Ultra-fine coaxial wire stripping and drawing machine

A coaxial line and drawing machine technology, applied in the direction of line/collector parts, electrical components, connections, etc., can solve the problems that affect the welding quality of cutting and stripping devices, messy stripped ends, difficult to locate accurately, etc., to achieve The effect of improving stripping efficiency and stripping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

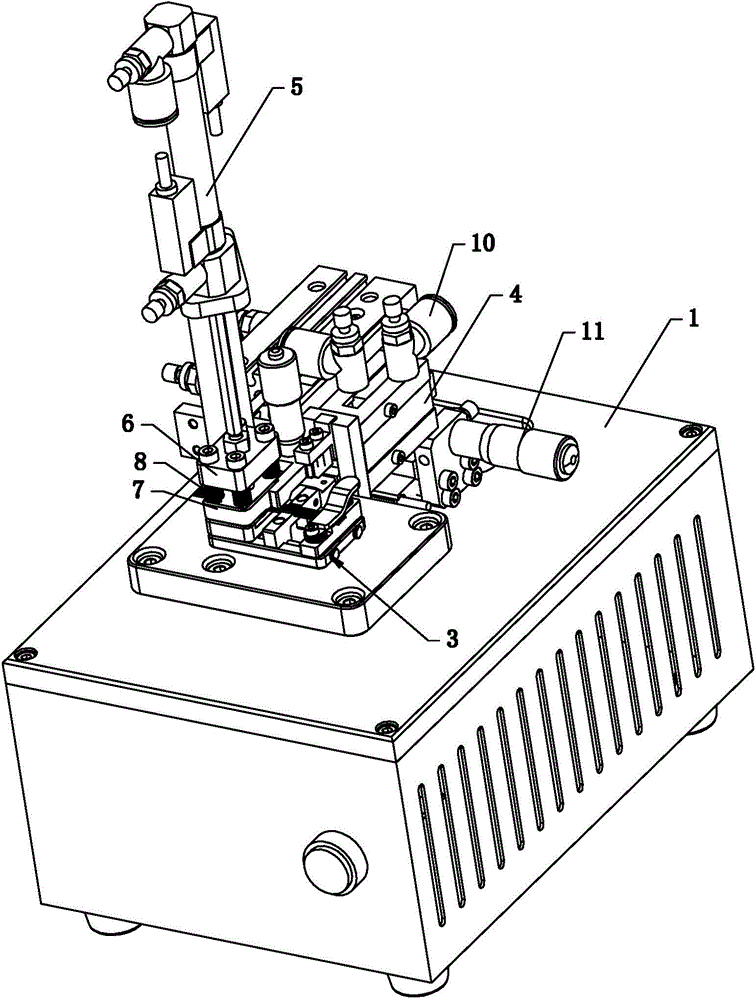

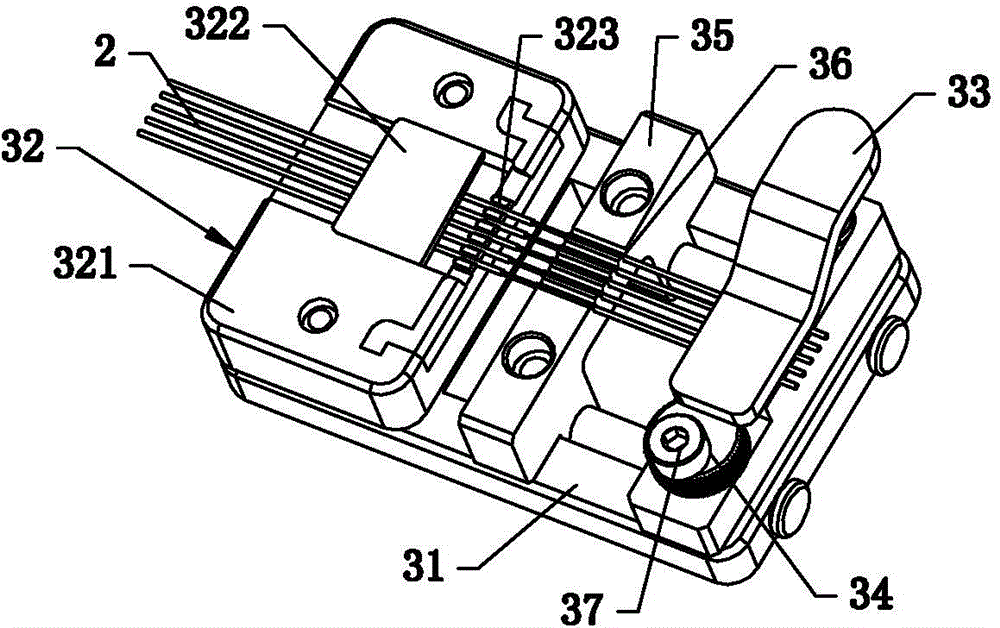

[0028] like figure 1 , figure 2 and image 3 Commonly shown, the ultra-fine coaxial wire stripping and drawing machine includes a frame 1, and also includes: a wiring tool 3 installed on the frame 1 for arranging the ultra-fine coaxial wires 2 in sequence and fixing both ends, The cable arrangement tool 3 includes a base plate 31, which is a hollow frame, and one end of the base plate 31 is provided with a first clamping seat 32 for fixing the first end of the ultra-thin coaxial line 2, and the other end of the base plate 31 is provided with Clamp or loosen the second clamping seat at the second end of the ultra-thin coaxial line 2, and a drawing space is provided between the first clamping seat 32 and the second clamping seat; The power unit drives the pressing device for pressing the first clamping seat 32; the gripper 4 driven by the two-axis manipulator installed on the frame 1, the first-axis manipulator 10 is used to drive the gripper 4 to extend into the drawing The...

Embodiment 2

[0038] like Figure 5 As shown, the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the first clamping seat 32 is vertically slidably installed on the bottom plate 31; the pressing device is an elastic pressing device; the ultra-thin coaxial cable 2 The middle stripping and drawing machine also includes a second power device installed on the frame 1 for driving the first wire clamping seat 32 to reciprocate up and down. The second power unit is the second cylinder 9 .

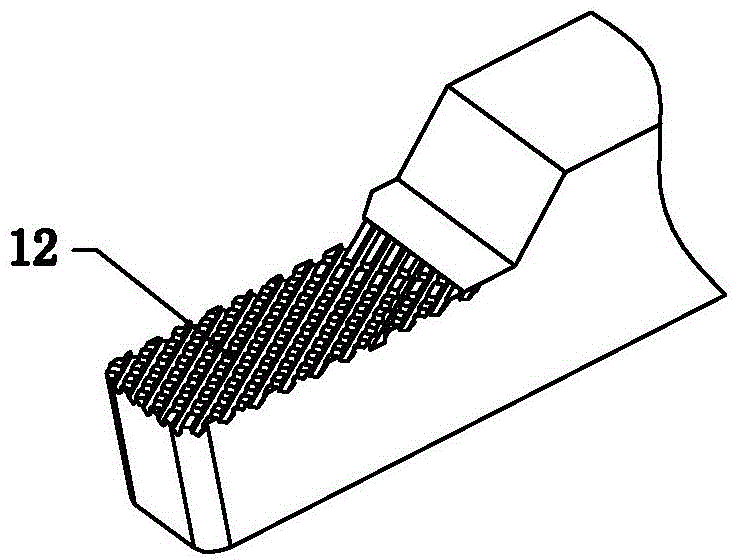

[0039] The elastic pressing device includes an upper pressing block 6 and a lower pressing block 7, the upper pressing block 6 is connected to the first cylinder 5, the lower pressing block 7 is vertically slidably installed on the upper pressing block 6, and the lower pressing block 7 is connected with the first clamping seat 32 corresponds to each other, and a compression spring 8 is arranged between the upper pressing block 6 and the lower pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com