Highly secure and non-combustible voltage-dependent resistor

A varistor, safety technology, applied in varistors, non-adjustable metal resistors, resistors, etc., can solve the problem of long fuse time of thermal fuses, and achieve the effect of preventing fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

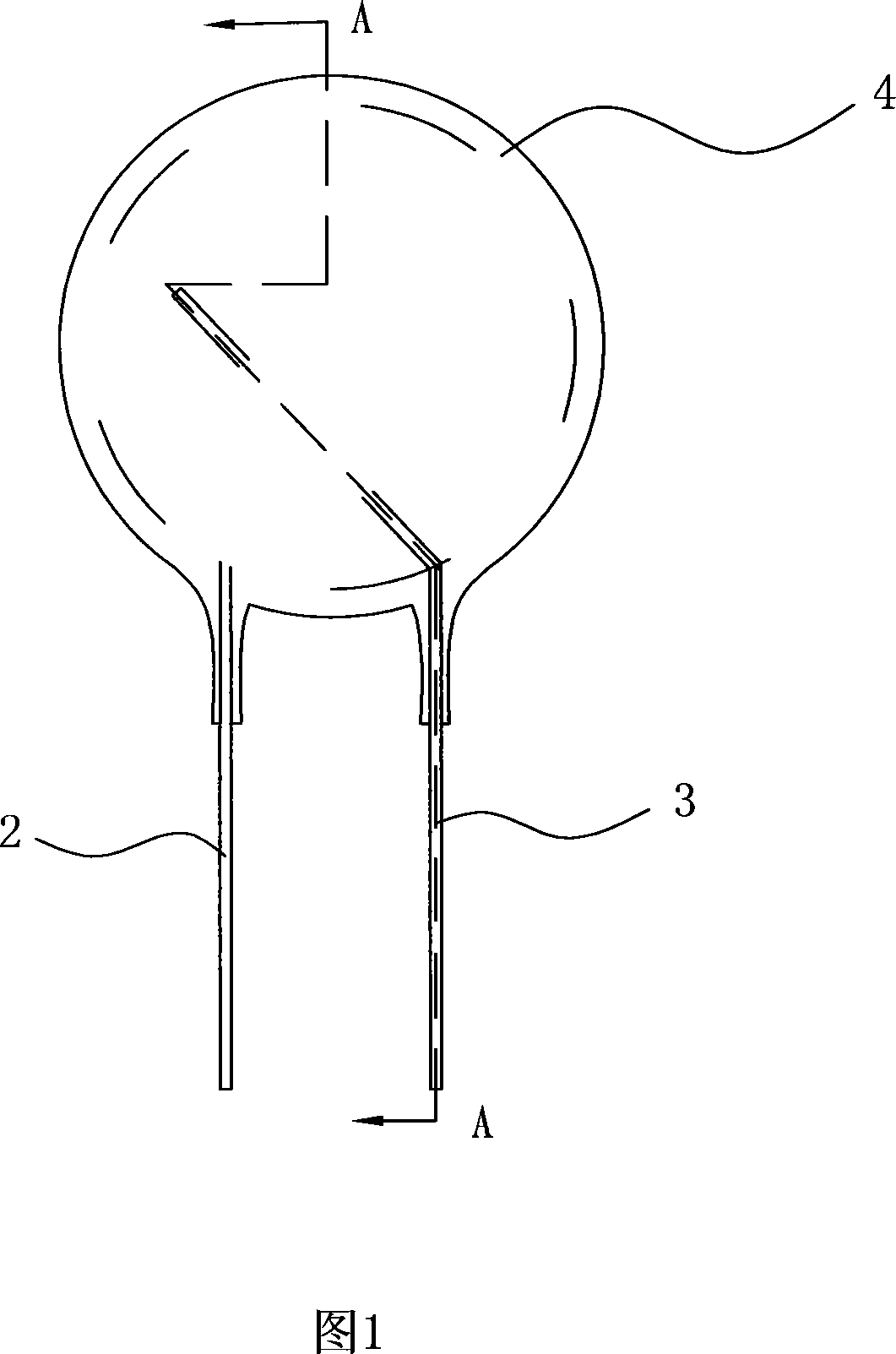

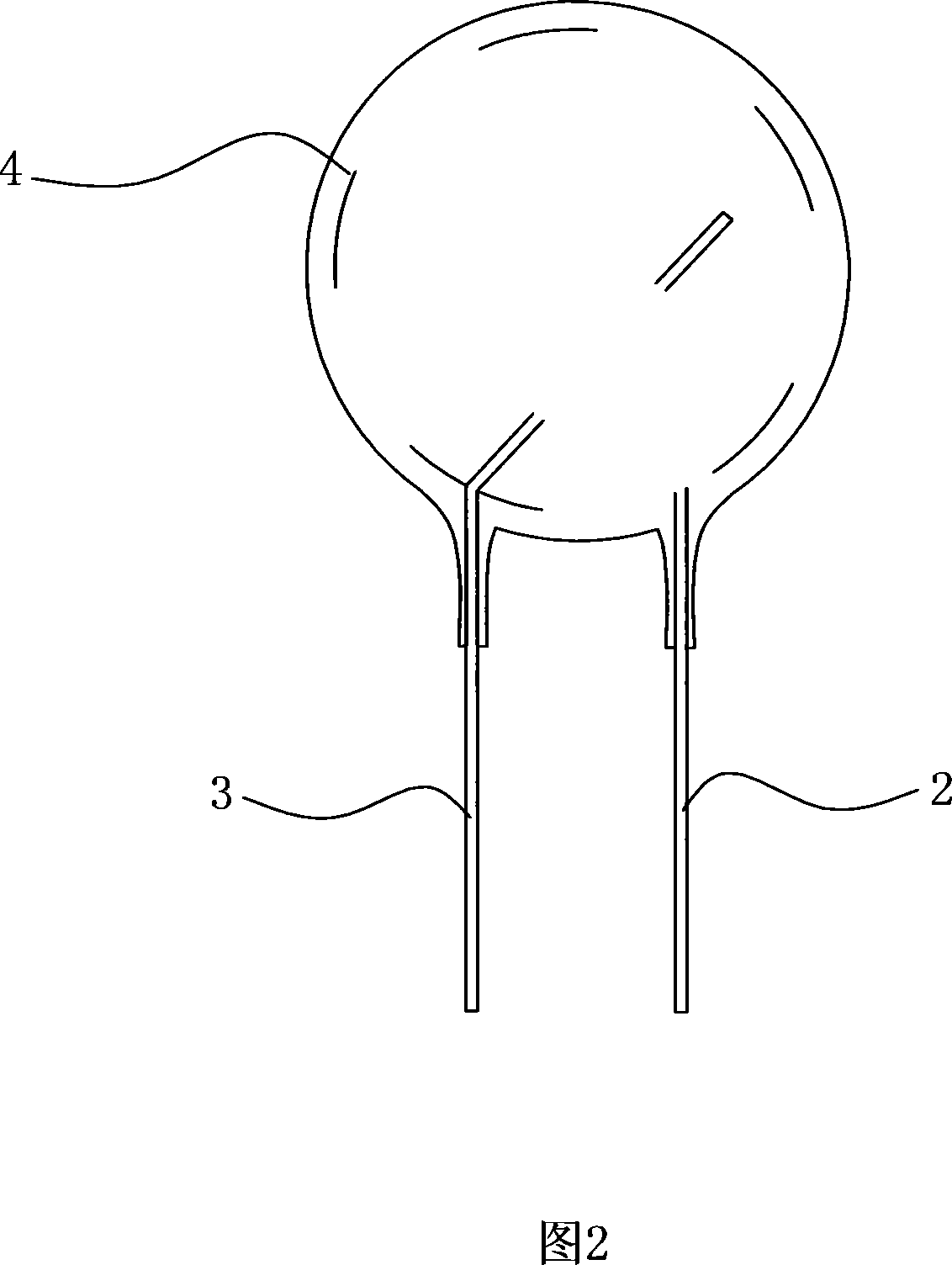

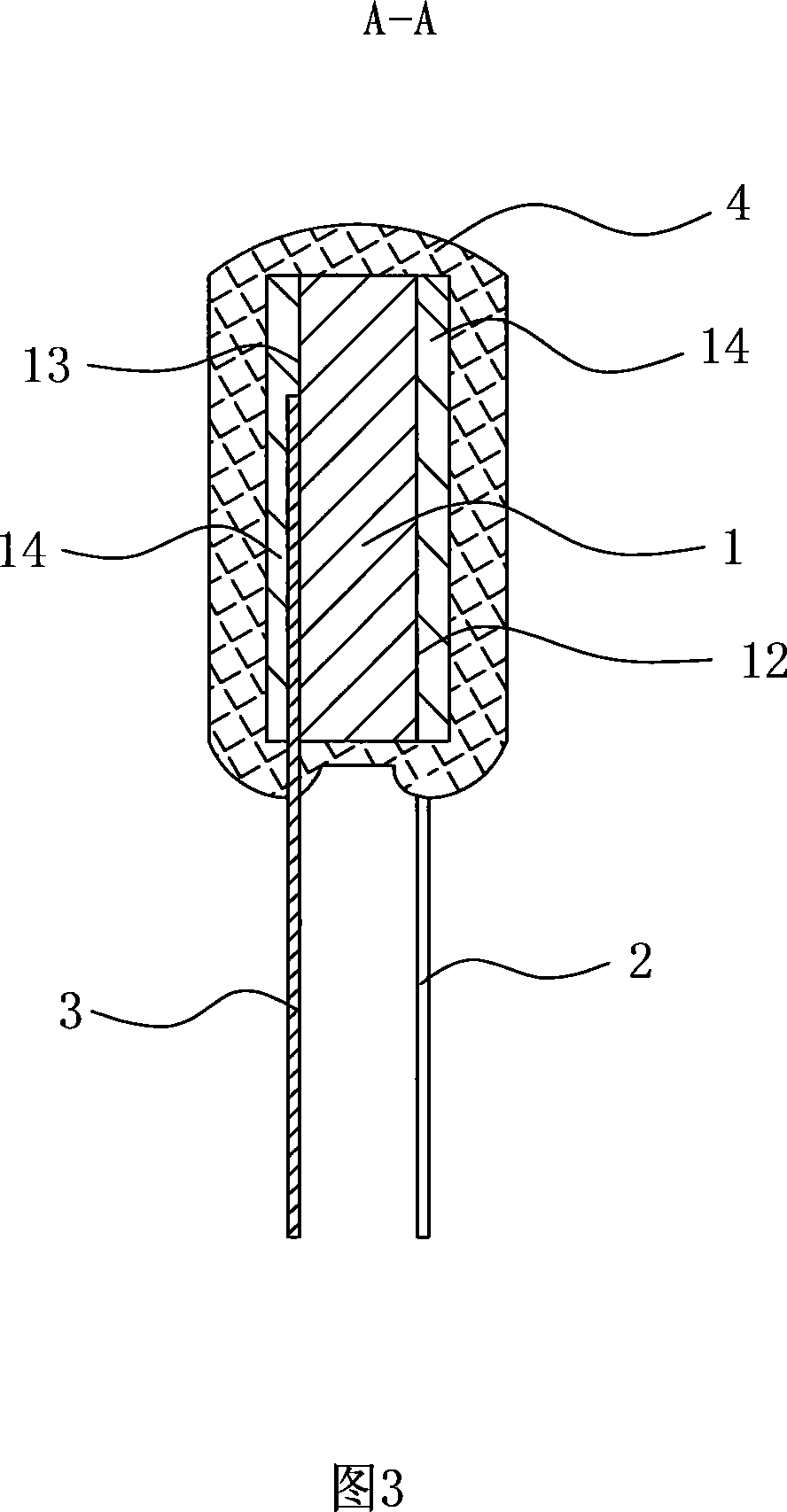

[0061] First embodiment: as shown in accompanying drawing 1 to accompanying drawing 3 a kind of high safety non-combustible varistor, it comprises the varistor substrate 1 with two opposite surfaces 12,13, is directly connected to described The first lead-out electrode 2 on one surface 12 of the varistor substrate 1 is directly connected to the second lead-out electrode 3 on the other surface 13 of the varistor substrate 1. Low-melting-point metal sheets 14 (such as tin sheets, tin alloy sheets, etc.) that can be melted when the temperature is 155-450° C. are respectively pasted on the surfaces 12 and 13, and there are no benign conductors between the low-melting-point metal sheets 14 on both sides. Phase electrical connection.

[0062] An insulating encapsulation layer 4 is wrapped on the outside of the varistor substrate 1, and one end of the first lead-out electrode 2 and the second lead-out electrode 3 respectively passes through the insulating encapsulation layer 4 and fa...

no. 2 example

[0069] Second embodiment: a kind of high safety non-combustible varistor as shown in accompanying drawing 4, it comprises the varistor substrate 1 that has two opposite surfaces 12,13, is directly connected to described varistor The first lead-out electrode 2 on one surface 12 of the substrate 1 is directly connected to the second lead-out electrode 3 on the other surface 13 of the piezoresistor substrate 1, and on the two opposite surfaces 12, 13 The low-melting-point metal conductive layers 5 that can be melted when the temperature is 155-450°C are respectively coated on them, and there is no good electrical connection between the low-melting-point metal conductive layers 5 on both sides, and the low-melting-point metal conducts electricity Layer 5 is glue or paint containing more than 50% low-melting point metal powder (such as pure tin flakes, tin-copper alloy flakes, tin-lead alloy flakes, etc.).

[0070] An insulating encapsulation layer 4 is wrapped on the outside of th...

no. 3 example

[0077] The third embodiment: a kind of high safety non-combustible varistor as shown in accompanying drawing 5, it comprises the varistor substrate 1 with two opposite surfaces 12,13, is directly connected to described varistor The first lead-out electrode 2 on one surface 12 of the substrate 1 is directly connected to the second lead-out electrode 3 on the other surface 13 of the piezoresistor substrate 1, and on the two opposite surfaces 12, 13 There are low-melting-point metal conductive layers 5 that can be melted when the temperature is 155-450° C., and an insulating coating 6 is provided between the low-melting-point metal conductive layer 5 and the first lead-out electrode 2. An insulating coating 6 is also arranged between the low-melting-point metal conducting layer 5 and the second lead-out electrode 3, and the insulating coating 6 makes the low-melting-point metal conducting layer 5 and the first lead-out electrode 2 are in an electrical insulation state, and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com