Environment-friendly and flame-proof nylon 66 with high conductivity and preparation method thereof

A high-conductivity, flame-retardant technology, which is applied in the field of high-conductivity, environmentally friendly, flame-retardant nylon 66 and its preparation, can solve the problems of one-sided optimization of nylon 66, complicated and time-consuming processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

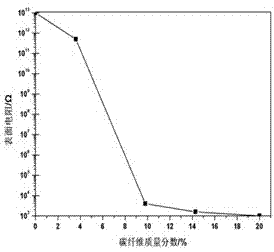

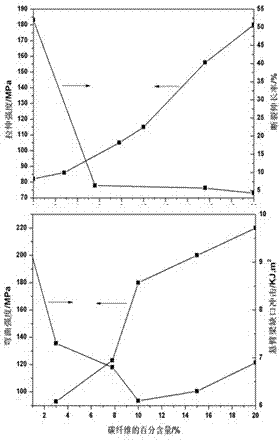

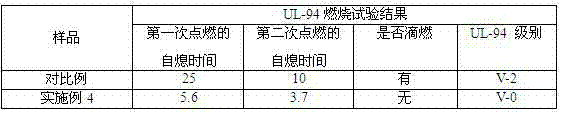

Image

Examples

Embodiment 1

[0023] (1) Weigh 80 parts of nylon 66 resin, 5 parts of phosphorus-nitrogen flame retardant, 1 part of coupling agent, and 0.6 part of antioxidant;

[0024] (2) Stir the above mixture evenly at high speed, and send it into the twin-screw extruder through a feeder with metering, and add 10 parts of carbon fiber long fibers by side feeding;

[0025] (3) The obtained material is drawn, cooled, pelletized, dried, and finally packaged: the environmentally friendly flame-retardant nylon 66 with high conductivity can be obtained.

[0026]

Embodiment 2

[0028] Only change batching amount, all the other are with embodiment 1. 70 parts of nylon 66 resins, 15 parts of carbon fiber long fibers, 8 parts of phosphorus nitrogen flame retardants, 1.1 parts of coupling agents, 0.5 parts of antioxidants, 0.3 parts of processing aids;

Embodiment 3

[0030] Only change batching amount, all the other are with embodiment 1. 75 parts of nylon 66 resins, 25 parts of carbon fiber long fibers, 10 parts of phosphorus nitrogen flame retardants, 1.5 parts of coupling agents, 0.5 parts of antioxidants, 0.4 parts of processing aids;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com