Patents

Literature

53results about How to "Wide processing temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-flame-retardance high-heat-resistance halogen-free flame-retardant thermoplastic polyurethane elastomer cable material and preparation method thereof

InactiveCN102816427AImprove heat resistanceImprove brightnessInsulated cablesInsulated conductorsChemistryShore

The invention relates to a high-flame-retardance high-heat-resistance halogen-free flame-retardant thermoplastic polyurethane elastomer cable material and a preparation method thereof, belonging to the field of halogen-free flame-retardant cable materials. The cable material is prepared from the following raw materials in percentage by weight: 20-50% of thermoplastic polyurethane elastomer, 15-40% of styrene elastomer, 3-8% of plasticizer, 20-30% of expansion flame retardant, 4-7% of flatting agent, 0.5-1% of lubricant, 0.5-1% of antioxidant and 1.5-3% of master batch. The thermoplastic polyurethane elastomer is a polyether-type thermoplastic polyurethane elastomer of which the hardness range is Shore A 60-90. The invention improves the problem of too narrow processing temperature region for the thermoplastic polyurethane elastomer cable material, and also improves the heat resistance of the cable material. The thermoplastic polyurethane elastomer, which is used as a base, is subjected to melt blending with the high-temperature-resistant material; and the novel expansion flame retardant which is nonmigratory in contact with water is used as the flame retardant of the base.

Owner:BEIJING UNIV OF CHEM TECH +1

Polyphenylene sulfide/polyamide composite material and method for making same

The present invention discloses one kind of polyphenyl thioether / polyamide composite material and its preparation process. The polyphenyl thioether / polyamide composite material is prepared with polyphenyl thioether 23-69.3 wt%, polyamide 10-30 wt%, glass fiber 20-40 wt%, heat stabilizer 0.2-2 wt%, silane coupler 0.1-2 wt%, processing lubricant 0.2-2 wt% and crystallization promoter 0.1-1 wt%. The polyphenyl thioether / polyamide composite material has high shock toughness, simple preparation process and low cost.

Owner:ANHUI KEJU NEW MATERIALS

Tungsten disulfide based high-temperature dry-film lubricant

InactiveCN101560432AImprove wear resistanceWide processing temperature rangeAdditivesBase-materialsWear resistantSolvent

The invention relates to a tungsten disulfide based high-temperature dry-film lubricant which comprises the following components according to the weight percent: 20-70 of caking agent, 5-30 of tungsten disulfide, 5-30 of polyfluortetraethylene, 0.2-20 of wear resistant filling material, 10-40 of component solvent and the balance of addition agent. Compared with the prior art, the invention has the characteristics of high loading capacity, better wear resistance under the condition of high rotating speed, wide processing temperature range and the like.

Owner:上海鑫氟化工材料有限公司

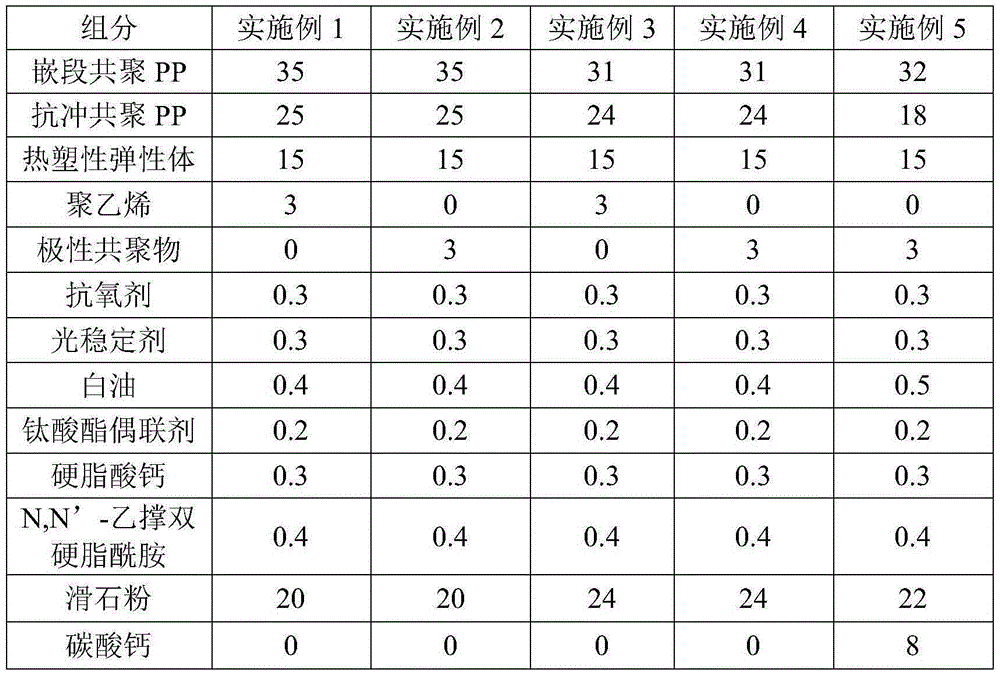

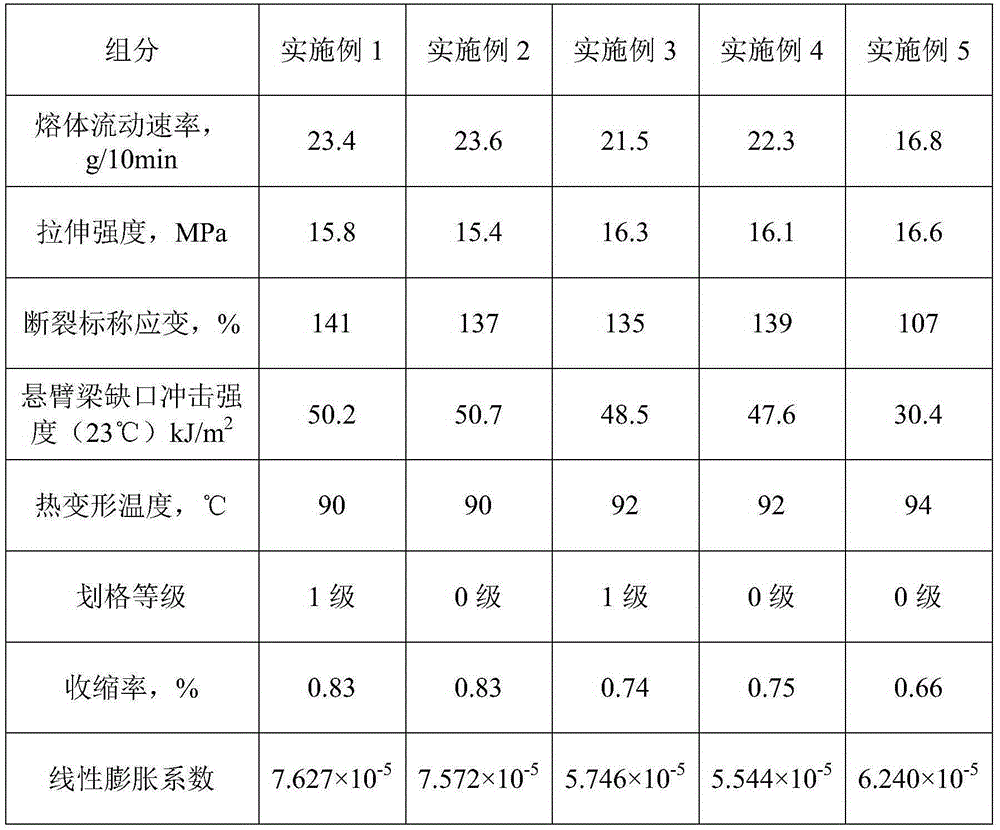

Easily-sprayed polypropylene composite material and preparation method and application thereof

ActiveCN106752633AWide processing temperature rangeImprove impact resistanceCoatingsPolypropylene compositesLow speed

The invention relates to an easily-sprayed polypropylene composite material which can be used for automobile parts and a preparation method and application thereof. The easily-sprayed polypropylene composite material is mainly prepared by mixing the following ingredients (by weight): 40-65 parts of polypropylene, 10-18 parts of a thermoplastic elastomer, 0-3 parts of polyethylene, 0-3 parts of a polar copolymer, 20-30 parts of a mineral filler and a few amount of an anti-oxidant, a light stabilizer and other functional aids. The preparation method comprises the following steps: successively adding polypropylene, the thermoplastic elastomer, polyethylene, the polar copolymer, the mineral filler, the anti-oxidant, the light stabilizer and other functional aids into a low speed mixer and mixing for at least 2 min; adding the mixture into a twin-screw extruder and mixing, setting the extrusion temperature to be 170-240 DEG C, extruding and granulating, and uniformly mixing to obtain the product. The easily-sprayed polypropylene composite material can be used for preparation of automobile bumper products and has comprehensive properties such as excellent impact resistance, fluidity, rigidity, heat stability, dimensional stability, sprayability, etc.

Owner:株洲时代工程塑料科技有限责任公司

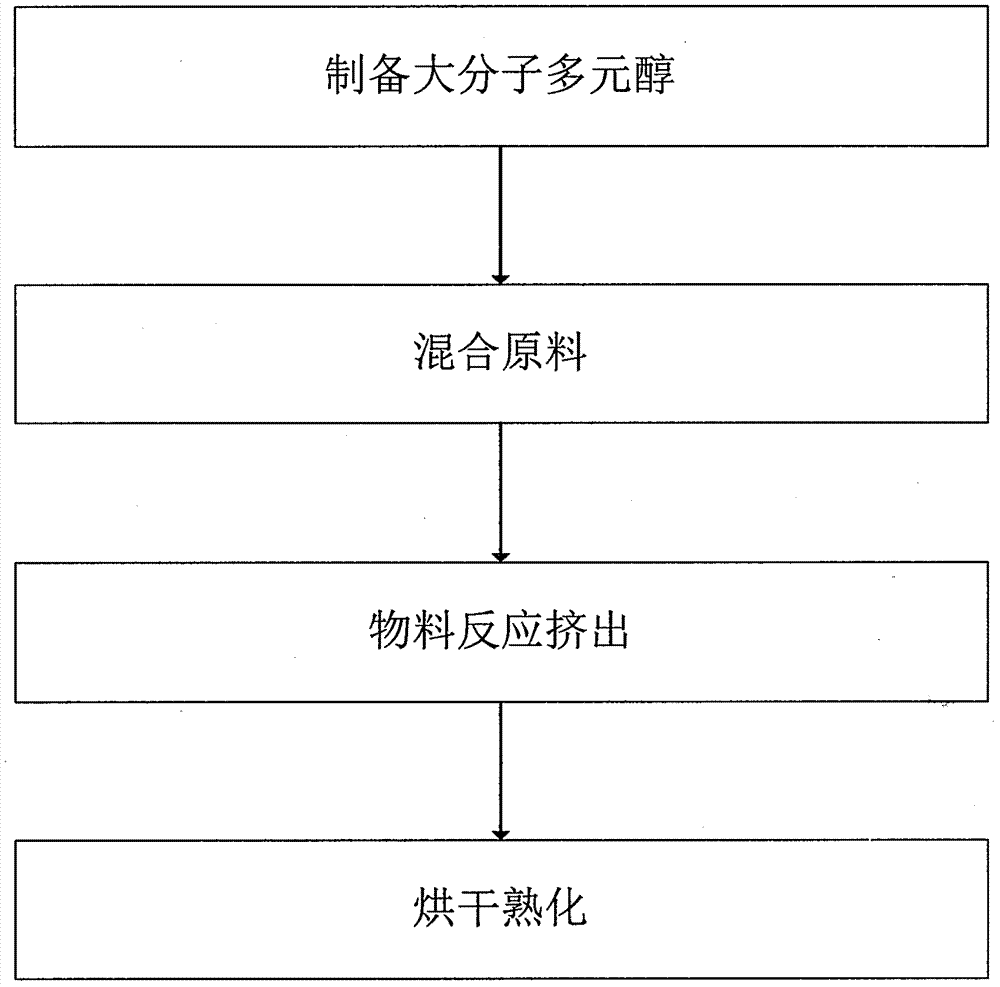

Temperature-resistant type high-permeable waterproof and moisture-penetration thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN107057021AGood plastic processingStable plasticizing processThermoplasticEnvironmental resistance

The invention discloses a temperature-resistant type high-permeable waterproof and moisture-penetration thermoplastic polyurethane elastomer. The temperature-resistant type high-permeable waterproof and moisture-penetration thermoplastic polyurethane elastomer is prepared from the following components in parts by mass: 30 to 100 parts of macromolecular polyols, 5 to 50 parts of diisocyanate, 3 to 40 parts of micromolecular chain extender, and 0 to 20 parts of additive. The prepared temperature-resistant type high-permeable waterproof and moisture-penetration thermoplastic polyurethane elastomer has the advantages that the temperature-resistant type high-permeable waterproof and moisture-penetration thermoplastic molecule structure adopts a rigid section-environment sensing area-amorphous region multiple-block structure, a non-regular group is introduced to adjust the crystallizing temperature of the environment sensing area, the high temperature-resistant property is good, the processing temperature range is widened, the processing property is good, and the mechanical property is excellent; a one-step method is adopted, the preparation technology is stable, the requirement on equipment is low, the cost is low, and the large-scale production effect is realized; the plasticizing processing is good, the moisture-penetration property is adjusted according to requirements, the degradability is realized, and the green, environment-friendly and non-pollution effects are realized; the elastomer can be widely applied to the fields of clothes, home, medical articles and the like.

Owner:SHANGHAI HENGAN POLYURETHANE CO LTD

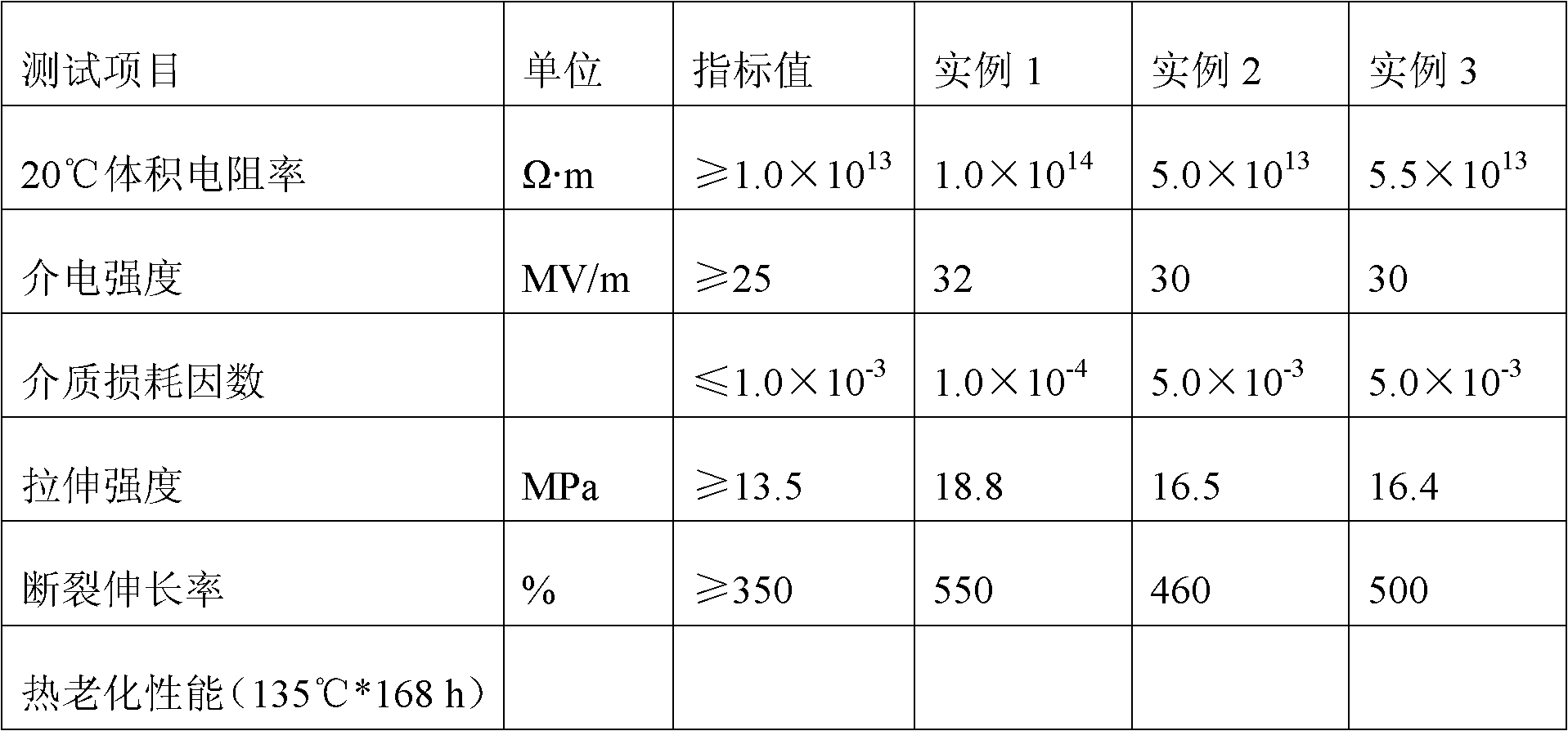

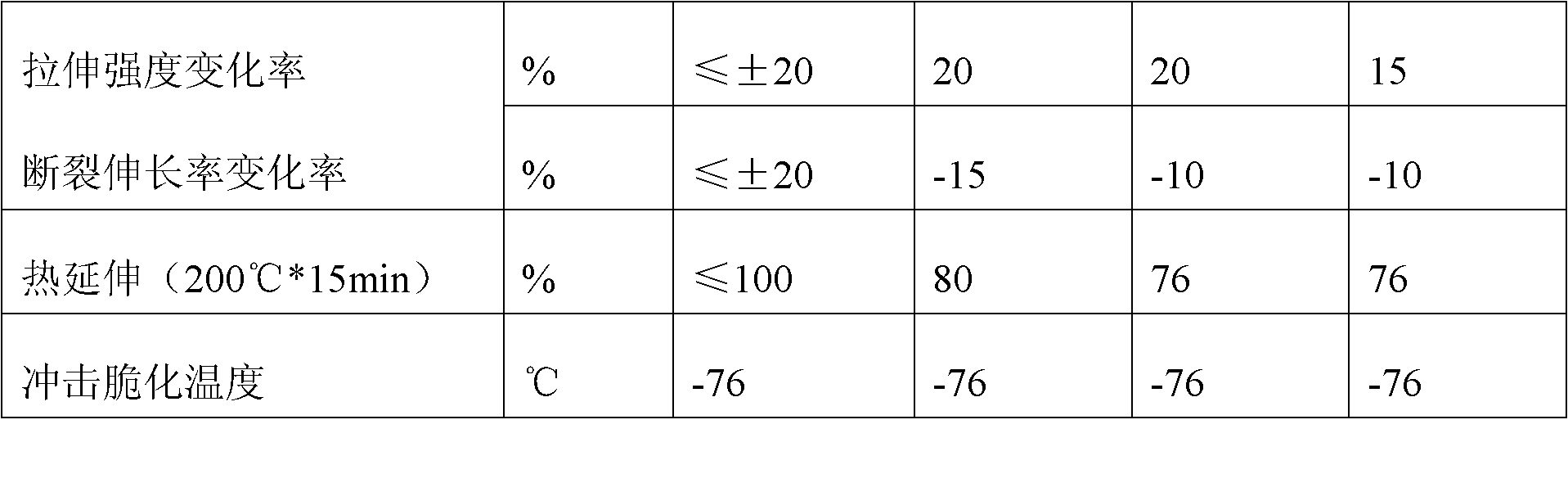

Easily processed and quickly crosslinked silane crosslinked polyethylene insulating material and preparation method thereof

ActiveCN102070812APromote cross-linking and curingImprove permeabilityPlastic/resin/waxes insulatorsAntioxidantSilanes

The invention discloses a preparation method of an easily processed and quickly crosslinked silane crosslinked polyethylene insulating material. The insulating material consists of a material A and a material B, wherein the material A comprises the following components in part by weight: 100 parts of polyethylene, 5 to 15 parts of ethylene-acrylate copolymer, 2 to 5 parts of silane and 0.1 to 0.5 part of initiator; and the material B comprises the following components in part by weight: 100 parts of ethylene-acrylate copolymer, 2 to 5 parts of catalyst, 2 to 10 parts of lubricating agent, 1 to 10 parts of silicon dioxide, 1 to 5 parts of antioxidant and 2 to 5 parts of copper inhibitor. A cable material prepared by the method has high natural crosslinking speed; and the required crosslinking can be achieved at room temperature in 2 to 3 days. Compared with the conventional natural crosslinked product, the material has the advantages of high crosslinking speed, wide processing temperature range, low corrosion to equipment, low probability of foaming and pre-crosslinking and the like, and can be used as the insulating material for wires and cables of 3kv or below.

Owner:上海新上化高分子材料有限公司

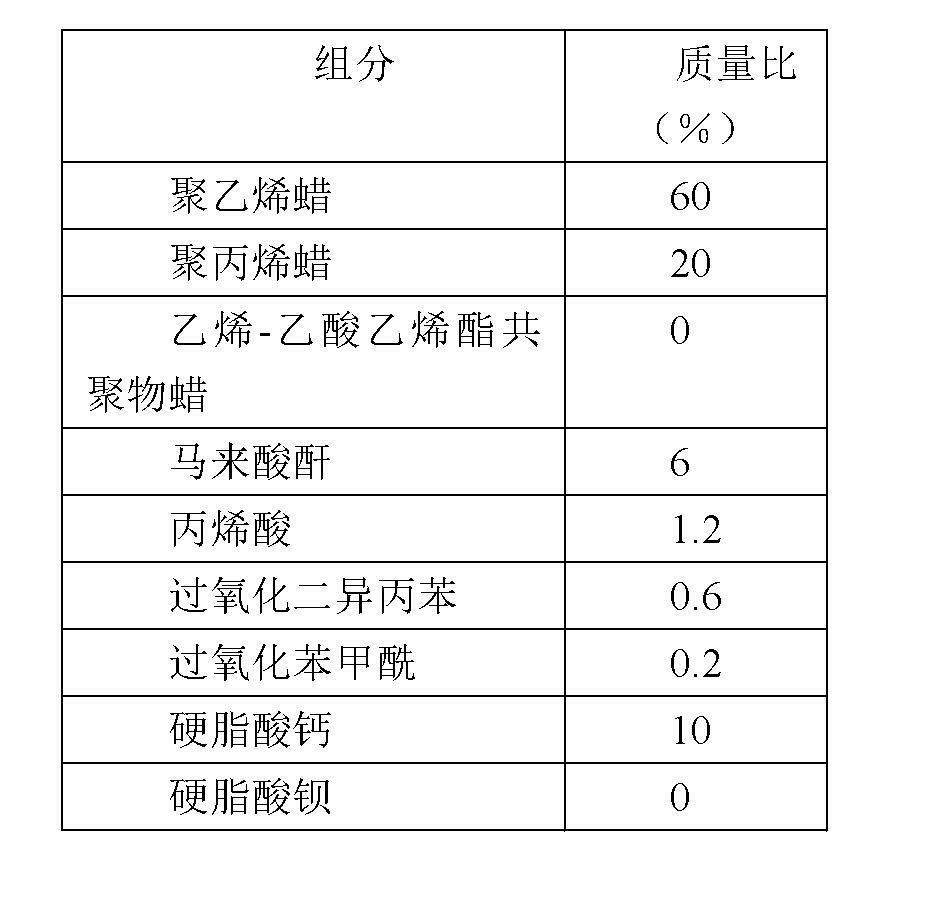

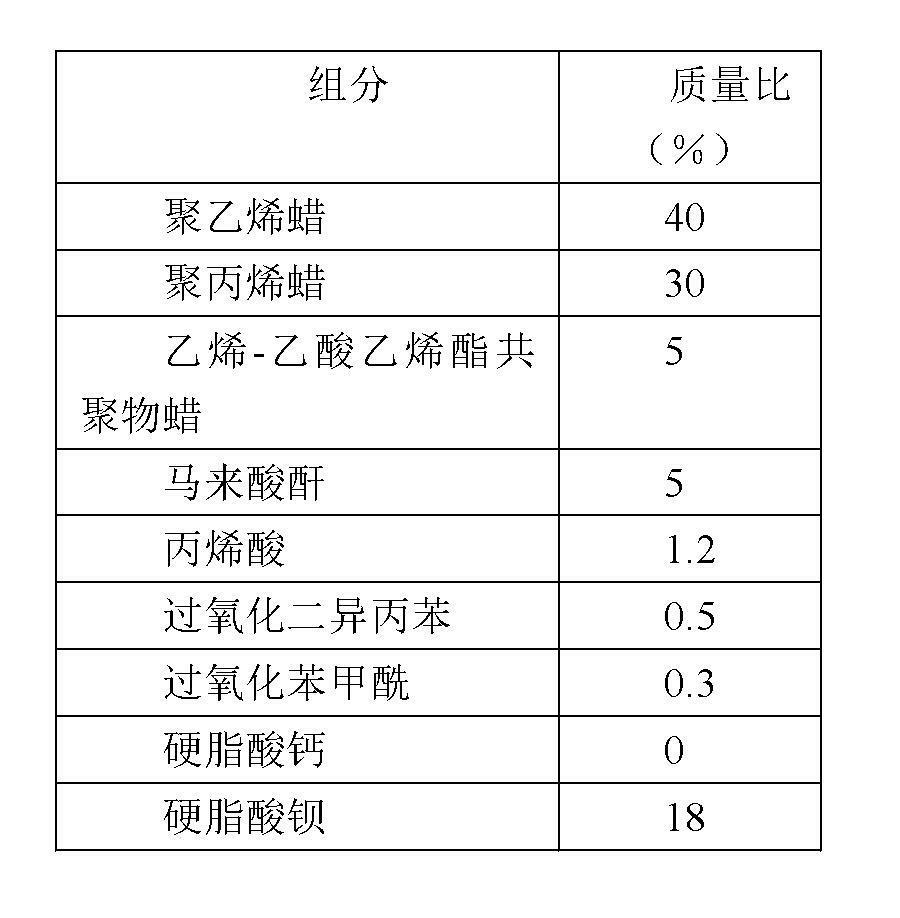

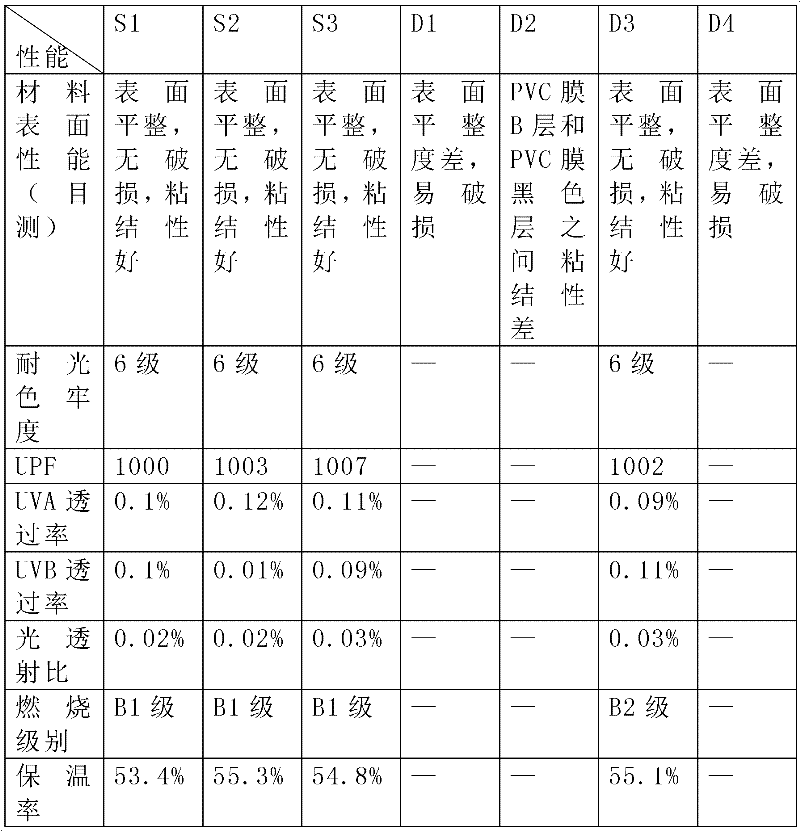

Plastic composite lubricating agent and preparation method thereof

ActiveCN102690440AManufacturing Method AdvantagesFine grainPigment treatment with macromolecular organic compoundsPolymer scienceHeat stability

The invention belongs to the technical field of plastic auxiliaries and specifically relates to a plastic composite lubricating agent and a preparation method thereof. The plastic composite lubricating agent comprises a spherical or near-spherical inorganic powder kernel with lubricating property and a graft-modified polymer wax housing coated on the outer layer. The preparation method comprises the following process steps of: a) performing graft modification: uniformly mixing polymer wax, grafting monomers, an initiator and metal soap, and then performing modification and granulation througha screw extruder; and b) coating powder: using a coating device to coat spherical or near-spherical inorganic powder with the lubricating property in the graft-modified polymer wax. Through optimal selection and improvement of raw materials, optimization of a process and reasonable compounding of all components, the formed composite lubricating agent has good lubricating property inside and outside a full temperature range during plastic processing, and integrates the effects such as heat stability, compatibilization and the like; and the preparation method is favorable for simplifying the formula and process of the modified plastics, and can improve the processing performance of the plastics and lower the cost.

Owner:广州峰华化工科技有限公司

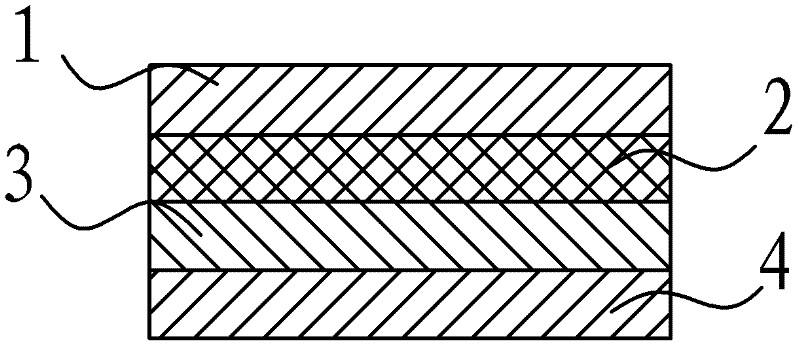

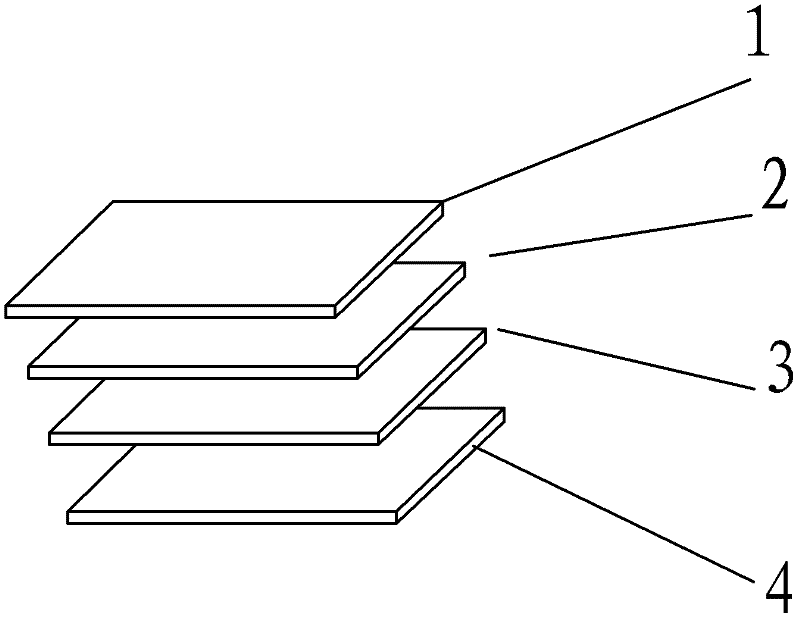

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

ActiveCN102555352AWith shadingWith heat insulation effectSynthetic resin layered productsLaminationFiberGlass fiber

The invention provides a glass fiber / PVC (polyvinyl chloride) composite membrane material. The glass fiber / PVC composite membrane material comprises a first PVC membrane layer, a second PVC membrane layer, a glass fiber base fabric layer and a third PVC membrane layer from bottom to top in sequence, wherein the second PVC membrane layer is a black PVC membrane layer. The invention also provides a preparation method for the glass fiber / PVC composite membrane material. The glass fiber / PVC composite membrane material provided by the invention has good shading and thermal insulation performances on the premise of ensuring good comprehensive color fastness and combustion performances. The preparation method for the glass fiber / PVC composite membrane material, provided by the invention, is simplified in the process and easy to perform.

Owner:NINGBO XIANFENG NEW MATERIAL

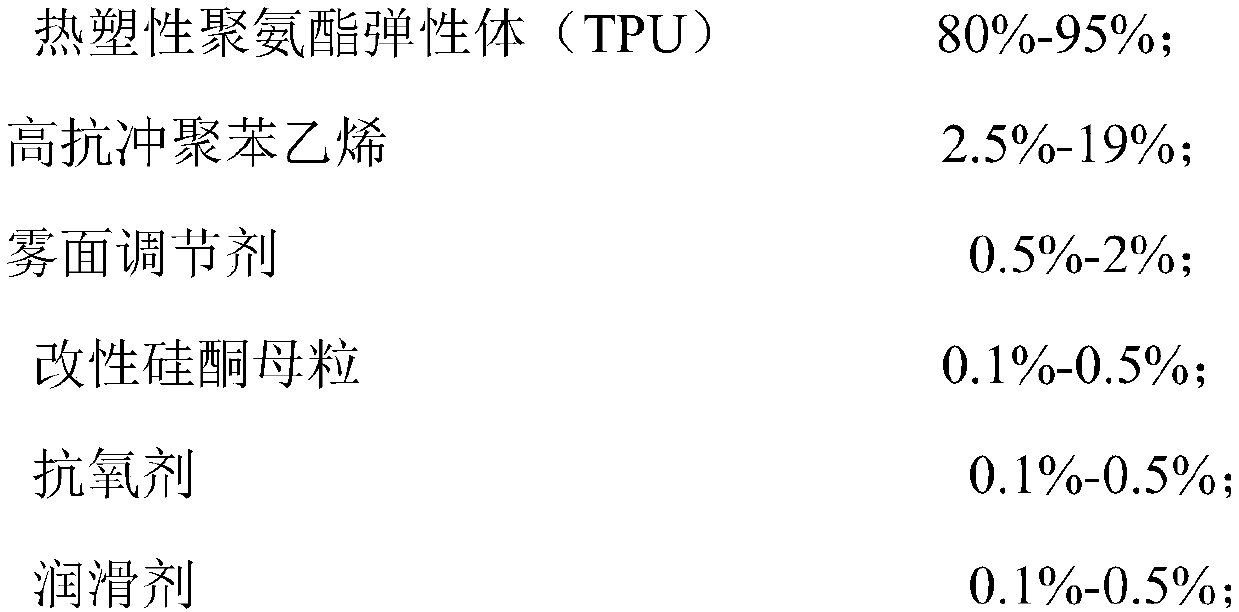

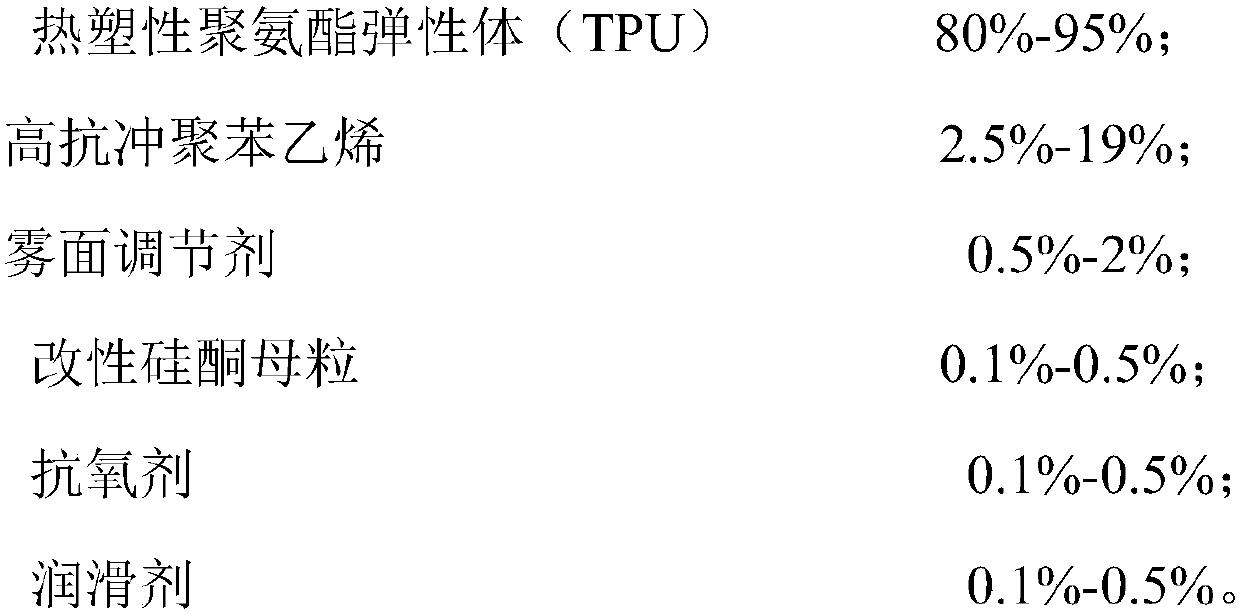

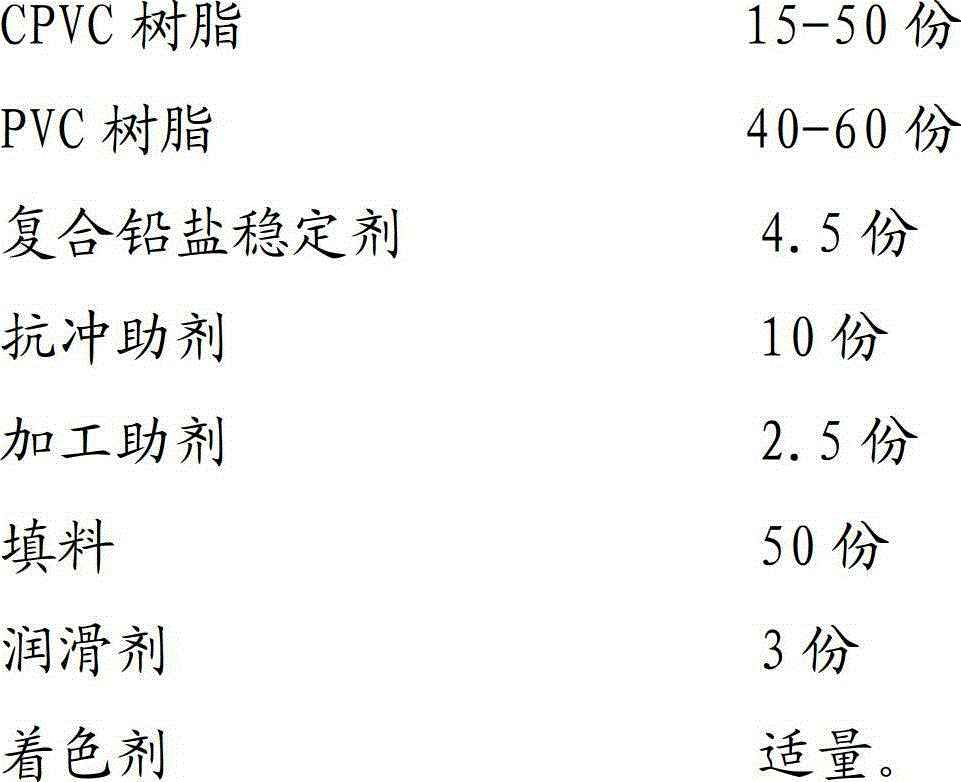

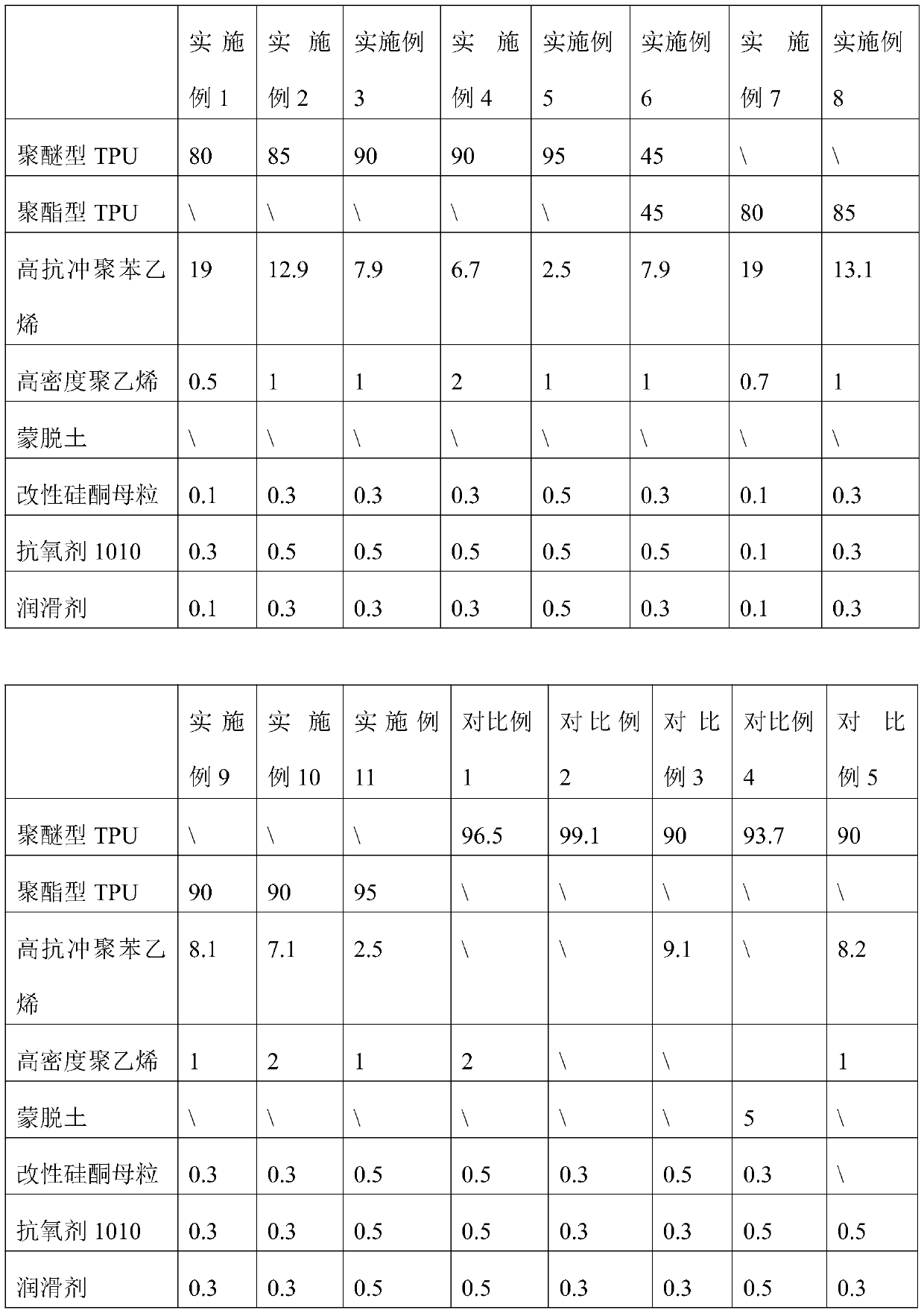

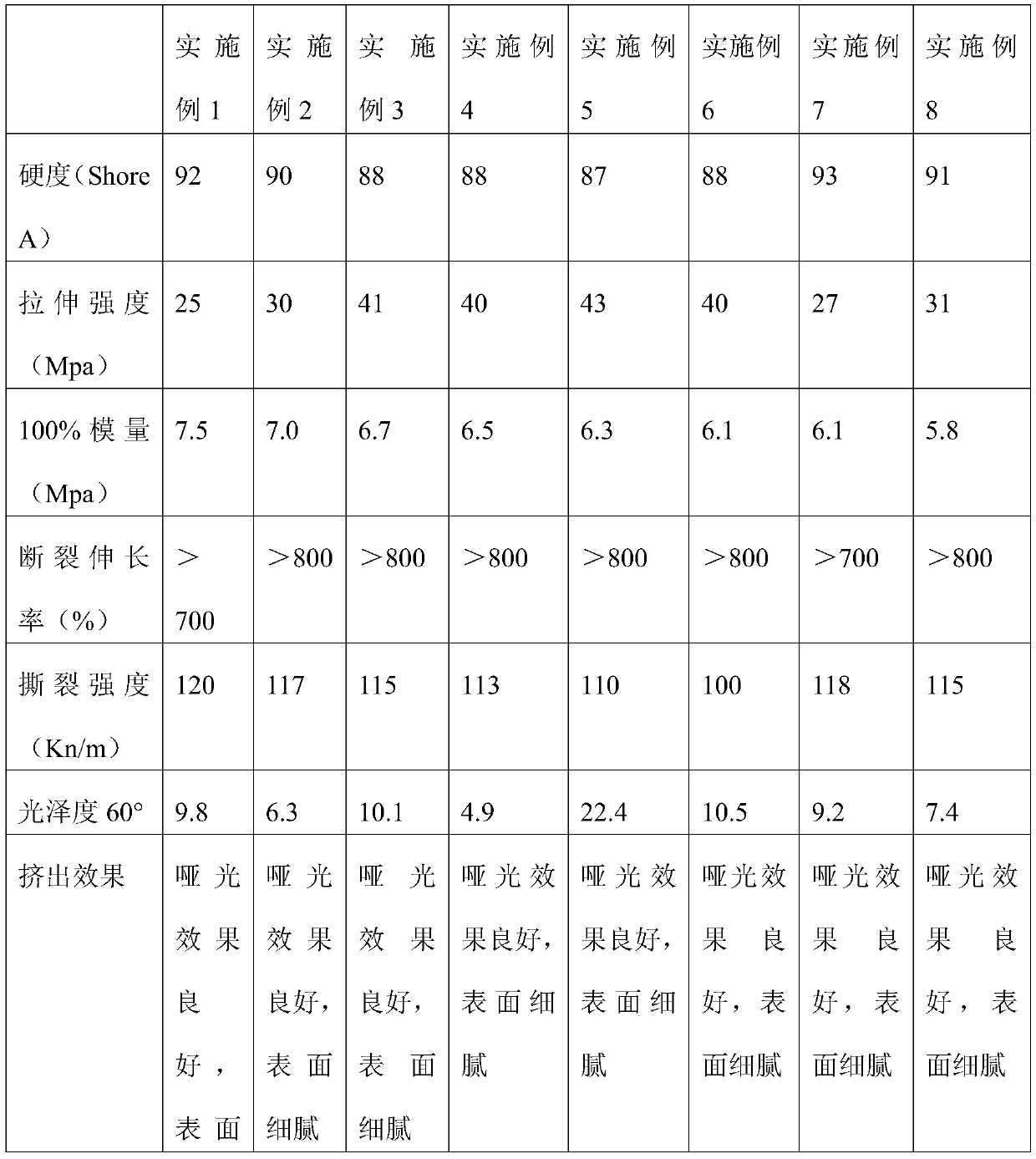

High-physical-property matte thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN108102347AImprove the disadvantages of reduced physical properties and poor matte effectGood matte effectAntioxidantThermoplastic polyurethane

The invention discloses a high-physical-property matte thermoplastic polyurethane elastomer and a preparation method thereof. The high-physical-property matte thermoplastic polyurethane elastomer is prepared from the following ingredients in percentage by mass: 80 to 95 percent of thermoplastic polyurethane elastomer, 2.5 to 19 percent of high impact polystyrene, 0.5 to 2 percent of matte surfaceregulating agents, 0.1 to 0.5 percent of modified silicone master batch, 0.1 to 0.5 percent of antioxidant and 0.1 to 0.5 percent of lubricating agent. Compared with the prior art, the high-physical-property matte thermoplastic polyurethane elastomer has the advantages that the matte surface effect is good; the cost is lower; the defects of material physical property reduction due to the use of inorganic matte surface agent and poor matte surface effect are avoided; the defect of higher cost due to the use of other organic macromolecular material matte surface agents is avoided; in addition, the processing process can be regulated according to practical requirements to obtain the ideal matte effect.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

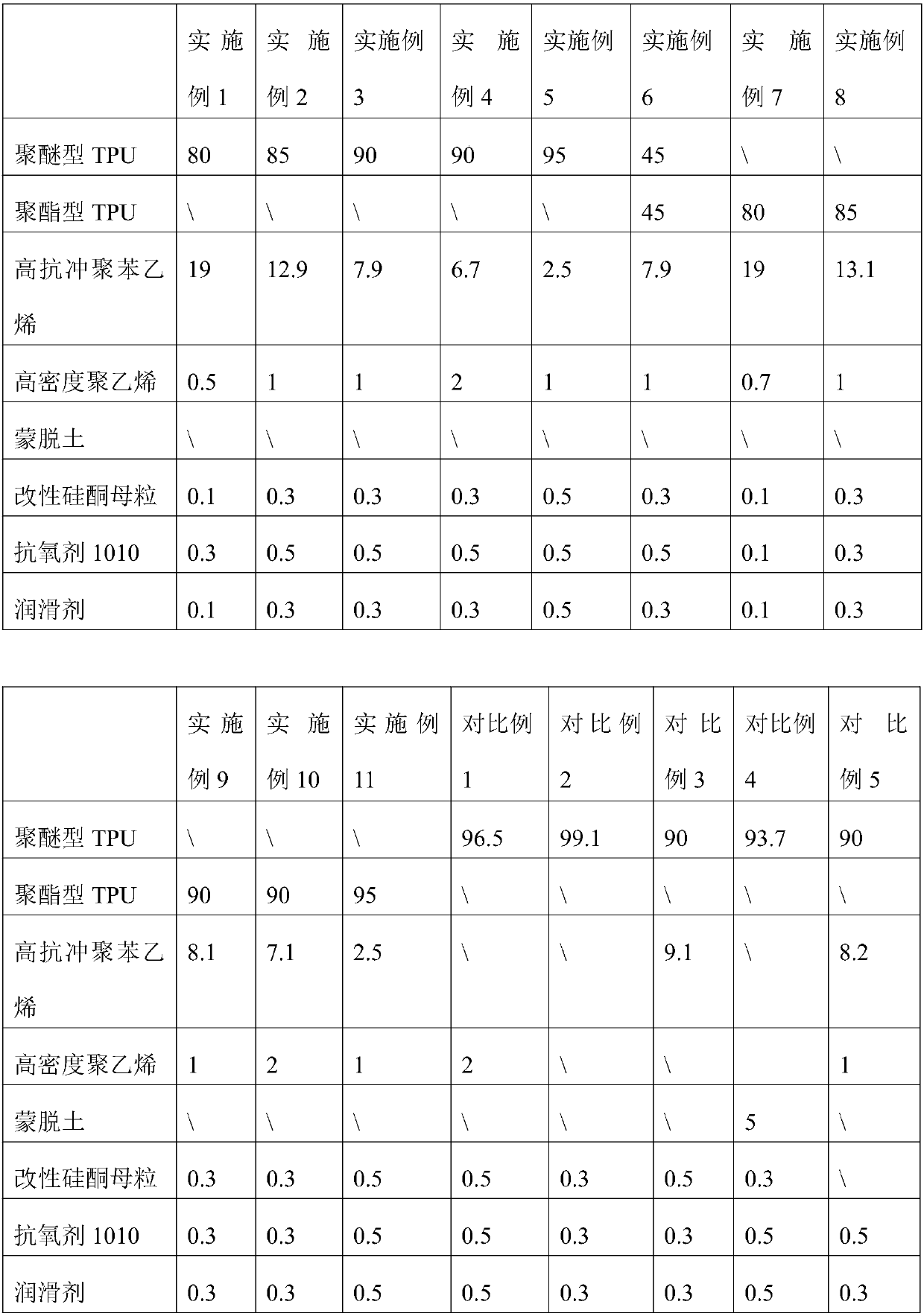

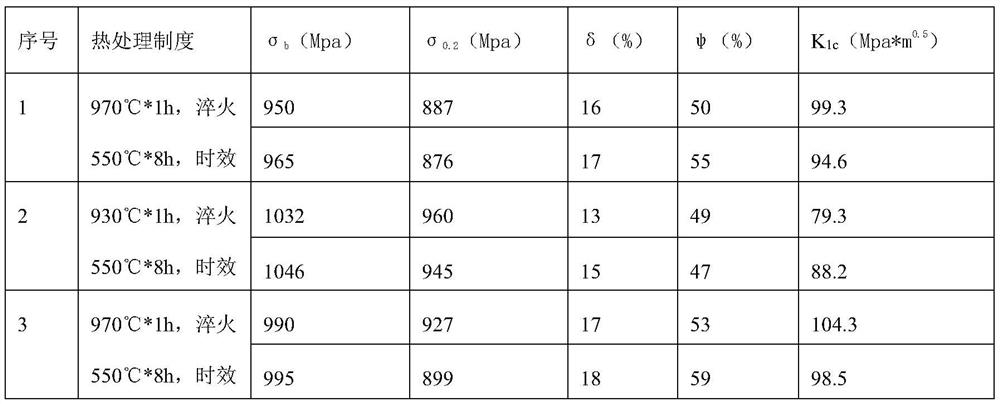

Preparation method of titanium alloy plate

The invention discloses a preparation method of a titanium alloy plate. A TC4 casting blank is prepared by adopting a plasma-vacuum consumable arc combined process; the first heating number finish forging temperature is 880 DEG C, and the deformation is 60-75%; the second heating number finish forging temperature is 850 DEG C, and the deformation is 25-65%; and the third heating number final heating temperature is 800 DEG C, and the deformation is 45-75%. A 20mm finished plate is rolled, the pass deformation is 4-6mm, and reversing rolling is carried out when the deformation is 50%; and when a 2-10 mm plate strip is rolled, hot rolling is conducted firstly, then warm rolling is conducted, the rolling temperature of the first heating number is 960-1050 DEG C, the rolling temperature of the second heating number is 950-1000 DEG C, and the warm rolling technology is adopted in the third heating number and the fourth heating number. The annealing temperature is 600-650 DEG C, and the heat preservation time is 5-10 hours. According to the preparation method, high-temperature melting, dissolving, flotation and sedimentation are adopted to remove inclusions, and a partial pressure principle is utilized to remove gas, so that burning loss of low-melting-point alloy element aluminum is reduced, an electrode preparation process is omitted, and a production process is simplified; titanium residues can be directly utilized, so that the ingot casting cost is reduced; and a product has a uniform fine grain structure, and the preparation method has the advantages of being wide in machining temperature range, good in strength, plasticity and fracture toughness matching property.

Owner:XINJIANG UNIVERSITY

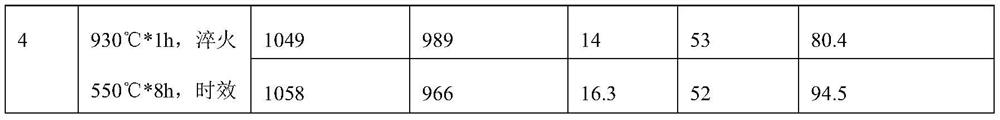

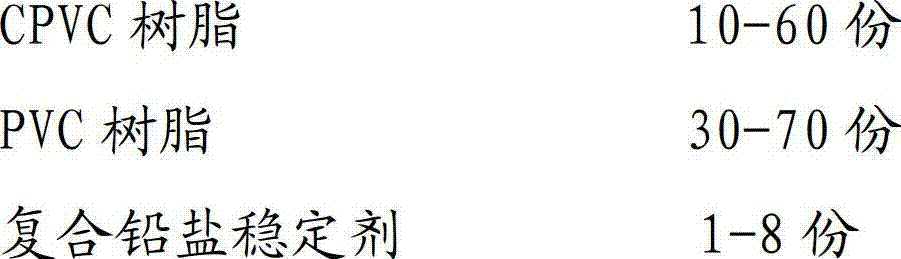

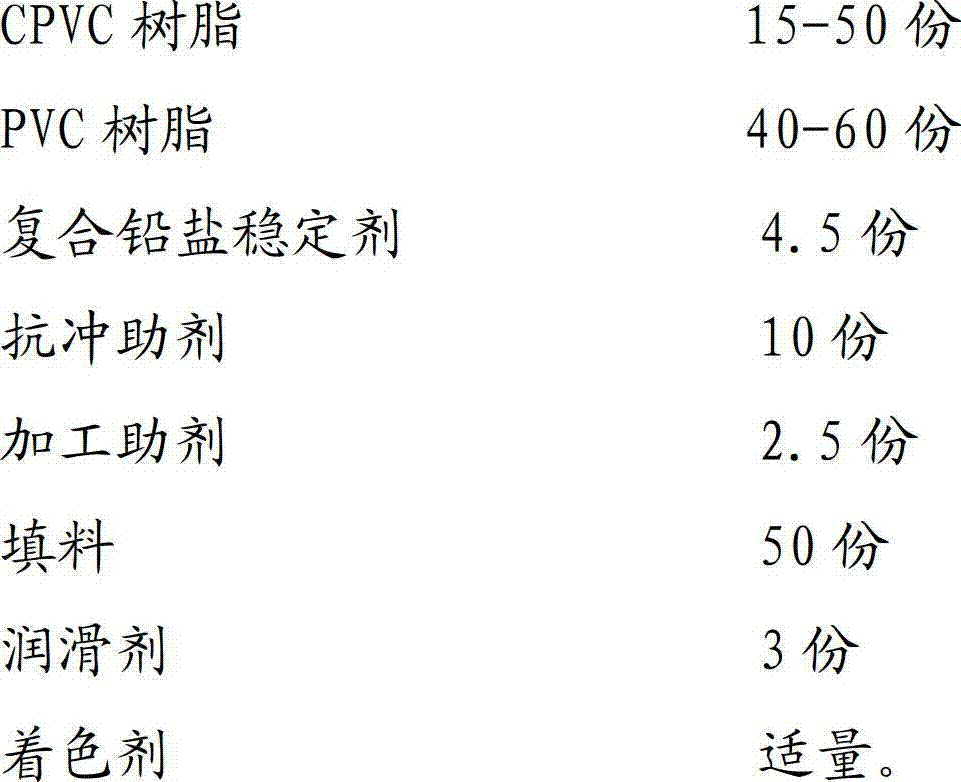

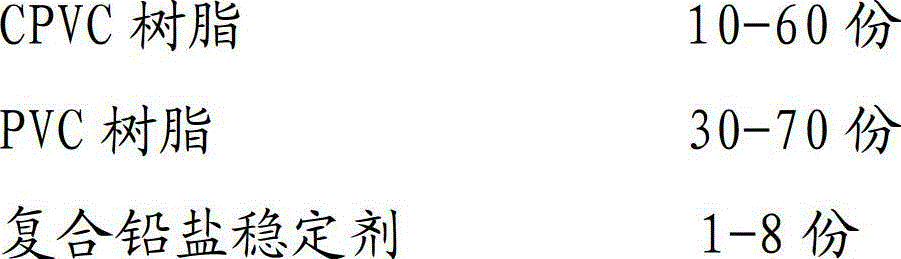

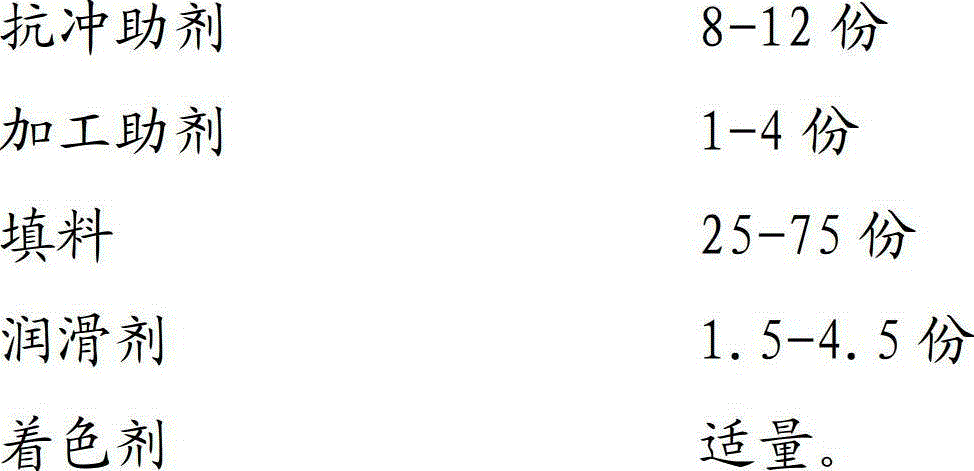

High-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and preparation method of chlorinated polyvinyl chloride (CPVC) corrugated board

ActiveCN102924851AImprove corrosion resistanceReduce thermal conductivity and heat absorptionStabilizing AgentsChemical stability

The invention discloses a high-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and a preparation method of the chlorinated polyvinyl chloride (CPVC) corrugated board. The corrugated board is prepared from the following raw materials by weight: 10-60 parts of CPVC resin, 30-70 parts of PVC (polyvinyl chloride) resin, 1-8 parts of composite lead salt stabilizer, 1-4 parts of processing aids, 8-12 parts of anti-impact aids, 25-75 parts of filler, 1.5-4.5 parts of lubricant, and a reasonable amount of colorant. The corrugated board has the advantages of high mechanical strength, excellent weatherability, high aging resistance and chemical stability and the like, and the formed raised corrugated board has higher thickness uniformity and uniform stress distribution, thereby being not easy to break due to stress concentration.

Owner:山东高信化学股份有限公司

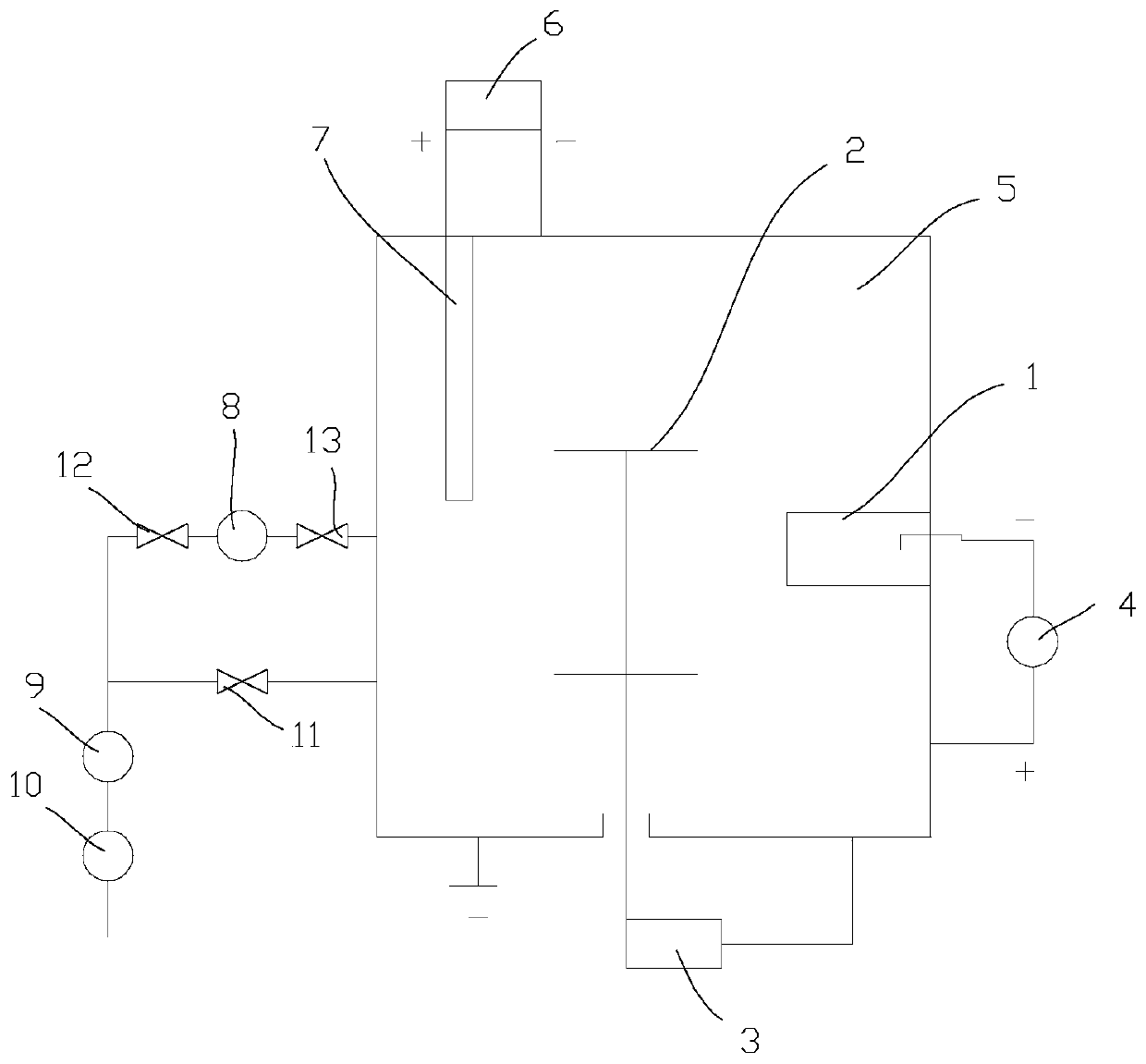

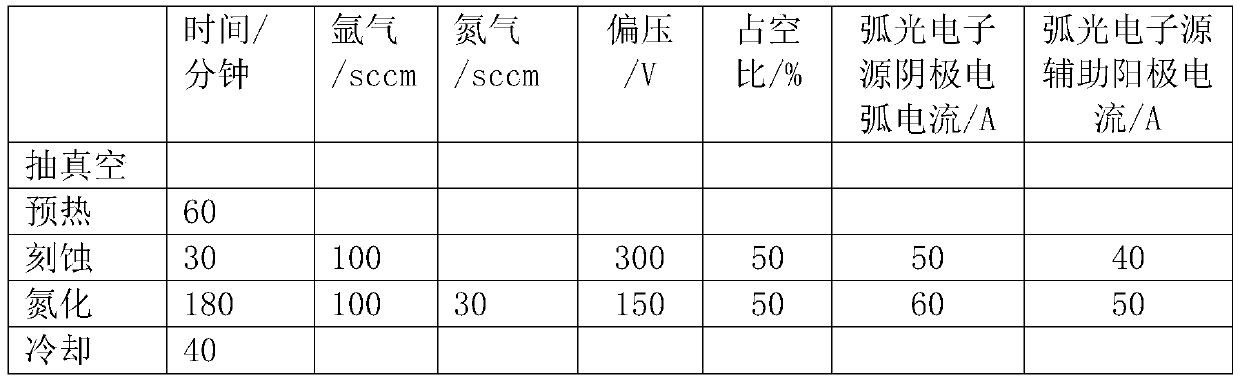

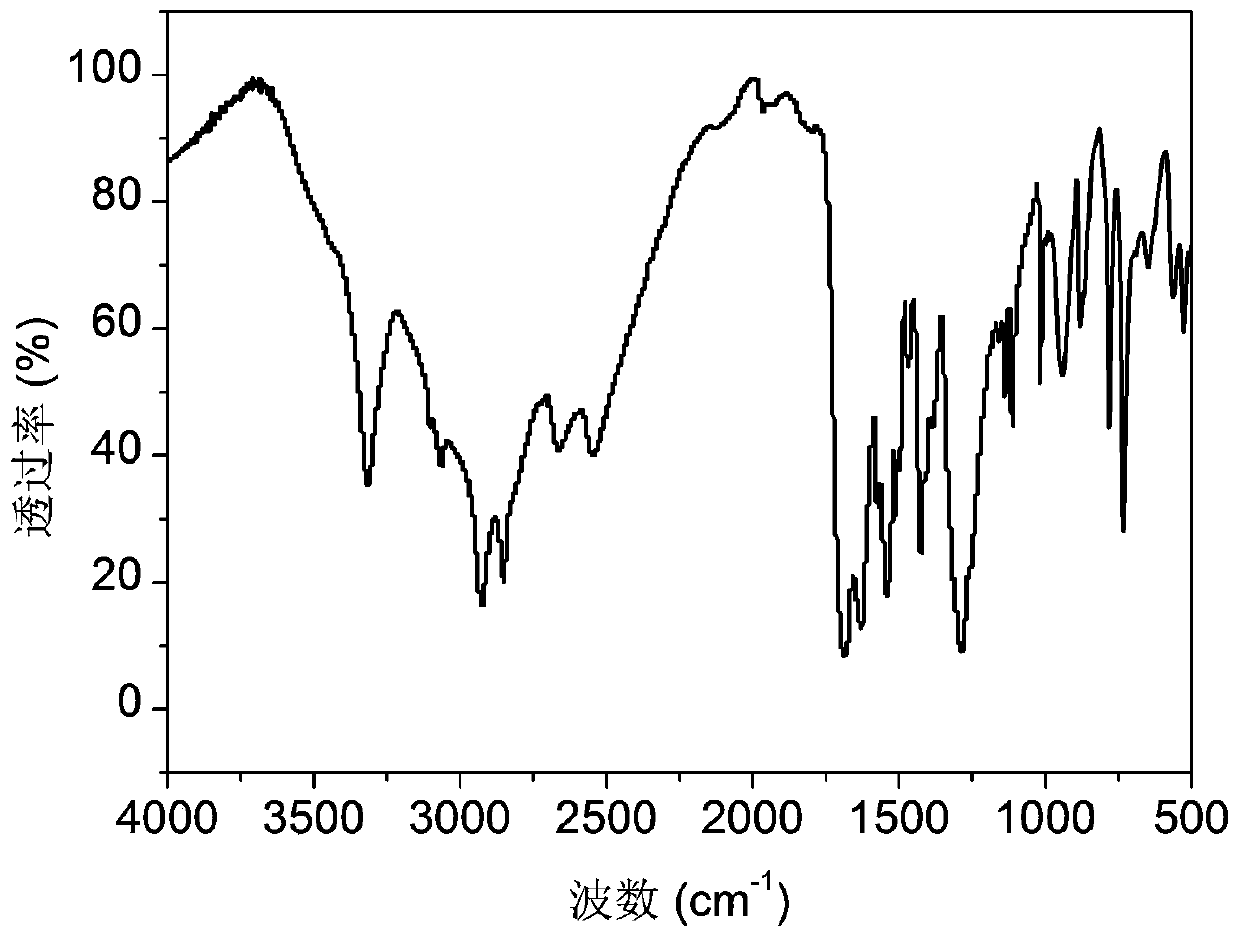

Ionic nitriding technology assisted by arc electron source

ActiveCN109797363AReduce consumptionIncrease ionization rateSolid state diffusion coatingNitrogen gasSupply current

The invention provides an ionic nitriding technology assisted by an arc electron source. The ionic nitriding technology assisted by the arc electron source comprises the steps that S1, vacuumizing iscarried out; S2, preheating is carried out; S3, mechanical corrosion is carried out, specifically, argon is pumped to keep vacuum of 0.1-1Pa, the temperature is 200-600 DEG C, a bias voltage is applied between a workpiece and a cavity body, meanwhile, a furnace inner arc electron source is started, a main power supply current is 40-150 A, and arc discharge plasma is generated; an auxiliary anode electrode power supply is turned on, a current is 10-100 A, an electron current in the arc discharge plasma is led to enter a nitriding chamber space, and ironic bombardment mechanical corrosion is carried out on the workpiece for 5-30mins; S4, nitriding is carried out, the furnace inner temperature is kept 200-600 DEG C, the argon and nitrogen are pumped, the vacuum degree is kept at 0.1-1Pa, a voltage is applied between the workpiece and the cavity by a direct current bias voltage power supply, the arc electron source main power supply is turned on, the current is 40-150 A, and the arc discharge plasma is generated; the auxiliary anode electrode power supply is turned on, the current is 10-100A, the electron current of the arc discharge plasma is led to enter the nitriding chamber space,and ironic nitriding is carried out for 0.5-6 hours; and S5, cooling is carried out below 250 DEG C. According to the ionic nitriding technology assisted by the arc electron source, a glow discharge plasma can be enhanced, the reactivity is improved, time is shortened, and gas and energy consumption are reduced.

Owner:DONGGUAN HUICHENG VACUUM TECH

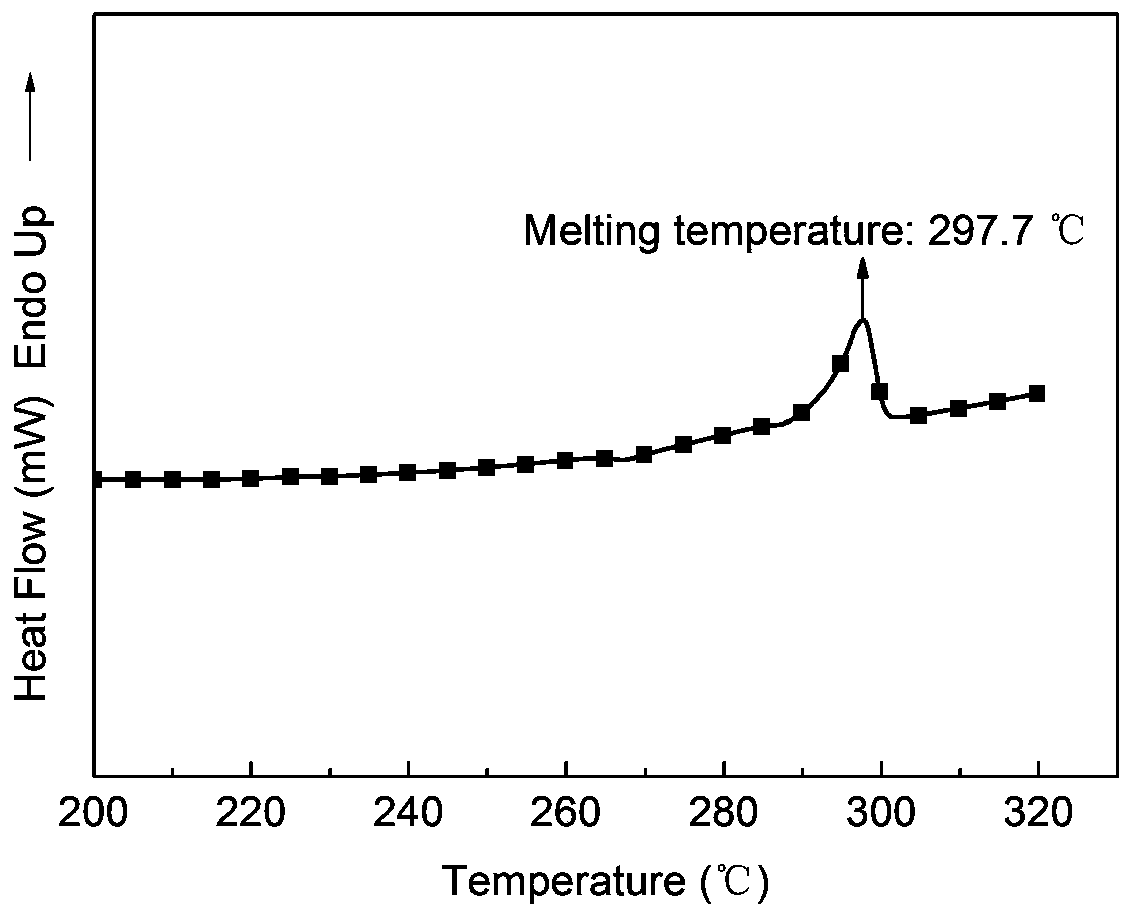

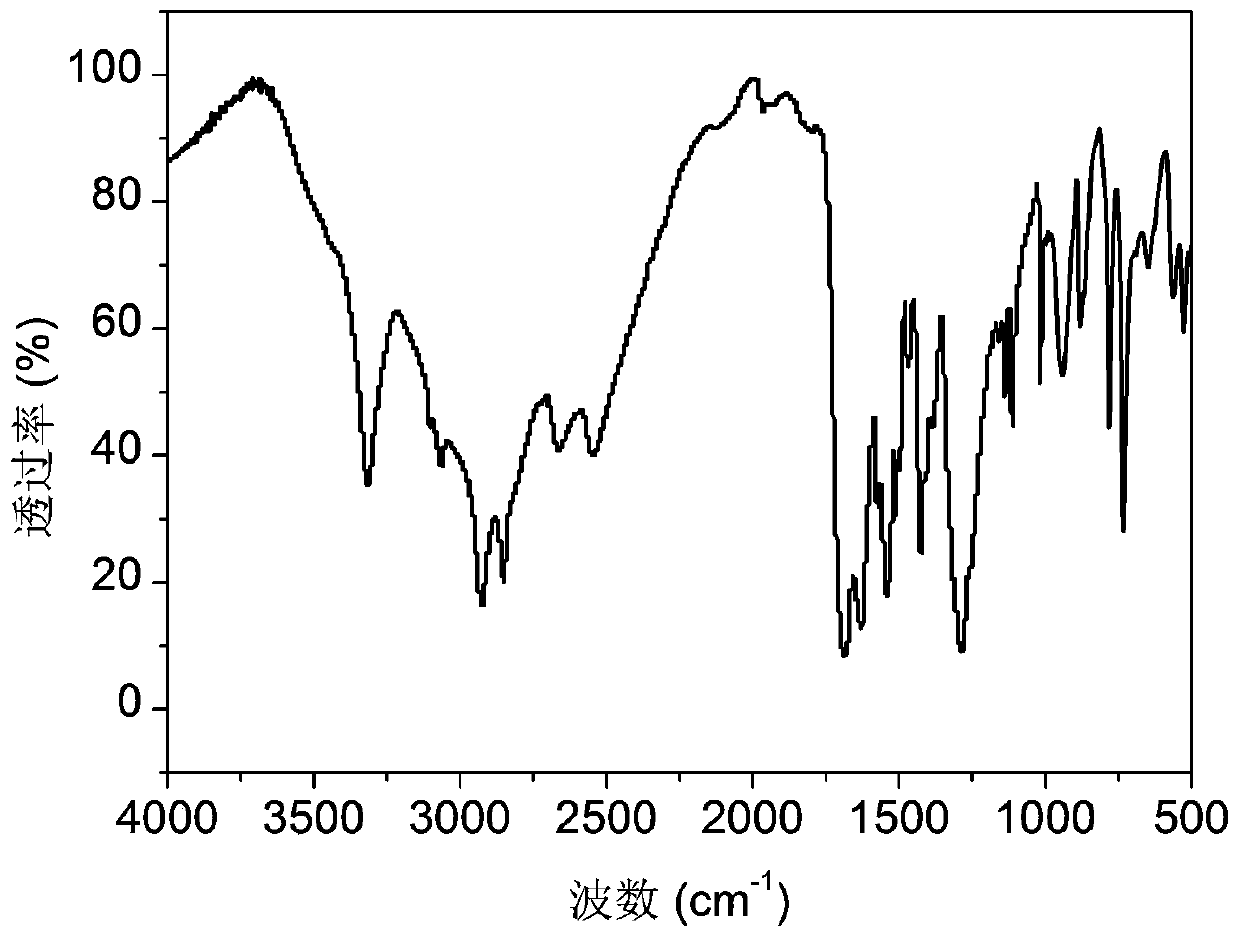

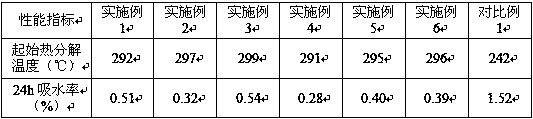

High-temperature-resisting and easy-to-process semi-aromatic polyamide and preparation method thereof

InactiveCN110041520AQuantitative molar ratio of polymerization reactionThe molar ratio of the polymerization reaction is controllablePolyamideToughness

The invention provides high-temperature-resisting and easy-to-process semi-aromatic polyamide and a preparation method thereof. A preparation process of the high-temperature-resisting and easy-to-process semi-aromatic polyamide mainly comprises three steps including preparation of dimer acid salt, a pre-polycondensation reaction and a solid-phase polymerization reaction. According to the high-temperature-resisting and easy-to-process semi-aromatic polyamide, dimer acid with a long flexible chain is introduced into semi-aromatic polyamide, so that the melting temperature is reduced, a processing temperature range is widened, and meanwhile, the toughness of the semi-aromatic polyamide is greatly increased; the size stability and performance retention rate of the semi-aromatic polyamide undera humid environment are improved and the semi-aromatic polyamide has a wide application prospect.

Owner:DONGGUAN HUAYING NEW MATERIAL CO LTD

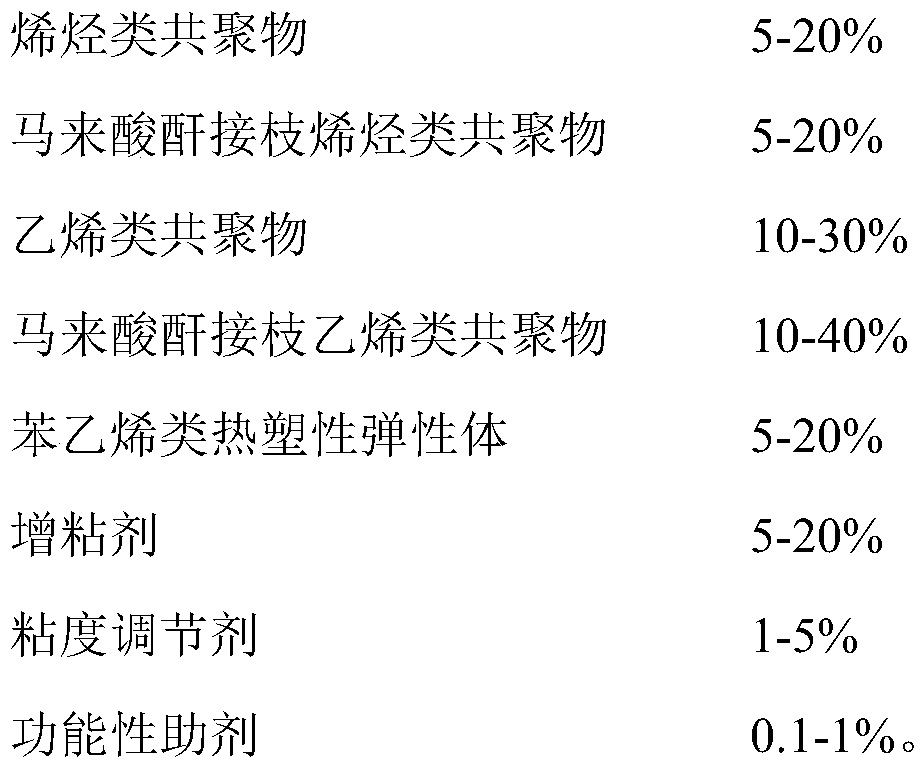

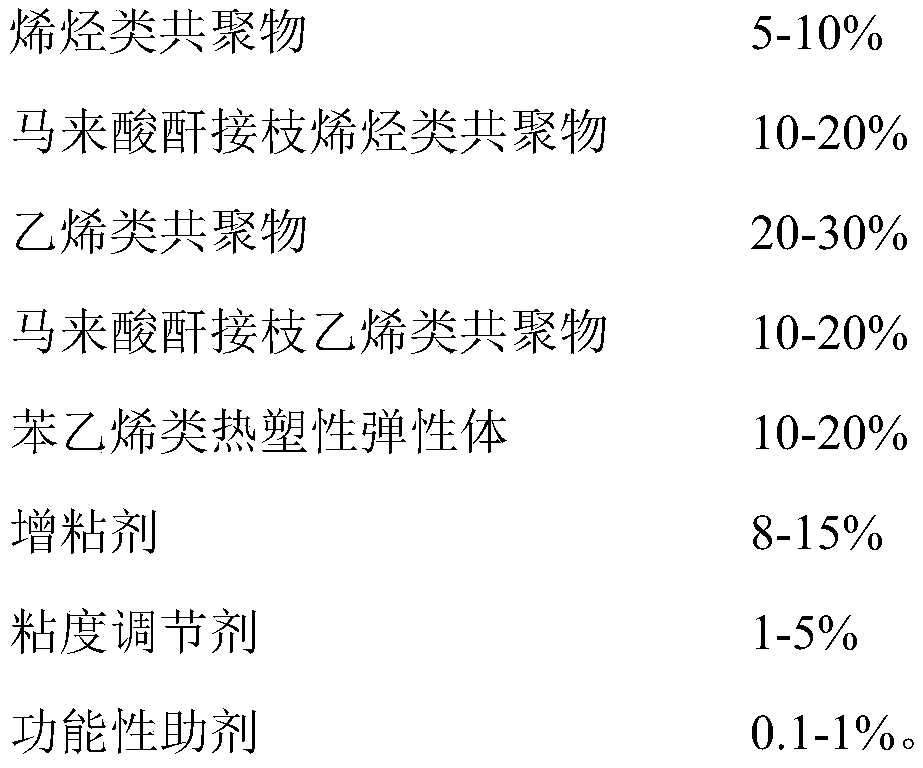

Hot melt adhesive for PVC profiled bar co-extrusion bonding and preparation method thereof

InactiveCN110982460AEffective bondingEasy to processConjugated diene hydrocarbon adhesivesGraft polymer adhesivesElastomerPolymer science

The invention discloses a hot melt adhesive for PVC profiled bar co-extrusion bonding and a preparation method thereof. The hot melt adhesive comprises following components in percentage by weight: 5to 20% of olefin copolymers, 5 to 20% of maleic anhydride grafted olefin copolymers, 10 to 30% of ethylene copolymers, 10 to 40% of maleic anhydride grafted ethylene copolymers, 5 to 20% of a styrenethermoplastic elastomer, 5 to 20% of a tackifying agent, 1 to 5% of a viscosity adjusting agent, and 0.1 to 1% of a functional auxiliary agent. Compared with a conventional technology, the provided hot melt adhesive can effectively bond PVC resin and a metal basic material in a three layer co-extrusion mode. The processing is convenient. The compounding strength of the products can be effectivelyimproved. The service life is prolonged. Moreover, the hot melt adhesive has the characteristics of high bonding strength, wide processing temperature range, environmental friendliness, no pollution,and excellent weatherability.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

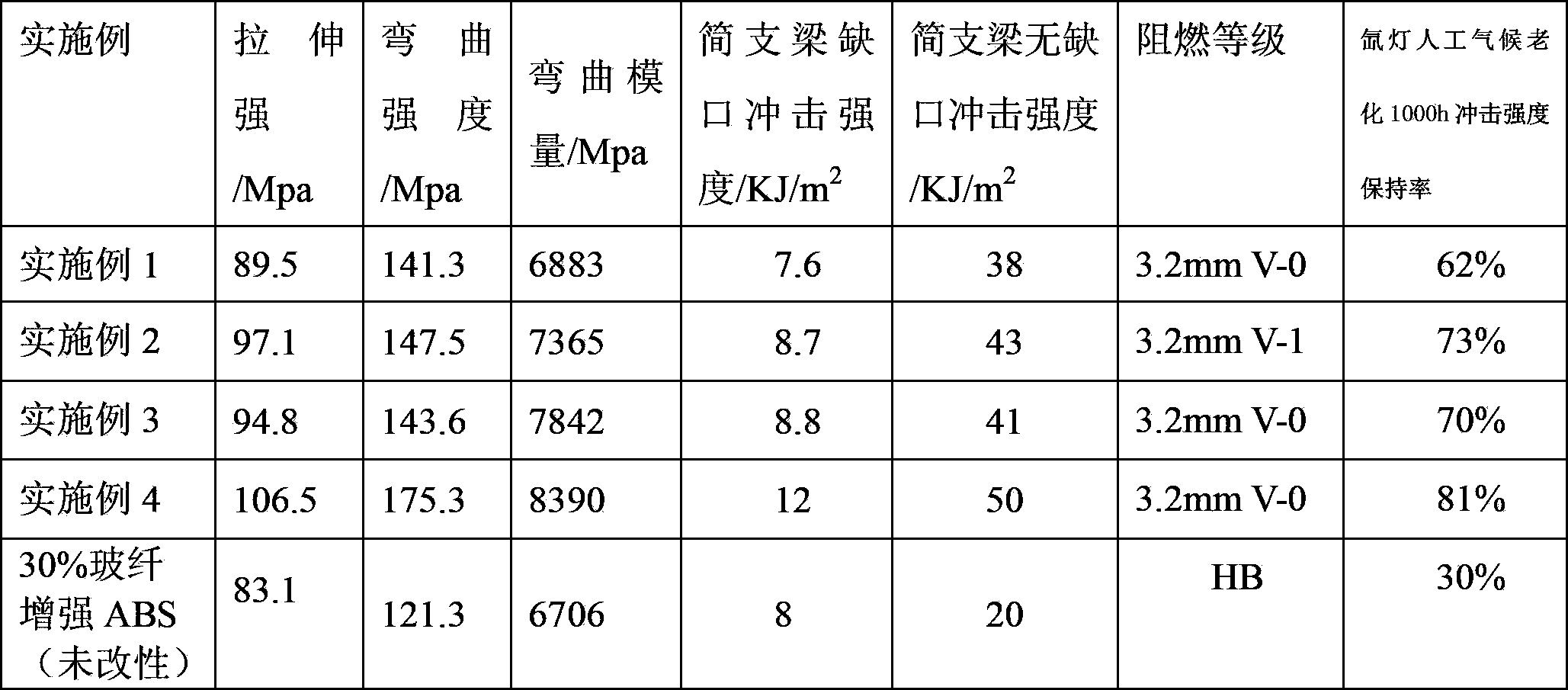

Weather-proof flame retardant ABS/PET material for extrusion process and preparation method of ABS/PET material

The invention belongs to the technical field of high polymer materials, and relates to an ABS / PET material and a preparation method thereof. The ABS / PET material comprises the following components by weight: 100 parts of ABS resin, 10-50 parts of PBT resin, 20-80 parts of glass fiber, 12-24 parts of a flame retardant, 5-15 parts of a compatilizer, 0.2-1.0 part of a light stabilizer, 0.2-1.5 parts of a lubricant, and 0.4-1.2 parts of an antioxidant. The ABS / PET material has excellent extrusion moldability, and outstanding flame retardance and weather resistance, can meet the requirement of outdoor use, and greatly extends the application range of the ABS material, the oil resistance, the solvent resistance and the physical and mechanical properties of the ABS / PET material are remarkably superior to those of an unmodified ABS material, the extruded product is high in performance, and an extrusion-grade plastic material with an excellent combination property is prepared.

Owner:HEFEI GENIUS NEW MATERIALS

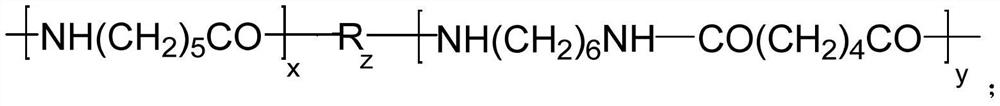

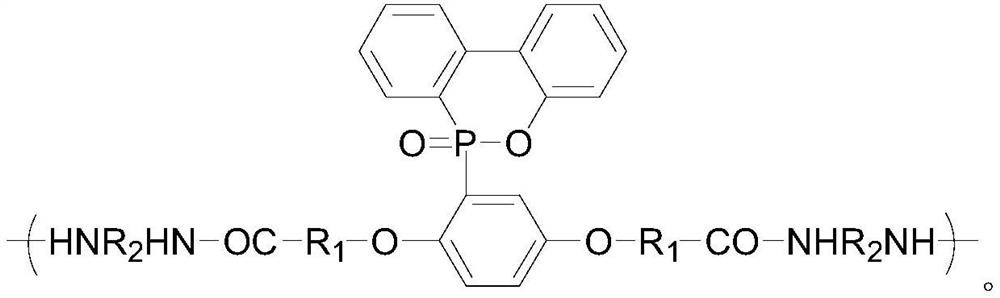

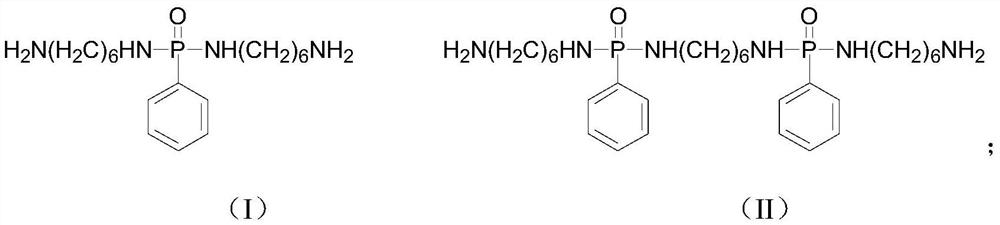

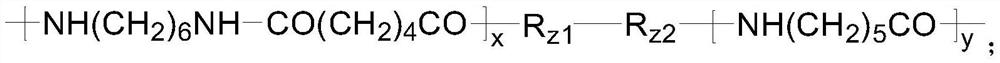

Copolymerized flame-retardant polyamide and preparation method thereof

The invention relates to copolymerized flame-retardant polyamide and a preparation method thereof. The preparation method comprises the following steps: mixing a flame retardant salt with a polyamide6 oligomer and / or a polyamide 66 oligomer, and carrying out condensation polymerization to obtain copolymerized flame-retardant polyamide. The flame retardant salt is prepared from a DOPO derivative and diamine NH2R2NH2 through a high-temperature and high-pressure reaction. The temperature of the high temperature is 200-250 DEG C, and the pressure of the high pressure is 1.2-1.8 MPa. The structural formula of the finally obtained copolymerized flame-retardant polyamide is as follows. In the structural formula, x is the polymerization degree of the polyamide 6 oligomer, y is the polymerizationdegree of the polyamide 66 oligomer, and the structural formula of Rz is as follows. The preparation method disclosed by the invention is simple to operate, and the prepared product has excellent flame retardance, good impact resistance and processability.

Owner:DONGHUA UNIV

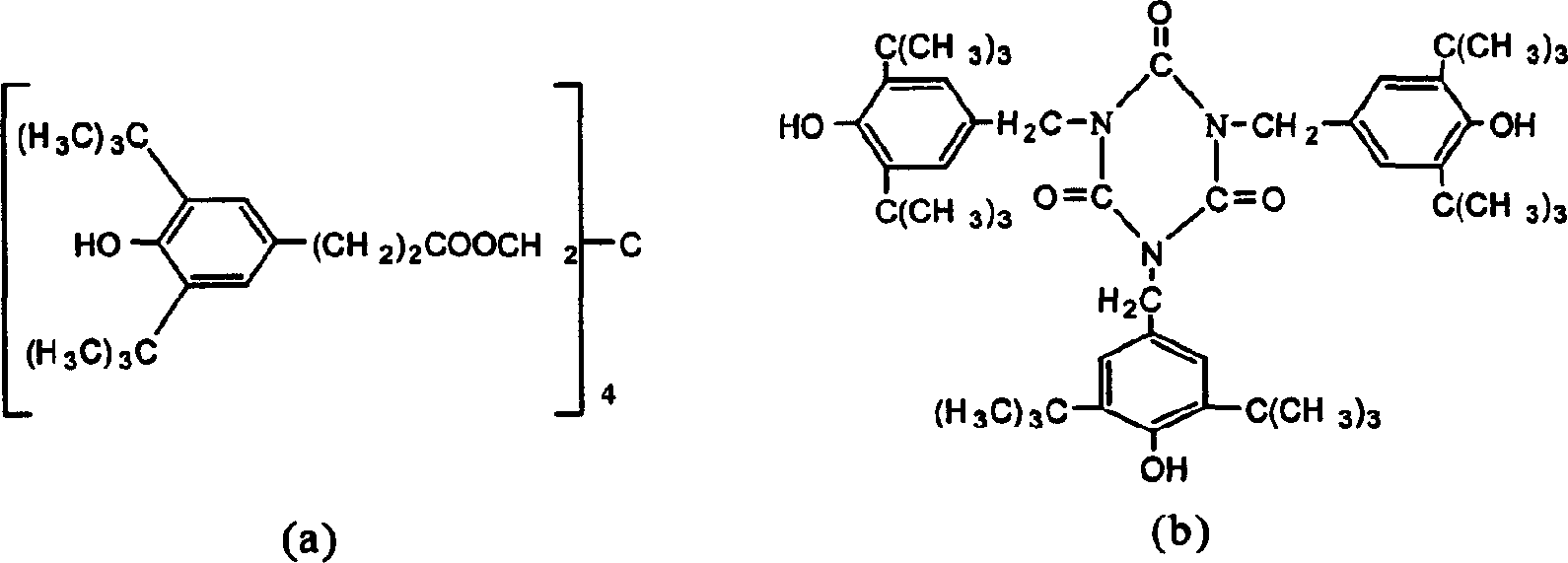

Combination of stabilizing agent in use for producing polyolefine resin

A composite stabilizer used for preparing the polyolefine resin contains hindered phenol as primary antioxidizing agent, phosphite as secondary antioxidizing agent and deacidifying agent.

Owner:宁波金海雅宝化工有限公司

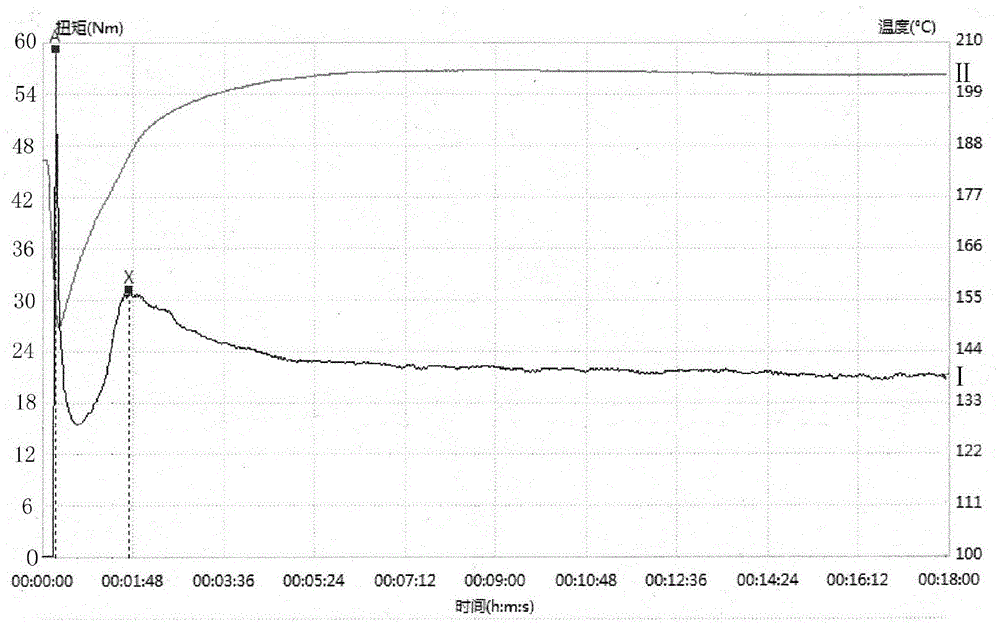

Enhanced electric power information cable conduit and preparation method thereof

The invention discloses an enhanced electric power information cable conduit and a preparation method thereof. Materials of the cable conduit mainly comprise components as follows: CPVC (chlorinated polyvinyl chloride), PVC (polyvinyl chloride), ACR (an acrylic polymer), calcium carbonate, a calcium / zinc composite stabilizer, beta-diketone, hydrotalcite, spherical organosilicone micro-powder and a processing agent. The preparation method of the enhanced electric power information cable conduit comprises the steps as follows: putting all the components into a planetary mixer, and preparing a premix by full stirring; feeding the obtained premix into a double-screw extruder, and preparing a special CPVC tube material by melt extrusion, as well as air-cooling powder milling and particle cutting; feeding the special CPVC tube material into a single-screw extruder, extruding a tube blank in a molten state, subjecting the tube blank to forming, cooling, drawing, cutting and stacking, and obtaining the enhanced electric power information cable conduit. According to the enhanced electric power information cable conduit, a dispersion strengthening technology is used, and rigid particles, namely, spherical organosilicone micro-powder, are taken as a second phase and uniformly distributed in a CPVC phase in a manner of fine and dispersed particles, therefore, a reinforcement effect is generated, and the comprehensive performance of the tube material is improved.

Owner:四川鑫森管业有限公司

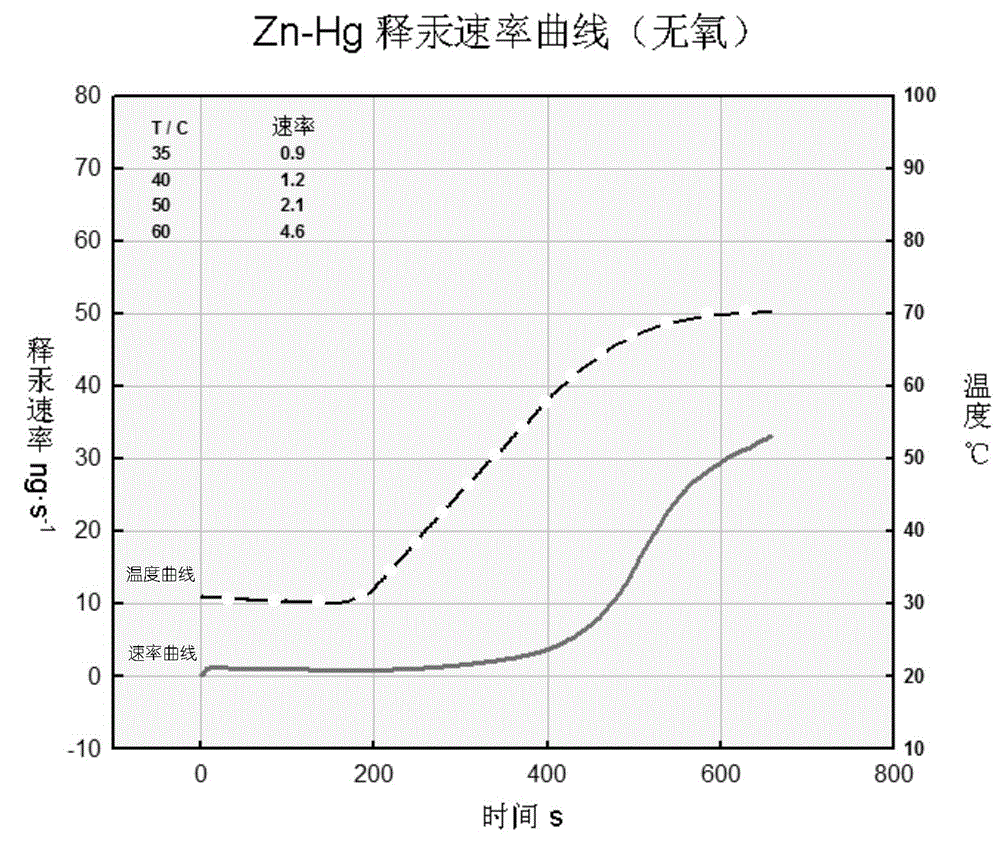

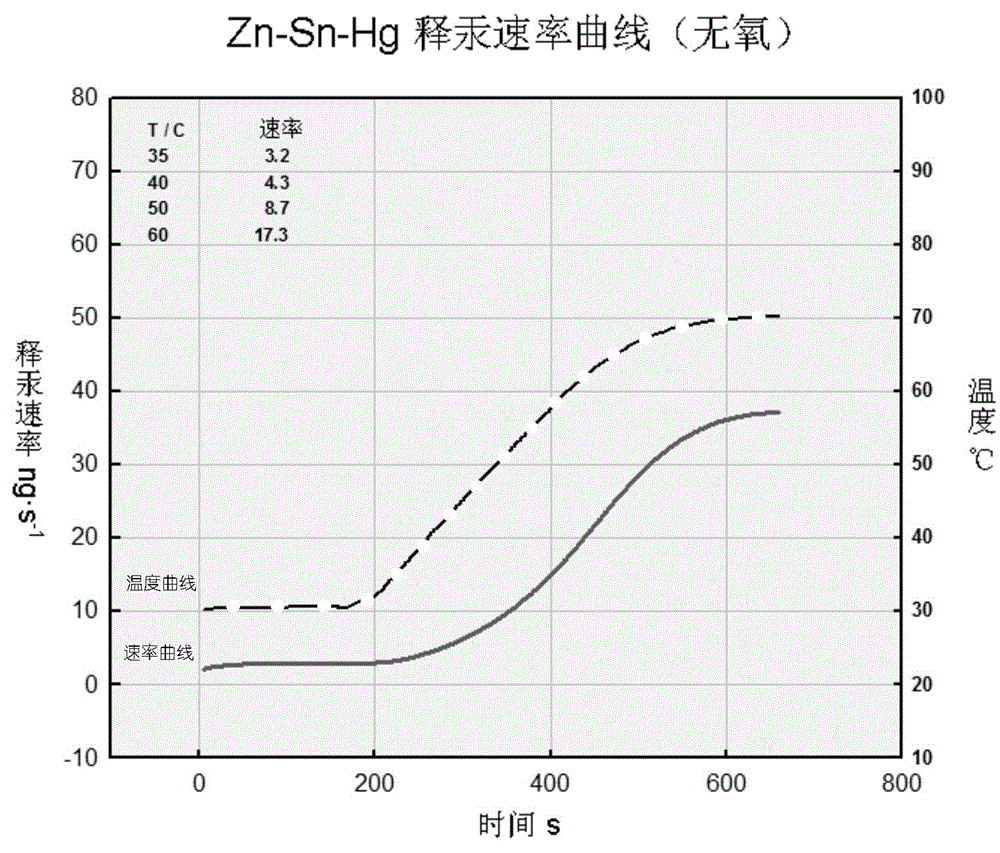

Silver tin mercury alloy particle and preparation technology thereof

The invention relates to a silver tin mercury alloy particle and a preparation technology thereof. A silver tin amalgam of a spherical structure, formed by silver tin mercury alloy, is arranged in the silver tin mercury alloy particle. A silver layer coats the outer surface of the spherical structure. The silver tin mercury alloy is prepared from below constituents of 0.5-10wt% of silver, 29.5-75wt% of tin and 15-70wt% of mercury. The preparation technology of the silver tin mercury alloy particle includes steps: adding raw materials in a sealed container and then heating the raw materials so as to fuse the raw materials under inert gas atmosphere, and evenly mixing the raw materials so as to obtain an alloy solution; manufacturing the alloy solution into alloy liquid drops 0.5-2mm in diameter under the inert gas atmosphere, and using inert gas currents to condense the alloy liquid drops under temperature of 100-190 degree centigrade below zero so as to obtain a silver tin amalgam molded body; finally, placing the silver tin amalgam molded body under temperature of 0-25 degree centigrade, and coating the silver tin amalgam molded body with silver powder so as to obtain the silver tin mercury alloy particle. Compared with the prior art, the silver tin mercury alloy particle has the advantages of being low in adhesion degree, excellent in amalgam release characteristic and the like.

Owner:上海亚尔精密零件制造有限公司

A dry-film lubricant

InactiveCN105733751AImprove wear resistanceWide processing temperature rangeAdditivesWear resistantAdhesive

The invention relates to the technical field of chemical materials and particularly relates to a dry-film lubricant. The dry-film lubricant comprises 8-23% by weigh of mixed solvents, 17-39% by weight of polytetrafluoroethylene, 12-33% by weight of tungsten disulfide, 0.5-7% by weight of a wear-resistant filler, 30-50% by weight of an adhesive and 3-9% by weight of an auxiliary agent. The objective of the invention is to provide the dry-film lubricant good in wear resistance and wide in processing temperature range.

Owner:田建频

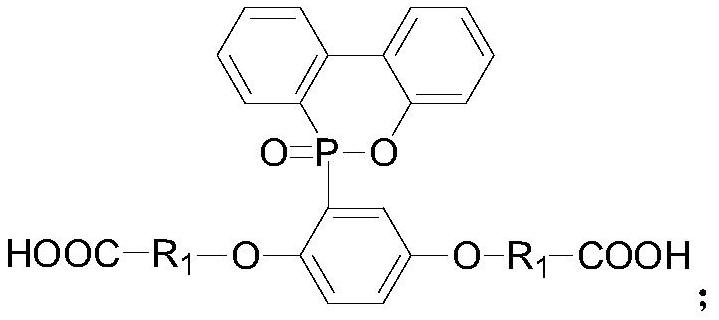

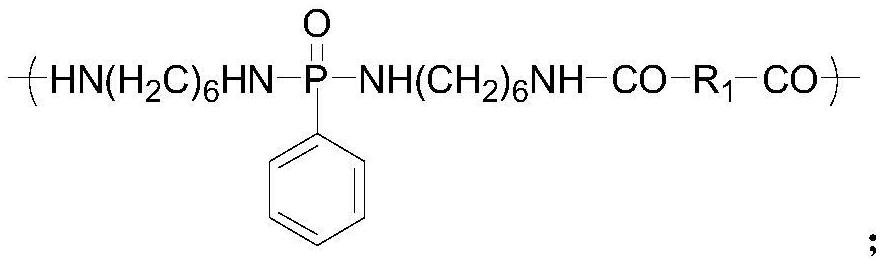

Copolymerized flame-retardant polyamide and preparation method thereof

The invention relates to copolymerized flame-retardant polyamide and a preparation method thereof. The preparation method comprises the following steps: mixing a flame retardant salt with a polyamide66 oligomer and / or a polyamide 6 oligomer, and carrying out condensation polymerization to obtain copolymerized flame-retardant polyamide; wherein the flame retardant salt is prepared from N, Ndi (6aminohexyl) phenyl phosphoramide and binary acid HOOCR1COOH through a high-temperature and high-pressure reaction; wherein the temperature of the high temperature is 210-220 DEG C, and the pressure of the high pressure is 1.7-1.9 MPa; wherein in the structural formula, x is the polymerization degree of the polyamide 66 oligomer, y is the polymerization degree of the polyamide 6 oligomer, and the structural formula of Rz1 is as follows: the structural formula of Rz2 is as follows: the preparation method disclosed by the invention is simple to operate, and the prepared product has excellent flameretardance, good impact resistance and processability.

Owner:DONGHUA UNIV

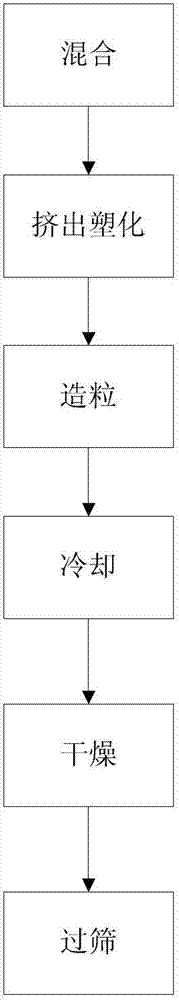

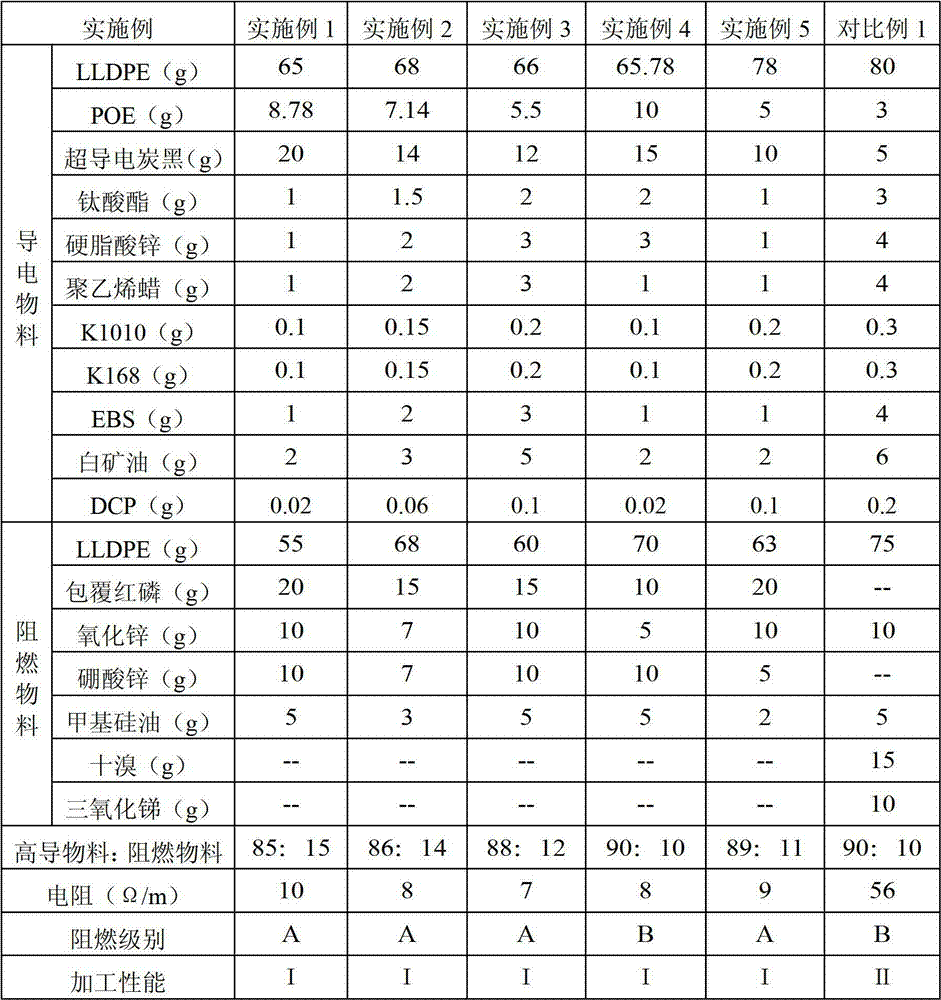

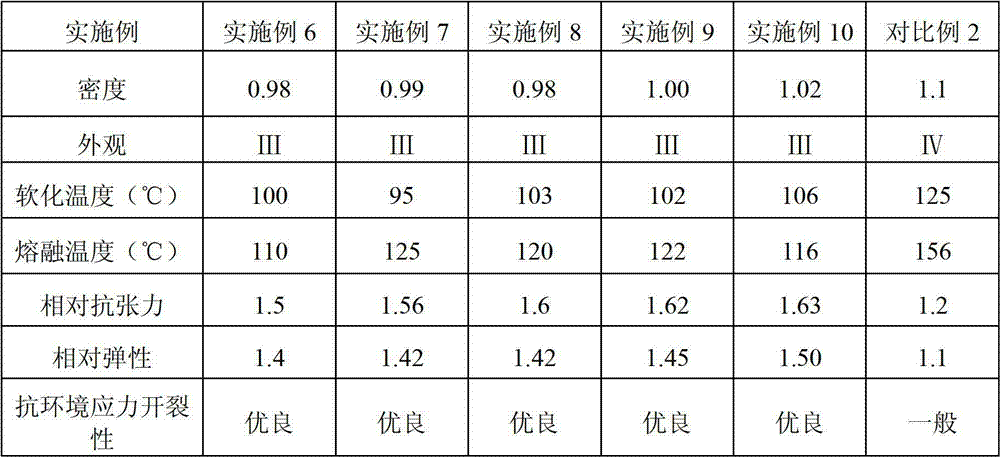

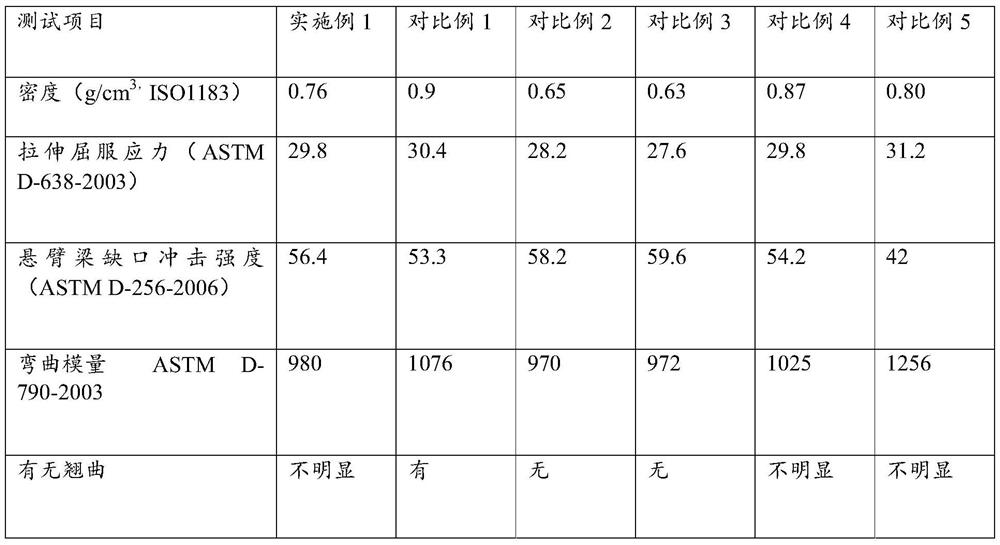

Composition for preparing highly-conductive flame retardant plastic, highly-conductive flame retardant plastic prepared thereby and preparation method thereof

The invention provides a composition for preparing highly-conductive flame retardant plastic. The composition comprises 85-90wt% of electric conductive material and 10-15wt% of flame retardant material, wherein the flame retardant material comprises 55-70wt% of low linear density polyethylene, 10-20wt% of encapsulated red phosphorous, 5-10wt% of zinc oxide, 5-10wt% of zinc borate and 2-5wt% of impregnating compound, according to the mass of the flame retardant material. With the adoption of the composition for preparing highly-conductive flame retardant plastic provided by the invention, the technical problems of the prior art that the highly-conductive flame retardant material is low in flame rating and dangerous in use are solved.

Owner:CHANGSHA QIANYUAN PLASTIC TECH DEV

Foaming composite material and preparation method thereof

PendingCN114316311ALight weightHigher than strongAdditive manufacturing apparatusMicrosphereAntioxidant

The invention provides a foamed composite material and a preparation method thereof, and belongs to the technical field of 3D printing, the foamed composite material specifically comprises, by weight, 80-100 parts of a polymer matrix, 1-10 parts of a foaming functional master batch and 1-10 parts of a processing aid, the foaming functional master batch at least comprises a low-melting-point carrier, expandable microspheres, a foaming agent and a functional aid, and the processing aid is a polymer matrix. The particle size distribution of the expandable microspheres is 10-50 [mu] m, the initial foaming temperature is 120-145 DEG C, the foaming peak temperature is 190-200 DEG C, the true density is 1000-1300 kg / m < 3 >, and the processing aid is at least one of an antioxidant, a lubricant, a flexibilizer, a compatilizer and a heat stabilizer. According to the treatment scheme, by using the foaming functional master batch, the prepared foaming composite material product is small in specific gravity, high in specific strength, uniform in internal foam hole, low in shrinkage rate, free of warping and low in cost.

Owner:CRERAX SCI & TECH CO LTD

Plastic masterbatch for starch-based degradable packaging film and preparation method of plastic masterbatch

The invention relates to the field of plastic packaging films, and discloses a plastic masterbatch for a starch-based degradable packaging film and a preparation method of the plastic masterbatch. Thepreparation method comprises the following preparation process: (1) mixing starch microparticles, a titanate coupling agent, an alcohol solution and inorganic porous microspheres, and conducting ultrasonic dispersion to obtain inorganic porous microspheres loaded with the starch microparticles; (2) adding the inorganic porous microspheres into silica hydrogel for immersion treatment, and conducting drying to obtain a modified starch filler; and (3) conducting mixing extrusion granulation on polyethylene, an ethylene-acrylic acid copolymer, an ethylene-vinyl alcohol copolymer, hydroxymethyl cellulose, nano calcium carbonate, a plasticizer and the modified starch filler, so as to obtain the plastic masterbatch for the starch-based degradable packaging film. The plastic masterbatch preparedby the invention improves the heat resistance of the starch, broadens the processing temperature range, reduces the temperature sensitivity, the starch has good fluidity in a matrix, also moisture isprevented from making contact with the starch, and the later-stage water resistance is improved.

Owner:山东壹贰叁塑胶有限公司

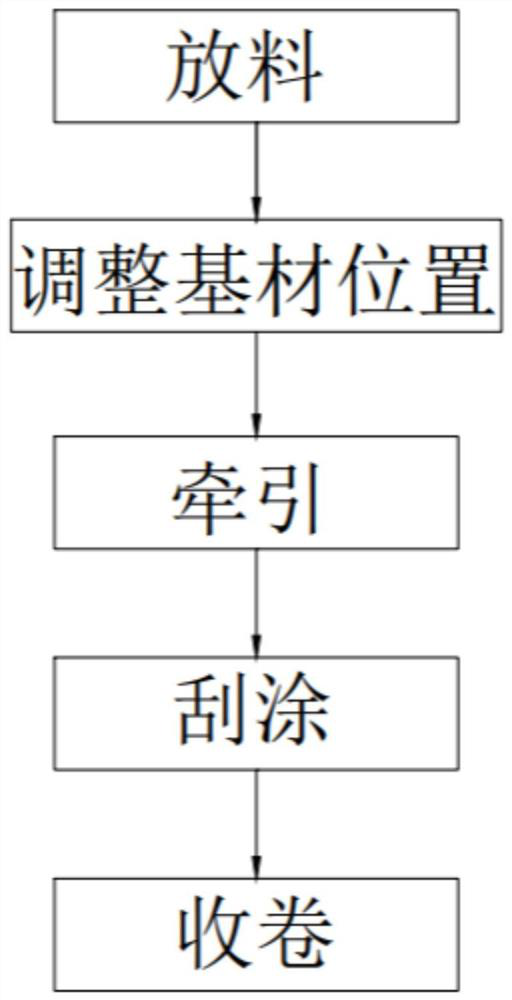

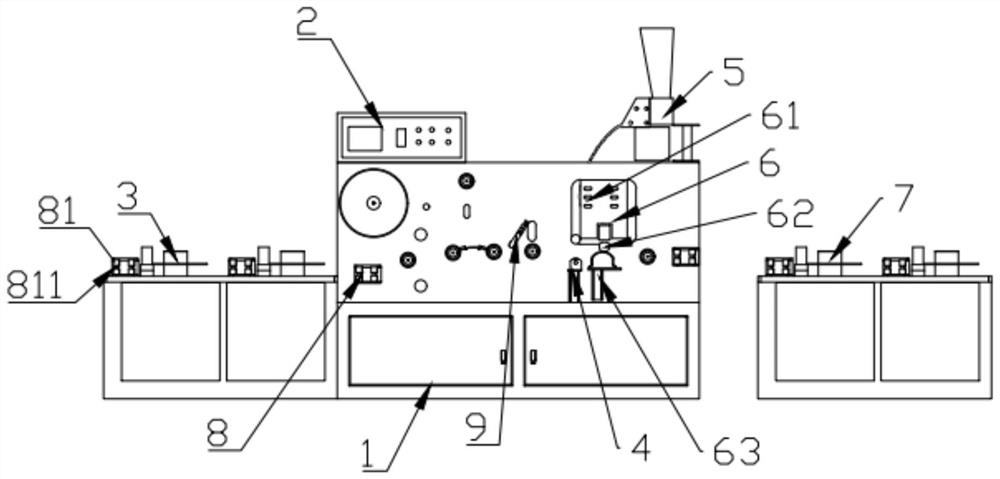

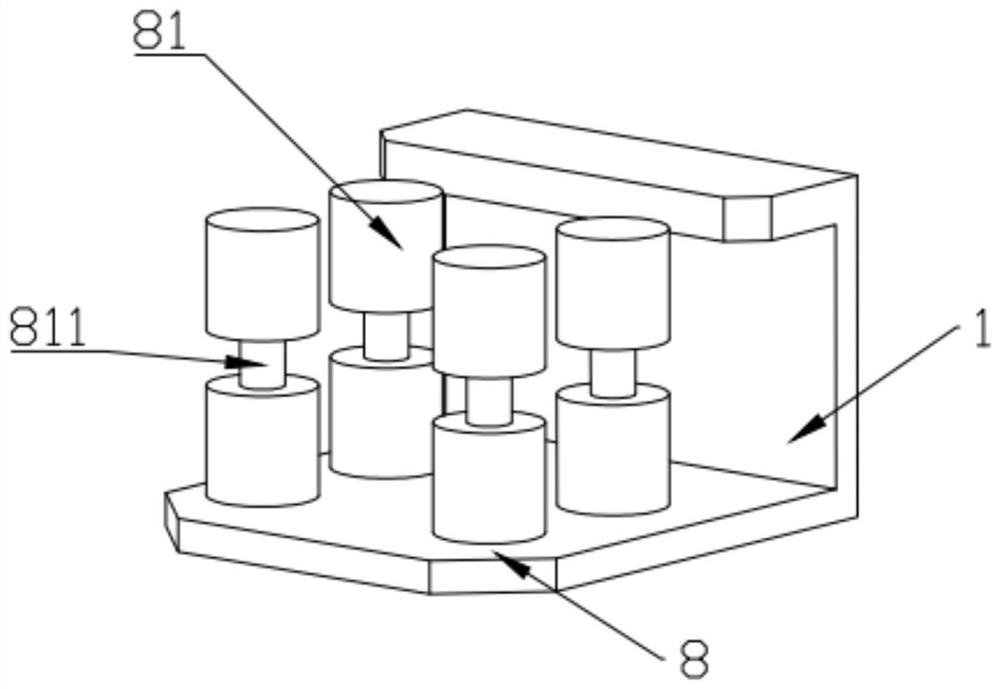

Furniture edge sealing strip processing process and device

InactiveCN113262948APrevent stratificationImprove the effect of edge bandingLiquid surface applicatorsCoatingsMolten stateMachining process

The invention relates to the technical field of edge sealing strip processing, in particular to a furniture edge sealing strip processing process and device. According to the furniture edge sealing strip processing process, a precise scraper is adopted for blade coating a base material with back coating glue in a molten state, the situation that the back coating glue and the base material are layered is effectively avoided, and the blade coating effect is good. The furniture edge sealing strip processing device comprises a rack and a control component and further comprises a material placing component, a traction component, a glue pre-melting component, a blade coating component and a winding component which are sequentially arranged on the rack and correspondingly connected with the control component, and the blade coating component is provided with a glue melting hopper. The furniture edge sealing strip processing device is simple and reasonable in structural design, automatic processing and production can be realized, by means of the arrangements of the glue pre-melting component and the glue melting hopper, in the processing process, part of molten back coating glue flowing out of the glue pre-melting component can be molten in the glue melting hopper, the processing temperature range is wider, and the heating efficiency is high, the heating efficiency is effectively improved, furthermore, the furniture edge sealing strip processing process and device are suitable for blade coating of high-melting-point materials, and the application range of the furniture edge sealing strip processing process and device is made to be wider.

Owner:何惠玲

High-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and preparation method of chlorinated polyvinyl chloride (CPVC) corrugated board

ActiveCN102924851BImprove corrosion resistanceHigh mechanical strengthStress concentrationStress distribution

The invention discloses a high-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and a preparation method of the chlorinated polyvinyl chloride (CPVC) corrugated board. The corrugated board is prepared from the following raw materials by weight: 10-60 parts of CPVC resin, 30-70 parts of PVC (polyvinyl chloride) resin, 1-8 parts of composite lead salt stabilizer, 1-4 parts of processing aids, 8-12 parts of anti-impact aids, 25-75 parts of filler, 1.5-4.5 parts of lubricant, and a reasonable amount of colorant. The corrugated board has the advantages of high mechanical strength, excellent weatherability, high aging resistance and chemical stability and the like, and the formed raised corrugated board has higher thickness uniformity and uniform stress distribution, thereby being not easy to break due to stress concentration.

Owner:山东高信化学股份有限公司

Matte thermoplastic polyurethane elastomer with high physical properties and preparation method thereof

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

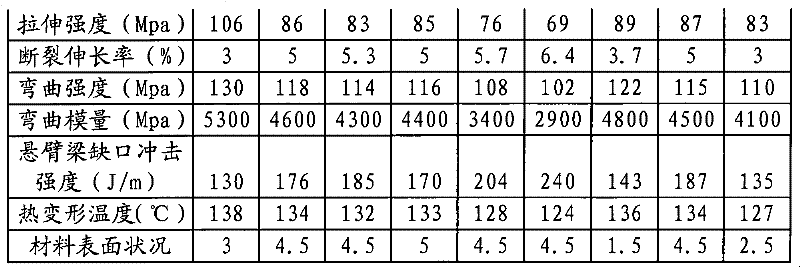

Polyphenylene sulfide/polyamide composite material and method for making same

Owner:ANHUI KEJU NEW MATERIALS

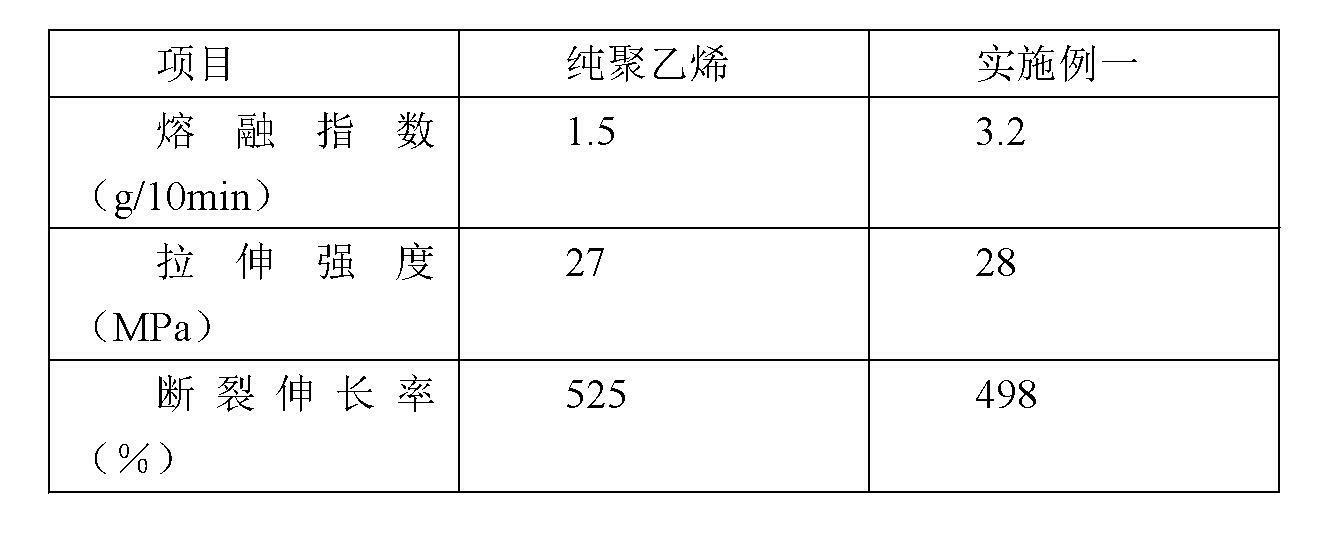

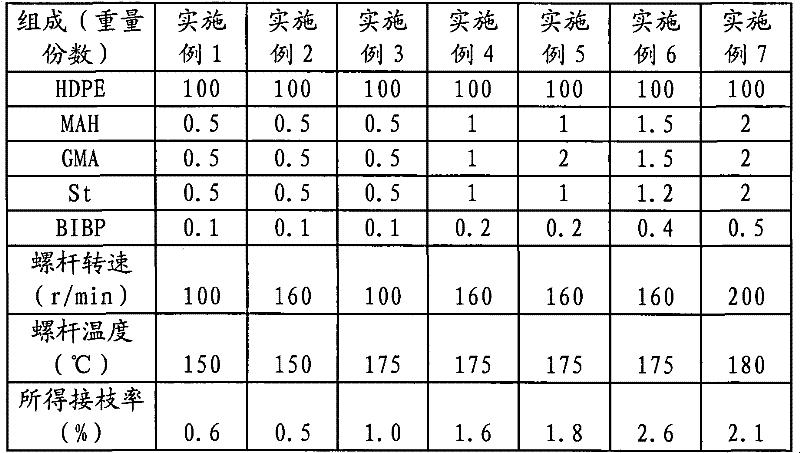

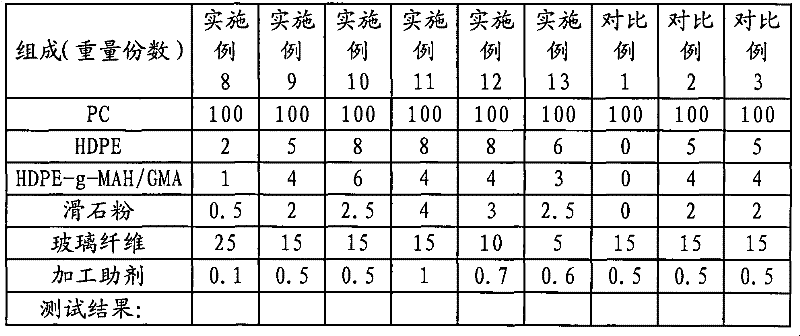

Glass fiber reinforced PC/PE alloy material and preparation method thereof

The invention discloses a glass fiber reinforced PC / PE alloy material and a preparation method thereof. The glass fiber reinforced PC / PE alloy material comprises the following components in parts by weight: 100 parts of polycarbonate, 2-20 parts of high-density polyethylene, 1-10 parts of maleic anhydride-glycidyl methacrylate double-grafted high-density polyethylene, 0.5-5 parts of talcum powder, 5-25 parts of glass fiber and 0.1-2 parts of processing aid. In the invention, because the home-made maleic anhydride-glycidyl methacrylate double-grafted high-density polyethylene is used as compatilizer and toughening modifier of PC / PE in the glass fiber reinforced PC material, the affinity of a glass fiber and a resin matrix is improved, thereby obtaining the glass fiber reinforced PC / PE alloy material with good surface appearance and better performance.

Owner:SHENZHEN KEJU NEW MATERIAL

Modified polyvinyl butyral waterproof coiled material

InactiveCN101845186BReduce viscosityHigh mechanical strengthRoof covering using flexible materialsProtective foundationElastomerPolymer chemistry

The invention relates to a waterproof material for construction, in particular to a waterproof coiled material prepared from modified waste polyvinyl butyral materials as raw materials, belonging to the technical field of construction engineering waterproof materials. The modified polyvinyl butyral waterproof coiled material is prepared by using recovered waste PVB (Polyvinyl Butyral) as main rawmaterials and rubber or elastic bodies as main auxiliary materials and matching with a plasticizer, a releasing agent, a stuffing and other auxiliary materials, and a preparation method comprises thesteps of: mixing the materials in an internal mixer according to a certain ratio, plasticating into strips or slabs in an open mill, entering a rubber single-screw extrusion molding machine for molding, and then processing on a tri-roll calender production line to obtain the coiled material of a determined thickness. The modified waste polyvinyl butyral waterproof coiled material has the properties of ageing resistance, good elasticity, bending resistance, ultraviolet radiation resistance, chemical corrosion resistance, water penetration resistance and the like.

Owner:ZHENGZHOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com