Patents

Literature

1100 results about "Electronic load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

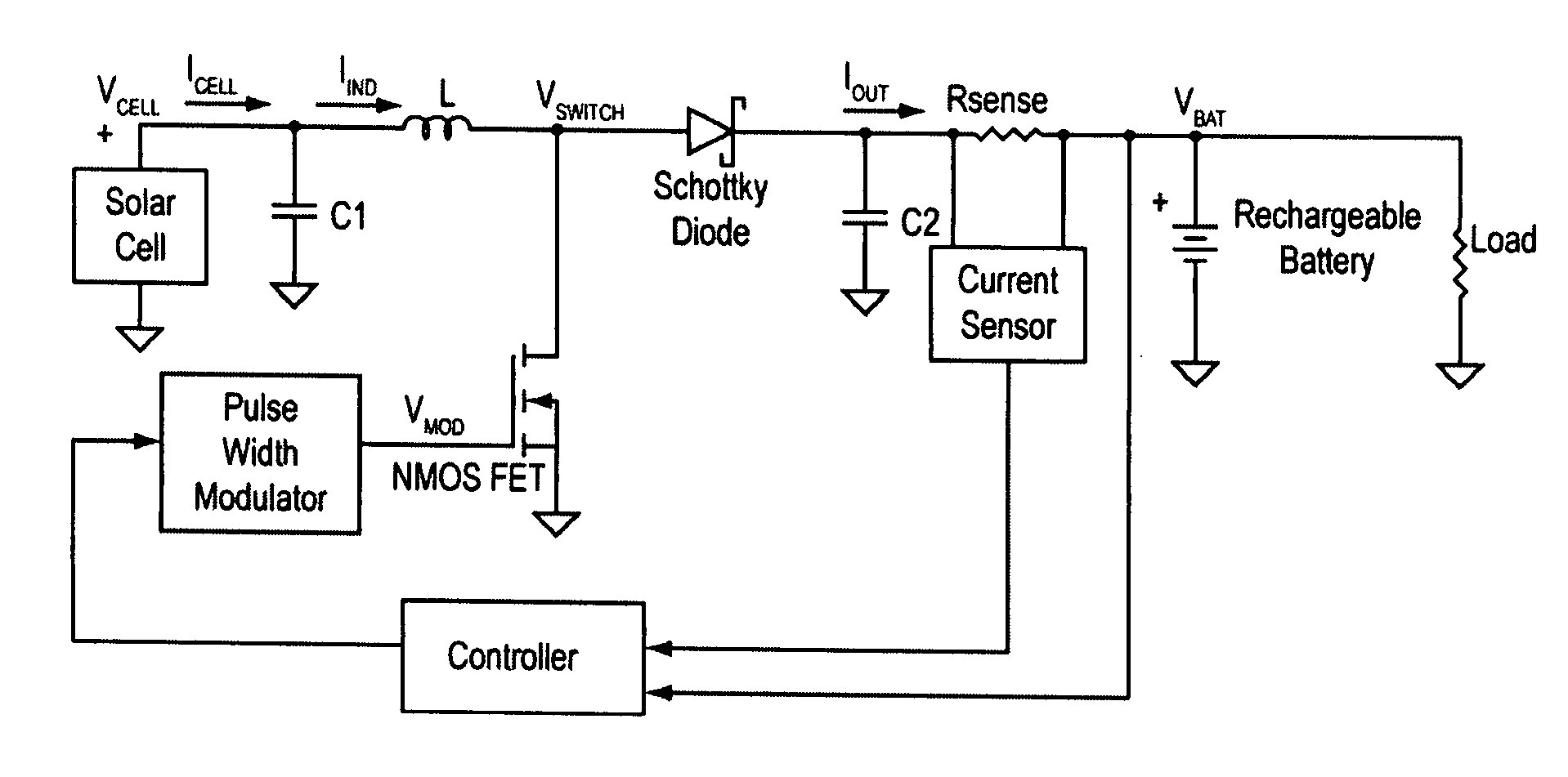

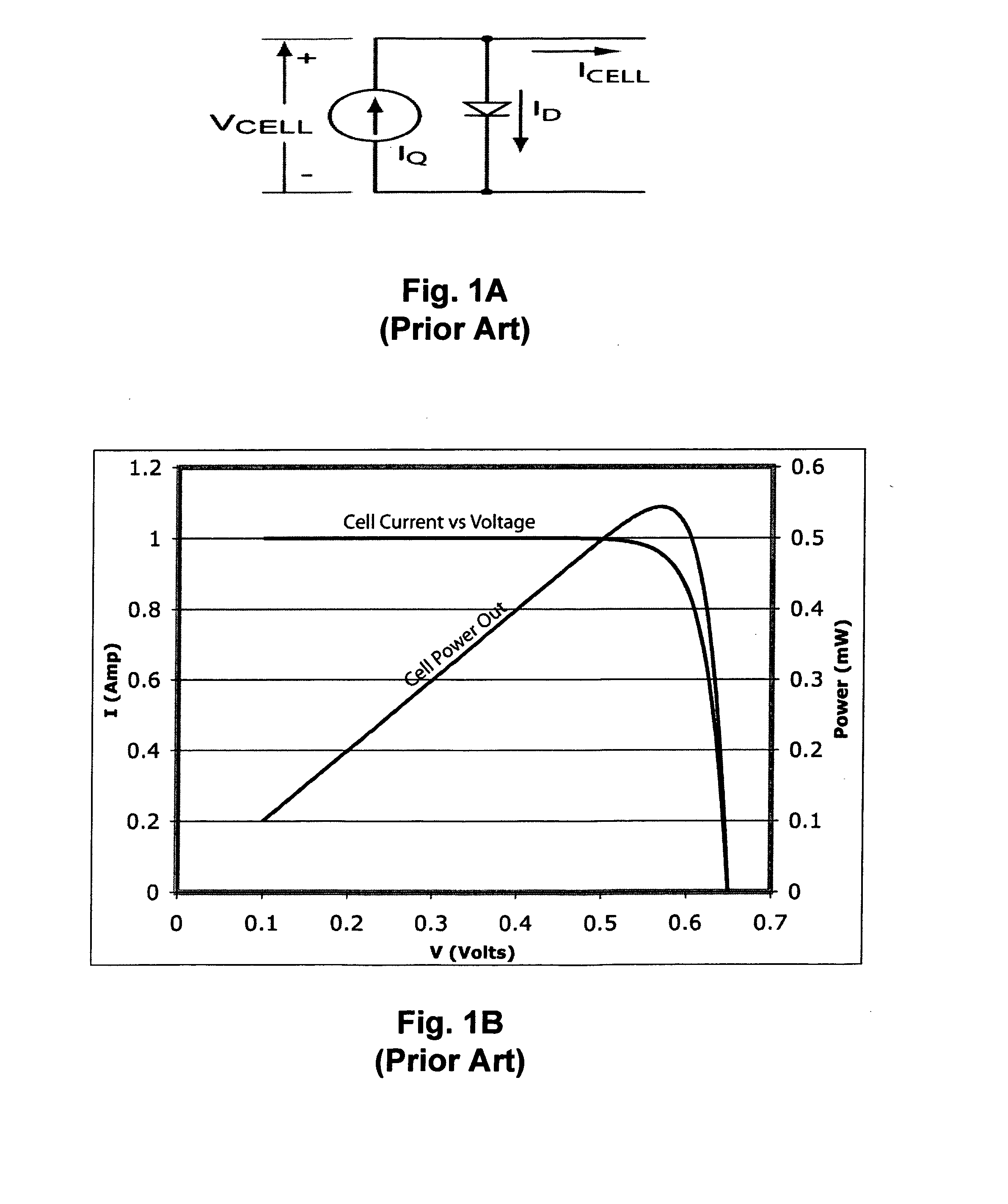

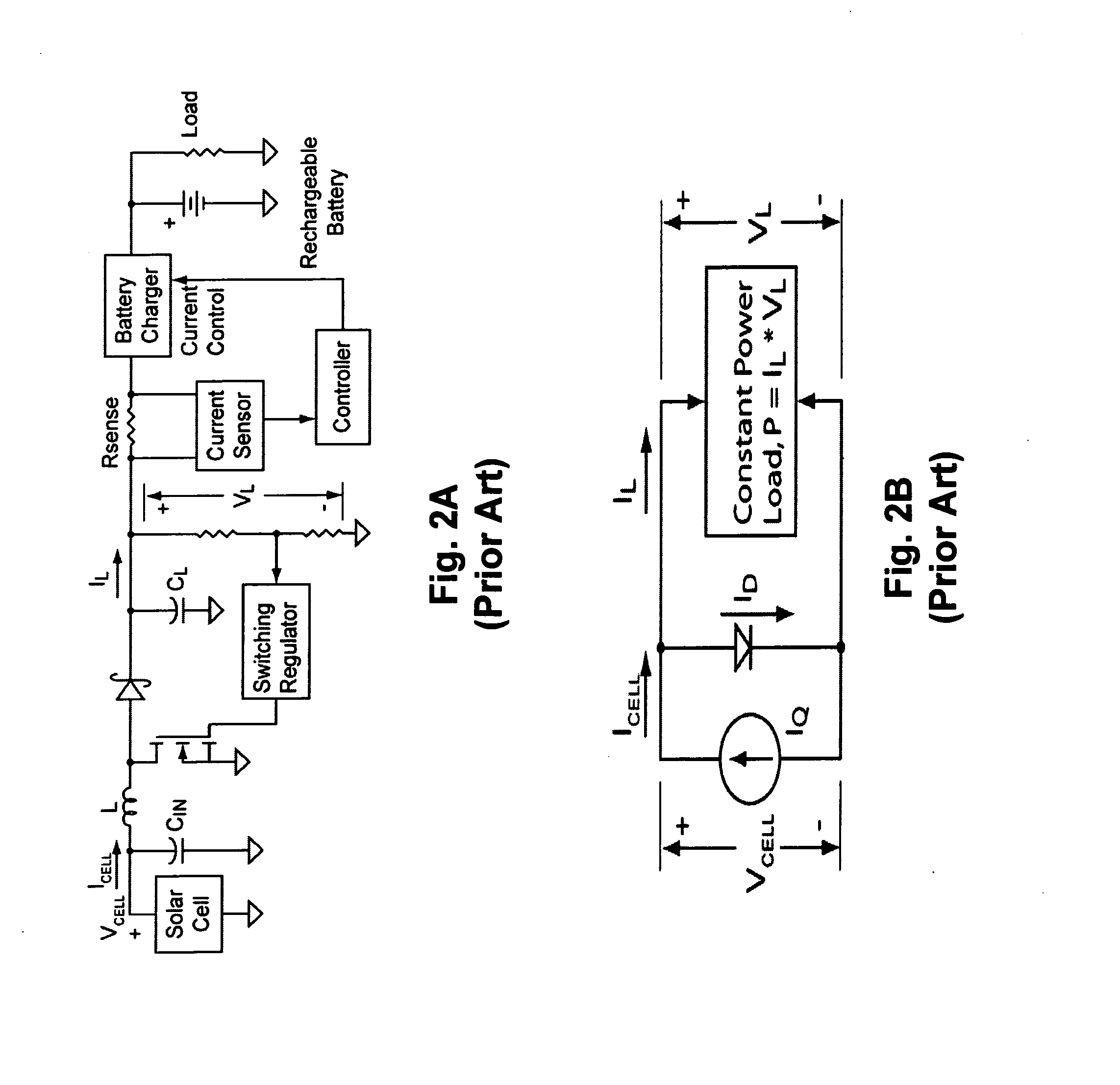

Methods and apparatuses for operating devices with solar power

ActiveUS8004113B2Batteries circuit arrangementsElectric power transfer ac networkVoltage converterElectronic load

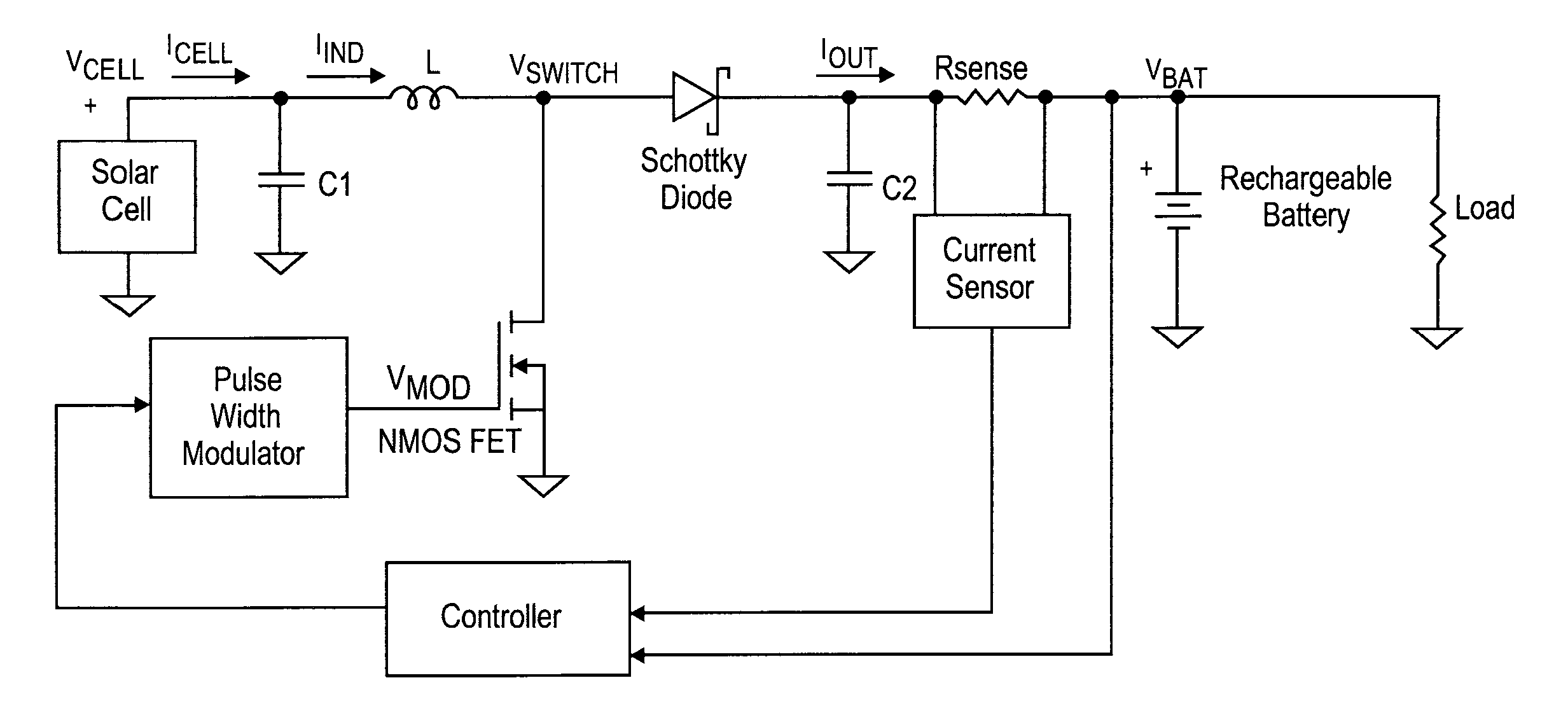

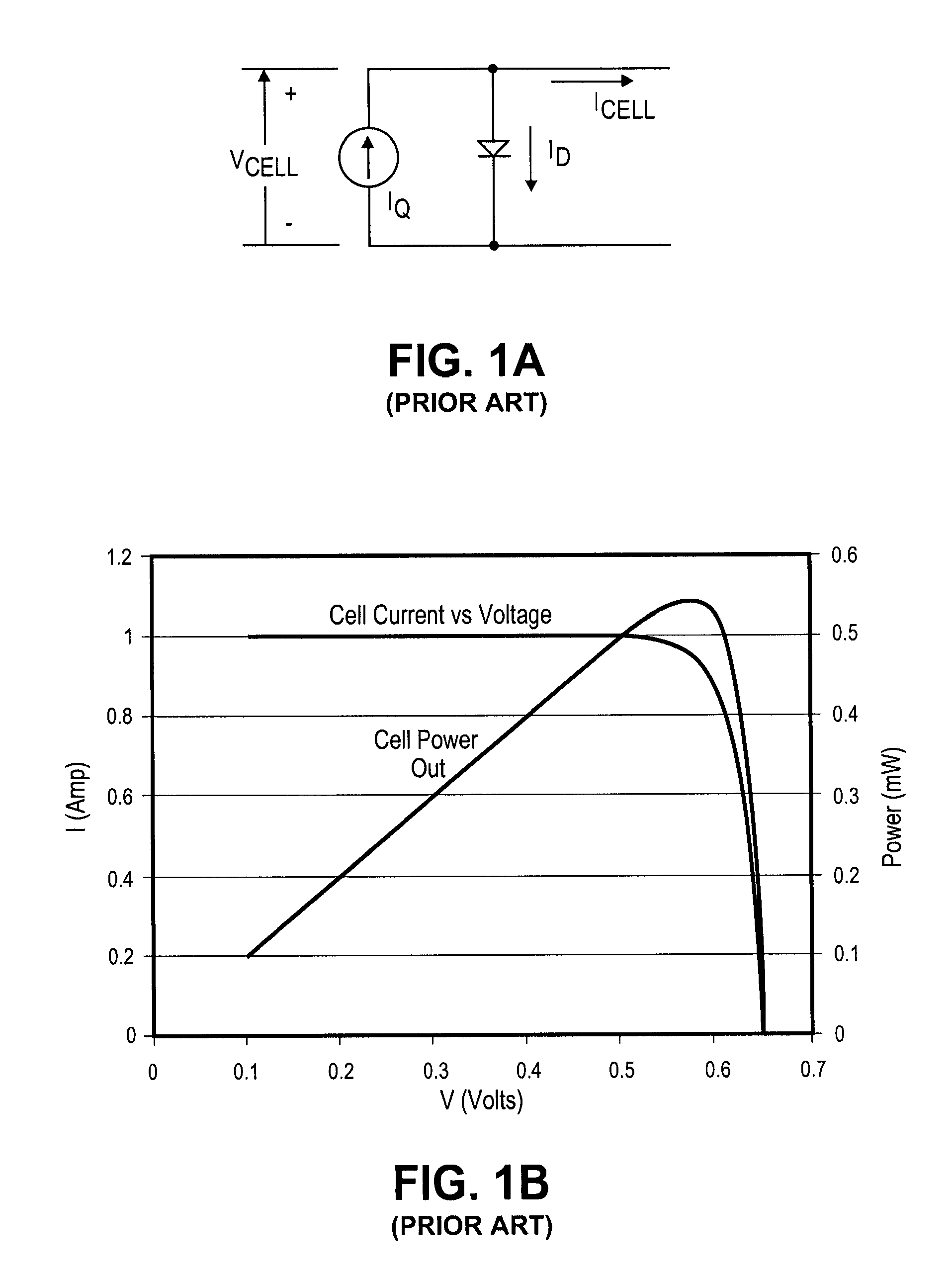

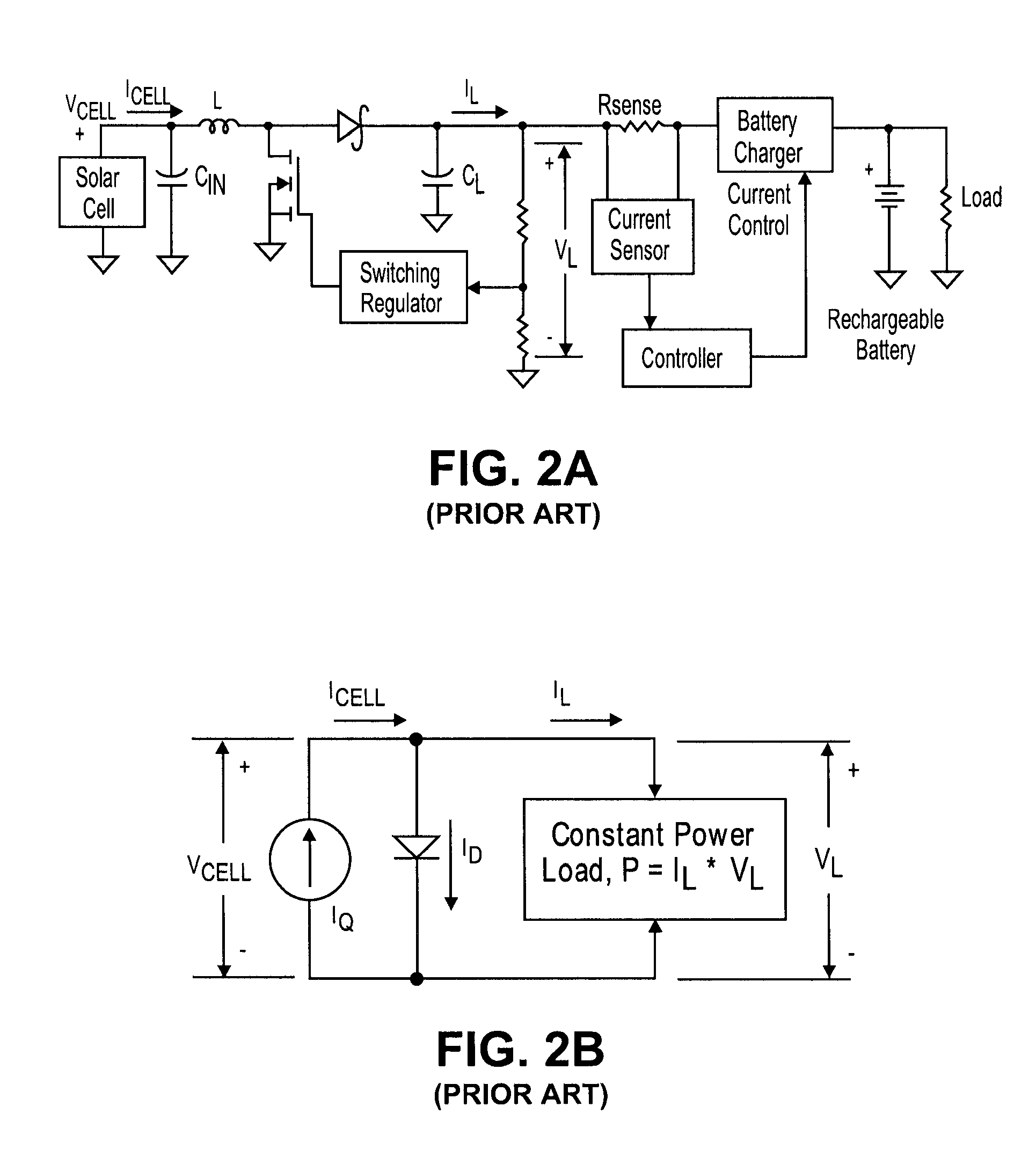

Solar power tracking techniques are described herein. In one aspect of the invention, a solar power tracking apparatus includes, but is not limited to, a voltage converter and a controller coupled to the voltage converter. The voltage converter includes an input capable of being coupled to a solar power source and an output capable of being coupled to an electronic load, such as, for example, a portable electronic device. The voltage converter is configured to monitor or detect an amount of power drawn by the electronic load at the output of the voltage converter. In response to the monitored power drawn, the controller is configured to control the voltage converter to reduce amount of power to be drawn subsequently if the monitored amount of power exceeds a predetermined threshold. As a result, the output voltage from the solar power source is maintained within a predetermined range. Other methods and apparatuses are also described.

Owner:APPLE INC

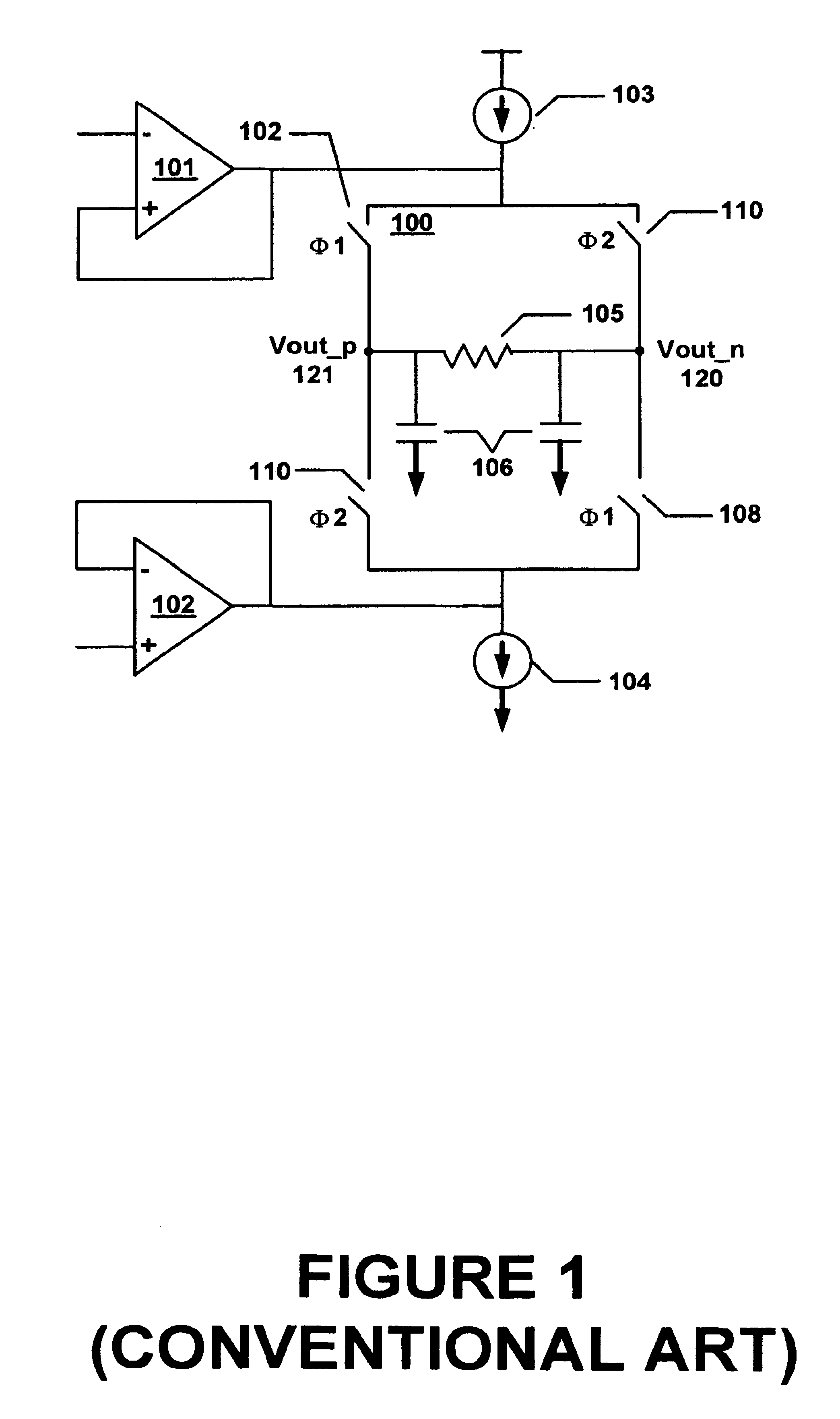

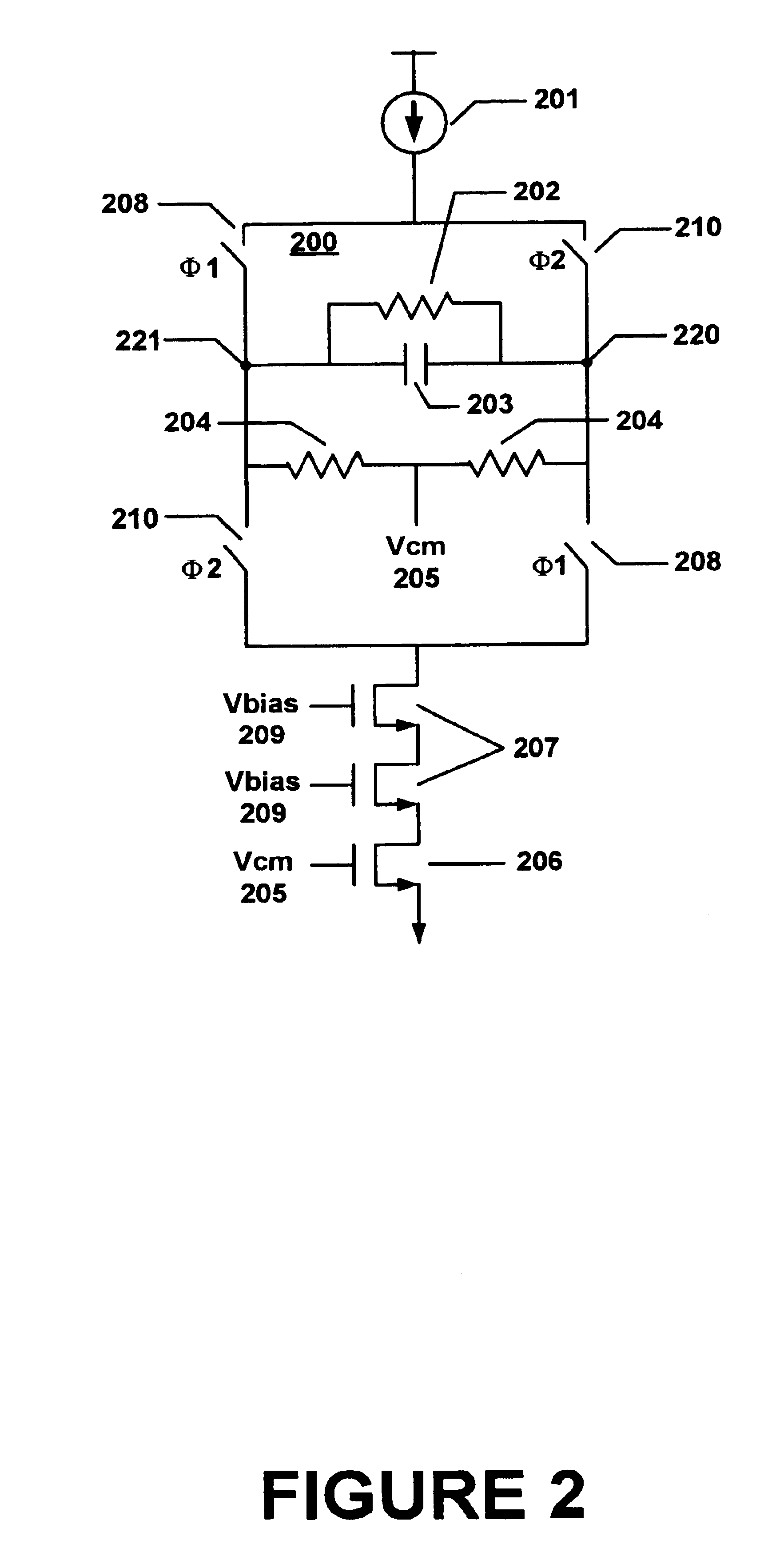

Low voltage differential signal driver circuit and method

InactiveUS6900663B1Small RC-delaysSpeed maximizationTransmission line coupling arrangementsLogic circuit coupling/interface arrangementsDriver circuitElectronic load

Embodiments of the present invention relate to a low voltage differential signal driver (LVDS) circuit which comprises a current source, logic controlled switches for controlling the driver's output, an electronic load circuit coupled across the circuit, and a common-mode resistor feedback circuit coupled across the circuit, in parallel with the RC load, for tuning the driver's impedance. The driver is enabled to operate without op-amps and achieves optimum performance at 1.8 v supply voltages.

Owner:TAIWAN SEMICON MFG CO LTD

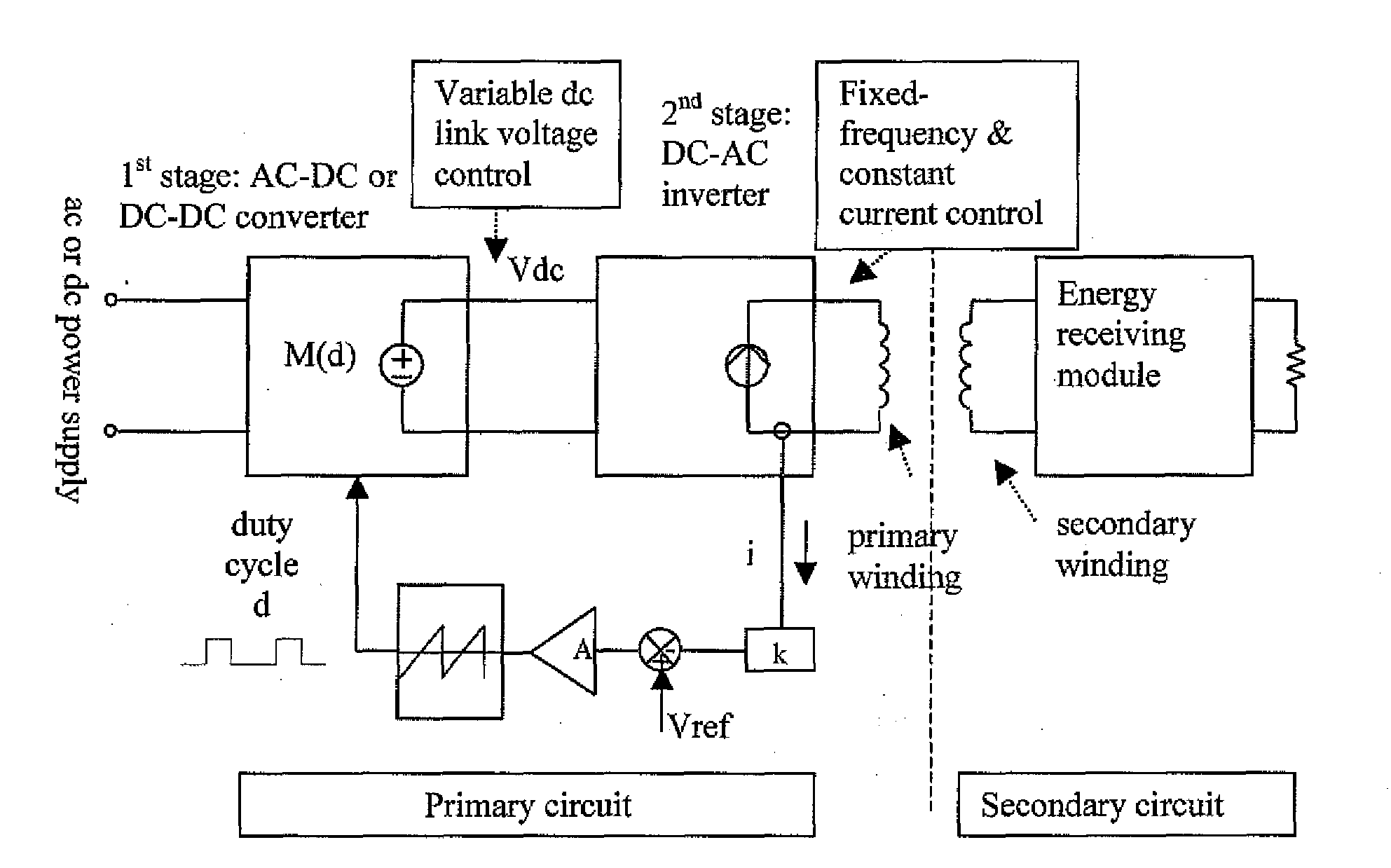

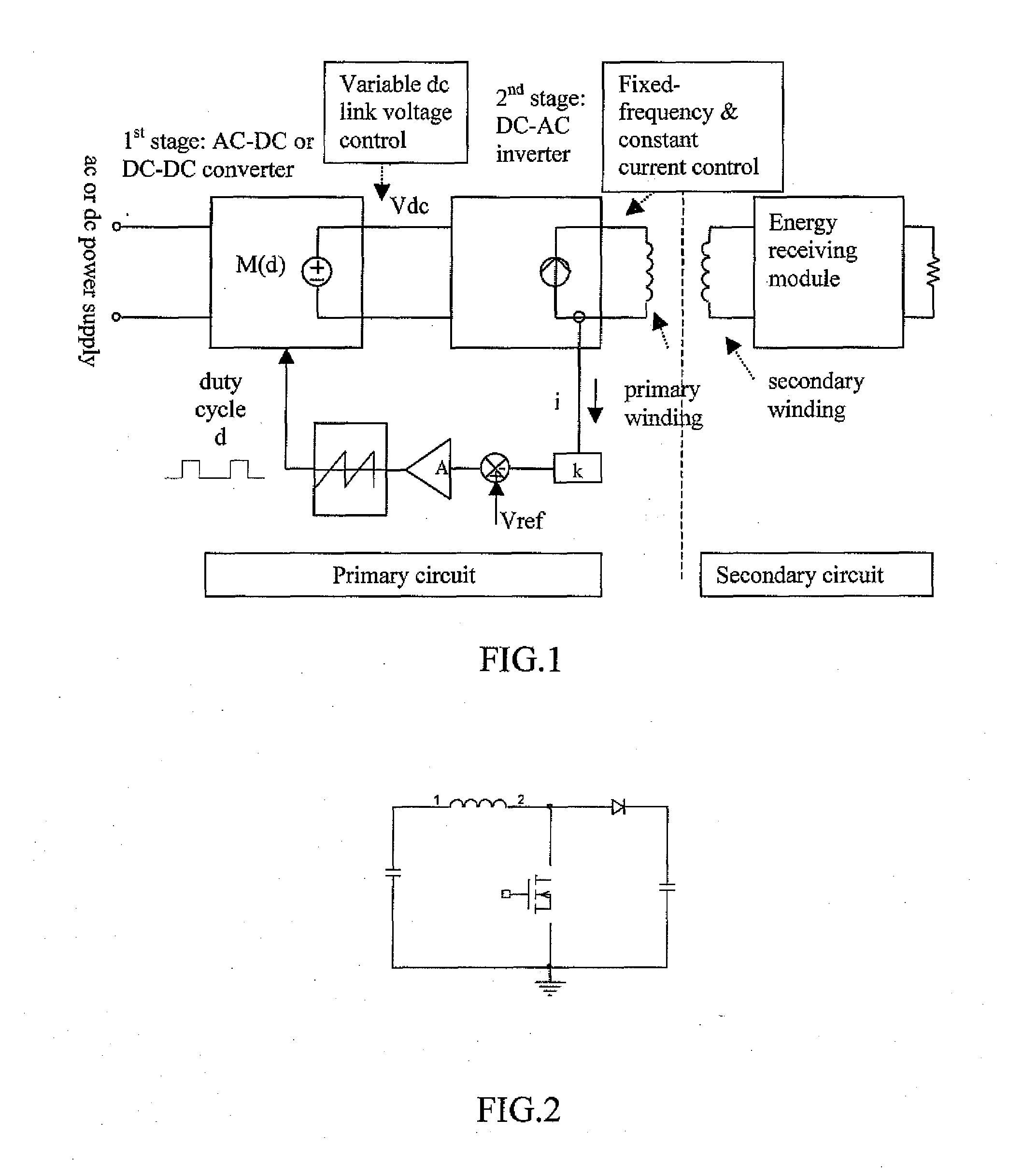

Electronic control method for a planar inductive battery charging apparatus

ActiveUS20090121675A1Batteries circuit arrangementsAc-dc conversion without reversalElectronic loadBattery charge

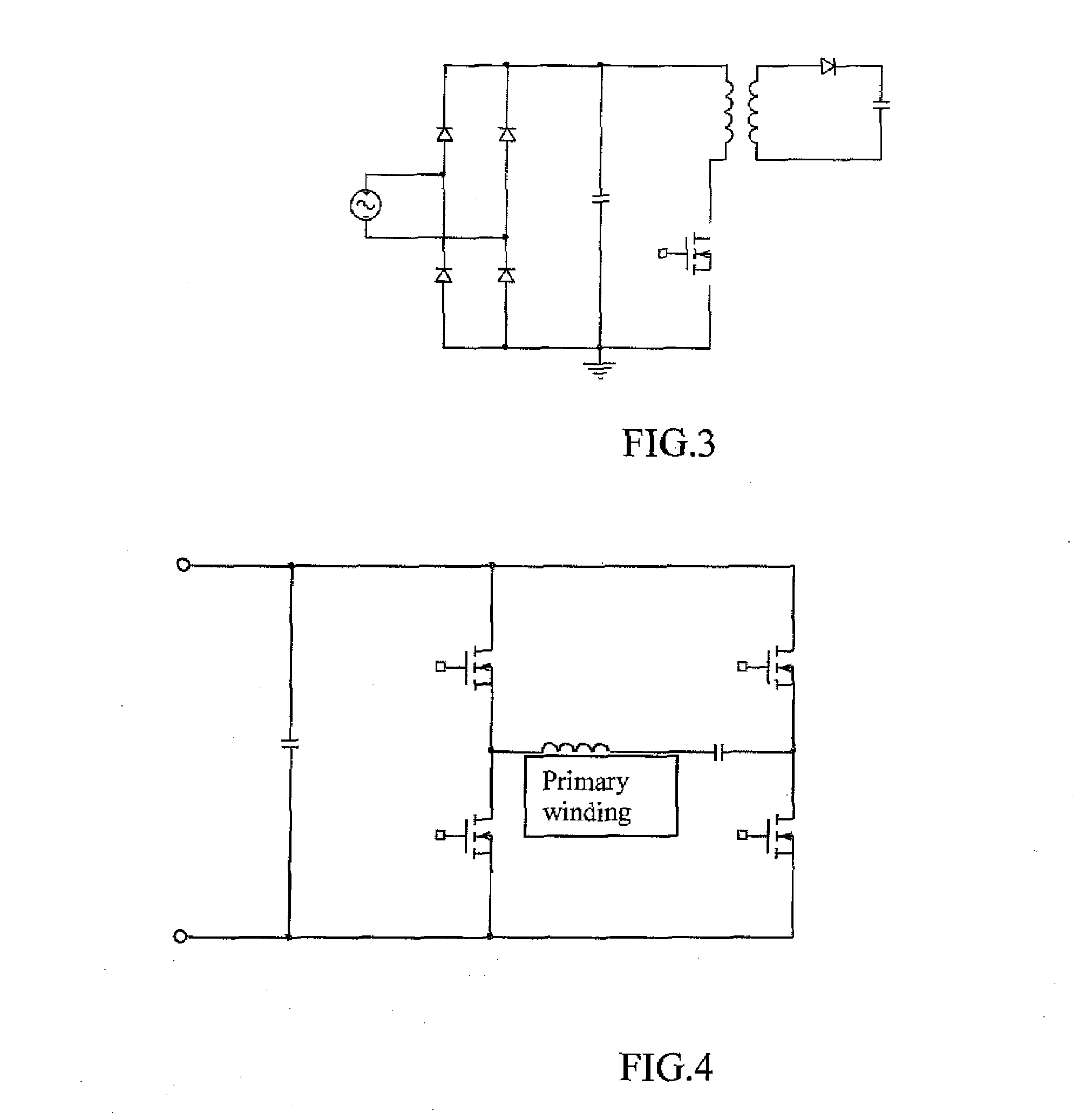

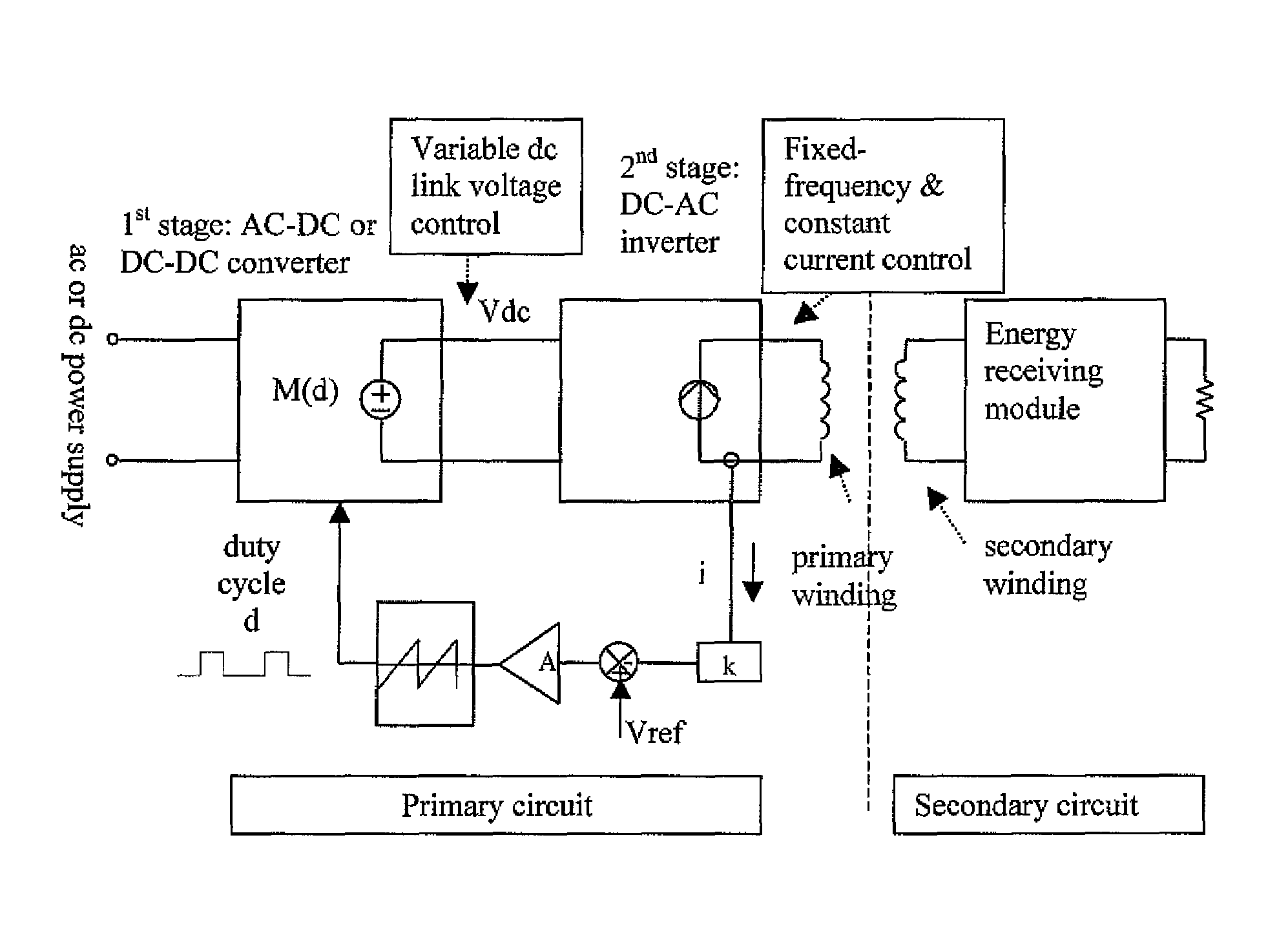

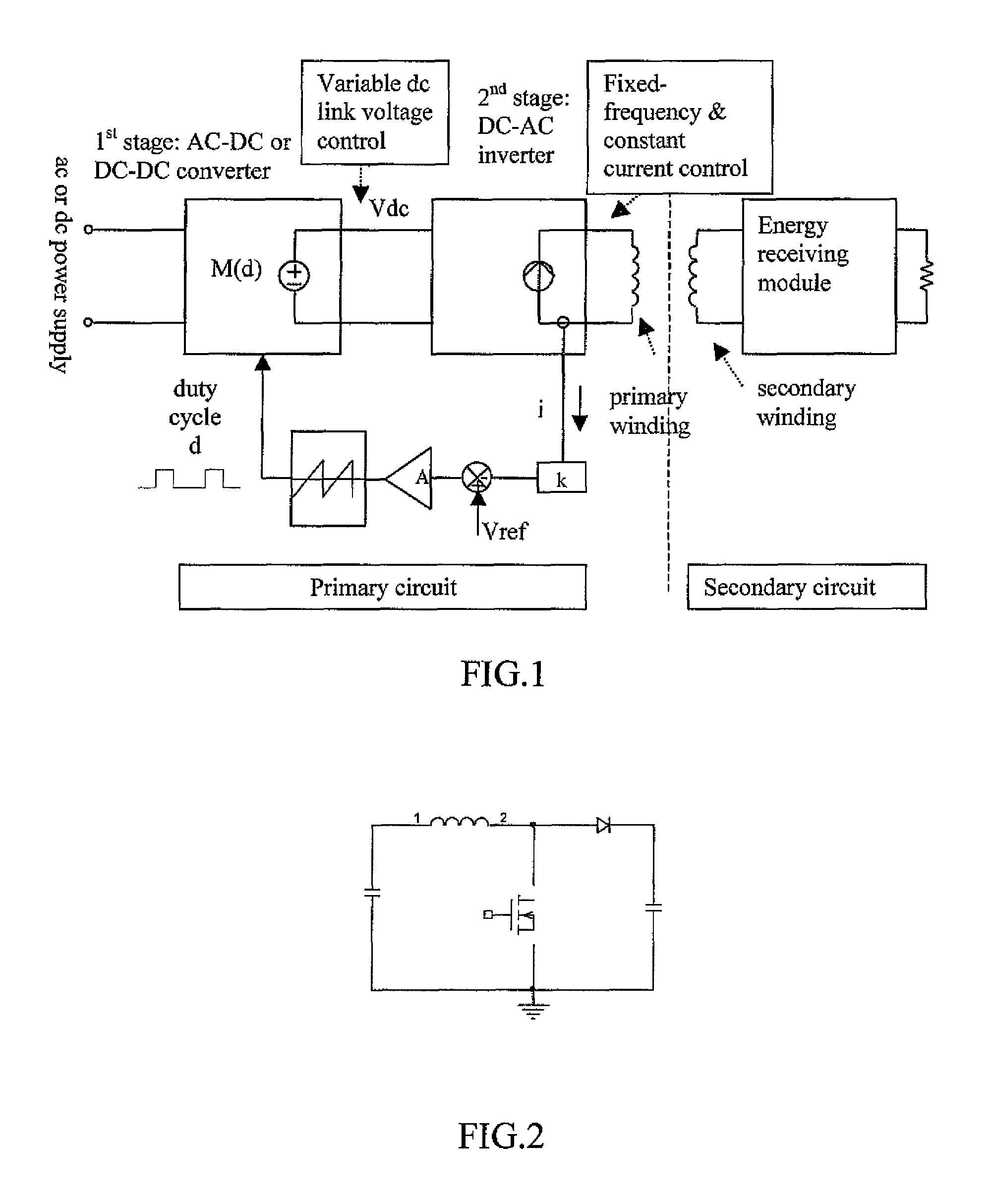

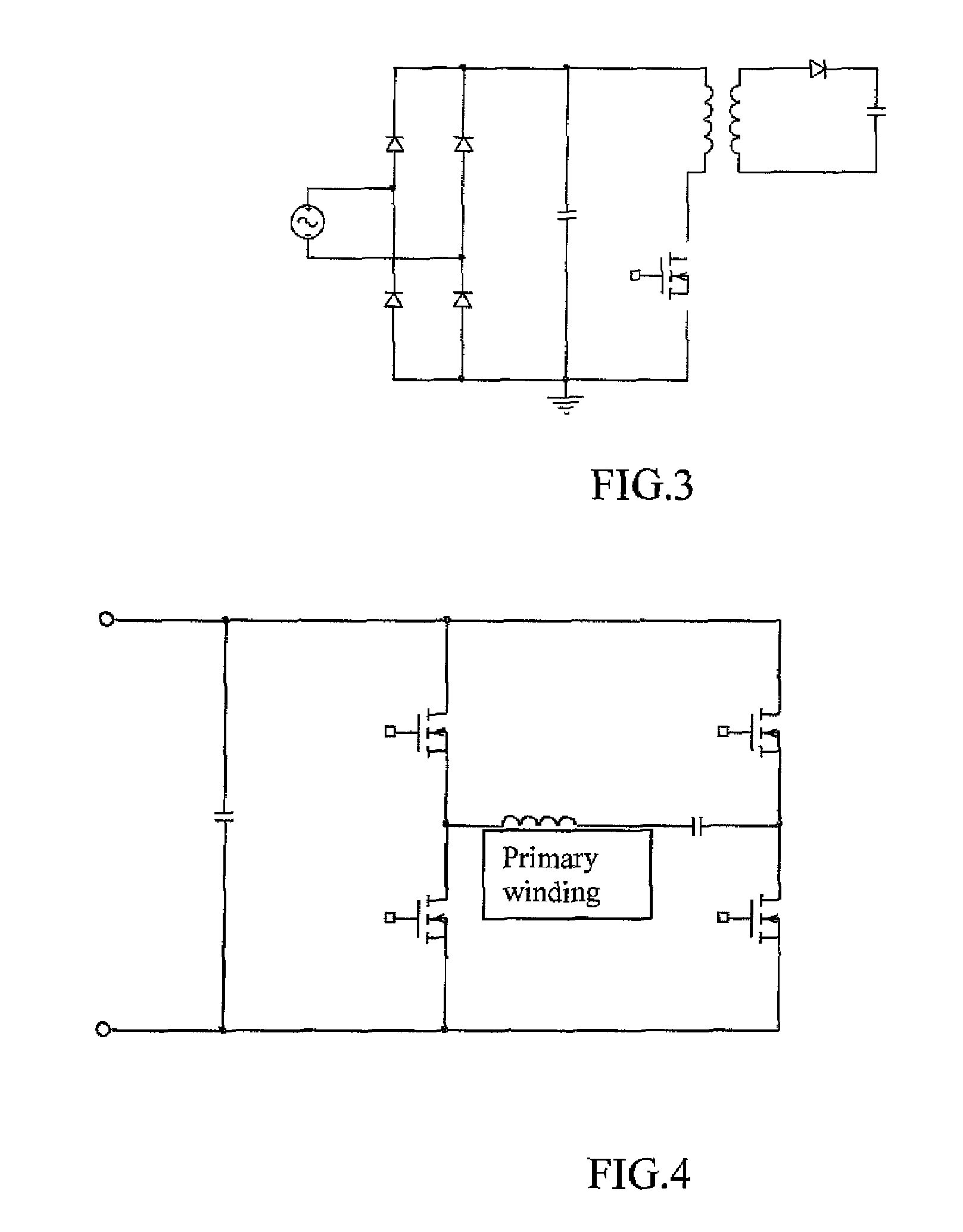

This invention provides an electronic control method for a planar inductive battery charging apparatus on which one or more electronic loads such as mobile phones, MP3 players etc can be placed and charged simultaneously. The power control circuit of the charging pad consists of two power conversion stages. Depending on the nature of the input power supply, the first power stage is an AC-DC power converter with variable output voltage control and a second stage is a DC-AC power inverter with constant current control. The combination of the two stages provides power control of the charging pad and generates AC magnetic flux of ideally constant magnitude over the charging areas within a group of primary windings that are excited.

Owner:CITY UNIVERSITY OF HONG KONG

Electronic control method for a planar inductive battery charging apparatus

ActiveUS8228025B2Batteries circuit arrangementsAc-dc conversion without reversalElectronic loadBattery charge

This invention provides an electronic control method for a planar inductive battery charging apparatus on which one or more electronic loads such as mobile phones, MP3 players etc can be placed and charged simultaneously. The power control circuit of the charging pad consists of two power conversion stages. Depending on the nature of the input power supply, the first power stage is an AC-DC power converter with variable output voltage control and a second stage is a DC-AC power inverter with constant current control. The combination of the two stages provides power control of the charging pad and generates AC magnetic flux of ideally constant magnitude over the charging areas within a group of primary windings that are excited.

Owner:CITY UNIVERSITY OF HONG KONG

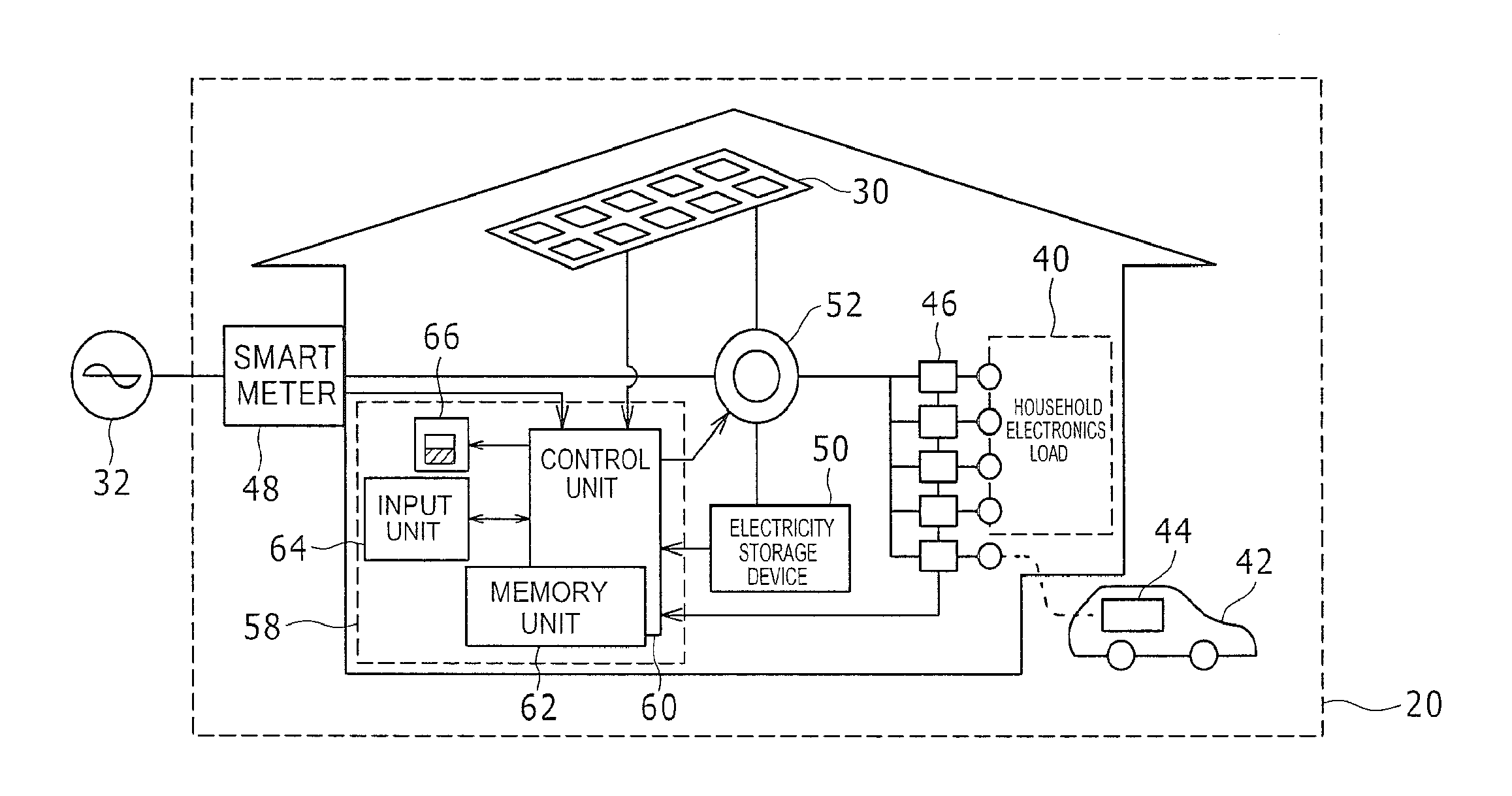

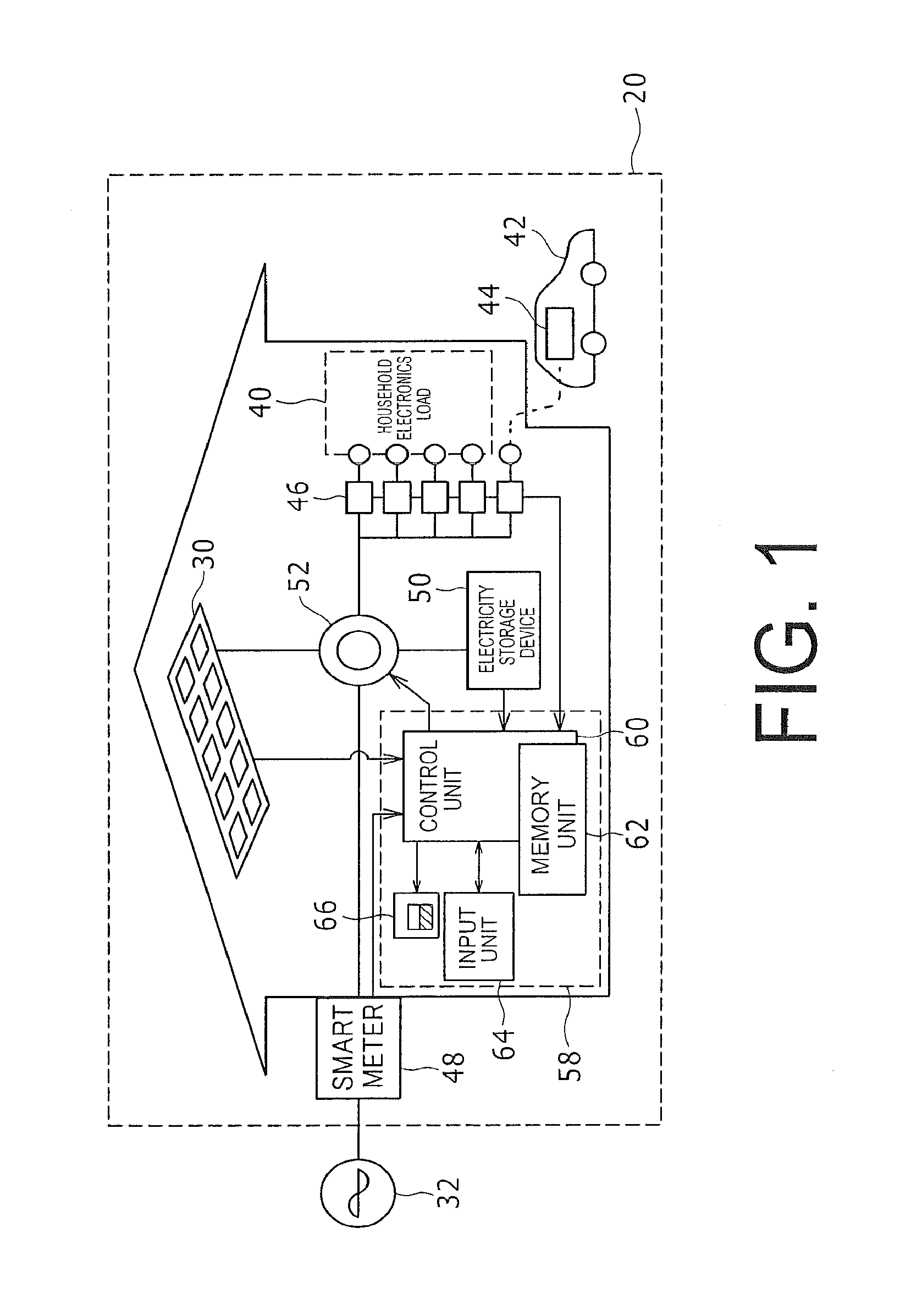

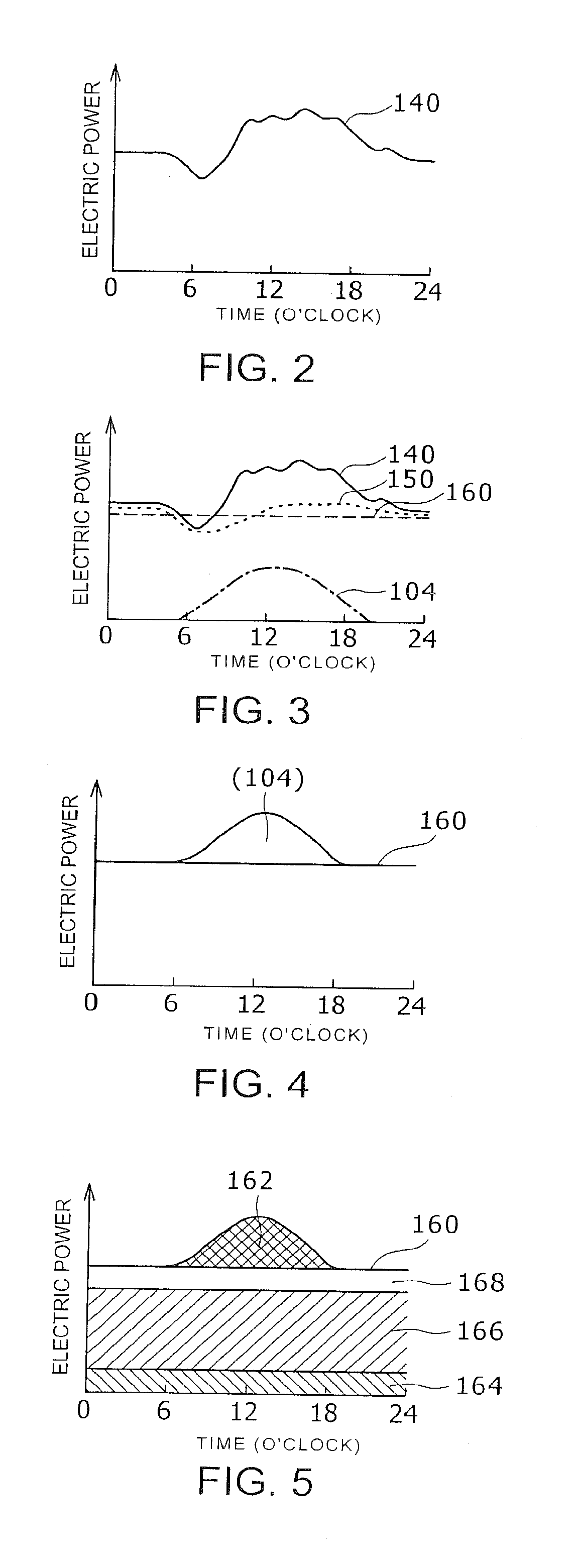

Electric power visualization method and electric power visualization device

A house uses solar light generated electric power and external commercial electric power and consumes the electric power with a household electronics load or the like. The house includes an electricity storage device and an electric power management device. The electric power management device further has a function to calculate transition of the load electric power, transition of the solar battery generated electric power, and transition of a leveled external commercial electric power during one day, classify the electric power by the power generation methods, apply a green index serving as a standardized index which is defined in advance to each power generation method to calculate an electric power green index, and display a result thereof on a display unit.

Owner:SANYO ELECTRIC CO LTD

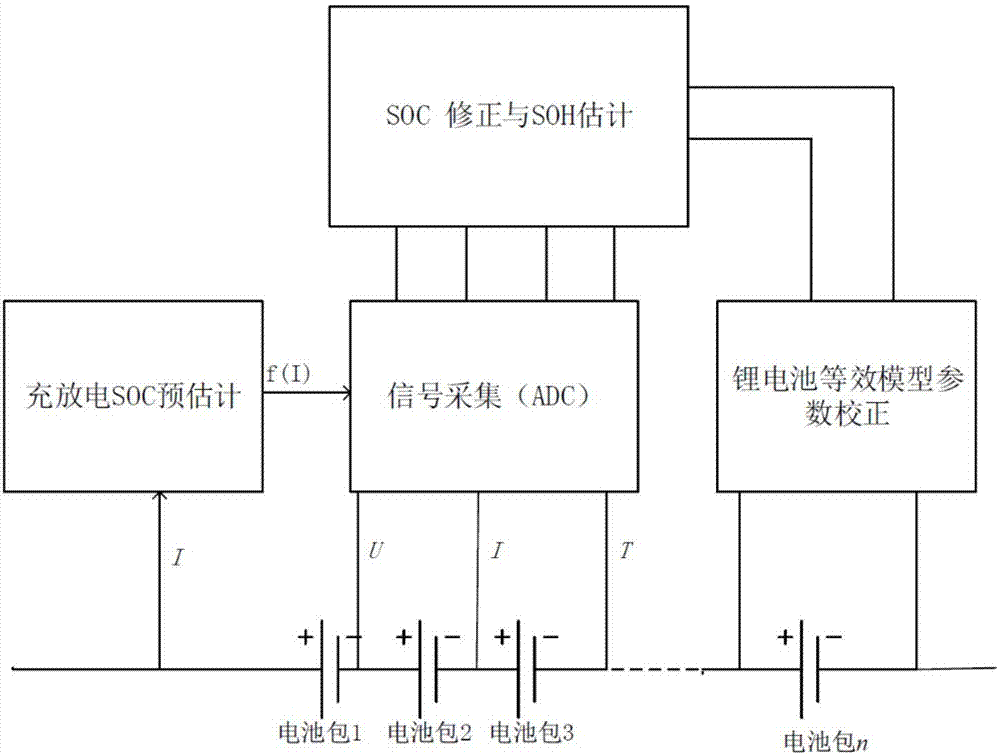

SOC-SOH joint on-line real-time estimation and on-line modification method

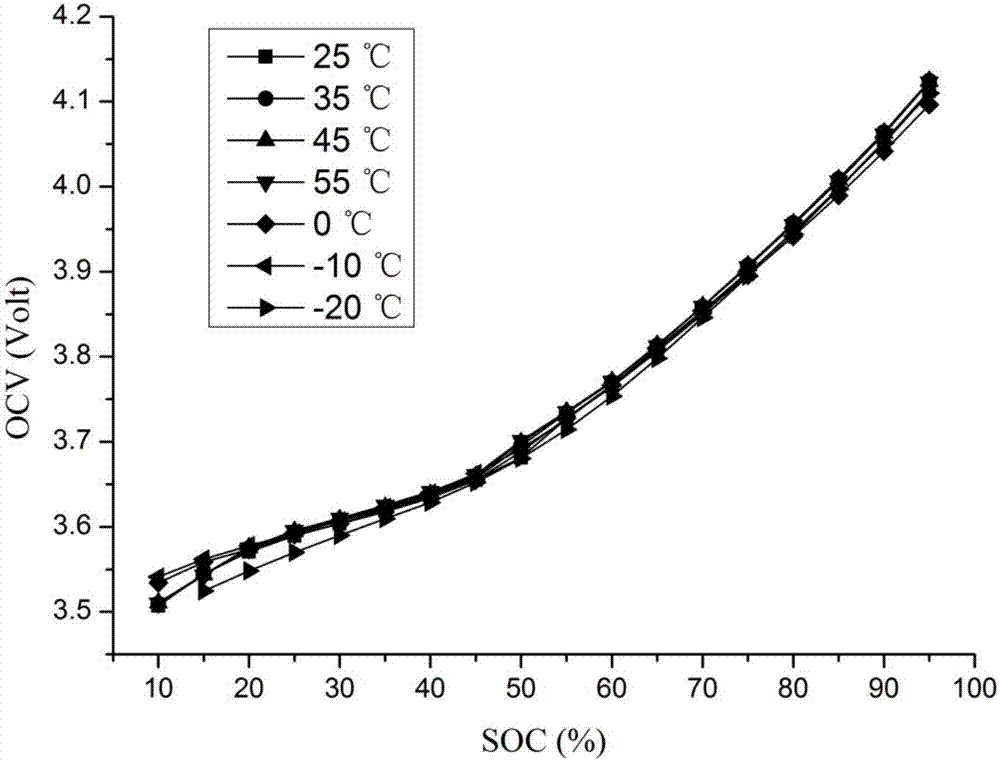

ActiveCN106918789AGuaranteed stabilityGuaranteed reliabilityElectrical testingIntegratorElectronic load

The invention discloses a SOC-SOH joint on-line real-time estimation and on-line modification method, the method comprises an SOC hardware pre-estimation module and a lithium battery equivalent-circuit parameter correction module, wherein the SOC hardware pre-estimation module utilizes a Hall current sensor to convert a heavy current signal into a low voltage signal, noise filtering is performed on the signal through a band-pass filter, the filtered signal is transmitted to an RC integrator to indirectly realize the integral for the current signal, and an integral signal acquired by an ADC is transmitted to an MCU chip to correct; the lithium battery equivalent-circuit parameter correction module comprises a square-wave pulse switch current source and a controllable electronic load, the square-wave pulse switch current source or the controllable electronic load is utilized to perform charge or discharge test on the lithium battery, the ADC is utilized to acquire terminal voltage of a battery pack, and according to the input response of charge or discharge curve, parameters of a battery equivalent model in a charge-discharge process are corrected. According to the invention, the method overcomes a circuit model parameter correction problem and realizes SOC-SOH real-time accurate on-line joint estimation.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

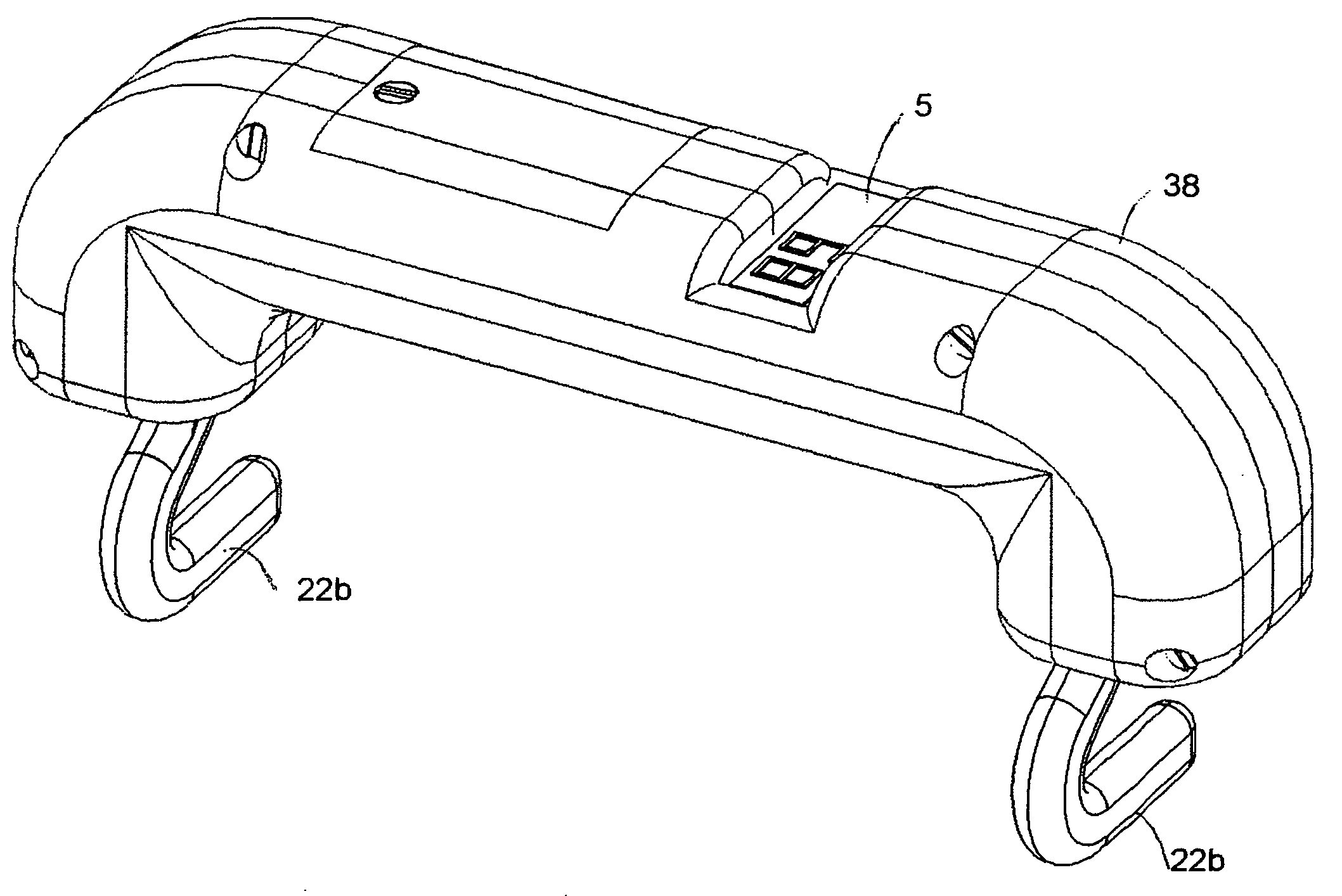

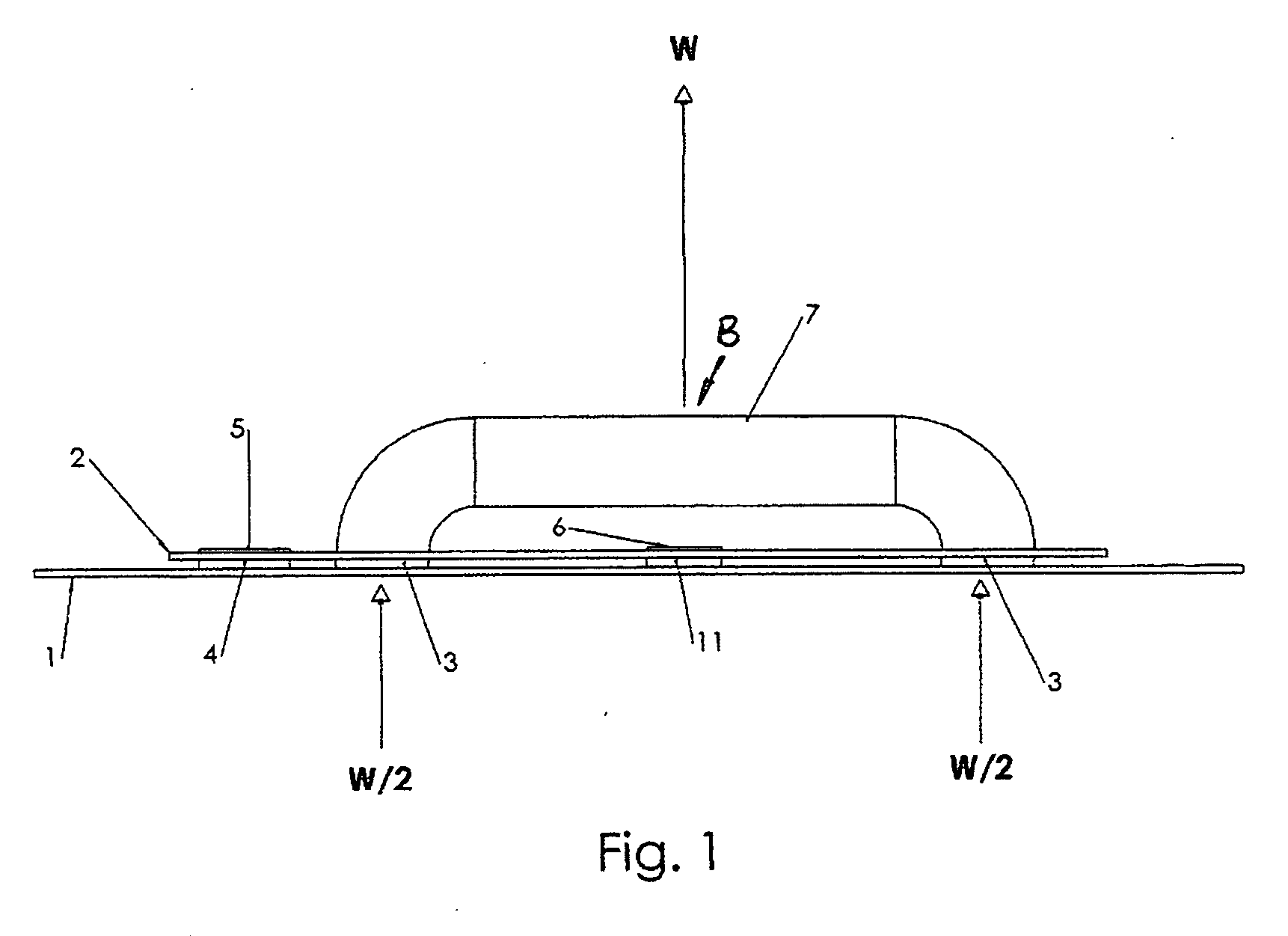

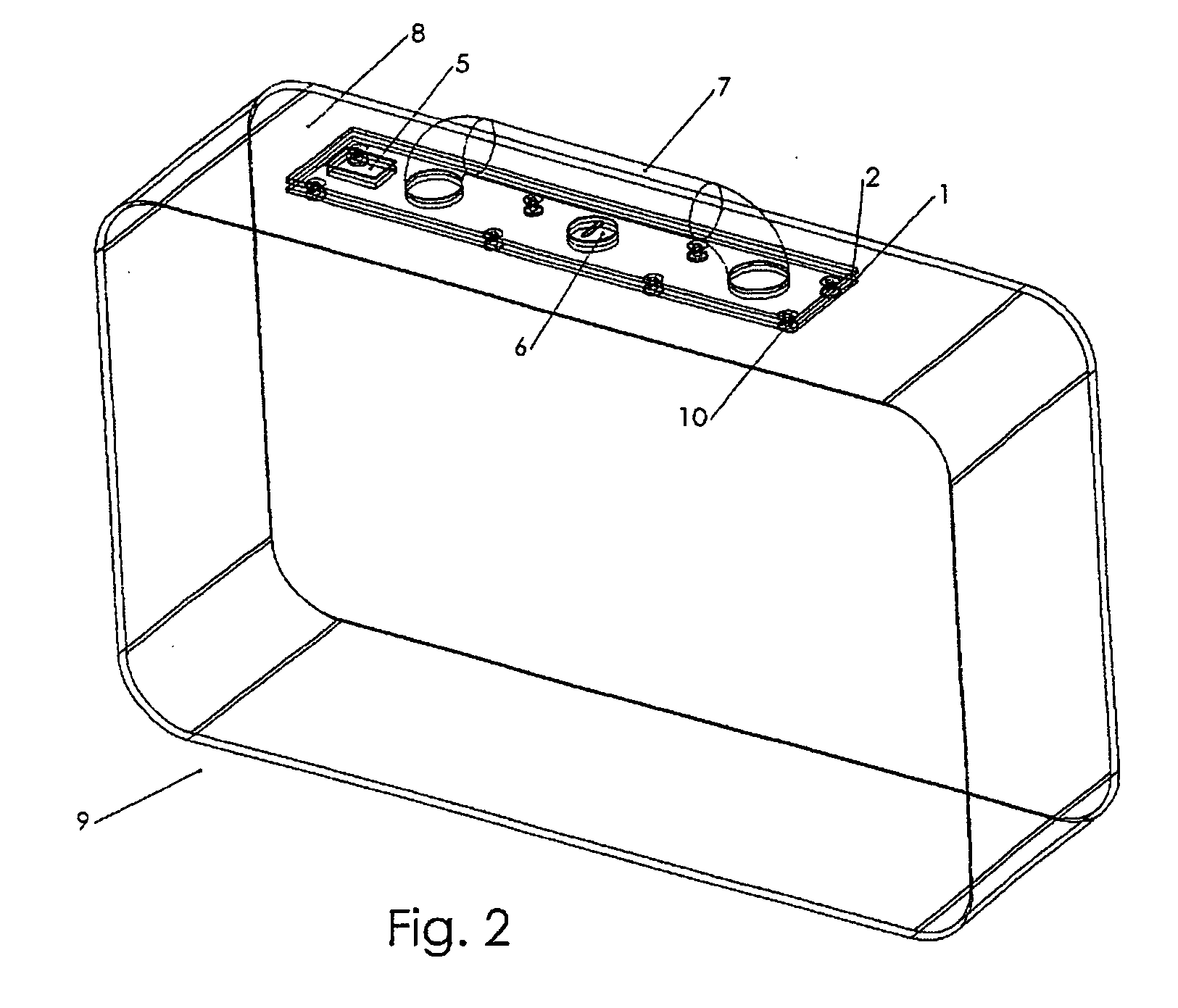

Luggage scale

A luggage weight measuring device for integration into a luggage case, or between the luggage case and handle or for mounting to the luggage case handle. In one embodiment at least one electronic load measuring sensor is mounted directly between the handle and the luggage case, for example to a deformable member which deforms as the handle is lifted to take up the load carried by the luggage case. Deformation is mathematically related to the load. A processor determines the load corresponding to the deformation as detected by the sensors and displays the load on a user viewable display on the luggage case or handle.

Owner:GILL MICHAEL R

Methods and apparatuses for operating devices with solar power

ActiveUS20080084117A1Batteries circuit arrangementsElectric power transfer ac networkVoltage converterElectronic load

Solar power tracking techniques are described herein. In one aspect of the invention, a solar power tracking apparatus includes, but is not limited to, a voltage converter and a controller coupled to the voltage converter. The voltage converter includes an input capable of being coupled to a solar power source and an output capable of being coupled to an electronic load, such as, for example, a portable electronic device. The voltage converter is configured to monitor or detect an amount of power drawn by the electronic load at the output of the voltage converter. In response to the monitored power drawn, the controller is configured to control the voltage converter to reduce amount of power to be drawn subsequently if the monitored amount of power exceeds a predetermined threshold. As a result, the output voltage from the solar power source is maintained within a predetermined range. Other methods and apparatuses are also described.

Owner:APPLE INC

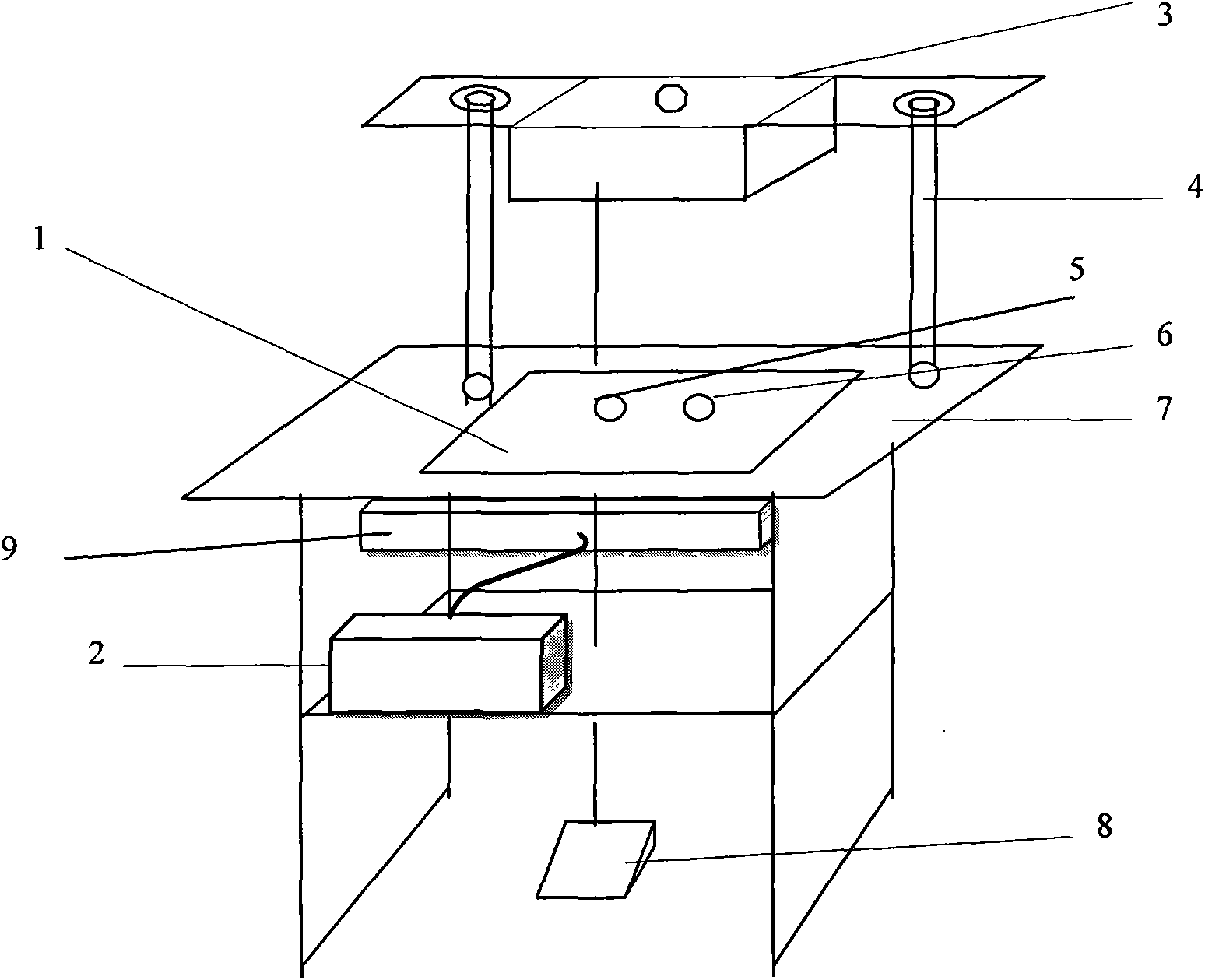

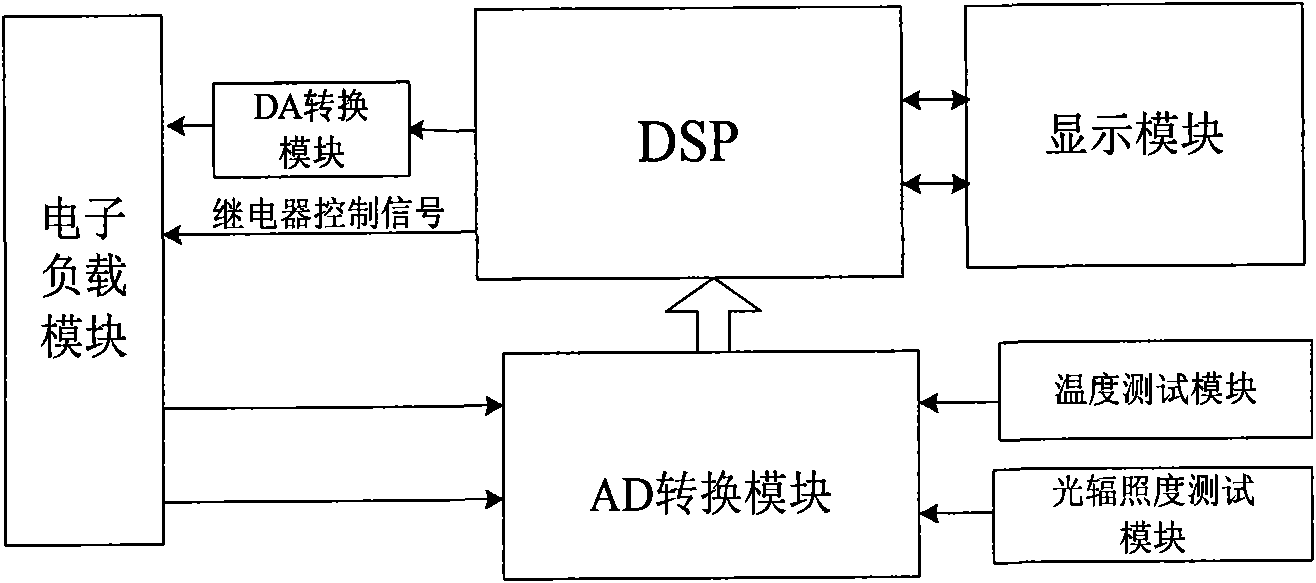

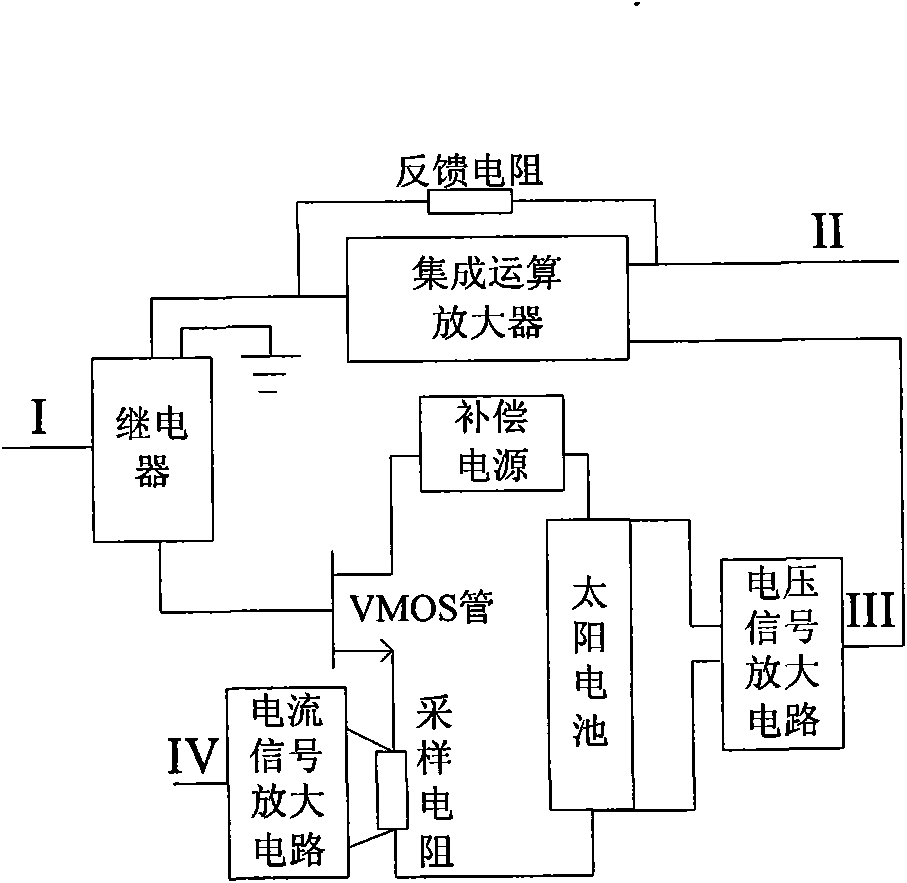

Device for testing solar cell parameter

InactiveCN101551437ASmall temperature changeThe test result is accurateThermometer detailsPhotovoltaic monitoringElectronic loadV curve

Owner:HUAZHONG UNIV OF SCI & TECH

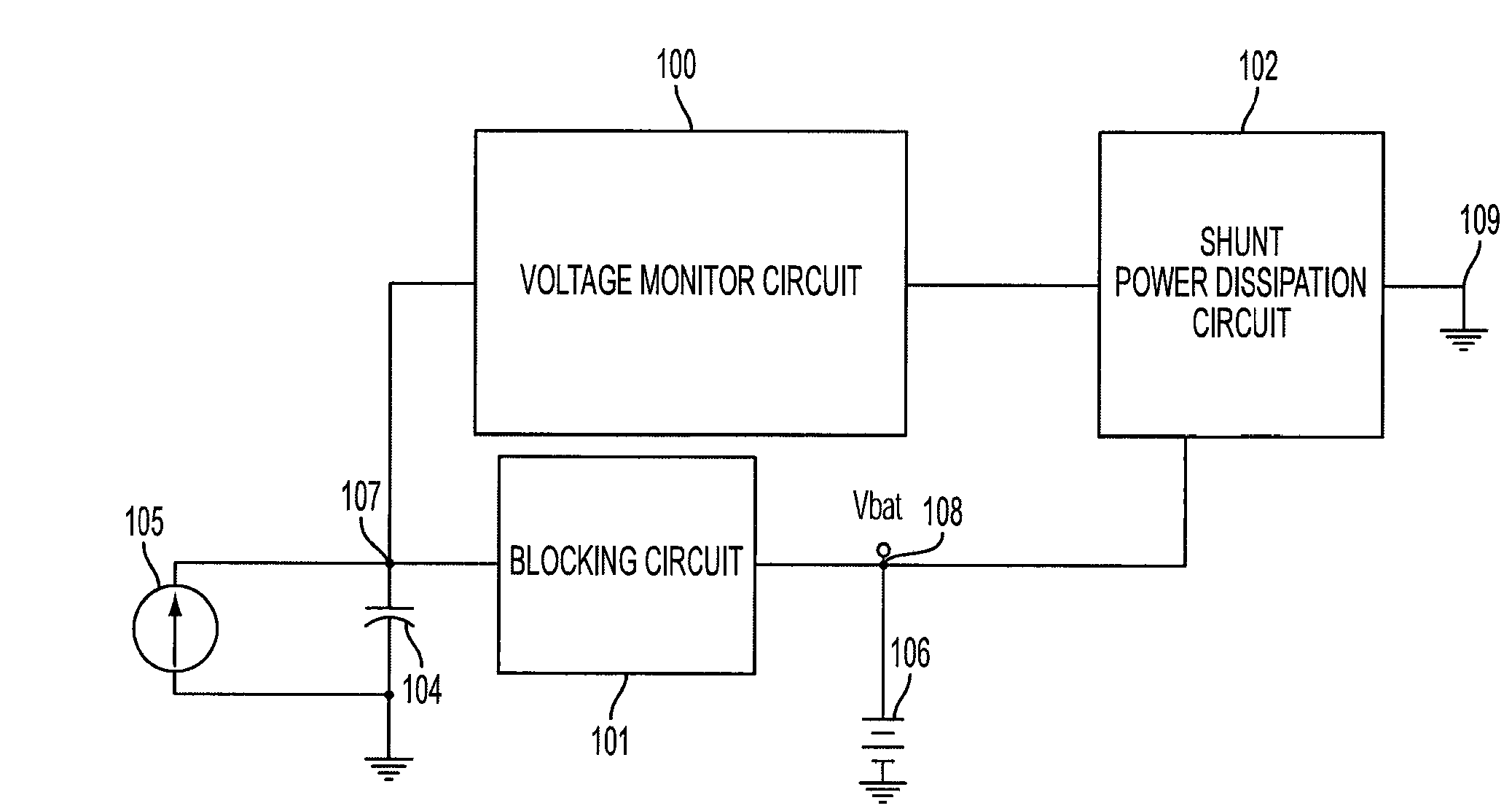

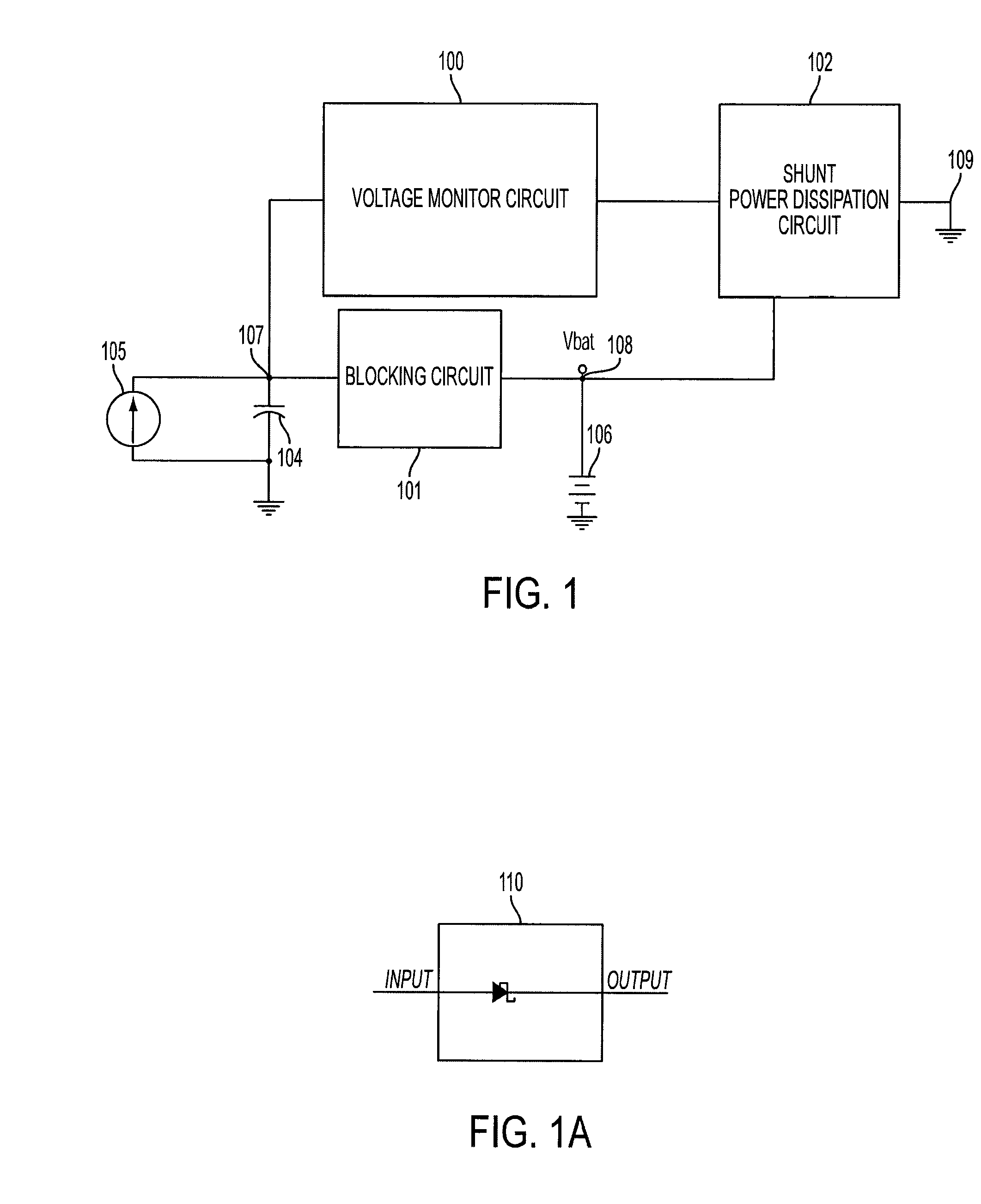

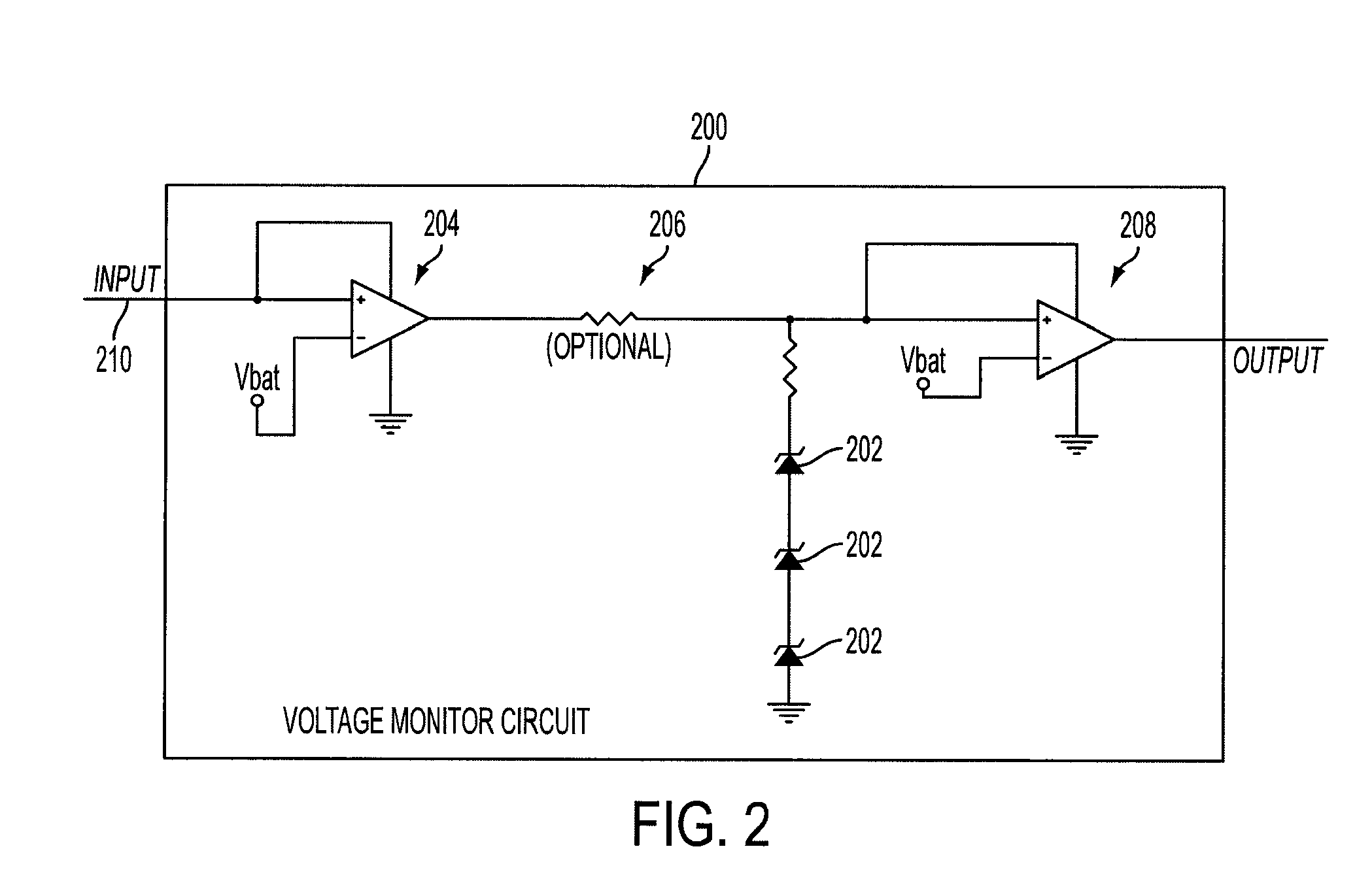

Passive over/under voltage control and protection for energy storage devices associated with energy harvesting

ActiveUS20090251099A1Connection securitySecondary cells charging/dischargingElectric powerElectronic loadZener diode

Described herein is, for example, a battery or capacitor over voltage (overcharge) and under-voltage protection circuit, that, for example, is adapted to not draw current from the battery or capacitor to be charged unless charge energy is detected and to not charge an energy storage device when an over-charge condition is sensed. The protection circuit may, for example, not be turned on unless an over voltage condition is present. Incoming energy to the system can be shunted to ground via a shunt load of various types including resistive loads and active components such as a zener diode. In some embodiments, no switching of the inbound power is required. Within limits, no regulation of inbound power is needed. When inbound power is sufficient to charge the battery or capacitor, regulation can occur via the applied shunt regulator if overcharge voltage conditions exist. Either type of charge source, voltage or current, can be used to provide charge energy. Combining said battery or capacitor over voltage (overcharge) and under-voltage protection circuit with electronic loads, such as wireless sensors, may lead to autonomously-powered wireless sensor systems.

Owner:SAPURAST RES

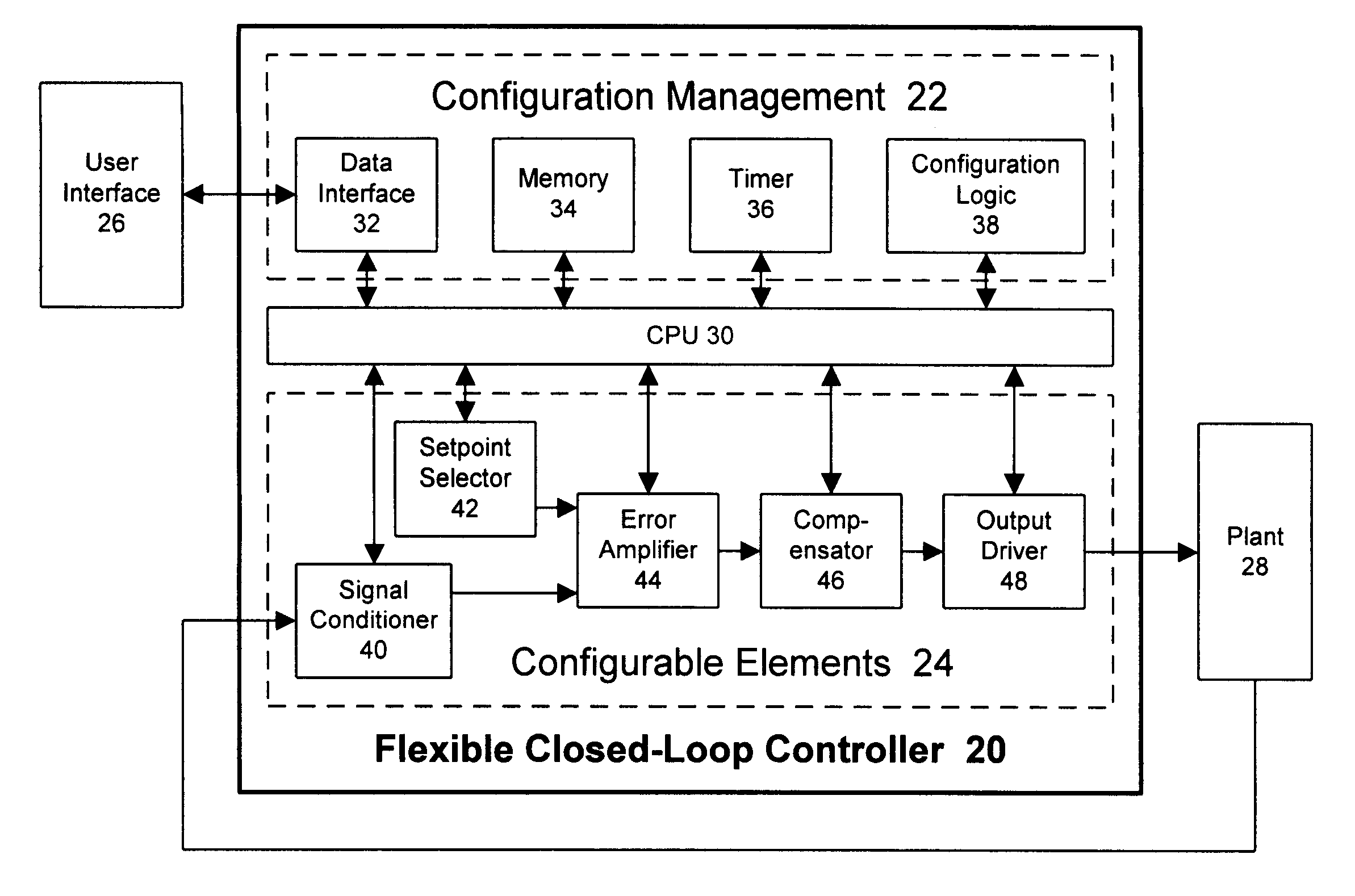

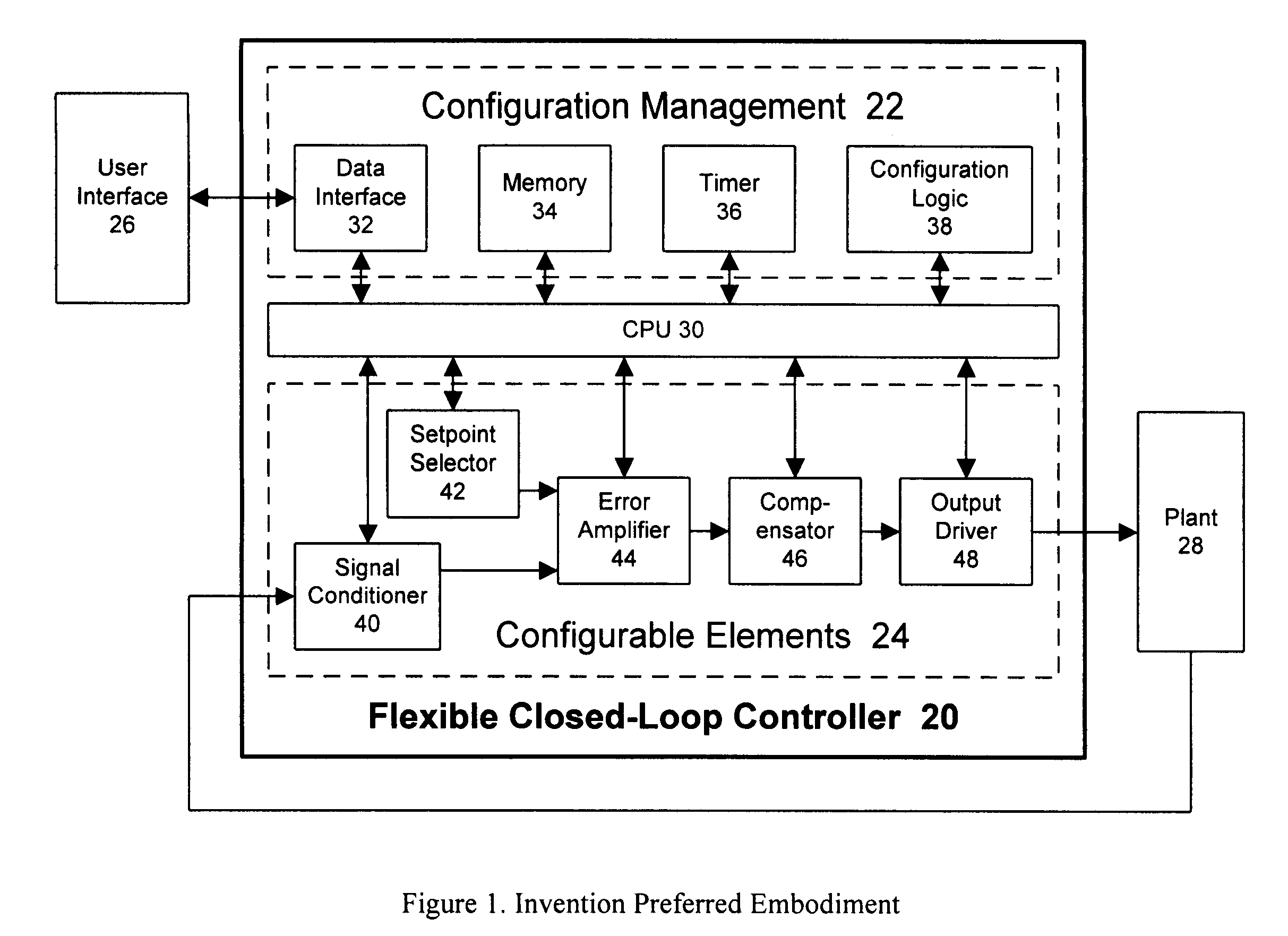

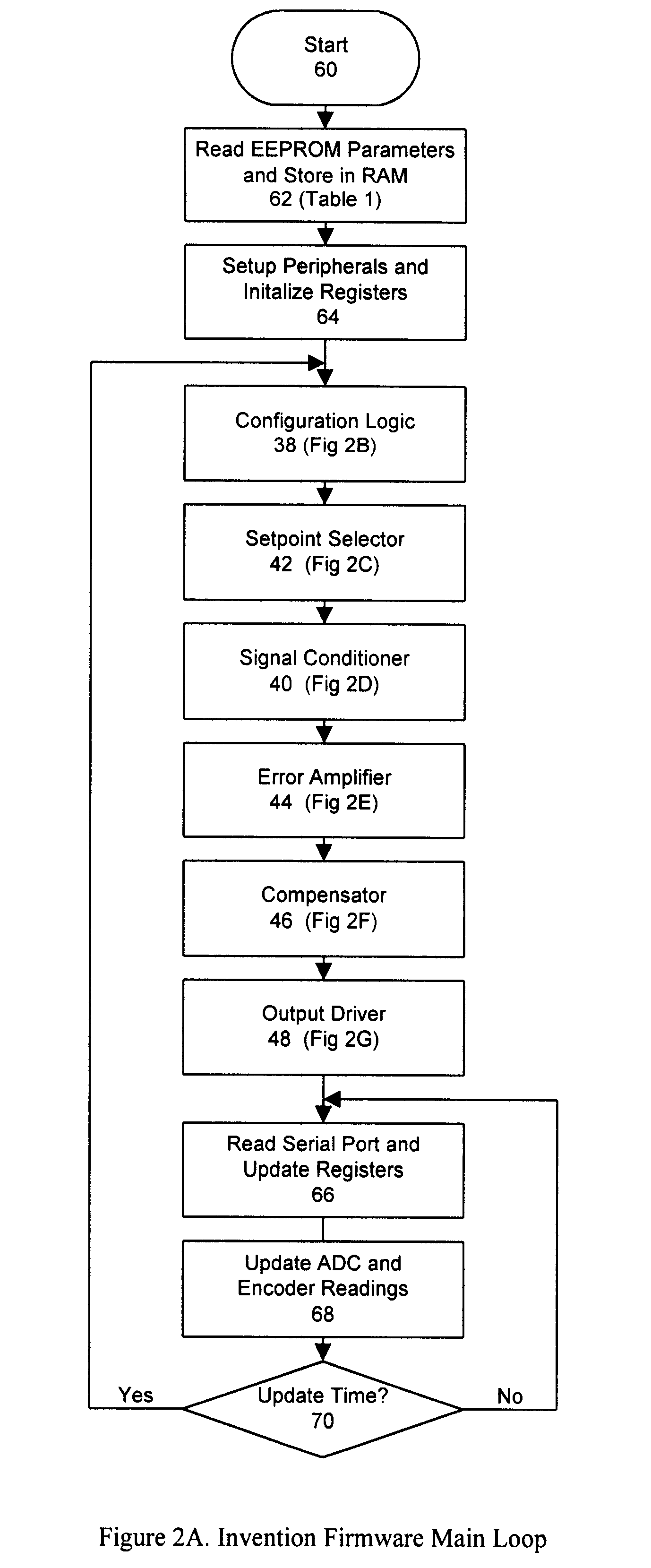

Flexible closed-loop controller

A flexible closed-loop controller capable of being quickly and easily configured for a broad range of applications. The controller contains a set of control elements that may be configured or reconfigured for any specific application. Built-in configuration management automates configuration of the control elements dependent on user commands or operating conditions. The controller is autonomous after initial configuration, although it may be used interactively. This flexible closed-loop controller is suitable for switching power supplies, linear amplifiers, AC inverters, battery chargers, electronic loads, temperature and pressure management, motor or actuator drives, as well as industrial automation, data acquisition, and automatic test equipment. The controller reduces development time and cost, reduces parts count and cost, and improves performance and reliability of real-time closed-loop systems.

Owner:CALDWELL DAVID J

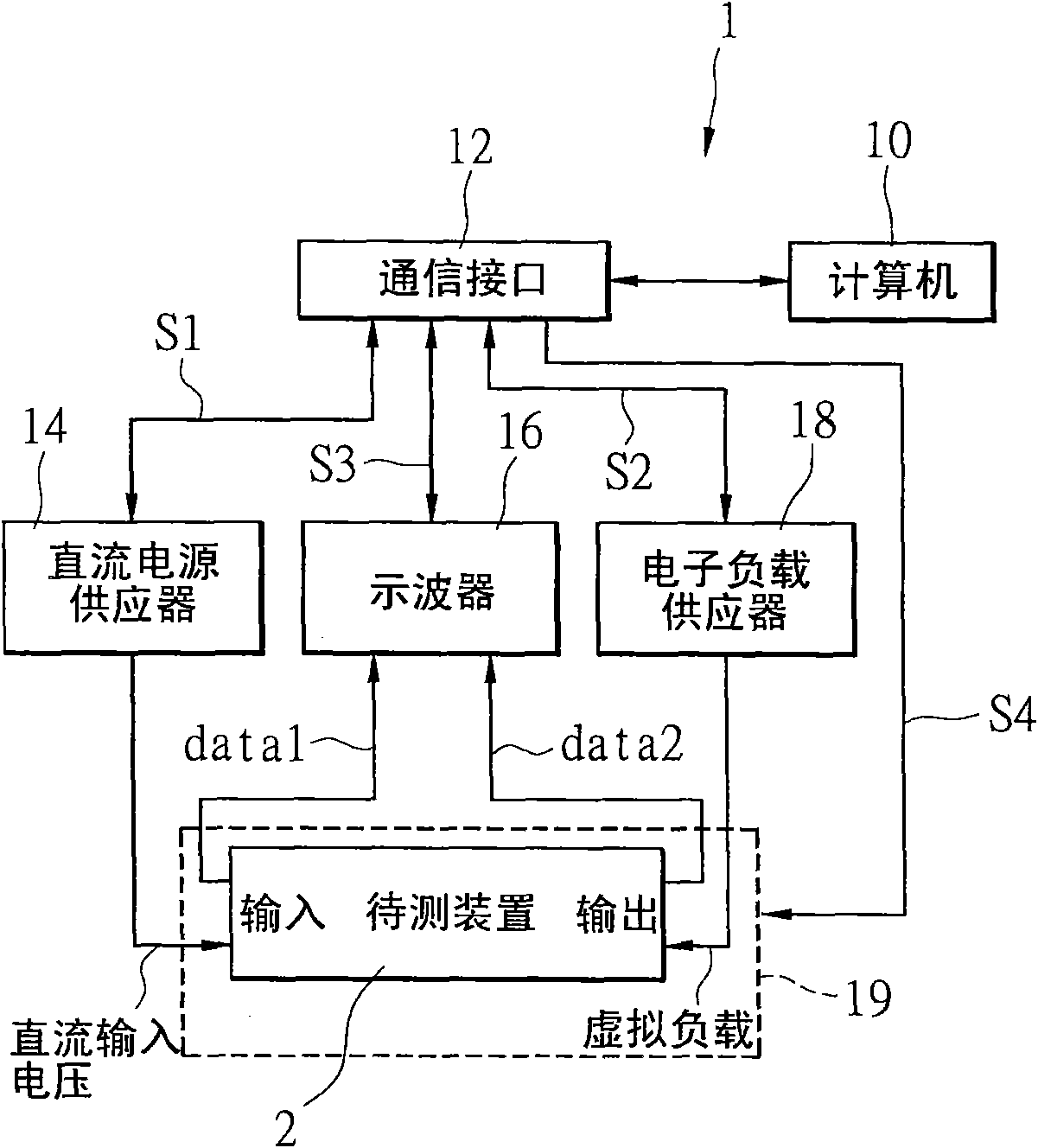

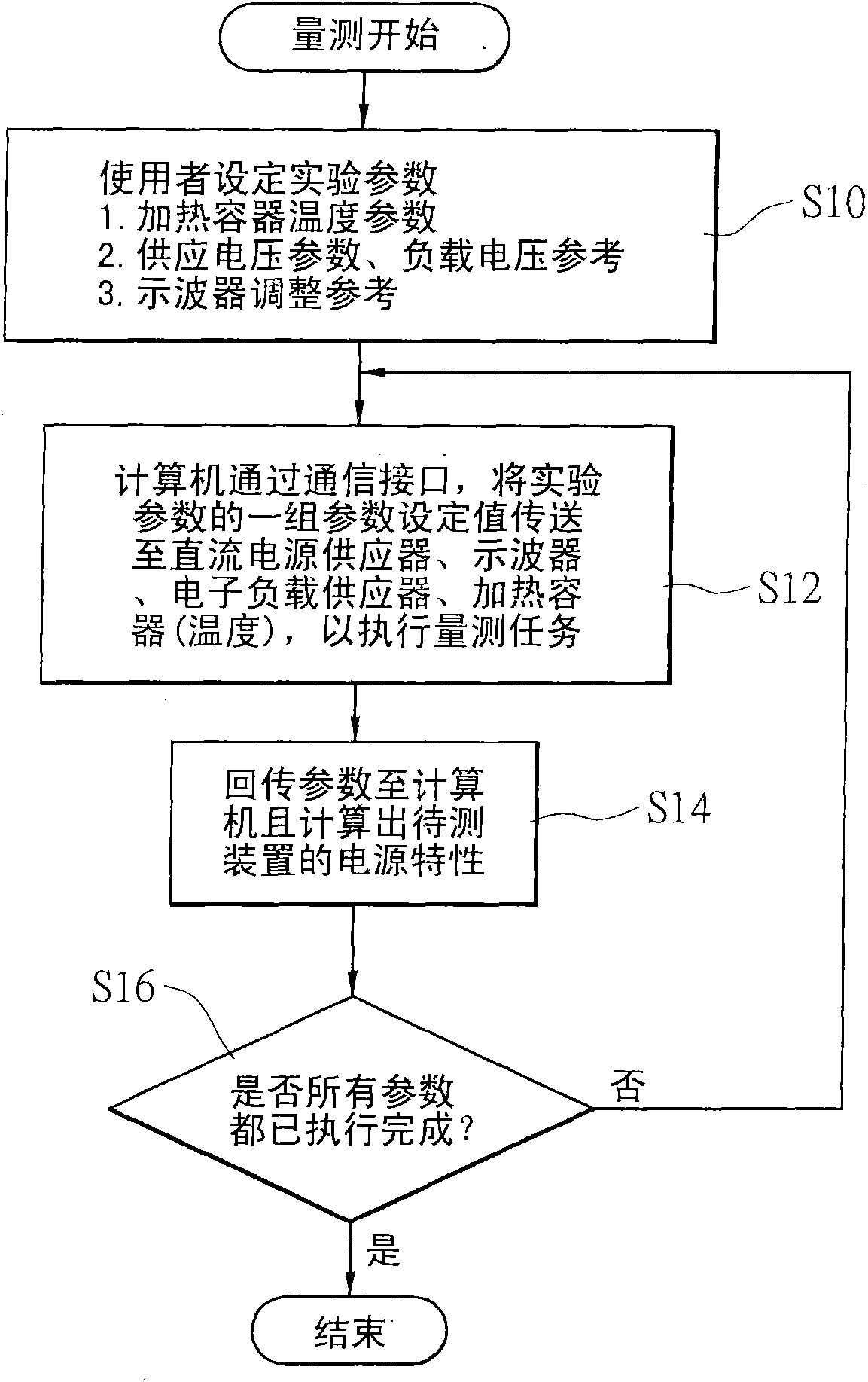

System and method for testing power supply properties

The invention relates to a system and a method for testing power supply properties. The system for testing the power supply properties comprises a computer, a DC power supply, an electronic load supply, an oscilloscope and a heater. An operator can operate the computer to control the DC power supply, the electronic load supply and the heater to respectively provide DC input voltage, virtual load and environmental temperature required by measurement for a device to be tested, and utilizes the oscilloscope to acquire the property value / wave of an input power supply and the property value / wave of an output power supply of the device to be tested; and the oscilloscope sends the property value / wave of the input power supply and the property value / wave of the output power supply back to the computer for the confirmation of the operator, and the aim of automatically testing the power supply properties of the device to be tested is achieved. The system and the method can automatically test the power supply properties of the device to be tested at a preset environmental temperature to achieve the aims of saving time and saving human resources, and simultaneously can ensure that the device to be tested is in accordance with the requirement of each power supply property at the design stage.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD +1

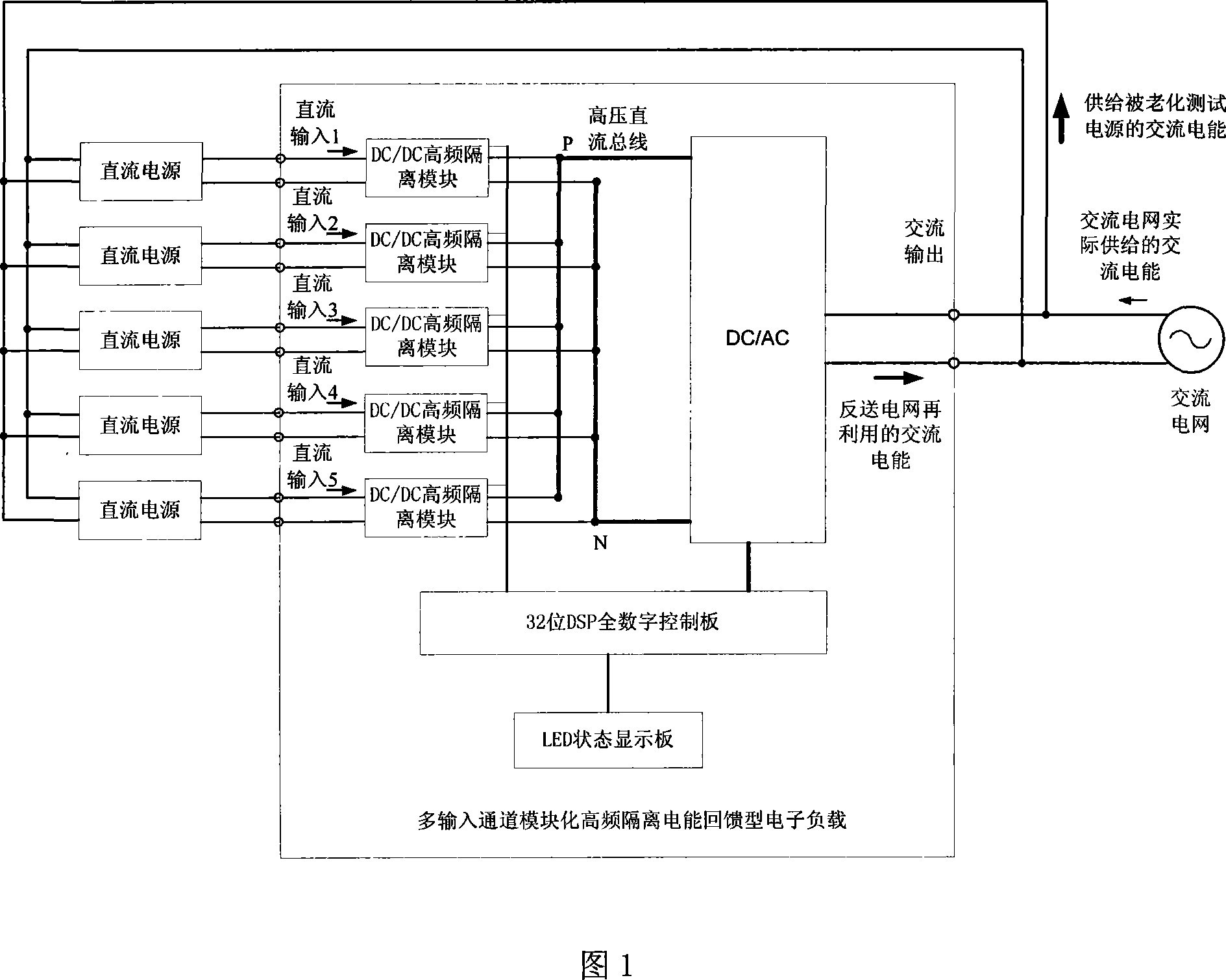

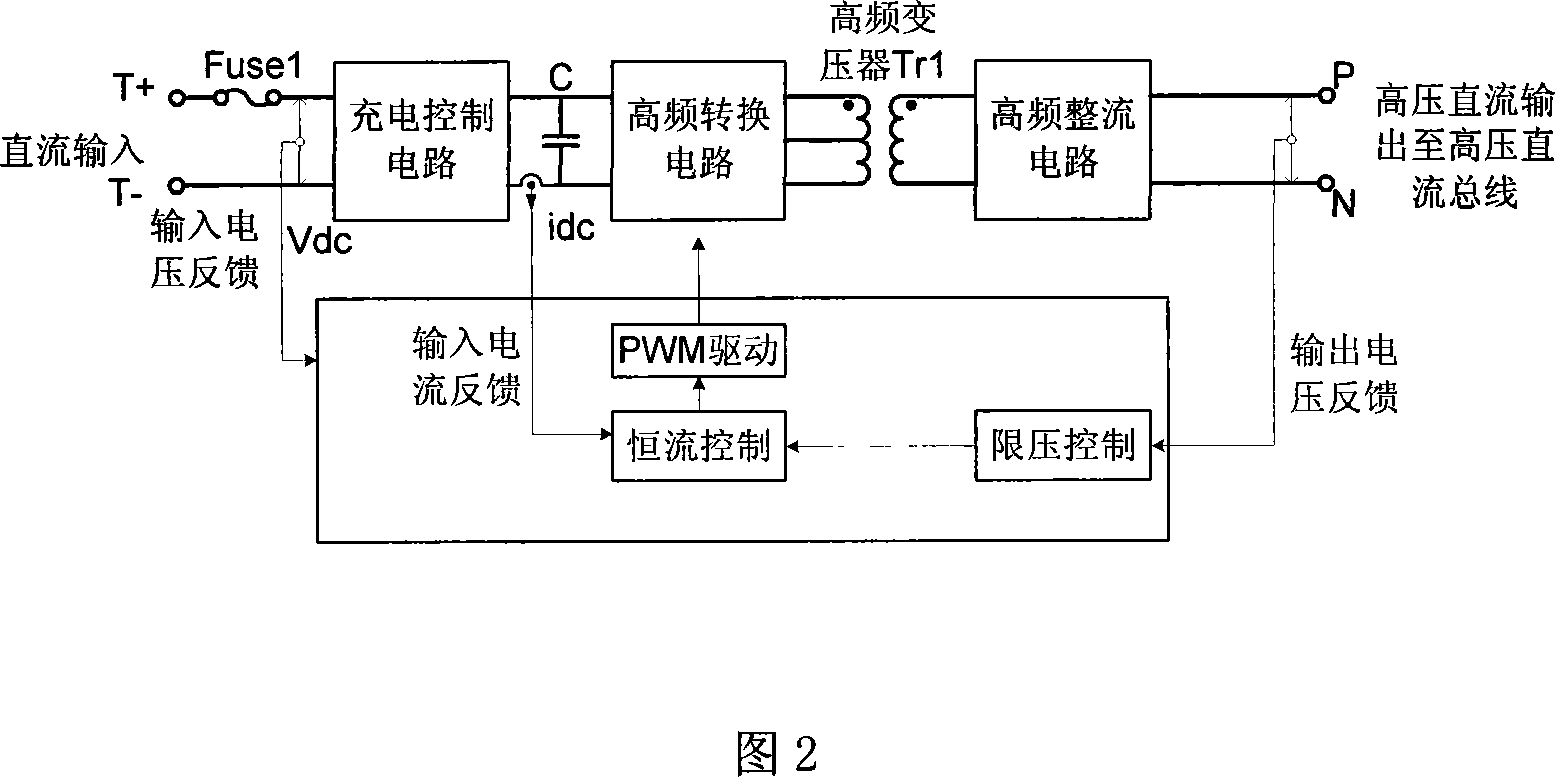

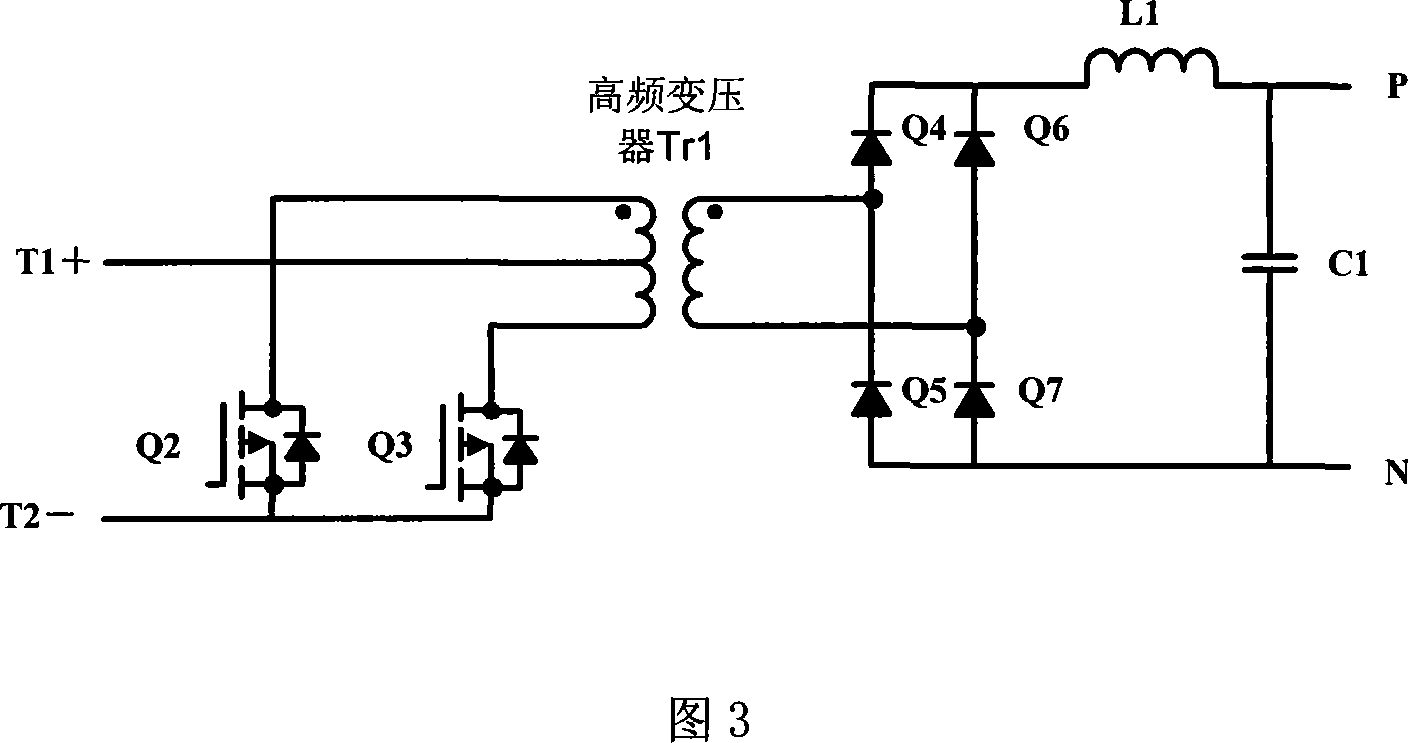

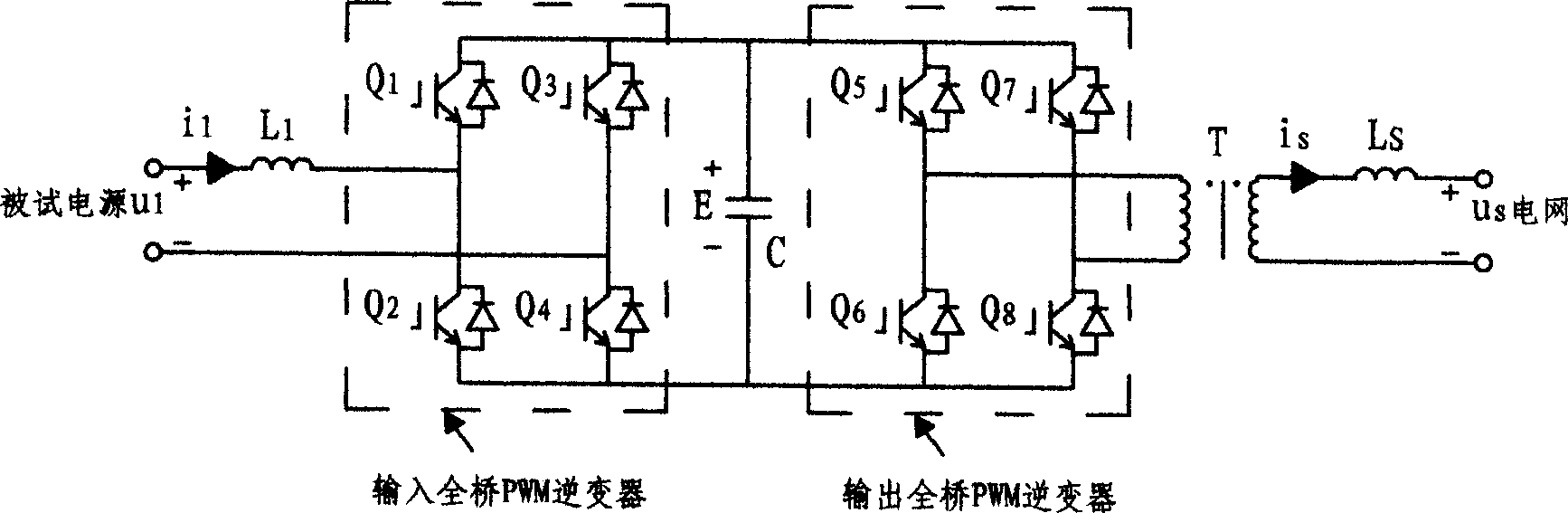

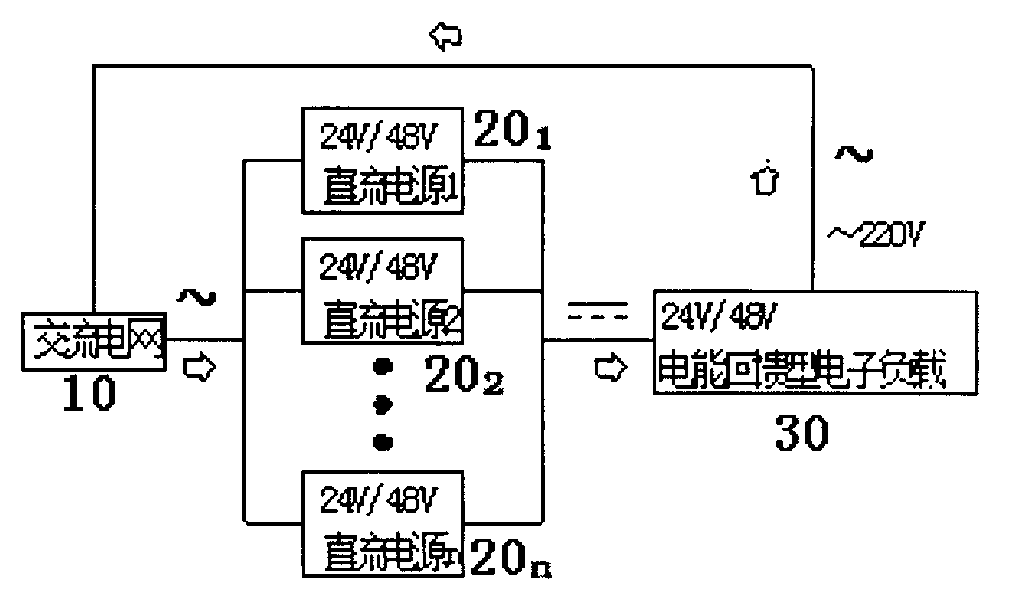

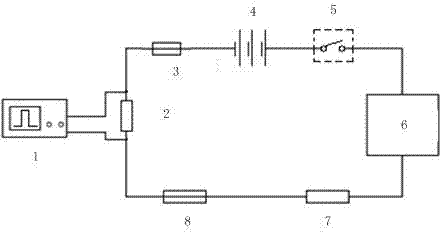

Multiple input path modular high frequency isolation single phase power feedback type electronic load

ActiveCN101051071AImprove work efficiencySimplify workApparatus with intermediate ac conversionPower supply testingMulti inputElectronic load

A feedback electronic load of high frequency isolated single-phase electric energy in multi-input channel modularization mode is prepared for forming each DC voltage conversion module by connecting high frequency conversion circuit and high frequency transformer as well as high frequency rectification circuit in sequence, forming inverter unit by connecting inverter and AC filter with each other, then connecting DC output end of DC voltage conversion module to DC input end of inverter unit.

Owner:BEIJING SOARING ELECTRIC TECH CO LTD

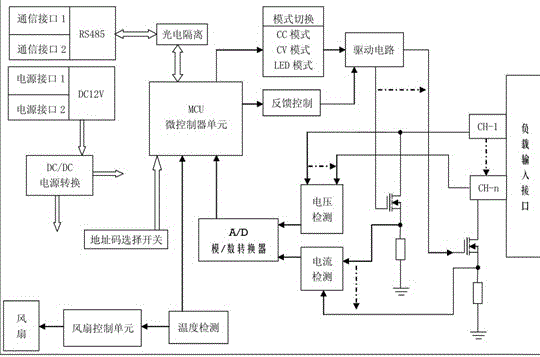

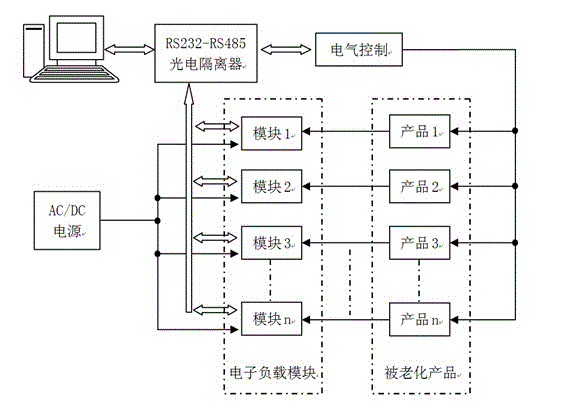

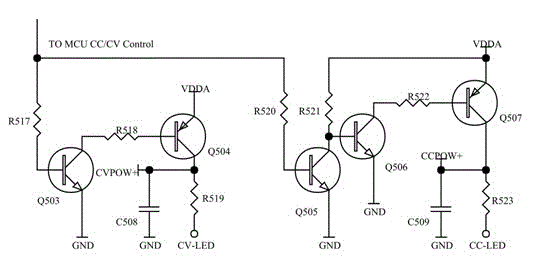

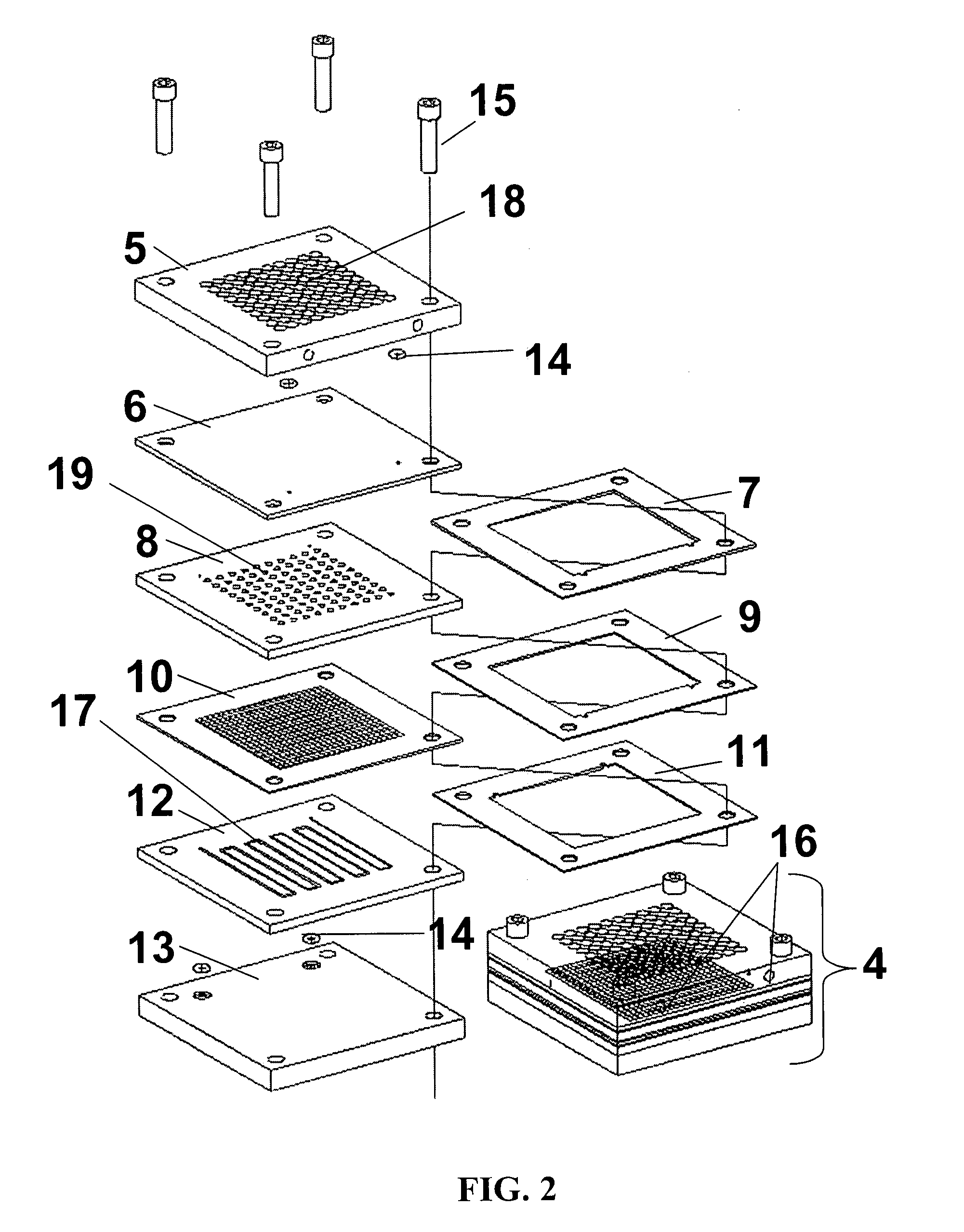

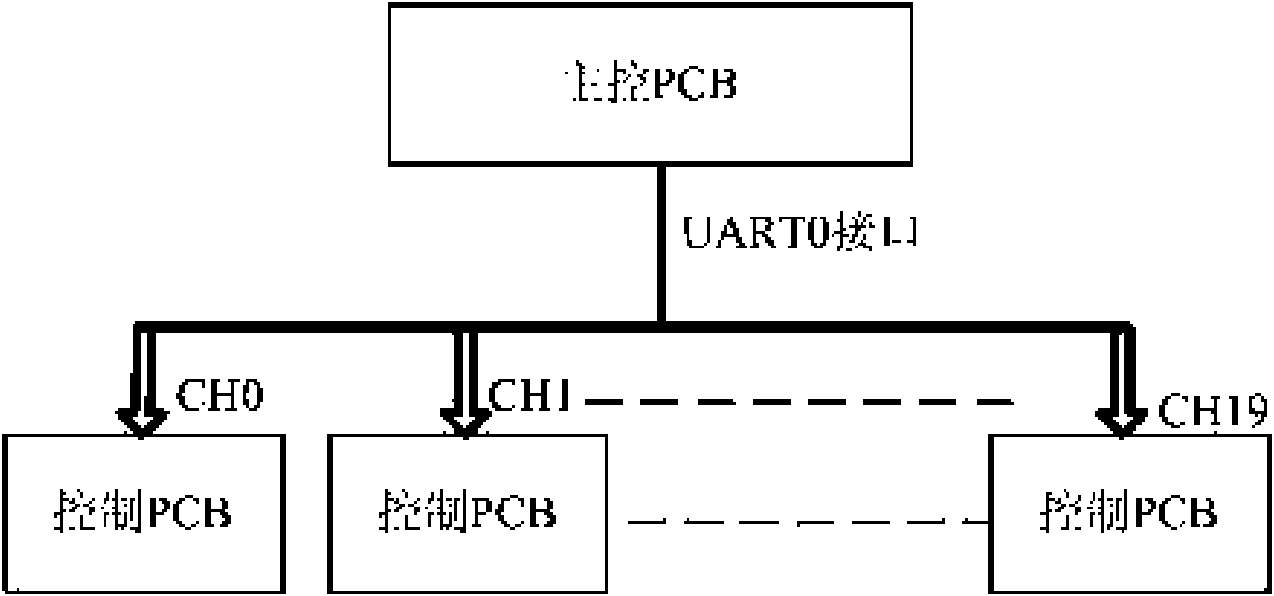

Electronic load module of power supply aging test and power supply aging test system

InactiveCN103149386AFlexible and quick setupPrecise positioningElectrical measurement instrument detailsPower supply testingElectronic loadComputer module

The invention provides an electronic load module of a power supply aging test and a power supply aging test system. The electronic load module of the power supply aging test provides an intelligent electronic load module controlled by an MCU (Microprogrammed Control Unit). According to the power supply aging test system, a plurality of electronic load modules of the power supply aging test are uniformly managed, displayed and stored by adopting an upper computer, so that the system is the intelligent power supply aging test system.

Owner:SHENZHEN ZHONGKEYUAN ELECTRONICS

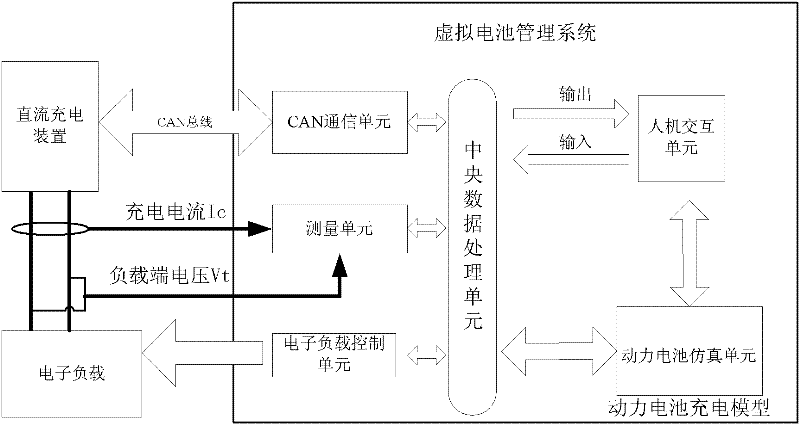

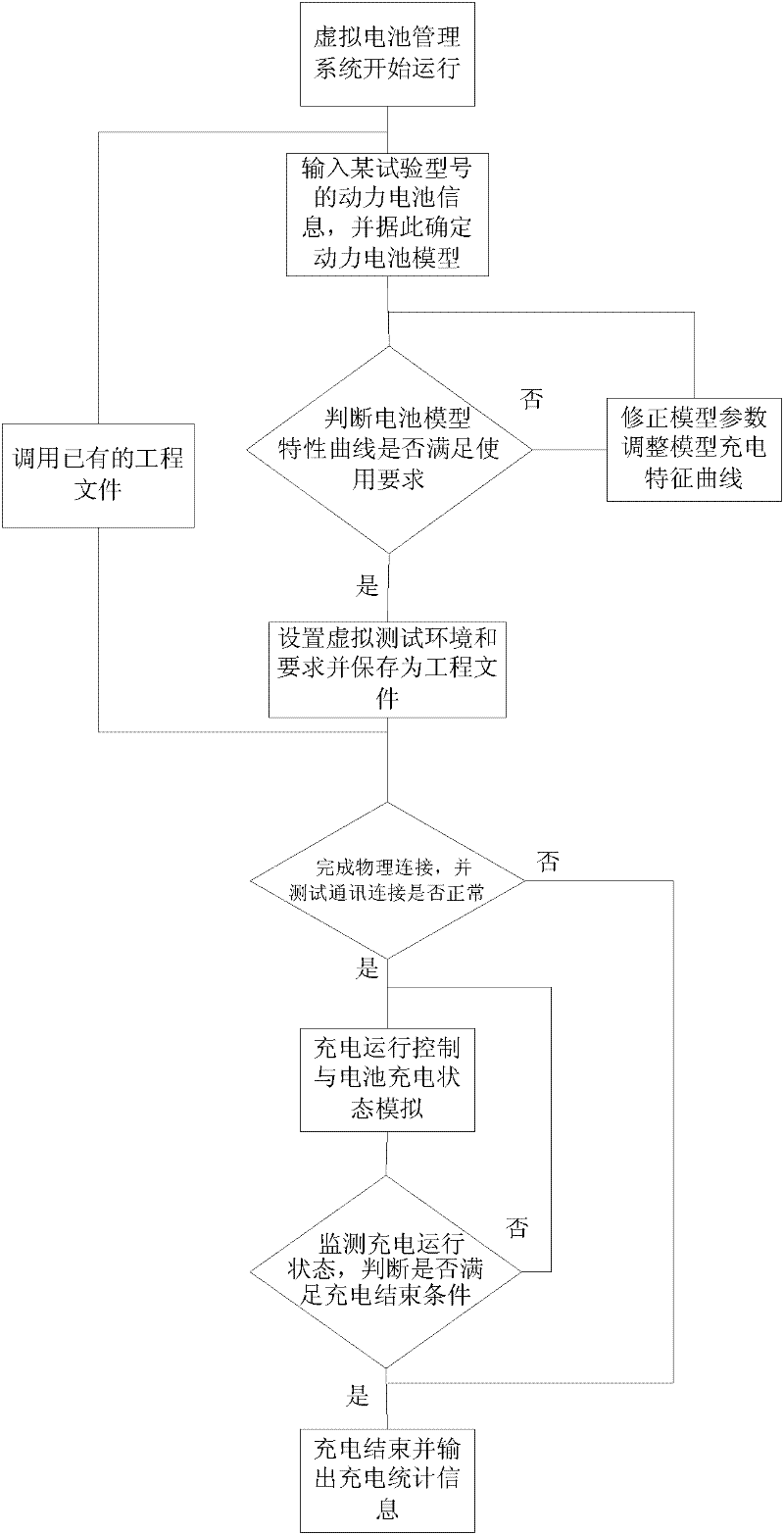

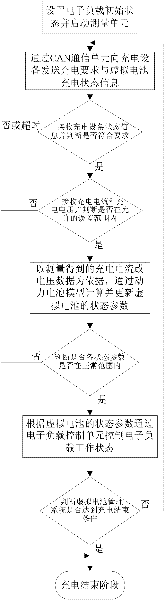

Virtual battery management system and application method thereof

ActiveCN102411128AExtended simulation runImprove controllabilityElectrical testingArea networkElectrical battery

The invention discloses a virtual battery management system and an application method thereof, belonging to the technical field of new energies. The virtual battery management system has the structure as follows: a central data processing unit is respectively connected with a man-machine interaction unit, a power battery emulation unit, a CAN (Controller Area Network) communication unit, a measuring unit and an electron load control unit. The virtual battery management system has the advantages that: firstly, the state and charging requirements of a charging object which is possibly encountered in the actual use process are integrated in one system; secondly, charging state information interaction between the virtual battery management system and charging equipment to be tested is realized; thirdly, the model parameters and time coefficients of the test type power battery can be adjusted, and the controllability and work frequency of the charging equipment are improved; and fourthly, the invention provides reference for the influence of the charging equipment on the power battery in the charging process of the power battery, and diversity of the charging loads and universality of the test environment of the charging equipment are realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

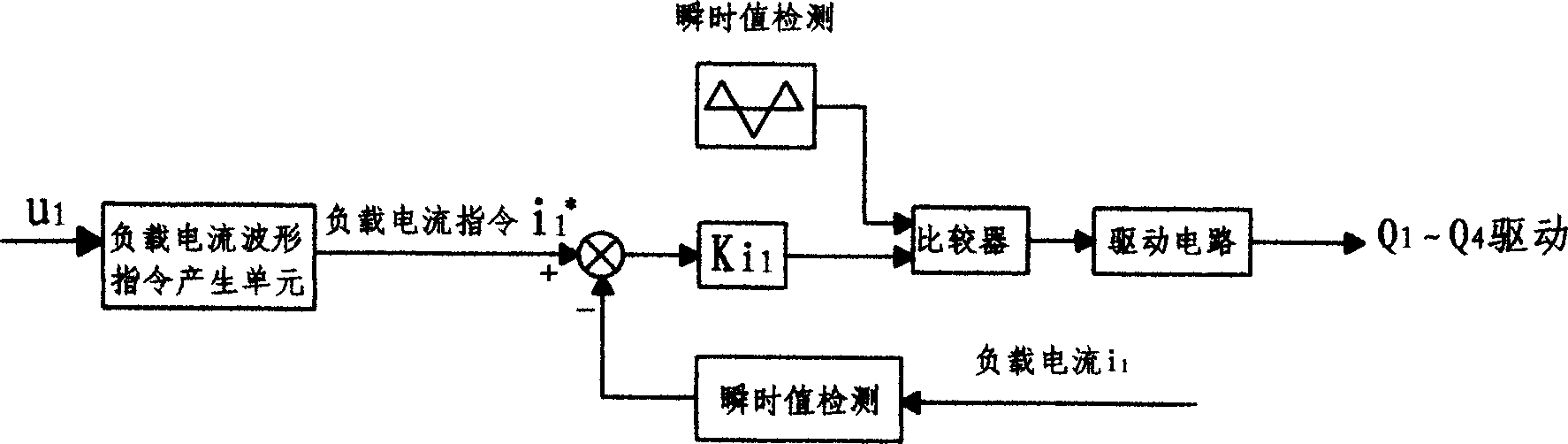

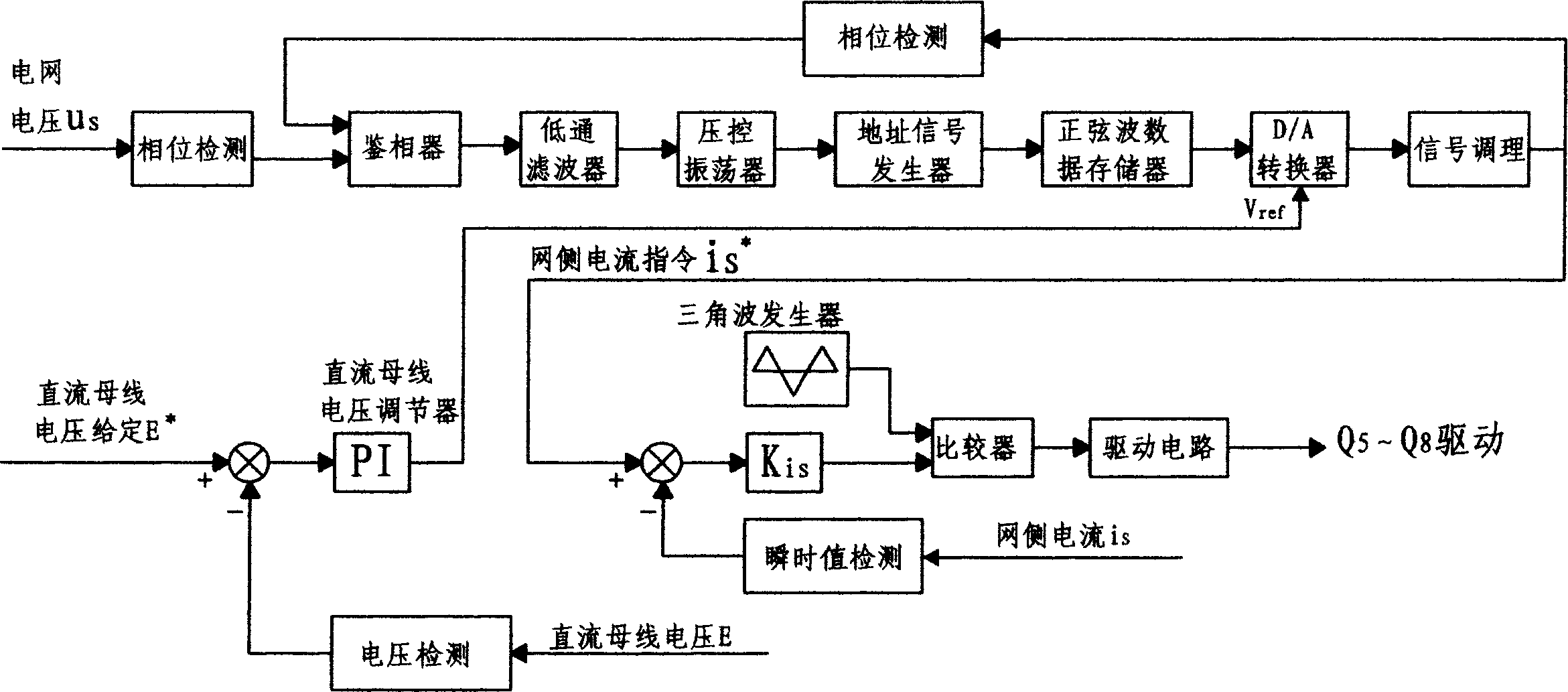

Energy feedback type AC/DC electronic load simulator

ActiveCN1847865ASelf loss is smallHigh grid side power factorElectrical testingPower conversion systemsTest powerElectronic load

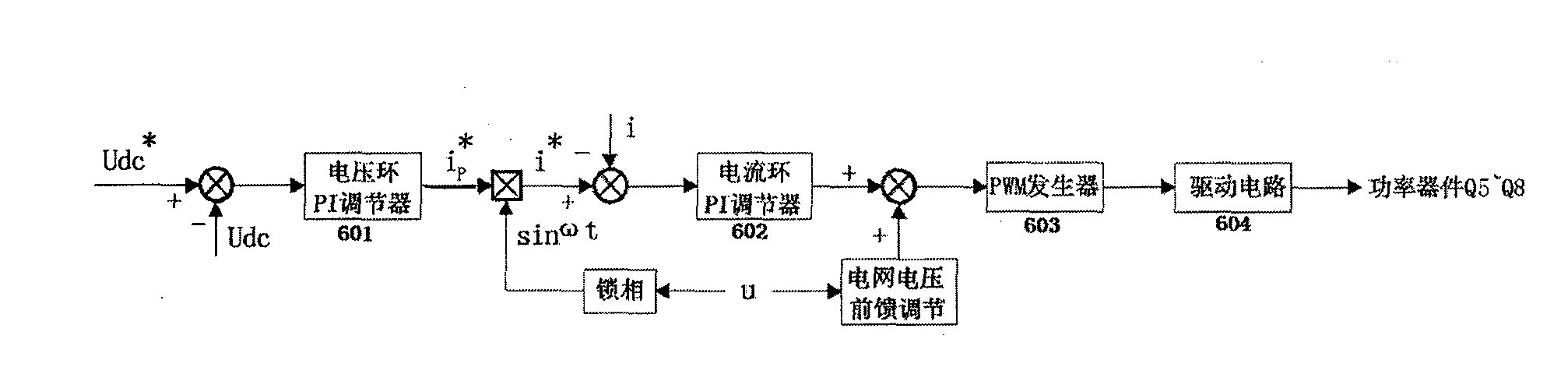

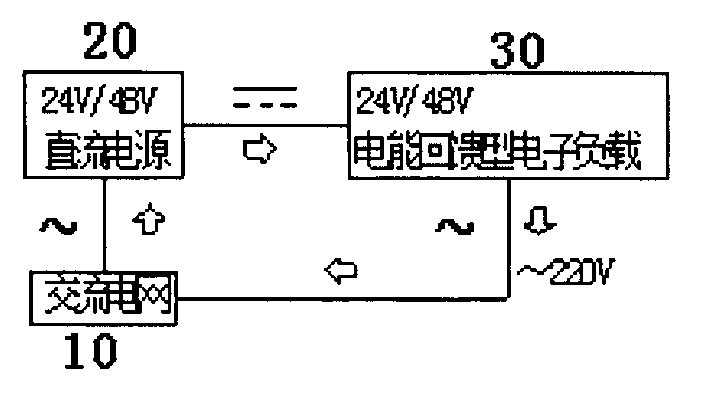

The energy feedback type AC / DC electronic load simulator consists of two stages of PWM inverters with common DC bus as key parts. The input PWM inverter stage is connected through input filter inductor to the tested power source to constitute the load characteristic simulating part of electronic load; the output PWM inverter stage is connected through the isolating transformer and output filter inductor to the power network to constitute the energy feedback part of electronic load; and the load characteristic simulating part and the energy feedback part are independently controlled. The load characteristic simulating has single instantaneous current value control mode controlling the input load current amplitude and waveform, and the energy feedback has current and voltage double closed-loop control mode including phase lock loop to control the current waveform in the output network side and the bus voltage in the DC side. The present invention has small loss and high network side power factor.

Owner:XIAN ACTIONPOWER ELECTRIC

Combinatorial method and apparatus for screening electrochemical materials

InactiveUS20070218329A1Unified performanceBatteries circuit arrangementsFuel cell heat exchangeElectronic loadElectrical battery

The present invention provides an apparatus and method to combinatorially screen a plurality of electrochemical material compositions for use in an electrochemical cell such as a fuel cell, battery or electro-catalytic cell. The apparatus includes an electrochemical cell with one or more windows, sealed with an infrared (IR) transparent material for direct thermal imaging of an internal electrode, an electronic load for applying a voltage or current to the electrochemical cell, and a device, external to the cell, for monitoring the relative temperature of the internal electrode through each window of the cell when the load is applied. When a load is applied to the cell, the temperature observed through each window may be used as a relative measure of the electrochemical efficiency of the discreet region of the electrode being viewed and of the material compositions contained therein. The electrochemical cell may comprise discreet compositions of electrode materials. The device for monitoring the temperature of the cells may include a thermal imaging device, infrared camera and array of thermocouples.

Owner:KEITH KEPLER DOUGLAS +3

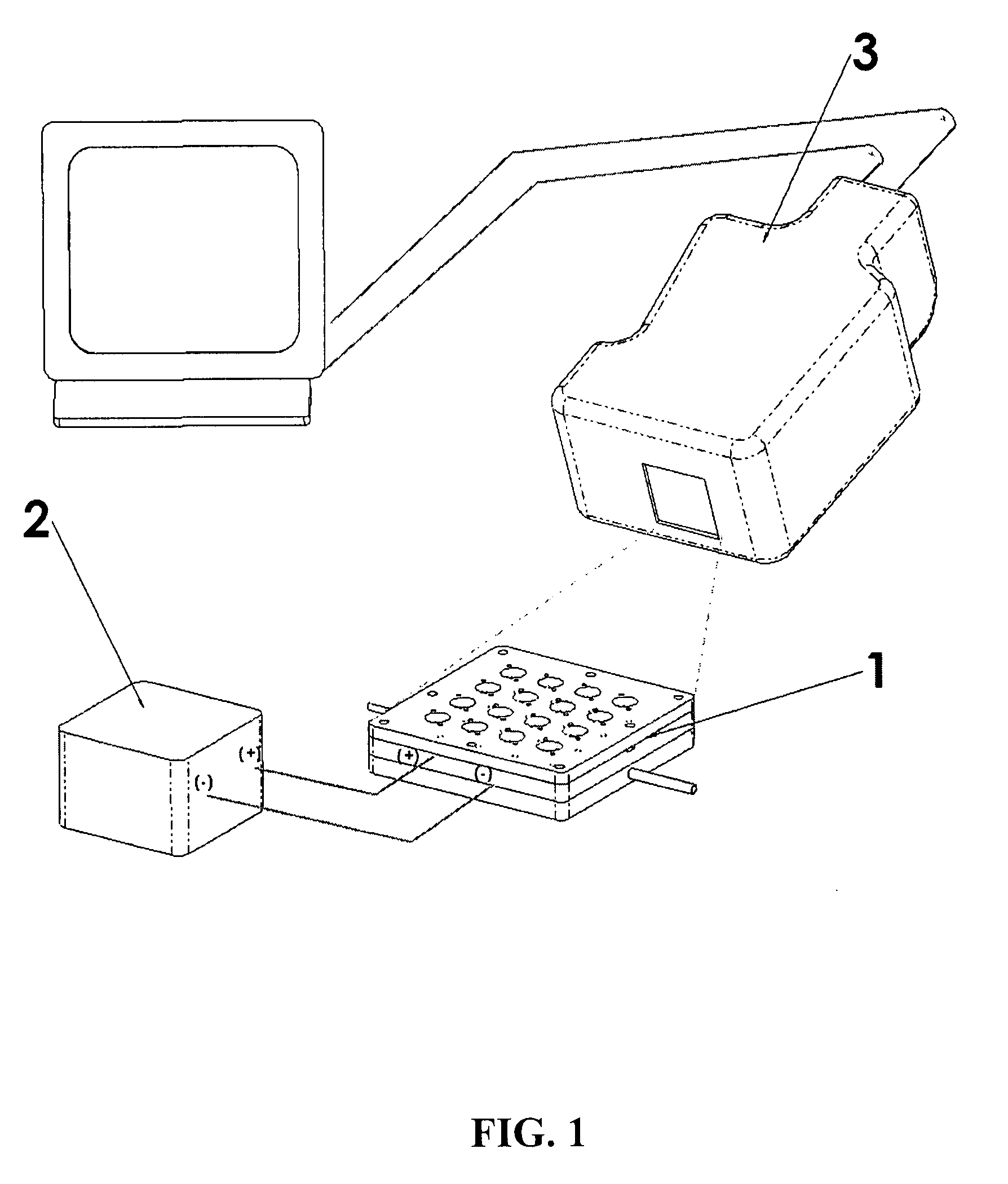

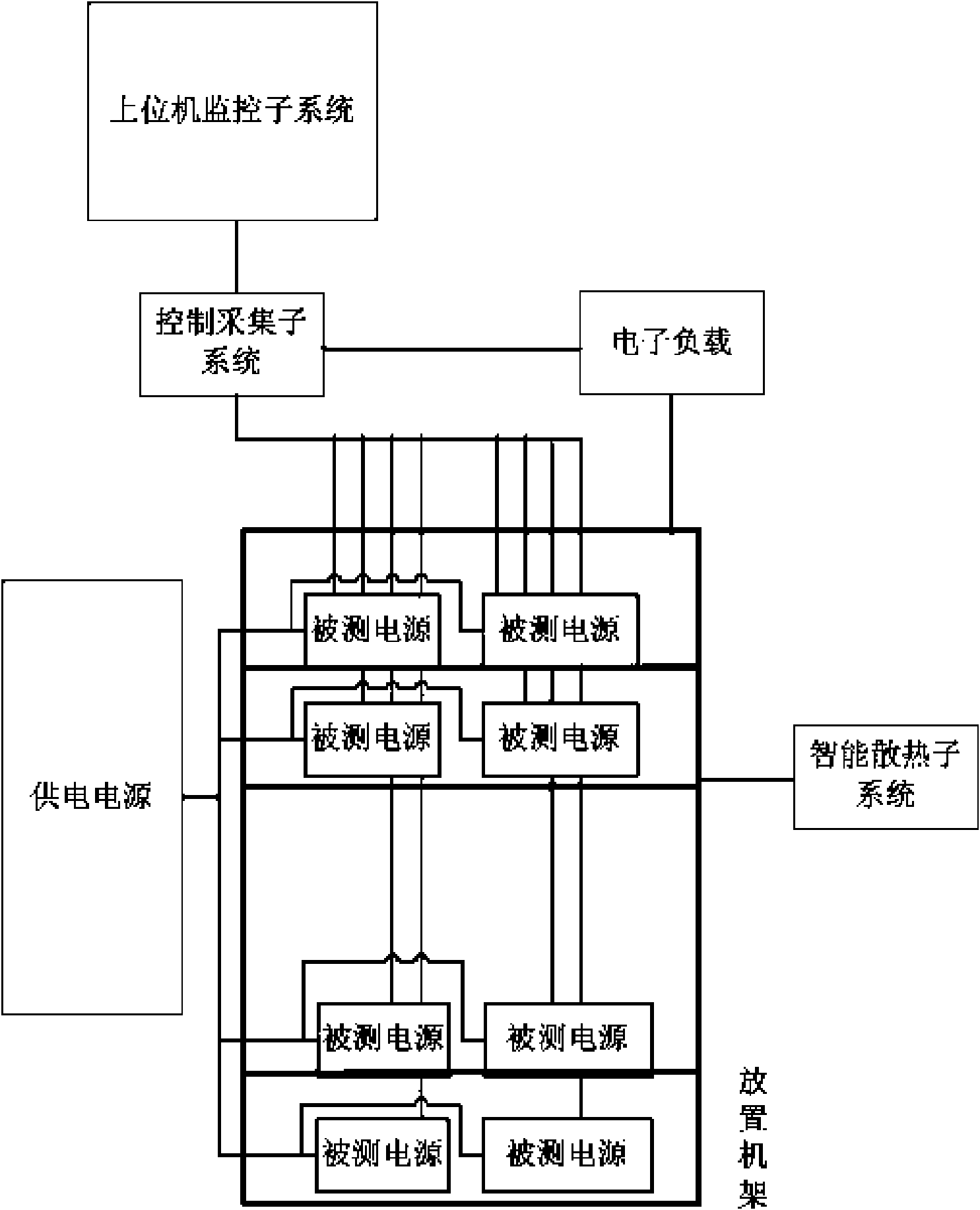

Universal power-aging testing system

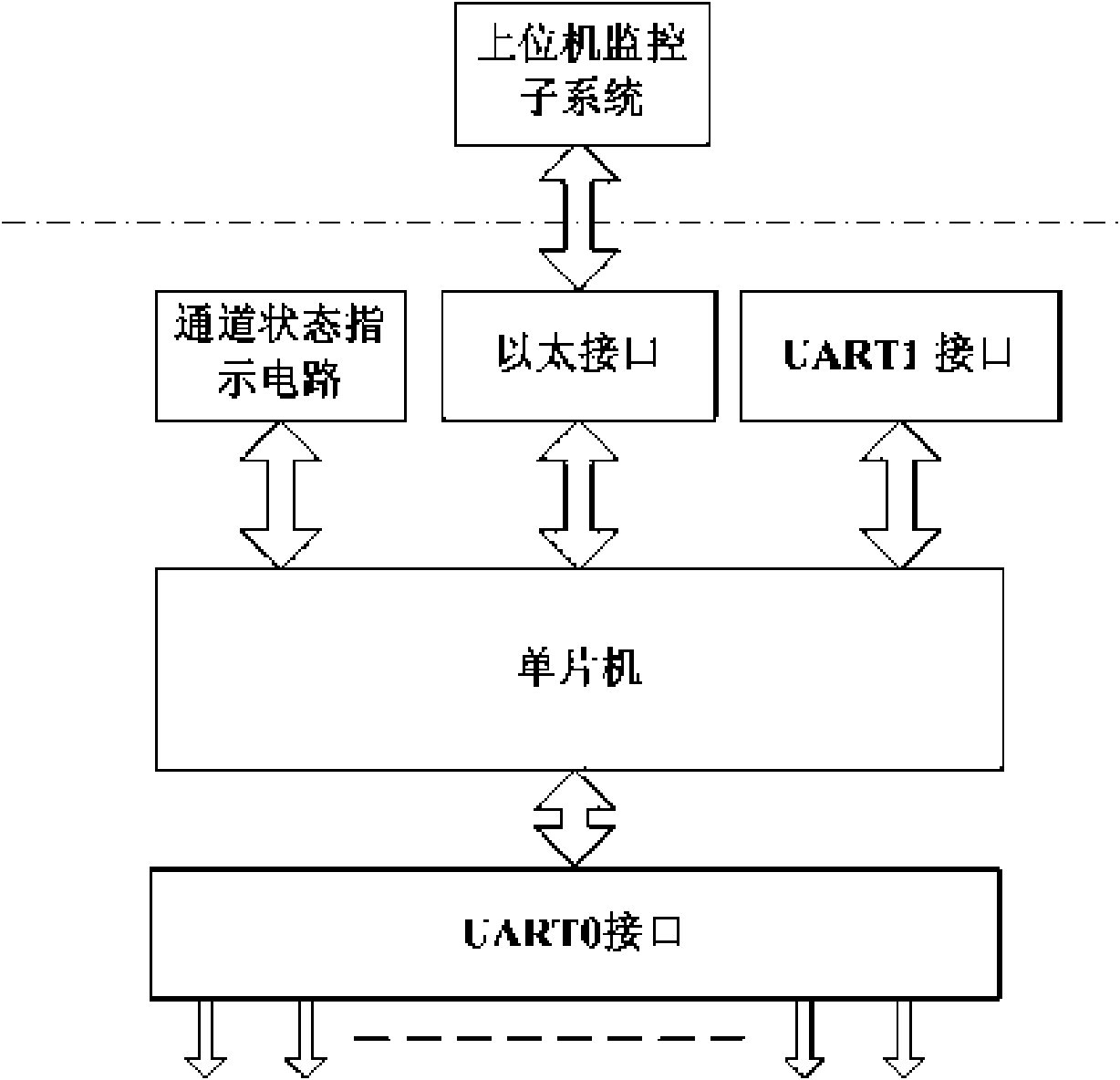

InactiveCN101650411AMeet aging test needsReal-time modificationPower supply testingComputer monitorElectronic load

The invention discloses a universal power-aging testing system which belongs to aging testing systems of electronic products and aims to solve the problems of poor universal property, flexibility, real-time performance and operability of the prior power aging systems. The system comprises a placement frame, a power supply source, an electronic load, a host computer monitor and control subsystem and a control and collection subsystem, wherein the placement frame bears the power supply to be tested, the power supply source supplies power to the power supply to be tested, and the electronic loadis used as the load of the power supply to be tested; and the host computer monitor and control subsystem is used for receiving data of the control and collection subsystem and transmitting test parameters and control commands to the control and collection subsystem; and the control and collection subsystem is respectively connected with the power supply to be tested, the electronic load and the host computer monitor and control subsystem, and used for receiving the test parameters and the control commands of the host computer monitor and control subsystem as well as the status information ofthe power supply to be tested, and also used for adjusting the electronic load signals according to the status information of the power supply to be tested so as to control the aging testing process.

Owner:MAIPU COMM TECH CO LTD

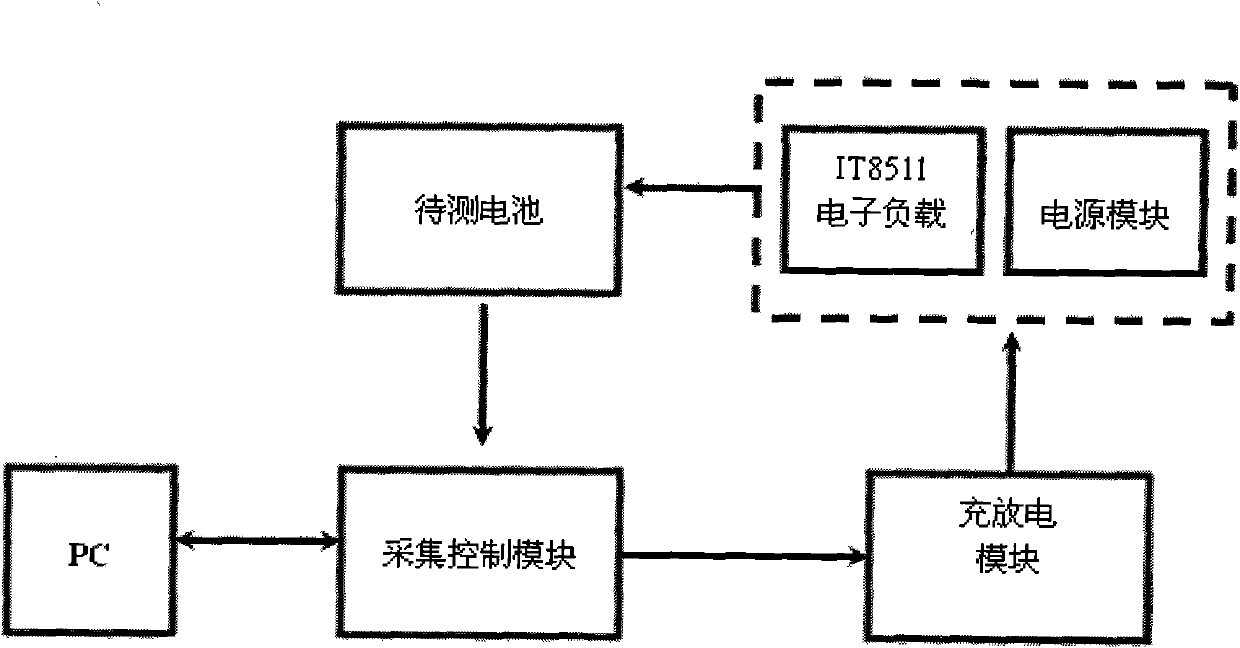

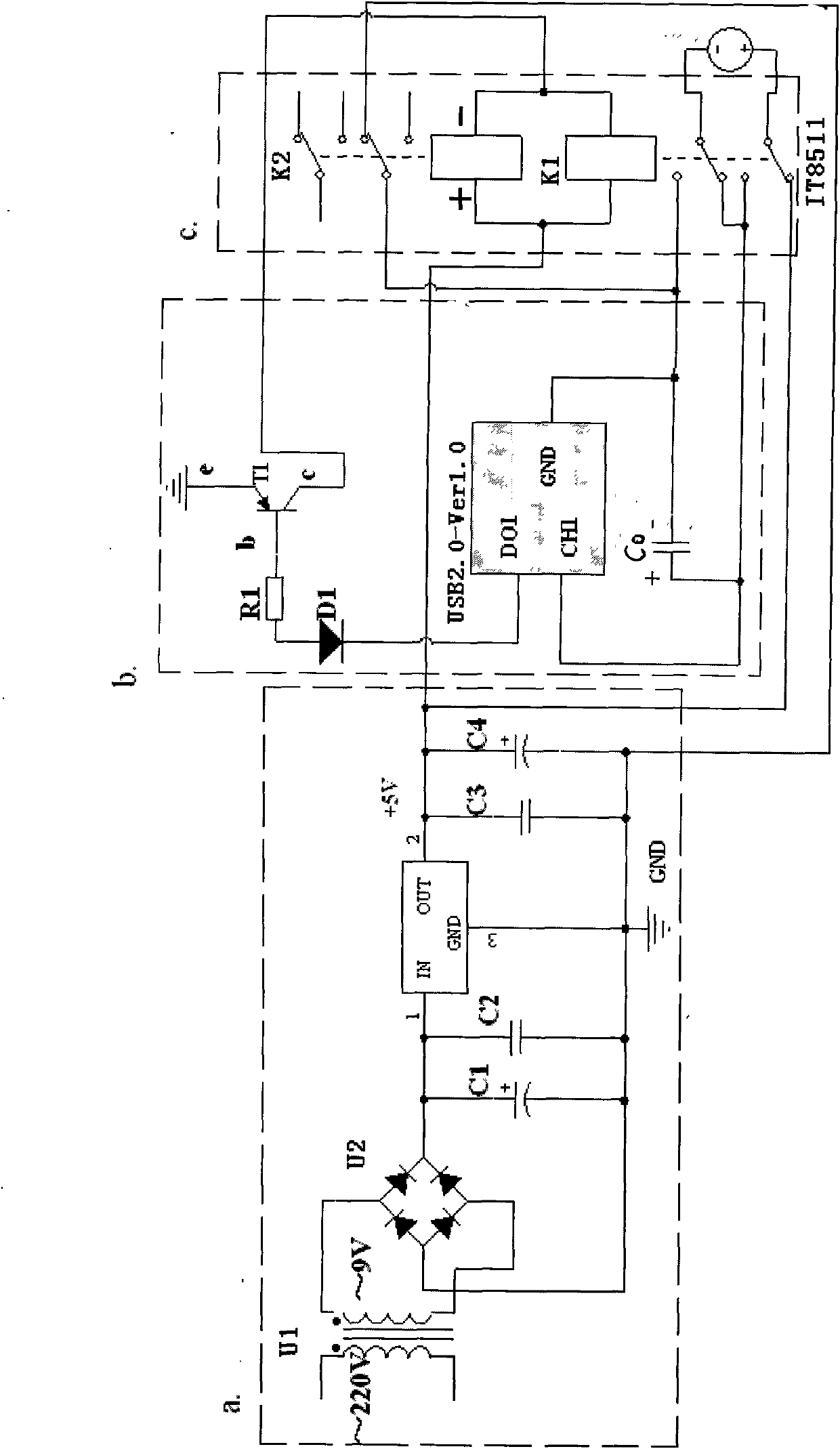

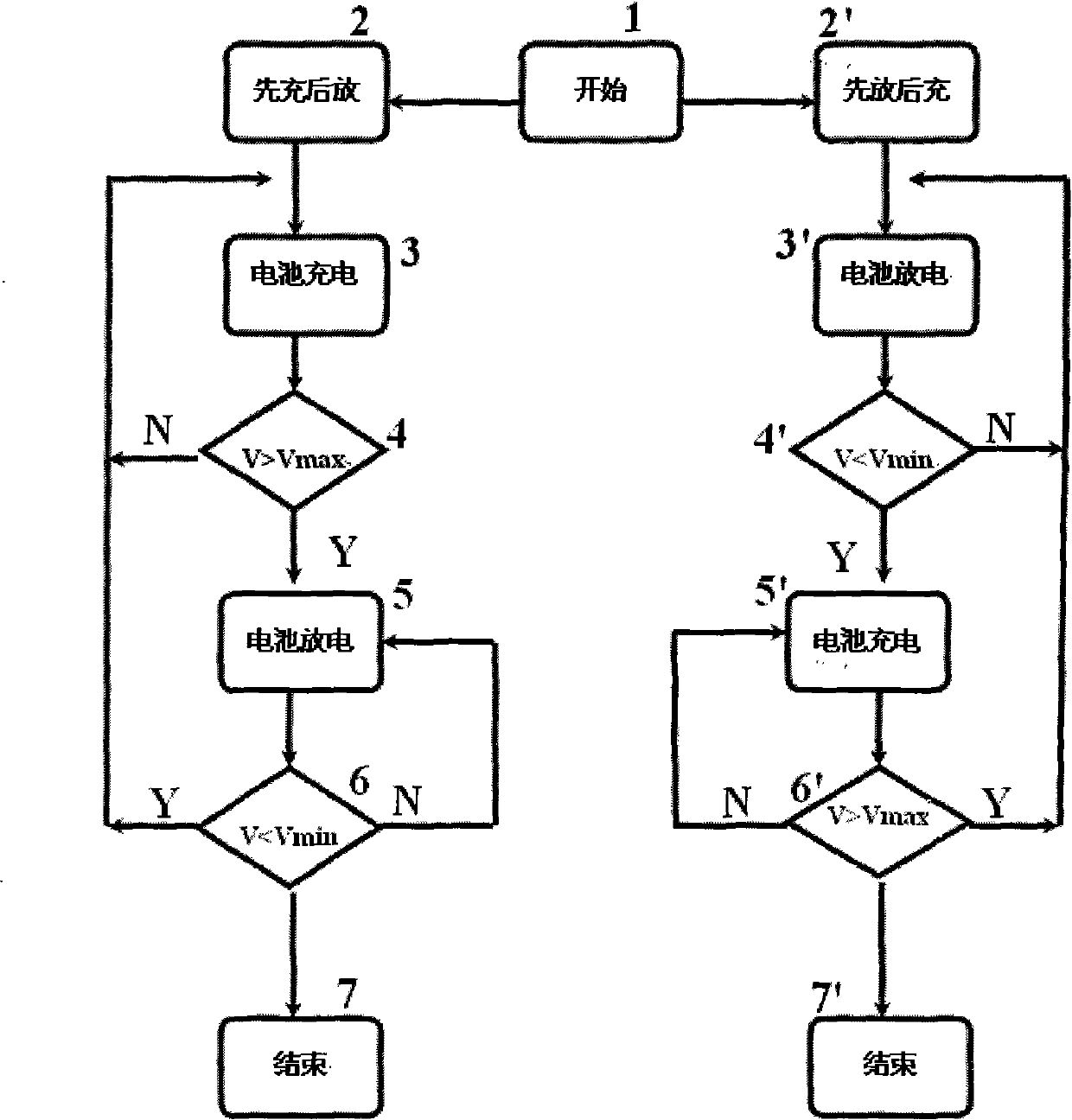

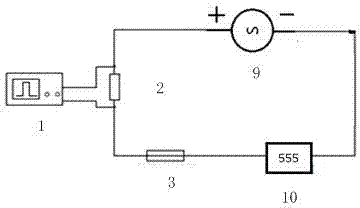

Intelligent battery cycle charge-discharge testing device

The invention provides an intelligent battery cycle charge-discharge testing device. The device is a secondary battery automatic charge-discharge testing device with low price, high precision and good stability. The device can test main parameters of a secondary battery, has safe and reliable performance and has wide application prospect. The device comprises a power supply module, an electronic load, an acquisition control module, a PC machine and a charge-discharge module, wherein an output of the power supply module is connected with the electronic load and the charge-discharge module; a battery to be tested is connected with the electronic load by the charge-discharge module; a signal acquisition end of the acquisition control module is connected with the battery to be tested, while a control end thereof is connected with the charge-discharge module; and the acquisition control module is on-line with the PC machine by a USB data wire.

Owner:NANJING UNIV OF TECH

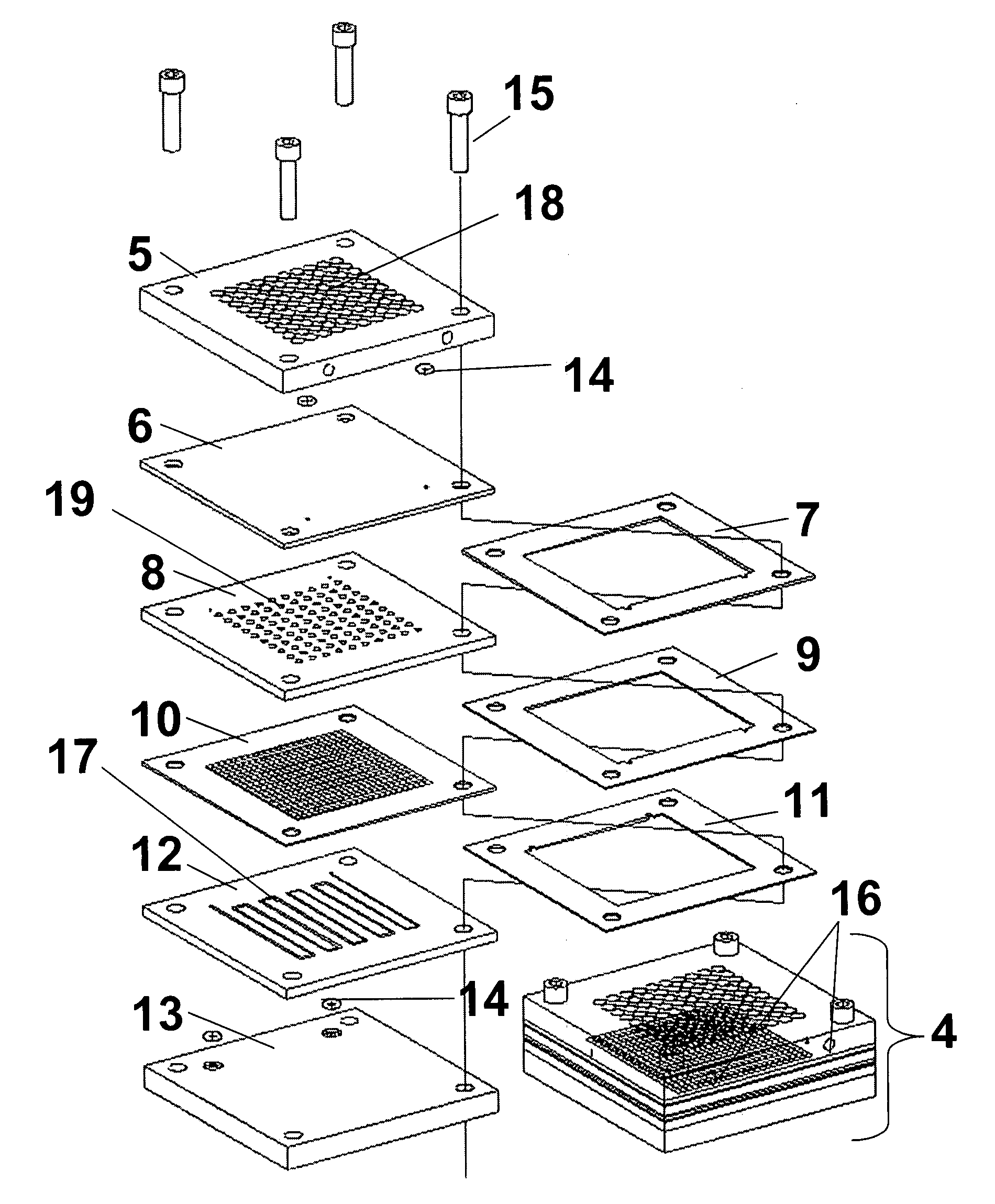

Electrochemical machining method for auxiliary anode tube electrode

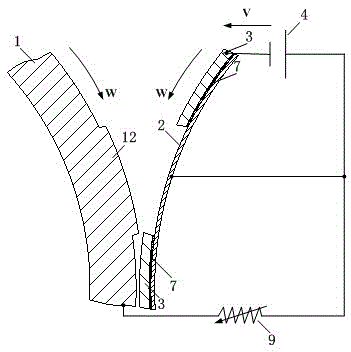

ActiveCN103317196AInhibition of stray corrosionReduce sensitivityElectrochemical machining apparatusElectrolysisElectronic load

The invention relates to an electrochemical machining method for an auxiliary anode tube electrode and belongs to the technical field of electrochemical machining. The electrochemical machining method includes the following processes: 1, manufacturing a perforated plate (5); 2, positioning and clamping a workpiece anode (4), the perforated plate (5) and an auxiliary anode (6); 3, connecting the positive pole of a power source (2) with one end of a substrate clamp (7) and one end of the workpiece anode (4), connecting the negative pole of the power source (2) with a tube electrode (1), and connecting the other end of the electronic load (3) with the workpiece anode (4); 4, leading in electrolyte, setting a constant voltage working mode of the electronic load (3) to achieve voltage drop, starting the power source, and performing electromechanical machining on the tube electrode when the potential of the workpiece anode (4) is lower than that of the auxiliary anode; 5, separating and cleaning the workpiece anode (4), the perforated plate (5) and the auxiliary anode (6). The electrochemical machining method for the auxiliary anode tube electrode has important meaning in improving aperture outlet accuracy of tube electrode electrochemical machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

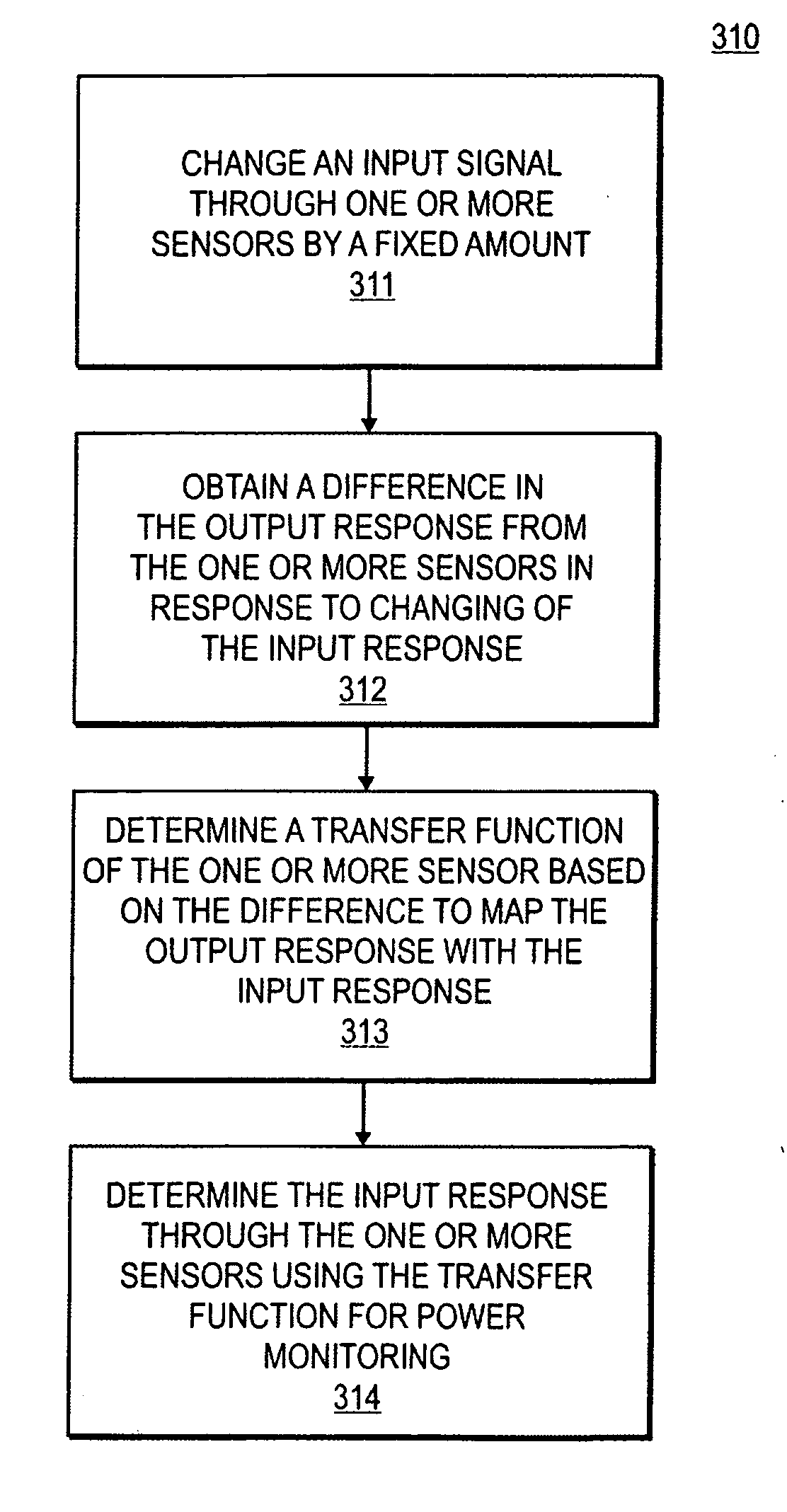

Methods and apparatuses for calibrating sensors

InactiveUS20080040055A1Accurate predictionMaximize probabilityTesting/calibration apparatusTesting/calibration of speed/acceleration/shock measurement devicesData processing systemElectronic load

Methods and apparatuses to perform calibration of imprecise sensors for power monitoring in a data-processing system are described. The system includes a load coupled to one or more sensors. An electronic load changes a first input signal through one or more sensors by a predetermined amount. A difference in an output signal from the one or more sensors in response to the changing is obtained. The output signal is measured and sampled. A distribution of samples of the output signal is determined. The estimated parameters of the distribution that most likely to explain actual data are determined. Next, a transfer function of the one or more sensors is determined based on the estimated parameters. The input signal through the load is accurately predicted using the transfer function of the one or more sensors to monitor the power usage by the load.

Owner:APPLE INC

Electric energy feedback type electronic load

InactiveCN104052079AImprove machine efficiencyReduce the temperatureSingle network parallel feeding arrangementsPower supply testingPower qualityMOSFET

The invention relates to an electric energy feedback type electronic load. The input end of the electronic load employs a large-current single-channel access mode. A main circuit mainly comprises a DC / DC conversion circuit, a DC / AC inverter circuit, and an AC filter output circuit, wherein the DC / DC conversion circuit employs a phase-shifted full-bridge circuit to achieve the control of DC input, and boosts DC input voltage. In order to adapt to large-current input, a switching device is formed by parallel connection of a plurality of MOSFETs. The DC / DC conversion circuit is connected with the DC / AC inverter circuit through a DC bus. The DC / AC inverter circuit employs a single-phase full-bridge inverter circuit to control AC output current so as to stabilize the voltage of the DC bus and feeds the AC current back to a power network by a unit power factor. The DC / AC inverter circuit employs an IGBT module as a power device. The AC filter circuit can employ an LC low-pass filter circuit so as to eliminate the higher harmonic waves in the output current of the DC / AC inverter circuit and improve the quality of grid-connected electric energy.

Owner:余名俊

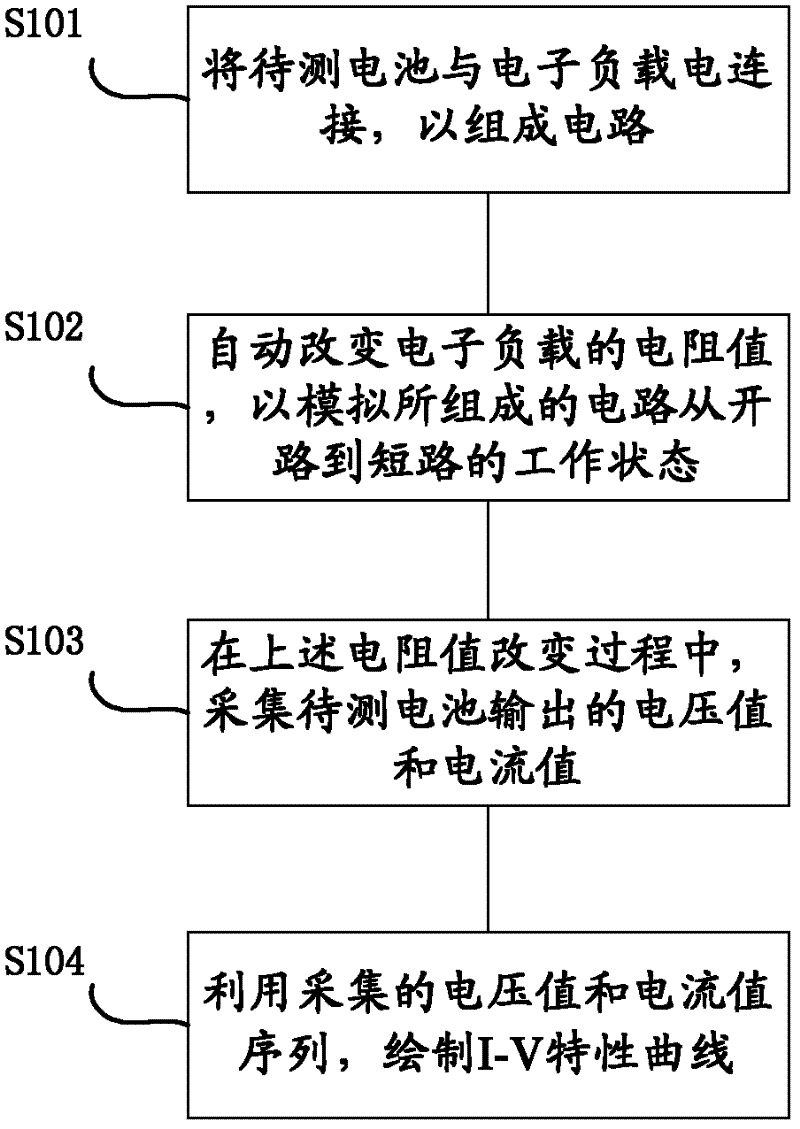

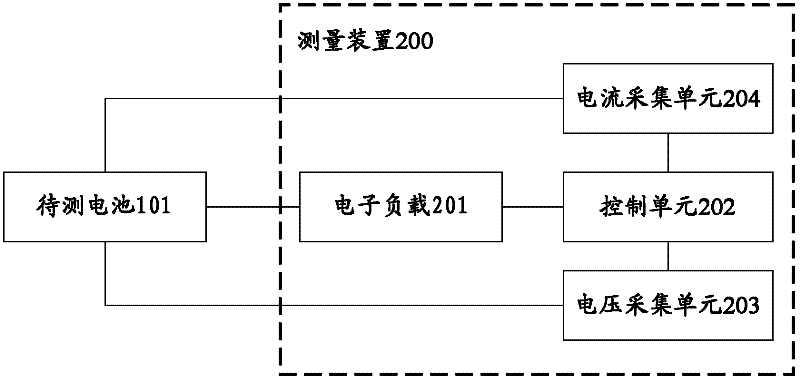

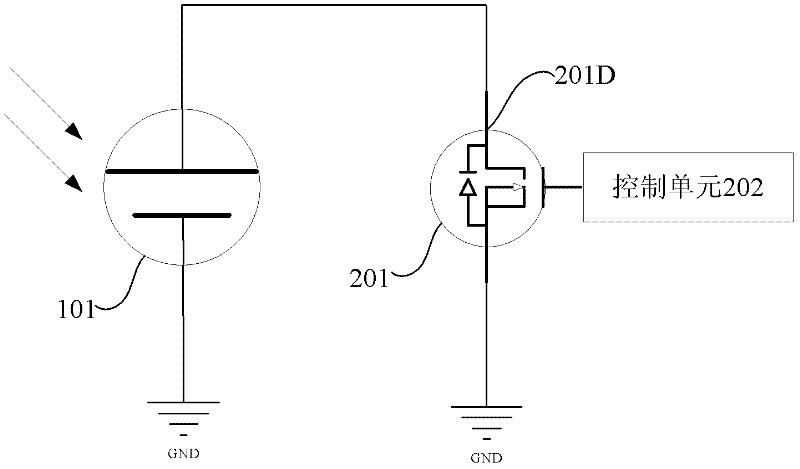

Method and device for measuring electrical characteristics of solar cells

InactiveCN102298110AImprove measurement efficiencyReduce mistakesPhotovoltaic monitoringPhotovoltaic energy generationMeasurement deviceElectronic load

The invention provides a method for measuring the electrical characteristics of a solar cell, comprising: step 1, electrically connecting the solar cell to be tested with an electronic load to form a circuit; step 2, using a control unit to change the resistance value of the electronic load to simulate the formed circuit The working state of the circuit from open circuit to short circuit; and Step 3, during the change process of the above resistance value, collecting the voltage value and current value sequence output by the battery to be tested. A measuring device is also provided, including: an electronic load, adapted to provide a load for the battery under test; a voltage acquisition unit, adapted to acquire the voltage of the battery under test; a current acquisition unit, adapted to acquire the voltage of the battery under test and a control unit adapted to send a control signal to the electronic load to change the resistance of the electronic load, while receiving voltage and current values from the voltage acquisition unit and the current acquisition unit. The measurement efficiency is improved, errors are reduced, and real-time detection is possible.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

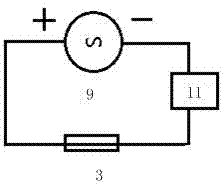

Method and device of testing surge current impact resistant property of fuse

InactiveCN103163421AWork reliablySuitable for fuse testingFuses testingElectrical resistance and conductanceElectronic load

The invention discloses a method and a device of testing surge current impact resistant property of a fuse and can be used for testing the surge current impact resistant property and a fusing characteristic. The technical scheme is that the device of testing the surge current impact resistant property of the fuse comprises a tested fuse, a monitoring portion, a current-limiting resistance, an electronic load and a power source. The device of testing the surge current impact resistant property of the fuse is characterized in that the monitoring portion comprises a monitoring oscilloscope and a sampling resistance. The sampling resistance is connected with the tested fuse, the current-limiting resistance, the electronic load and the power source in sequence to form a closed loop. The monitoring oscilloscope is parallel connection with two ends of the sampling resistance. The power source is a storage battery set, wherein the storage battery is connected in parallel. The electronic load is used for producing periodic surge pulses. The monitoring oscilloscope can monitor resistance variation and fusing time of the tested fuse when the sampling resistance produces corresponding current pulses.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

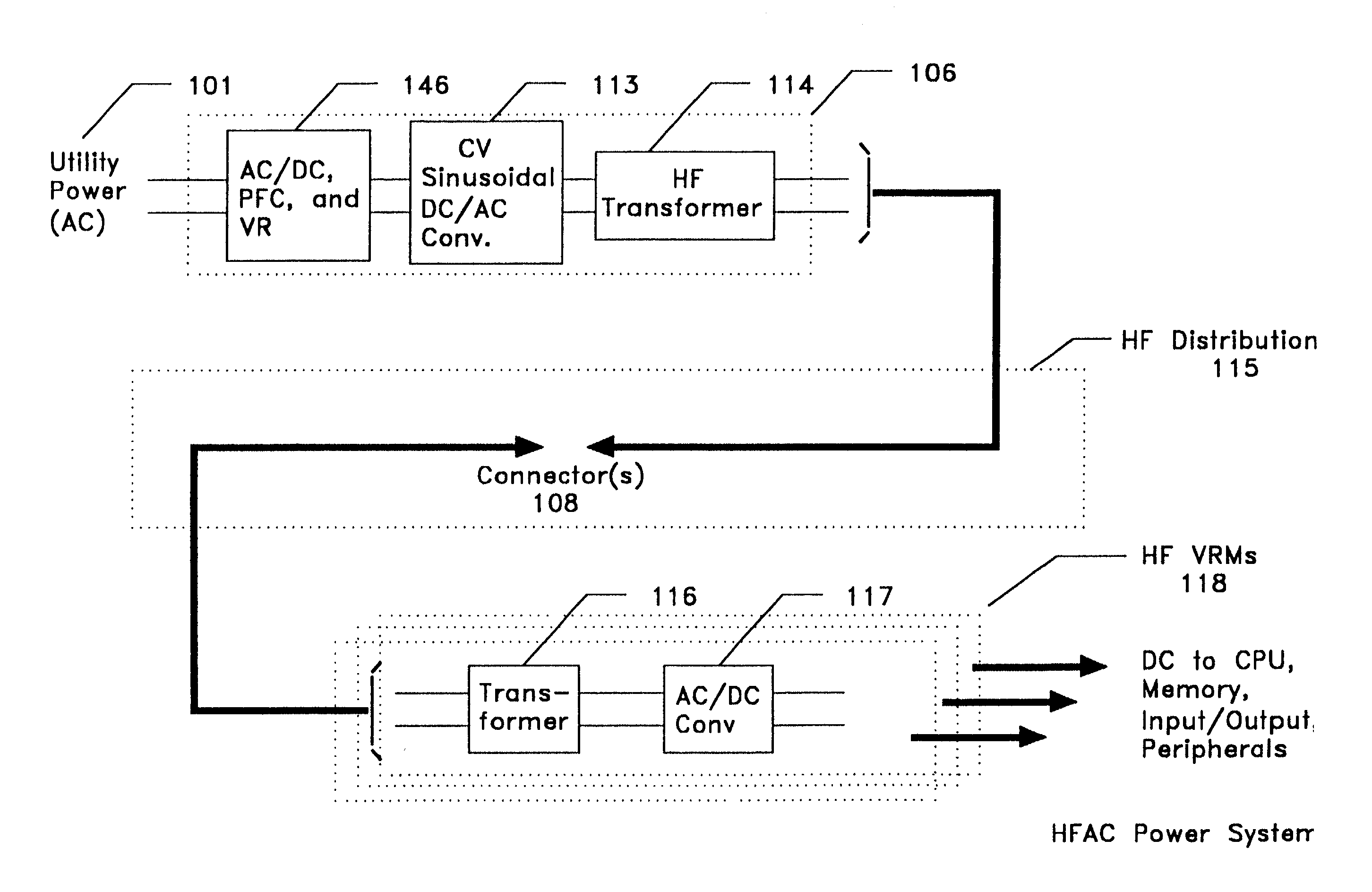

Multiple element rectification circuit

InactiveUS7110266B1Inductance connectionImprove efficiencyBatteries circuit arrangementsAc-dc conversion without reversalElectronic loadLow voltage

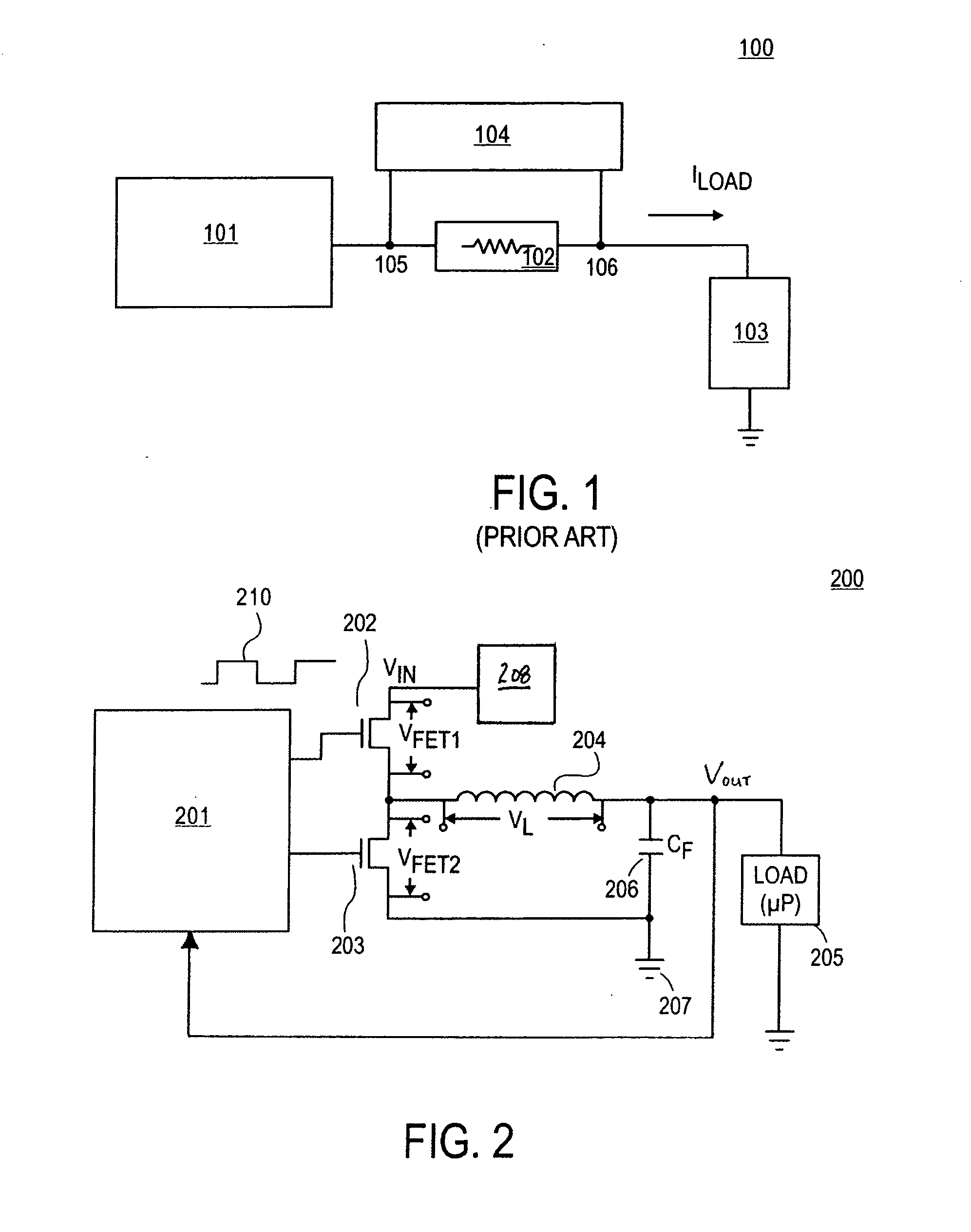

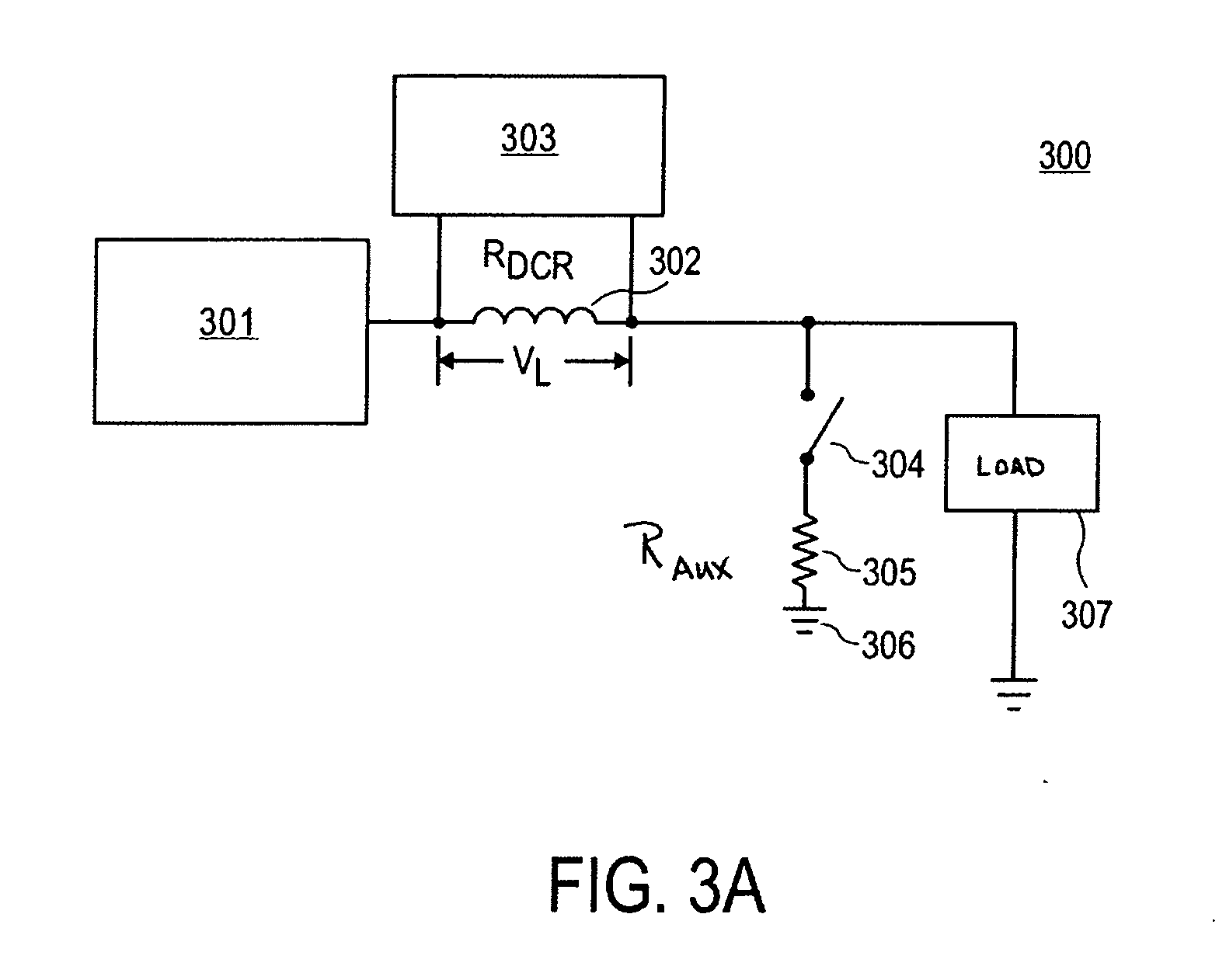

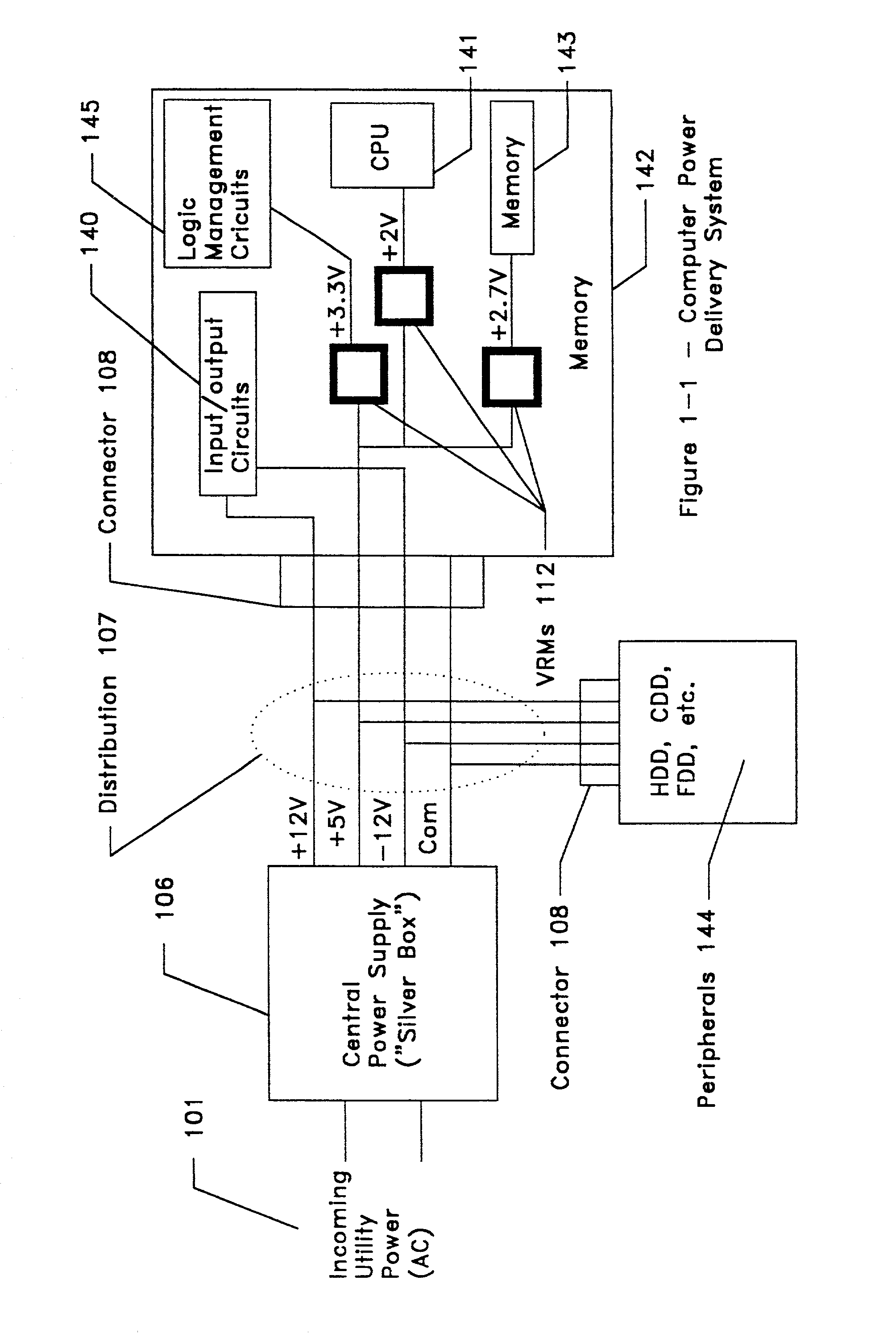

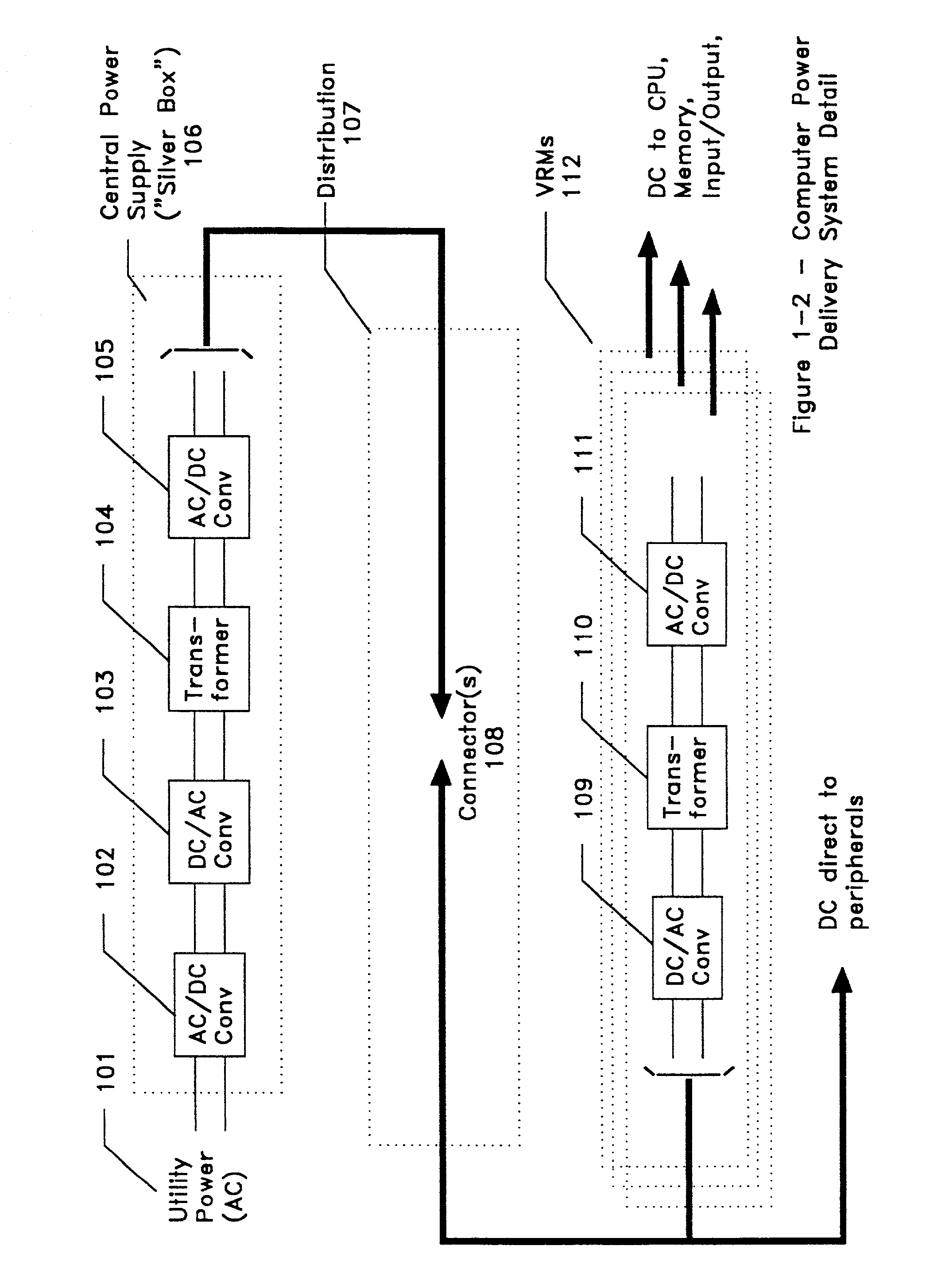

Apparatus are disclosed for controlling the delivery of power to DC components such as computer components, microprocessors or the like. Designs of rectifier circuitry are presented which are appropriate for faster components, lower voltages, and higher currents. Embodiments are especially suited to applications which cause rapid changes in the conductance of the load, even in the sub-microsecond time domain as is common in computer applications and the like and in powering electronics equipment, especially a distributed system and especially a system wherein low voltage at high current is required. Embodiments and sub elements provide energy storage for low voltage, high current electronic loads, an ability to supply current with rapid time variation, providing extremely low inductance connections, permitting components to be located relatively remotely from the powered electronic load.

Owner:INTEGRATED DEVICE TECH INC +2

Electrochemical machining bipolar electrode of revolution body surface boss structure and electrochemical machining method of electrochemical machining bipolar electrode

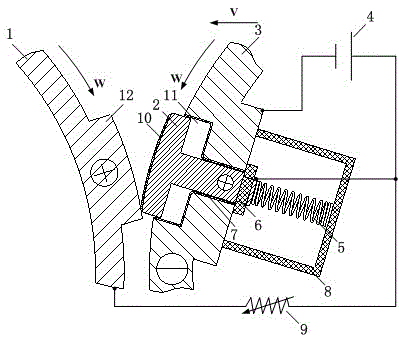

ActiveCN105522239AElimination of surface stray corrosionEliminate stray currentMachining electrodesElectrical-based machining electrodesElectronic loadElectrolysis

The invention relates to an electrochemical machining bipolar electrode of a revolution body surface boss structure and the electrochemical machining method of the electrochemical machining bipolar electrode, and belongs to the technical field of electrochemical machining. The method is characterized in that a tool electrode is the bipolar electrode, according to different boss heights, an auxiliary electrode is arranged to be in a fixed and reciprocating motion manner, and a constant positive potential difference is applied to the auxiliary electrode and a workpiece positive pole through an electronic load in the machining process; and as the distance between the auxiliary electrode and a boss is short, according to the electric field distribution principle, the auxiliary electrode with the higher potential can effectively change electric field distribution on the surface of the boss in a machining zone, stray current on the surface of the boss is eliminated, and the effect of protecting the surface of the boss from dispersive corrosion is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

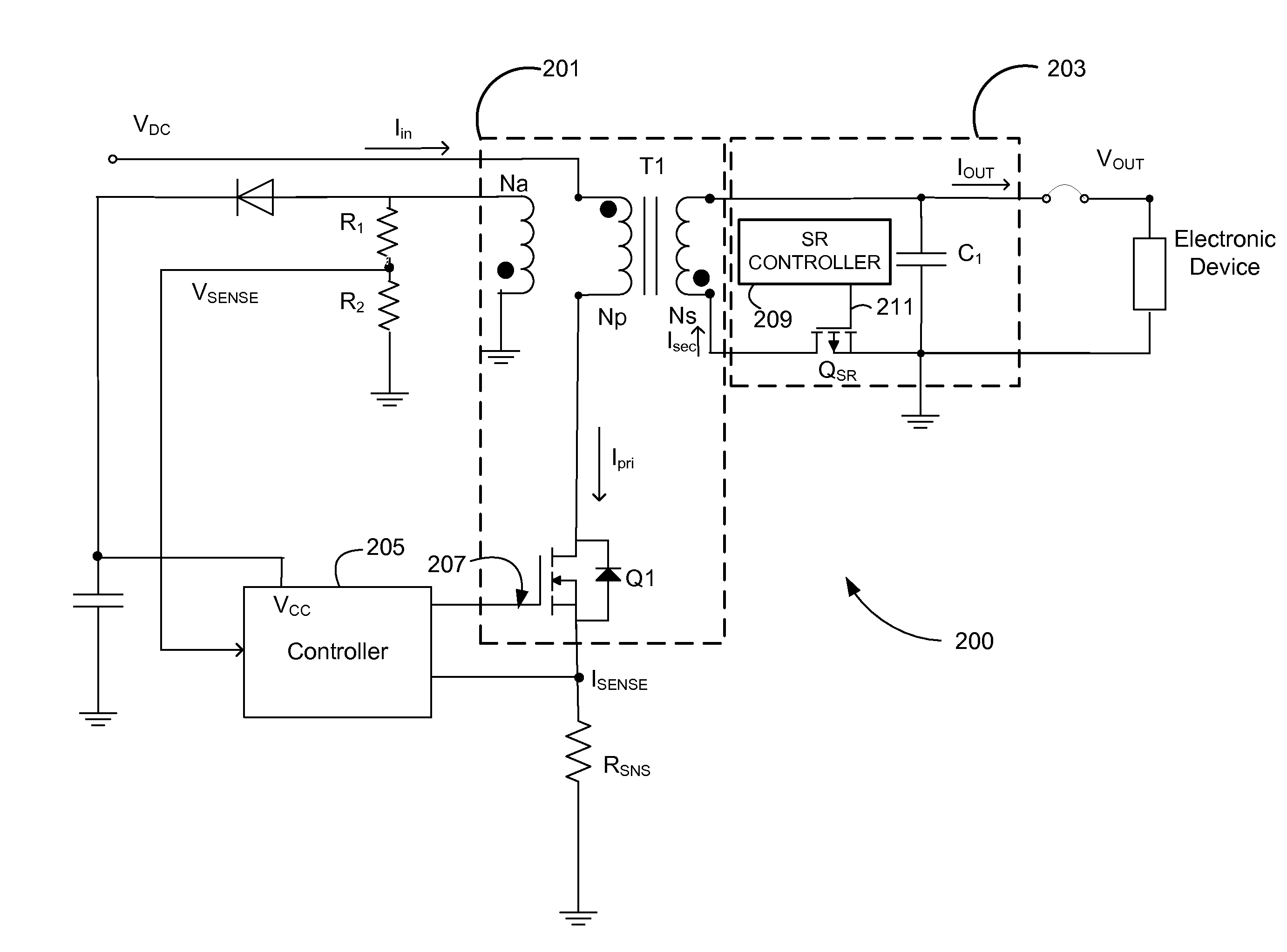

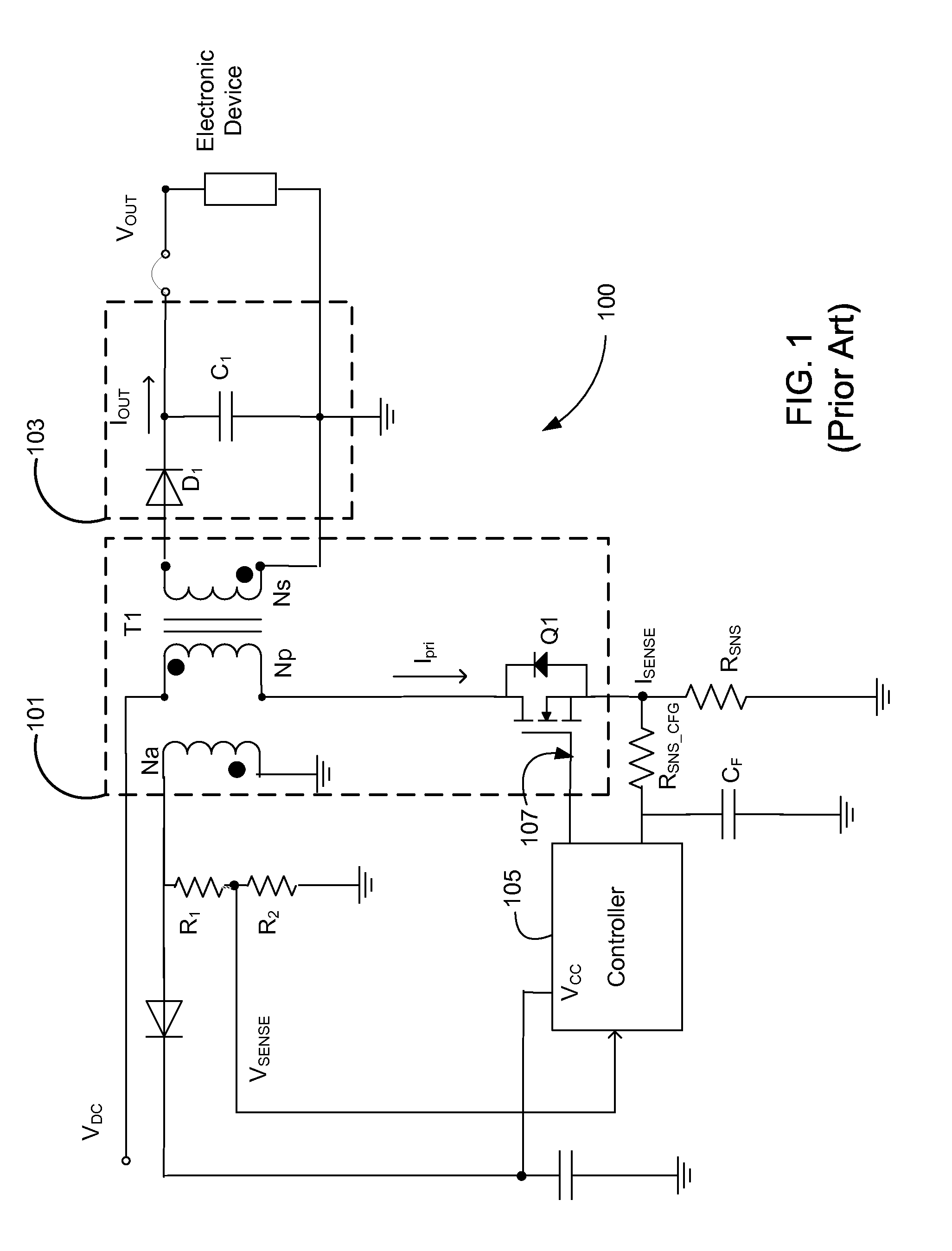

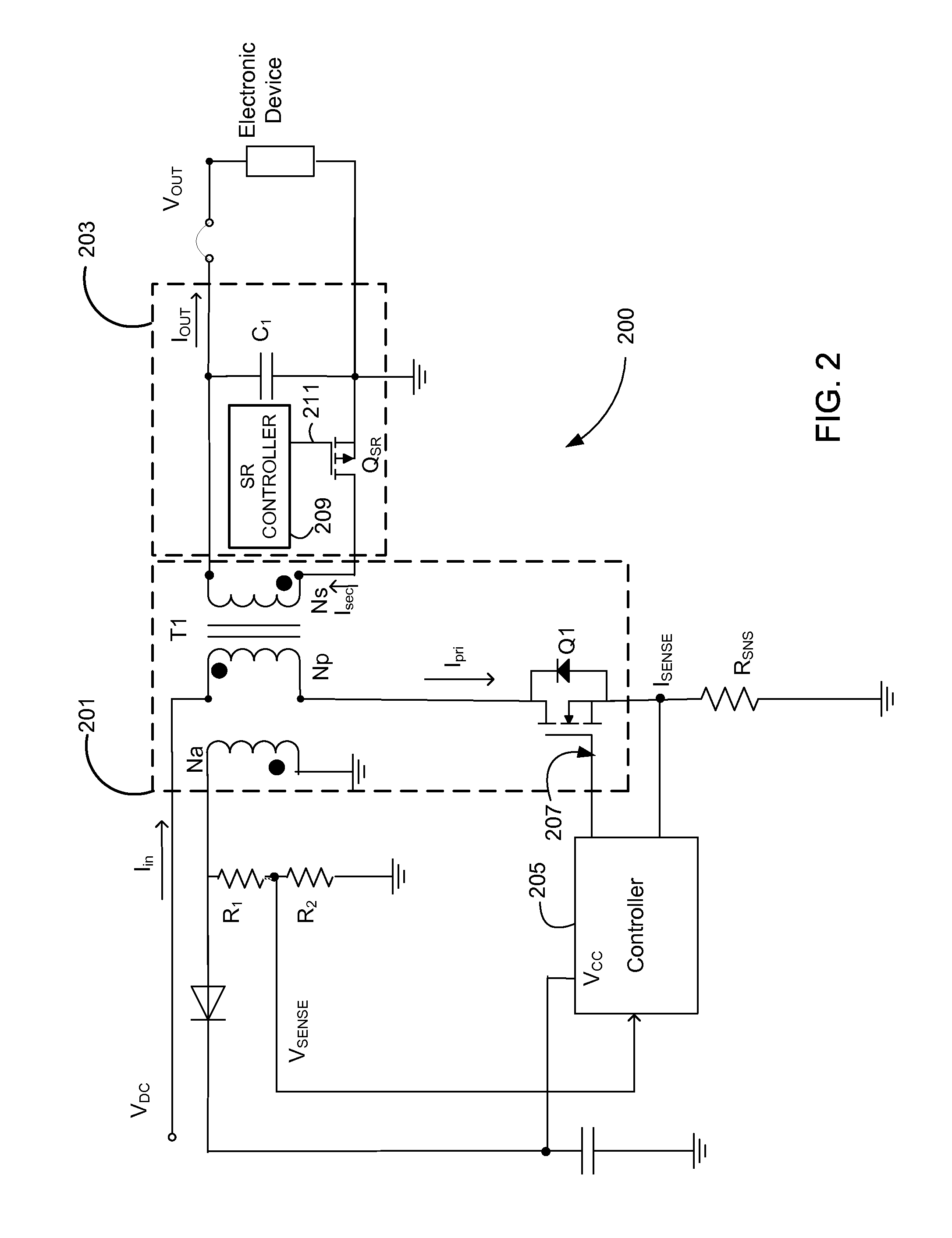

Adaptive synchronous rectifier control

InactiveUS20150124494A1Efficient power electronics conversionDc-dc conversionElectronic loadSwitching cycle

The embodiments herein describe a switched mode power converter. In particular, the embodiments herein disclose techniques for adaptive synchronous rectification control. The switched mode power supply includes a synchronous rectifier controller that determines when to turn off the synchronous rectifier during each switching cycle based on a reference signal corresponding to when substantially all the power stored in a transformer of the power supply has been delivered to an electronic load. The synchronous rectifier controller may determine whether to adjust the reference signal used by the synchronous rectifier controller to turn off the synchronous rectifier during subsequent switching cycles.

Owner:DIALOG SEMICONDUCTOR INC

Rope capable of prompting fatigue degree

The invention relates to the technical field of rope processing, in particular to a rope capable of prompting the fatigue degree. The rope comprises a rope core, a sheath and a jacket, wherein the rope core is covered with the sheath; the jacket is arranged outside the sheath; circular areas are arranged on the sheath and comprise an inner circular area and outer circular areas, the outer circular area, the inner circular area and the outer circular area are sequentially distributed from top to bottom, and the inner circular area and the outer circular areas are coated with two pigments different from the sheath in color respectively; the width of the jacket is equal to that of the circular areas on the sheath, and the jacket just covers the circular areas of the sheath. The rope capable of prompting the fatigue degree fills in the gap in the prior art, a user can directly see whether the rope reaches or exceeds the own safe load, complex and high-cost equipment such as electronic load sensors and the like are not required, and the rope can be made of various materials and is simple, practical and low in cost.

Owner:QINGDAO HUAKAI OCEAN SCI & TECH

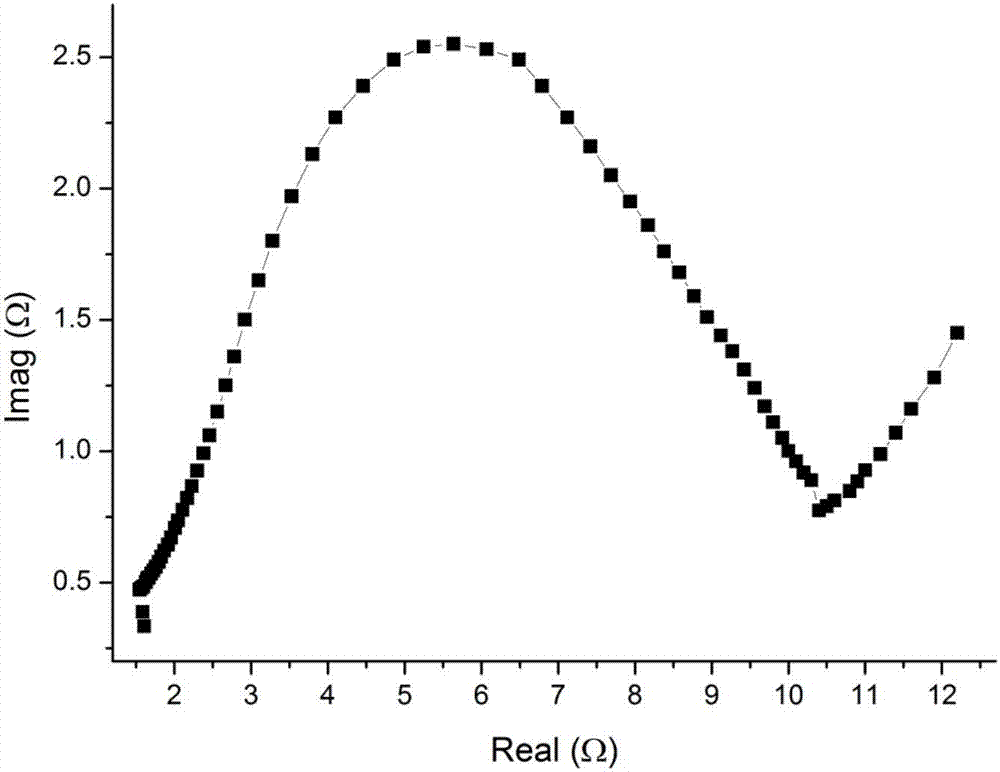

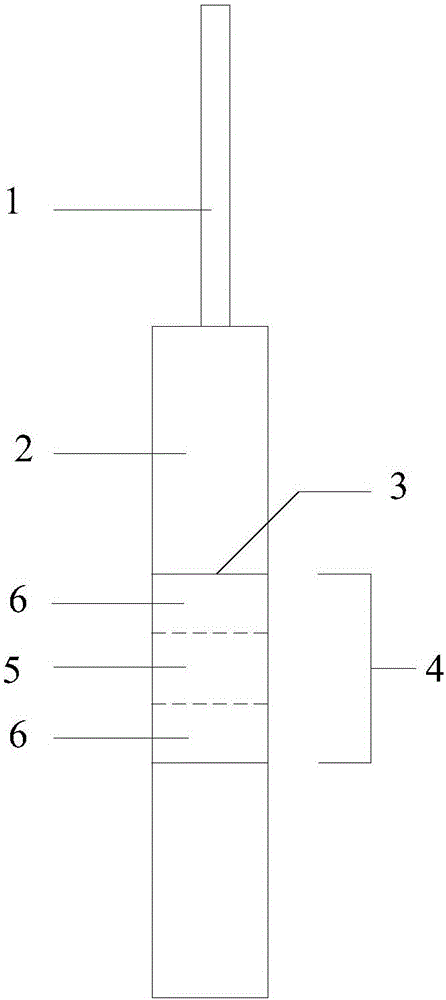

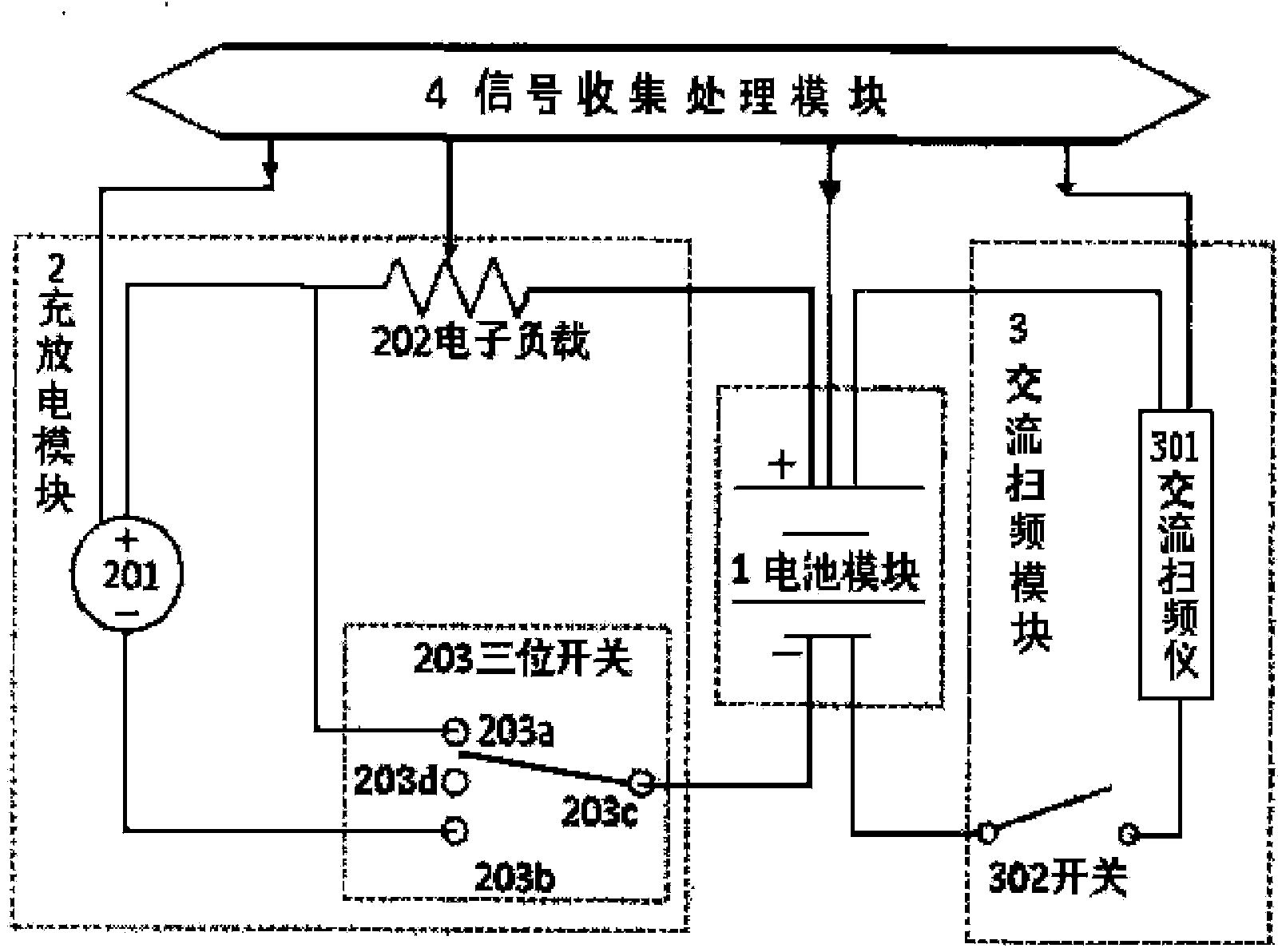

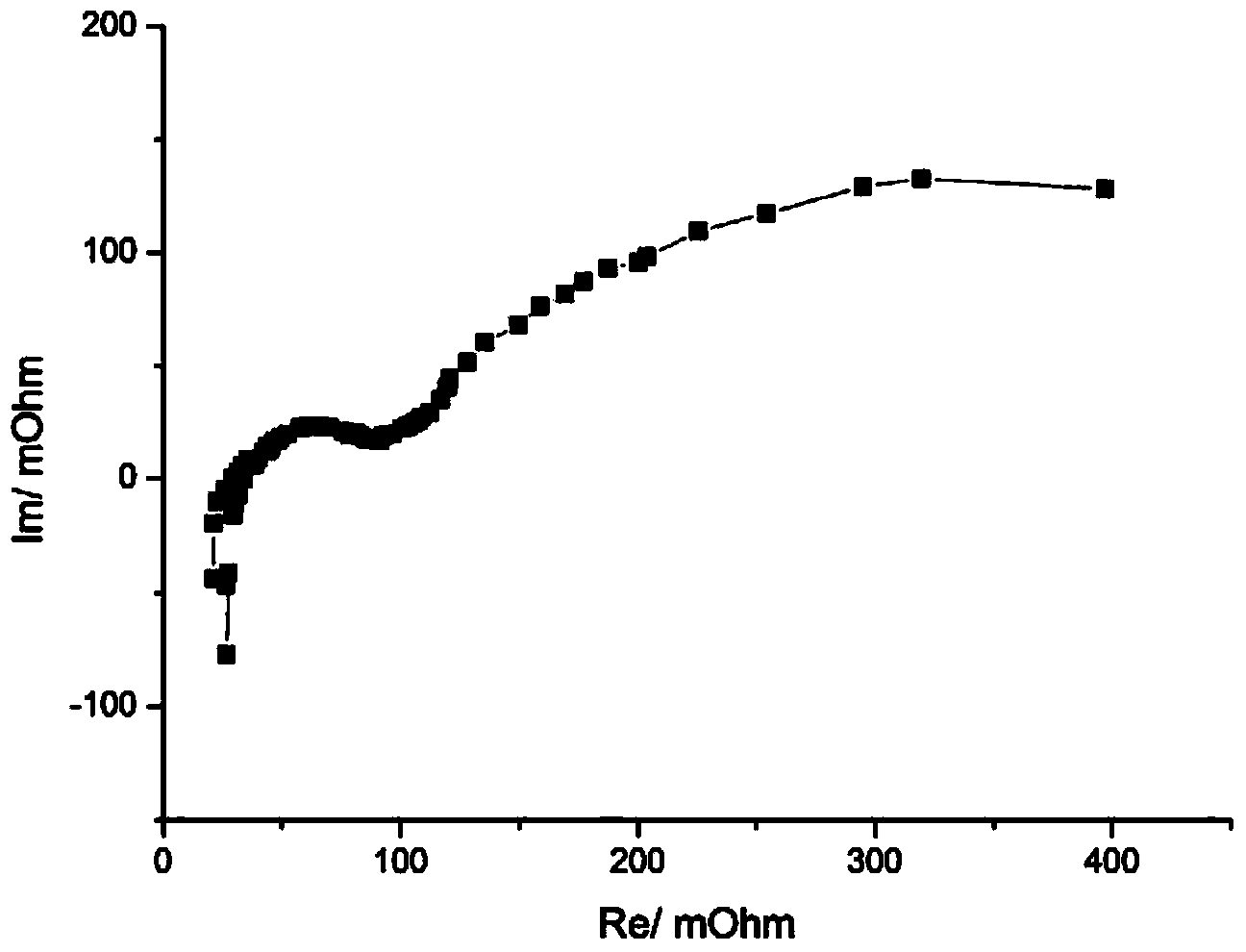

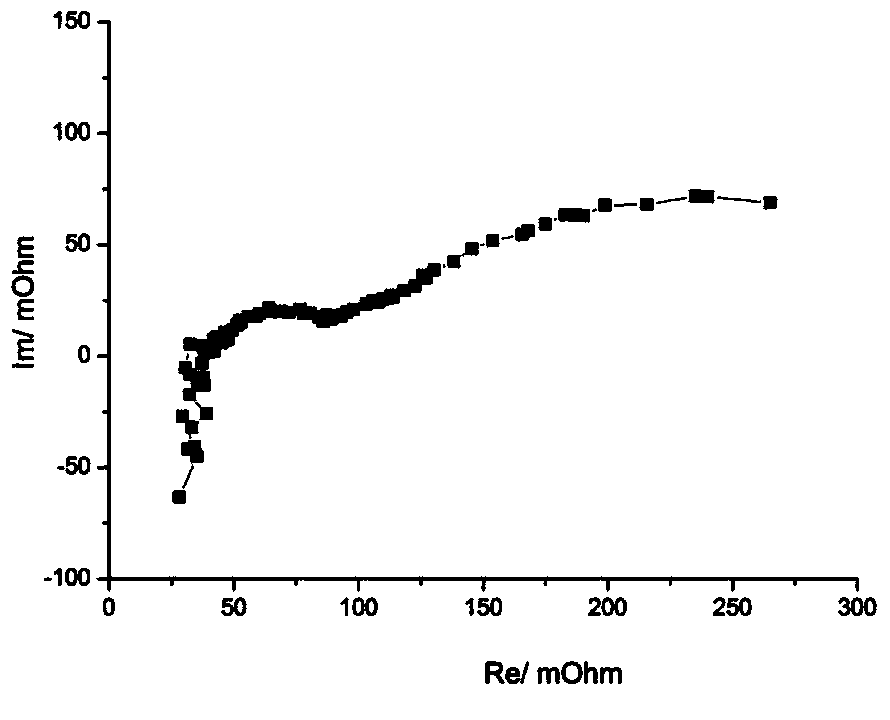

Impedance measurement system and method for secondary batteries

InactiveCN103884995AImprove performanceGuaranteed uptimeResistance/reactance/impedenceElectrical testingElectronic loadInternal resistance

The invention discloses an impedance measurement system and method for secondary batteries and belongs to a battery measurement technology. The system comprises a battery module, a charging and discharging module, an alternating current frequency scanning module and a signal collecting and processing module. A 203c point of a 203 three-position switch of the charging and discharging circuit is connected with the negative electrode of the battery module 1, and by selecting a switch arm connected with the 203c point, the negative electrode of the battery module 1 is connected with a 202 electronic load and the positive electrode of the battery module 1 through a 203a point to form a discharging circuit. The impedance measurement system and method for the secondary batteries are applied to tests on impedance of the secondary batteries in the working state and can be used for measuring all the single secondary batteries contained in a secondary battery pack in parallel through multiple channels. The Ohm internal resistance, the electrochemical polarization impedance and the concentration polarization impedance of each secondary battery are tested out, the impedance of each secondary battery is analyzed, and the impedance measurement system and method are used for analyzing the charging and discharging performance of the batteries. The service life of the batteries is estimated, and the batteries can run more safely, stably and reliably.

Owner:TSINGHUA UNIV +1

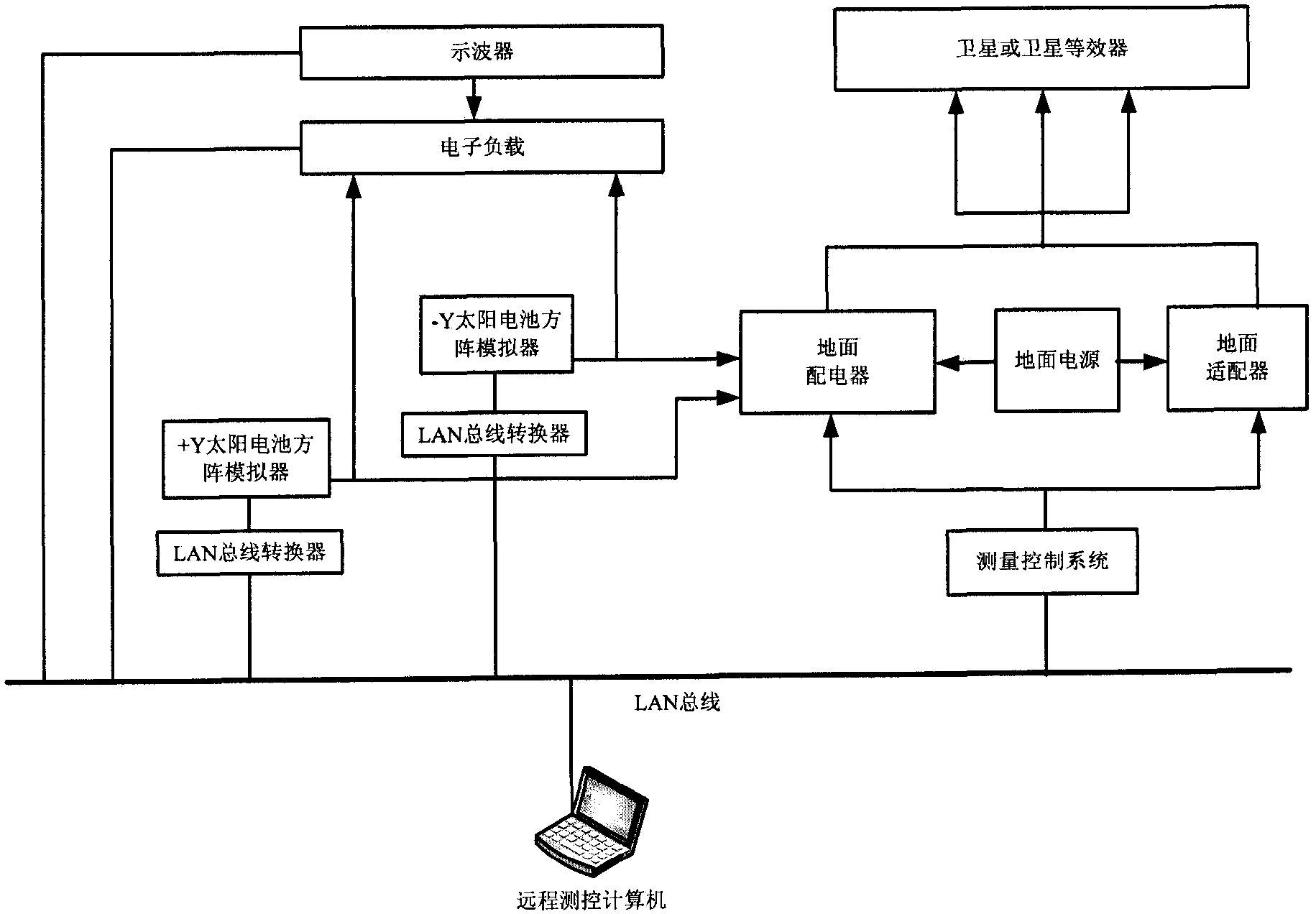

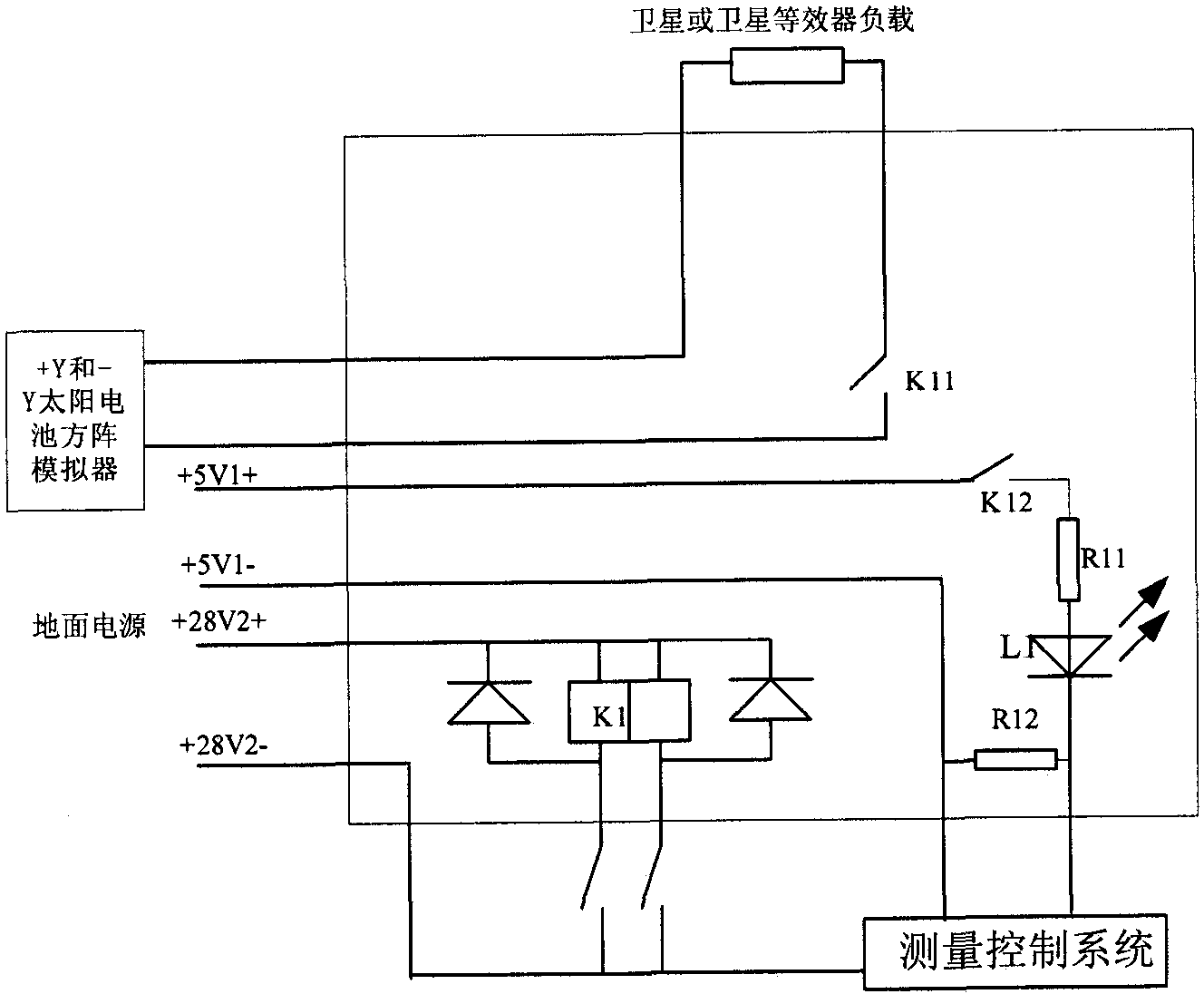

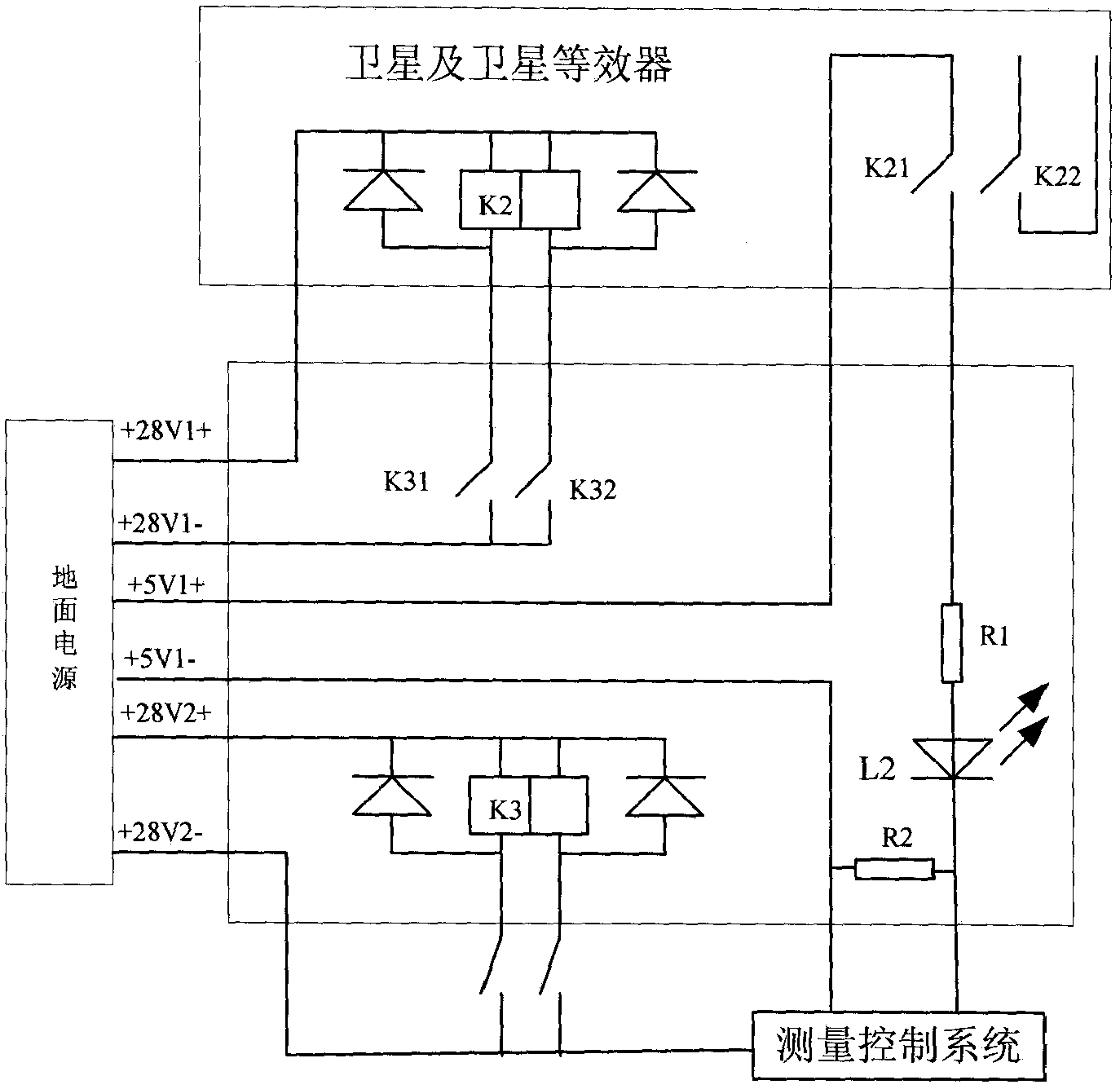

A satellite power supply and distribution test system based on lan bus

A satellite power supply and distribution test system based on LAN bus, including remote measurement and control computer, measurement control system, ground power supply, ground adapter, ground power distributor, +Y solar battery array simulator, -Y solar battery array simulator, LAN bus converters, electronic loads and oscilloscopes. The present invention uses the solar array simulator to simulate the output characteristics of satellite solar cells, and realizes the test control function and simulation of satellite power supply and distribution signals through ground distributors, ground adapters and satellite equivalents. The test equipment is connected together through the LAN bus, the test layout is flexible, and the test system can be remotely controlled without being affected by the test environment. The system structure is simple and the development cycle is short.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com