Patents

Literature

47results about How to "Prevent stratification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid mixing and uniform shaking device for preparation of glucose solution for injection

InactiveCN107684873AAvoid displacementImprove versatilityShaking/oscillating/vibrating mixersMixing methodsDrive motorGlucose polymers

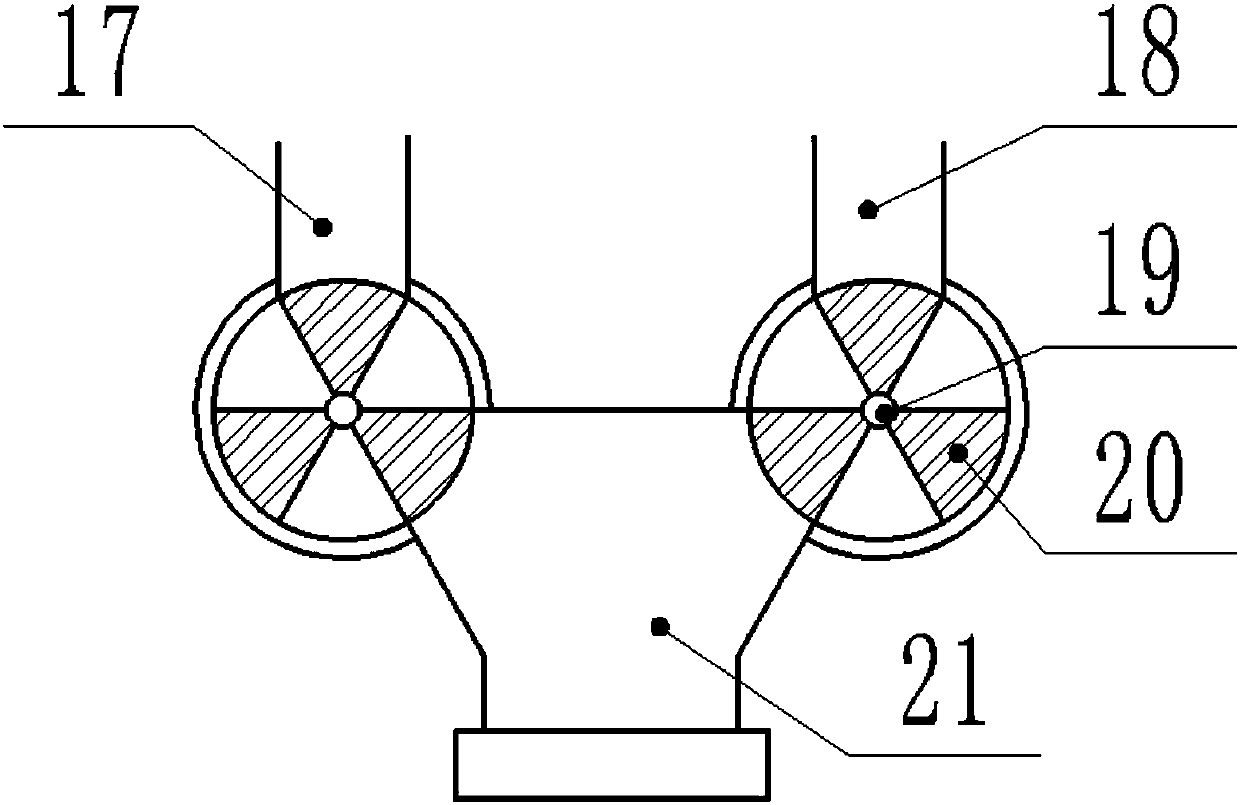

The invention discloses a liquid mixing and uniform shaking device for preparation of a glucose solution for injection. The liquid mixing and uniform shaking device comprises a base, a first drive motor, a material mixing box, a filtering box and a second drive motor; a joint bearing is rotationally mounted on a rotating base, and a spherical surface on the upper side of the joint bearing is fixedly mounted at the bottom of a fixed seat; material distribution wheels are rotationally mounted under a first feeding opening and a second feeding opening through rotating shafts; the filtering box ismounted on a slide bar in a sliding manner; a cylinder output shaft is horizontally connected with the filtering box leftwards. The liquid mixing and uniform shaking device disclosed by the inventionhas the beneficial effects that as the material distribution wheels are arranged in the liquid mixing and uniform shaking device, and material storage cavities in the material distribution wheels areconstant in volume, interval quantitative feeding can be realized, so that the excessive solution addition from any side is avoided. Therefore, the concentration of the prepared glucose solution is ensured to meet the requirements; meanwhile, after being mixed, the glucose solution can be uniformly shook again, so that the mixing degree of the glucose solution is improved, and the situation of layering due to long-time placement is avoided.

Owner:浦江县宏创科技开发有限公司

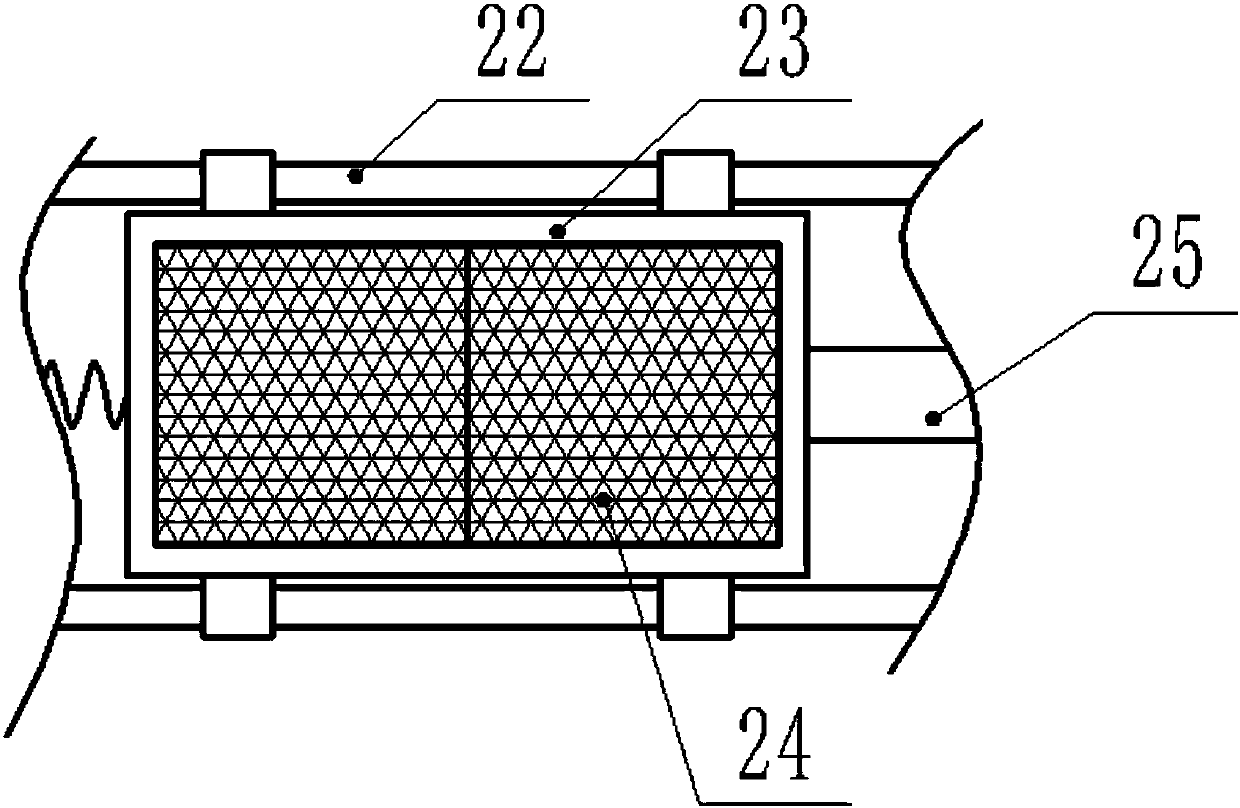

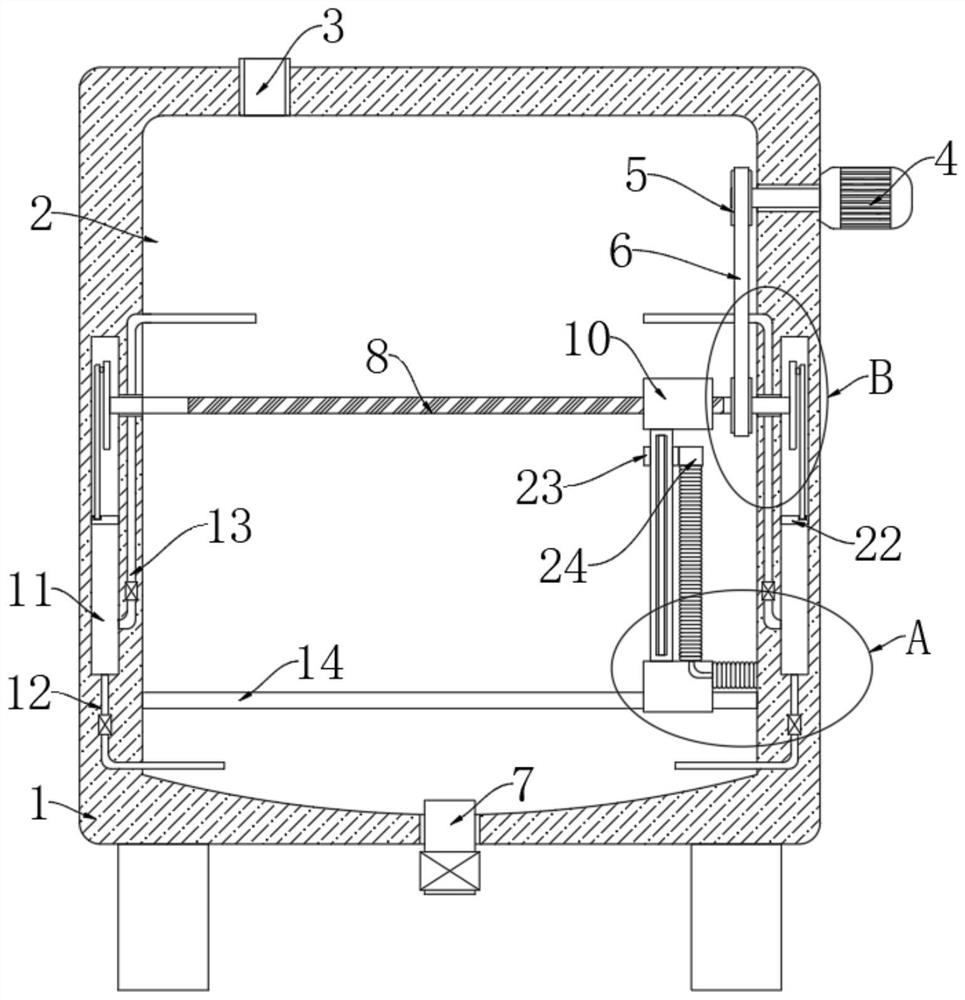

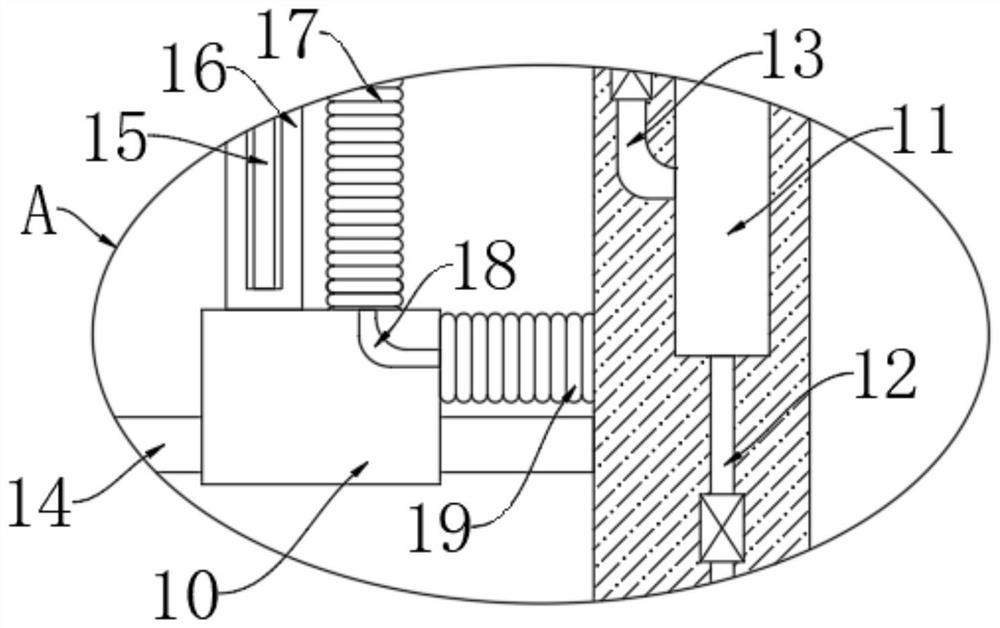

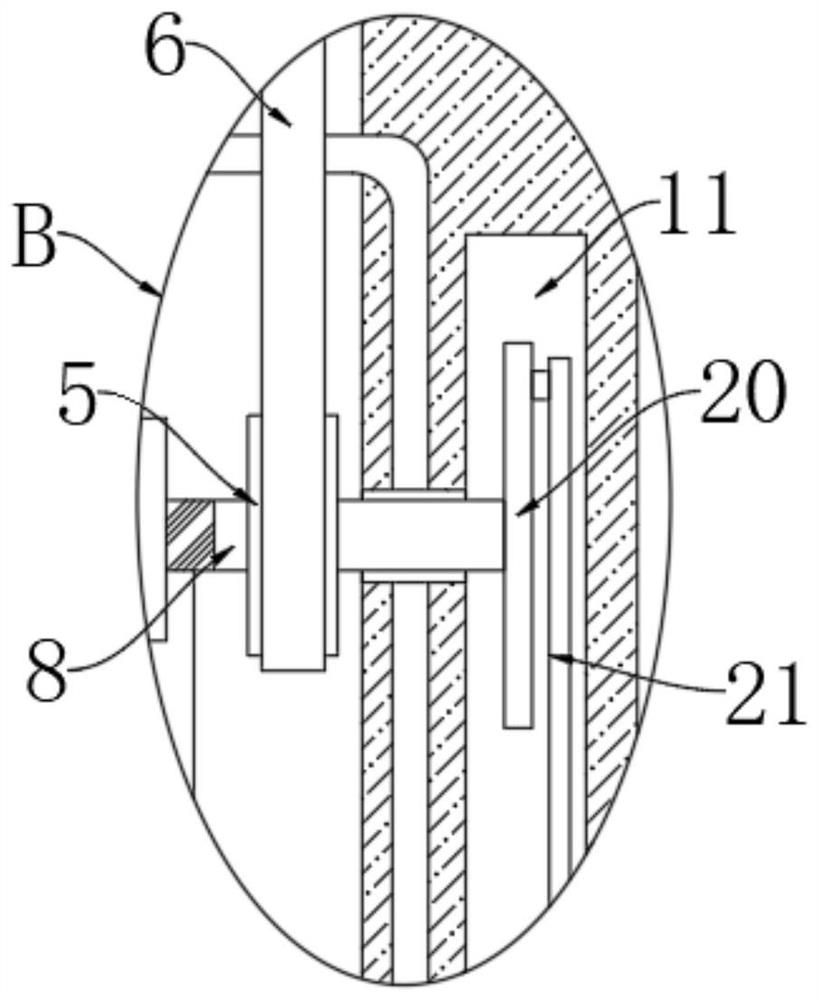

Material mixing device capable of realizing uniform heating

InactiveCN107694410APrevent stratificationImprove uniformityRotary stirring mixersTransportation and packagingSpiral bladeEngineering

The invention belongs to the technical field of stirring devices, discloses a material mixing device capable of realizing uniform heating and aims to solve the problems that existing stirring devicesare low in stirring efficiency and not uniform in heating. The material mixing device comprises a barrel body, wherein the barrel body comprises an inner barrel body and an outer barrel body, the outer barrel body is nested on the periphery of the inner barrel body to form a vacuum steam cavity, a liquid suction core is arranged on the inner wall of the steam cavity, the steam cavity is filled with a work liquid, and an electrical heating wire layer is arranged on the outer wall of the outer barrel body; a stirring shaft is arranged in the inner barrel body, stirring blades are mounted on thestirring shaft, a cavity is formed in the lower section of the stirring shaft, air vents communicated with the cavity are formed in the stirring shaft, and the cavity is communicated with an externalcompressed air source; spiral blades are mounted on the stirring shaft located above the stirring blades, and the spiral blades are spirally downwards arranged.

Owner:SICHUAN QIXING ELECTRONICS

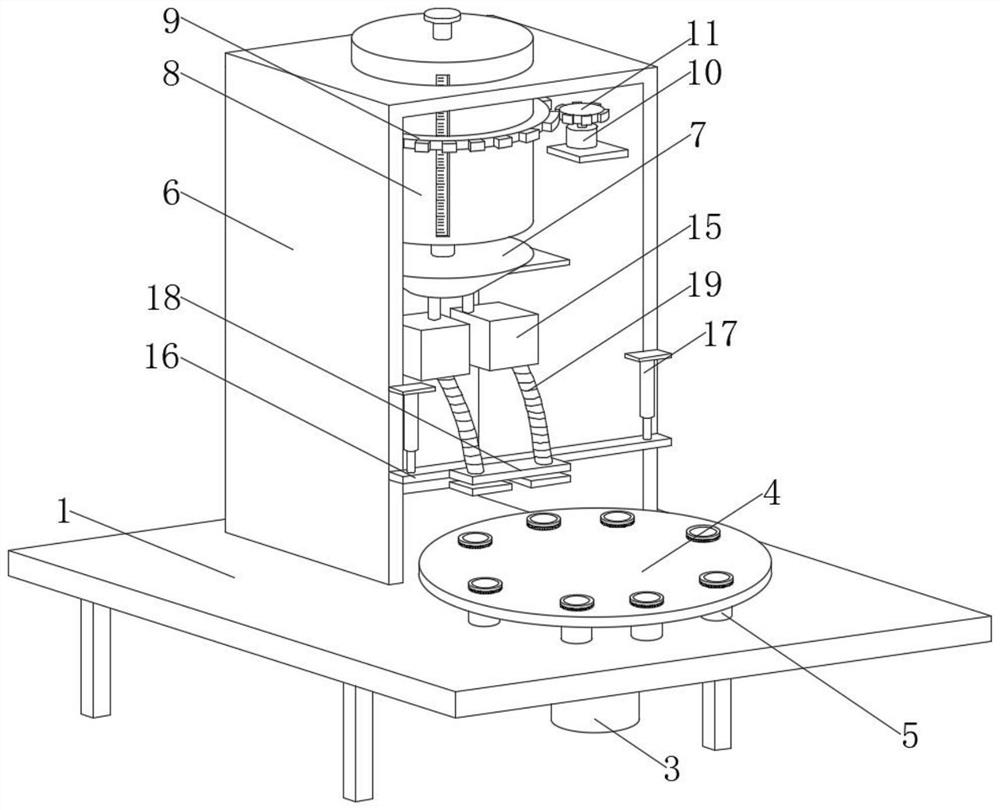

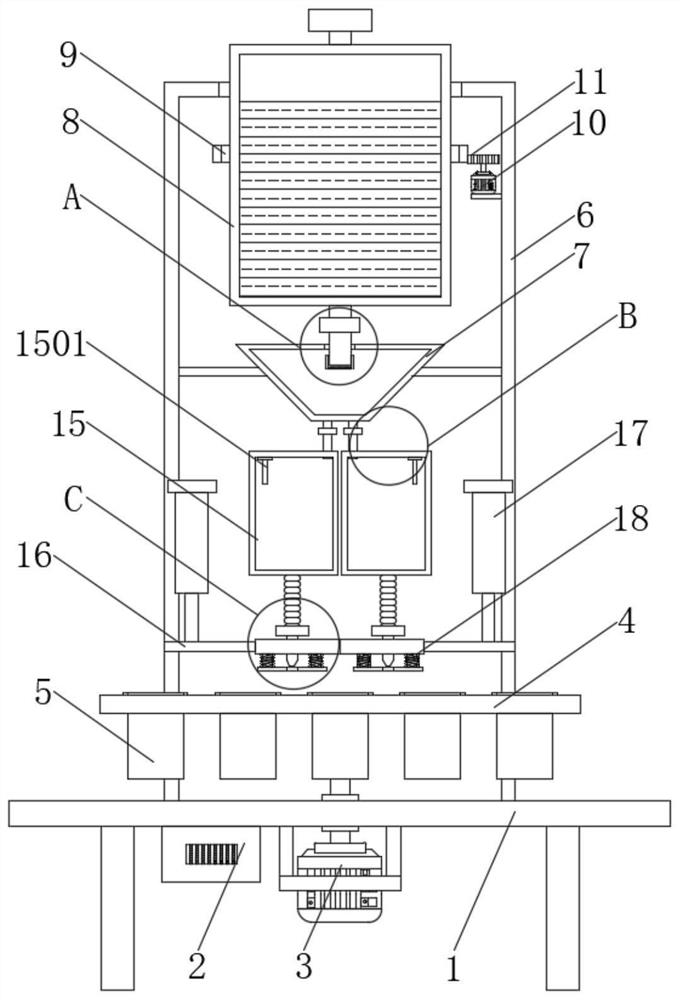

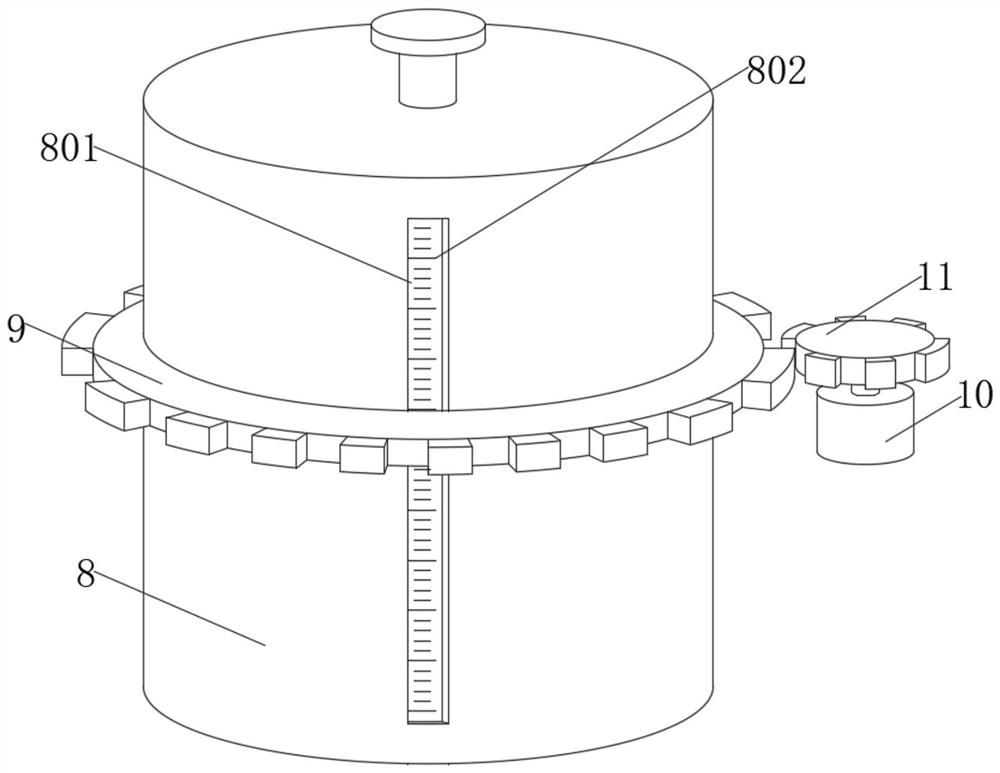

Efficient filling machine for clothing detergent processing and processing technology of efficient filling machine

PendingCN112850614AHigh precisionPracticalRotating receptacle mixersLarge containersMachining processManufacturing engineering

The invention discloses an efficient filling machine for clothing detergent processing and a processing technology of the efficient filling machine, and belongs to the field of detergent production. According to the technical scheme, the efficient filling machine comprises a workbench, the top of the workbench is fixedly connected with a frame, and the bottom of the workbench is fixedly connected with a first motor. An output shaft of the first motor penetrates through the workbench and is fixedly connected with a containing disc, filling bottles which are uniformly distributed are arranged at the top of the containing disc, penetrate through the containing disc and extend to the outside of the containing disc, a controller is fixedly connected to the bottom of the workbench, a storage hopper is fixedly connected to the inner wall of the frame, and a pretreatment tank is rotationally connected to the top of the frame. According to the efficient filling machine, by arranging pressing devices, under driving of electric push rods and fixing plates, perfect contact between pressing plates and the filling bottles is achieved, a third electromagnetic valve enters the filling bottles, the filling precision is high, the situation of drip leakage in the filling process is avoided, and practicability is high.

Owner:时协全

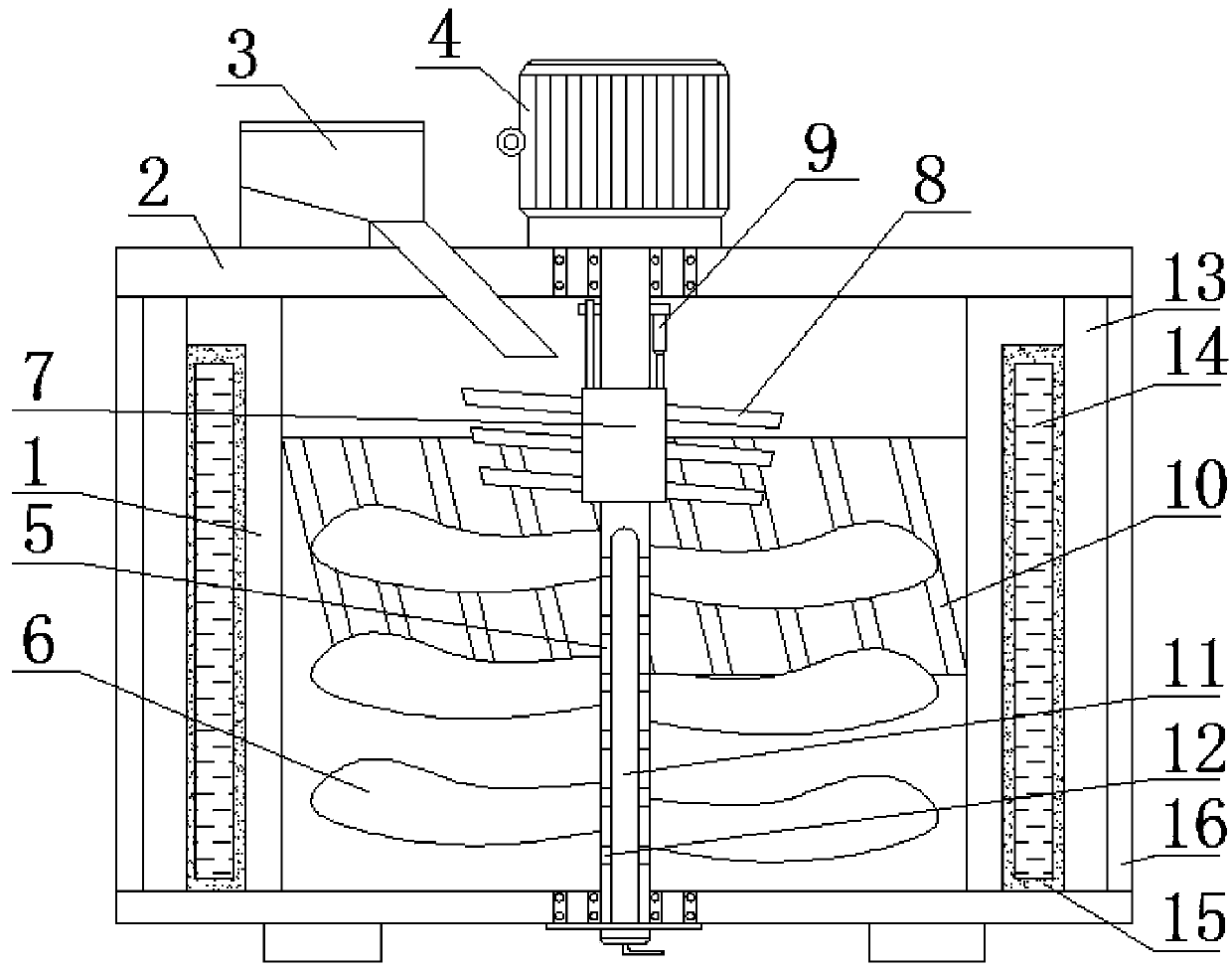

Lifting type stirring structure used in sewage treatment tank

ActiveCN108654448AReasonable structureImprove the mixing effectRotary stirring mixersTransportation and packagingRight triangleBiochemical engineering

The invention discloses a lifting type stirring structure used in a sewage treatment tank. The lifting type stirring structure comprises a bracket fixed on a stirring tank; a stirring motor is arranged on the bracket; a stirring shaft rod is arranged on a main shaft of the stirring motor; stirring blades are arranged on the stirring shaft rod; a vertical sliding groove is formed in the bracket; adriving screw rod is arranged inside the vertical sliding groove; a driving motor connected with the driving screw rod is fixed at the top of the bracket; a sliding block is arranged inside the vertical sliding groove; a stirring seat is fixed on the sliding block; a descaling strut is arranged at the middle part of the bracket; spiral stirring water guiding grooves are formed in the surface of right triangles; a circular ring is arranged on the descaling strut; and curved elastic pieces are uniformly fixed on the bottom surface of the circular ring. The lifting type stirring structure provided by the invention is reasonable in structure, and has the advantages that the stirring effect is improved and the stratification is avoided; the descaling operation on the surface of the stirring blades is completed at the same time of lifting, so that the guarantee of the stability and reliability of stirring is facilitated; and the lifting type stirring structure is good in stability and strongin practicality.

Owner:杭州西斗环境科技有限公司

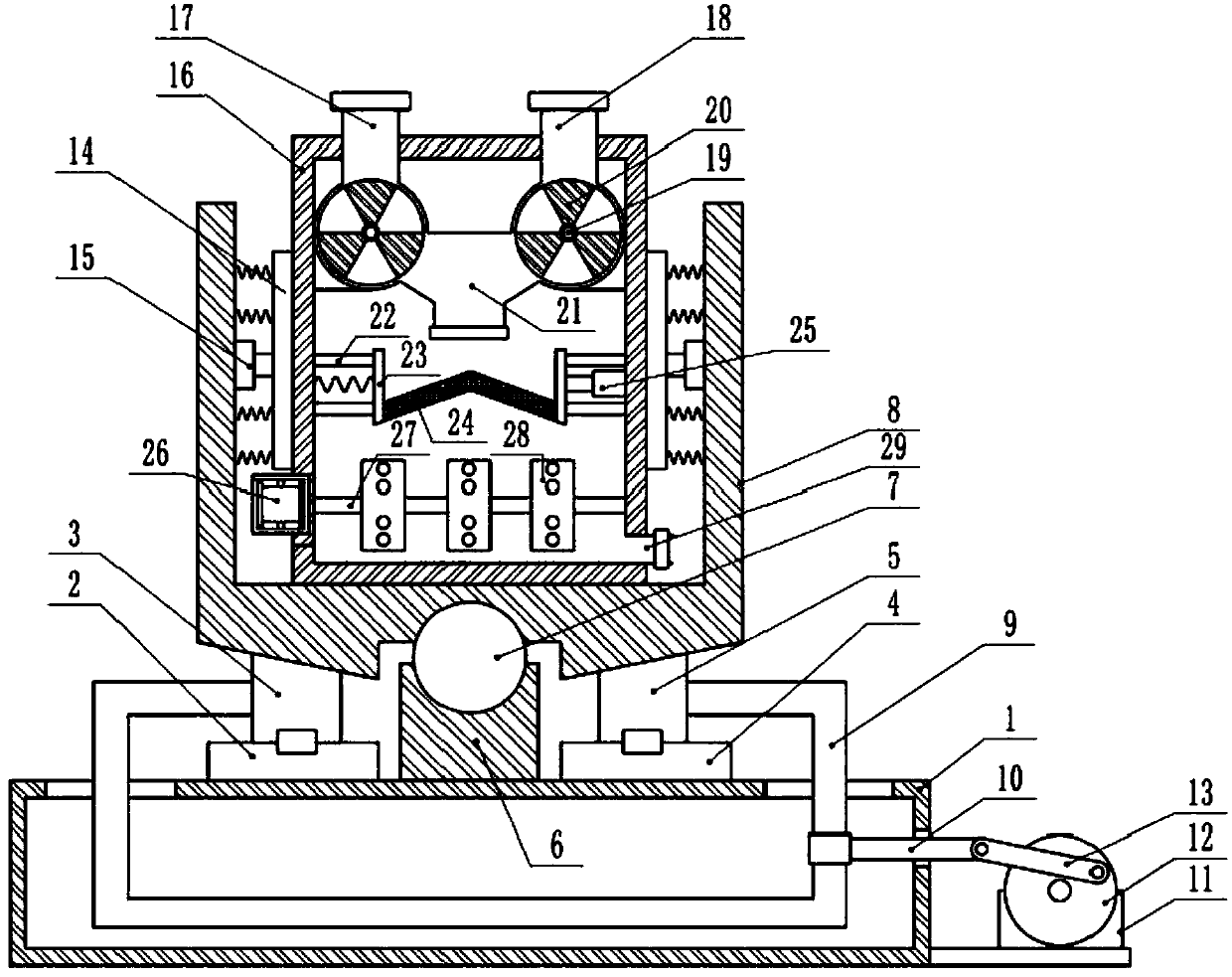

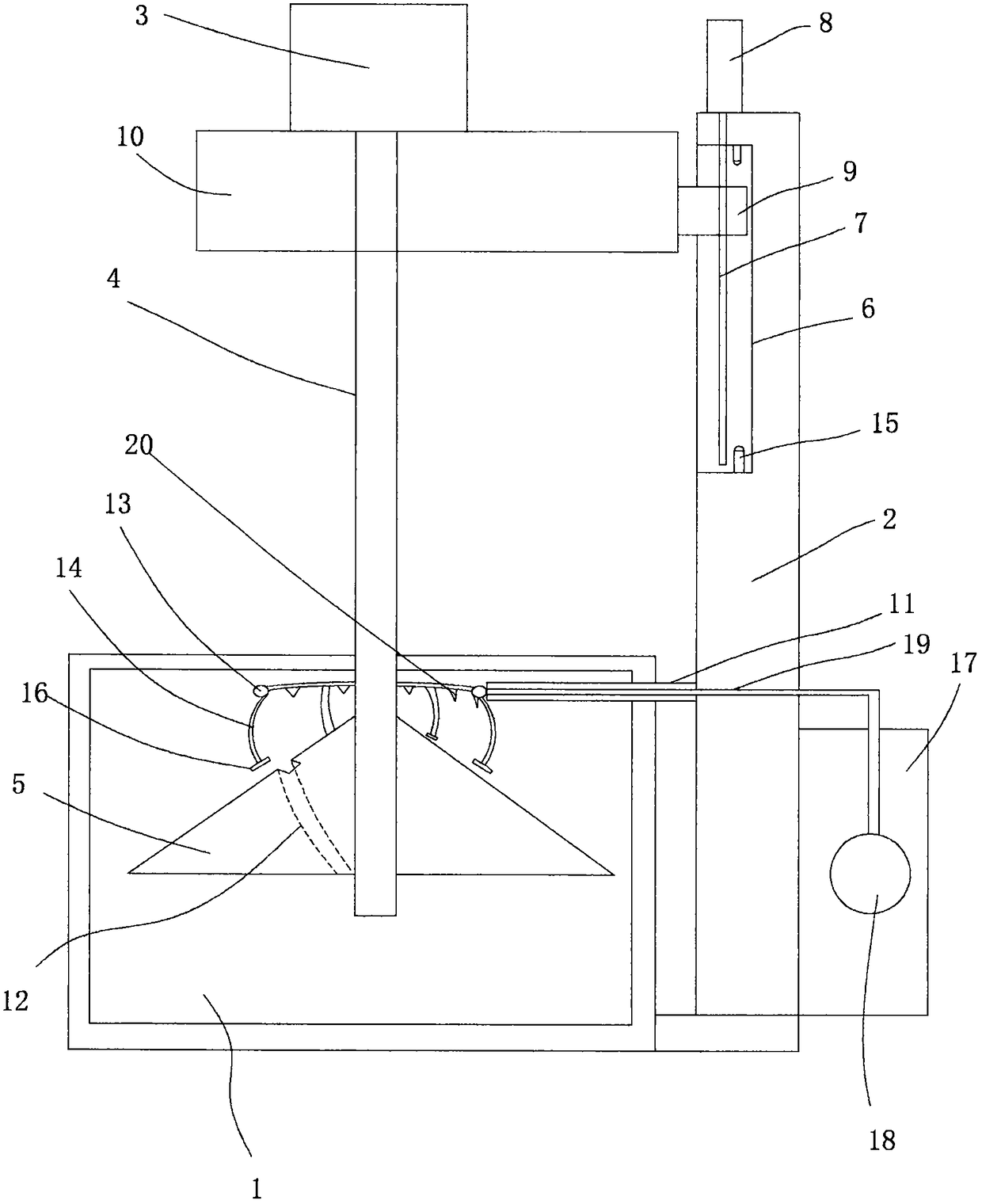

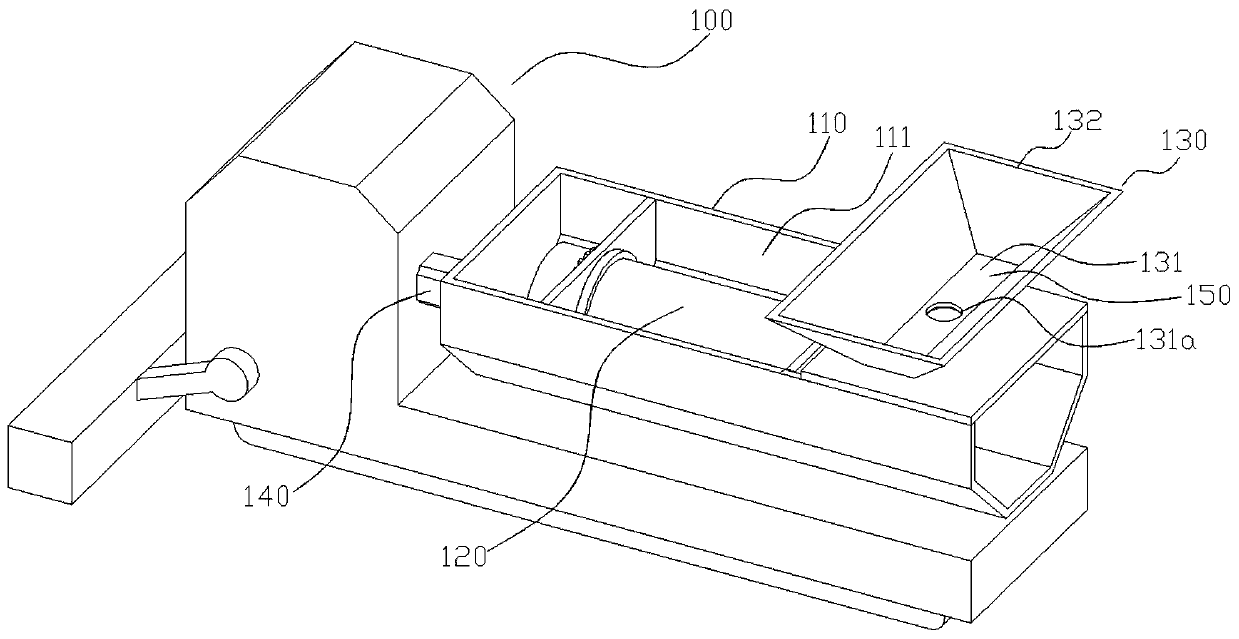

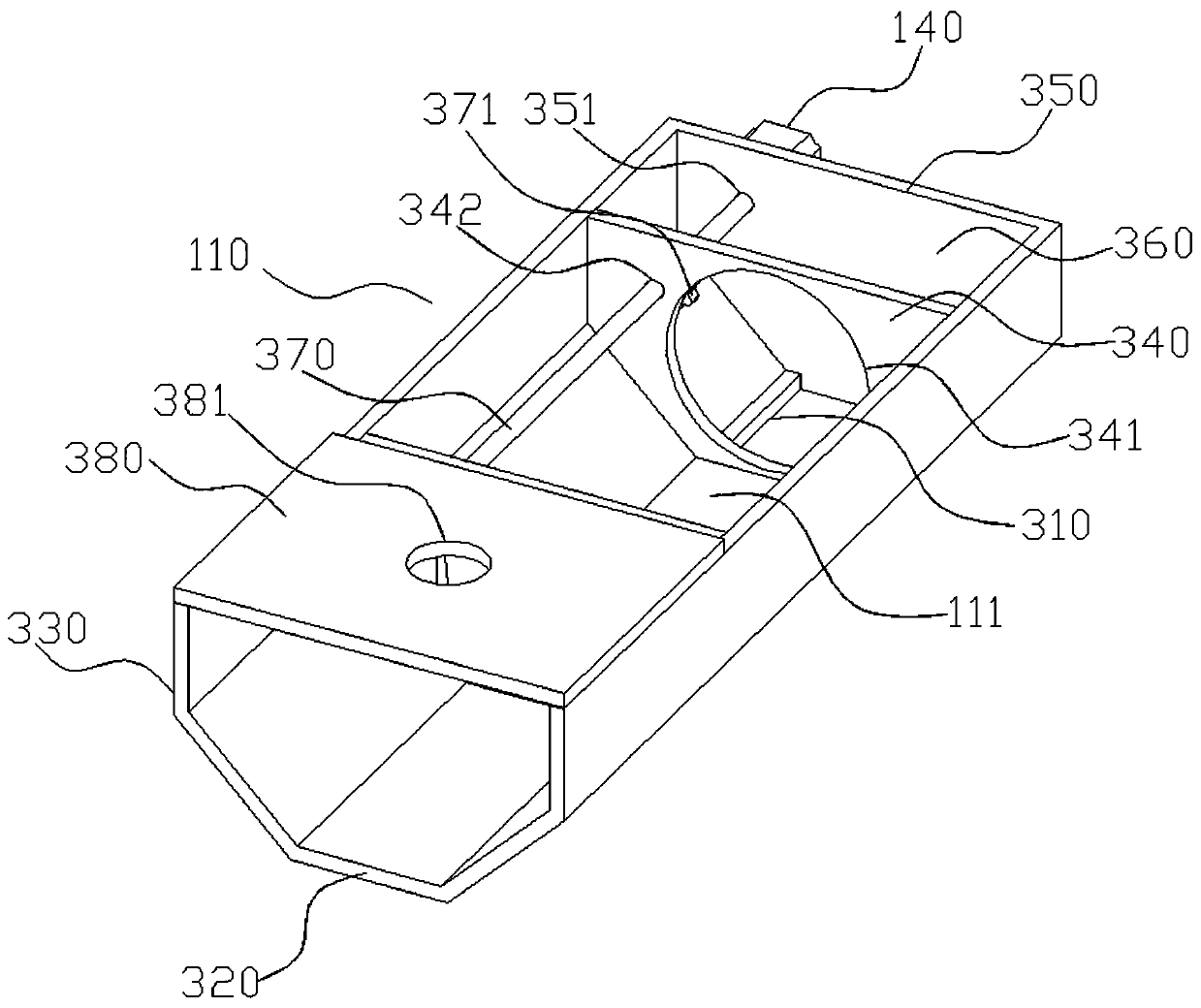

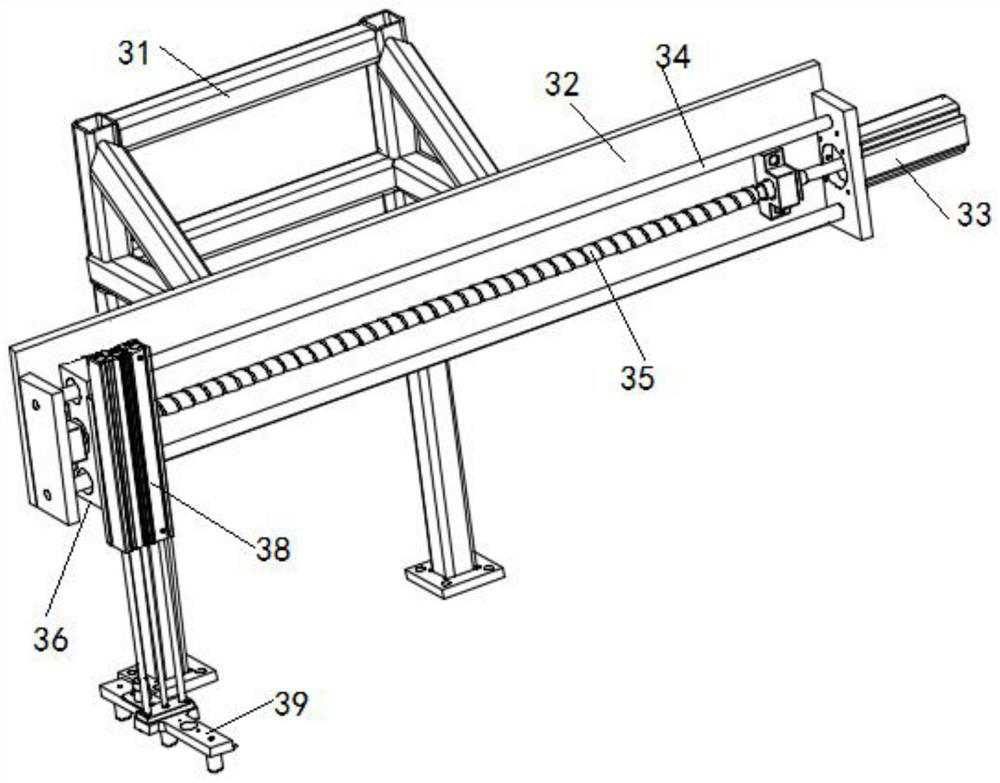

Crankshaft linkage type quantitative mixing device for hormone pesticide preparation

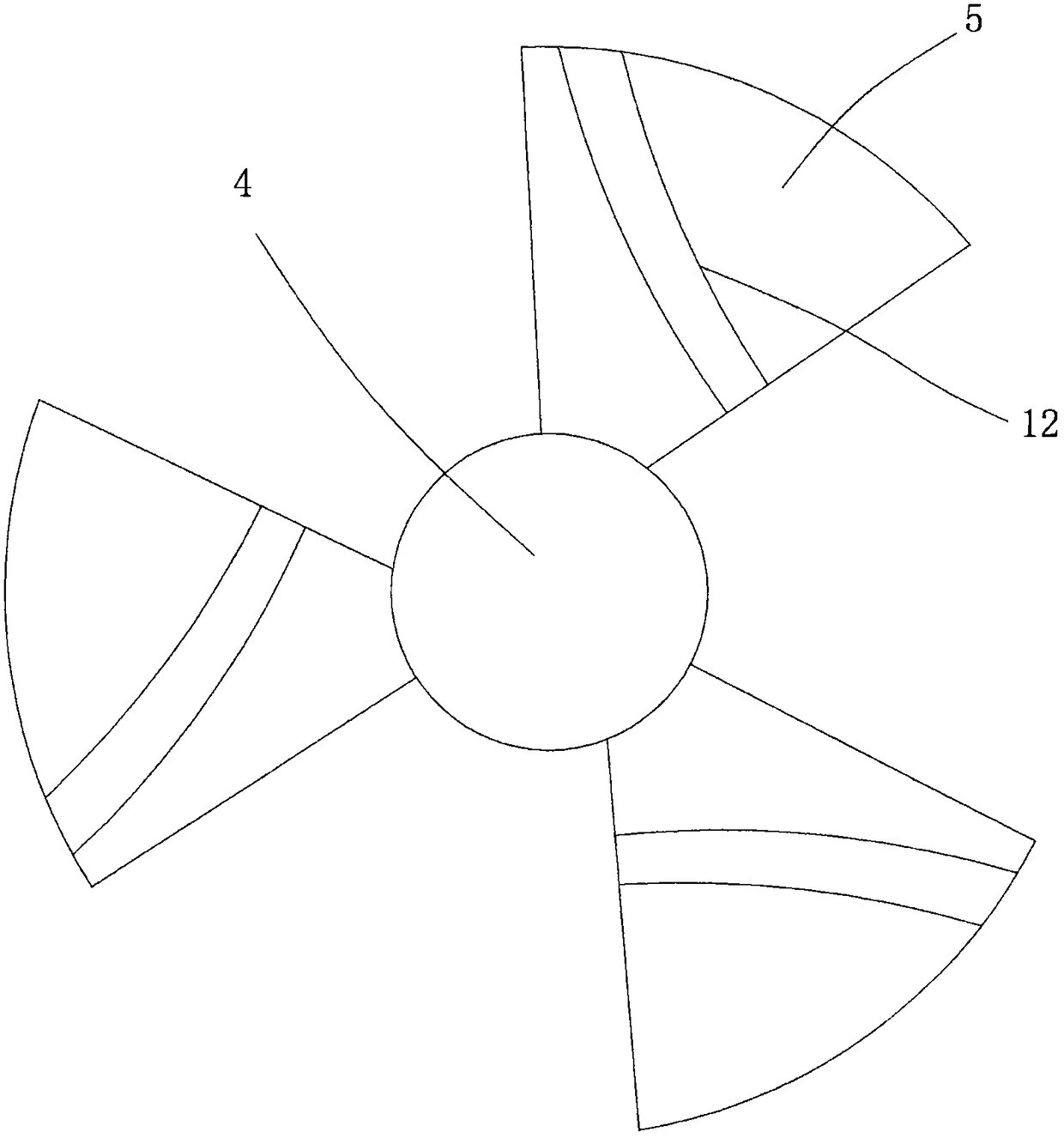

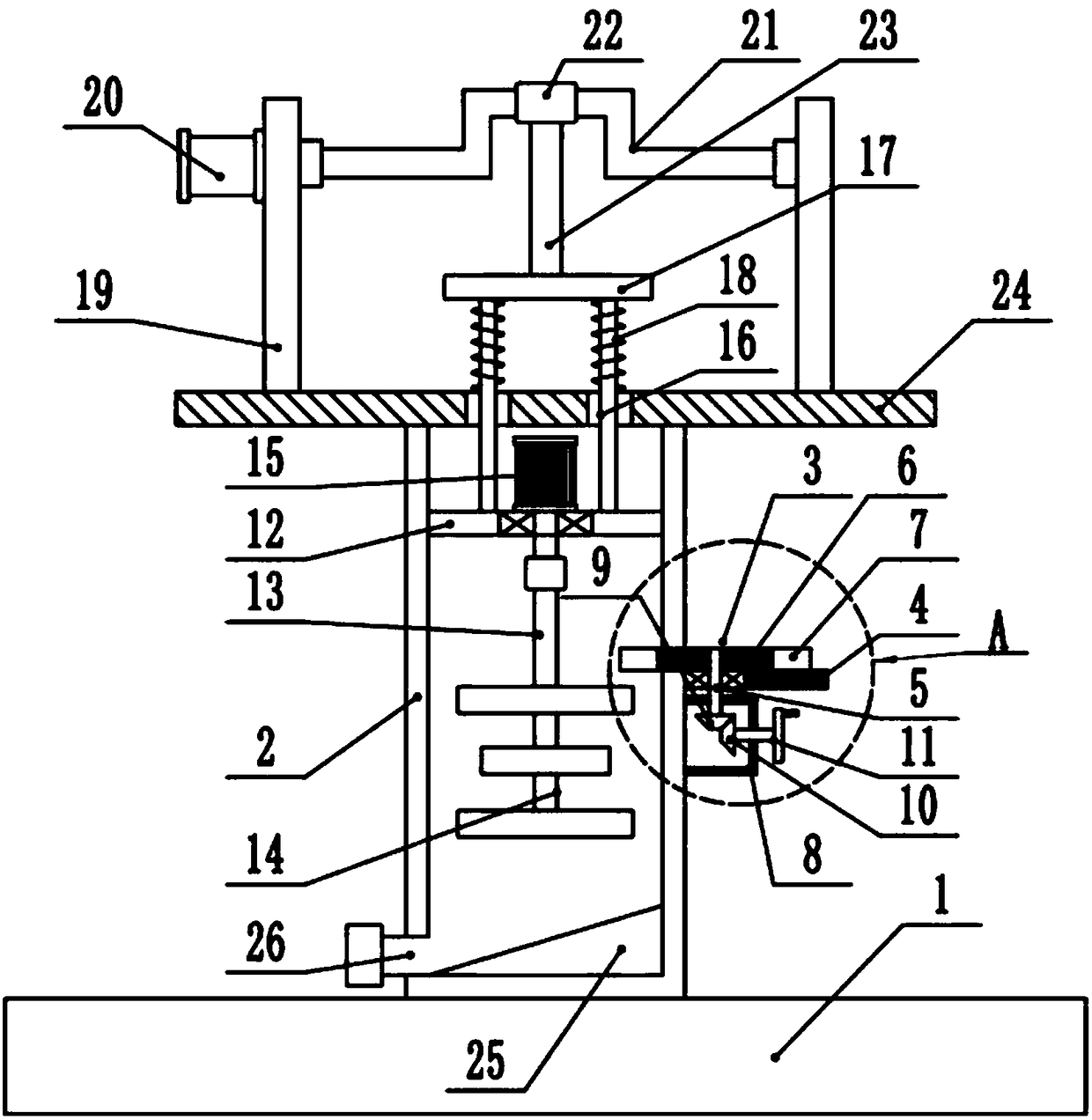

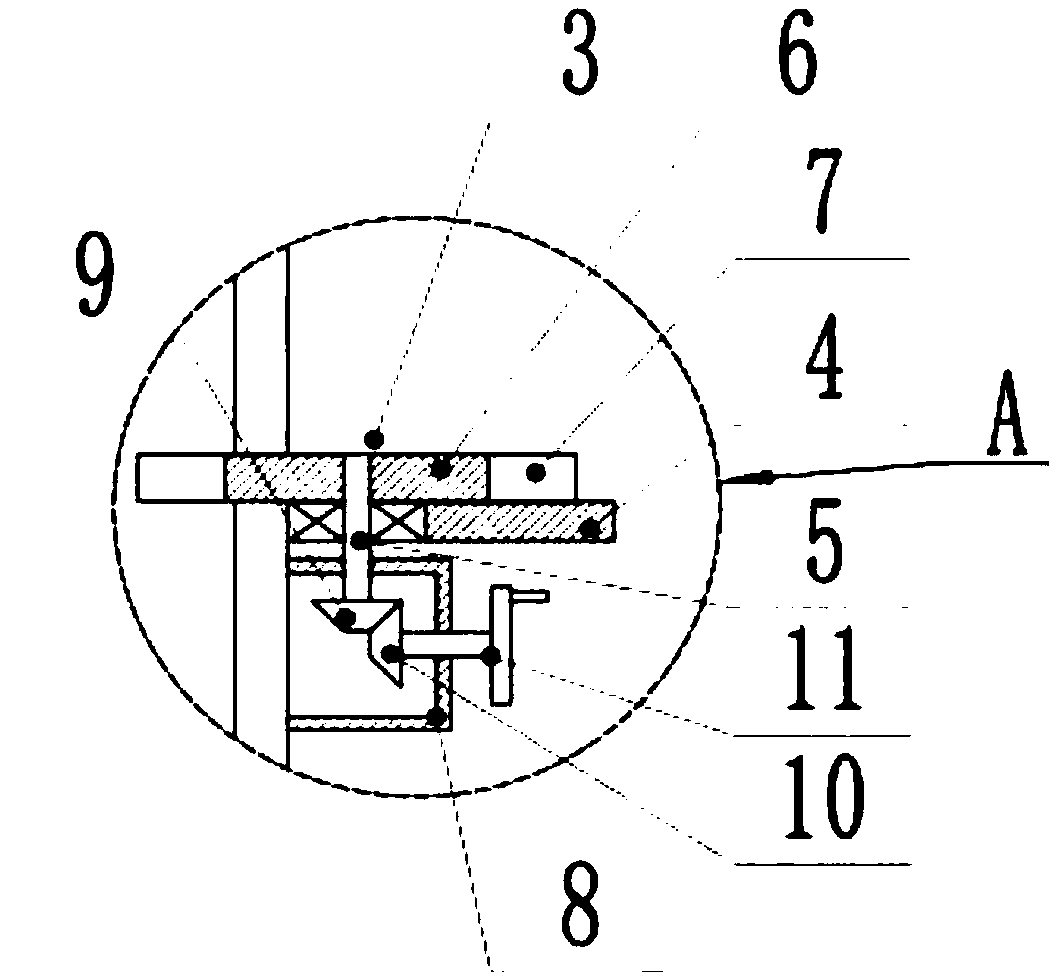

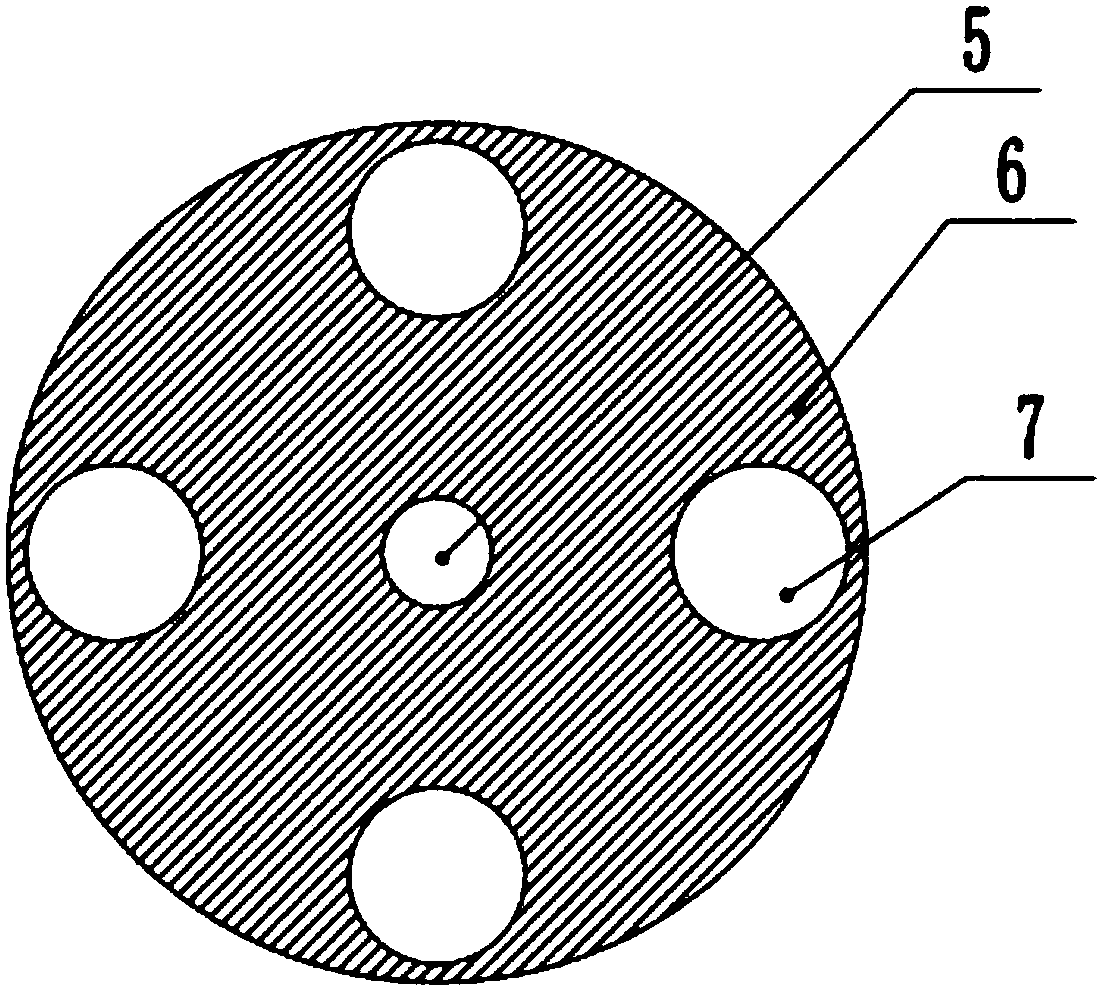

InactiveCN108295700APrevent stratificationAvoid Inadequate StirringShaking/oscillating/vibrating mixersTransportation and packagingHormones regulationDrive motor

The invention discloses a crankshaft linkage type quantitative mixing device for hormone pesticide preparation. The crankshaft linkage type quantitative mixing device comprises a mixing box, a quantitative feeding device, a quantitative disc, stirring blades, a stirring motor, a drive motor and a crankshaft, wherein the quantitative feeding device is arranged on the right side of the mixing box; alifting plate is glidingly mounted in the mixing box; the stirring motor is fixedly mounted on the upper side of the lifting plate; the stirring blades are fixedly mounted on the lower side of a stirring shaft. By means of arrangement of the quantitative feeding device, the adding quantity of pesticides can be accurately calculated according to the number of rotation turns of the quantitative disc, so that a quantitative feeding function is realized, and working efficiency of large-scale pesticide spraying and mixing operation is greatly improved; the stirring blades move up and down in the stirring process, therefore, the stirring effect can be greatly improved, the condition of insufficient stirring of the pesticides at the bottom is prevented, the pesticide layering situation is effectively avoided, and the device is simple and effective.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

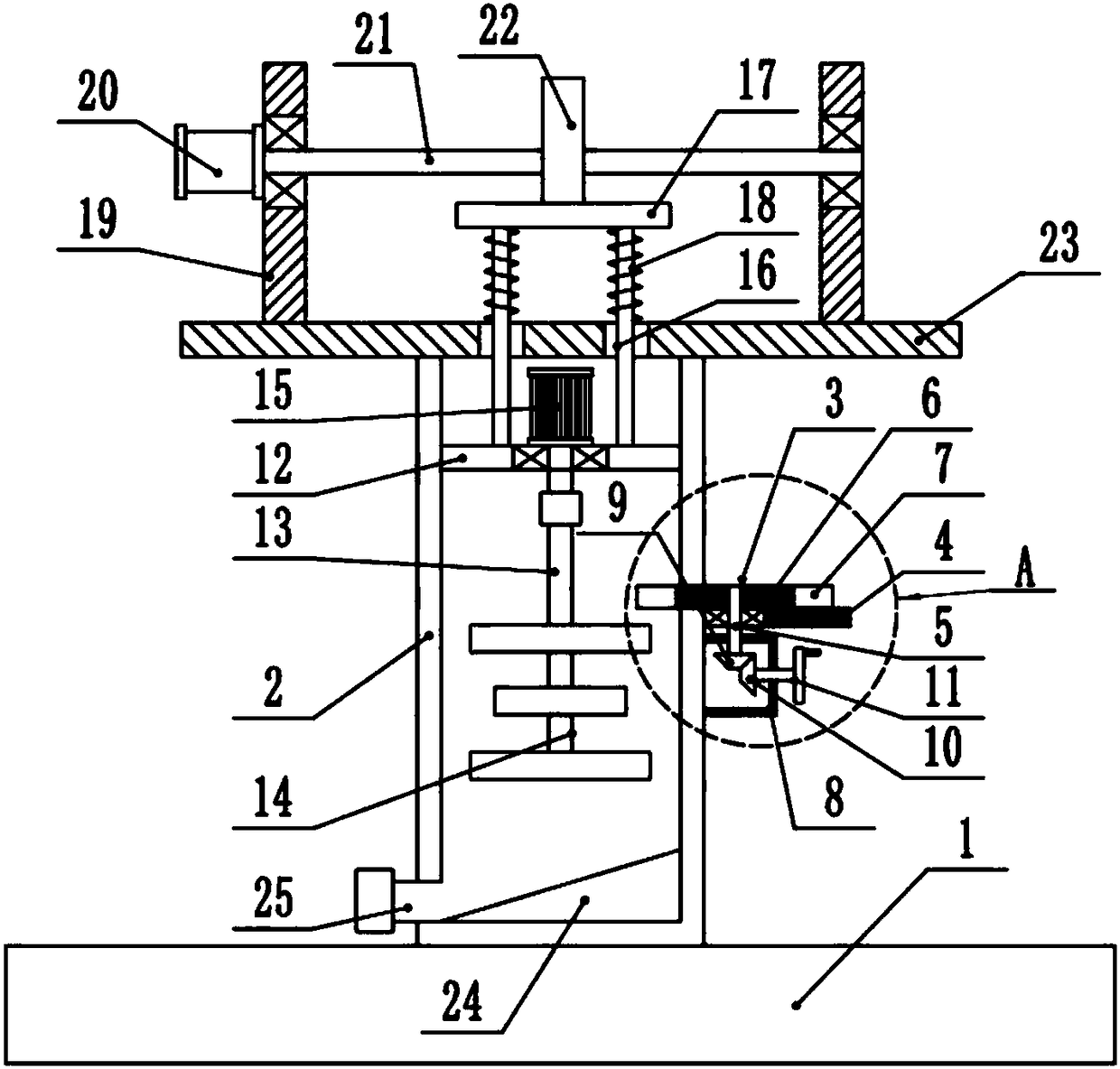

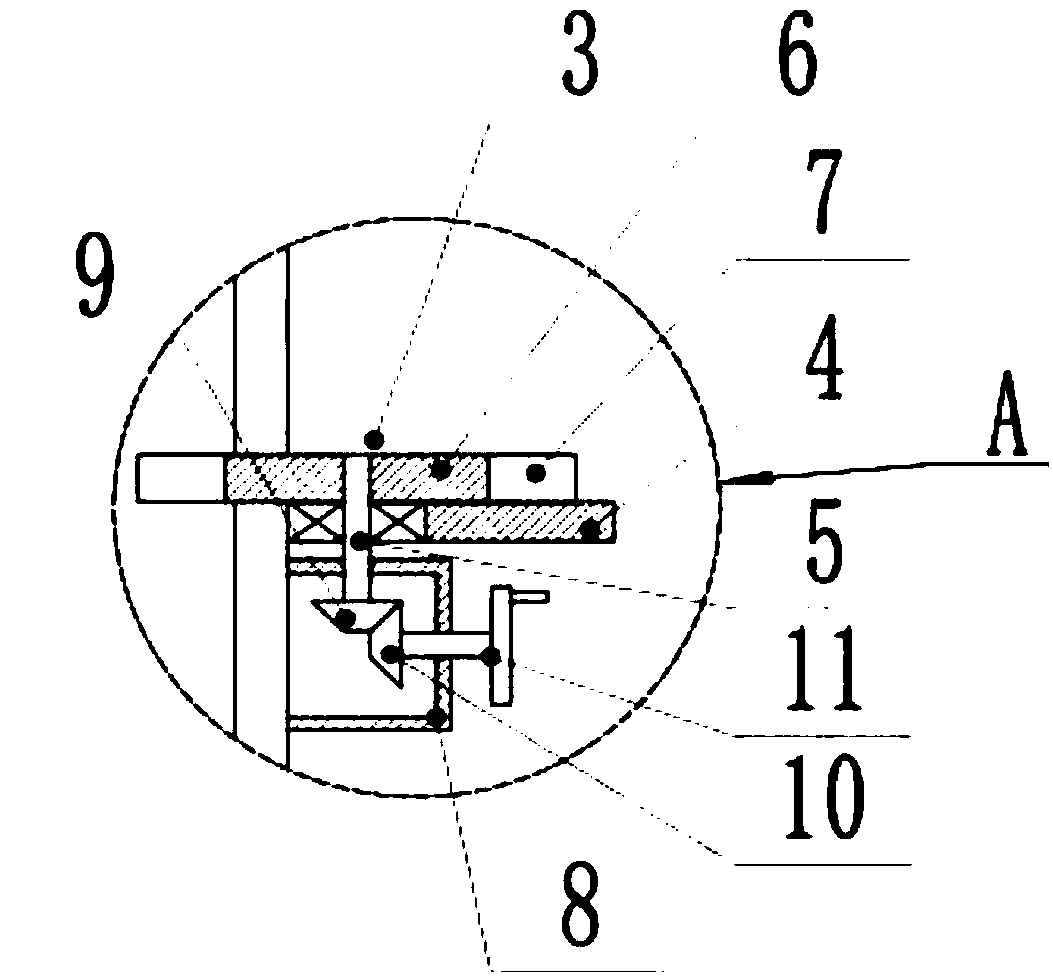

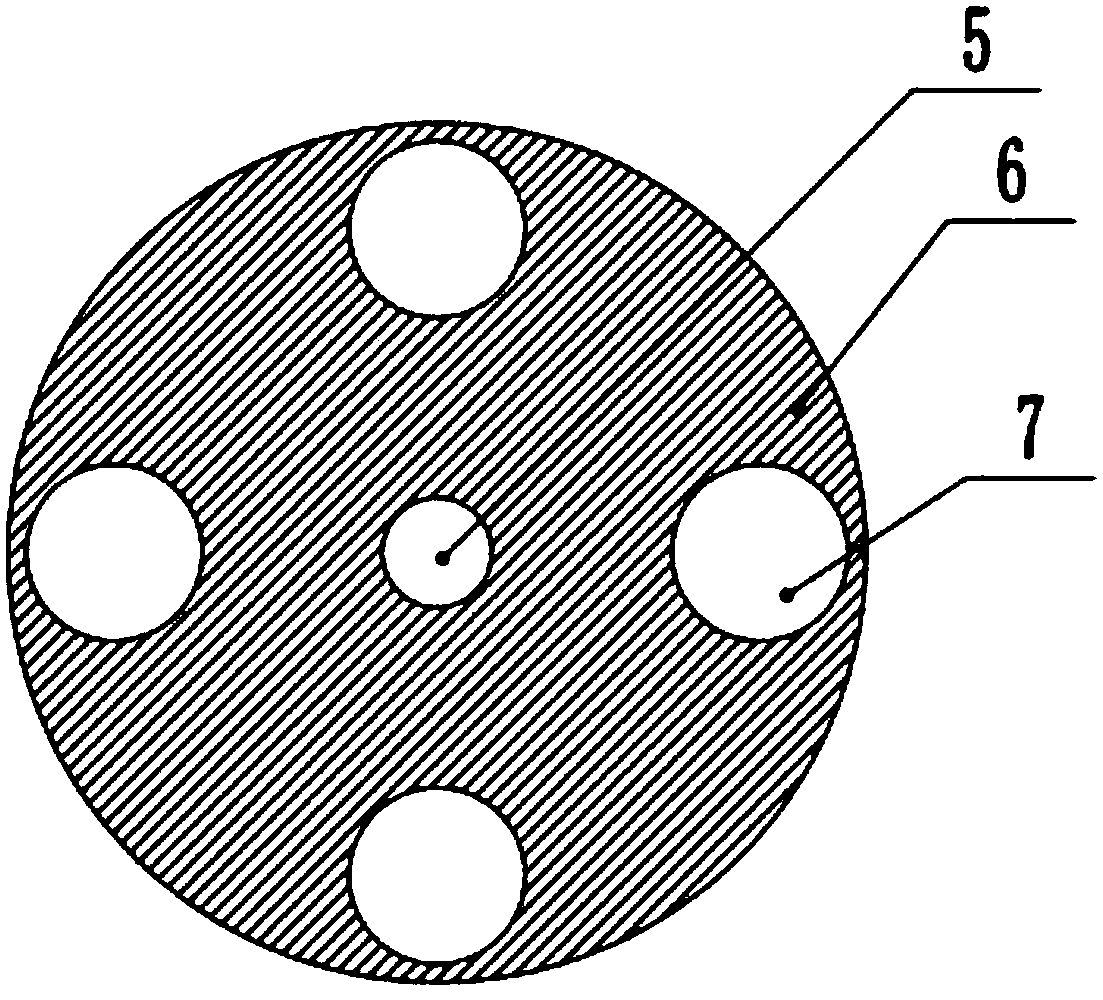

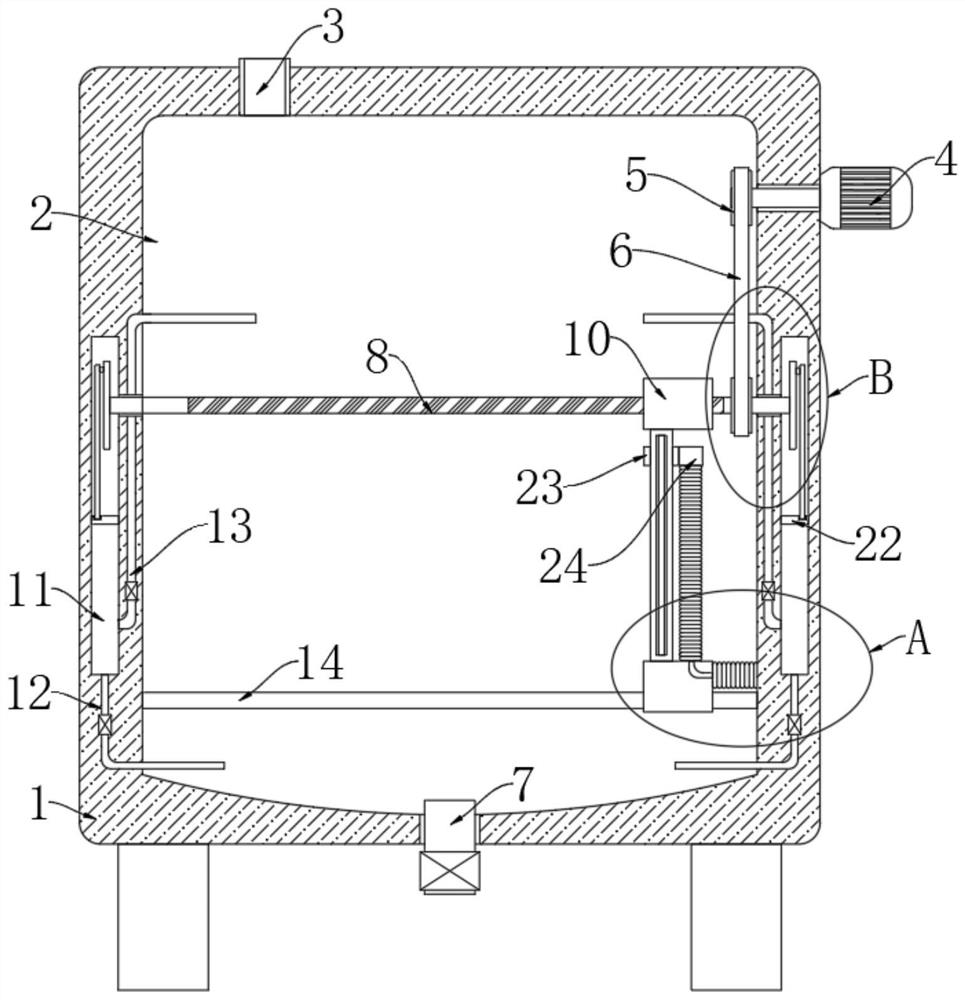

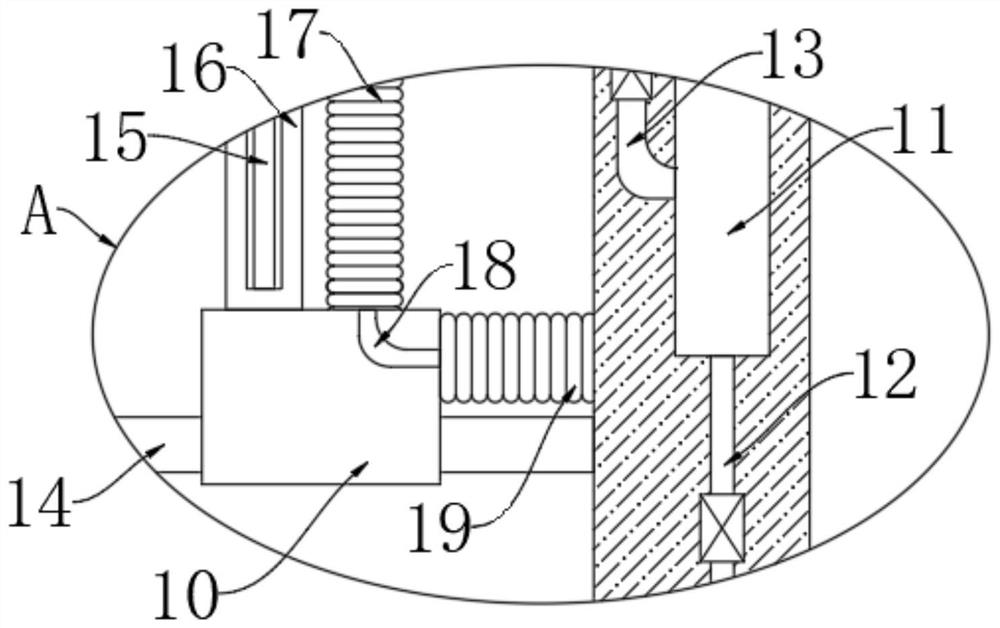

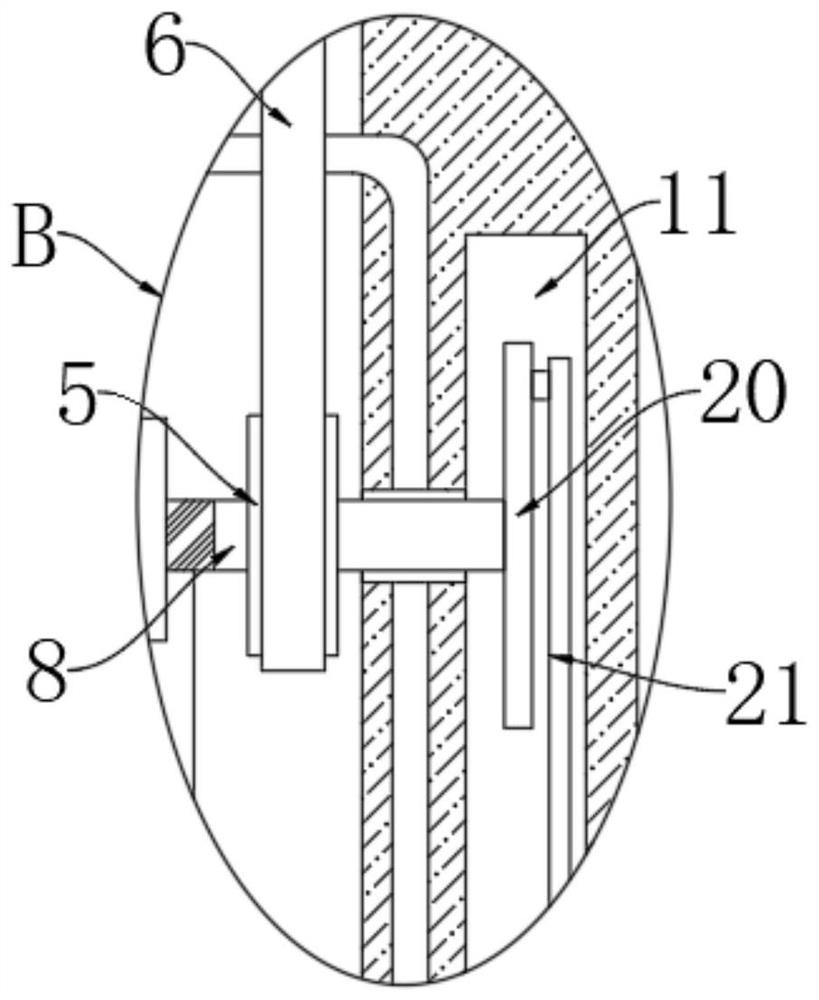

Cam-driven type quantitative mixing device for preparing hormone pesticide

InactiveCN108211882APrevent stratificationAvoid Inadequate StirringRotary stirring mixersTransportation and packagingHormones regulationDrive motor

The invention discloses a cam-driven type quantitative mixing device for preparing hormone pesticide. The device comprises a mixing box, a quantitative dosing device, a quantifying plate, a stirring blade, a stirring motor, a drive motor and a cam, wherein the quantitative dosing device is arranged on the right side of the mixing box; a lifting plate is mounted, in a sliding manner, inside the mixing box; the stirring motor is fixedly mounted on the upper side of the lifting plate; the stirring blade is fixedly mounted on the lower side of a stirring shaft. With the quantitative dosing device,the added amount of a pesticide agent can be accurately calculated according to the rotation turns of the quantifying plate, so as to realize a function of quantitative dosing; the working efficiencyis greatly improved for a large-scale pesticide spray and mixing operation; in a stirring process, the stirring effect can be greatly improved through the up-down movement of the stirring blade, so as to prevent insufficient stirring of the pesticide at the bottom and effectively avoid pesticide layering, thereby being simple and effective.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

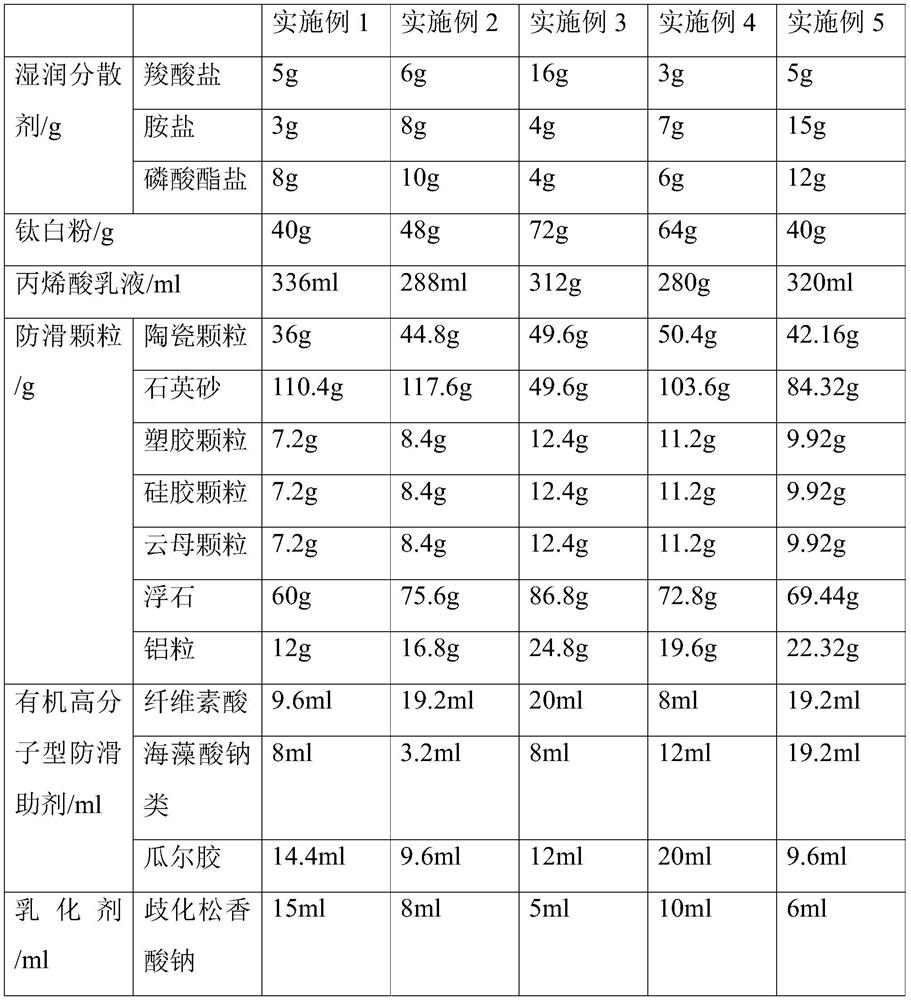

Water-based anti-skid coating and preparation method thereof

ActiveCN113214710AImprove bindingStable physical and chemical propertiesCoatingsFirming agentSuspending Agents

The invention provides a water-based anti-skid coating and a preparation method thereof. The water-based anti-skid coating comprises a component A and a component B. The component A comprises, by mass, 8-10 parts of water, 35-40 parts of an acrylic emulsion, 30-35 parts of anti-skid particles with a particle size range of 0.2-2 mm and 15-30 parts of a functional auxiliary agent, and the component B is a water-based acrylic curing agent; and the functional auxiliary agent comprises 0.5-2 parts of a suspending agent, 1-5 parts of an emulsifier and 4-5 parts of an organic polymer anti-skid auxiliary agent. The invention relates to the water-based anti-skid coating which comprises 30-35 parts of the anti-skid particles with the particle size range of 0.2-2mm, the anti-skid particles can be stably combined with an emulsion coating and are stable in physicochemical property, and due to the fact that the particle size of the anti-skid particles is controlled within 0.2-2 mm, the water-based anti-skid coating can be directly sprayed to a coated base material from a spray gun. Compared with an existing coating, the coating of the invention has the advantages of more convenient spraying mode and film forming speed, reduction of the existing process flow and saving of the construction time cost.

Owner:ZHANGJIAGANG TIANYUAN PAINTING & COATING APPL

New energy automobile tire performance detection system

ActiveCN112345274AThe detection work is real and effectiveConvenient detection workVehicle tyre testingNew energyAgricultural engineering

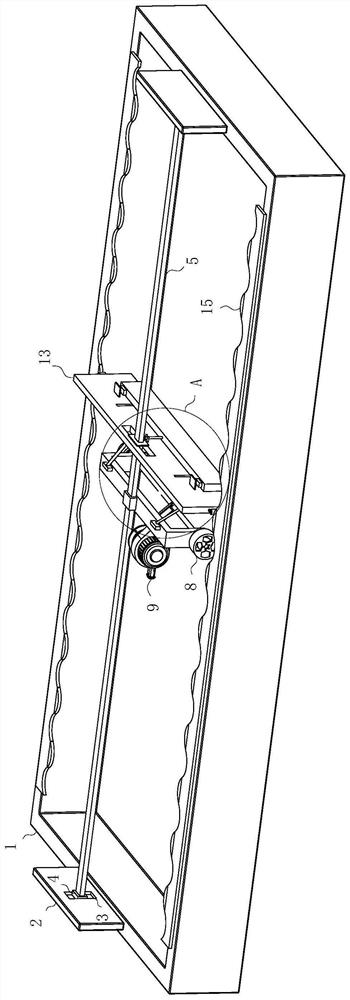

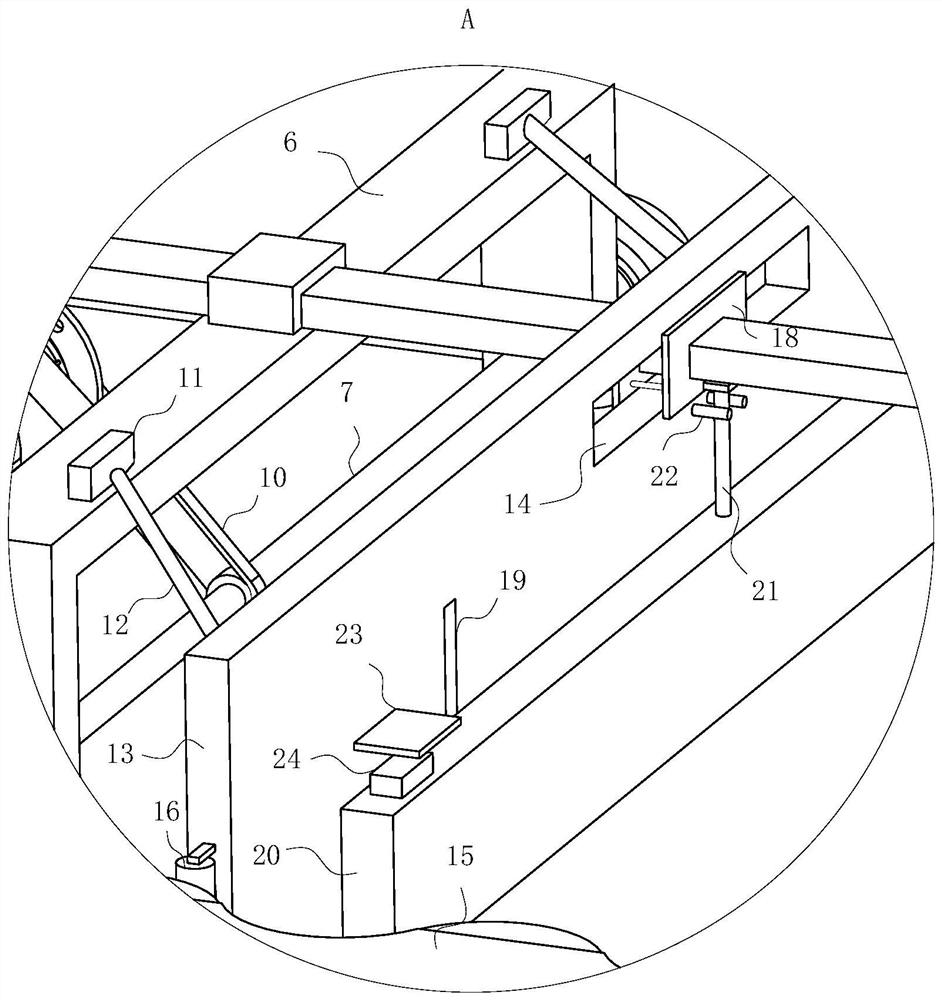

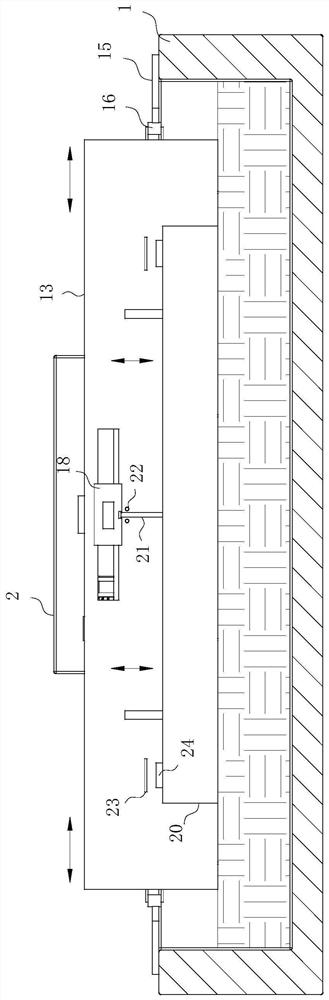

The invention belongs to the technical field of tire detection, and particularly relates to a new energy automobile tire performance detection system which comprises a box body, wherein an opening isformed in the top end of the box body, the box body is used for being filled with soil, two rectangular plates are fixed to the top end of the box body, sliding grooves are formed in the sides, whichare close to each other, of the two rectangular plates, sliding blocks are arranged in the two sliding grooves correspondingly, a limiting plate is fixed between the two sliding blocks, a support is slidably mounted at the bottom of the limiting plate, a rotating shaft is rotatably mounted at the bottom of the support, hubs are fixed to the two ends of the rotating shaft correspondingly, and a driving motor is fixed to the side wall of the support. According to the invention, the anti-skid performance of a mud tire is detected by simulating the outdoor situation indoors, so that the detectionwork is more real and effective, field on-site detection is not needed at the same time, great convenience is brought to the detection work, the detection efficiency is extremely high, and a large amount of detection cost is saved.

Owner:GUANGDONG INST OF SCI & TECH

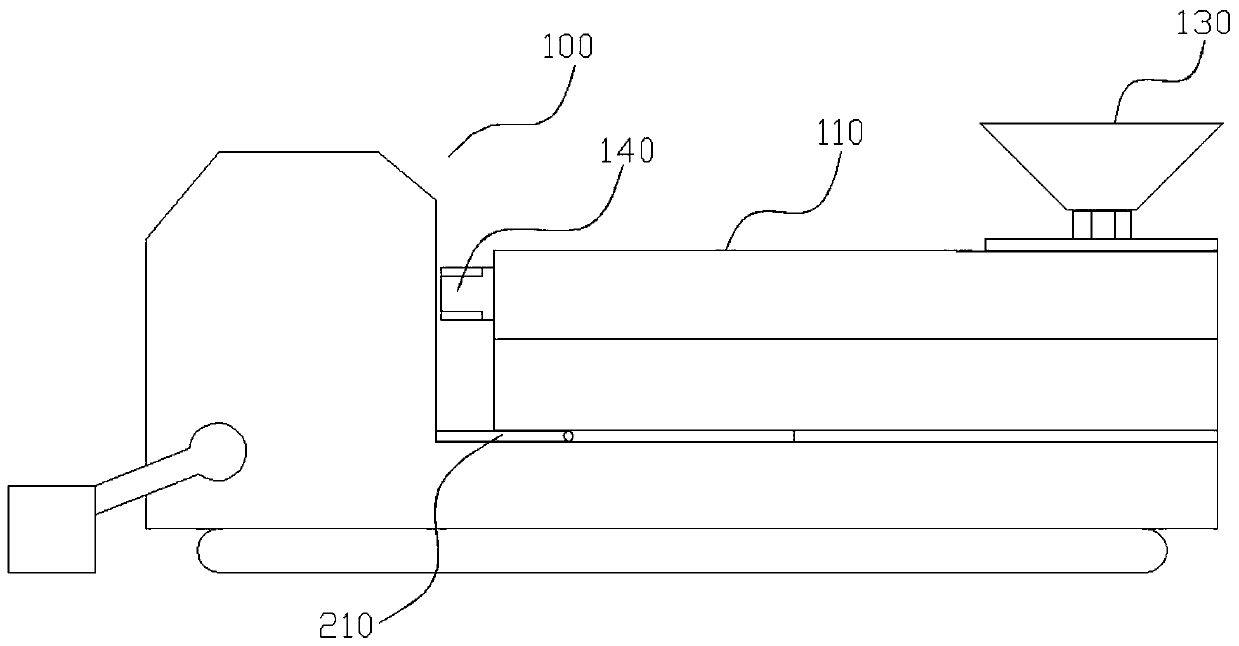

Paving device for highway base layer stabilized soil

ActiveCN110593052AImprove construction efficiencyGuaranteed structural strengthRoads maintainenceEngineeringSoil horizon

The invention relates to the technical field of road construction equipment, in particular to a paving device for highway base layer stabilized soil. The paving device involve a paving machine body, wherein a paving machine hopper is arranged on the paving machine body, a roller mounting cavity is formed in the paving machine hopper, a roller is arranged in the roller mounting cavity, and screw blades are arranged on the inner wall of the roller; and a material conveying belt is arranged below the paving machine hopper, a material conveying opening is formed on the end part, close to the material conveying belt, of the paving machine hopper, a discharging opening is formed on the side wall, close to the material conveying opening, of the roller, a feed opening is formed in the side wall, far away from the discharging opening, of the roller, the feed opening is a through hole with a circular section, a feeding hopper is arranged at the end part, close to the feeding opening, of the paving machine hopper, a feeding pipeline is arranged at the bottom end of the feeding hopper, and the end part of the feeding pipeline penetrates through the feeding opening to extend into the roller mounting cavity. According to the paving device, the phenomenon that the stabilized soil paved on highway is segregated is avoided, the structural strength of a highway stabilized soil layer is ensured,and the construction efficiency of the highway stabilized soil paving operation is improved.

Owner:王莉华

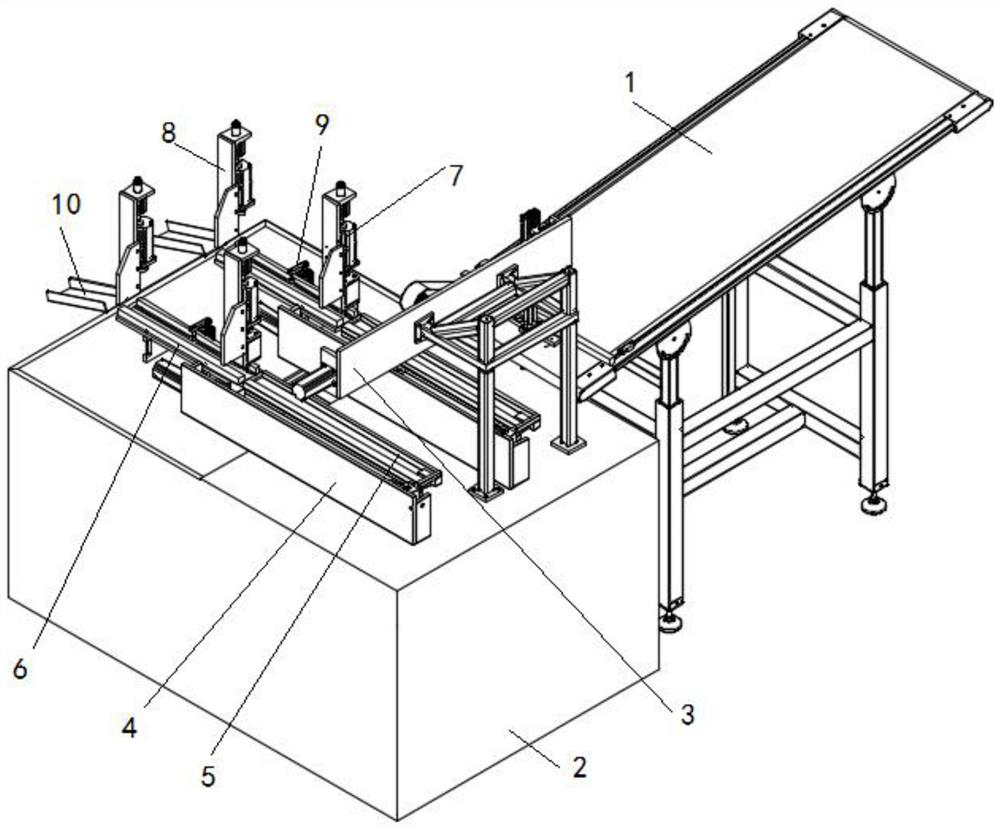

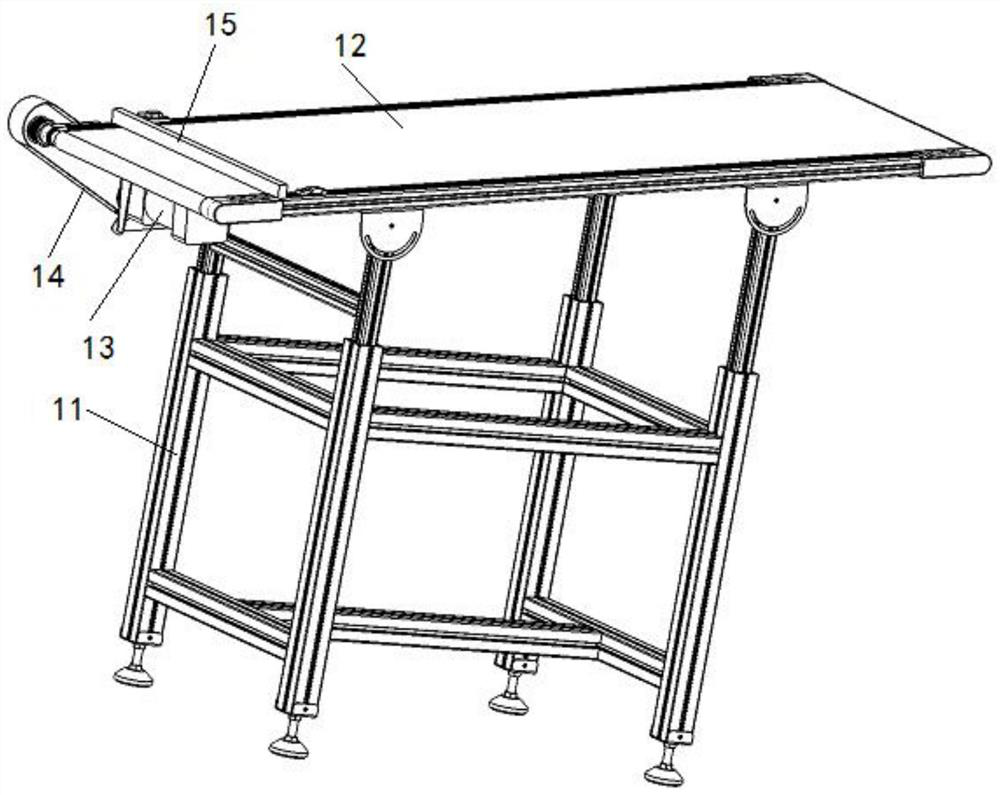

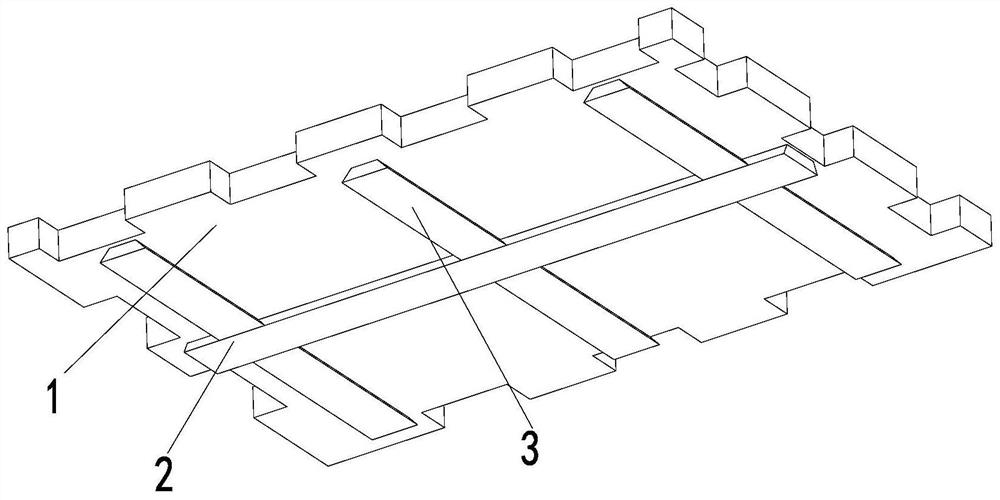

Cutting device and cutting method for composite steel plate processing

ActiveCN110815055BReduced range of movementEfficient use of surface areaAbrasive blasting machinesStructural engineeringMaterial transfer

The invention discloses a cutting device for composite steel plate machining and a cutting method of the cutting device. The cutting device comprises a feeding device and a machining platform. A material transfer device, translation devices, material clamping devices, conveying rails, pressing devices and finished material feeding openings are fixedly mounted on the machining platform. Gaps are reserved between the material clamping devices and the conveying rails, water cutting knives are arranged above the gaps, and gas spray heads are arranged above the positions, close to one ends of the finished material feeding openings, of the conveying rails. According to the cutting device, a composite steel plate is subjected to translation through the translation devices, the composite steel plate does not need to be located many times, the cutting distance of the water cutting knives in the horizontal direction is normally slightly larger than the width of the machined composite steel plate, and therefore the moving range of the water cutting knives is greatly narrowed, and the superficial area of the machining platform is effectively utilized; and by means of the cutting method, the situation that a steel plate on the bottommost layer and adjacent layers and other layers bear pressure to be separated can be avoided, and cutting quality is improved.

Owner:HUAIBEI HUABO MACHINERY MFG

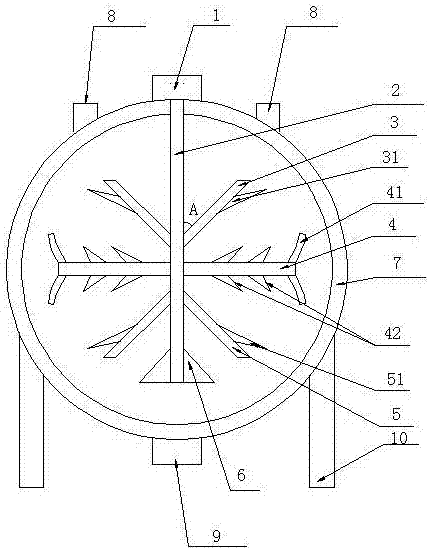

High-performance reaction kettle special for conductive slurry production

InactiveCN106964308AIncrease contact areaImprove mixing effectChemical/physical/physico-chemical stationary reactorsElectric machineryRight triangle

A special high-performance reactor for the production of conductive paste. The reactor housing is equipped with a motor, a stirring shaft, a feed inlet, a discharge outlet and support feet; the motor is fixed on the highest point of the top center of the reactor housing by bolts, The bottom is connected to the stirring shaft, and the stirring shaft is provided with a first stirring rod, a second stirring rod, a third stirring rod and a stirring bottom plate; each second stirring rod is provided with two arc rods and four first blades; The number of the first stirring rod is two. The first stirring rod is inclined on the stirring shaft, and the second blade is arranged on one side of the first stirring rod; the number of the third stirring rod is two, and the third stirring rod and the first stirring rod On the stirring shaft, the second stirring rod is used as the symmetrical axis, and it is arranged in axisymmetric manner; the shape of the stirring bottom plate is a right-angled triangle structure; the spherical reactor shell adopts a special stirring rod and a variety of blades to carry out mixing in all directions and from multiple angles. Avoid uneven distribution of the upper and lower slurry, and improve the use effect.

Owner:江苏昱星科技股份有限公司

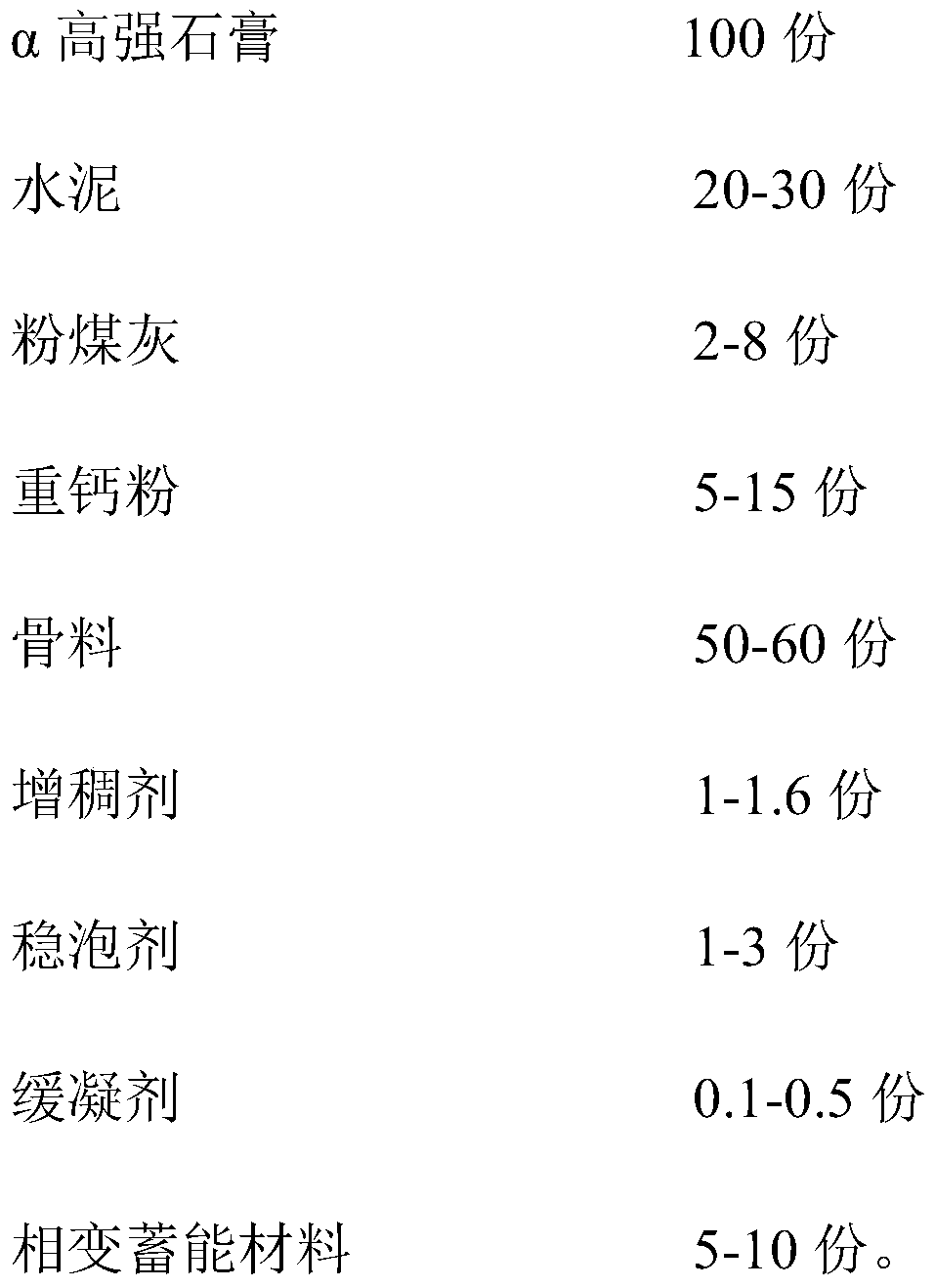

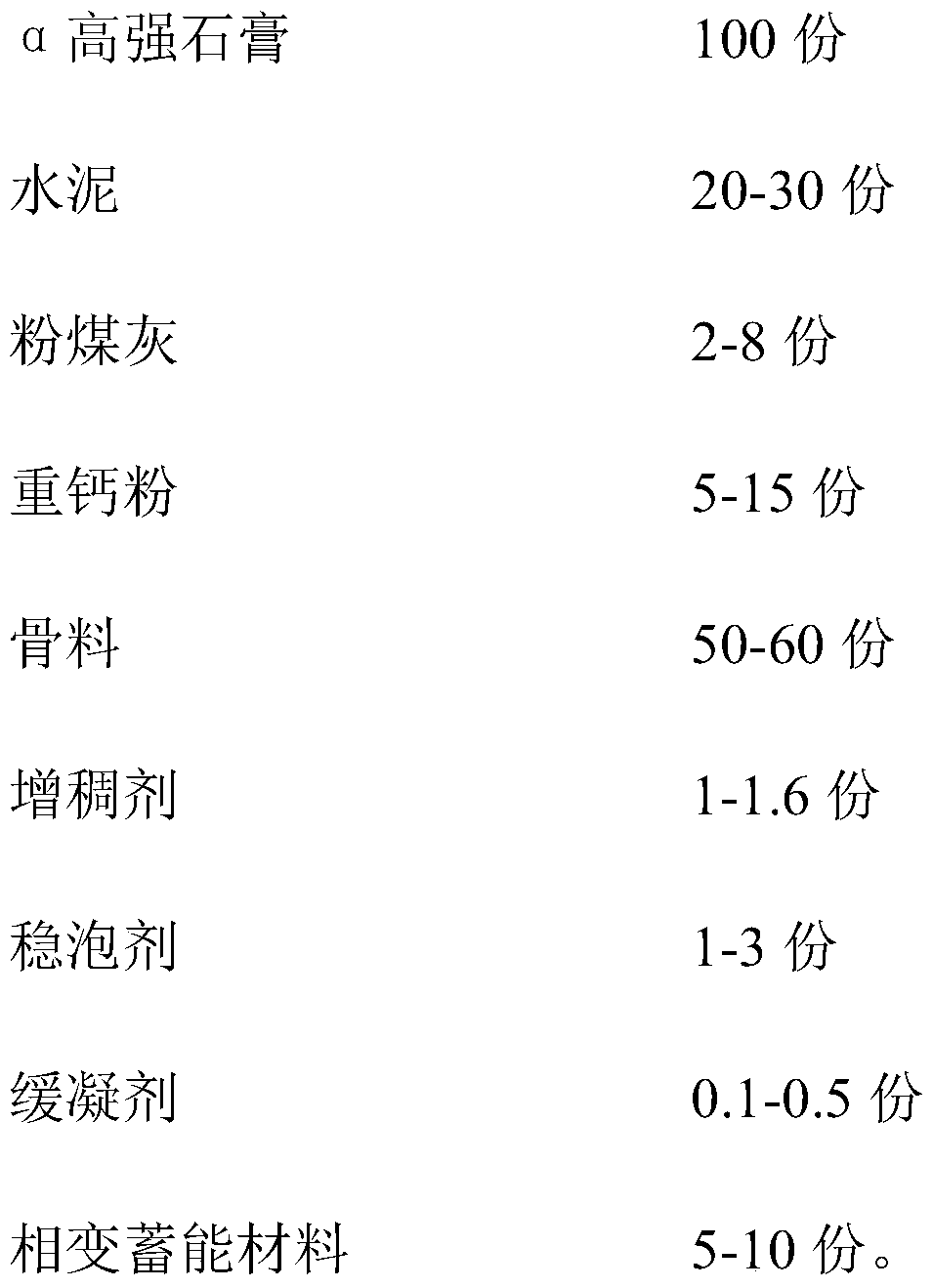

Self-leveling thermal-insulation mortar and preparation method thereof

The invention provides self-leveling thermal-insulation mortar and a preparation method thereof. The self-leveling thermal-insulation mortar takes high-strength alpha gypsum as a raw material, and uses cement, fly ash, coarse whiting powder, aggregate, a thickening agent, a foam stabilizer, a flocculating agent and a phase-change energy storage material as additives, so the thermal insulation effect of the thermal-insulation mortar is effectively improved, and cooling time is delayed. The preparation method is simple in steps and comprises the following concrete steps: preparing a composite phase-change material; pretreating the phase-change material; and mixing the phase-change material with the additives to prepare the self-leveling thermal-insulation mortar. The self-leveling thermal-insulation mortar has the advantages good mechanical properties, good thermal insulation effect and good latent heat energy storage effect, can effectively reduce a heat dissipation speed so as to achieve the goal of energy saving and emission reduction, and has good market application prospects.

Owner:武汉每天建材科技有限公司

Tricholoma matsutake sauce and preparation method thereof

InactiveCN112772900AMaintain strong flavorGuaranteed hardnessFood scienceBiotechnologyMonosodium glutamate

The invention relates to the technical field of seasoning sauce processing, and discloses a tricholoma matsutake sauce preparation method, which comprises the following steps: placing dried tricholoma matsutake in an enzymolysis mushroom liquid, dipping, and dicing to make the rehydration ratio be 2.5-3.5 so as to obtain rehydrated tricholoma matsutake; sequentially coating the surface of the rehydrated tricholoma matsutake with egg yolk liquid and starch, and putting the rehydrated tricholoma matsutake into a frying pan to be fried until the surface is golden yellow; cooking beans until the beans are cooked, grinding the cooked beans into bean paste, and adding egg yolk powder; and taking refined edible oil, putting the refined edible oil into a pot, heating until the oil temperature is 80-100 DEG C, adding the bean paste, bean halves, white sugar, monosodium glutamate, chili oil, minced ginger, minced garlic and the five spice powder, stir-frying for 3-5 minutes, adding the fried tricholoma matsutake, continuously stir-frying for 1-2 minutes, taking the tricholoma matsutake out of the pot while the tricholoma matsutake is hot, filling and sterilizing to obtain a finished product. According to the tricholoma matsutake sauce disclosed by the invention, the mushroom grains are elastic and chewy, the sauce is soft and fine, and the seasoning sauce is matched with mushrooms, beans, fatty acid and protein, contains various micromolecular amino acids, and is rich in nutrition.

Owner:木里县巴登拉姆农业投资有限责任公司

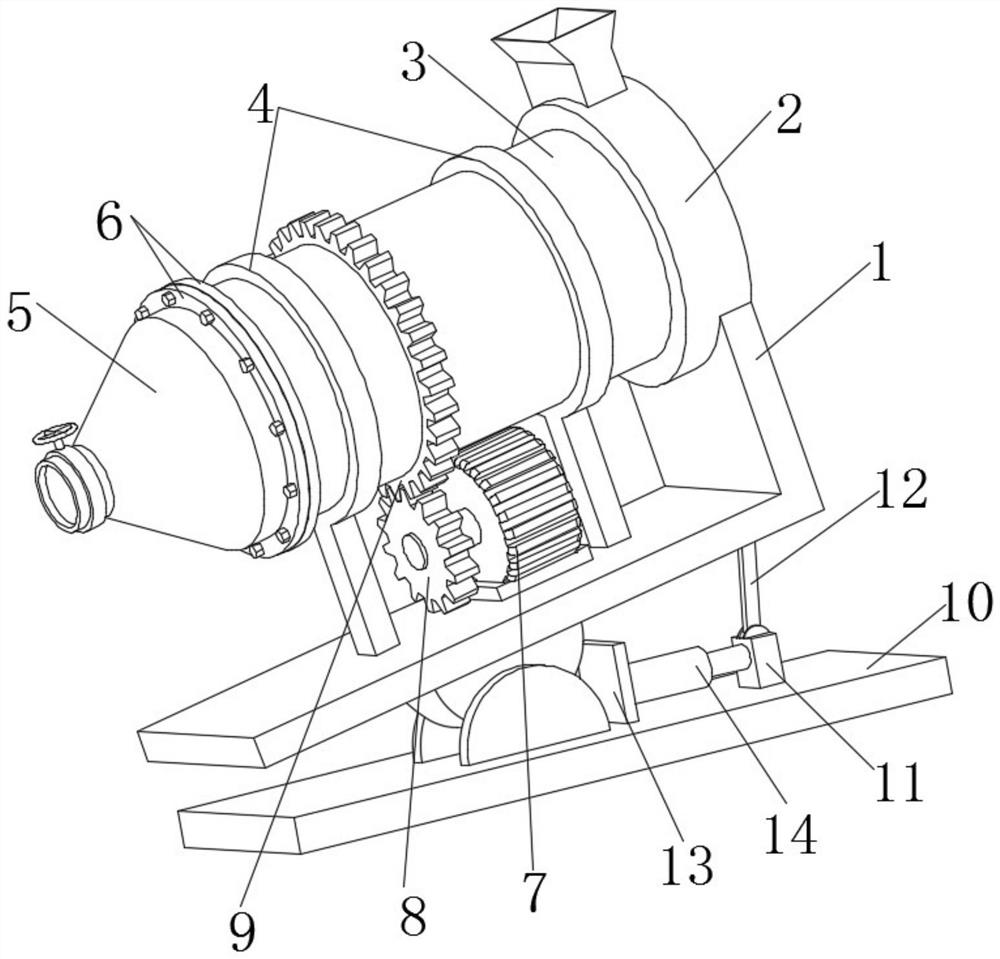

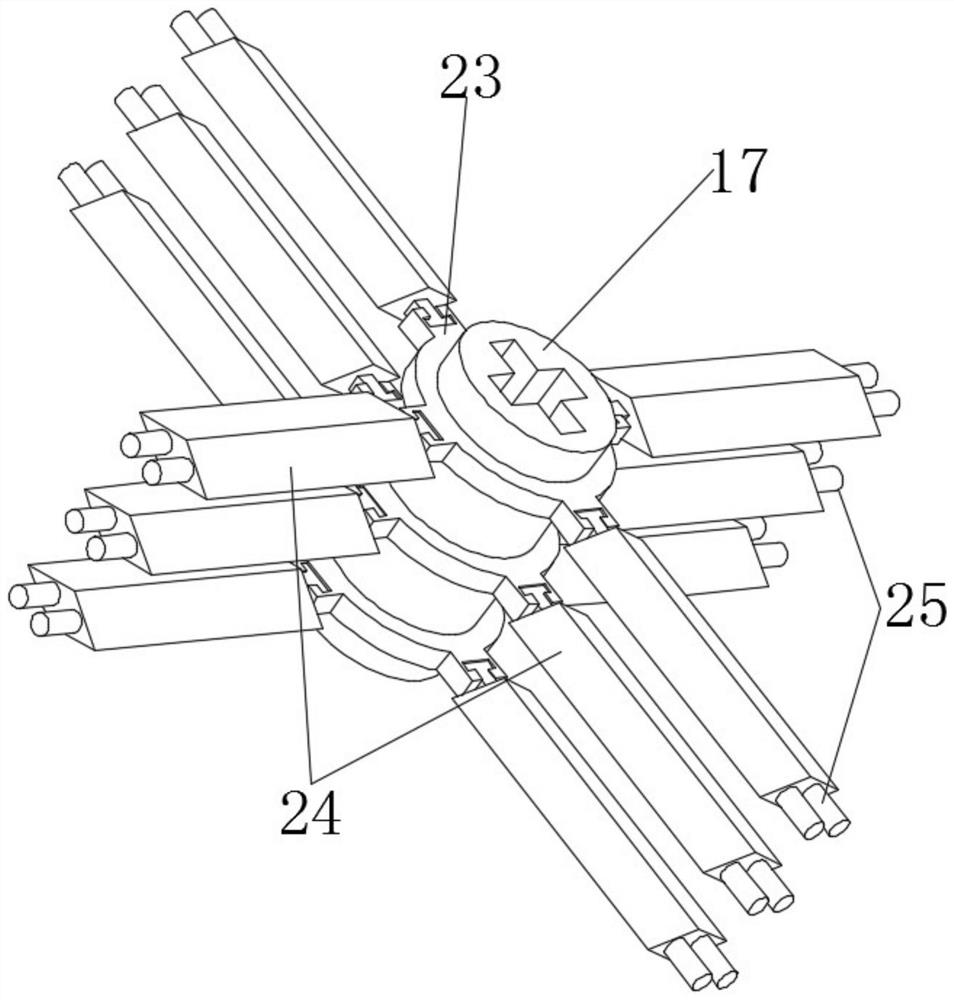

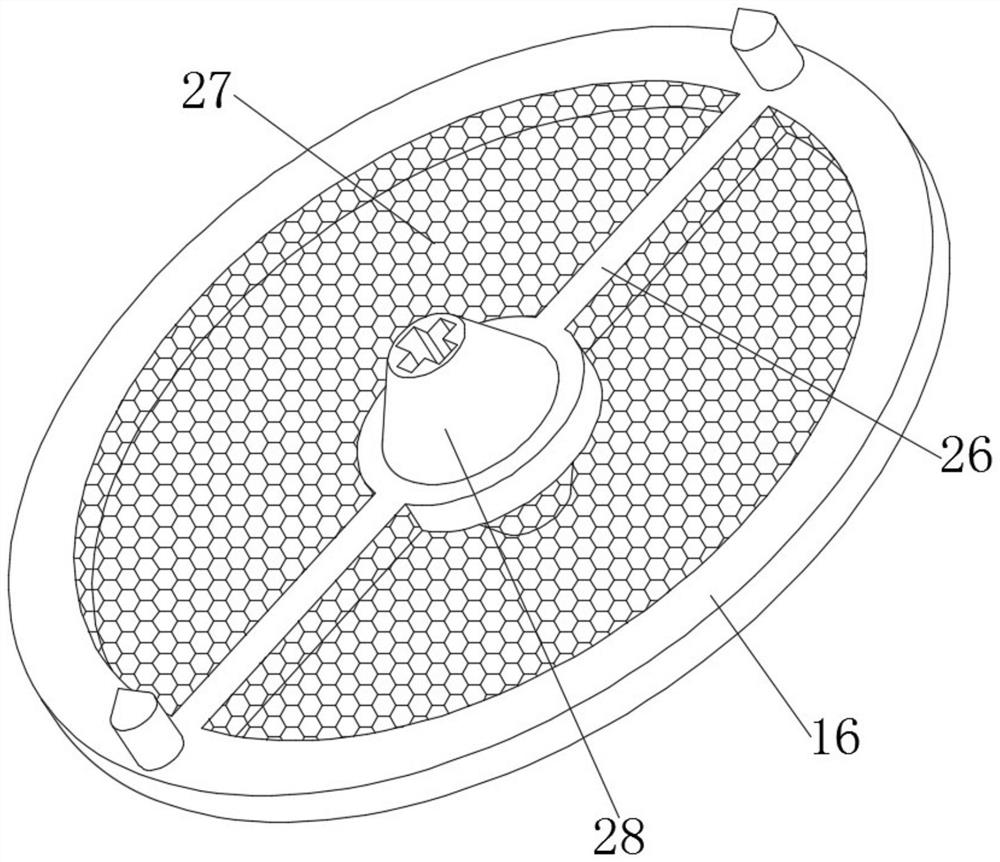

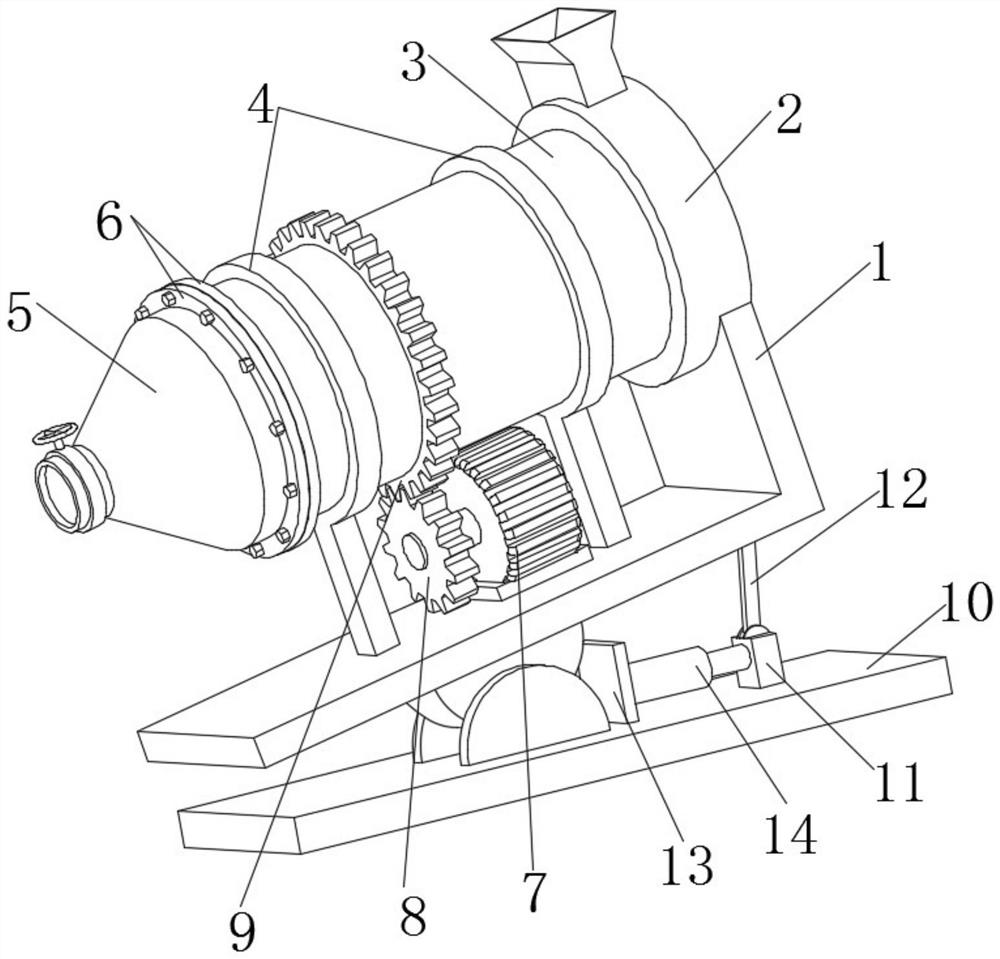

Material mixing device for house building construction

ActiveCN112109205AEvenly brokenPrevent stratificationCement mixing apparatusGrain treatmentsArchitectural engineeringElectric machinery

The invention discloses a material mixing device for house building construction. The material mixing device for house building construction comprises a connecting base, the connecting base is of an L-shaped structure, a connecting disc is fixedly connected to the upper portion of the right side of the connecting base, a rotary drum is rotatably connected to the left side of the connecting disc, aconnecting shell is arranged on the left side of the rotary drum, a feeding port is formed in the upper portion of the connecting disc, a discharging port is formed in the left side of the connectingshell, a valve is arranged in the discharging port, connecting tables are fixedly connected to the left side of the rotary drum and the right side of the connecting shell, the two connecting tables are connected through bolts, a foundation is arranged below the connecting base, the foundation is hinged to the middle of the connecting base, a baffle is fixedly connected to the hinged position of the right side of the foundation, an electric push rod is fixedly connected to the right side of the baffle, two connecting rings are rotationally connected to the two sides of the rotary drum, the lower ends of the connecting rings are fixedly connected with the connecting base, a motor is fixedly connected to the position, located between the two connecting rings, of the connecting base, a connecting shaft is fixedly connected to the middle of the connecting disc, and the connecting shaft is of a cross-shaped structure located in the rotary drum. According to the material mixing device for house building construction, the purpose of avoiding layering and crushing caked and large-particle raw materials is achieved.

Owner:泰州淳蓝环保科技有限公司

Cutting device for composite steel plate machining and cutting method of cutting device

ActiveCN110815055AReduced range of movementEfficient use of surface areaAbrasive blasting machinesStructural engineeringMaterial transfer

The invention discloses a cutting device for composite steel plate machining and a cutting method of the cutting device. The cutting device comprises a feeding device and a machining platform. A material transfer device, translation devices, material clamping devices, conveying rails, pressing devices and finished material feeding openings are fixedly mounted on the machining platform. Gaps are reserved between the material clamping devices and the conveying rails, water cutting knives are arranged above the gaps, and gas spray heads are arranged above the positions, close to one ends of the finished material feeding openings, of the conveying rails. According to the cutting device, a composite steel plate is subjected to translation through the translation devices, the composite steel plate does not need to be located many times, the cutting distance of the water cutting knives in the horizontal direction is normally slightly larger than the width of the machined composite steel plate, and therefore the moving range of the water cutting knives is greatly narrowed, and the superficial area of the machining platform is effectively utilized; and by means of the cutting method, the situation that a steel plate on the bottommost layer and adjacent layers and other layers bear pressure to be separated can be avoided, and cutting quality is improved.

Owner:HUAIBEI HUABO MACHINERY MFG

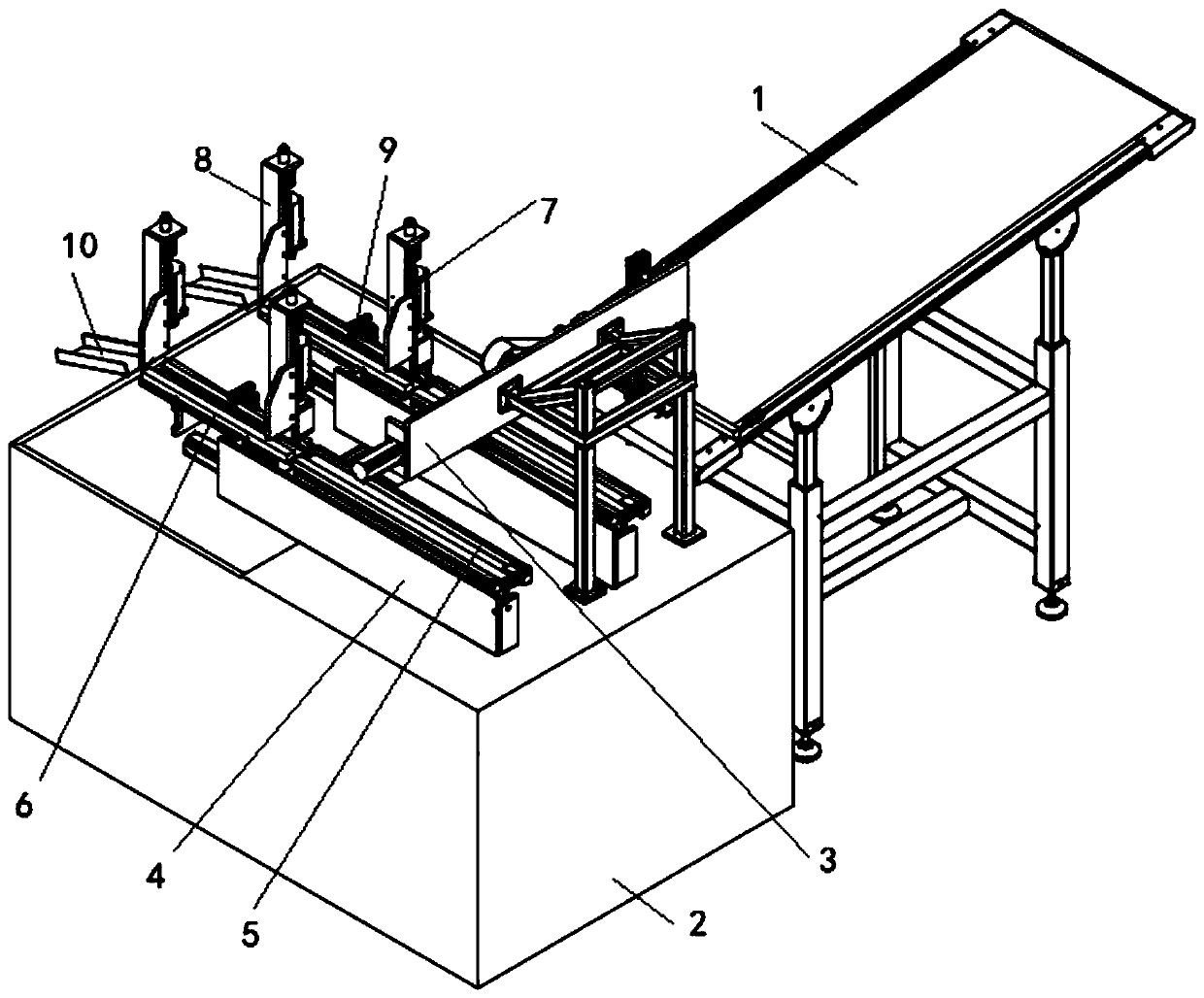

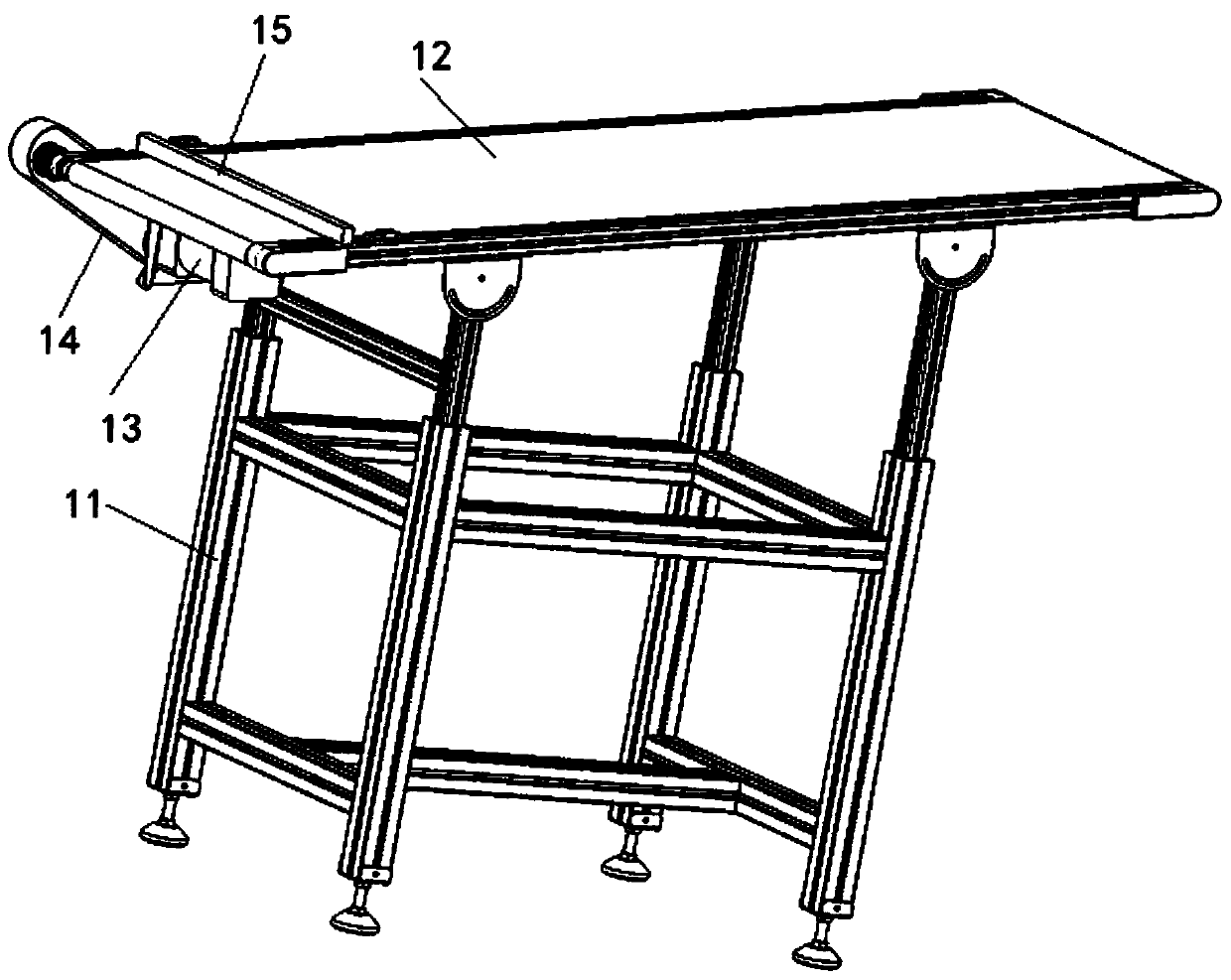

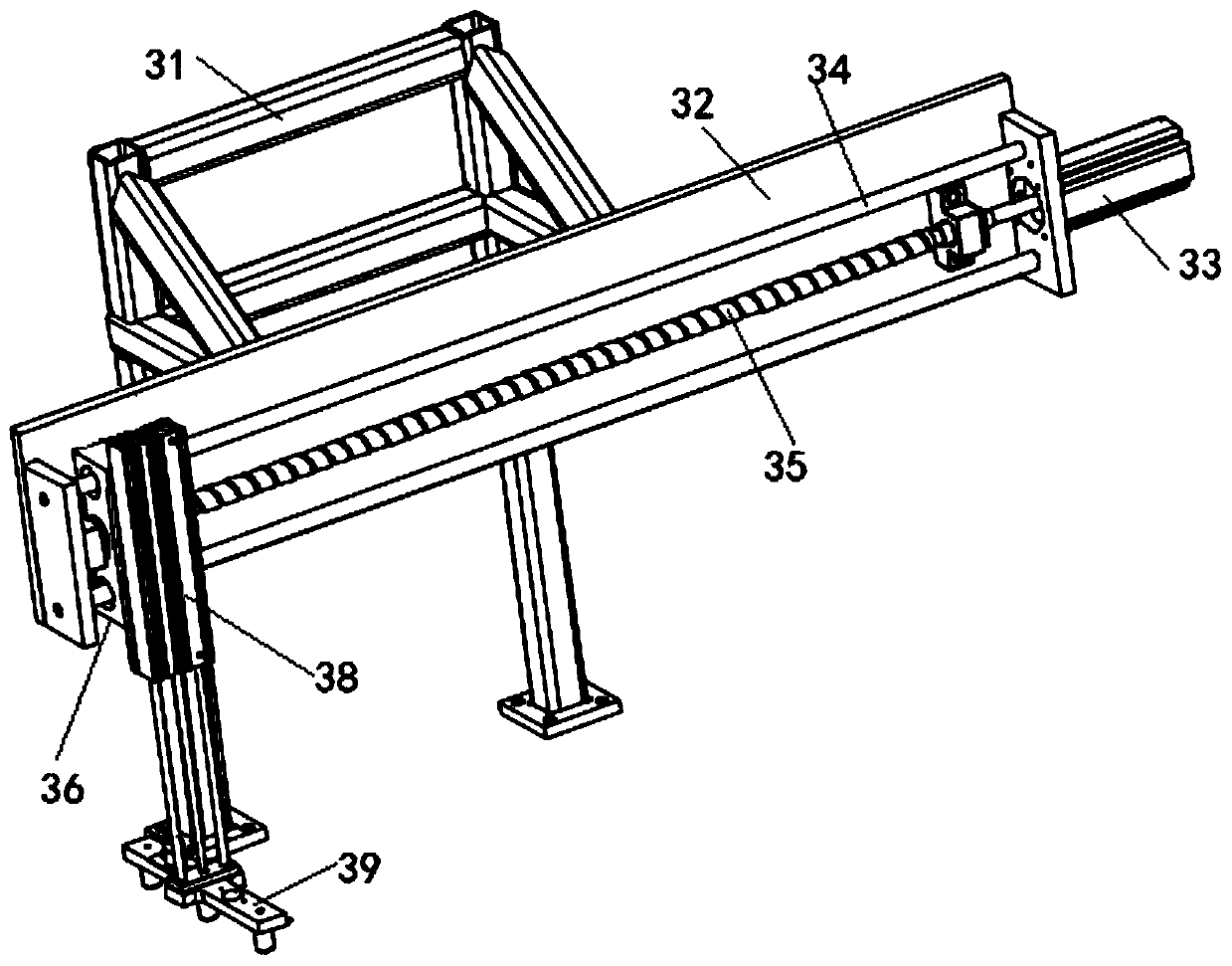

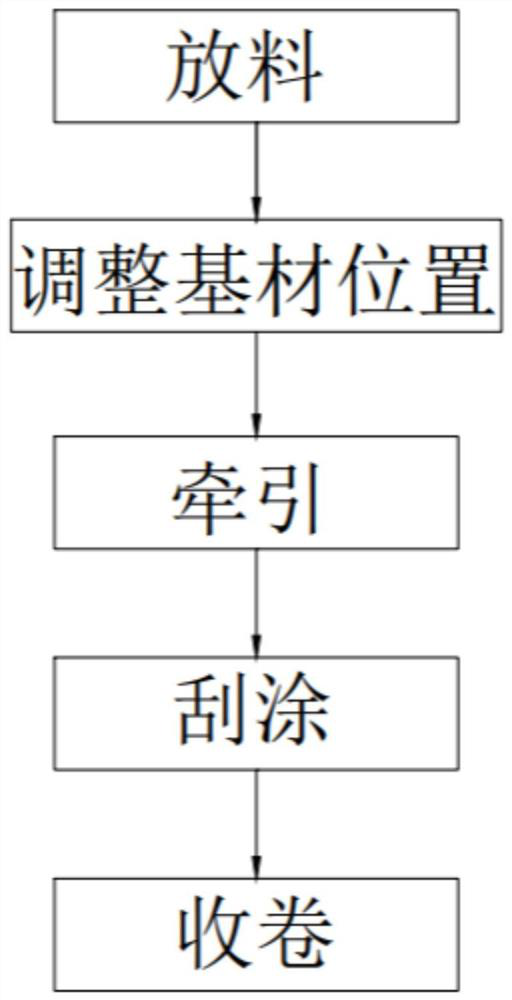

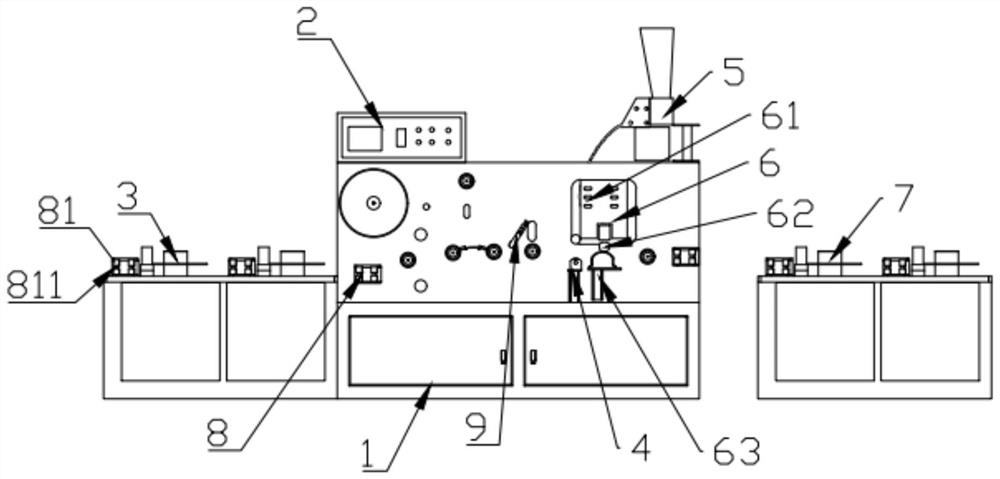

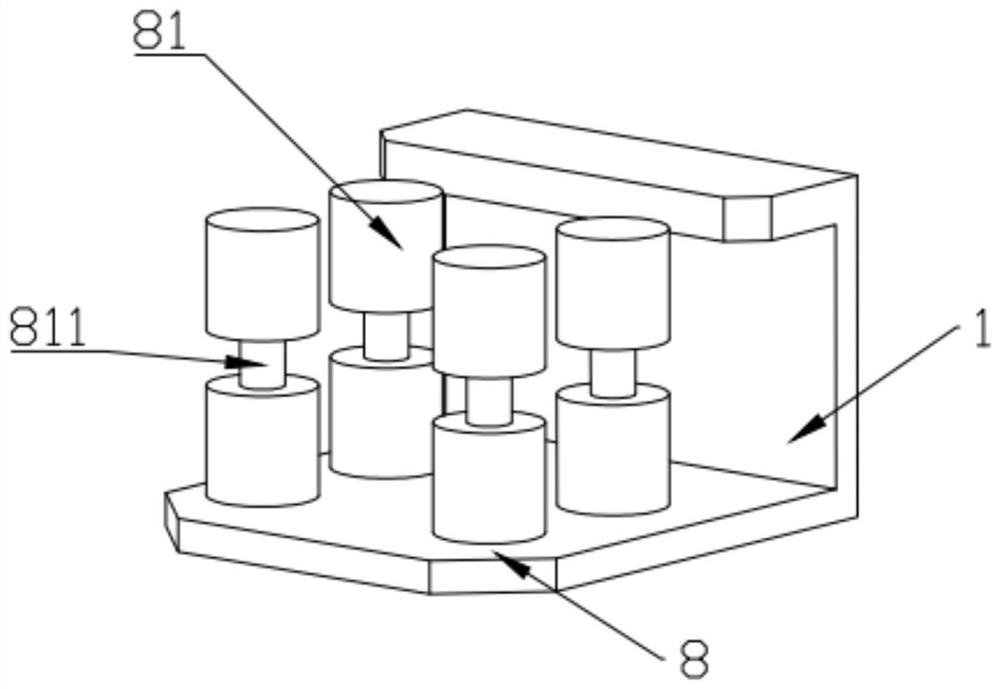

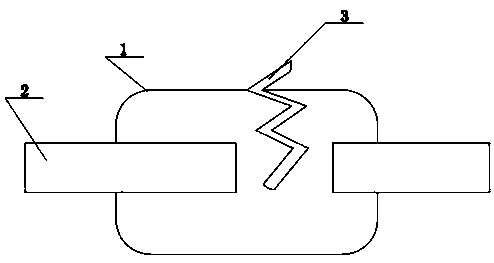

Furniture edge sealing strip processing process and device

InactiveCN113262948APrevent stratificationImprove the effect of edge bandingLiquid surface applicatorsCoatingsMolten stateMachining process

The invention relates to the technical field of edge sealing strip processing, in particular to a furniture edge sealing strip processing process and device. According to the furniture edge sealing strip processing process, a precise scraper is adopted for blade coating a base material with back coating glue in a molten state, the situation that the back coating glue and the base material are layered is effectively avoided, and the blade coating effect is good. The furniture edge sealing strip processing device comprises a rack and a control component and further comprises a material placing component, a traction component, a glue pre-melting component, a blade coating component and a winding component which are sequentially arranged on the rack and correspondingly connected with the control component, and the blade coating component is provided with a glue melting hopper. The furniture edge sealing strip processing device is simple and reasonable in structural design, automatic processing and production can be realized, by means of the arrangements of the glue pre-melting component and the glue melting hopper, in the processing process, part of molten back coating glue flowing out of the glue pre-melting component can be molten in the glue melting hopper, the processing temperature range is wider, and the heating efficiency is high, the heating efficiency is effectively improved, furthermore, the furniture edge sealing strip processing process and device are suitable for blade coating of high-melting-point materials, and the application range of the furniture edge sealing strip processing process and device is made to be wider.

Owner:何惠玲

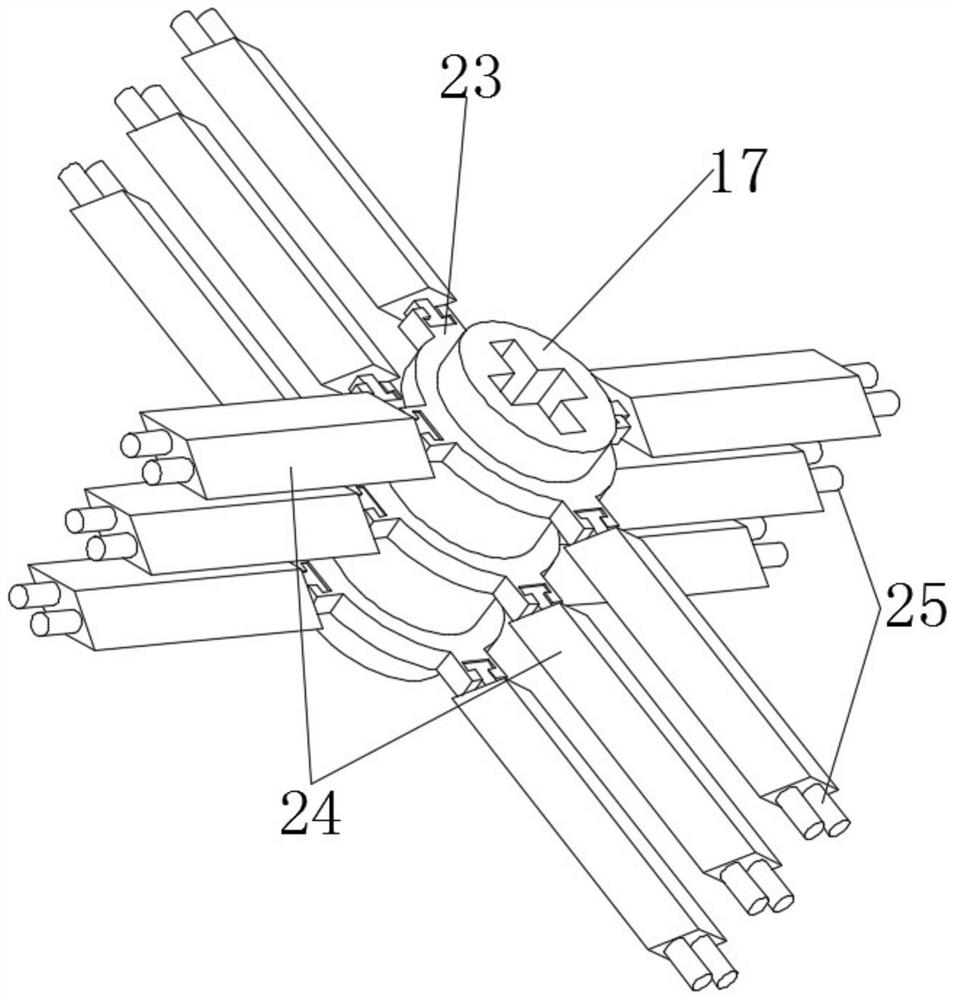

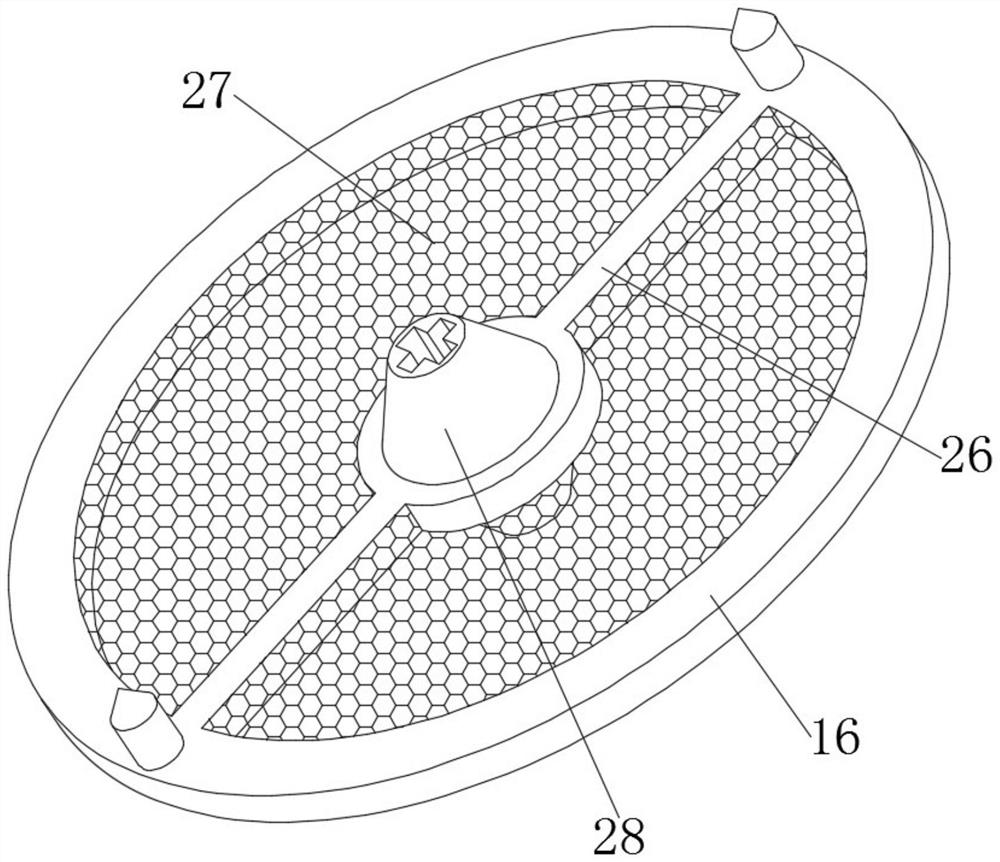

Process invention about CCGA welding column

InactiveCN111230325AHave a cooling effectNot prone to voids, oxidation and other problemsLaser beam welding apparatusLaser processingShielding gas

The invention provides a process invention about a CCGA welding column and relates to the field of CCGA welding column welding material industry. The process invention about the CCGA welding column iscomposed of a gas protection device, a material and a laser generator, wherein the gas protection device comprises a material inlet, a material outlet and a gas protection device shell, the materialinlet and the material outlet are arranged in the two sides of the gas protection device shell, and the laser generator is arranged above the inner edge of the gas protection device shell. The processinvention about the CCGA welding column has the beneficial effects that the process invention about the CCGA welding column is simple in structure and wide in adaptability, by means of the process invention about the CCGA welding column, a laser processing method is adopted to perform surface nondestructive processing inside the gas protection device filled with an inert gas, compared with a traditional processing process mainly based on pouring, cavitation, oxidation and other problems are not prone to appearing in finished products, the inert gas performs a cooling effect and serves as a shielding gas, mixing in of oxygen is reduced, the oxidation of the processed and molded material in the air is reduced, and the layering situation of a chip on a final product due to oxidation is prevented.

Owner:上海锡喜材料科技有限公司

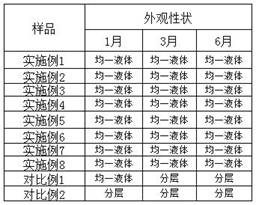

Tilmicosin solution and preparation method thereof

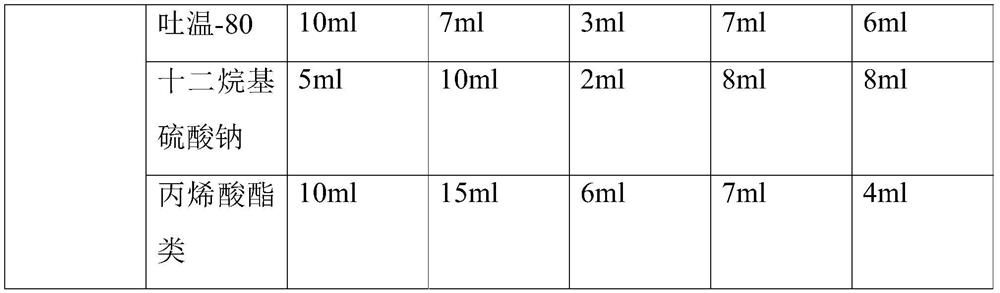

ActiveCN114796108ASimple processImprove solubilityAntibacterial agentsOrganic active ingredientsEster sulfateTilmicosin

The invention provides a tilmicosin solution and a preparation method thereof, and solves the technical problems that the existing tilmicosin solution is inevitably layered after being stored for a long time, and the quality guarantee storage and subsequent use of a product are influenced. The tilmicosin solution is prepared from the following raw materials in parts by weight: 1-2 parts of hydroxypropyl methylcellulose, 0.1-0.2 part of a raw material A, 8-12 parts of tilmicosin and a proper amount of purified water; wherein the viscosity of the hydroxypropyl methylcellulose ranges from 3 mPas to 2000 mPas; the raw material A is one of sodium alginate, sulfate alginate and sodium alginate polysaccharide diester; the invention further discloses a preparation method of the tilmicosin solution. The invention can be widely applied to the technical field of pharmaceutical preparations.

Owner:SHANDONG GUOBANG PHARMA +1

Ultraviolet sterilization device for sewage treatment and treatment method thereof

ActiveCN111892122AImprove the bactericidal effectGood light transmission stateWater/sewage treatment by irradiationSpecific water treatment objectivesEngineeringSewage treatment

The invention discloses an ultraviolet sterilization device for sewage treatment and a treatment method thereof. The ultraviolet sterilization device includes a housing, the lower end of the shell isfixedly connected with a plurality of supporting blocks, and a treatment chamber is arranged in the shell; a liquid inlet is formed in the inner top of the treatment chamber; a liquid outlet is formedin the inner bottom of the treatment chamber; two vertical cavities are symmetrically formed in the shell and located on the two sides of the treatment chamber correspondingly, a rotating rod is rotatably connected between the inner walls of the two sides of the treatment chamber, a sliding rod is fixedly connected between the inner walls of the two sides of the treatment chamber, sliding blocksare arranged on the rotating rod and the sliding rod in a penetrating mode, and a threaded layer is arranged on the rotating rod. When the sterilization device is used, an ultraviolet lamp for sterilization is in a moving state, the sterilization range is enlarged, meanwhile, in the moving process, the surface of the sterilization lamp can be scraped and cleaned, and it is guaranteed that the sterilization lamp is in a high-light-transmission state all the time.

Owner:GUANGDONG XINGPU ENERGY SAVING LIGHT CO LTD

An ultraviolet sterilizing device for sewage treatment and its treatment method

ActiveCN111892122BImprove the bactericidal effectGood light transmission stateWater/sewage treatment by irradiationSpecific water treatment objectivesSewage treatmentMechanical engineering

The invention discloses an ultraviolet sterilizing device for sewage treatment and a treatment method thereof, which comprises a casing, a plurality of support blocks are fixedly connected to the lower end of the casing, a processing chamber is arranged inside the casing, and a processing chamber is disposed inside the casing. The top is provided with a liquid inlet, the inner bottom of the processing chamber is provided with a liquid outlet, and two vertical cavities are symmetrically arranged in the housing, and the two vertical cavities are respectively located on both sides of the processing chamber. Rotating rods are connected between the inner walls on both sides of the treatment chamber, and sliding bars are fixedly connected between the inner walls on both sides of the treatment chamber. The rotating rods and the sliding rods are provided with sliders, and the rotating rods are provided with threaded layers. . When the sterilizing device is in use, the sterilizing ultraviolet lamp is in a moving state to increase the range of sterilization. At the same time, in the process of moving, the surface of the sterilizing lamp can be scraped and cleaned to ensure that the sterilizing lamp is always in a high light transmission. sexual state.

Owner:GUANGDONG XINGPU ENERGY SAVING LIGHT CO LTD

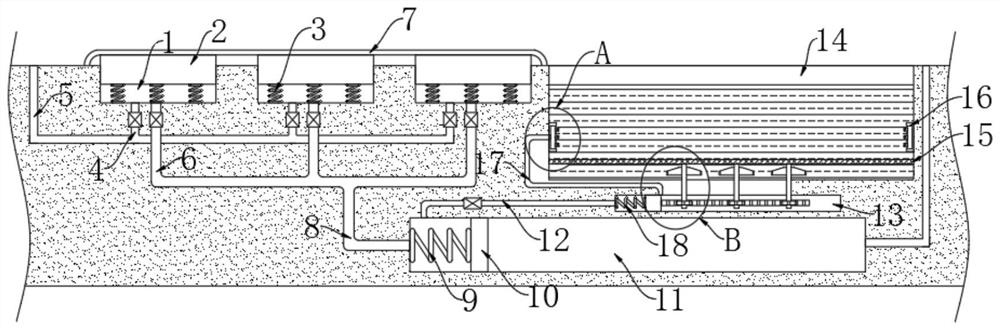

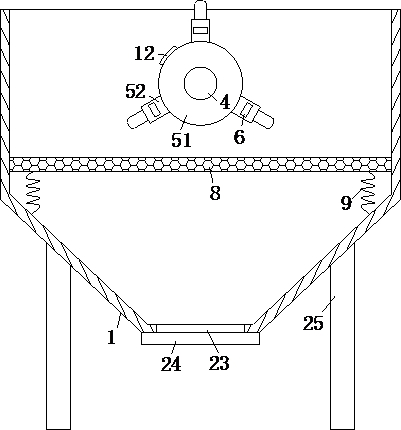

Animal hoof medicated bath system for livestock breeding

PendingCN111728733APrevent stratificationGood effectVeterinary washing devicesCrop livestockLivestock breeding

The invention discloses an animal hoof medicated bath system for animal breeding. The animal hoof medicated bath system comprises a medicated bath tank, a plurality of sliding grooves and a pressure accumulation mechanism. The medicated bath tank and the sliding grooves are all located in the ground, and the ground is internally provided with a horizontal cavity and a strip cavity; the pressure accumulation mechanism includes sliding blocks respectively and slidably connected in the sliding grooves, the lower ends of the sliding blocks are elastically connected to the inner bottoms of the corresponding sliding grooves through first connection springs, the spaces, located below the sliding blocks, of the sliding grooves communicate with air inlet pipes, the ends, away from the correspondingsliding grooves, of the air inlet pipes jointly communicate with a first main pipeline, the end, away from the air inlet pipes, of the first main pipeline communicate with outside, and the spaces, located below the sliding blocks, of the sliding grooves communicate with air outlet pipes. In the system, pressure is accumulated by animals passing through the pressure accumulating mechanism to drivea disturbance mechanism and an impact mechanism to work, so that a medicine and water are mixed extremely even, the occurrence of stratification is avoided, and the overall medicated bath effect is improved.

Owner:徐任妹

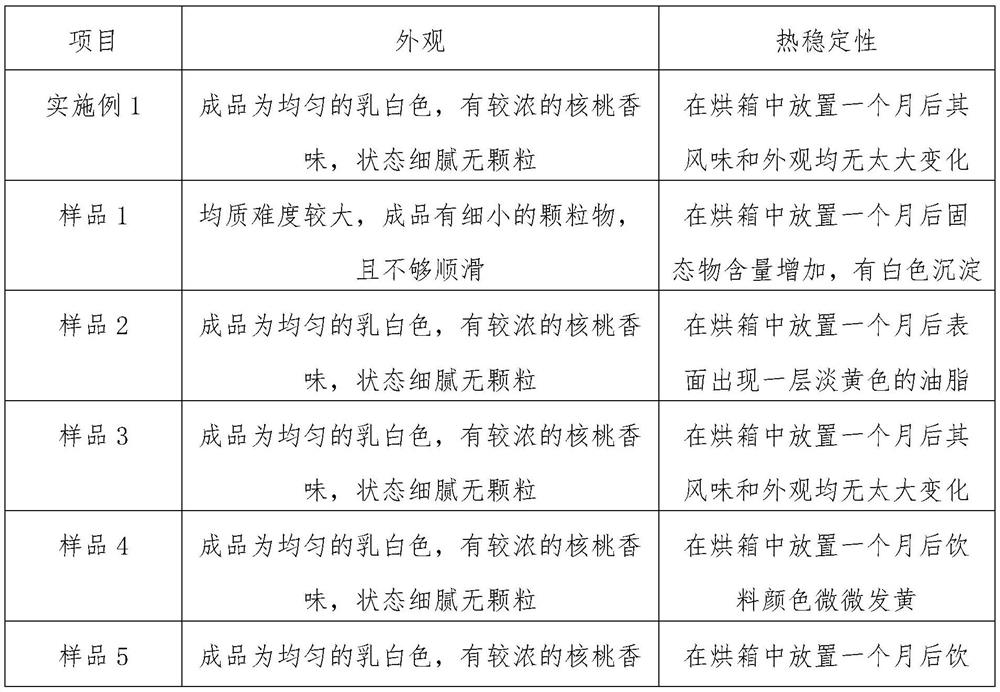

Walnut endosperm protein beverage and preparation method thereof

The invention belongs to the technical field of food processing, and particularly relates to a walnut endosperm protein beverage and a preparation method thereof. The walnut kernels, walnut seed coatsand walnut shells are extracted respectively, all parts of walnuts are fully utilized, and the additional cost of a factory is reduced. The walnut kernels are subjected to enzymolysis, refining and other treatment, endosperm protein of the walnut kernels is decomposed into polypeptide small molecules and used for making walnut beverages, and protein in walnuts is reserved in the beverages to themaximum extent; the walnut shells and the walnut seed coats are respectively extracted to prepare the walnut essential oil and an antioxidant, so that the nutritional ingredients of the walnut beverage are further enriched, and the shelf life of the beverage can be prolonged under the condition of not adding preservatives.

Owner:黔西南州蒂辉生物科技有限公司

A kind of soft tissue repair collagen membrane and preparation method thereof

ActiveCN114053480BImprove uniformityPrevent stratificationTissue regenerationProsthesisTissue repairSlurry coating

The invention relates to a soft tissue repair collagen film and a preparation method thereof. The preparation method comprises the following steps: adding type I collagen to the acetic acid solution to prepare a collagen-acetic acid swelling solution; then adding sodium chondroitin sulfate, stirring evenly to obtain a collagen-chondroitin sulfate sodium slurry; The collagen chondroitin sulfate sodium slurry is defoamed, then freeze-dried and pressed to obtain a collagen basement membrane; the collagen chondroitin sulfate sodium slurry is poured between two layers of the collagen base membrane, and Slurry is applied to make the thickness of the slurry uniform and smooth without air bubbles to obtain a pre-collagen film; the pre-collagen film is firstly subjected to secondary freeze-drying, and then sequentially cross-linked and sterilized to obtain the collagen film for soft tissue repair. Among them, the slurry defoaming process is added to reduce the phenomenon of holes and delamination on the membrane surface caused by air bubbles in the production process; and the use of a slurry coating device greatly improves the uniformity of the membrane thickness and avoids the occurrence of delamination.

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

A mixing device for building construction

ActiveCN112109205BEvenly brokenPrevent stratificationCement mixing apparatusGrain treatmentsArchitectural engineeringElectric machinery

The invention discloses a material mixing device for building construction, which comprises a connecting seat, the connecting seat has an L-shaped structure, a connecting plate is fixedly connected to the upper right side of the connecting seat, and a rotating cylinder is connected to the left side of the connecting plate in rotation. There is a connection shell on the left side of the drum, a feed port on the top of the connection plate, a discharge port on the left side of the connection shell, and a valve at the discharge port. The left side of the drum and the right side of the connection shell are fixed. There is a connection platform, and the two connection platforms are connected by bolts. There is a base under the connection seat. The base and the connection seat are hinged in the middle. The right side of the base is fixed at the hinge and connected to the baffle. There is an electric push rod, and two connecting rings are connected to the two sides of the rotating drum. The lower end of the connecting ring is fixedly connected to the connecting seat. The connecting seat is located in the middle of the two connecting rings and is fixedly connected to the motor. Connecting shaft, the connecting shaft is located in the cross-shaped structure in the rotating drum, the mixing device for building construction can achieve the purpose of avoiding stratification, breaking agglomerates and raw materials with large particles.

Owner:泰州淳蓝环保科技有限公司

A kind of preparation method of beryllium copper casting roll sleeve and beryllium copper casting roll sleeve

The invention discloses a method for preparing a beryllium-copper casting roll sleeve, comprising: step 1, preparing raw materials; step 2, melting metal copper, metal nickel and metal cobalt, and then sequentially melting copper-beryllium master alloy, silicon, metal magnesium, and metal iron Melting and casting followed by metal aluminum; Step 3, homogenizing the ingot; Step 4, adopting a direction of 45° with the axial direction of the ingot, forging the homogenized ingot and sequentially Punching, reaming, ring rolling, heat treatment and machining. The invention also discloses a beryllium copper casting roll sleeve. The invention not only ensures the strength requirements of the beryllium copper casting roll sleeve, but also improves the hardness, conductivity and grain size of the beryllium copper casting roll sleeve, and can significantly improve the service life of the beryllium copper casting roll sleeve.

Owner:宁夏中色新材料有限公司

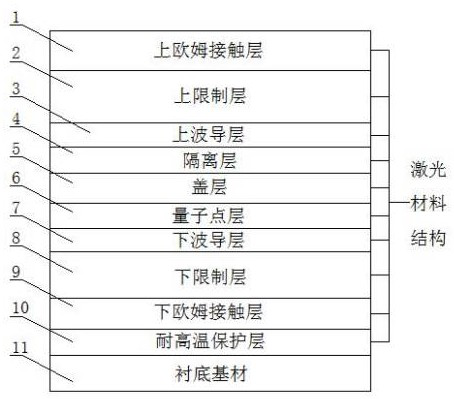

Photoelectric composite material and preparation method thereof

PendingCN113872050AImprove high temperature resistanceExtended service lifeLaser active region structureChemical vapor deposition coatingProtection layerLaser

The invention discloses a photoelectric composite material and a preparation method thereof. The photoelectric composite material comprises a high-temperature-resistant protective layer and a substrate base material, wherein the high-temperature-resistant protective layer is installed at the upper end of the substrate base material, a lower ohmic contact layer is arranged at the upper end of the high-temperature-resistant protective layer, and a lower limiting layer is arranged at the upper end of the lower ohmic contact layer. The high-temperature-resistant protective layer is additionally arranged between the traditional photoelectric composite material and the substrate base material, due to the fact that a main body of the photoelectric composite material is a laser material, and the high-temperature-resistant protective layer is additionally arranged between the laser material and the substrate base material, the substrate base material and the laser material can be protected when the laser material is manufactured and normally used, the high-temperature-resistant protective layer has excellent high-temperature-resistant performance, under the influence of high temperature, the high-temperature-resistant protective layer can protect the laser material from being separated from the substrate base material, so that the service life of the whole laser material after being mounted on the substrate base material can be prolonged, and the use stability of the whole laser material can be improved.

Owner:河南亿维建筑材料有限公司

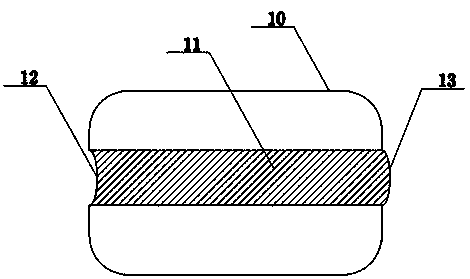

A kind of environment-friendly floor tile structure and its preparation molding method

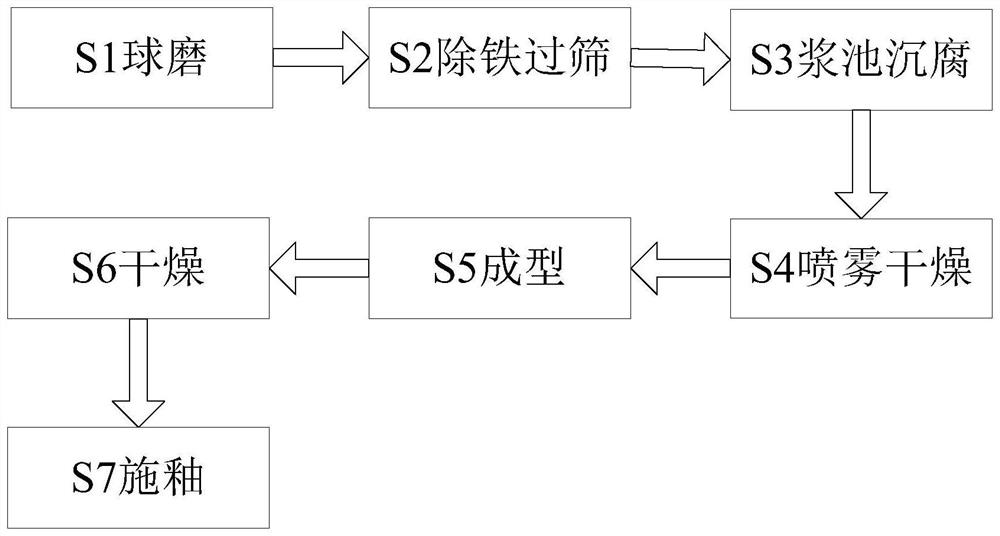

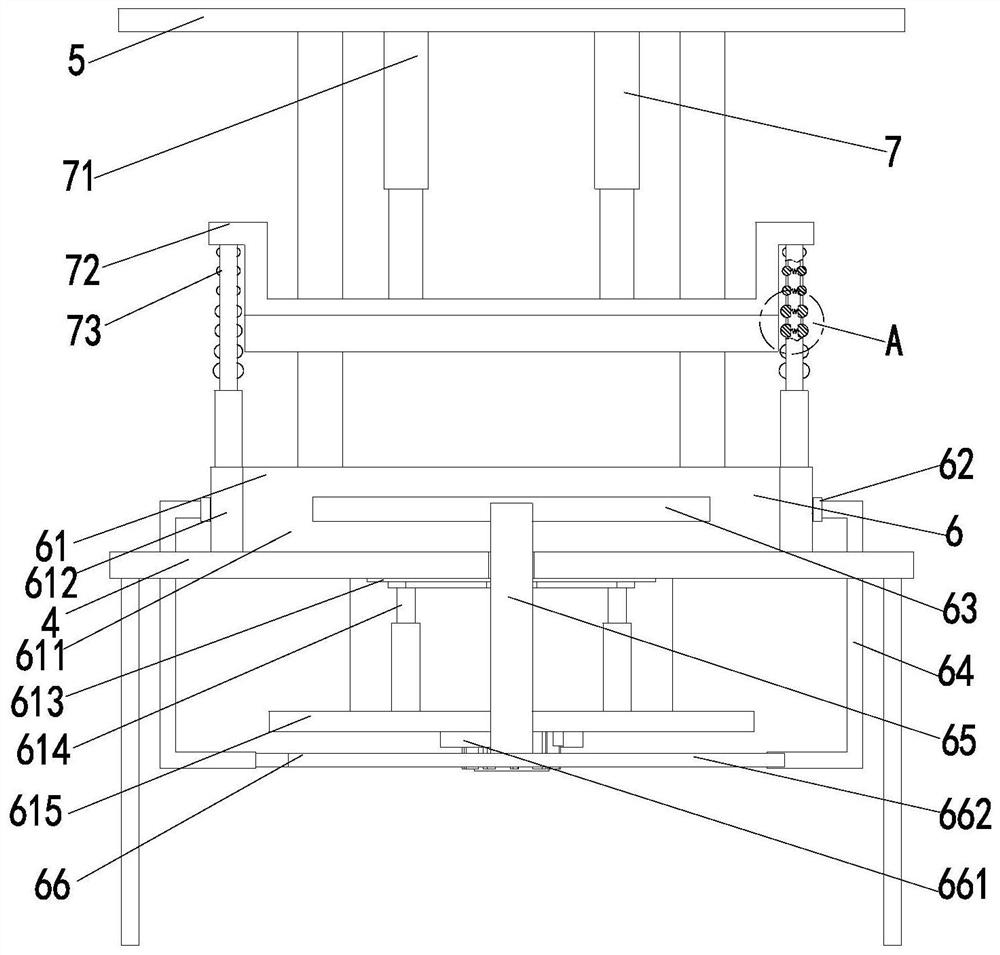

ActiveCN110714587BHigh strengthPrevent stratificationShaping press ramFlooringAdhesiveStructural engineering

The invention relates to an environmental-friendly floor tile structure and a preparing and forming method thereof. The environmental-friendly floor tile structure comprises a main body, horizontal reinforcing ribs and vertical reinforcing ribs, wherein the vertical reinforcing ribs are uniformly arranged on the back surface of the main body from left to right; the horizontal reinforcing ribs areconnected between the vertical reinforcing ribs; butt-joint grooves are formed in the front end surface, the back end surface, the left end surface and the right end surface of the main body; the butt-joint grooves formed in the front end surface and the back end surface of the main body are arranged in a staggered way; and the butt-joint grooves formed in the left end surface and the right end surface of the main body are arranged in a staggered way. The preparing and forming method of the environmental-friendly floor tile structure comprises the steps of ball-milling, deironing and sieving,settling and corroding a pulp chest, spray-drying, forming, drying and glazing. According to the environmental-friendly floor tile structure provided by the invention, the butt-joint grooves and butt-joint blocks are arranged on the side edges, so that adjacent tiles can be accurately butt-jointed without the need of a measuring tool; and through arranging the reinforcing ribs with inverted isosceles trapezoid-shaped cross sections, the tile strength is improved, and meanwhile, an adhesive can be further limited when being applied.

Owner:邵阳市神州实业有限公司

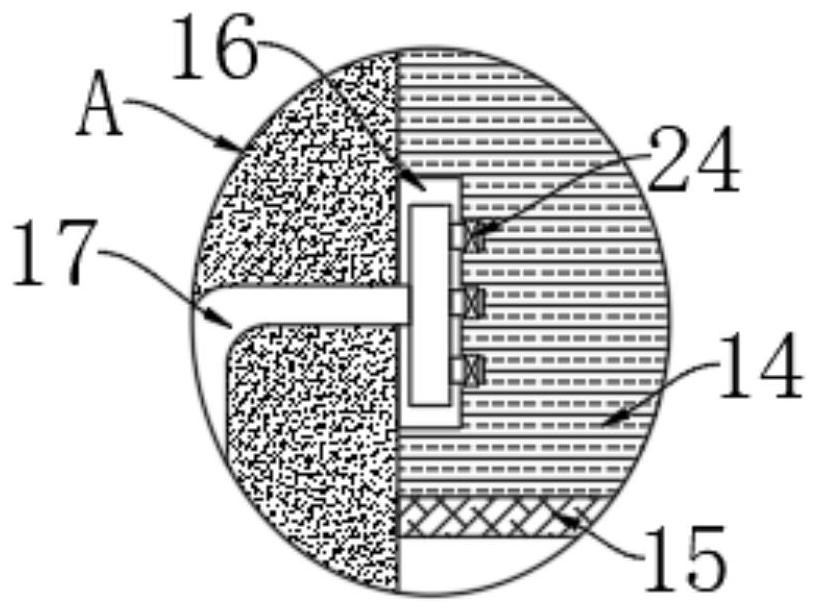

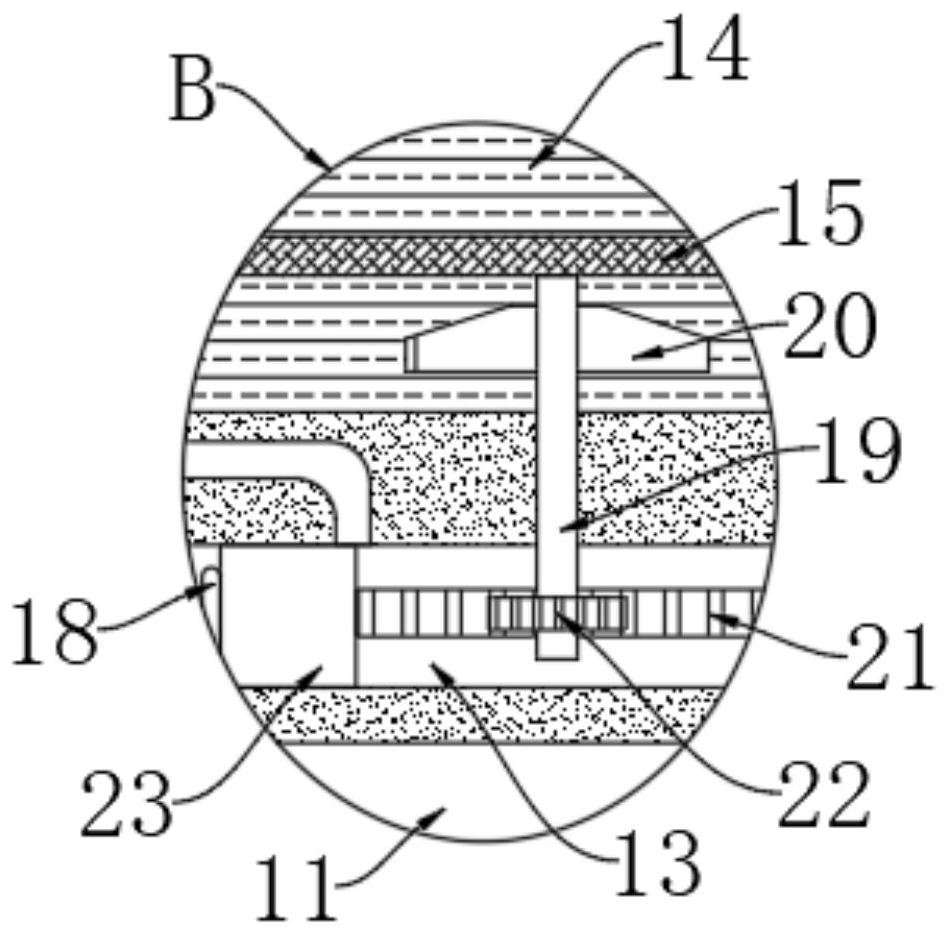

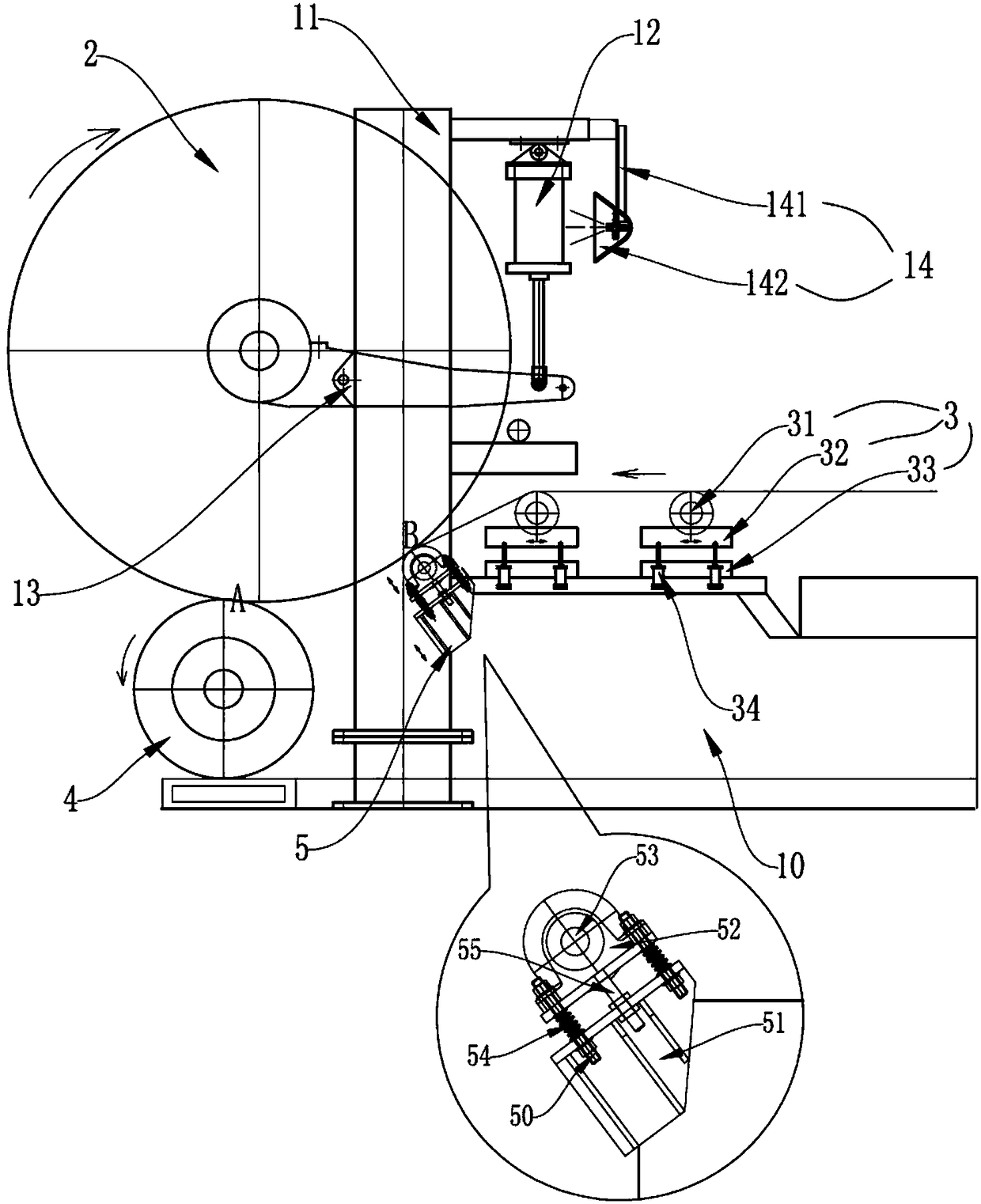

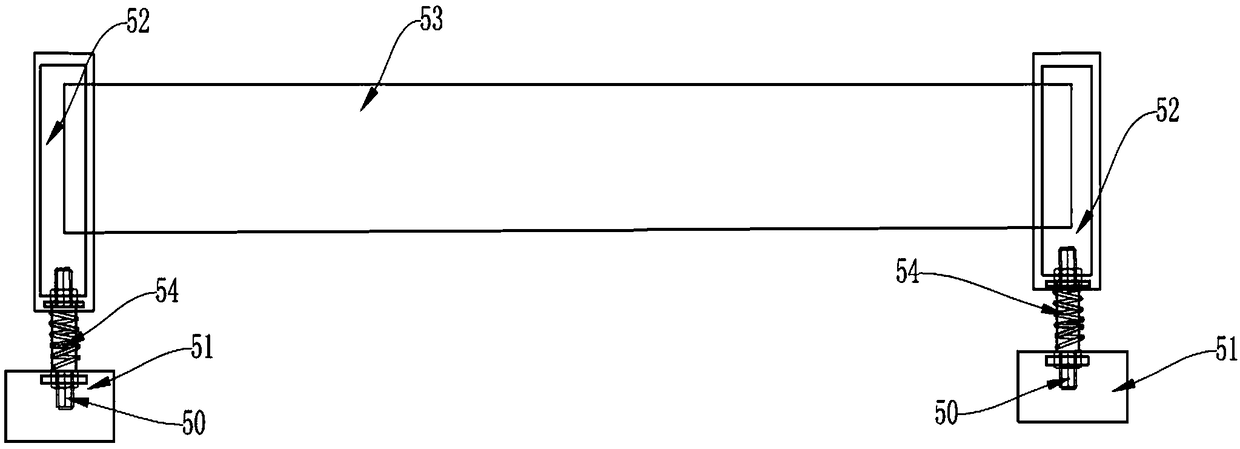

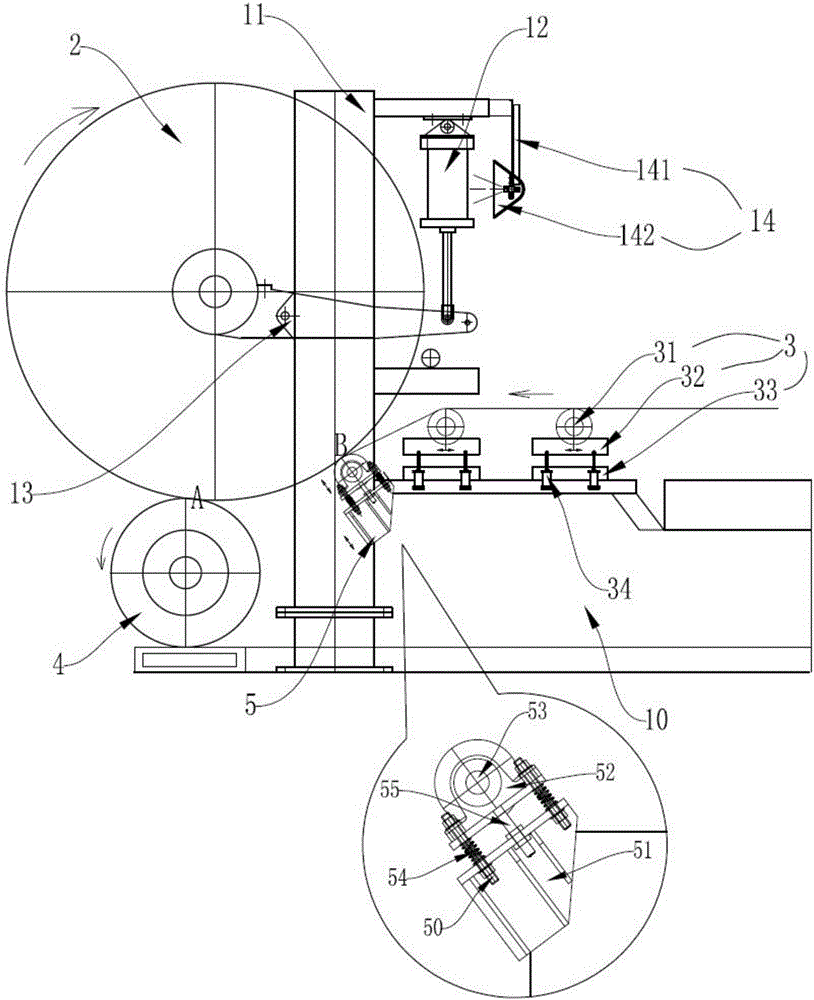

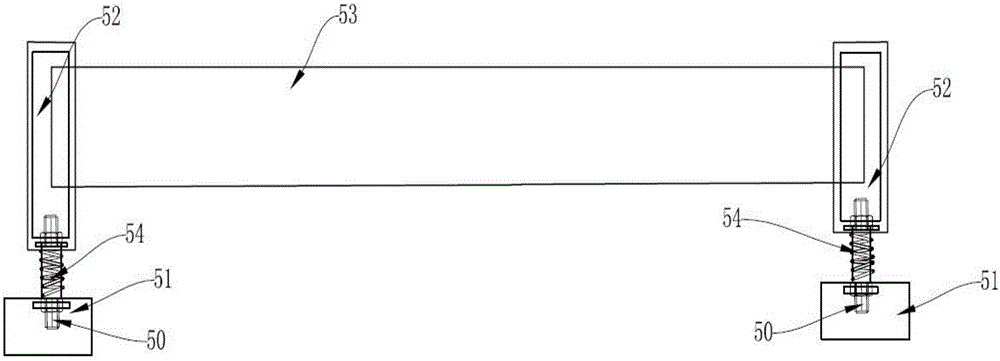

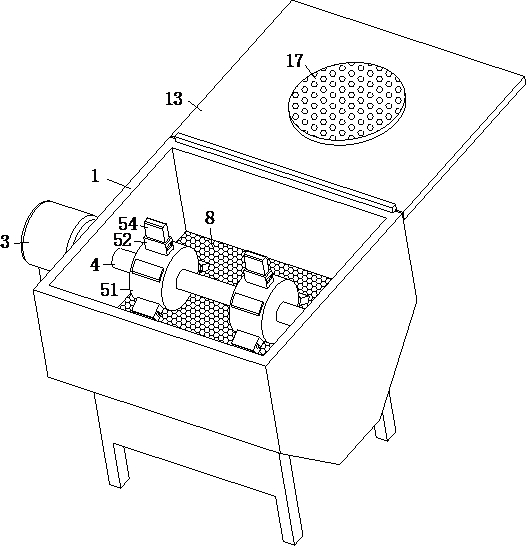

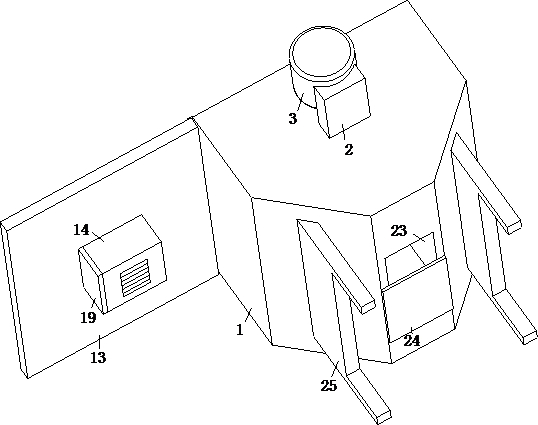

A cardboard forming device with guide rollers

ActiveCN106182905BAvoid breakageReduce entryMechanical working/deformationPaper-making machinesCardboardEngineering

A paperboard forming device with a guide roller comprises a rack, a forming cylinder, a conveying roller table, a grooved roller and a guide roller device. The grooved roller is arranged under the forming cylinder, and makes contact with and presses the forming cylinder to form a first contact face A. The guide roller device is fixed to a pedestal and is parallel to the radial direction of the forming cylinder; the guide roller device makes contact with and presses the forming cylinder to form a second contact face B; and the guide roller device comprises two bases, two bearing seats and the guide roller. The two bases are symmetrically fixed to the pedestal; the two sides of each bearing seat are connected with the corresponding bases through guide rods; the guide rods between the bearing seats and the bases are sleeved with springs; and the two ends of the guide roller are rotatably arranged on the two bearing seats. The paperboard forming device achieves the pre-pressing effect of the forming cylinder on paperboards; paper layers are twined and attached more compactly; the height of the guide roller device can be adjusted to guarantee the effective contact between the guide roller device and the forming cylinder, and proper pre-pressure is kept; and the roller pressing effect is good, the application range is wide, the adjustability is high, the fault rate is low, and continuous production is achieved.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

Paperboard forming device with guide roller

A paperboard forming device with a guide roller comprises a rack, a forming cylinder, a conveying roller table, a grooved roller and a guide roller device. The grooved roller is arranged under the forming cylinder, and makes contact with and presses the forming cylinder to form a first contact face A. The guide roller device is fixed to a pedestal and is parallel to the radial direction of the forming cylinder; the guide roller device makes contact with and presses the forming cylinder to form a second contact face B; and the guide roller device comprises two bases, two bearing seats and the guide roller. The two bases are symmetrically fixed to the pedestal; the two sides of each bearing seat are connected with the corresponding bases through guide rods; the guide rods between the bearing seats and the bases are sleeved with springs; and the two ends of the guide roller are rotatably arranged on the two bearing seats. The paperboard forming device achieves the pre-pressing effect of the forming cylinder on paperboards; paper layers are twined and attached more compactly; the height of the guide roller device can be adjusted to guarantee the effective contact between the guide roller device and the forming cylinder, and proper pre-pressure is kept; and the roller pressing effect is good, the application range is wide, the adjustability is high, the fault rate is low, and continuous production is achieved.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

Animal feed mixing equipment capable of quickly and uniformly mixing

PendingCN114797650AFully contactedAffect eatingFeeding-stuffRotary stirring mixersTreated animalElectric machinery

The invention discloses animal feed mixing equipment capable of quickly and uniformly mixing, and relates to the technical field of feed mixing, and the technical scheme is characterized in that the animal feed mixing equipment comprises a mounting plate fixed on a mixing box, a motor is arranged on the mounting plate, and a rotating shaft is fixedly connected to an output shaft of the motor; one end of the rotating shaft penetrates through the mixing box and extends into the mixing box. A feed additive is put into a disc and enters a discharging channel under the action of rotating centrifugal force, then a screening net is extruded, a first opening and a second opening coincide, the additive is discharged and mixed with feed, the additive makes full contact with the feed in different layers through pushing of an extrusion plate, and the feed in different layers is fully mixed. The mixing effect is achieved, and the situation that the eating of animals is affected due to layering is avoided, so that the effect of treating the animals is also affected.

Owner:盐城栖岭农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com