Furniture edge sealing strip processing process and device

A processing technology and processing device technology, which is applied in the field of furniture edge banding processing technology and devices, can solve problems such as delamination of back glue and base material, difficult scraping of high melting point materials, narrow processing temperature range, etc., to achieve sealing Good edge effect, wide processing temperature range, and the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

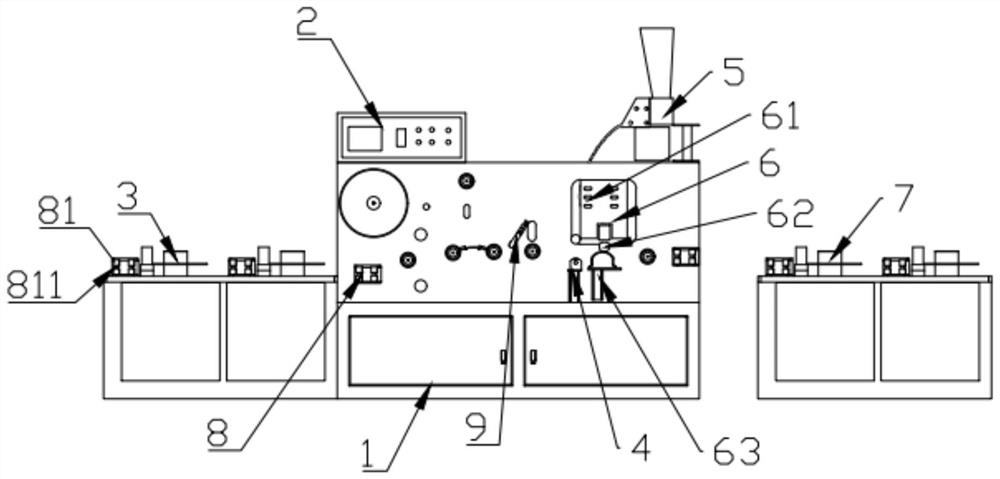

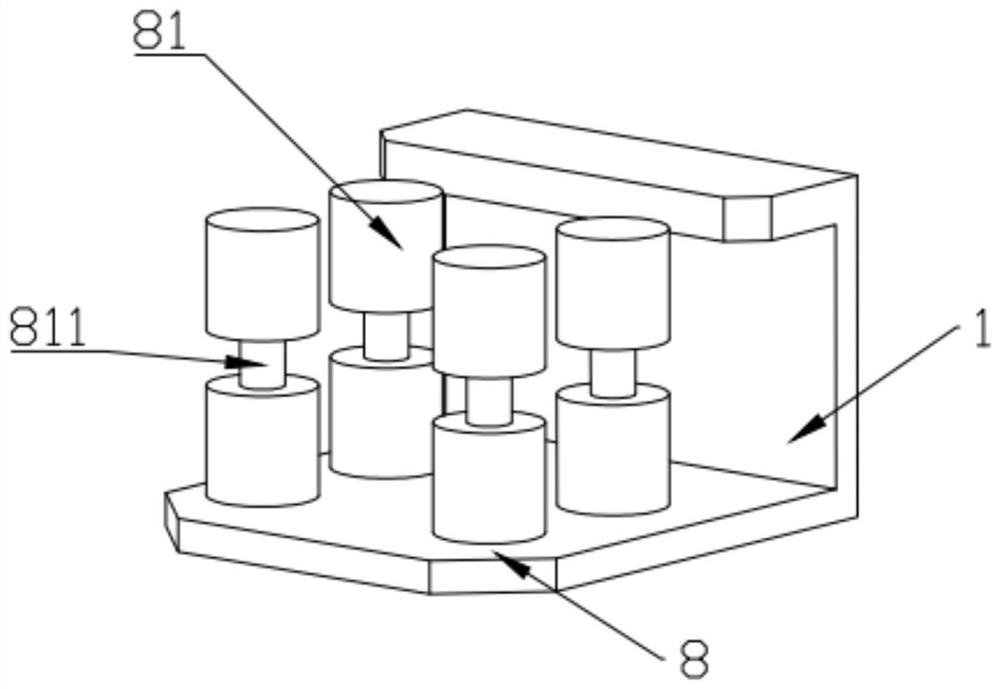

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

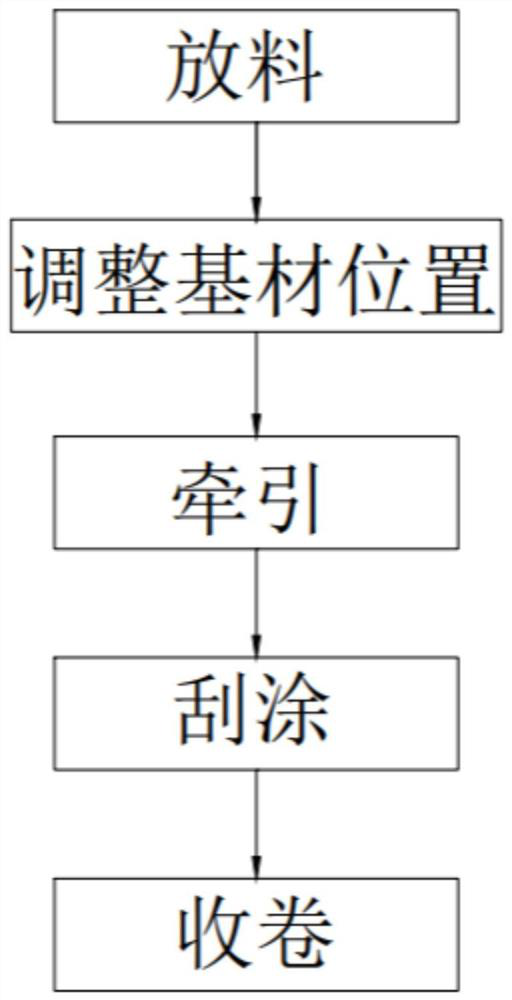

[0031] see figure 1 , the processing steps of the decorative edge banding of the present invention are as follows:

[0032] S1: Place the substrate to be scraped and adjust the position of the substrate, then use the motor to drive two plastic rollers to pull the adjusted substrate to the lower end of the scraping part at a pulling speed of 40m / min;

[0033] S2: Heat and pre-melt the back-coating glue first, then flow out to the scraping parts, set the temperature of the scraping parts to 260°C, so that the back-coating glue is in a completely melted state;

[0034] S3: Extrude the completely melted back glue from the motor-driven screw to the precision scraper, the precision of the precision scraper is 1°C, and scrape the back glue on one side of the substrate through the precision scraper;

[0035] S4: Use the synchronous motor to draw the base material that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com