation.

[0050] 2) Tellurium infiltration

[0051] Wrap 0.5 wt% of pure tellurium and press it into the furnace bottom of a power frequency induction furnace near the mouth of the melting channel. At this time, the furnace temperature is 1200° C. and the time is 60 minutes.

[0052] 3) Add trace elements

[0053] The trace element P 0.01wt% is melted and casted in the atmosphere condition, and the trace element master alloy is infiltrated with the above-mentioned tellurium into the copper for 60 minutes, and the trace element master alloy is added. After 20 minutes, the melting of the tellurium-copper alloy l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com