Patents

Literature

39results about How to "Realize drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

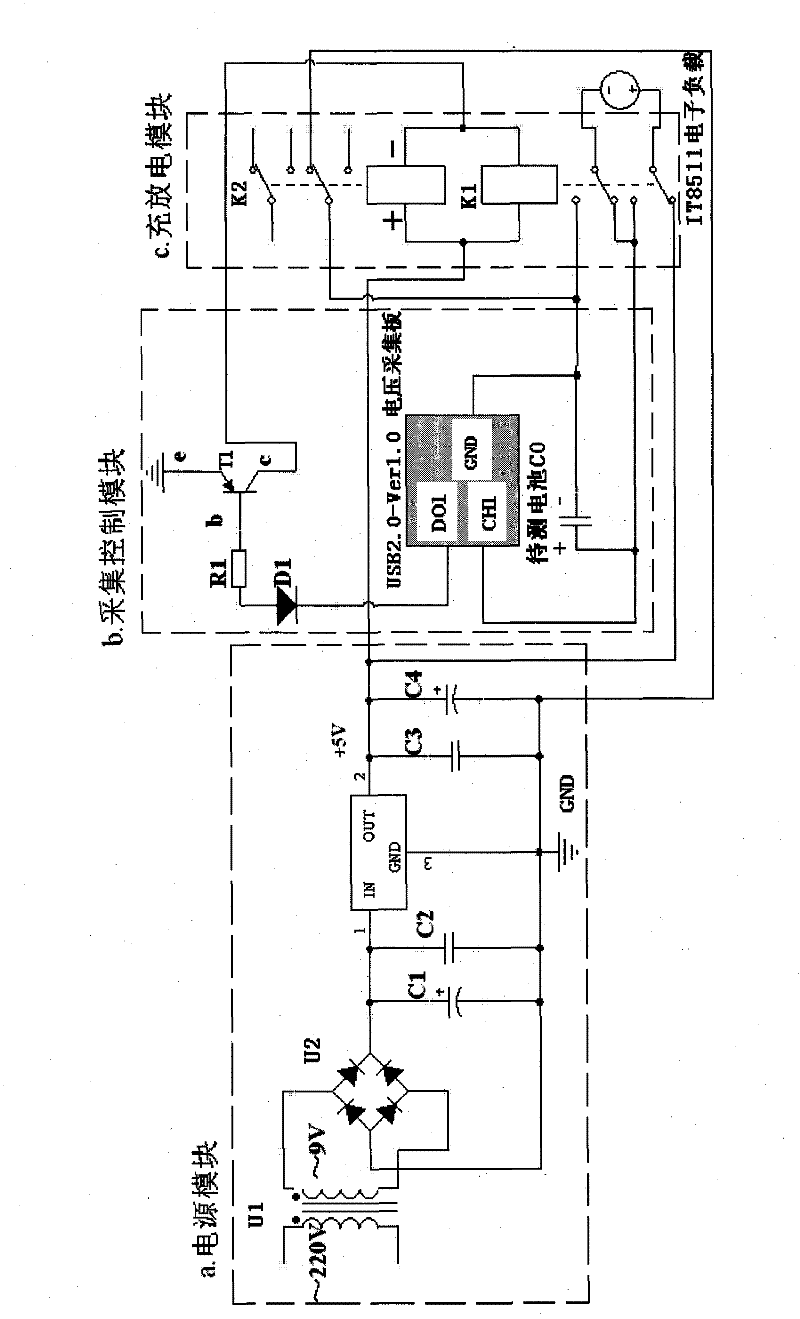

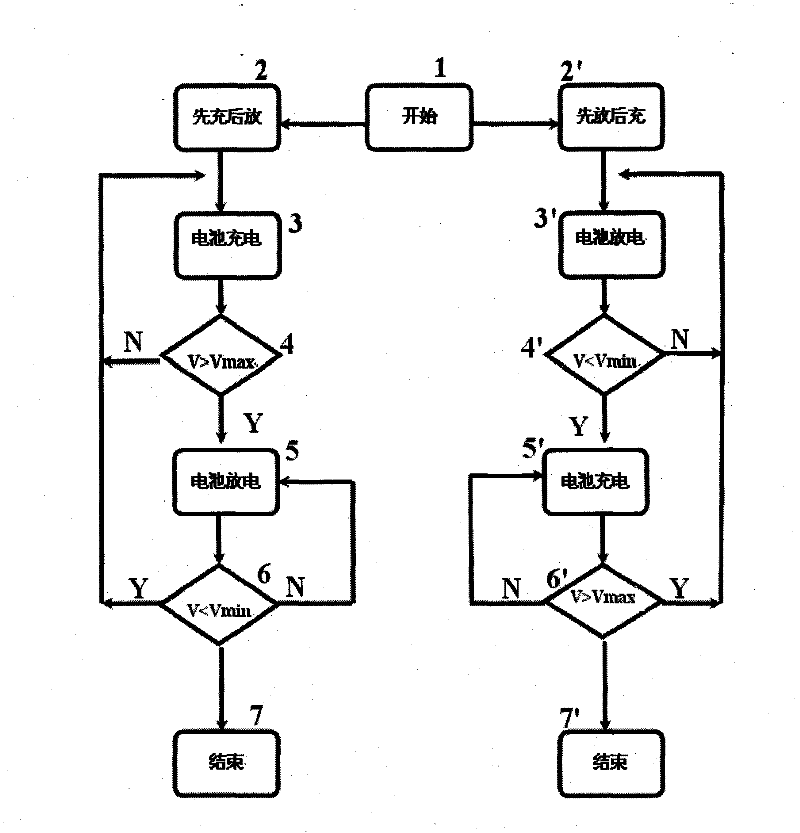

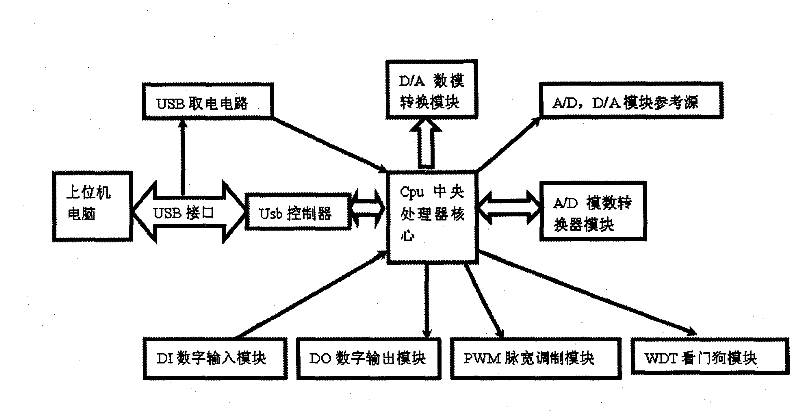

Intelligent battery cycle charge-discharge testing device

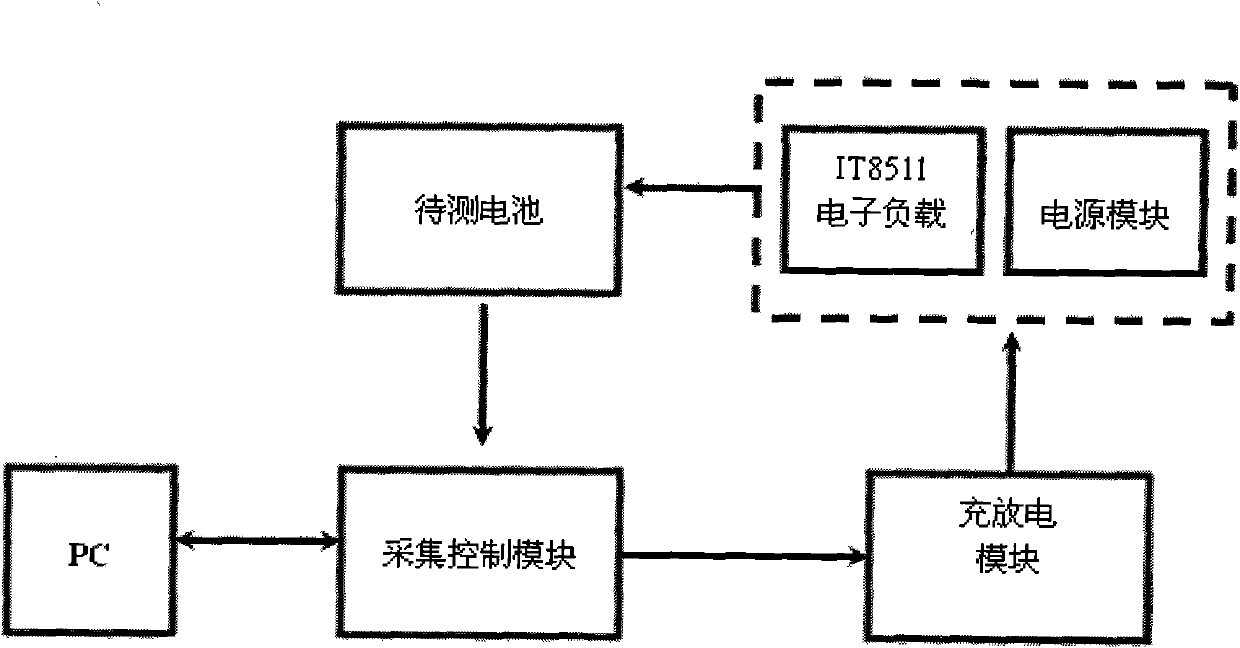

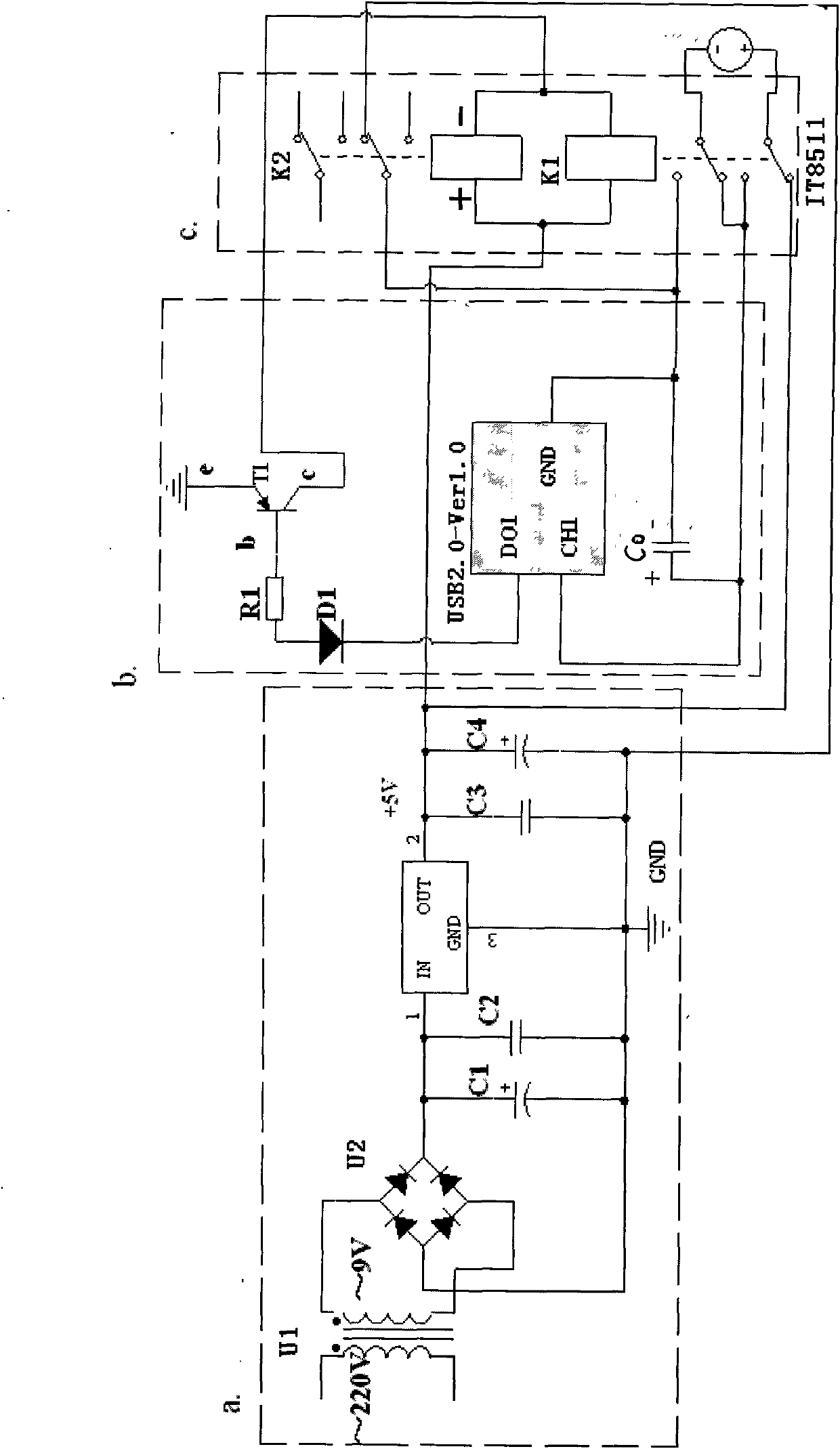

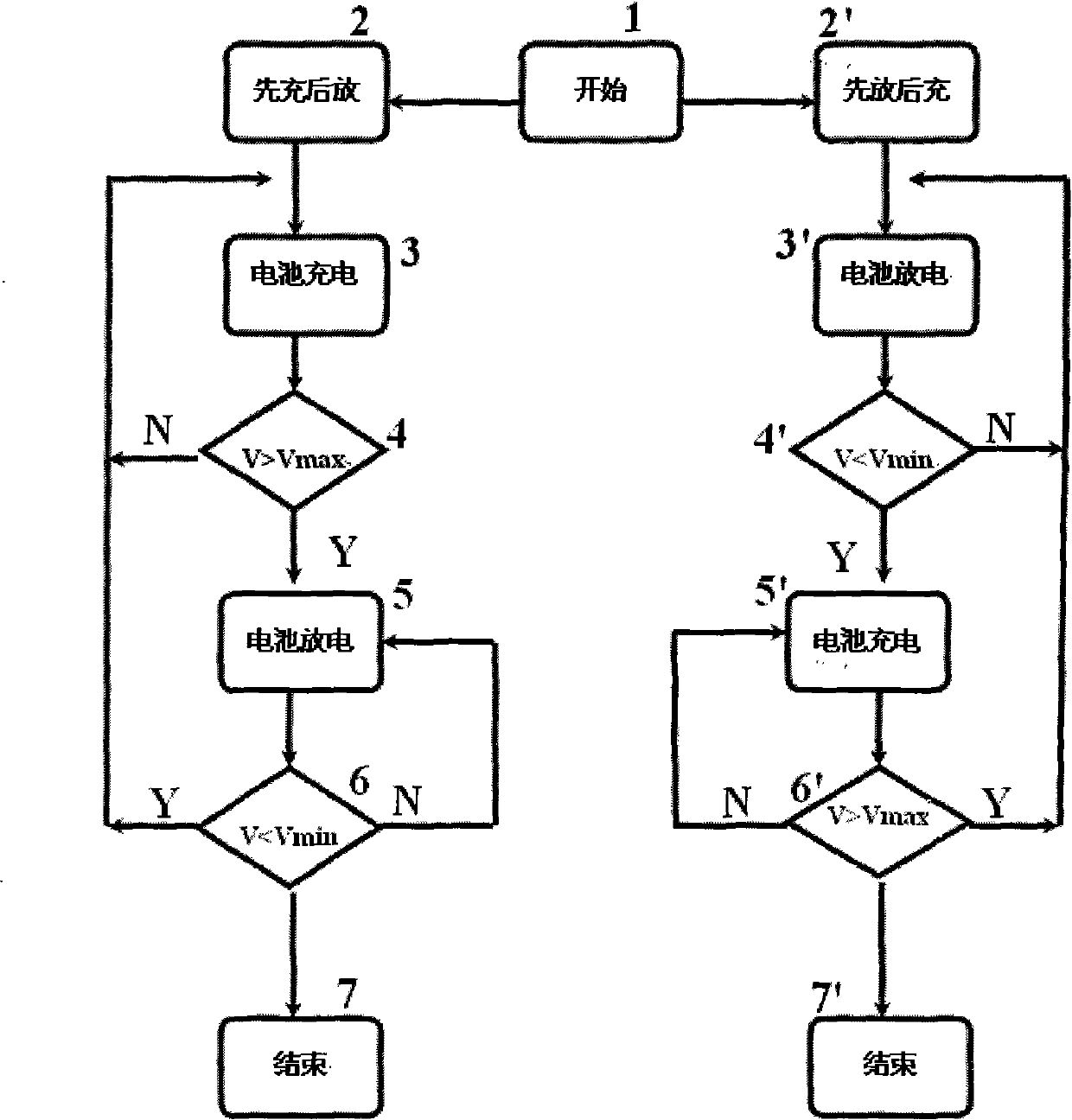

The invention provides an intelligent battery cycle charge-discharge testing device. The device is a secondary battery automatic charge-discharge testing device with low price, high precision and good stability. The device can test main parameters of a secondary battery, has safe and reliable performance and has wide application prospect. The device comprises a power supply module, an electronic load, an acquisition control module, a PC machine and a charge-discharge module, wherein an output of the power supply module is connected with the electronic load and the charge-discharge module; a battery to be tested is connected with the electronic load by the charge-discharge module; a signal acquisition end of the acquisition control module is connected with the battery to be tested, while a control end thereof is connected with the charge-discharge module; and the acquisition control module is on-line with the PC machine by a USB data wire.

Owner:NANJING UNIV OF TECH

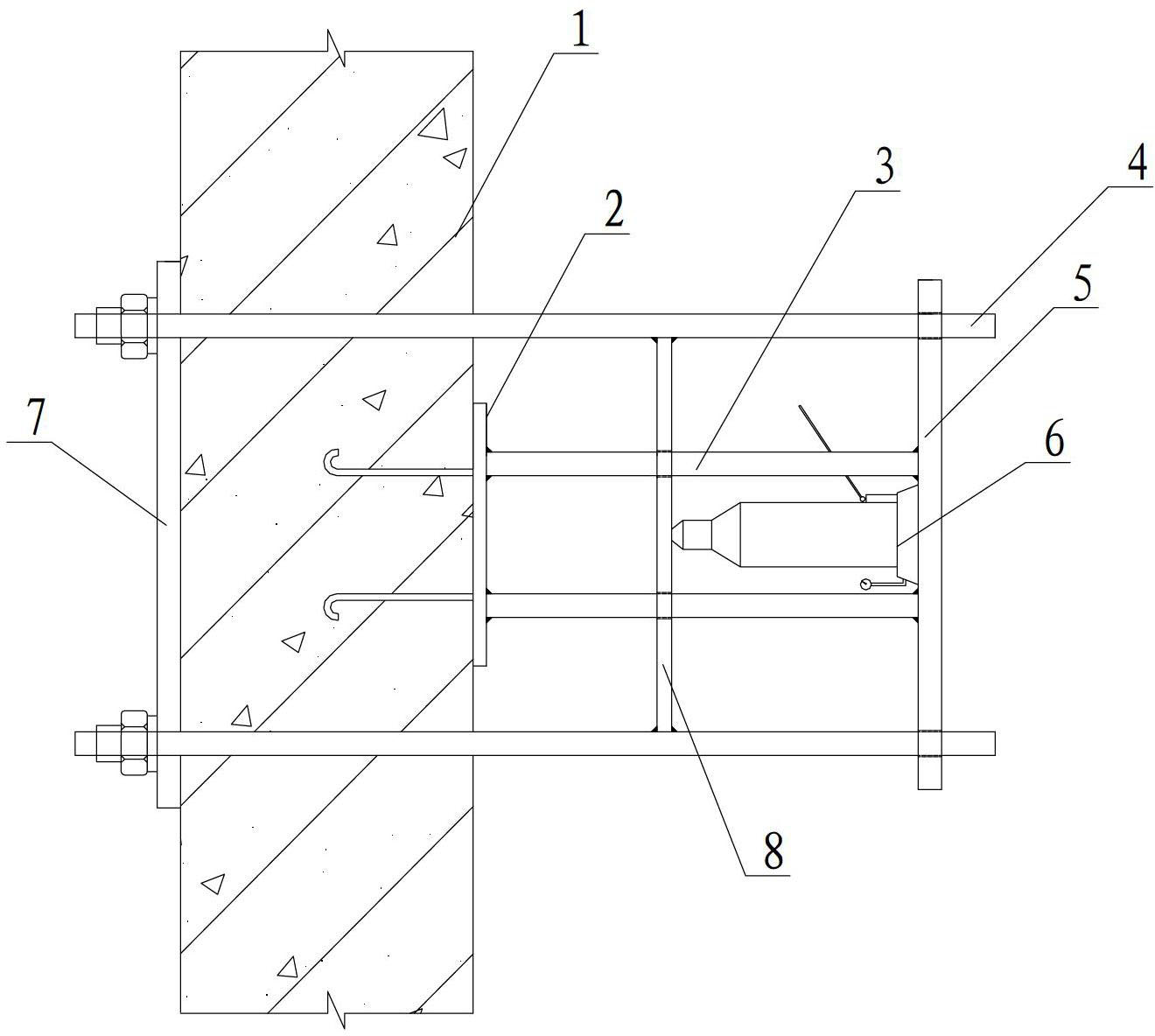

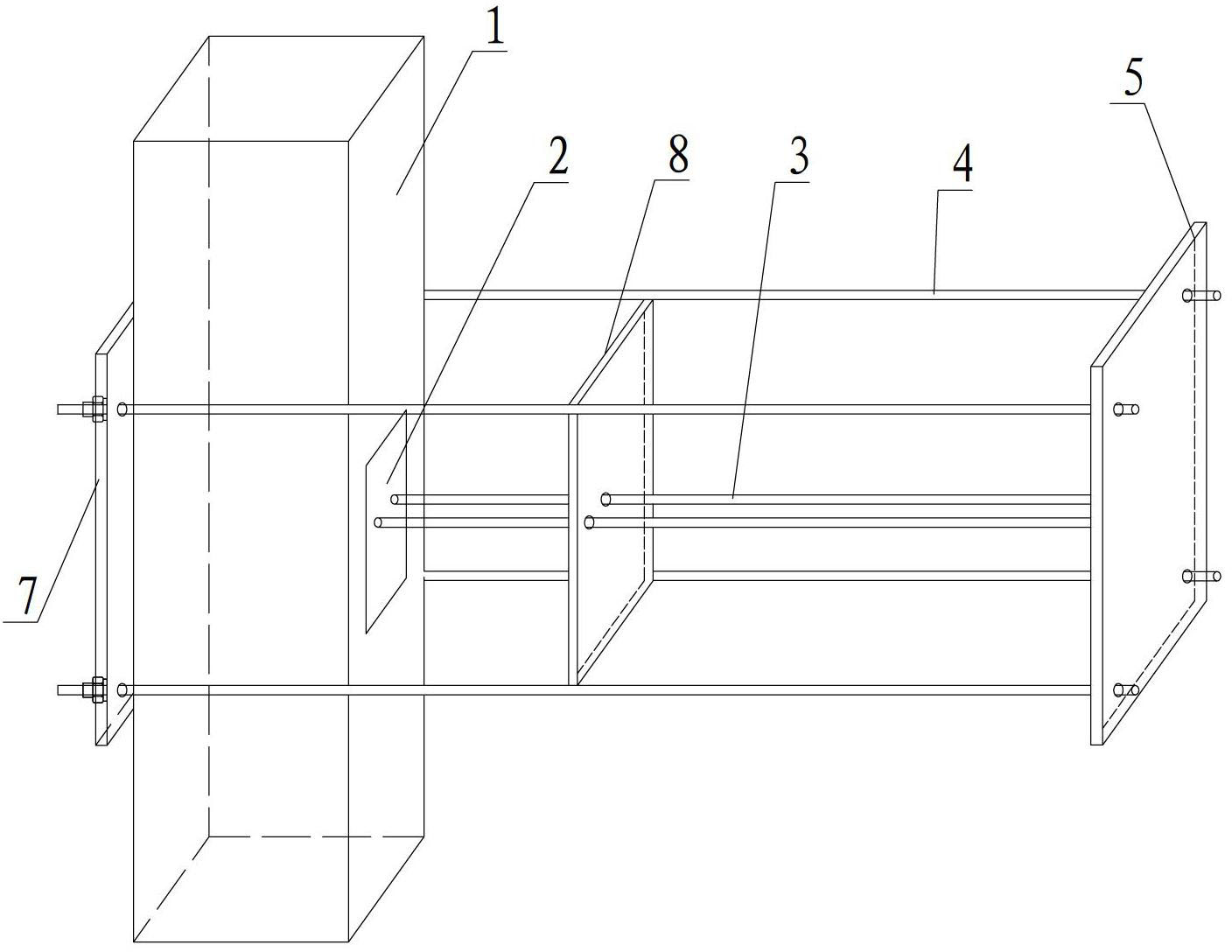

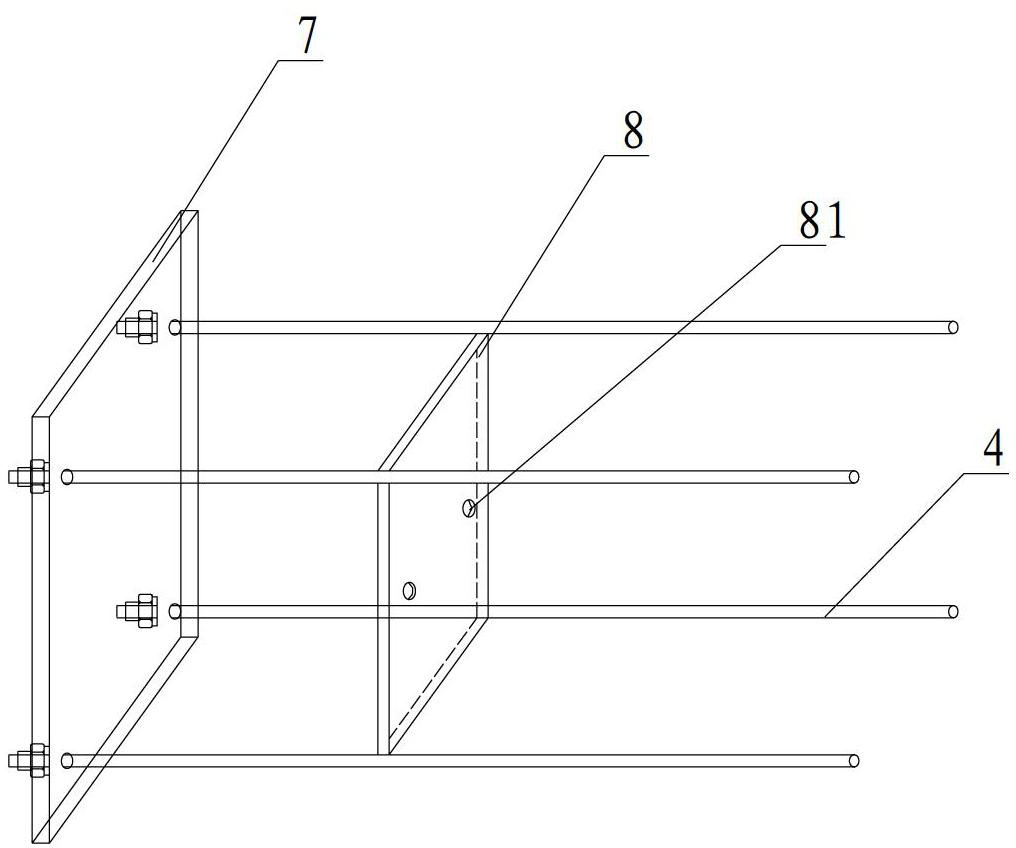

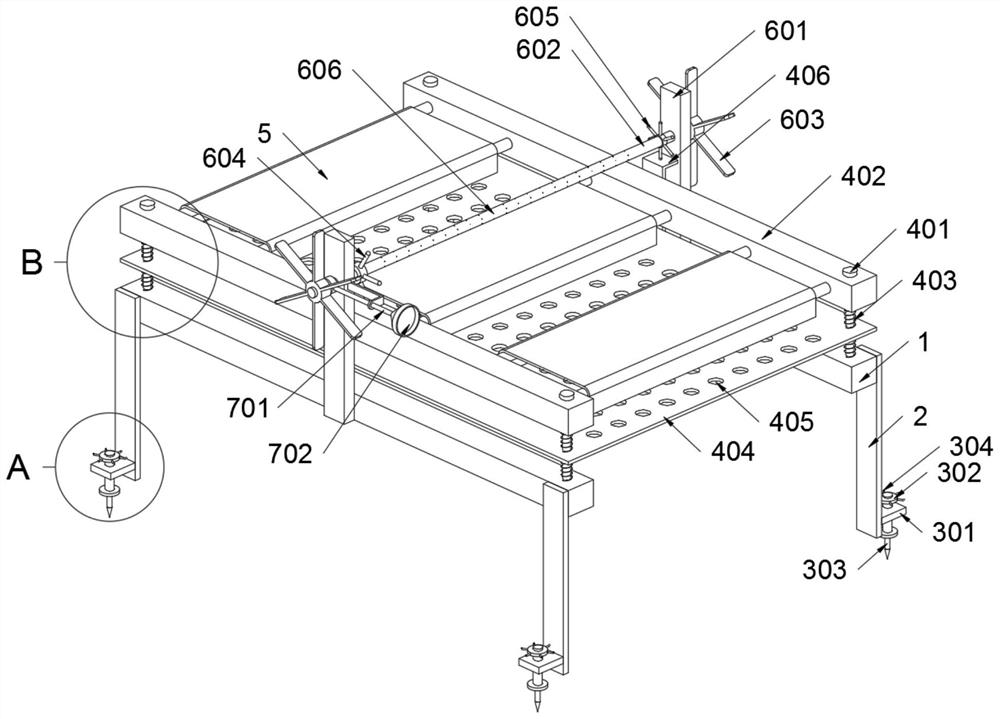

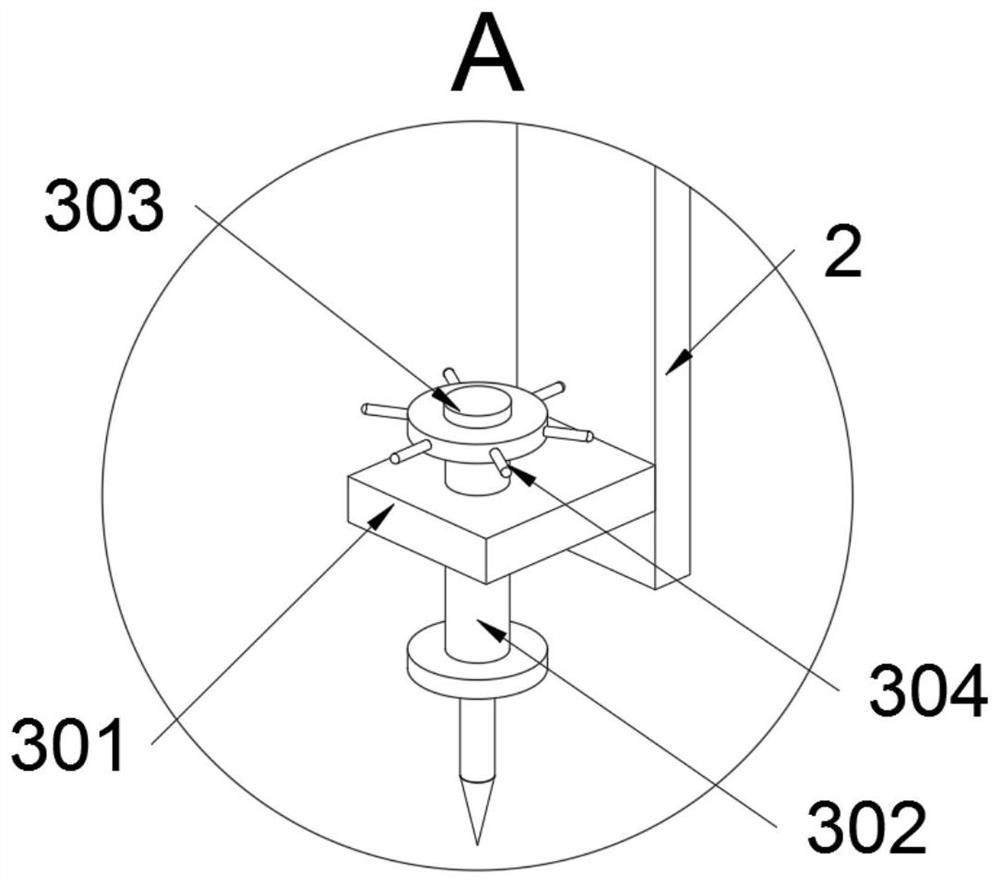

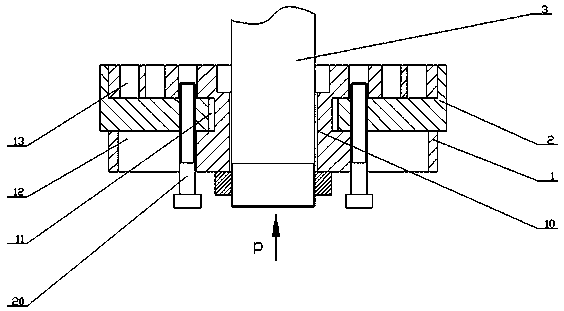

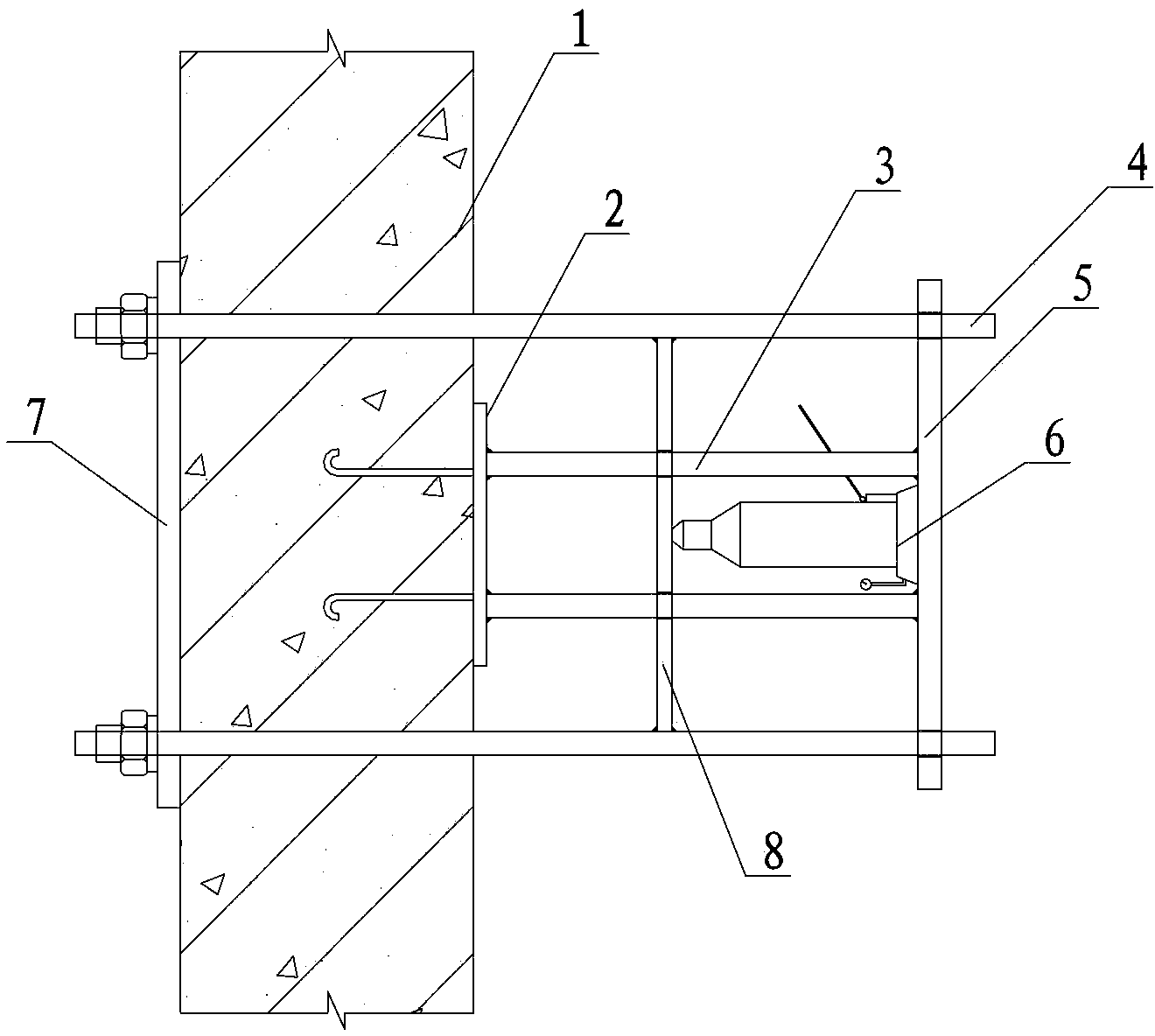

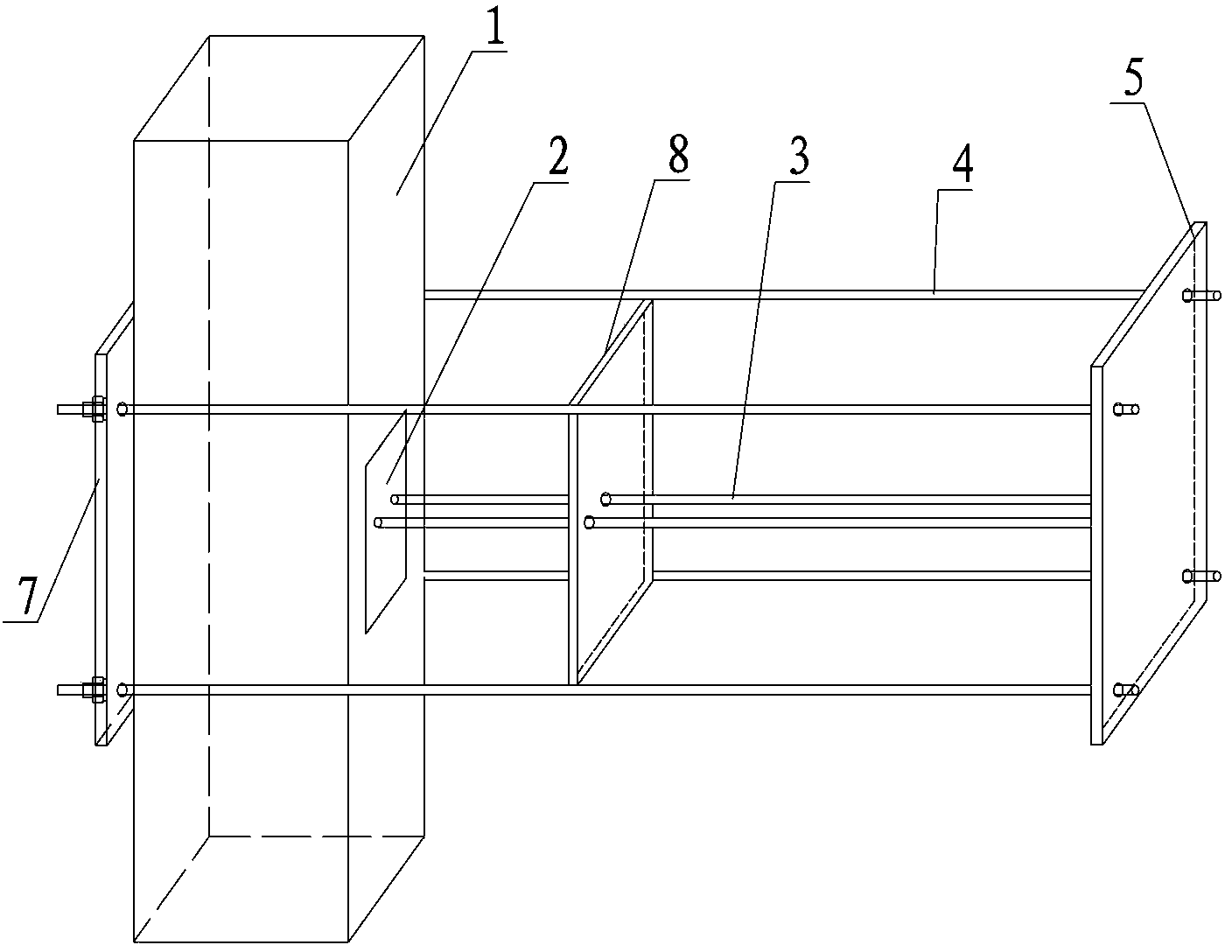

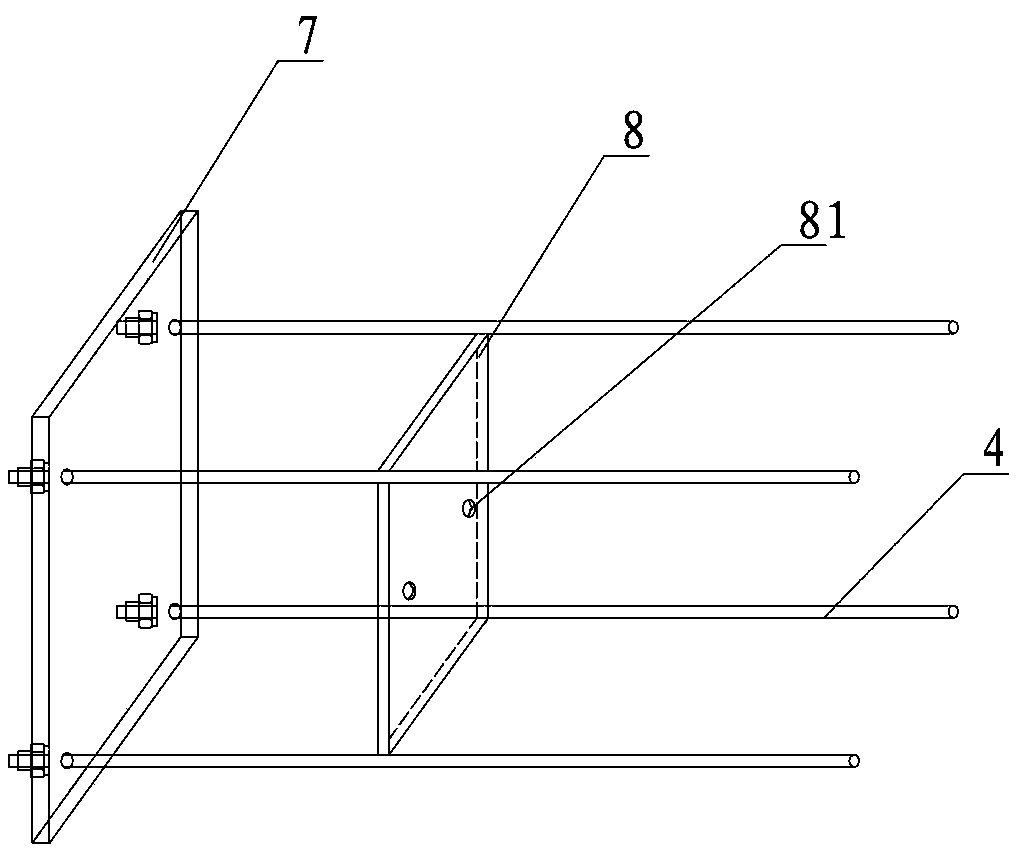

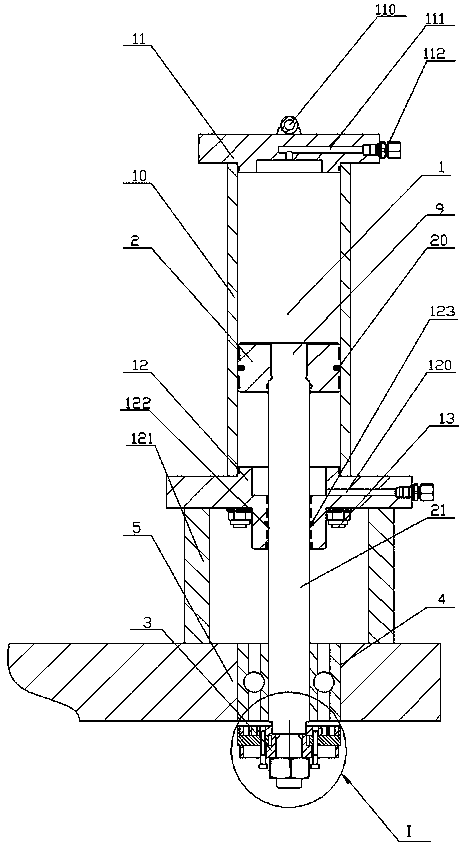

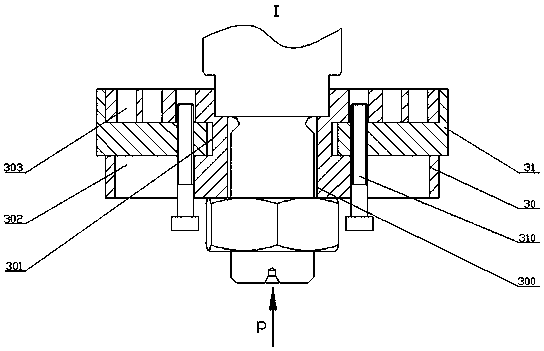

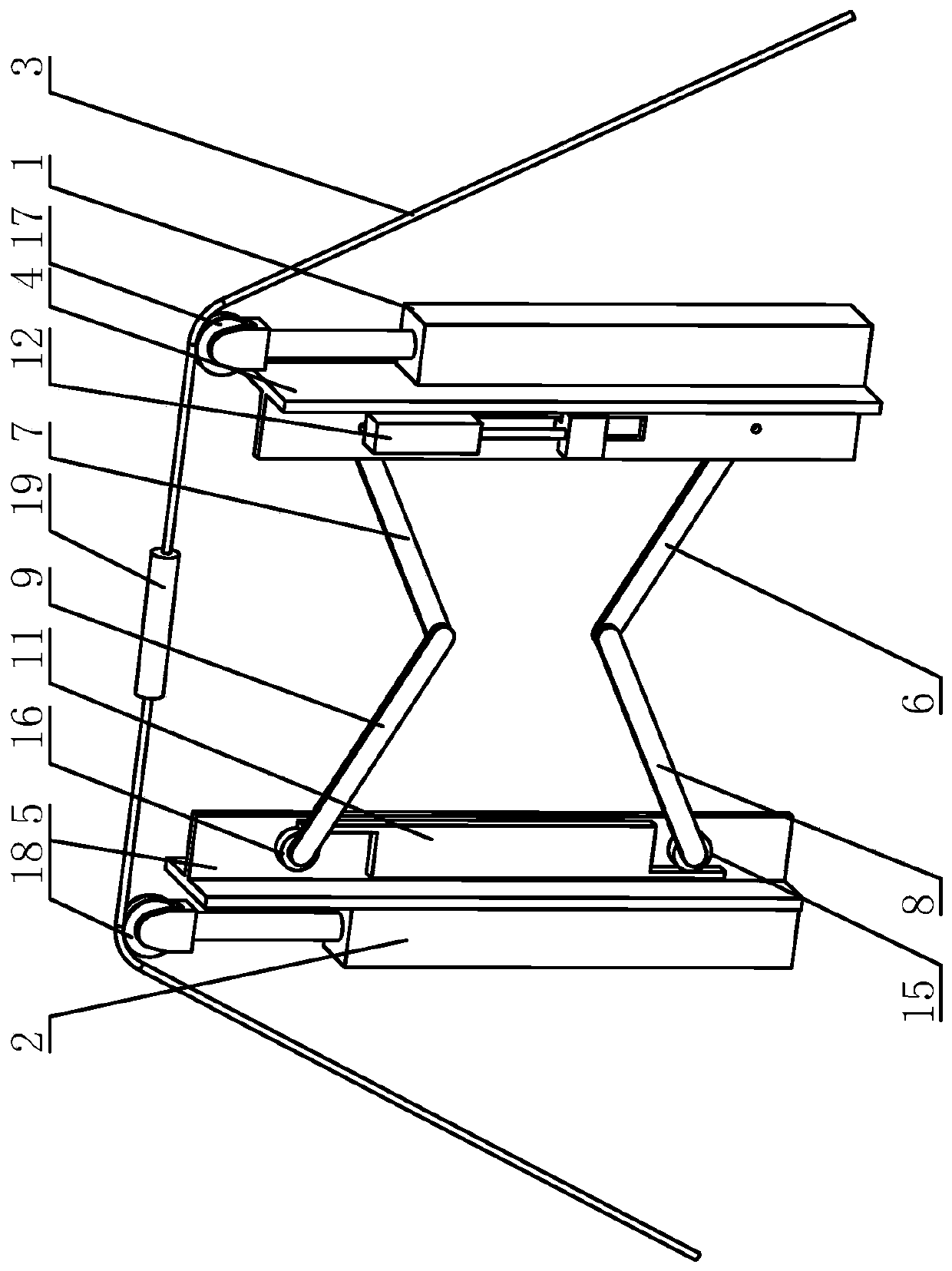

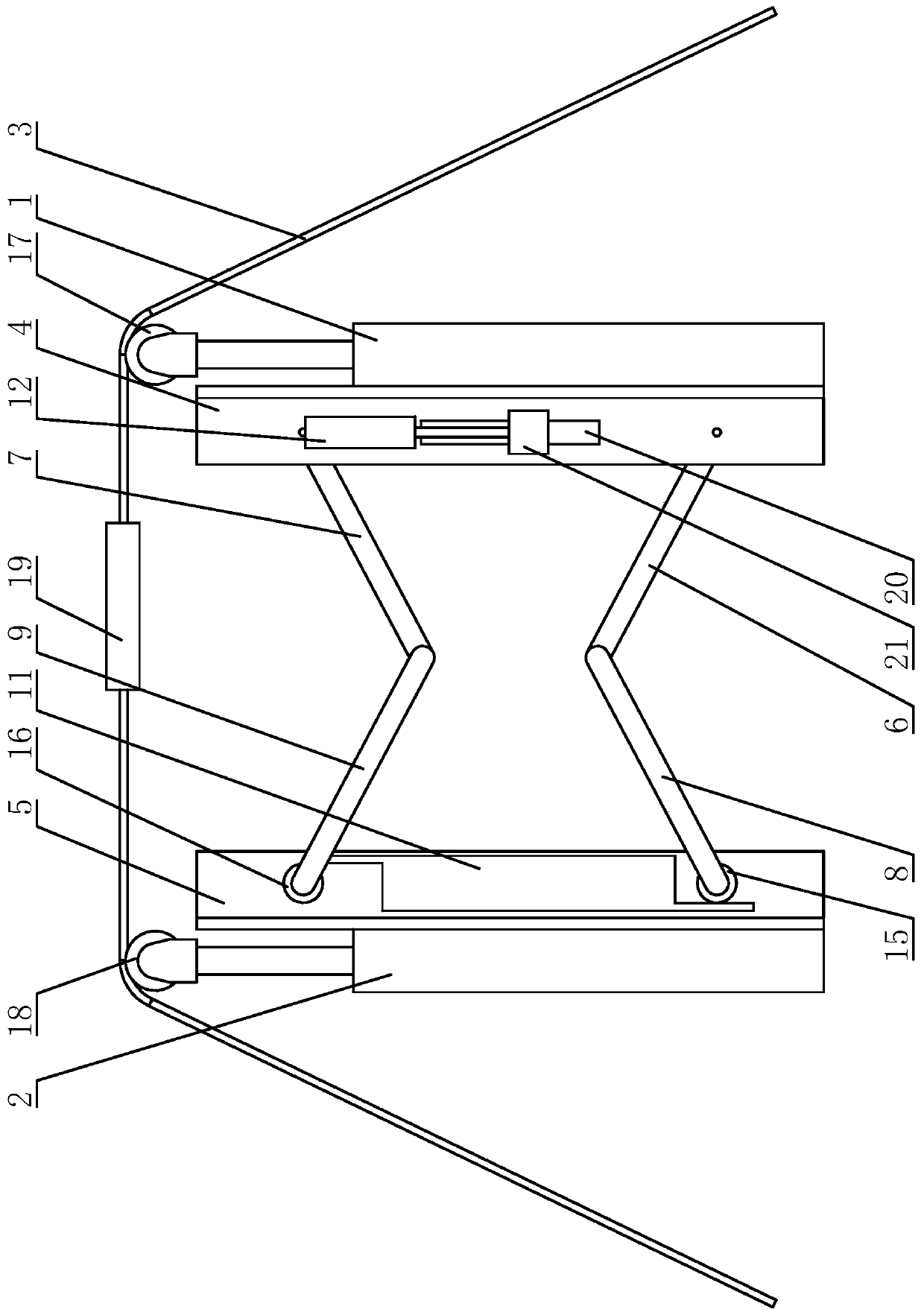

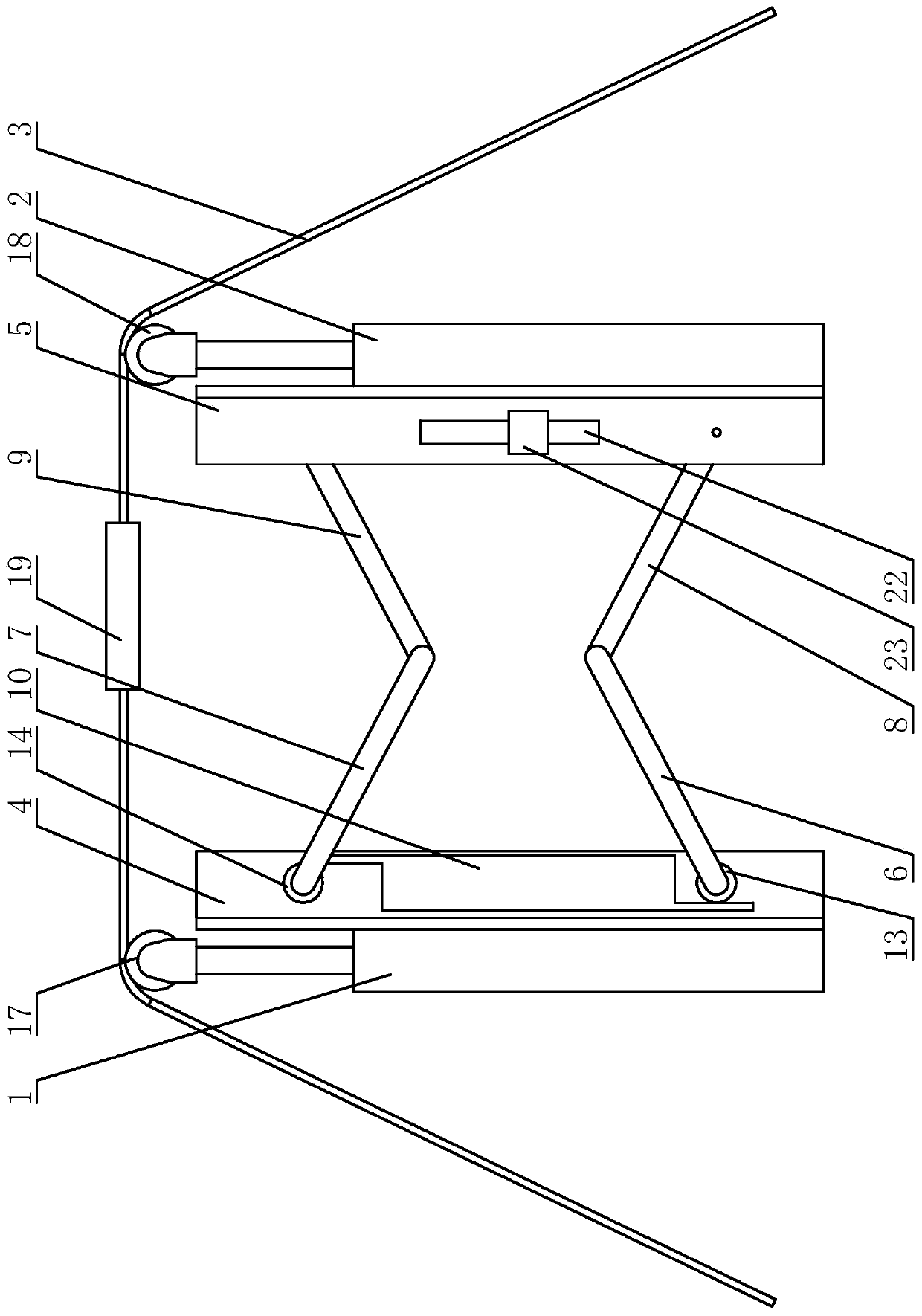

Stretching resistance detection device of curtain wall embedded part used for anchor plate construction after embedded

ActiveCN102628777ARealize drawingOn-site inspection after burialMaterial strength using tensile/compressive forcesPull forceEngineering

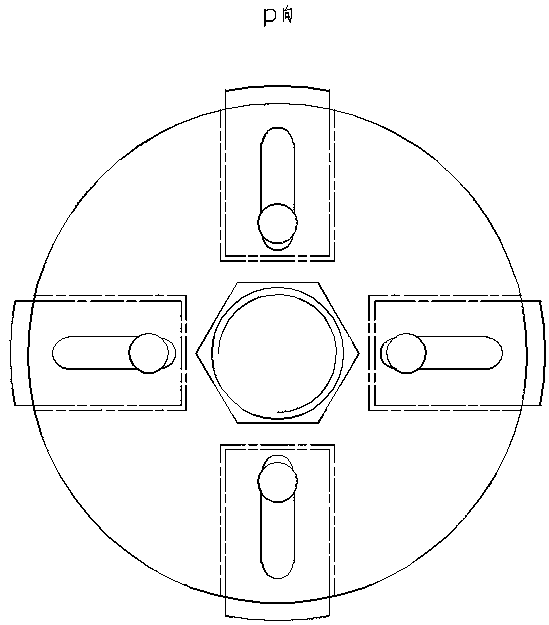

The invention discloses a stretching resistance detection device of a curtain wall embedded part used for anchor plate construction after embedded, which comprises a fixing support attached to the outer vertical face of a main body structure and a sliding support installed on the fixing support in sliding penetrating mode. The fixing support comprises a pair of rod pieces vertically attached to the main body structure, all the rod pieces are fixedly connected with a connection plate, the connection plate is perpendicular to the rod pieces, and a guide hole is arranged in the middle portion. The sliding support comprises a pull rod support plate installed on the end portions of the rod pieces in sliding penetrating mode, the pull rod support plate is parallel to the connection plate, and the pull rod support plate and the main body structure are respectively arranged on two sides of the connection plate, the pull rod support plate is fixedly connected with one ends of at least two pull rods perpendicular to the pull rod support plate, the other ends of the pull rods penetrate through the guide hole to be fixedly connected with an anchor plate of the curtain wall embedded part and are symmetrically distributed on the curtain wall embedded part. A hydraulic jack perpendicular to the connection plate and the pull rod support plate and with a pressure meter is arranged between the connection plate and the pull rod support plate, and all the pull rods are evenly distributed on the periphery of the hydraulic jack. The stretching resistance detection device is capable of conducting onsite detection of the curtain wall embedded part after embedded.

Owner:中建六局第一建设有限公司 +1

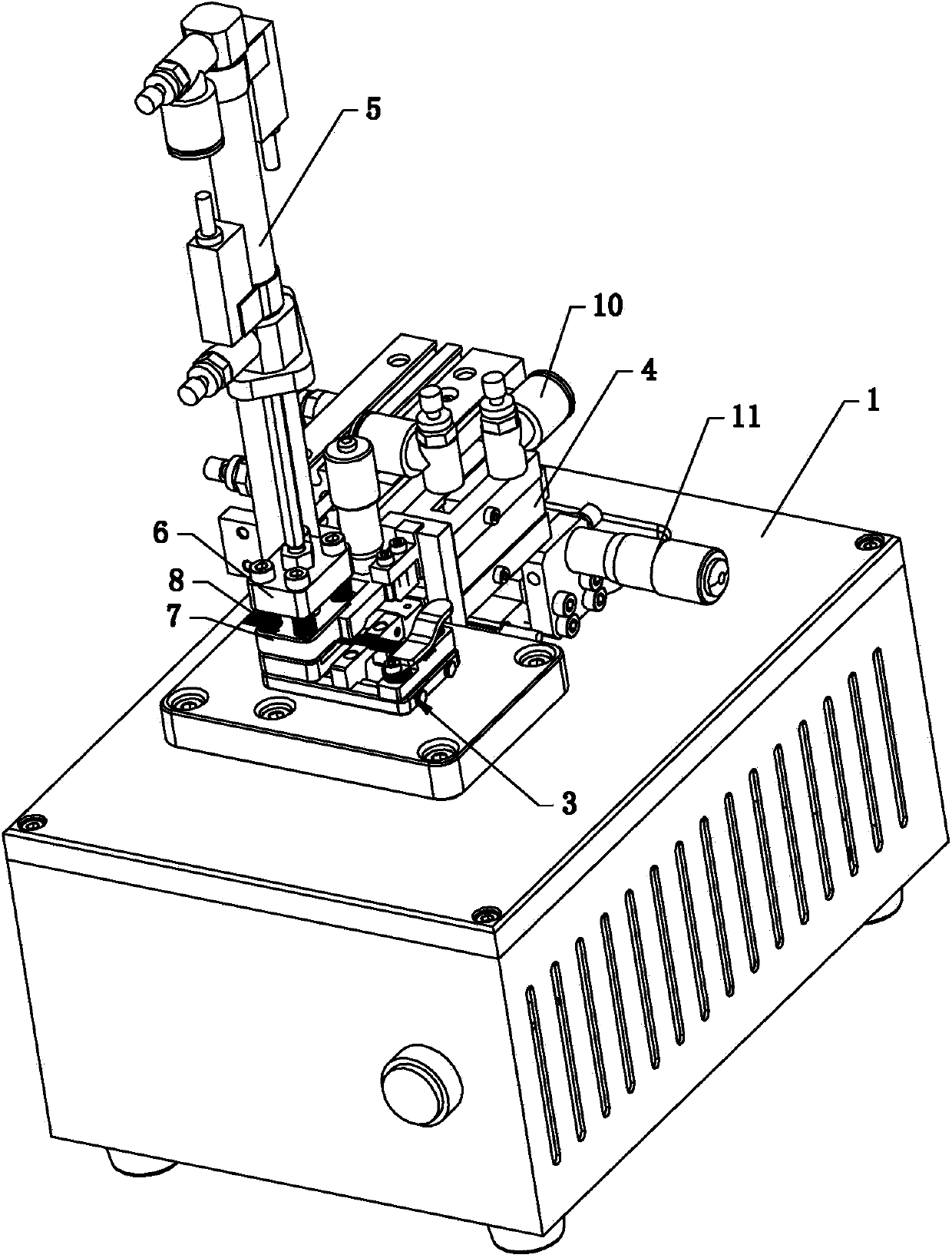

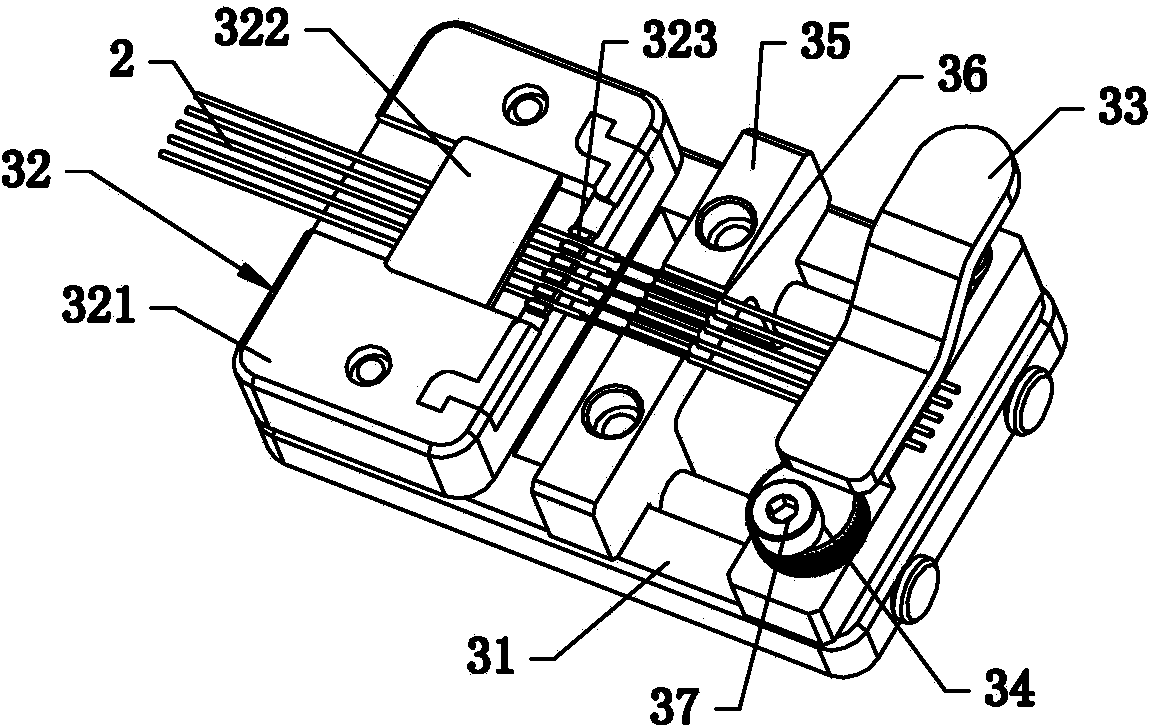

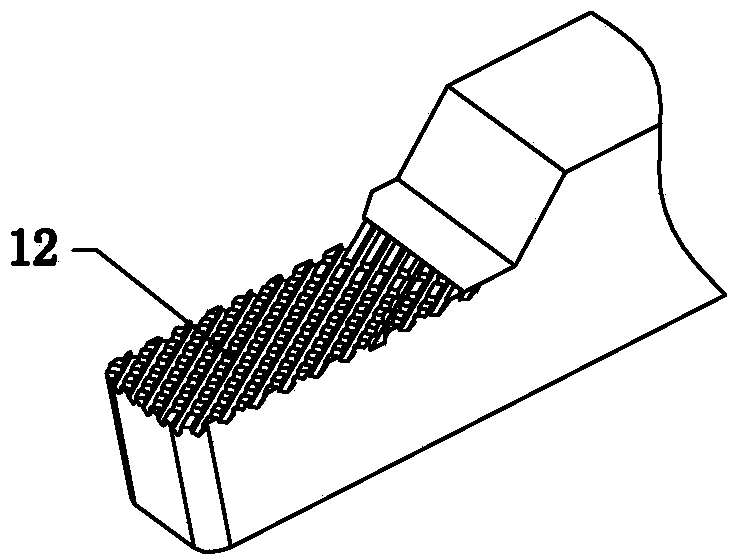

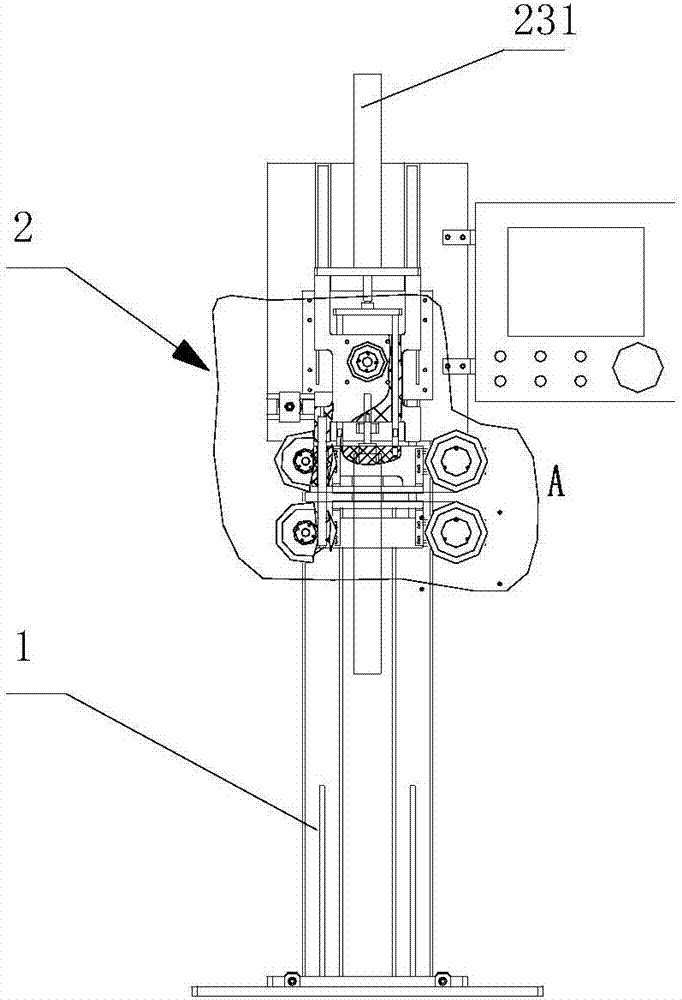

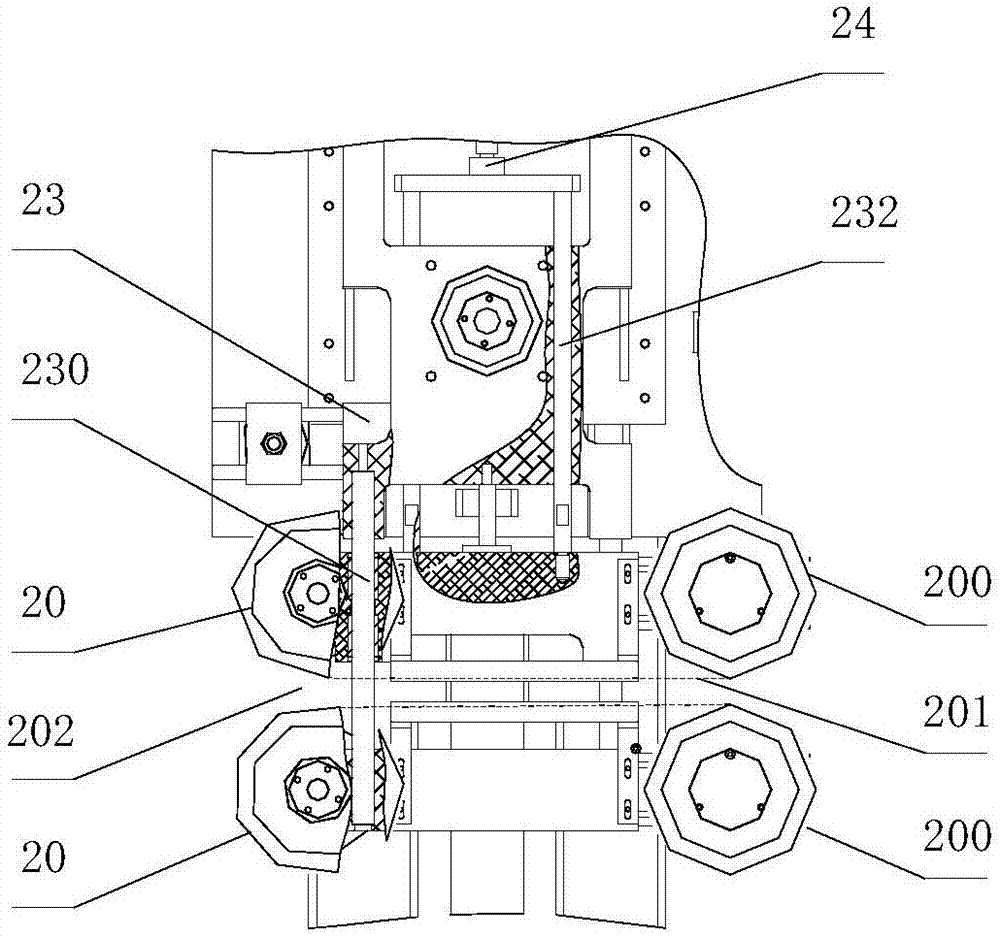

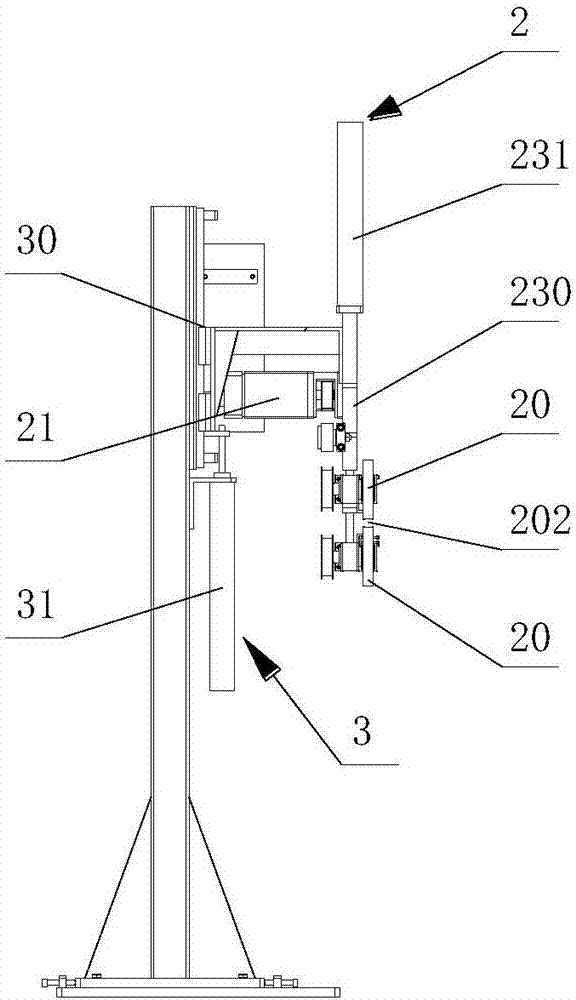

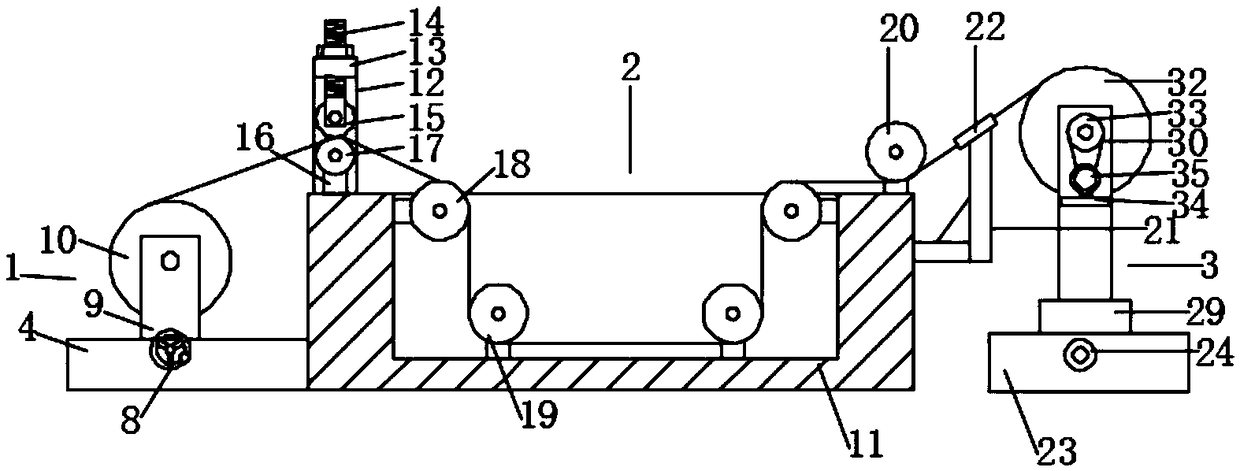

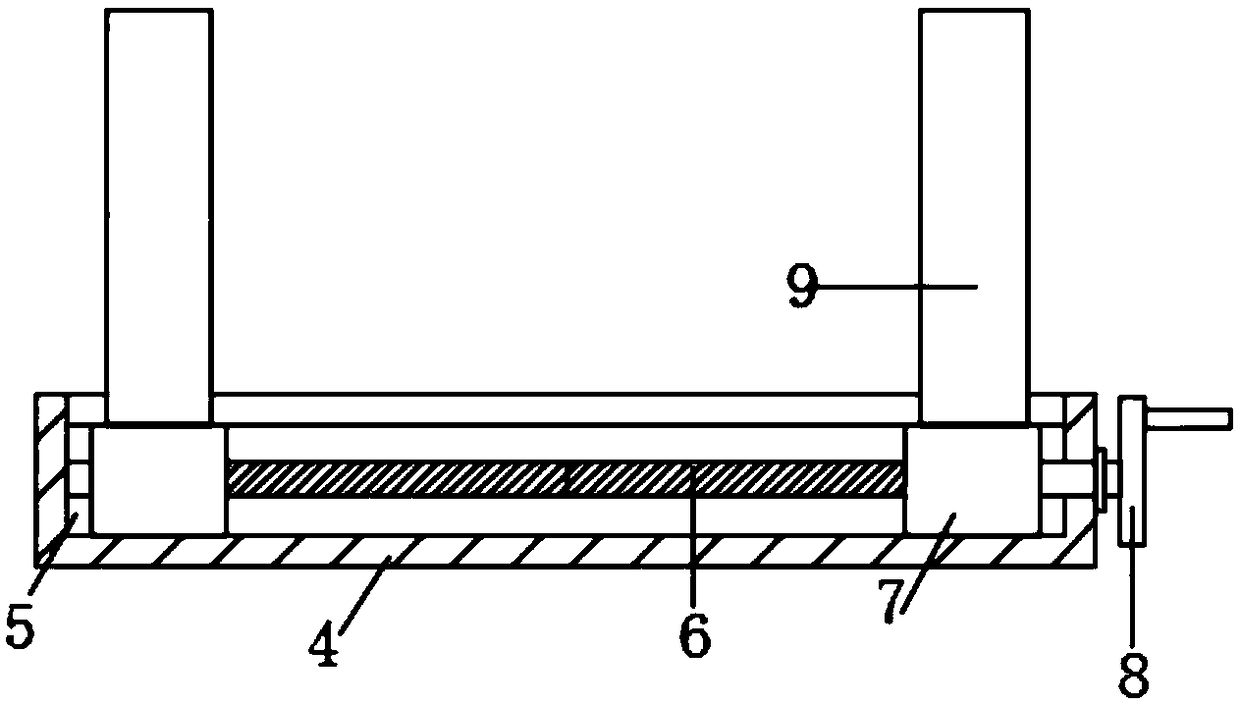

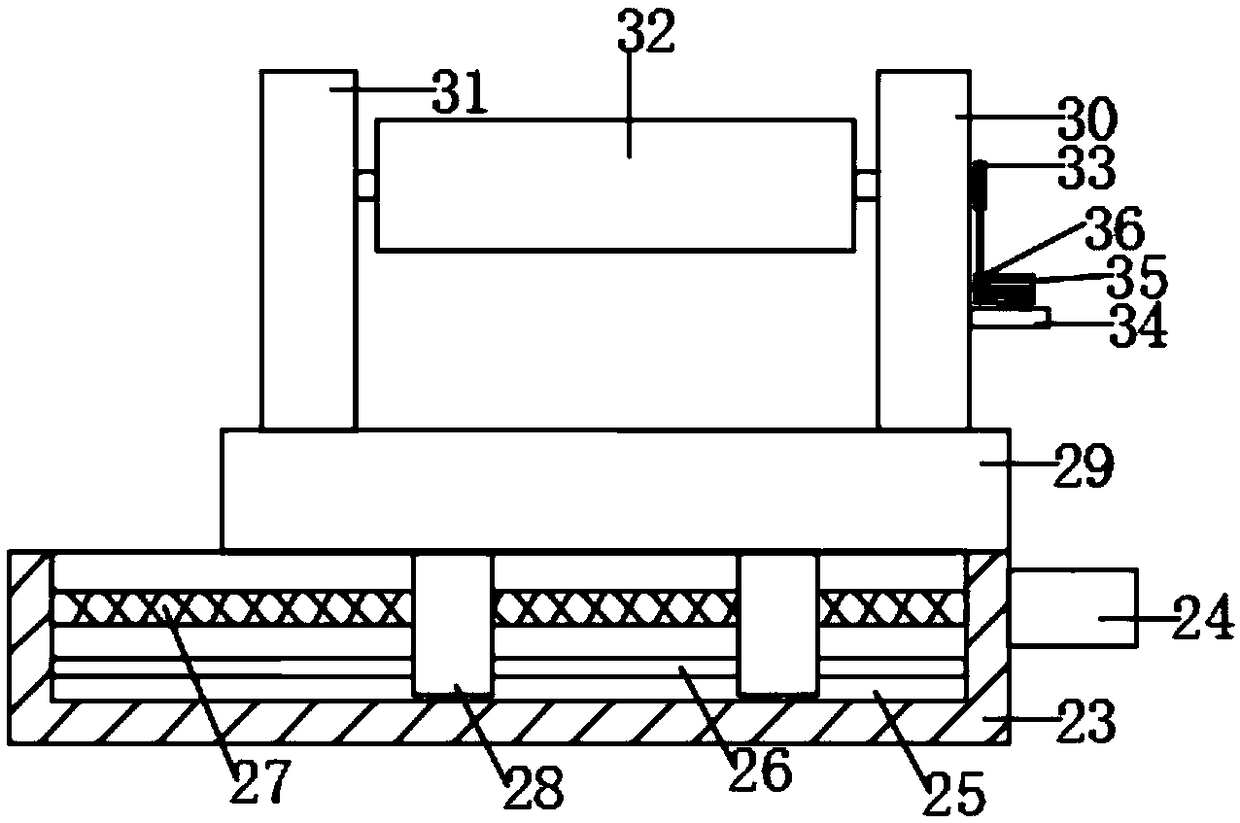

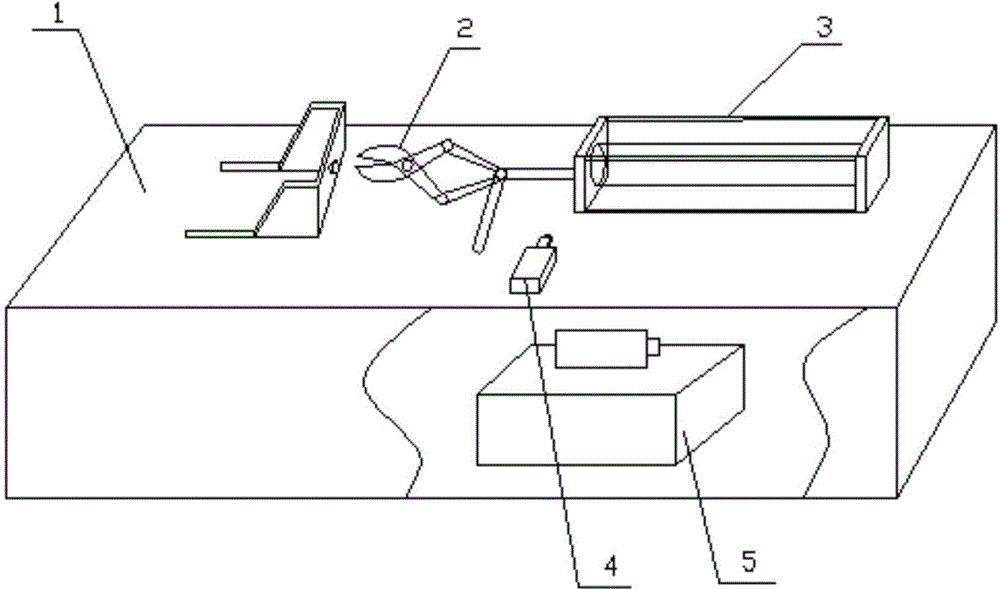

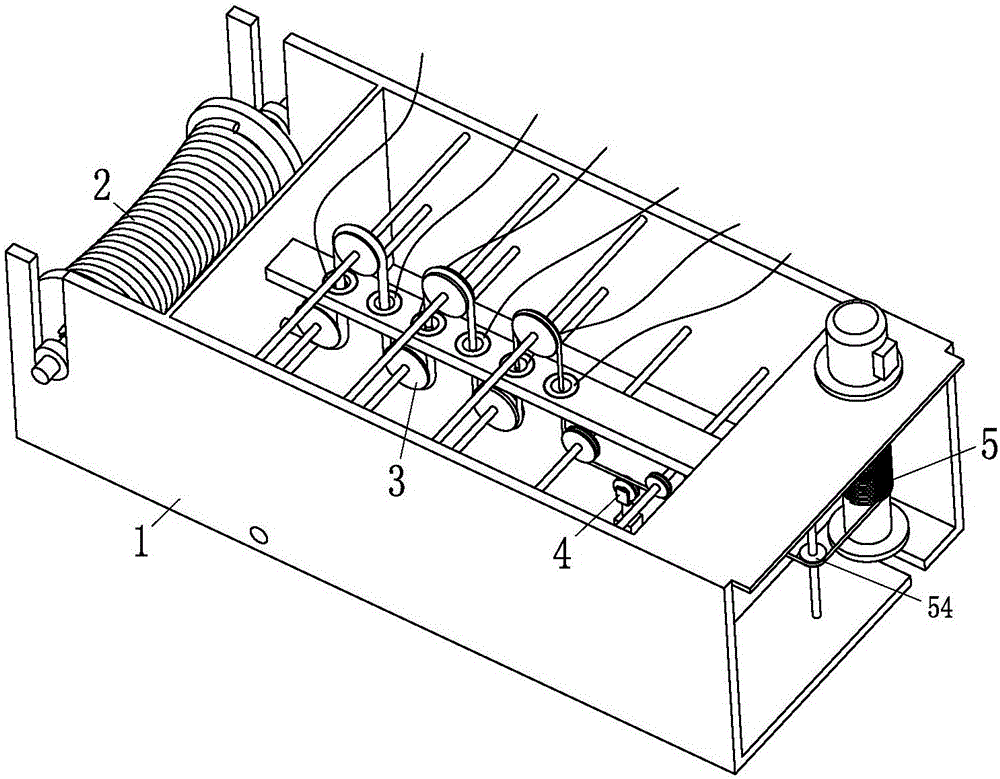

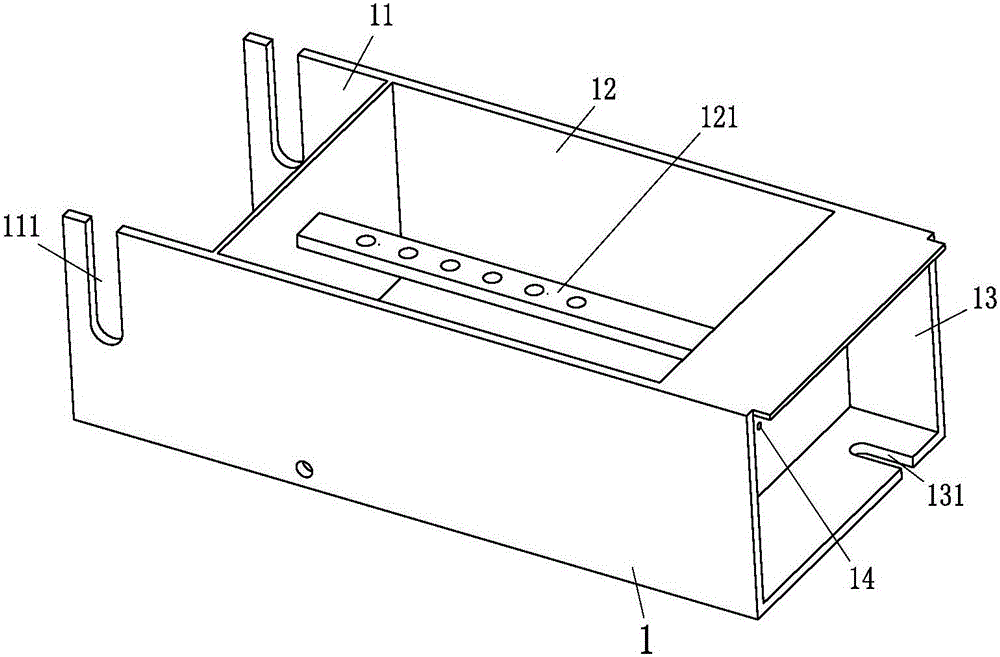

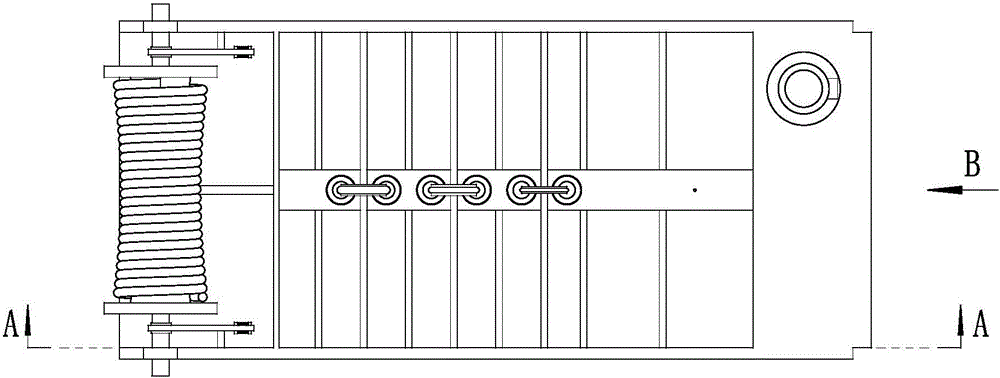

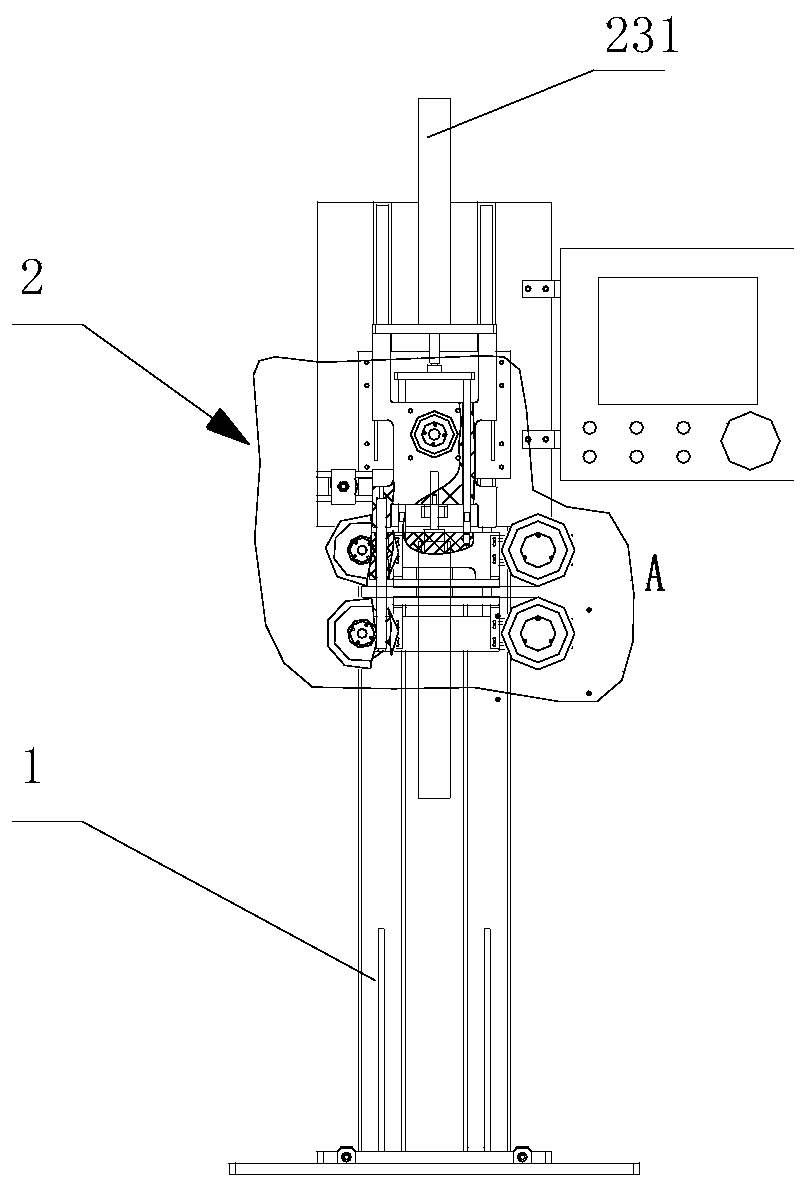

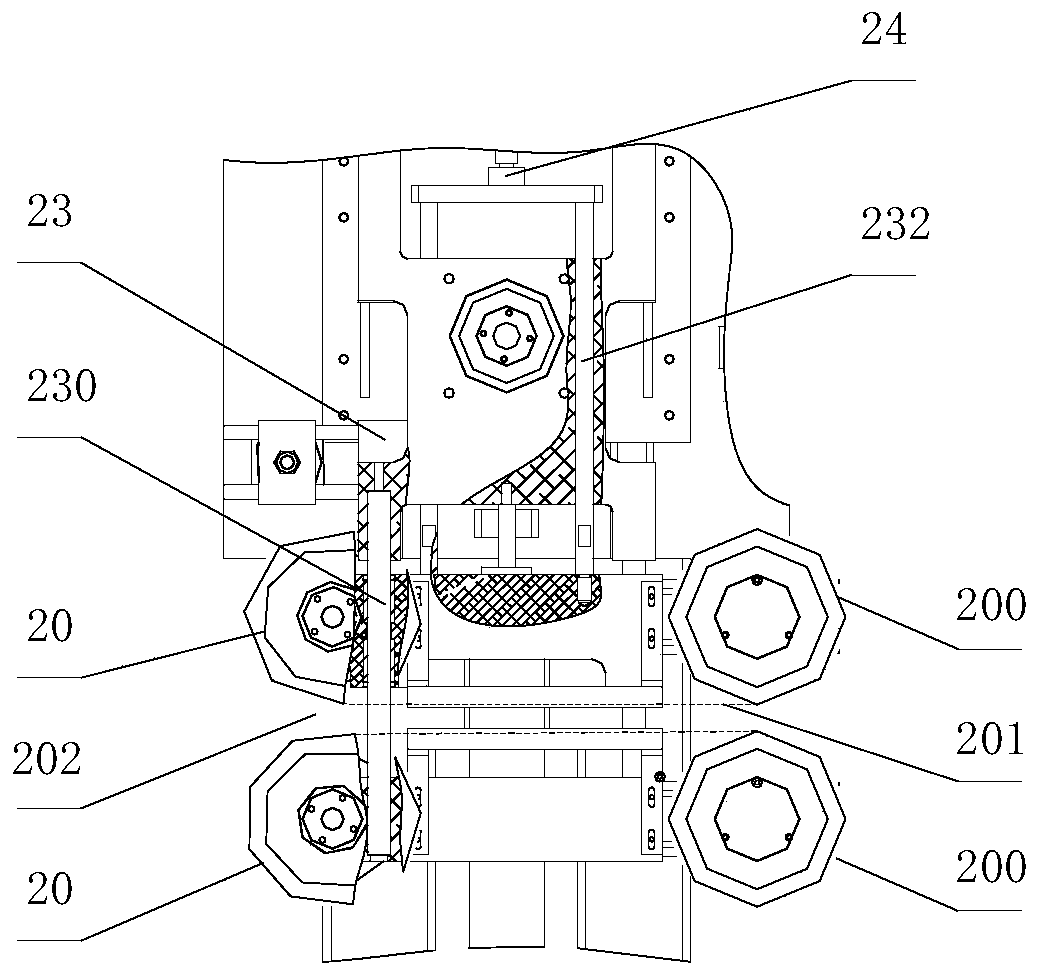

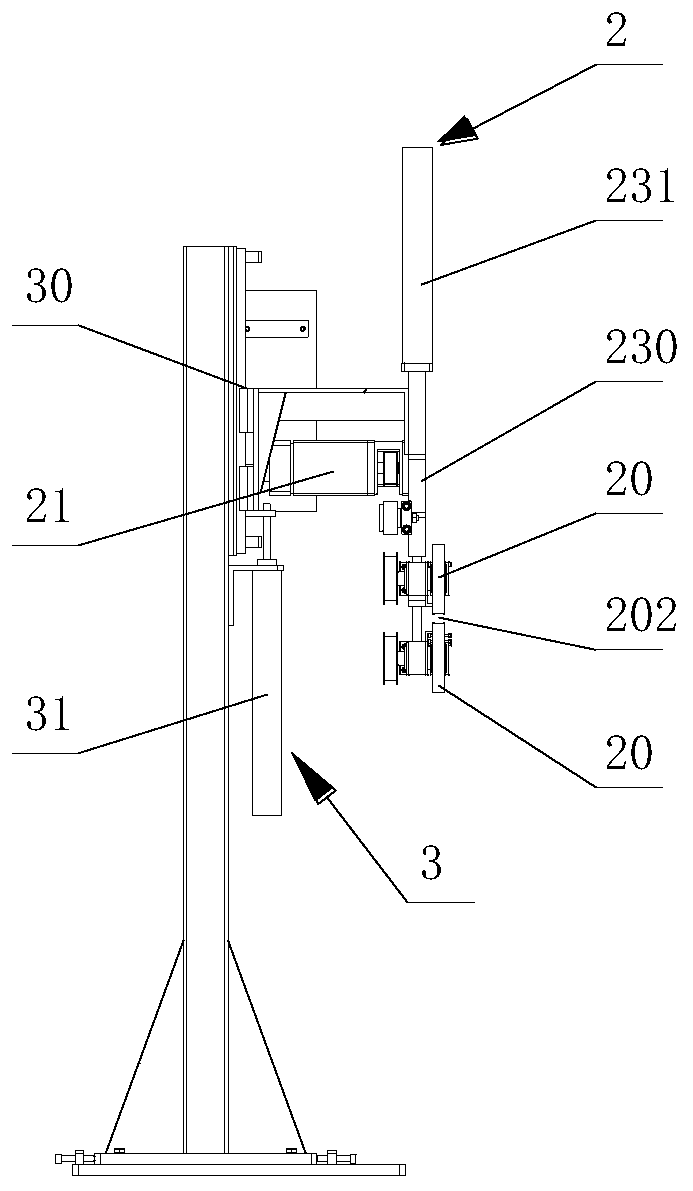

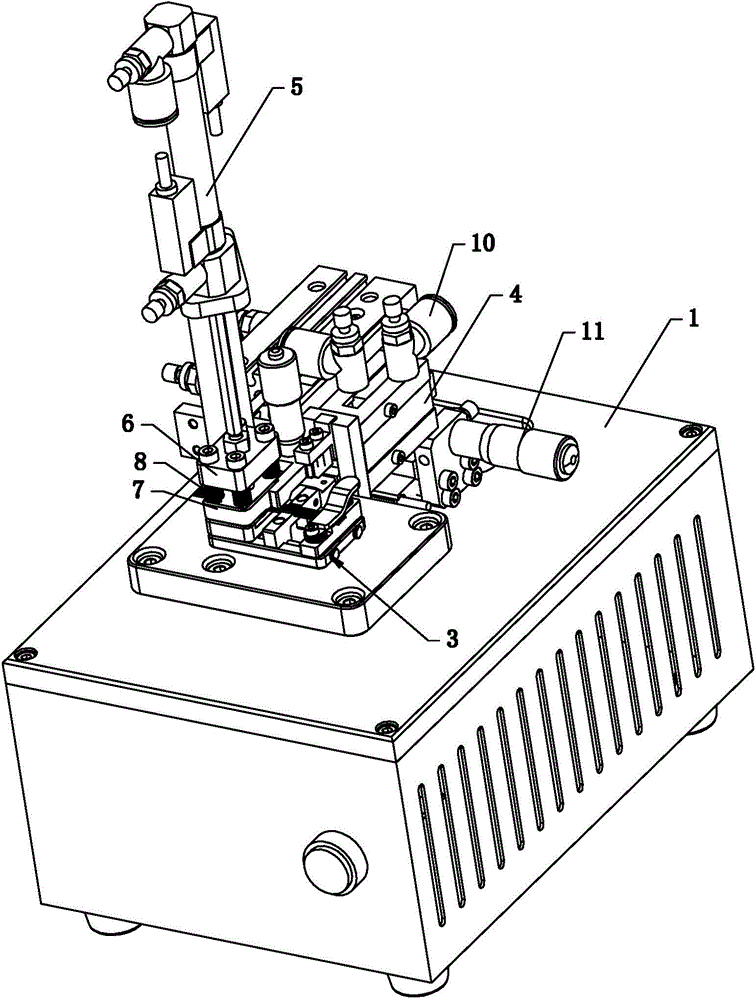

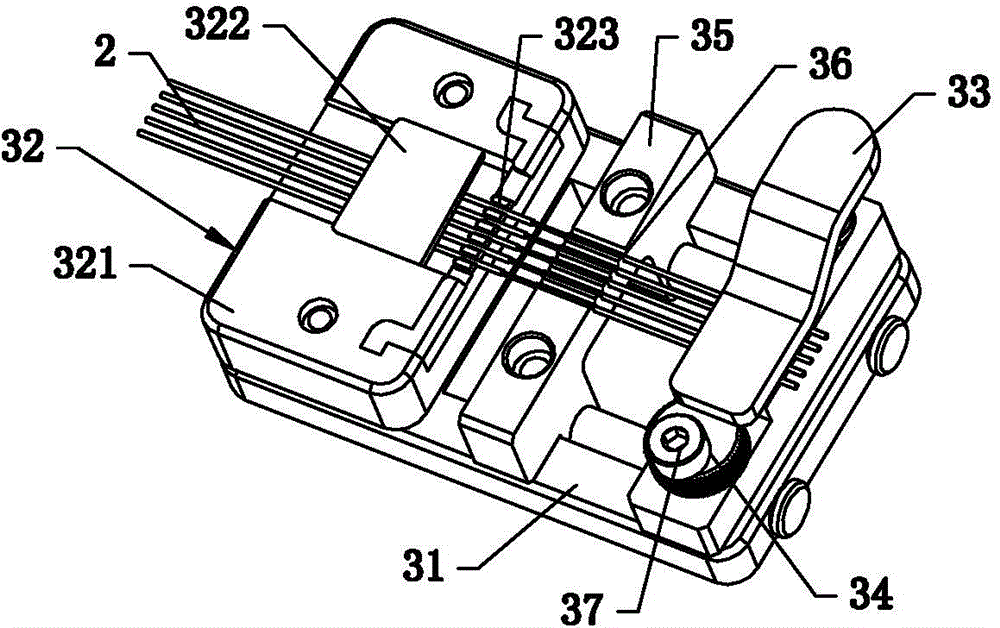

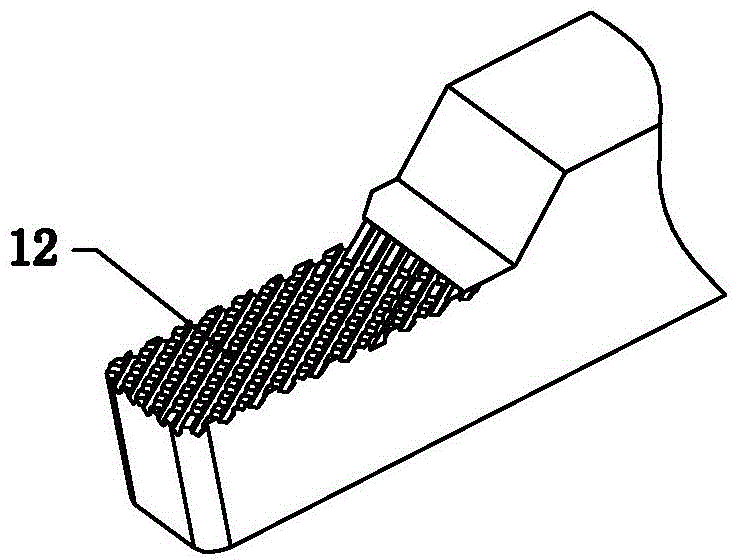

Micro coaxial cable stripping and drawing machine

ActiveCN103427315ANovel structureImprove stripping efficiencyLine/current collector detailsCoaxial cableEngineering

The invention discloses a micro coaxial cable stripping and drawing machine comprising a frame, a cable arranging tool, a pressing device and a clamping jaw. The cable arranging tool is arranged on the frame and comprises a base plate which is a hollow frame, a first cable clamping seat for fixing a first end of a micro coaxial cable is arranged at one end of the base plate, a second cable clamping seat for clamping or loosening a second end of the micro coaxial cable is arranged at the other end of the base plate, a stripping and drawing space is formed between the first cable clamping seat and the second cable clamping seat, the pressing device driven by a first power unit and used for pressing the first cable clamping seat is disposed on the frame, the clamping jaw driven by two axis manipulators is disposed on the frame, the first axis manipulator is used for driving the clamping jaw to extend into the stripping and drawing space to clamp the middle of a cladding of the micro coaxial cable, and the second axis manipulator is used for driving the clamping jaw to move towards the second cable clamping seat to have the middle of the cladding of the micro coaxial cable peeled and drawn. The micro coaxial cable stripping and drawing machine is convenient to operate, and manual work is omitted, so that efficiency of stripping of the micro coaxial cable and quality of products are greatly improved.

Owner:GOERTEK INC

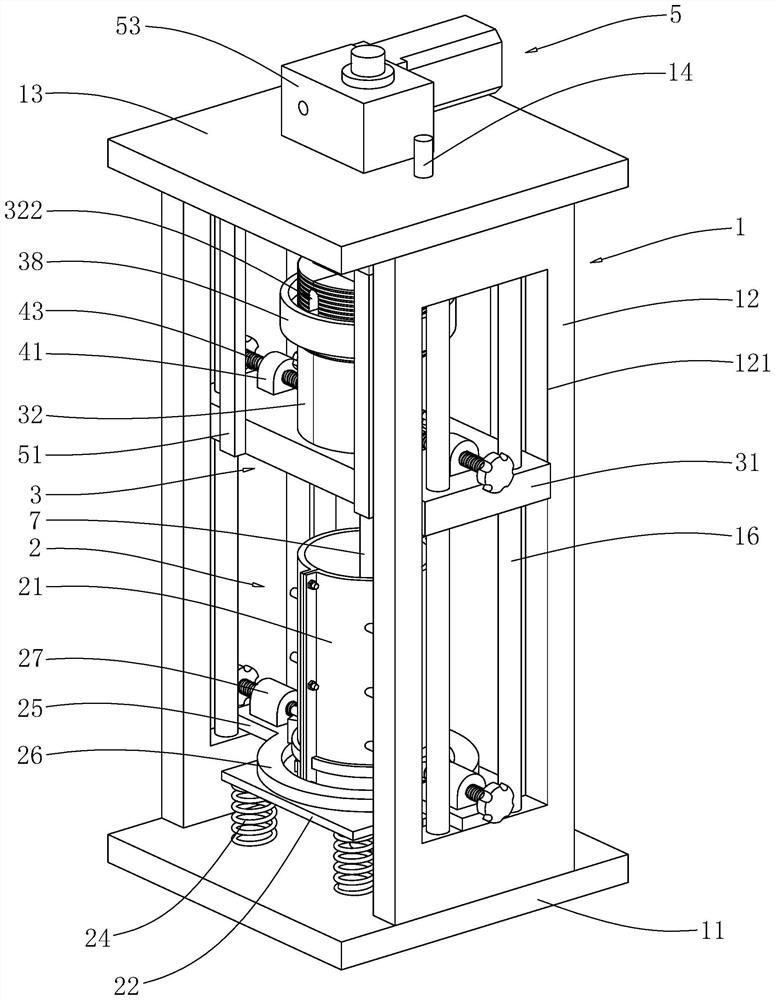

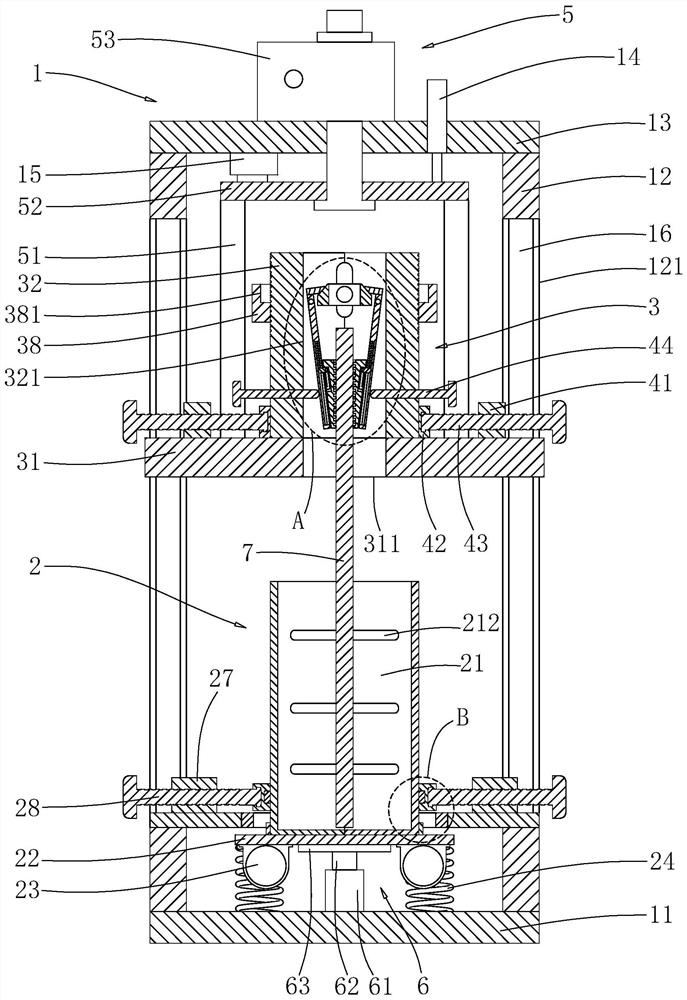

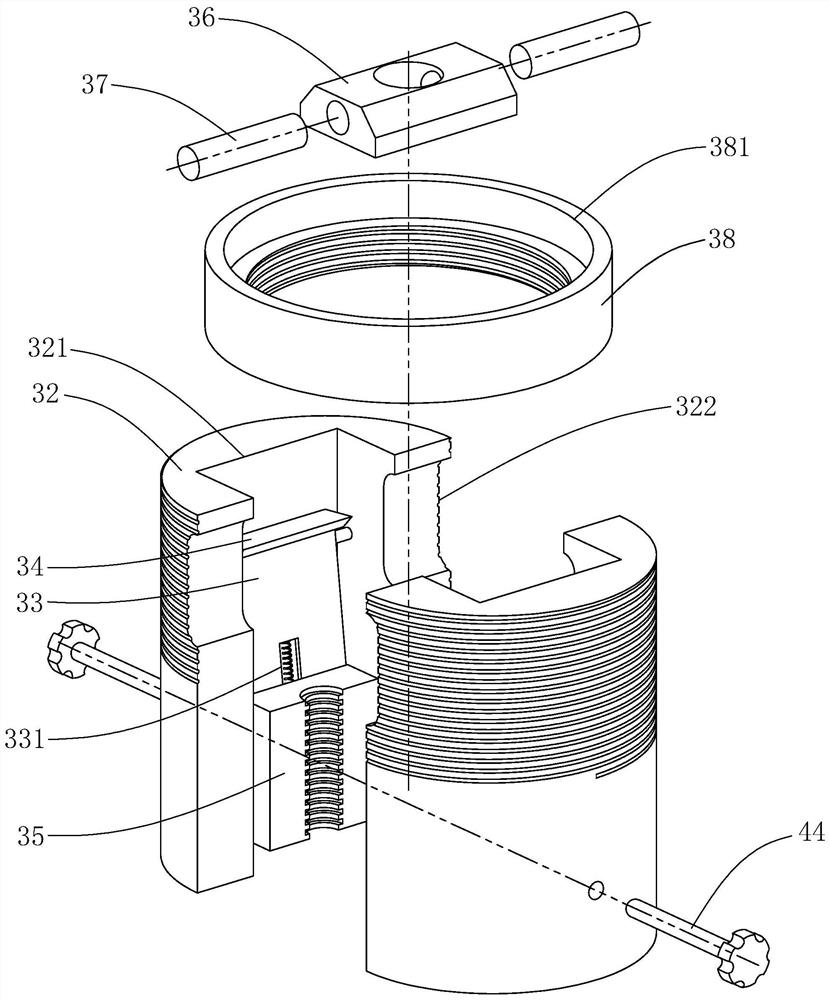

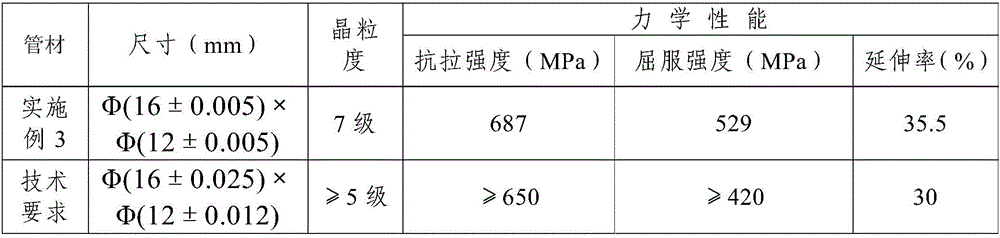

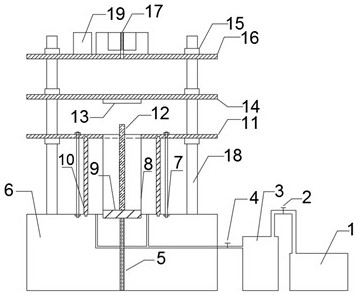

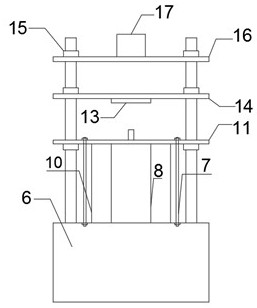

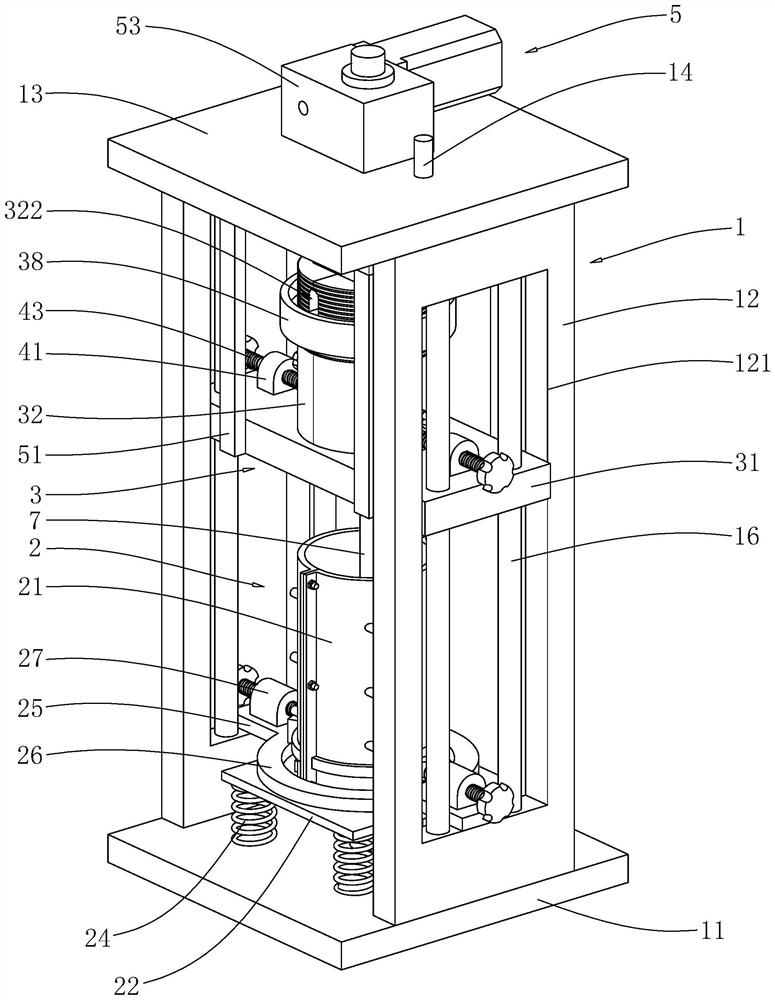

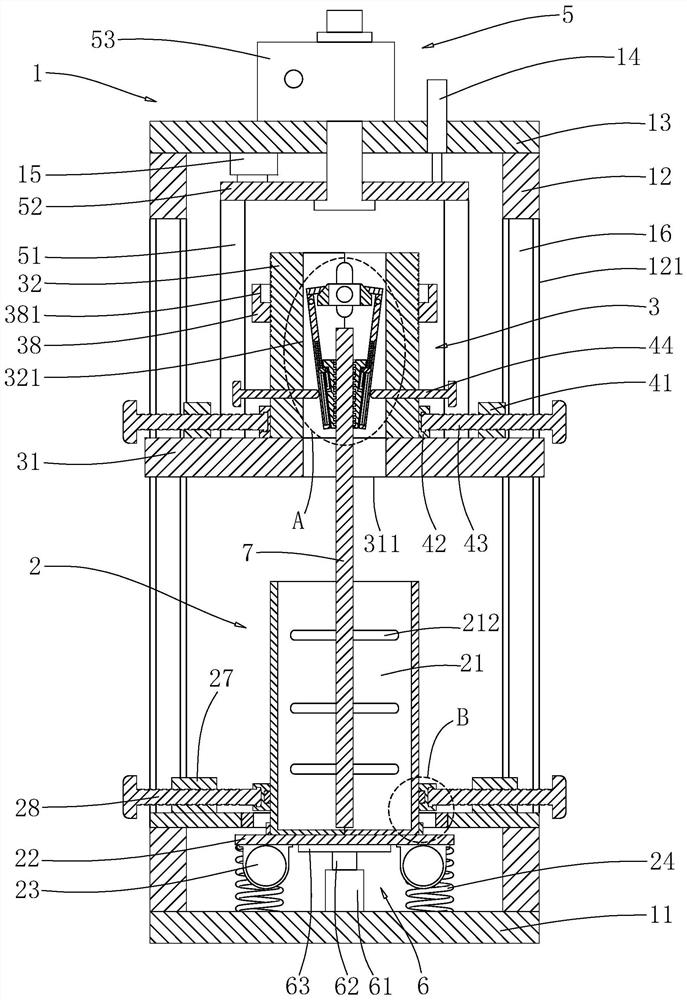

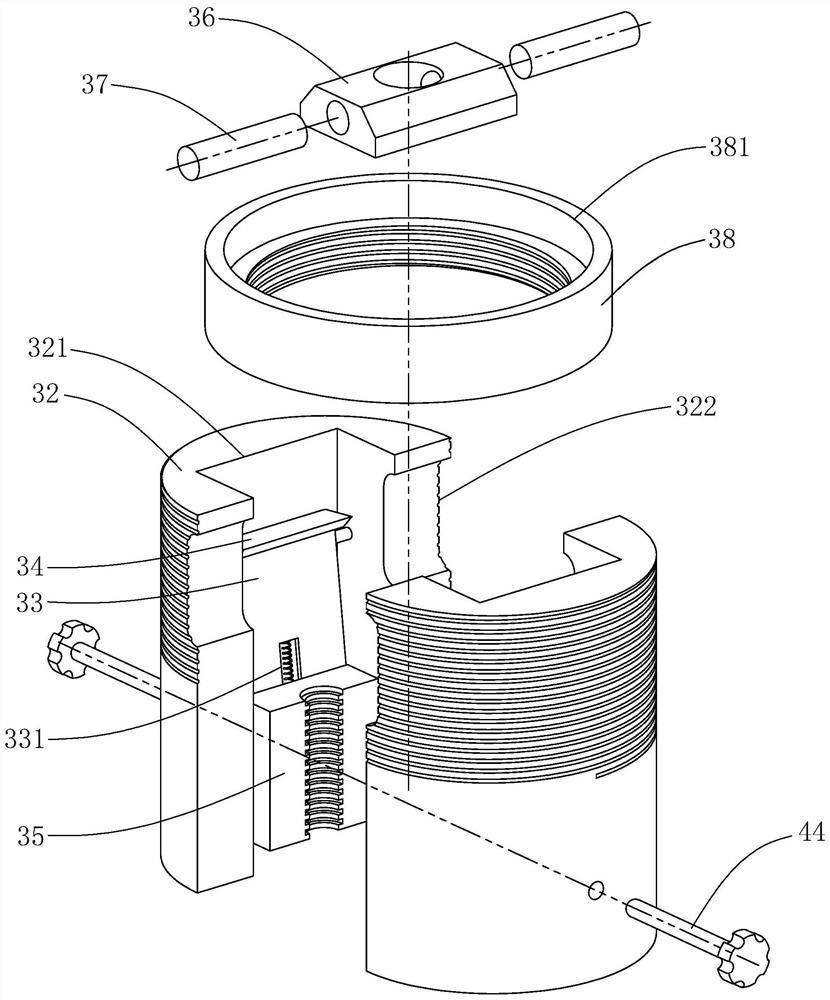

Anchor rod drawing experiment device and detection method thereof

ActiveCN112683670ARealize drawingEasy to detectMaterial strength using tensile/compressive forcesStructural engineeringMechanical engineering

The invention relates to an anchor rod drawing experiment device and a detection method thereof, wherein the device is applied to the technical field of anchor rod drawing detection. The anchor rod drawing experiment device comprises a rack, wherein the rack comprises a base, a side frame is arranged on the base, a top plate is arranged on one side, away from the base, of the side frame, an anchoring mechanism is arranged on the base of the rack, a clamping mechanism is arranged on one side, deviating from the base, a lifting mechanism used for lifting the clamping mechanism is arranged on the top plate, a displacement sensor and a pressure sensor are arranged on the side, close to the clamping mechanism, of the top plate, and the displacement sensor and the pressure sensor abut against the clamping mechanism. According to the invention, the clamping mechanism is lifted through the lifting mechanism to achieve the purpose of drawing the anchor rod, and then data fed back by the pressure sensor and the displacement sensor are calculated to obtain anchoring strength data, so that the effect of detecting the anchoring strength of the anchor rod is achieved, an operator can conveniently and accurately measure the anchoring strength data of the anchor rod, and the operator can conveniently detect the anchor rod.

Owner:南京南房建设工程检测有限公司

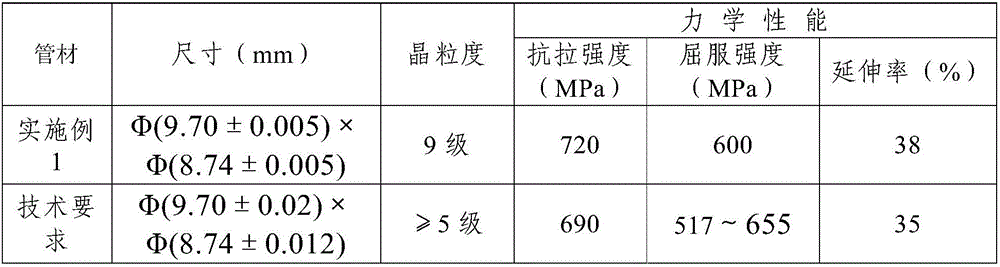

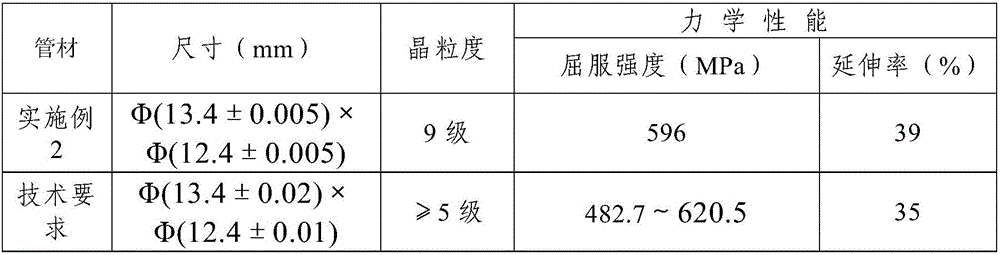

Processing method for improving quality of inner surface of austenite stainless steel tube

InactiveCN106755770AIncrease productivityStable and reliable dimensional accuracyFurnace typesHeat treatment furnacesSteel tubeThin walled

The invention provides a processing method for improving quality of an inner surface of an austenite stainless steel tube. The method comprises the following step: successively carrying out solution treatment, straightening, pulling of a fixed mandrel and aftertreatment on a rolled austenite stainless steel insertion tube to obtain the austenite stainless steel tube with the high-quality inner surface. The processing method is simple in process, easy to implement, high in production efficiency and low in energy consumption; and the austenite stainless steel tube processed by the method is good in quality of the inner surface and the outer surface, even in structure and excellent in mechanical property; the yield of one-time detection in nondestructive test reaches 90% or above; and therefore, the processing method can be widely applied to the processing industry of stainless steel thin-walled slender tubes.

Owner:西安诺博尔稀贵金属材料股份有限公司

Finger knitting auxiliary method using computer drawing

InactiveCN1737809ARealize drawingHand lacing/braidingSpecial data processing applicationsTight frameAuxiliary memory

This invention discloses one computer assistant hand knitting method, which comprises the following steps: opening Word graph process on Windows platform and inputting fonts and graph formed pattern; pre-processing step by the amplifying, color filling and extending in tool box. The steps comprise form process, frame unit copy process and the finally graph printing step.

Owner:刘立宏

Airing rack for textile processing and capable of improving airing efficiency of textiles

ActiveCN113048739ARealize up and down reciprocating motionAchieve wind dryingDrying gas arrangementsDrying chambers/containersEngineeringAnnular array

The invention provides an airing rack for textile processing and capable of improving the airing efficiency of textiles, relates to the technical field of textile processing, and solves the problems that the airing position cannot be changed under the driving of natural wind power through structural improvement, and automatic wind collection and diffusion type airflow auxiliary airing cannot be realized. The airing rack comprises a rack body; four supporting legs are welded to the rack body, and a fixing structure is welded to each supporting leg. Exhaust holes are formed in a pipe body in the annular array shape, the pipe body is of a cylindrical pipe structure, and the exhaust holes formed in the annular array shape jointly form a diffusion type air injection structure of the pipe body; a connecting pipe is fixedly connected to a rotating seat, the tail end of the connecting pipe is rotationally connected with the pipe body, and the connecting pipe is communicated with the pipe body; and a cover body is installed at the head end of the connecting pipe, and the connecting pipe and the cover body jointly form a wind collecting structure of the pipe body.

Owner:HUANGGANG POWER SUPPLY COMPANY HUBEI ELECTRIC POWER

Extruding and pulling device for cable loose tubes

ActiveCN107186994ARealize drawingControl excess lengthTubular articlesMechanical engineeringEngineering

Owner:FENGHUO COMM SCI & TECH CO LTD

Steel wire drawing and winding mechanism

The invention discloses a steel wire drawing and winding mechanism. The steel wire drawing and winding mechanism comprises a wire unwinding mechanism, a drawing mechanism and a wire winding mechanism,wherein one side of the wire unwinding mechanism is provided with the drawing mechanism, the side, away from the wire unwinding mechanism, of the drawing mechanism is provided with the wire winding mechanism, and the wire unwinding mechanism is composed of a first fixed seat, a distance adjusting sliding groove, a distance adjusting screw rod, distance adjusting sliding blocks, a distance adjusting hand wheel, fixed supporting columns and a wire unwinding roller. According to the steel wire drawing and winding mechanism, by means of the arrangements of the distance adjusting screw rod and thedistance adjusting hand wheel, the separation distance between the fixed supporting columns can be flexibly adjusted according to the wire unwinding rollers of different specifications, and the practicality range of the steel wire drawing and winding mechanism is broadened; by means of the arrangements of a first pressing wheel and a second pressing wheel, squeezing and drawing on steel wires arerealized; and the steel wires are winded through a wire winding roller, under the action of a reciprocating screw rod, the wire winding roller is made to perform reciprocating motions, arranging of the steel wires in the winding process is realized, the steel wires are prevented from being wound in one place, and the machining efficiency of the steel wires is greatly improved.

Owner:王嘉政

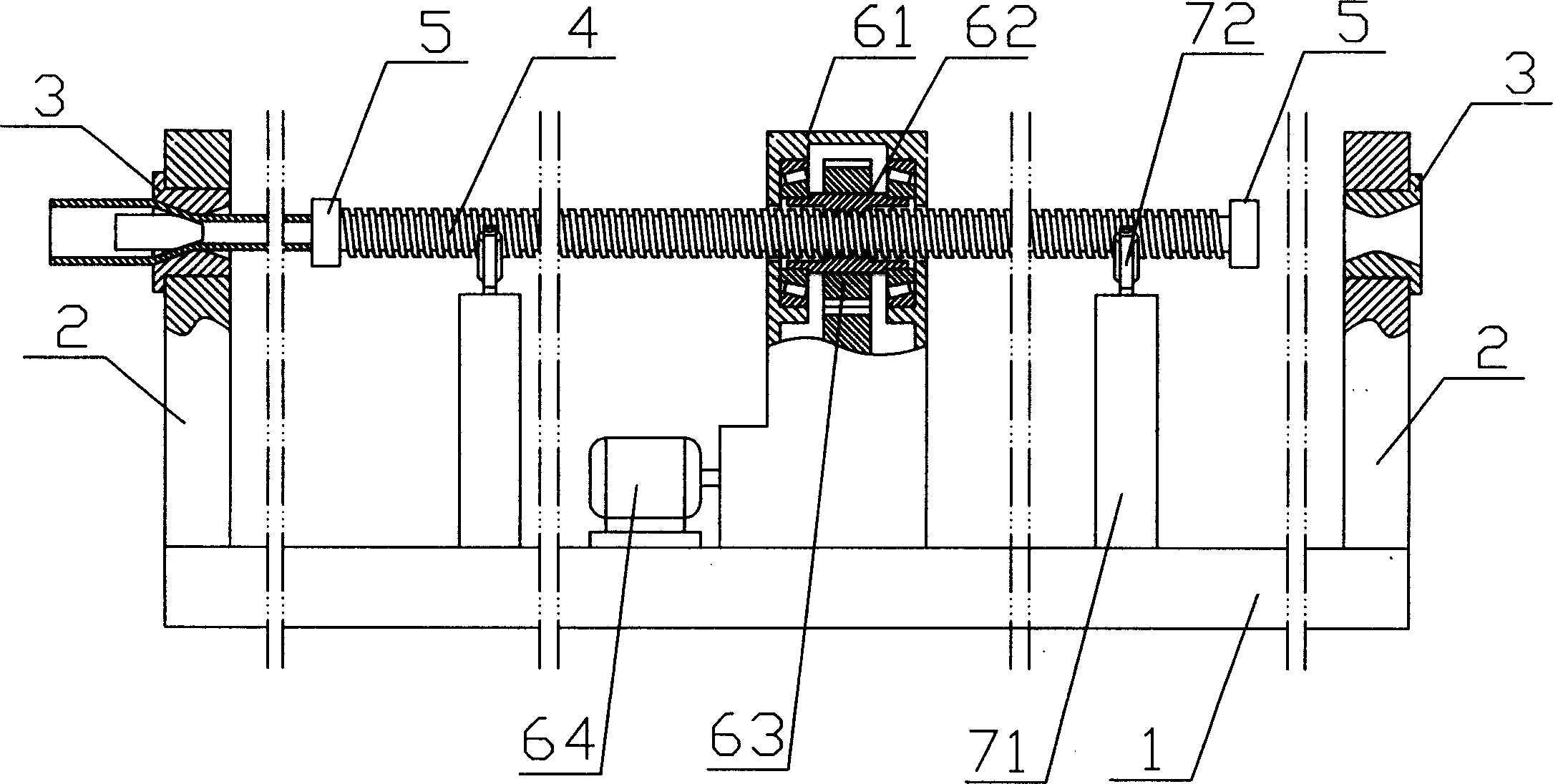

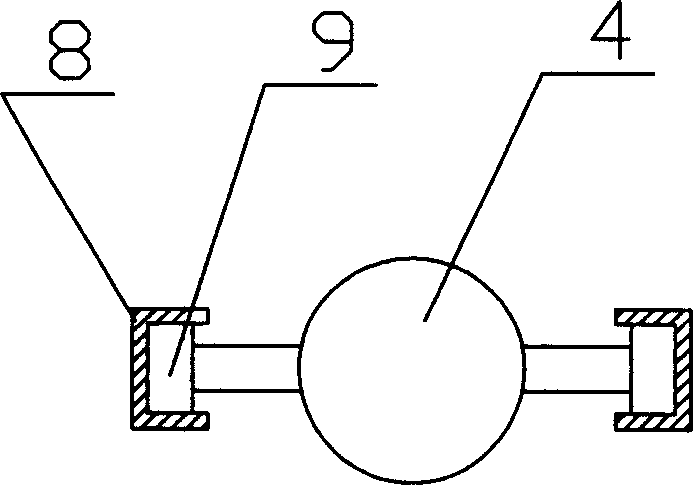

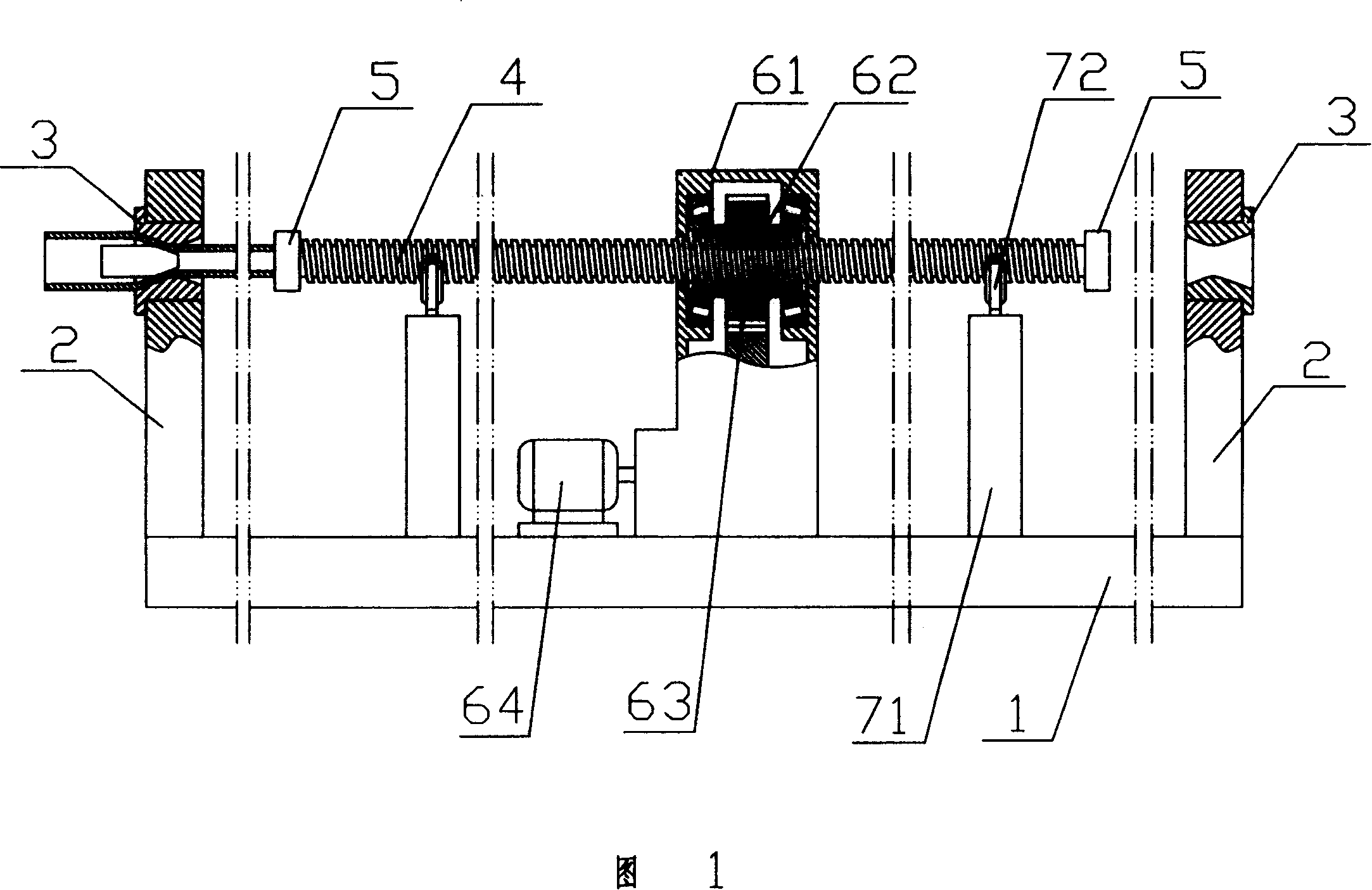

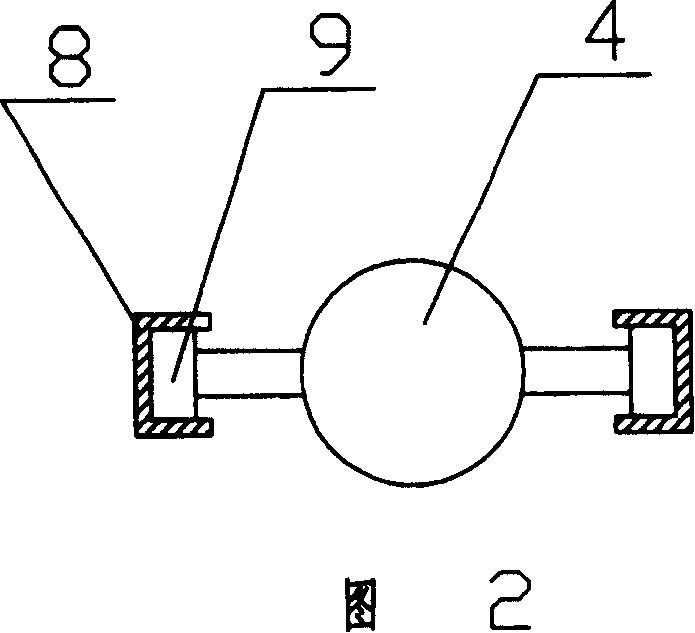

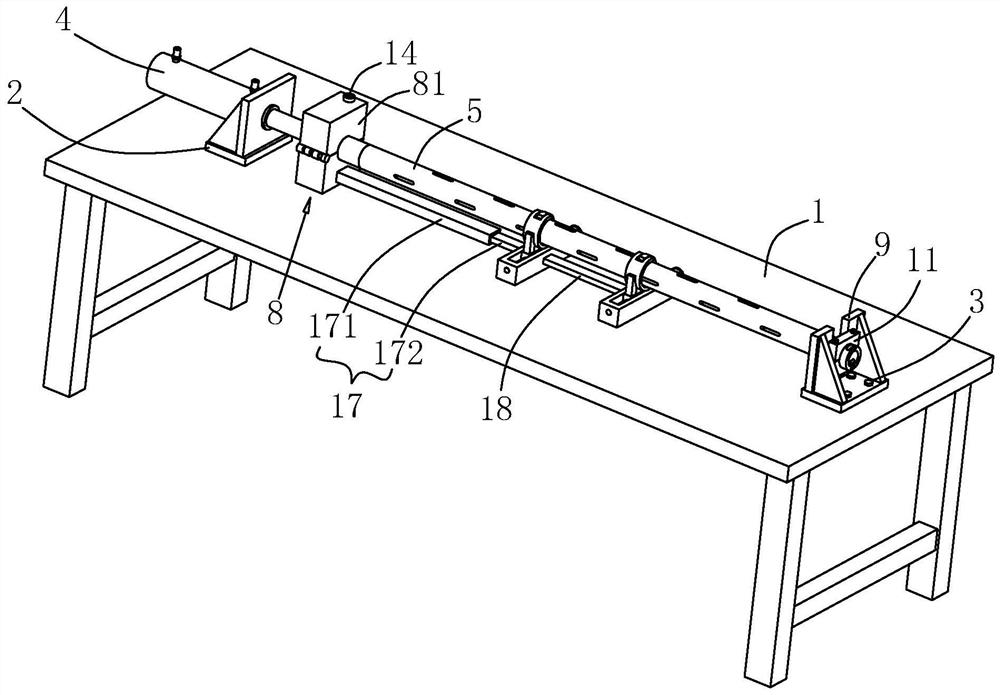

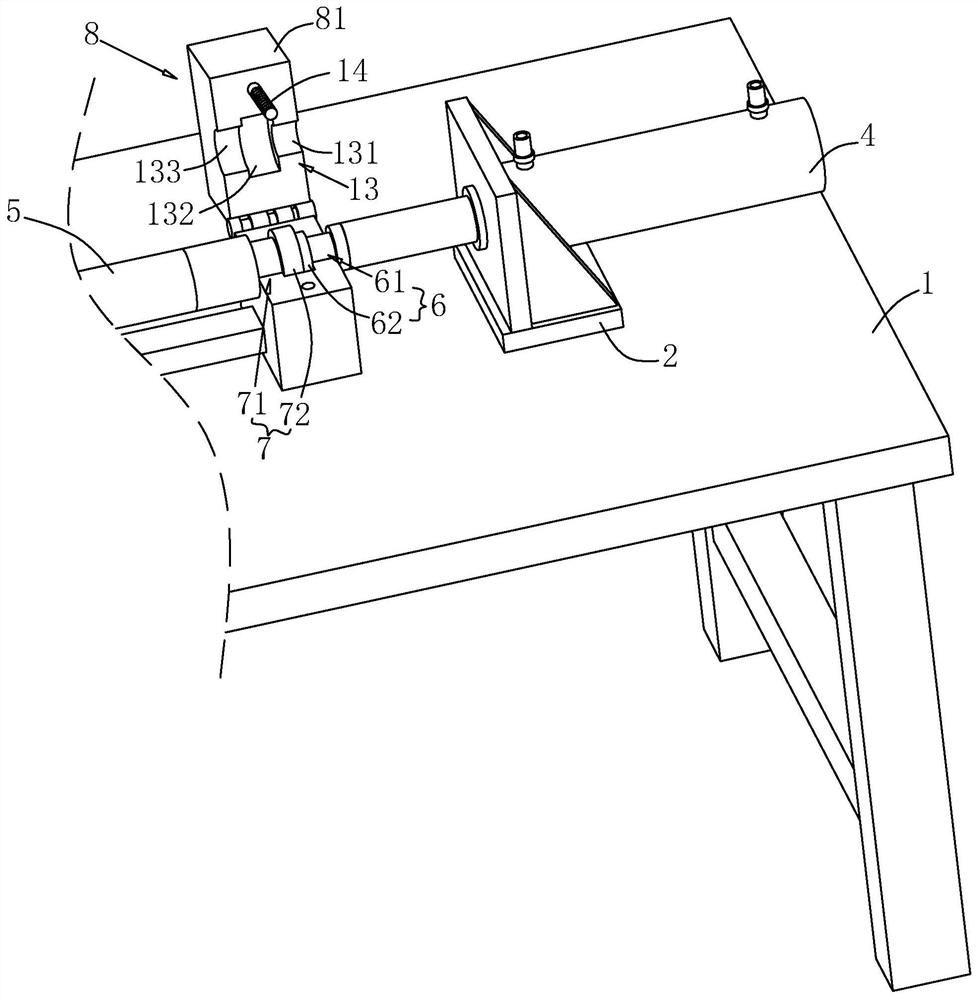

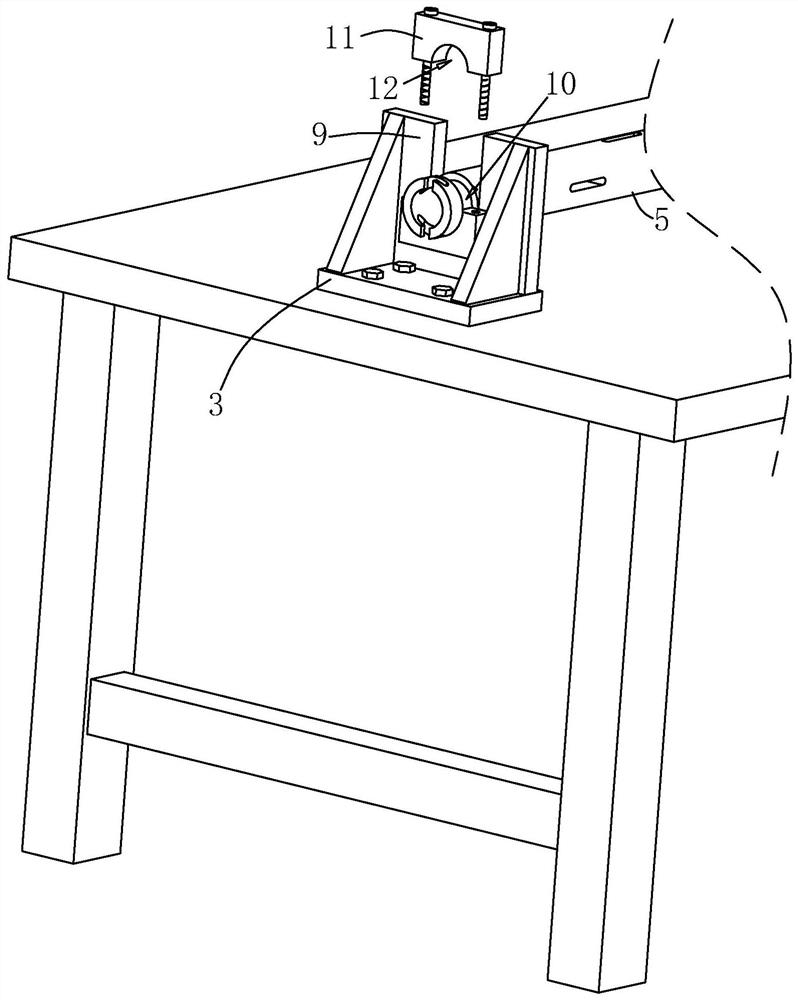

Reciprocating steel pipe drawer

A reciprocating steel pipe drawing machine is composed of machine frame, reducing dies and their supporters at both ends of machine frame, screw bolt between said reducing dies for drawing steel pipe and its driver, and steel pipe clamps installed to both ends of said screw bolt. It features its bidirectional drawing for high productivity.

Owner:王剑波 +1

Anchor rod pull-out test device and test method considering temperature and pressure influences

PendingCN111721612AEase of ejectionAchieve compactionMaterial strength using tensile/compressive forcesRubber membraneRebar

The invention discloses an anchor rod pull-out test device and test method considering temperature and pressure influences. The test device comprises a base, a lower assembly plate is arranged above the base, a workpiece sleeve or a test piece cover is arranged in an assembly hole in the lower assembly plate, a high-strength glass sleeve is arranged between the base and the lower assembly plate, and a closed temperature-control and pressure-control filling space is formed among the base, the lower assembly plate, the high-strength glass sleeve and the test piece cover; the test method comprises the following steps: mounting the test device, filling the test device into a soil body, compacting the soil body, coating the soil body with a rubber film, grouting, inserting reinforcing steel bars, pressing and covering a test piece, and carrying out a pull-out test. The medium-high strength glass sleeve can form a filling space for temperature and pressure control, a manufactured test pieceis subjected to a temperature and pressure control test through a pipeline, the test piece is pressed through a lifting type middle lifting plate, compaction and drawing can be achieved through the pressing piece on a top pulling and pressing plate, and temperature and pressure influence factors are added to the test.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Automatic copper pipe drawing device

The invention discloses an automatic copper pipe drawing device. The automatic copper pipe drawing device comprises a machine body, a hydraulic system, an automatic clamping clamp and a drawing device body. The hydraulic system is arranged in the machine body. The automatic clamping clamp and the drawing device body are arranged on the upper surface of the machine body. The drawing device body further comprises a drawing hydraulic cylinder and a drawing length detecting travel switch. The problem of copper pipe drawing is solved, and the design mechanism is reasonable. The hydraulic cylinder is driven by the hydraulic system to draw a copper pipe clamped through the automatic clamping clamp, drawing is stopped when the drawing length detecting travel switch transmits signals, the automatic copper pipe drawing is achieved, and operation is fast and convenient.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Crucible for growing monocrystalline silicon and preparation method thereof

InactiveCN106191987ALow purity requirementSatisfy Crucible Purity RequirementsPolycrystalline material growthBy pulling from meltGas pressure sinteringOxygen content

The invention relates to a crucible for growing monocrystalline silicon and a preparation method thereof. The crucible comprises various nitride ceramic crucible billets and a C / C reinforcement layer, wherein the C / C reinforcement layer is wrapped on the outer surface of the crucible billet, and various nitride crucible billets can be prepared by a chemical vapor deposition method, a reaction sintering method and a gas pressure sintering method. According to the present invention, the crucible billet has characteristics of molten silicon erosion resistance, long service life and crystal oxygen content reducing; and with the closely adhered C / C reinforcement layer, the problem that the brittle ceramic is suddenly broken to cause the silicon leakage can be effectively prevented.

Owner:罗万前

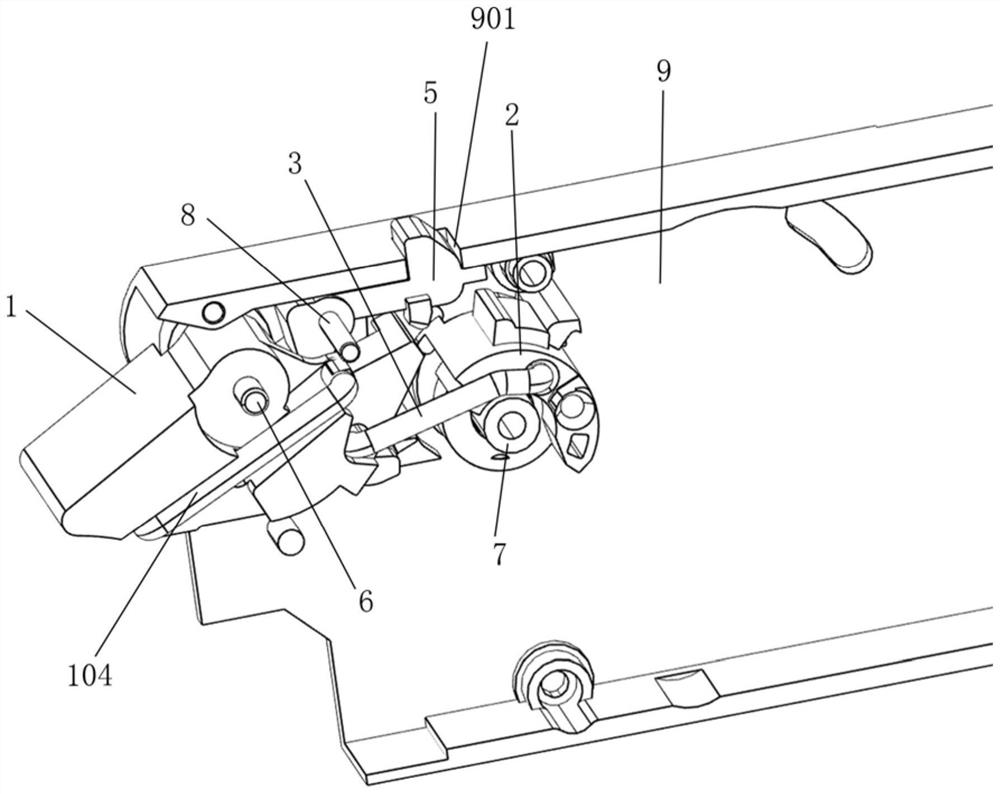

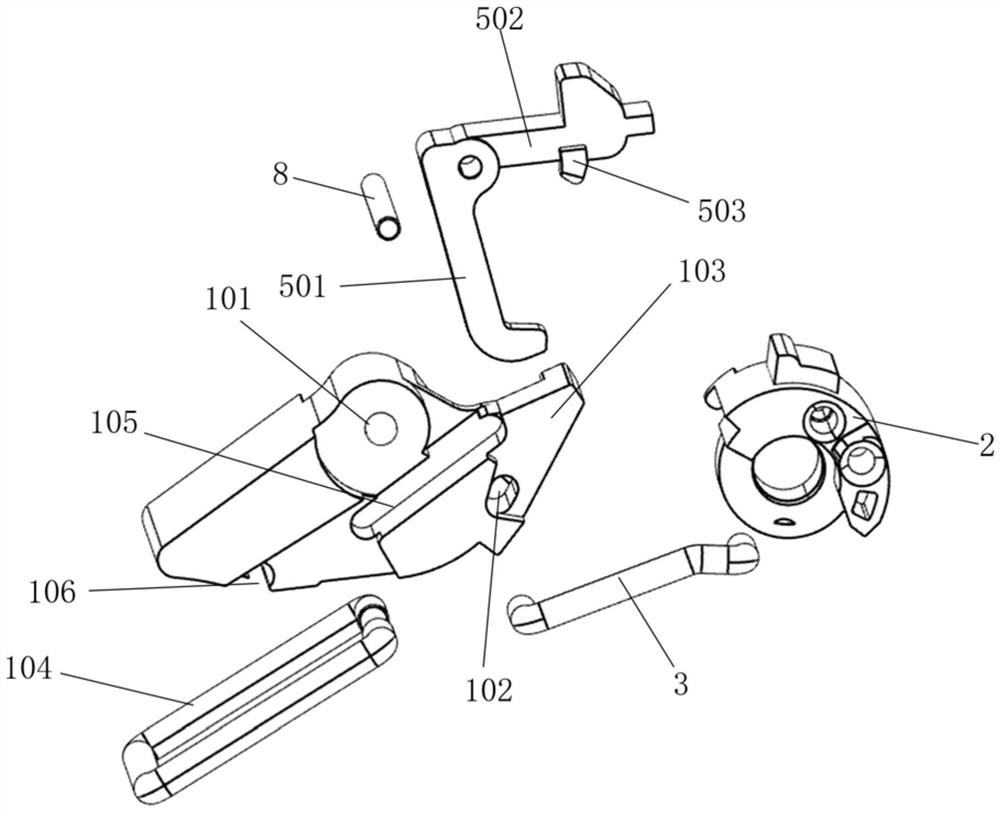

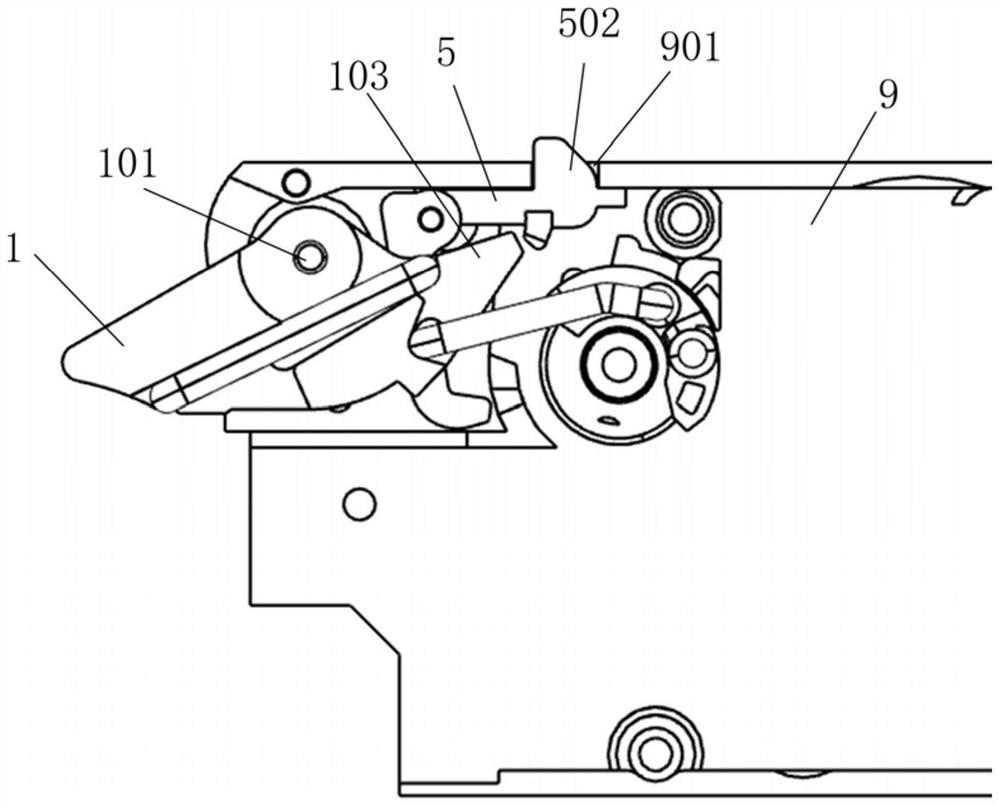

Switching-on and switching-off handle mechanism of plug-in circuit breaker and circuit breaker

PendingCN111883398AGuaranteed stabilityImprove stabilityProtective switch operating/release mechanismsControl theoryRocker arm

The invention relates to a switching-on and switching-off handle mechanism of a plug-in circuit breaker and the circuit breaker. The handle mechanism comprises a handle rocker arm, a turntable, a first connecting rod, a second connecting rod and a locking piece, the handle rocker arm is hinged in a shell of the plug-in circuit breaker through a first rotating shaft, and the turntable is hinged inthe shell through a second rotating shaft; the handle rocker arm is connected with the turntable through a first connecting rod, the turntable is connected with an operating mechanism in the plug-in circuit breaker through a second connecting rod, the handle rocker arm is provided with a first shaft hole and a second shaft hole, the first shaft hole is a round hole, and the second shaft hole is anelongated bent hole. Compared with the prior art, the switching-on and switching-off of the plug-in circuit breaker are controlled through the common poking of the handle rocker arm, excessive rotation of the handle rocker arm is carried out through drawing the handle rocker arm, so that the locking piece is operated to be unlocked, and the installation stability of the circuit breaker is improved by adopting different operation logics.

Owner:DELIXI ELECTRIC

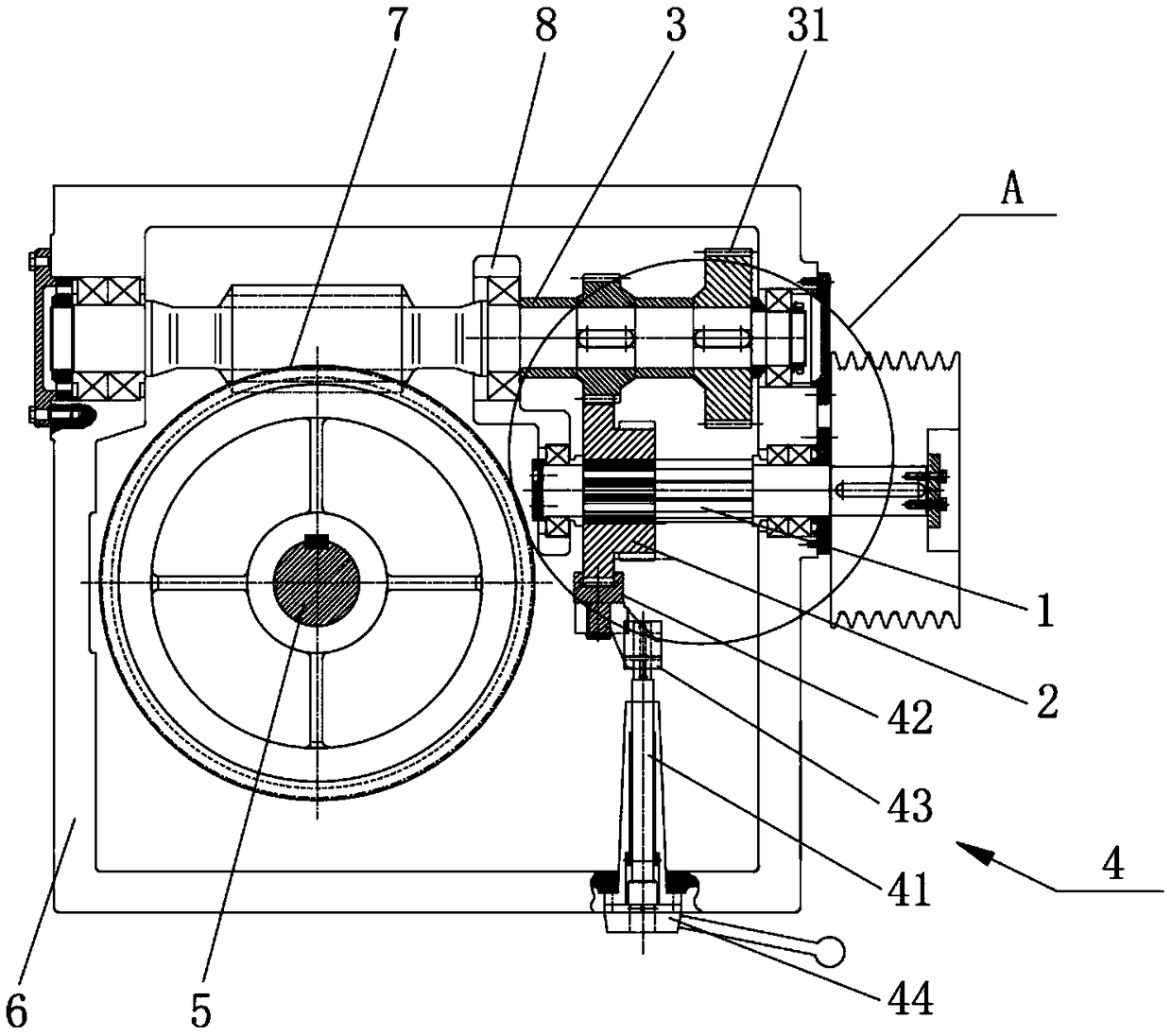

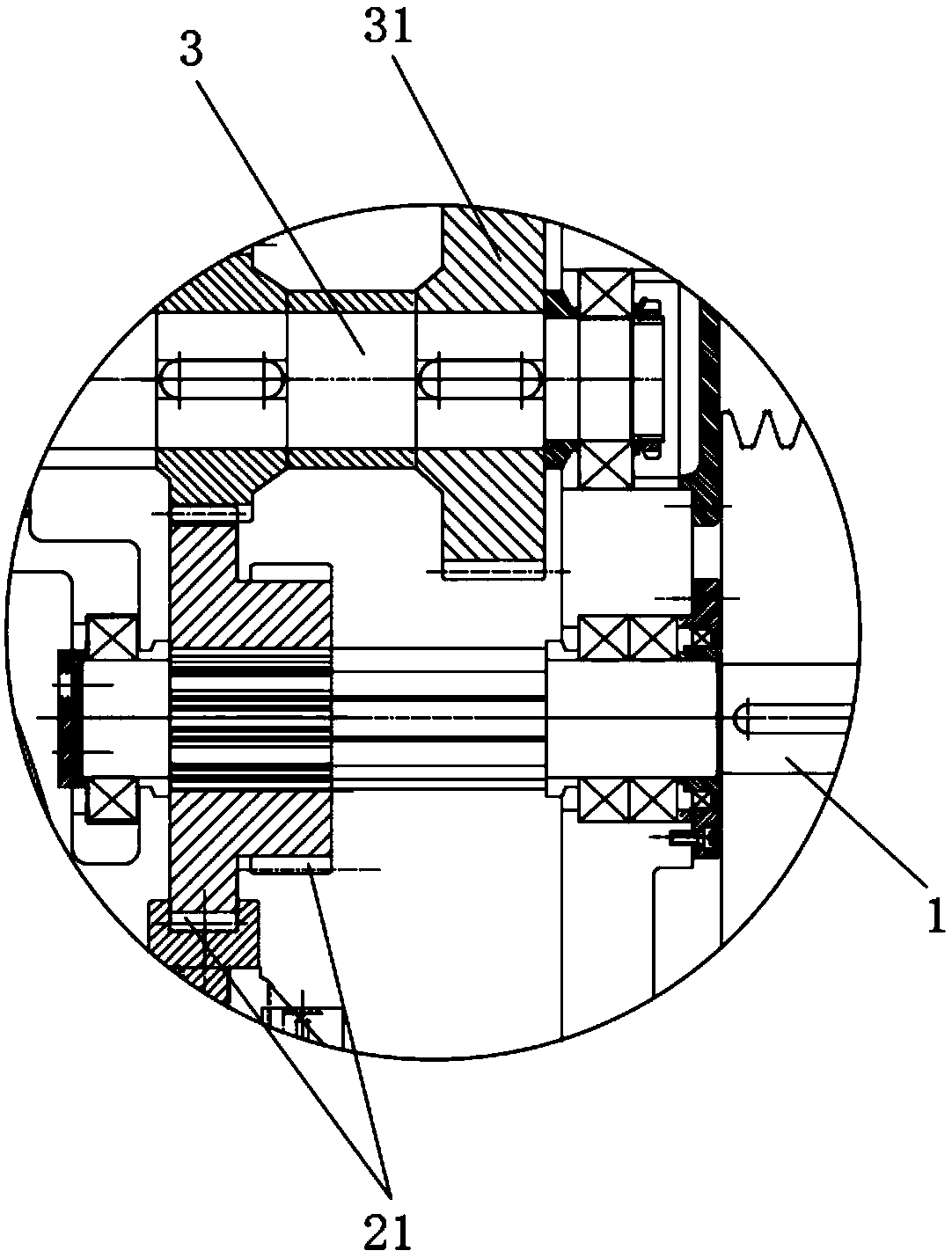

Multi-gear variable speed drawing machine

PendingCN109139880ARealize drawingAchieve high pull-out forceToothed gearingsGearing detailsGear wheelDrive shaft

The invention belongs to the field of steel bar drawing equipment, and discloses a multi-gear variable speed drawing machine. The multi-gear variable speed drawing machine comprises an input shaft, amulti-stage gear, a driven shaft, a driving piece and an output shaft, wherein the multi-stage gear rotates along with the input shaft, can move in the axial direction of the input shaft, and is provided with at least two driving gears which rotate synchronously and are different in diameter; the driven shaft is fixedly provided with driven gears, and the driven gears and the driving gears are arranged in pairs; one end of the driving piece is connected to the multi-stage gear, and the driving piece is used for driving the multi-stage gear to move axially and be engaged with one of the drivengears; and the output shaft is in driving connection with a driven shaft and is driven by the driven shaft to rotate. Through the structure, drawing of steel bars different in diameter can be achieved, when the steel bars with different diameters are drawn, the multi-stage gear is driven to axially move through the driving piece, the driven gears and the driven gears which correspond to the steelbars with the diameter are engaged, large drawing force for the large-diameter steel bars and the high drawing speed of the small-diameter steel bars are achieved, and the motor power is sufficientlyutilized.

Owner:TJK MACHINERY TIANJIN

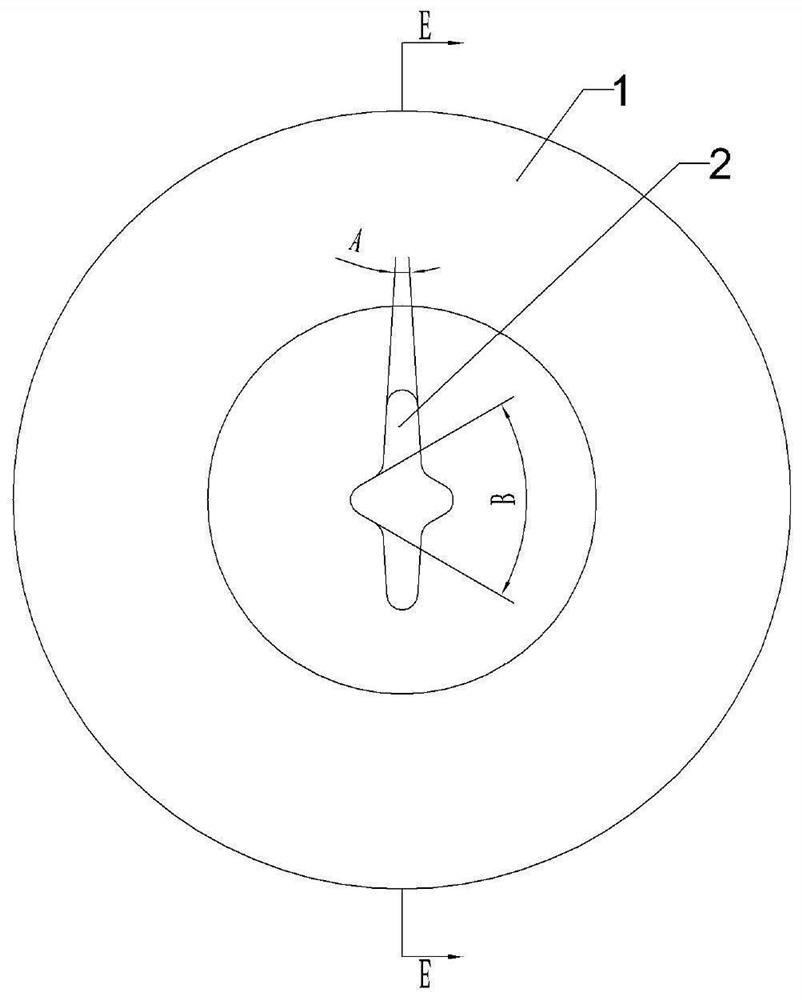

Production equipment for drawing copper pipe

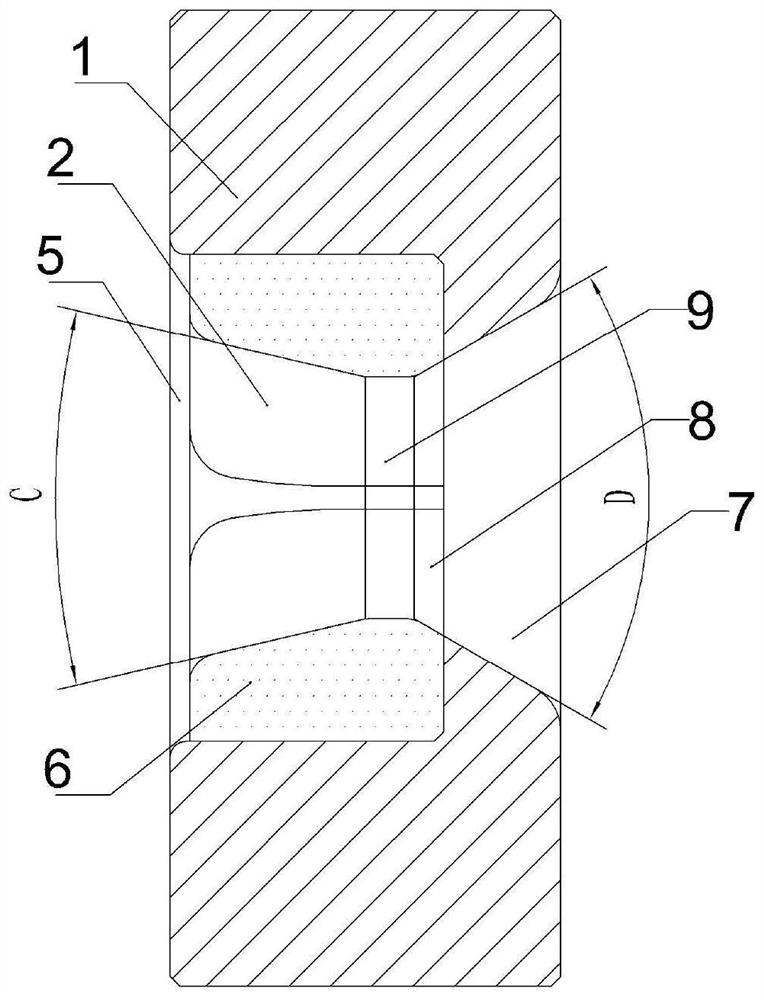

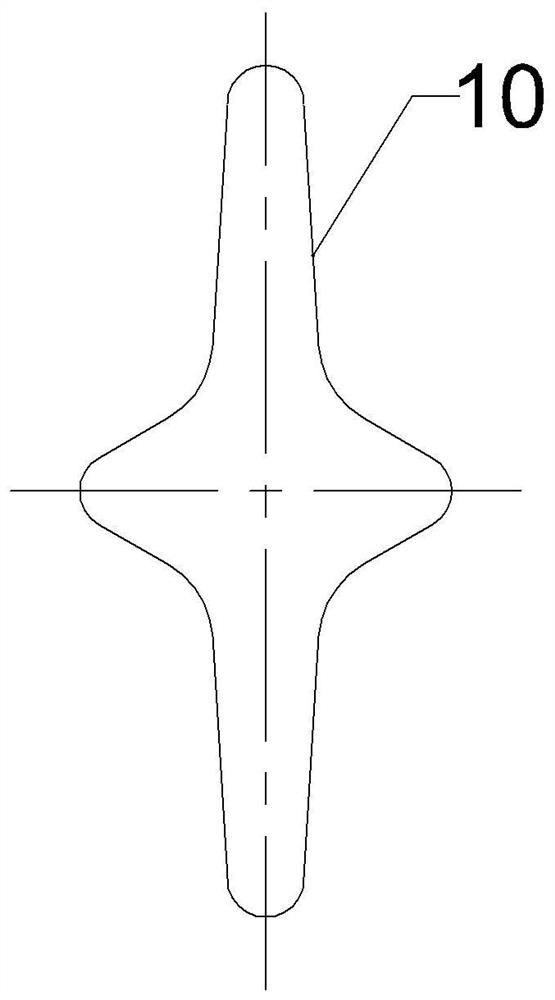

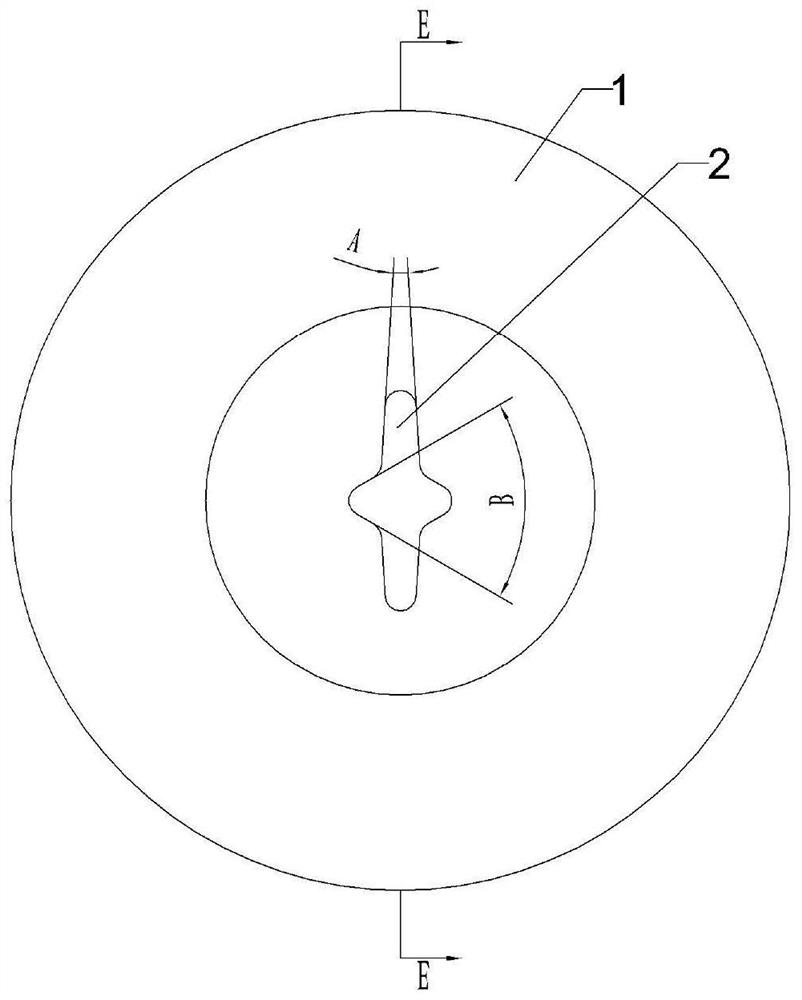

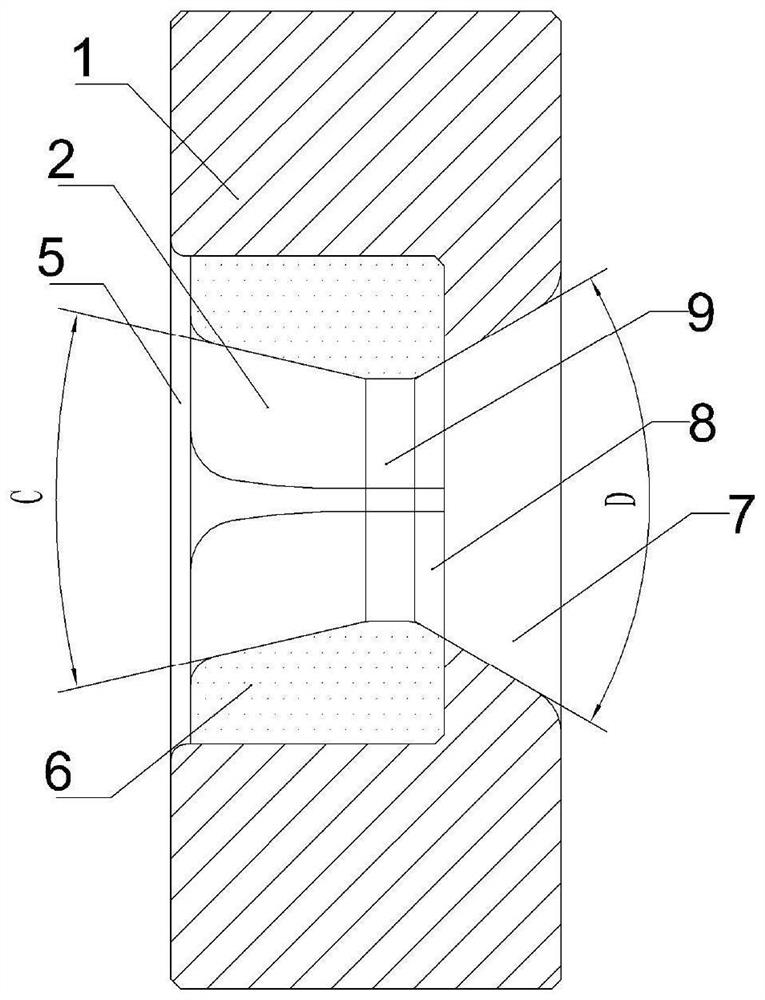

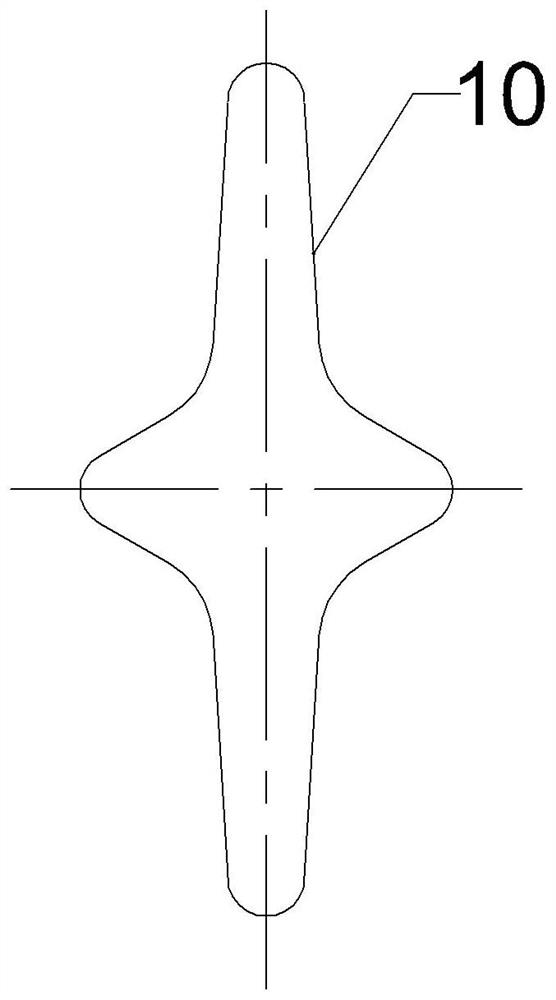

PendingCN113290065AEasy to swimReduce frictionDrawing mandrelsDrawing diesMolding machineMechanical engineering

The invention relates to the technical field of copper pipe drawing, in particular to production equipment for drawing a copper pipe. The production equipment comprises an inner oil coating mechanism, a straightening mechanism, a pre-forming mechanism, a drawing die and a cutting mechanism; the drawing die comprises an outer die and a moving core head, the outer die comprises a die sleeve and a die core, a through hole is axially formed in the die sleeve, the die core is embedded in the through hole, a conical core hole is formed in the die core, the core hole is communicated with the through hole, the cross section of the core hole is cross-shaped, and the core hole is used for being matched with the moving core head; and the moving core head comprises a large-diameter section, a small-diameter section and a transition section, the transition section is smoothly connected between the large-diameter section and the small-diameter section, and the shape of the cross section of the moving core head is the same as that of the cross section of the core hole. The production equipment can solve the problem that an existing drawing manner is low in production efficiency.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

Production process for drawing copper pipe

PendingCN113290066ASmooth throughReduce frictionDrawing mandrelsDrawing diesCopper coilMechanical engineering

The invention relates to the technical field of copper pipe drawing, in particular to a production process for drawing a copper pipe. The production process comprises the following steps of A, mounting a core head; B, straightening a copper coil pipe through a straightening mechanism; C, conducting performing; D, conducting one-time drawing forming; and E, conducting cutting, specifically, a pipe obtained after drawing forming is cut, and a finished product is obtained. A drawing die comprises an outer die and a moving core head, the outer die comprises a die sleeve and a die core, the die sleeve is axially provided with a through hole, the die core is embedded in the through hole, the die core is provided with a conical core hole, the core hole is communicated with the through hole, the cross section of the core hole is in a cross shape, and the core hole is used for being matched with the moving core head; and the moving core head comprises a large-diameter section, a small-diameter section and a transition section, the transition section is smoothly connected between the large-diameter section and the small-diameter section, and the shape of the cross section of the moving core head is the same as that of the cross section of the core hole. The production process can solve the problem that an existing drawing manner is low in production efficiency.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

Copper wire drawing machine capable of being used conveniently and fast

The invention relates to the field of cable devices, in particular to a copper wire drawing machine capable of being used conveniently and fast. The copper wire drawing machine comprises a machine body, a paying-off device, a wire drawing device, a tightening device and a taking-up device. The paying-off device is located on the left side of the machine body. The wire drawing device is located in the middle of the machine body. The tightening device is located on the right side of the wire drawing device. The taking-up device is located on the right side of the tightening device. According to the small copper wire drawing machine used for cables, the whole process of automatic paying-off, drawing, taking-up and the like of copper wires can be achieved, the machine is simple in structure, and the automation degree is high.

Owner:安庆潜江电缆有限公司

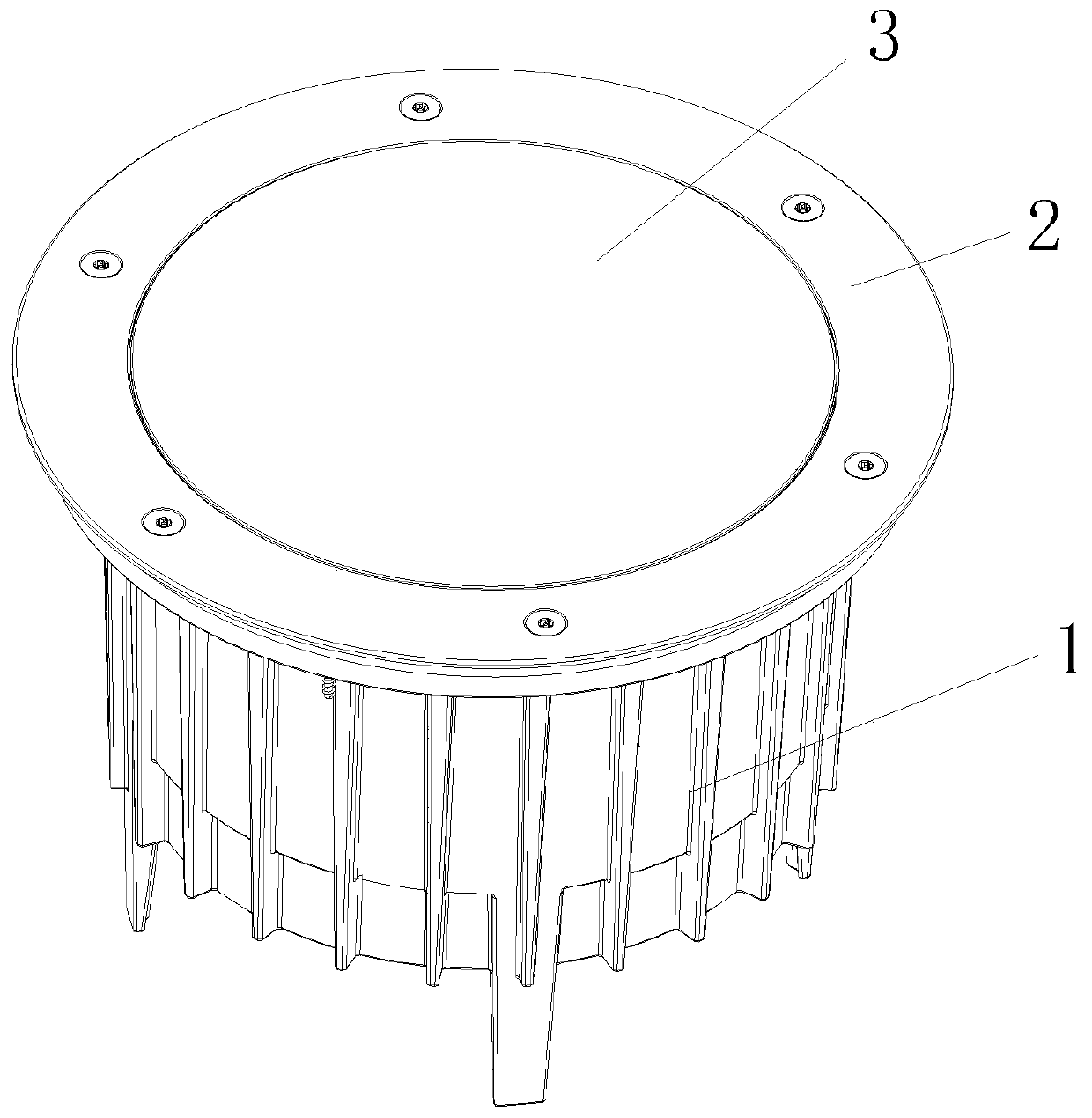

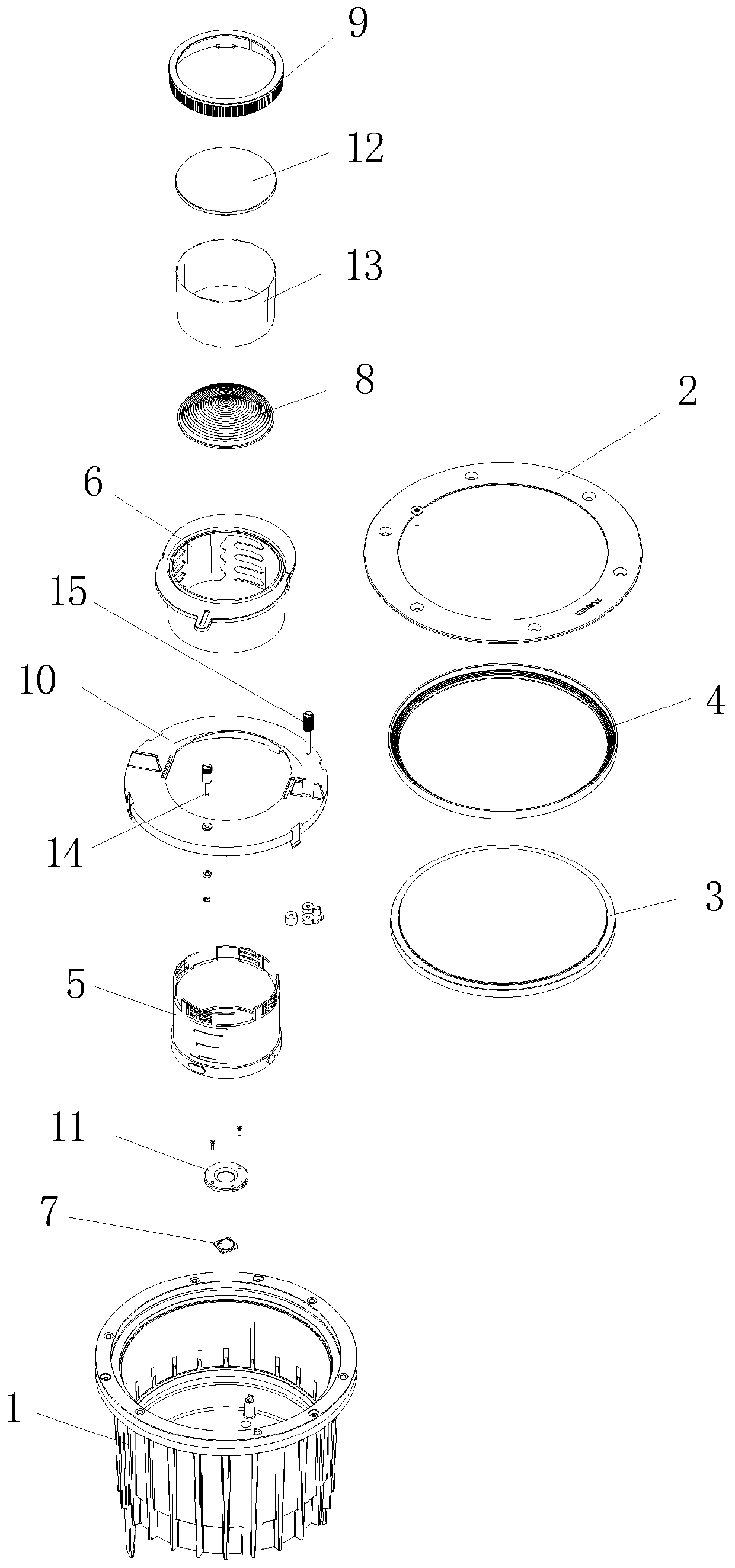

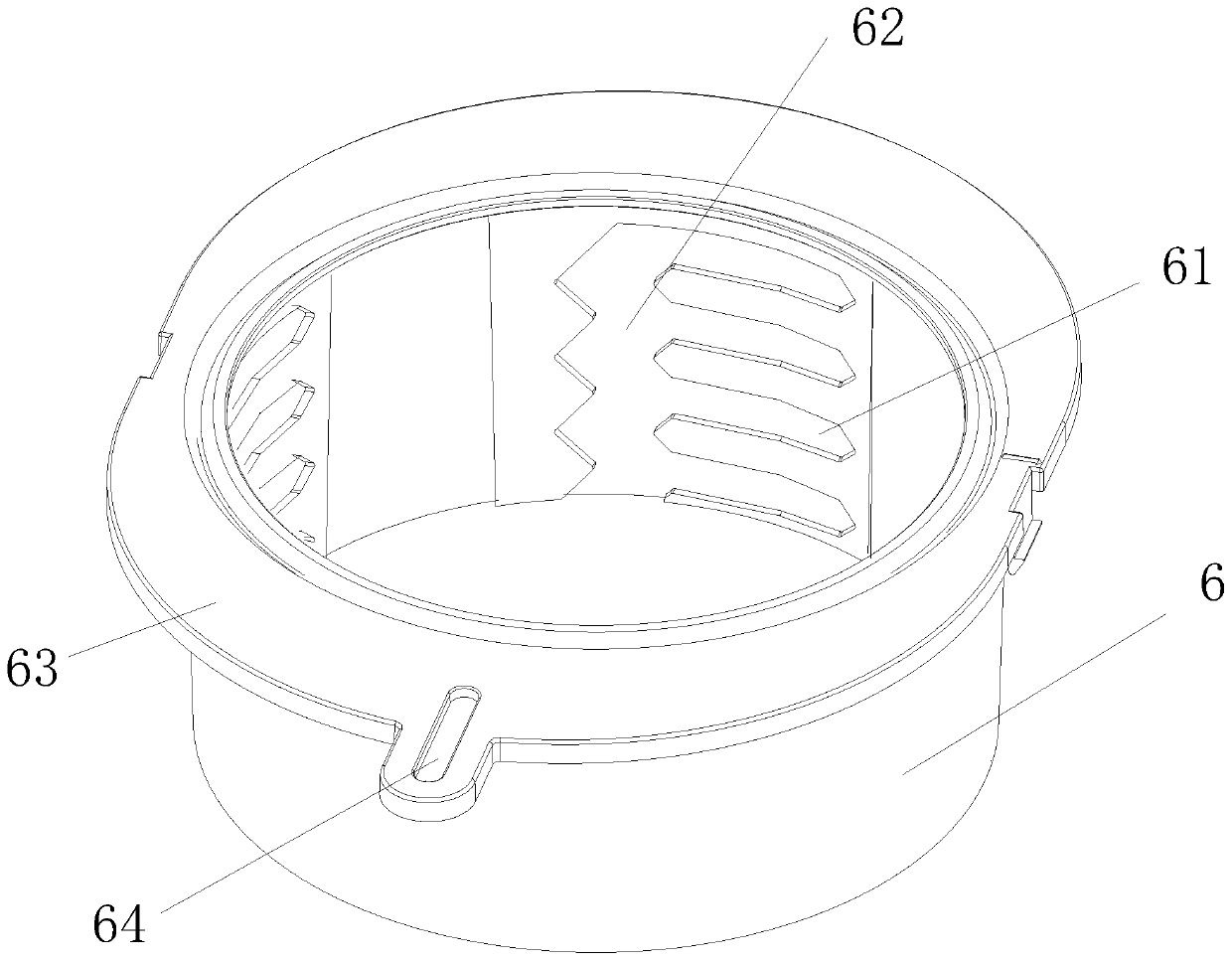

Underground lamp with adjustable beam angle

PendingCN111578195AImprove applicabilityAchieve relative rotationLighting support devicesLight fasteningsBeam angleLight beam

The invention relates to an underground lamp with an adjustable beam angle. The underground lamp comprises a radiating lamp body and a glass lamp cover, and a dimming module with an adjustable light beam angle is arranged in the radiating lamp body; the dimming module comprises a light source, a convex lens, an upper stretching rotary matching part and a lower stretching rotary matching part. Thelight source is fixed in the center of the bottom end of the lower stretching rotary matching part, the convex lens is fixed at the bottom end of the upper stretching rotary matching part, a beam angle is formed between the convex lens and the light source, the lower stretching rotary matching part sleeves the upper stretching rotary matching part, and the upper stretching rotary matching part canrelatively rotate along the lower stretching rotary matching part and can be pushed and pulled up and down. According to the underground lamp with the adjustable beam angle, the specially-designed upper stretching rotary matching part and the specially-designed lower stretching rotary matching part are matched,relative rotation and drawing can be achieved, so that the beam angle between the convex lens and the light source is adjusted, the beam angle can be directionally adjusted to 20 degrees, in addition, the horizontal position of the whole dimming module can be adjusted, and therefore theapplicability of the underground lamp with the adjustable beam angle is greatly improved.

Owner:达尔杰帝照明(常州)有限公司

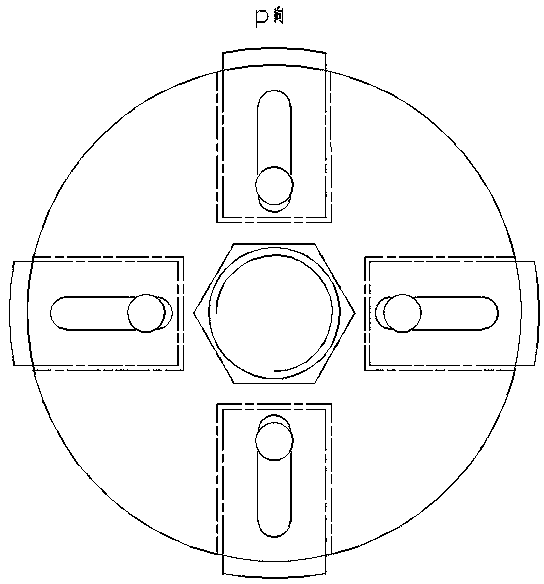

Pull disc

PendingCN110802547ANot easy to damageRealize drawingMetal-working hand toolsEngineeringMechanical engineering

The invention provides a pull disc. The pull disc comprises a tray and a sliding block. The center of the tray is provided with a through hole connected with one end of a pull rod. The middle of the side face of the tray is provided with a plurality of sliding slots extending horizontally to the center of the tray at intervals along the circumference. A plurality of guide slots communicating withthe sliding slots correspondingly is formed in the lower surface the tray. A plurality of positioning holes communicating with the sliding slots correspondingly and corresponding to the guide slots are formed in the upper surface of the tray. The sliding block is arranged in the sliding slots on the tray. One end of the sliding block is provided with a positioning pin. One end of the positioning pin can be inserted into the positioning holes in the upper surface of the tray, and the other end of the positioning pin extends out of the guide slots in the lower surface of the tray. The pull dischas the remarkable advantages that the structure is firm and not likely to be broken, the size of the diameter is adjustable, a bearing is pulled overall, the connection is reliable and the bearing isnot likely to be broken.

Owner:南通高盛机械制造有限公司 +1

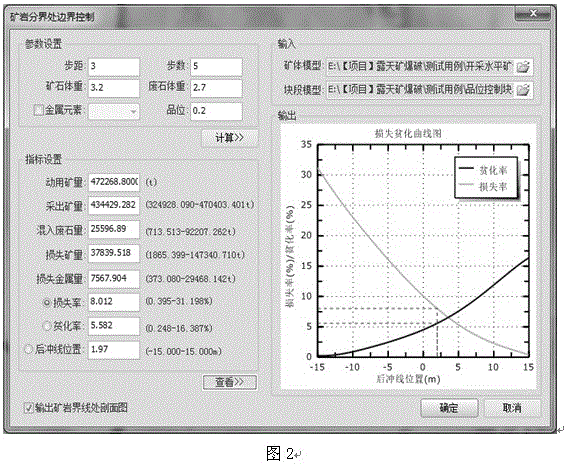

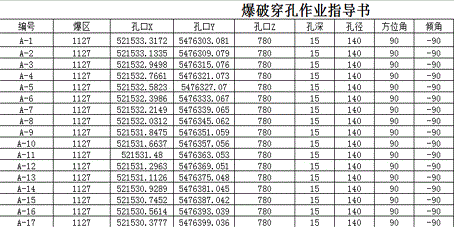

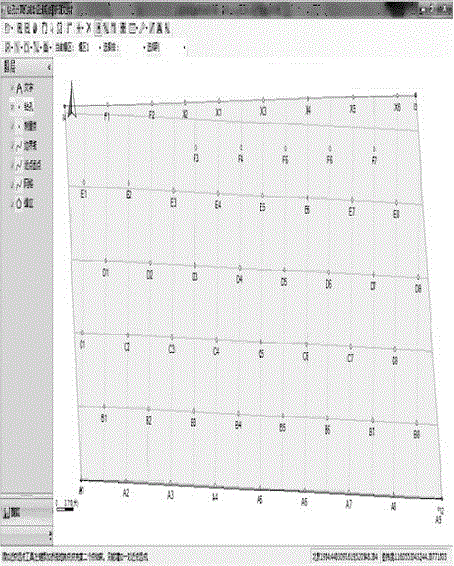

Strip mine drilling and blasting design, construction and management method

InactiveCN106640081AUnderstand the shapeImprove design efficiencyUnderground miningBlastingSoftware designDrilling system

The invention discloses a strip mine drilling and blasting design, construction and management method. The method comprises the steps that drilling design is conducted automatically within a planed range, and a drilling coordinate report is automatically formed; drilling coordinates are transmitted to an automatic drilling system through a wireless terminal; and after drilling is completed, actual drilling coordinates and hole depth information data are automatically transmitted to a mining MES, and drilling and blasting design is automatically conducted. By adoption of the strip mine drilling and blasting, construction and management method, the drilling design efficiency is improved, it is guaranteed that construction on the site is conducted according to the design, a drilling standard operation procedure is automatically generated, semi automation of drilling and blasting design is achieved by adoption of software assistance, the design efficiency is extremely improved, the previous two-dimensional software design is replaced with three-dimensional software design, the design is more visualized, and the morphology of an ore body is understood more authentically through a three-dimensional profile. The blasting design is more close to actual situations through importing of measured data.

Owner:CHINA GOLD INNER MONGOLIA MINING

A bolt pulling experiment device and detection method thereof

ActiveCN112683670BRealize drawingEasy to detectMaterial strength using tensile/compressive forcesClassical mechanicsRock bolt

The application relates to a bolt pulling experiment device and its detection method, which is applied in the technical field of bolt pulling detection. It includes a frame, and the frame includes a base. The base is provided with a side frame, and the side frame is far away from the side of the base. There is a top plate, the base of the frame is provided with an anchoring mechanism, the side frame is provided with a clamping mechanism on the side of the anchoring mechanism away from the base, the top plate is provided with a lifting mechanism for lifting the clamping mechanism, and the top plate is close to one side of the clamping mechanism. A displacement sensor and a pressure sensor are arranged on the side, and both the displacement sensor and the pressure sensor are in contact with the clamping mechanism. In this application, the lifting mechanism is used to lift the clamping mechanism to achieve the purpose of pulling the anchor rod, and then calculate the data fed back by the pressure sensor and the displacement sensor to obtain the data of the anchoring strength, so as to achieve the effect of detecting the anchoring strength of the anchor rod, and It is convenient for the operator to accurately measure the anchoring strength data of the anchor rod, and at the same time, it is convenient for the operator to detect the anchor rod.

Owner:南京南房建设工程检测有限公司

Squeeze and pull device for loose tube of optical cable

ActiveCN107186994BRealize drawingControl excess lengthTubular articlesEngineeringMechanical engineering

Owner:FENGHUO COMM SCI & TECH CO LTD

Stretching resistance detection device of curtain wall embedded part used for anchor plate construction after embedded

ActiveCN102628777BRealize drawingOn-site inspection after burialMaterial strength using tensile/compressive forcesEngineeringBuilding construction

The invention discloses a stretching resistance detection device of a curtain wall embedded part used for anchor plate construction after embedded, which comprises a fixing support attached to the outer vertical face of a main body structure and a sliding support installed on the fixing support in sliding penetrating mode. The fixing support comprises a pair of rod pieces vertically attached to the main body structure, all the rod pieces are fixedly connected with a connection plate, the connection plate is perpendicular to the rod pieces, and a guide hole is arranged in the middle portion. The sliding support comprises a pull rod support plate installed on the end portions of the rod pieces in sliding penetrating mode, the pull rod support plate is parallel to the connection plate, and the pull rod support plate and the main body structure are respectively arranged on two sides of the connection plate, the pull rod support plate is fixedly connected with one ends of at least two pull rods perpendicular to the pull rod support plate, the other ends of the pull rods penetrate through the guide hole to be fixedly connected with an anchor plate of the curtain wall embedded part and are symmetrically distributed on the curtain wall embedded part. A hydraulic jack perpendicular to the connection plate and the pull rod support plate and with a pressure meter is arranged between the connection plate and the pull rod support plate, and all the pull rods are evenly distributed on the periphery of the hydraulic jack. The stretching resistance detection device is capable of conducting onsite detection of the curtain wall embedded part after embedded.

Owner:中建六局第一建设有限公司 +1

Reciprocating steel pipe drawer

A reciprocating steel pipe drawing machine is composed of machine frame, reducing dies and their supporters at both ends of machine frame, screw bolt between said reducing dies for drawing steel pipe and its driver, and steel pipe clamps installed to both ends of said screw bolt. It features its bidirectional drawing for high productivity.

Owner:王剑波 +1

Intelligent battery cycle charge-discharge testing device

InactiveCN101769995BRealize automatic recordingRealize drawingElectrical testingElectronic loadElectrical battery

The invention provides an intelligent battery cycle charge-discharge testing device. The device is a secondary battery automatic charge-discharge testing device with low price, high precision and good stability. The device can test main parameters of a secondary battery, has safe and reliable performance and has wide application prospect. The device comprises a power supply module, an electronic load, an acquisition control module, a PC machine and a charge-discharge module, wherein an output of the power supply module is connected with the electronic load and the charge-discharge module; a battery to be tested is connected with the electronic load by the charge-discharge module; a signal acquisition end of the acquisition control module is connected with the battery to be tested, while a control end thereof is connected with the charge-discharge module; and the acquisition control module is on-line with the PC machine by a USB data wire.

Owner:NANJING TECH UNIV

Bearing assembly and disassembly tool

The invention relates to a bearing assembly and disassembly tool which is composed of an oil cylinder, a piston and a pull disk. The piston is connected to one end of a piston rod, and the other end of the piston rod is connected to the pull disk. The pull disk is composed of a tray and a slider. The center of the tray is provided with a second through hole, a plurality of chutes horizontally extending towards the center of the tray are arranged in the middle of the side face at intervals along the circumference, the lower side is provided with a plurality of guide grooves correspondingly communicating with the horizontal chutes, and the upper side is provided with a plurality of positioning holes correspondingly communicating with the horizontal chutes and corresponding to the guide grooves. The slider is arranged in a tray chute, one end of the slider is provided with positioning pins, one ends of the positioning pins can be inserted into the positioning holes in the upper face of the tray, and the other ends of the positioning pins extend out of the guide grooves in the lower side of the tray. The bearing assembly and disassembly tool has the significant advantages of being large in pulling force, sturdy and durable and not prone to being damaged; and bearing drawing is reliable, and slippage is not prone to happening; and the bearing is not prone to being damaged.

Owner:南通高盛机械制造有限公司 +1

Anti-drawing bearing capacity detection device of concrete prefabricated part lifting points

The invention discloses an anti-drawing bearing capacity detection device of concrete prefabricated part lifting points and mainly relates to the field of building detection equipment. The device comprises a sling and an ejection device, wherein a force measuring device is arranged on the sling, the two ends of the sling are provided with the lifting points for hooking, the ejection device can perform upward ejection, the top of the ejection device is connected with the sling, and the ejection device drives the sling to move upwards. The device has the advantages that the state of the diagonallifting points in actual lifting is simulated, and the two lifting points are tested simultaneously.

Owner:张海良

An inflatable shaft repair device

ActiveCN112936197BRealize drawingRelatively easy to alignWork holdersWork benchesHydraulic cylinderEngineering

The present application relates to a maintenance device for an inflatable shaft, which includes a workbench, a first clamping piece and a second clamping piece, the workbench is provided with a first base and a second base, the first base is provided with a hydraulic cylinder, and the first base is provided with a hydraulic cylinder. A clamping part is coaxially arranged at the end of the piston rod of the hydraulic cylinder, the first clamping part includes a first groove part and a first clamping head, the second clamping part is coaxially arranged at the inflation end of the inflatable shaft; The clamping part includes a second groove part and a second clamping head, a clamp for clamping the first clamping head and the second clamping head is arranged on the worktable, a first abutting plate is vertically arranged on the second base, and the first clamping head is arranged on the working table. An opening for the inflatable shaft to pass through is formed through the plate, and an annular groove is coaxially provided at one end of the inflatable shaft away from its inflatable end. The second abutting plate is connected, and the second abutting plate is provided with an arc-shaped groove which is clamped and connected with the annular groove. The present application has the effect of facilitating the drawing of the inflatable tip.

Owner:上海贝承机械制造有限公司

Ultra-fine coaxial wire stripping and drawing machine

ActiveCN103427315BNovel structureImprove stripping efficiencyLine/current collector detailsCoaxial cableManipulator

The invention discloses a micro coaxial cable stripping and drawing machine comprising a frame, a cable arranging tool, a pressing device and a clamping jaw. The cable arranging tool is arranged on the frame and comprises a base plate which is a hollow frame, a first cable clamping seat for fixing a first end of a micro coaxial cable is arranged at one end of the base plate, a second cable clamping seat for clamping or loosening a second end of the micro coaxial cable is arranged at the other end of the base plate, a stripping and drawing space is formed between the first cable clamping seat and the second cable clamping seat, the pressing device driven by a first power unit and used for pressing the first cable clamping seat is disposed on the frame, the clamping jaw driven by two axis manipulators is disposed on the frame, the first axis manipulator is used for driving the clamping jaw to extend into the stripping and drawing space to clamp the middle of a cladding of the micro coaxial cable, and the second axis manipulator is used for driving the clamping jaw to move towards the second cable clamping seat to have the middle of the cladding of the micro coaxial cable peeled and drawn. The micro coaxial cable stripping and drawing machine is convenient to operate, and manual work is omitted, so that efficiency of stripping of the micro coaxial cable and quality of products are greatly improved.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com