Graphene-based nitrogen-doped hierachical-pore carbon nanosheet/sulfur composite material for cathode of lithium sulfur battery, as well as preparation method and application of graphene-based nitrogen-doped hierachical-pore carbon nanosheet/sulfur composite material

A technology of carbon nanosheets and lithium-sulfur batteries, which is applied in the field of electrochemical energy and nanomaterials, can solve the problems of limiting the assembly of sulfur nanoparticles, low battery capacity and discharge platform, and affecting battery energy density, so as to facilitate diffusion and ionization The effects of improved transportation, cycle stability, and low cost of raw materials and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

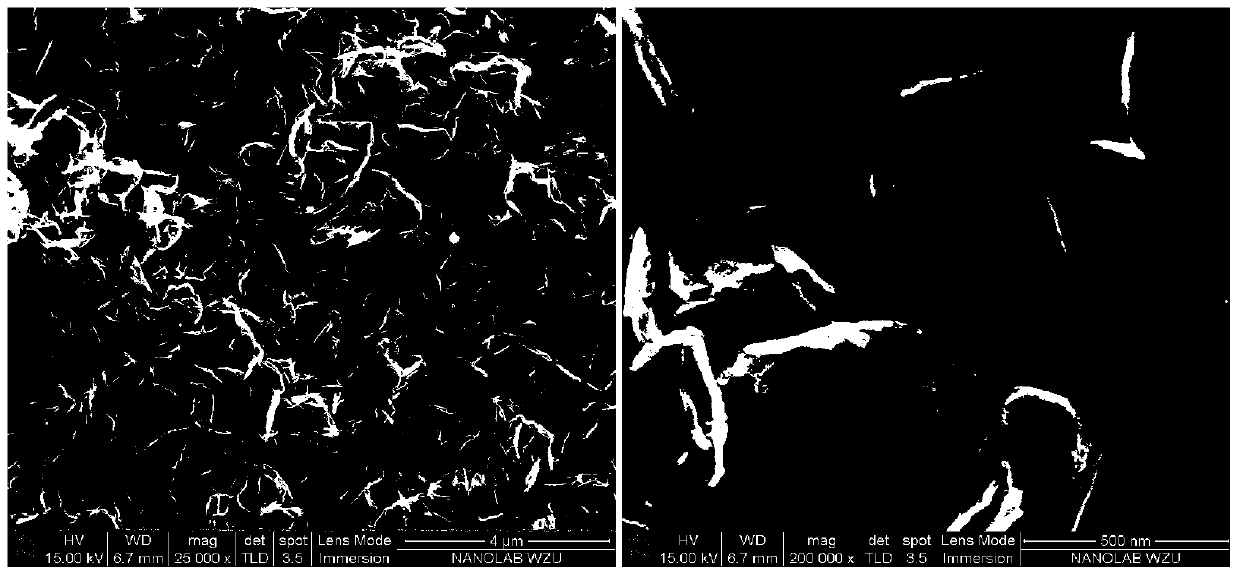

[0038] Synthesis of carbon nanosheets / sulfur composites:

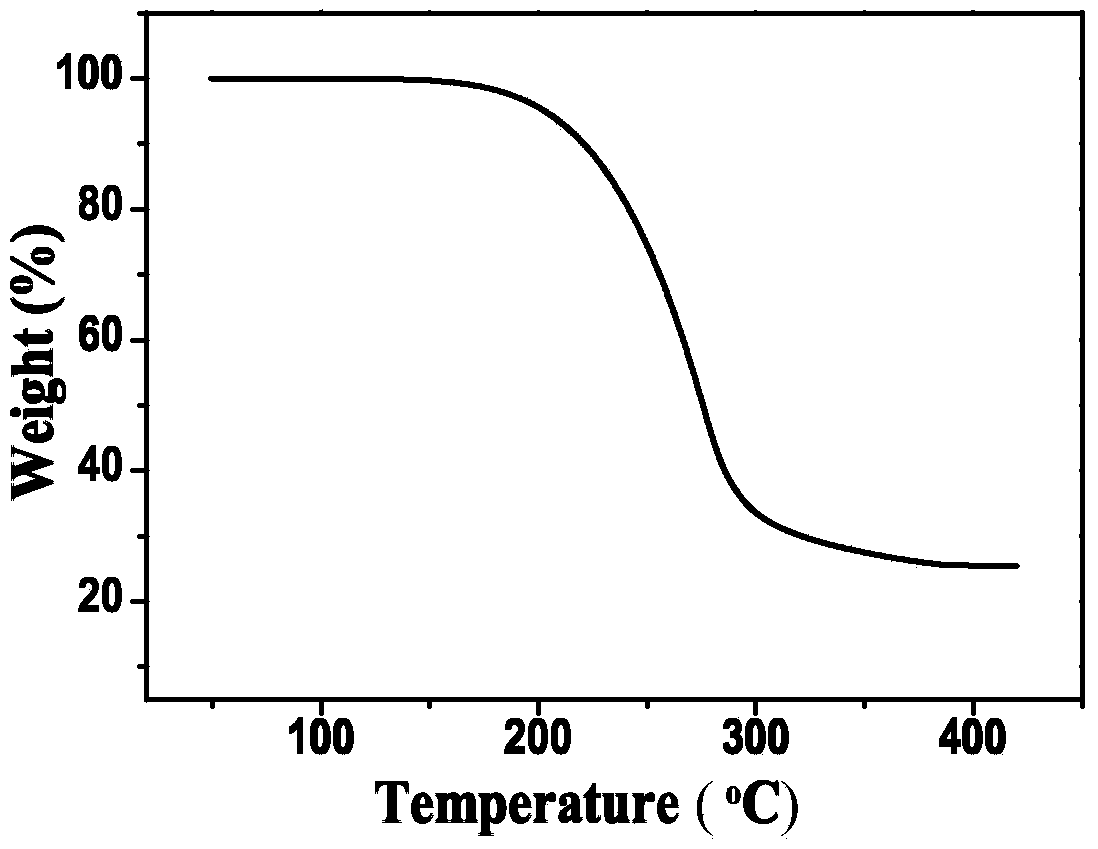

[0039] Add 600 ml H to the beaker successively 2 O, 100 ml graphene oxide solution (1mg ml -1 ), 100 ml SiO 2 Solution (2mg ml -1 ) and 4 g of pyrrole, stirred magnetically in an ice-water bath for 1 h, then added 50 ml of concentrated HCl and 12 g of APS aqueous solution to the beaker, reacted for 12 h, then suction filtered, then washed with distilled water until the filtrate was colorless, and the resulting solid Dry in an oven at 110°C. Take 6 grams of the above solid in a crucible, pass N 2 , at 5 ℃ min -1 The temperature was raised to 850°C for 2 h and then cooled naturally. Transfer to 20% hydrofluoric acid solution, stir for 2 hours, filter, wash, and dry at 110°C to obtain the corresponding carbonized product (PPG). Take 0.4g of this product and place it in a beaker, add 2ml water, 20ml ethanol and 1.2g KOH solid successively, heat and evaporate the solvent under stirring, transfer to a nickel crucible,...

Embodiment 2

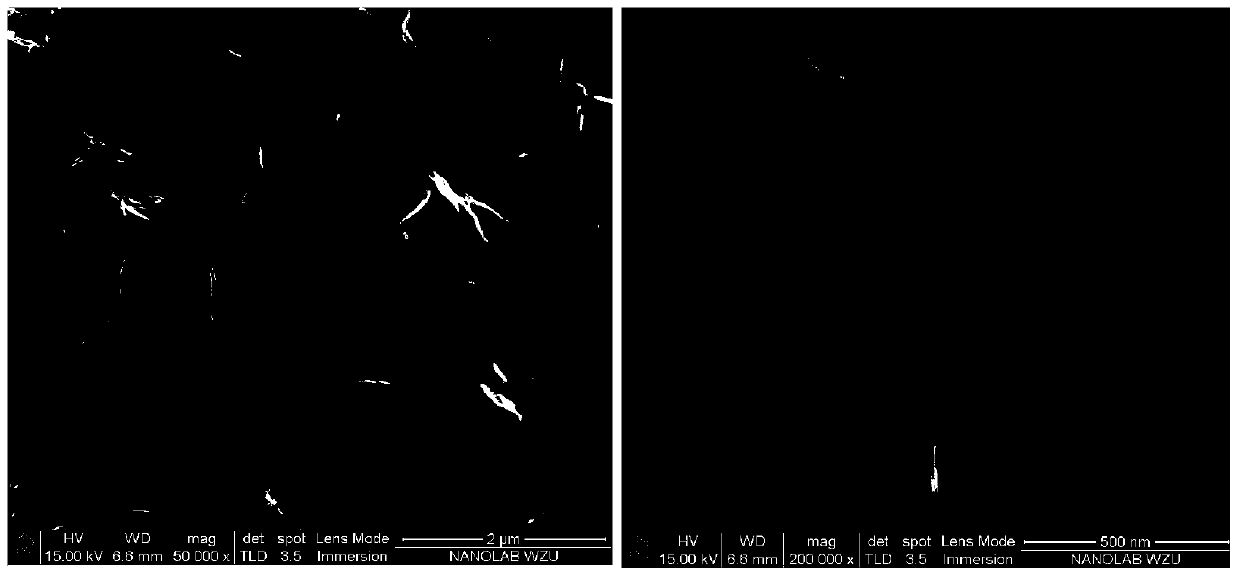

[0046] Take 0.4 g of the APPG sample prepared in Example 1, mix with 0.20 g of sulfur powder, seal it, heat it in an oven at 160° C., cool it out after 10 hours, and obtain a carbon nanosheet / sulfur composite material. According to the method in Example 1, the electrode and assembled battery were prepared, and the performance was routinely tested. The discharge capacity was 1120 mA h g at a rate of 0.5C. -1 .

[0047]

Embodiment 3

[0049] Take 0.4 g of the APPG sample prepared in Example 1, mix with 0.36 g of sulfur powder, seal it, heat it in an oven at 160° C., cool it out after 10 hours, and obtain a carbon nanosheet / sulfur composite material. According to the method in Example 1, prepare the electrode and assemble the battery, and carry out the routine performance test, the discharge capacity is 965 mA h g at 0.5C rate -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com