Plastic composite lubricating agent and preparation method thereof

A compound lubricant and manufacturing method technology, applied in the field of plastic additives, can solve problems such as single function and no adaptive optimization, and achieve the effects of improving production efficiency, improving mechanical properties, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition of lubricating powder in this implementation is as follows:

[0028] Core: spherical barium sulfate, mass ratio 40%;

[0029] Shell: grafted modified polymer wax, 60% by mass.

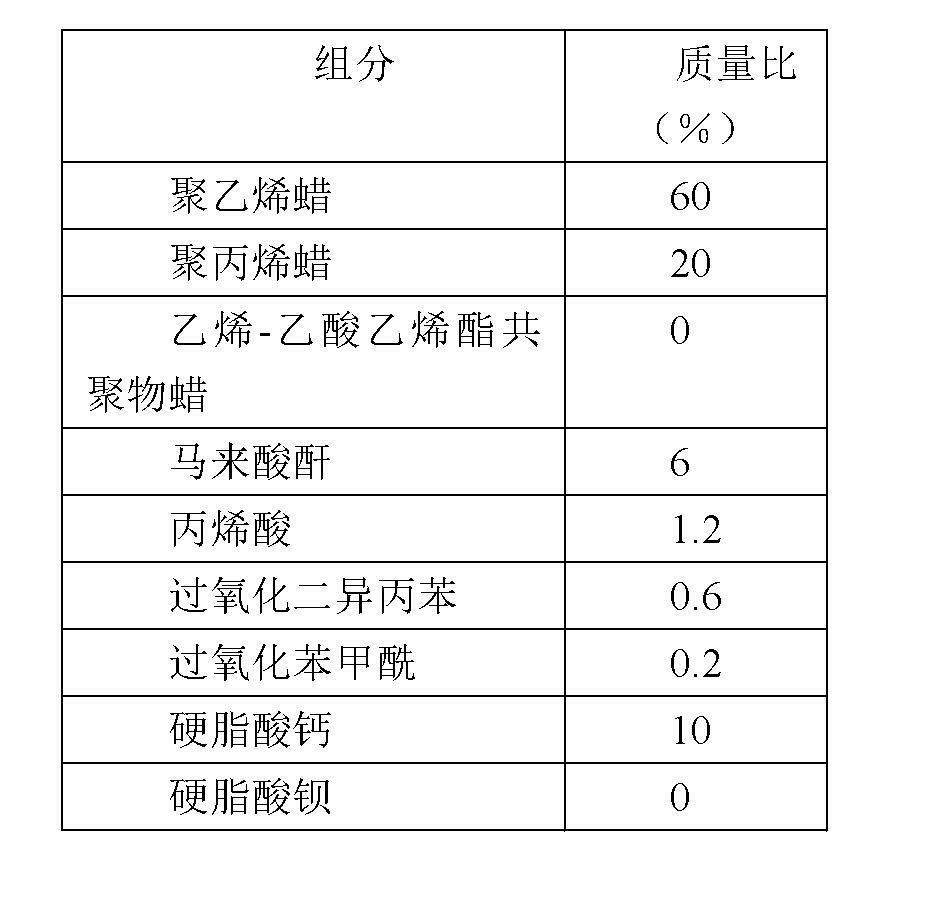

[0030] The formula of the graft modification of the shell is shown in Table 1:

[0031] Table 1

[0032]

[0033] The shell graft extrusion temperature is 90-120°C, of which the feed section is 90°C, and the head temperature is 100°C.

[0034] The coating process conditions are a rotating speed of 2000r / min and a temperature of 110°C.

[0035] The final powder is added into polyethylene plastic by 1% to blend and granulate.

Embodiment 1

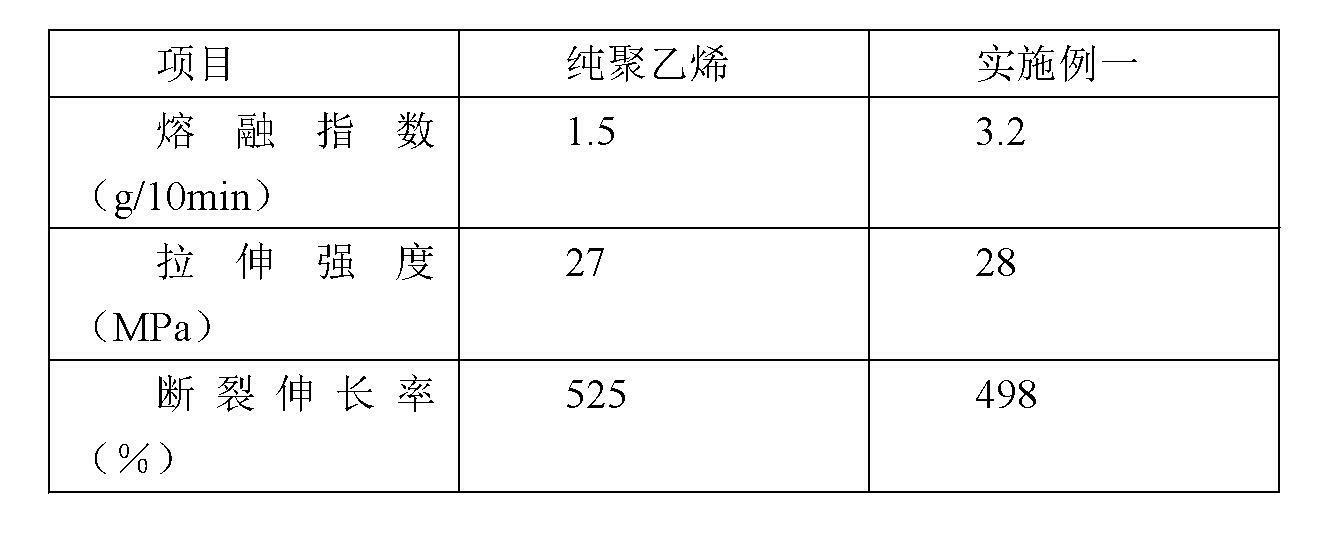

[0036] The various performance data of embodiment one contrast pure polyethylene pellets are as table 2:

[0037] Table 2

[0038]

[0039] As can be seen from Table 2, after adding the plastic composite lubricant of the present invention, the fluidity of polyethylene increases, and the processability is improved; meanwhile, the mechanical properties are not significantly affected.

Embodiment 2

[0041] The composition of lubricating powder in this implementation is as follows:

[0042] Core: glass microspheres, mass ratio 60%;

[0043] Shell: grafted modified polymer wax, 40% by mass.

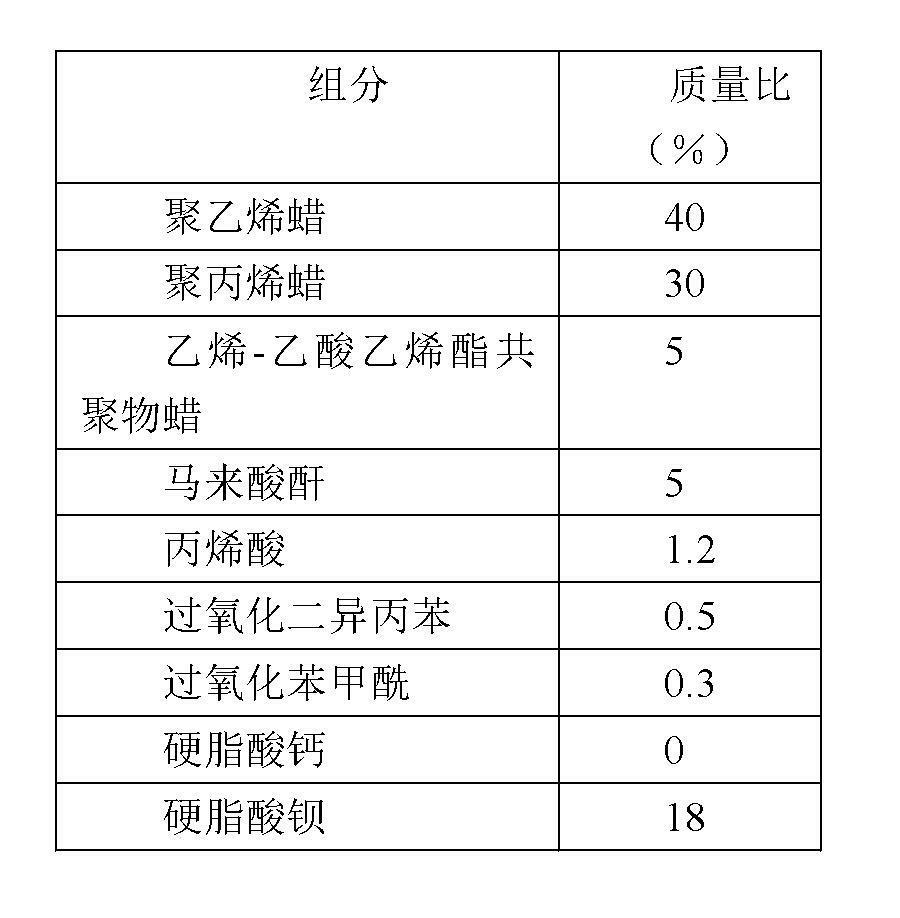

[0044] The formula of the graft modification of the shell is shown in Table 2:

[0045] table 3

[0046]

[0047] The shell graft extrusion temperature is 90-130°C, of which the feed section is 90°C, and the head temperature is 110°C.

[0048] The coating process conditions are a rotating speed of 2300r / min and a temperature of 115°C.

[0049] Add 5% of the final powder to polypropylene plastic and add 40% calcium carbonate to blend and granulate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com