Copolymerized flame-retardant polyamide and preparation method thereof

A technology for copolymerization of flame retardant and polyamide, which is applied in the fields of copolymerization flame retardant polyamide and its preparation, preparation of flame retardant salt, and preparation of triblock phosphorus-containing copolymer flame retardant polyamide, and can solve the problem of easy flame retardant salt. Destruction, low reactivity, affecting the polymerization process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

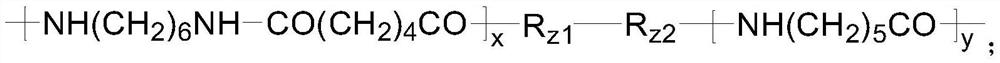

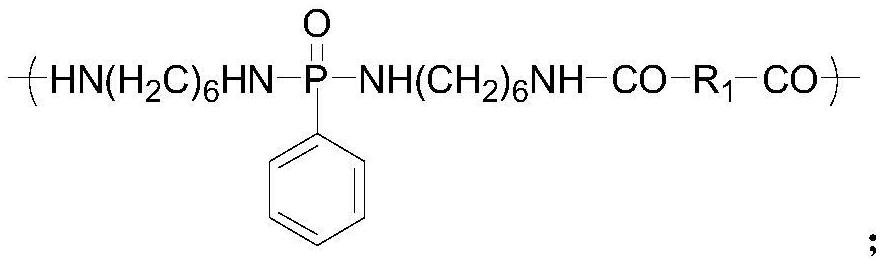

[0055]A preparation method of copolymer flame-retardant polyamide 66 / 6, the steps are as follows:

[0056](1) Preparation of flame retardant salt;

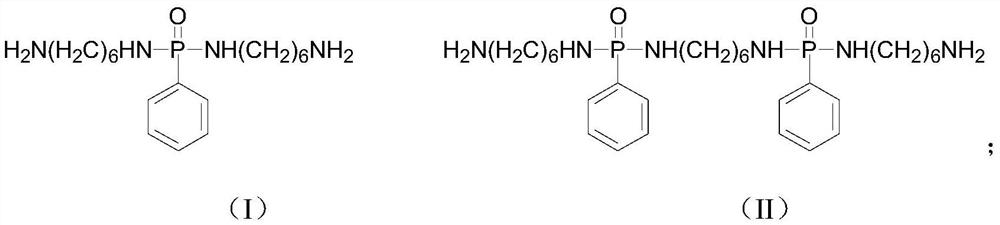

[0057](1.1) Mix N,N-bis(6-aminohexyl)phenylphosphoramide and adipic acid in an equimolar ratio, and then add 55wt% of the total mass of the system as the reaction solvent, and increase the temperature under nitrogen protection (The starting point of heating is 25°C) and stirring, the stirring speed is 50r / min, N,N-bis(6-aminohexyl)phenylphosphoramide is a mixture of the structure compound of formula (I) and the structure compound of formula (II) ;

[0058]The preparation process of N,N-bis(6-aminohexyl)phenylphosphoryl diamide is as follows: Dissolve hexamethylene diamine and phenylphosphoryl dichloride in an organic solvent (chloroform) at 25℃, and stir Next, add the organic solution of hexamethylene diamine to the organic solution of phenylphosphoryl dichloride. The molar ratio of phenylphosphoryl dichloride to hexamethylene diamine is 1:2. Af...

Embodiment 2

[0089]A preparation method of copolymer flame-retardant polyamide 66 / 6, the steps are as follows:

[0090](1) Preparation of flame retardant salt;

[0091](1.1) Mix N,N-bis(6-aminohexyl)phenyl phosphorodiamide and malonic acid in an equimolar ratio, and then add deionized water accounting for 56wt% of the total mass of the system as the reaction solvent, and proceed under nitrogen protection Increase the temperature (starting point is 25℃) and stir. The stirring speed is 70r / min. N,N-bis(6-aminohexyl)phenylphosphoramide is the difference between the structure compound of formula (I) and the structure compound of formula (II). mixture;

[0092]The preparation process of N,N-bis(6-aminohexyl)phenylphosphoryl diamide is as follows: Dissolve hexamethylene diamine and phenylphosphoryl dichloride in an organic solvent (acetonitrile) at 25°C. Add the organic solution of hexamethylene diamine dropwise to the organic solution of phenylphosphoryl dichloride. The molar ratio of phenylphosphoryl dichlor...

Embodiment 3

[0114]A preparation method of copolymer flame-retardant polyamide 66 / 6, the steps are as follows:

[0115](1) Preparation of flame retardant salt;

[0116](1.1) Mix N,N-bis(6-aminohexyl)phenyl phosphorodiamide and succinic acid in an equimolar ratio, and then add deionized water accounting for 58wt% of the total mass of the system as the reaction solvent, and proceed under nitrogen protection Raise the temperature (starting point is 25℃) and stir, the stirring speed is 65r / min, N,N-bis(6-aminohexyl)phenylphosphoramide is the difference between the structure compound of formula (I) and the structure compound of formula (II) mixture;

[0117]The preparation process of N,N-bis(6-aminohexyl)phenylphosphoramide is the same as in Example 1;

[0118](1.2) After the temperature rises to 213℃, keep the pressure at 1.75MPa, keep the temperature and keep the pressure for 2h;

[0119](1.3) Reduce the pressure to normal pressure within 0.8h, reduce the stirring speed to 50r / min, and vacuum to -0.07MPa for 0.6h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com