Patents

Literature

103results about How to "Improve the effect of edge banding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

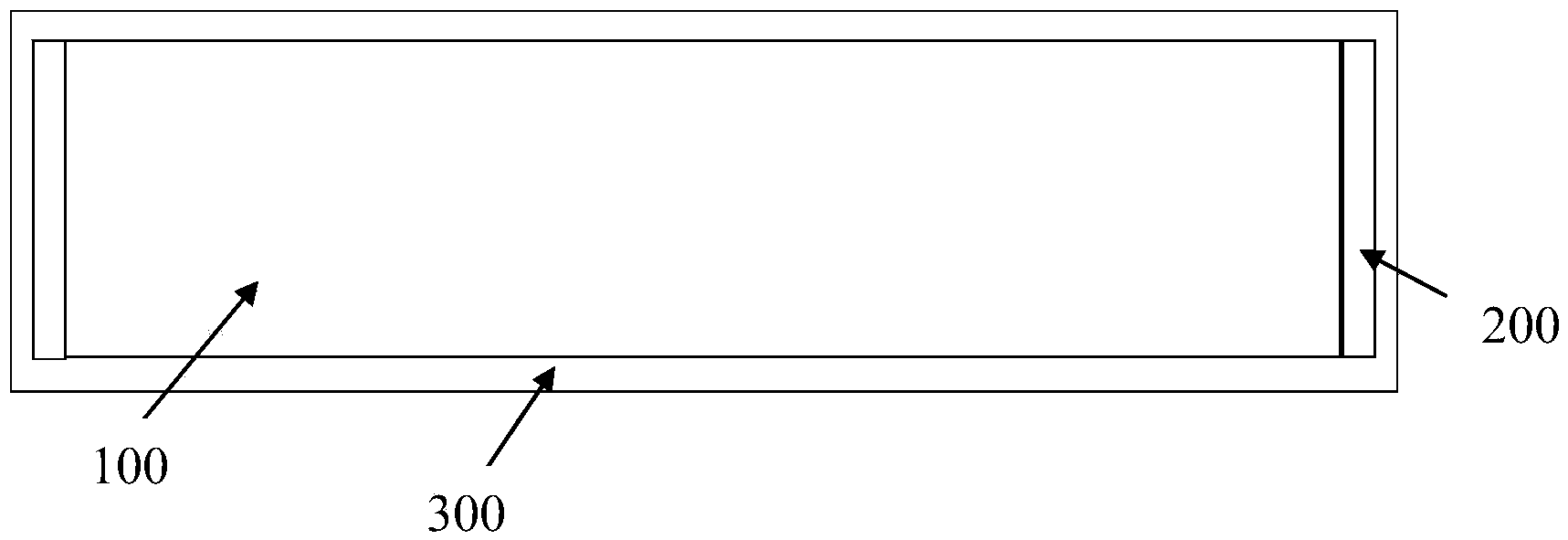

Smart film edge sealing technology for laminated PVB (polyvinyl butyral) smart glass

ActiveCN107390436AEliminate edge shrinkage and other problemsIsolated contactNon-linear opticsPolyvinyl butyralSmart film

The invention discloses a smart film edge sealing technology for laminated PVB (polyvinyl butyral) smart glass. The smart film edge sealing technology includes: cleaning: placing a smart film on a platform, cleaning areas within 0.5-10mm from edges of the smart film, and removing oil contaminations and other impurities; cutting: cutting the edges (except the positions of electrodes) of the smart film to form 0.5-3mm width of steps by a cutting tool; cleaning again: wiping and cleaning the cut steps; protecting the electrodes: protecting the electrodes of the smart film by adhesive tape; applying glue: subjecting the cut steps (including steps at the positions of the electrodes) of the edges of the smart film to glue application by a glue applicator; curing: curing applied glue by curing equipment so as to finish edge sealing of the smart film. The smart film edge sealing technology for the laminated PVB smart glass has advantages of good using effect and high rate of finished products.

Owner:ZHUHAI SINGYES NEW MATERIALS TECH CO LTD

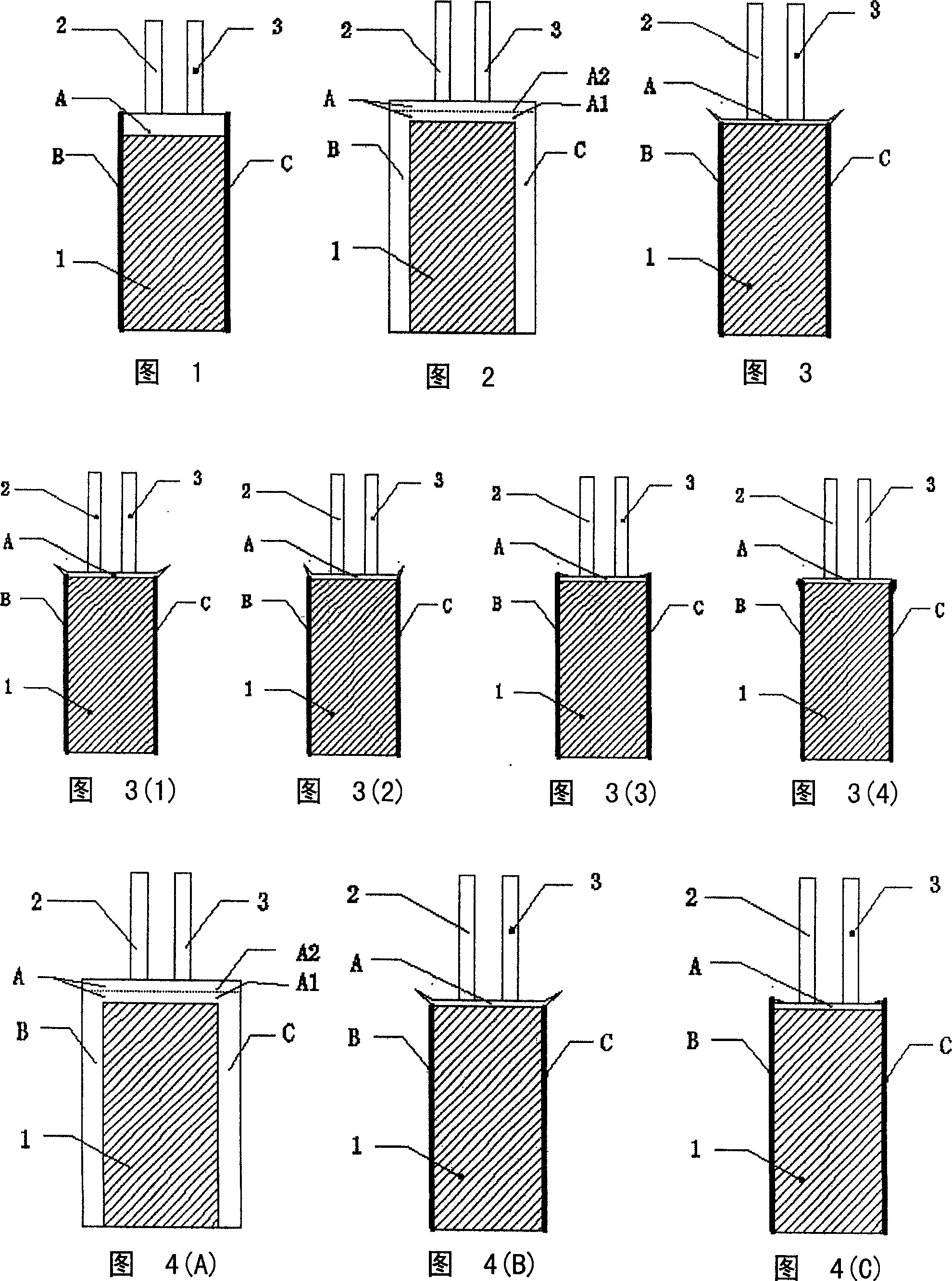

Automatic edge sealing process for vacuum glass

InactiveCN101481205AImprove the effect of edge bandingBeautiful edge bandingGlass reforming apparatusHeating furnaceAir tightness

The invention relates to an automatic edge sealing technology for vacuum glass, which comprises the following steps of arranging supporters on basal board glass, arranging upper plate glass on the basal board glass, using low melting-point glass powder between the upper plate glass and the basal board glass for sealing edges, placing the upper plate glass and the basal board glass into a vacuum heating furnace to be heated and taking out upper plate glass and the basal board glass to get a finished vacuum glass, wherein in the step of using the low melting-point glass powder for sealing the edge, a section bar of low melting-point glass powder or the low melting-point glass powder is arranged on the basal board glass, and a gap of air escaping in the evacuation in the heating furnace is left in a chamber formed between the basal board glass and the upper plate glass. The invention has simple integrated structure, greatly shortens the evacuation time, increases the work efficiency, has reliable automatic evacuation and sealed package, good air tightness, little air leakage hazard, attractive appearance and production technology simplification, greatly promotes the development of the vacuum glass industry, and is particularly suitable for the industrialized, the scale and the standardized production of the vacuum glass.

Owner:左树森

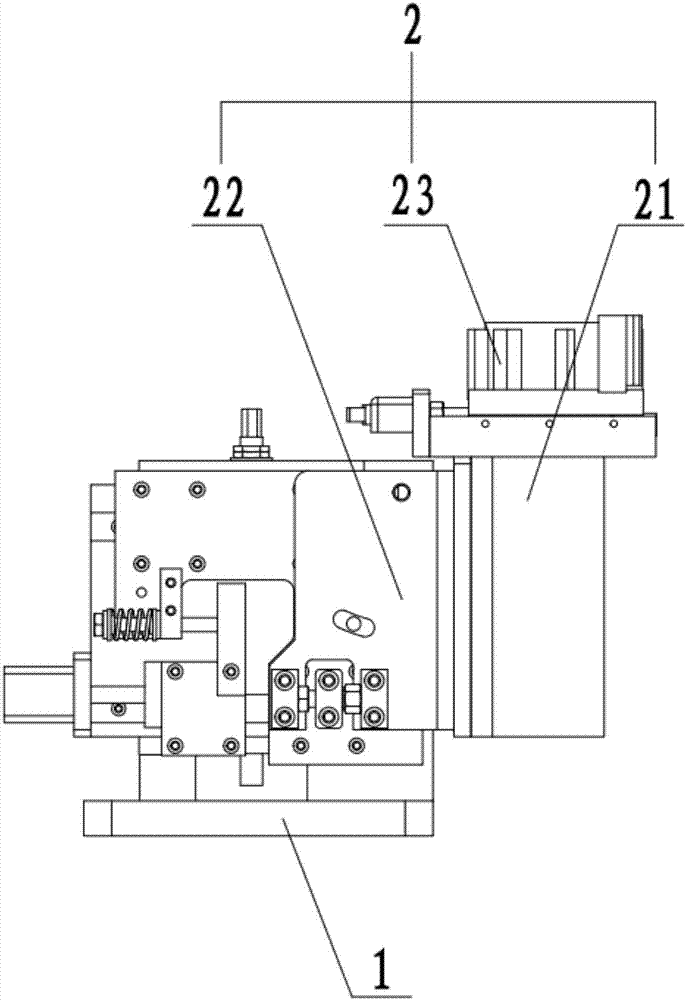

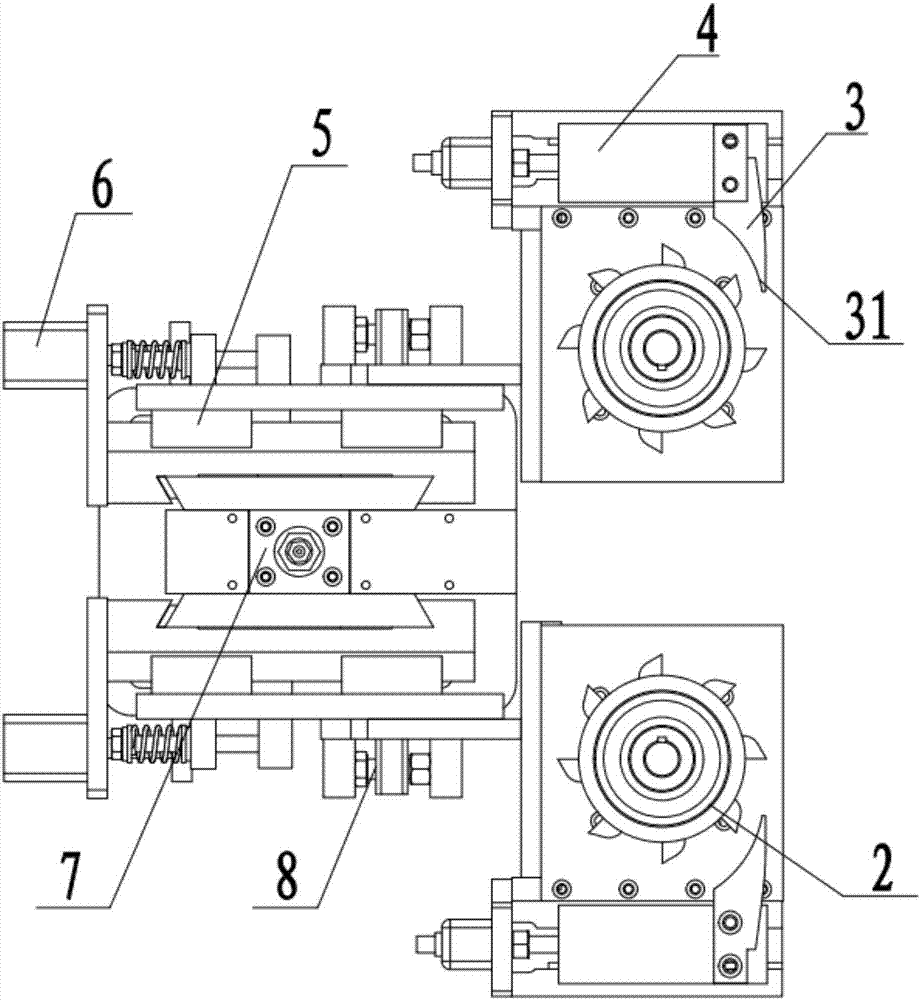

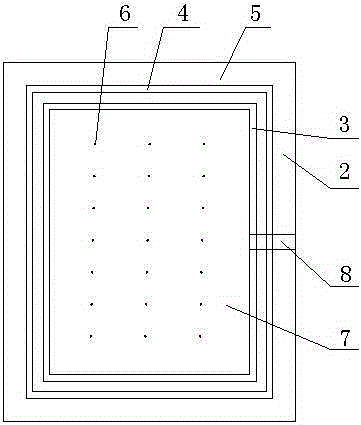

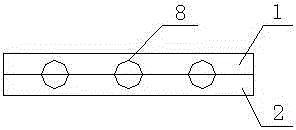

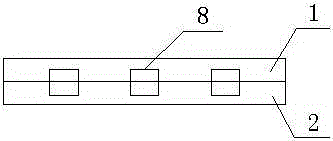

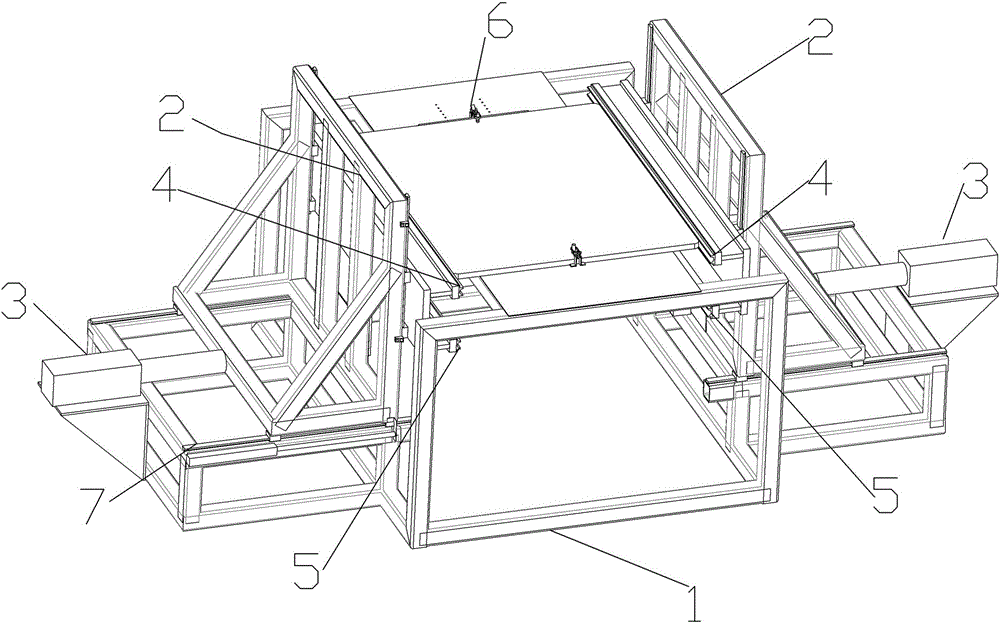

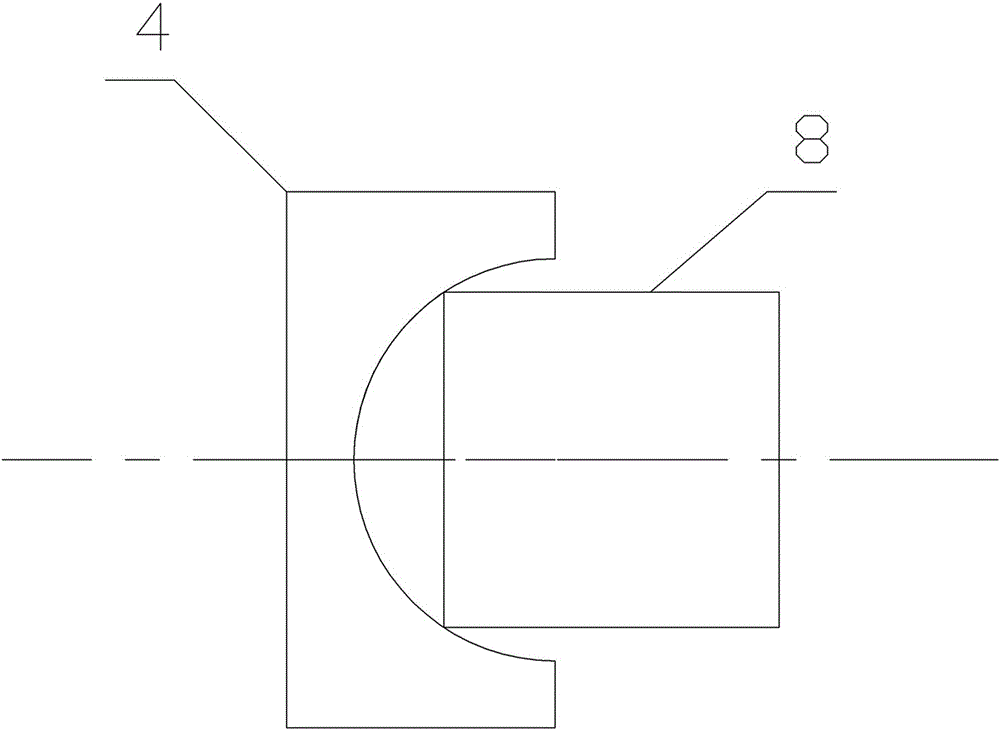

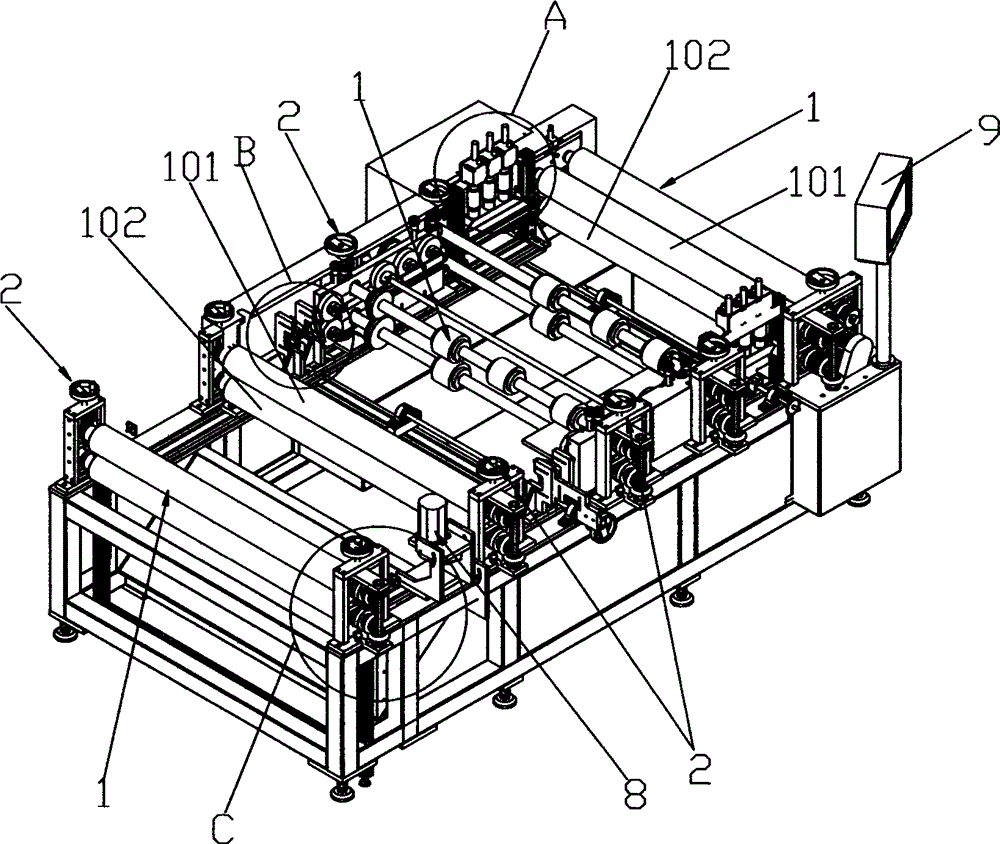

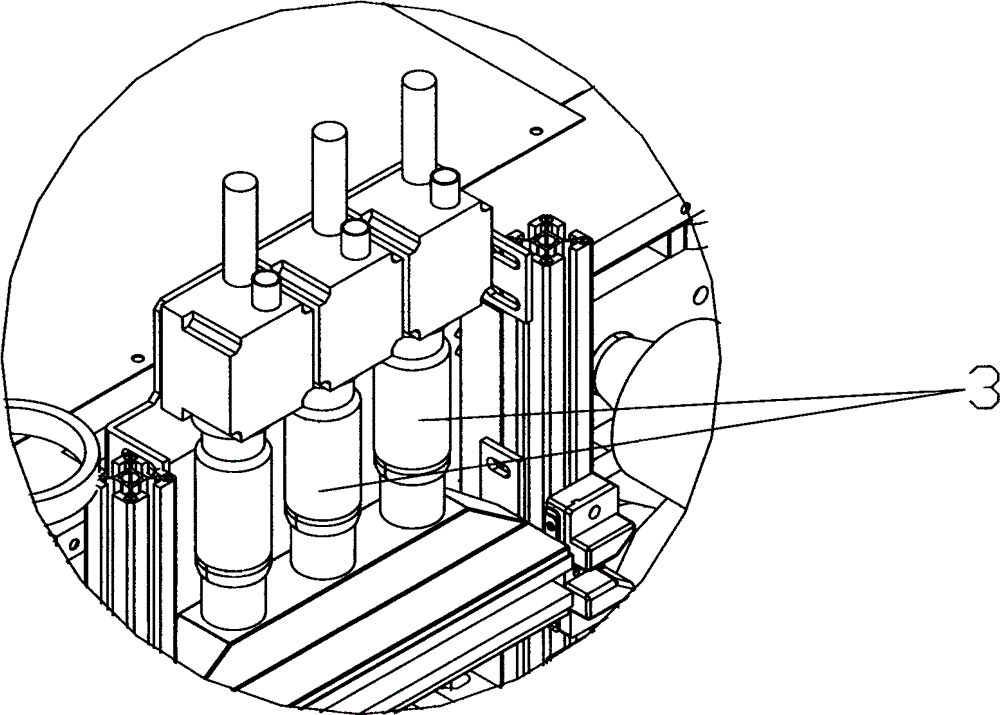

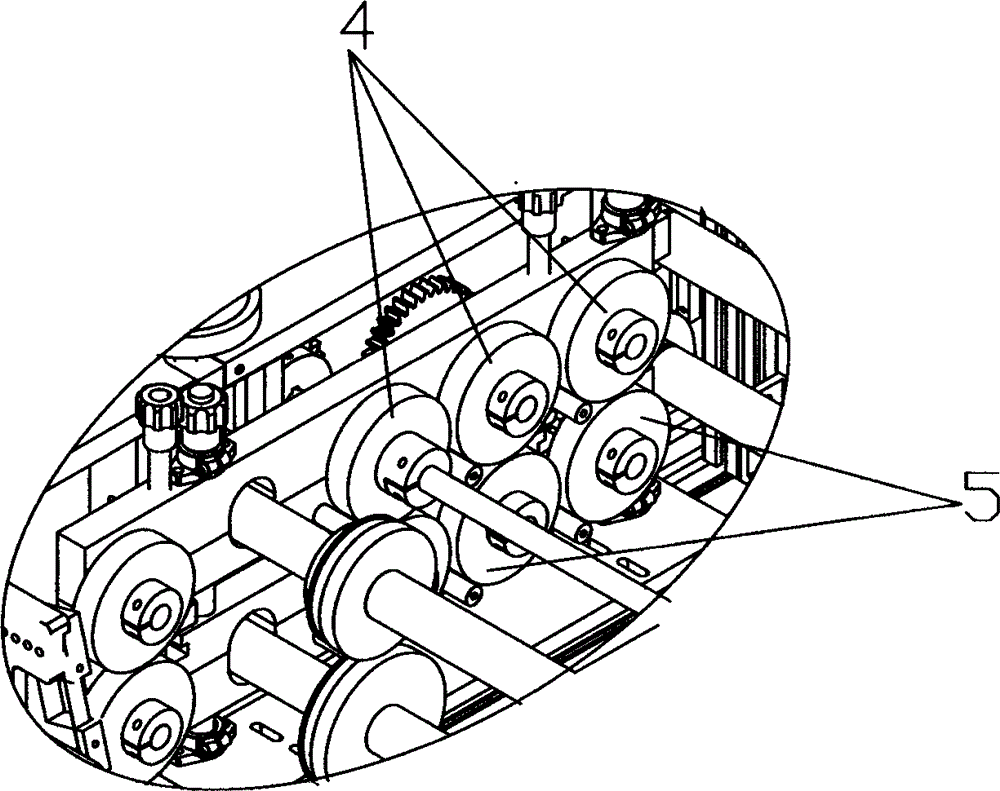

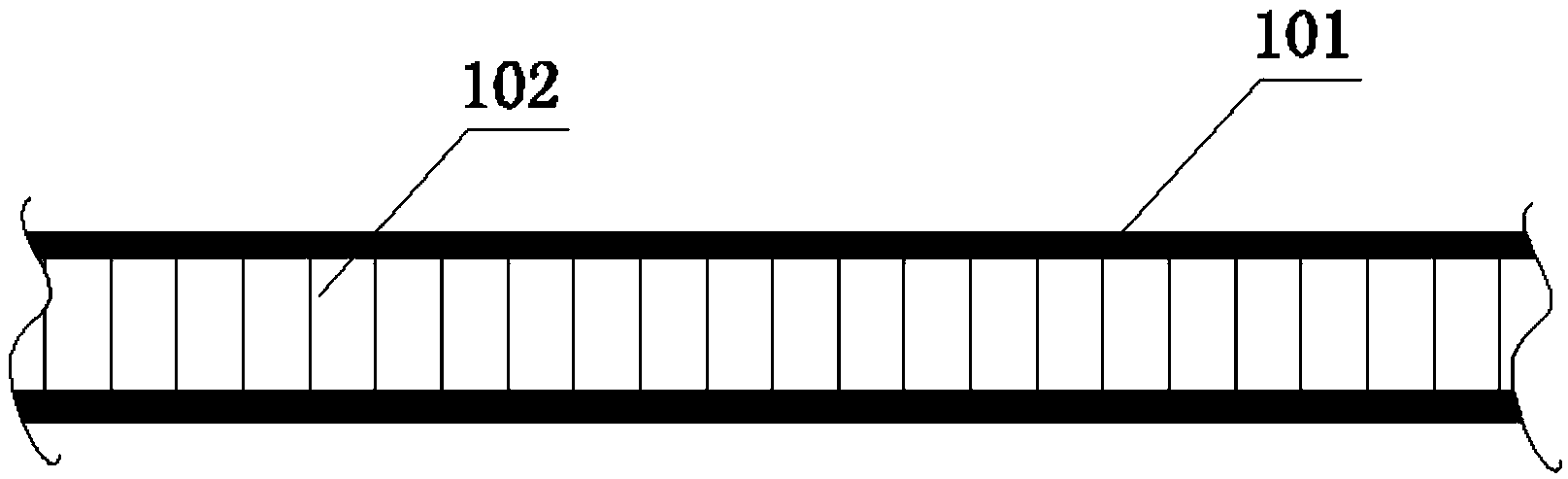

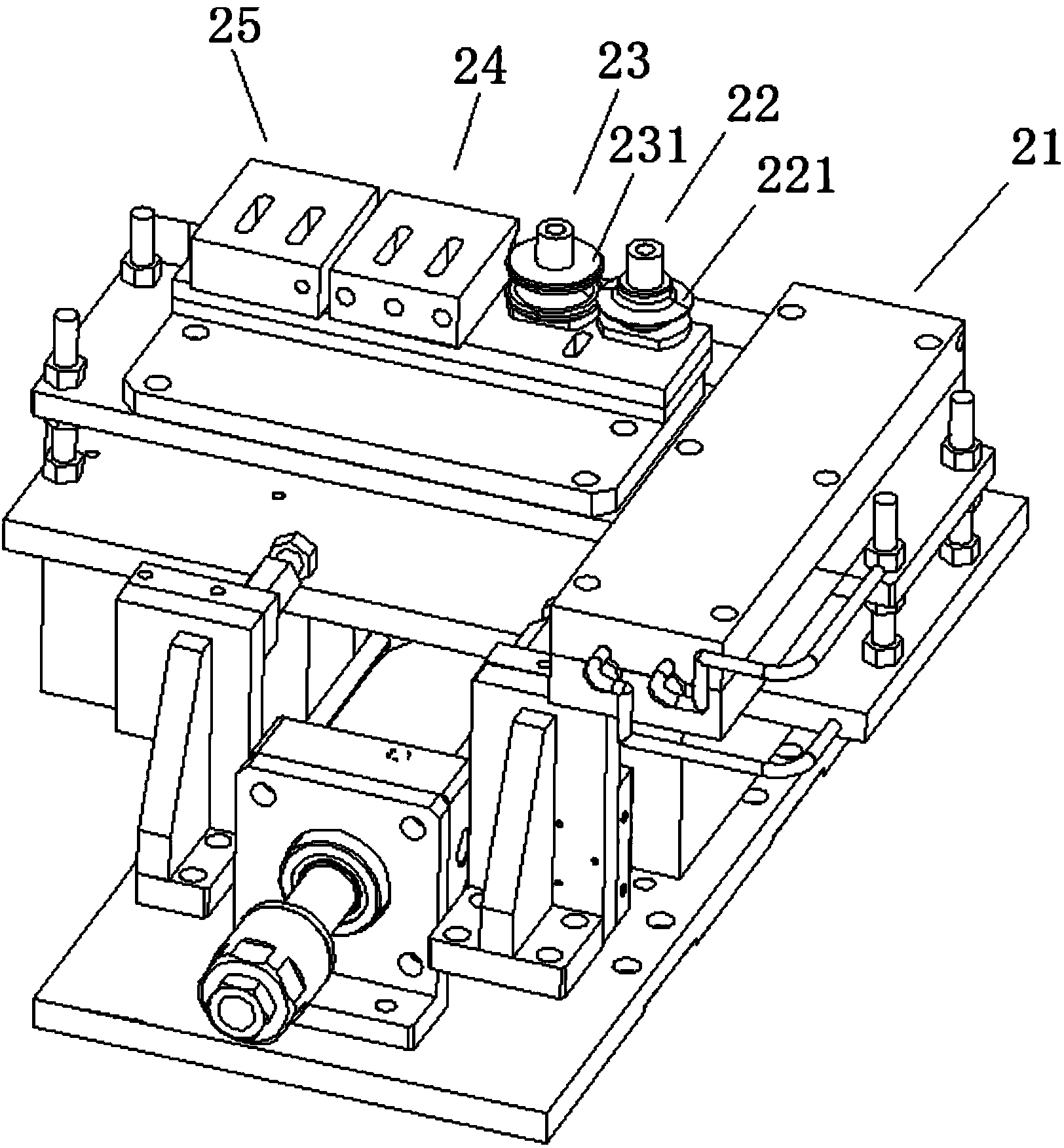

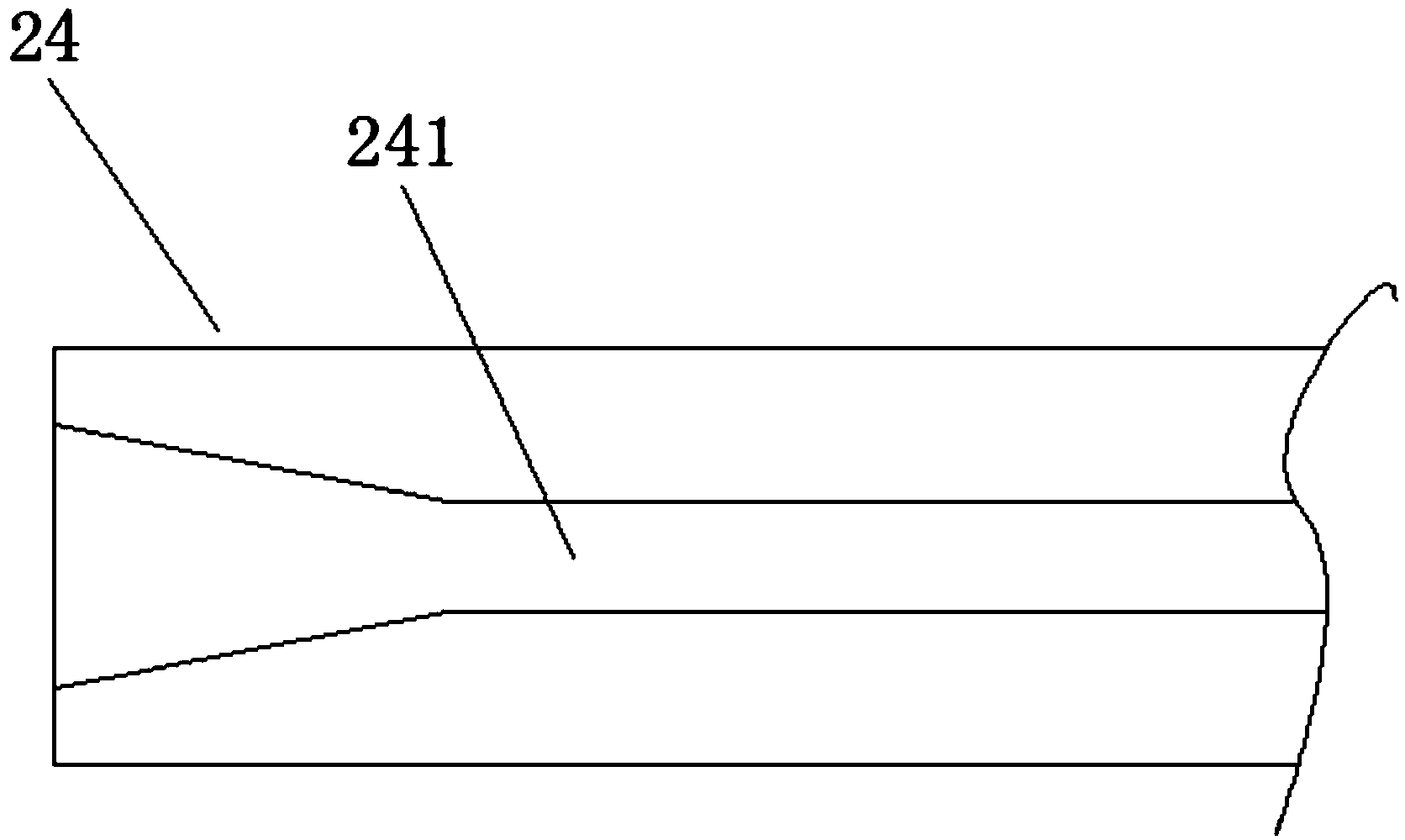

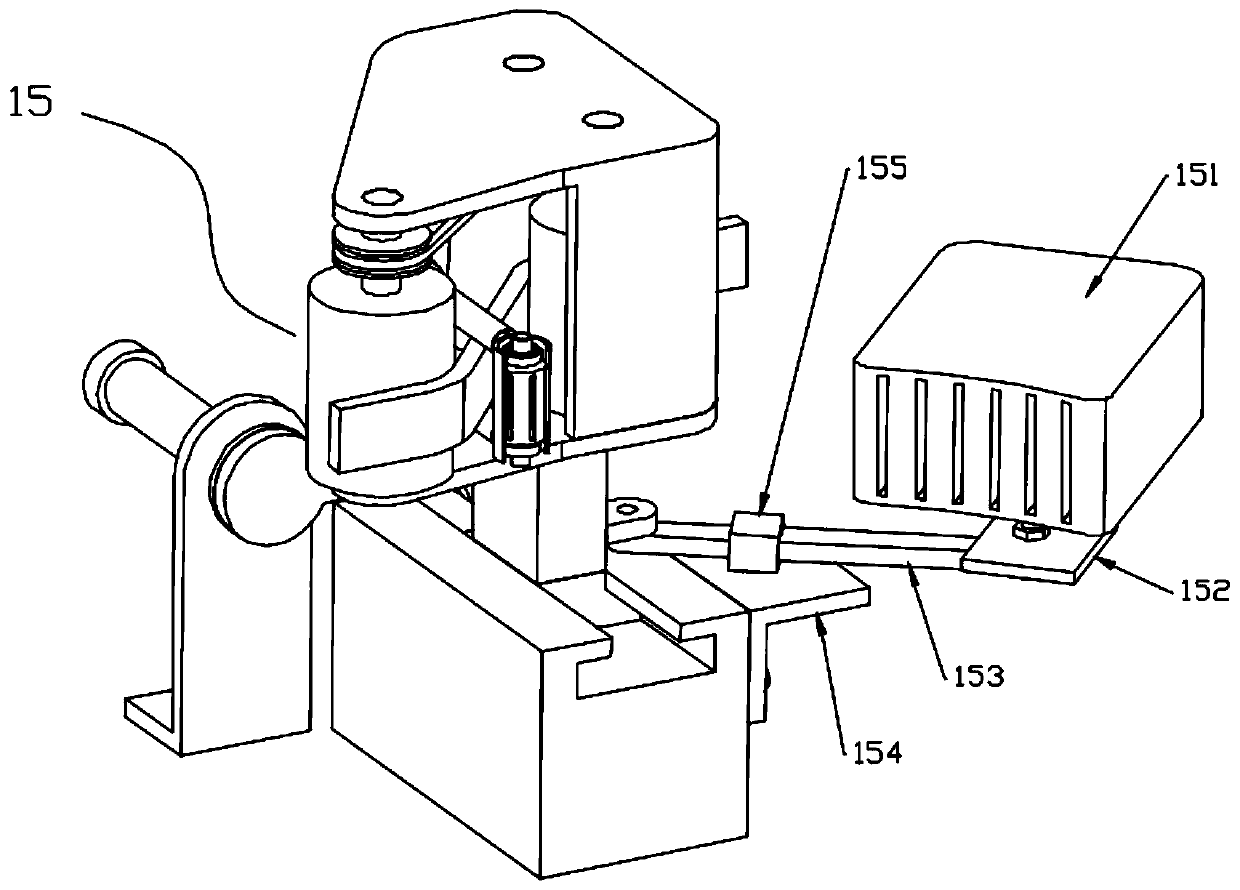

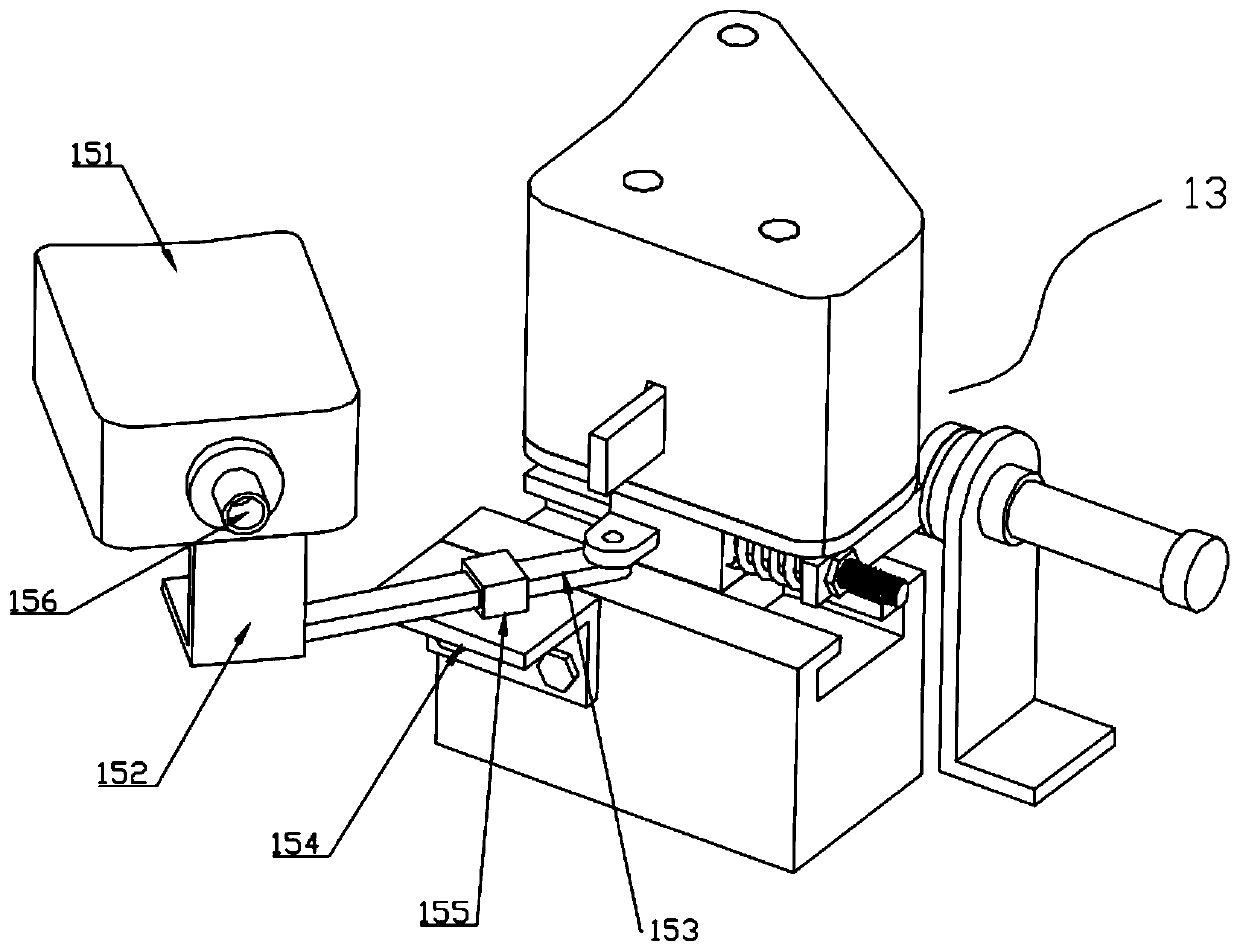

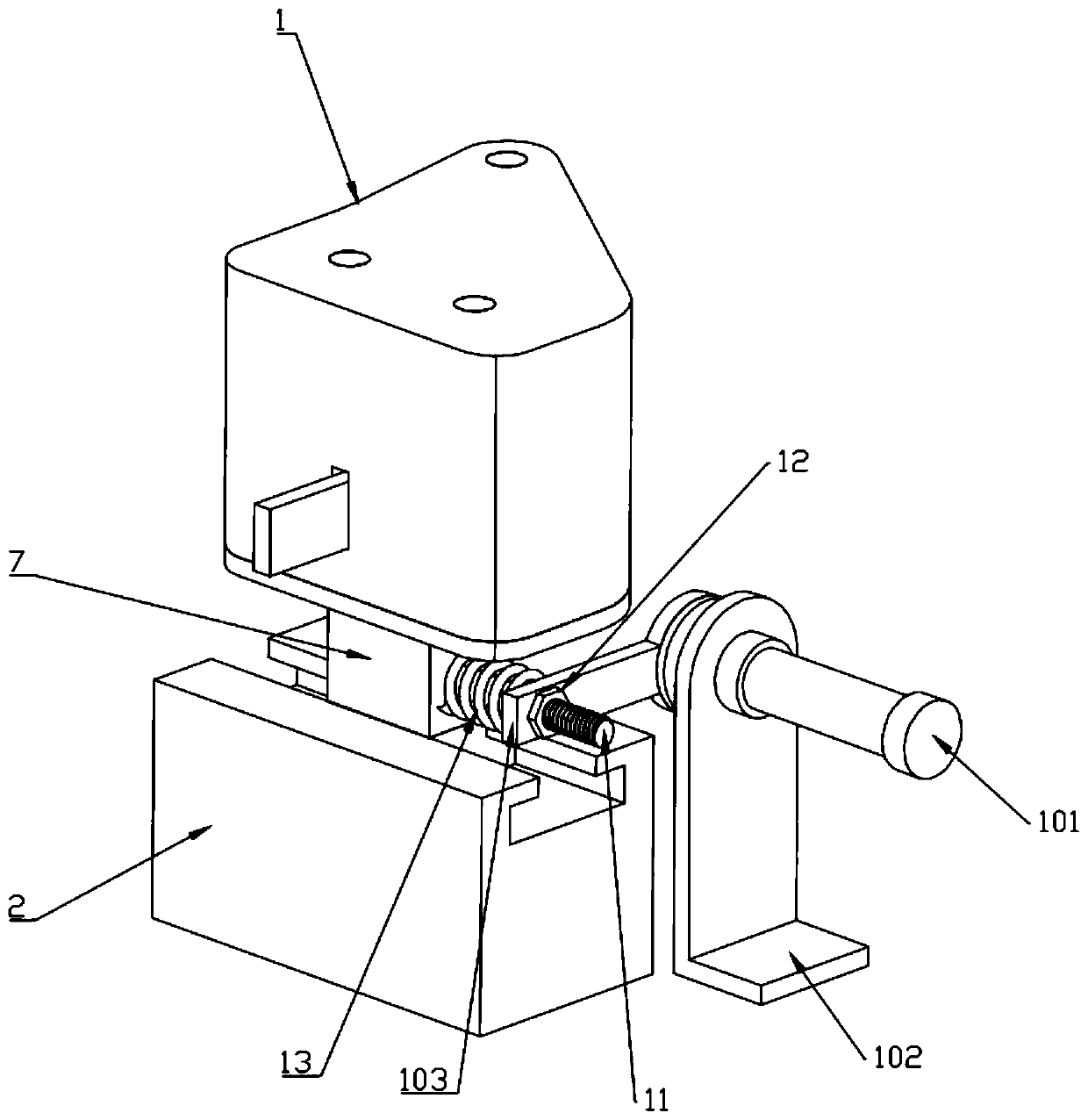

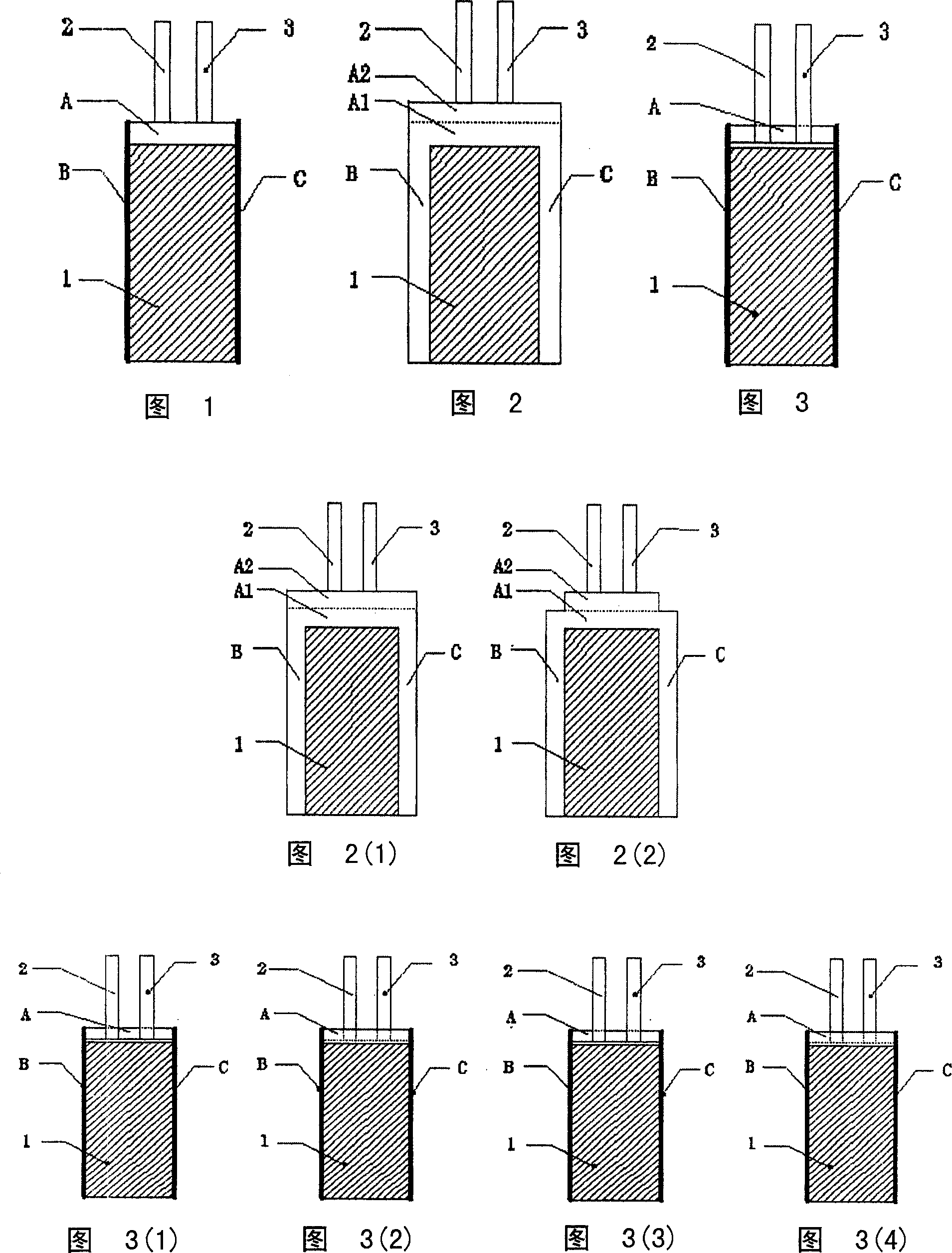

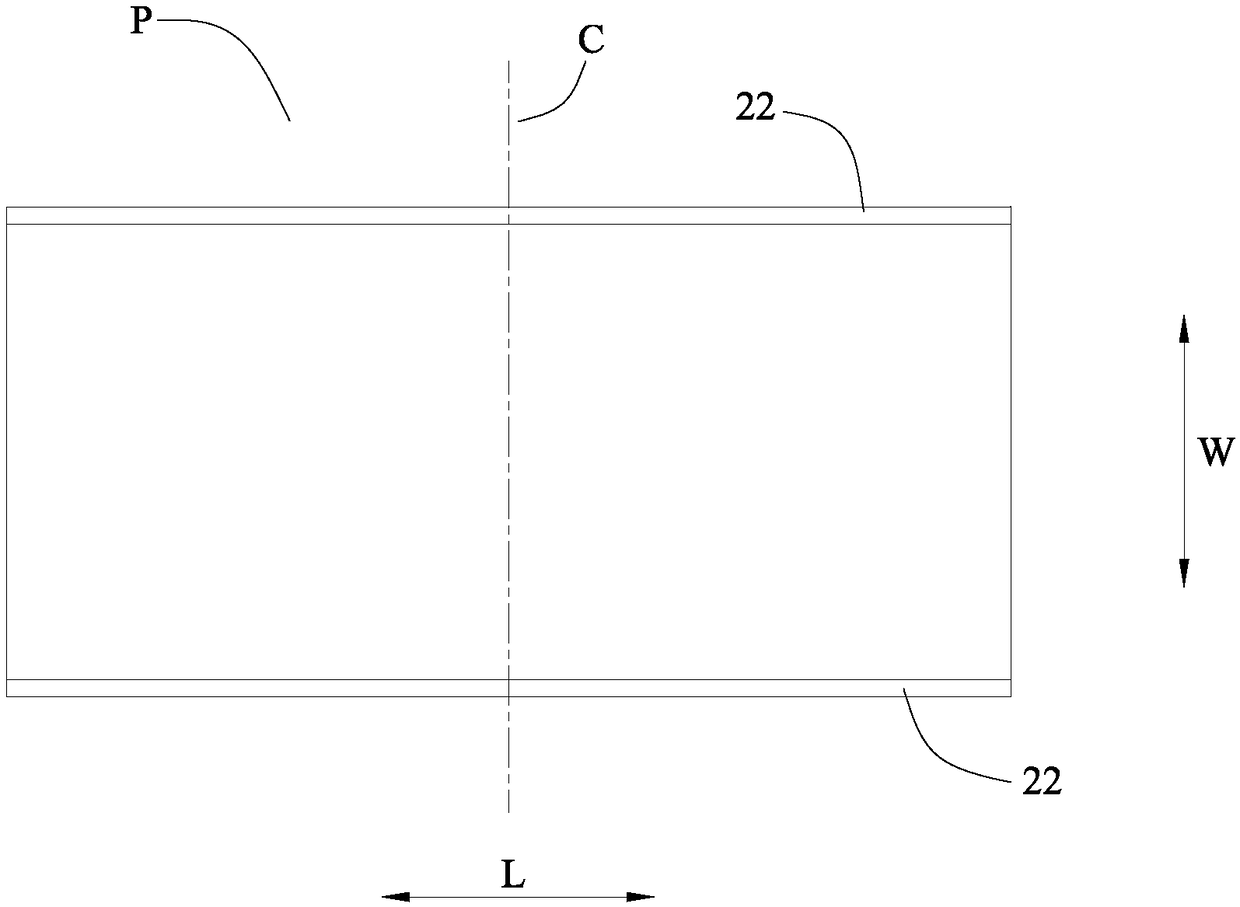

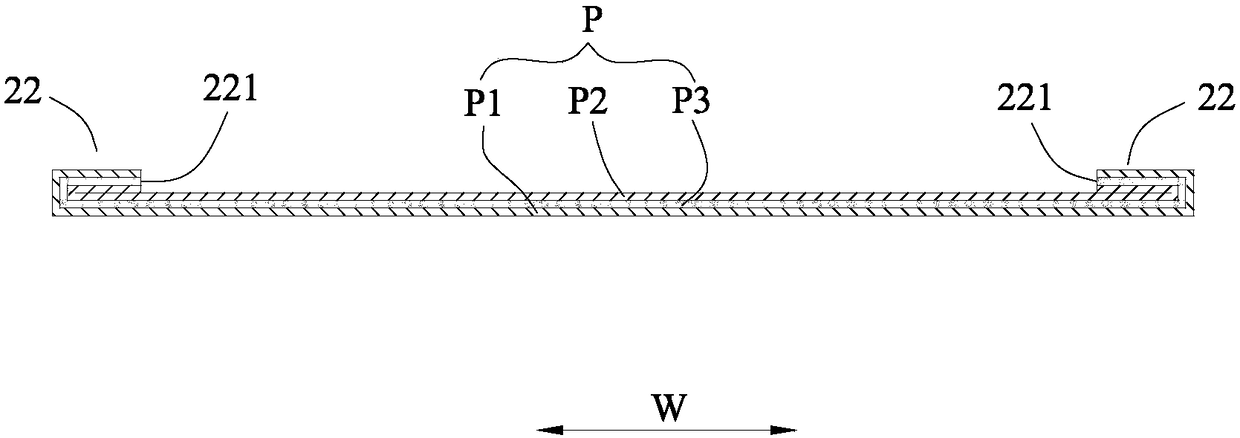

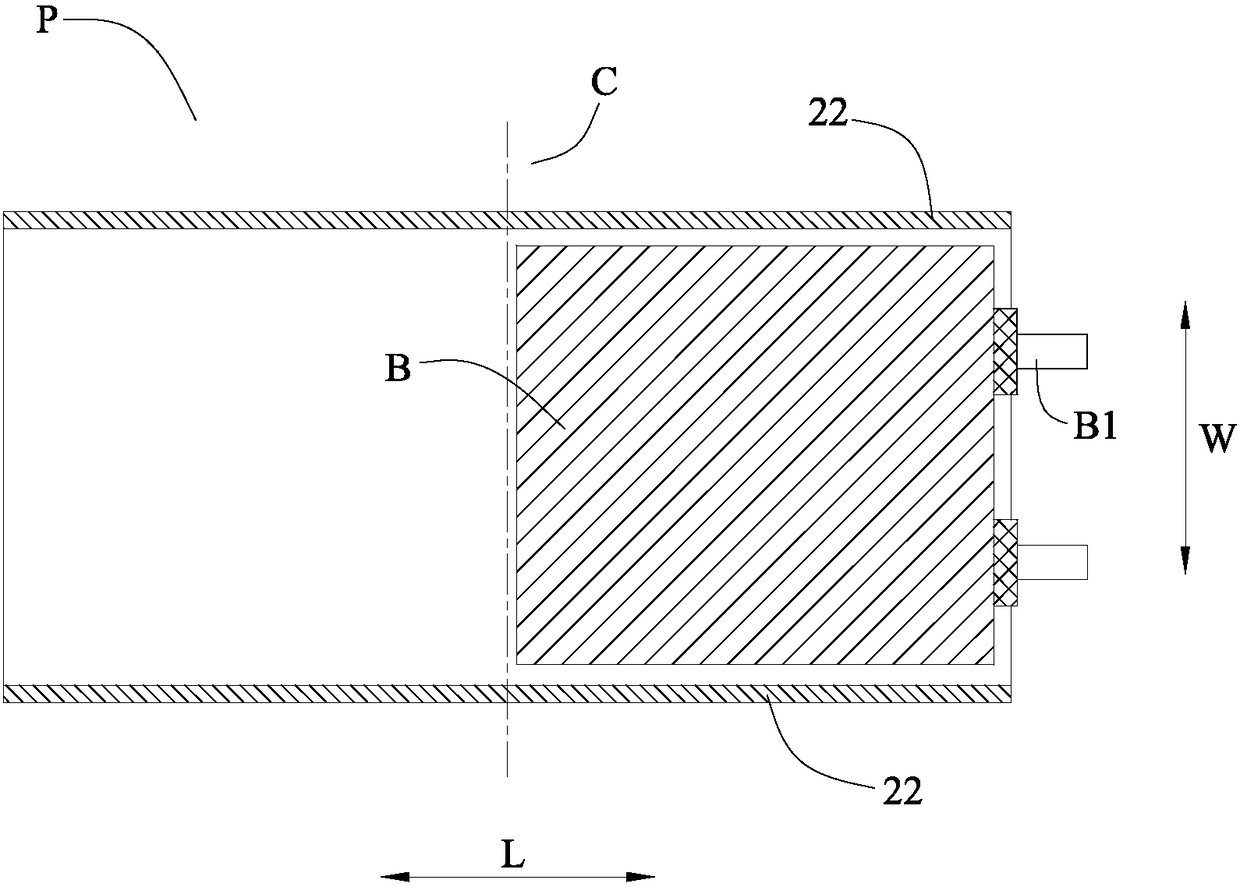

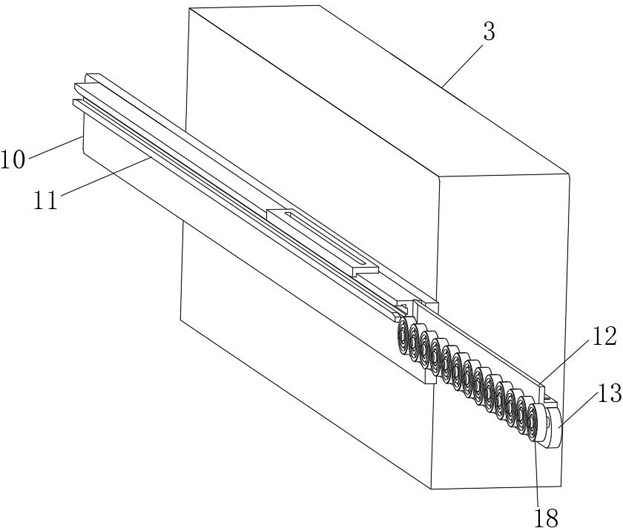

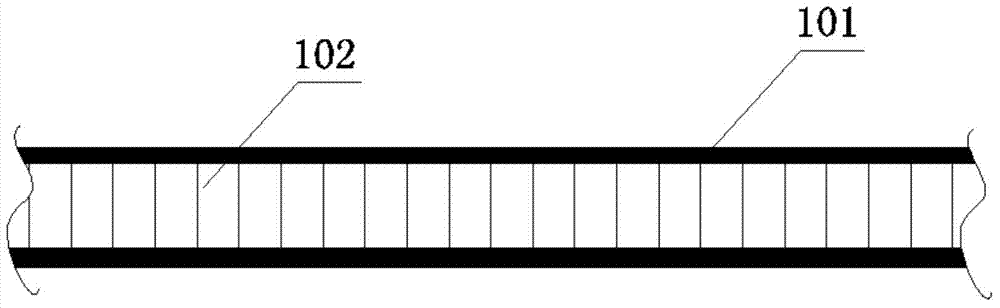

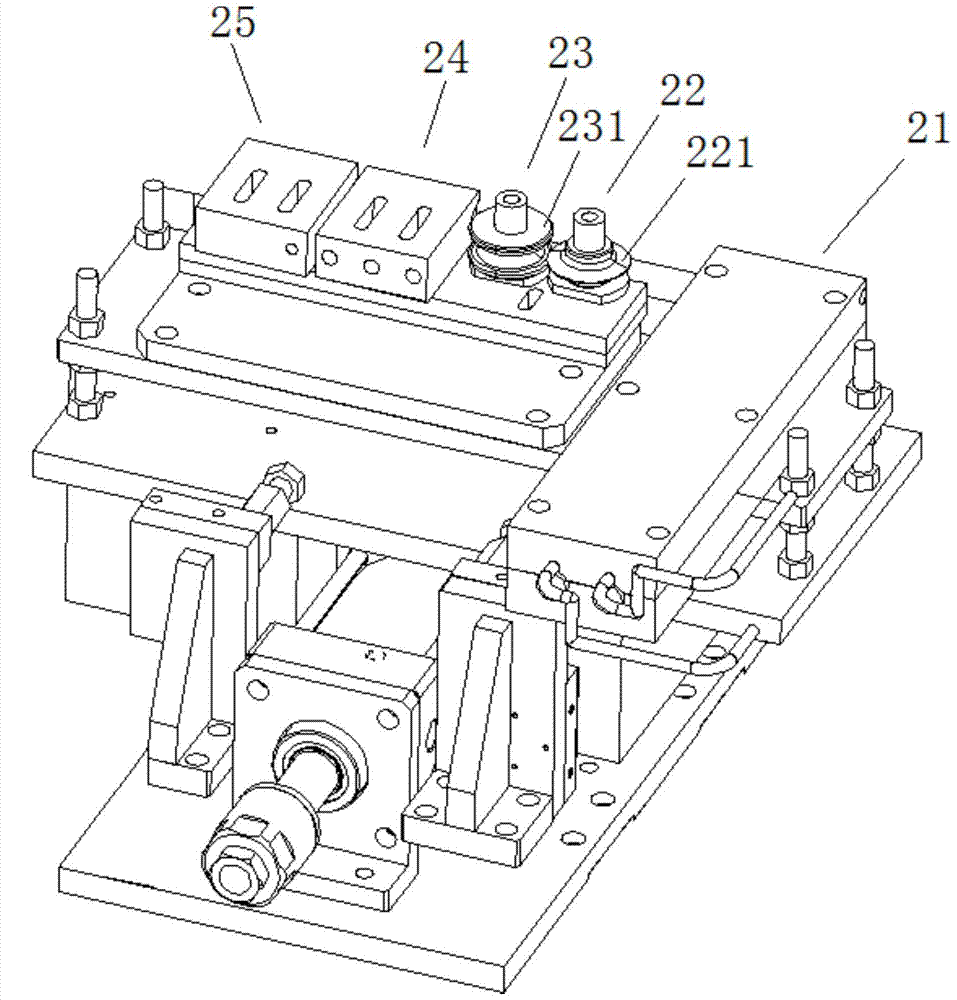

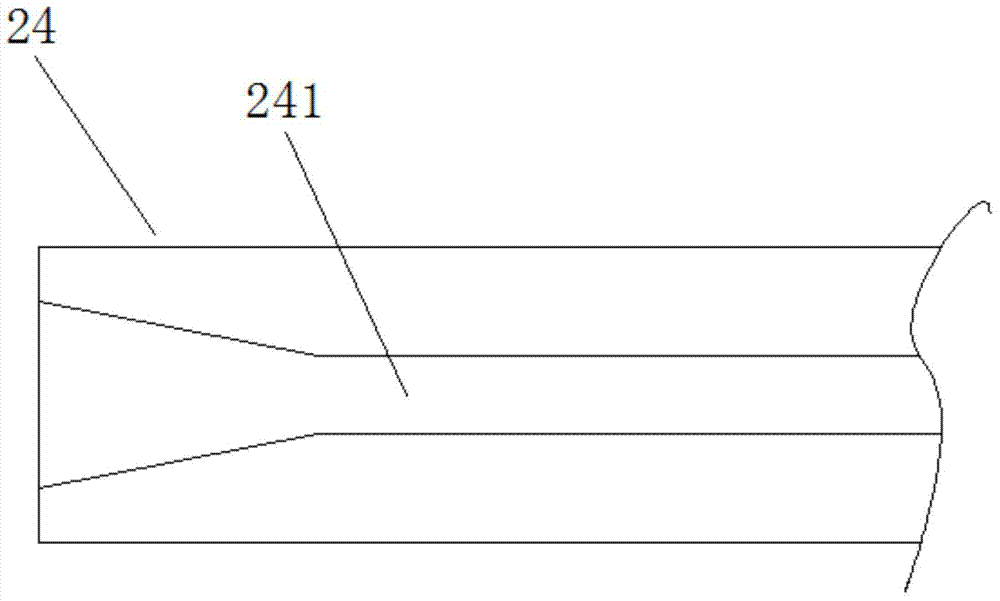

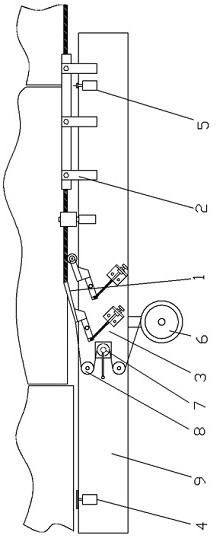

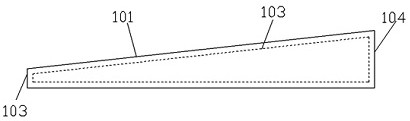

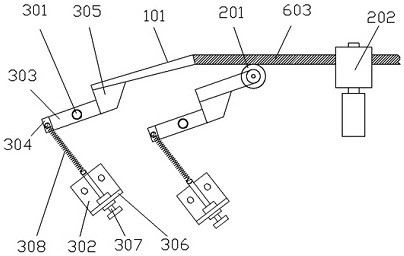

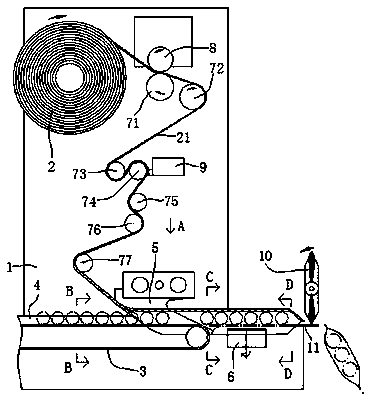

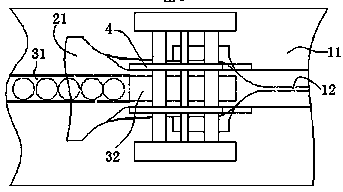

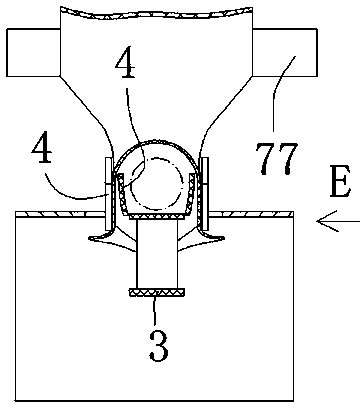

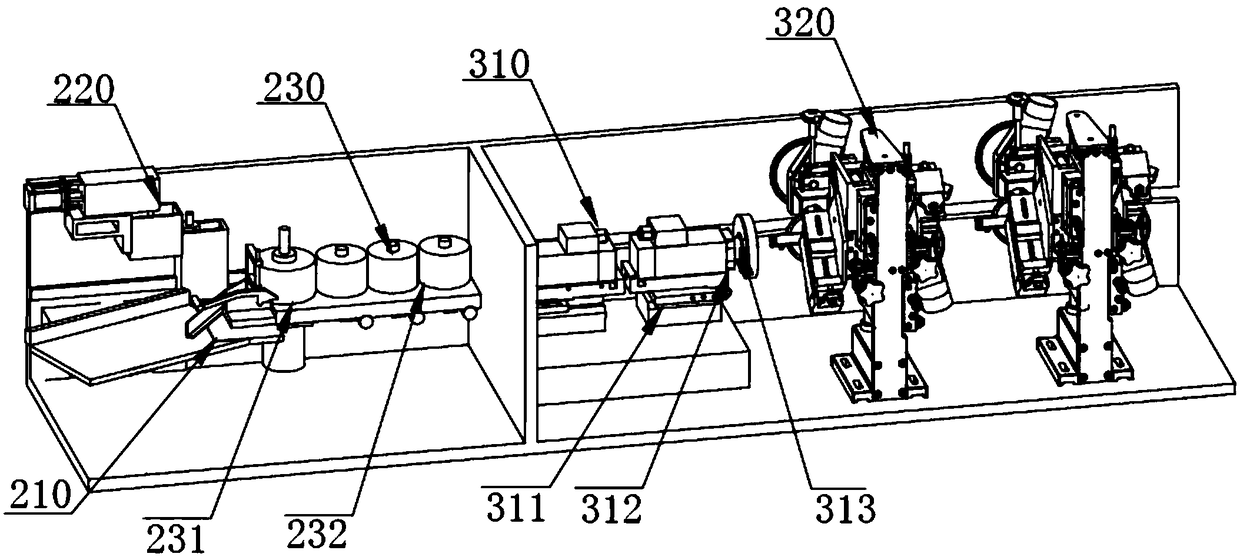

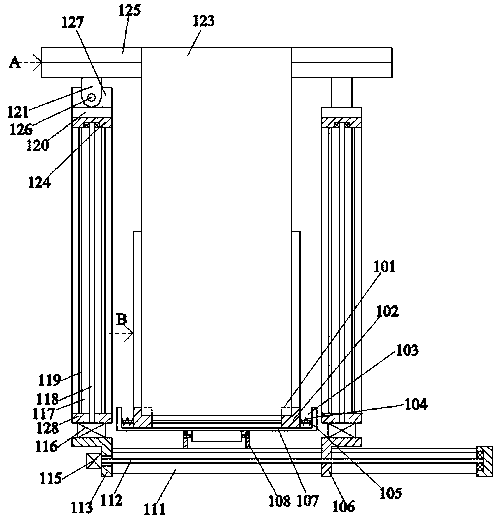

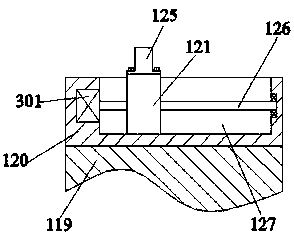

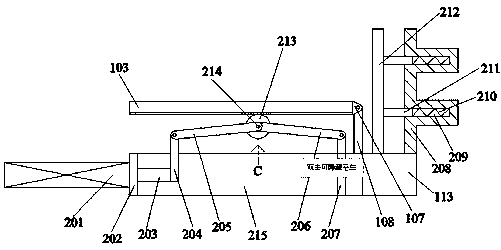

Pre-milling device and edge banding machine

InactiveCN107263669AGood edge banding effectFit tightlyProfiling/shaping machinesDomestic articlesRipple marksEngineering

The invention discloses a pre-milling device and an edge banding machine, relates to the technical field of wood machinery, and solves the technical problems of incompact fitting between an edge band and a workpiece and relatively low integrality and aesthetic degree. The pre-milling device comprises a pedestal and a milling cutter assembly. By the arrangement of the milling cutter assembly, ripple marks, burrs or a non-vertical phenomenon, which are or is caused by machining of a cut-to-size saw or a cutting saw, on the workpiece (a plate) can be modified again to achieve a better edge banding effect; furthermore, the milling cutter assembly can move along the longitudinal direction perpendicular to the axial line of a milling cutter, so that a distance between the milling cutter and the workpiece along the longitudinal direction can be adjusted, namely enabling the milling cutter to be far away from or close to the workpiece; and therefore, the fitting between the edge band and the plate is more compact, and the integrality and the aesthetic degree are higher.

Owner:青岛红强伟业机械有限公司

Vacuum glass and preparation method thereof

The invention discloses vacuum glass and a preparation method thereof. The vacuum glass comprises an upper glass body and a lower glass body which are bonded through organic binders and inorganic metal materials. At least one of the faces, oppositely bonded, of the upper glass body and the lower glass body is provided with an annular groove used for containing gas absorbents. The outer edges of the upper glass body and / or the lower glass body are / is provided with the inorganic metal materials arranged along the annular groove. The organic binders are arranged on the outer edges of the inorganic metal materials. The interior areas, provided with the inorganic metal materials, of the upper glass body and the lower glass body form a vacuum layer which is internally provided with supporting matter arranged in a lattice shape. According to the vacuum glass, the bonding mode that organic bonding is fused with inorganic bonding is adopted, and compact and sealing bonding of the vacuum glass is achieved; a brand-new getter adding mode is put forward, and getter can be fully and effectively utilized.

Owner:南京埃德夫机电工程技术有限公司

Edge sealing device for oil baffle plate

The invention discloses an edge sealing device for a plastic hollow plate for the manufacturing of an oil baffle plate, which is used for sealing perforated edges of the plastic hollow plate. The device includes a frame, a drawing mechanism, edge sealing mechanisms, an edge sealing mechanism adjusting mechanism, and a plate positioning and guiding mechanism. In the experimental device, a high-temperature gas injection device and a heating die device which are connected with each other are arranged in each edge sealing mechanism, so that the plastic hollow plate is preheated through high-temperature gas to achieve a melted status, and is remelted and formed in a heating die to achieve the edge sealing effect. The device is applicable for plastic hollow plates with various specifications and models, and has the advantages of simplicity and convenience in edge sealing operation, good edge sealing effect, and good appearance of plate edges.

Owner:NORTHEAST GASOLINEEUM UNIV

Edge sealing method and device for thermoplastic cellular board

The invention discloses an edge sealing method and device for a thermoplastic cellular board. The edge sealing device comprises a workbench, mold supports, hot molds, cold molds and linear driving mechanisms, wherein the mold supports are arranged at the two ends of the workbench correspondingly; the hot molds and the cold molds are arranged on the mold supports, arranged up and down, and provided with circular arc grooves matched with the thermoplastic cellular board in thickness; and the linear driving mechanisms are connected with the mold supports to drive the mold supports to move. The edge sealing method comprises the steps that the thermoplastic cellular board is placed at the preset position of the workbench; the hot molds are heated, the mold supports at the two ends are driven through the linear driving mechanisms, so that the hot molds are pushed to move forwards to make contact with the thermoplastic cellular board, and pressure is applied slowly to enable the thermoplastic cellular board to reach the specified position; and the hot molds are moved away, the hot-pressed thermoplastic cellular board is moved into the cold molds to be cooled and shaped, and edge sealing is achieved when the thermoplastic cellular board is taken out. According to the edge sealing method and device, two edges can be sealed simultaneously, so that the working efficiency is improved; the device is simple in structure and easy to operate; and according to the method, extra edge sealing bars and bonding agents are not needed, and the edge sealing effect is good.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

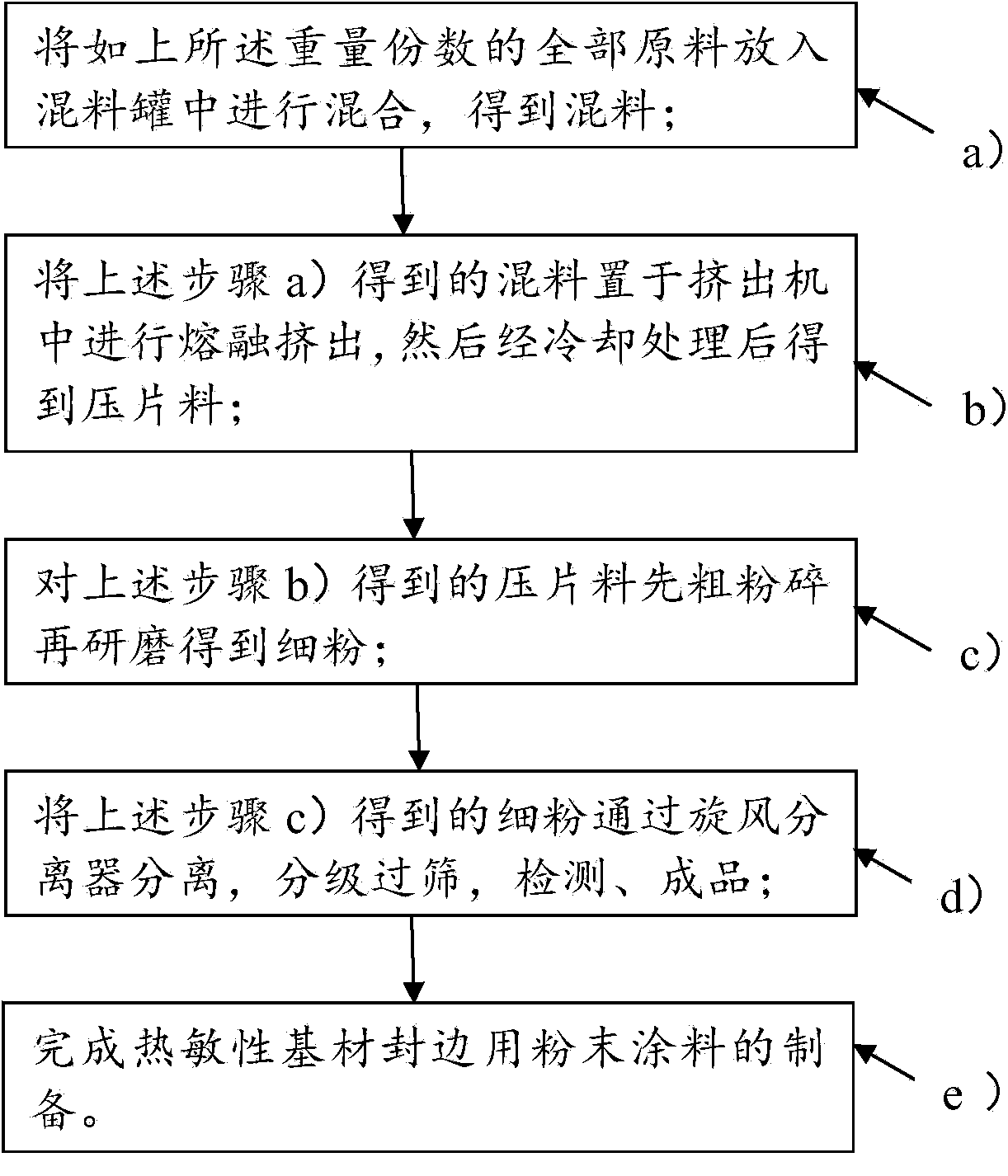

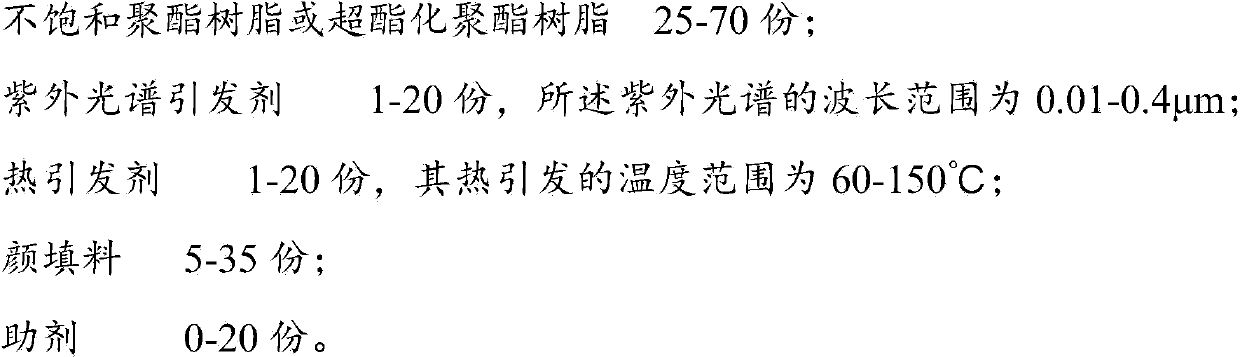

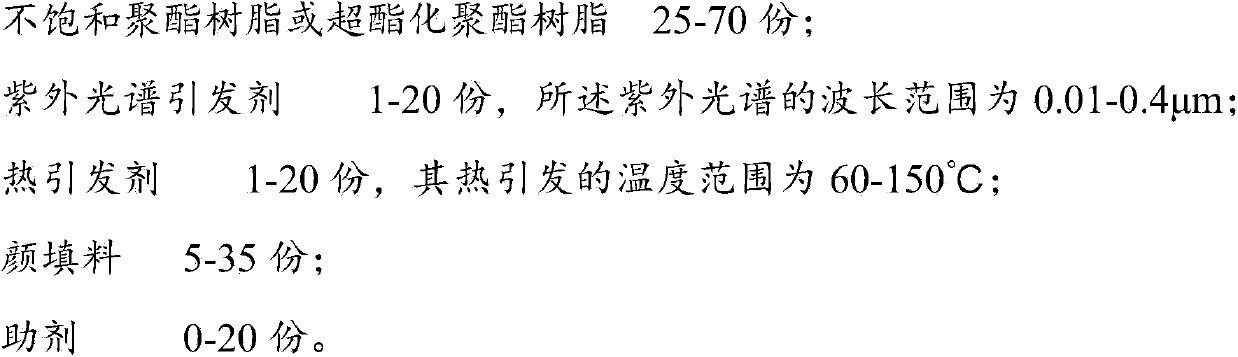

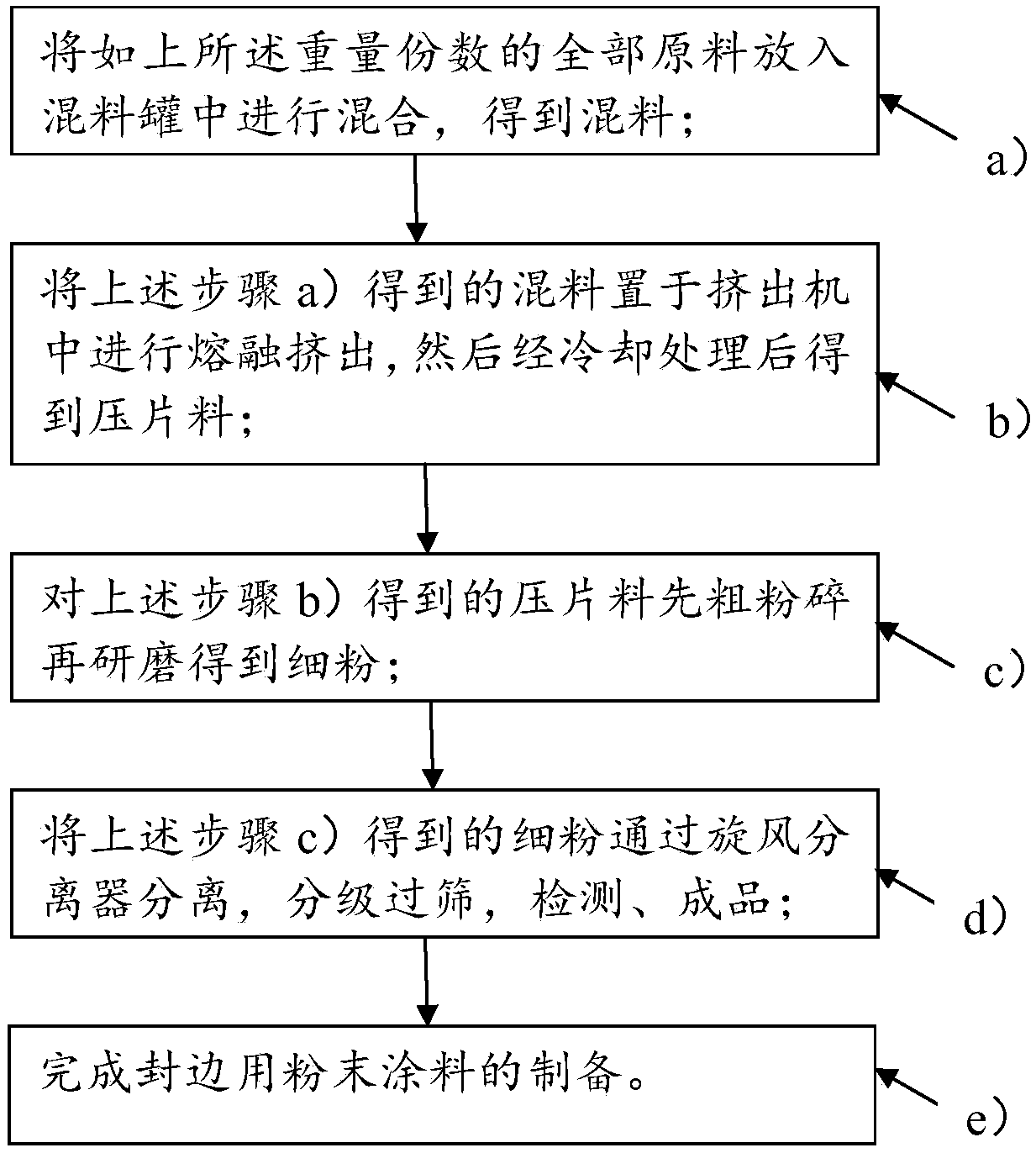

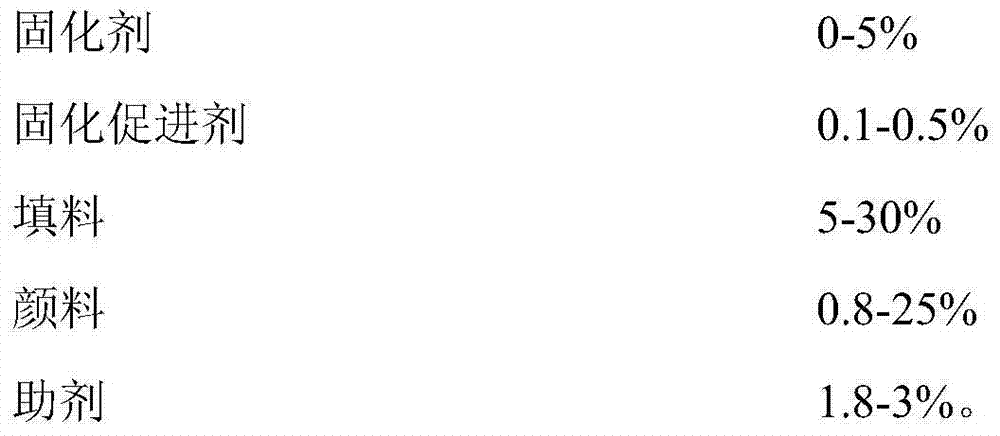

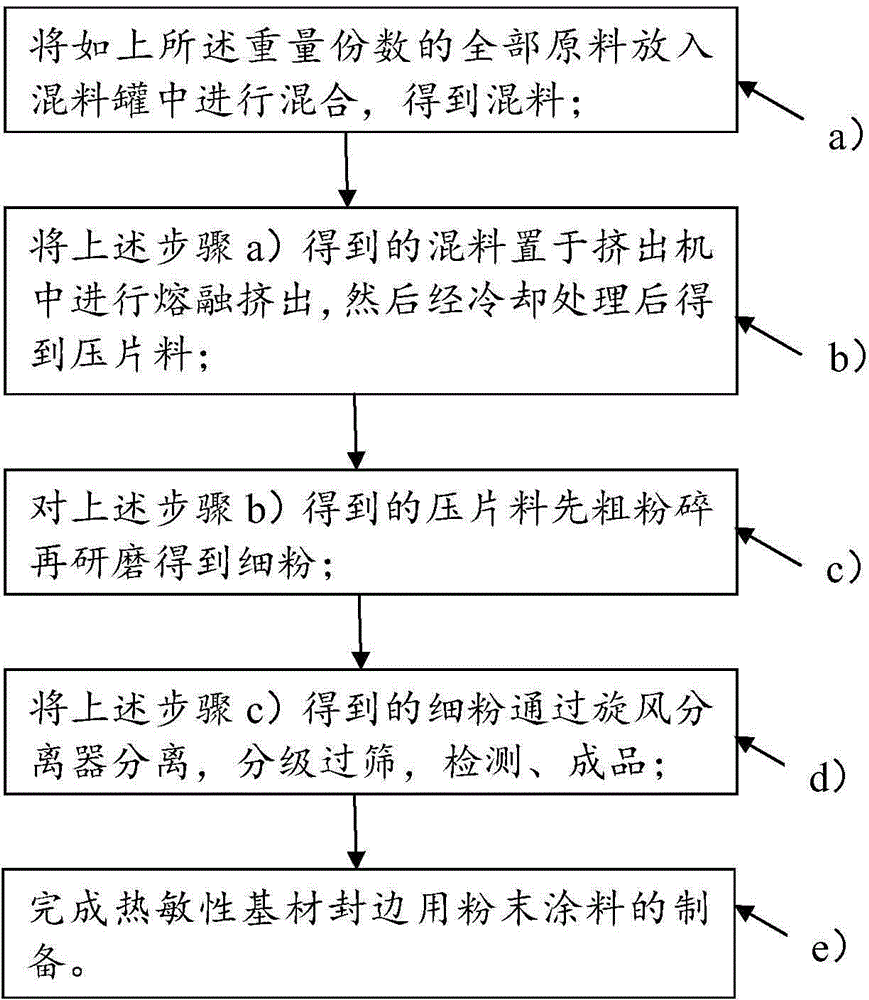

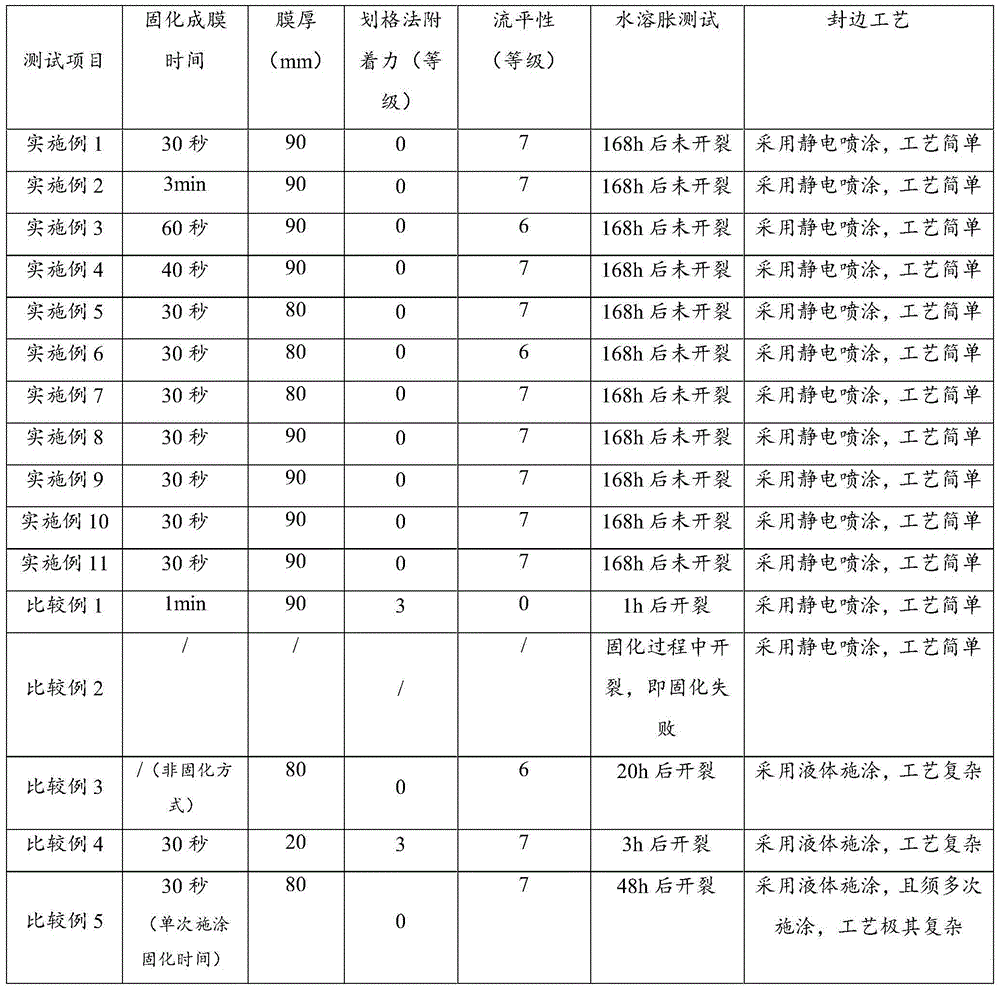

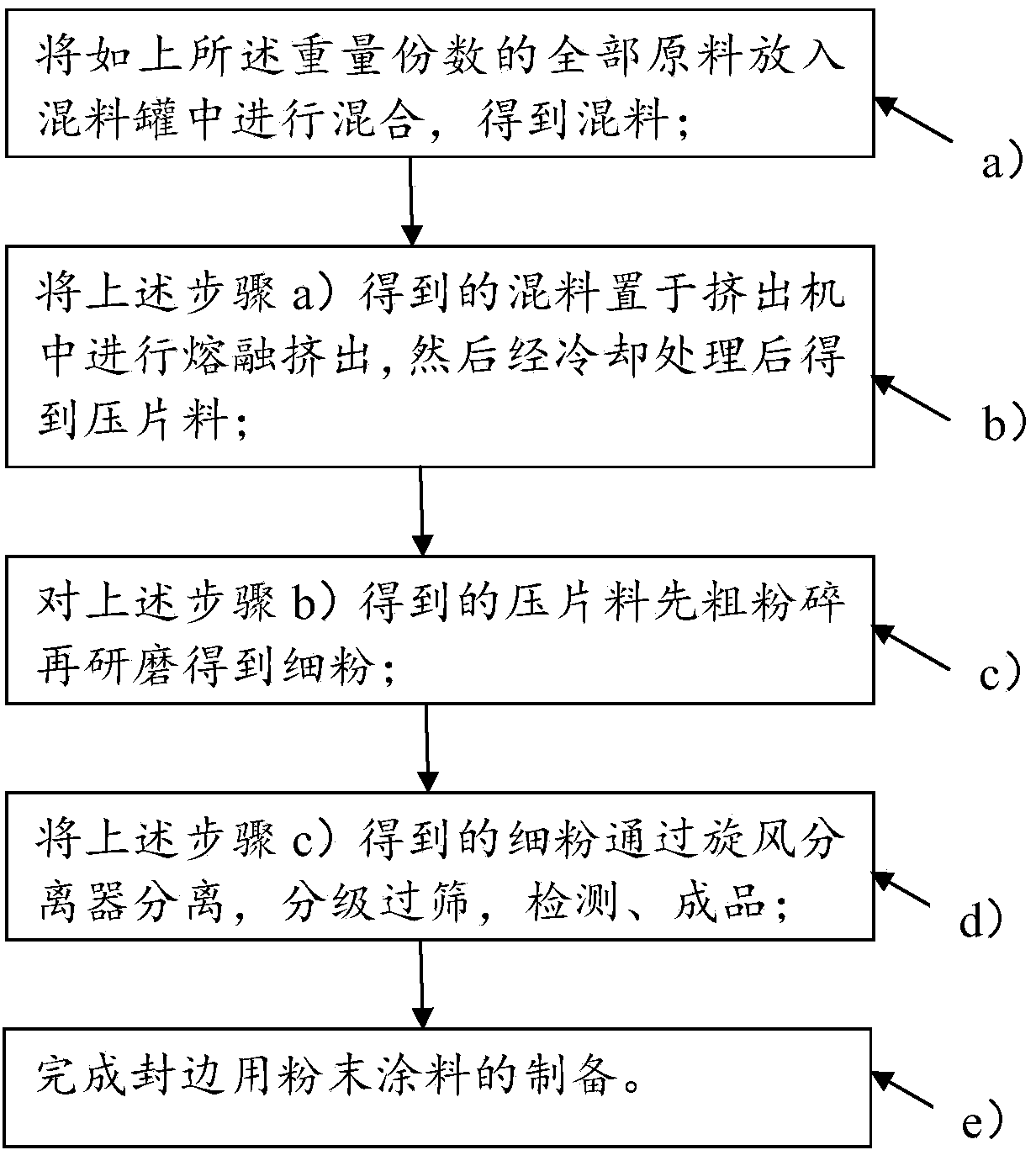

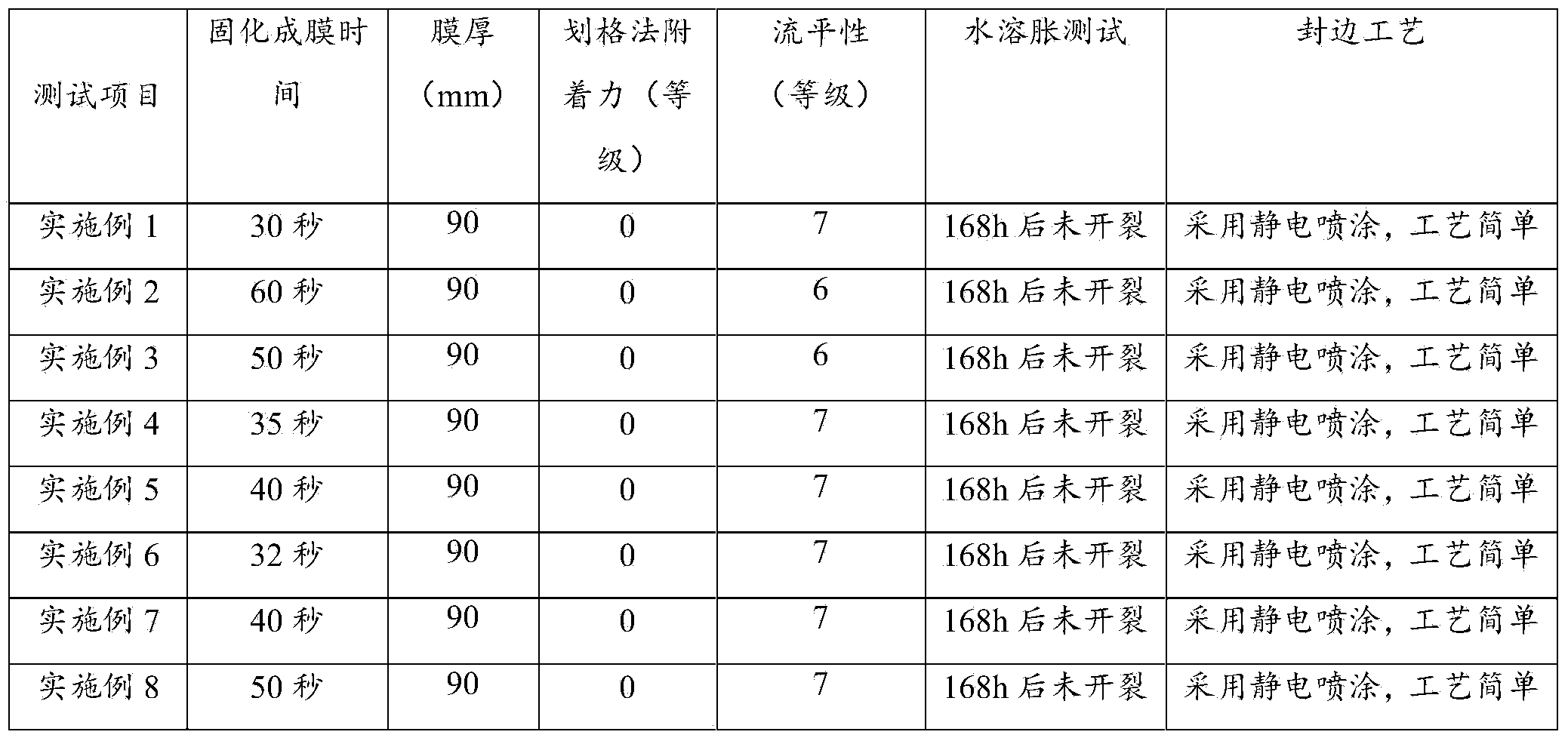

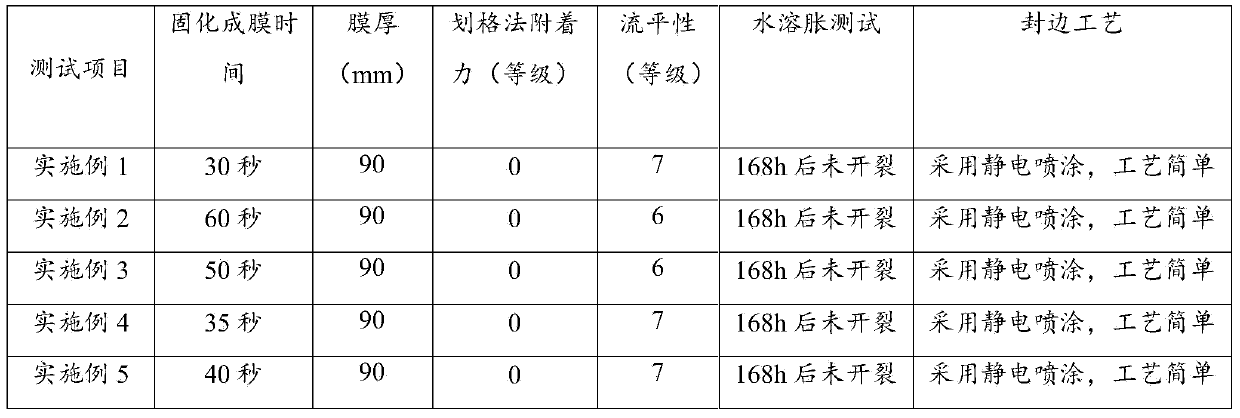

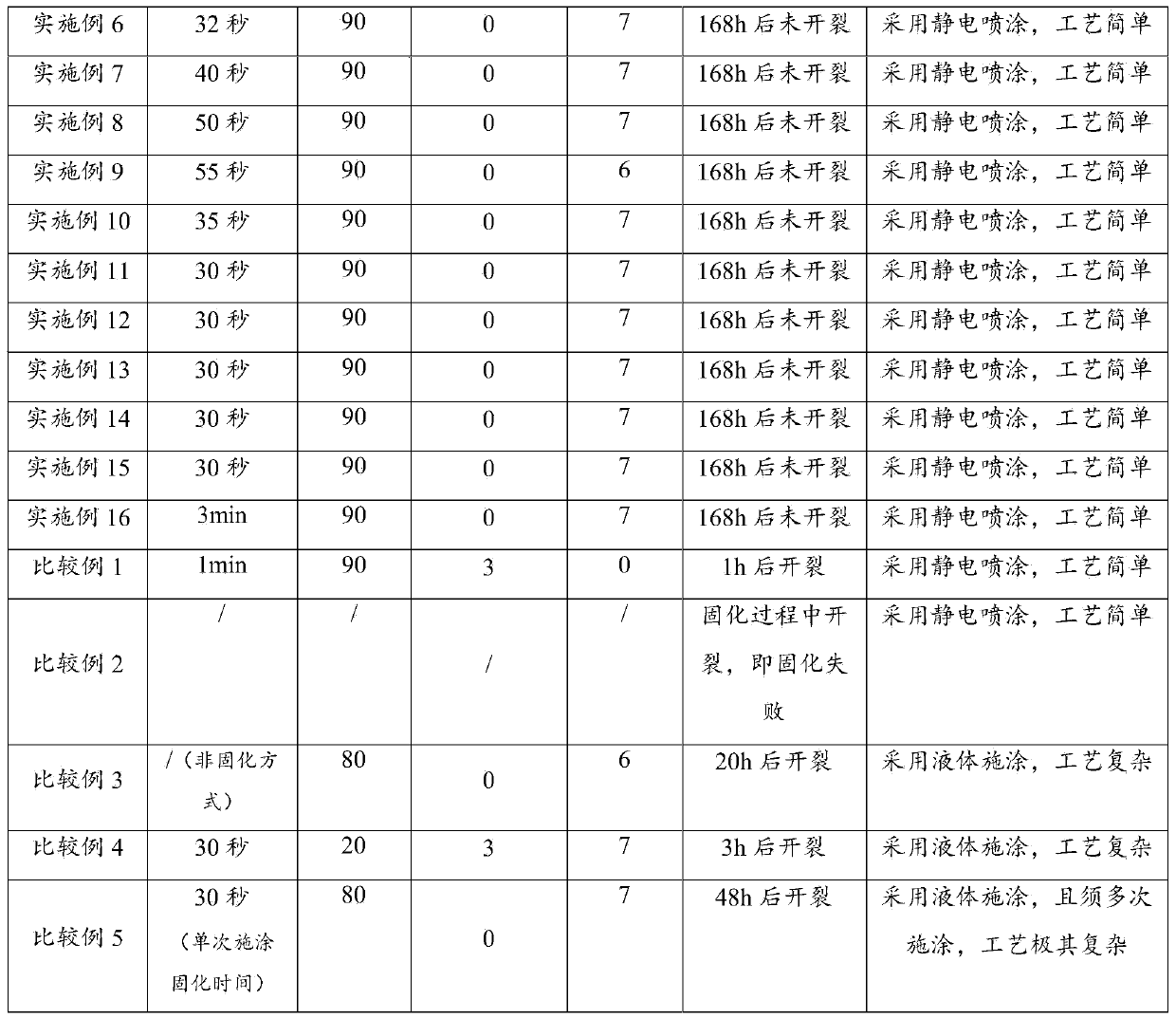

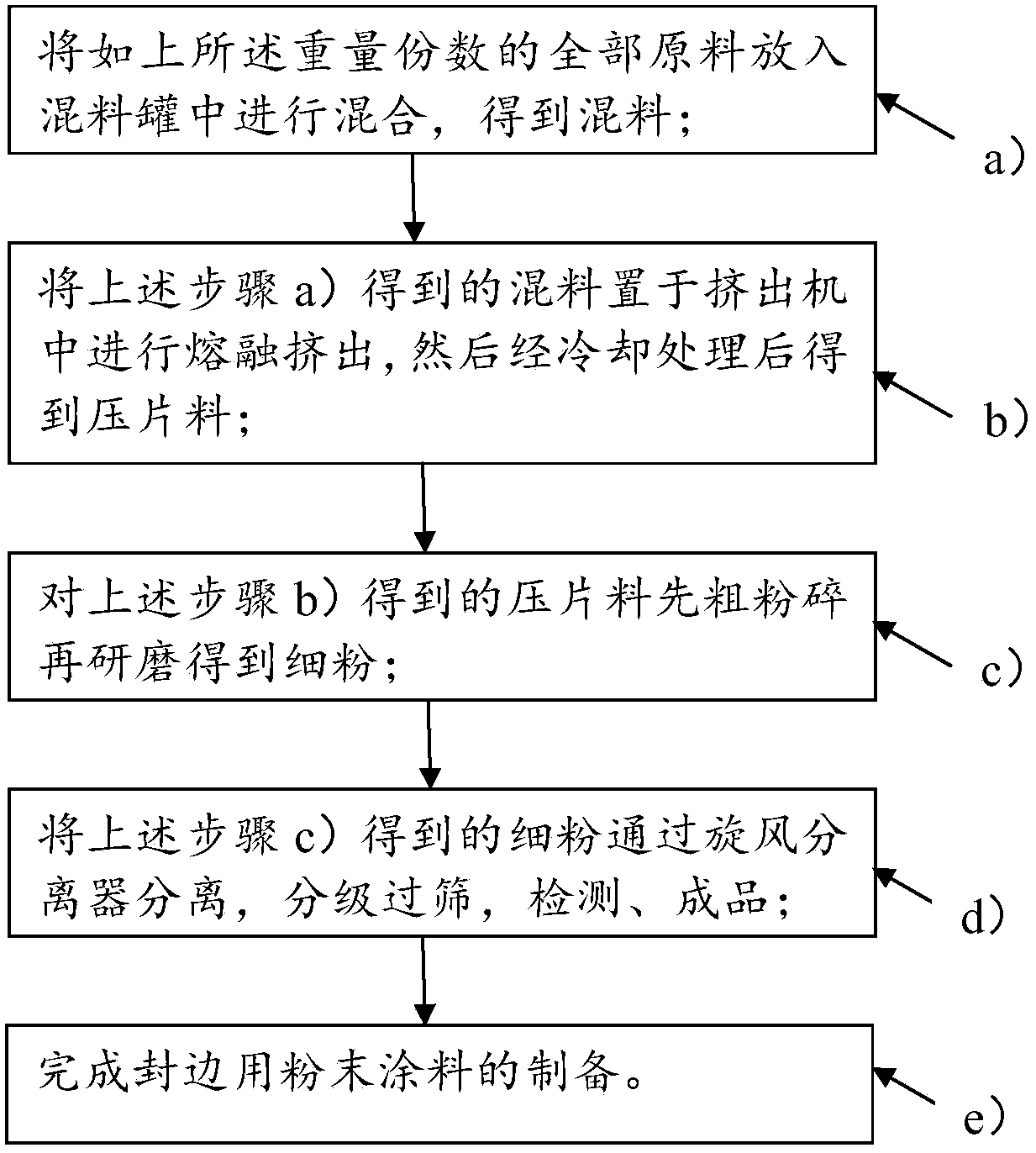

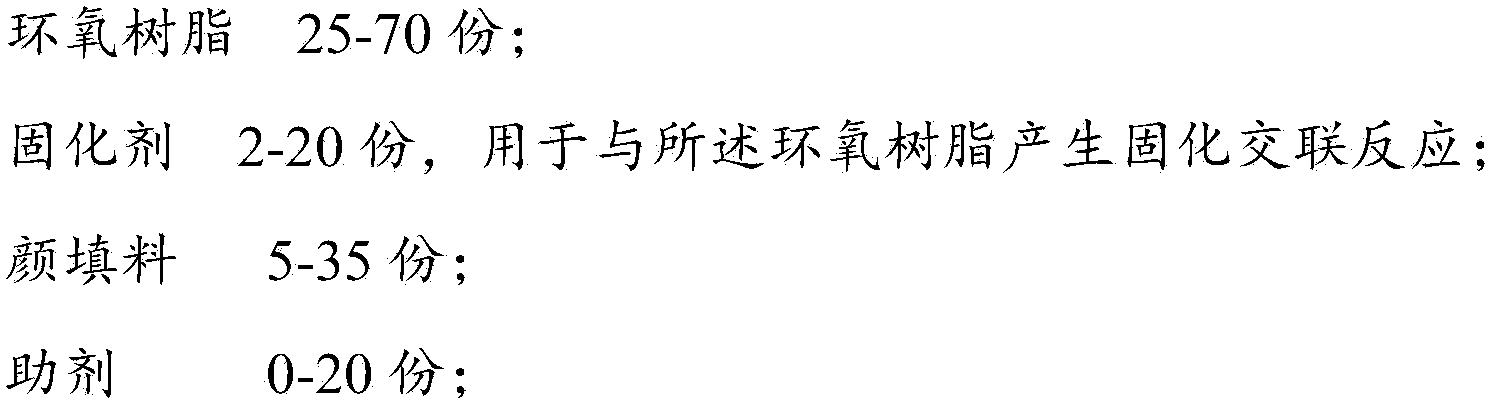

Powder coating for edge sealing of heat-sensitive base material and edge-sealing coating and preparation method thereof

InactiveCN103773189AImprove the level ofMeet strength requirementsRadiation-absorbing paintsPowdery paintsPolyester resinWavelength range

The invention relates to a powder coating for edge sealing of a heat-sensitive base material and an edge-sealing coating and a preparation method thereof. The powder coating is prepared from the following raw materials in parts by weight: 25-70 parts of unsaturated polyester resin or super-esterified polyester resin, 1-20 parts of ultraviolet spectrum initiator in the wavelength range of 0.01-0.04mu m, 1-20 parts of thermal initiator in the thermal initiation temperature range of 60-150 DEG C, 5-35 parts of pigments and fillers and 0-20 parts of aids. A good edge-sealing effect on the heat-sensitive base material is achieved, cracks generated on the side face of the heat-sensitive base material are effectively avoided, electrostatic spraying is adopted, the edge-sealing process is simple and convenient, and the powder coating is suitable for edge sealing of base material workpieces of various shapes.

Owner:TIGER DRYLAC TAICANG

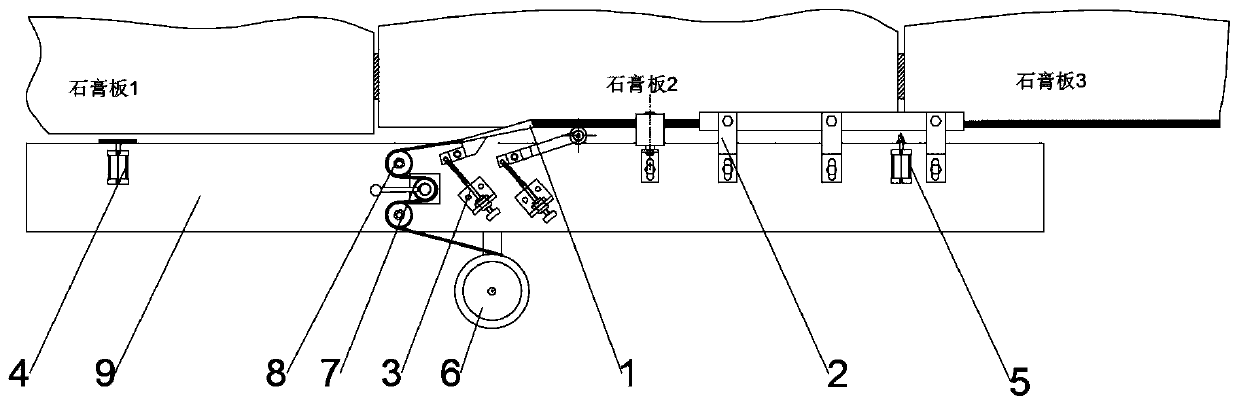

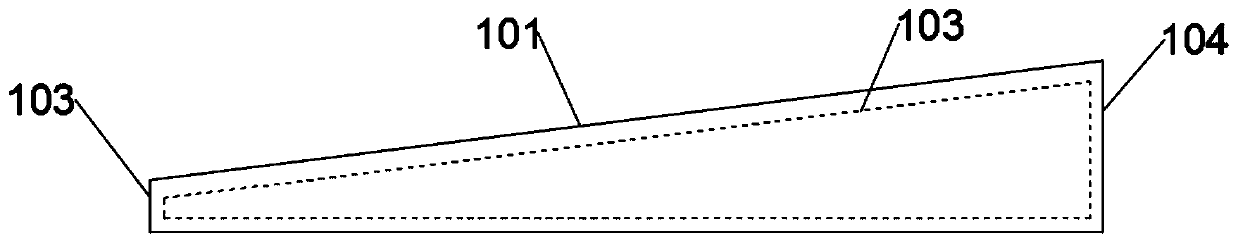

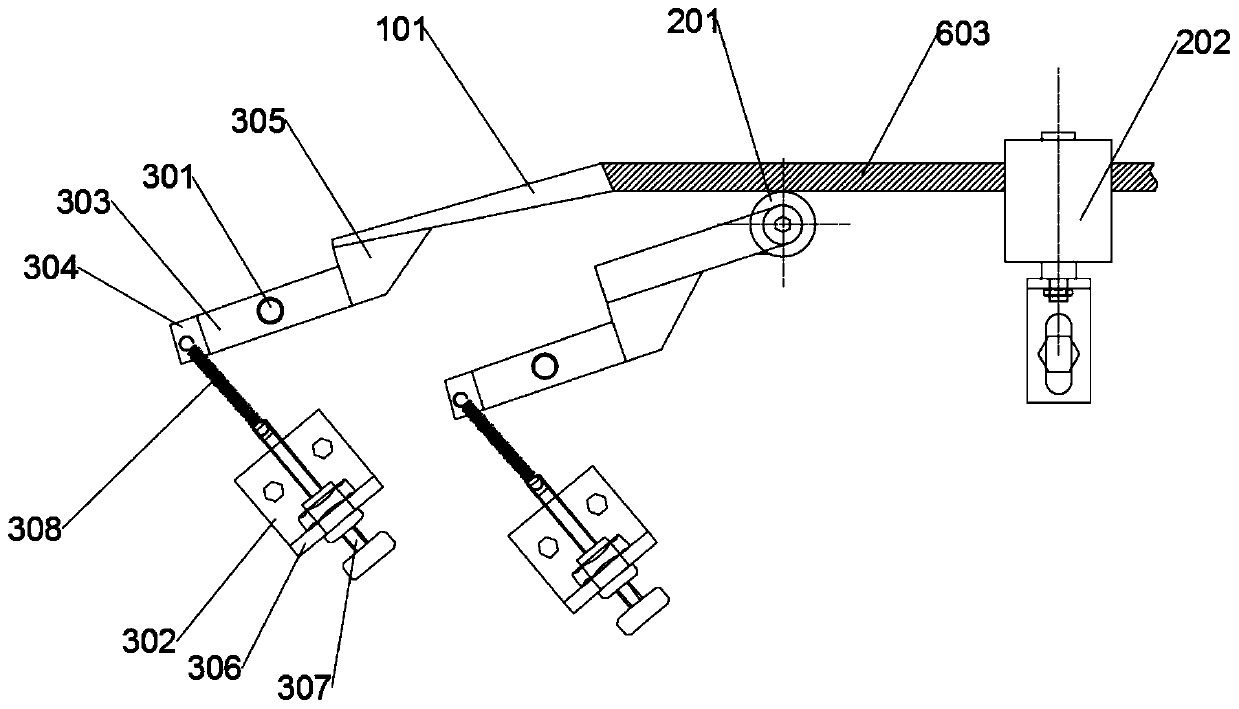

Paperbacked plasterboard edge sealing device

ActiveCN110480822AImprove toughnessAvoid breakingAuxillary shaping apparatusEngineeringOff phenomenon

An embodiment of the invention discloses a paperbacked plasterboard edge sealing device which is arranged on two sides of a plasterboard. The paperbacked plasterboard edge sealing device comprises a rack, wherein an edge sealing band paper outlet device, a water supply device, a paper folding device, a positioning device and a cut-off device are arranged on the rack; the paper folding device comprises a paper folding board; the positioning device comprises an end part positioning roller, side positioning rollers and a positioning brush, the end part positioning roller is opposite to the end part of the plasterboard, the two side positioning rollers are opposite to two sides of the end part of the plasterboard; the positioning brush is in a U-shaped structure in the side direction and is fixed on the rack through a support frame. One group of edge sealing press rollers are adopted to realize the edge sealing positioning effect, the positioning brush is adopted to apply pressure to stickan edge sealing band on a board, three groups of edge sealing press rollers in the prior art are replaced, pressure of the plasterboard is reduced while a good edge sealing effect is realized, core air holes in the edge sealing position of the end part of the plasterboard are prevented from being damaged by pressing, and the paper taking-off phenomenon is prevented.

Owner:HUAINAN BEIXIN BUILDING MATERIAL +1

PDLC dimming membrane and edge sealing process thereof

ActiveCN110794608AImprove the effect of edge bandingIncrease contact areaNon-linear opticsPolyurethane adhesiveAdhesive belt

The invention provides a PDLC dimming membrane and an edge sealing process thereof. The process comprises the following steps of manufacturing an electrode of the PDLC dimming membrane and forming a groove between the electrode and the PDLC dimming membrane; placing the PDLC dimming membrane with the electrode on a platform and cleaning the PDLC dimming membrane by using a cleanser; covering the electrode area for protection by using an adhesive tape; in the area, without the electrode, of the PDLC dimming membrane, cutting an edge sealing groove at a position more than 5mm inwards from the edge by using a cutting device; cleaning the materials cut from the edge sealing groove by using a solvent which is capable of dissolving PDLC; painting a cementation accelerant at the edge sealing groove; and filling polyurethane flue into the groove between the electrode and the PDLC dimming membrane and the edge sealing groove for curing by using a gluing device, and ripping out the adhesive tapeafter the curing is finished. The dimming membrane produced by adoption of the edge sealing process is favorable in edge sealing, firm in edge sealing glue cementation, good in bending resistance anddifficult to break.

Owner:FUYAO GLASS IND GROUP CO LTD

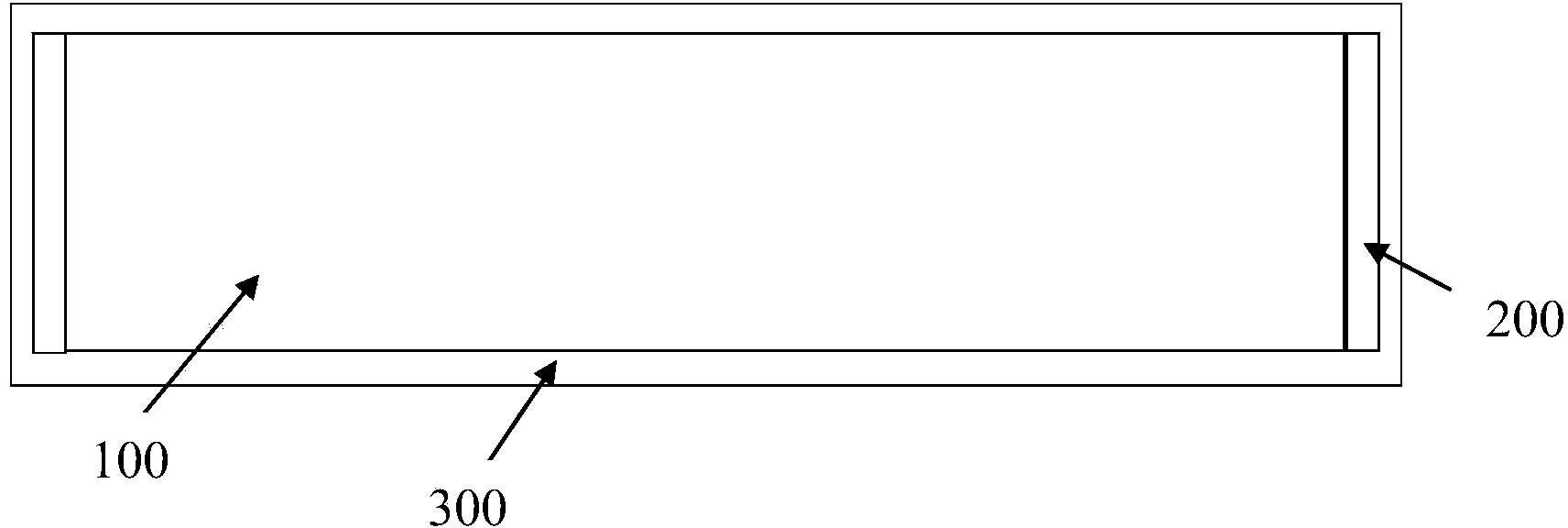

Medium-density fiberboard

InactiveCN103805026AMechanical strength requirements are metThe edge banding process is simple and convenientPretreated surfacesPowdery paintsMetallurgySpray coating

The invention relates to a medium-density fiberboard, which comprises a medium-density fiberboard body, wherein an edge-sealing coating is arranged on the lateral surface of the board body; a thermosetting coating is arranged on the edge-sealing coating and the surface of the board body; the edge-sealing coating is obtained by electrostatically spray-coating and curing an edge-sealing powder coating on the lateral surface of the board body; the thermosetting coating is obtained by electrostatically spray-coating and curing a low-temperature curing powder coating on the edge-sealing coating and the surface of the board body. According to the medium-density fiberboard, a good edge sealing effect can be achieved, and cracks in the lateral surface of the medium-density fiberboard are effectively avoided; an electrostatic spray-coating mode is adopted, so that an edge-sealing process is simple, convenient and suitable for the edge sealing of substrate workpieces in various shapes.

Owner:TIGER DRYLAC TAICANG

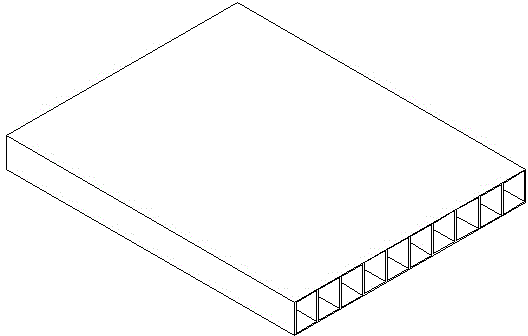

Edge sealing machine for hollow plates

PendingCN104985803AImprove safety and reliabilityImprove the effect of edge bandingEngineeringAutomation

The invention discloses an edge sealing machine for hollow plates. The edge sealing machine comprises a feeding mechanism, a heating mechanism, an edge pressing mechanism and a burr trimming mechanism, wherein the feeding mechanism comprises a plurality of traction assemblies; two height adjusting structures are respectively arranged at both ends of each traction assembly; the heating mechanism comprises two heating assemblies, and the two heating assemblies respectively correspond to two parallel edges of a heated hollow plate; the edge pressing mechanism comprises two rolling assemblies, and the two rolling assemblies respectively correspond to two parallel edges of the processed hollow plate; the burr trimming mechanism comprises two trimming cutter assemblies, and the two trimming cutter assemblies respectively correspond to two parallel edges of the processed hollow plate; a detection device is arranged in front of the burr trimming mechanism and used for detecting the existence of the hollow plate, so that the start and the stop of the heating mechanism are controlled; the feeding mechanism, the heating mechanism, the edge pressing mechanism, the burr trimming mechanism and the detection device are respectively connected with a PLC controller. The edge sealing machine disclosed by the invention can realize an ideal edge sealing effect for hollow plates, and is high in degree of automation, so that the edge sealing machine can be suitable for hollow plates of any specifications.

Owner:昆山劲荣精密机械有限公司

Hollow plate edge bonding forming system

The invention discloses a hollow plate edge bonding forming system. The hollow plate bonding forming system comprises a heating unit which is at least used for heating the side part of a hollow plate until softening, a thermal cutting unit which is at least used for cutting a reinforcing rib in the side part of the softened hollow plate, a hot contracting unit for contracting the side part of the cut hollow plate, a thermal forming unit for processing the side part of the contracted hollow plate to be in a set sealing form and a cooling forming unit for cooling the side part of the hollow plate with a set form for forming. The hollow plate edge bonding forming system has the advantages that the structure is simple, the manufacture cost is low, the cutting location of the hollow plate is accurate, the edge bonding effect is good, the cost is effectively lowered, the product quality is improved, and the yield is increased.

Owner:SUZHOU HOLDEN AUTO

Reactive polyurethane hot melt adhesive for edge sealing

ActiveCN110157370AHigh strengthLower melting temperatureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesion strength

The invention discloses a reactive polyurethane hot melt adhesive for the edge sealing, and belongs to the technical field of adhesives. The reactive polyurethane hot melt adhesive comprises the following raw materials in parts by mass: 5-15 parts of diisocyanate, 60-80 parts of polyester diol, 10-30 parts of tackifying resin, 2-8 parts of a filler, 0-2 parts of a pigment, 0.1-0.5 part of a stabilizer, 1-2 parts of maleic anhydride, and 0.1-0.5 part of graphene. The product has excellent initial adhesion strength and final strength, relatively low melting temperature and extremely short curingtime, and good heat resistance and storage stability, and is particularly suitable for the edge sealing processing of boards, the edge sealing effect is good, and the hot melt adhesive is safe, greenand pollution-free; and the product has no drying process and simple operation, is conducive to improving work efficiency and automation, and has low production cost and broad application prospects.

Owner:永隆高新科技(青岛)有限公司

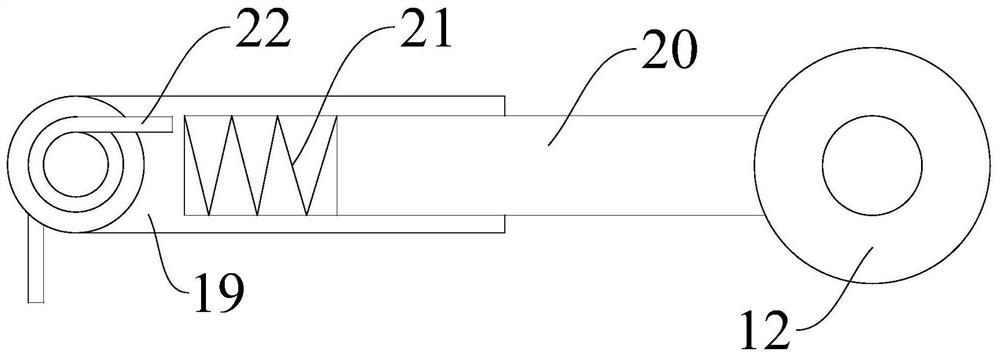

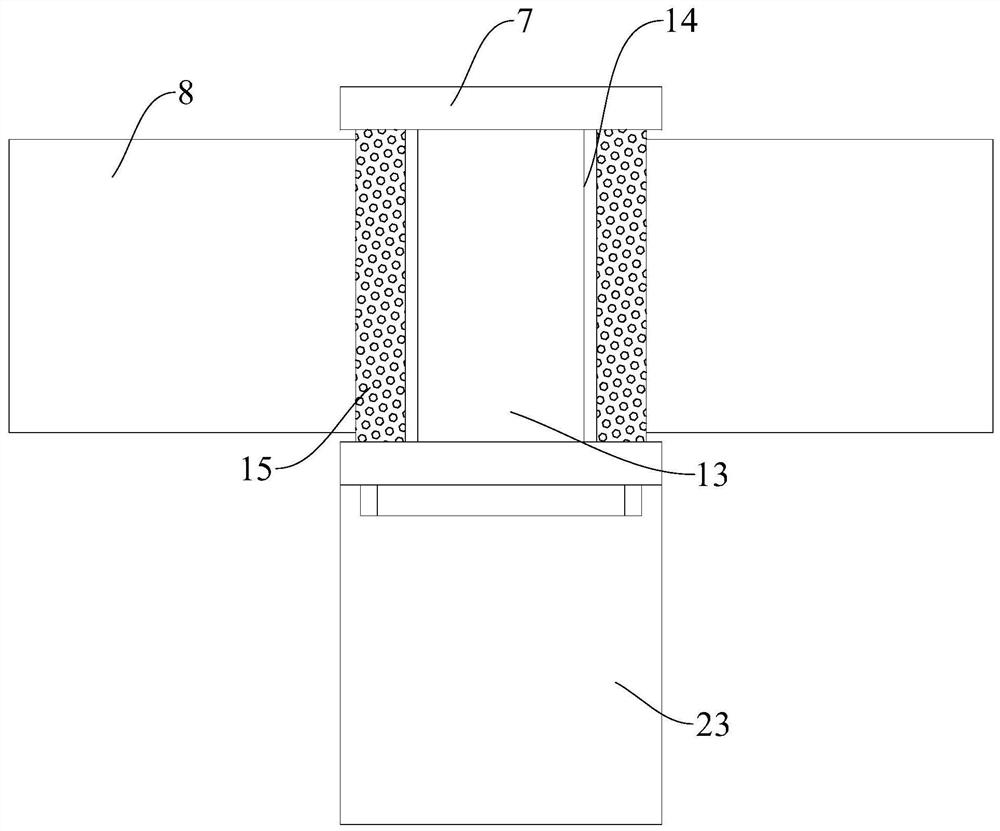

Gluing device used for plate edge sealing

ActiveCN110774386AGood edge banding effectImprove close contactOther plywood/veneer working apparatusPretreated surfacesStructural engineeringMechanical engineering

The invention discloses a gluing device used for plate edge sealing, and relates to the technical field of plate machining. The device comprises a rack, a first feeding wheel, a second feeding wheel,a pressure connecting wheel, a guide mechanism, a gluing assembly and a drying assembly. The edge sealing gluing mechanism can be in tight contact with the edge of a plate through a buffer spring, theguide mechanism achieves the guide effect in the pressure connecting process of an edge sealing strip, and also achieves the effects of supporting the gluing assembly and driving the gluing assemblyto be in contact with the plate, a reset spring is arranged in the gluing assembly, the effect of tight contact between the gluing assembly and the plate is further improved, and the edge sealing effect of the plate reaches the optimal state.

Owner:安徽忠盛新型装饰材料有限公司

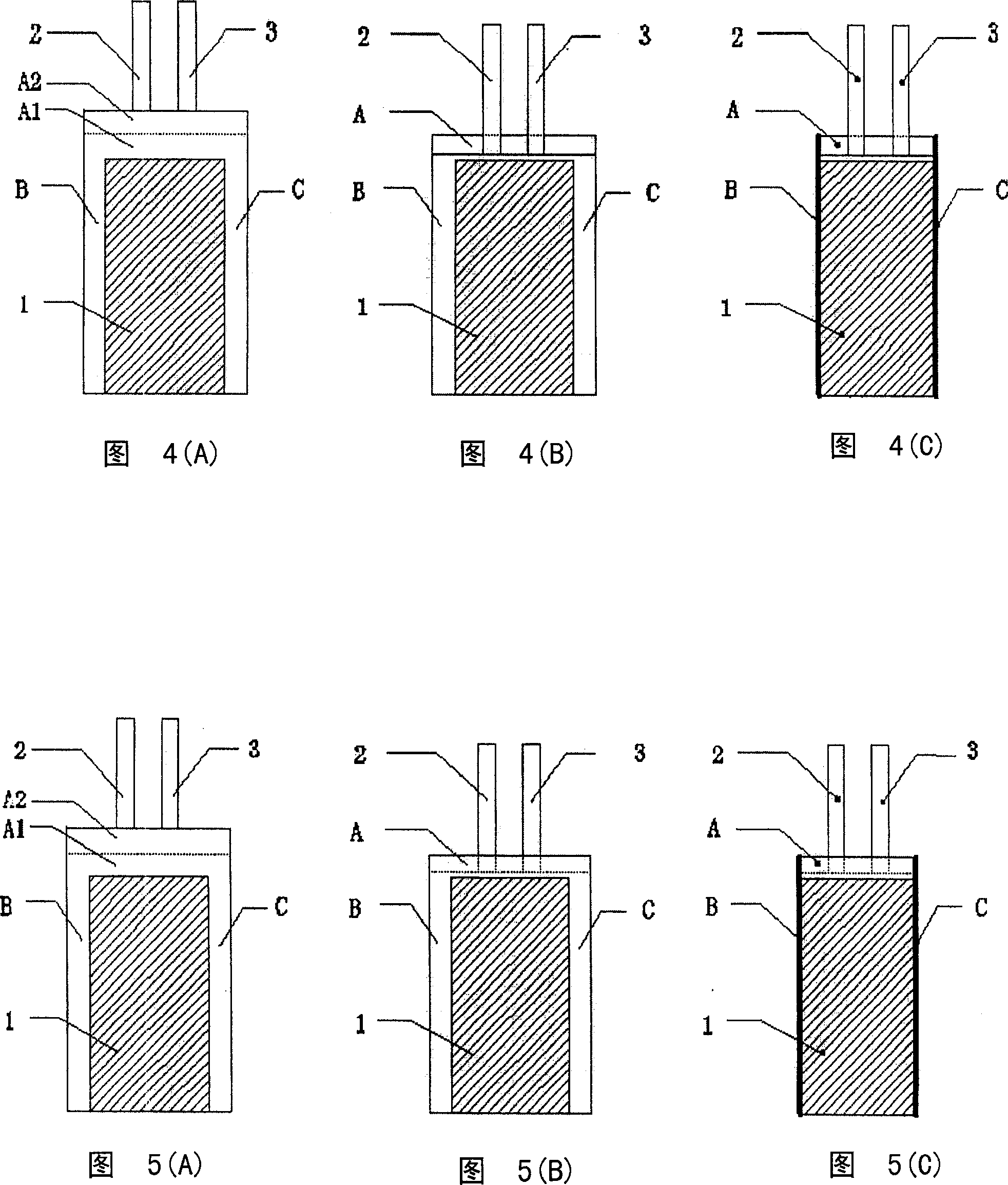

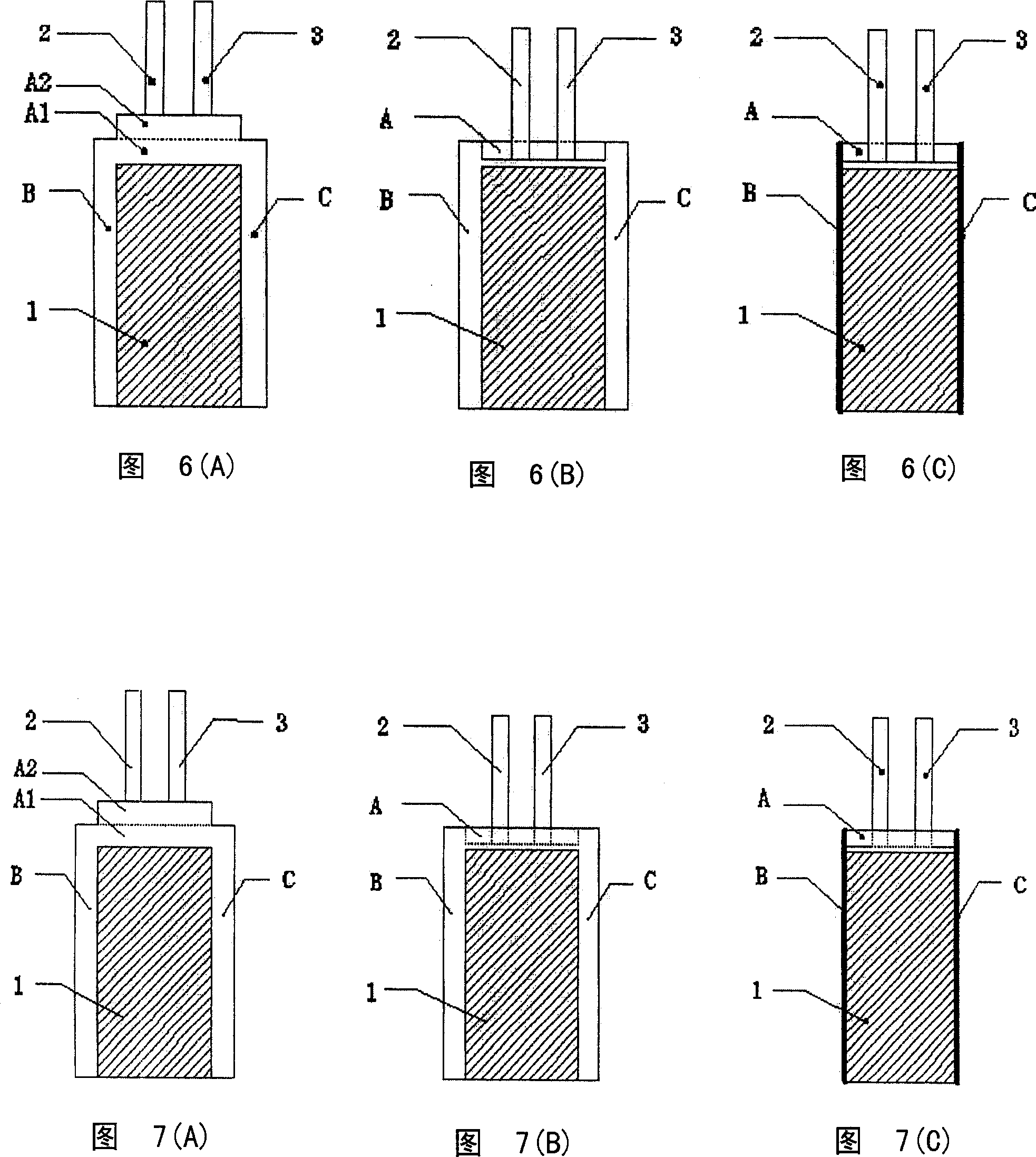

Structural design of soft package for the core of lithium ion cell, and fabricating method

InactiveCN101093899AImprove the effect of edge bandingFinal product manufactureCell component detailsLithiumElectrolyte

Increasing width of sealed edge for pole ear side and folded side, and making multiple times of sealed edge raises performance for sealing edge markedly, and reduces risk of leaking electrolyte from sealing edges of battery. Folding sealed edge for pole ear side makes unchanged ratio between pole ear side and length of battery. The disclosed method gathers advantages of current batteries in soft package for the battery prepared by using the invention. Moreover, under condition of not changing side utilized by sealed edge of battery, the invention raises performance of sealed edge markedly.

Owner:DANLIAN BATTERY SHENZHEN

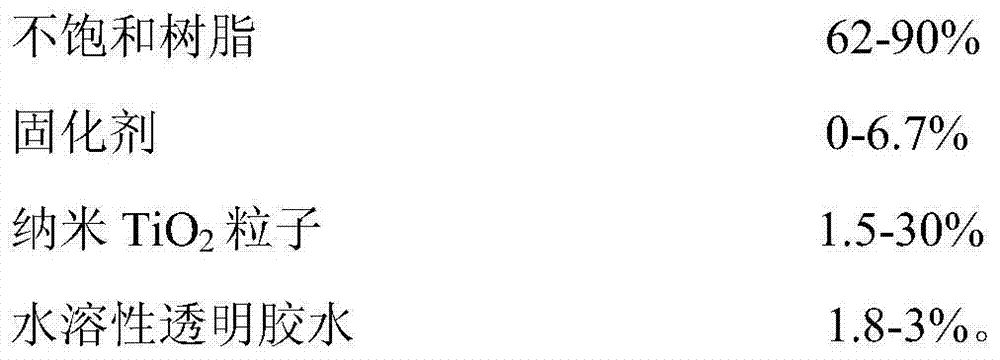

Medium density fiberboard employing high-permeability nano water-based resin edge banding

PendingCN104497816AImprove corrosion resistanceImprove insulation performancePowdery paintsEpoxy resin coatingsWater basedMedium density

The invention relates to a board, and particularly relates to a medium density fiberboard employing high-permeability nano water-based resin edge banding. The medium density fiberboard comprises a medium density fiberboard body, wherein the side surface of the board body is provided with an edge banding coating; thermosetting coatings are arranged on the edge banding coating and the surface of the board body; the thermosetting coatings are obtained by electrostatic spraying and curing treatment of low-temperature curing powder coatings on the edge banding coating and the surface of the board body; the edge banding coating is obtained by edge banding and drying treatment of the high-permeability nano water-based resin on the side surface of the board body; and the high-permeability nano water-based resin is prepared from the following raw materials in percentage by mass: 62%-90% of unsaturated polyester resin, 0-6.7% of a curing agent, 1.5%-30% of nanometer TiO2 particles, and 1.8%-3% of water-soluble transparent glue. The medium density fiberboard is good in edge banding effect; cracks are effectively prevented from being generated on the side surface of the medium density fiberboard; the blocking technology is simple and convenient, and is suitable for edge banding of base material workpieces with various shapes; and the requirements of different medium density fiberboards on the mechanical strength of the edge banding coating can be met.

Owner:山东朗法博粉末涂装科技有限公司

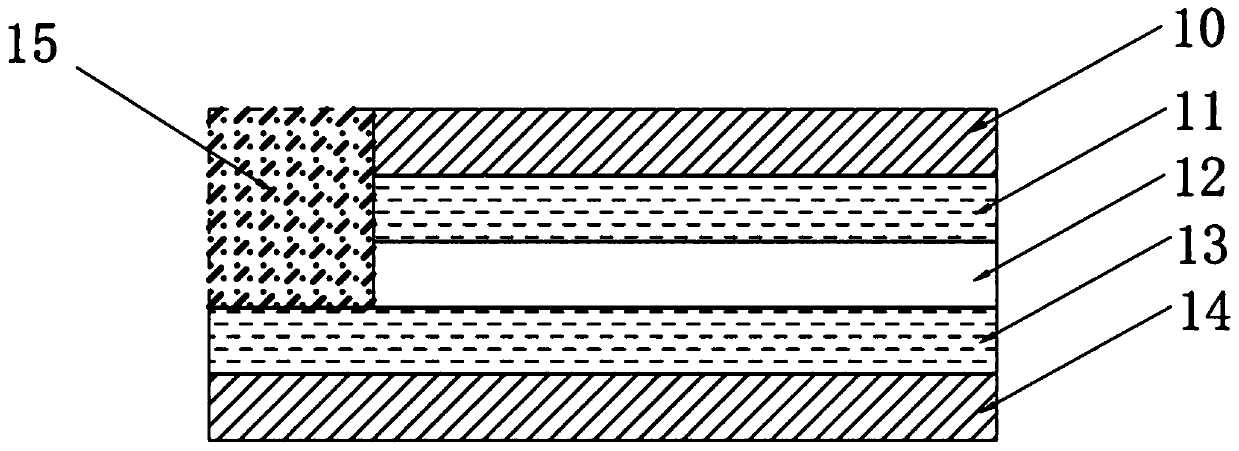

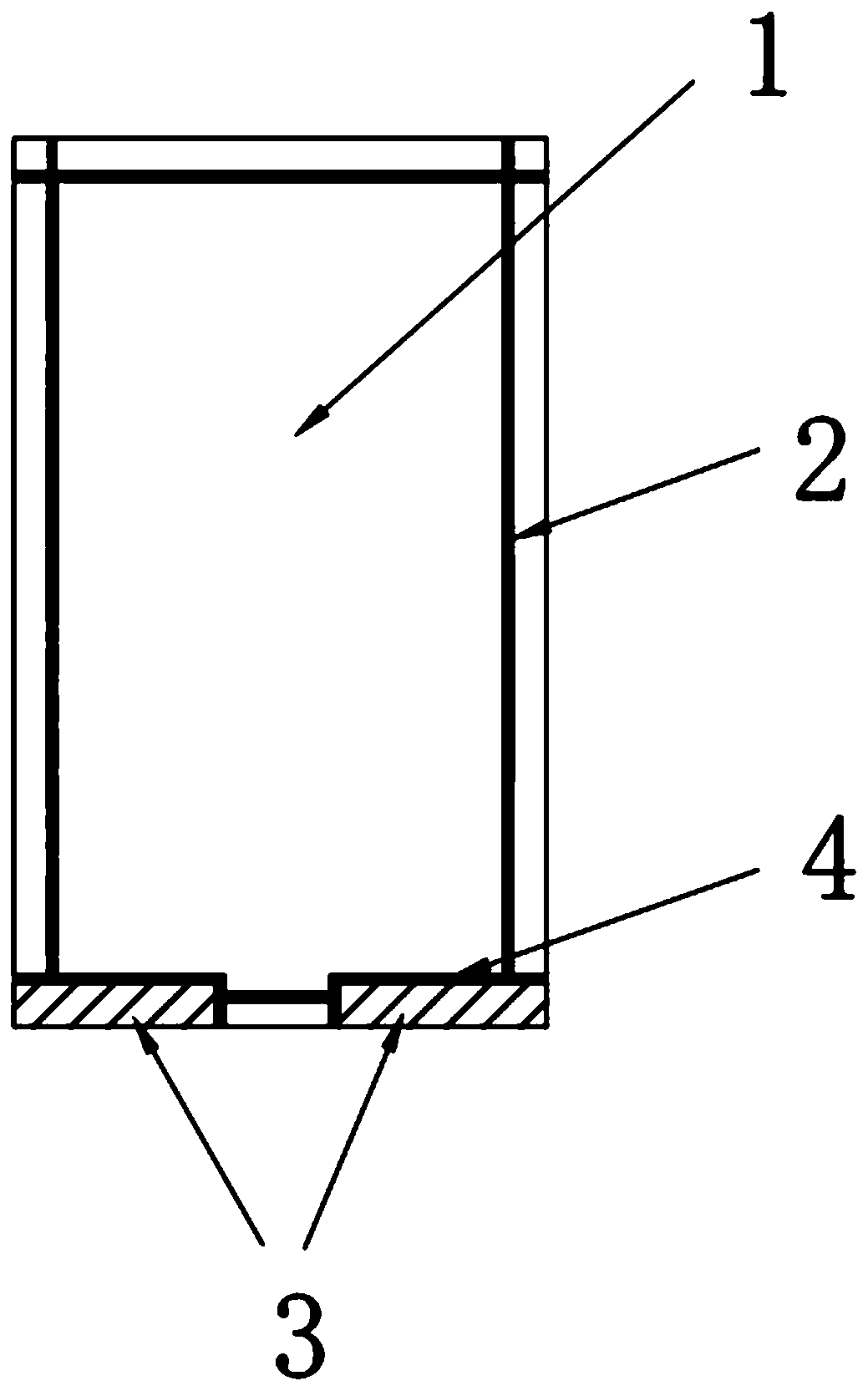

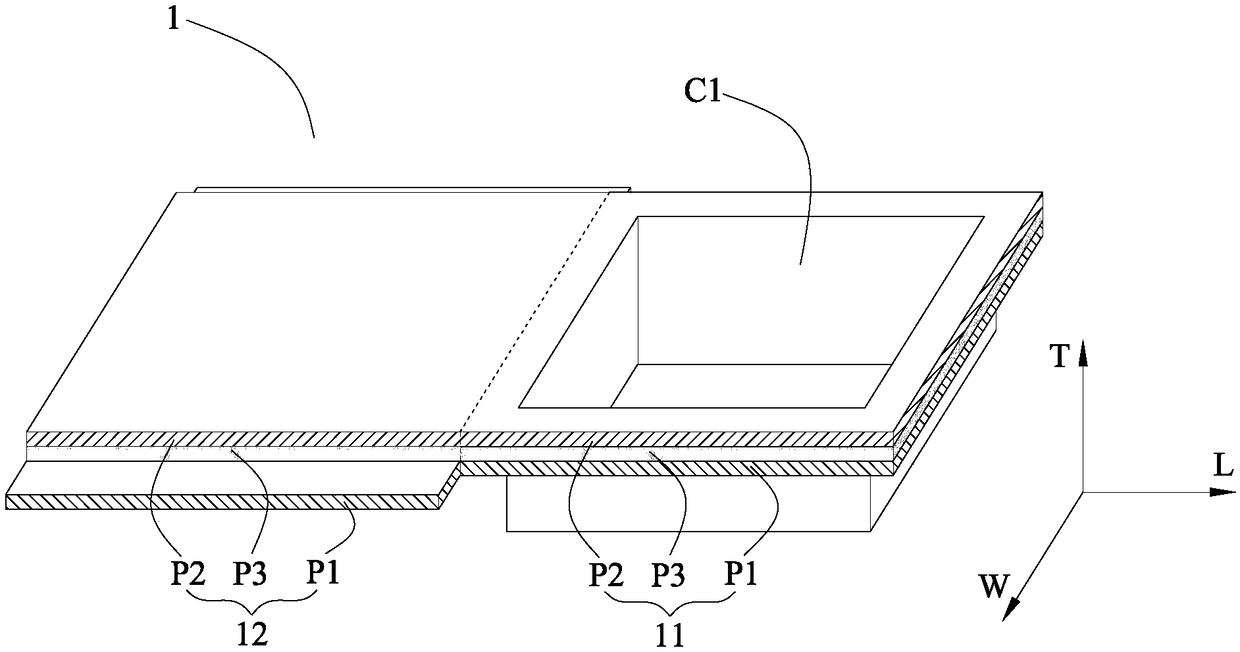

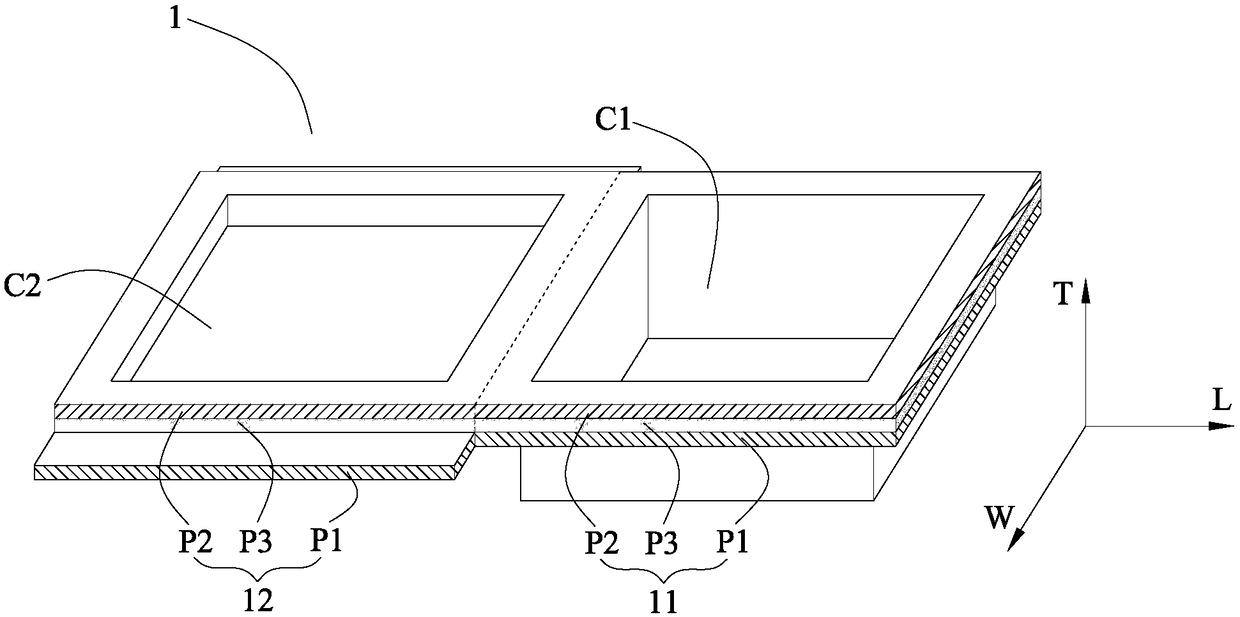

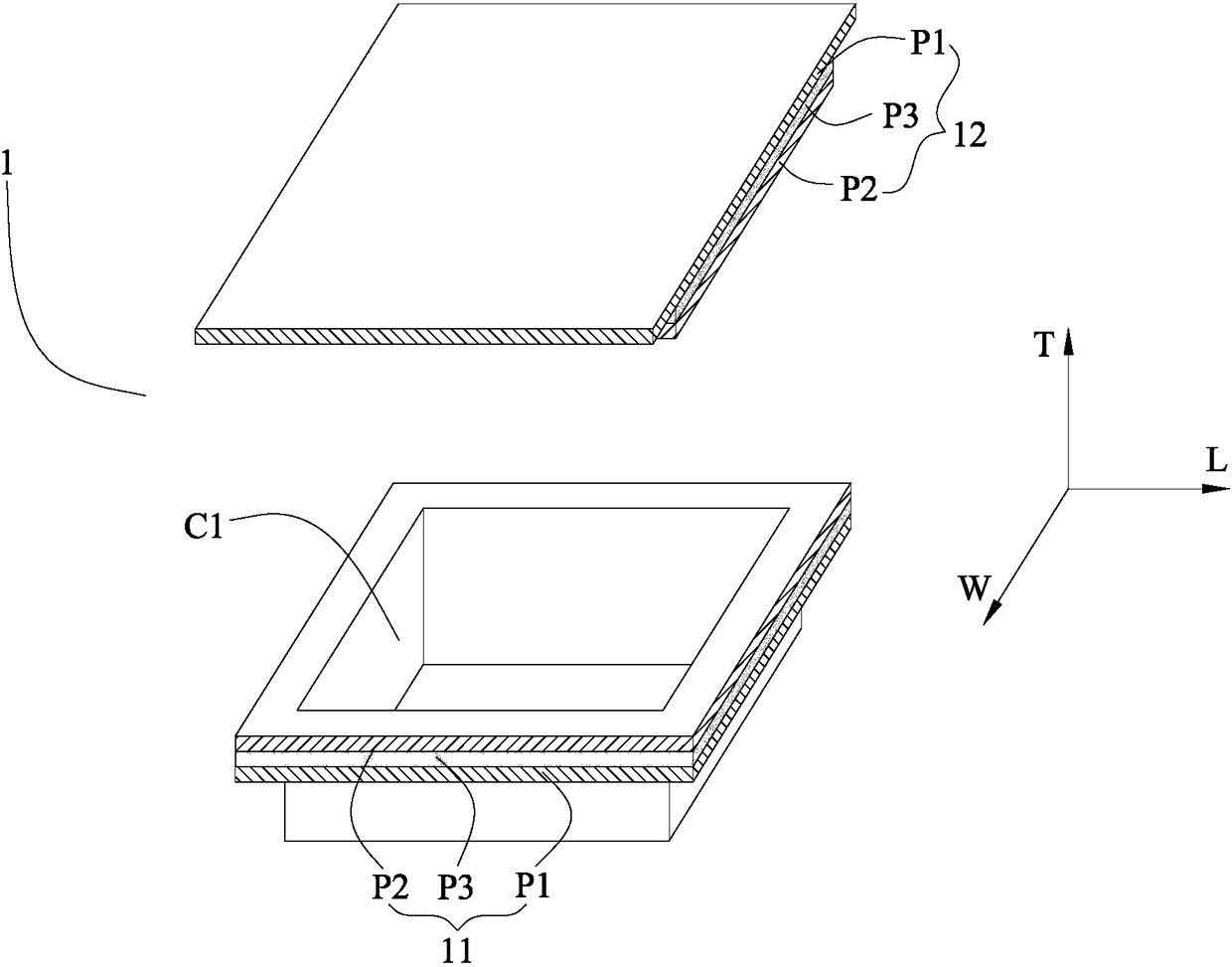

Package shell and soft package battery

ActiveCN108428812AReduce thicknessIncrease energy densitySecondary cellsJackets/cases materialsProtection layerElectrical and Electronics engineering

The invention provides a package shell and a soft package battery. The package shell comprises a first packaging film and a second packaging film, wherein the first packaging film and the second packaging film respectively comprise an outer protection layer, an inner fusion layer and a metal layer positioned between the outer protection layer and the inner fusion layer, and the first packaging film forms a concave cavity. The soft package battery comprises: the package shell, wherein the inner fusion layer of the second packaging film is integrally connected to the inner fusion layer, around the concave cavity, of the first packaging film; and a battery core received in the concave cavity of the first packaging film, wherein the connection portion of the second packaging film and the firstpackaging film forms side sealing edges and a top sealing edge, the side sealing edges are folded and adhered to the outer wall of the concave cavity, at least the edge at one side of the outer protection layer of the second packaging film exceeds the metal layer of the second packaging film, at least one of the edges exceeding the metal layer of the second packaging film is positioned on the side sealing edge, and on the side sealing edge, the part, exceeding the metal layer of the second packaging film, of the outer protection layer of the second packaging film is folded and fixed on the outer protection layer of the first packaging film.

Owner:NINGDE AMPEREX TECH

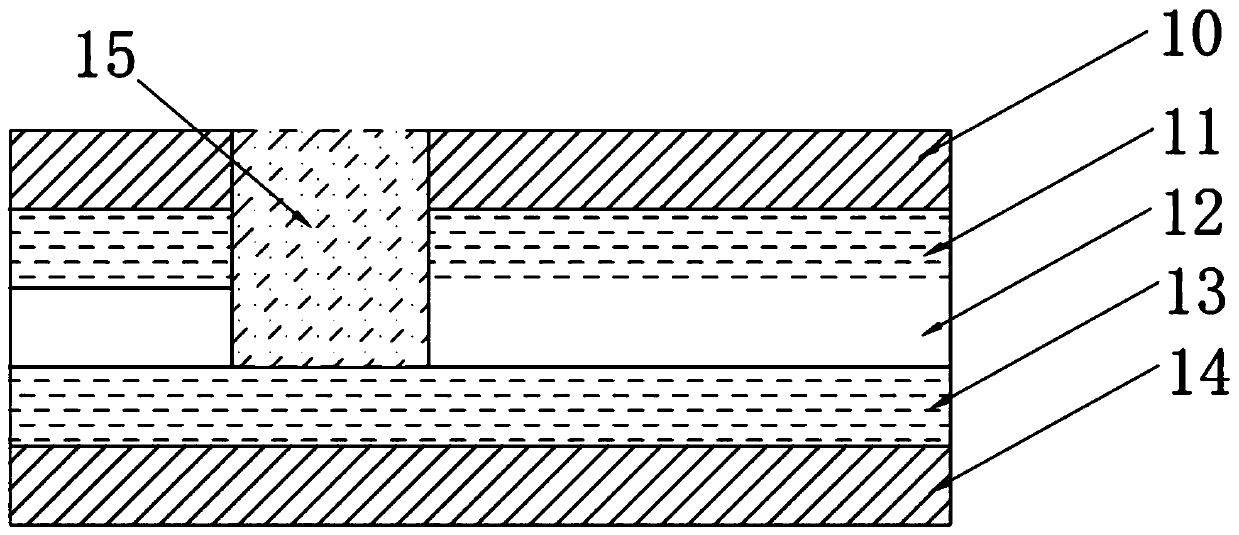

Soft package battery

InactiveCN108428809ASimplify the edge banding processImprove the effect of edge bandingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical batteryEngineering

The present invention provides a soft package battery, which comprises two layers of packaging films and a battery core packaged between the two packaging film layers, wherein each packaging film layer comprises an outer protection layer, an inner fusion layer and a metal layer positioned between the outer protection layer and the inner fusion layer, the two packaging film layers form a main bodypart for accommodating the battery core at the middle portions, and are sealed and connected around the main body part to form a top sealing part and side sealing parts, the side sealing parts are folded and adhered to the side surfaces of the main body part, each packaging film is divided into a body and a free end on the side sealing part, the free end is folded back to the corresponding body, the metal layer is exposed to the end surfaces of each free end, and the free ends of the two packaging film layers are integrally fixed and are clamped between the bodies of the two packaging films. According to the present invention, the insulating sealing of the metal layer exposed to the end surface can be achieved by using the folding structure of each packaging film on the side sealing partswithout other edge sealing materials so as to simplify the edge sealing process of the battery and improve the edge sealing effect.

Owner:NINGDE AMPEREX TECH

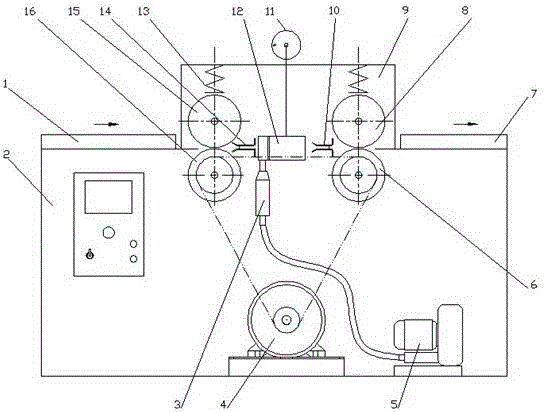

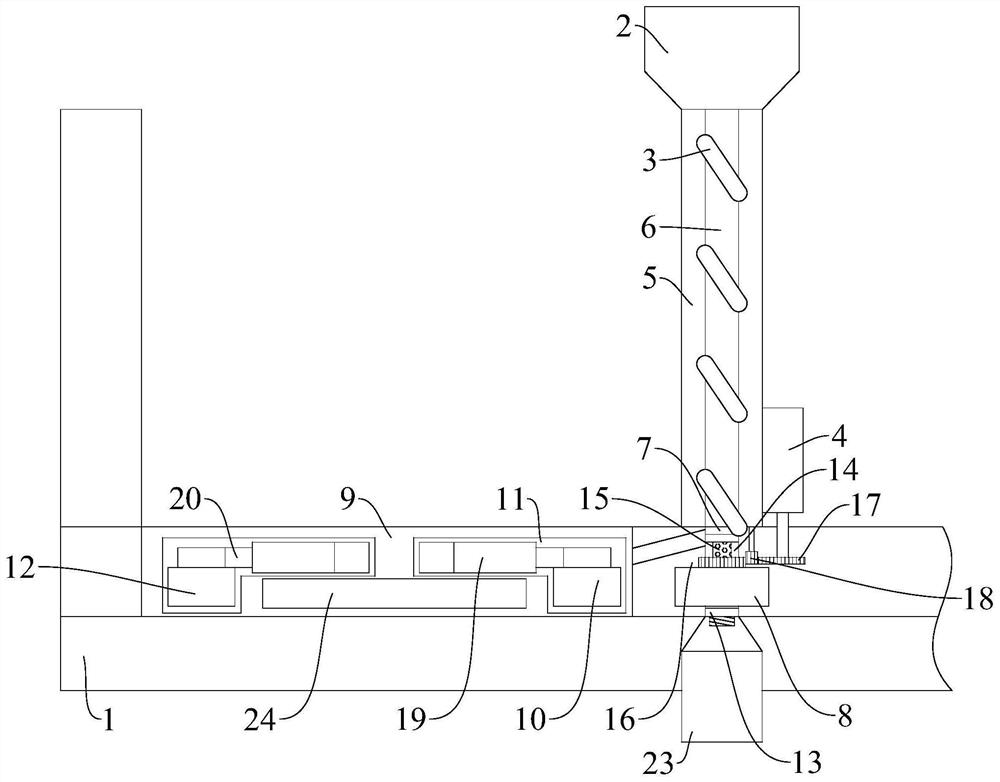

Material guiding and heating mechanism of plate machining edge bonding machine

ActiveCN112297175AImprove fitImprove the effect of edge bandingOther plywood/veneer working apparatusDomestic articlesElectric machineEngineering

The invention relates to the technical field of plate machining and production, in particular to a material guiding and heating mechanism of a plate machining edge bonding machine. The material guiding and heating mechanism comprises a plate guiding platform mounted on the plate machining edge bonding machine, an overhead container with built-in edge bonding glue, an electric heating pipe and a driving motor. According to the material guiding and heating mechanism of the plate machining edge bonding machine, a lateral fixed frame is fixed to the upper surface of the plate guiding platform through bolts, a longitudinal discharging pipe externally provided with the electric heating pipe of a spiral structure is fixed to the opening position of the lower end of the overhead container, the electric heating pipe penetrates through a transversely-arranged extrusion heating box, multiple positions can be heated synchronously, the edge bonding glue can be heated and melted, the attaching performance of plates and edge bonding strips can be improved, and the edge bonding effect is improved; and the smearing position and area of the edge bonding glue can be improved, smearing is more uniform, and pasting is firmer; and by tightening the edge bonding strips, not only can the attaching performance of the plates and the edge bonding strips be improved, but also the guidance quality and theedge bonding precision can be improved.

Owner:嘉美瑞智能家居科技东台有限公司

Glass cutting and edge sealing equipment for building decoration and use method

InactiveCN112793015AAvoid Broken AccidentsEasy to fixLiquid surface applicatorsWorking accessoriesHydraulic cylinderMaterials science

The invention relates to the technical field of glass processing, in particular to glass cutting and edge sealing equipment for building decoration and a use method. The glass cutting and edge sealing equipment comprises a base table, a supporting table, a supporting frame, a cutting assembly, a first moving assembly, a second moving assembly and an edge sealing assembly, wherein top blocks are driven to extrude a piece of glass by using a fifth hydraulic cylinder, fixing of glass needing to be processed is achieved, the processed glass can be stabler in a cutting process, and therefore the cutting accuracy of the device is improved, meanwhile, the accident that the glass is broken due to the fact that the glass is not firmly fixed in the glass cutting process is avoided, the using safety of the equipment is improved, plastic pads are arranged at the tops of the top blocks, a buffering effect is achieved, the top blocks are prevented from bumping the glass, meanwhile, the plastic pads also has an anti-skid effect, the fixing effect on the glass can be further improved, and therefore the cutting accuracy and safety of the equipment are further improved.

Owner:胡芳艳

Edge sealing forming system for hollow plate

The invention discloses an edge sealing forming system for a hollow plate. The edge sealing forming system comprises a heating unit, a heat cutting unit, a heat closing unit, a heat forming unit and a cooling forming unit, wherein the heating unit is at least used for heating the side part of the hollow plate to be softened; the heat cutting unit is at least used for cutting a reinforcing rib inside the side part of the softened hollow plate; the heat closing unit is used for closing the side part of the cut hollow plate; the heat forming unit is used for processing the closed side part of the hollow plate to be in a set sealing state; the cooling forming unit is used for cooling and forming the side part of the hollow plate in the set state. The edge sealing forming system provided by the invention is simple in structure, low in manufacturing cost, accurate in positioning and cutting of the hollow plate and good in edge sealing effect, so that the cost is effectively reduced, and the product quality is improved and the yield is increased.

Owner:SUZHOU HOLDEN AUTO

Device for edge sealing of gypsum plaster board

InactiveCN112140297AImprove toughnessAvoid breakingAuxillary shaping apparatusPaperboardMechanical equipment

The invention discloses a device for edge sealing of a gypsum plaster board, and belongs to the technical field of mechanical equipment. According to the technical scheme, the gypsum board edge sealing machine is characterized by comprising a rack, an edge sealing belt paper outlet device, a water supply device, a paper folding device, positioning devices and a cutting-off device are arranged on the rack, the paper folding device comprises a paper folding plate, each positioning device comprises an end positioning roller, two side positioning rollers and a positioning brush, and the end positioning rollers are opposite to the ends of gypsum boards; and the two side positioning rollers are opposite to the two sides of the end of the gypsum board, the positioning brush can be seen as an inwards-concave structure in the side direction, the positioning brush is fixed to the rack through a supporting frame, a set of edge sealing pressing rollers are adopted to play a role in edge sealing and positioning, and then the positioning brush is adopted to apply pressure to adhere an edge sealing belt to the board. The pressure on the gypsum board is reduced while a good edge sealing effect isachieved, a board core air hole in the edge sealing position of the end of the gypsum board is prevented from being crushed, and the paper disengaging phenomenon is prevented.

Owner:泉州市泉润吉明科技有限公司

Structural design of soft package for the core of lithium ion cell, and fabricating method

InactiveCN101093898AImprove the effect of edge bandingFinal product manufactureCell component detailsLithiumEngineering

Increasing width of sealed edge for pole ear side and folded side, and making multiple times of sealed edge raises performance for sealing edge markedly, and reduces risk of leaking electrolyte from sealing edges of battery. Folding sealed edge for pole ear side makes unchanged ratio between pole ear side and length of battery. The disclosed method gathers advantages of current batteries in soft package for the battery prepared by using the invention. Moreover, under condition of not changing side utilized by sealed edge of battery, the invention raises performance of sealed edge markedly.

Owner:DANLIAN BATTERY SHENZHEN

Capsella bursa-pastoris pill and preparation method and packaging device thereof

InactiveCN103622050ABalanced nutritional valueDeliciousFood ingredient functionsFood preparationMouthfeelFat content

Owner:河南海壹食品股份有限公司

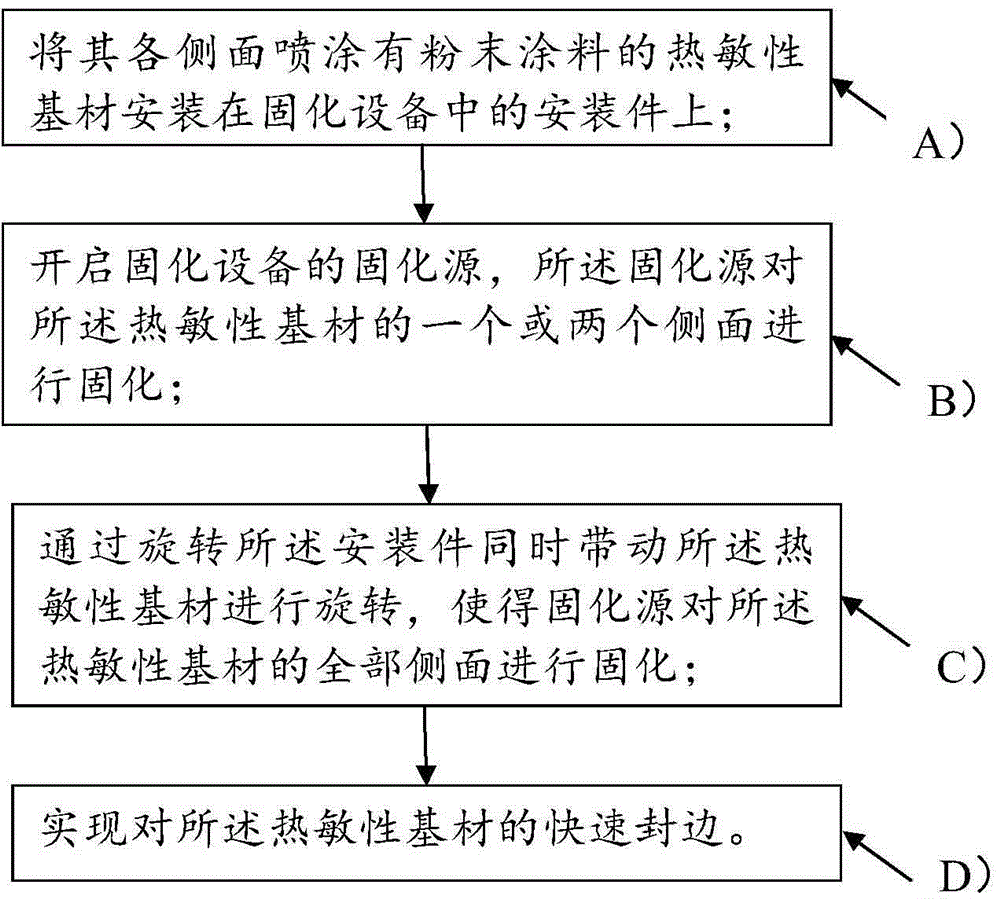

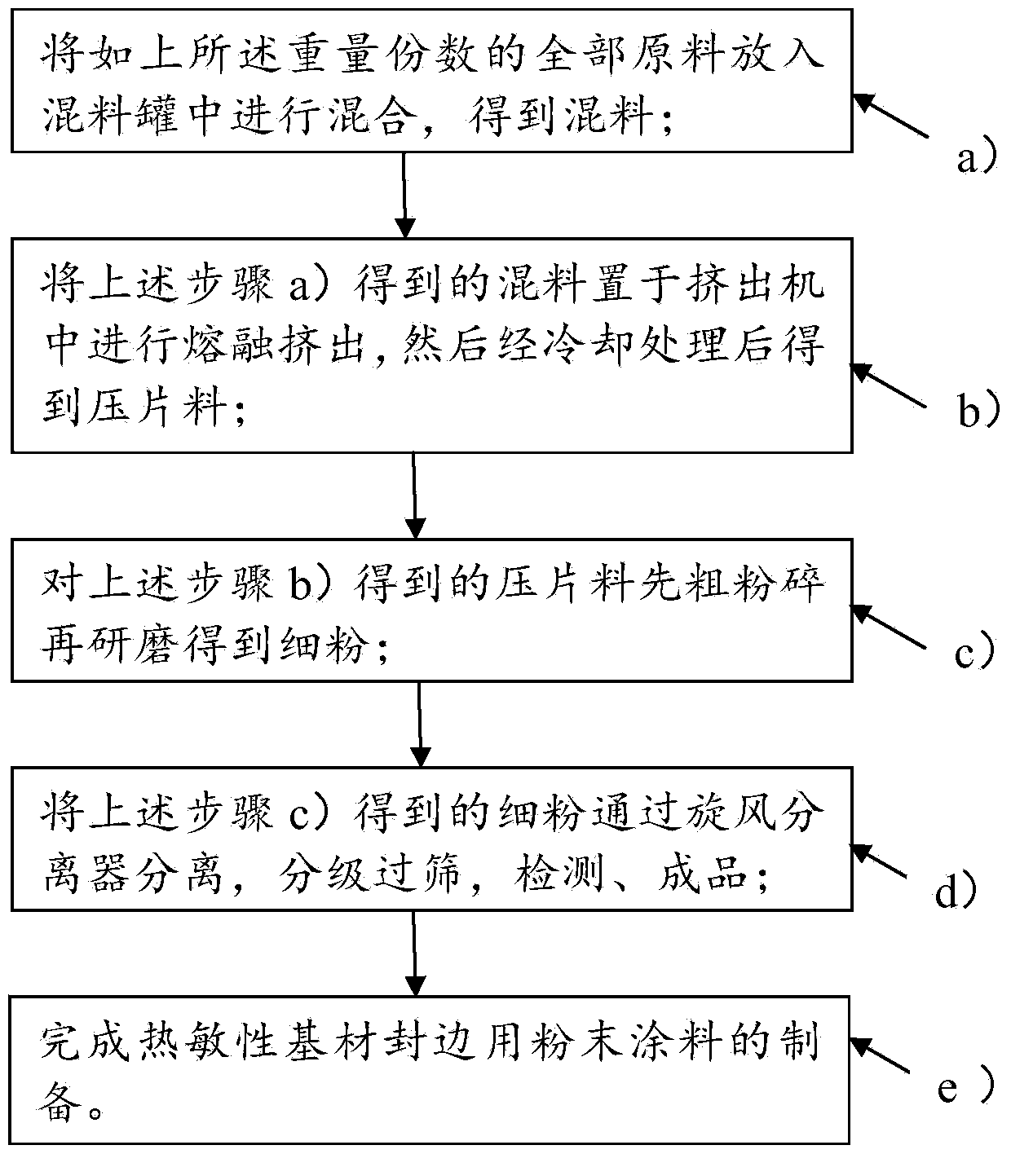

Method for solidifying edge seals of thermally sensitive base material

InactiveCN103817058AImprove edge banding efficiencySuitable for large-scale industrial applicationsPretreated surfacesPowdery paintsEngineeringMoisture

The invention relates to a method for solidifying edge seals of a thermally sensitive base material. The method includes: A) mounting the thermally sensitive base material with powder coating sprayed on every lateral side on a mounting piece of solidifying equipment; B) turning on the solidifying equipment so that a solidifying source can solidify one or two lateral sides of the thermally sensitive base material; C) rotating the mounting piece to drive the thermally sensitive base material to rotate so that the solidifying source can solidify all the laterals sides of the thermally sensitive base material; D) realizing quick edge sealing of the thermally sensitive base material. The method has the advantages that the problem that edge seal coating solidification may fail due to large impact in an edge seal coating solidification process since water moisture is evaporated from the interior of the thermally sensitive base material to the lateral sides of the thermally sensitive base material massively and quickly is avoided, edge sealing efficiency of the thermally sensitive base material is improved greatly, and the method is suitable for large-scale industrialized application.

Owner:TIGER DRYLAC TAICANG

Honeycomb plate

InactiveCN103770426AMechanical strength requirements are metThe edge banding process is simple and convenientLayered productsPowdery paintsLow temperature curingHoneycomb

The invention relates to a honeycomb plate. The honeycomb plate comprises a honeycomb plate body, wherein an edge sealing coating is arranged on the side of the plate body; thermosetting coatings are arranged on the edge sealing coating and the surface of the plate body; the edge sealing coating is obtained by electro-statically coating edge sealing powder coating on the side of the plate body and curing; the thermosetting coatings are obtained by electro-statically coating low-temperature curing powder coating on the edge sealing coating and the surface of the plate body and curing. According to the honeycomb plate, a good edge sealing effect is achieved; the cracking of the side of the honeycomb plate can be effectively prevented; due to the adoption of the electro-static coating, the edge sealing process is simple, convenient and suitable for sealing edges of substrate workpieces in various shapes.

Owner:TIGER DRYLAC TAICANG

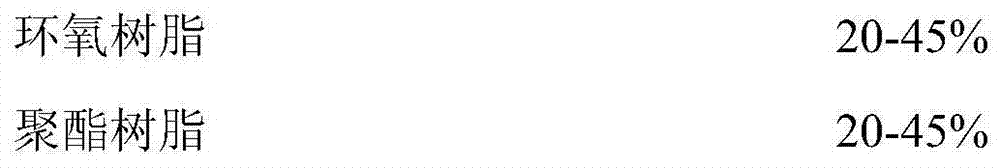

Powder coating for banding edge of heat sensitive substrate as well as edge banding coating and preparation method thereof

InactiveCN103788822AExcellent curing and crosslinking propertiesLow viscosityPowdery paintsEpoxy resin coatingsEpoxyHeat sensitive

The invention relates to a powder coating for banding the edge of a heat sensitive substrate as well as an edge banding coating and a preparation method of the powder coating. The powder coating comprises the following raw materials in parts by weight: 25-70 parts of epoxy resin, 2-20 parts of curing agent, 5-35 parts of pigment and filler and 0-20 parts of auxiliary agent, wherein the curing agent is used for having crosslinking curing reaction with the epoxy resin; the epoxy resin is prepared by a hypocrystallization, holocrystallization or super esterification technology and is used for reducing the viscosity and increasing the curing speed. The powder coating has good edge banding effect for the heat sensitive substrate and is capable of effectively avoiding the side of the heat sensitive substrate cracking; furthermore, electrostatic spraying is realized; the edge banding technology is simple and convenient, and the powder coating is suitable for banding the edges of substrates with various shapes.

Owner:TIGER DRYLAC TAICANG

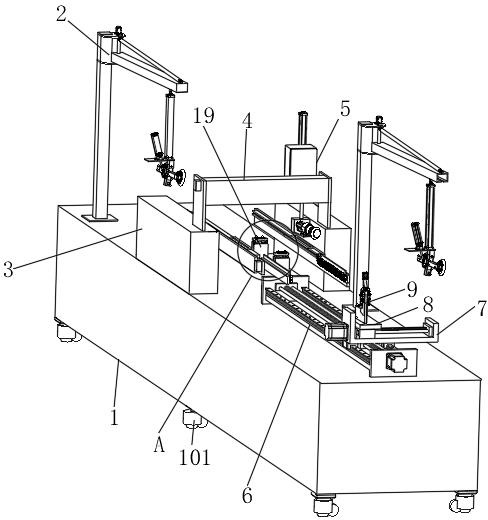

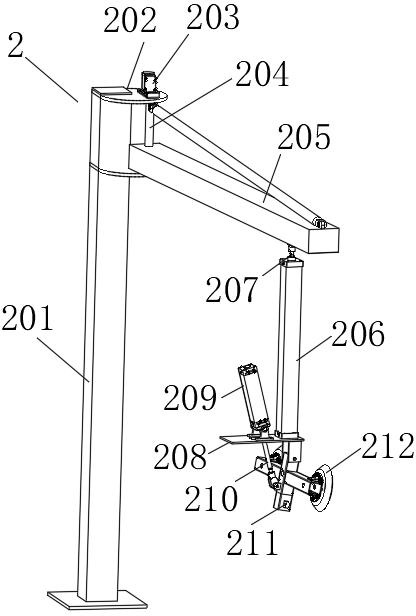

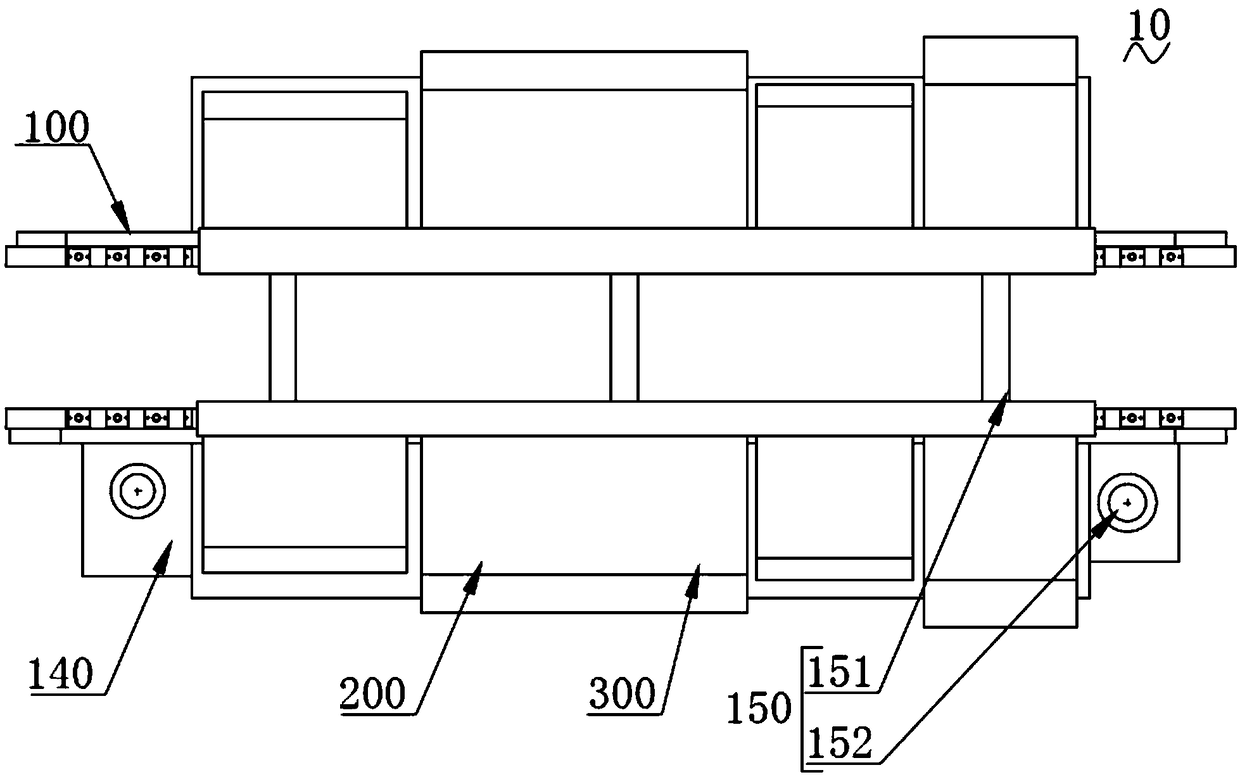

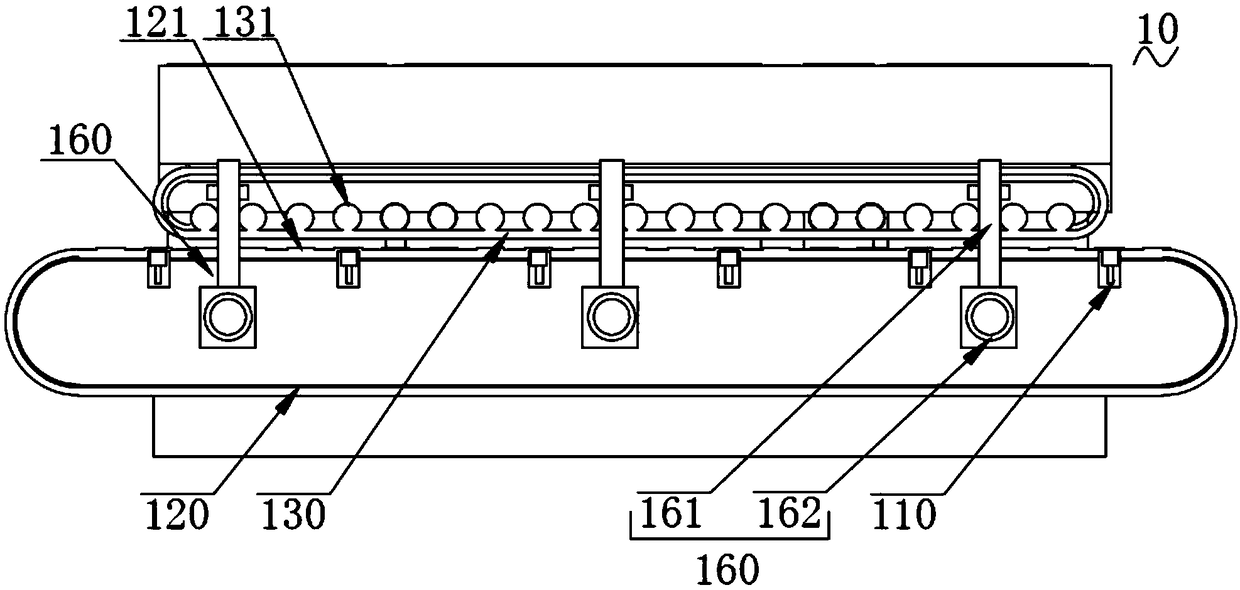

Automatic positioning, edge sealing and edge trimming system for furniture plate

PendingCN109129806AImprove edge qualityImprove the effect of edge bandingWood working apparatusDomestic articlesMaterial resourcesEngineering

The invention relates to the technical field of plate processing, in particular to an automatic positioning, edge sealing and edge trimming system for a furniture plate. The automatic positioning, edge sealing and edge trimming system comprises a conveying device, and an edge sealing device and an edge trimming device symmetrically arranged on the two sides of the conveying device, wherein the conveying device comprises a conveyor belt; a positioning component for performing positioning, edge sealing and edge trimming on the plate is arranged on the conveyor belt; the edge sealing device comprises a belt discharging component, a gluing component and a pressing component; the belt discharging component is used for discharging the edge sealed belt; the gluing component is used for gluing theedge of the plate; the pressing component is used for pressing the edge sealed belt on the plate; the trimming device comprises a cutting component for cutting off the edge sealed belt;, and a trimming component for trimming the cut-off edge sealed belt; and the gluing component is positioned above the belt discharging component. Through the adoption of the system, the plate is automatically conveyed, and then is positioned after being conveyed to the specified position, the plate in the positioning process is subjected to edge sealing and pressing, and then the edge sealed plate is trimmed,so that the defect of a manual edge sealing device or a heavy complicated device is overcome, the working efficiency is greatly improved, manpower and material resources are saved, and the degree of automation is high.

Owner:东莞市春旭机械科技有限公司

Shaving board

InactiveCN103802194AMechanical strength requirements are metThe edge banding process is simple and convenientWood working apparatusDomestic articlesEngineeringPowder coating

The invention relates to a shaving board. The shaving board comprises a shaving board body. The side face of the board body is provided with edge banding coatings, and the edge banding coatings and the surface of the board body are provided with thermosetting coatings. The edge banding coatings are obtained by carrying out the electrostatic spraying and solidifying process on a powder coating used for edge banding on the side face of the board body. The edge banding coatings are obtained by carrying out the electrostatic spraying and solidifying process on a powder coating used for low-temperature solidifying on the edge banding coatings and the surface of the board body. According to the shaving board, the good edge banding effect is achieved, the side face of the shaving board is effectively prevented from being cracked, electrostatic spraying is achieved, and the edge banding technology is simple, convenient to carry out and suitable for edge banding of base material workpieces with various shapes.

Owner:TIGER DRYLAC TAICANG

Energy-saving thermal insulation plate edge sealing equipment

InactiveCN110549460AImprove the effect of edge bandingEasy to pre-bandOther plywood/veneer working apparatusDomestic articlesThermal insulationDrive motor

The invention discloses energy-saving thermal insulation plate edge sealing equipment. The equipment comprises a lower side box. An accommodating cavity penetrating up and down is arranged in the lower side box. A transmission connecting shaft is arranged between the left and right end walls of the accommodating cavity rotationally. A driving motor is fixedly arranged on the left end surface of the lower side box. The driving motor is in power connection with the transmission connecting shaft. A moving connecting plate is connected to the outer surface of the transmission connecting shaft in ascrew-thread fit mode. An alignment transition device is arranged on the upper end surfaces of the moving connecting plate and the lower side box, and the height of the alignment transition device can be adjusted and has a plate aligning effect. The equipment provided by the invention is simple in structure, an internal adjusting structure in the equipment can be automatically adjusted by adopting the alignment transition device and an overturning device, a plate is fully clamped and fixed by internal relevant structures inside the equipment, the plate is conveniently placed into the equipment and vertically arranged, and the plate edge sealing equipment in an external space can perform edge sealing in advance efficiently, so that a plate edge sealing effect is improved.

Owner:齐卢虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com