Patents

Literature

150results about How to "Thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

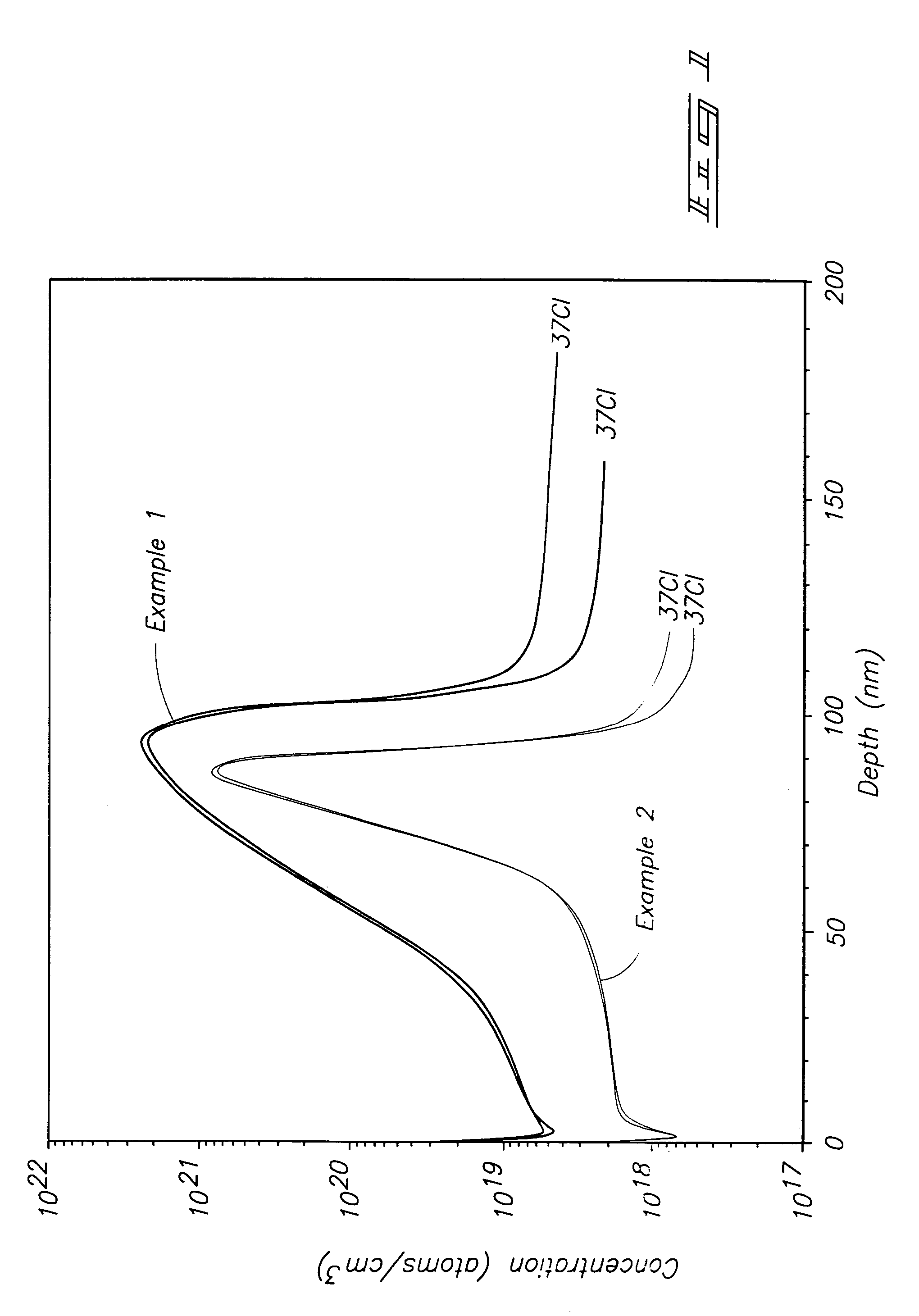

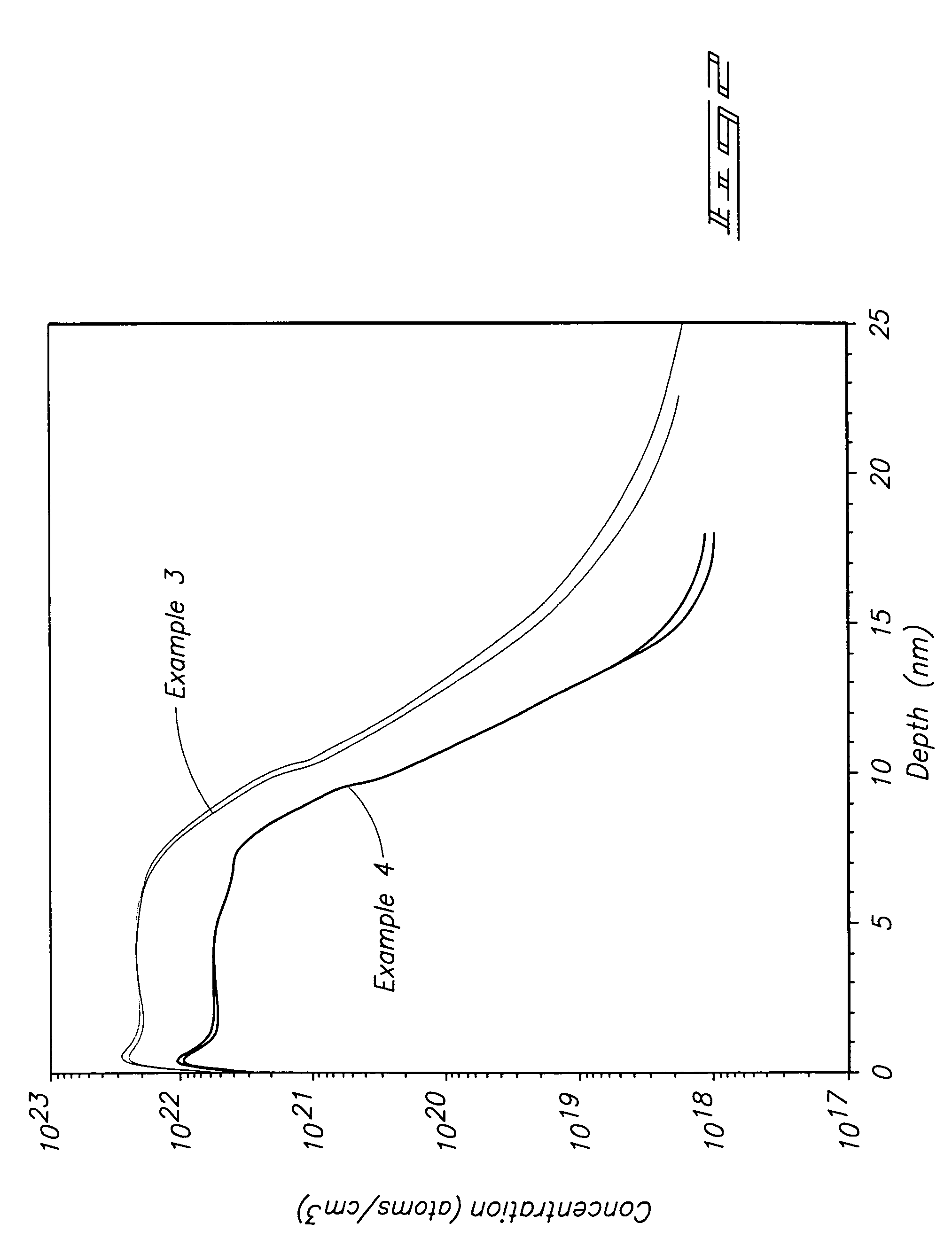

Deposition methods using heteroleptic precursors

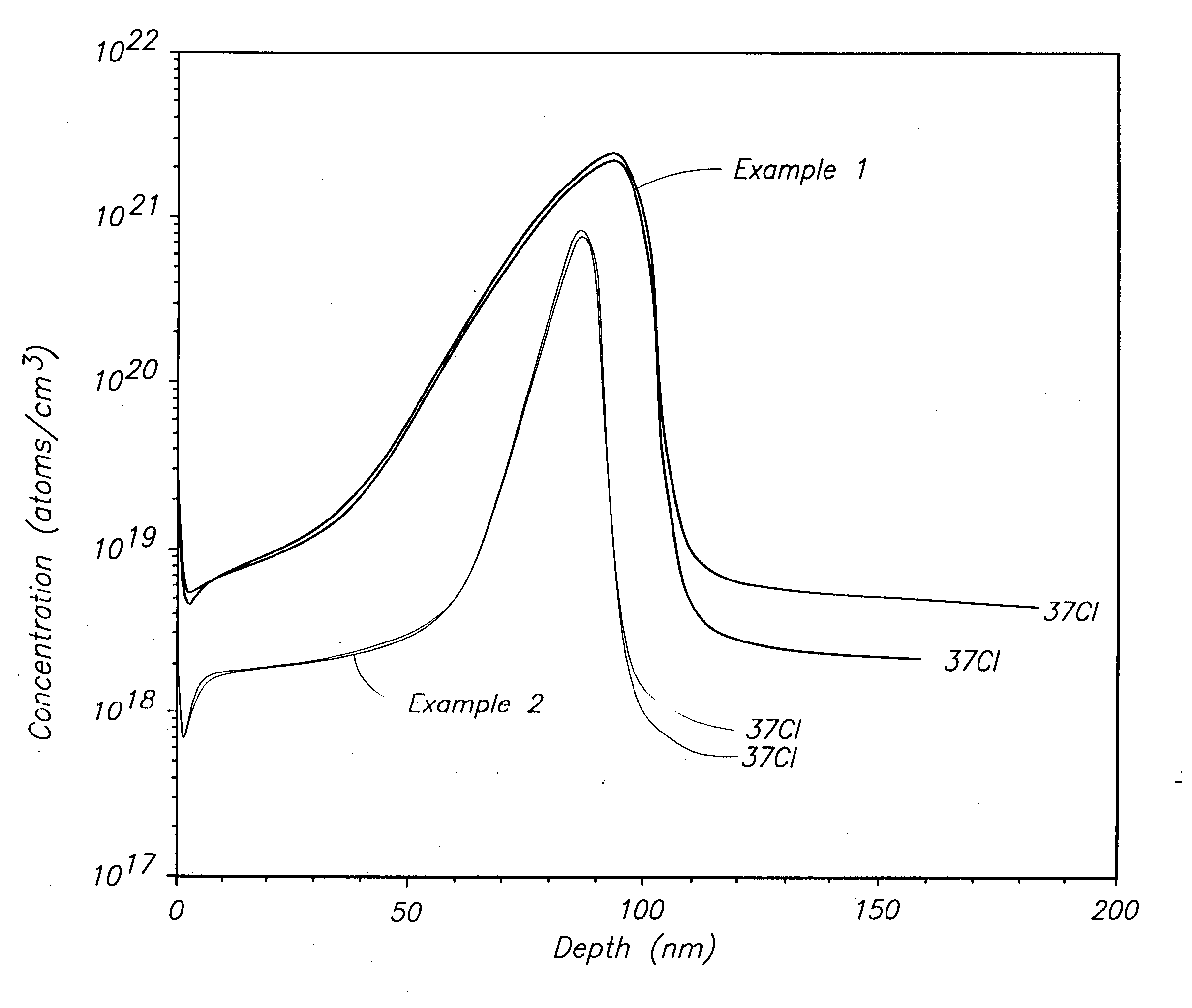

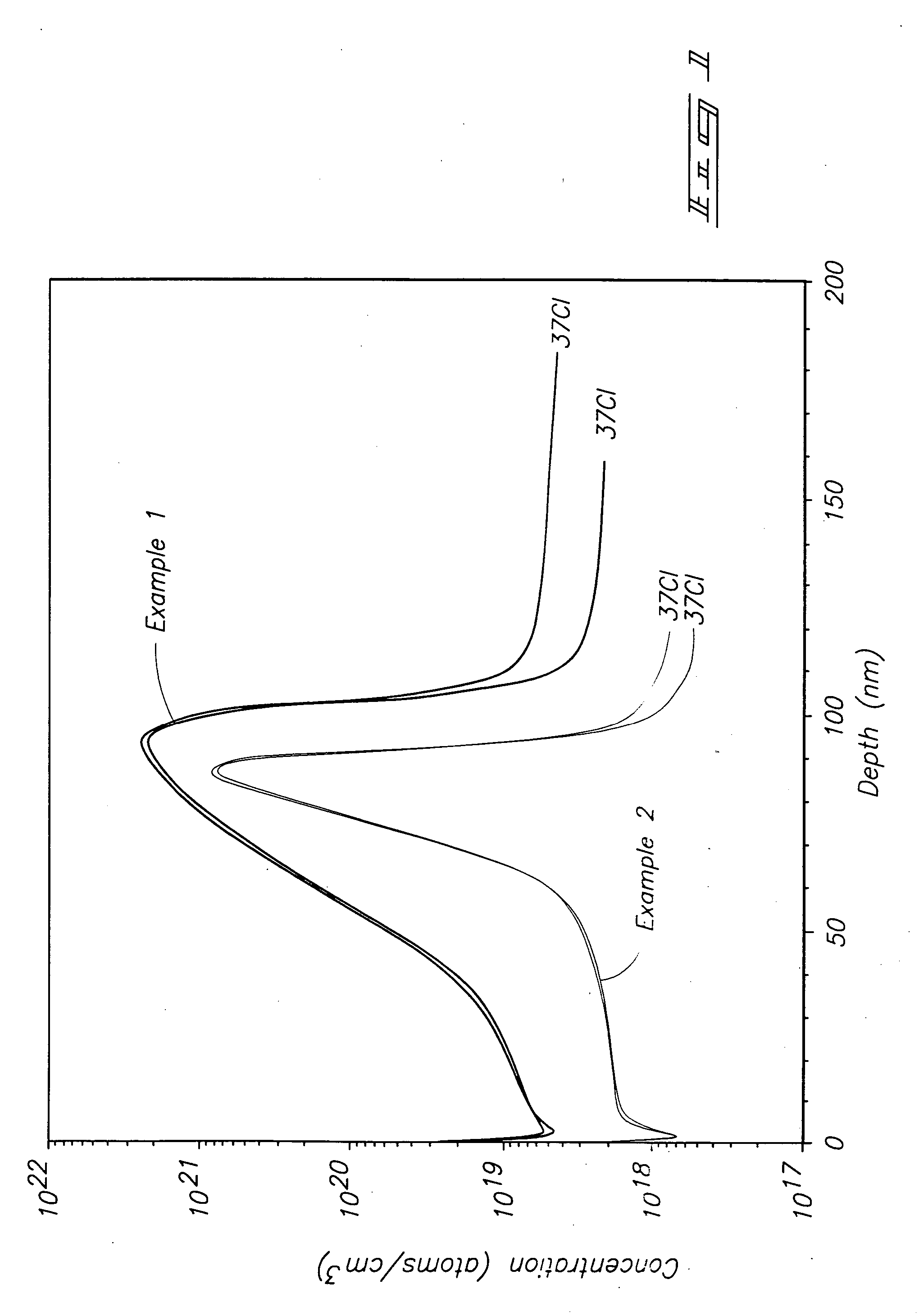

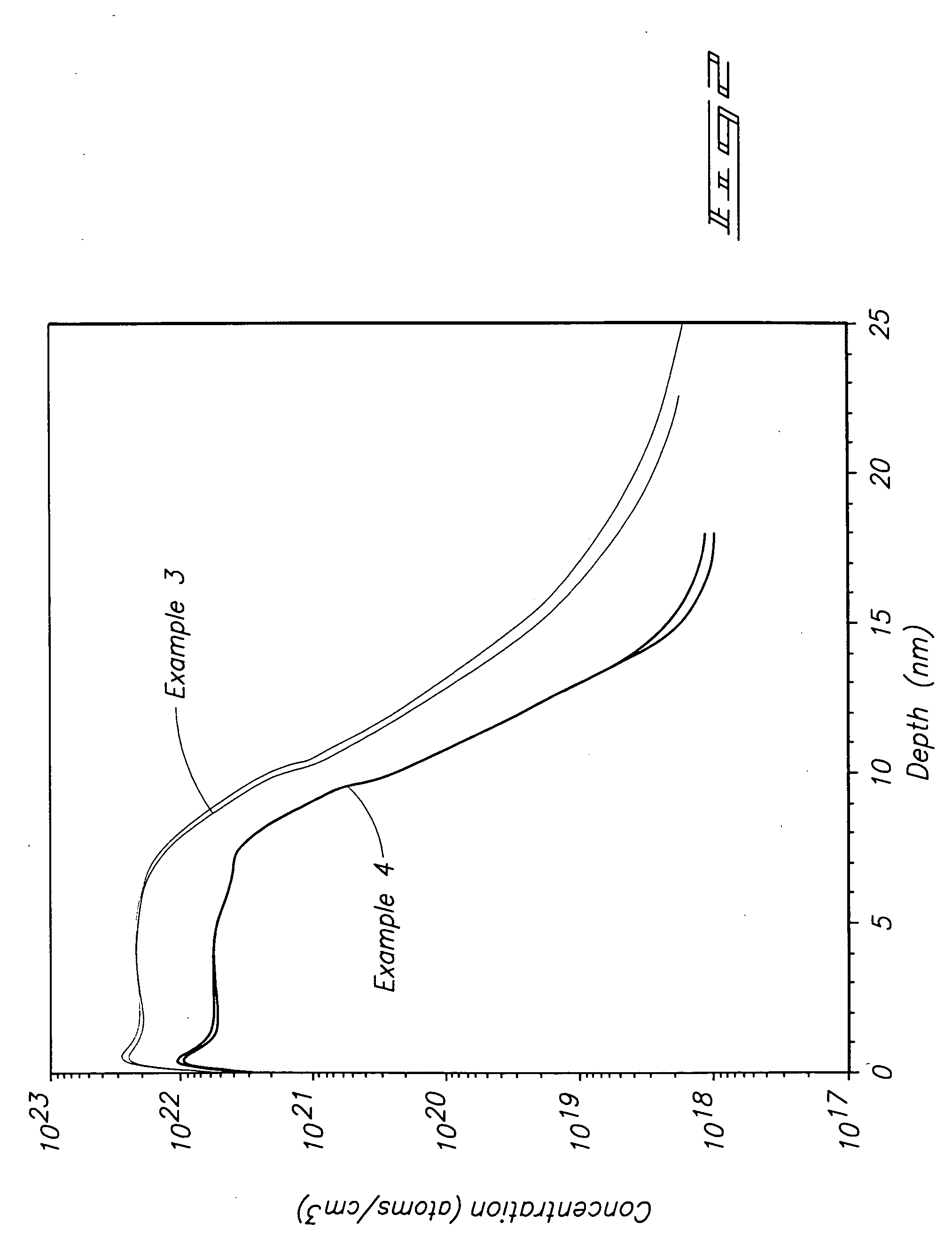

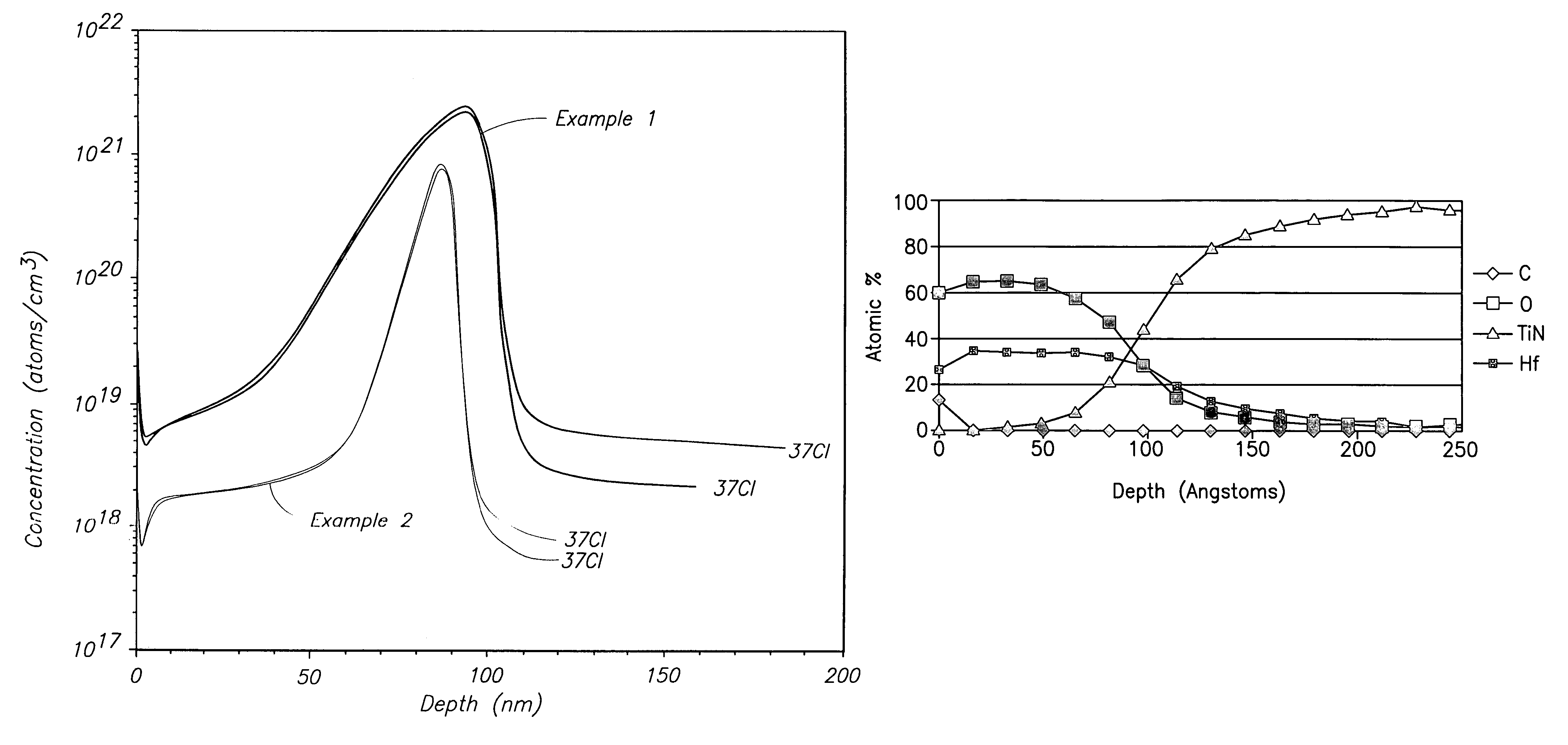

ActiveUS20060046521A1Less halogen contentThermal stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHalogenChemisorption

An ALD method includes exposing a substrate to a first precursor including a plurality of different ligands, chemisorbing a precursor monolayer on the substrate, and reacting a second precursor with the precursor monolayer to yield a product monolayer. A surface reactive ligand exhibits a chemisorption affinity that exceeds the chemisorption affinity exhibited by a gas reactive ligand. Another deposition method includes exposing a substrate to a precursor containing an amino and / or imino ligand and a halide ligand and depositing a layer. The precursor exhibits a volatility that exceeds the volatility with a halide ligand taking the place of each amino and / or imino ligand. The precursor exhibits a thermal stability that exceeds the thermal stability with an amino and / or imino ligand taking the place of each halide ligand. The layer may exhibit less halogen content than with a halide ligand taking the place of each amino and / or imino ligand.

Owner:MICRON TECH INC

Deposition methods using heteroleptic precursors

ActiveUS7250367B2Less halogen contentThermal stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHalogenChemisorption

An ALD method includes exposing a substrate to a first precursor including a plurality of different ligands, chemisorbing a precursor monolayer on the substrate, and reacting a second precursor with the precursor monolayer to yield a product monolayer. A surface reactive ligand exhibits a chemisorption affinity that exceeds the chemisorption affinity exhibited by a gas reactive ligand. Another deposition method includes exposing a substrate to a precursor containing an amino and / or imino ligand and a halide ligand and depositing a layer. The precursor exhibits a volatility that exceeds the volatility with a halide ligand taking the place of each amino and / or imino ligand. The precursor exhibits a thermal stability that exceeds the thermal stability with an amino and / or imino ligand taking the place of each halide ligand. The layer may exhibit less halogen content than with a halide ligand taking the place of each amino and / or imino ligand.

Owner:MICRON TECH INC

Compound biological antiseptic and preservation agent for food

The invention relates to a compound biological antiseptic and preservation agent for food. The compound biological antiseptic and preservation agent is prepared by evenly mixing pure biological solid preparations or products such as epsilon-polylysine, nisin, natamycin, lysozyme, bacillus subtilis, ascorbic acid, a toona sinensis leaf extract, a water-soluble resveratrol preparation, tea polyphenol and chitosan. The compound biological antiseptic and preservation agent has a strong inhibition effect on spoilage bacteria and pathogenic bacteria in various foods and good inhibition action on oxidative deterioration of the food. Compared with the existing various preservatives, the compound biological antiseptic and preservation agent has the characteristics of broad antibacterial spectrum, high safety, high efficiency and convenience in use.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

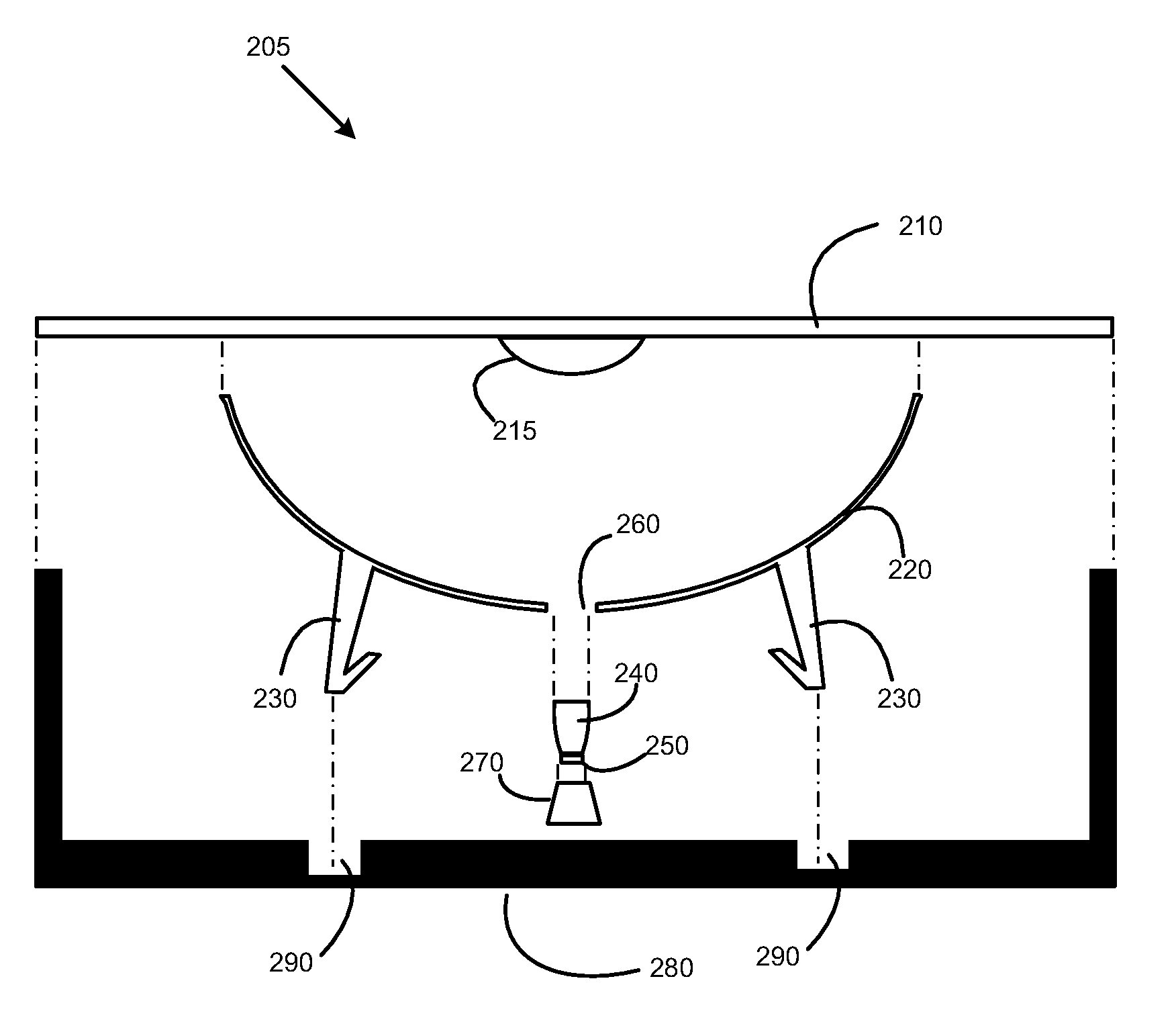

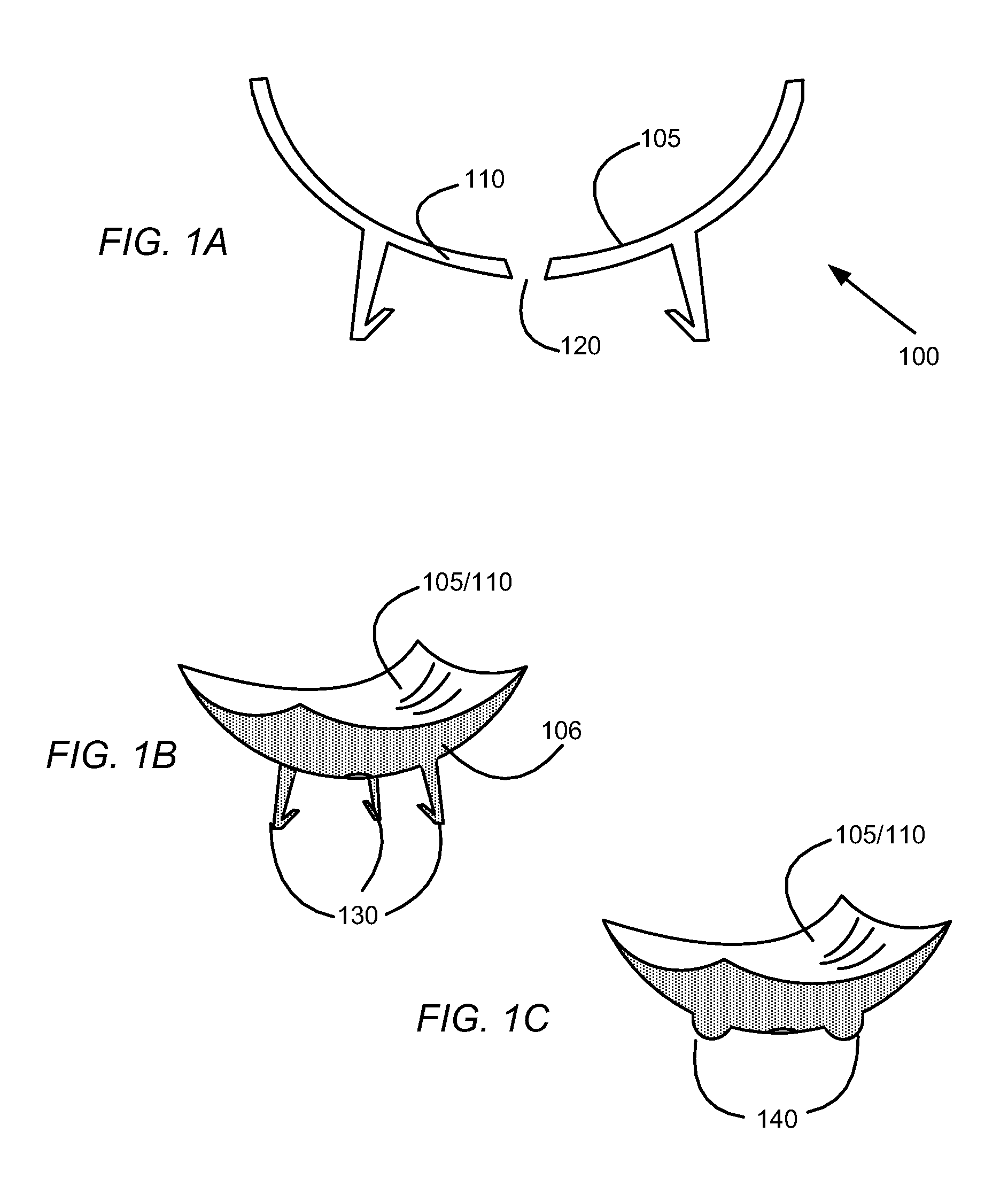

Monolithic Mirror Array

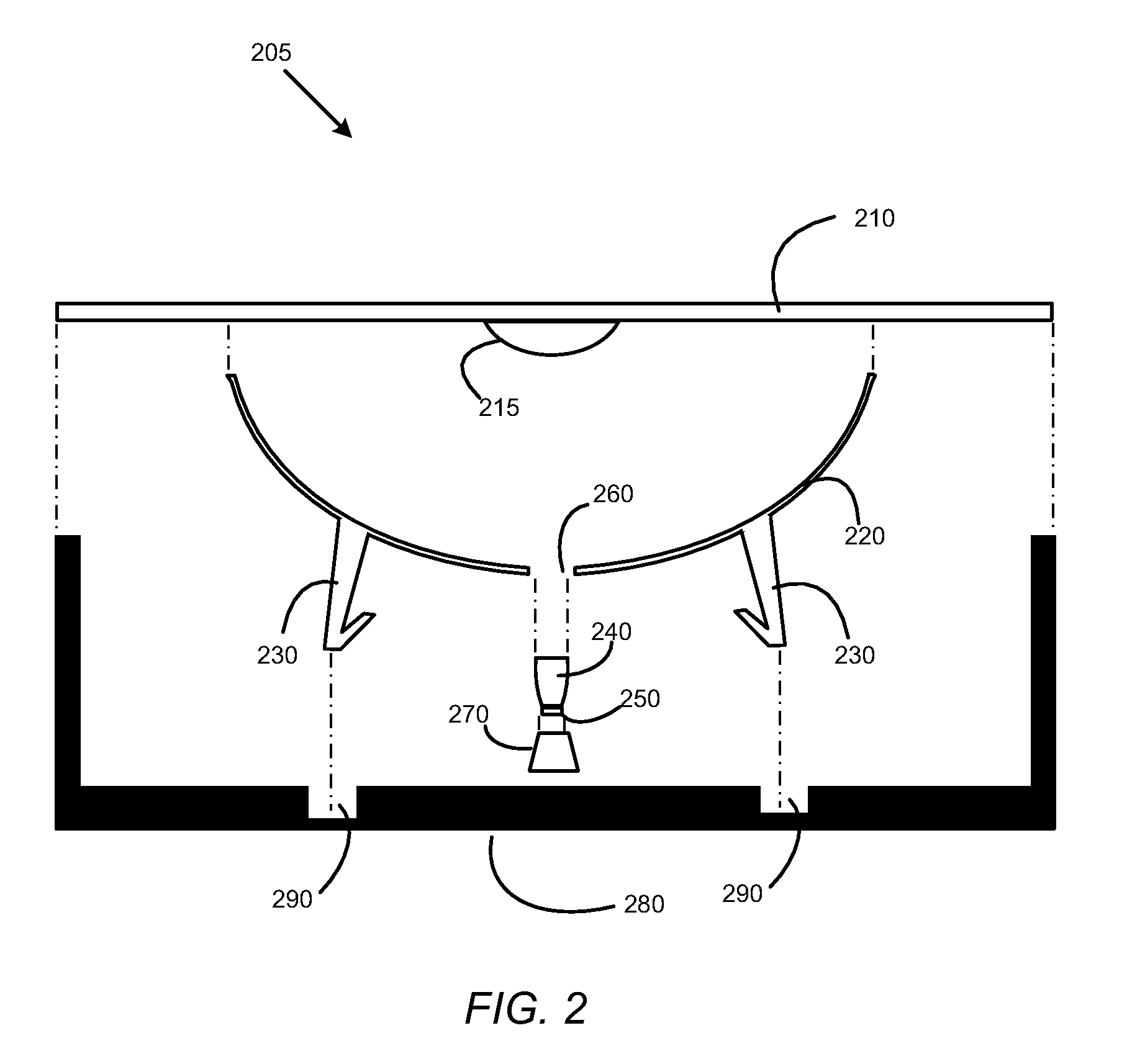

InactiveUS20090056790A1Easy to optimizeLow production costSolar heating energyMirrorsEngineeringThermal stability

The present invention is an improved solar concentrator array utilizing a monolithic array of primary mirrors fabricated from a single sheet of formable material. The material may include glass, plastic, and metal of a high thermal stability to be able to withstand a broad range of temperature conditions. The monolithic array of this invention may include integral alignment or attachment features for attachment to a supporting structure.

Owner:SOLFOCUS

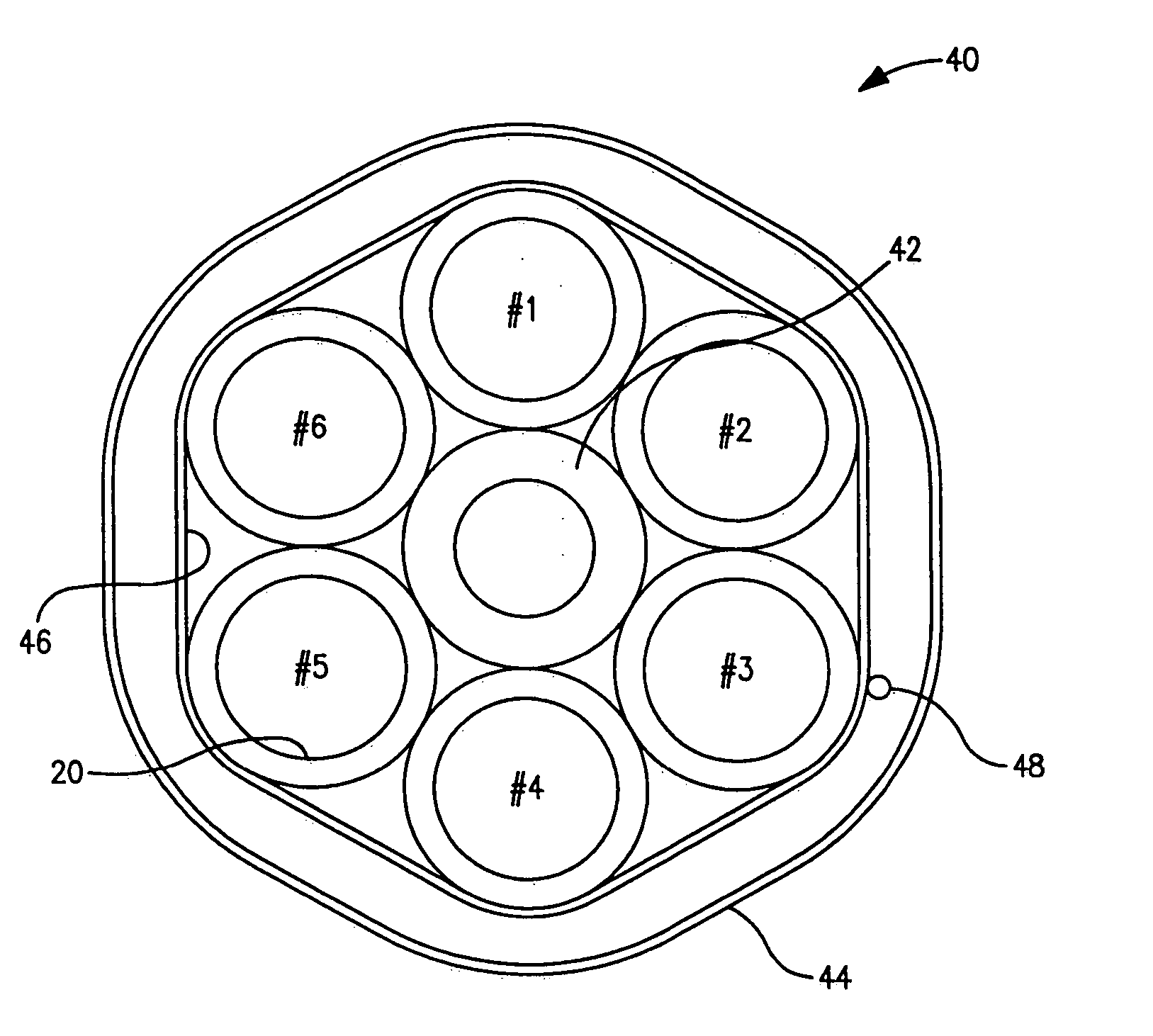

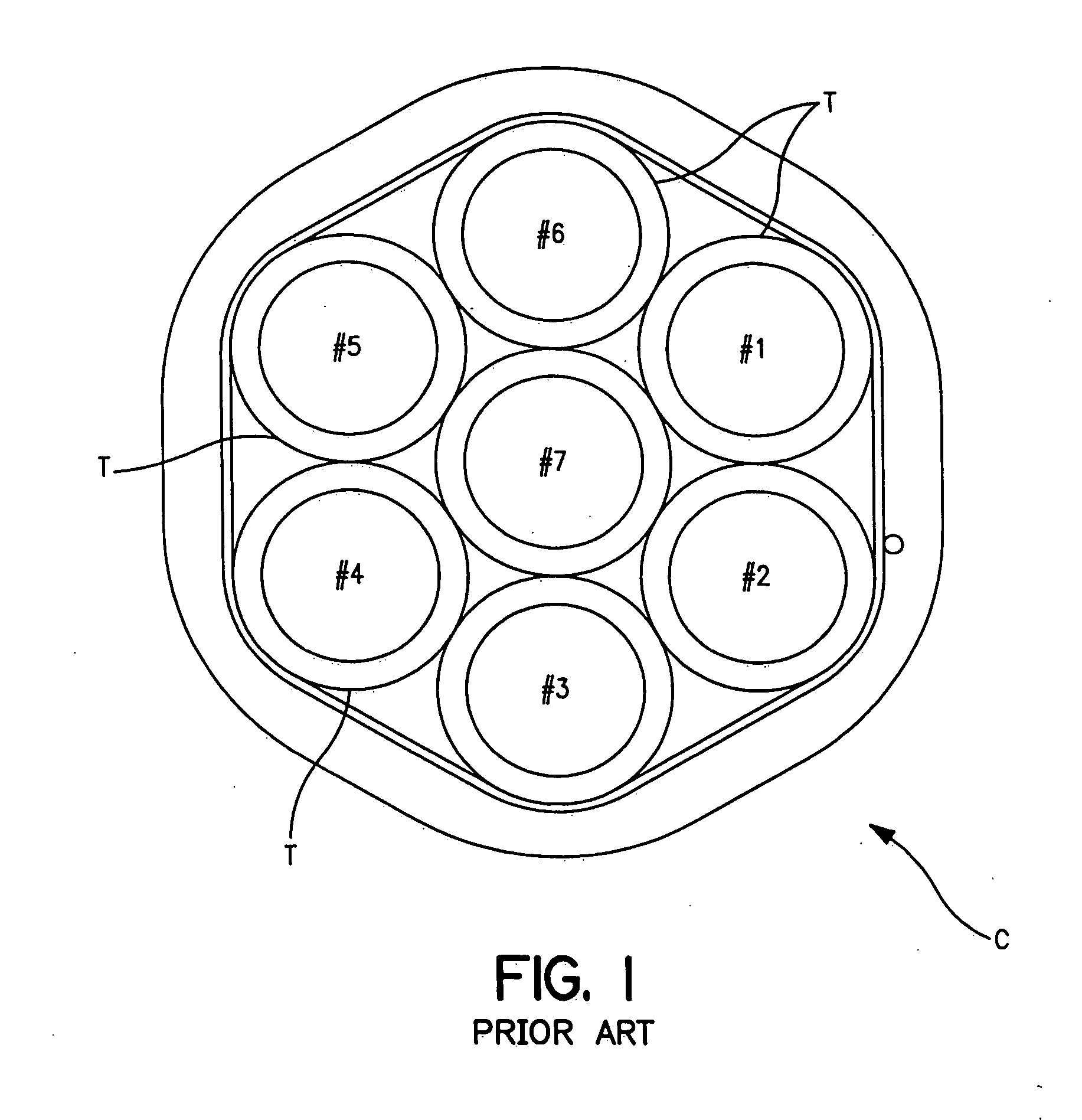

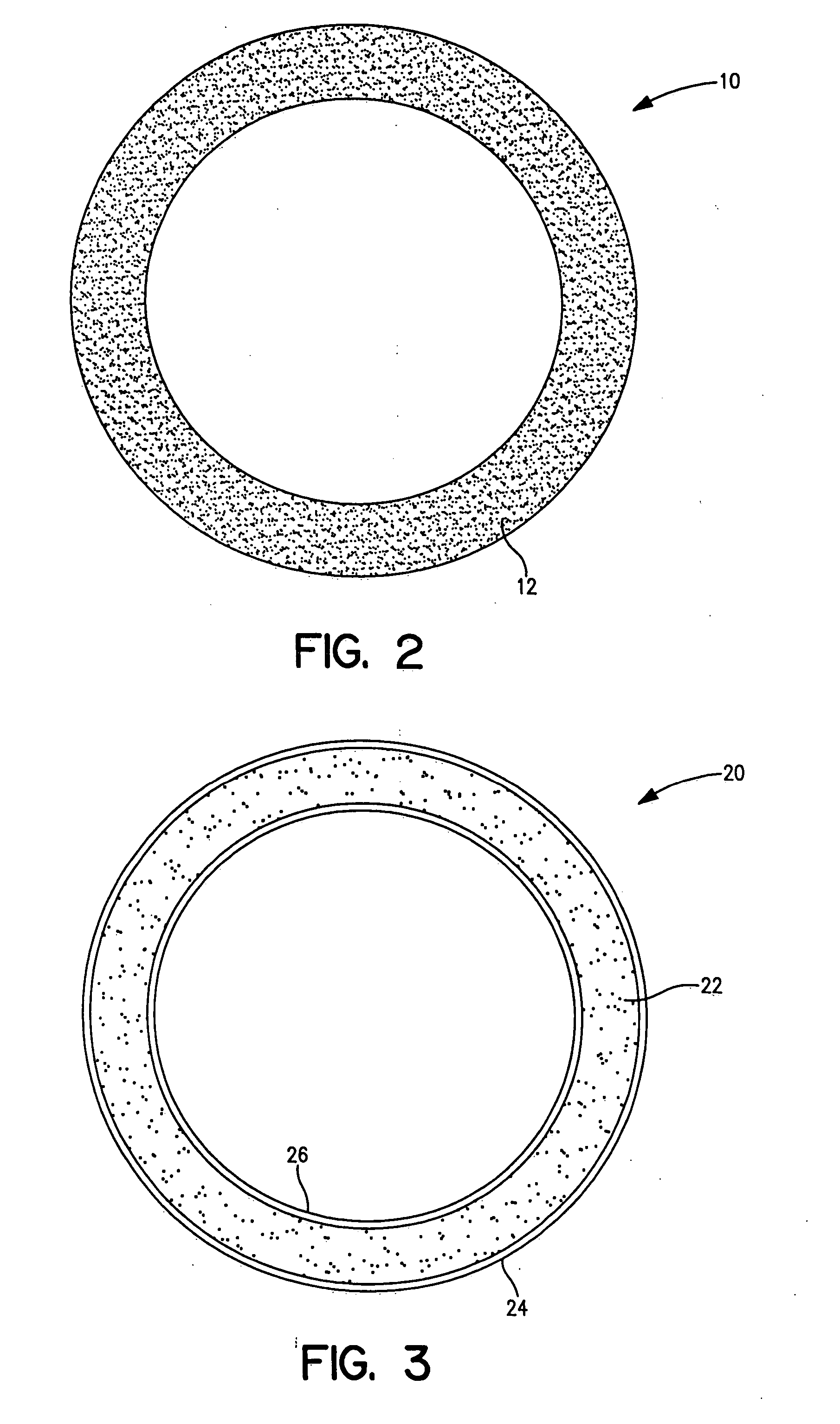

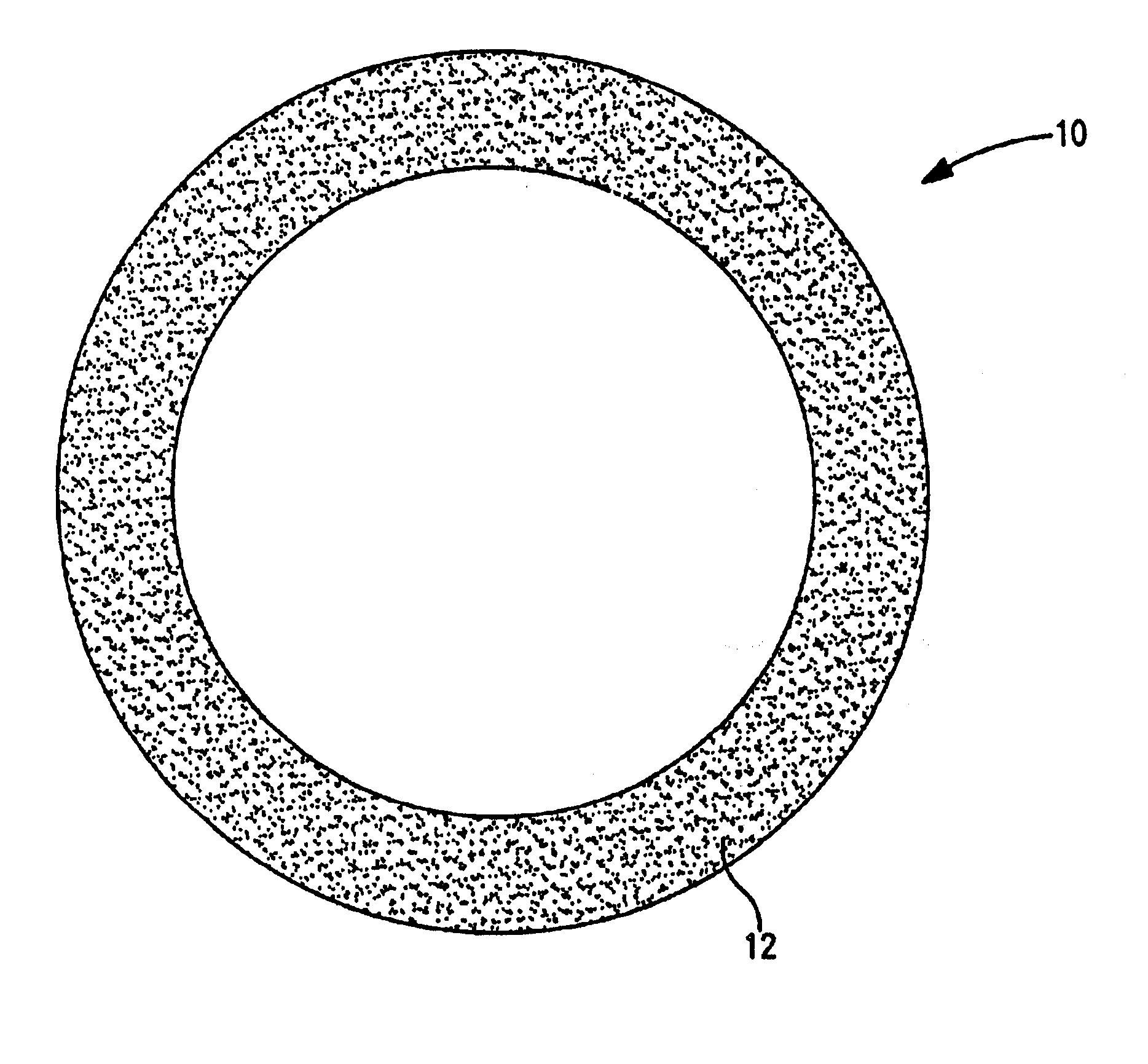

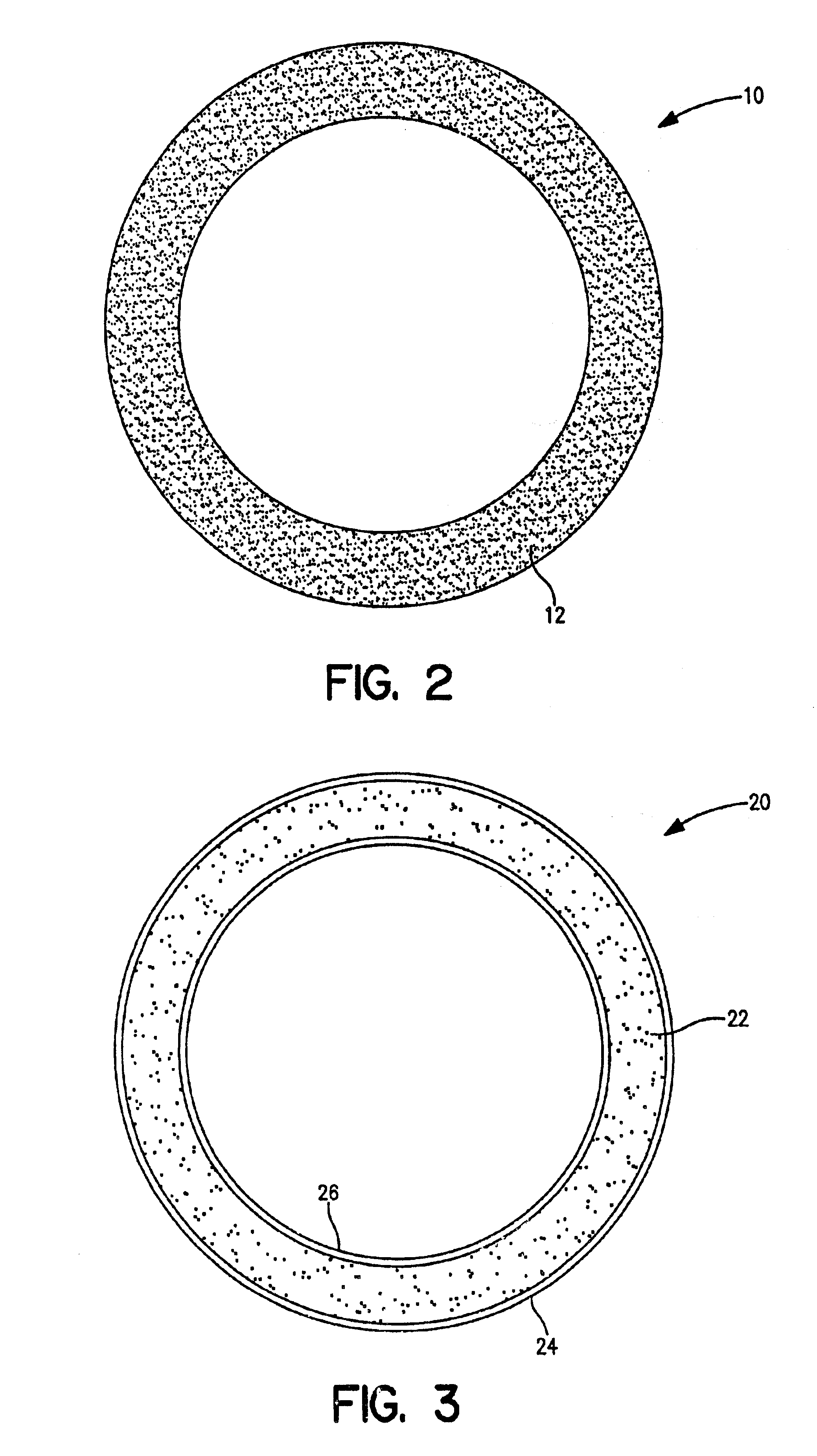

Air blown fiber (ABF) cable with low composite coefficient of thermal expansion

InactiveUS20050147363A1Inhibit deteriorationImprove thermal stabilityFibre mechanical structuresFiberCross-link

An air blown fiber tube cable having improved thermal stability in contrast to conventional air blown fiber (ABF) tube cables and within which one or more air blown optical fiber units can be installed. The air blown fiber tube is formed from a cross-linked polyolefin (preferably cross-linked high density polyethylene) comprising at least one non-polymer filler material having a coefficient of thermal expansion less than the coefficient of thermal expansion of said tube.

Owner:DANFOSS AS

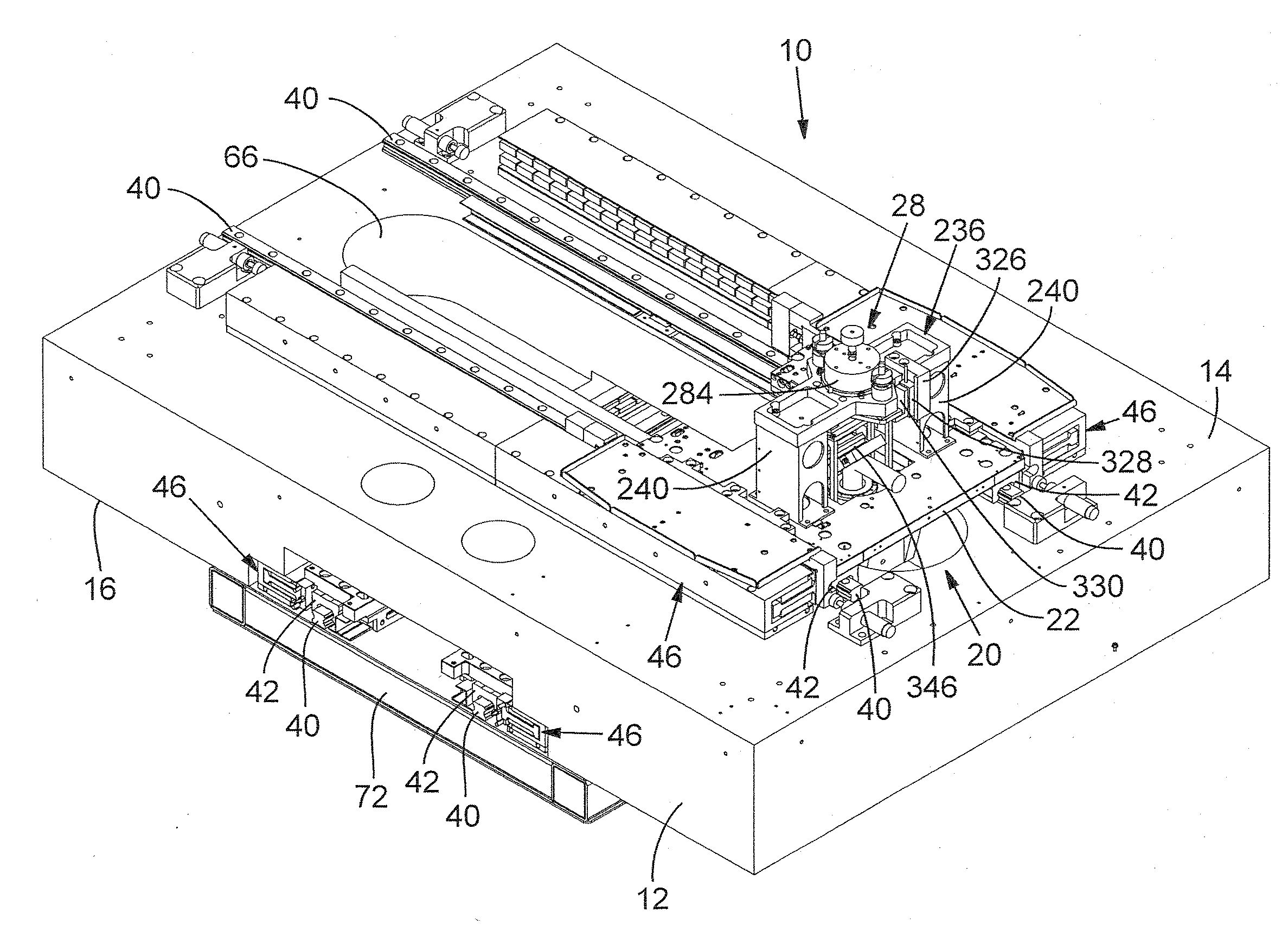

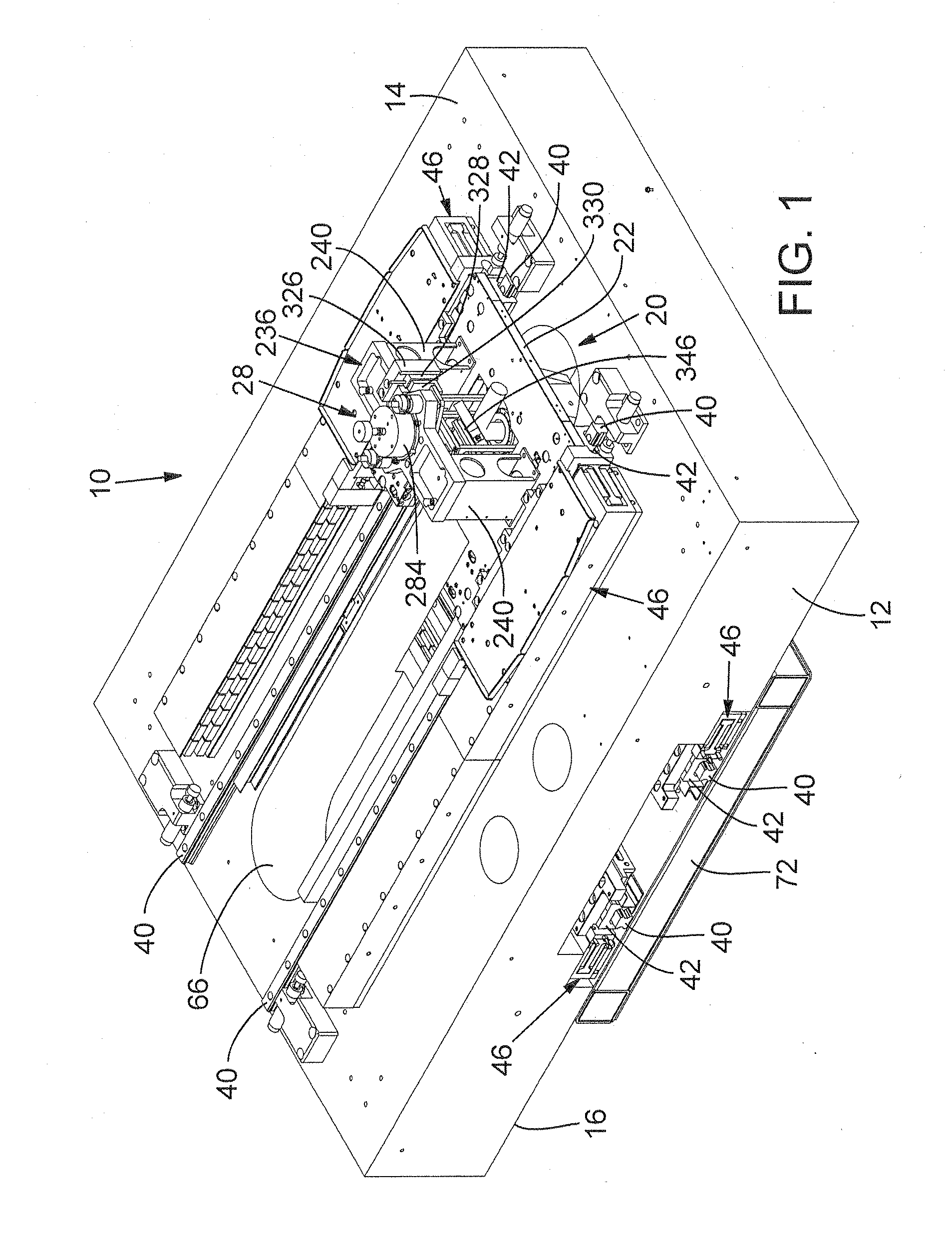

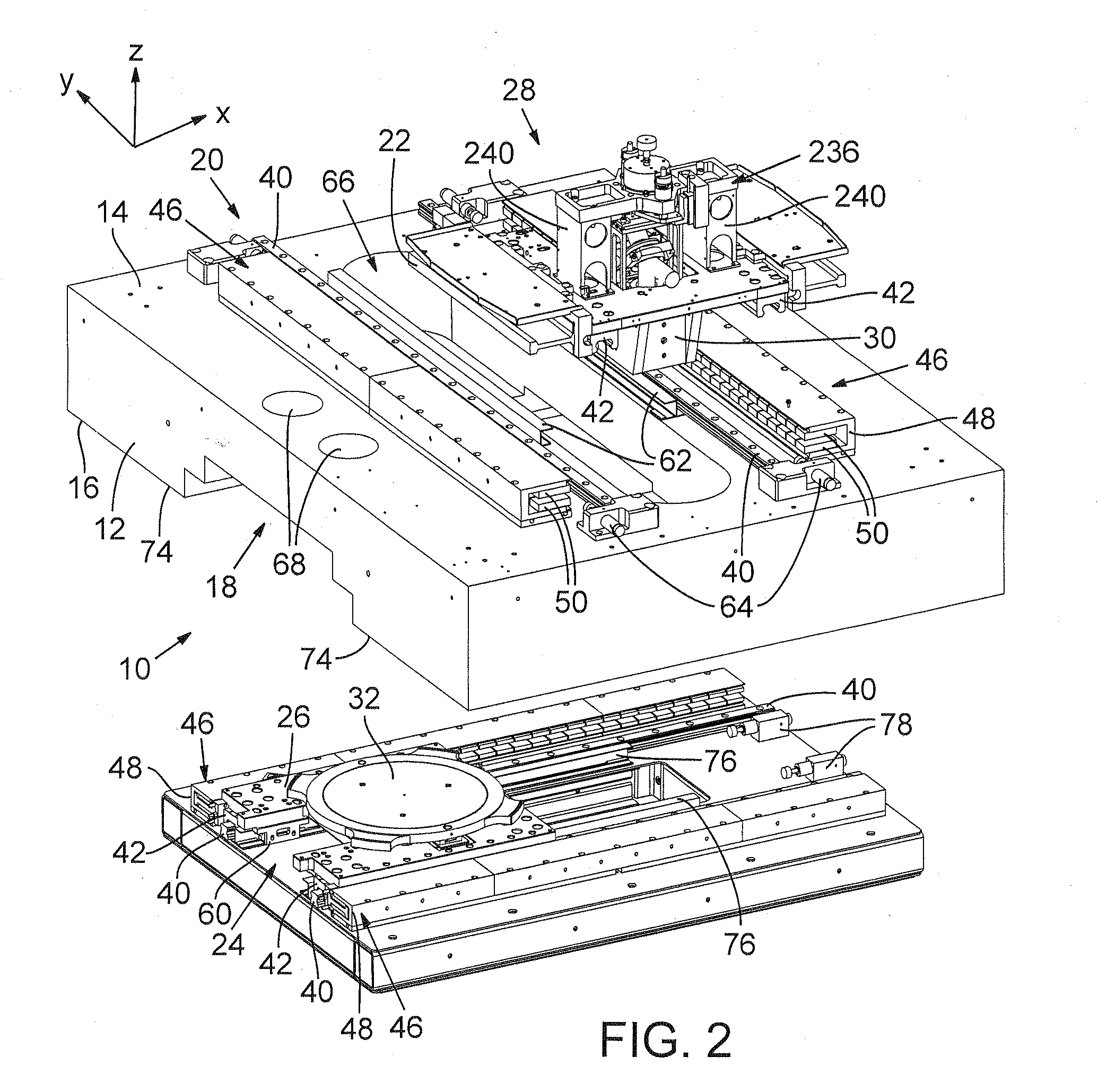

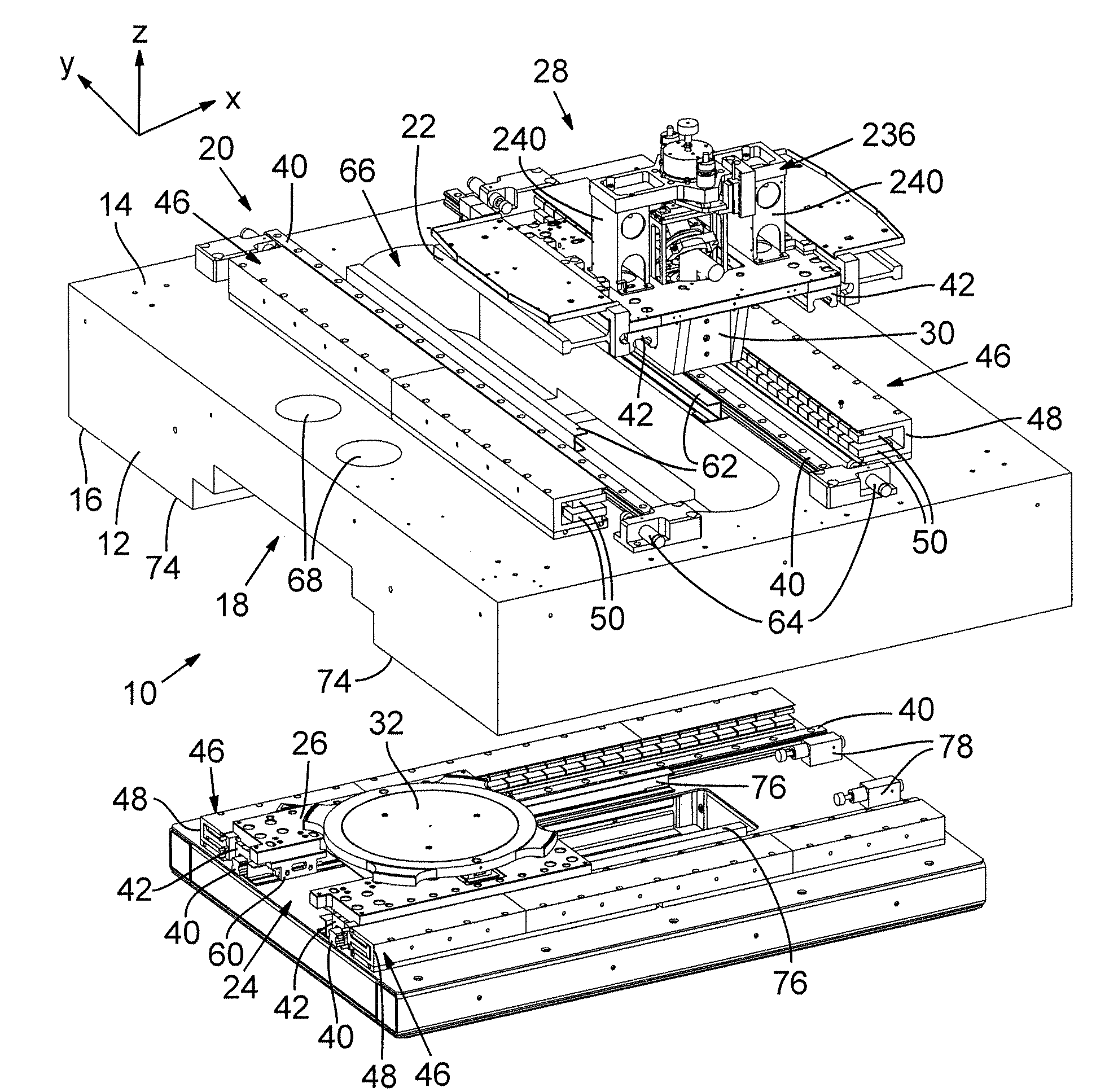

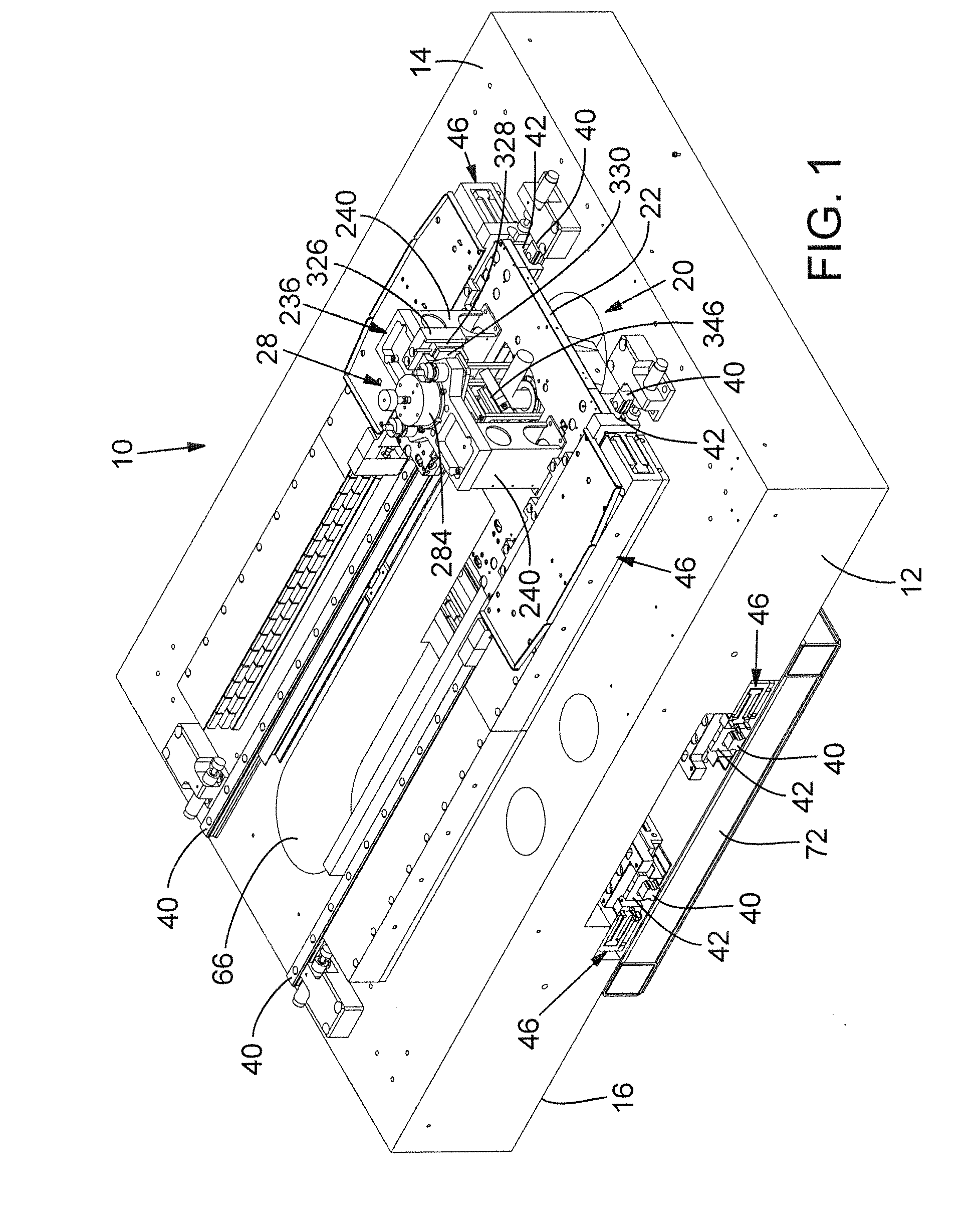

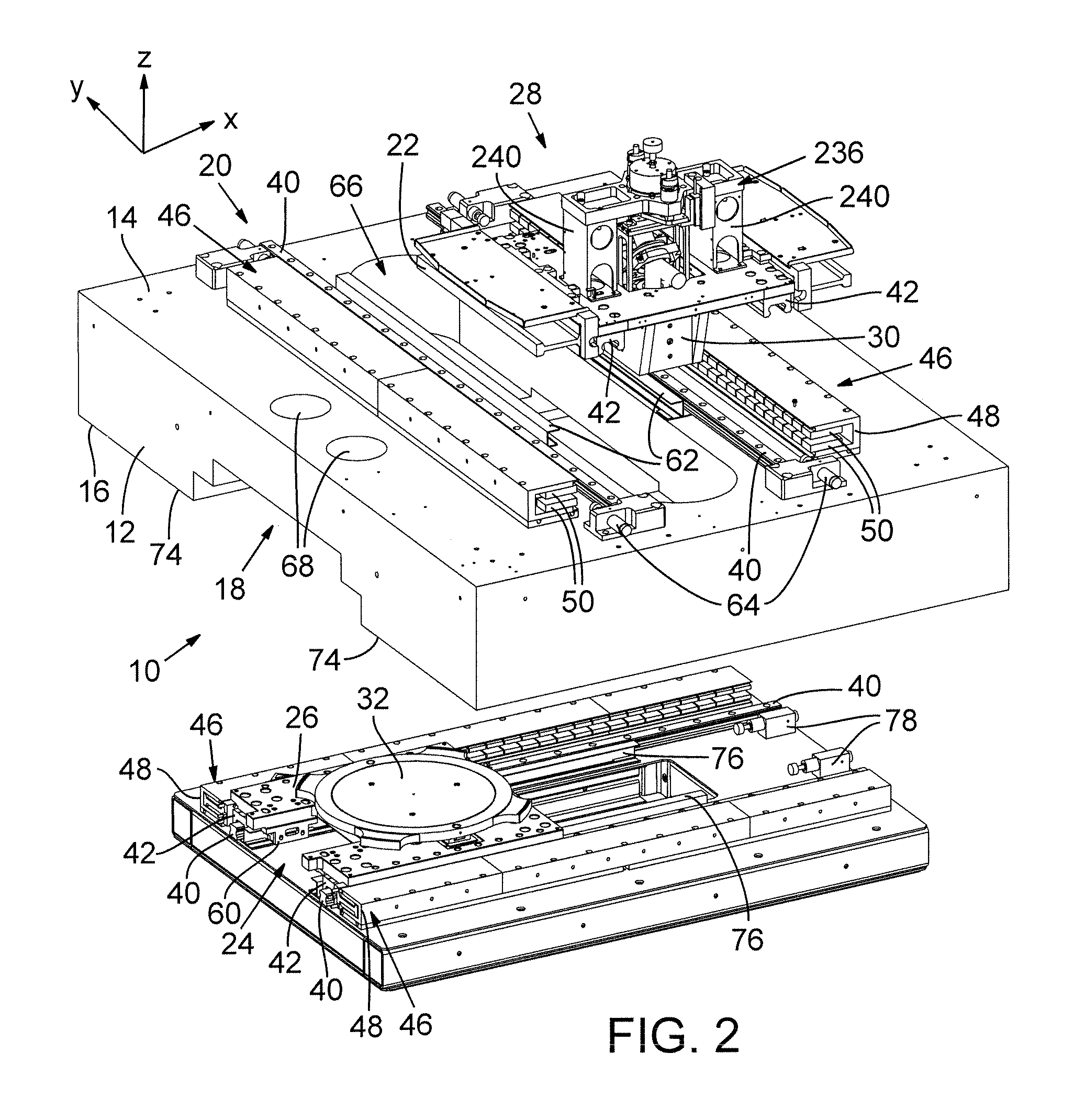

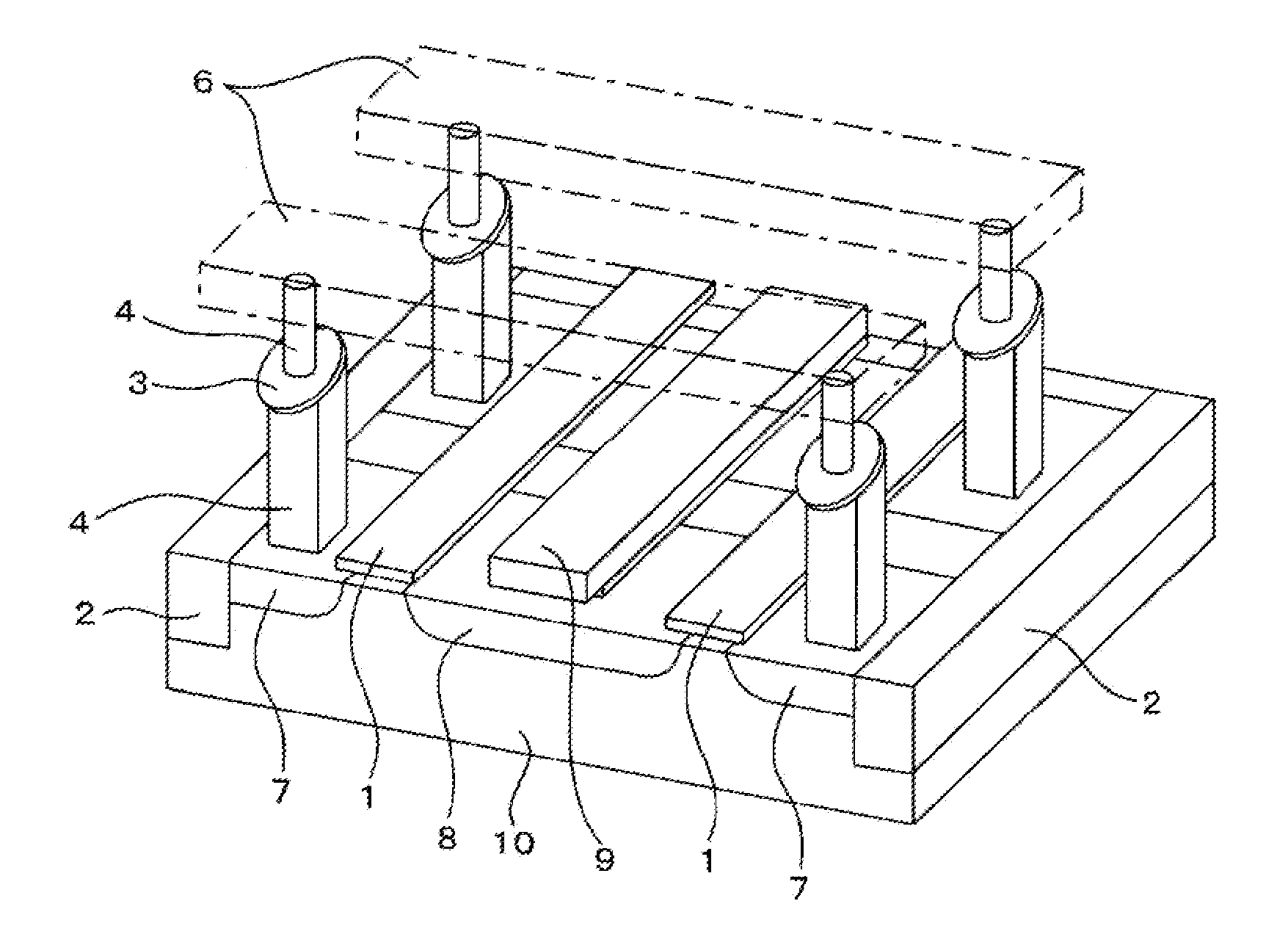

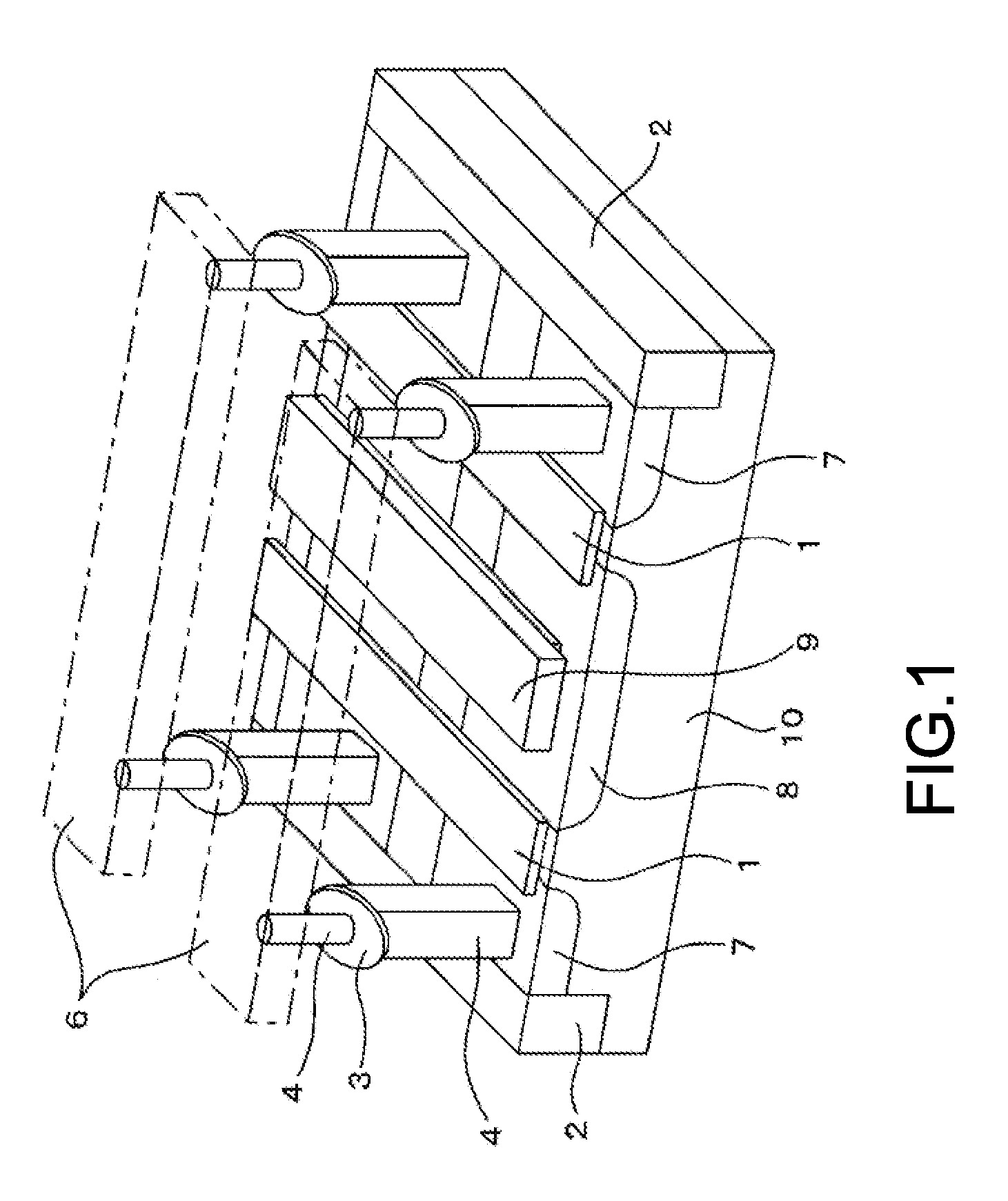

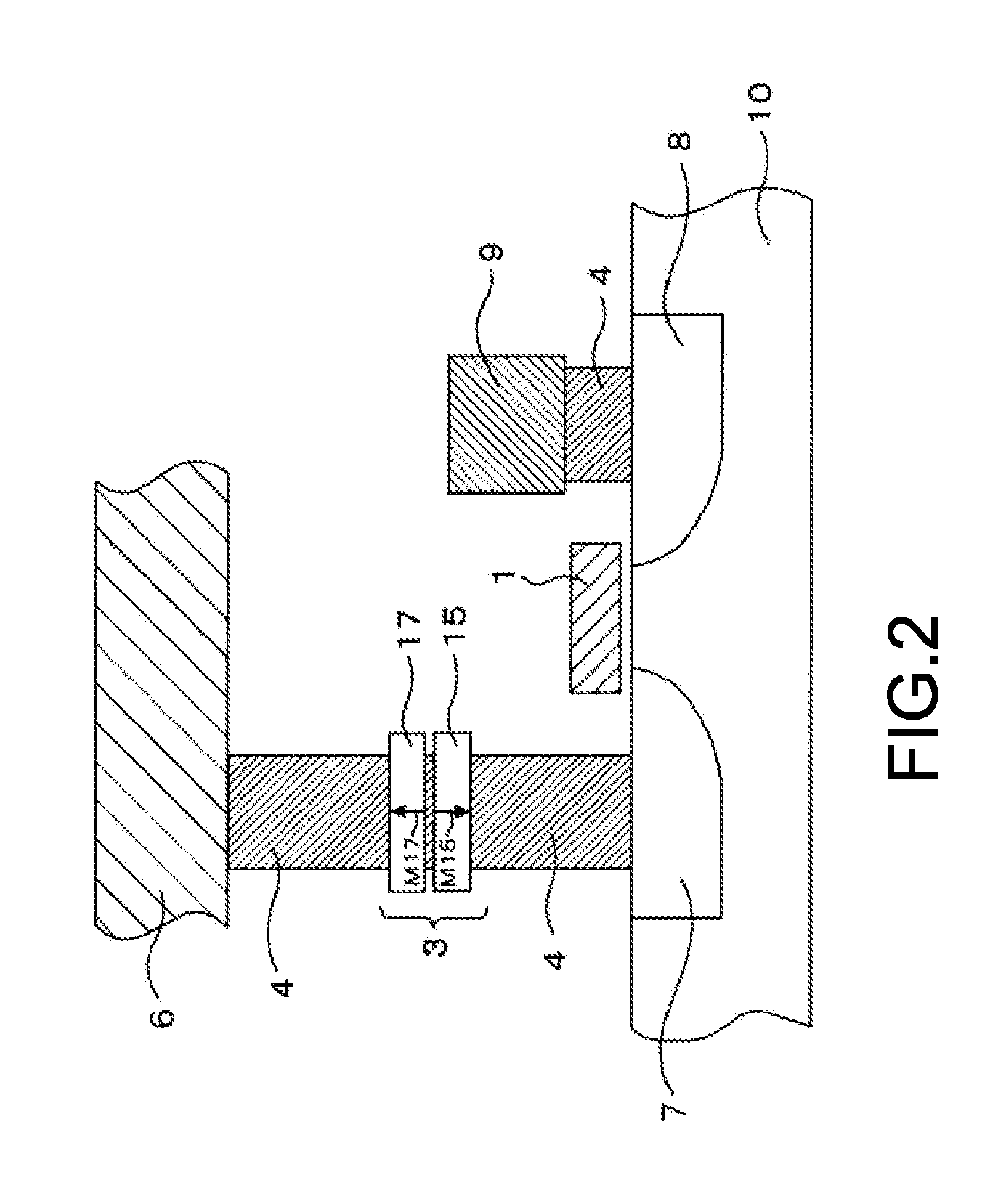

Decoupled, multiple stage positioning system

InactiveUS20080196631A1Smoother accelerationSmooth decelerationSemiconductor/solid-state device manufacturingPhotographic printingEngineeringHigh velocity

A split axis stage architecture is implemented as a multiple stage positioning system that is capable of vibrationally and thermally stable material transport at high speed and rates of acceleration. A split axis design decouples stage motion along two perpendicular axes lying in separate, parallel planes. A dimensionally stable substrate in the form of a granite, or other stone slab, or of ceramic material or cast iron, is used as the base for lower and upper stages. The substrate is precisely cut (“lapped”) such that its upper and lower stage surface portions are flat and parallel to each other.

Owner:ELECTRO SCI IND INC

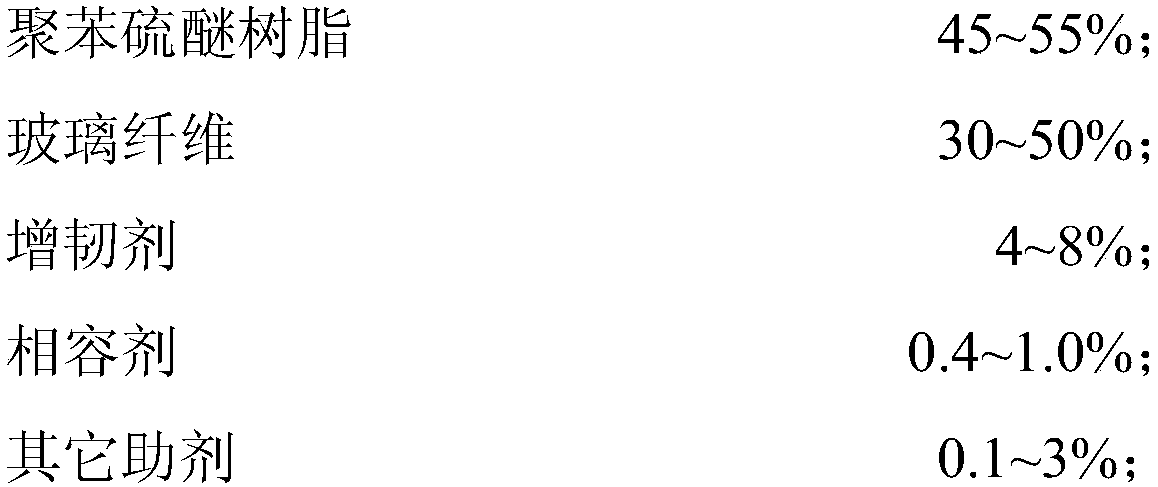

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

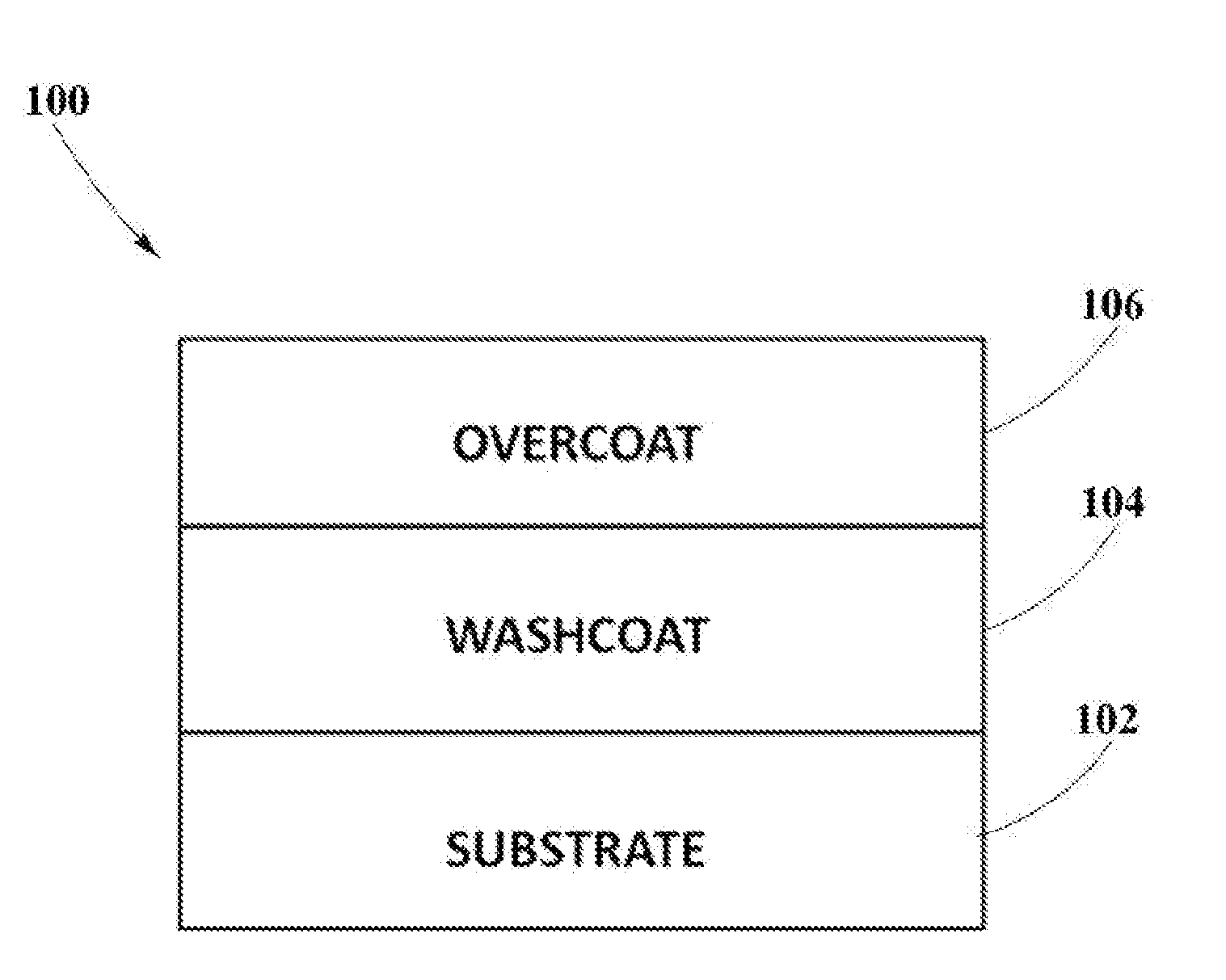

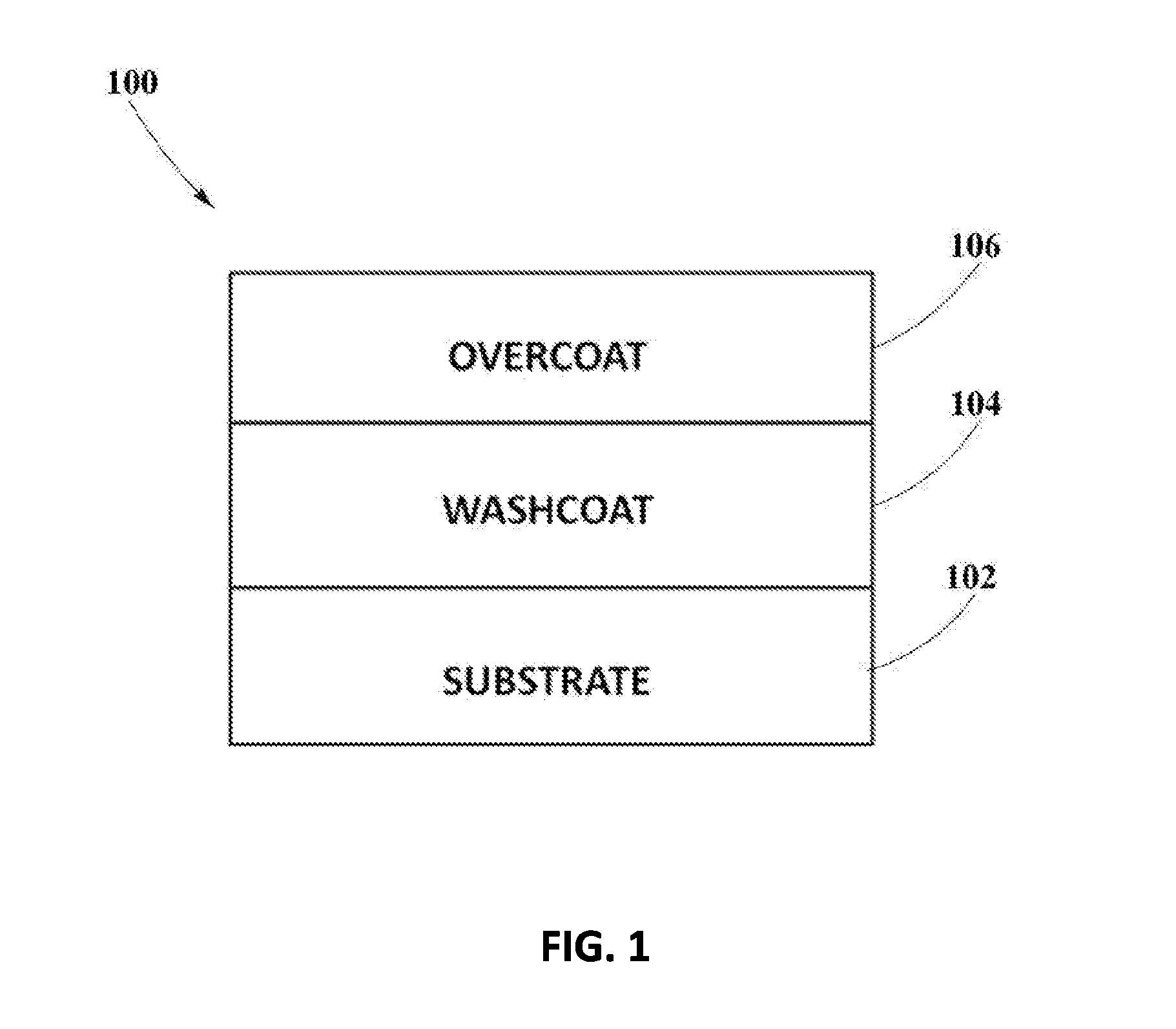

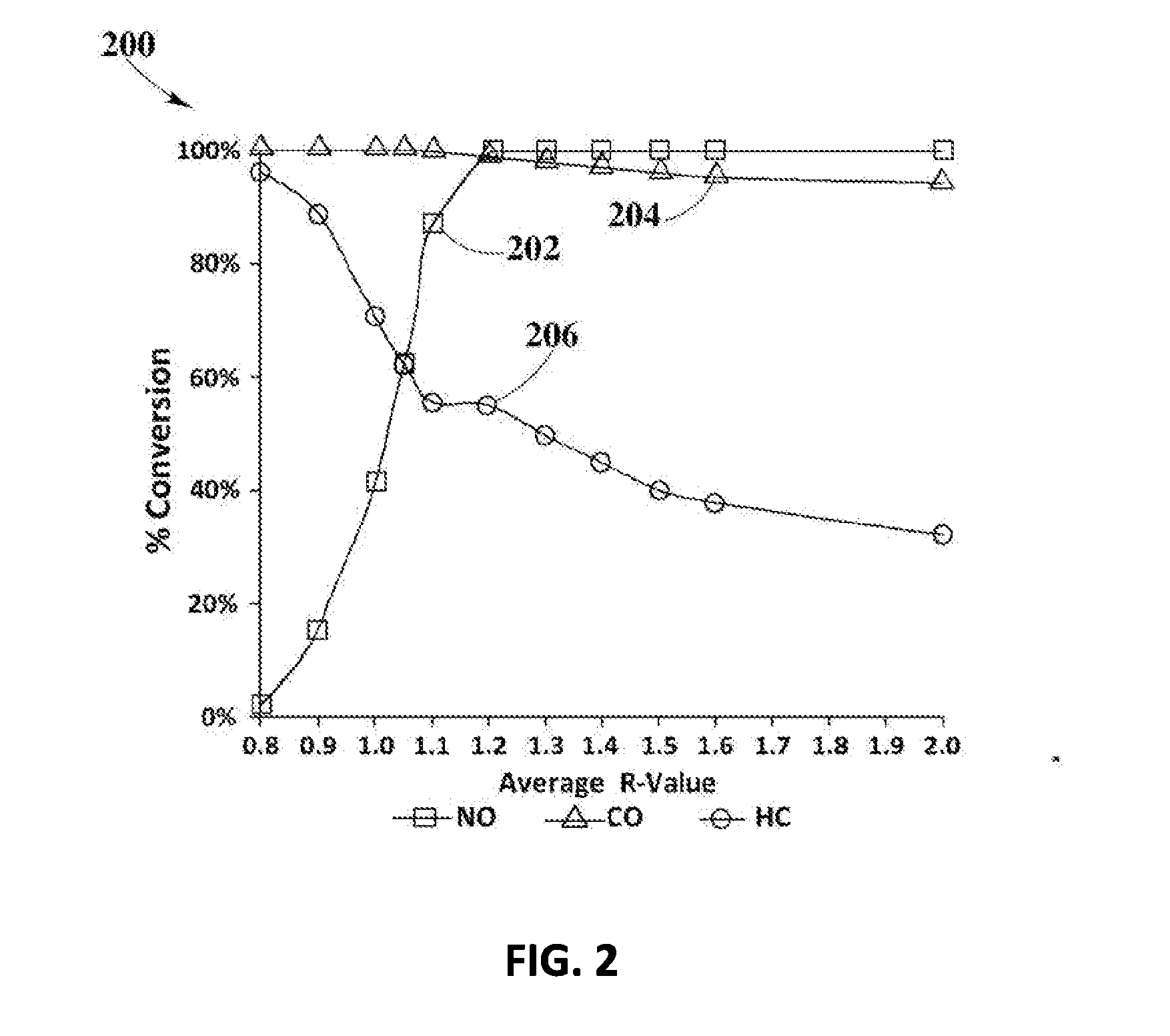

Optimal Composition of Copper-Manganese Spinel in ZPGM Catalyst for TWC Applications

InactiveUS20140271387A1High catalytic activityImprove thermal stabilityCombination devicesInternal combustion piston enginesChemical compositionSpinel

It is an object of the present disclosure, to provide an optimized catalyst composition with variations of Cu and Mn molar ratio, which may include a formulation CuxMn3-xO4 spinel, with a plurality of molar ratio variations for selecting the optimal Cu—Mn molar ratio for TWC application. The formulation may include a support oxide, such as Nb2O5—ZrO2. Employing this optimized Cu and Mn ratio in spinel as overcoat may achieve optimal NO conversion, high catalyst activity, and enhanced thermal stability, having a chemical composition substantially free from PGM and rare earth metals. According to principles of the present disclosure, the disclosed Cu—Mn spinel on Nb—Zr support oxide for TWC applications may require a washcoat of alumina, and overcoat of Cu—Mn spinel on Nb—Zr support oxide.

Owner:CLEAN DIESEL TECHNOLOGIES

Air bearing assembly for guiding motion of optical components of a laser processing system

InactiveUS20080198485A1Smoother accelerationSmooth decelerationLinear bearingsGas cushion bearingsLaser processingAir bearing

A rigid support structure allows for faster and more accurate positioning of axially adjustable optical components in a laser processing system. Vibrational and thermal stability is improved when an optics assembly is housed in a rigid air bearing sleeve that is mounted to a support structure above a specimen stage.

Owner:ELECTRO SCI IND INC

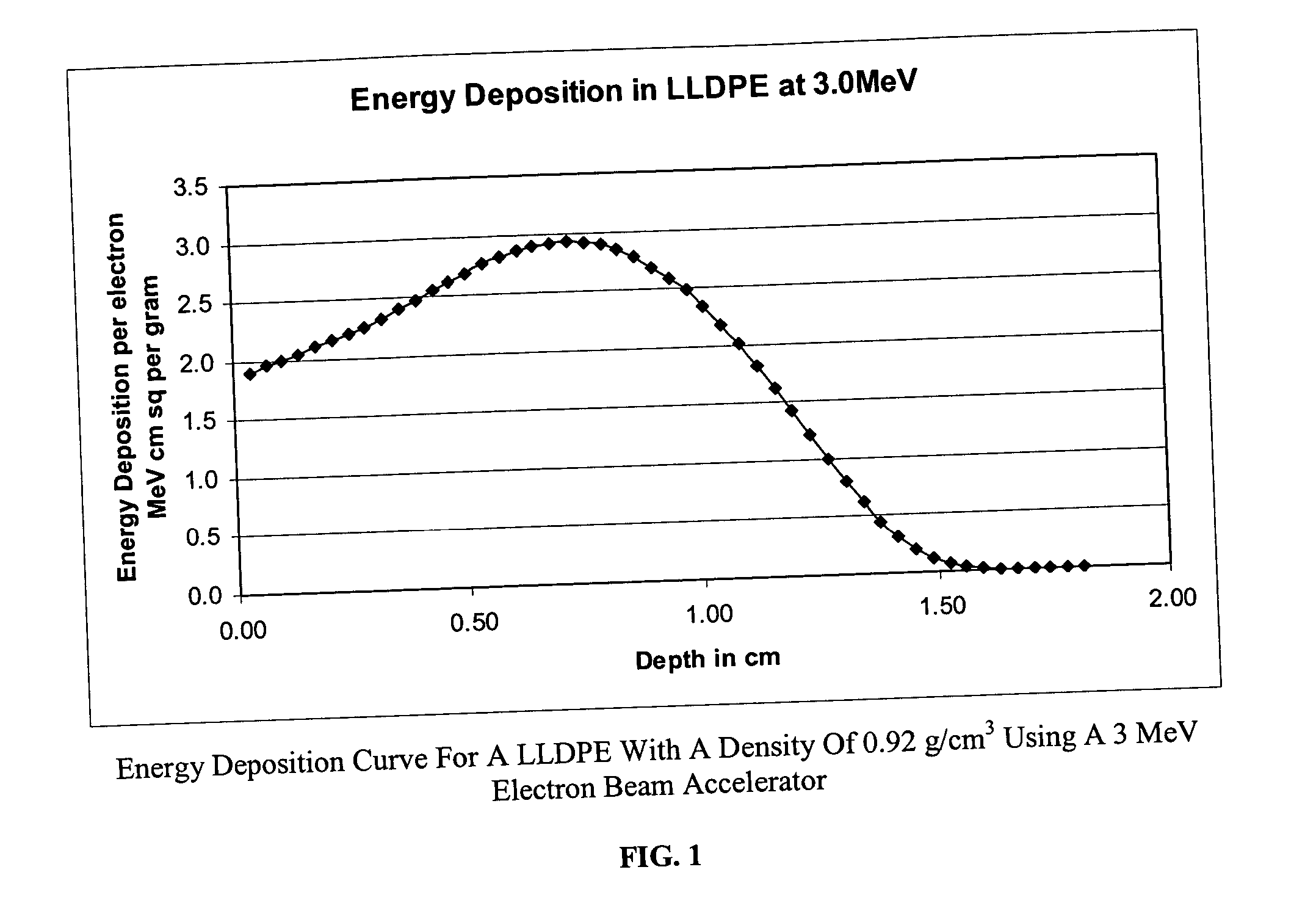

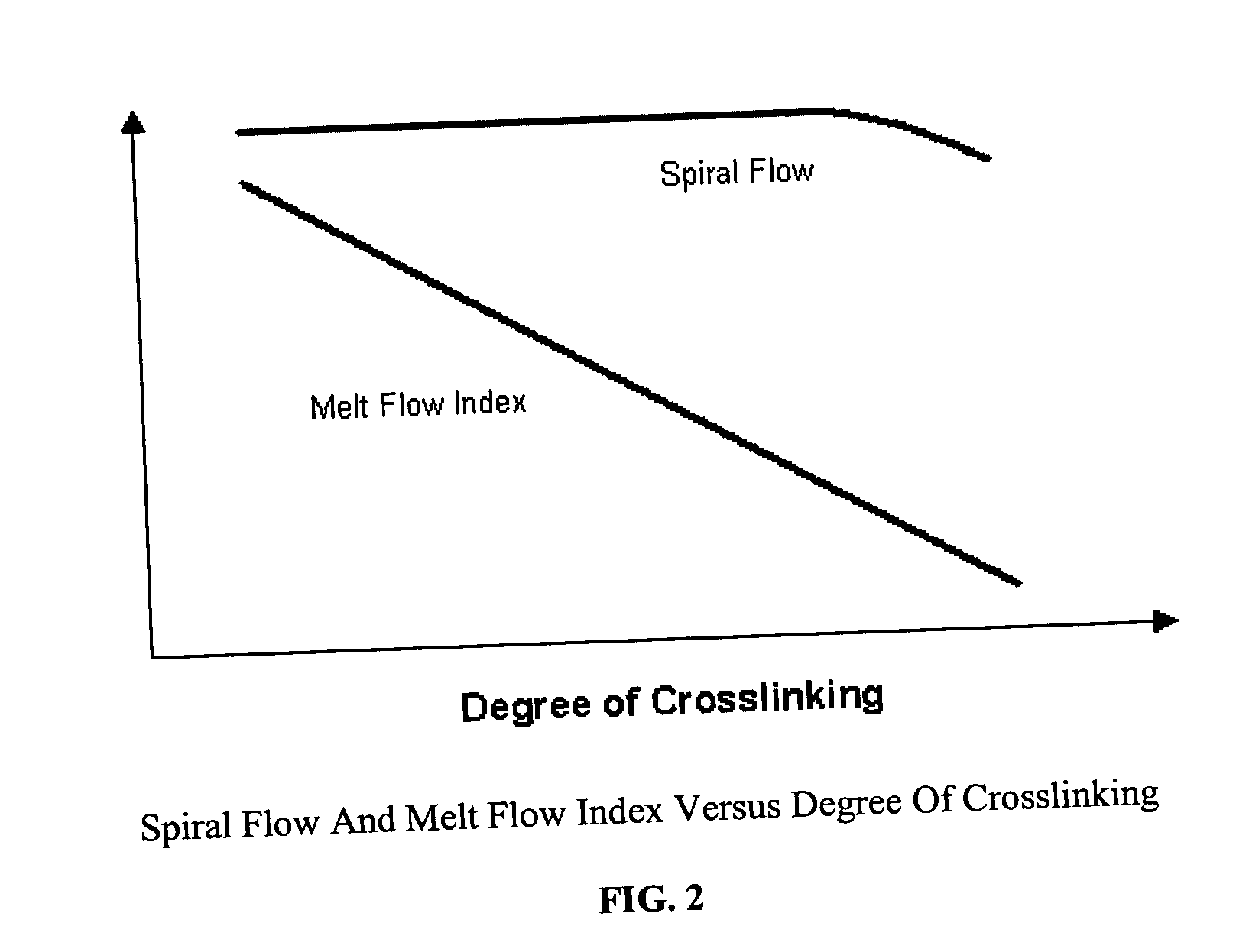

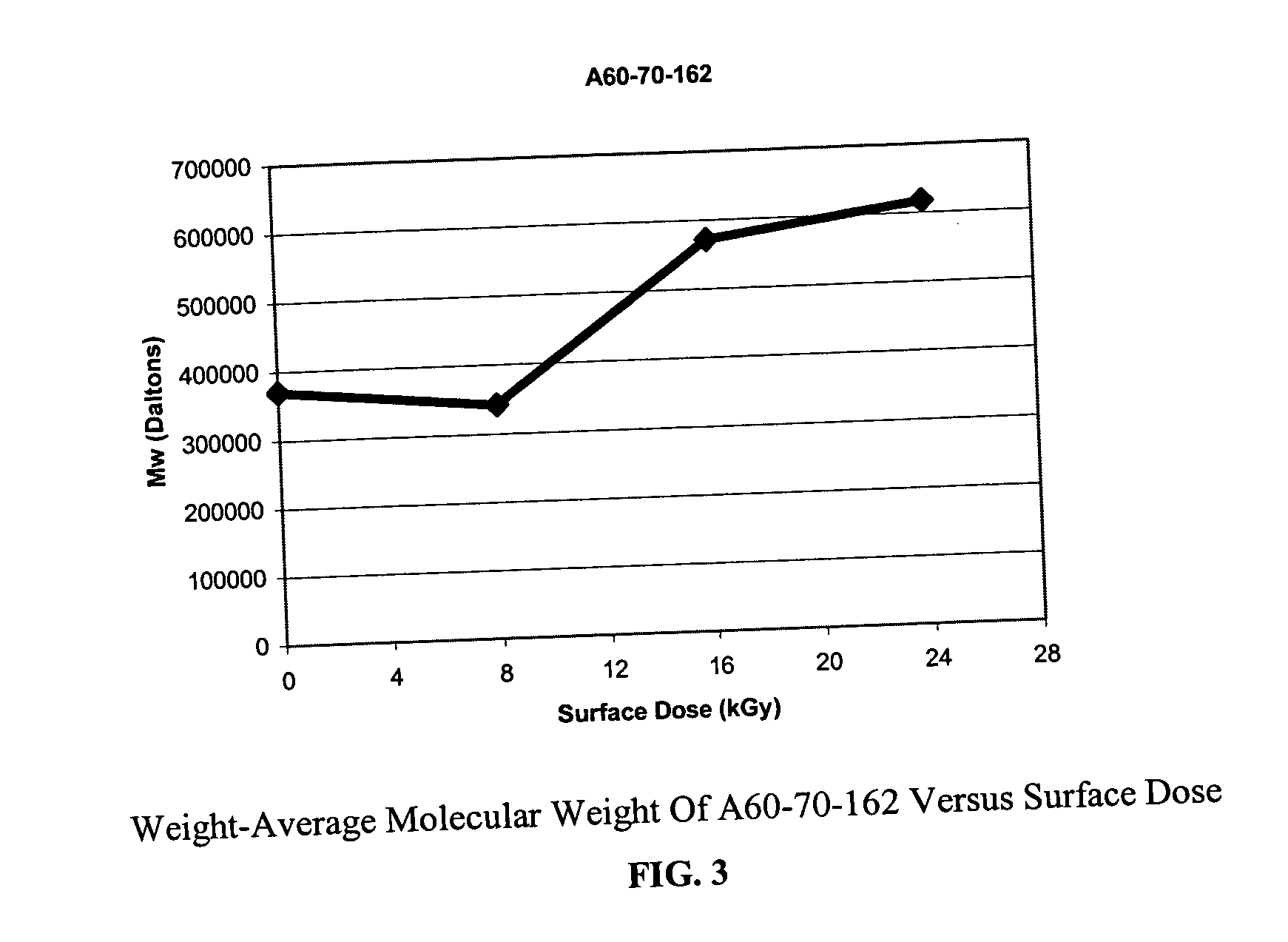

Radiation treated ethylene polymers and articles made from said polymers

InactiveUS20040132854A1Superior compatability and adhesion propertyEasily blendSynthetic resin layered productsGranular deliveryIonizing radiationPolymer

The invention relates to ethylene polymers that are modified by ionizing radiation, prior to article formation, at a temperature less than the crystalline melt temperature and preferably under ambient atmosphere, as well as articles made from said polymers. The irradiated ethylene polymers exhibit enhanced melt strength, tensile strength, impact resistance, tear strength, adhesion to polar substances and thermal stability, decreased elongation, and lower melt flow index, but are easily processed and converted into and onto articles by conventional technologies including injection molding, extrusion, film and bottle blowing and powder coating.

Owner:GAMMATRON +1

Air blown fiber (ABF) cable with low composite coefficient of thermal expansion

InactiveUS6853781B2Improve thermal stabilityInhibit deteriorationFibre mechanical structuresCross-linkFiber

An air blown fiber tube cable having improved thermal stability in contrast to conventional air blown fiber (ABF) tube cables and within which one or more air blown optical fiber units can be installed. The air blown fiber tube is formed from a cross-linked polyolefin (preferably cross-linked high density polyethylene) comprising at least one non-polymer filler material having a coefficient of thermal expansion less than the coefficient of thermal expansion of said tube.

Owner:SUMITOMO ELECTRIC LIGHTWAVE +1

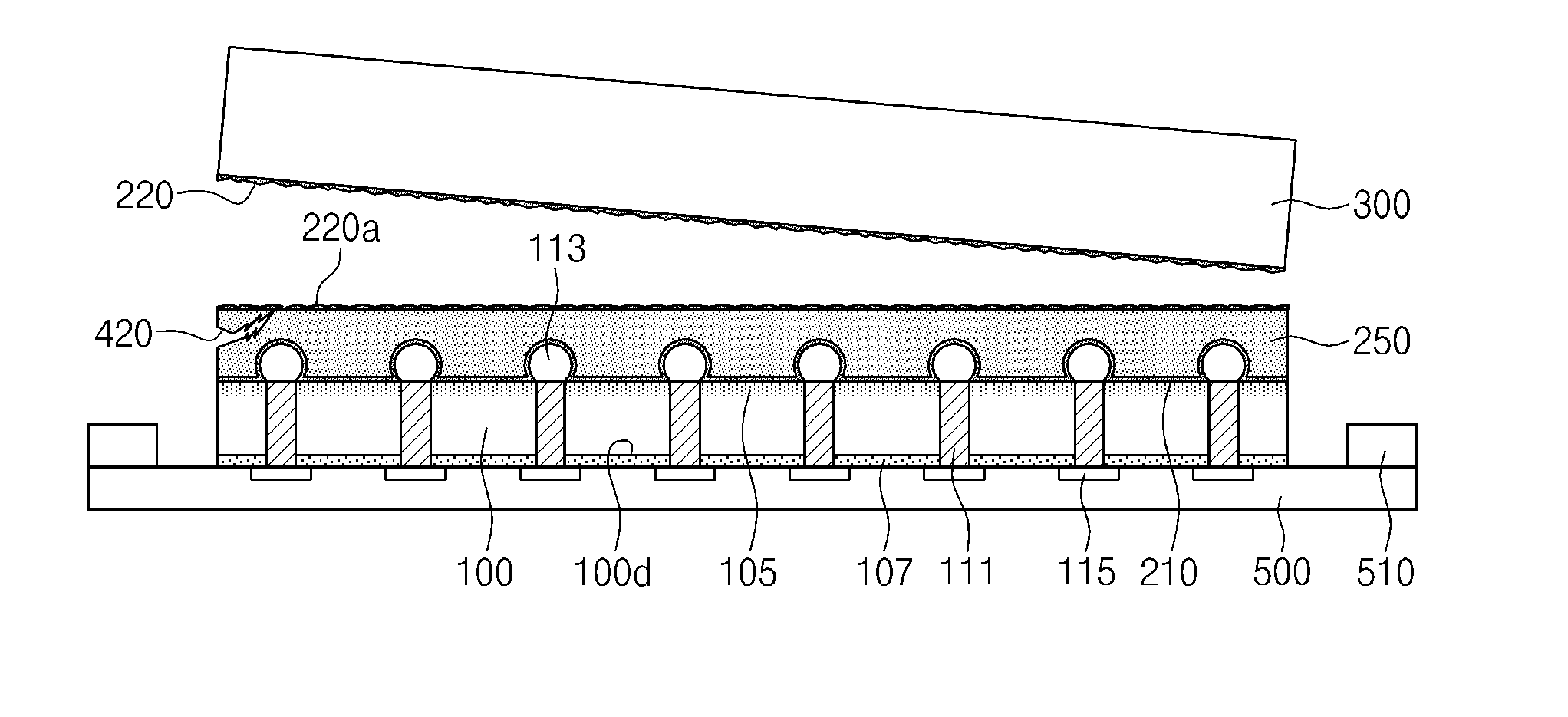

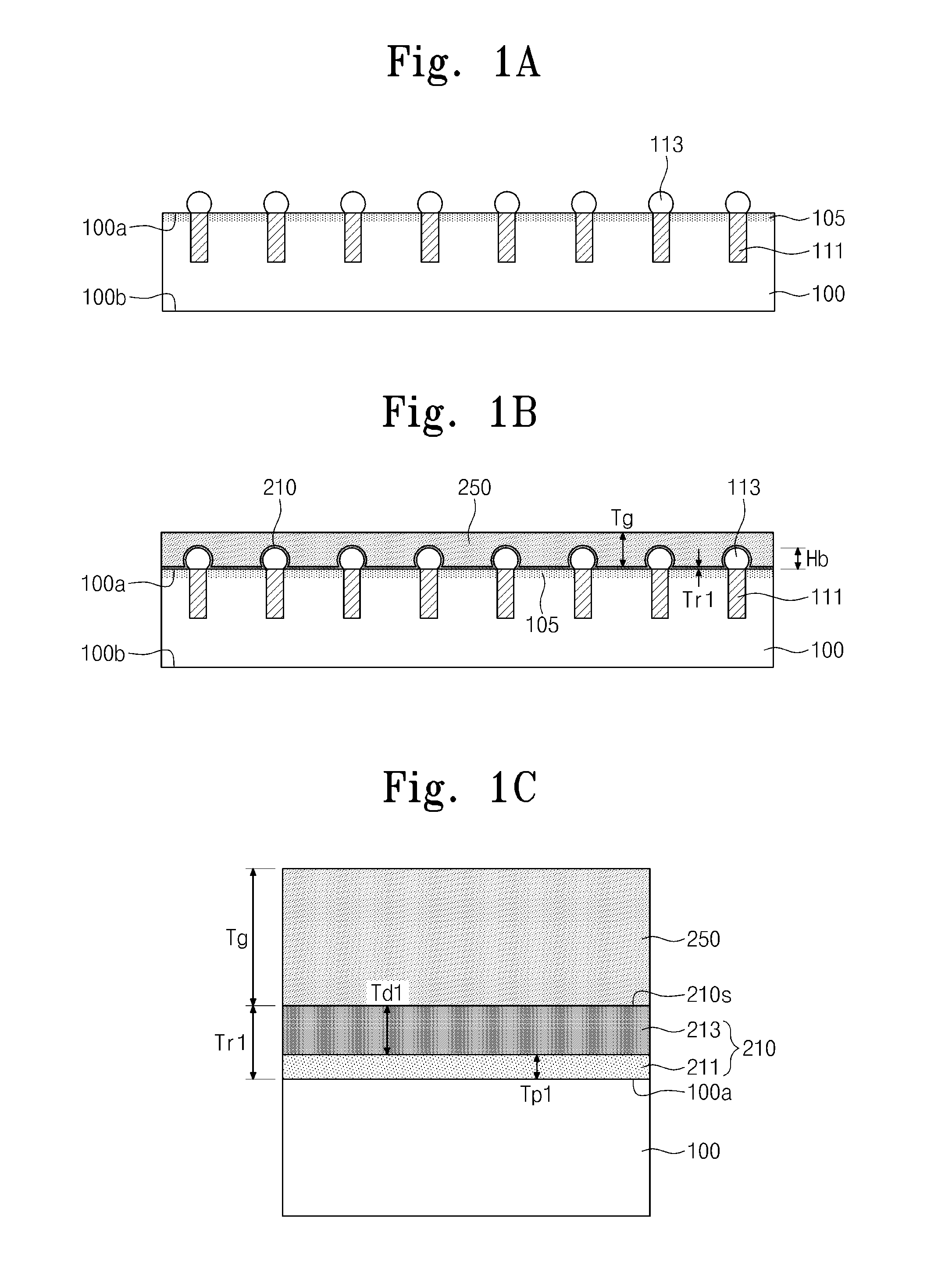

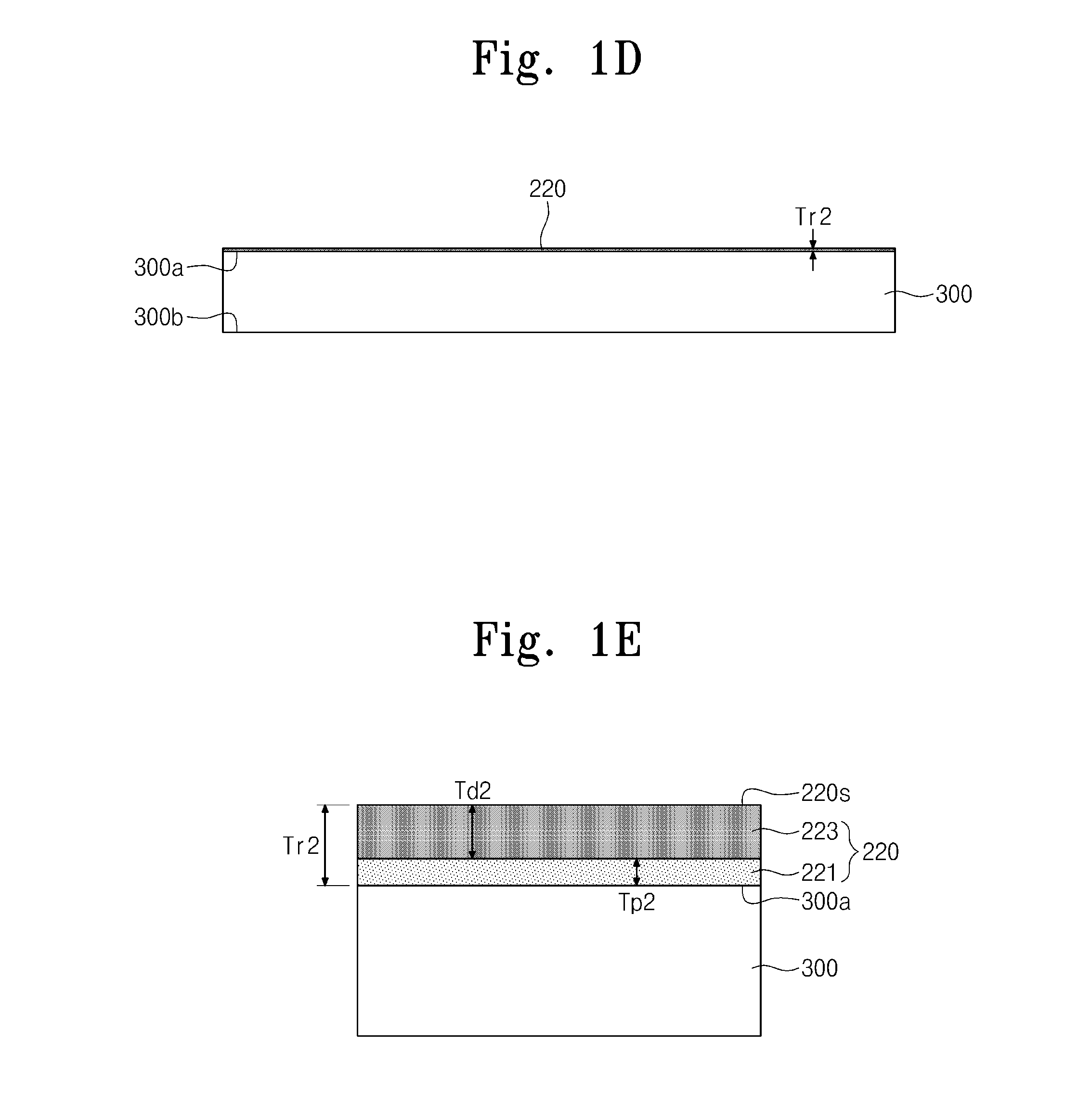

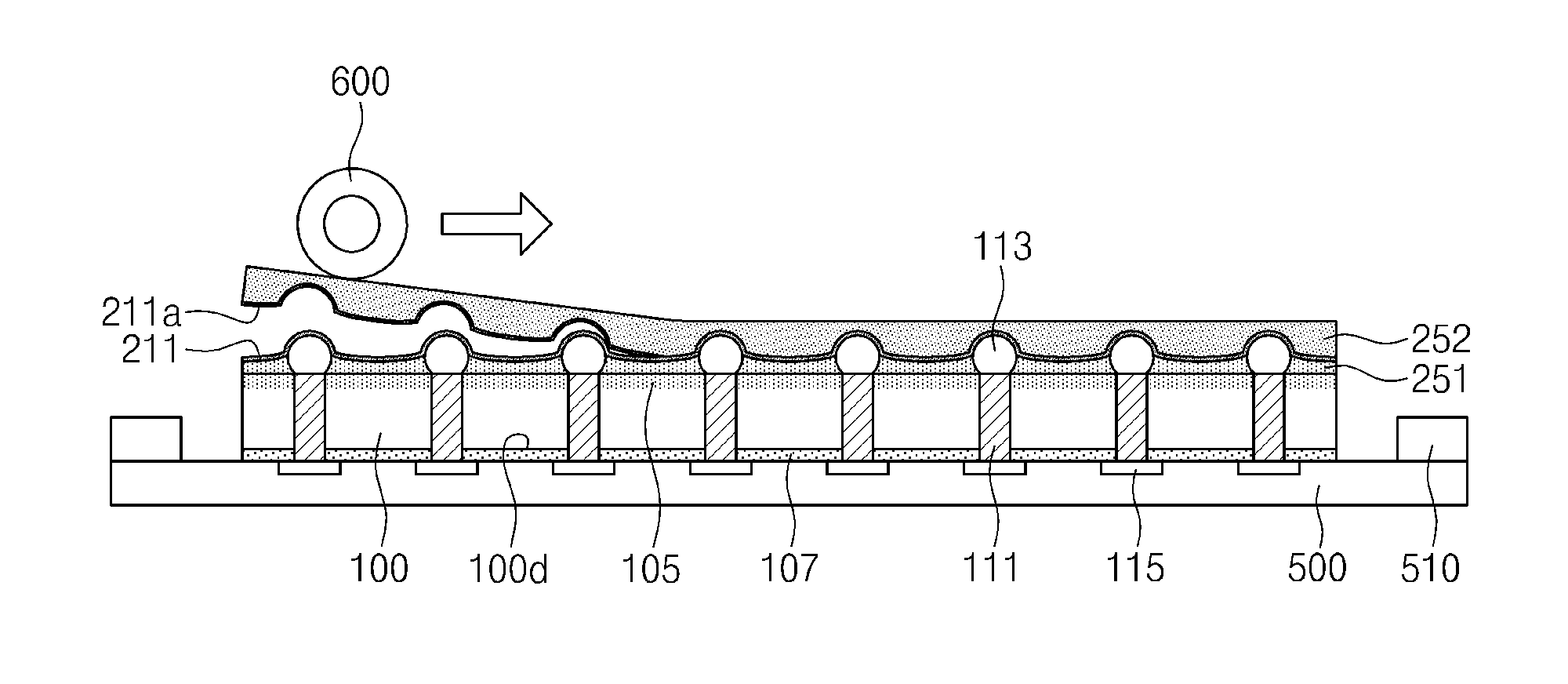

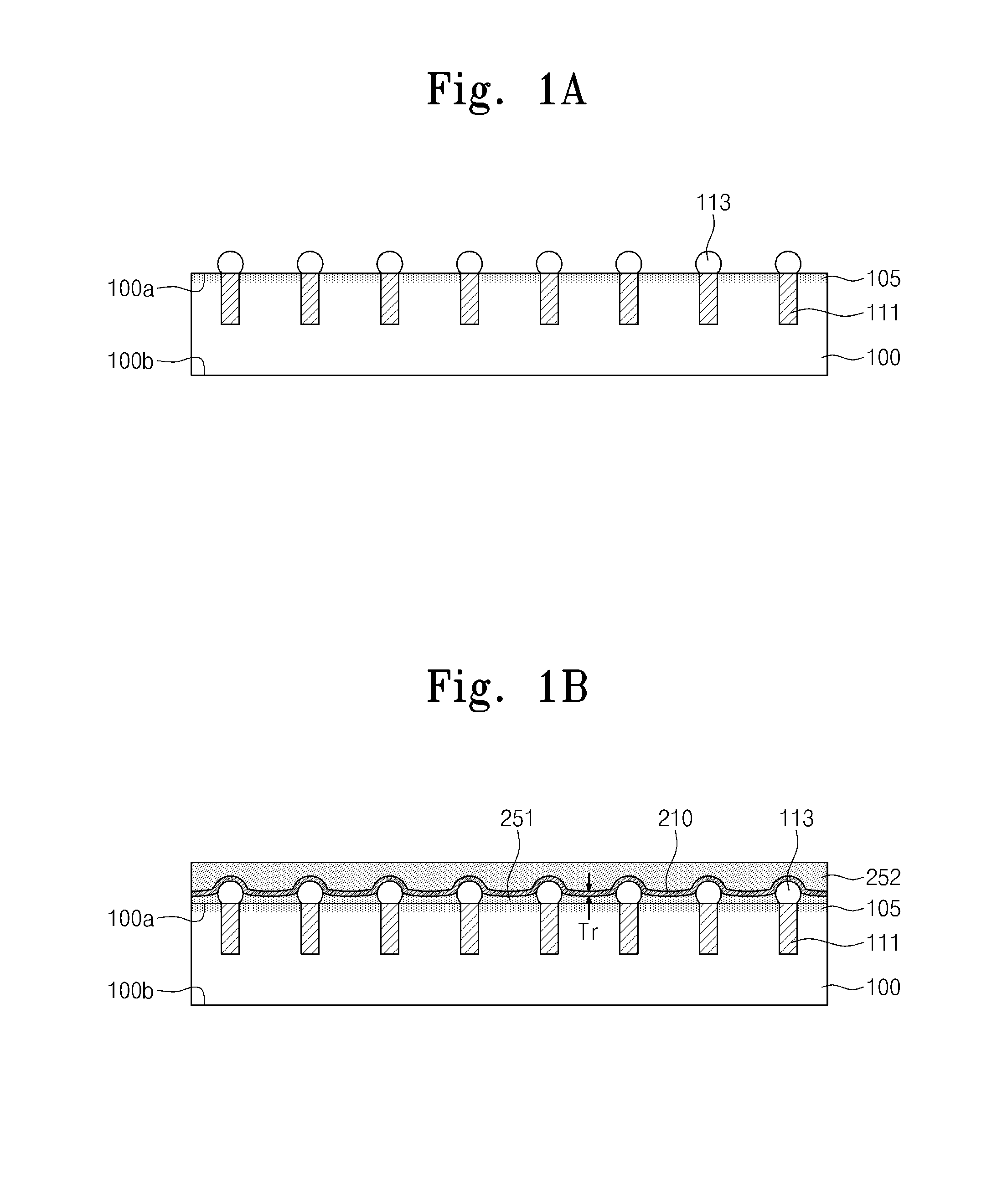

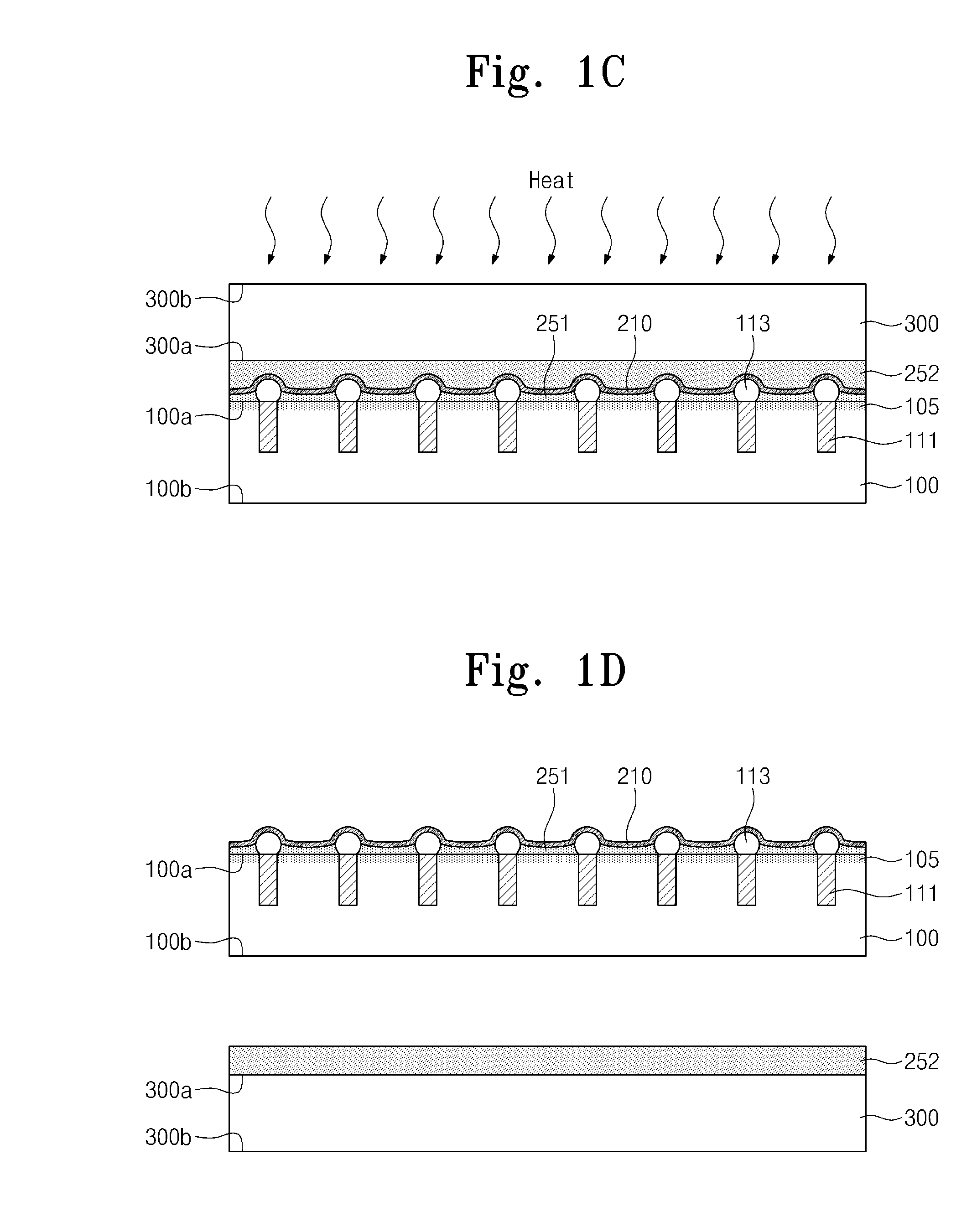

Methods of processing substrates

ActiveUS20140213039A1Thermal stabilityEasy to separateLamination ancillary operationsSolid-state devicesChemistry

Methods processing substrates are provided. The method may include providing a bonding layer between a substrate and a carrier to bond the substrate to the carrier, processing the substrate while the substrate is supported by the carrier, and removing the bonding layer to separate the substrate from the carrier. The bonding layer may include a thermosetting glue layer and thermosetting release layers provided on opposing sides of the thermosetting glue layer.

Owner:SAMSUNG ELECTRONICS CO LTD

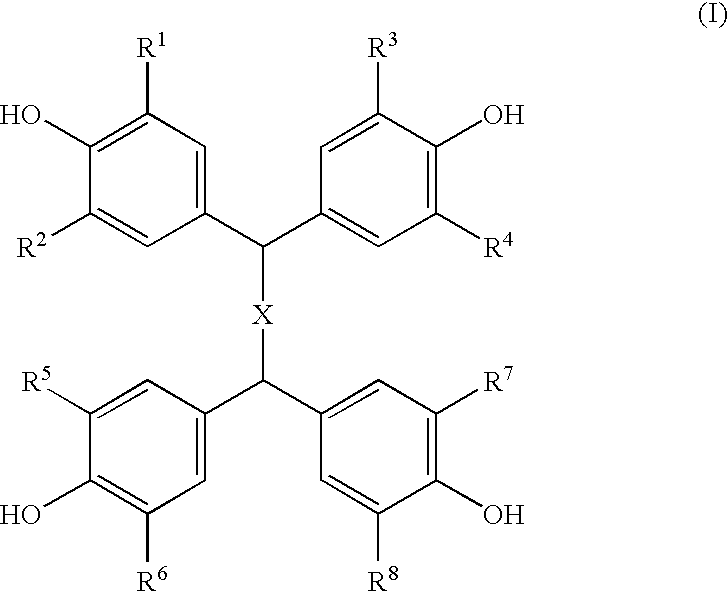

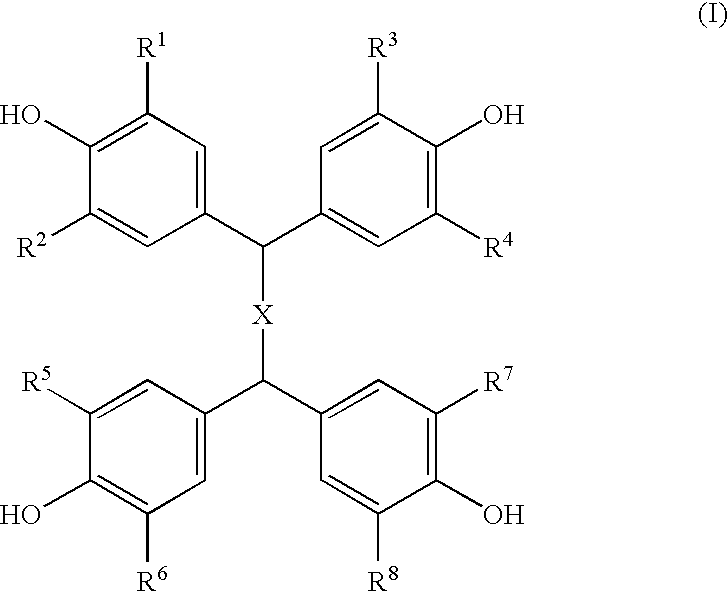

Composition of epoxy resin and clathrate of tetrakisphenol and epoxy-reactive curing compound

The present invention has an object to provide curatives for epoxy resins and curing accelerators for epoxy resins, which both have improved subliming and decomposing properties and which, when mixed with an epoxy resin, enable the mixture to be greatly improved in thermal stability that is extremely important for the control of a curing reaction and to have a prolonged pot life (stability as a one-pack mixture comprising the epoxy resin, curative, etc.) and improved curability at low temperatures.The curative is characterized by being a clathrate comprising a tetrakisphenol compound represented by a general formula [I];wherein X represents (CH2)n, wherein n is 0, 1, 2 or 3, and R<1 >to R<8 >each represents hydrogen, a lower alkyl, optionally-substituted phenyl, halogeno or a lower alkoxy, and the curing accelerator is characterized by being a clathrate comprising a tetrakisphenol compound represented by the general formula [I] shown above and a compound accelerating the curing of a compound which reacts with the epoxy group of an epoxy resin to cure the resin.

Owner:NIPPON SODA CO LTD

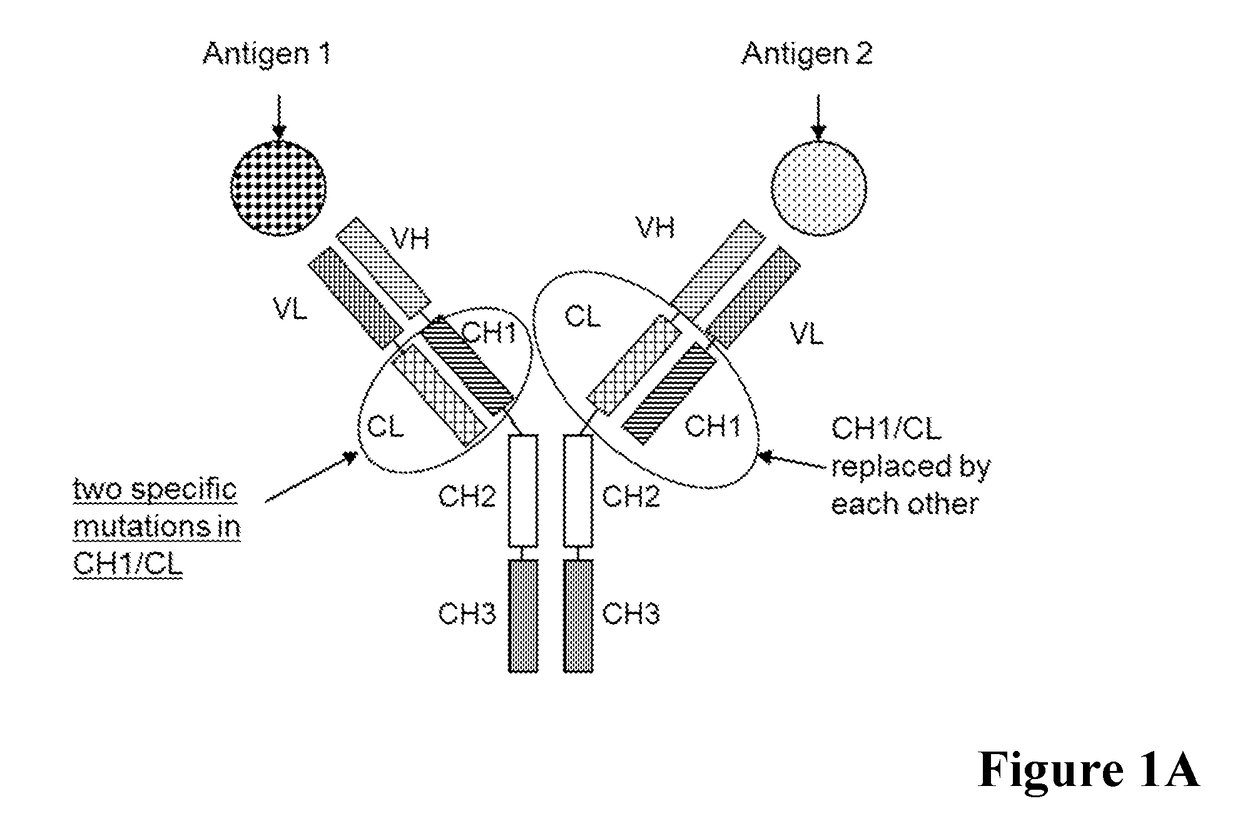

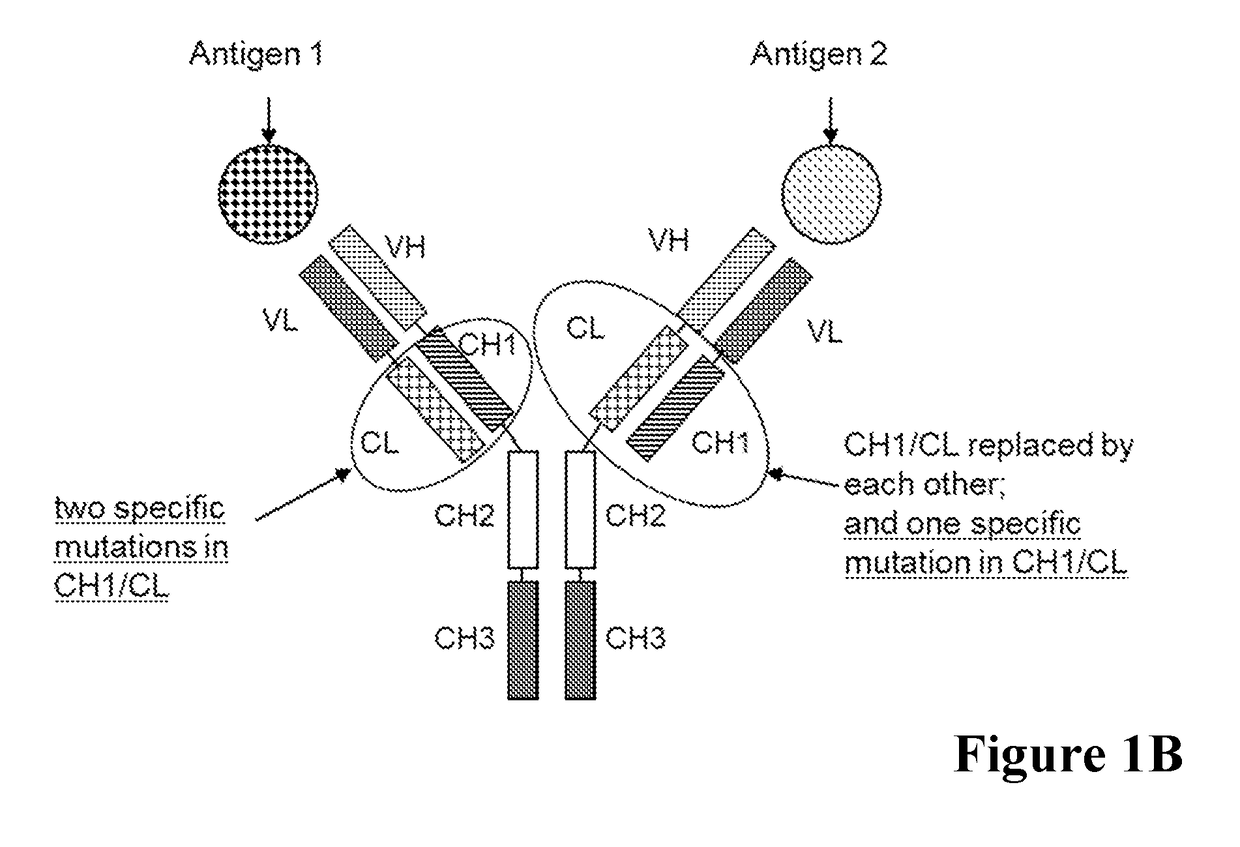

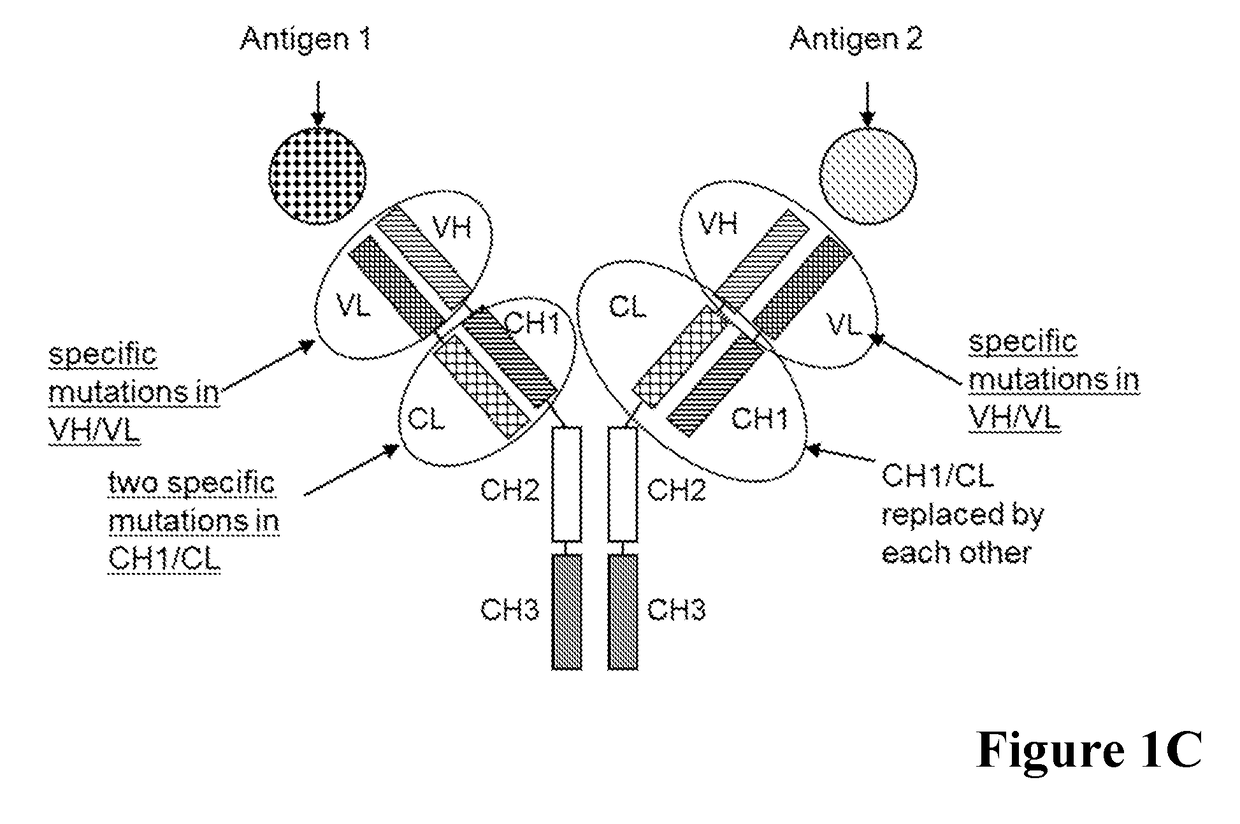

Multispecific antibodies

InactiveUS20170129962A1Reduce formationThermal stabilityNervous disorderAntipyreticSpecific antibody

Owner:F HOFFMANN LA ROCHE & CO AG

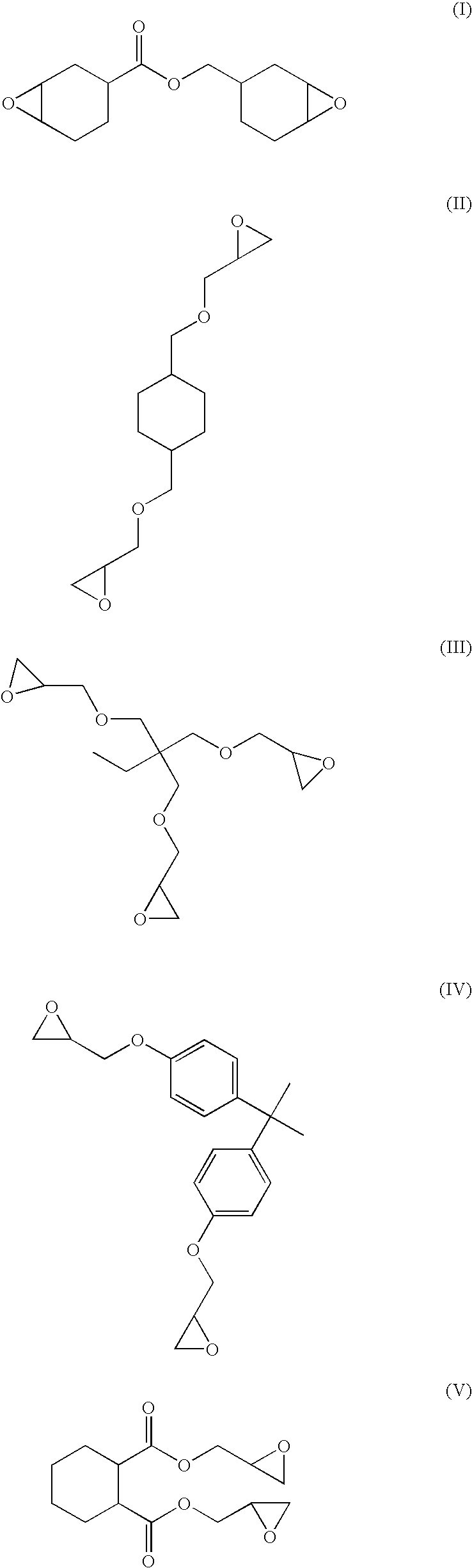

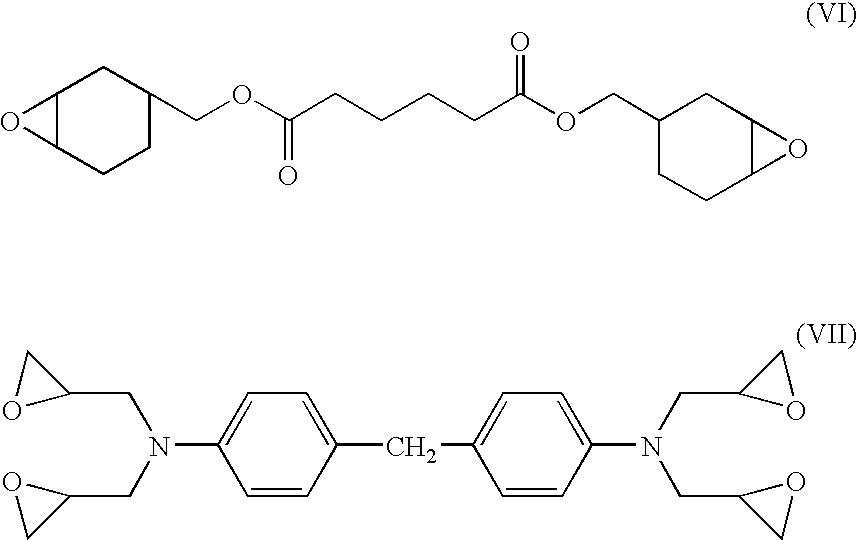

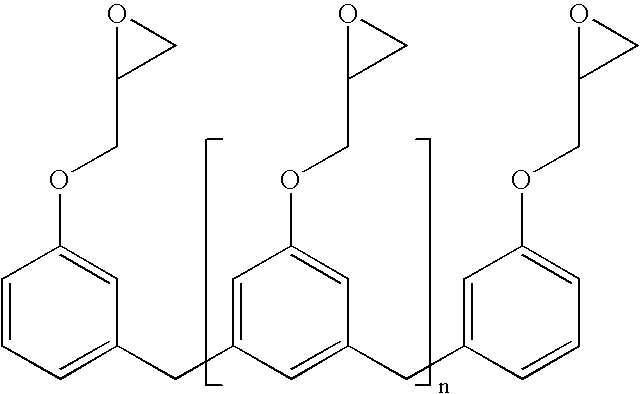

Hardenable reaction resin system

InactiveUS20070191513A1Low linear shrinkageHigh elongationMaterial nanotechnologyPrinted circuit aspectsNanoparticlePolymer chemistry

A hardenable reaction resin system, in particular a casting compound, laminating resin, or impregnating resin, which is to be processed as a two-component compound and contains a resin component, a mineral filler, and polymer particles dispersed in the resin component. The filler includes nanoparticles.

Owner:ROBERT BOSCH GMBH

Methods for processing substrates

ActiveUS20140210075A1Thermal stabilityEasy to separateLamination ancillary operationsSemiconductor/solid-state device detailsEngineering

A method for processing substrates includes providing a bonding layer between a substrate and a carrier to bond the substrate to the carrier, processing the substrate while the substrate is supported by the carrier, and removing the bonding layer to separate the substrate from the carrier. The bonding layer may include a thermosetting release layer and thermosetting glue layers, wherein at least one of the thermosetting glue layers is provided on each side of the thermosetting release layer.

Owner:SAMSUNG ELECTRONICS CO LTD

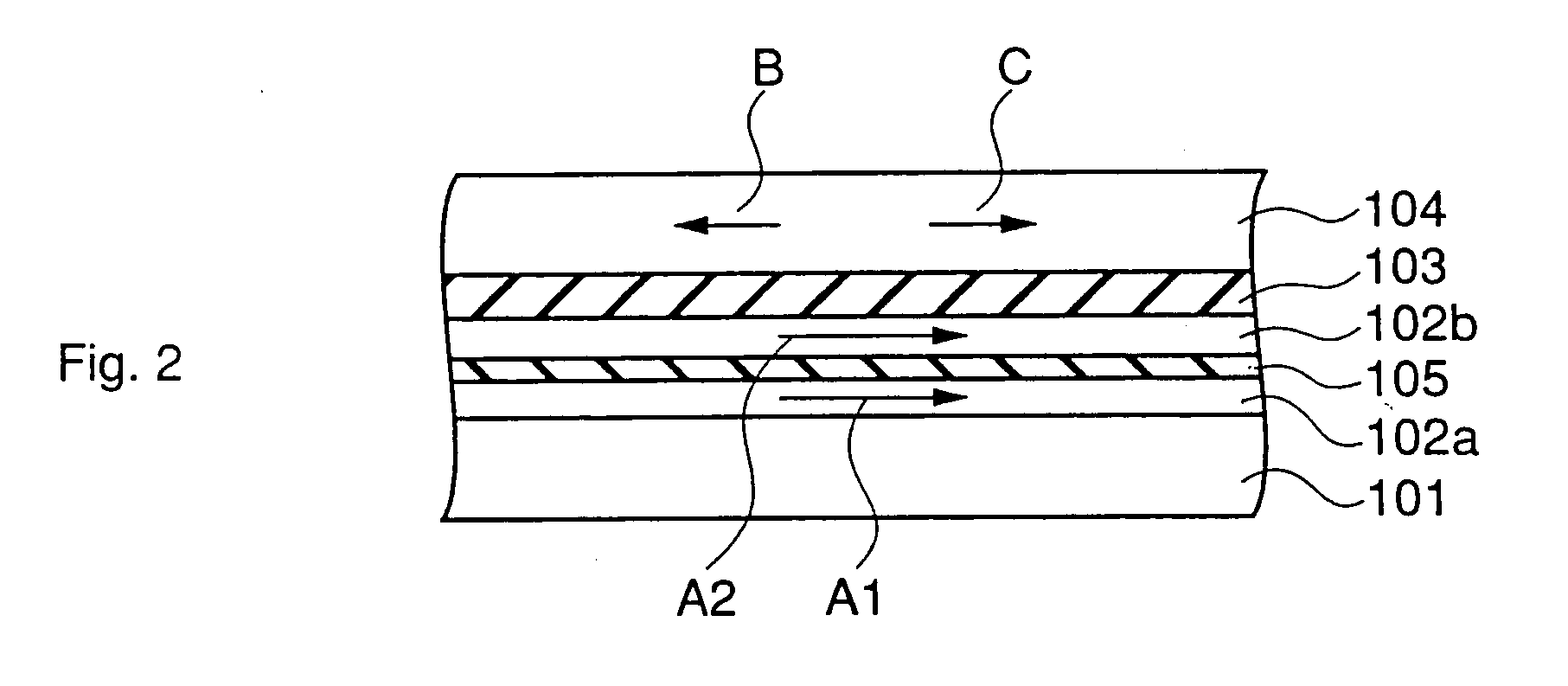

Memory element, memory apparatus

ActiveUS20140319521A1Well-balanced propertyThermal stabilityMagnetic measurementsGalvano-magnetic material selectionSoftware engineeringMechanical engineering

[Object] To provide a memory element having well-balanced properties while ensuring the thermal stability.[Solving Means] A memory element includes a layered structure including a memory layer having magnetization perpendicular to a film face in which a direction of the magnetization is changed depending on information, a magnetization-fixed layer having magnetization perpendicular to the film face, which becomes a base of the information stored in the memory layer, and an intermediate layer that is formed of a non-magnetic material and is provided between the memory layer and the magnetization-fixed layer.Then, the memory layer includes a multilayer structure layer in which a non-magnetic material and an oxide are laminated, the direction of the magnetization of the memory layer being changed by applying a current in a lamination direction of the layered structure to record the information in the memory layer.

Owner:SONY CORP

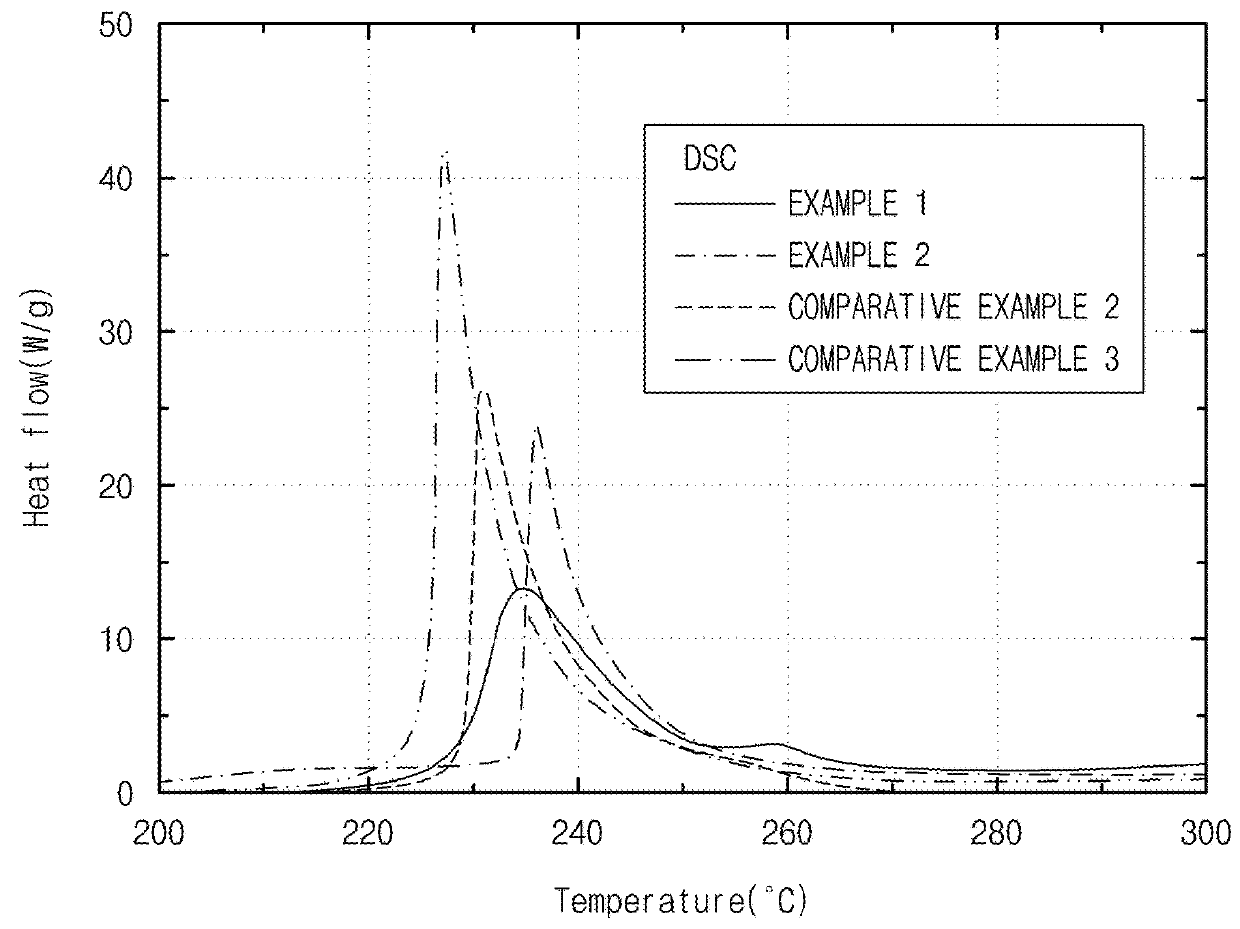

Positive electrode active material for lithium secondary battery, method for preparing the same, and lithium secondary battery including the same

PendingUS20180183046A1Improve structural stabilityImprove thermal stabilitySecondary cellsPositive electrodesLithiumHeat flow

Provided are a positive electrode active material having a concentration gradient in which concentrations of nickel and manganese are gradually changed from a center of a particle to a surface thereof, and a peak appears at 235° C. or more when heat flow of the positive electrode active material is measured by differential scanning calorimetry, a method of preparing the positive electrode active material, and a lithium secondary battery including the positive electrode active material.

Owner:LG ENERGY SOLUTION LTD

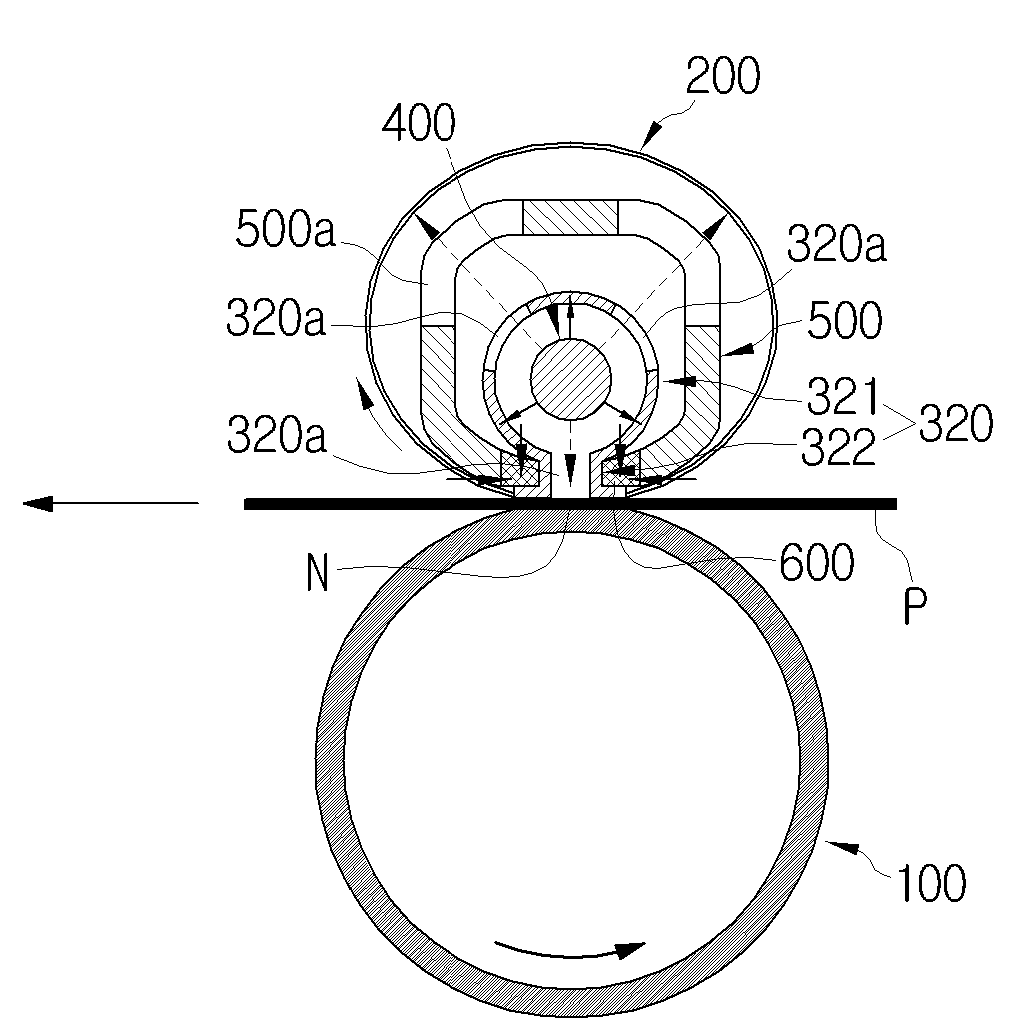

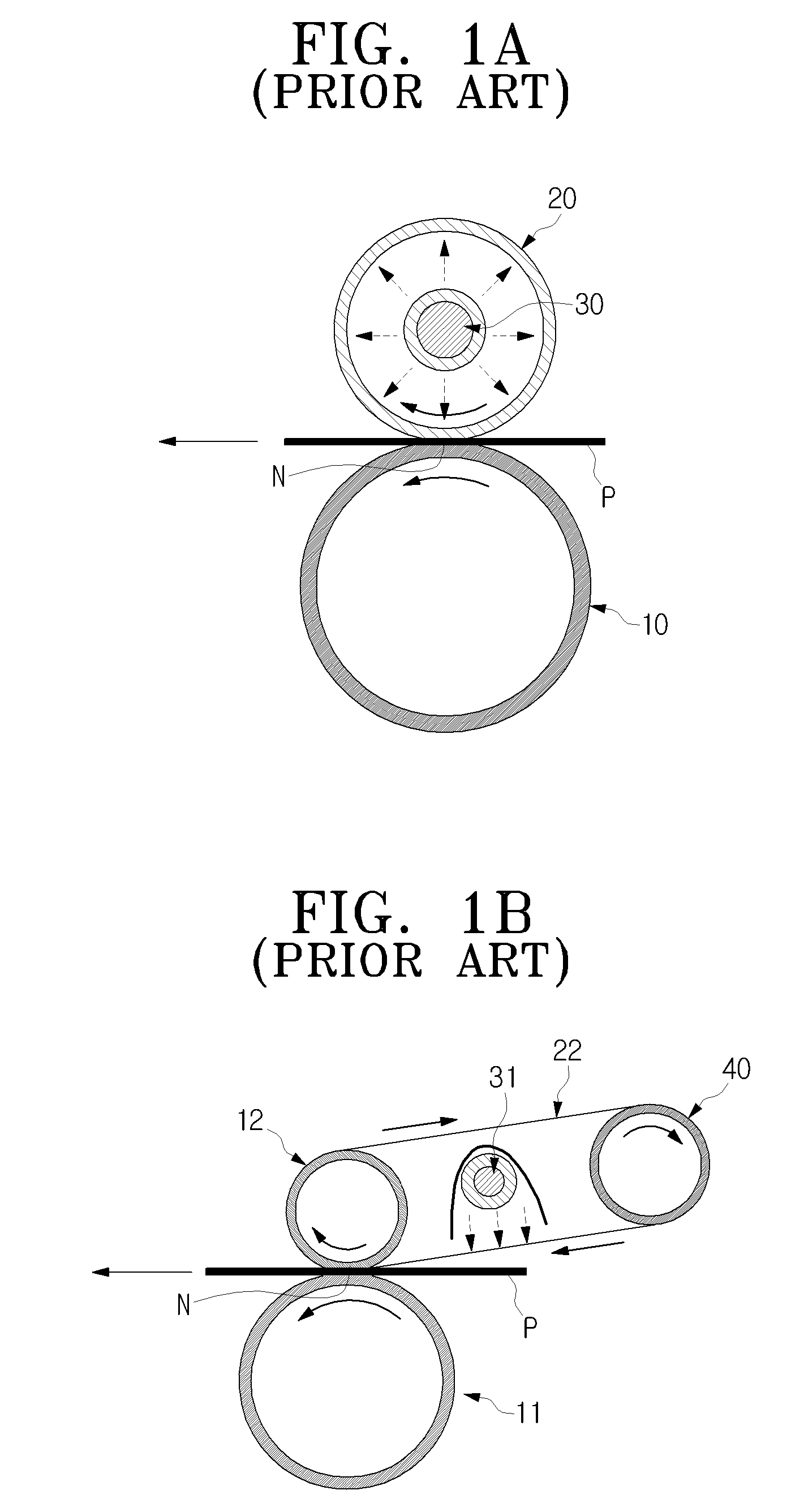

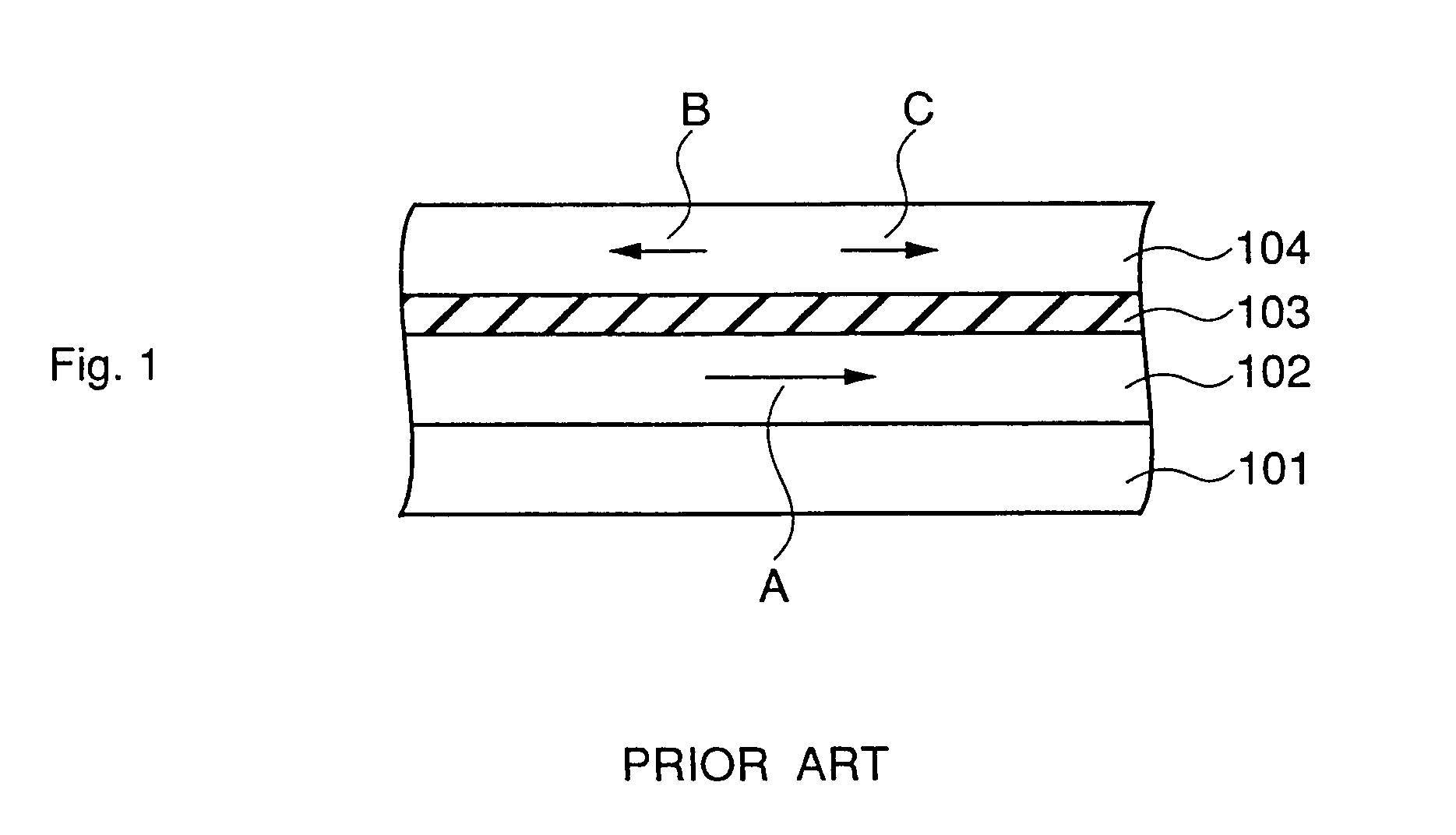

Fixing device and image forming apparatus having the same

ActiveUS7623817B2Heating up fastThermal stabilityOhmic-resistance heatingElectrographic process apparatusHeat transmissionImage formation

A fixing device includes a pressing roller, a fixing belt to receive a rotation force transferred from the pressing roller and to rotate thereby, a nip forming member which is mounted inside the fixing belt, the nip forming member including a heat transmission unit formed thereon, and a heat source, which is mounted inside the nip forming member, to simultaneously apply heat to the nip forming member and to the fixing belt through the heat transmission unit.

Owner:HEWLETT PACKARD DEV CO LP

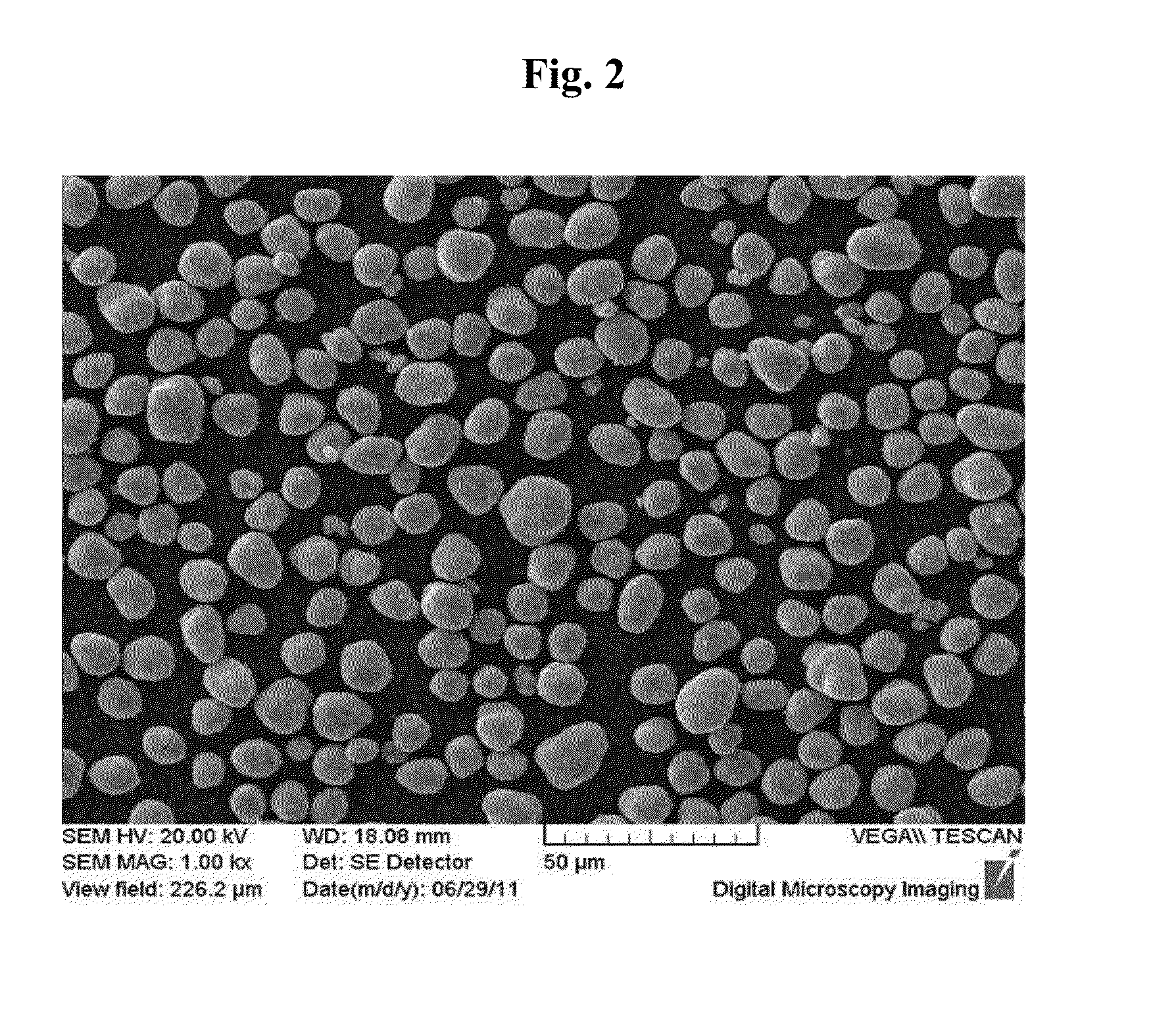

Method for manufacturing anode active material for lithium secondary battery, anode active material for lithium secondary battery manufactured thereby and lithium secondary battery using same

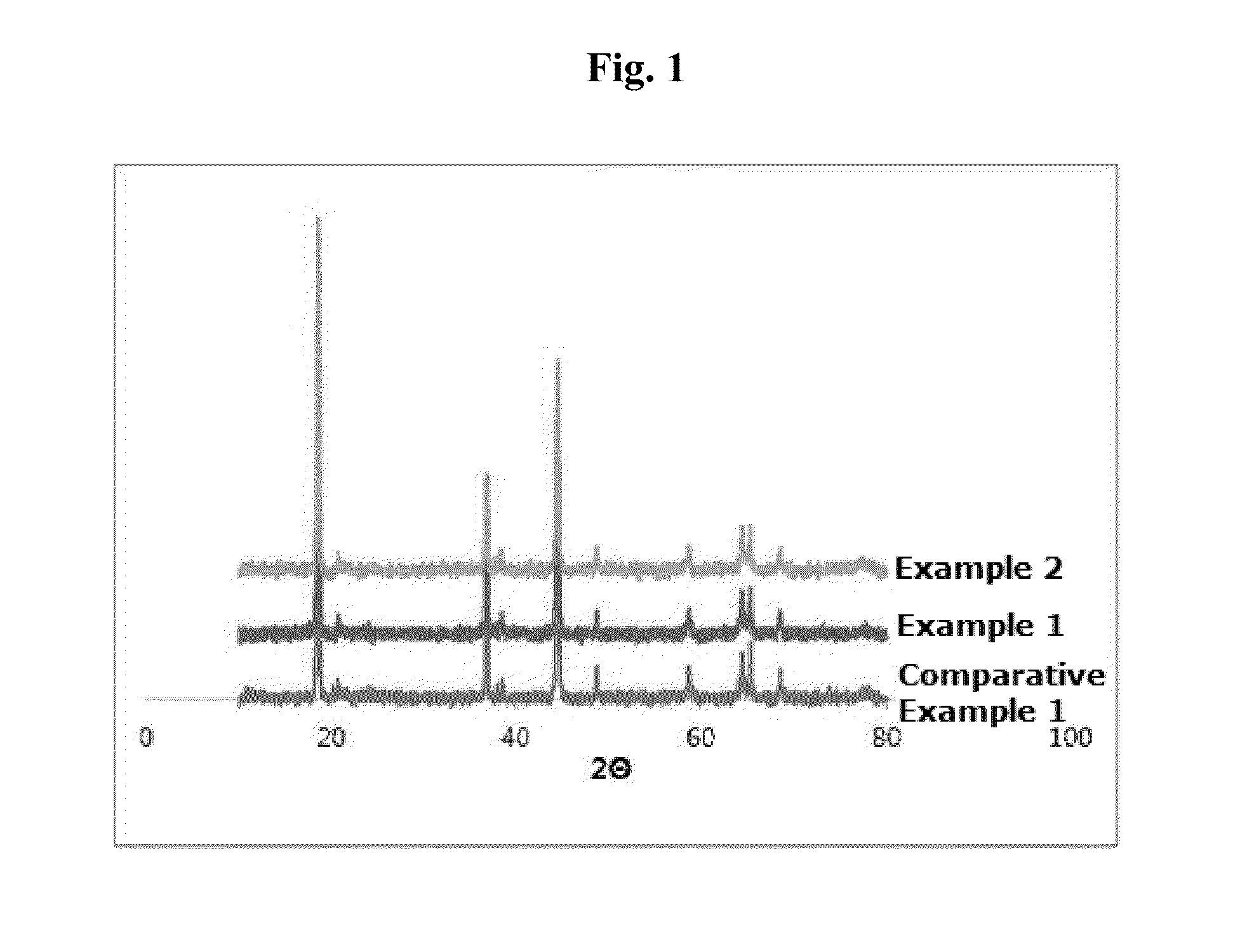

ActiveUS20130183583A1Thermal stabilityExtended service lifeFinal product manufactureNon-aqueous electrolyte accumulator electrodesPhysical chemistryManganese

The present invention provides a method for manufacturing an anode active material for a lithium secondary battery comprising the following steps of:a) simultaneously mixing a first metallic salt aqueous solution including nickel, cobalt, manganese and optionally a transition metal, a chelating agent, and a basic aqueous solution in a reactor, and mixing with a lithium raw material and calcining to manufacture a center part including the compound of following Chemical Formula 1:Lix1[Ni1−y1−z1−w1Coy1Mnz1Mw1]O2 Chemical Formula 1(wherein, 0.9≦x1≦1.3, 0.1≦y1≦0.3, 0.0≦z1≦0.3, 0≦w1≦0.1, and M is at least one metal selected from the group consisting of Mg, Zn, Ca, Sr, Cu, Zr, P, Fe, Al, Ga, In, Cr, Ge, and Sn);b) simultaneously mixing a second metallic salt aqueous solution including nickel, cobalt, manganese and optionally a transition metal, the chelating agent, and the basic aqueous solution in a reactor, mixing with the lithium raw material and calcining, and grinding thereof to the size of nanometers to manufacture a compound for forming an outer part including the compound of following Chemical Formula 2:Lix2[Ni1−y2−z2−w2Coy2Mnz2Mw2]O2 Chemical Formula 2(wherein, 0.9≦x2≦1+z2, 0≦y2≦0.33, 0≦z2≦0.5, 0≦w2≦0.1 and M is at least one metal selected from the group consisting of Mg, Zn, Ca, Sr, Cu, Zr, P, Fe, Al, Ga, In, Cr, Ge, and Sn);c) mixing the center part manufactured from step a) and the compound for forming the outer part manufactured from step b) to form the outer part on the center part surface; andd) heat-treating the compound obtained from step c) at 500-800° C. to form a bi-layer structure in which lithium is present at a continuous concentration-gradient from the contact interface of the center part and the outer part to the surface part of the outer part, and an anode active material for a lithium secondary battery manufactured thereby.

Owner:ECOPRO BM CO LTD

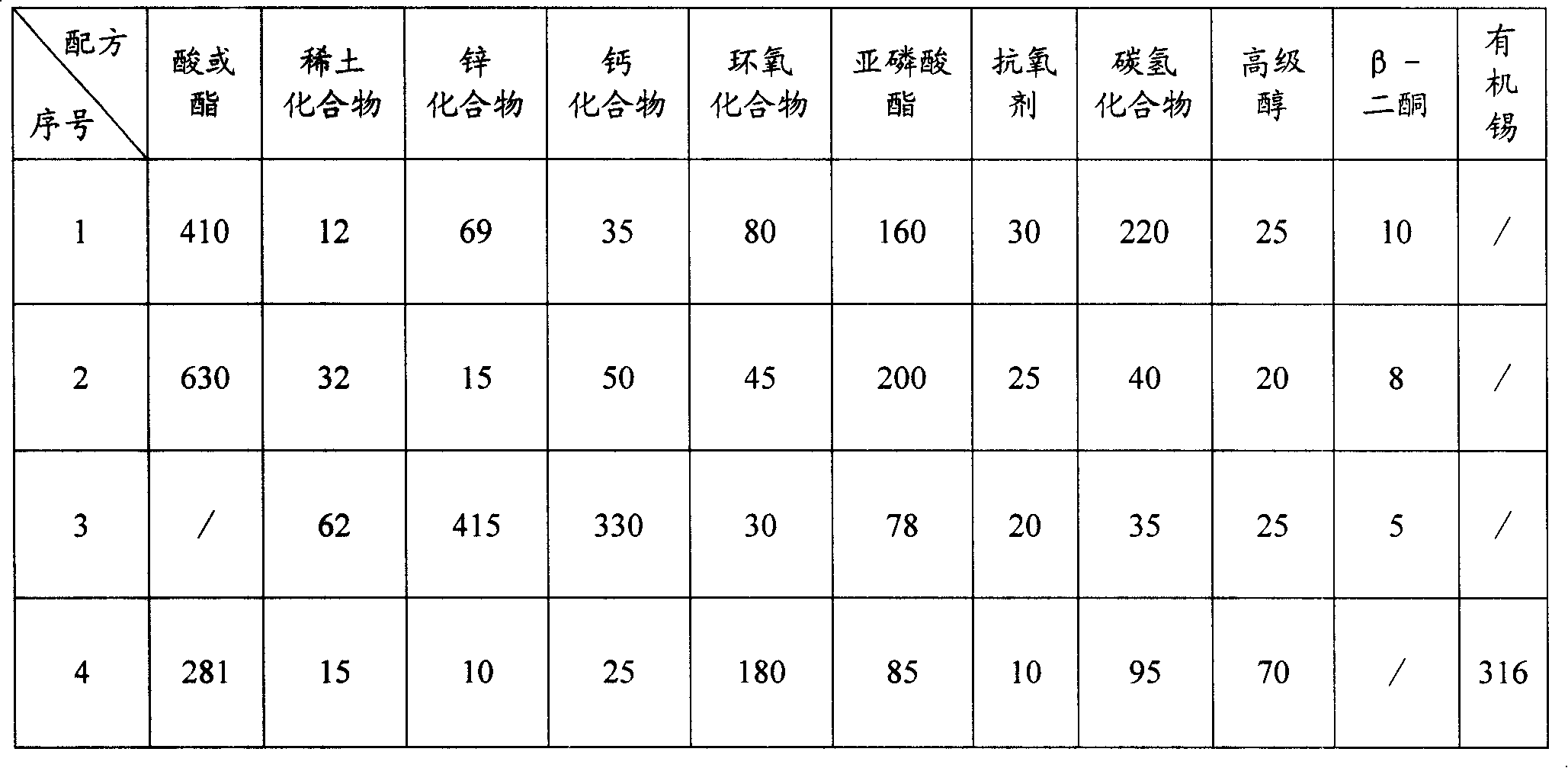

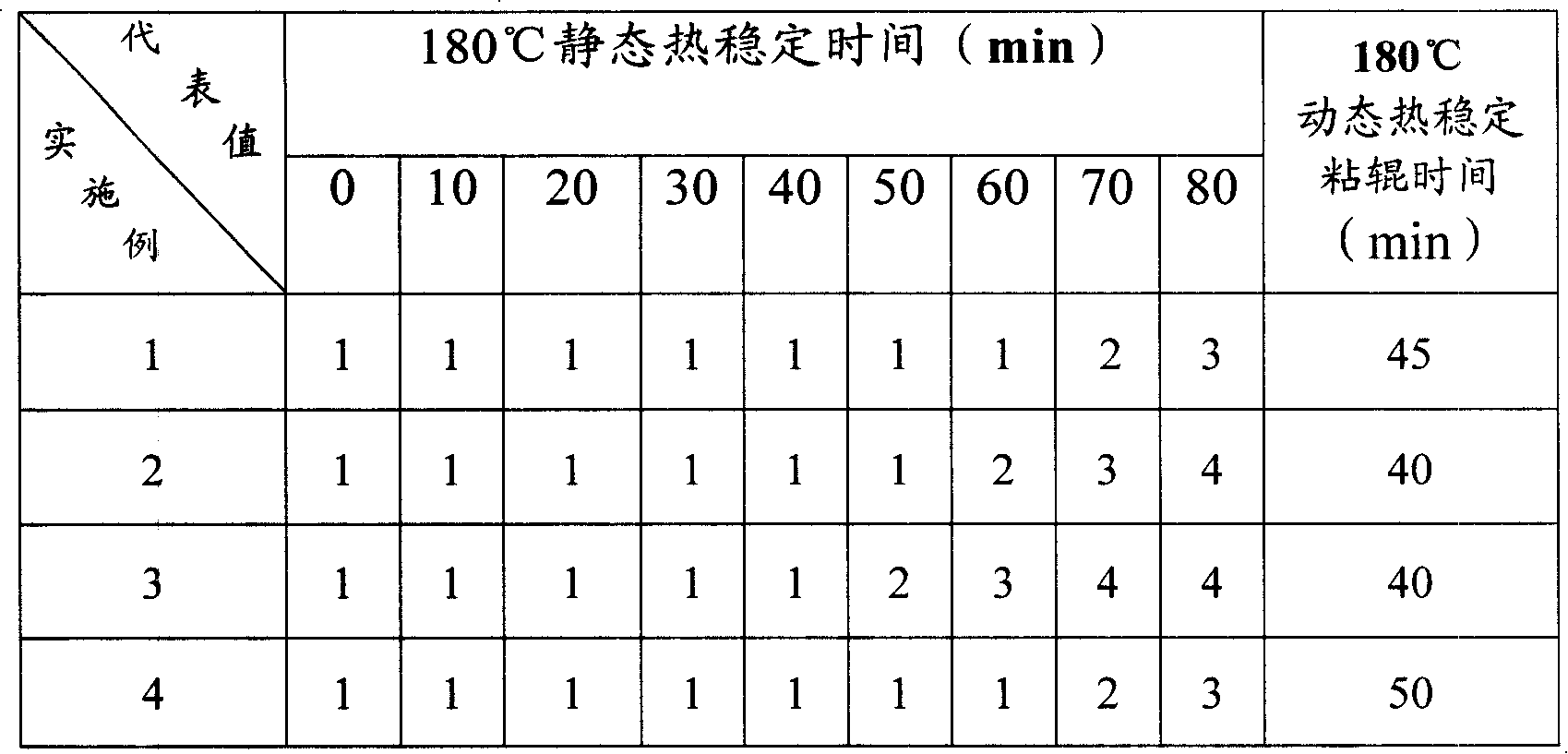

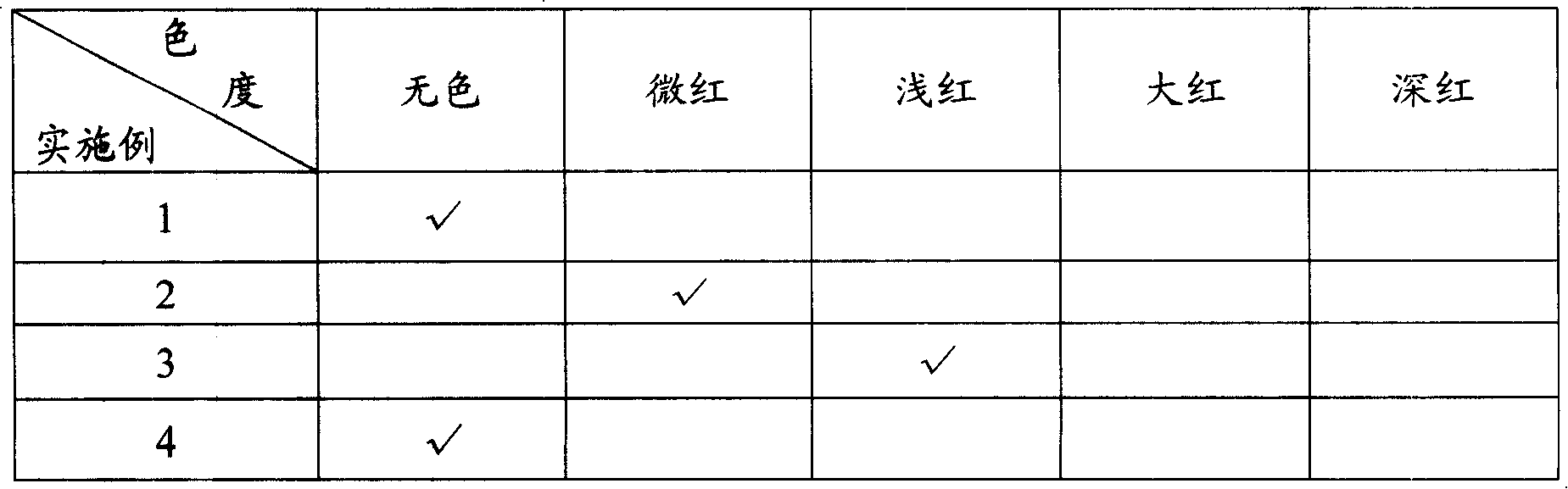

Liquid rare earth calcium zinc stabilizer and preparation method thereof

The present invention provides liquid rare-earth calcium-zinc stabilizer and the preparation method. The liquid rare-earth calcium-zinc stabilizer is compound made of rare-earth calcium-zinc compound and effectively cooperative material. The beneficial effects of the liquid rare-earth calcium-zinc stabilizer and the preparation method provided by the present invention is mainly shown in that (1) the liquid rare-earth calcium-zinc stabilizer has the advantages of high product quality, no toxin, environmental protection, no toxic heavy metal component in recipe, strong practicability and wide application range, which is particularly applicable to the transparent packaging material of food, candy and medicine, as well as the advantages of good processing performance, no precipitation, excellent lubricating performance, superior transparency, thermal stability and oxidation resistance; (2) the process condition is stable and easy to control, thus being applicable to industrialized mass production; the process flow has the advantages of simplicity, environment friendliness, easy access to raw materials and less energy consumption, thus greatly decreasing the production cost; in addition, the whole production process has anhydrous operation, safety and convenience, no discharge of three wastes and less environmental pollution.

Owner:高春福

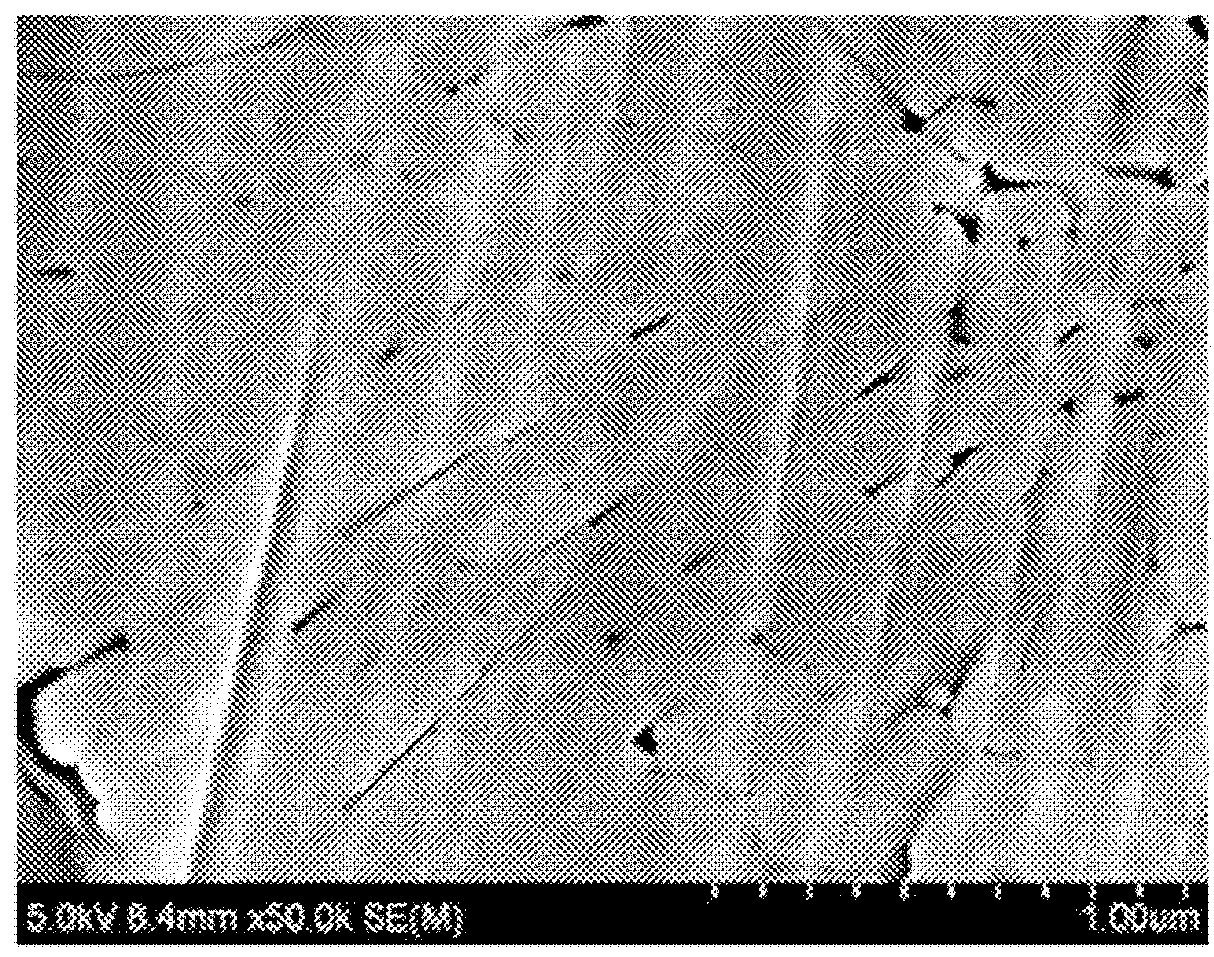

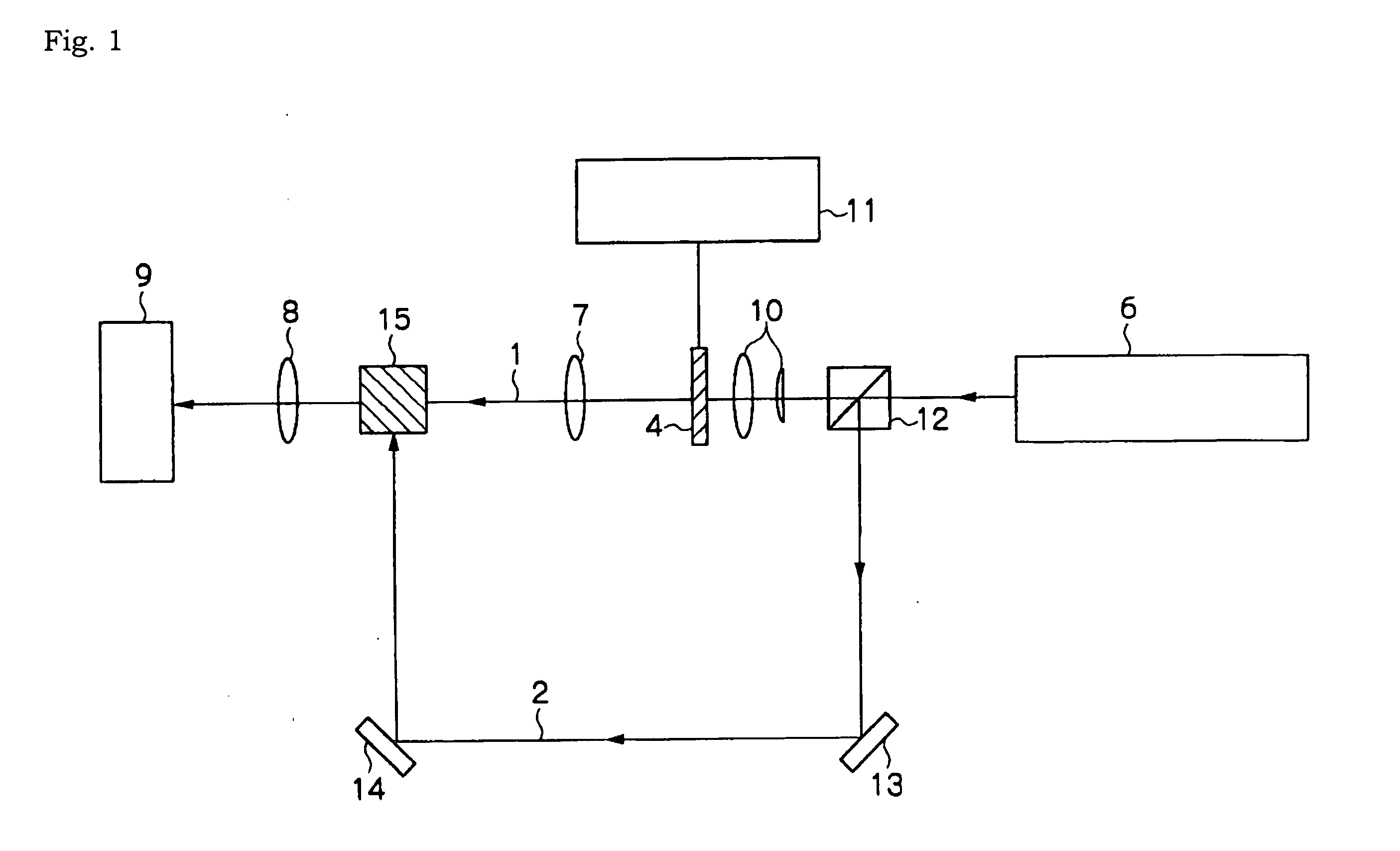

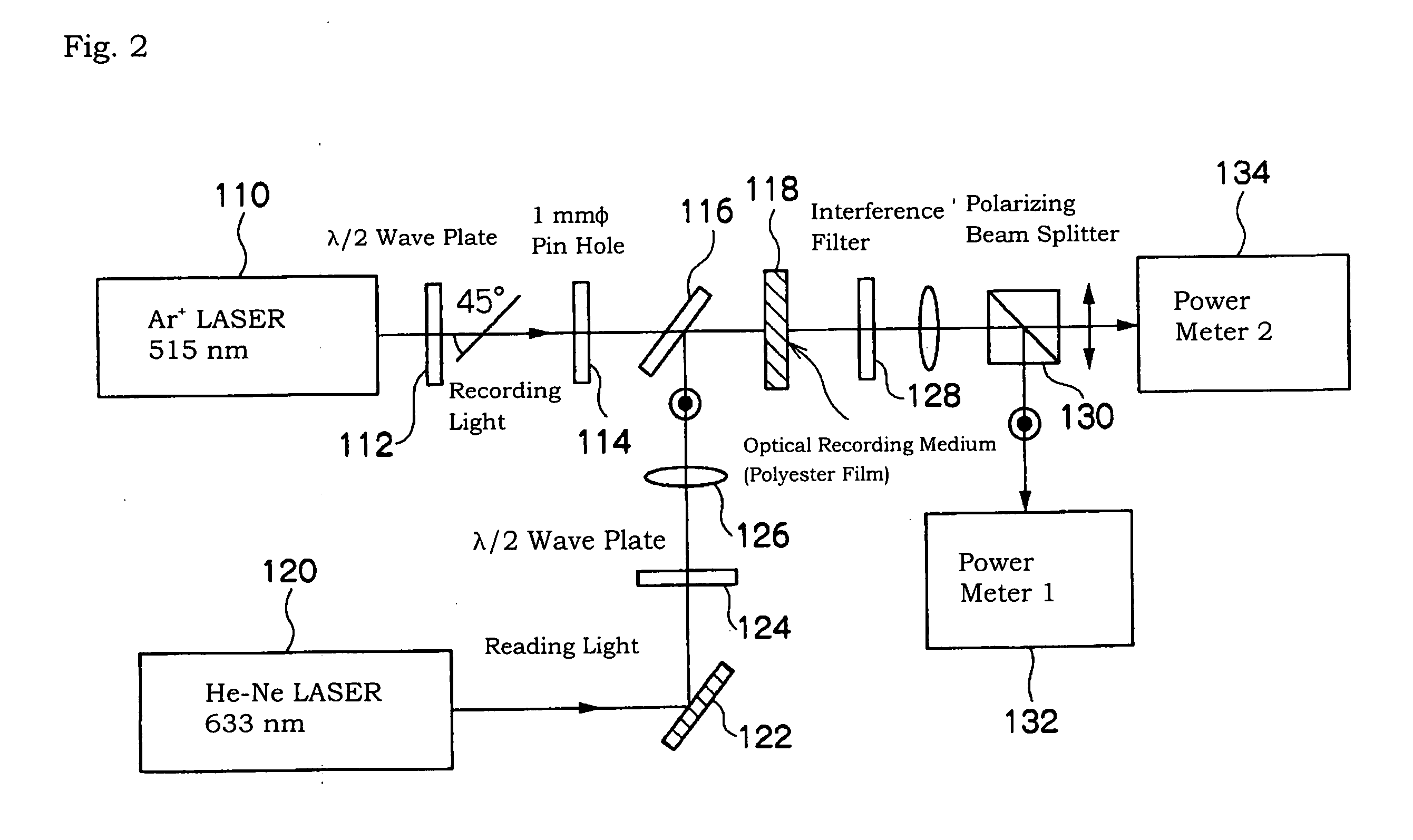

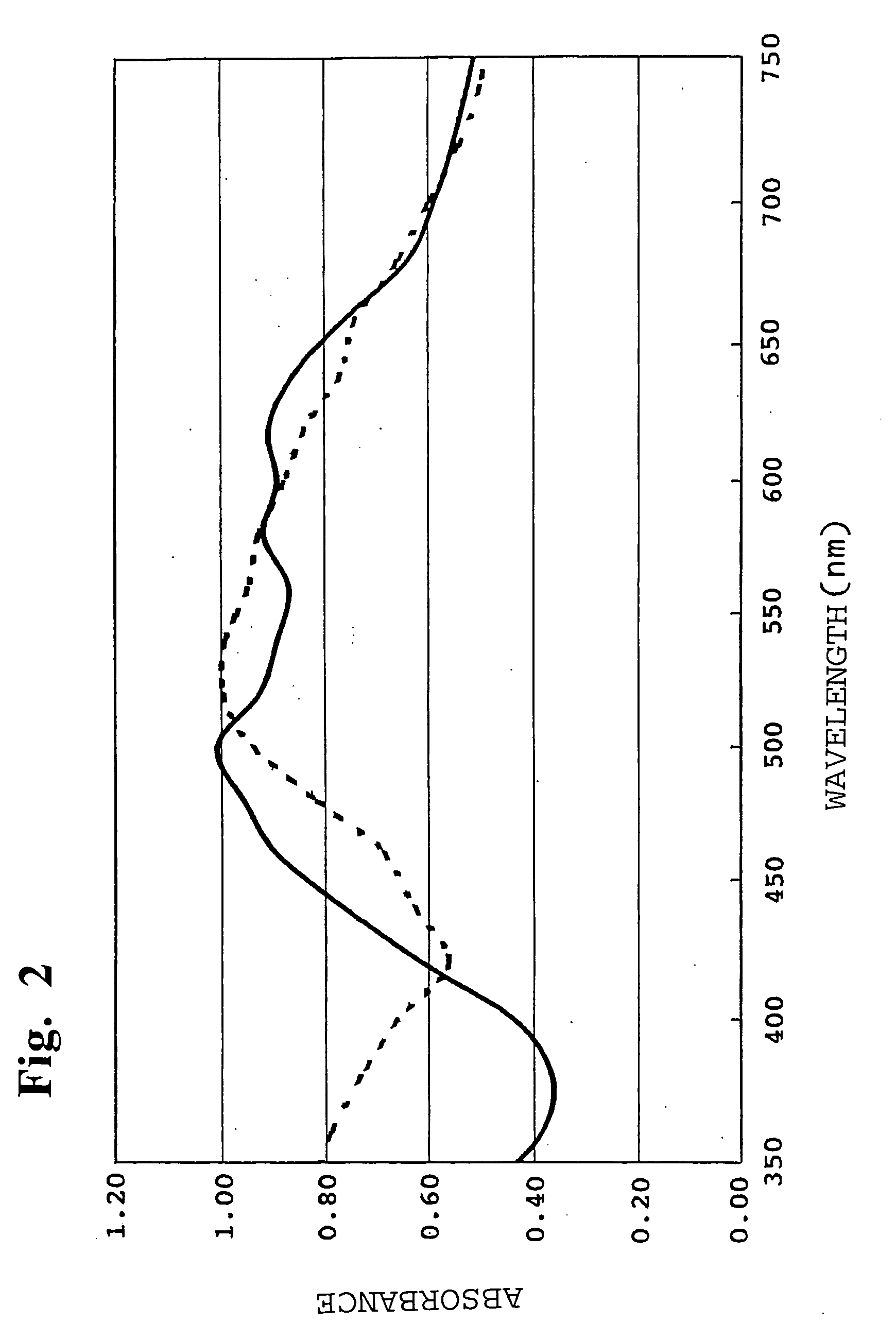

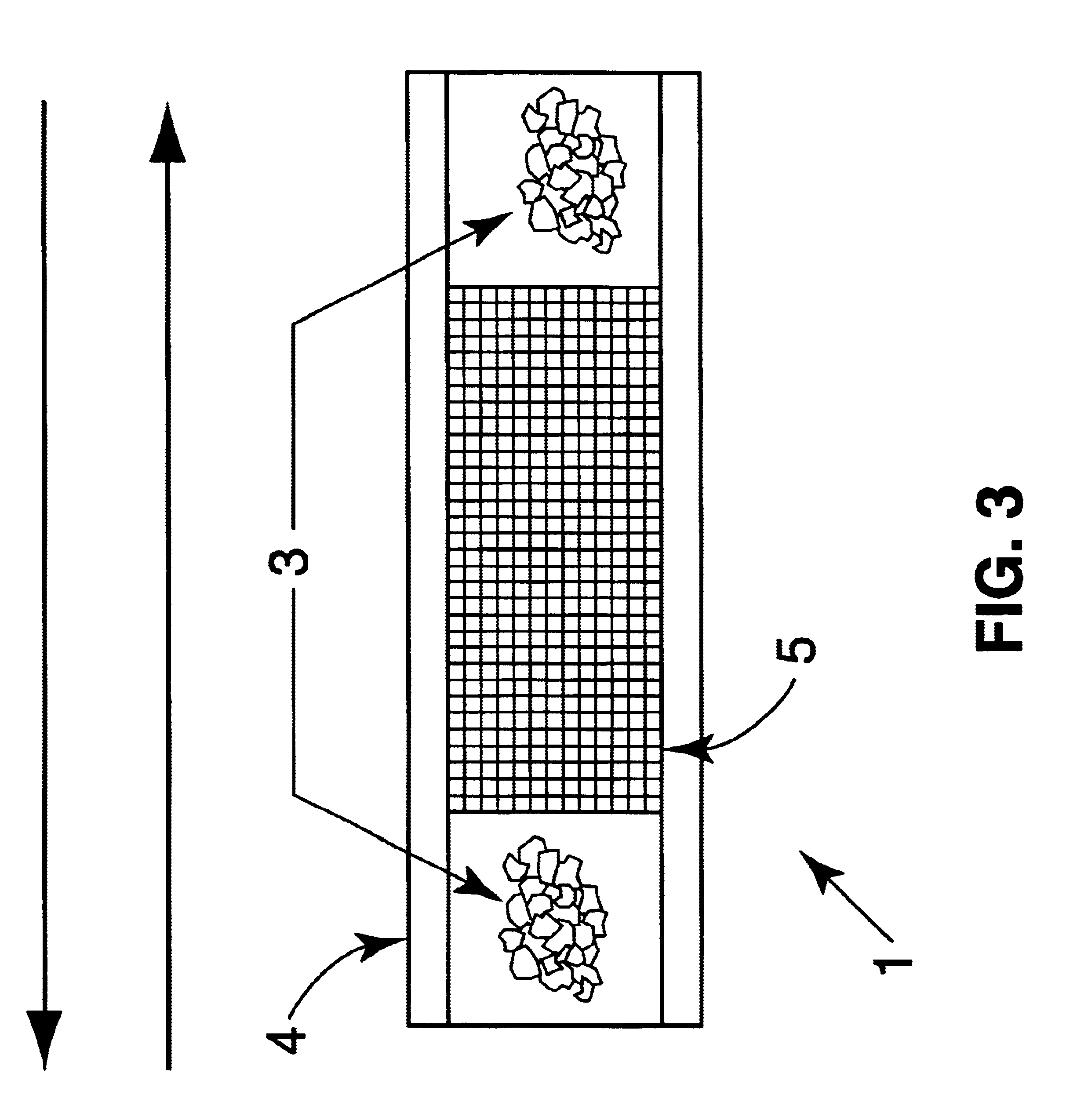

Optical recording medium, method for producing the same, and optical recording and reproducing devices using the same

InactiveUS20050208256A1Large optically induced birefringenceExcellent record holding propertyLayered productsRecord information storageOptical recordingRecording layer

An optical recording medium including an optically-active recording layer, wherein the recording layer includes a polymer microcrystalline phase.

Owner:FUJIFILM BUSINESS INNOVATION CORP

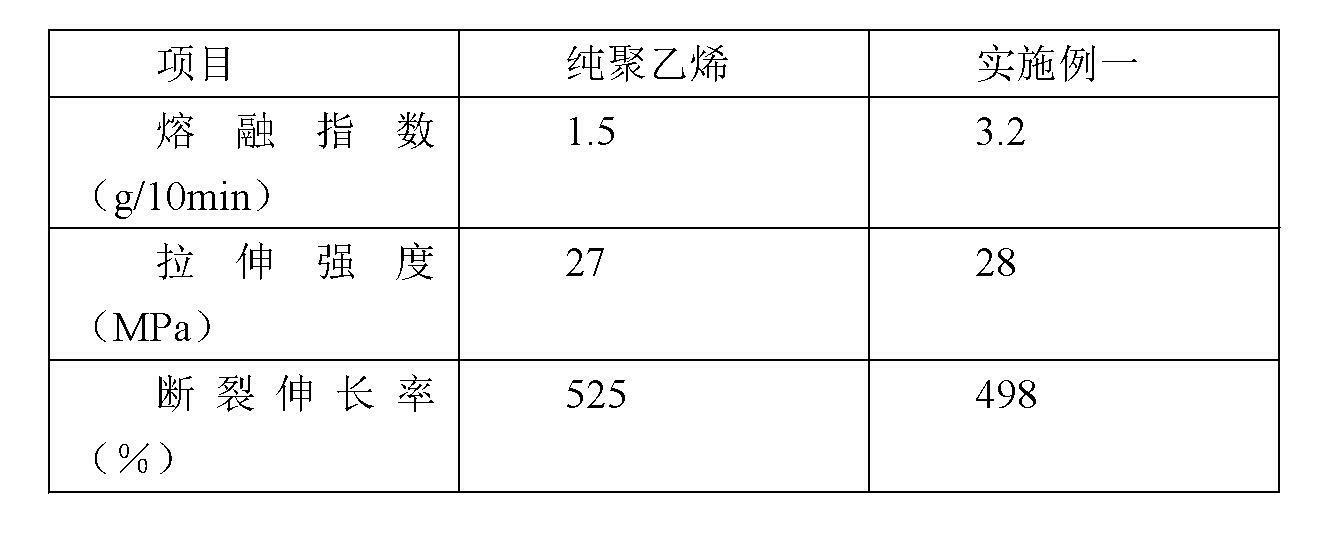

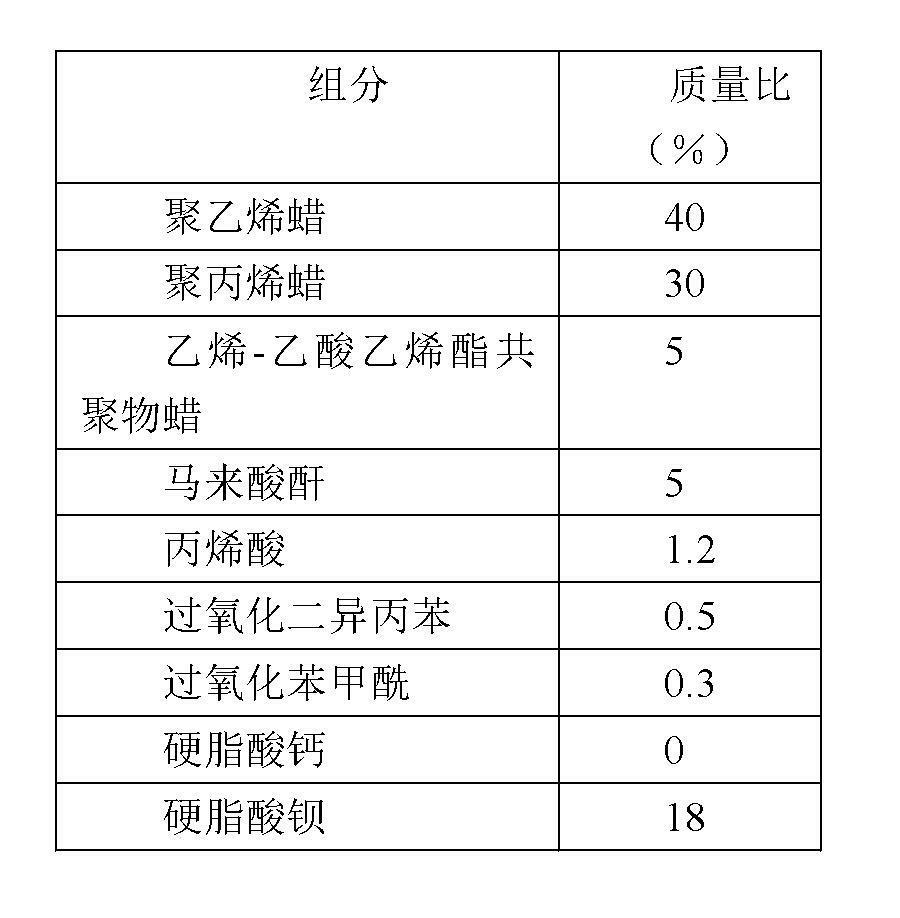

Plastic composite lubricating agent and preparation method thereof

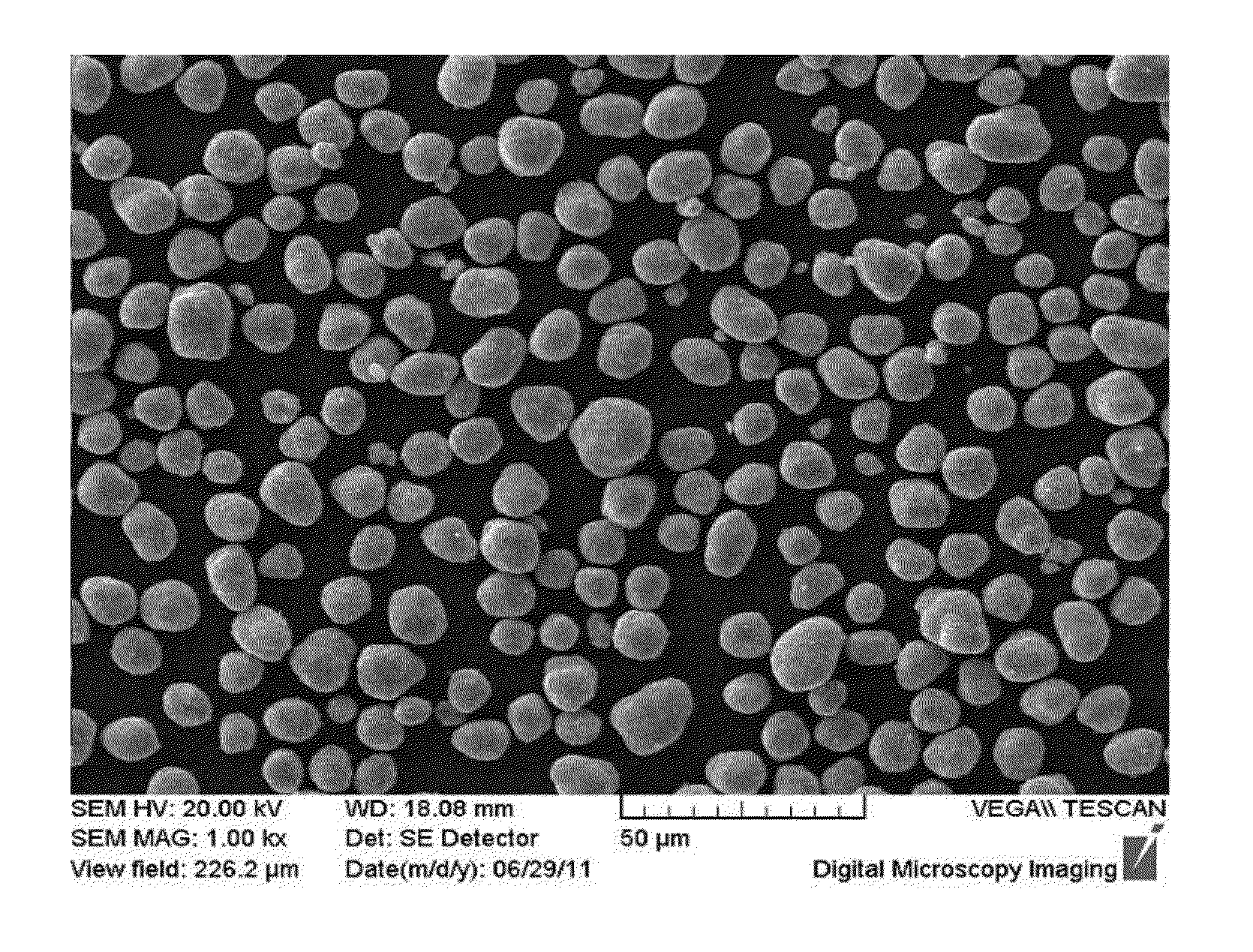

ActiveCN102690440AManufacturing Method AdvantagesFine grainPigment treatment with macromolecular organic compoundsPolymer scienceHeat stability

The invention belongs to the technical field of plastic auxiliaries and specifically relates to a plastic composite lubricating agent and a preparation method thereof. The plastic composite lubricating agent comprises a spherical or near-spherical inorganic powder kernel with lubricating property and a graft-modified polymer wax housing coated on the outer layer. The preparation method comprises the following process steps of: a) performing graft modification: uniformly mixing polymer wax, grafting monomers, an initiator and metal soap, and then performing modification and granulation througha screw extruder; and b) coating powder: using a coating device to coat spherical or near-spherical inorganic powder with the lubricating property in the graft-modified polymer wax. Through optimal selection and improvement of raw materials, optimization of a process and reasonable compounding of all components, the formed composite lubricating agent has good lubricating property inside and outside a full temperature range during plastic processing, and integrates the effects such as heat stability, compatibilization and the like; and the preparation method is favorable for simplifying the formula and process of the modified plastics, and can improve the processing performance of the plastics and lower the cost.

Owner:广州峰华化工科技有限公司

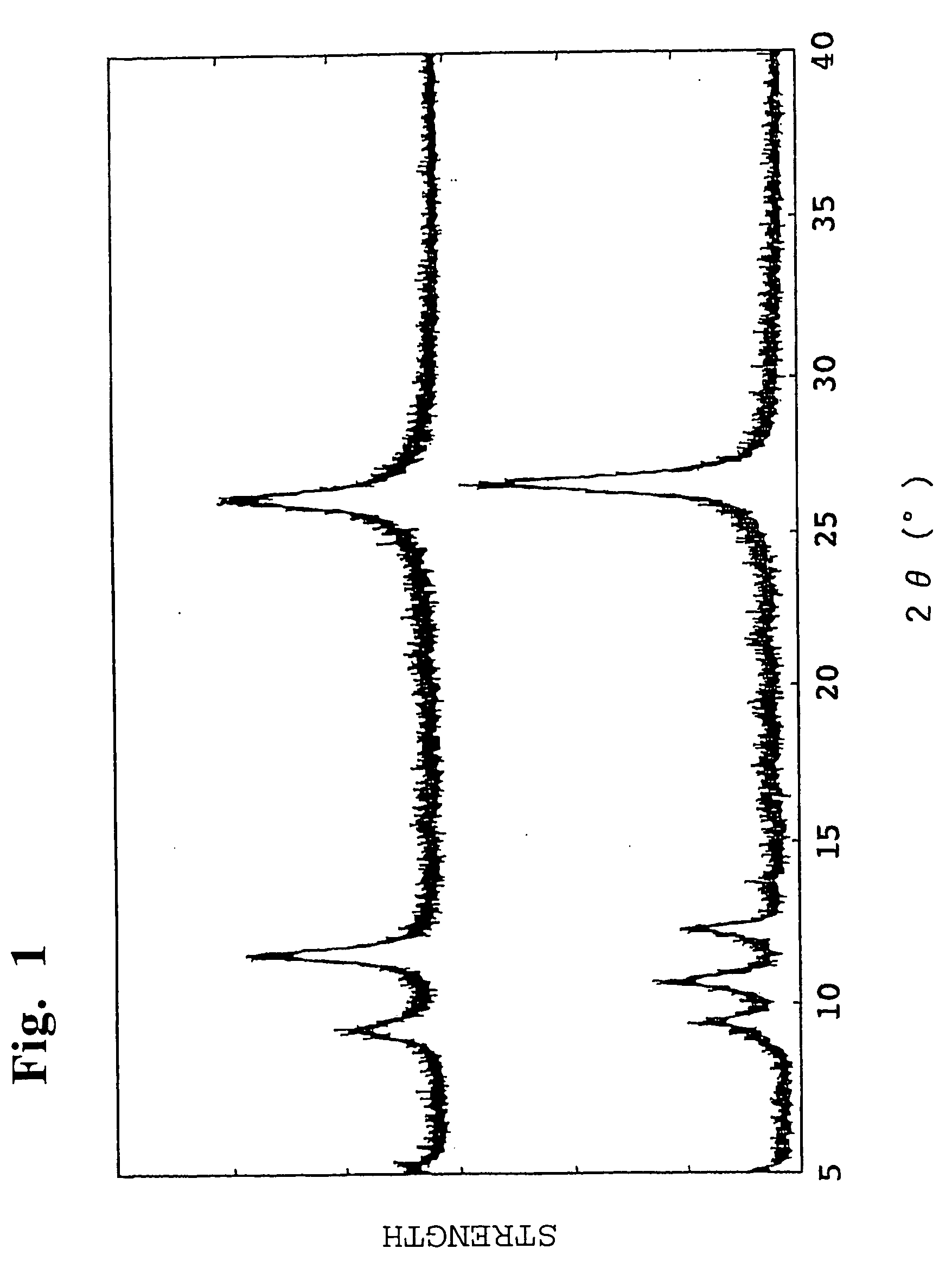

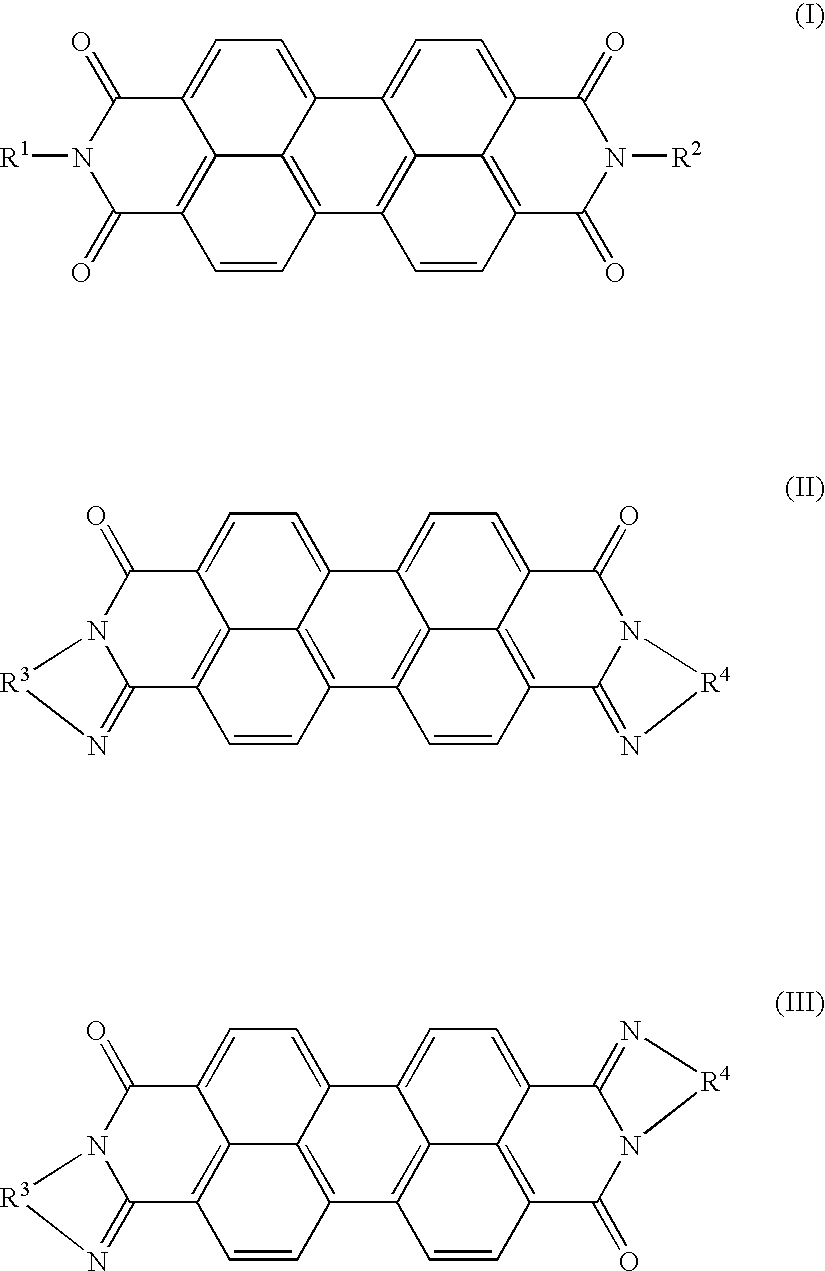

Black perylene pigment and process for producing the same

InactiveUS20050016420A1Improve thermal stabilitySuitable change in molecular arrangementArtificial dyesAnthracene dyesHigh resistancePerylene

A black perylene-based pigment produced by calcining at least one compound selected from the group consisting of diimide derivatives of perylene tetracarboxylic acid and diimide derivatives of perylene diiminodicarboxylic acid, at a temperature of 200 to 600° C. in vacuum or in an inert gas atmosphere, exhibits an excellent blackness, an excellent heat resistance and an excellent weather fastness as well as a high resistance and a high safety.

Owner:BASF AG

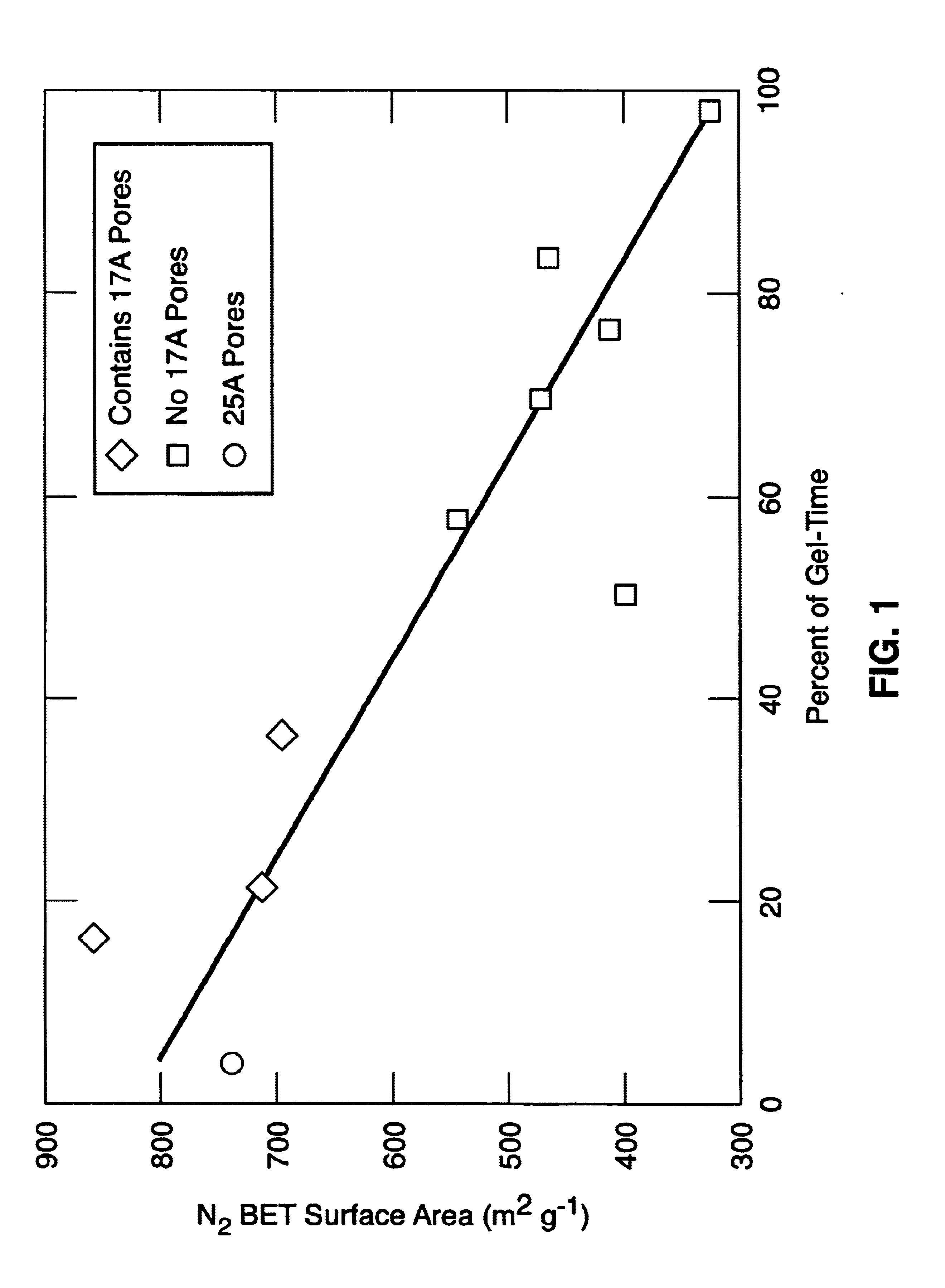

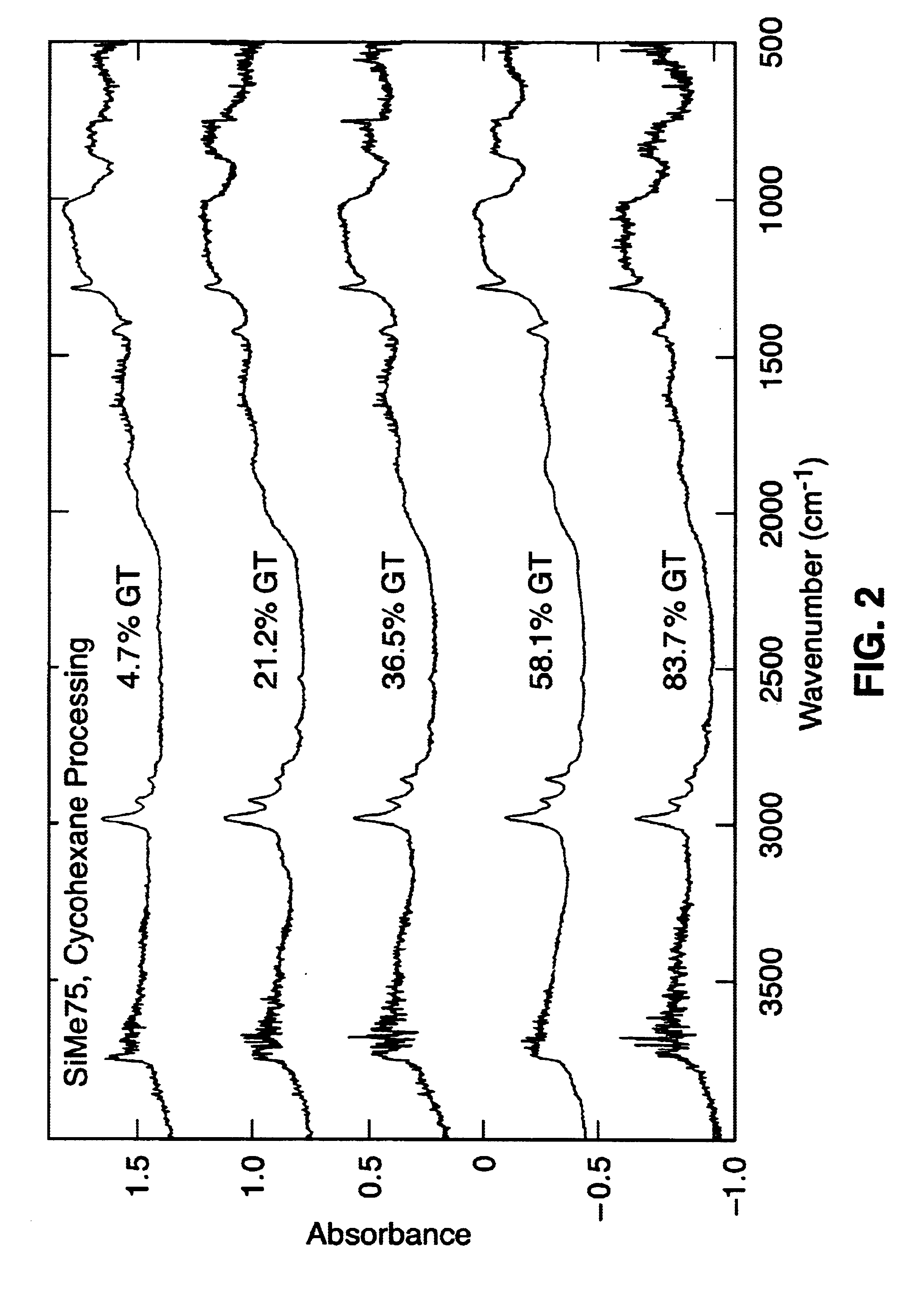

Sol-gel derived sorbents

InactiveUS6645908B1Effective combinationThermal stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsSorbentRoom temperature

Described is a method for producing copolymerized sol-gel derived sorbent particles for the production of copolymerized sol-gel derived sorbent material. The method for producing copolymerized sol-gel derived sorbent particles comprises adding a basic solution to an aqueous metal alkoxide mixture for a pH<=8 to hydrolyze the metal alkoxides. Then, allowing the mixture to react at room temperature for a precalculated period of time for the mixture to undergo an increased in viscosity to obtain a desired pore size and surface area. The copolymerized mixture is then added to an immiscible, nonpolar solvent that has been heated to a sufficient temperature wherein the copolymerized mixture forms a solid upon the addition. The solid is recovered from the mixture, and is ready for use in an active sampling trap or activated for use in a passive sampling trap.

Owner:UT BATTELLE LLC

Tunnel magnetoresistance effect device, and a portable personal device

InactiveUS20080144233A1Suppress DiffuseSuperior device characteristic and thermal stabilityNanomagnetismMagnetic measurementsBond energyMagnetization

A TMR device comprising an antiferromagnetic layer made of an antiferromagnetic material containing Mn, a magnetization fixed layer made of a ferromagnetic material, a tunnel barrier layer made of a dielectric material, and a magnetization free layer made of a ferromagnetic material. An insulator material layer is inserted in the magnetization fixed layer at a distance from the antiferromagnetic material layer and the tunnel barrier layer. One material can be expressed by NX, where X is a first element selected from the group consisting of oxygen, nitrogen and carbon; and N is a second element, provided that the bonding energy between the first and the second elements is higher than the bonding energy between manganese and the first element. A second material can be expressed by MX, where M is an element selected from the group consisting of titanium, tantalum, vanadium, aluminum, europium, and scandium; and X is an element selected from the group consisting of oxygen, nitrogen and carbon. The tunnel magnetoresistance effect device suppresses the diffusion of Mn from the Mn based alloy constituting the antiferromagnetic material layer even after heat treatment is performed.

Owner:TOSHIBA MEMORY CORP

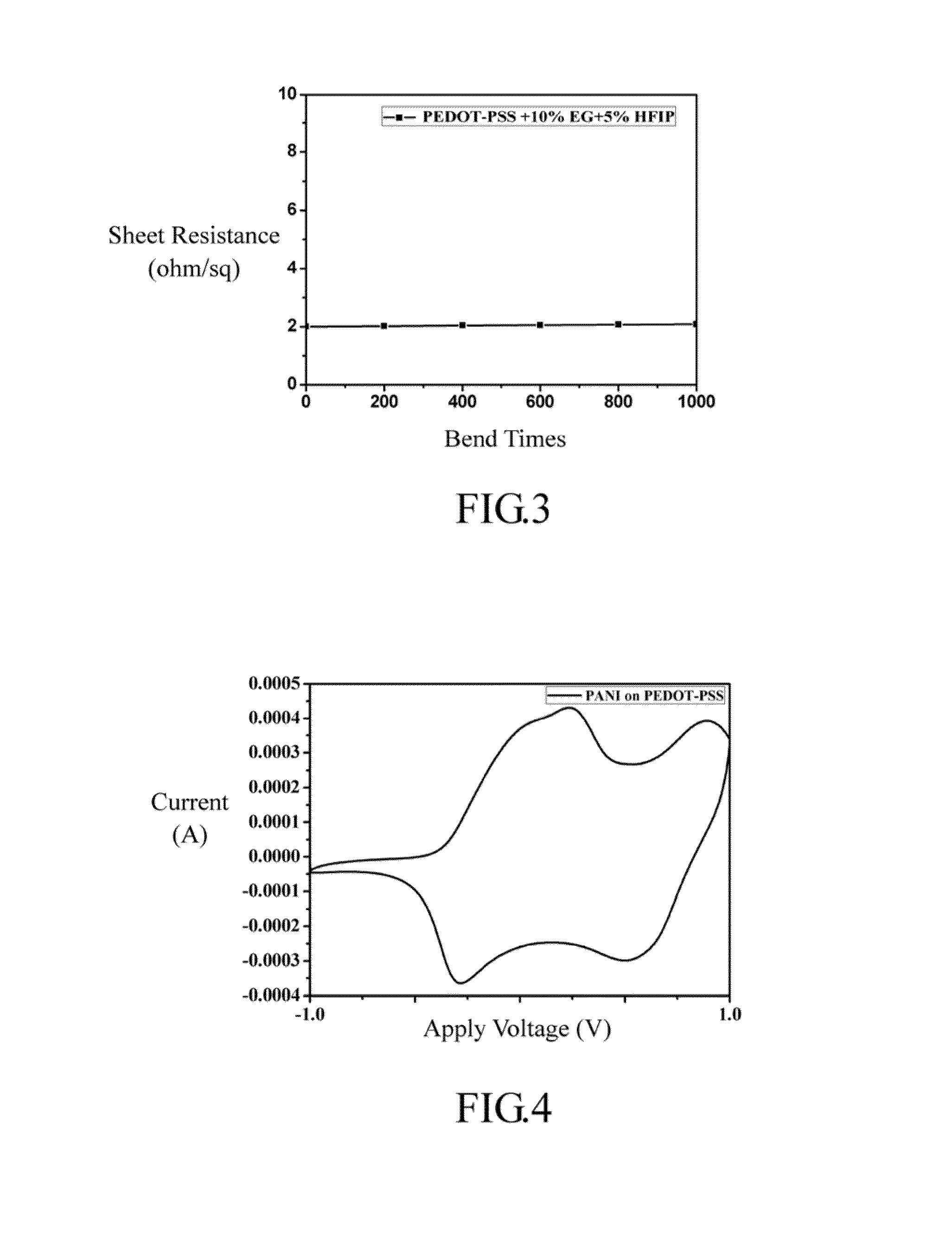

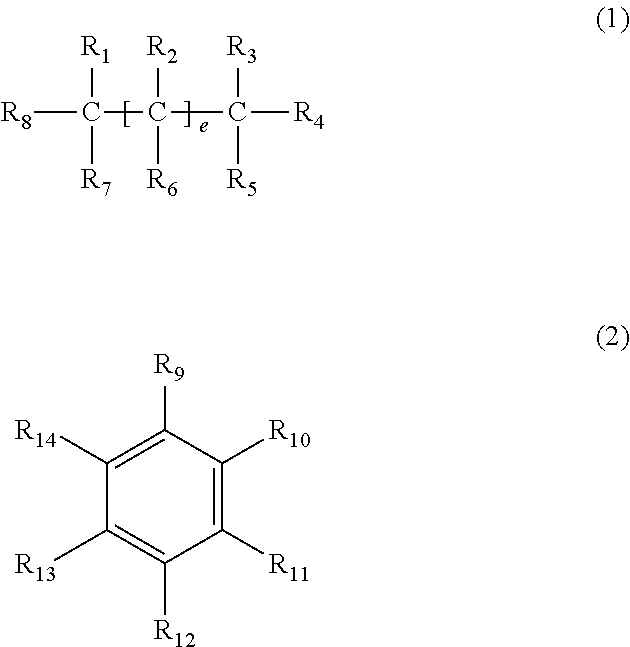

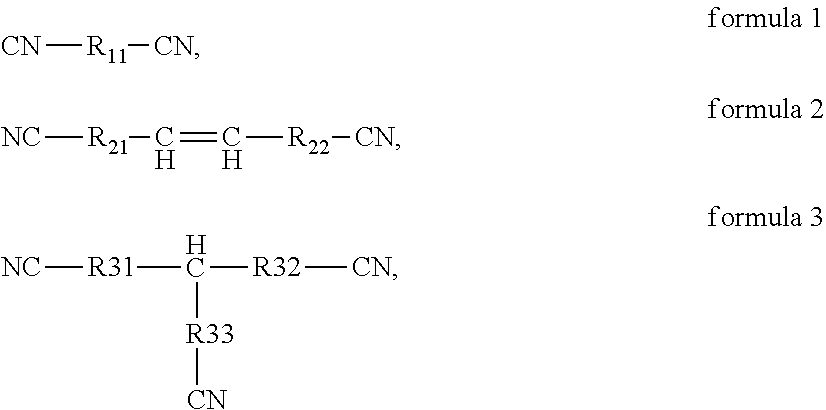

Methods for fabricating and treating doped conjugated polymer film

InactiveUS20130105740A1Reduce sheet resistanceHigh conductivity and thermal stabilityConductive materialSolid-state devicesComposite materialOrganic acid

A method for fabricating a doped conjugated polymer film includes the steps of: mixing a polar substance, a polar solvent and a doped conjugated polymer to form a doped conjugated polymer solution, and forming a conjugated polymer film with the doped conjugated polymer solution. In addition, a method for treating a doped conjugated polymer film includes the steps of: providing a doped conjugated polymer film, and adding a mixed solution which contains a polar substance and a polar solvent to the doped conjugated polymer film. In these cases, the polar substance is selected from the group consisting of formula (1), formula (2), inorganic acids, benzene-containing organic acids, or their combinations. The polar solvent is selected from the group consisting of water, ethers, alcohols, sulfoxides, alcohol ethers, ketones, amines, nitriles, carboxylic acids, amides, or their combinations.

Owner:NAT CENT UNIV

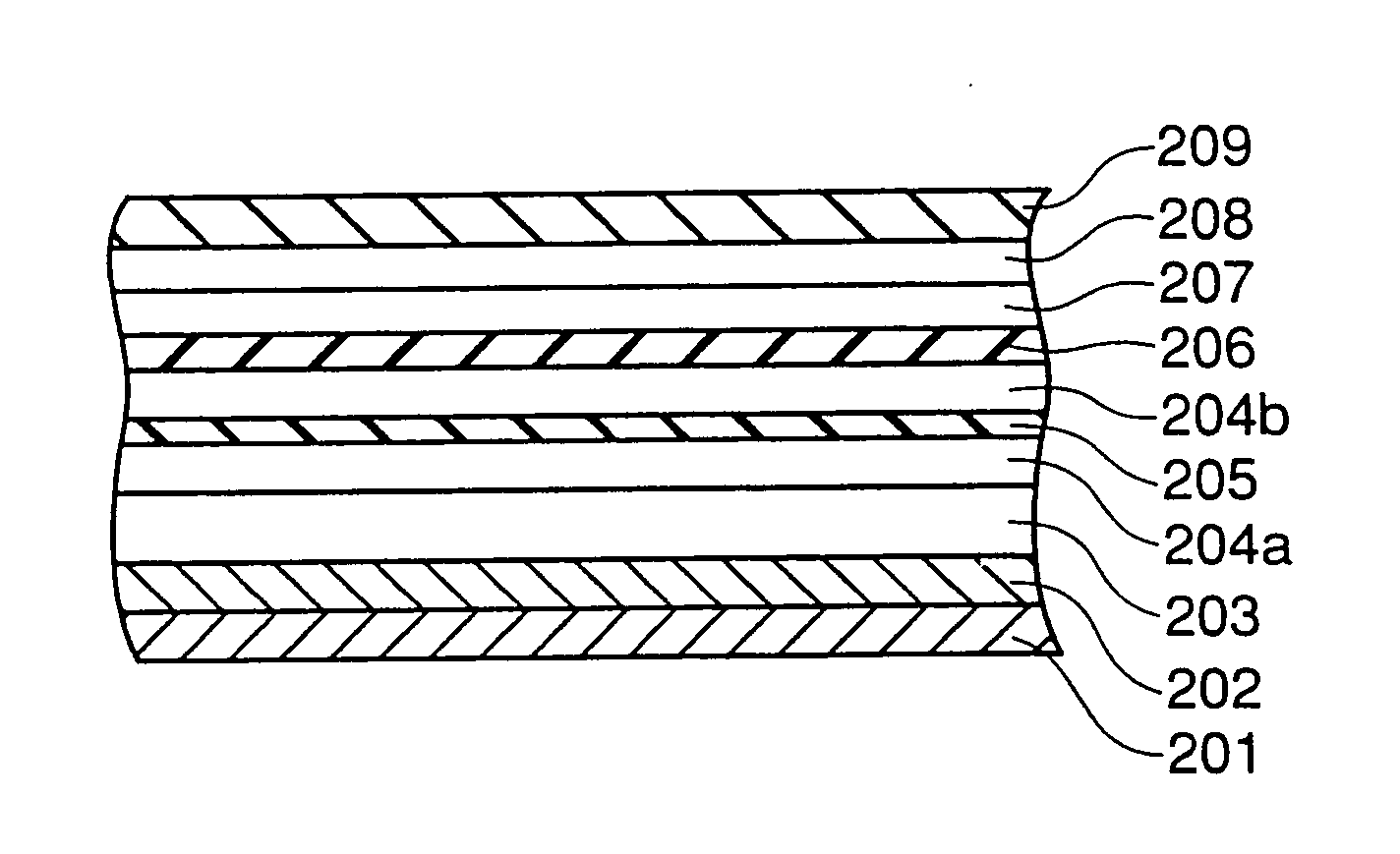

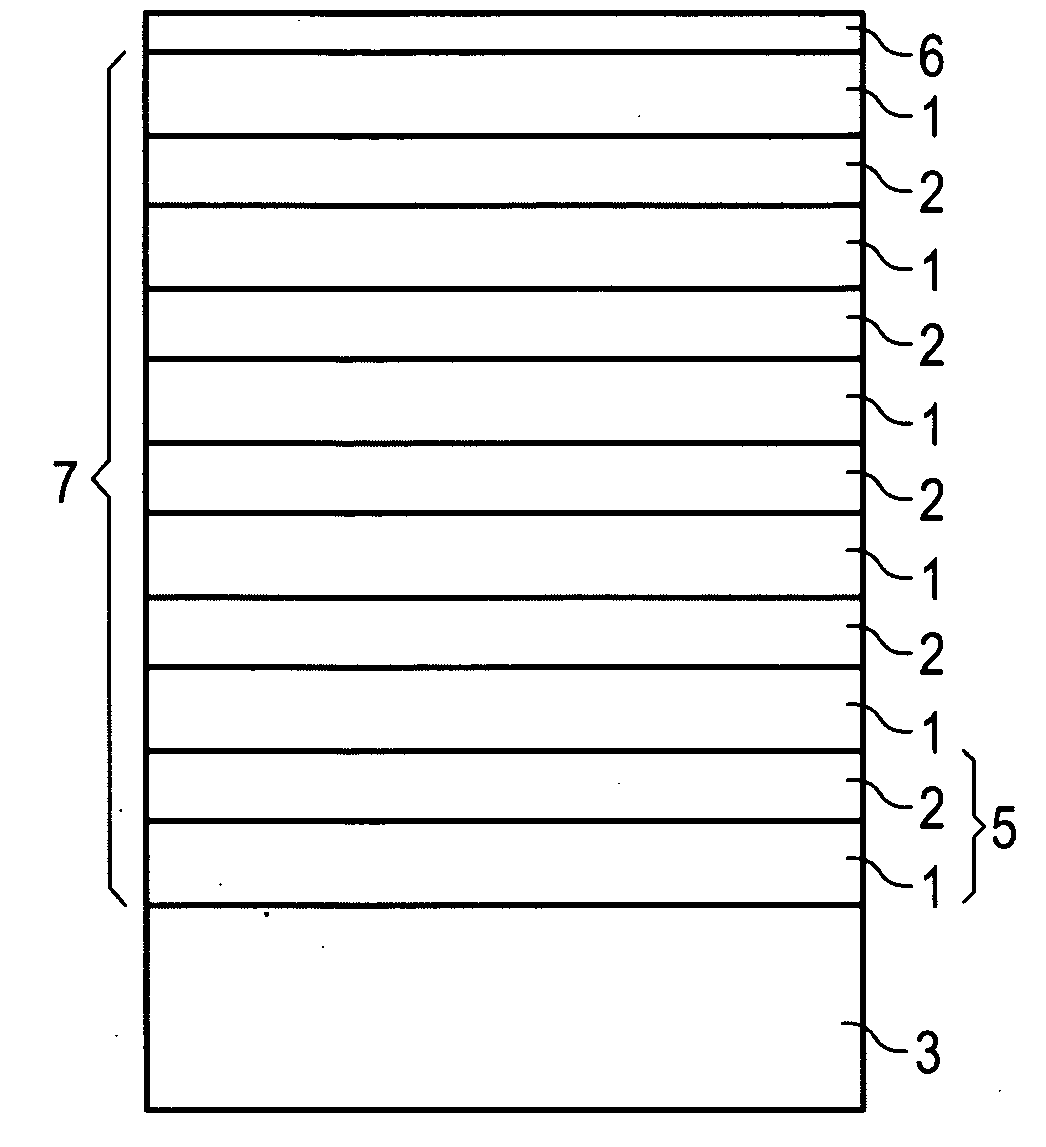

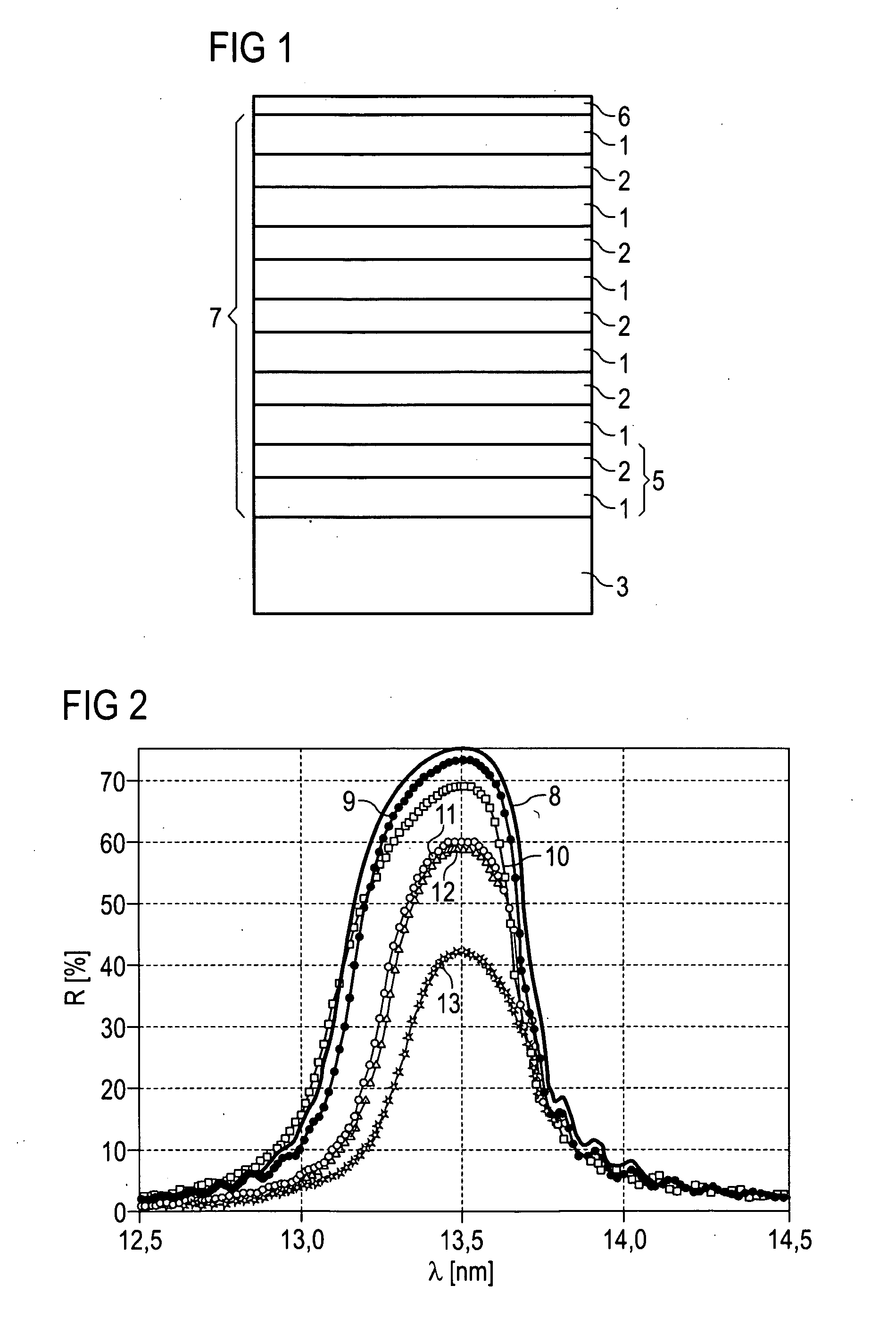

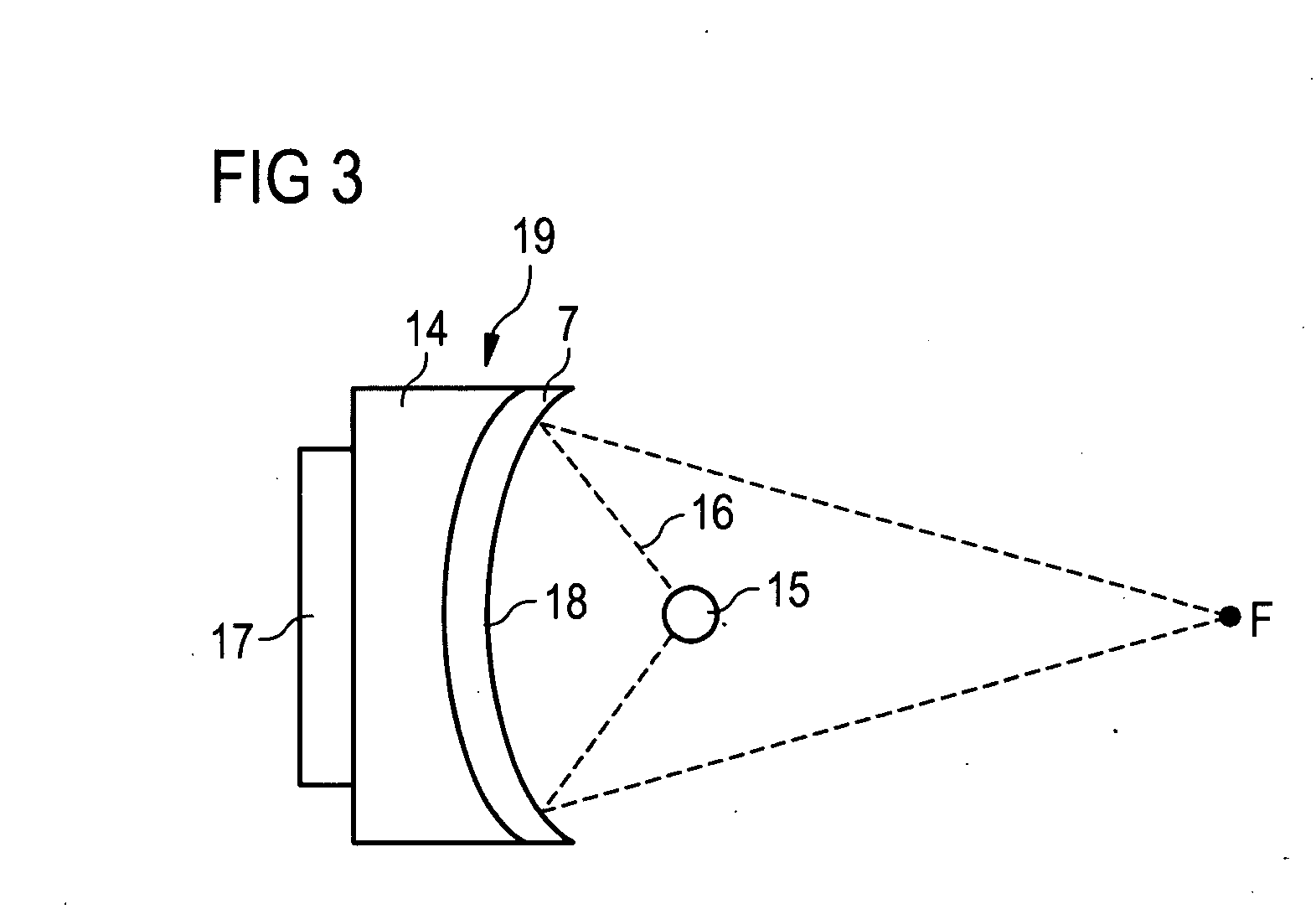

Thermally Stable Multilayer Mirror for the EUV Spectral Range

InactiveUS20090009858A1Improve thermal stabilityImprove long-term stabilityMirrorsNanoinformaticsComputational physicsSilicon boride

A multilayer mirror includes a layer sequence arranged on a substrate and a plurality of layer pairs. Each layer pair includes a first layer composed of a first material and a second layer composed of a second material. The first layers and the second layers each have a thickness of more than 2 nm, and the first material or the second material is a silicon boride or a molybdenum nitride.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

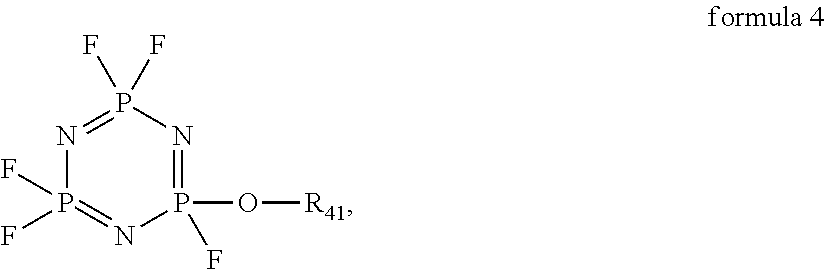

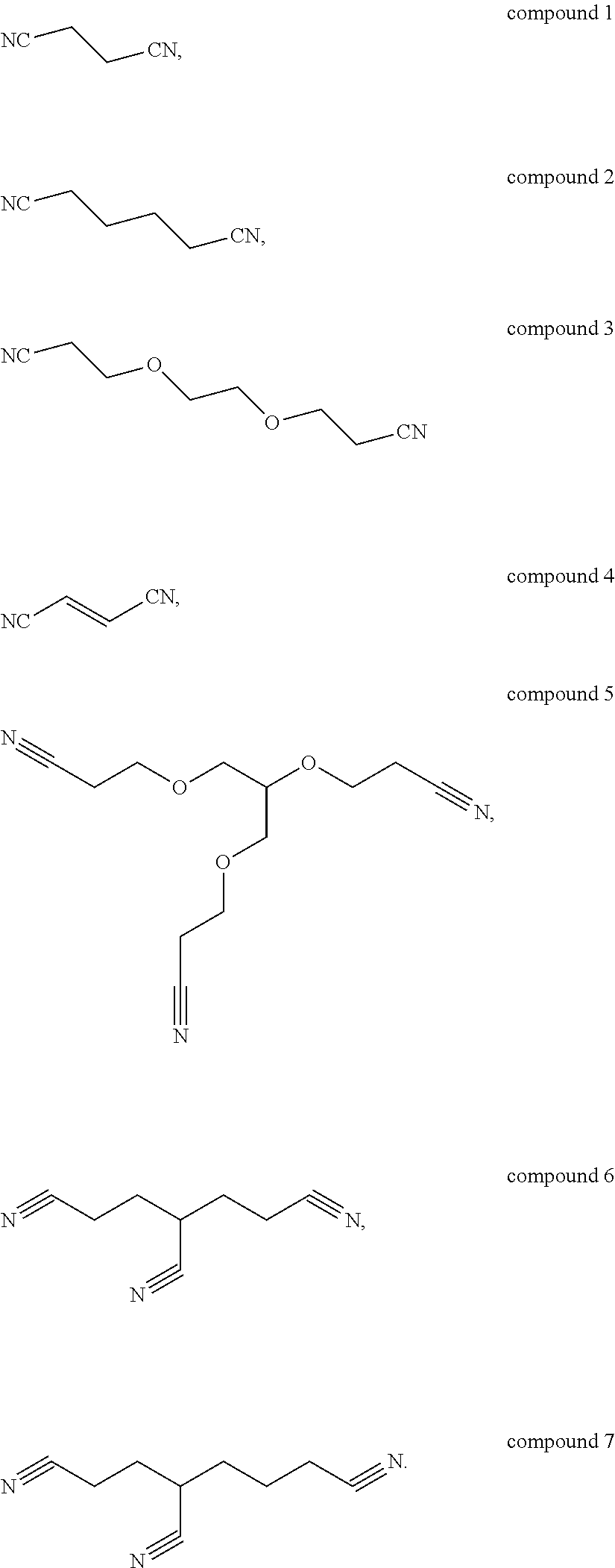

Electrolyte and lithium-ion battery

InactiveUS20190173124A1High flash pointReduce flammabilityFinal product manufactureCell electrodesDouble bondChemistry

Examples of the present application provide an electrolyte comprising a lithium salt, an organic solvent, and an additive, wherein the additive comprises a nitrile compound, a fluorophosphazene, and a fluoroether. By using the electrolyte comprising a nitrile compound, a fluorophosphazene, a fluoroether, the thermal stability of the electrolyte itself and the positive electrode material may be significantly improved through the synergistic effect of above three and the safety of the lithium-ion battery is greatly enhanced when the electrolyte is applied to the lithium-ion battery. In addition, by adding a cyclic carbonate with carbon-carbon double bond and fluorocyclic carbonate and by controlling the mass percentage of nitrile compound, fluorophosphazene, fluoroether in electrolyte, significant improvements in the safety of lithium-ion batteries may be achieved without significantly degrading the cycling performance of the lithium-ion battery.

Owner:NINGDE AMPEREX TECH

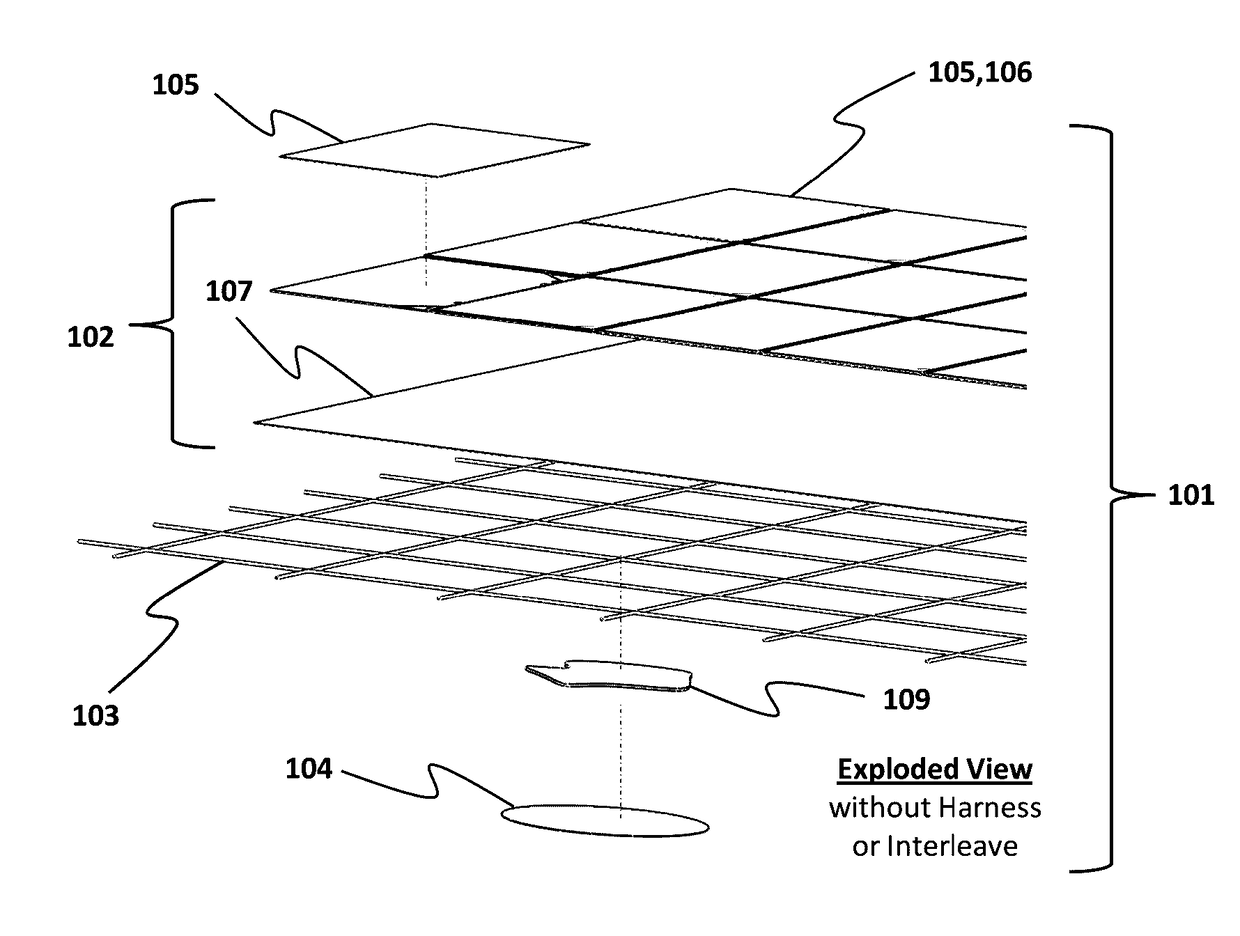

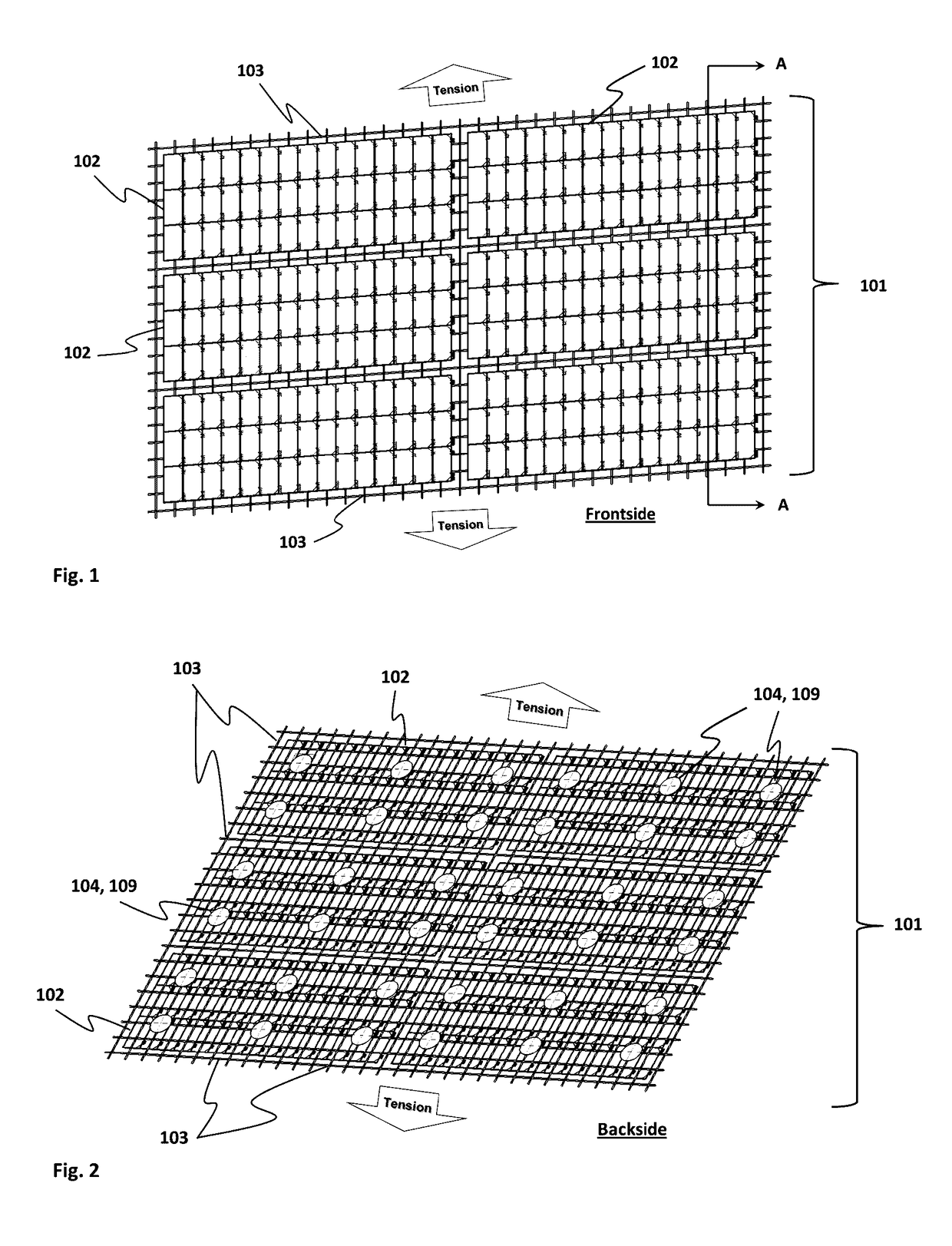

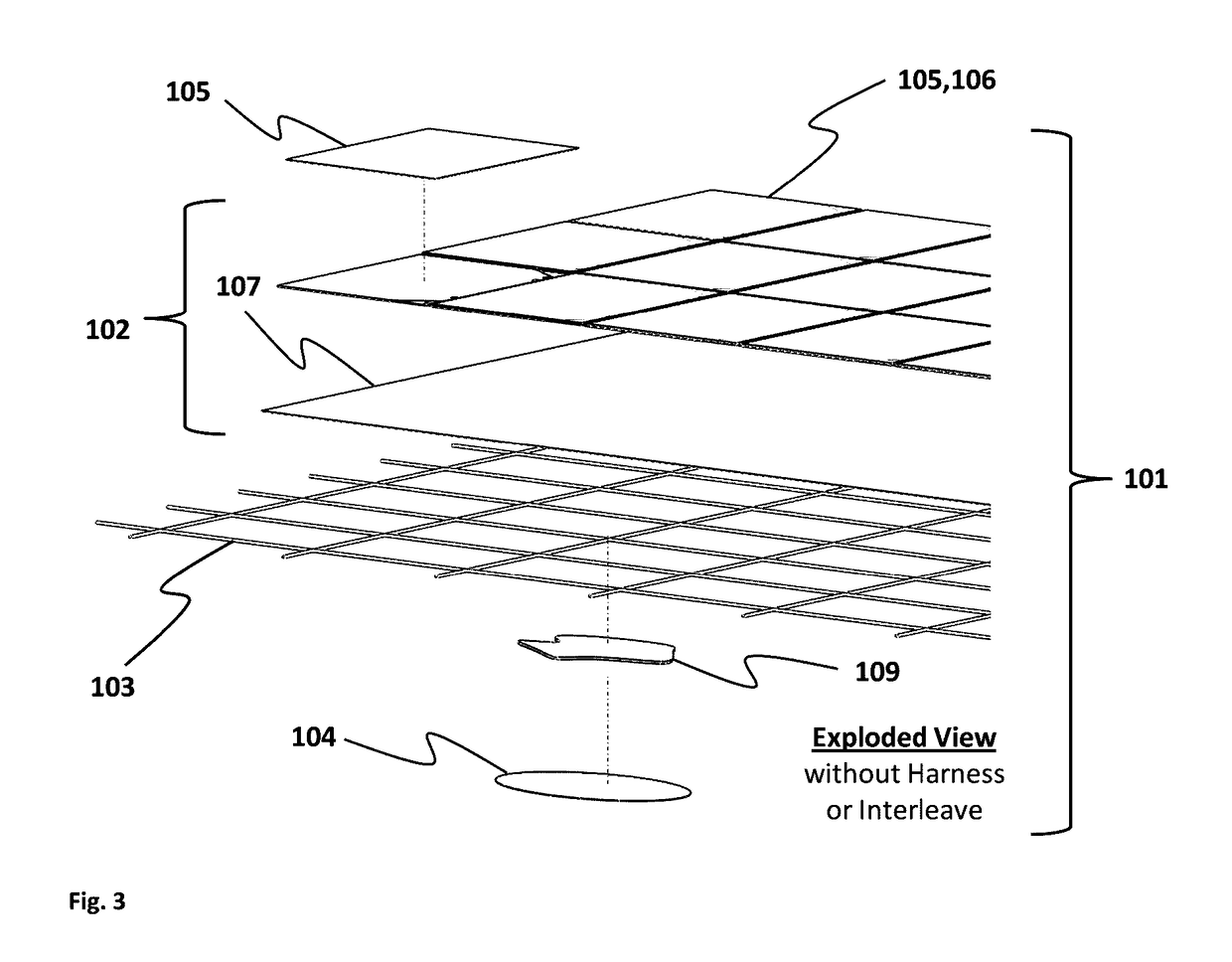

Integrated modular photovoltaic blanket assembly for space solar array

ActiveUS9620658B1Economically manufacturedEasy to operatePhotovoltaic supportsCosmonautic vehiclesSpace-based solar powerComputer module

A modular, lightweight, high-survivable, photovoltaic flexible blanket assembly for a space solar array is disclosed. The modular blanket is an accordion foldable or rollable flexible photovoltaic solar panel blanket assembly comprising a plurality of common photovoltaic modules spaced in an orthogonal pattern. Each module is mechanically attached with multiple low profile fasteners on their backside to an open weave mesh tensioned backplane structure. The backplane forms a tensioned dimensionally stable planar surface in the deployed configuration onto which the modules are suspended. Each module is common and comprised of a rectangular substrate that includes solar cell assemblies, circuitry, exposed electrical contacts for integration of blanket-level harnessing, and frontside and rearside shielding and coatings as required for the mission application. The blanket assembly may be dispersed with an open pattern of compliant and formable material on the backside to provide insulation against the vigorous vibration of the launch environment.

Owner:DEPLOYABLE SPACE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com