Double-functional catalyst of carbon-based non-noble-metal oxygen electrode and preparation method thereof

A bifunctional catalyst, non-precious metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The problems of poor acceptability and long-term operation stability, low catalytic activity, etc., achieve the effect of easy purchase and preparation, promotion of catalytic performance, and large surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Preparation of Fe-containing non-noble metal catalysts

[0037] Weigh the two substances according to the mass ratio of graphene oxide to vulcan XC-72 carbon black 3:1, and weigh FeSO with the mass ratio of vulcan XC-72 carbon black 2:5 4 .7H 2 O, weigh the nitrogen-containing heterocyclic compound at a mass ratio of 80:1 to vulcan XC-72 carbon black, disperse the above-mentioned substance in solvent water (add a small amount of ethanol to promote dispersion), and vigorously sonicate until it is evenly stirred, and then spin evaporate at 60 °C Dry to obtain a gray-brown powder precursor, put the precursor in a tube furnace under the protection of high-purity Ar inert gas, and pyrolyze it at 900 °C for 1 h to obtain a black Fe- and FeO-containing x Non-precious metal catalysts.

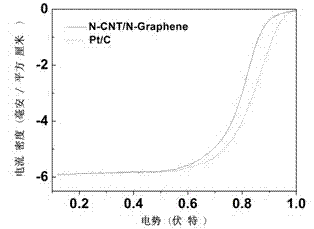

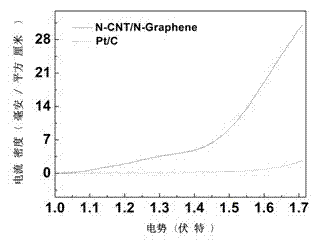

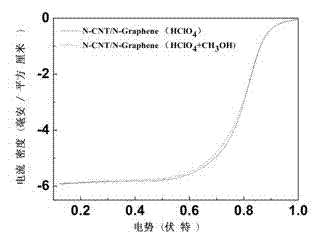

[0038] 2) Test the catalytic performance of Fe-containing non-noble metal catalysts

[0039]An appropriate amount of catalyst powder was uniformly dispersed in Nafion's isopropanol solutio...

Embodiment 2

[0049] 1) Preparation of Fe-containing non-noble metal catalyst with GO (graphene oxide) / C ratio of 4:1

[0050] Weigh the two substances according to the mass ratio of graphene oxide and vulcan XC-72 carbon black 4:1, and weigh FeSO with the mass ratio of vulcan XC-72 carbon black 2:5 4 .7H 2 O, weigh the nitrogen-containing heterocyclic compound at a mass ratio of 80:1 to vulcan XC-72 carbon black, disperse the above-mentioned substance in solvent water (add a small amount of ethanol to promote dispersion), and vigorously sonicate until it is evenly stirred, and then spin evaporate at 60 °C Dry to obtain the gray-brown powdery precursor, put the precursor in a tube furnace under the protection of high-purity Ar inert gas, and pyrolyze it at 900 °C for 1 h to obtain black Fe or FeO x Non-precious metal catalysts.

[0051] 2) Test the catalytic performance of non-precious metal catalysts

[0052] An appropriate amount of catalyst powder was uniformly dispersed in Nafion's i...

Embodiment 3

[0056] 1) Preparation of GO / C 3:2 Fe-containing non-noble metal catalyst

[0057] Weigh the two substances according to the mass ratio of graphene oxide and vulcan XC-72 carbon black 3:2, and weigh FeSO with the mass ratio of vulcan XC-72 carbon black 2:5 4 .7H 2 O, weigh the nitrogen-containing heterocyclic compound at a mass ratio of 80:1 to vulcan XC-72 carbon black, disperse the above-mentioned substance in solvent water (add a small amount of ethanol to promote dispersion), and vigorously sonicate until it is evenly stirred, and then spin evaporate at 60 °C Dry to obtain the gray-brown powdery precursor, put the precursor in a tube furnace under the protection of high-purity Ar inert gas, and pyrolyze it at 900 °C for 1 h to obtain black Fe or FeO x Non-precious metal catalysts.

[0058] 2) Test the catalytic performance of non-precious metal catalysts

[0059] An appropriate amount of catalyst powder was uniformly dispersed in Nafion's isopropanol solution, and the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com