Patents

Literature

31results about How to "High power load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

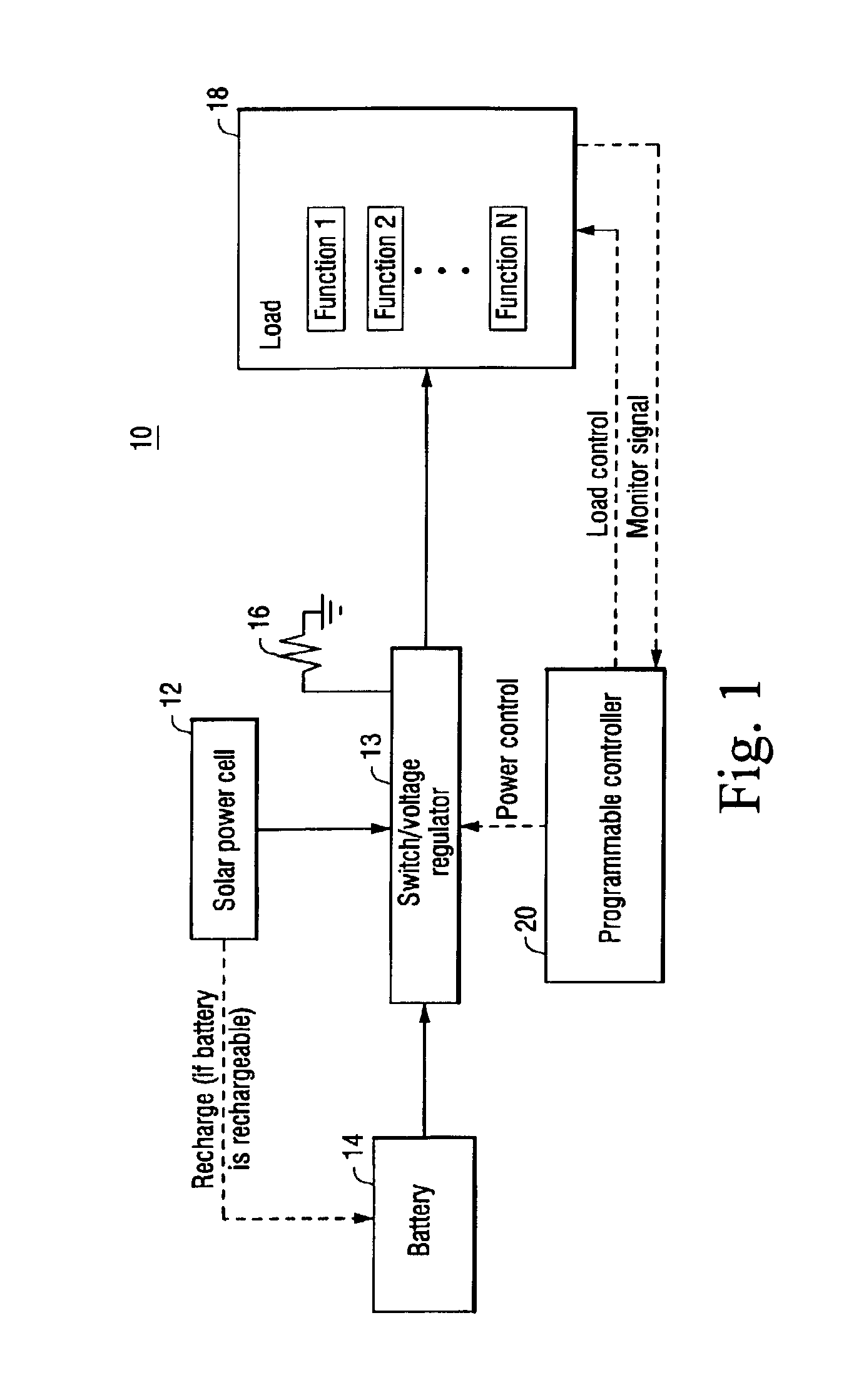

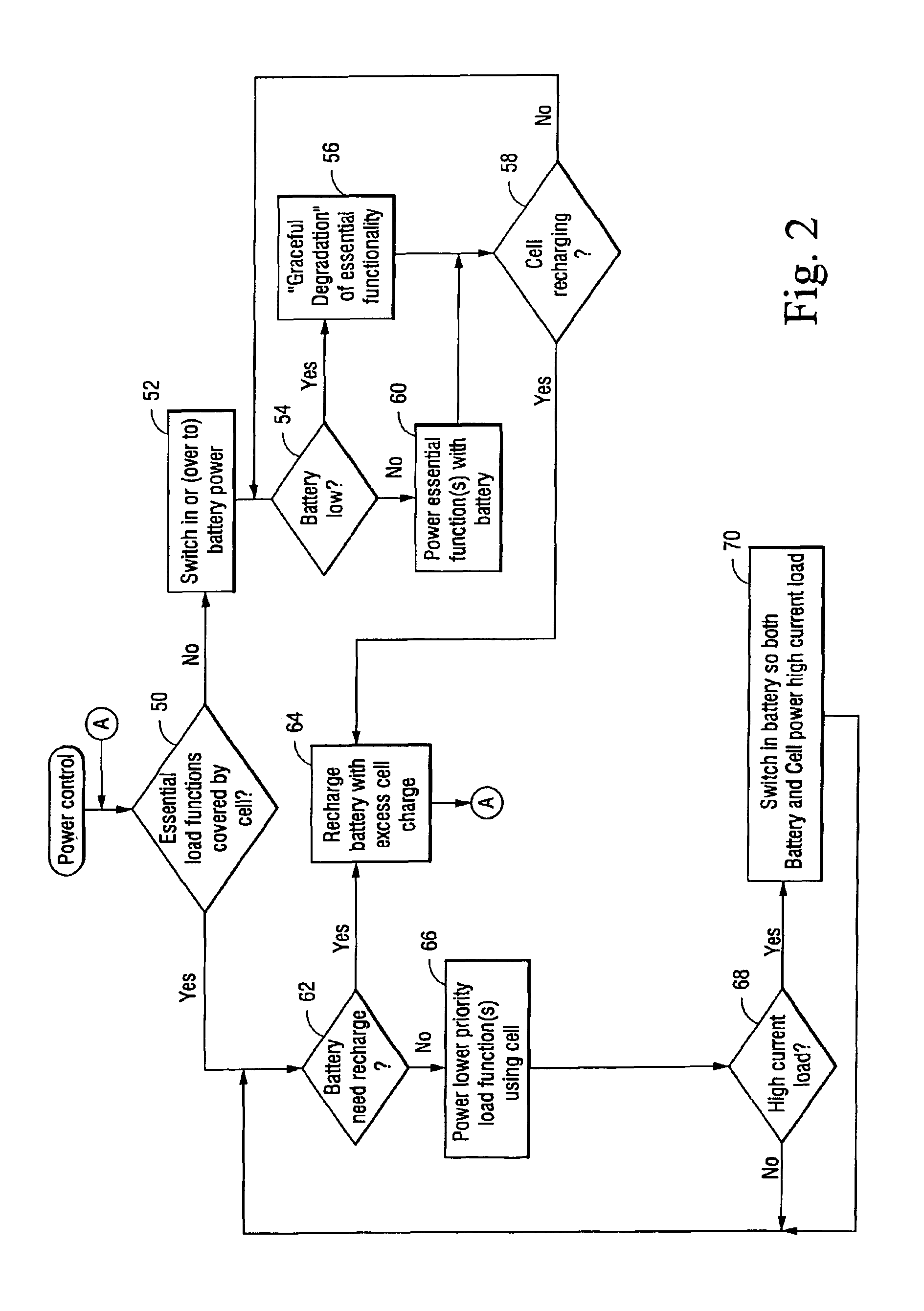

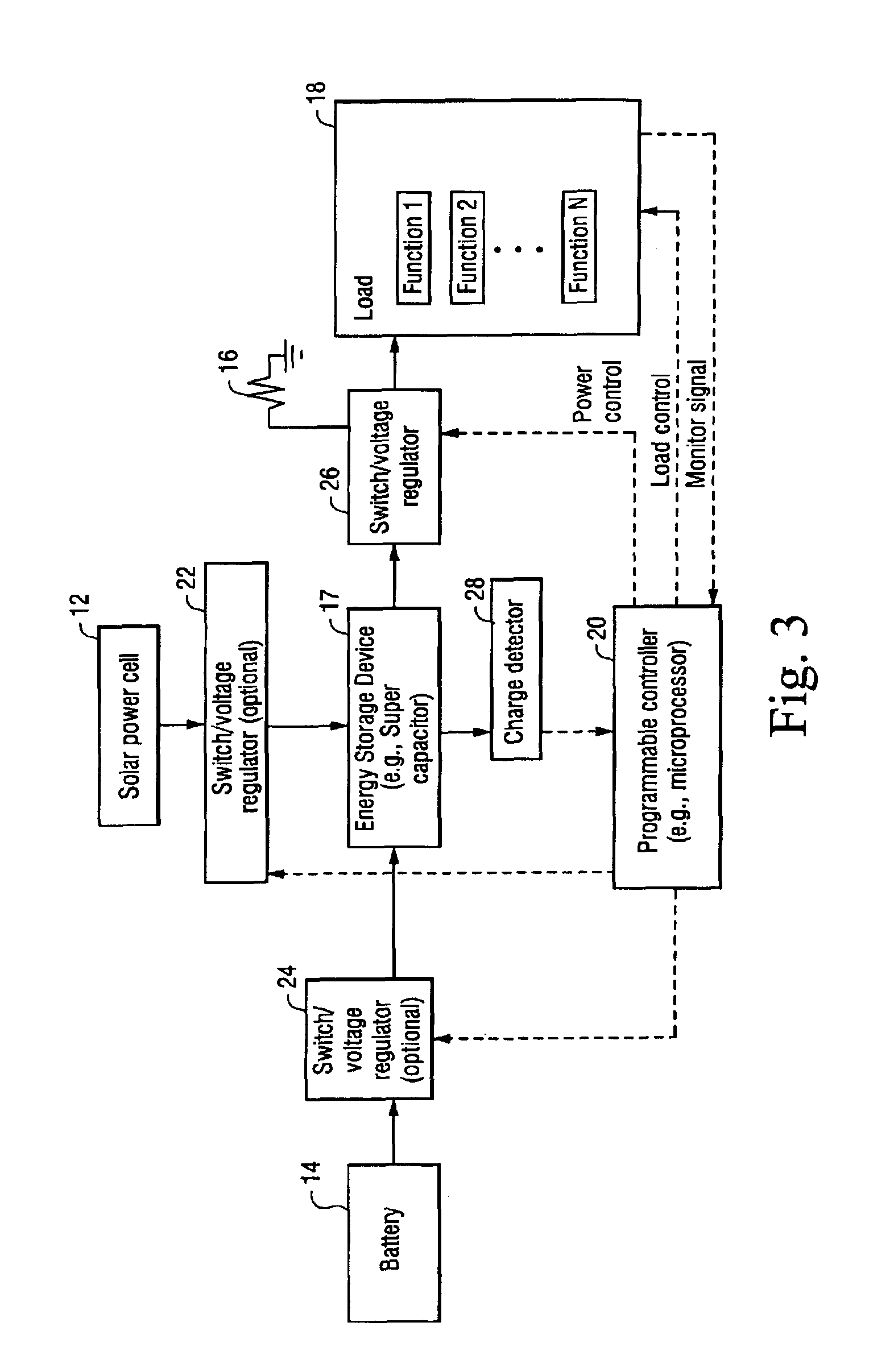

Power supply and method for controlling it

InactiveUS6914411B2High peak powerHigh power loadBatteries circuit arrangementsLoad balancing in dc networkSupply energySolar power

A self-powered apparatus includes a solar power cell, a battery, and a load. The load may include one or more load functions performed using power provided by one or both of the solar power cell and the battery. The inclusion of a battery permits the solar power cell to be sized much smaller than if the solar power cell was the only supply of power. A programmable controller selectively regulates power provided to one or more load functions and also selectively regulates whether one or both of the power cell and battery supplies the power. Switching circuitry, controlled by the programmable controller, selectively couples one or both of the battery and the solar cell to supply energy for powering the load. In a preferred example embodiment, the controller couples the battery and / or solar cell to charge a super capacitor, which then is selectively controlled to power the load. The programmable controller determines and prioritizes load function power requirements, and based thereon, determines which load functions will be powered based the priority of the load function requirements and the amount of power that can be supplied by the solar power cell as supplemented by the battery.

Owner:PCS FERGUSON

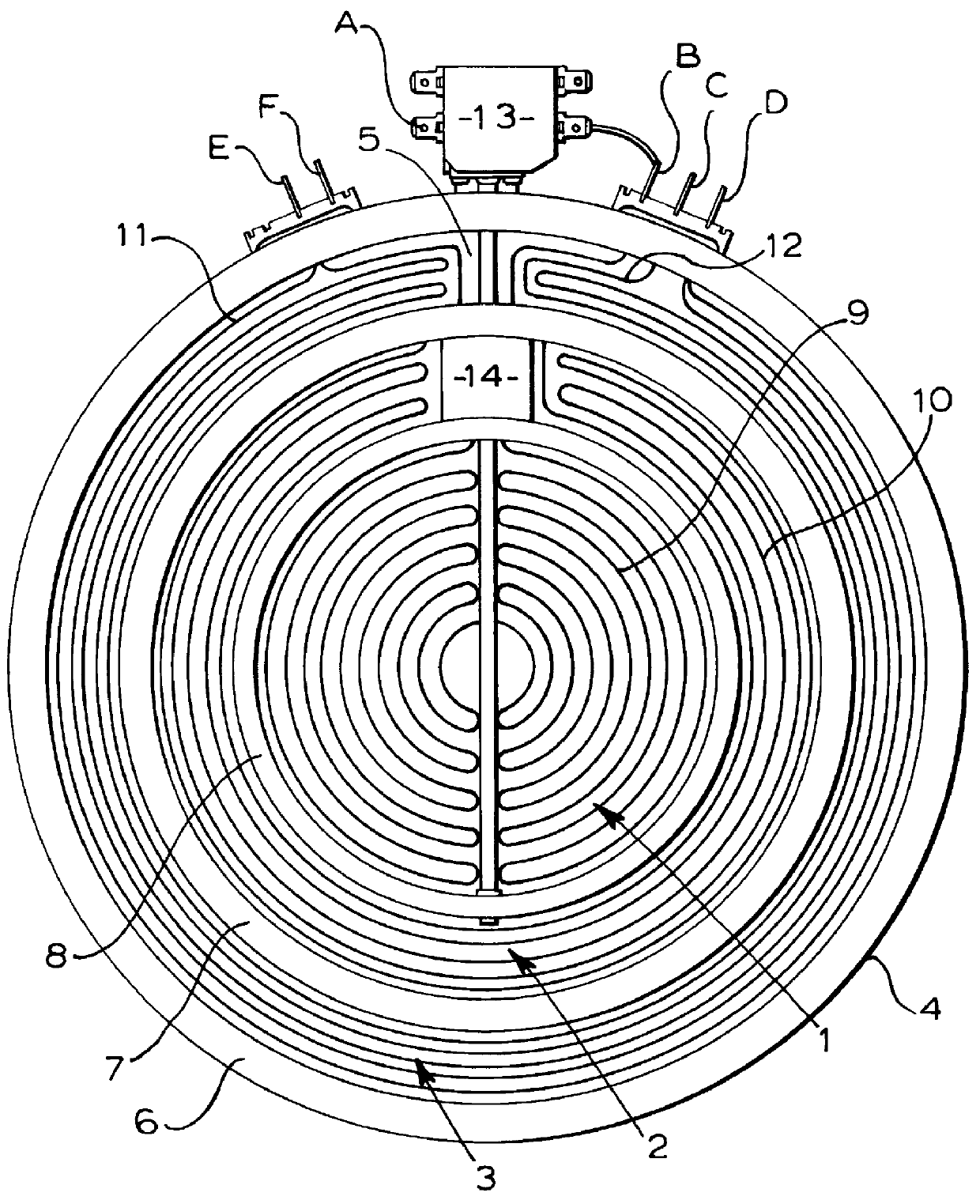

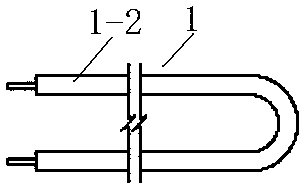

Radiant electric heater

InactiveUS6018149AHigh power loadReduce the required powerHeater elementsHot plates heating arrangementsHeating elementEngineering

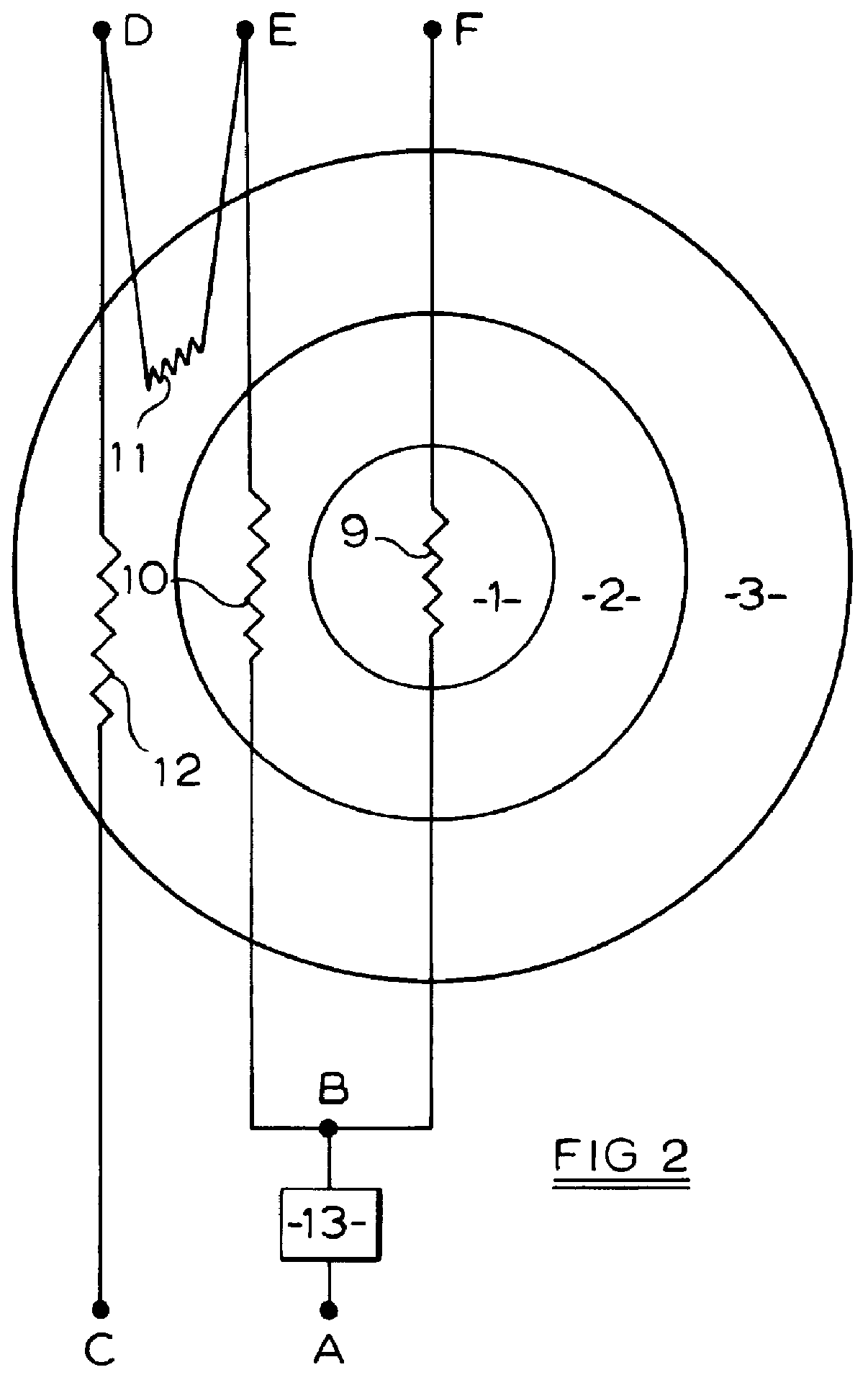

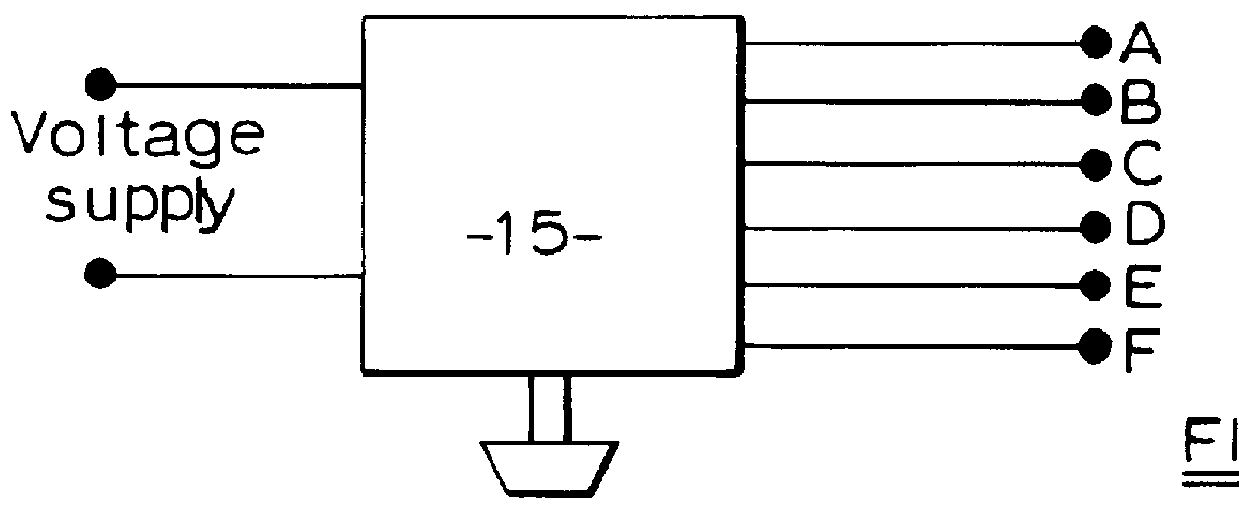

A radiant electric heater has first, second and third heating zones (1, 2, 3) arranged substantially side-by-side. The first heating zone (1) is provided with at least one first heating element (9). The second heating zone (2) is arranged adjacent to the first heating zone and is provided with at least one second heating element (10). The third heating zone (3) is arranged adjacent to the second heating zone and is provided with at least one third and one fourth heating element (11, 12). A switch (15) is provided for switching between first, second and third heating states. In the first heating state the at least one first heating element (9) of the first heating zone (1) is energised alone, the at least one second, third and fourth heating elements (10, 11, 12) of the second and third heating zones (2, 3) being de-energised. In the second heating state the at least one first heating element (9) of the first heating zone (1) is electrically connected and energised in parallel with the at least one second heating element (10) of the second heating zone (2), the at least one third and fourth heating elements (11, 12) of the third heating zone (3) being de-energised.

Owner:CERAMASPEED ACQUISITION COMPANY

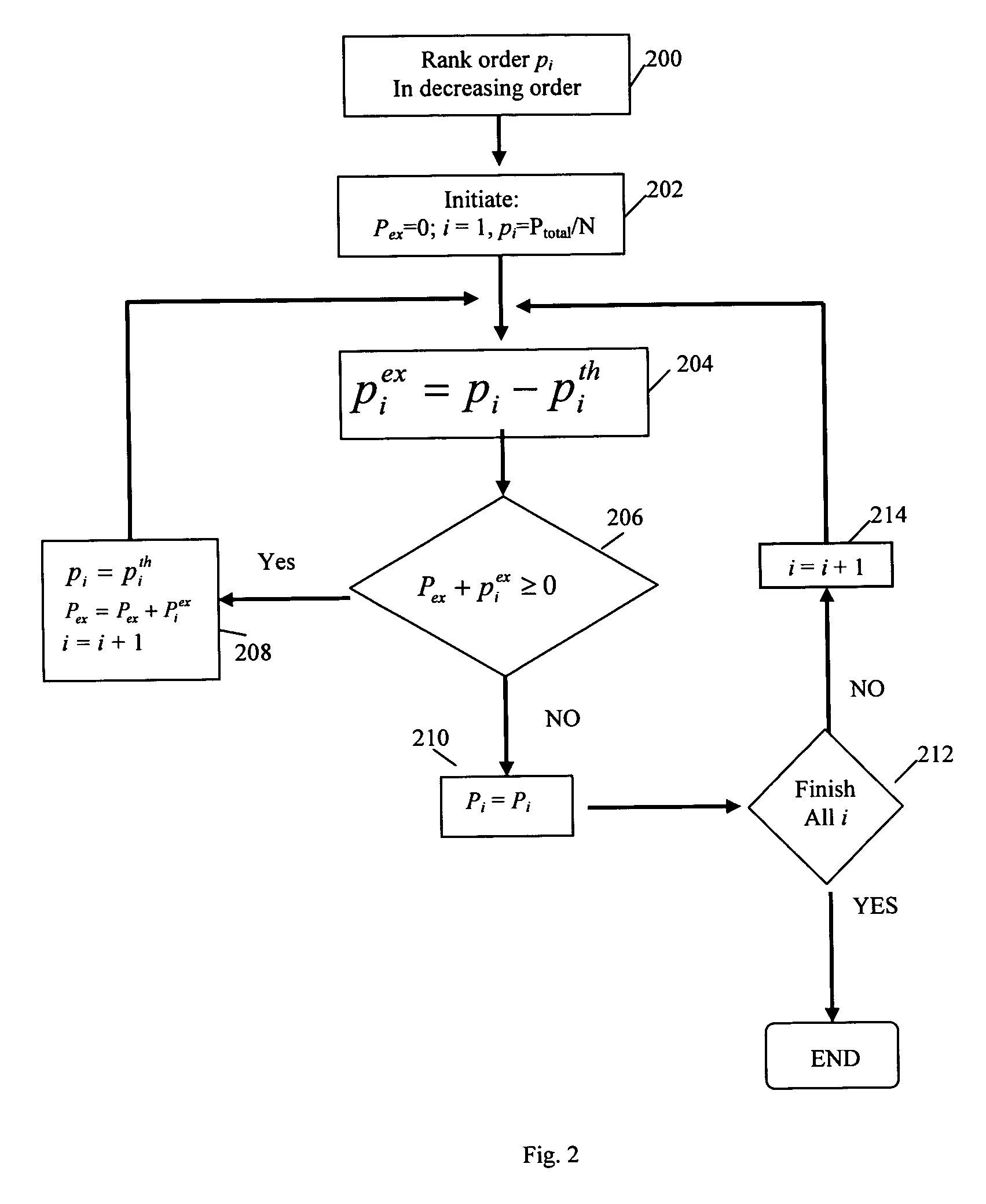

Power loading method and apparatus for throughput enhancement in MIMO systems

InactiveUS20060234751A1Improve system throughputConvenient power distributionPower managementSpatial transmit diversityClosed loopEngineering

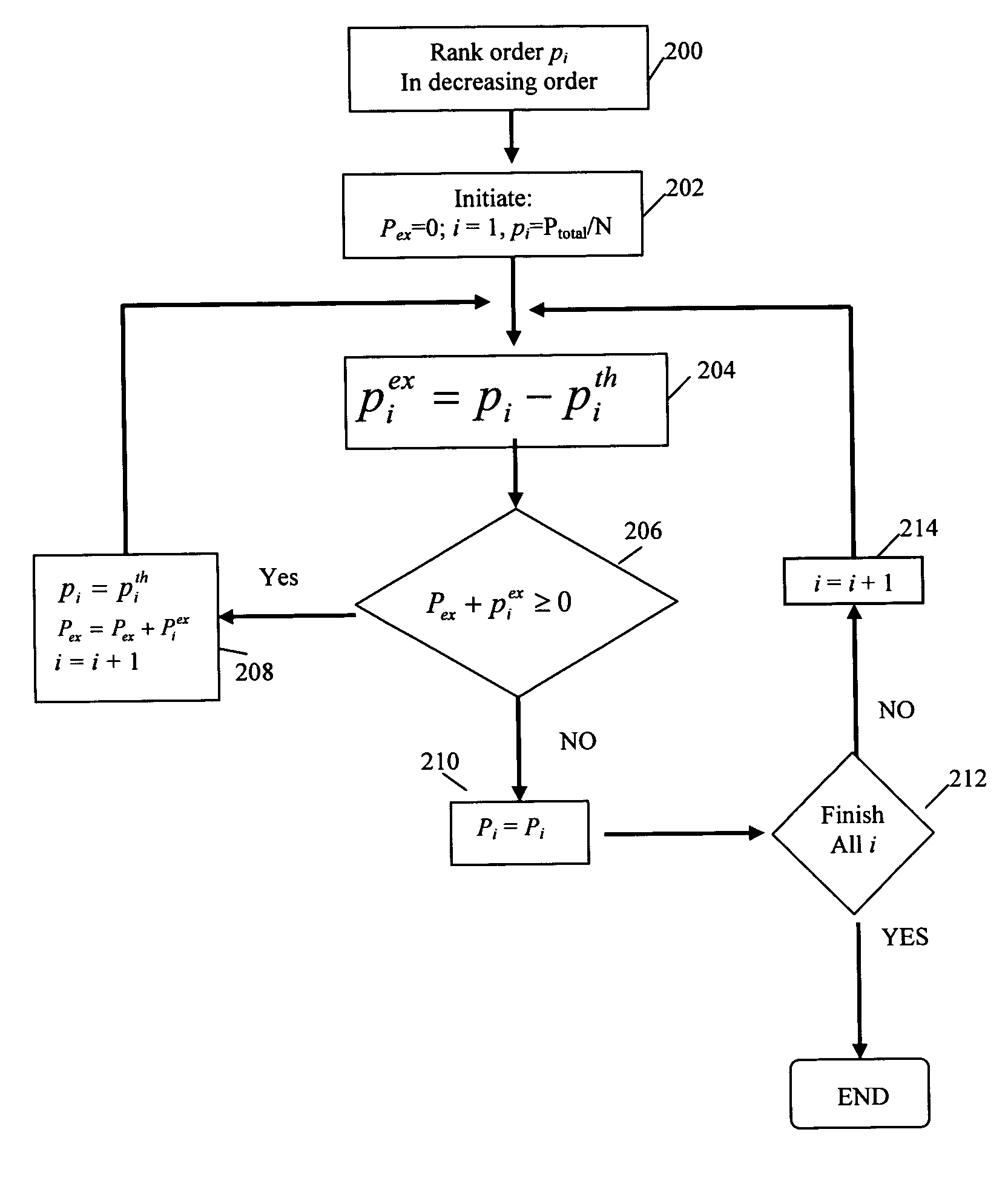

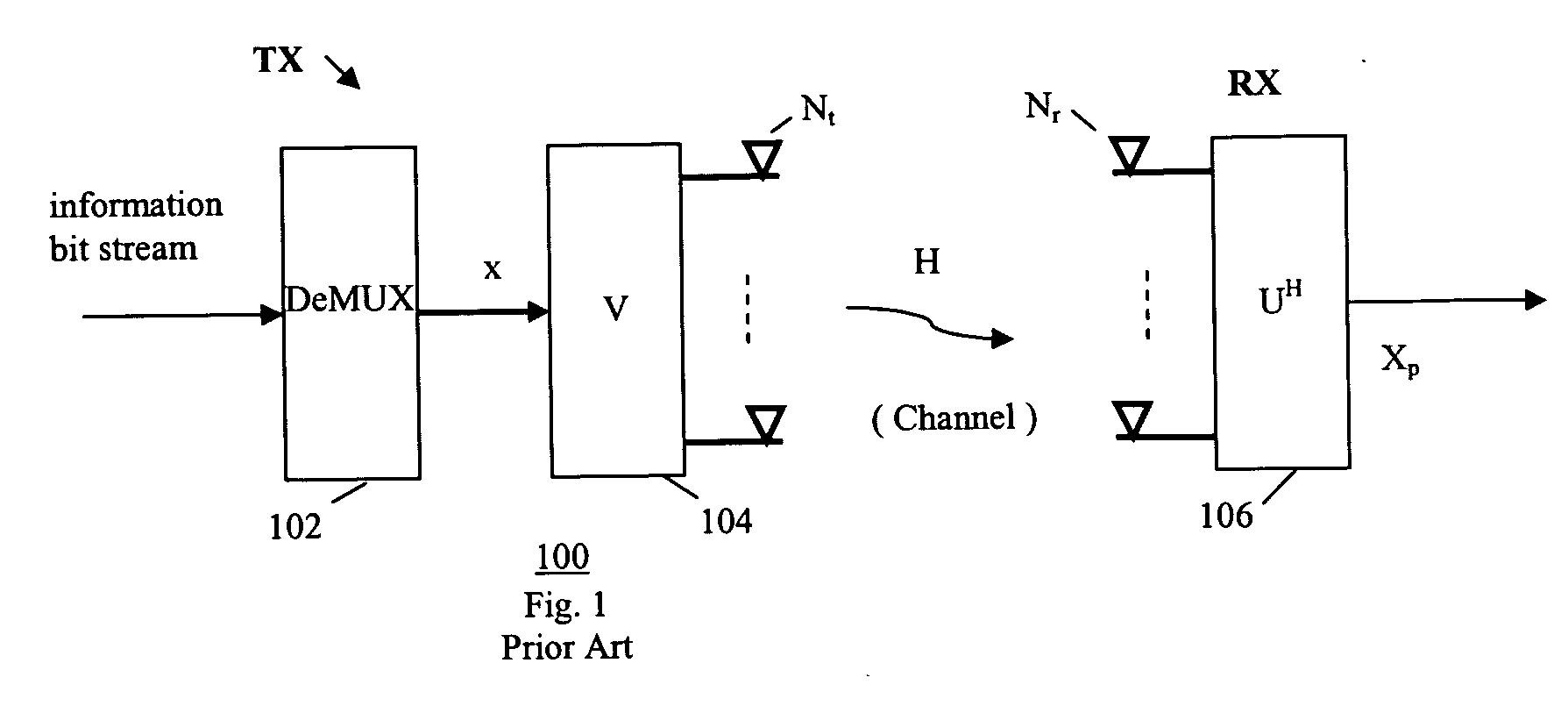

An apparatus and method for closed-loop signaling over multiple channels in a telecommunication system. Channel condition for each channel is obtained, and transmission power loading per channel is determined according to channel condition. The information bit streams is transmitted via the multiple channels over a plurality of transmitter antennas according to the power loading per channel.

Owner:SAMSUNG ELECTRONICS CO LTD

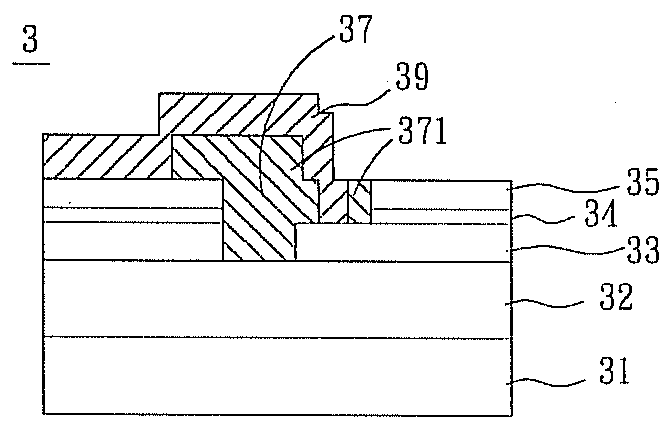

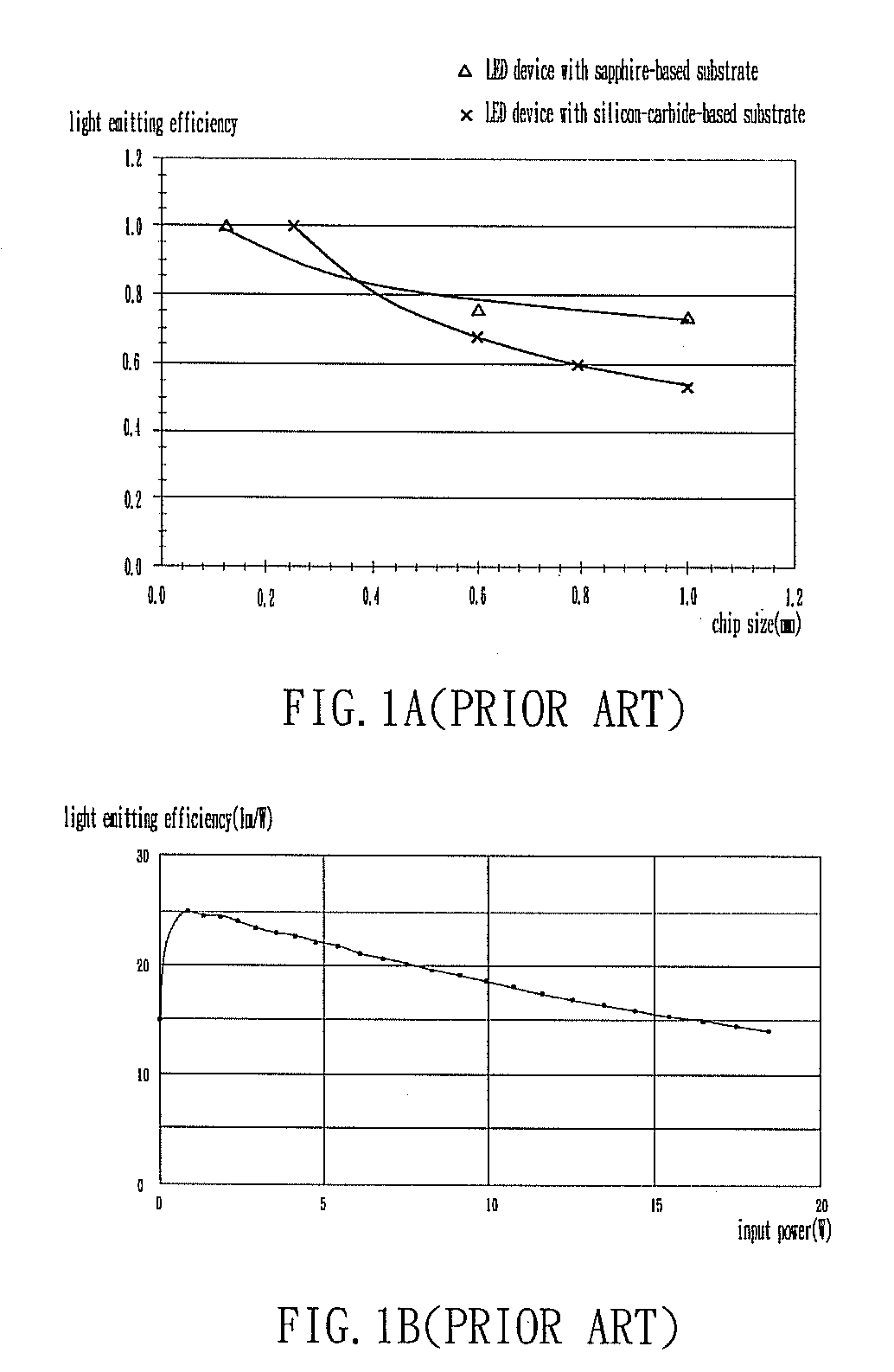

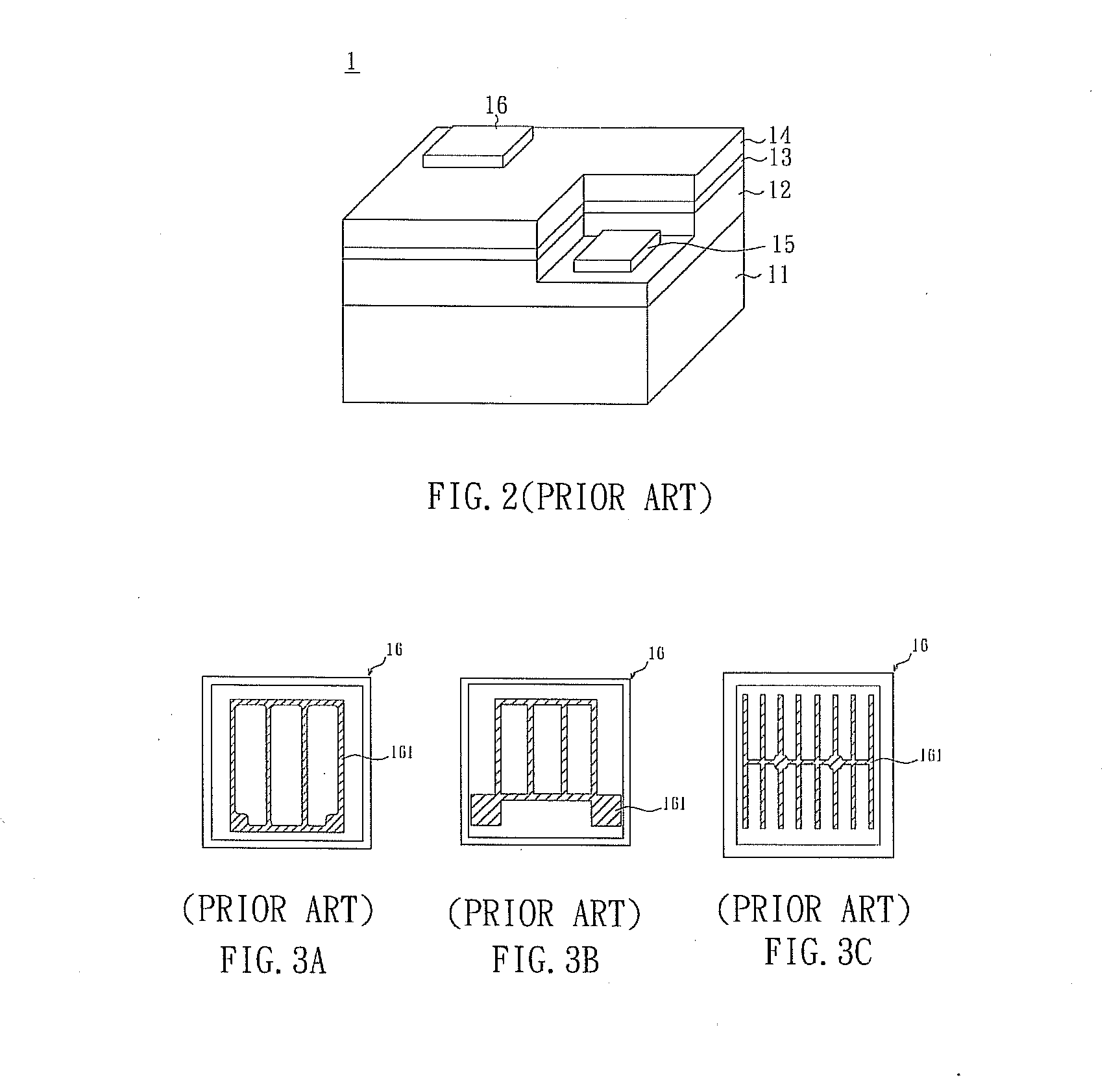

Light-emitting diode chip and manufacturing method thereof

InactiveUS20090090929A1Enhanced glowHigh power loadSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A light-emitting diode (LED) chip includes a substrate, a first semiconductor layer, an active layer, a second semiconductor layer and a groove. The first semiconductor layer, active layer and second semiconductor layer are formed on the substrate in sequence. The groove is formed in the first semiconductor layer, the active layer and the second semiconductor layer.

Owner:DELTA ELECTRONICS INC

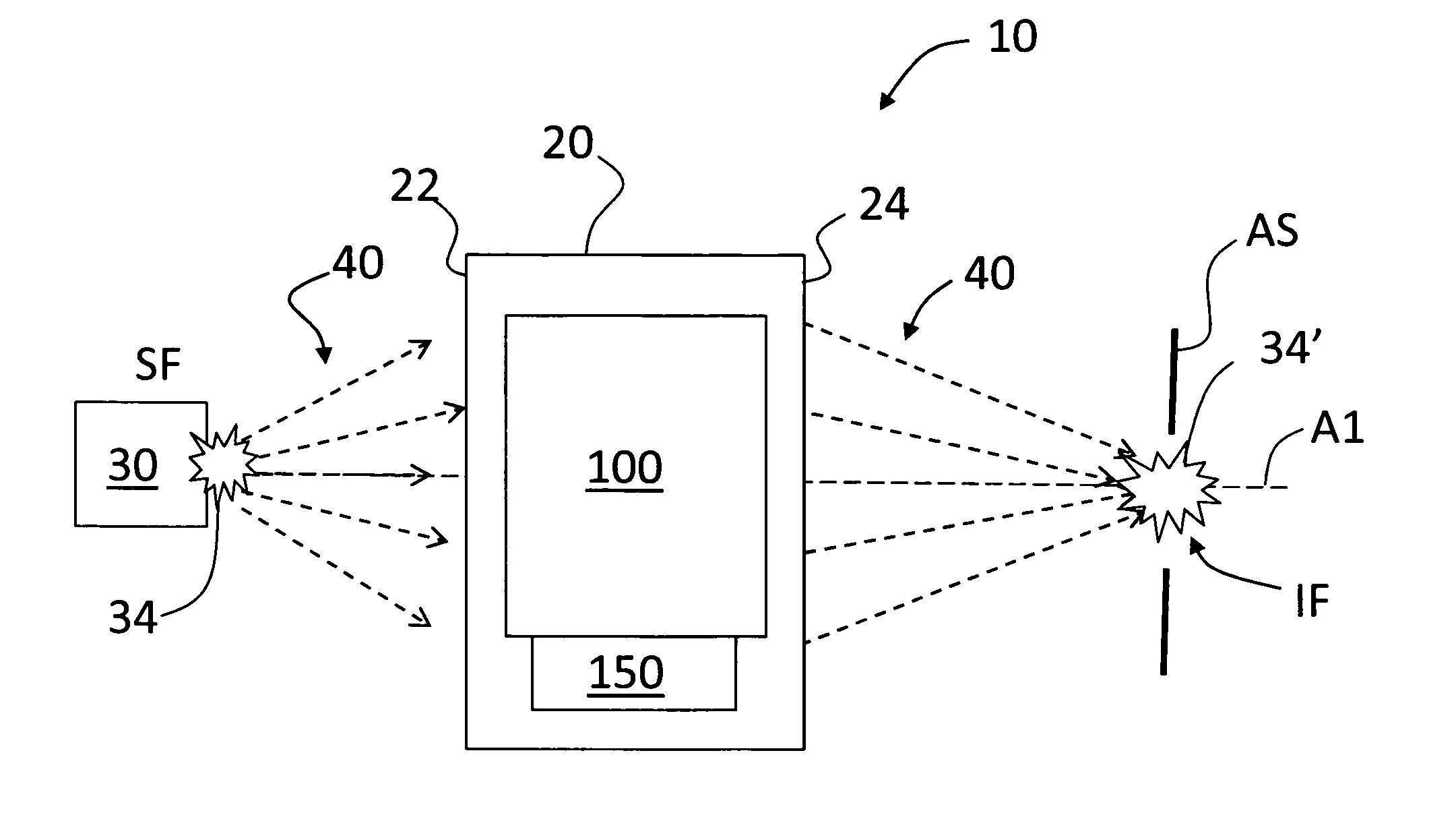

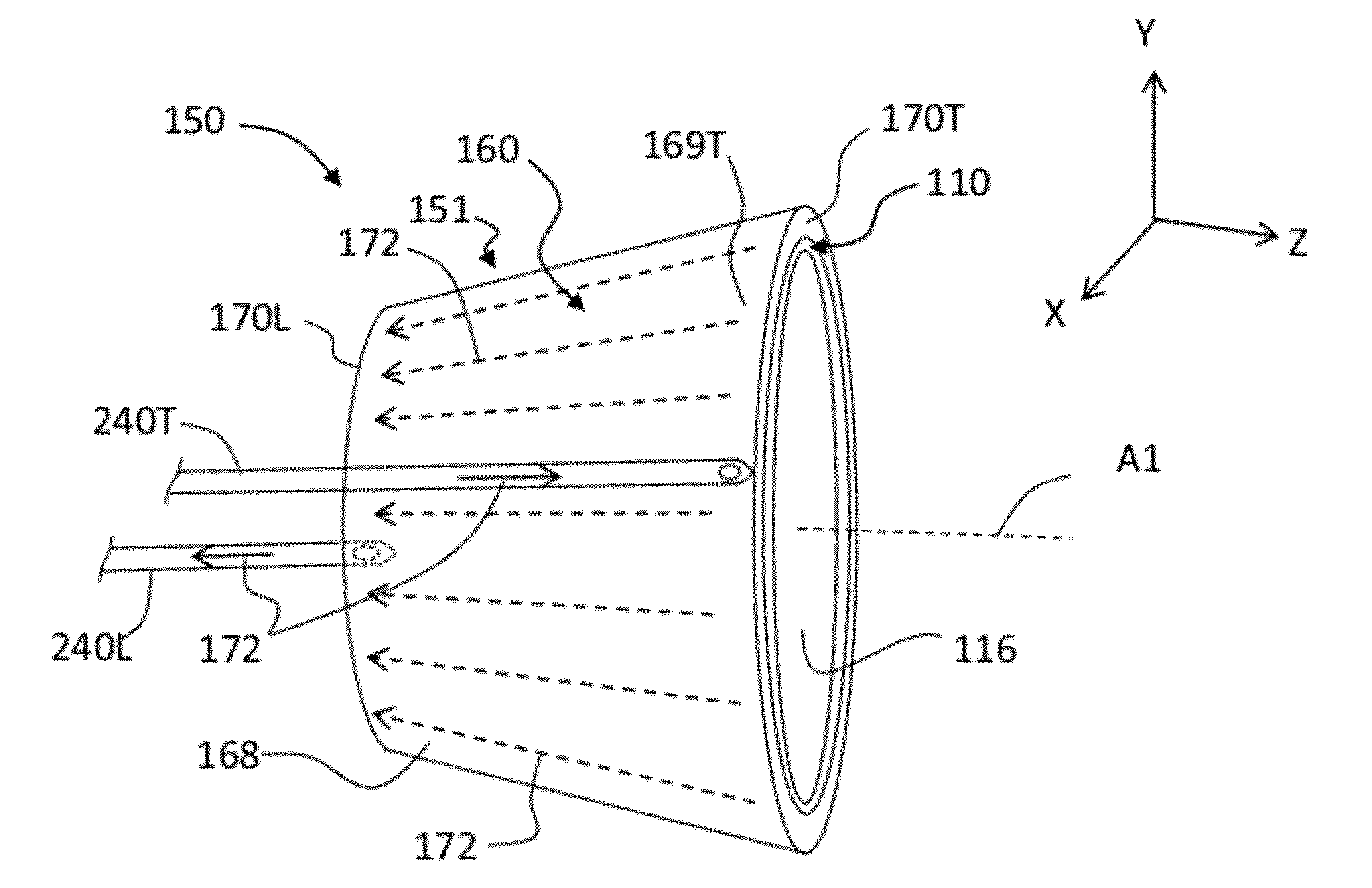

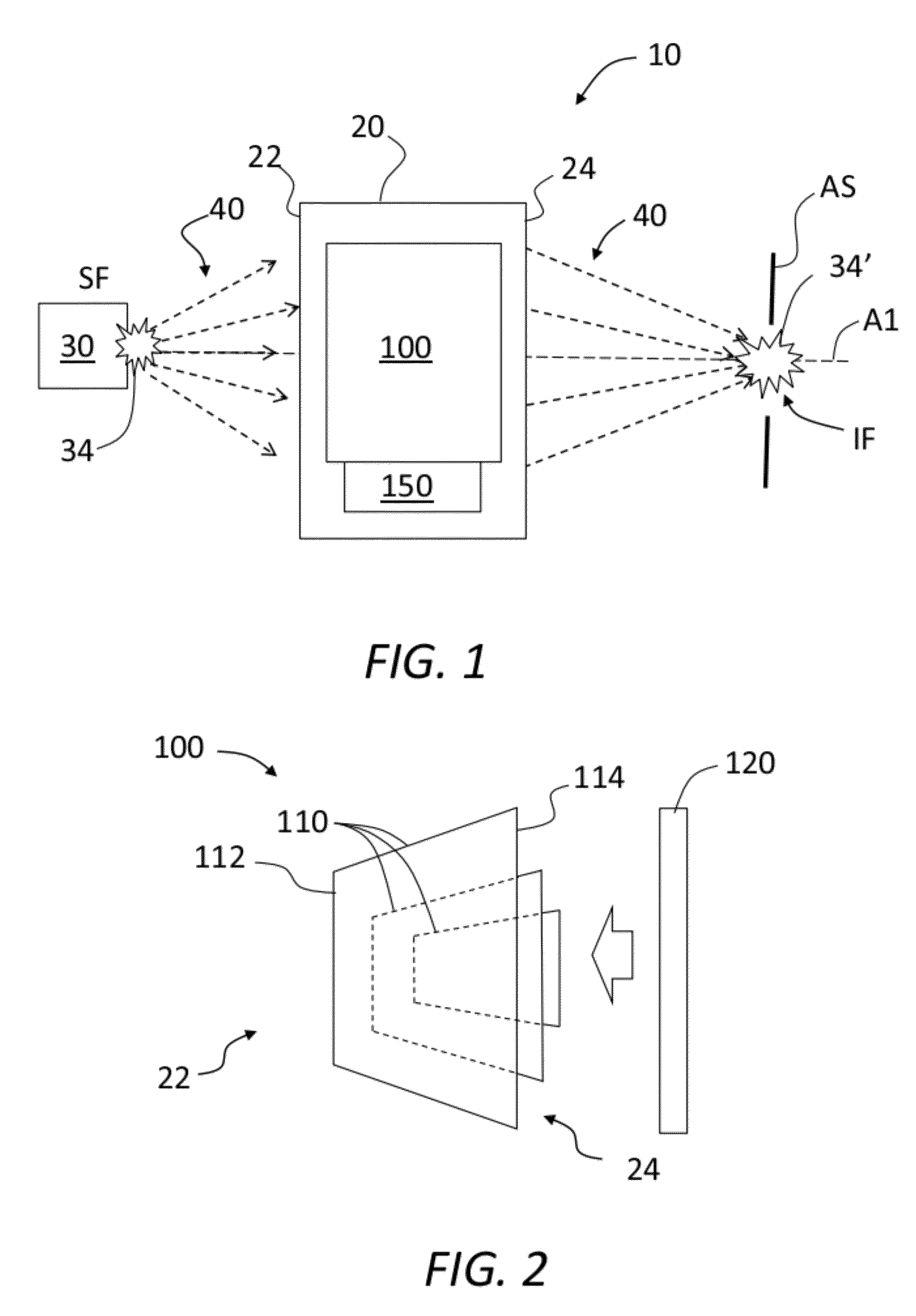

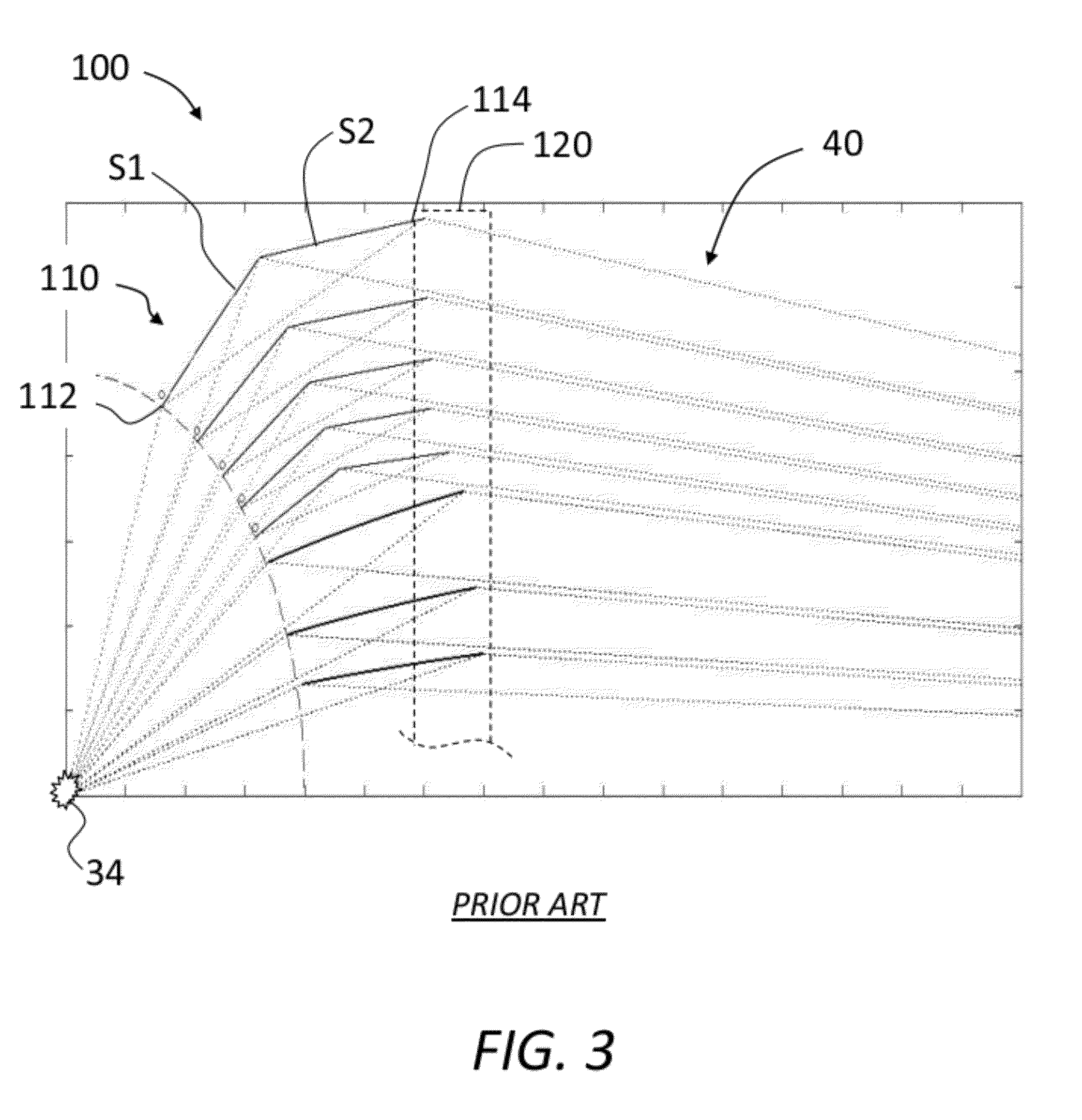

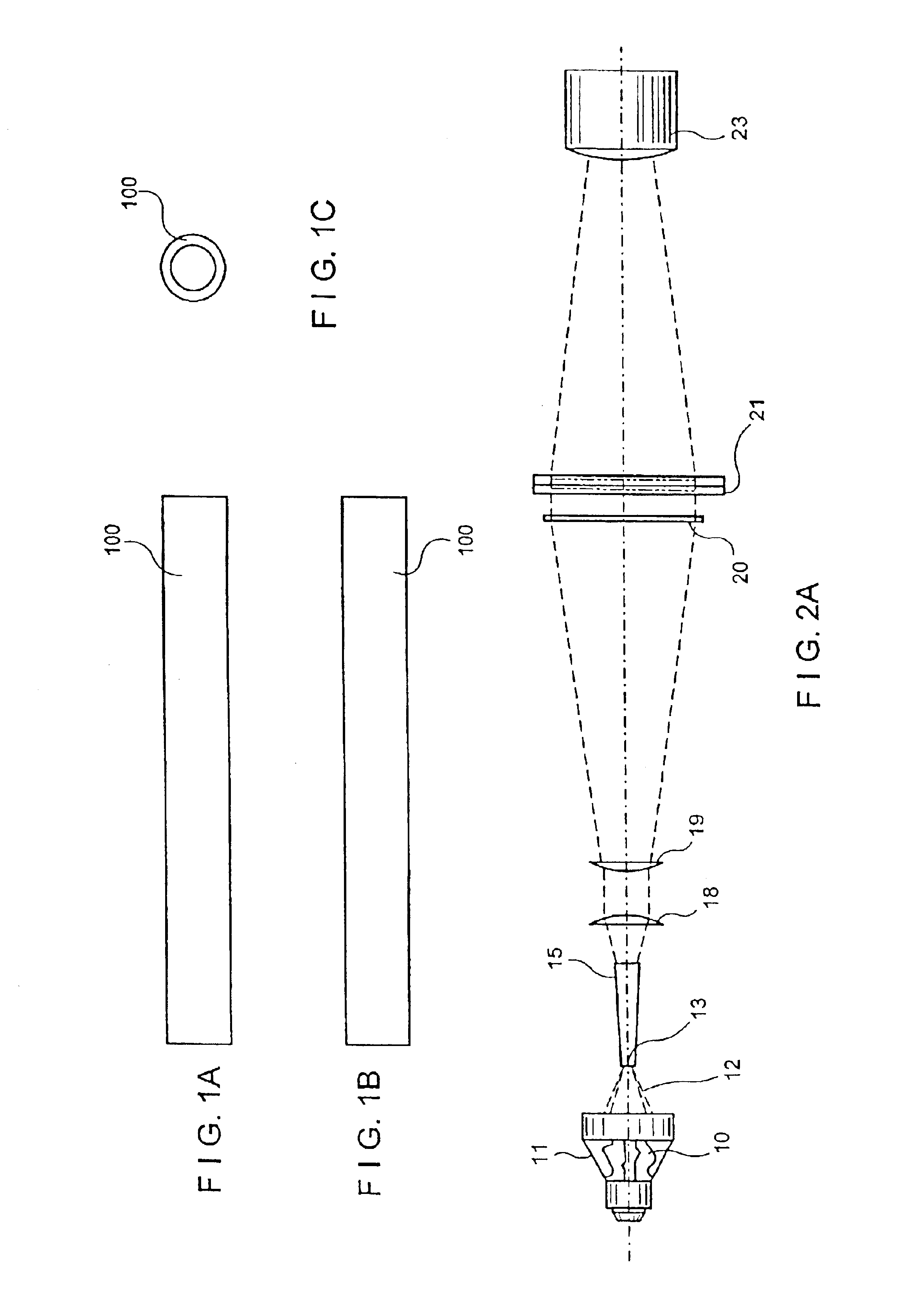

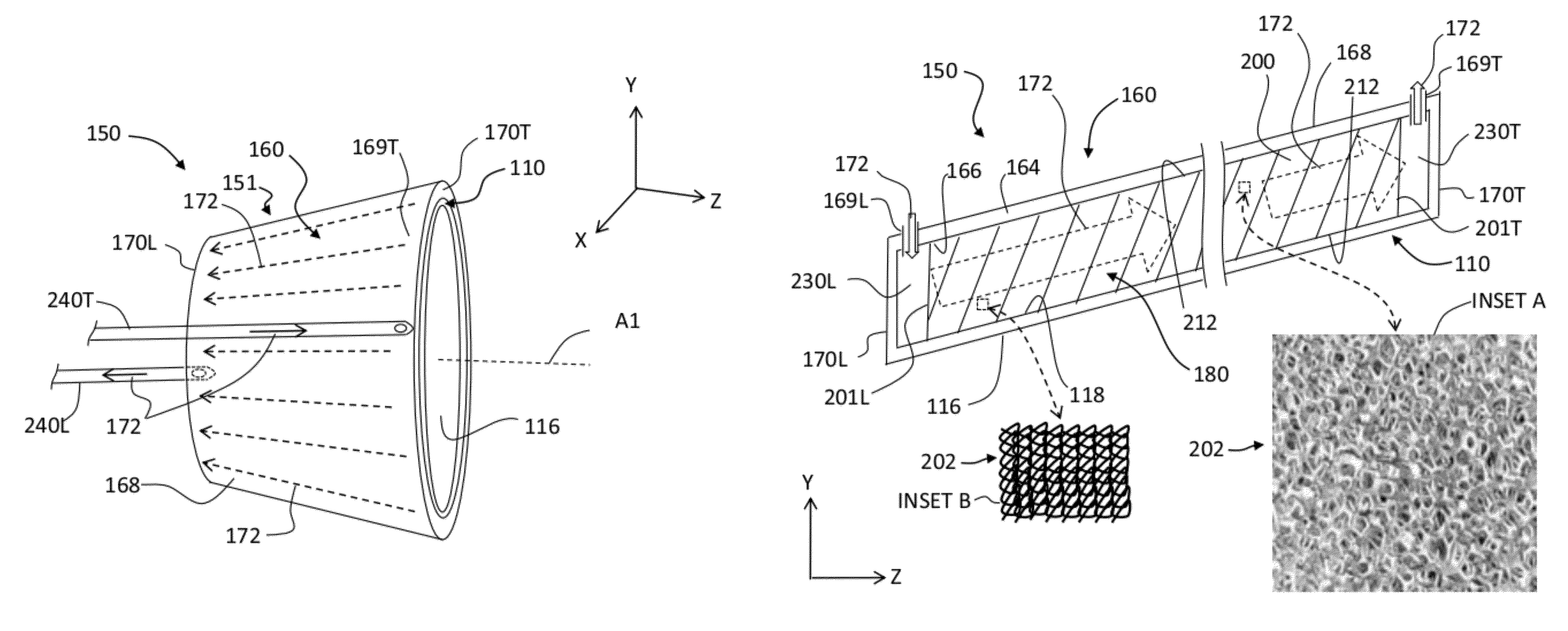

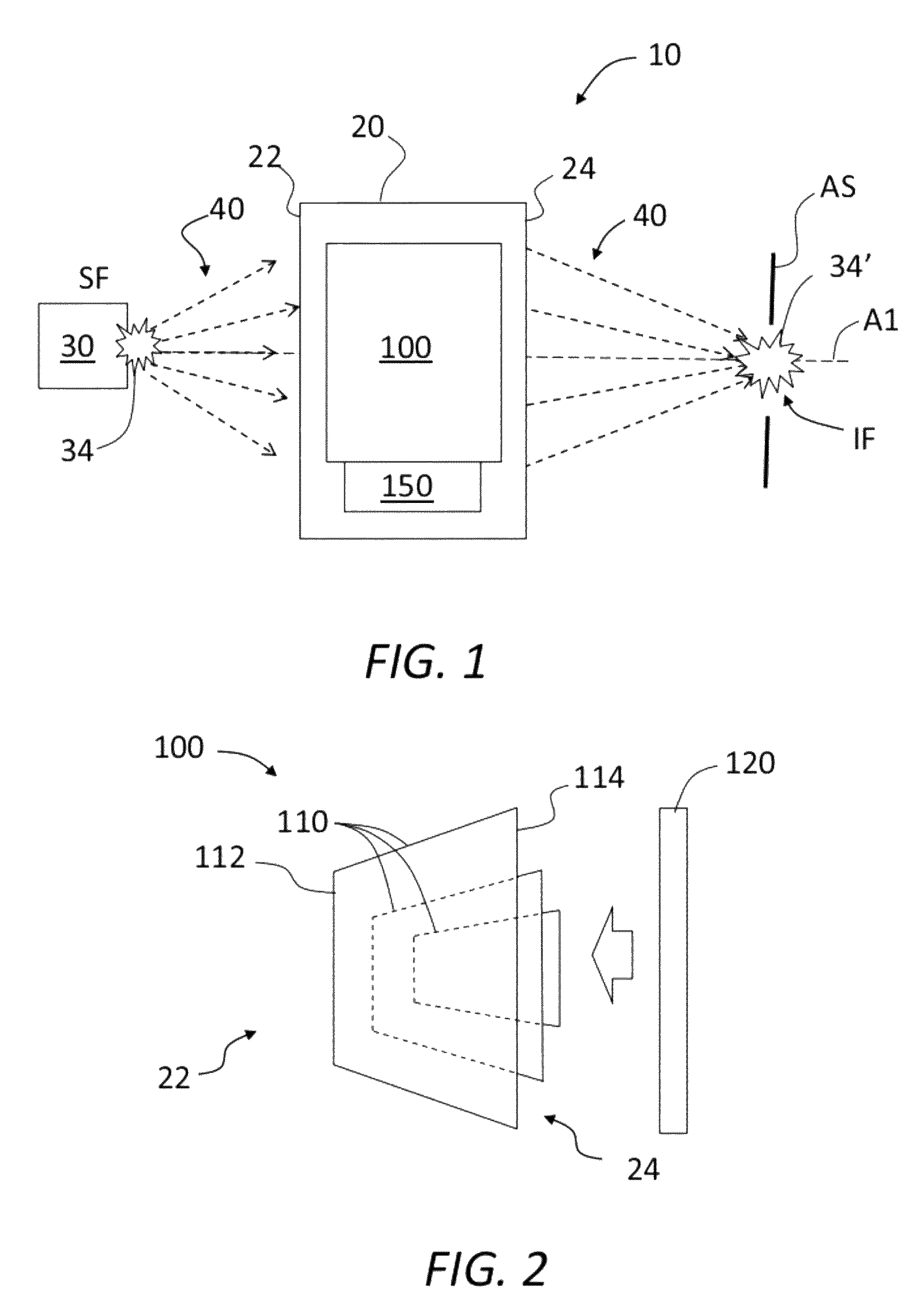

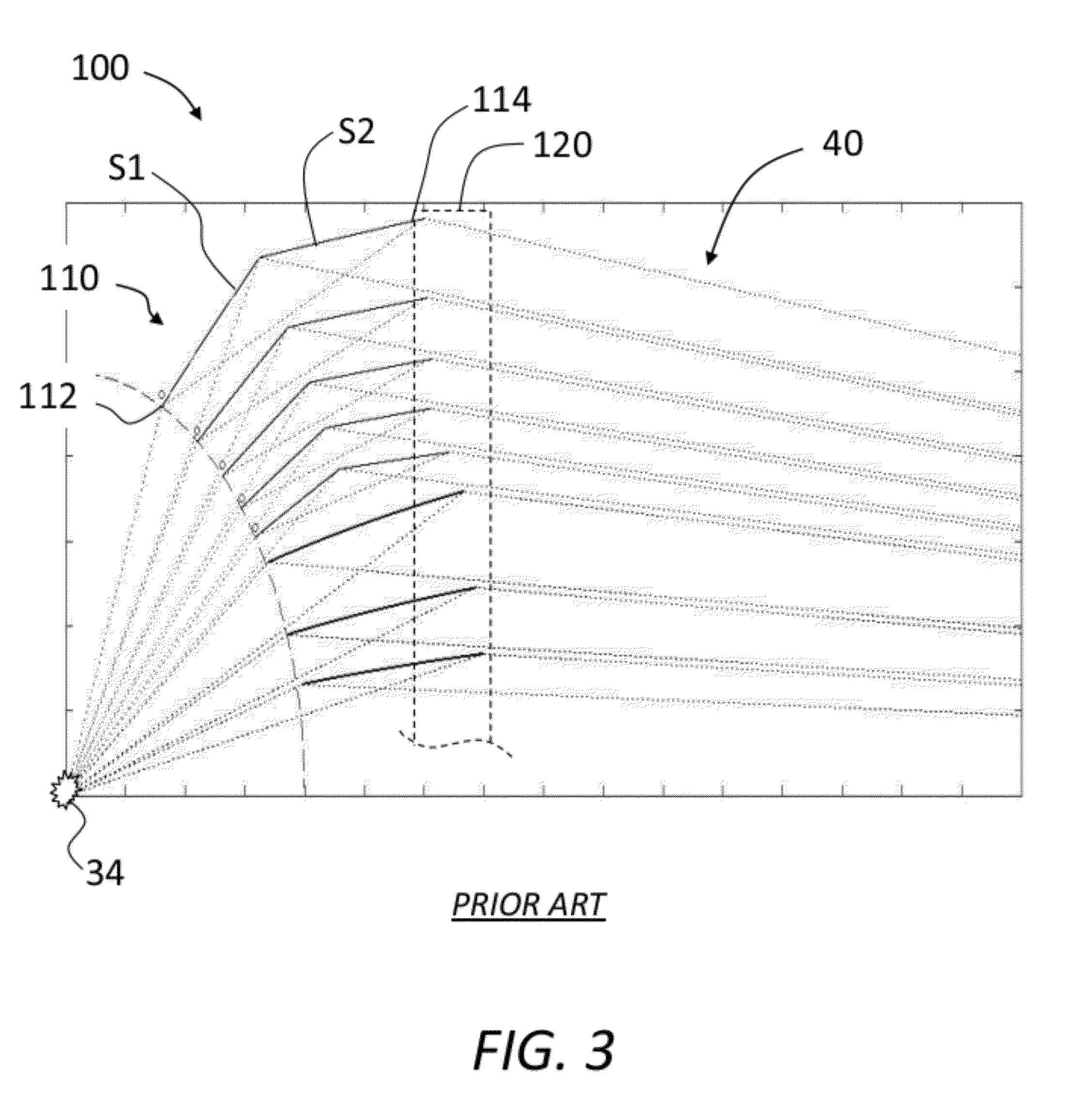

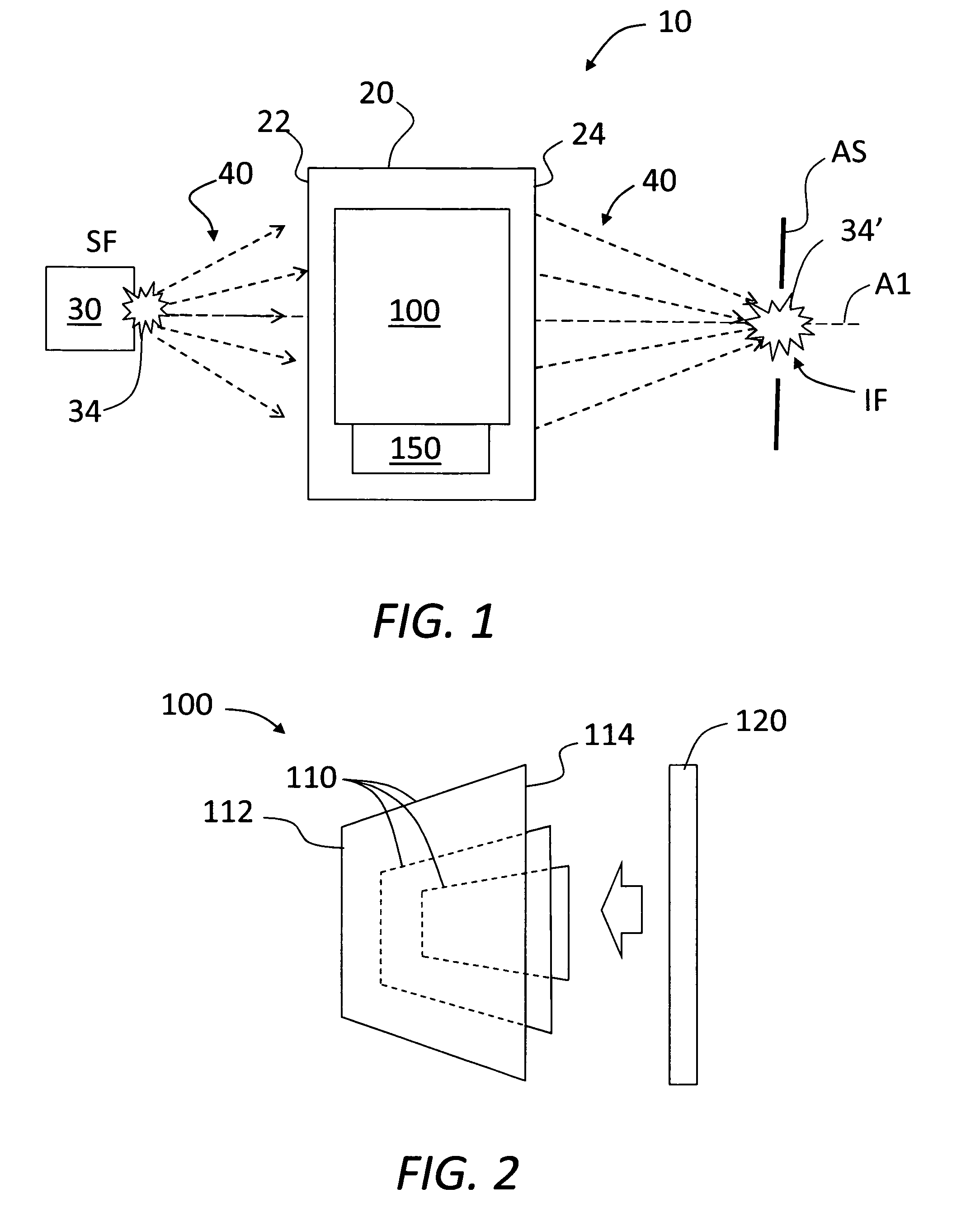

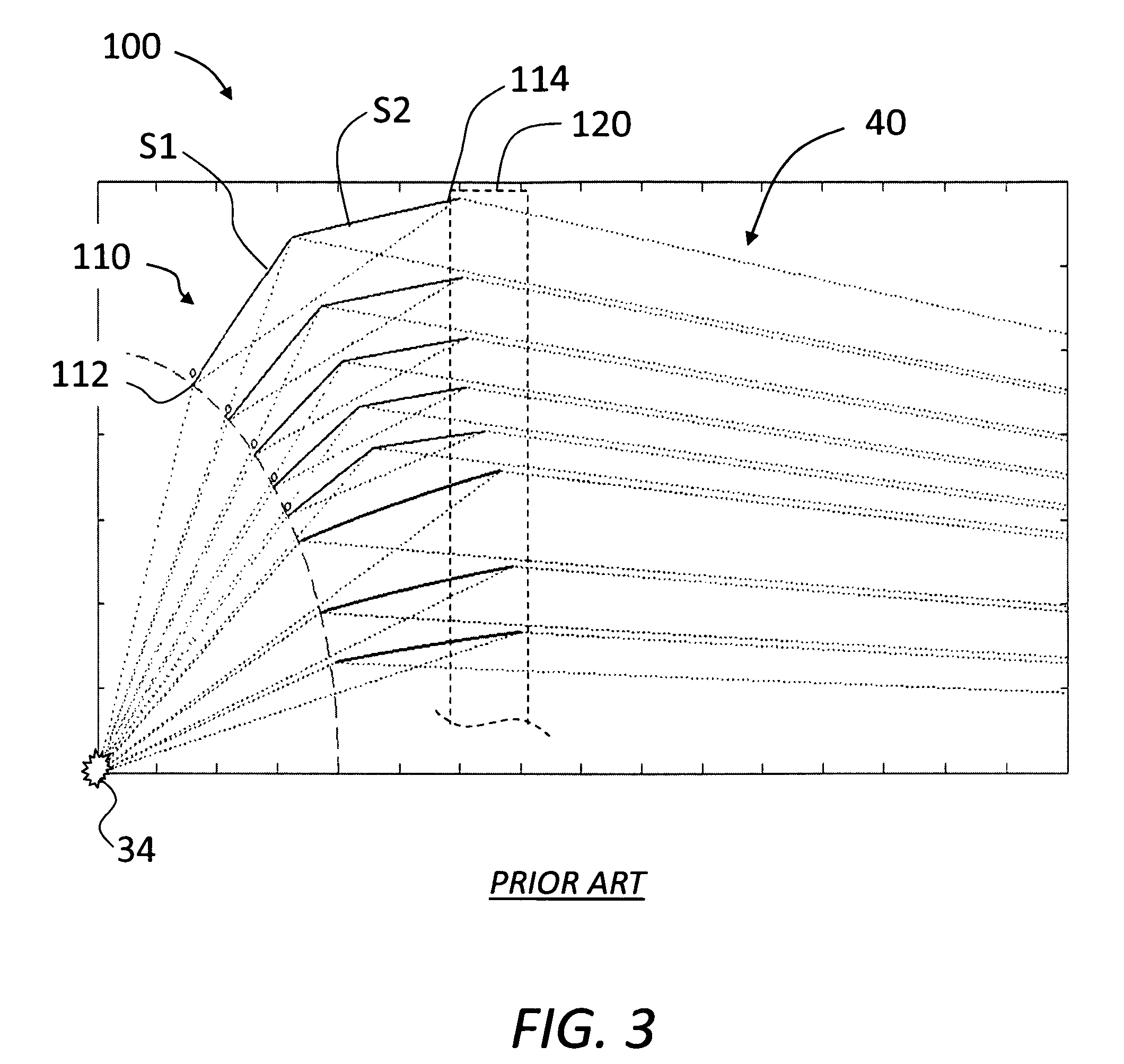

Evaporative thermal management of grazing incidence collectors for EUV lithography

ActiveUS20120281189A1Minimize thermal distortionUniform temperature distributionRadiation/particle handlingPhotomechanical apparatusThermal management systemEngineering

Evaporate thermal management systems for and methods of grazing incidence collectors (GICs) for extreme ultraviolet (EUV) lithography include a GIC shell interfaced with a jacket to form a structure having a leading end and that defines a chamber. The chamber operably supports at least one wicking layer. A conduit connects the wicking layer to a condenser system that support cooling fluid in a reservoir. When heat is applied to the leading end, the cooling fluid is drawn into the chamber from the condenser unit via capillary action in the wicking layer and an optional gravity assist, while vapor is drawn in the opposite direction from the chamber to the condenser unit. Heat is removed from the condensed vapor at the condenser unit, thereby cooling the GIC mirror shell.

Owner:MEDIA LARIO SRL

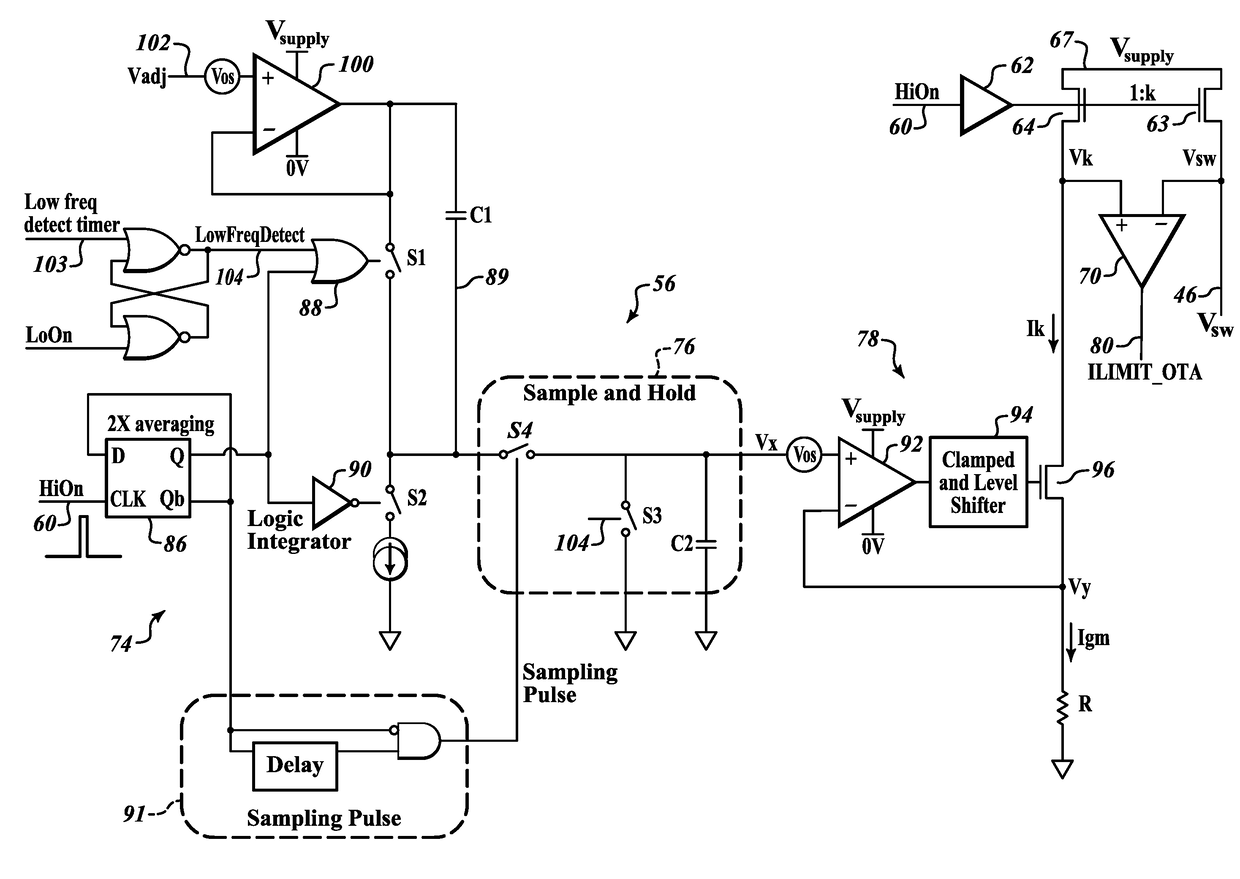

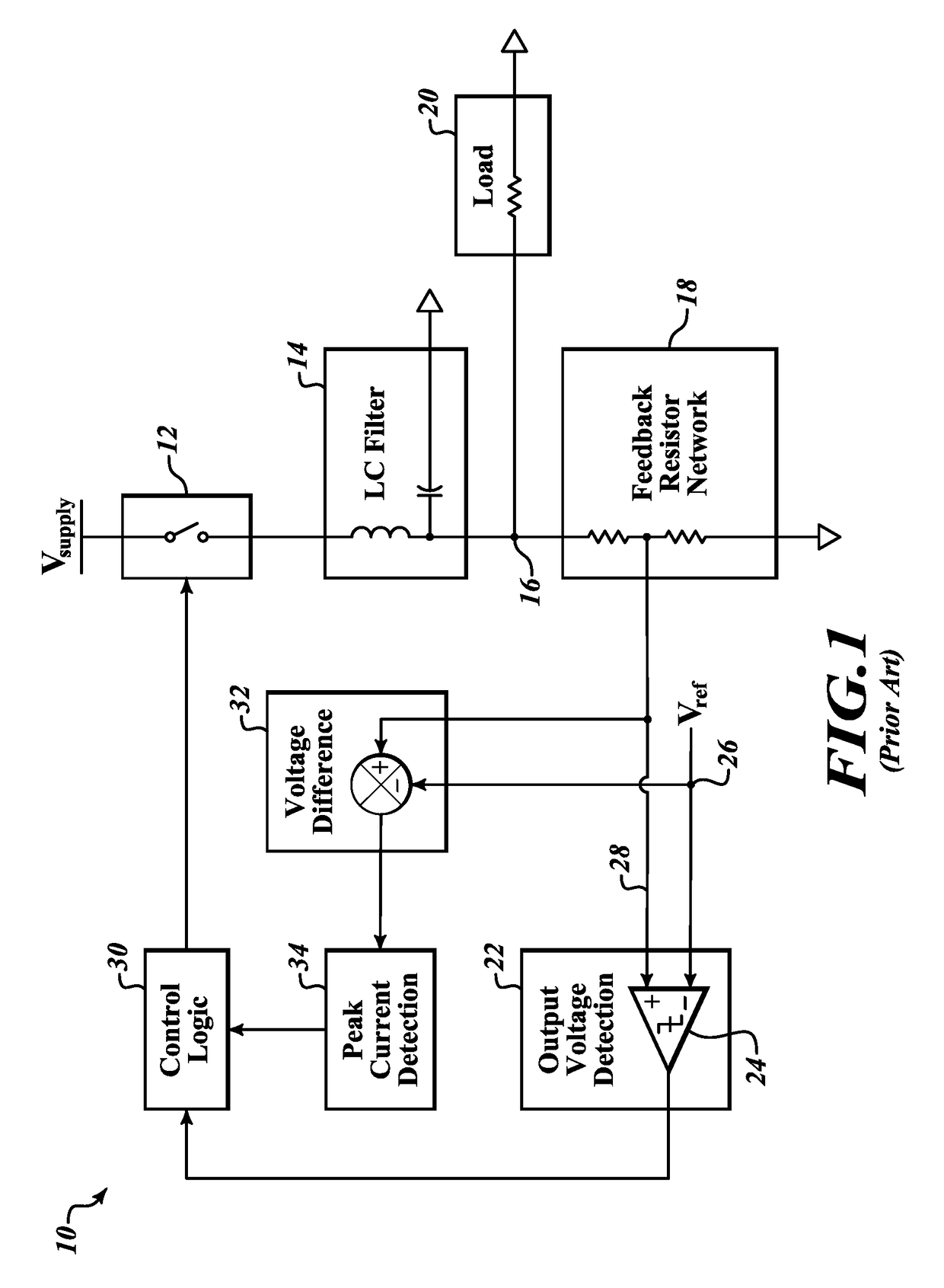

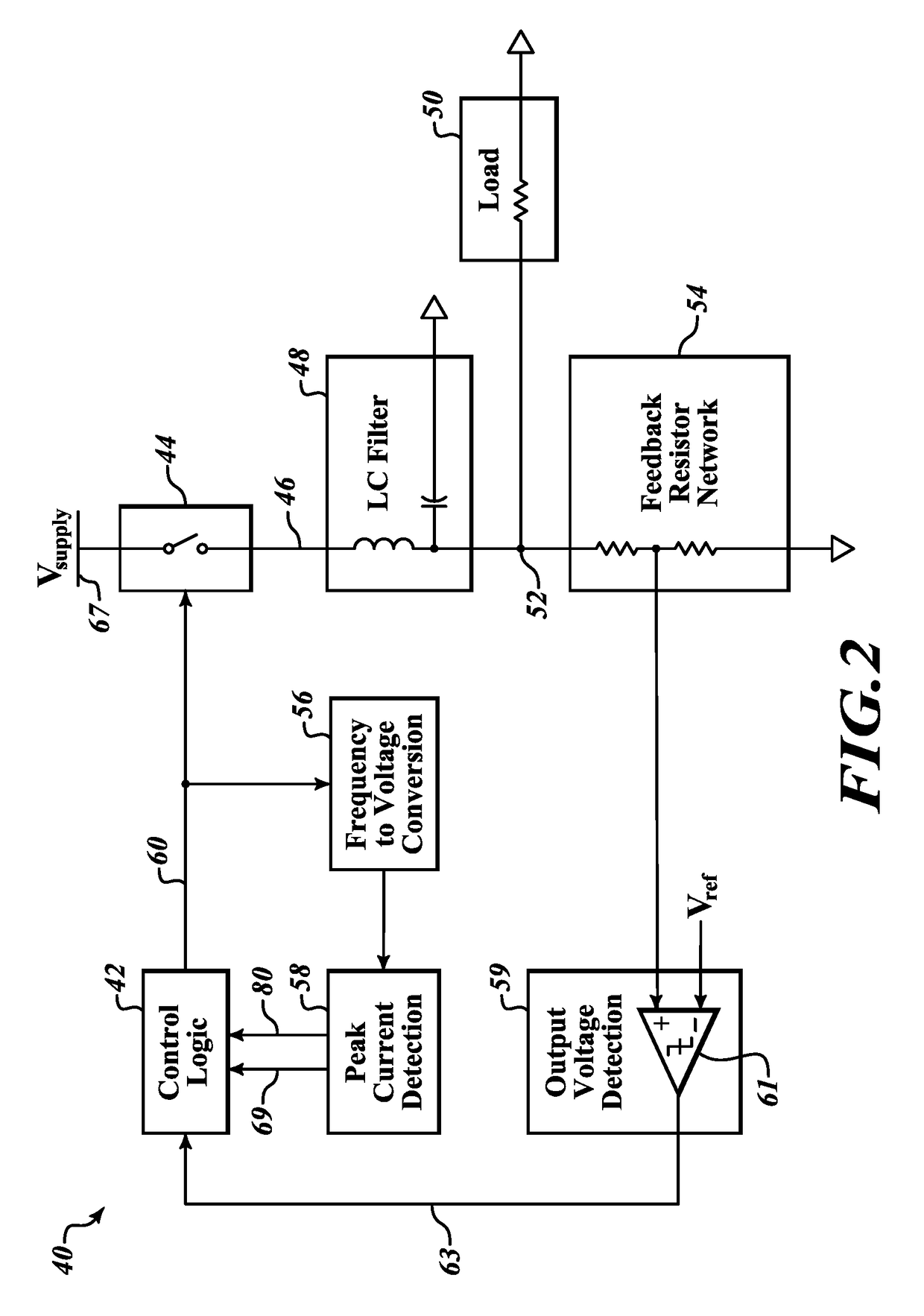

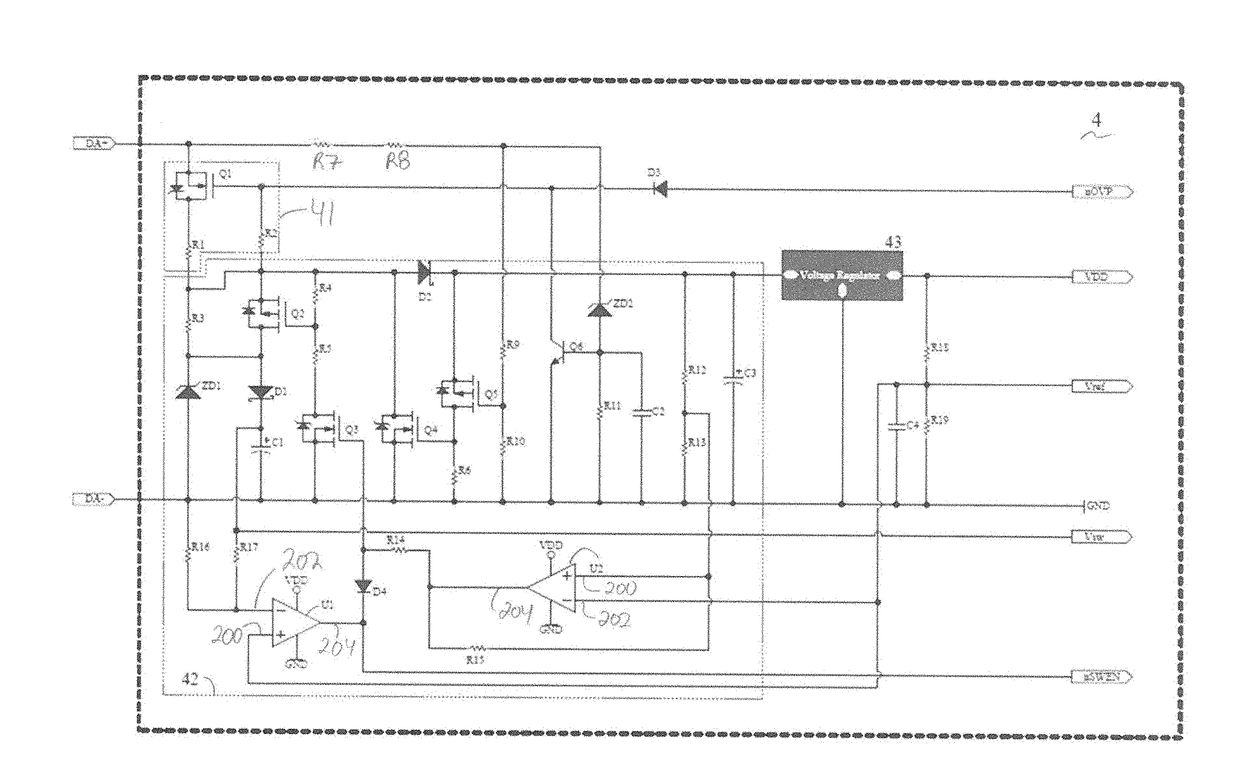

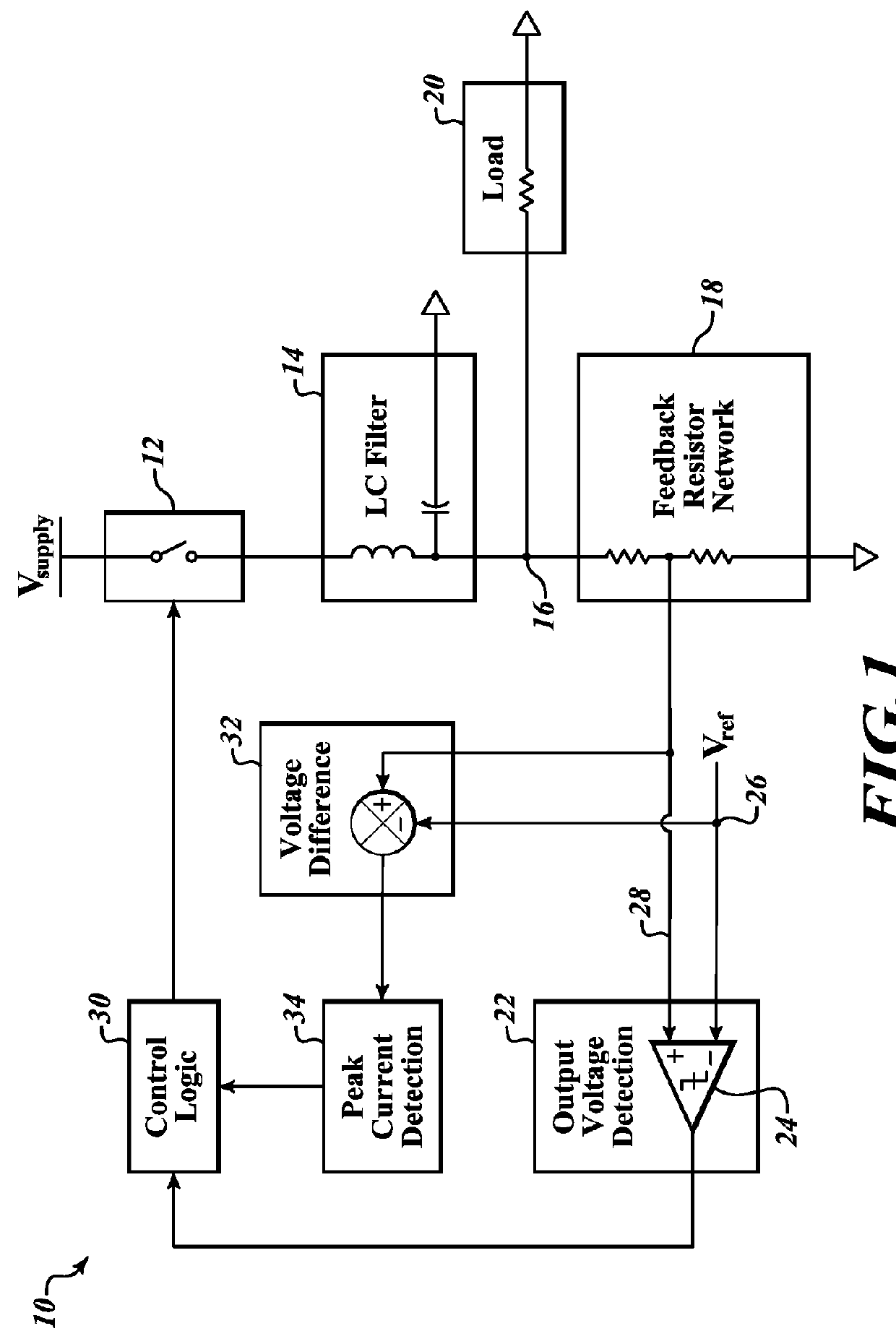

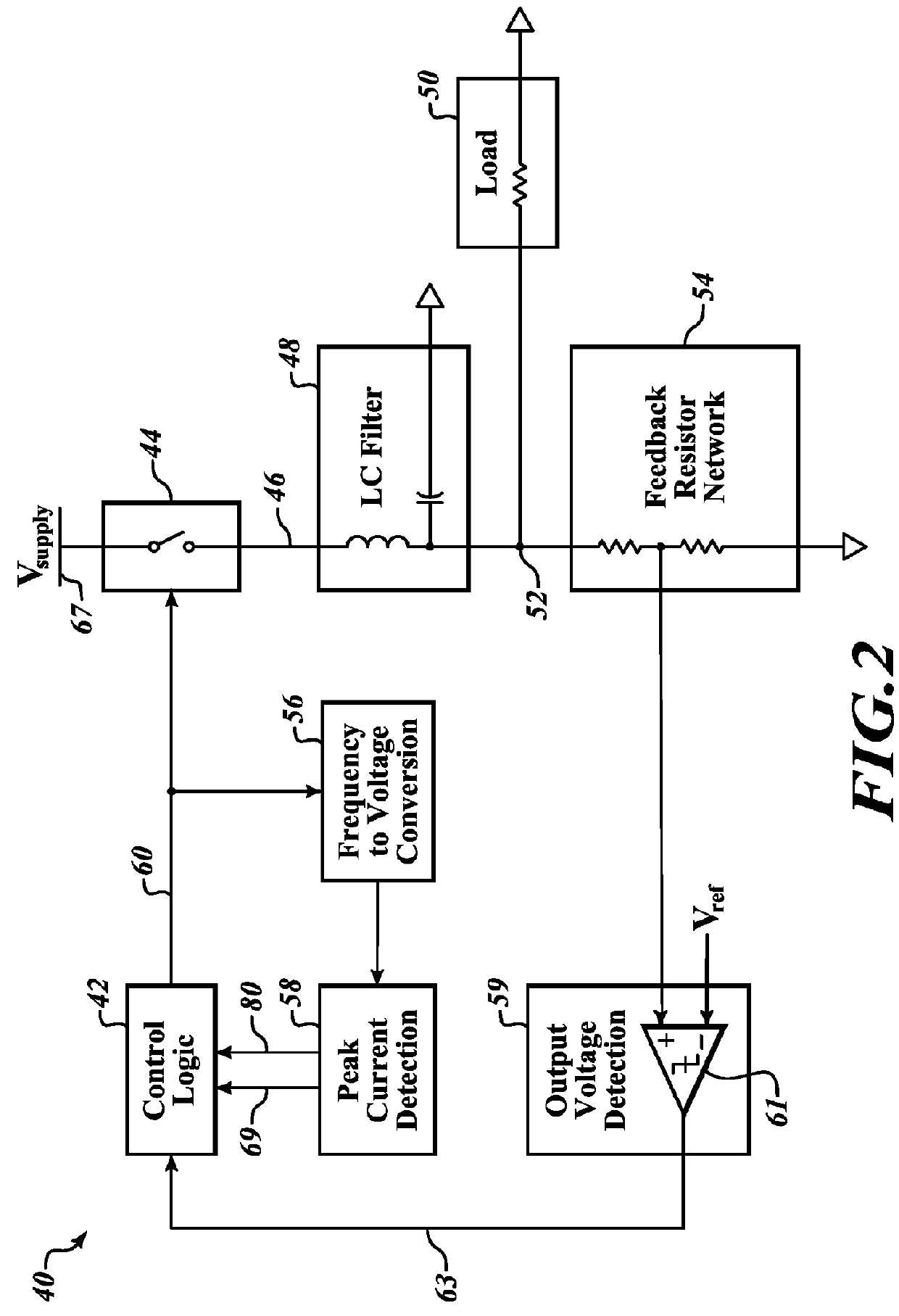

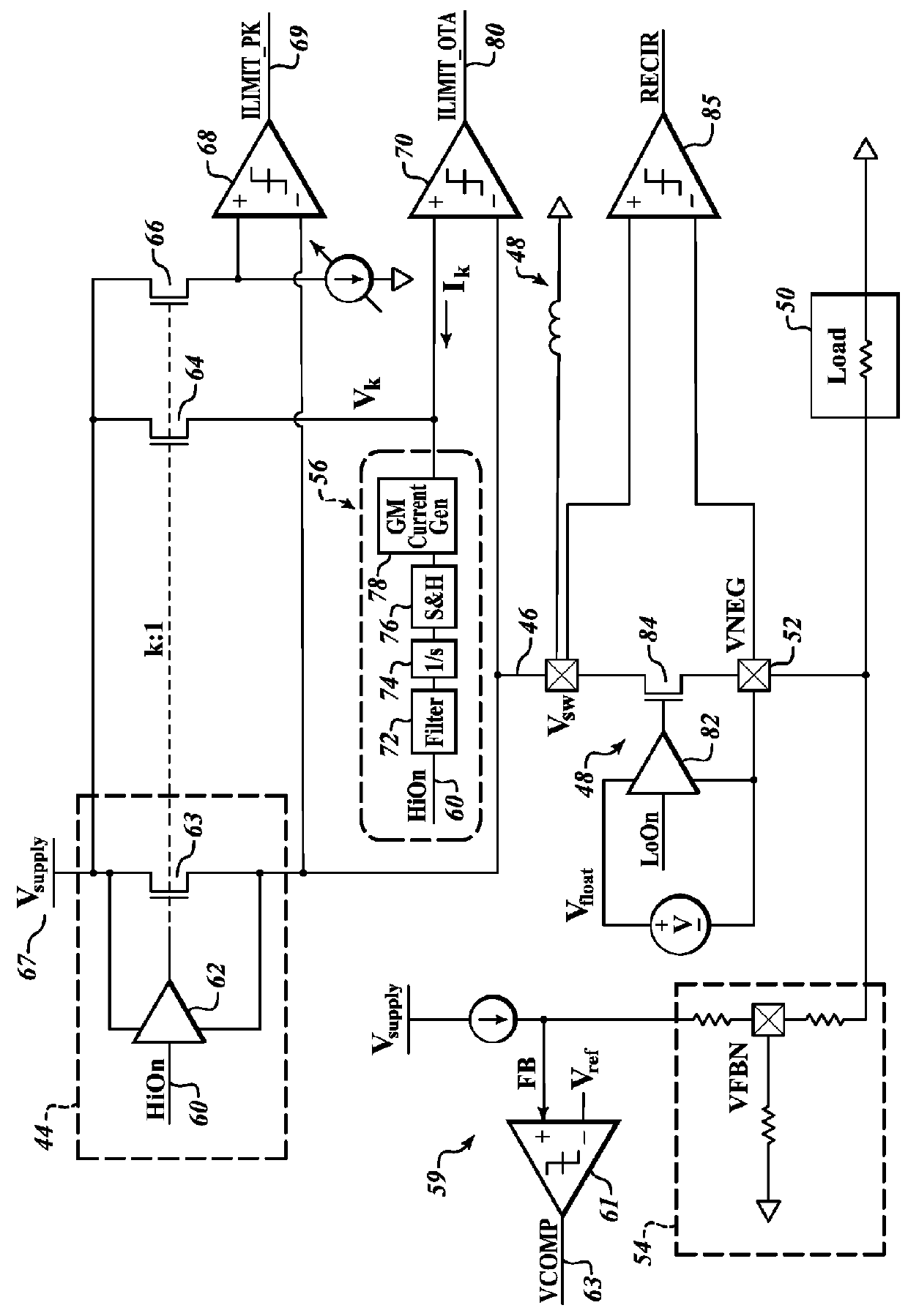

Frequency detection to perform dynamic peak current control

ActiveUS20180175730A1Demand of load can be quickly and accurately determinedHigh power loadDc-dc conversionElectric variable regulationPeak currentPeak value

The amount of power being output to the load is sensed by sampling the frequency of the pulse width modulation signal that is controlling the switch that is providing the power to the load. If the pulse width modulation signal has a high frequency, then it will be providing higher power to the load. As the power drawn by the load decreases, the frequency of the pulse width modulation power supply signal will decrease. By sensing and periodically sampling the frequency of the pulse width modulation signal that is providing power, the demand of the load can be quickly and accurately determined. As the power demand of the load decreases, the peak current that the power supply switch can provide also decreases. The permitted peak current dynamically changes to adapt to the power drawn by the load.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

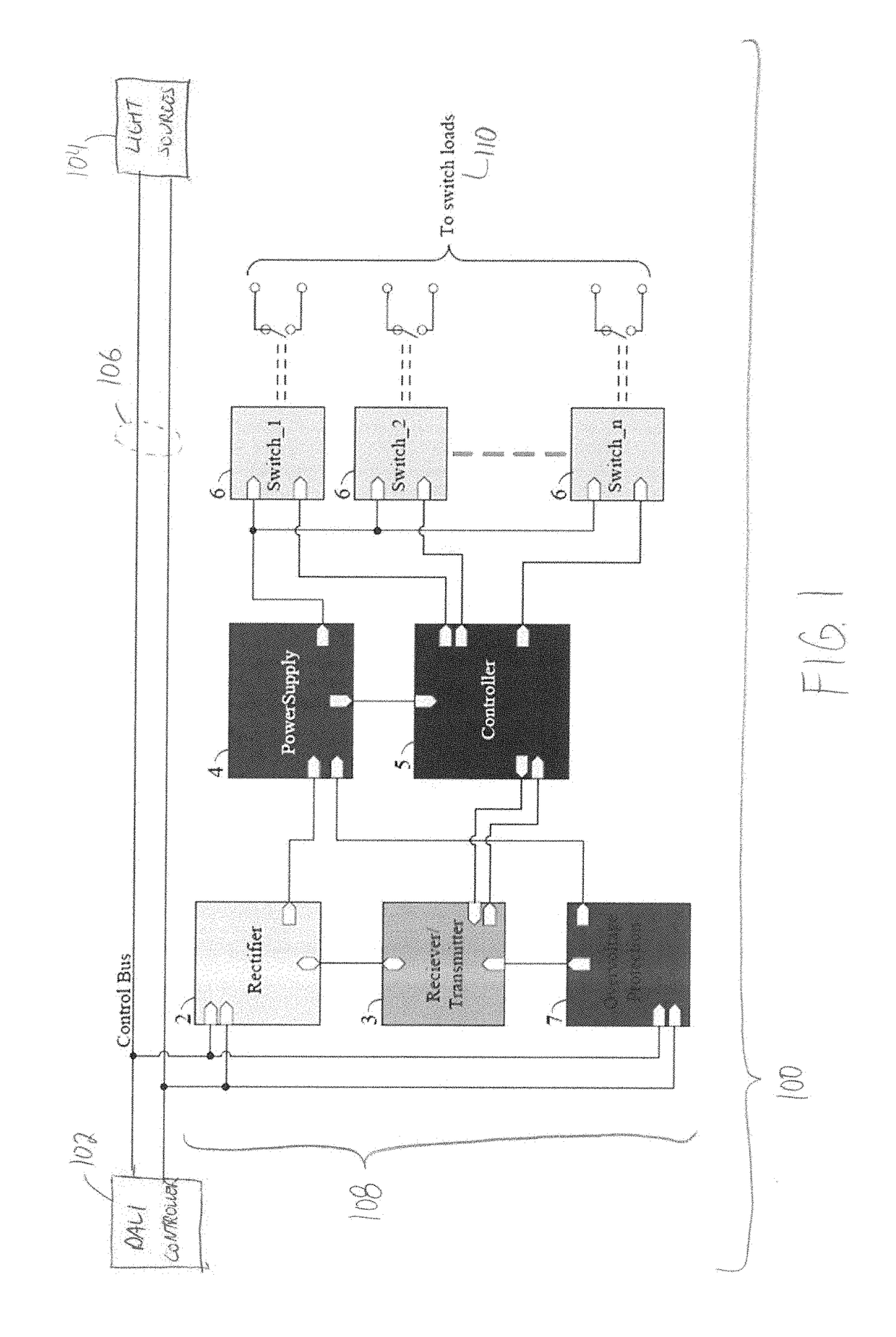

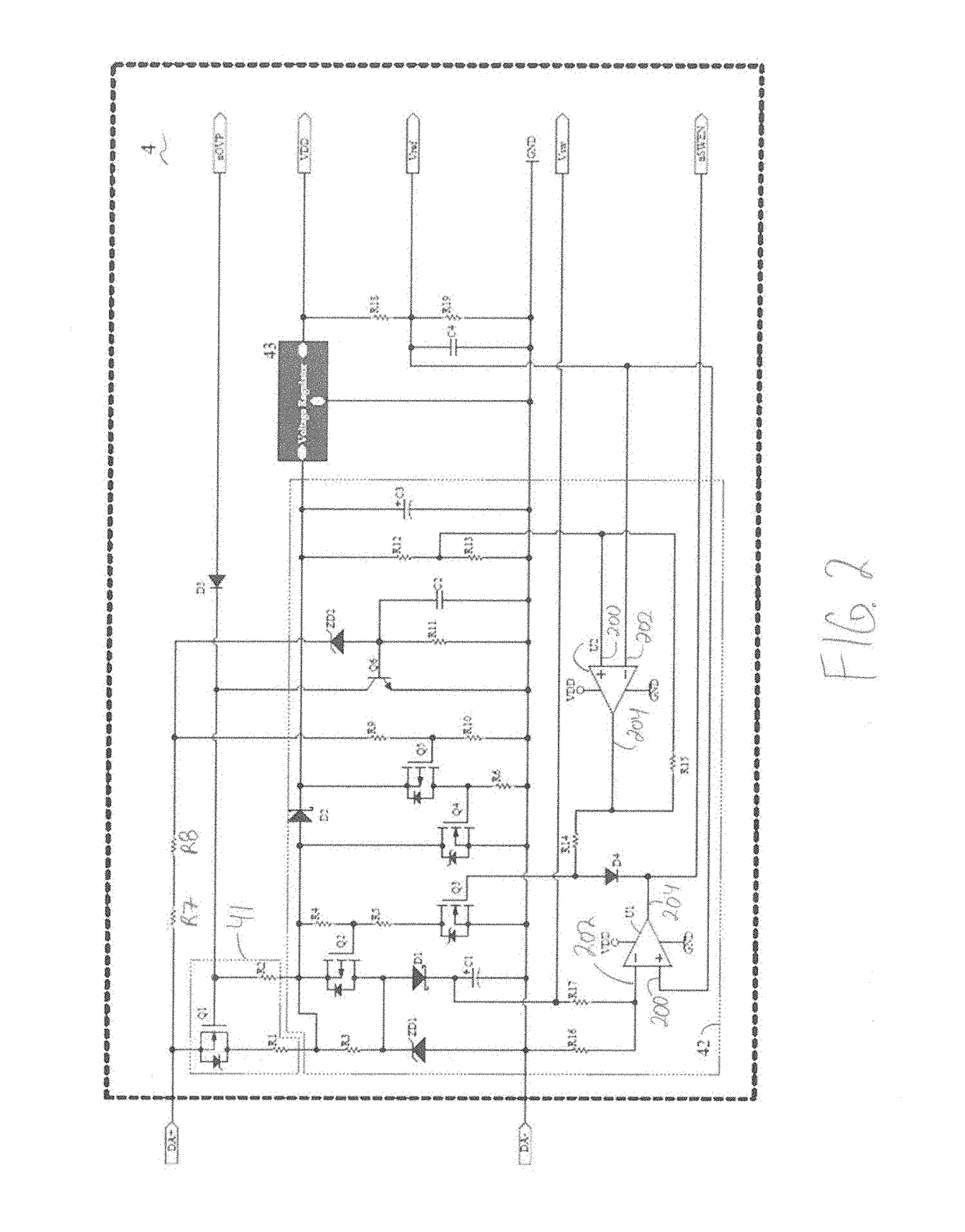

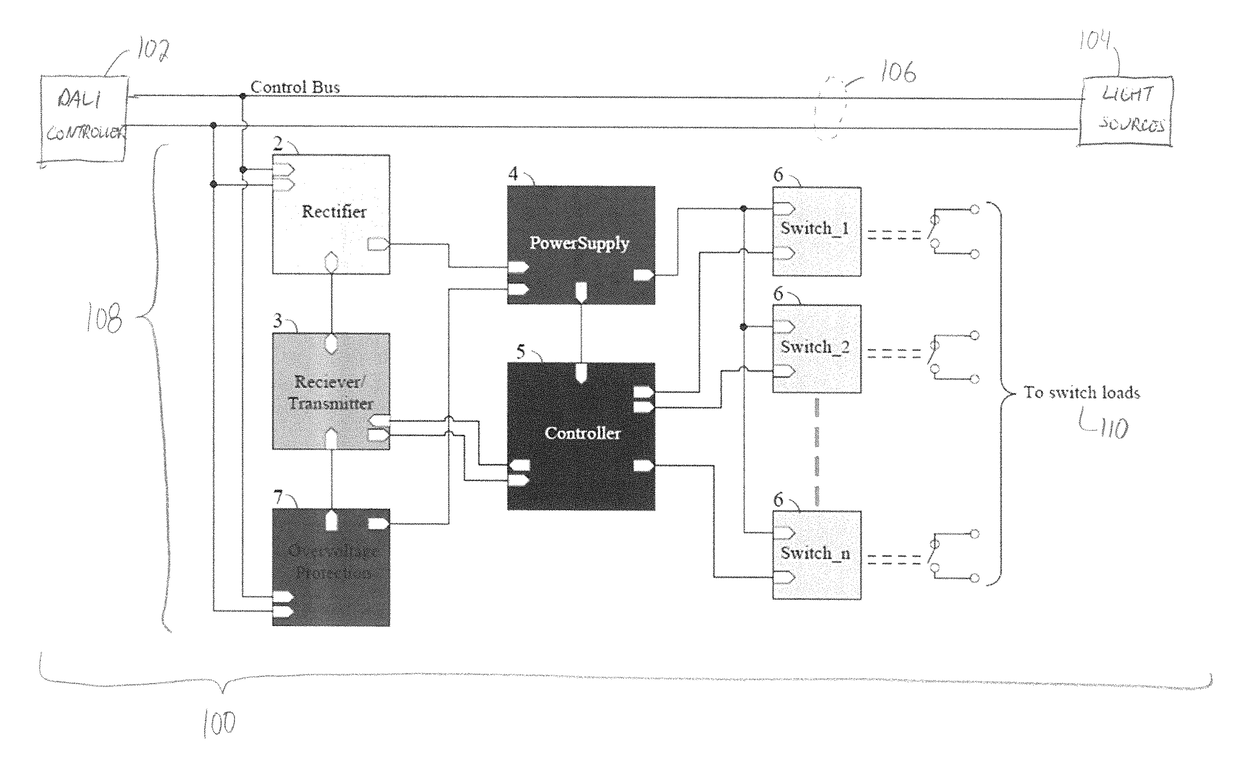

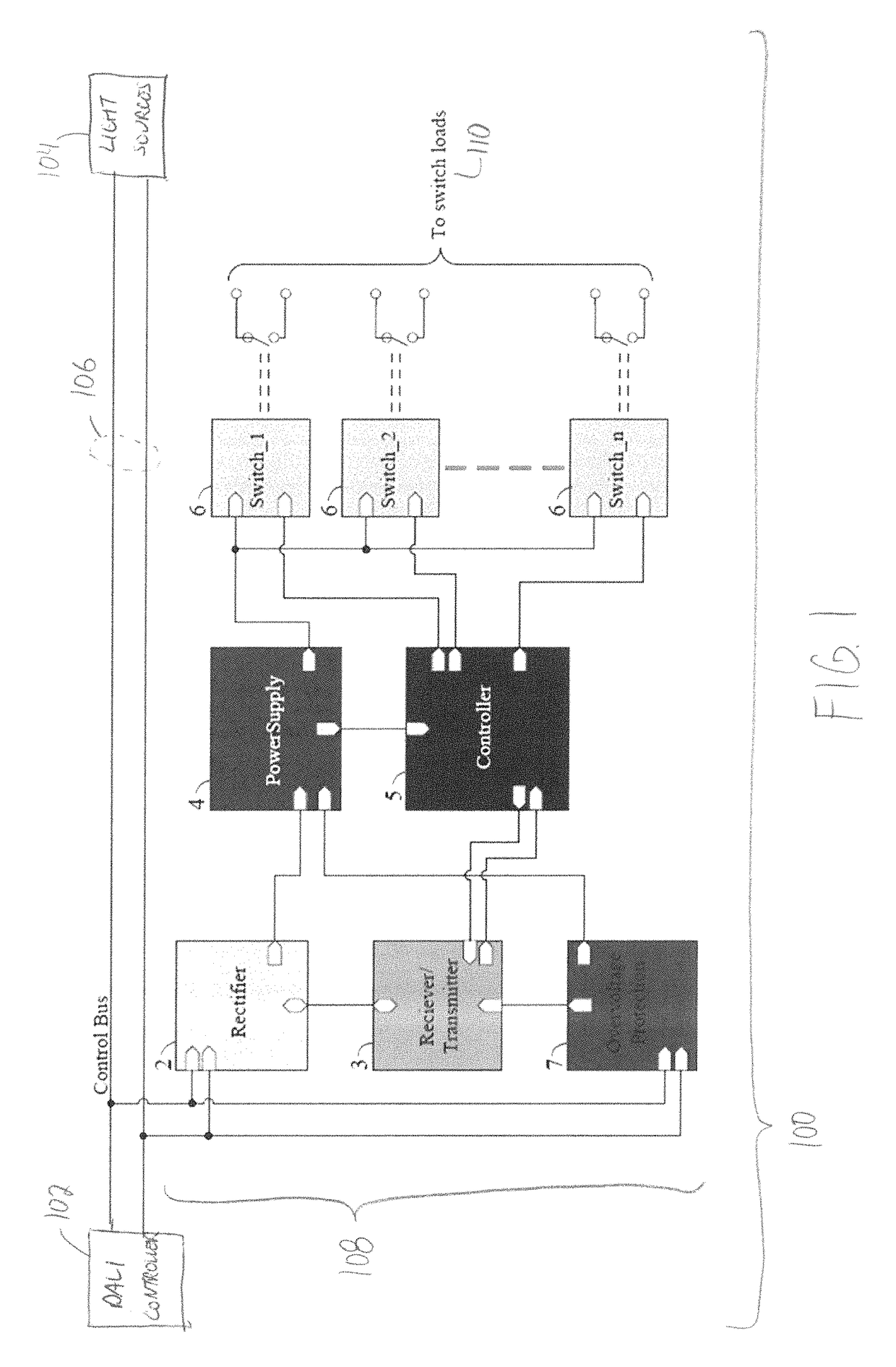

Power handling system and method

InactiveUS20170273158A1High power loadFirmly connectedElectric light circuit arrangementElectric powerElectric energyPower circuits

A power handling system of a digitally addressable lighting interface (DALI) system controls switches connected with a bus of the DALI system that powers lower power light sources. A power supply circuit receives energy conducted on the bus to the lower power light sources and conducts at least part of the energy to a capacitor. Electric energy is stored in the capacitor until the capacitor stores at least a designated threshold of input voltage of a controller. The capacitor powers the controller to close one or more switches using at least some of the stored electric energy.

Owner:GE LIGHTING SOLUTIONS LLC

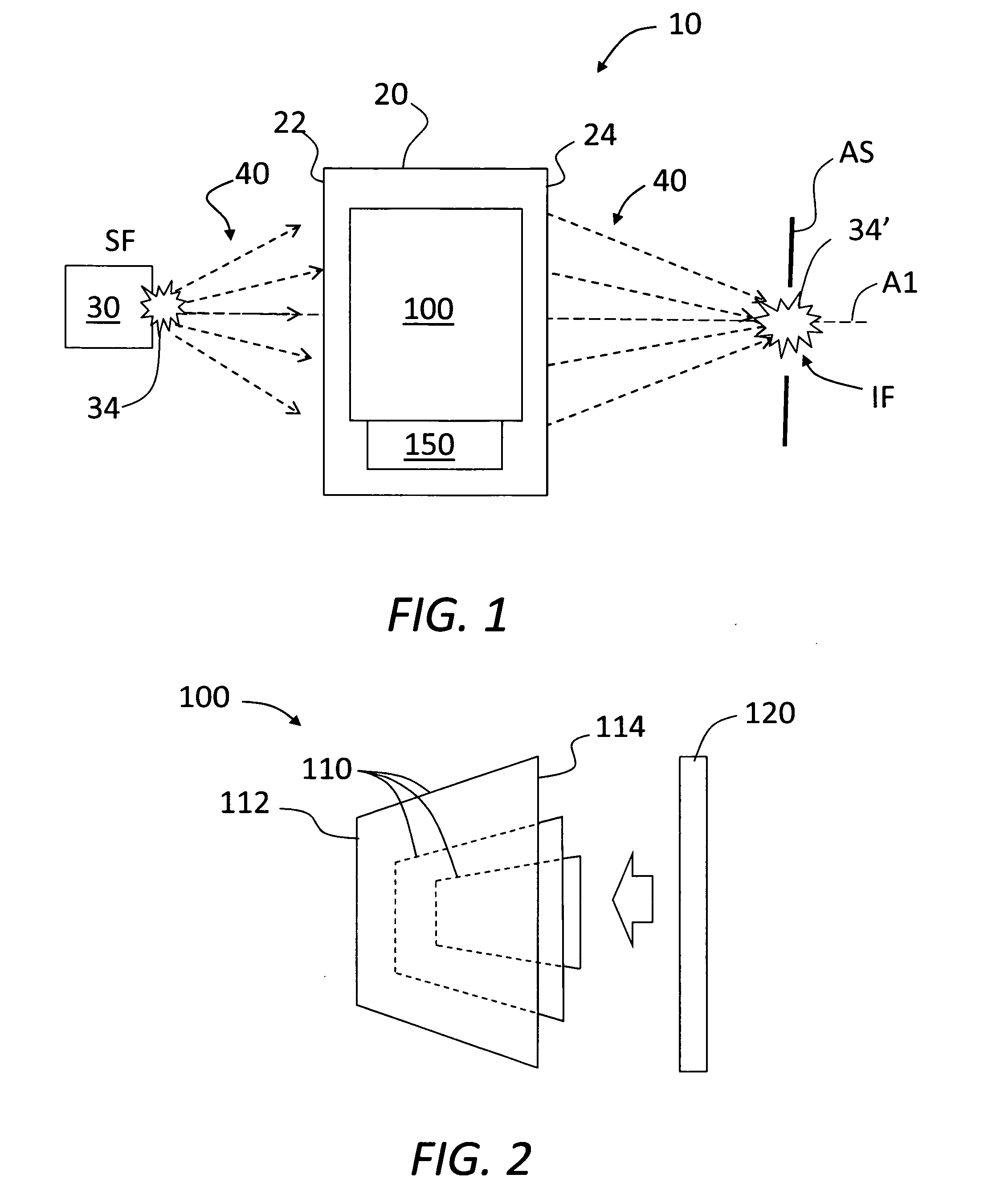

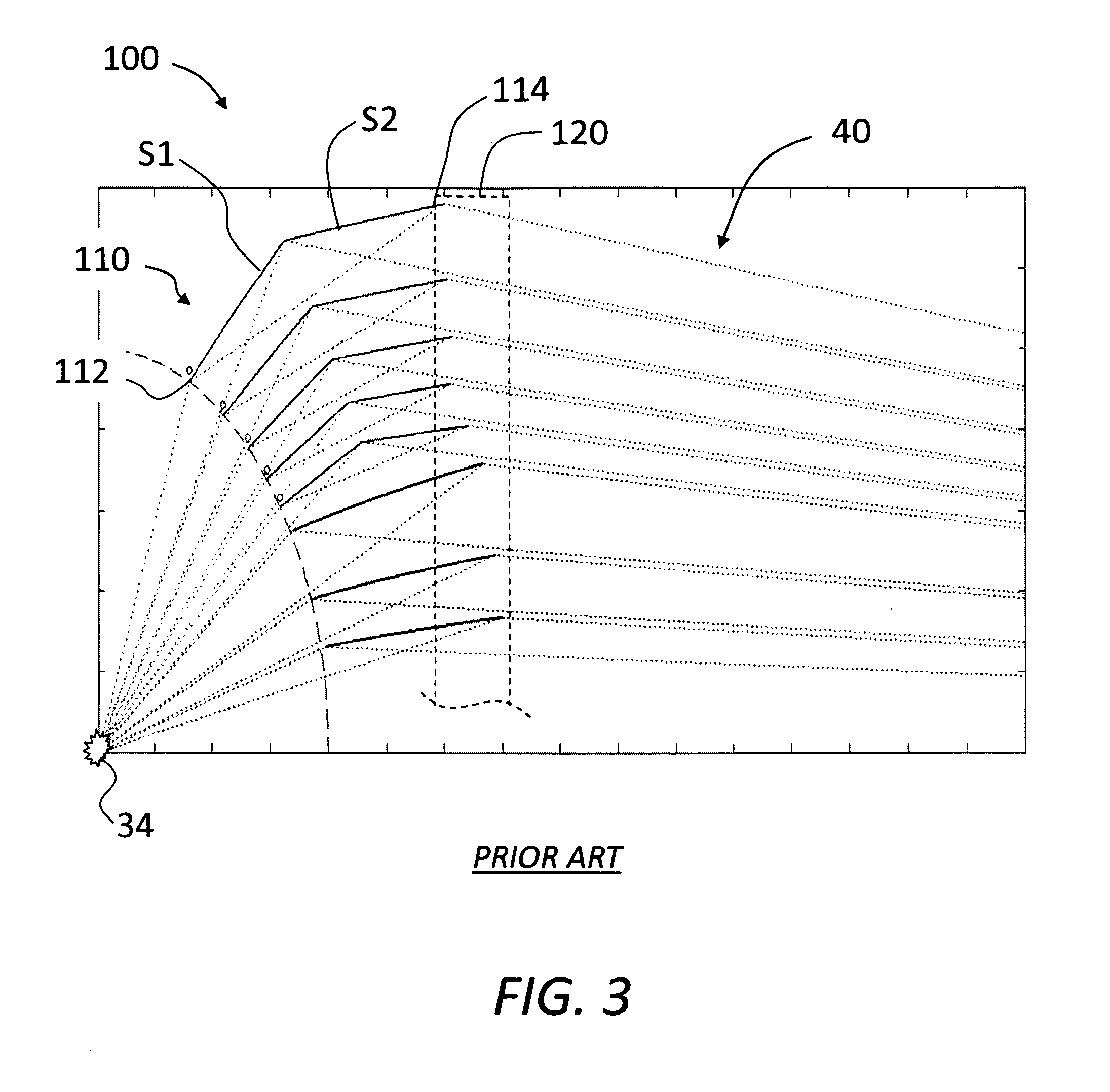

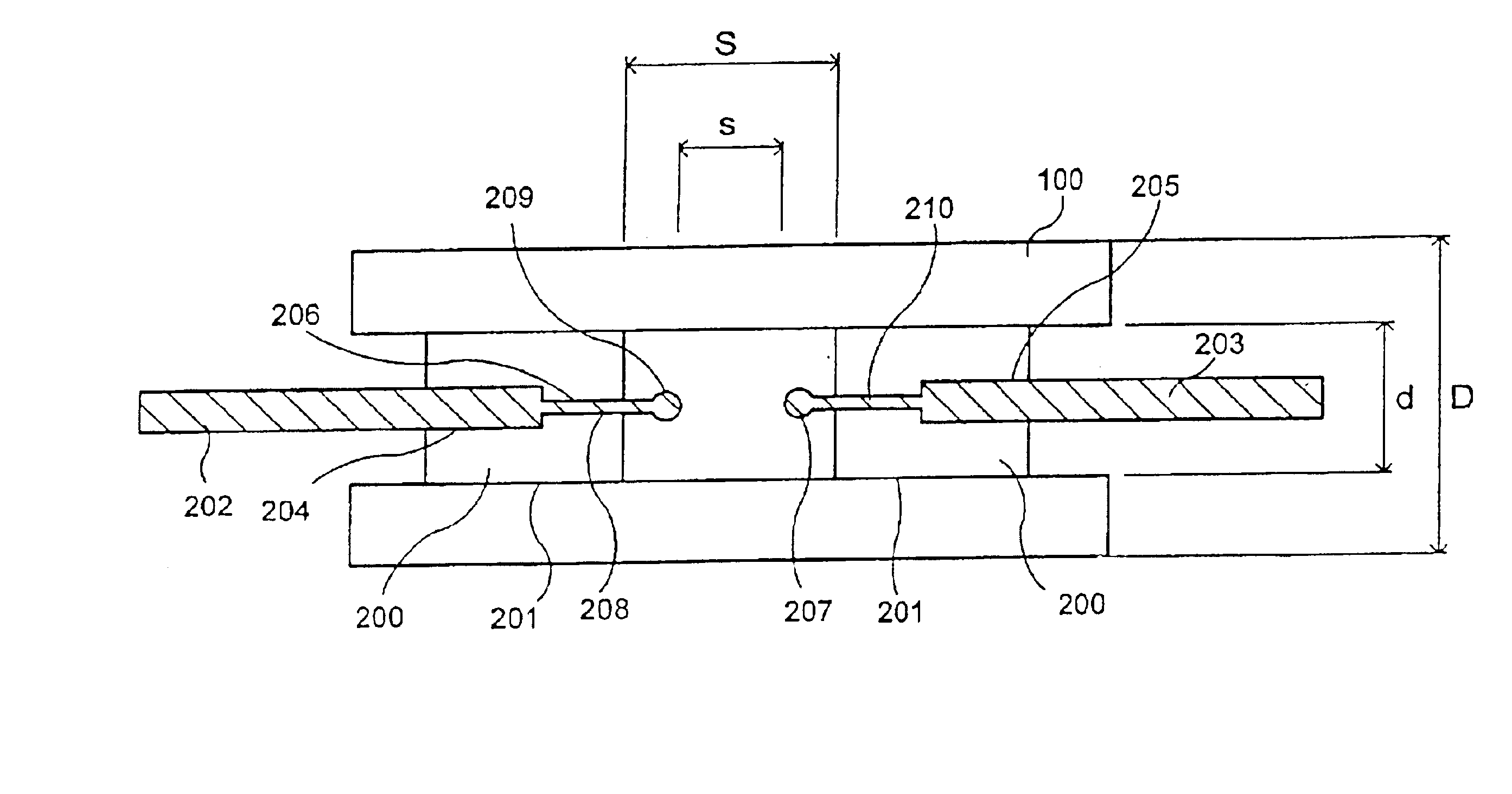

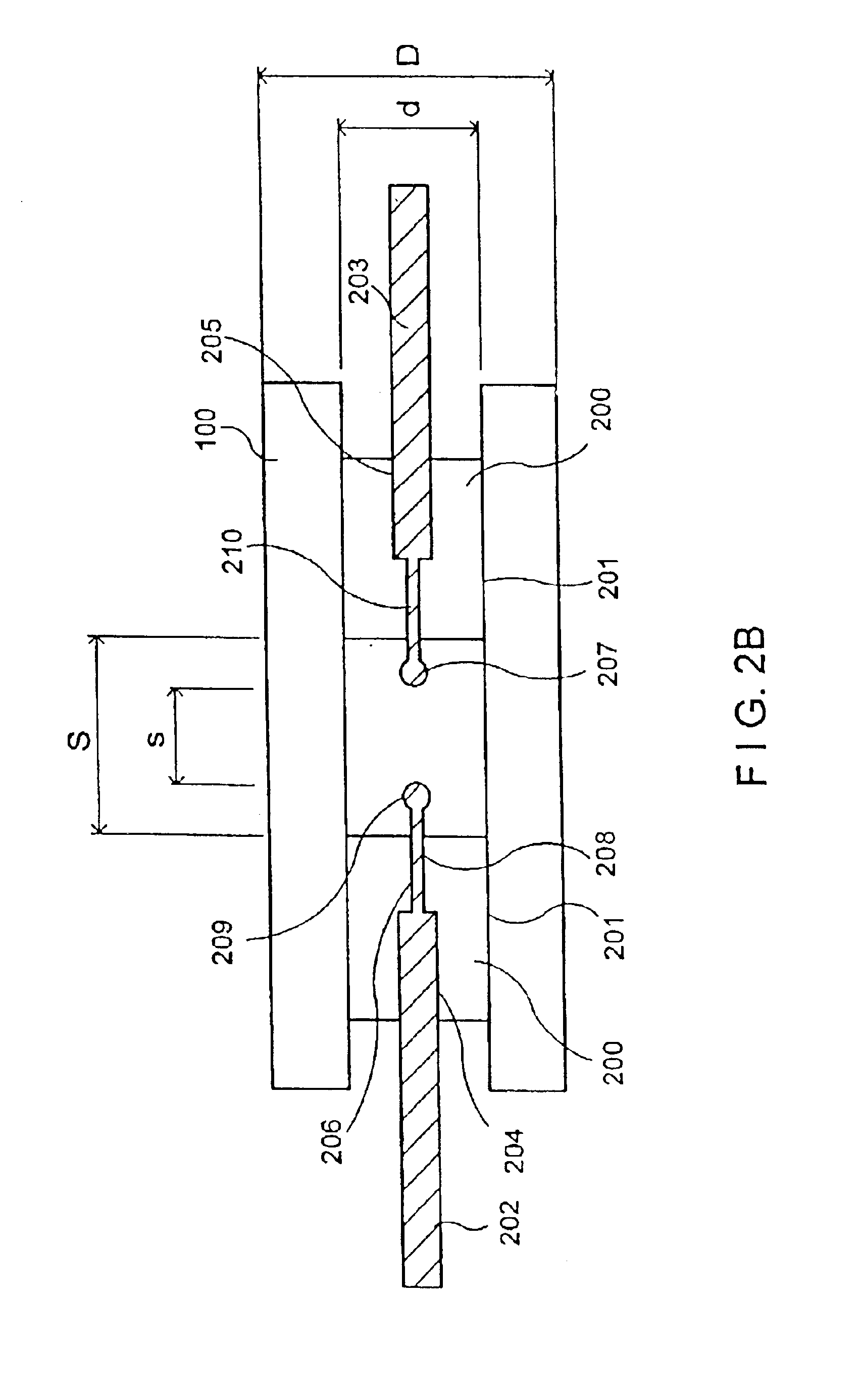

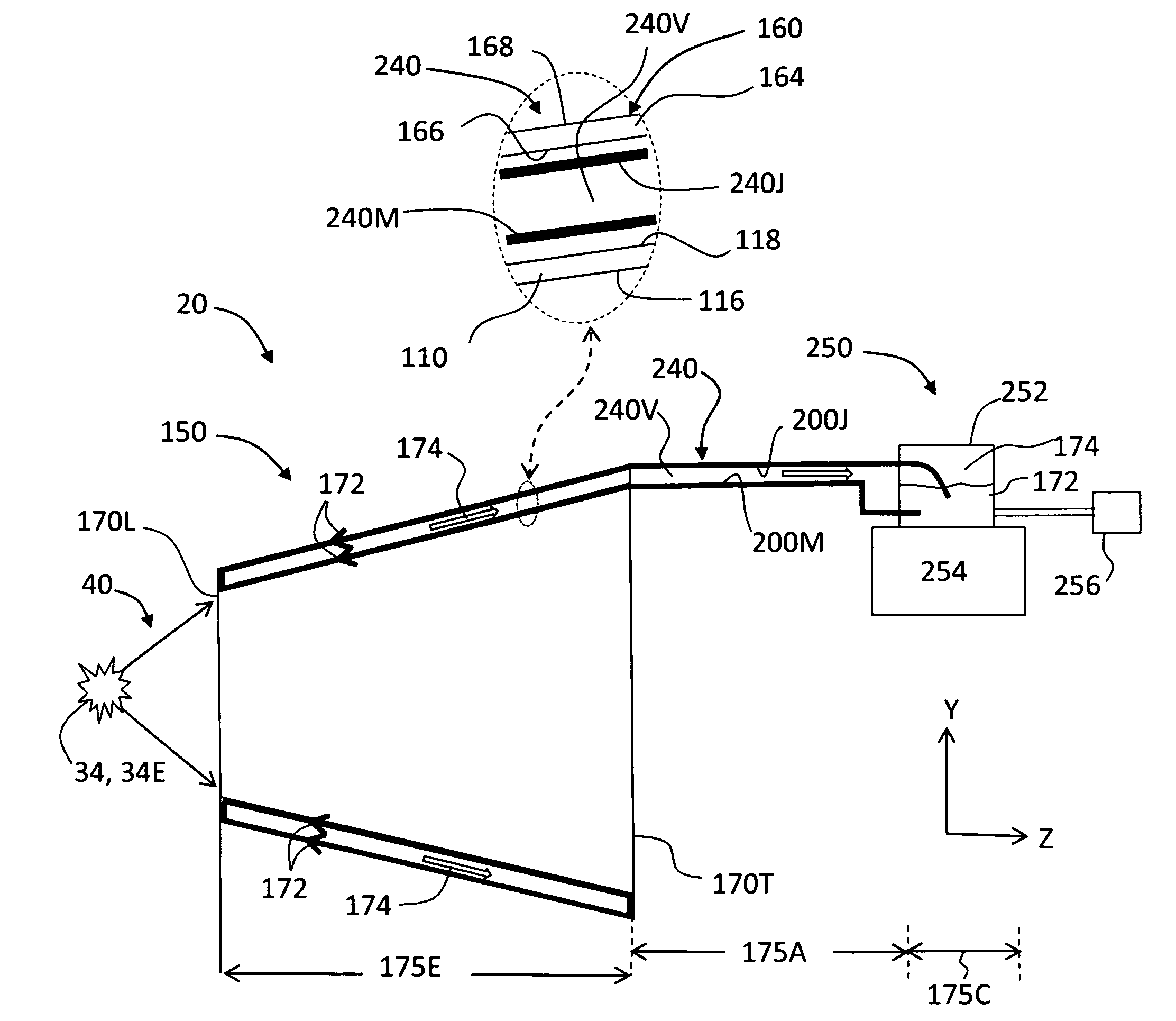

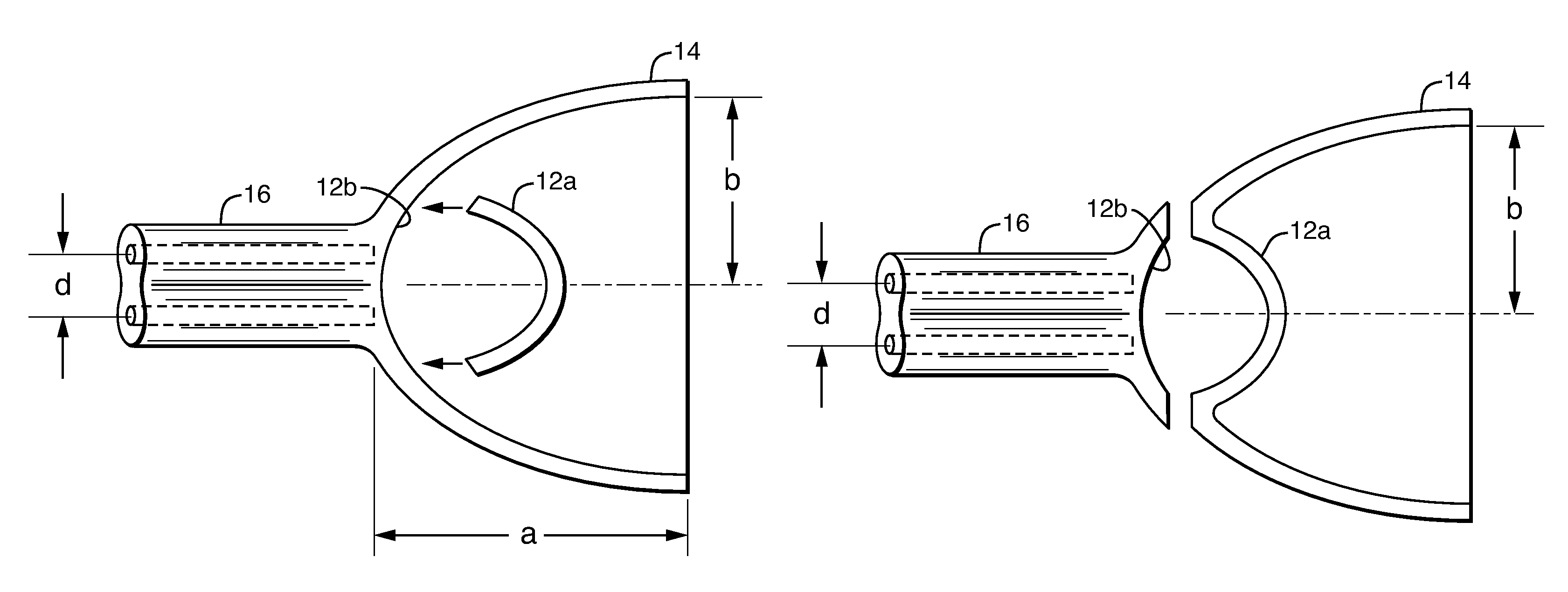

Thermal management systems, assemblies and methods for grazing incidence collectors for EUV lithography

ActiveUS20120212719A1Avoids spatial modulationEnables GIC mirror thermal stabilityMirrorsPhotomechanical apparatusLithographic artistEngineering

Systems, assemblies and methods for thermally managing a grazing incidence collector (GIC) for EUV lithography applications are disclosed. The GIC thermal management assembly includes a GIC mirror shell interfaced with a jacket to form a sealed chamber. An open cell, heat transfer (OCHT) material is disposed within the metal chamber and is thermally and mechanically bonded with the GIC mirror shell and jacket. A coolant is flowed in an azimuthally symmetric fashion through the OCHT material between input and output plenums to effectuate cooling when the GIC thermal management assembly is used in a GIC mirror system configured to receive and form collected EUV radiation from an EUV radiation source.

Owner:MEDIA LARIO SRL

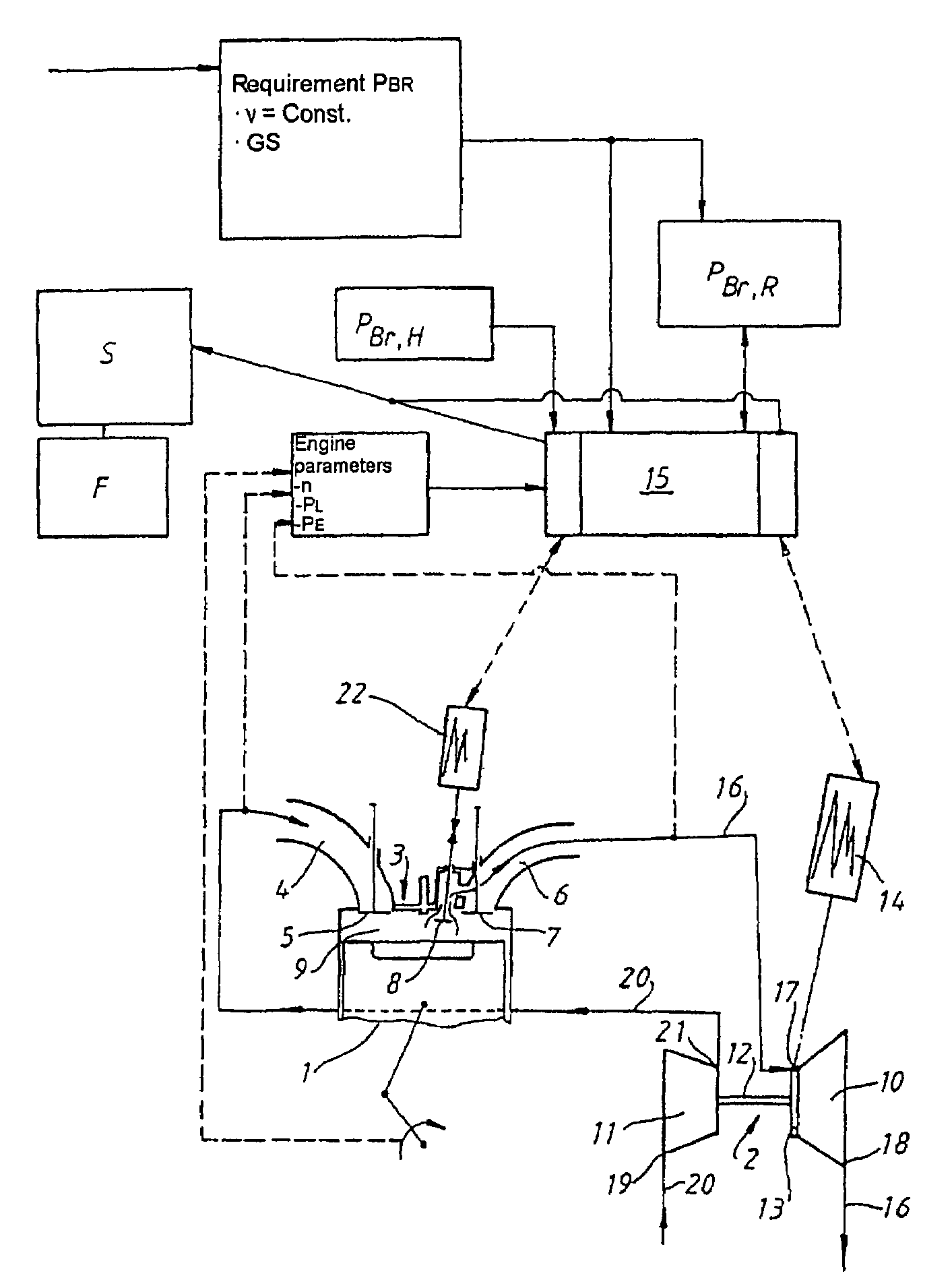

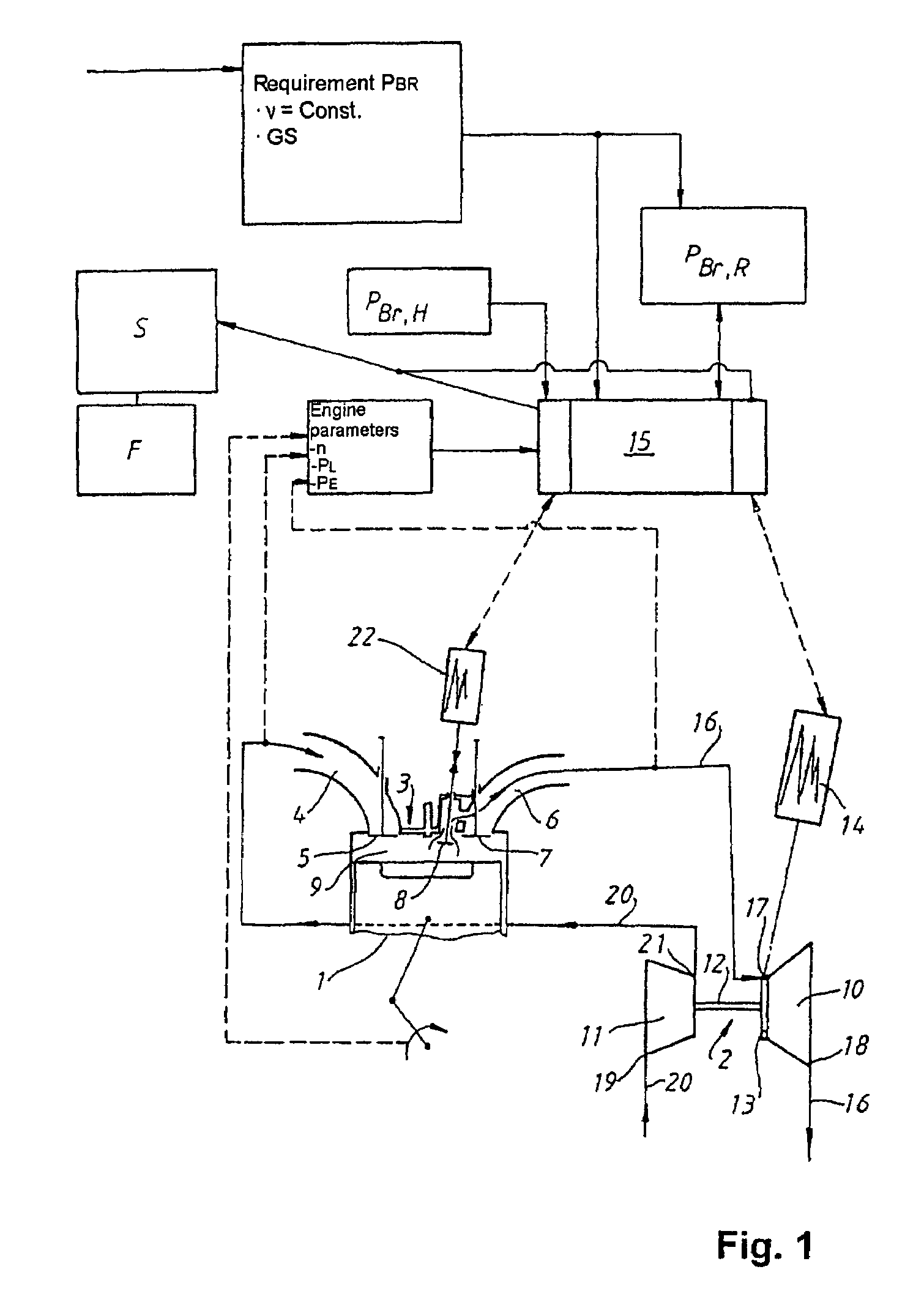

Engine braking method for a supercharged internal combustion engine

InactiveUS7409943B2Reduce loadImprove throughputElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

In an engine braking method for a supercharged internal combustion engine, wherein combustion air, which is under boost pressure and is supplied to the cylinders under the control of engine inlet and outlet valves, is compressed in the cylinders and is subsequently discharged into the exhaust tract, engine braking takes place in a two-stroke operating mode.

Owner:DAIMLER AG

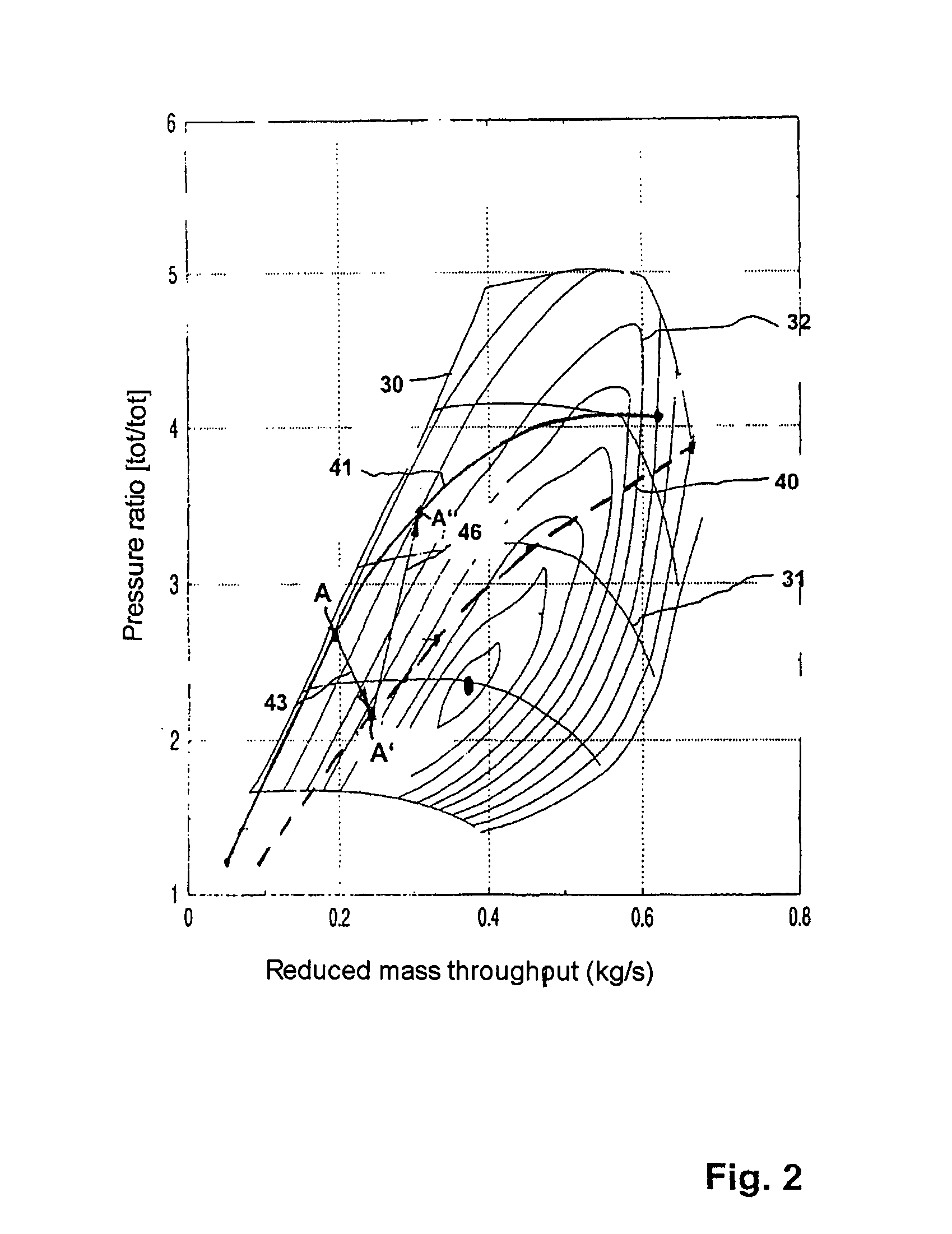

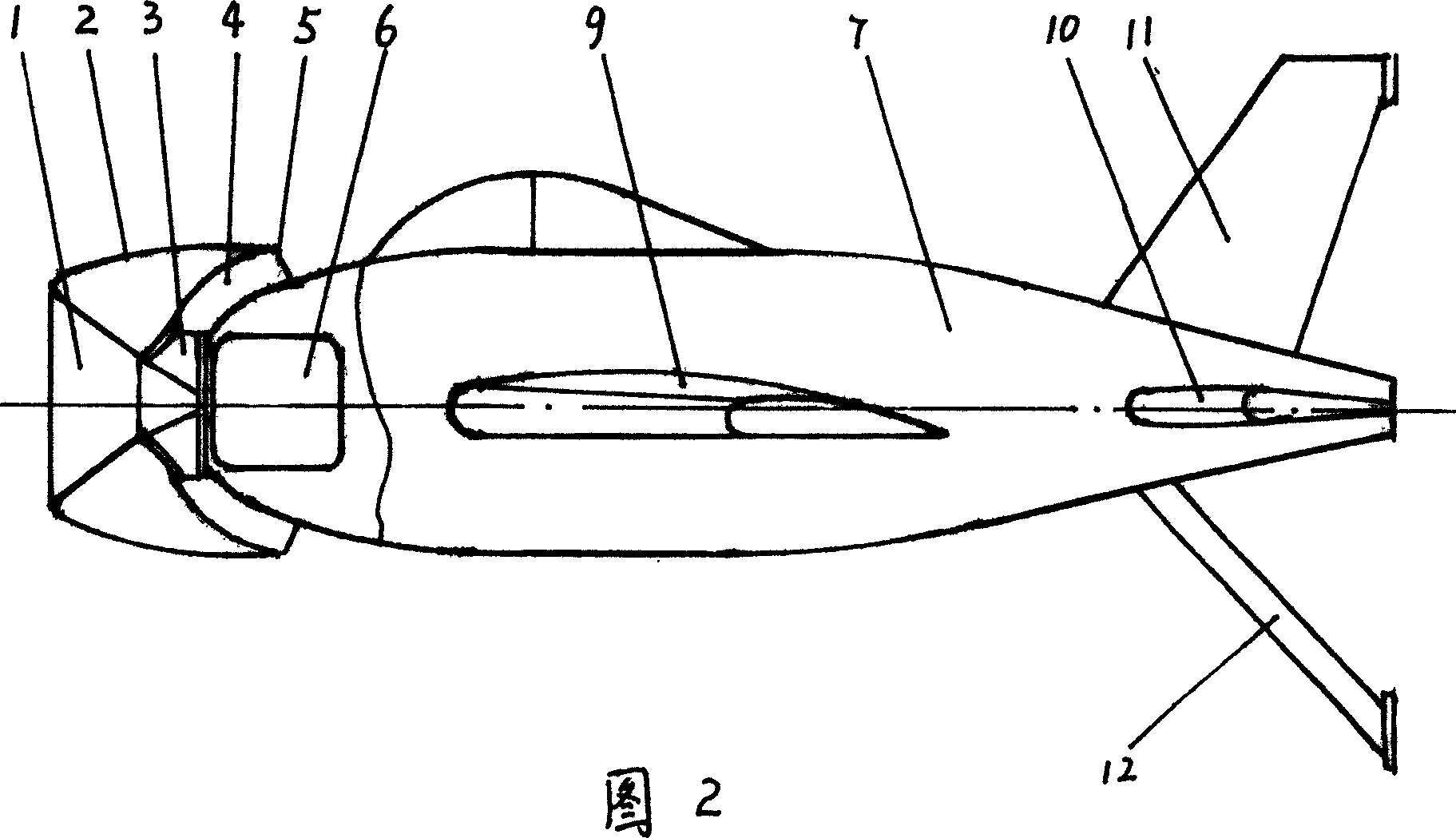

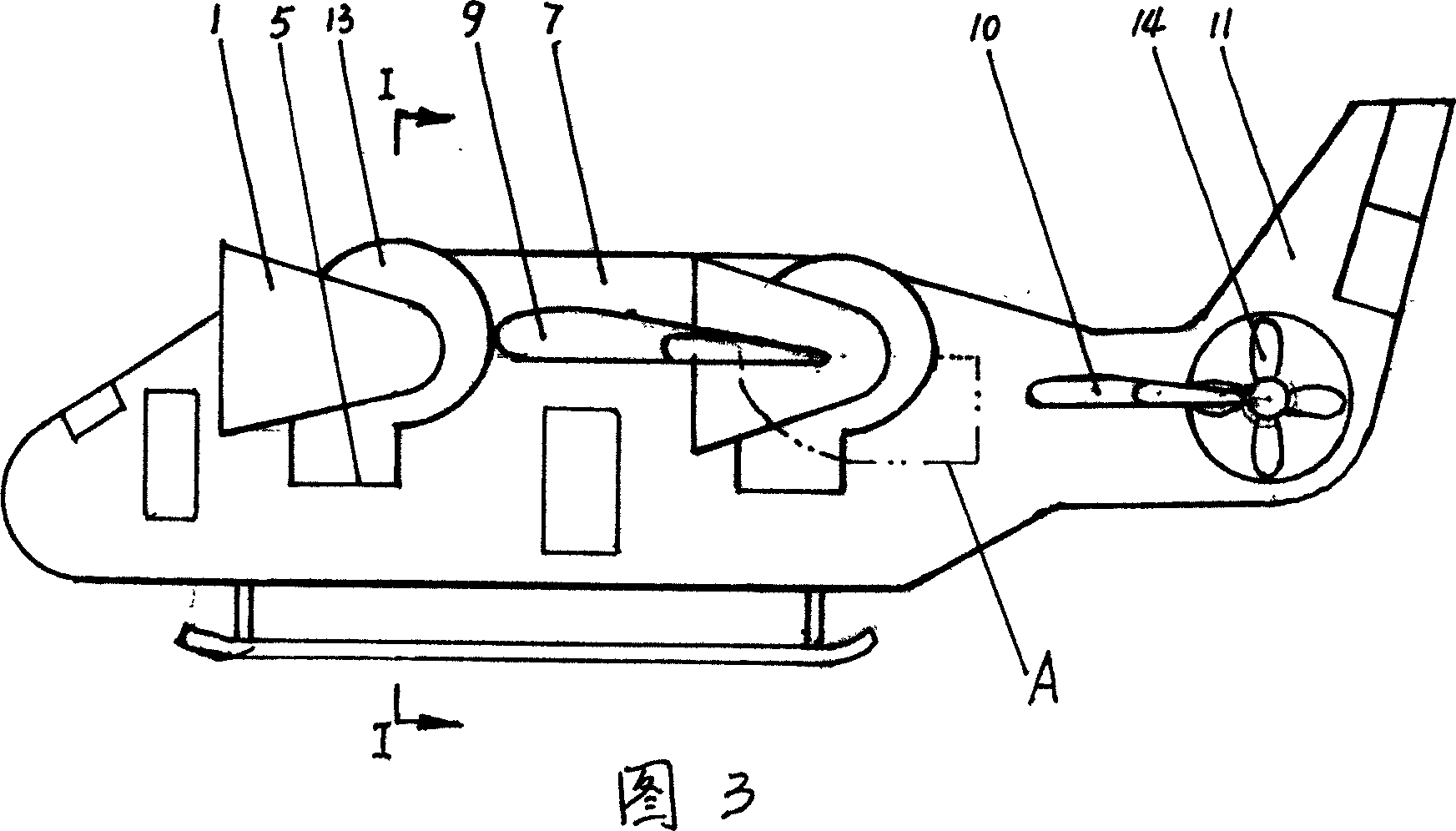

Aircraft with centrifugal fan capable of vertically taking off and landing

InactiveCN1944188AHigh power loadStable working fluid flowVertical landing/take-off aircraftsFlight vehicleCentrifugal fan

The aircraft with centrifugal fan for vertically taking off and landing has one centrifugal fan set in the front part or upper part. The centrifugal fan is driven with the engine to produce air work medium with dynamic pressure energy to push the aircraft to take off or land vertically, to hover or to fly forward.

Owner:王新云

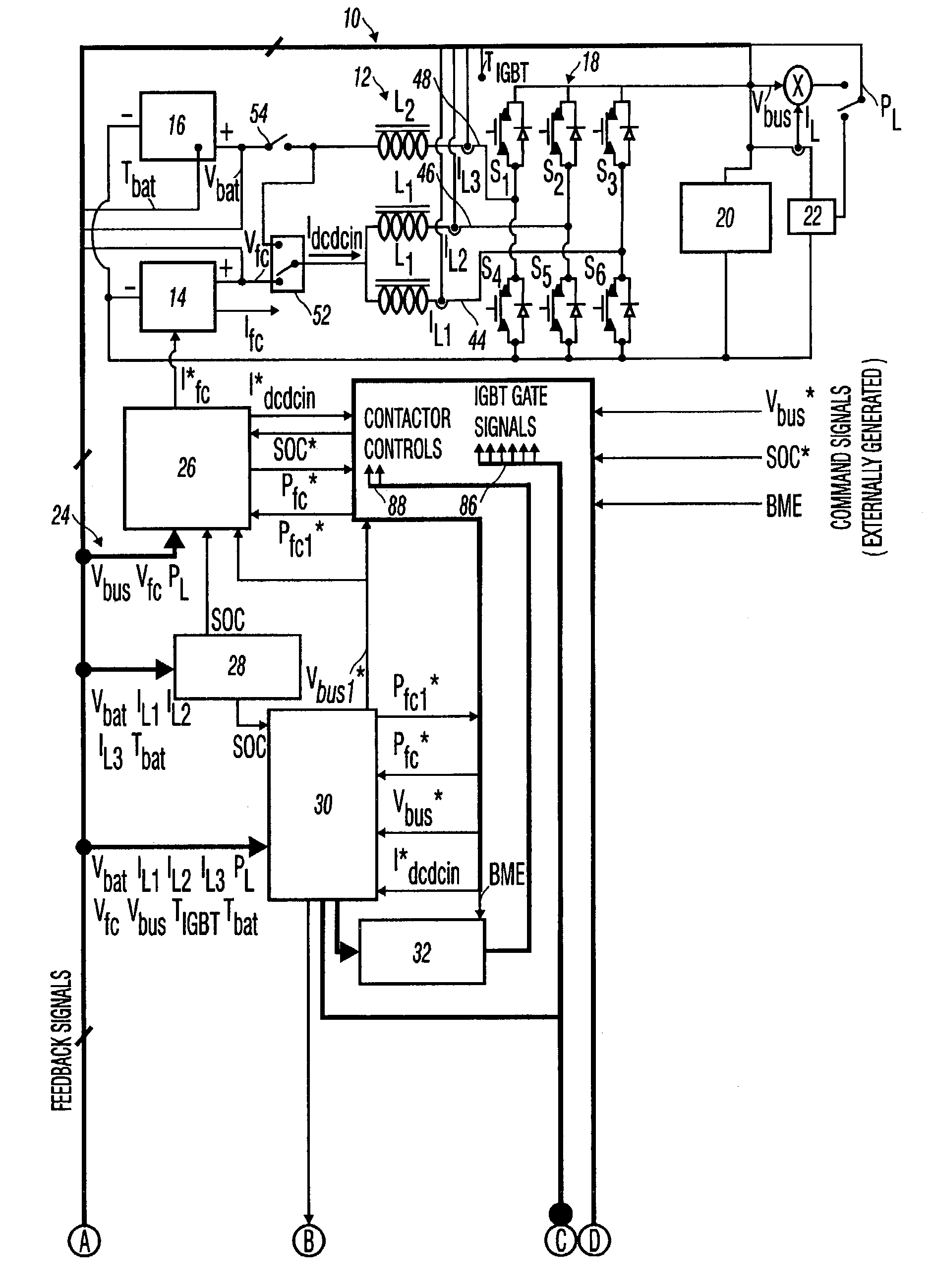

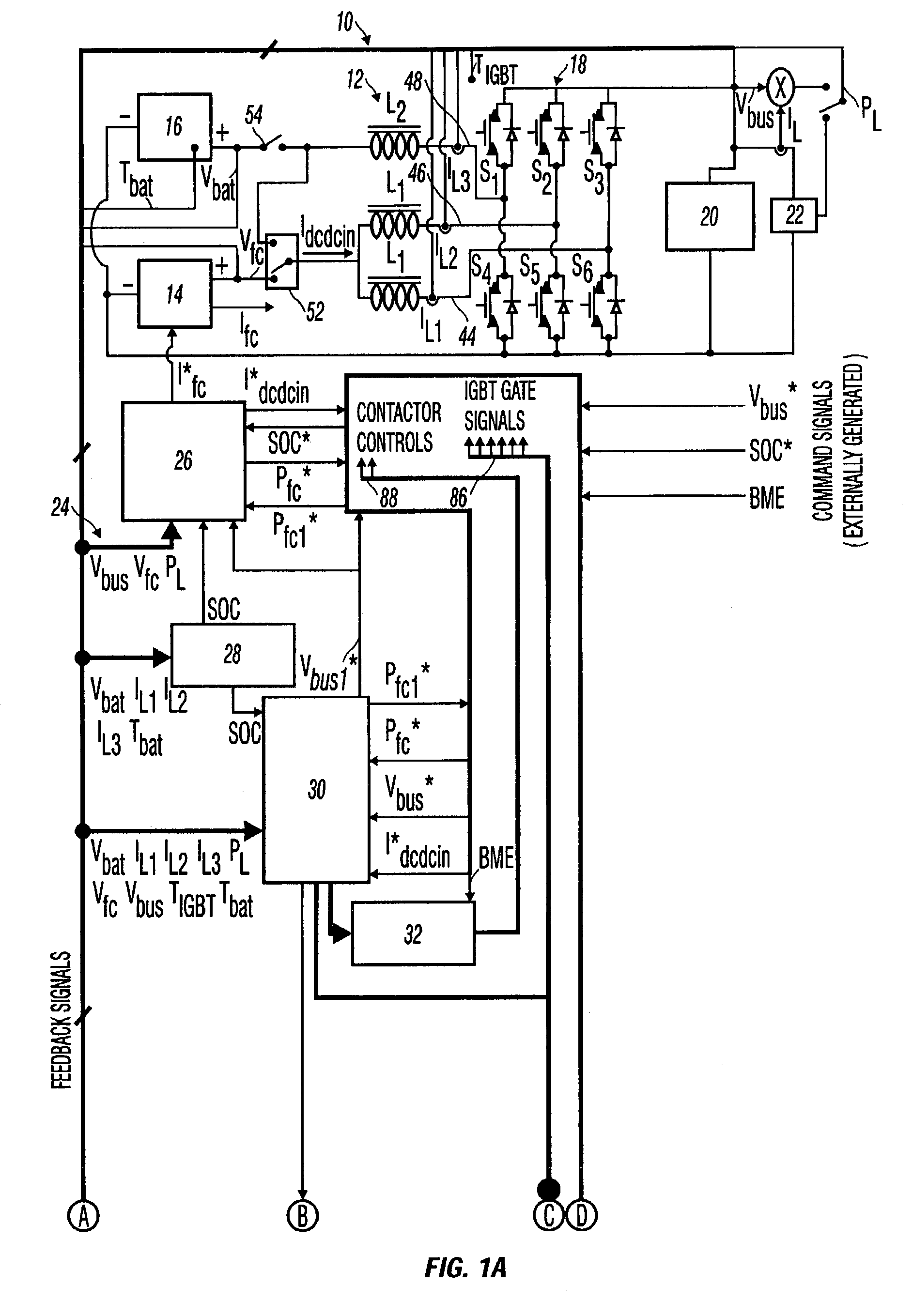

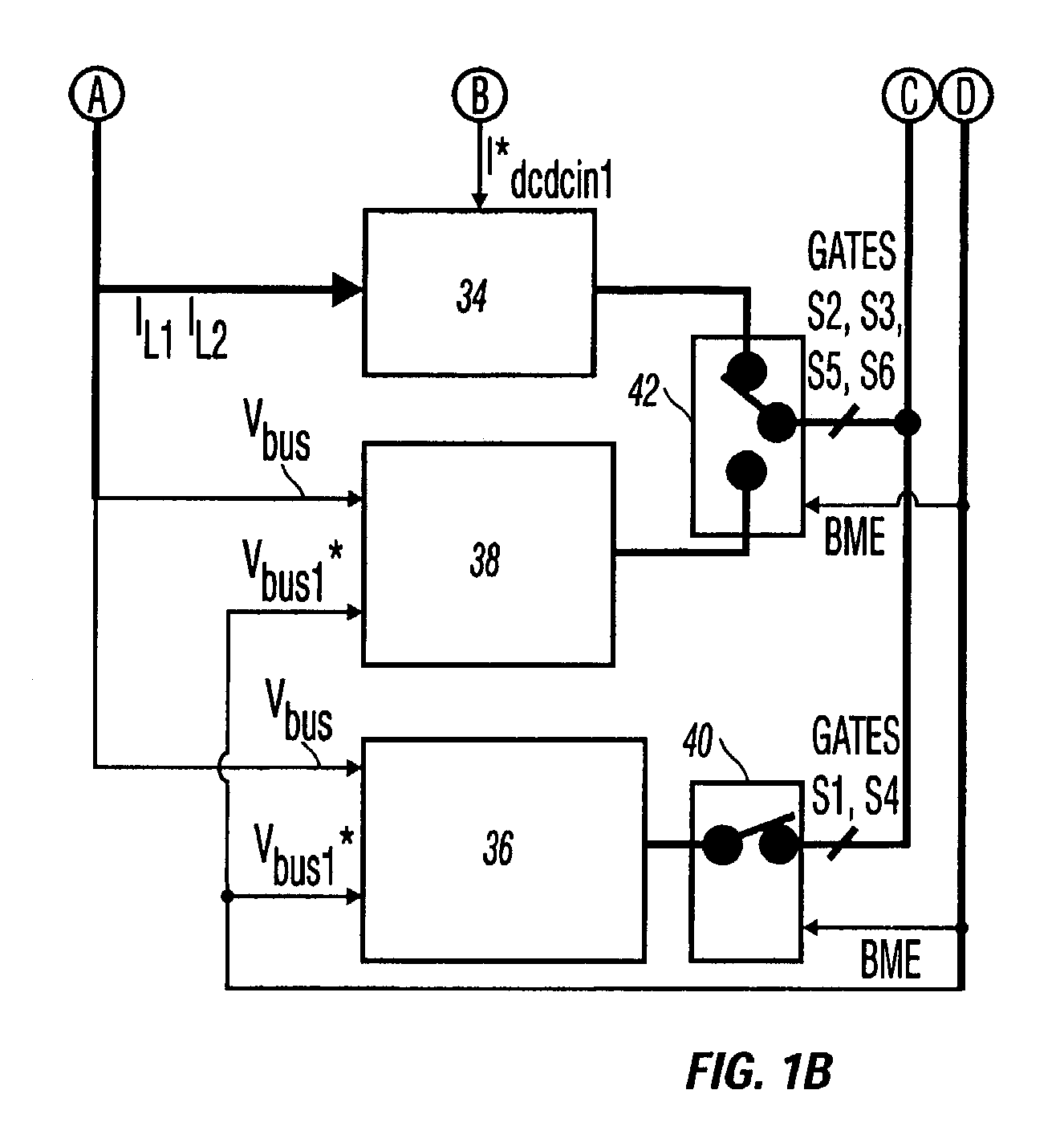

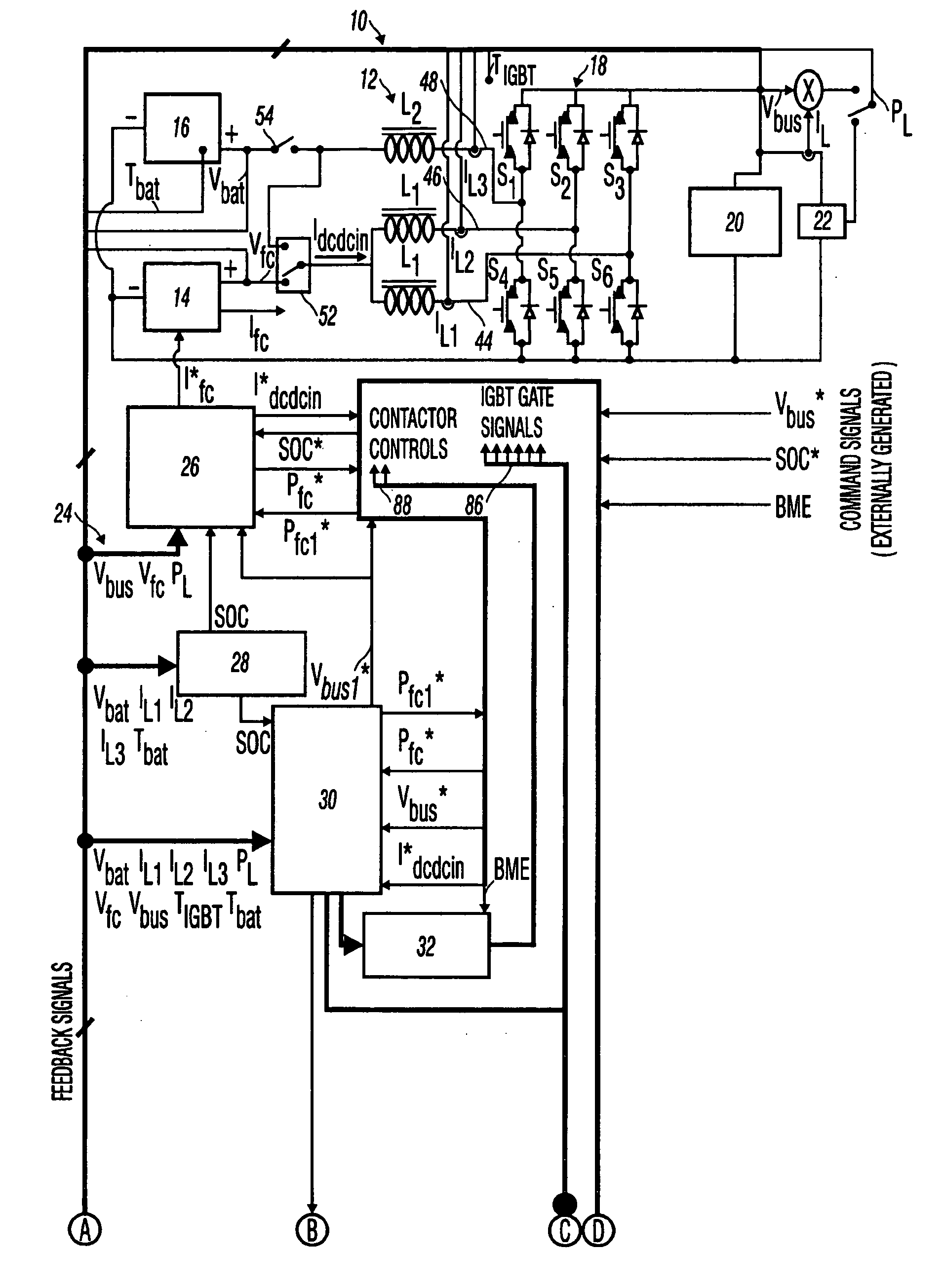

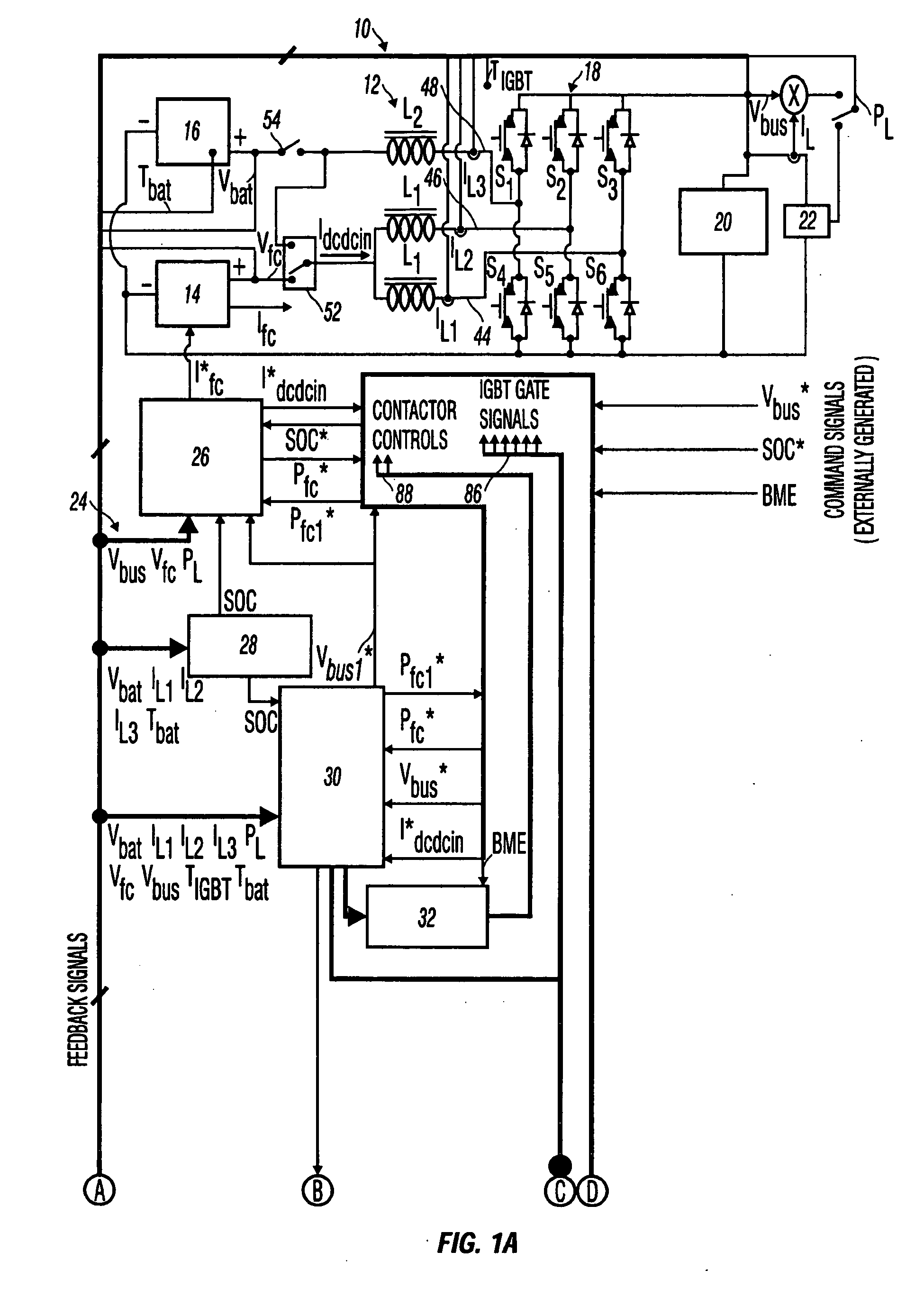

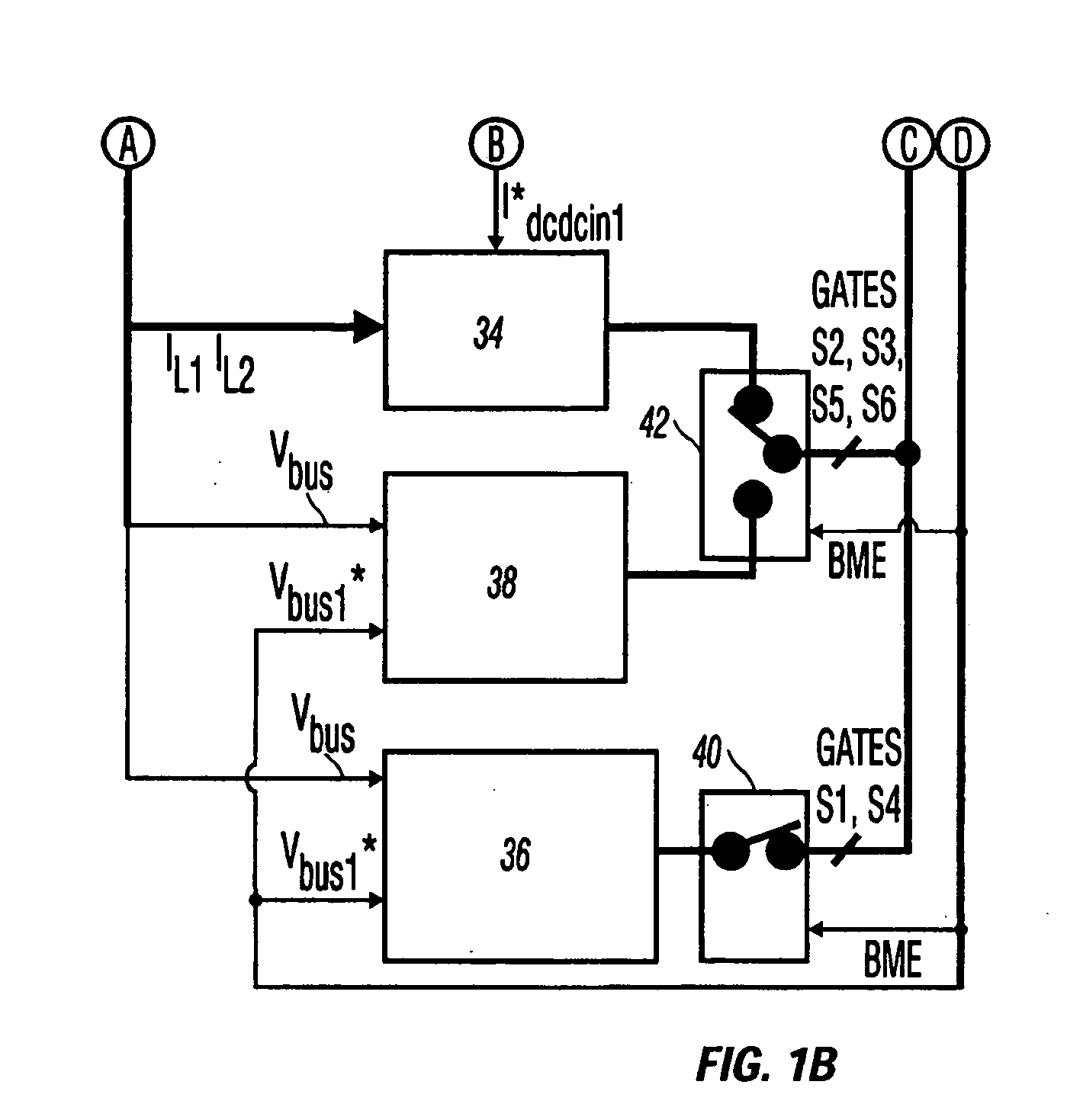

Direct current/direct current converter for a fuel cell system

ActiveUS7014928B2System cost topologyIncrease power conversion capabilityMechanical power/torque controlLevel controlFuel cellsBoost converter

Fuel cell systems and control methods including a fuel cell and a second energy source, such as a battery that is adapted to supplement the fuel cell. In addition, the fuel cell system utilizes a single bipolar switching module, such as an IGBT six pack module that is configured to implement a DC / DC converter, such as a DC / DC boost converter, for both the fuel cell and the battery. The fuel cell system also makes use of a controller that is configured to control either or both of input current and output voltage of the DC / DC converter.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

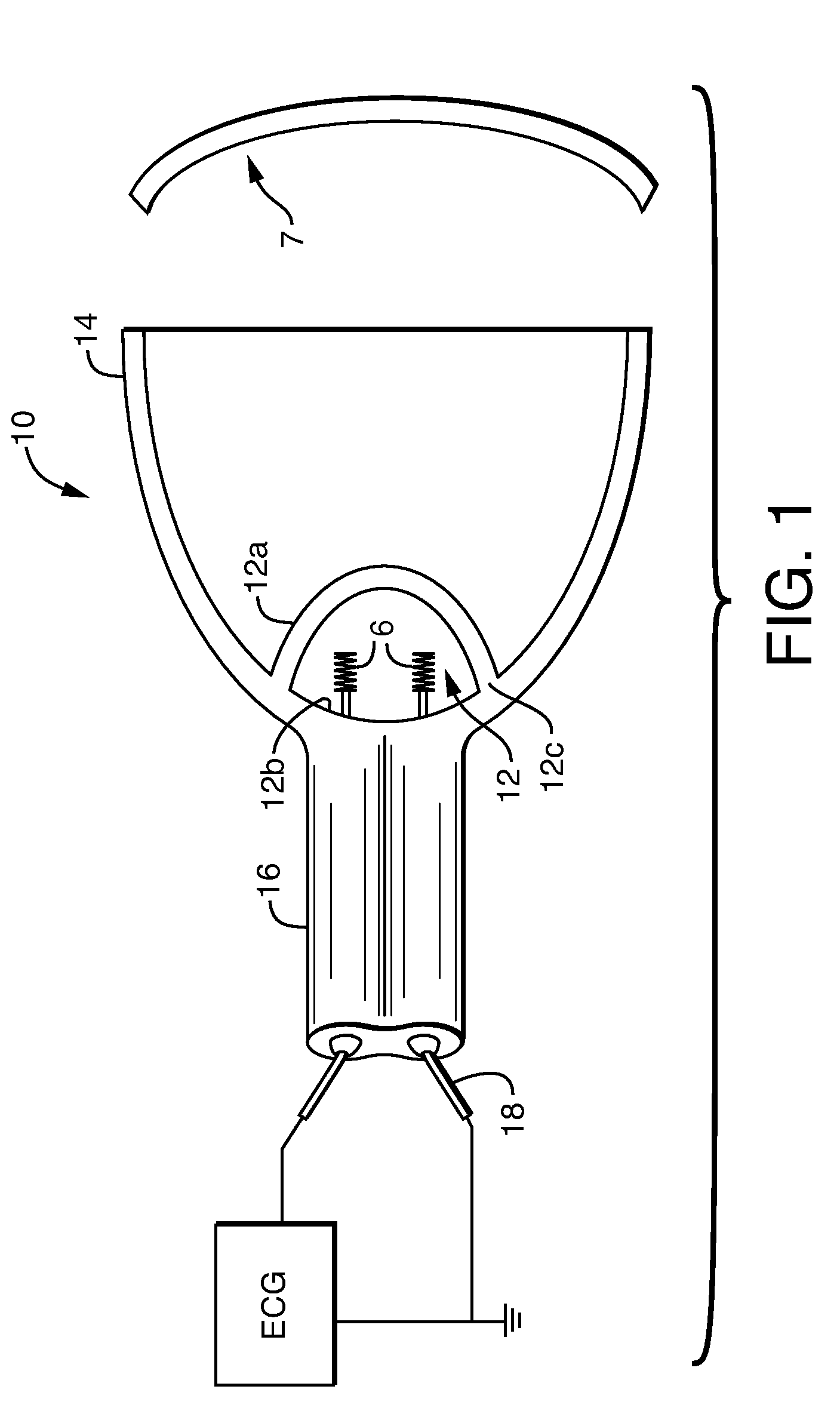

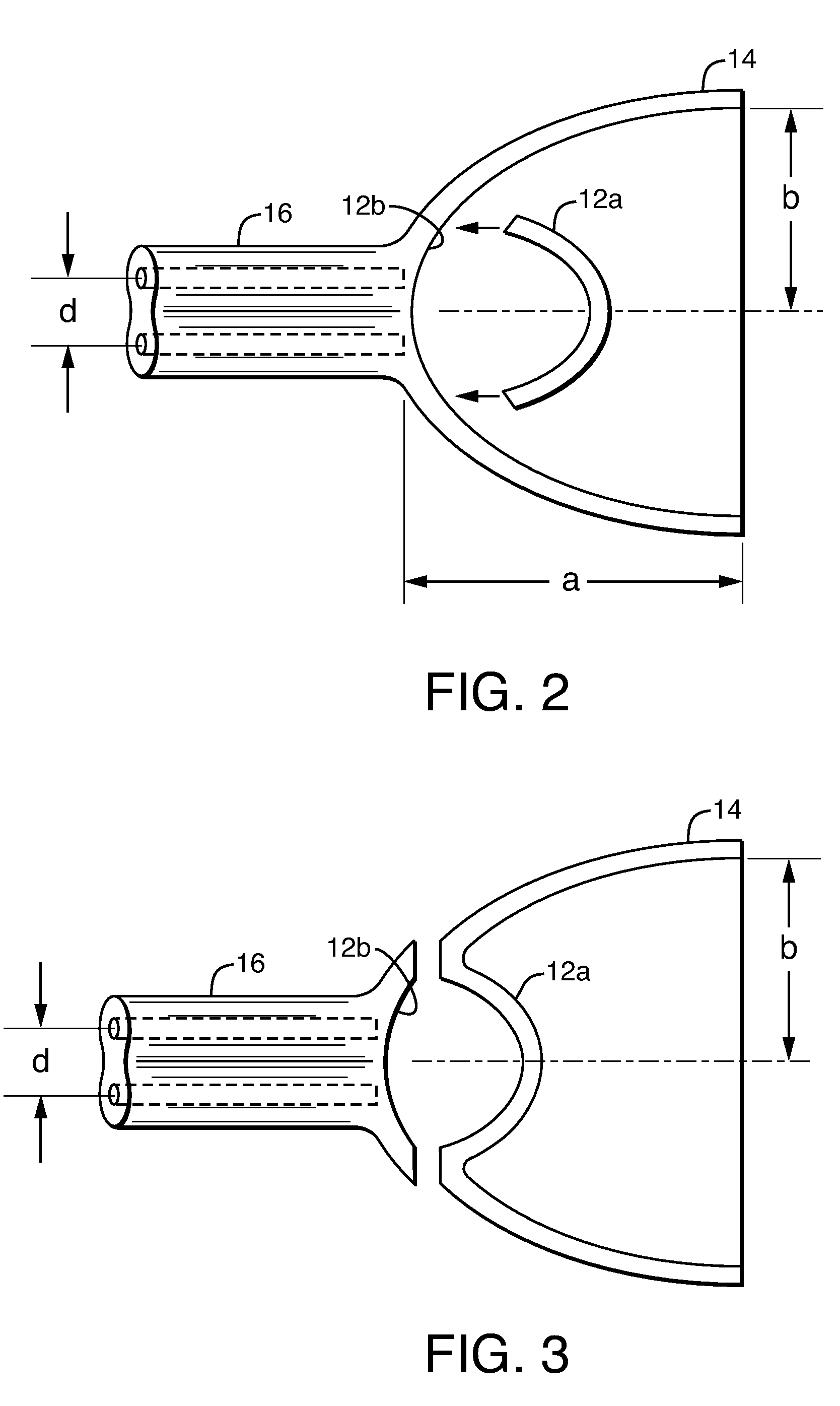

High intensity discharge lamp with single crystal sapphire envelope

InactiveUS6992445B2Improve efficacyImprove lifetimeElectroluminescent light sourcesDischarge tube main electrodesThree dimensional shapeHigh intensity

Described is a high intensity discharge lamp including a lamp bulb envelope, first and second electrodes, a seal and a fill situated within the lamp bulb envelope. The lamp bulb envelope is composed of single crystal sapphire tubing. The lamp bulb envelope includes end portions and a central portion, the central portion having a greater diameter than the end portions. The end portions may be a cylindrical tube shape and the central portion is a smooth three-dimensional shape. The first and second electrodes extend through opposite ends of the lamp bulb envelope so that at least a portion of each of the electrodes is situated within the lamp bulb envelope. The seal seals each of the first and second electrodes to an inside wall of the corresponding end of the lamp bulb envelope. A voltage is applied to the first and second electrodes to generate an arc plasma therebetween.

Owner:EASTLUND SCI ENTERPRISES +1

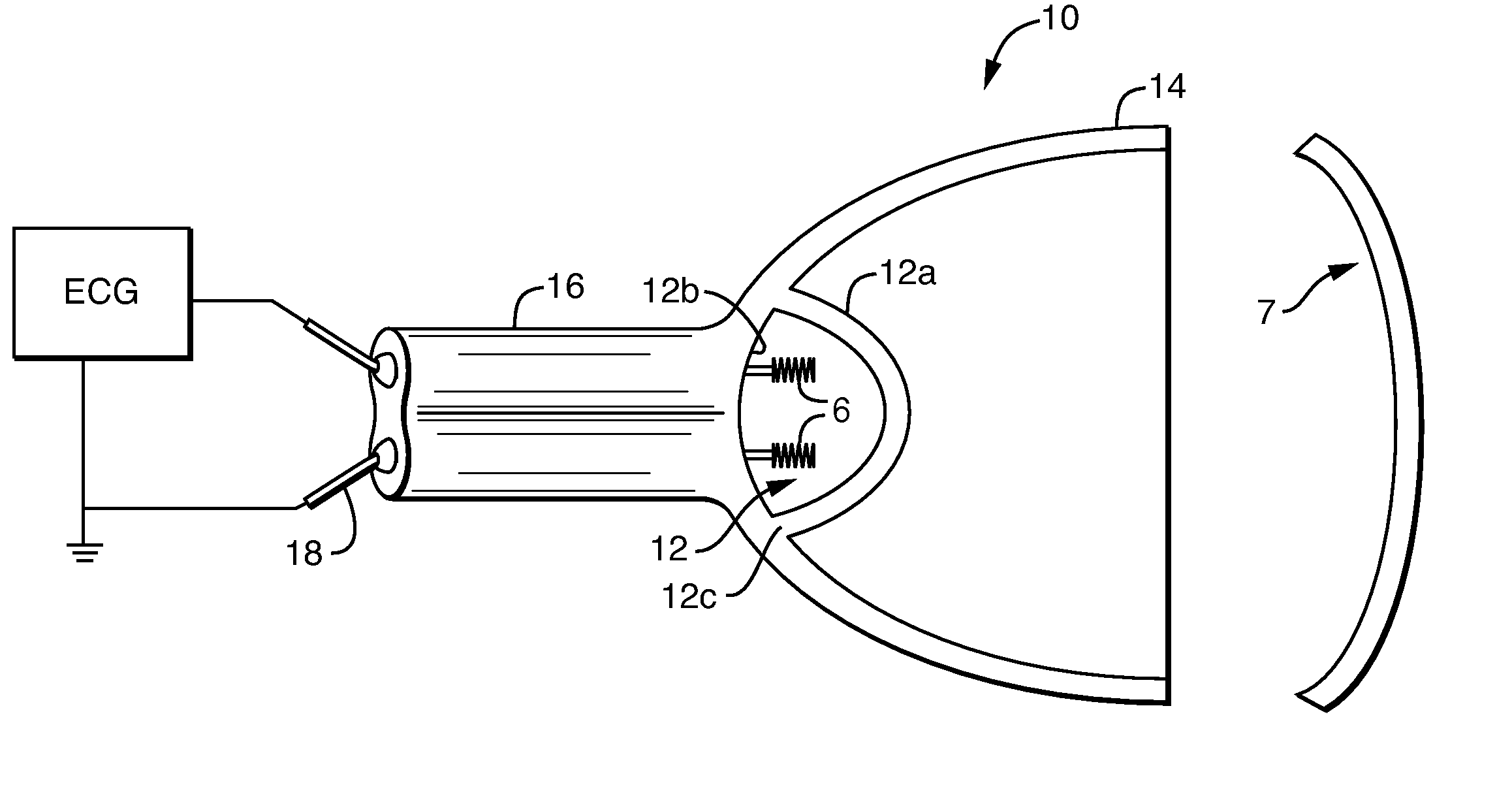

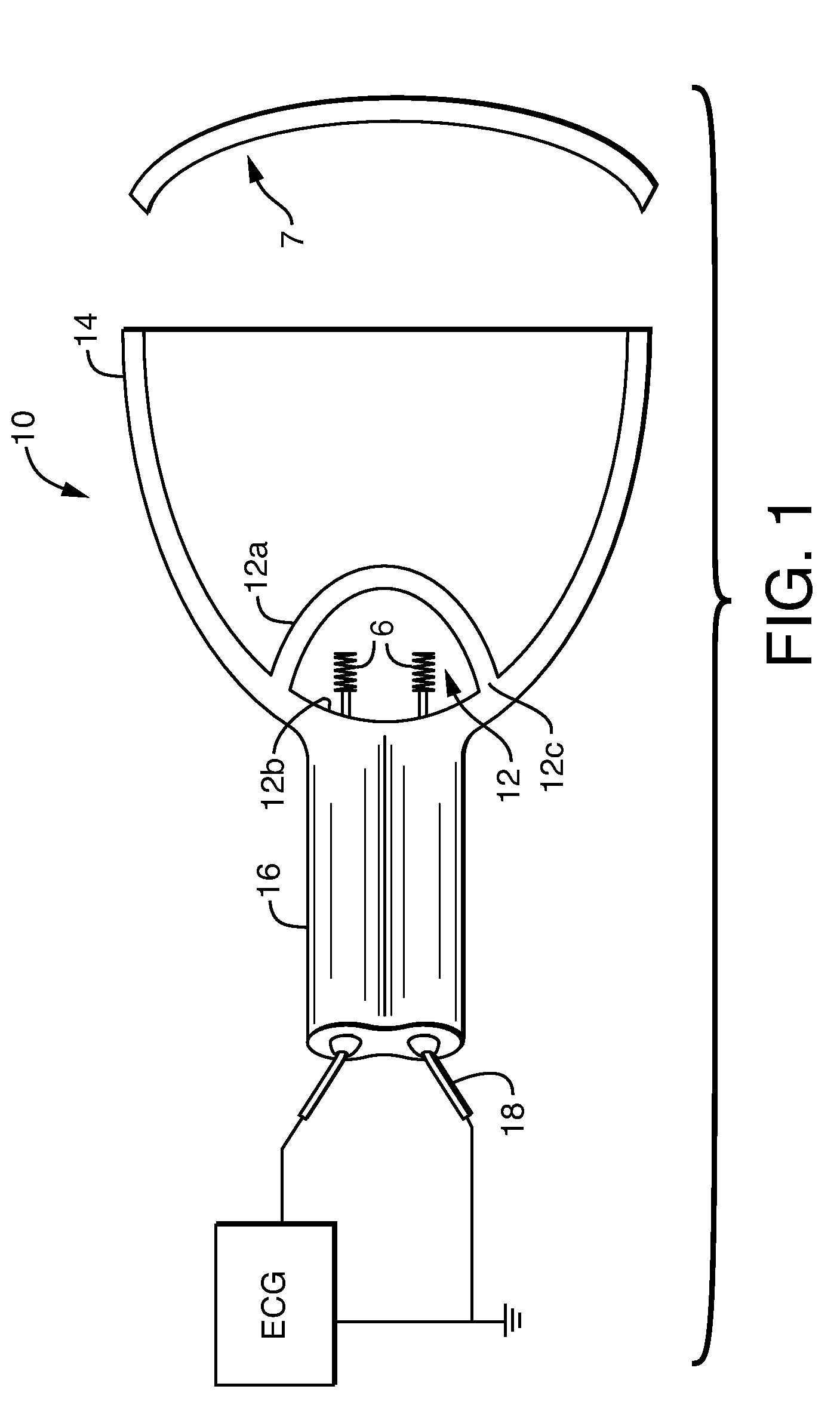

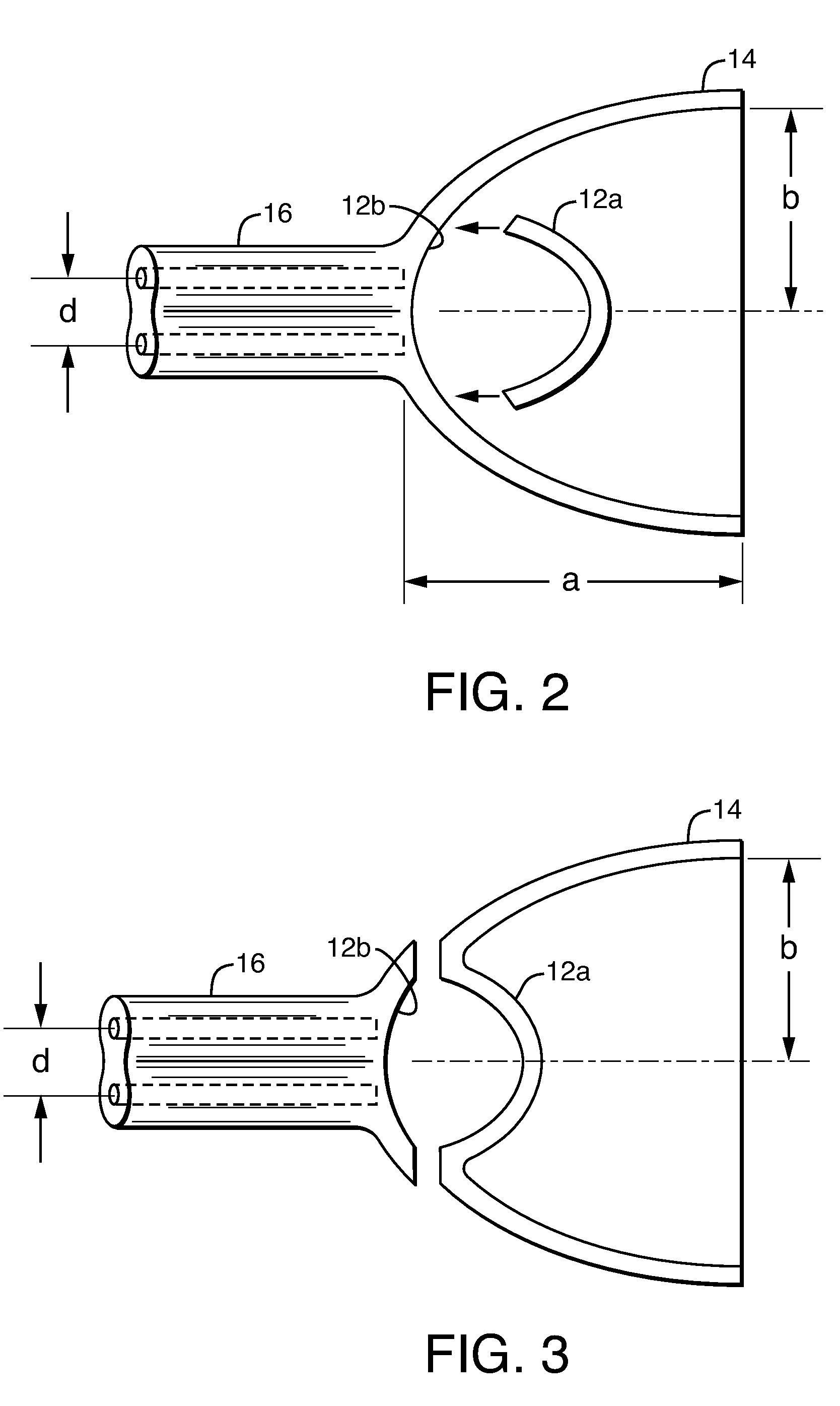

Ceramic discharge lamp with integral burner and reflector

InactiveUS20090284153A1High power loadElectroluminescent light sourcesSolid cathode detailsFiberCombustor

A ceramic discharge lamp and a method of making the lamp includes a ceramic discharge chamber with two concave parts that are attached to each other at a seam, and a ceramic reflector directly attached to an exterior surface of the discharge chamber at the seam, or directly attached to a ceramic capillary that is attached to one of the two concave parts. The lamp finds particular application where focused light is required, such as injection of light into a fiber optic device. The lamp can be very small and has an advantage that the discharge chamber is isolated from the reflective surfaces so that the optically active parts of the reflector are not covered with salt from the preferred metal halide lamp fill.

Owner:OSRAM SYLVANIA INC

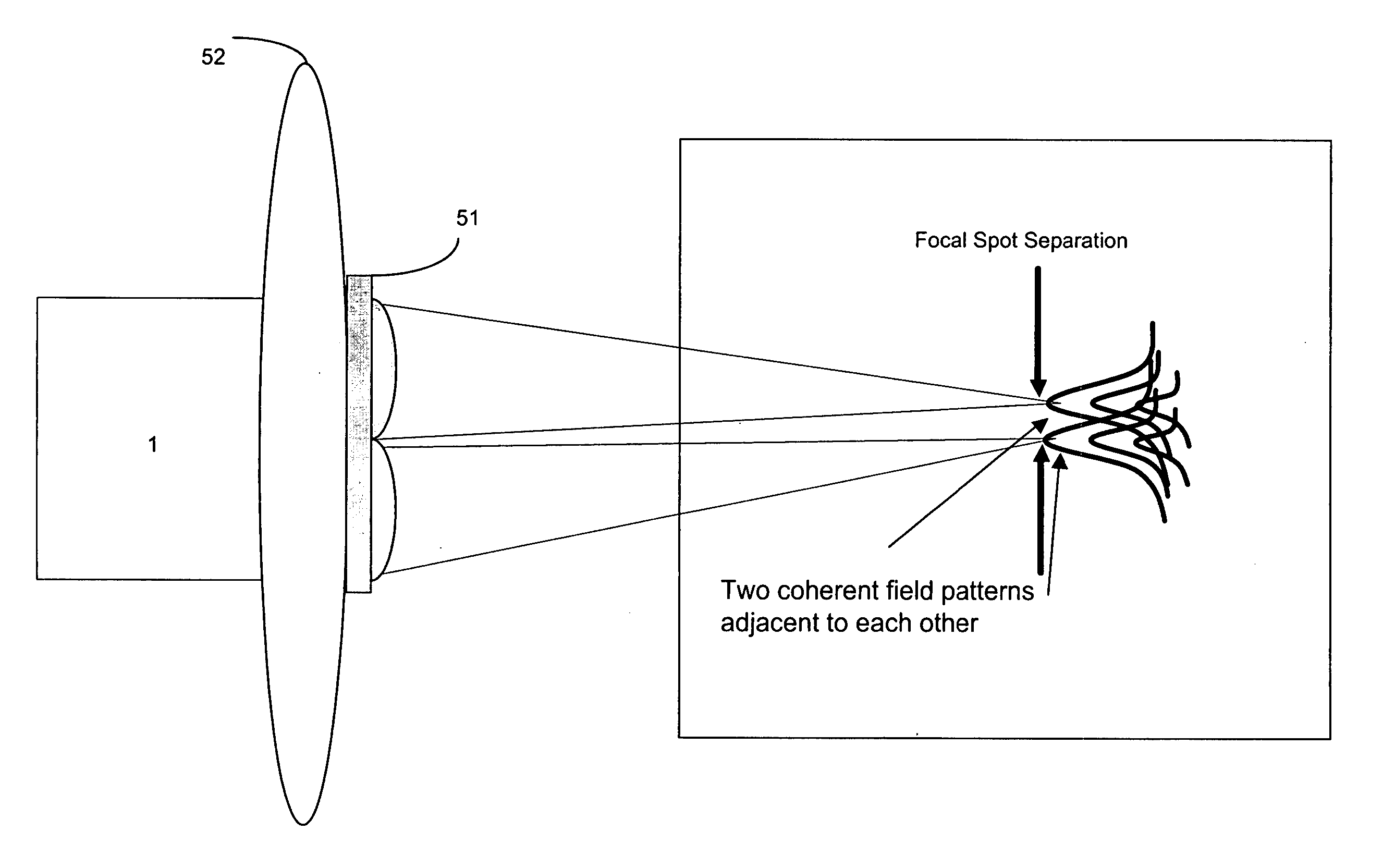

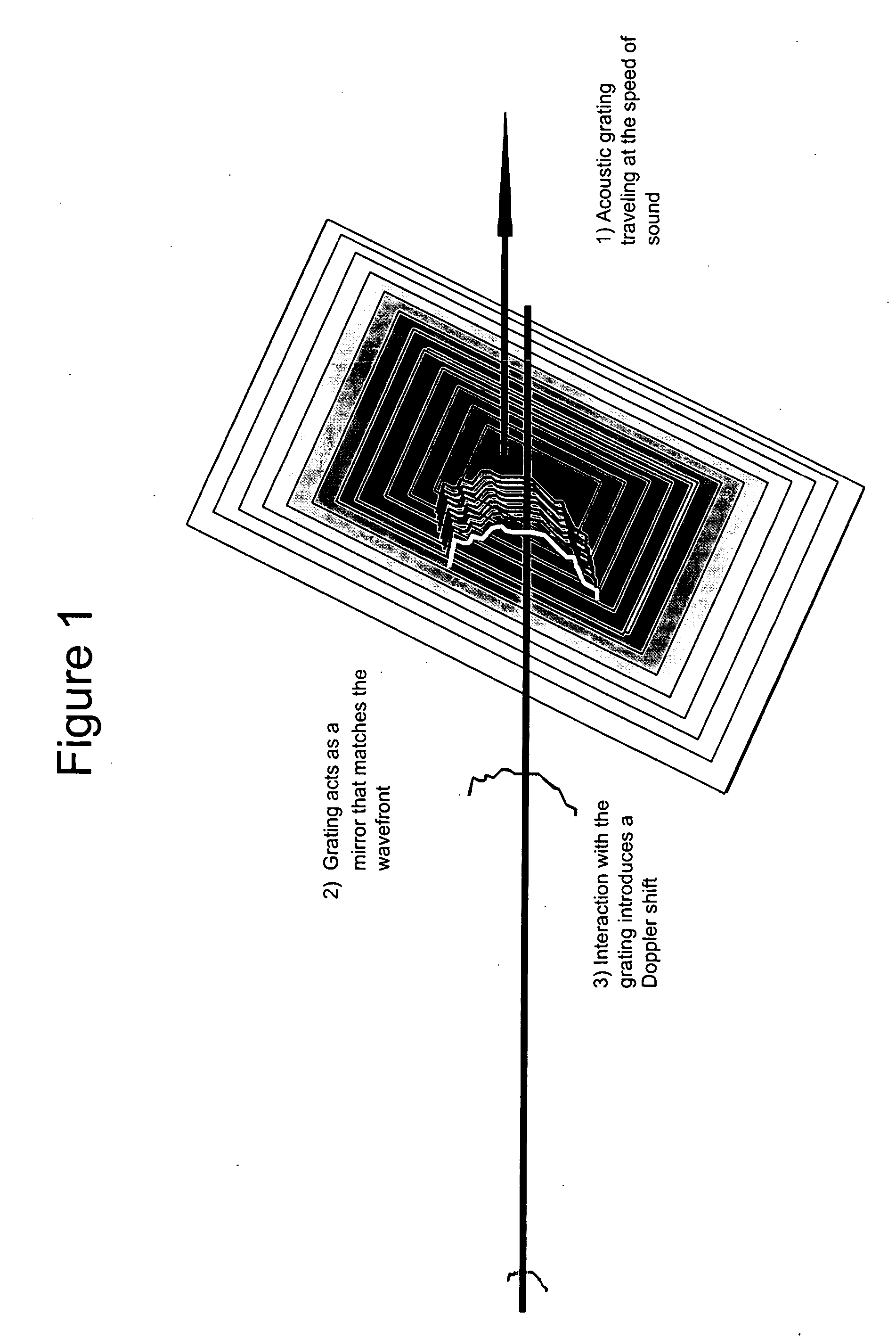

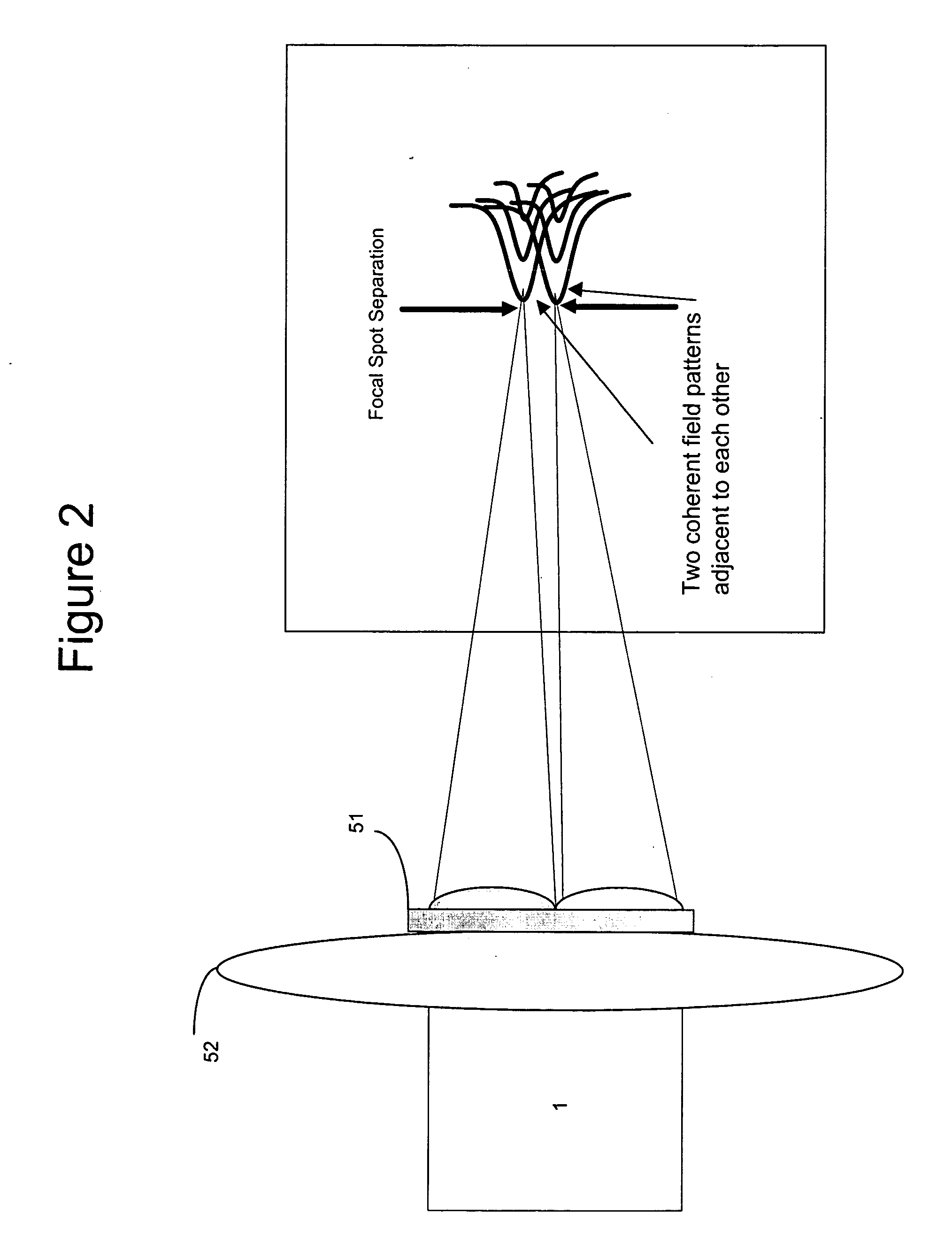

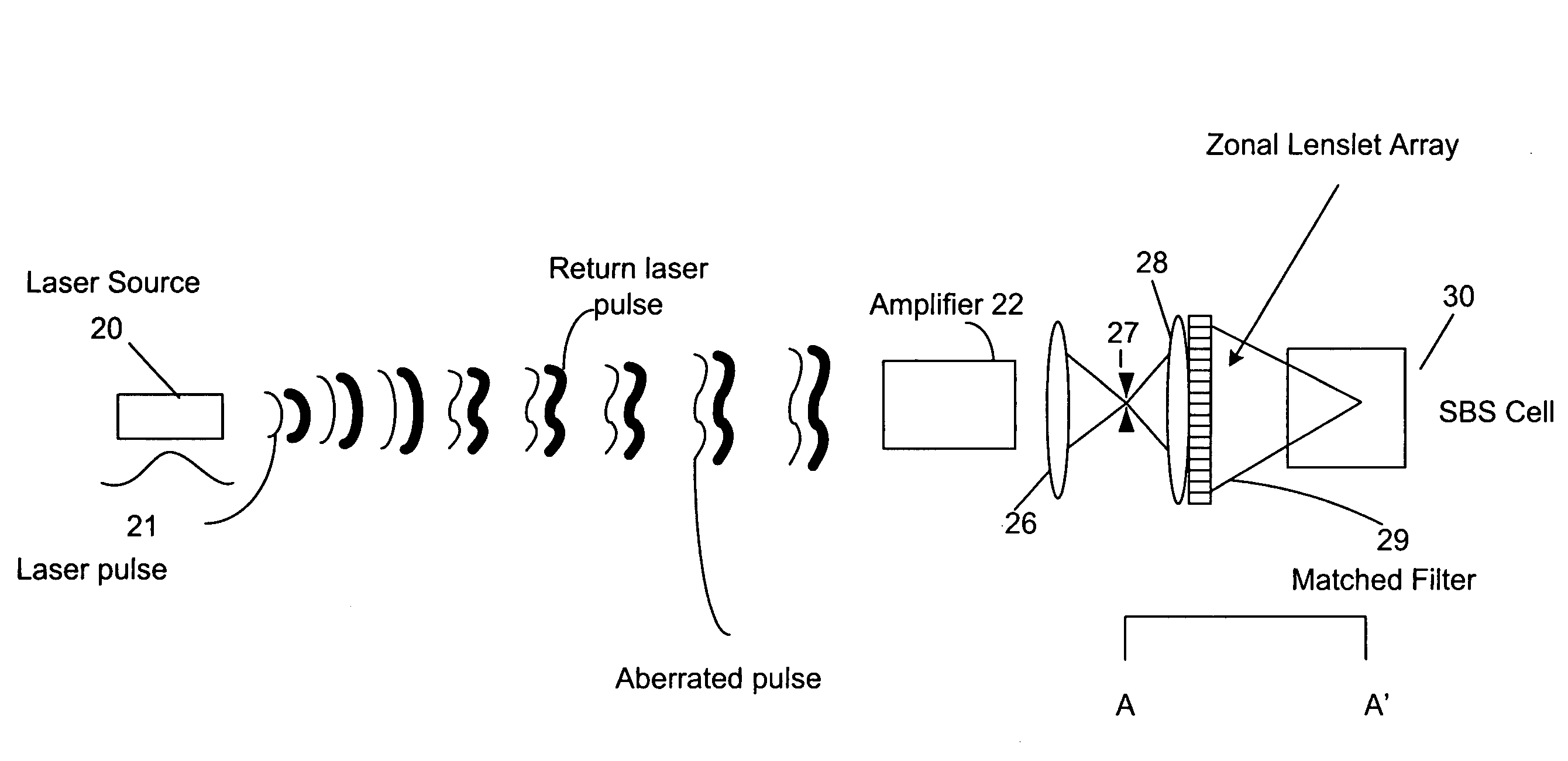

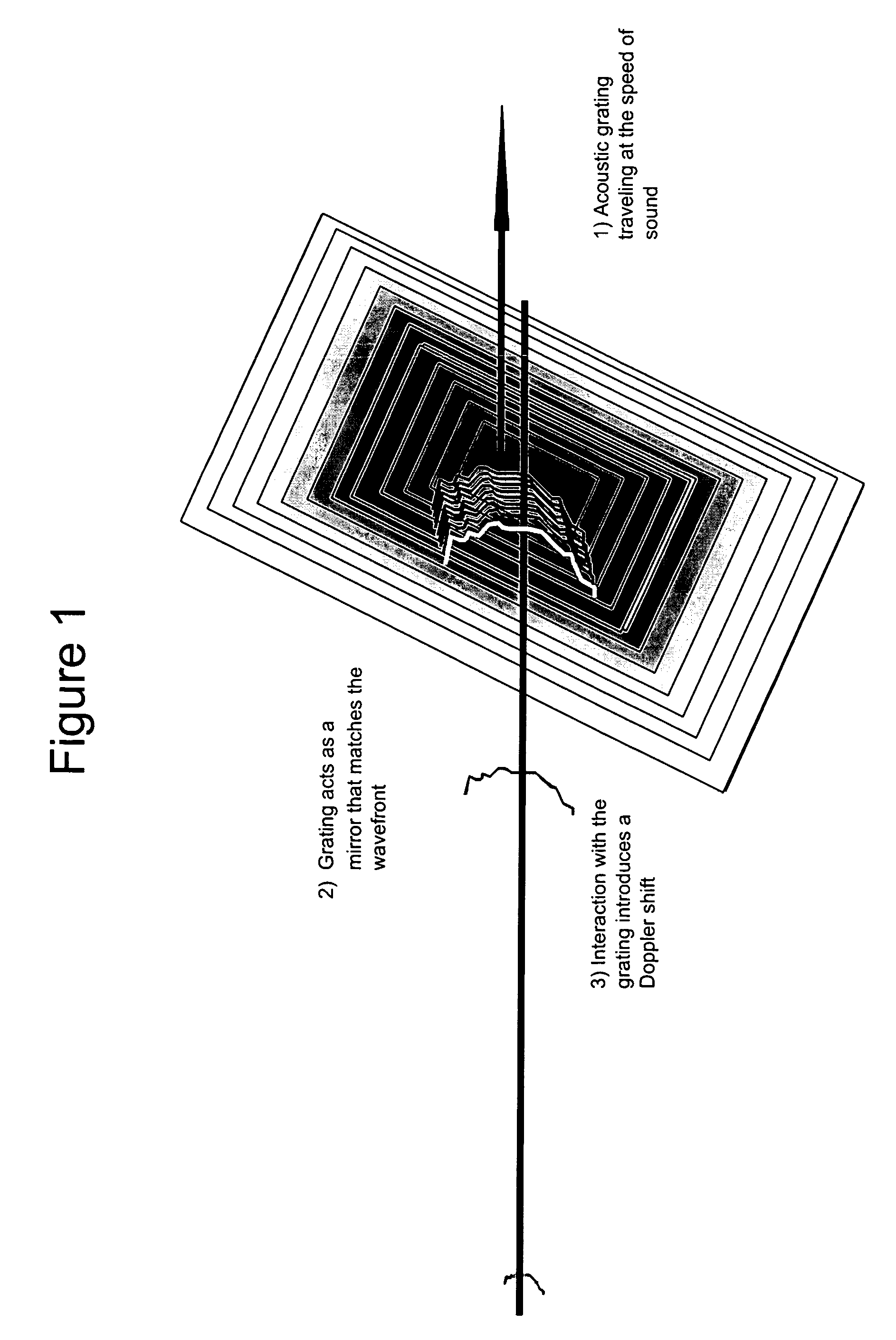

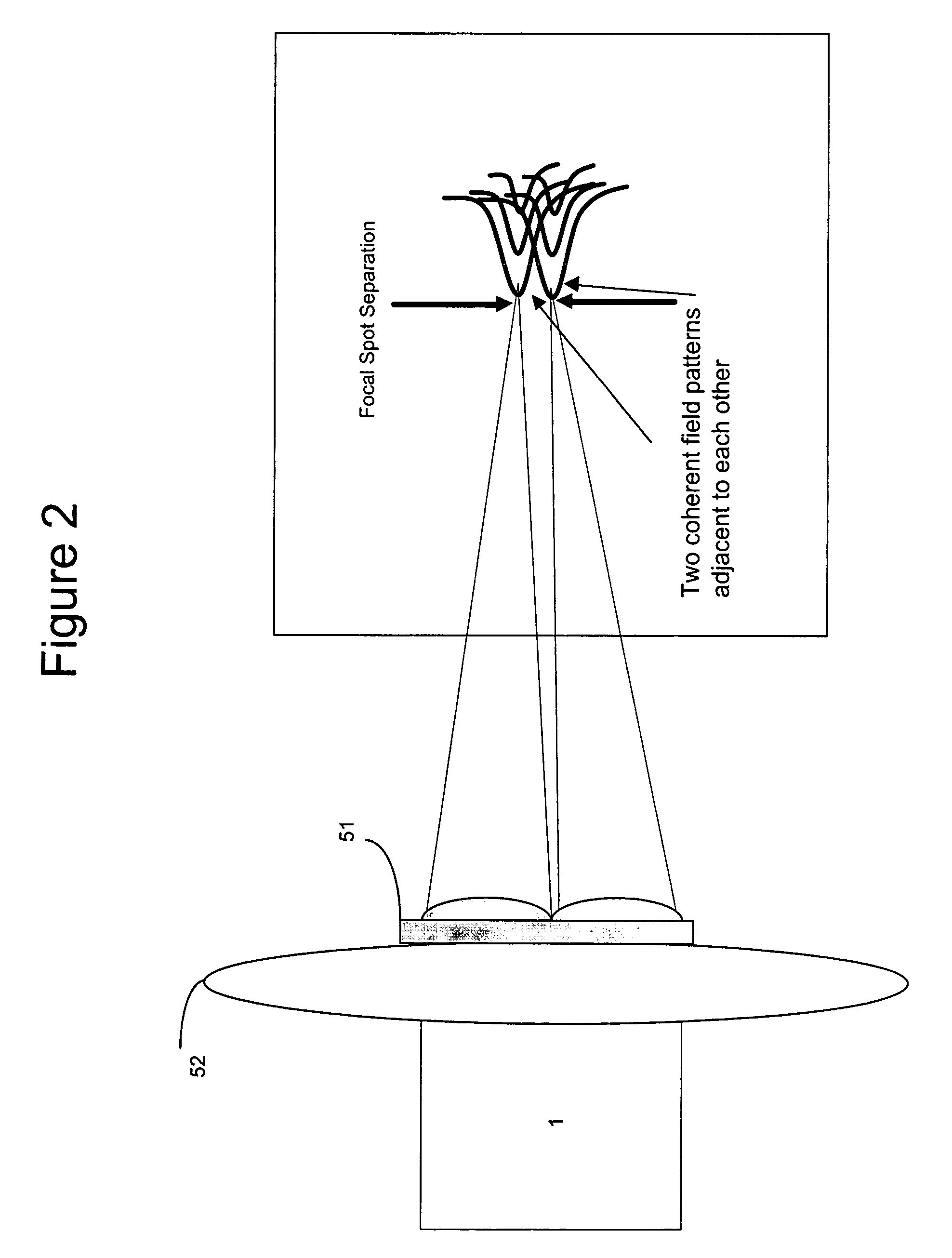

High power laser using controlled, distributed foci juxtaposed in a stimulate brillouin scattering phase conjugation cell

InactiveUS20060146897A1High quality phase conjugation fidelityHigh power loadLaser detailsGratingHigh power lasers

In the laser system of the present invention, an acoustic grating (AG) established in an SBS cell by an initial laser pulse is forced into oscillation from noise. Since the process is nonlinear, SBS Phase Conjugation does not take place until a specific level is achieved based on several factors such as the physical conditions and the SBS media. The invention segments the initial laser pulse with a zonal lenslet array that produces a set of beams that have their foci distribute in space. By coupling this segmented lenslet array with a master lens, the separation of the foci from each other can be controlled. At a large separation distance each foci independently produces an associated AG. As each AG forms from a local noise source the coherence between the segmented beams has been lost. However, the master lens controls the entire focal envelope and hence the separation distance between the foci. Increasing the power of the master lens causes the separation between the foci to decrease. At some minimum distance the AG couple and hence the phase relationship is restored and coherence is re-established.

Owner:ARMY DEPT OF THE UNITED STATE OF AMERICA

Direct current/direct current converter for a fuel cell system

InactiveUS20060099463A1Improve system efficiencyReduce system costBatteries circuit arrangementsFuel cell auxillariesFuel cellsBoost converter

Fuel cell systems and control methods including a fuel cell and a second energy source, such as a battery that is adapted to supplement the fuel cell. In addition, the fuel cell system utilizes a single bipolar switching module, such as an IGBT six pack module that is configured to implement a DC / DC converter, such as a DC / DC boost converter, for both the fuel cell and the battery. The fuel cell system also makes use of a controller that is configured to control either or both of input current and output voltage of the DC / DC converter.

Owner:CONTINENTAL AUTOMOTIVE SYST U S INC

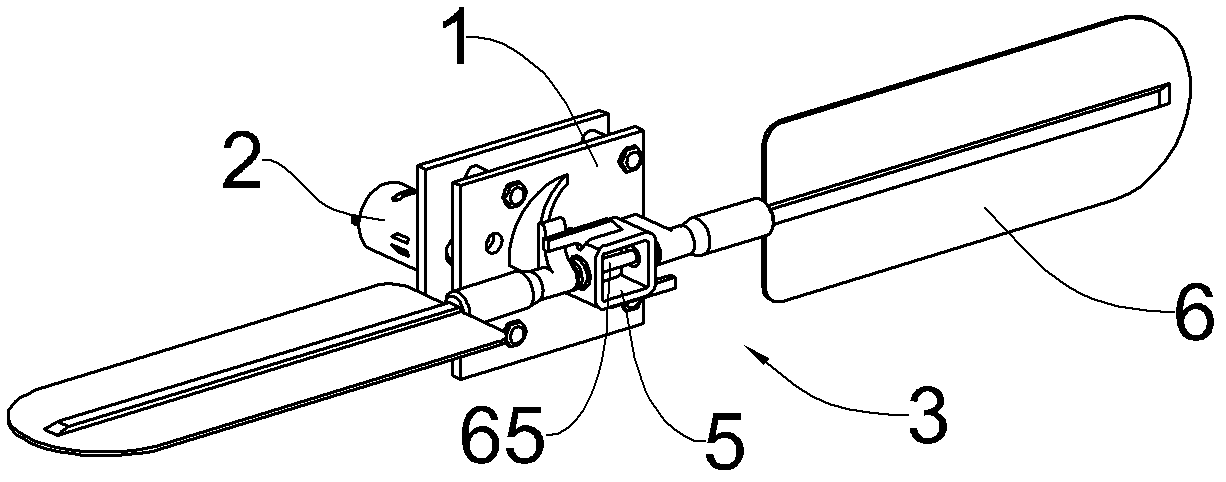

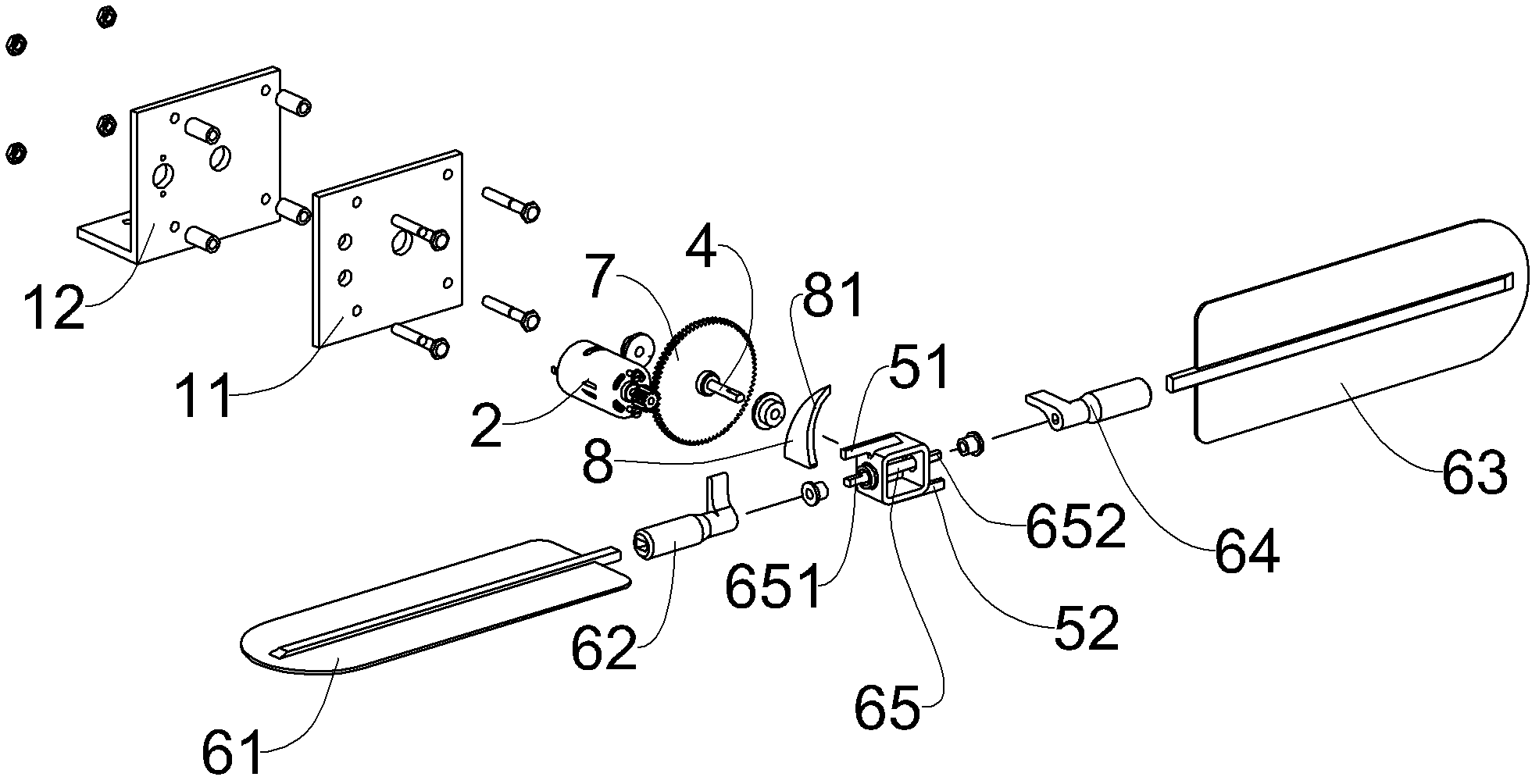

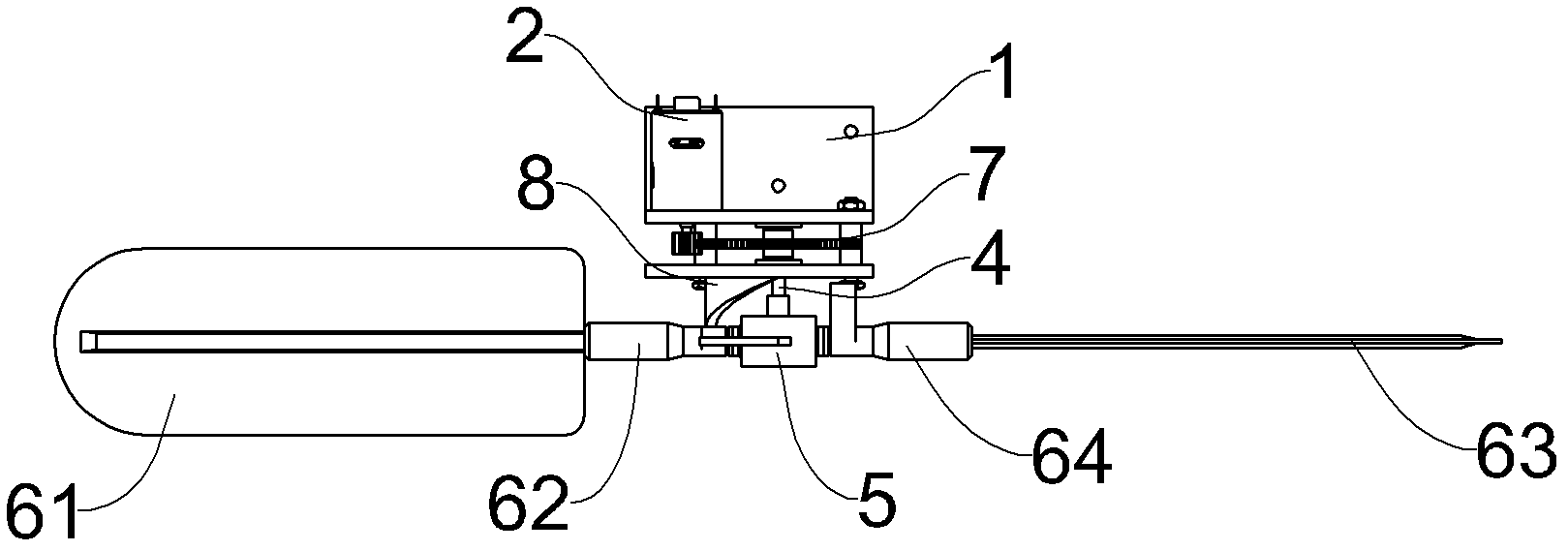

Power apparatus for aircraft

InactiveCN102358418AHigh power loadSimple structurePropellersDepending on number of propellersFlight vehiclePropeller

The present invention provides a power apparatus for an aircraft. The apparatus comprises a base, a drive source and a rotation propeller, wherein the drive source drives the rotation propeller to rotate. The rotation propeller comprises a rotation propeller shaft and a propeller blade assembly. The rotation propeller shaft forms a rotatable connection with the drive source. The propeller blade assembly is provided with a propeller blade shaft, wherein the propeller blade shaft is perpendicular to the rotation propeller shaft, and can rotate around the axial line of the propeller blade shaft. The base is provided with a cam part, and a guidance part with a preset shape is formed on the cam part. The propeller blade assembly is provided with a conduction part and a rotation angle spacing part, wherein the conduction part contacts the guidance part to drive the propeller blade assembly to rotate around the propeller blade shaft, the rotation angle spacing part limits the rotation angle of the propeller blade assembly around the propeller blade shaft. According to the present invention, the problems of requirements of large amount of continuous and stable air working medium with a certain dynamic pressure energy during the vertical aircraft taking off and landing process are solved; the power apparatus provided by the present invention has characteristics of simple structure, large power load, high efficiency and convenient and flexible operation.

Owner:陈志灵

Thermal management systems, assemblies and methods for grazing incidence collectors for EUV lithography

ActiveUS8746975B2Avoids spatial modulationThermal stabilityMirrorsX-ray tube electrodesLithographic artistEngineering

Systems, assemblies and methods for thermally managing a grazing incidence collector (GIC) for EUV lithography applications are disclosed. The GIC thermal management assembly includes a GIC mirror shell interfaced with a jacket to form a sealed chamber. An open cell, heat transfer (OCHT) material is disposed within the metal chamber and is thermally and mechanically bonded with the GIC mirror shell and jacket. A coolant is flowed in an azimuthally symmetric fashion through the OCHT material between input and output plenums to effectuate cooling when the GIC thermal management assembly is used in a GIC mirror system configured to receive and form collected EUV radiation from an EUV radiation source.

Owner:MEDIA LARIO SRL

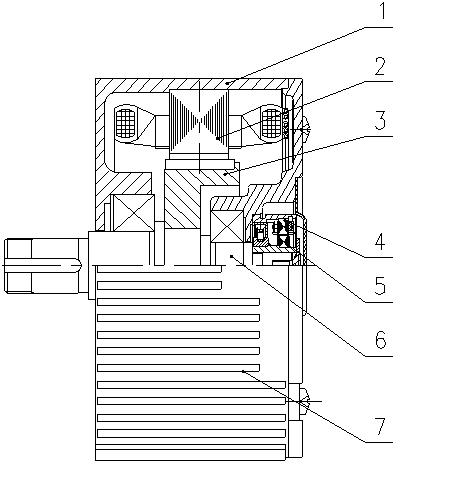

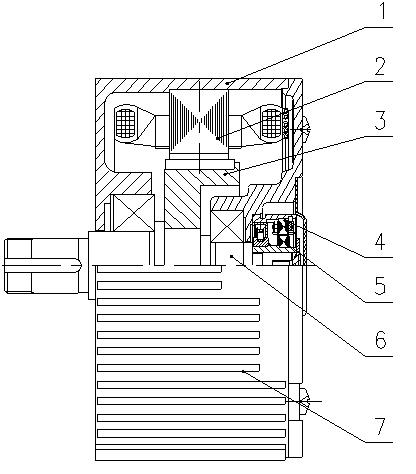

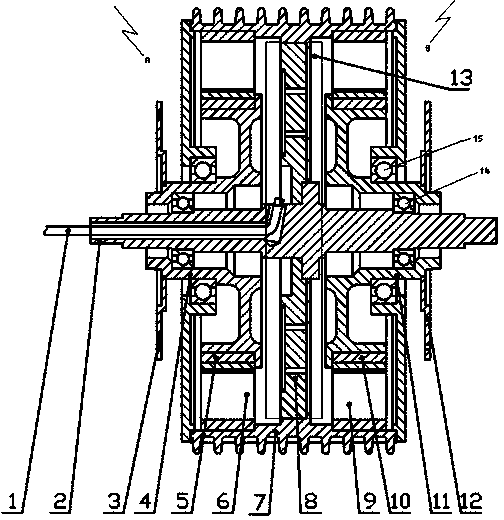

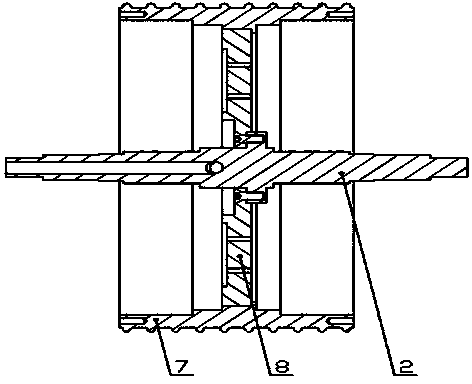

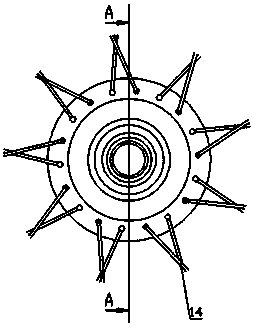

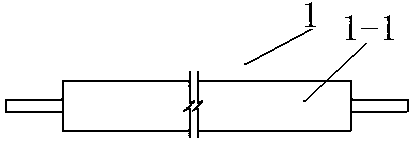

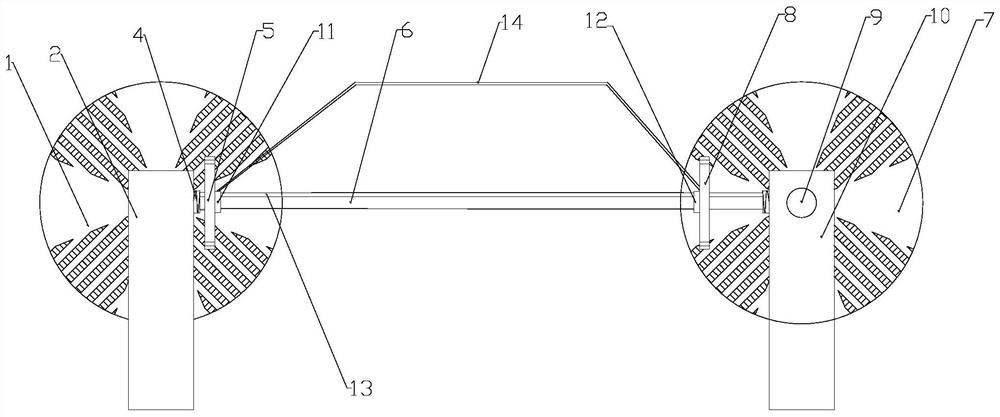

Integral direct drive device of gantry crane

The invention provides an integral direct drive device of a gantry crane, relating to a drive device in which a permanent magnet direct drive motor and a signal detector are manufactured into a whole. A radial radiating fin is arranged outside a shell; the shell is provided with a spindle; the spindle in the shell is connected with a permanent magnet direct drive motor rotor; a permanent magnet direct drive motor stator matched with the permanent magnet direct drive motor rotor is fixed in the shell; the spindle in the shell is connected with a signal detector rotor; and a signal detector stator matched with the signal detector rotor is fixed in the shell. The integral direct drive device is concise and compact, improves the drive control accuracy, strengthens the integral protection grade of products, simplifies the system structure of the gantry crane, saves the space, and is convenient to install, debug and maintain; in addition, by using the integral direct drive device, the system structure of the gantry crane can be effectively simplified, the system space is saved, the installation and debugging are more convenient and faster, and the cost of an elevator gantry crane system is reduced.

Owner:海安县宏菱新型材料机电有限公司 +1

High power laser using controlled, distributed foci juxtaposed in a stimulate Brillouin scattering phase conjugation cell

InactiveUS7515618B2High quality phase conjugation fidelityHigh power loadLaser detailsGratingHigh power lasers

In the laser system of the present invention, an acoustic grating (AG) established in an SBS cell by an initial laser pulse is forced into oscillation from noise. Since the process is nonlinear, SBS Phase Conjugation does not take place until a specific level is achieved based on several factors such as the physical conditions and the SBS media. The invention segments the initial laser pulse with a zonal lenslet array that produces a set of beams that have their foci distribute in space. By coupling this segmented lenslet array with a master lens, the separation of the foci from each other can be controlled. At a large separation distance each foci independently produces an associated AG. As each AG forms from a local noise source the coherence between the segmented beams has been lost. However, the master lens controls the entire focal envelope and hence the separation distance between the foci. Increasing the power of the master lens causes the separation between the foci to decrease. At some minimum distance the AG couple and hence the phase relationship is restored and coherence is re-established.

Owner:ARMY DEPT OF THE UNITED STATE OF AMERICA

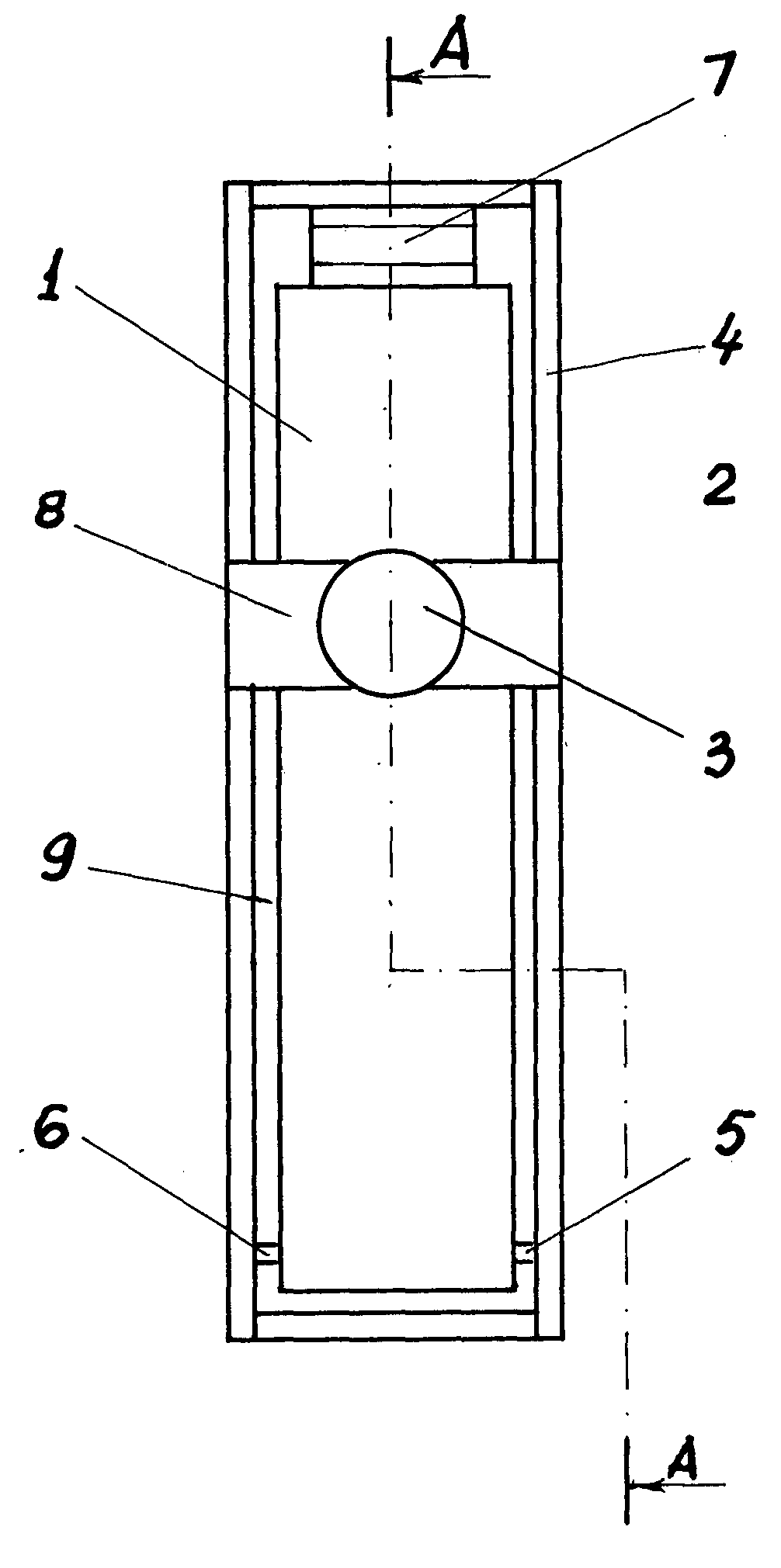

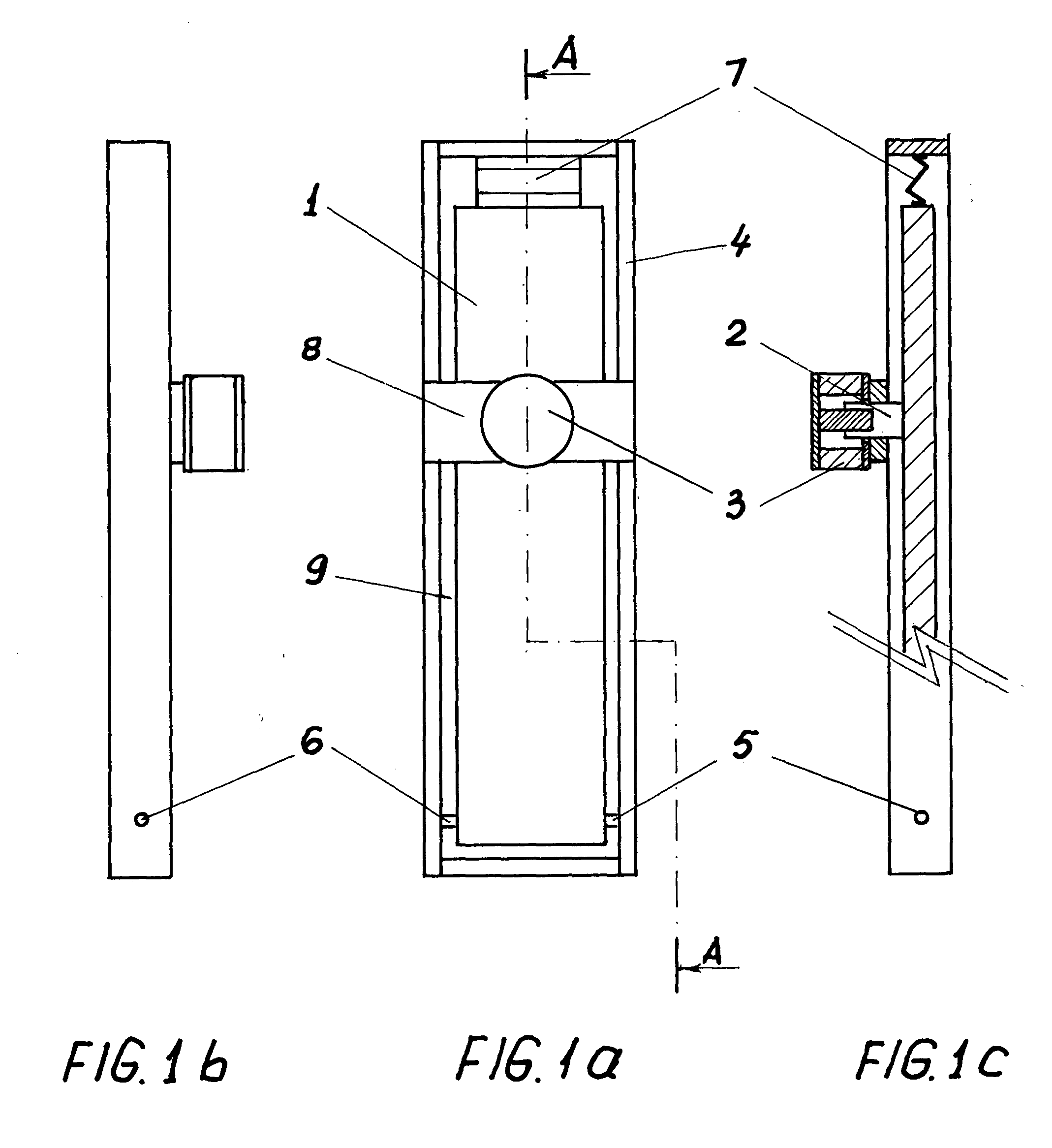

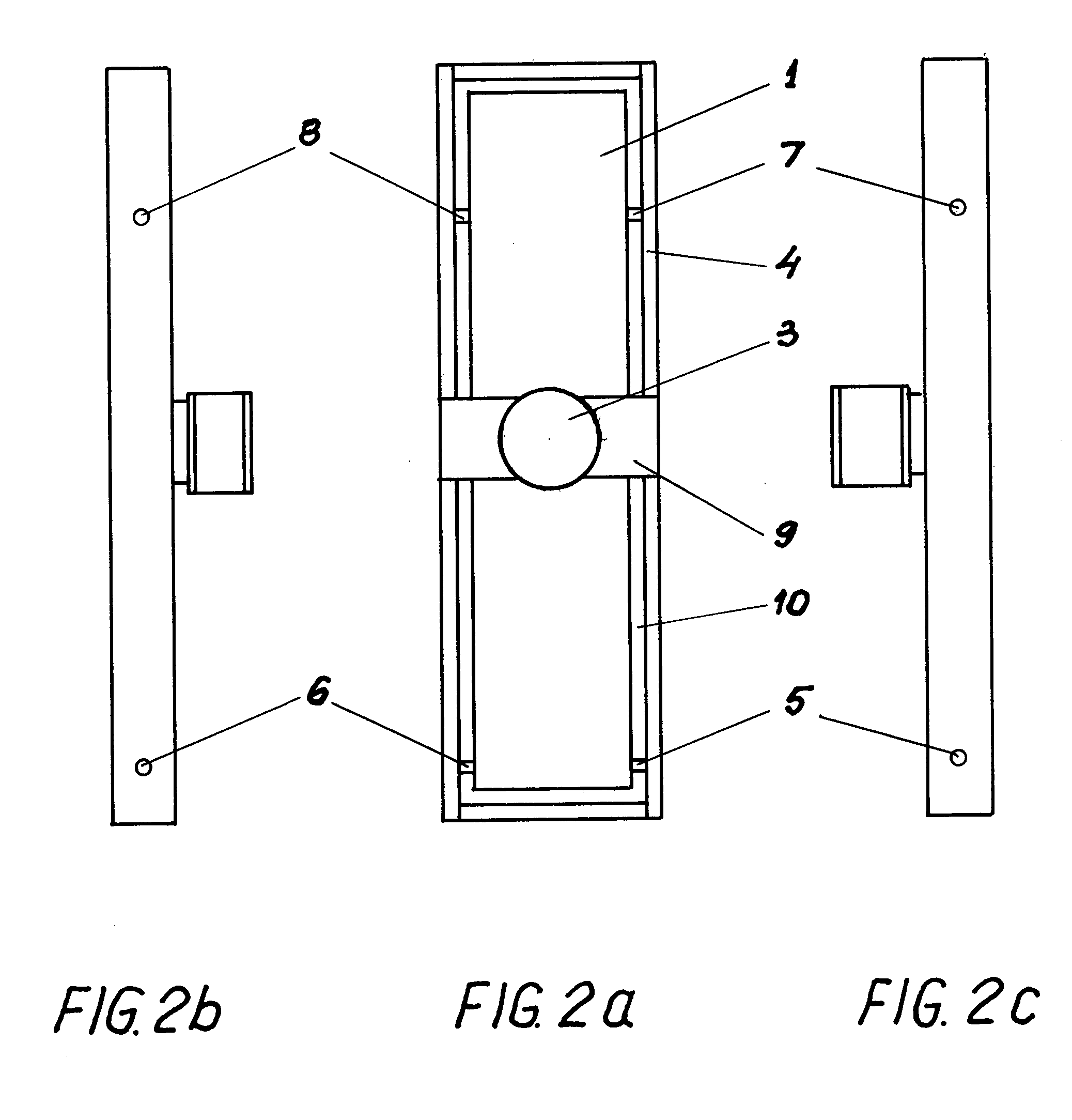

Loudspeaker based on the " center of percussion" or the " sweet spot" point, with gas filled hollow oscillating member and fluid flooded voice coil

InactiveUS20050013452A1Closer control of densityCloser control of distributionPlane diaphragmsTransducer casings/cabinets/supportsDynamic balanceEngineering

A loudspeaker, having a not necessarily rectangular, planar or constant thickness oscillating member, made of relatively thick, low density, stiff, acoustic insulating material, in an elongated form, surrounded by a solid frame, supporting the oscillating member in a minimum number of pivots or flexible elements, placed in areas of points of specific dynamic balance, like one end, center of mass and center of percussion about a certain axis of the oscillating member. The oscillating member is set in vibration by a permanent magnet driver having the voice coil attached to the oscillating member and the permanent magnet assembly supported by a bridge mounted across the frame. In an alternative preferred embodiment the oscillating member is built to incorporate at least one cavity filled with air or a gas different from air. In an alternative preferred embodiment the horizontally placed oscillating member has at least one voice coil immersed in a heat transferring fluid introduced in the cavity of the electromagnetic driver.

Owner:ILIES ANDREI N

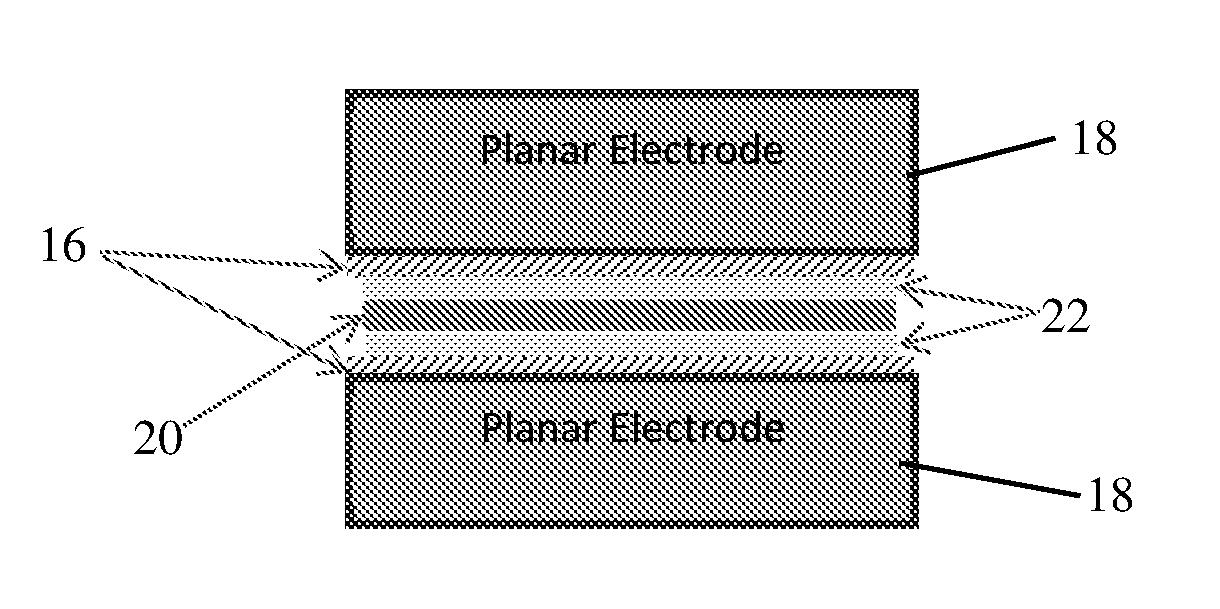

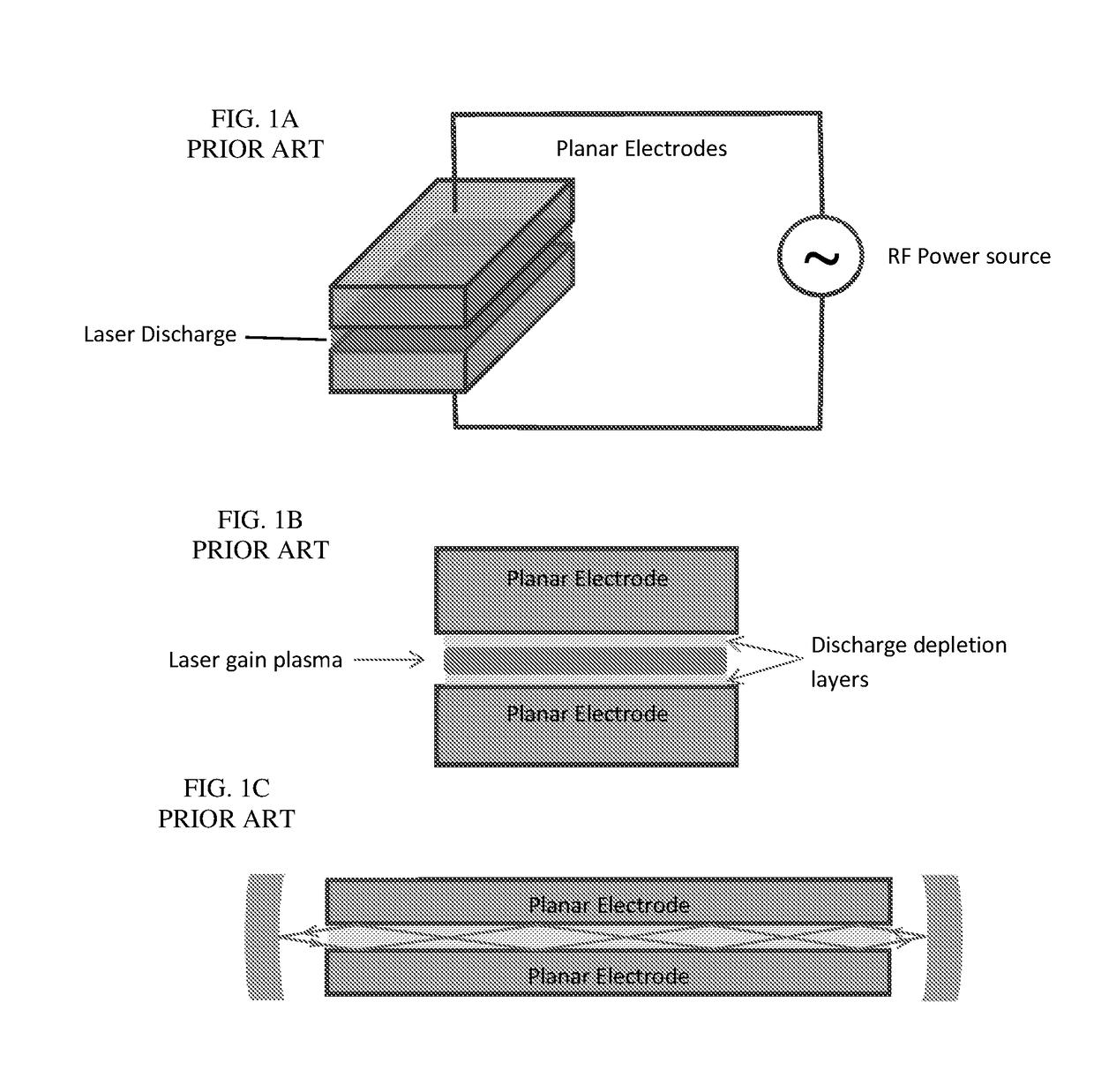

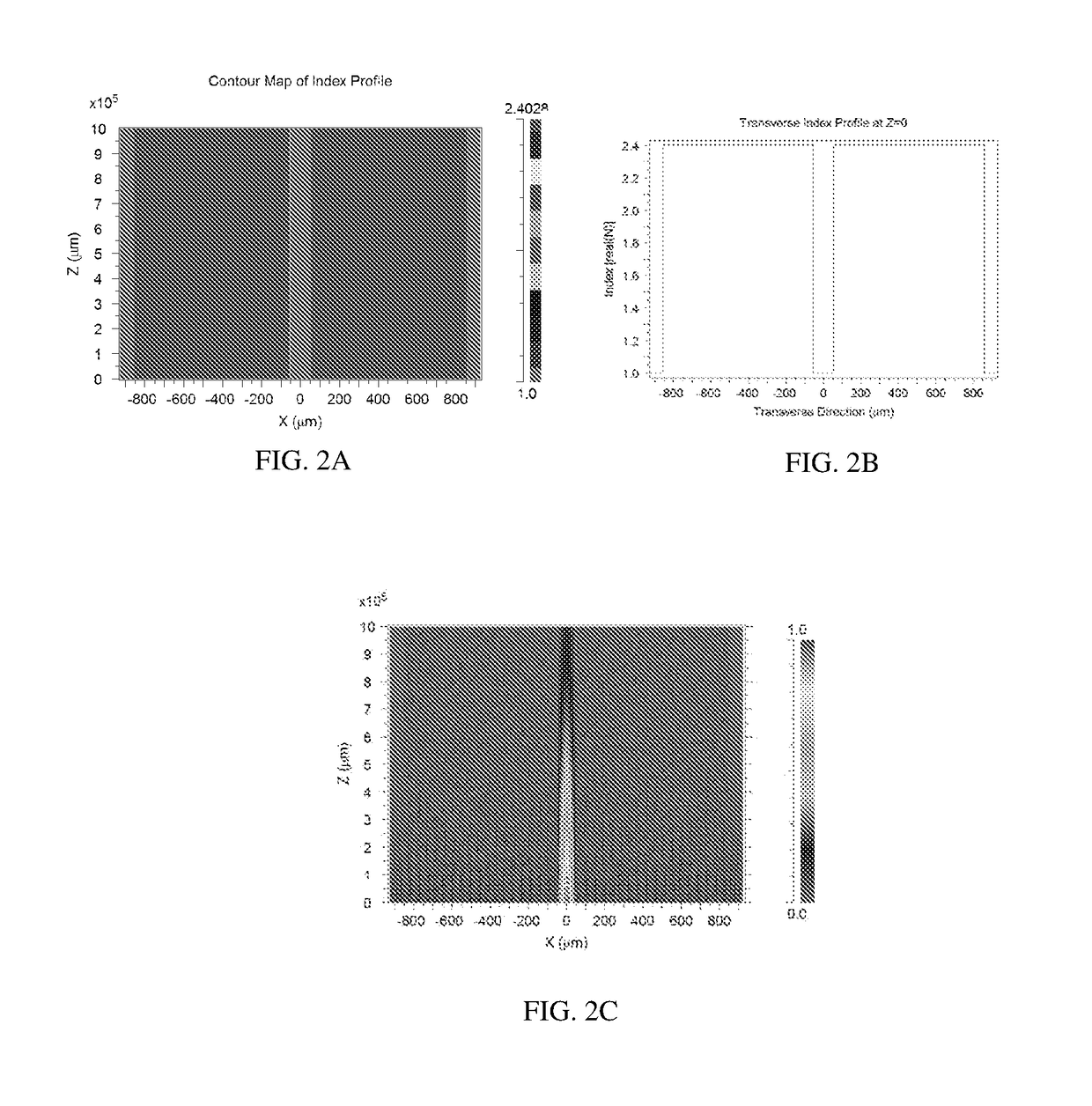

Gas slab laser

ActiveUS20180191123A1High power loadReduce electrode gapGas laser constructional detailsPhotonic bandgapRefractive index

A microwave excited gas slab laser comprising a waveguide wherein the electrodes are covered with multi-layered stripes either forming a photonic band-gap or having a refractive index lower than 1.

Owner:STATE OF ISRAEL - SOREQ NUCLEAR RES CENT

Power handling system and method

InactiveUS10104745B2Firmly connectedHigh power loadElectric light circuit arrangementElectric powerElectricityEngineering

A power handling system of a digitally addressable lighting interface (DALI) system controls switches connected with a bus of the DALI system that powers lower power light sources. A power supply circuit receives energy conducted on the bus to the lower power light sources and conducts at least part of the energy to a capacitor. Electric energy is stored in the capacitor until the capacitor stores at least a designated threshold of input voltage of a controller. The capacitor powers the controller to close one or more switches using at least some of the stored electric energy.

Owner:GE LIGHTING SOLUTIONS LLC

Frequency detection to perform dynamic peak current control

ActiveUS10008933B1Demand of load can be quickly and accurately determinedHigh power loadDc-dc conversionElectric variable regulationPeak valuePeak current

The amount of power being output to the load is sensed by sampling the frequency of the pulse width modulation signal that is controlling the switch that is providing the power to the load. If the pulse width modulation signal has a high frequency, then it will be providing higher power to the load. As the power drawn by the load decreases, the frequency of the pulse width modulation power supply signal will decrease. By sensing and periodically sampling the frequency of the pulse width modulation signal that is providing power, the demand of the load can be quickly and accurately determined. As the power demand of the load decreases, the peak current that the power supply switch can provide also decreases. The permitted peak current dynamically changes to adapt to the power drawn by the load.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

Novel inner rotor permanent magnet hub motor for moped scooter

InactiveCN104079132AImprove cooling effectHigh power loadSynchronous machines with stationary armatures and rotating magnetsControl theoryMotor shaft

The invention provides a novel inner rotor permanent magnet hub motor for a moped scooter. The novel inner rotor permanent magnet hub motor is characterized in that a left permanent magnet hub motor electromagnetic structure A and a right permanent magnet hub motor electromagnetic structure B are arranged on the left side and the right side of a motor shaft respectively and isolated by an outer shell support, the outer shell support is fixedly connected with the motor shaft, a motor outer shell is fixedly connected with the outer shell support, a motor stator is fixedly connected with the motor outer shell, a motor rotor and a hub are fixed, the hub is installed between the motor shaft and the motor outer shell through a bearing, the hub is connected with a disc-shaped shaft surface, a plurality of holes are formed in the periphery of the shaft surface to be connected with spokes of a bicycle, the rotor rotates to drive the hub to rotate, the hub rotates to drive the shaft surface to rotate, and the spokes of wheels of the bicycle are accordingly driven to rotate. The novel inner rotor permanent magnet hub motor has the advantages that the radiating effect of the motor is good, and large power loads can be borne; meanwhile, the one motor can be selected for working, or two motors can be selected for simultaneous work, and power selection space is large.

Owner:NANTONG LEISHENG SPECIAL MOTOR

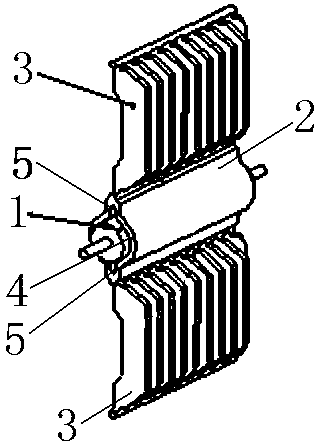

A kind of convective heat sink and its manufacturing method

ActiveCN105240911BReasonable designSimple designLighting and heating apparatusElectric heating systemCounter flowEngineering

The invention relates to a counter flow type radiator and a manufacturing method thereof. The structure is particularly suitable for devices with ordinary heating requirements. The counter flow type radiator comprises a cooling pipe, cooling fins and an electric heat pipe. The cooling pipe is provided with an electric heat pipe installing hole. Shrinkage joints are arranged in the cooling pipe installing hole. The electric heat pipe is installed in the electric heat pipe installing hole. The cooling fins are arranged outside the cooling pipe. Compensation shrinkage joints are reserved in the cooling fins. The manufacturing method of the counter flow type radiator comprises the steps that firstly, an aluminum sectional bar is adopted to be machined into the cooling pipe, the electric heat pipe installing hole is reserved in the middle of the cooling pipe, and the shrinkage joints are reserved in the electric heat pipe installing hole; secondly, the cooling fins are manufactured above and below the cooling pipe, and the compensation shrinkage joints are reserved in the length direction of the cooling fins; and thirdly, the electric heat pipe is installed and installed in the electric heat pipe installing hole in the middle of the cooling pipe, the electric heat pipe and the electric heat pipe installing hole are in close contact evenly through compression, a compression die is used through a press, the electric heat pipe installing hole formed in the middle of the cooling pipe is pressurized and wraps an electric heat pipe body, the electric heat pipe body and the electric heat pipe installing hole are in close contact evenly through compression, and the counter flow type radiator is manufactured.

Owner:世保康环境电器(南京)有限公司

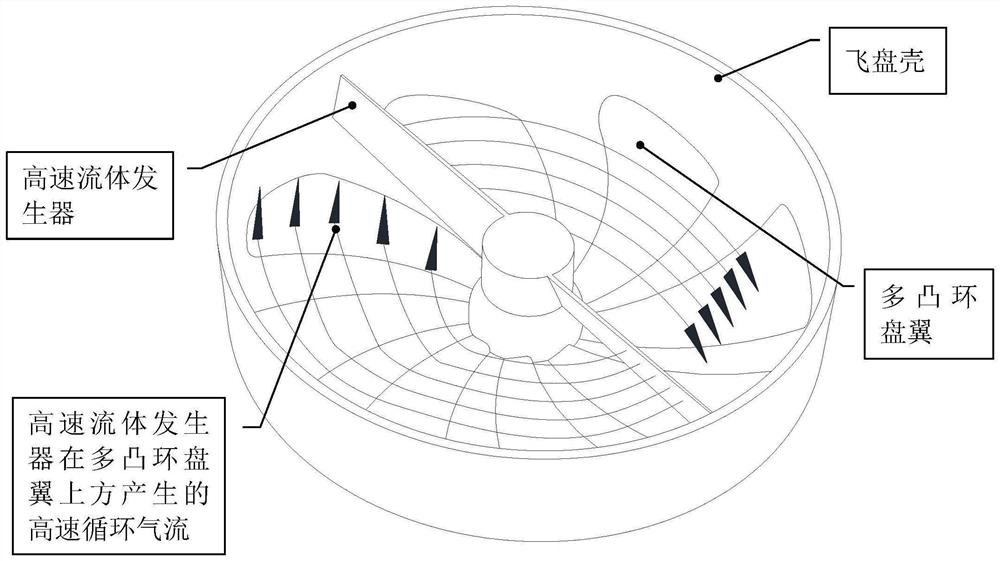

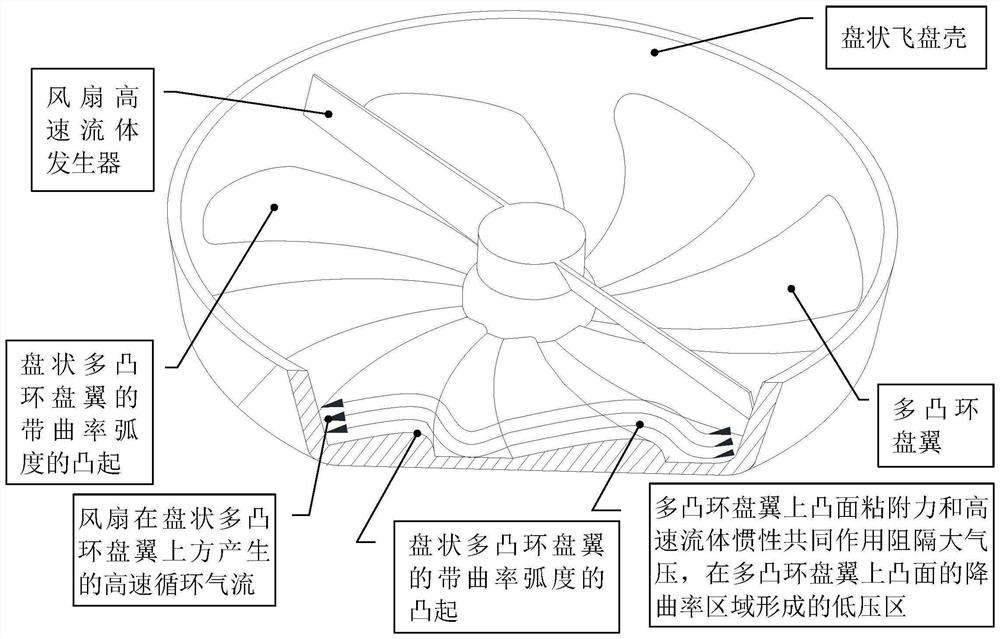

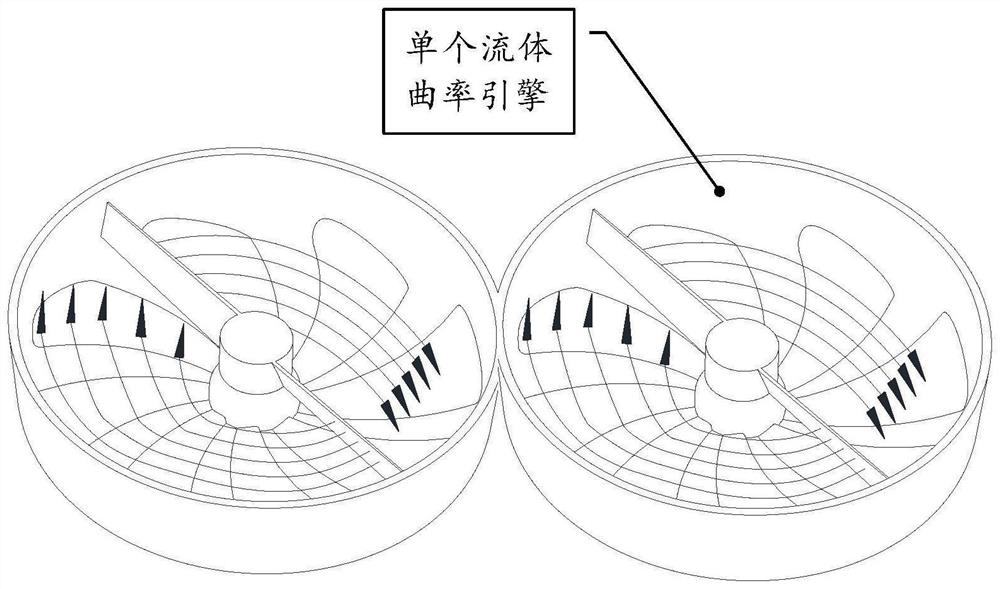

Fluid curvature engine, fluid curvature engine equipment and control method of fluid curvature engine equipment

PendingCN114715413AReduce noiseIncrease power loadWind energy generationPower plant typeFluid viscosityMechanical engineering

The invention discloses a fluid curvature engine, fluid curvature engine equipment and a control method of the fluid curvature engine equipment. The fluid curvature engine is mainly composed of a flying disc shell, a multi-convex-ring disc wing and a high-speed fluid generator, the flying disc shell is an annular or disc-shaped open half cavity, the multi-convex-ring disc wing is annular or disc-shaped, and a plurality of protrusions with curvature radians are arranged on the upper surface of the multi-convex-ring disc wing in the circumferential fluid flowing direction. The fluid curvature engine gives full play to the principle that the combined action of fluid viscosity and high-speed fluid inertia blocks atmospheric pressure to generate a low-pressure area in a curvature reduction area of an upper convex surface so as to generate lift force, and high-speed fluid is controlled to circularly flow in the frisbee shell and repeatedly flow through an arc-shaped curvature upper convex curved surface of a multi-convex-ring disc wing; accordingly, a plurality of corresponding low-pressure areas are generated in the curvature reduction area of the upper convex face of the multi-convex-ring disc wing to generate lift force, the lift-drag ratio of the multi-convex-ring disc wing can be hundreds of, and the problems that an existing engine is small in thrust-weight ratio and insufficient in lift force can be solved. The equipment for providing driving force by adopting the fluid curvature engine is fluid curvature engine equipment.

Owner:田贵川

Evaporative thermal management of grazing incidence collectors for EUV lithography

ActiveUS8731139B2Minimize distortionUniform temperature distributionMirrorsX-ray tube electrodesThermal management systemEngineering

Evaporate thermal management systems for and methods of grazing incidence collectors (GICs) for extreme ultraviolet (EUV) lithography include a GIC shell interfaced with a jacket to form a structure having a leading end and that defines a chamber. The chamber operably supports at least one wicking layer. A conduit connects the wicking layer to a condenser system that support cooling fluid in a reservoir. When heat is applied to the leading end, the cooling fluid is drawn into the chamber from the condenser unit via capillary action in the wicking layer and an optional gravity assist, while vapor is drawn in the opposite direction from the chamber to the condenser unit. Heat is removed from the condensed vapor at the condenser unit, thereby cooling the GIC mirror shell.

Owner:MEDIA LARIO SRL

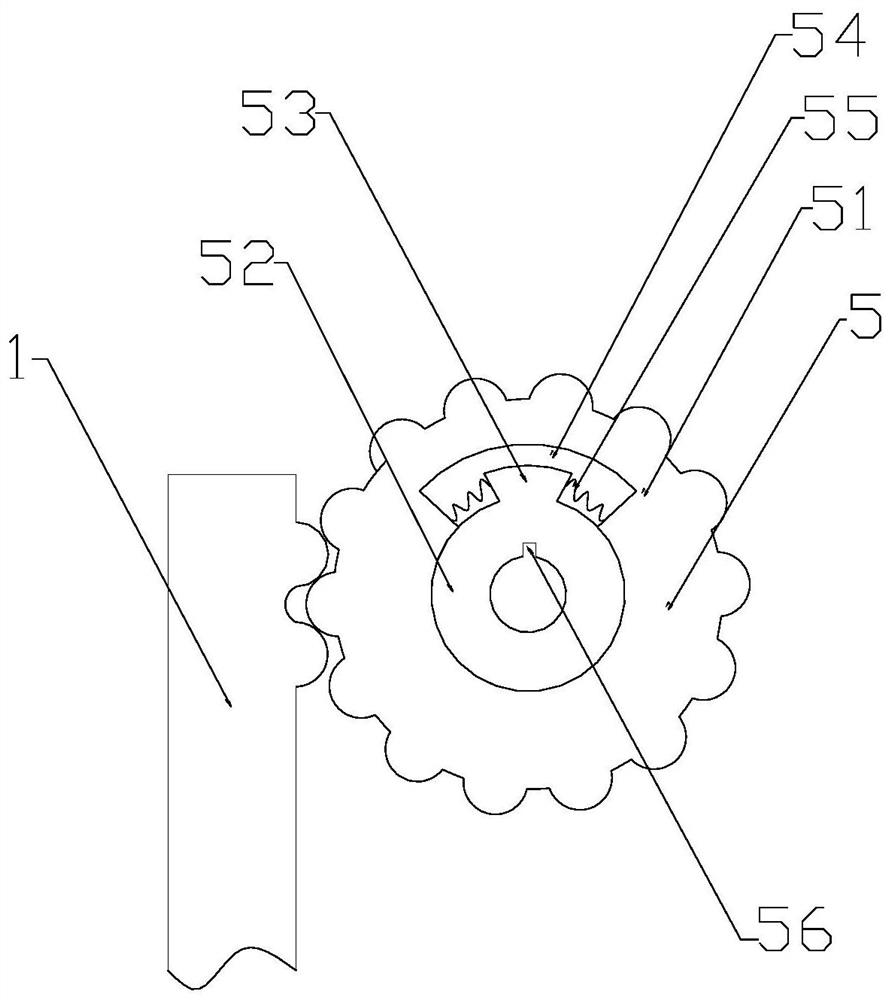

A stepless automatic gearbox with toothed active rod

InactiveCN110273990BImprove transmission stabilityImprove stabilityFriction gearingsAutomatic transmissionGear wheel

Owner:黄丹

Ceramic discharge lamp with integral burner and reflector

InactiveUS8247972B2High power loadElectroluminescent light sourcesSolid cathode detailsGas-discharge lampCombustor

A ceramic discharge lamp and a method of making the lamp includes a ceramic discharge chamber with two concave parts that are attached to each other at a seam, and a ceramic reflector directly attached to an exterior surface of the discharge chamber at the seam, or directly attached to a ceramic capillary that is attached to one of the two concave parts. The lamp finds particular application where focused light is required, such as injection of light into a fiber optic device. The lamp can be very small and has an advantage that the discharge chamber is isolated from the reflective surfaces so that the optically active parts of the reflector are not covered with salt from the preferred metal halide lamp fill.

Owner:OSRAM SYLVANIA INC

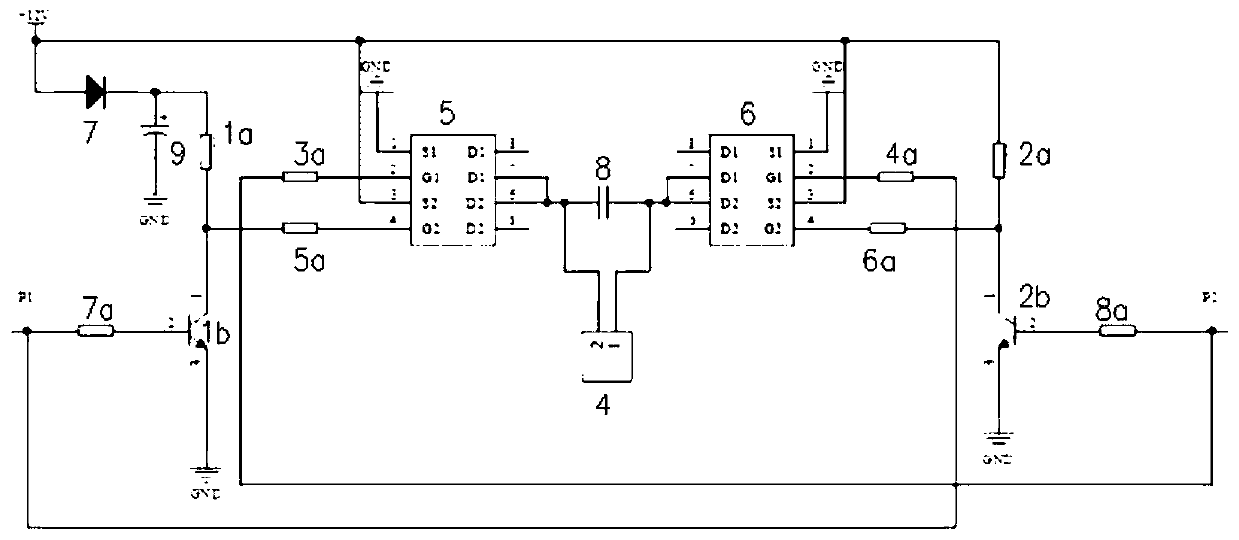

Novel DC-to-AC conversion circuit and method

The invention discloses a novel DC-to-AC conversion circuit and method. The circuit comprises a DC-to-AC module, a synchronous motor and a single-chip microcomputer. The input end of the DC-to-AC module is connected with a direct-current power supply, and the output end is in connection with the synchronous motor; the DC-to-AC module is also connected with the control end of the single-chip microcomputer; according to the invention, the working principle is simple, the cost is lower, and the motor works more stably; compared with the prior art, a higher-power load can be driven, a digital waveform with a certain frequency is provided by using the single chip microcomputer, the direct current 12V is converted into the digital waveform with a frequency to simulate an alternating current waveform, and then the synchronous motor is driven to work.

Owner:珠海市声驰电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com