Composition for preparing highly-conductive flame retardant plastic, highly-conductive flame retardant plastic prepared thereby and preparation method thereof

A technology of flame-retardant plastics and compositions, applied in the field of polymer composite materials, can solve the problems of unsafe use and low flame-retardant level, and achieve the effects of easy processing and molding, high flame-retardant level, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

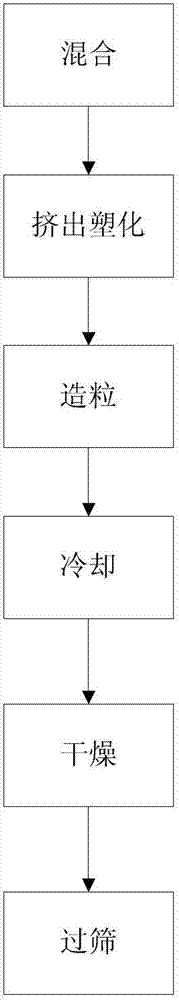

[0041] The present invention also provides a method for preparing the above-mentioned high-conductivity flame-retardant plastic, including the steps of mixing, extruding and plasticizing, granulating, cooling, drying, and sieving. The mixing steps are:

[0042] 1) Mix the conductive material at 300-500r / min for 3-5min at a temperature of 90-110°C to obtain the first conductive material, wherein, based on the mass of the conductive material, the conductive material includes 65-78wt% linear low-density polyethylene, 5~10wt% polyolefin elastomer, 10~20wt% superconducting carbon black, 1~2wt% coupling agent, 1~3wt% zinc stearate, 1~3wt% polyethylene wax, 0.2~0.4wt% antioxidant agent, 1~3wt% bis stearamide, 2~5wt% sizing agent and 0.02~0.1wt% initiator.

[0043] 2) Mixing the first conductive material at 180-210° C. and 800-1200 r / min for 5-10 minutes to obtain the second conductive material.

[0044] 3) The second conductive material is melted and plasticized to obtain a molten m...

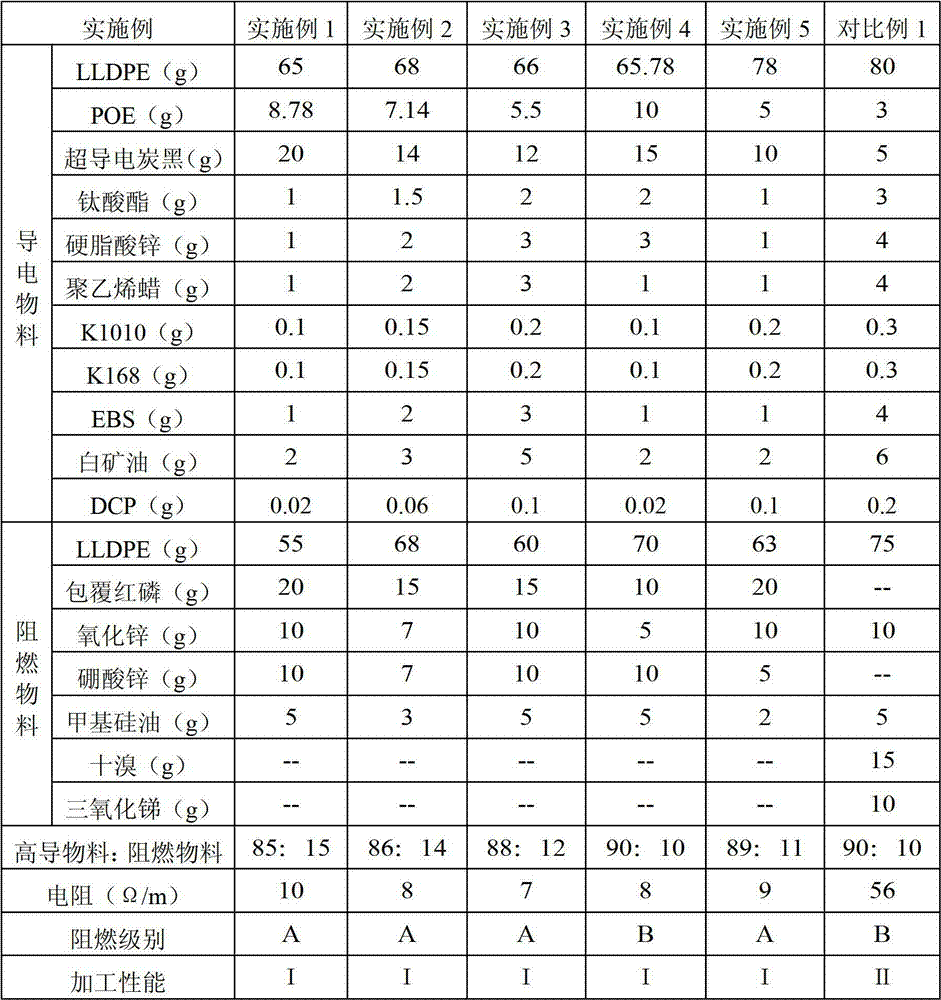

Embodiment 1~5

[0053] Combine the conductive material and the flame retardant material according to the recipes of Examples 1 to 5 and Comparative Example 1, put the conductive material and the flame retardant material into the mixer according to the ratio of 88:12, and mix them in the mixing machine. In a single-stage single-screw, extruding and plasticizing at 180 ° C to obtain a flame-retardant conductive plastic. Table 1 is the type and content of the prescriptions of Examples 1-5 and Comparative Example 1.

[0054] Processing performance: Symbol I indicates that the material is easy to process, and the material components do not migrate, do not dissociate, and do not dialysis; Symbol II indicates that hydrogen bromide and free bromine are produced, with high viscosity, easy to stick to the screw and die head, and there is a lot of retained material, which is not easy to clean. clear.

[0055] Flame retardant grade: According to the ZA-306.1-2007 standard, it is divided into four catego...

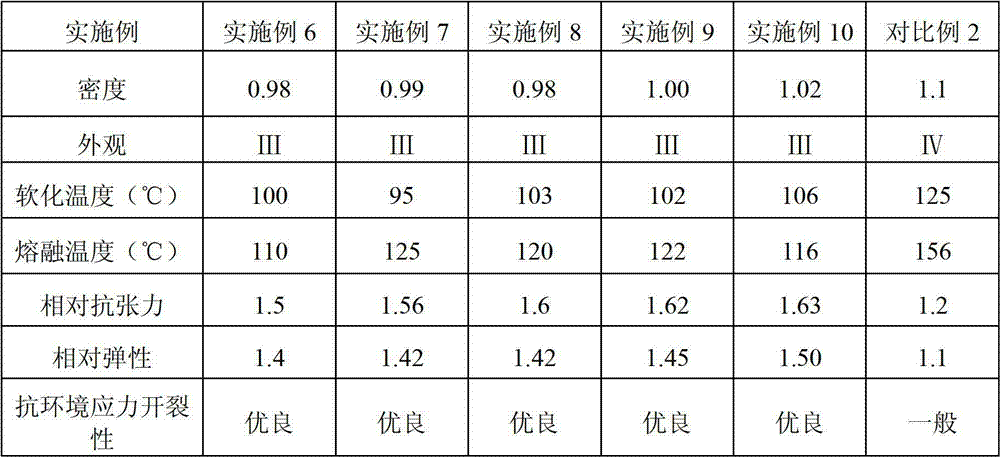

Embodiment 6

[0060]1) Mix 88% of the conductive material in Example 1 at 180°C at 500r / min for 3 minutes to obtain the first conductive material; mix the first conductive material at 180°C at 1200r / min for 5min to obtain the second Conductive material: transporting the second conductive material to the hopper of a twin-screw extruder, performing a melting and plasticizing step at a temperature of 220° C. and a pressure of 0.5 MPa to obtain a molten material;

[0061] 2) Stir 12% of the flame retardant material in Example 1 at room temperature at 50 r / min for 2 minutes to obtain the first flame retardant material;

[0062] 3) Adding the first flame retardant material to the molten material to obtain a mixed material.

[0063] 4) The mixed material was transported to the hopper of a single-screw extruder, and the melting and plasticizing step was carried out at a temperature of 200° C. and a pressure of 8 MPa to obtain a plasticized material.

[0064] 5) Cut the plasticized material into pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com