Bicycle chain-mounting mechanism and chain wheel set using same

A technology for bicycles and sprocket sets, which is applied to vehicle parts, vehicle gearboxes, chain/belt transmissions, etc. It can solve problems such as stuck chains, dropped chains, and the inability to reduce noise and wear during gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

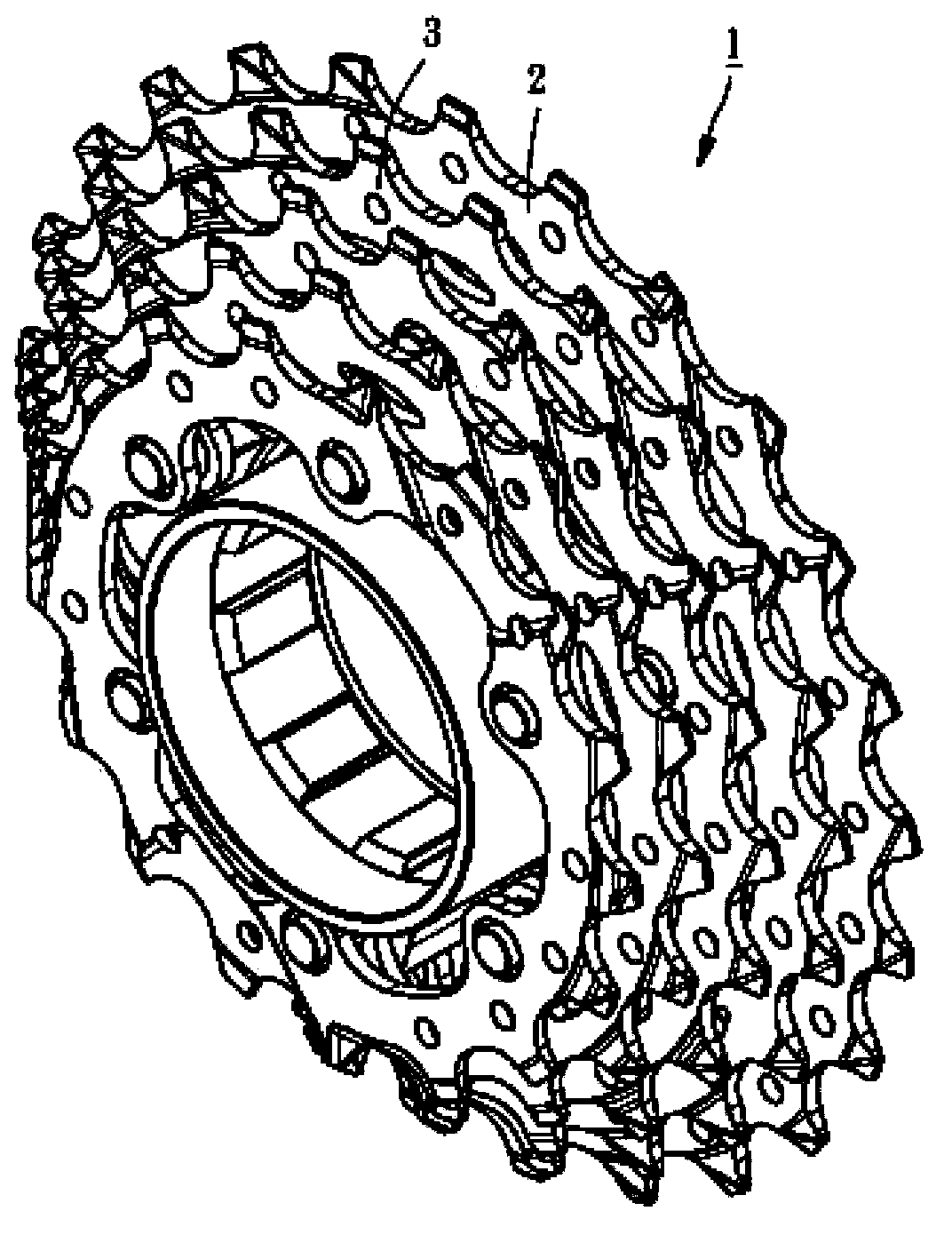

[0019] The present invention is arranged on the bicycle sprocket set 1 that is made of a plurality of sprockets, such as figure 1 As shown, the bicycle sprocket set 1 has a large sprocket 2 and a small sprocket 3, wherein the peripheries of the two sprockets 2 and 3 are provided with a plurality of teeth, and each tooth is composed of a tooth peak and a tooth valley. and the number of teeth of the large sprocket 2 is greater than that of the small sprocket 3, wherein the top of each tooth crest roughly extends along the tangential direction, and the bottom of each tooth valley forms a concave arc shape.

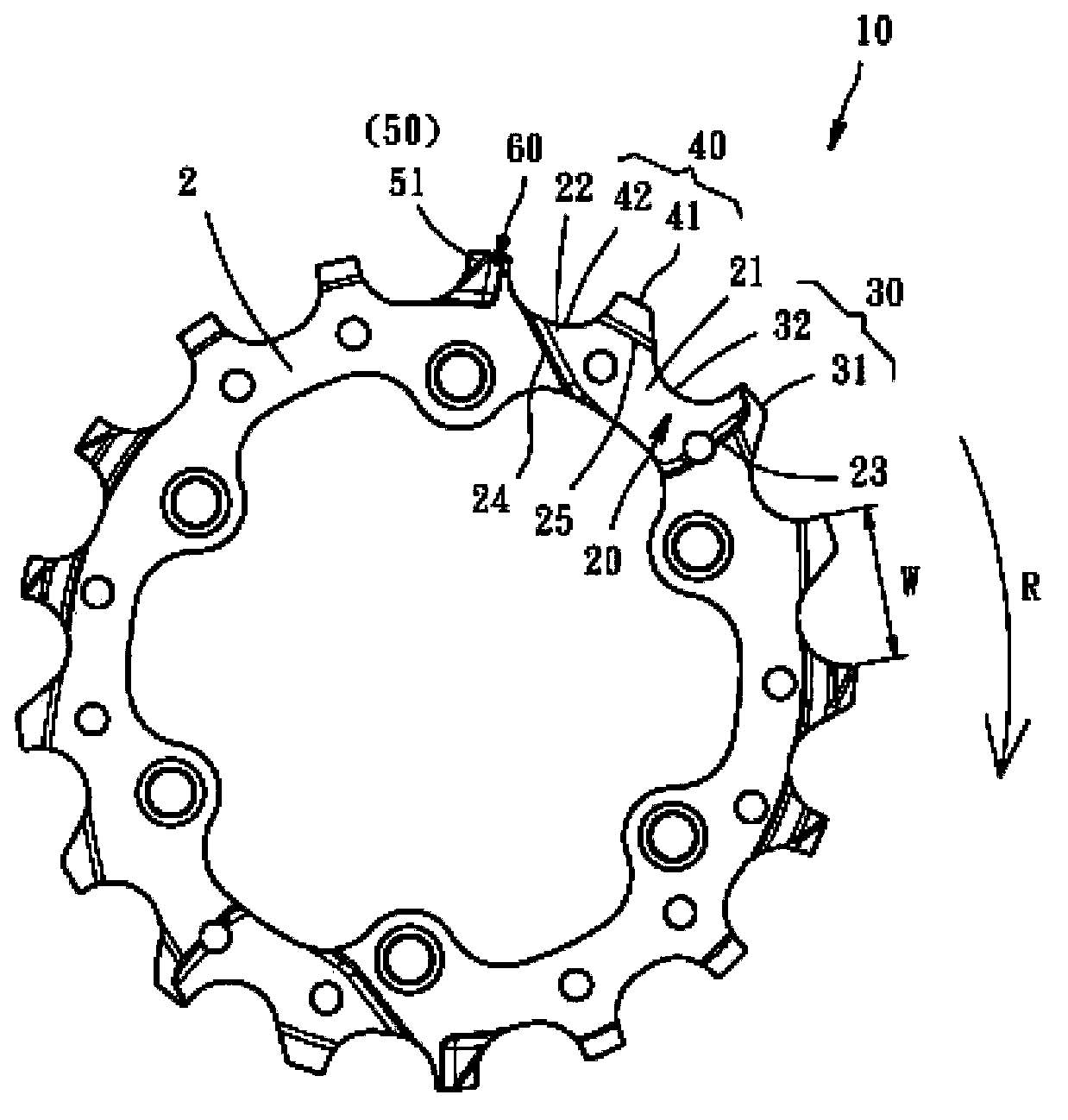

[0020] Such as figure 2 As shown, a preferred embodiment of the bicycle winding mechanism 10 provided by the present invention is located on the wheel surface of the large sprocket 2 close to the small spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com