Anti-drawing bearing capacity detection device of concrete prefabricated part lifting points

A technology of pull-out bearing capacity and prefabricated components, which is applied in the testing of machine/structural components, measuring devices, and testing of mechanical components, etc., which can solve the problems of large gaps and inability to intuitively reflect the lifting point of the hoisting state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Example: In the construction of prefabricated buildings, structural parts are generally prefabricated in the factory, and then the prefabricated structural parts are pulled to the construction site for assembly. In the building construction specification, the bearing capacity of the lifting point needs to be tested by batch sampling. The hoisting point of the reinforced concrete prefabricated structure is generally to bend the rebar into an inverted U shape, and there are return hooks on both sides of the bottom end to increase the grip with the concrete. The test is used to determine that the position of the lifting point can effectively carry the weight of the entire prefabricated structure and prevent the lifting point from being pulled out during the actual lifting process.

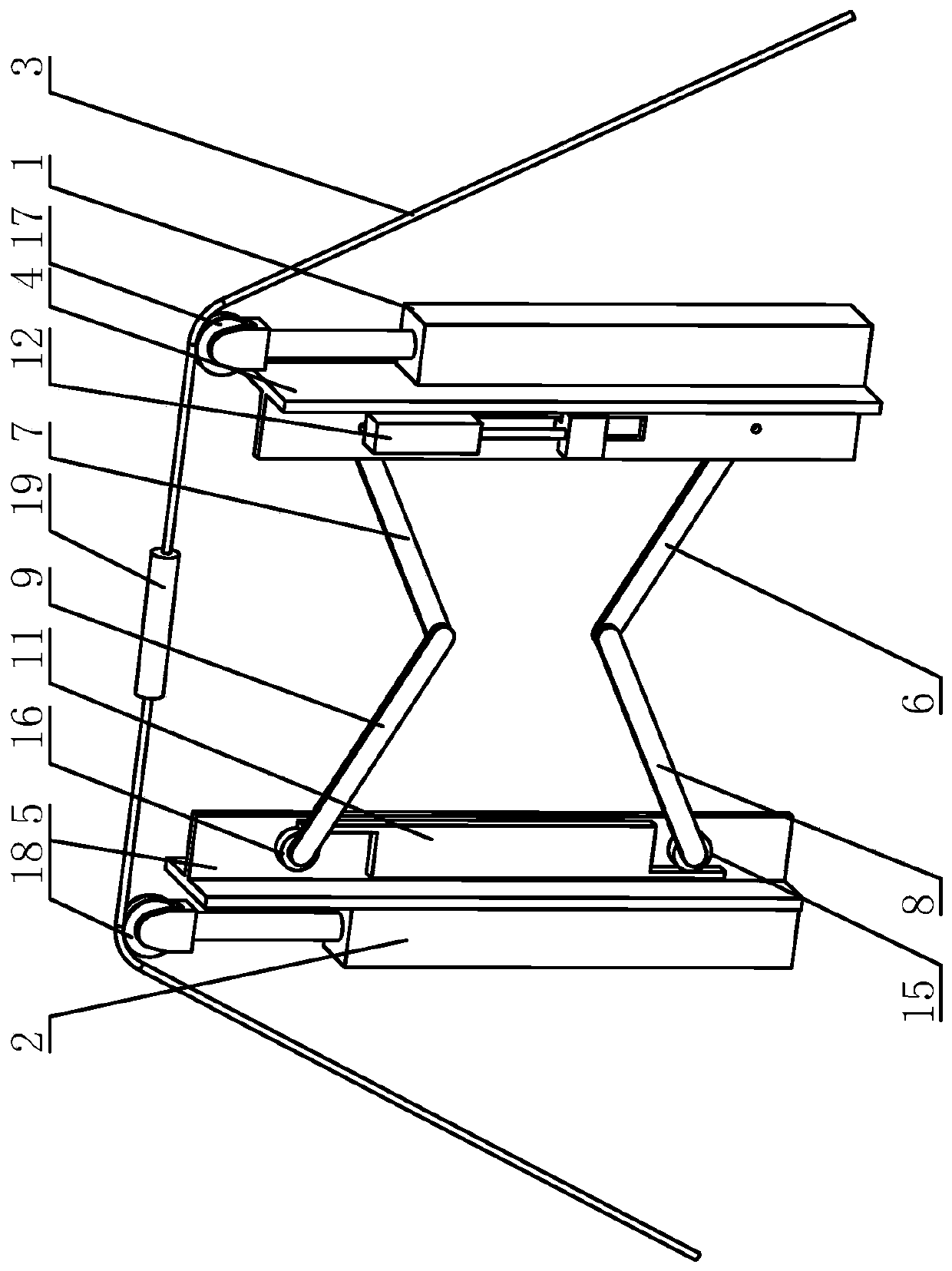

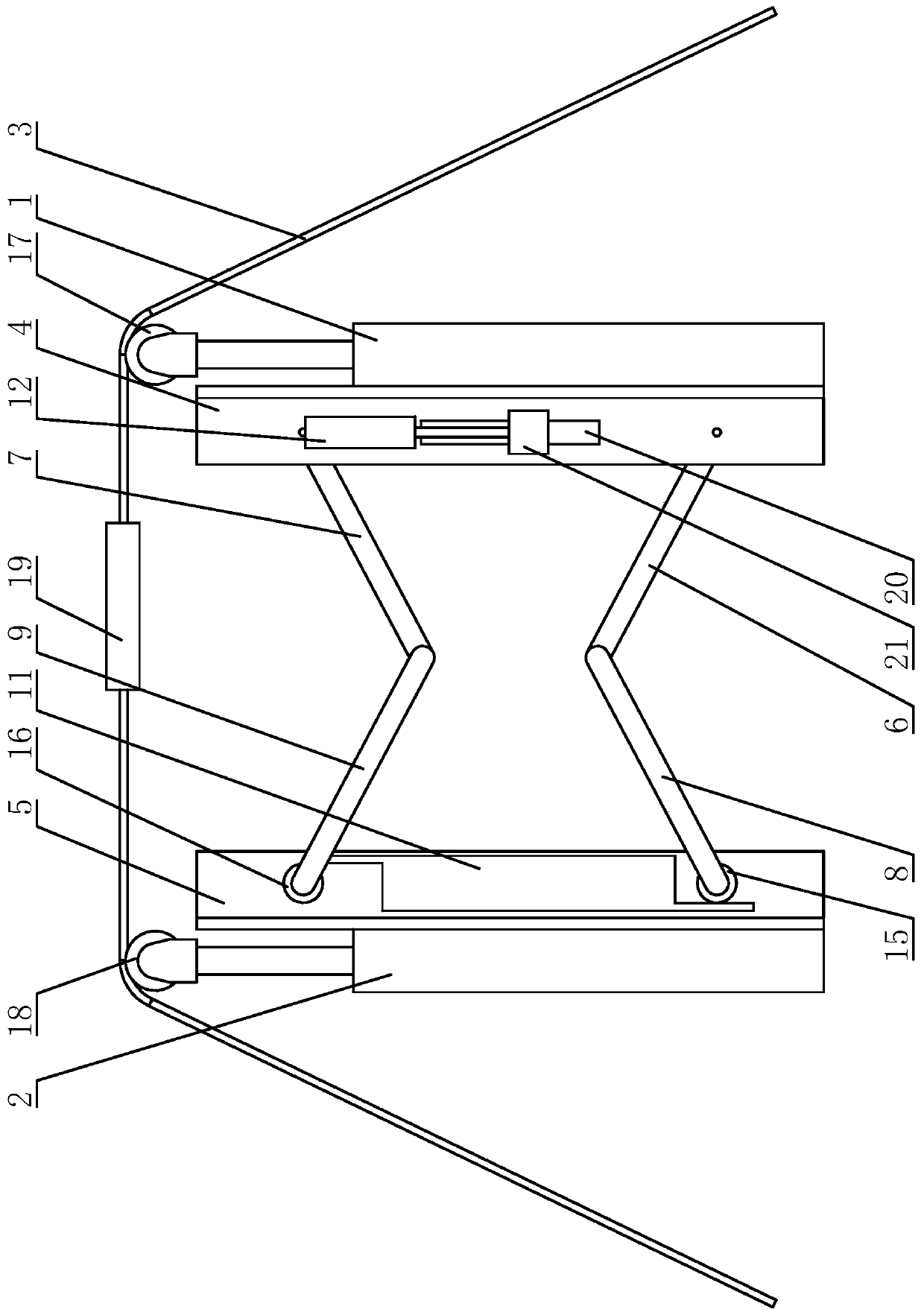

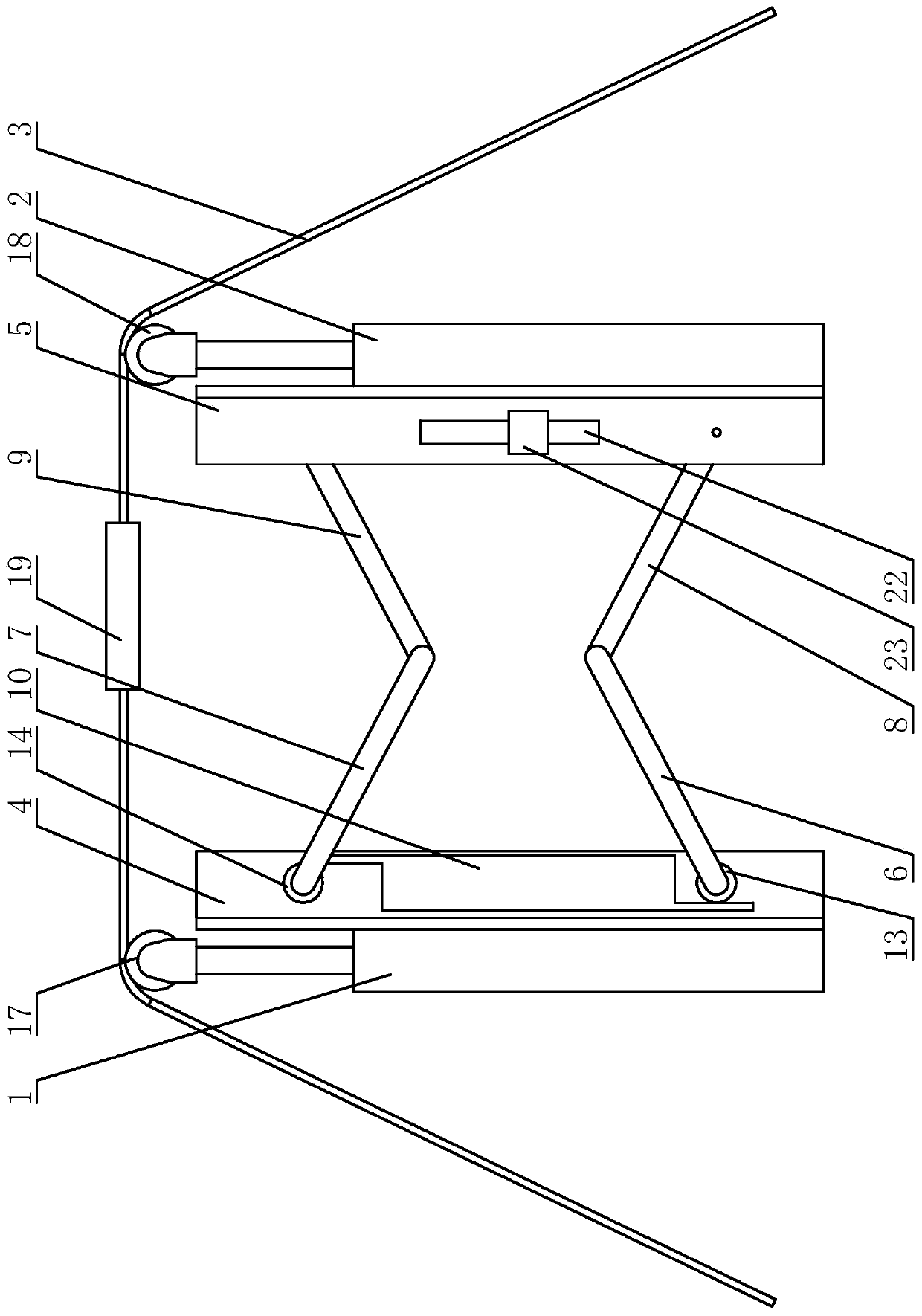

[0024] The pullout bearing capacity detection device of the lifting point of the concrete prefabricated member includes a first jacking cylinder 1, a second jacking cylinder 2, a sling 3, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com