Edge sealing device for oil baffle plate

An edge banding equipment and equipment technology, applied in the field of edge banding, can solve problems such as waste of raw materials, easily scratched operators, and affect the appearance, etc., and achieve the effect of good edge banding, simple and reliable edge banding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

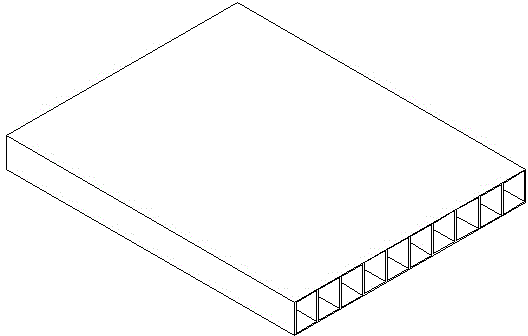

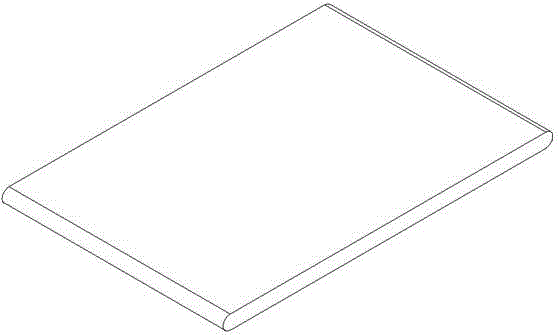

[0053] The invention provides an edge banding device for a plastic hollow board, such as figure 1 As shown, it can seal the plastic hollow board to achieve figure 2 The effect shown.

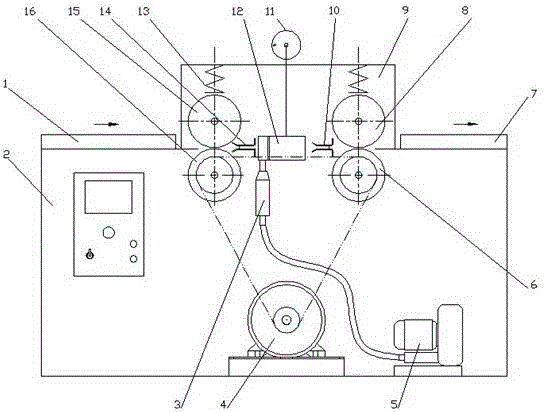

[0054] see image 3 , the edge banding equipment includes a frame, a traction mechanism, an edge banding mechanism, an edge banding mechanism adjustment mechanism and a plate positioning and guiding mechanism.

[0055] see image 3 , Figure 4 , Pic 4-1 , the frame is a metal frame 2, which has two side plates 9 to install various mechanisms.

[0056] The traction mechanism is a two-stage traction device. The first stage is the pull-in section, which is a pair of rubber rollers 15 and 16 arranged up and down. The segment is also a pair of rubber rollers 6, 8 arranged up and down, and the hollow plate after edge sealing is pulled out from the pair of rubber rollers. see Figure 5 , the rotating shaft two ends of lower roller 6 and 16 in every pair of cots are respectively equipped with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com