Patents

Literature

567 results about "Single tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

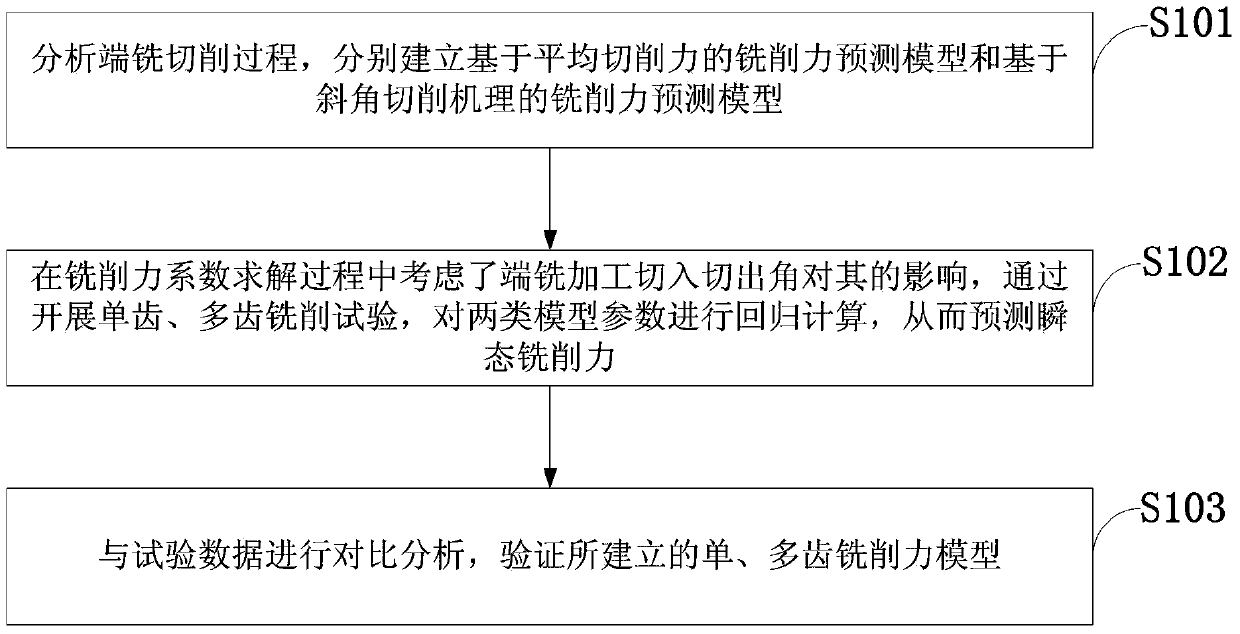

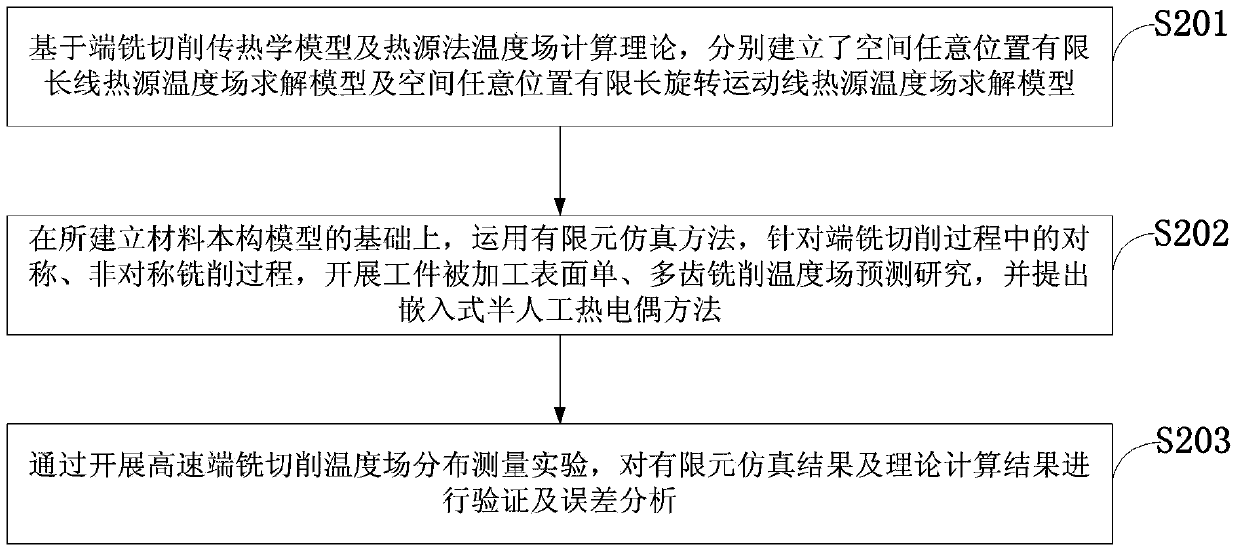

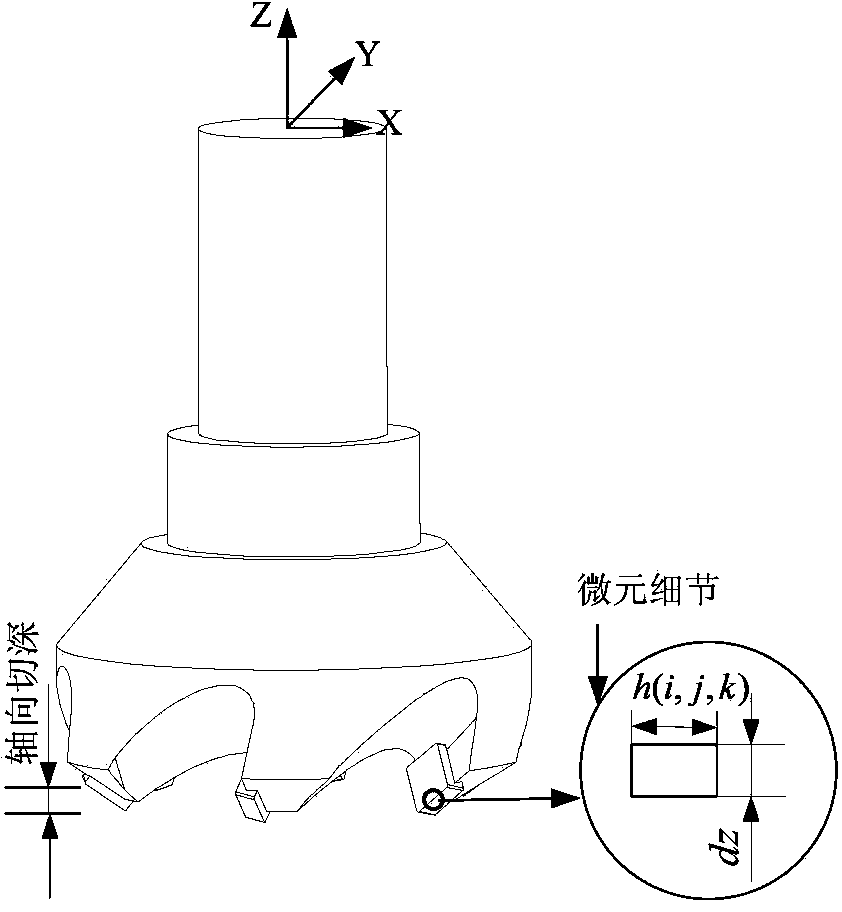

Method of cutting force prediction and temperature prediction for end-milling cutting

ActiveCN104268343ASimple methodEasy to operateSpecial data processing applicationsMethod developmentCutting force model

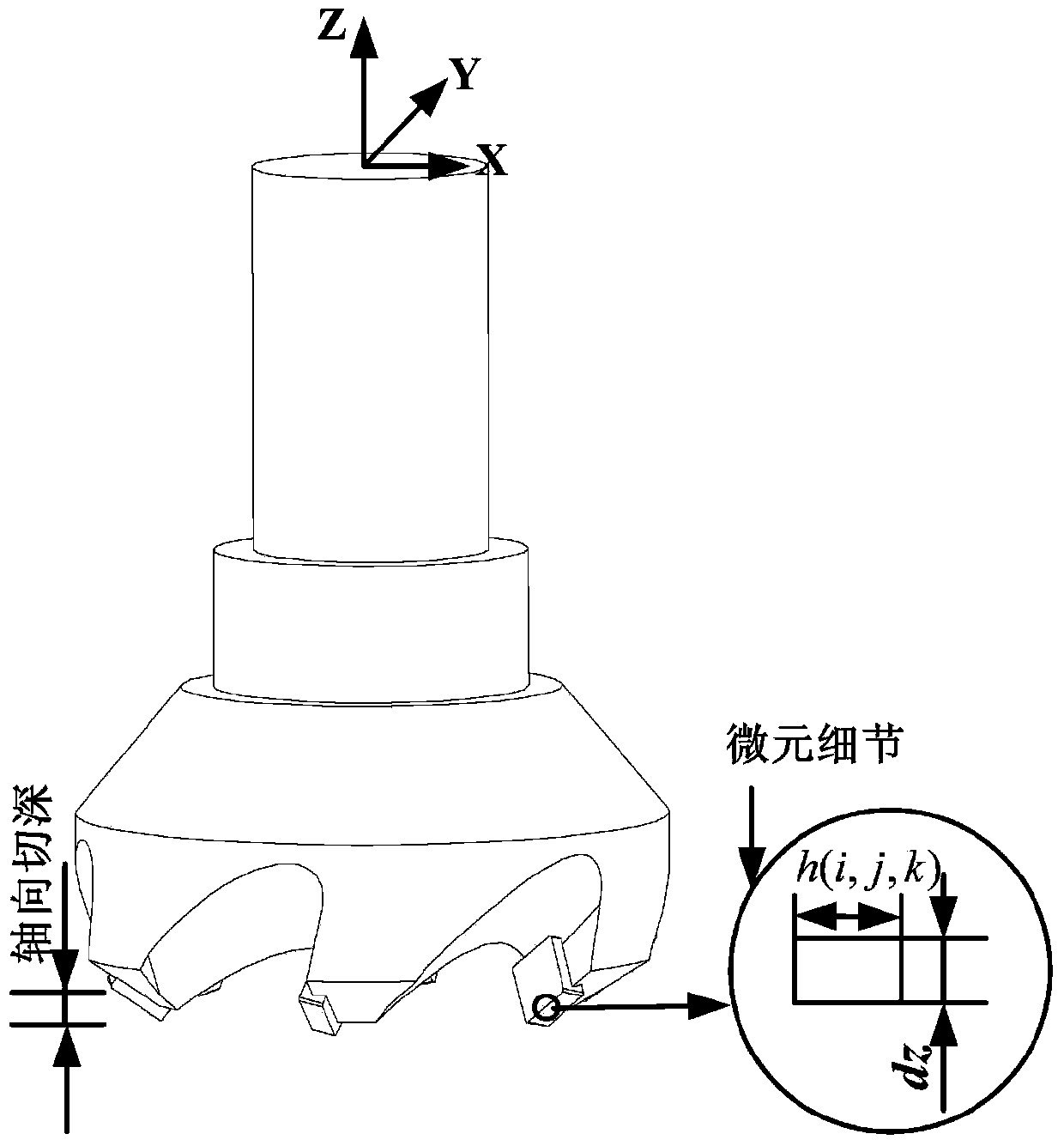

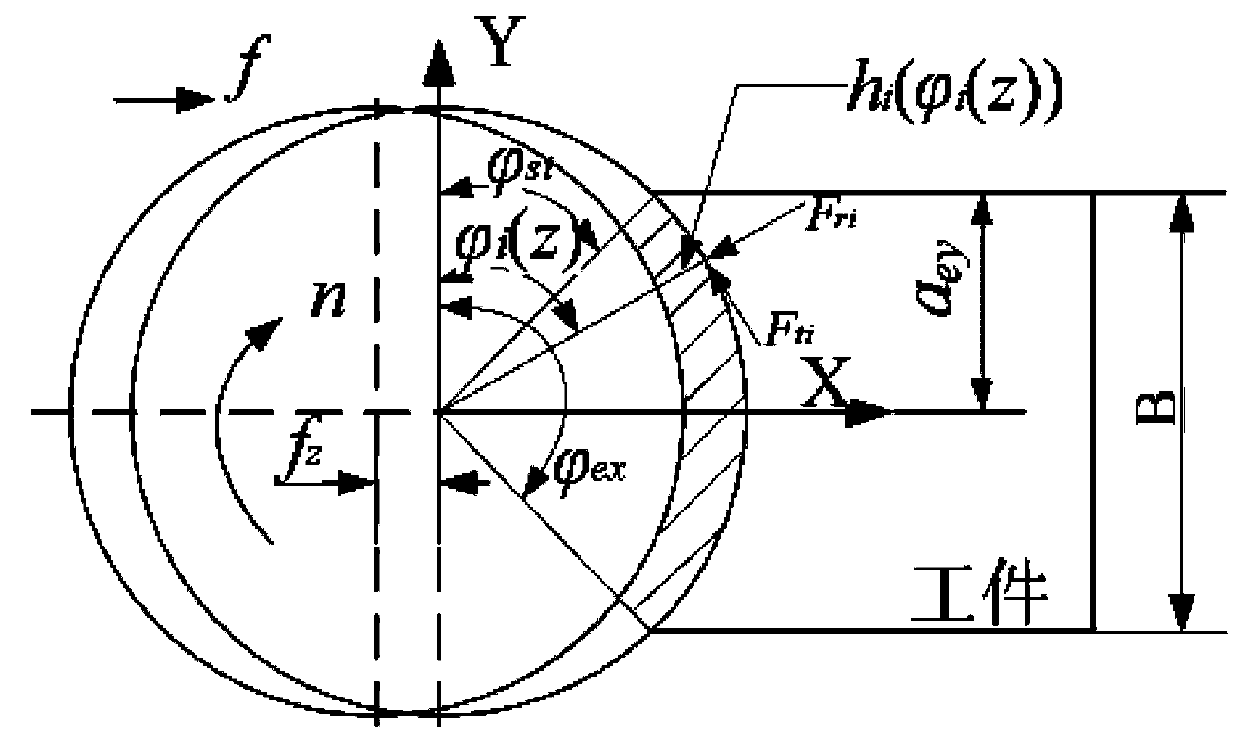

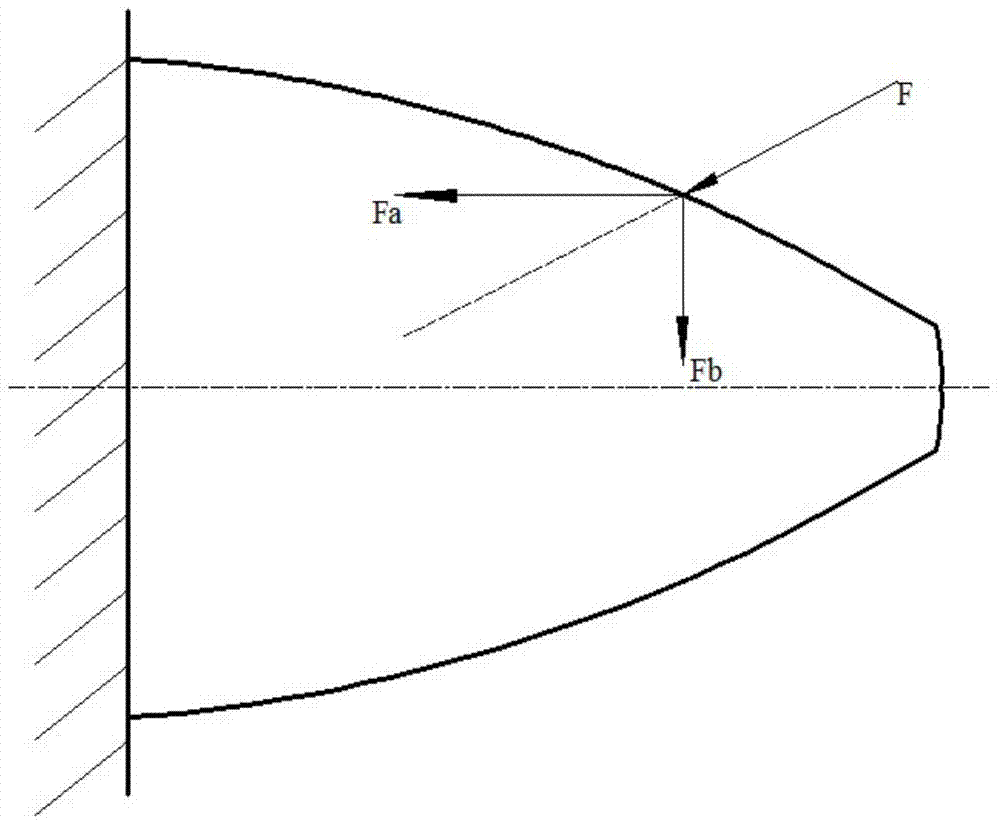

The invention discloses a method of cutting force prediction and temperature prediction for end-milling cutting, the method development of the cutting force prediction is based on a milling forces prediction model of average cutting forces and a milling forces prediction model of bevel angle cutting mechanism and is characterized by performing regression calculating on the two model parameters, predicting transient cutting force, performing comparative analysis with test data, and verifying established single-tooth and multi-teeth cutting force models; the method of cutting force temperature prediction establishes a temperature field solution model of a limited long-line heat source of space optional positions and a temperature field solution model of a limited long-rotation movement line heat source of space optional positions; by means of a limited element simulation method, an embedding semi-artificial thermocouple method is put forward, and by carrying out high speed end-milling cutting temperature field distribution measurement, verification and error analysis are performed on a limited element simulation result and a theoretical calculation result. The method of the cutting force prediction and the temperature prediction of the end-milling cutting has the advantages that the method is simple, operation is easy, reference foundation is provided for end-milling cutting technology, and the method is more beneficial to production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

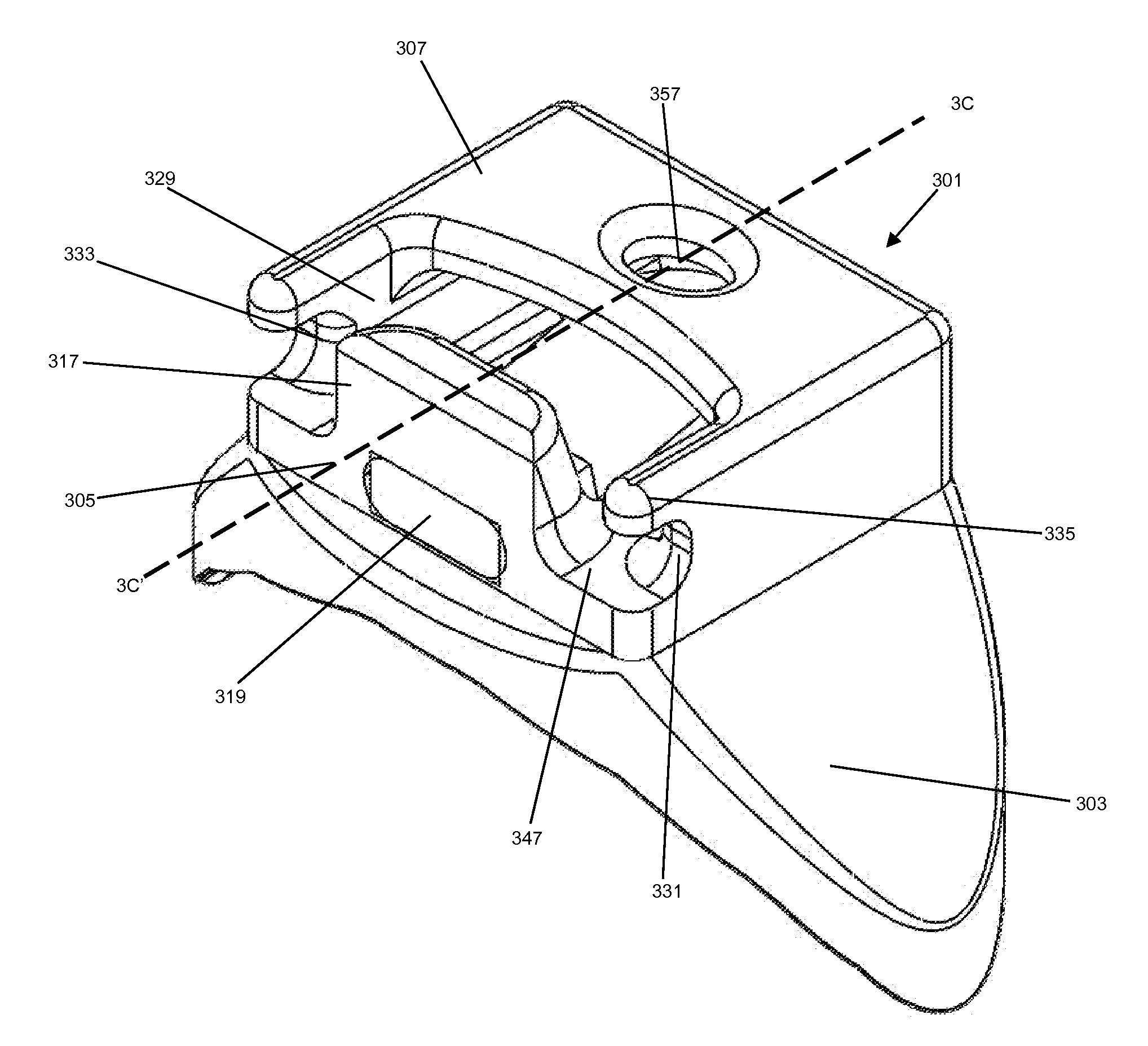

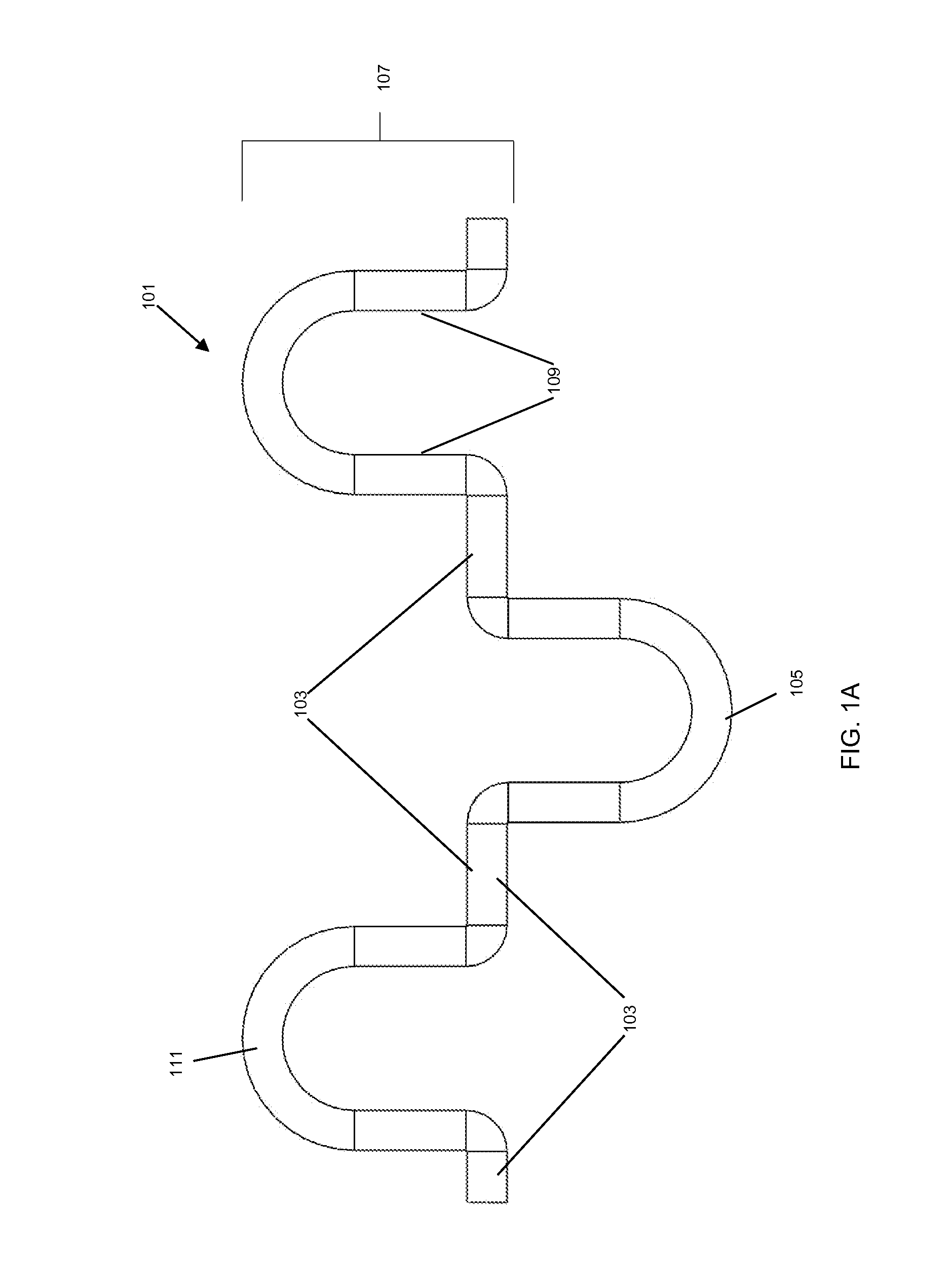

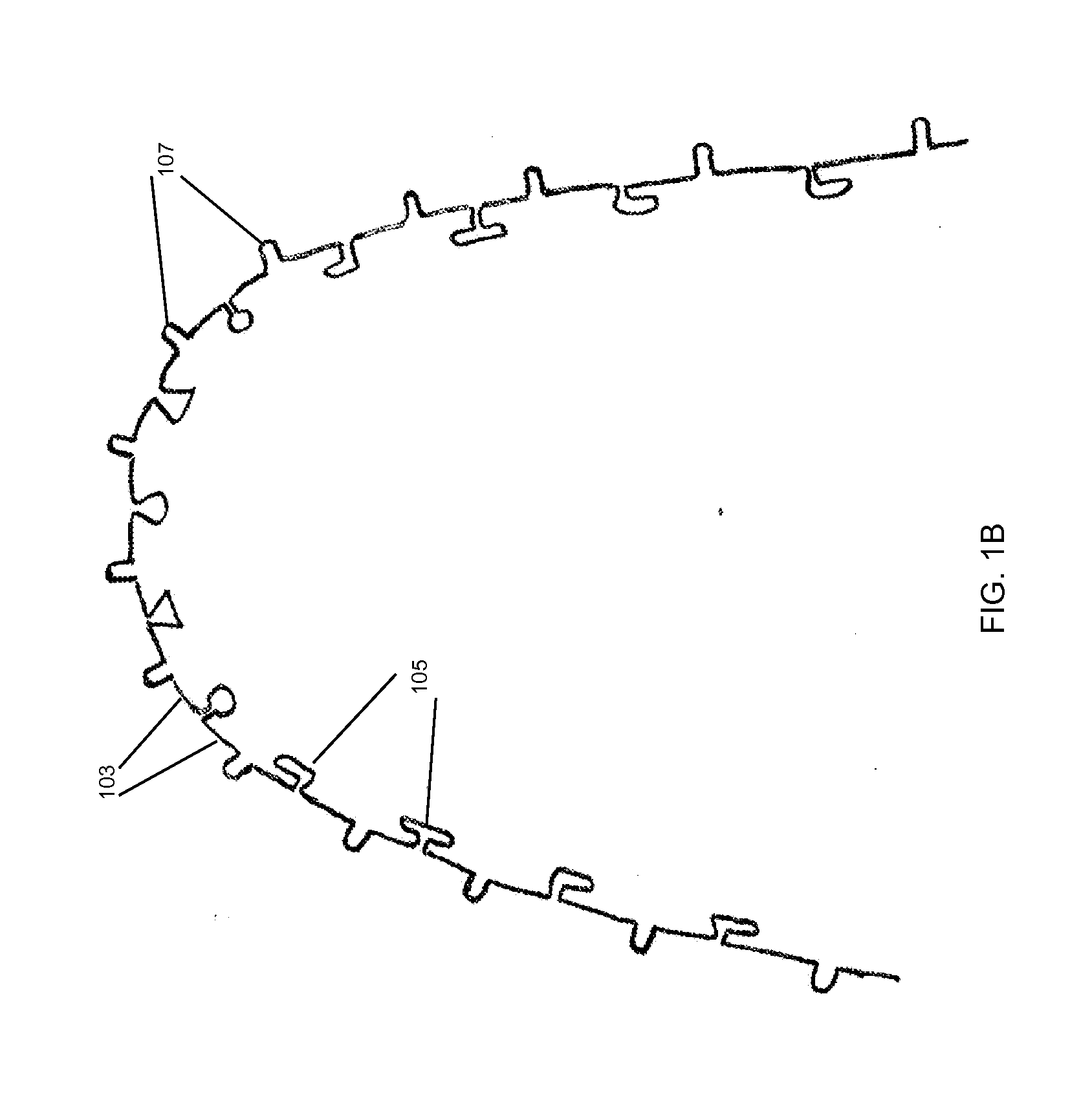

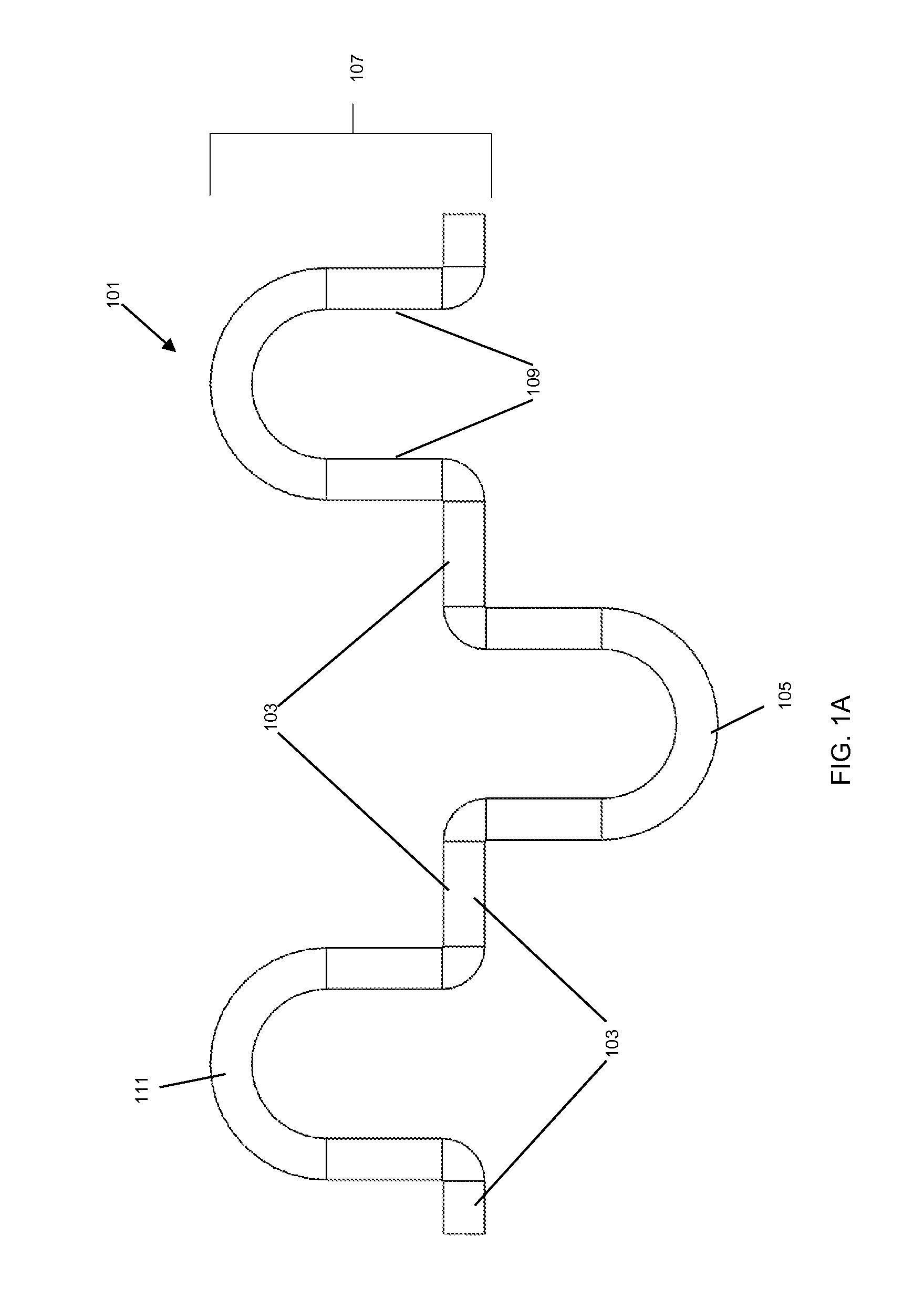

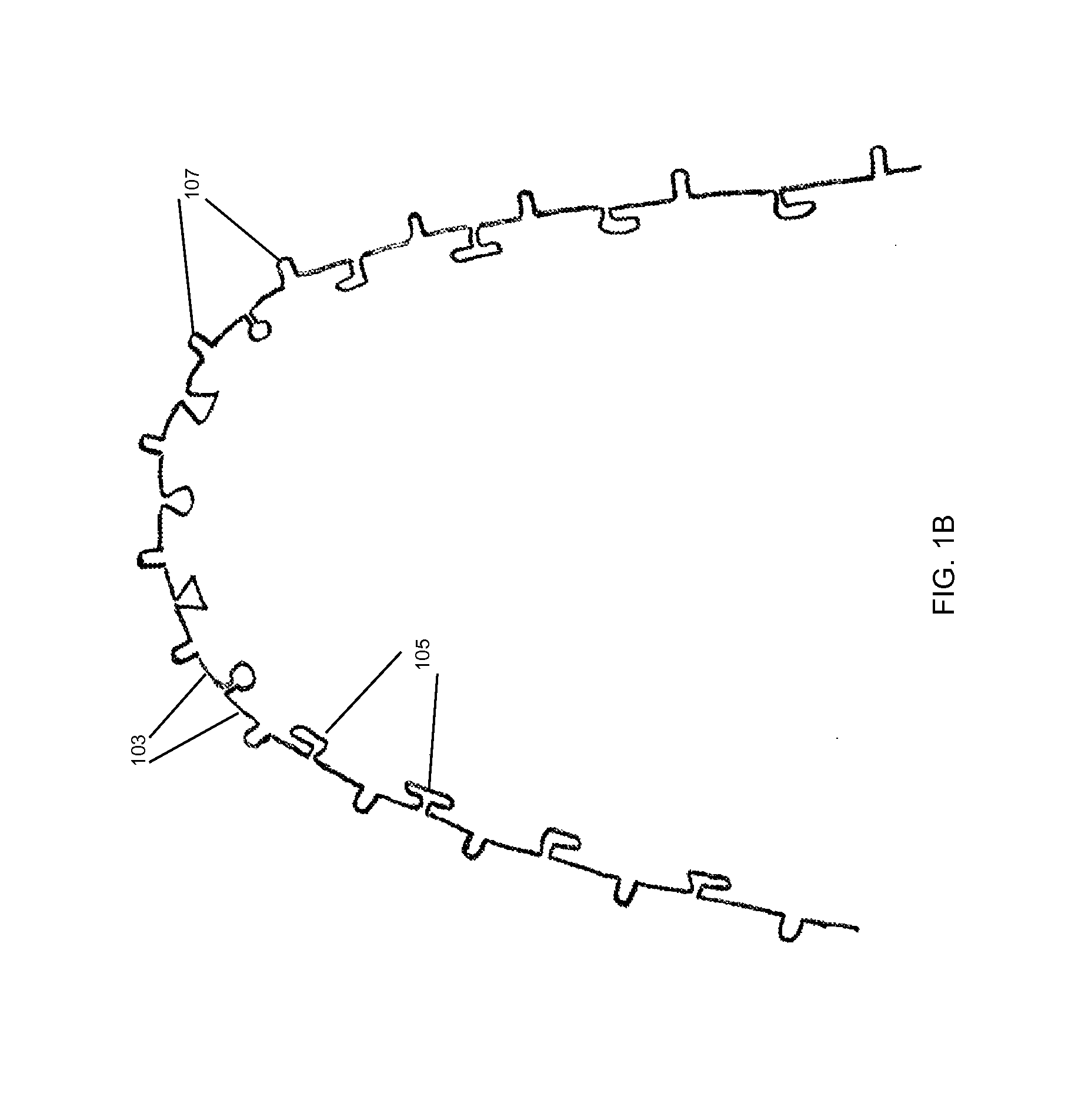

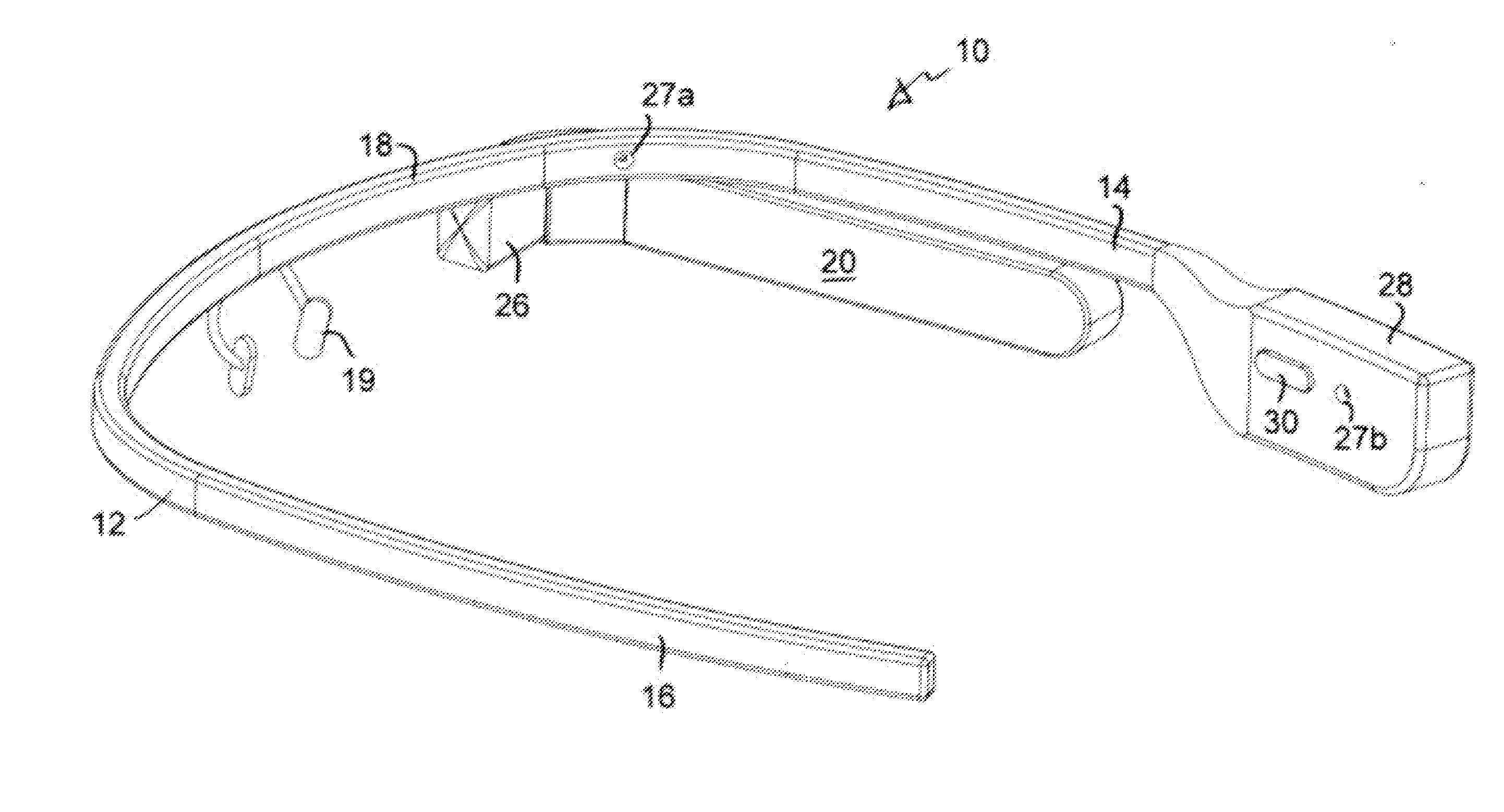

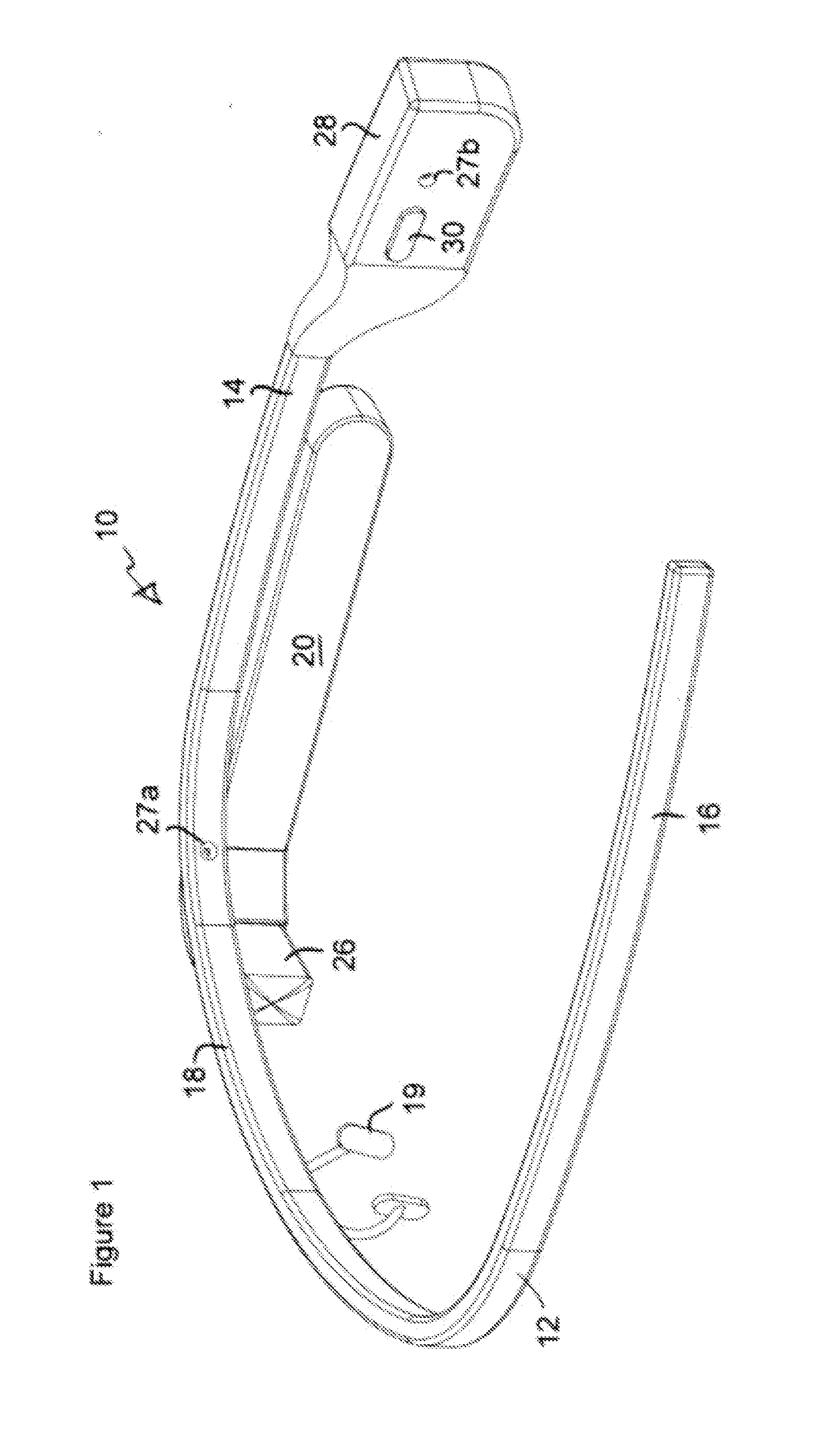

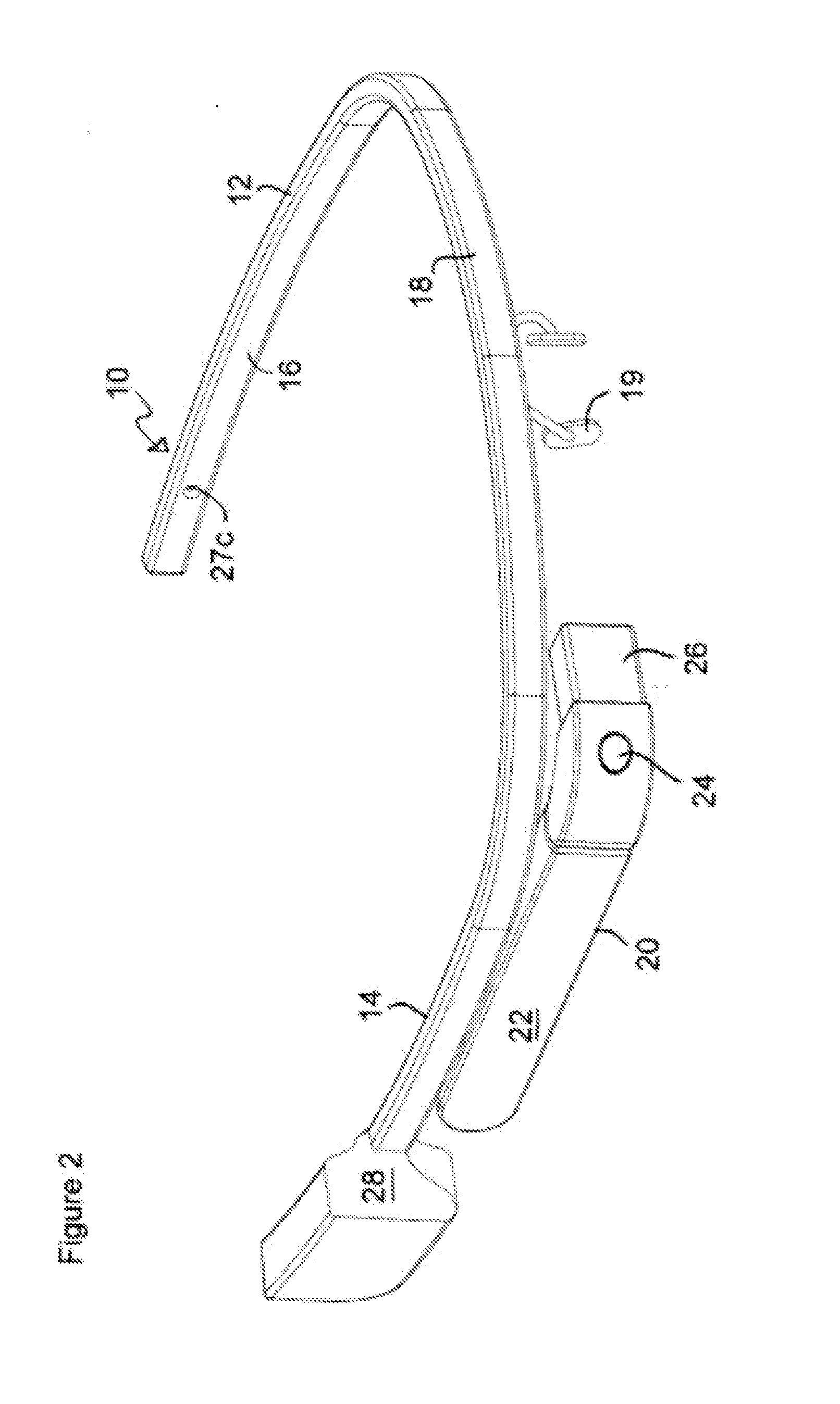

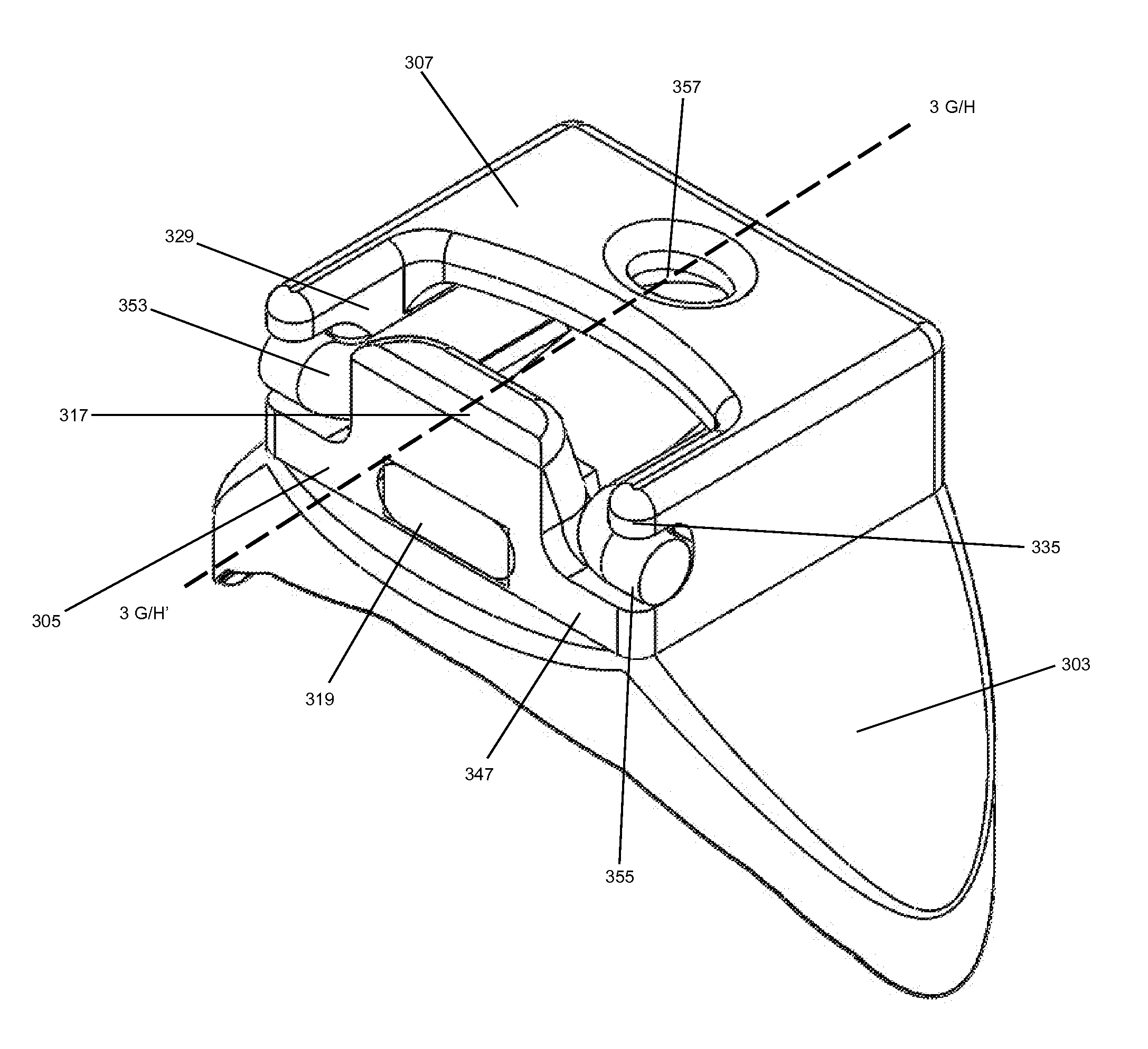

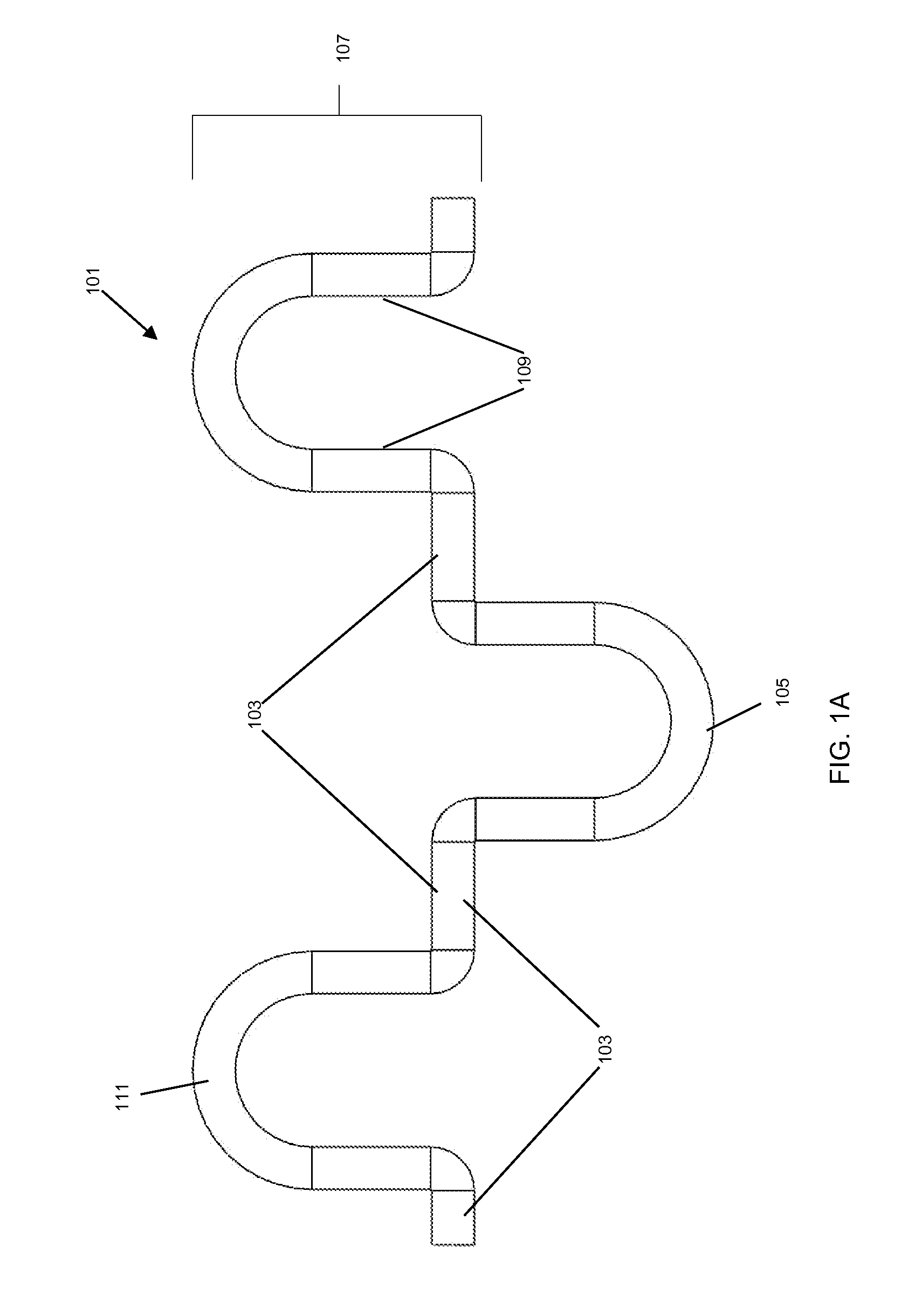

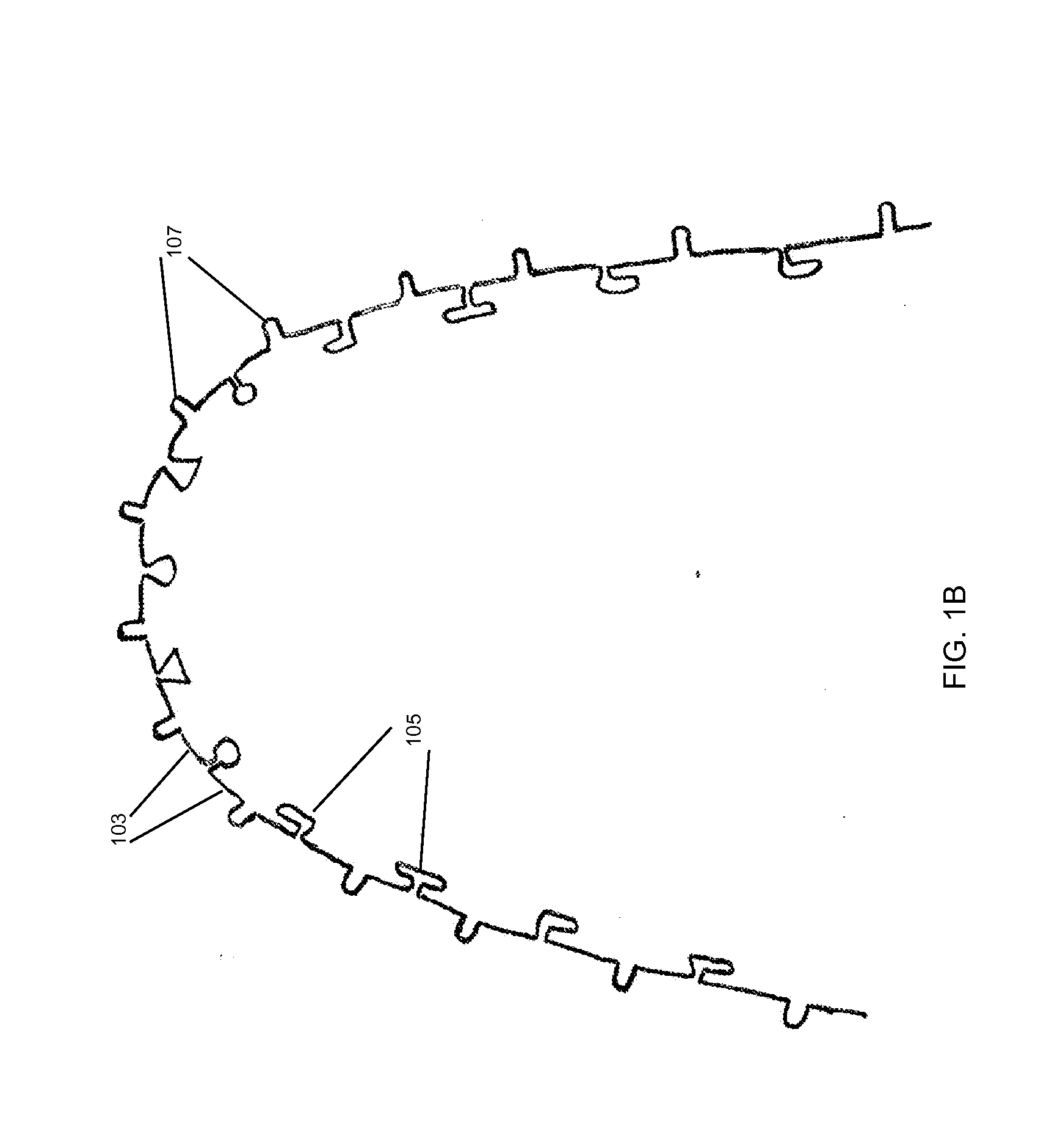

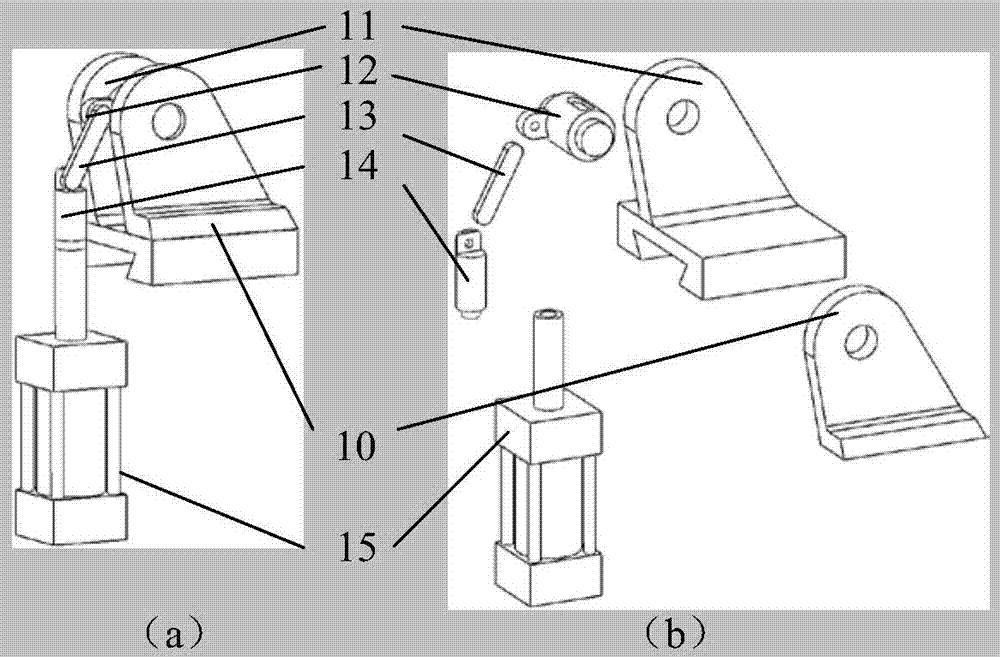

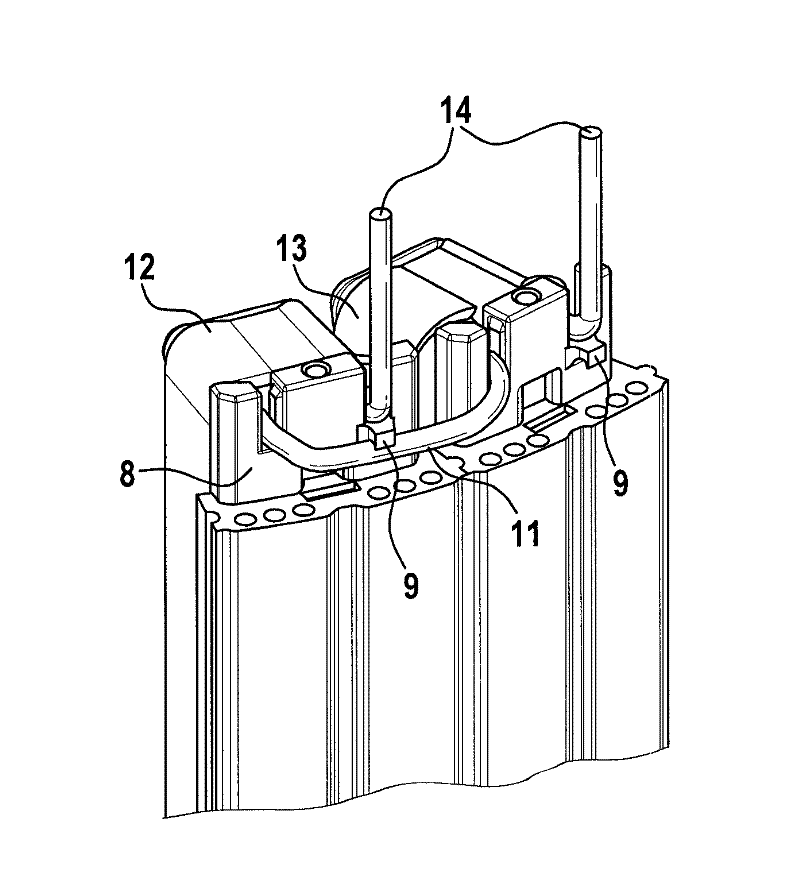

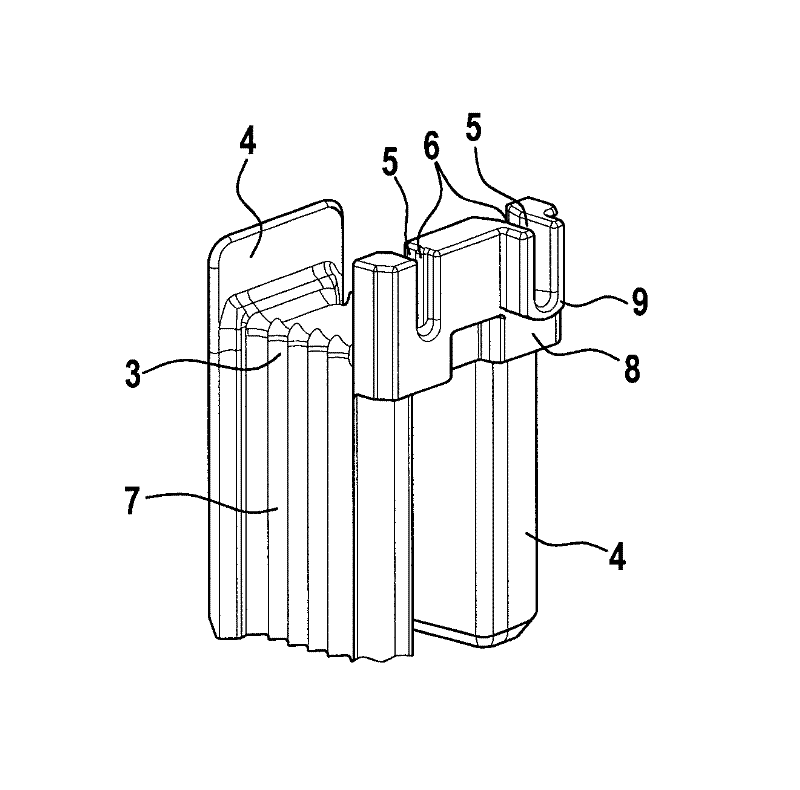

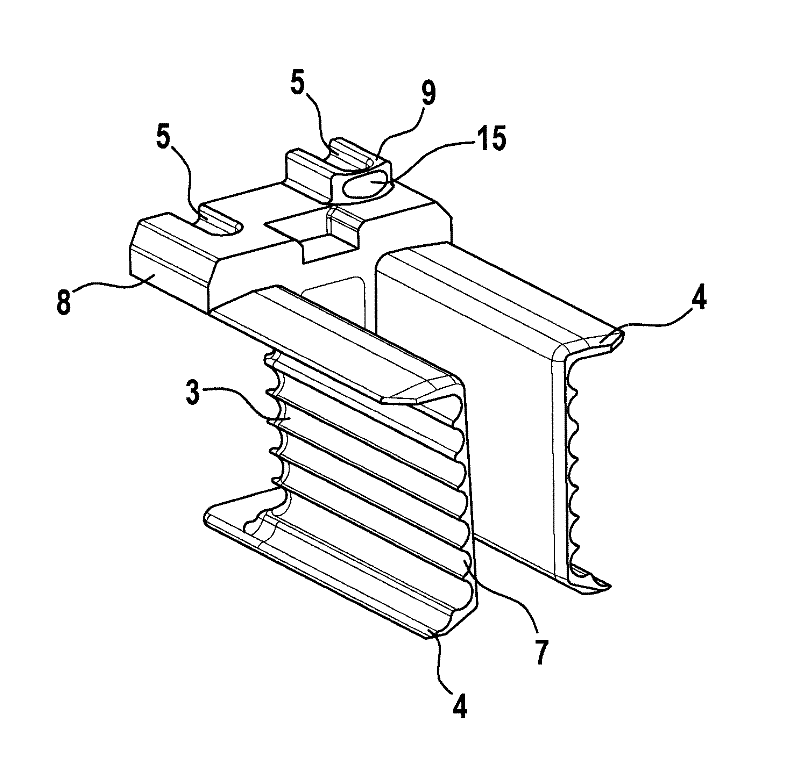

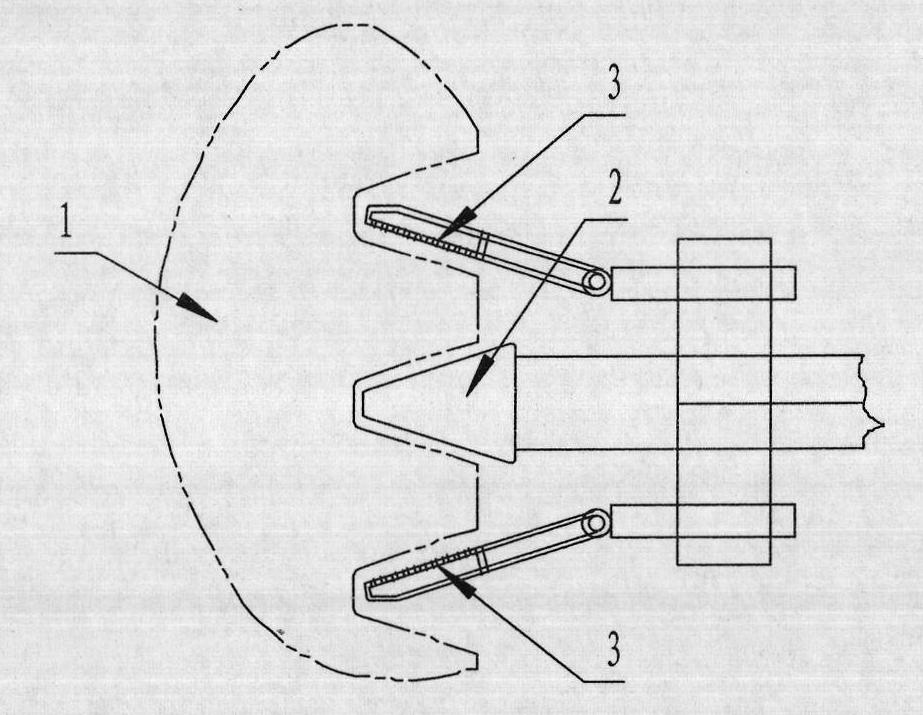

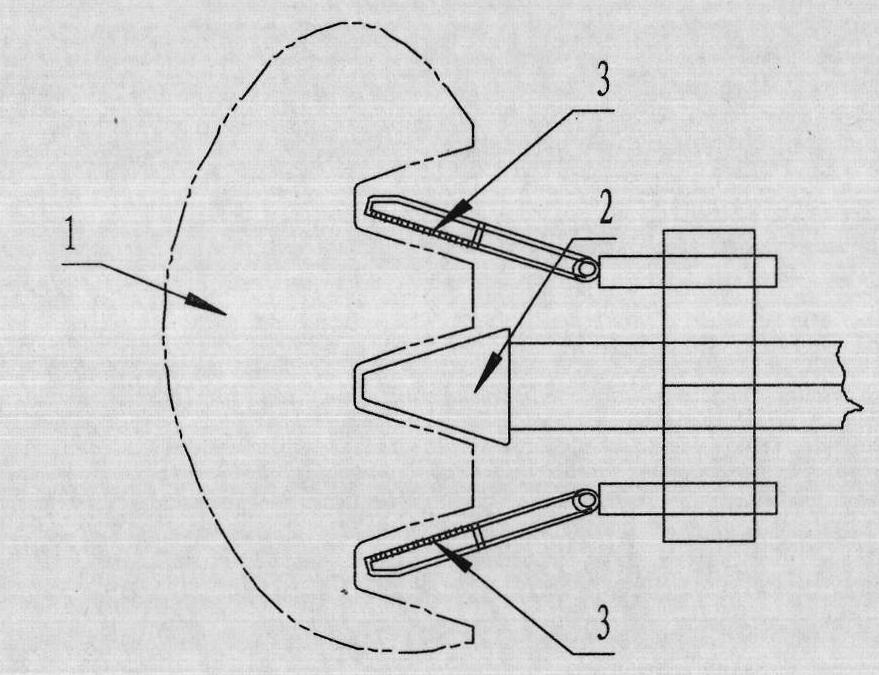

Orthodontic appliance with snap fitted, non-sliding archwire

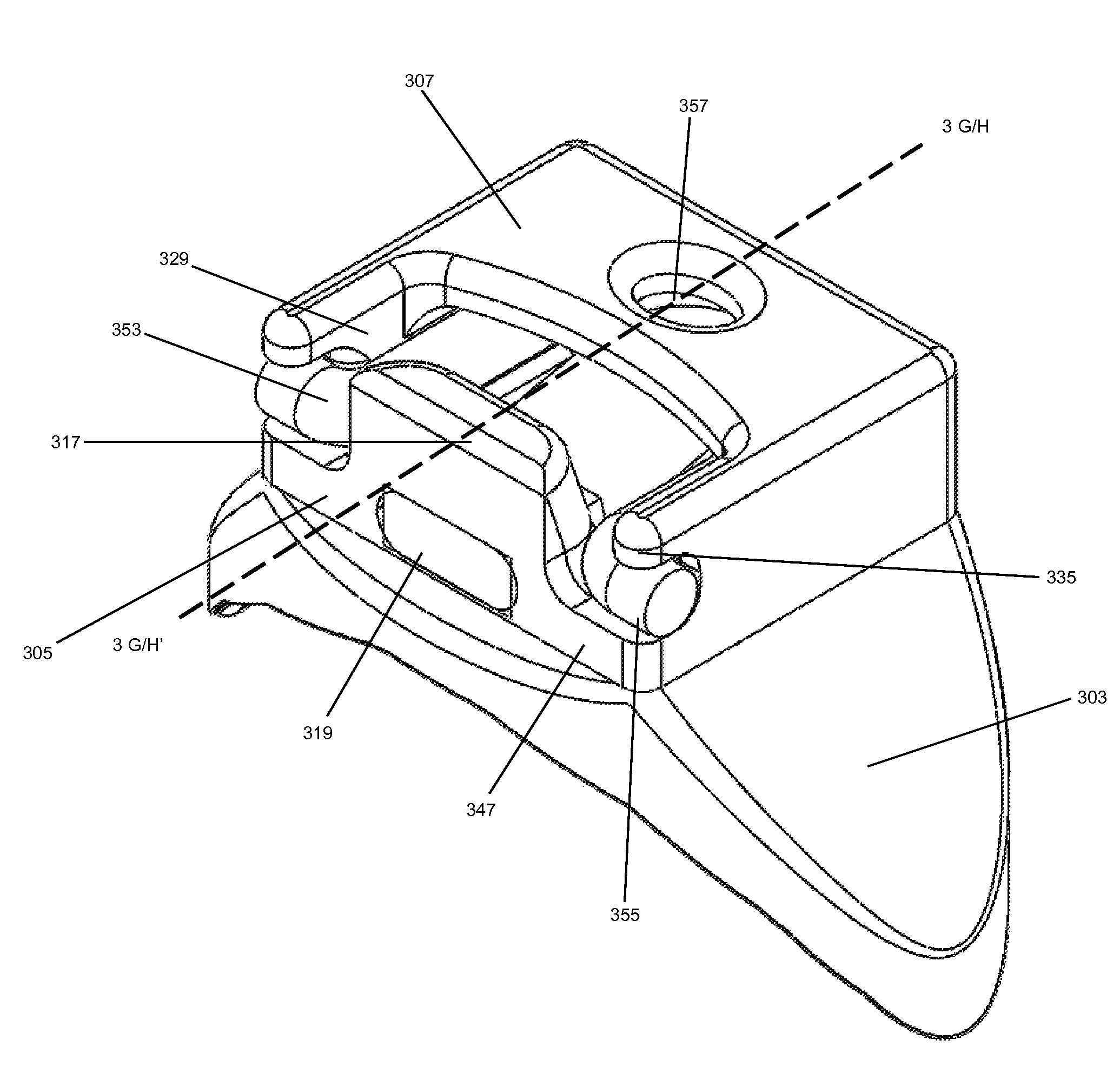

An orthodontic appliance may include an archwire and multiple orthodontic brackets. The archwire may fit within a human mouth and contain multiple male connectors. Each orthodontic bracket may have a configuration that facilitates attaching the orthodontic bracket to a single tooth. Each orthodontic bracket may allow one of the male connectors to be locked into the orthodontic bracket with a snapping action. The male connector may be unable to slide with respect to the orthodontic bracket after being locked in the orthodontic bracket. A manual unlocking action may allow the male connector to disengage from the orthodontic bracket.

Owner:UNIV OF SOUTHERN CALIFORNIA

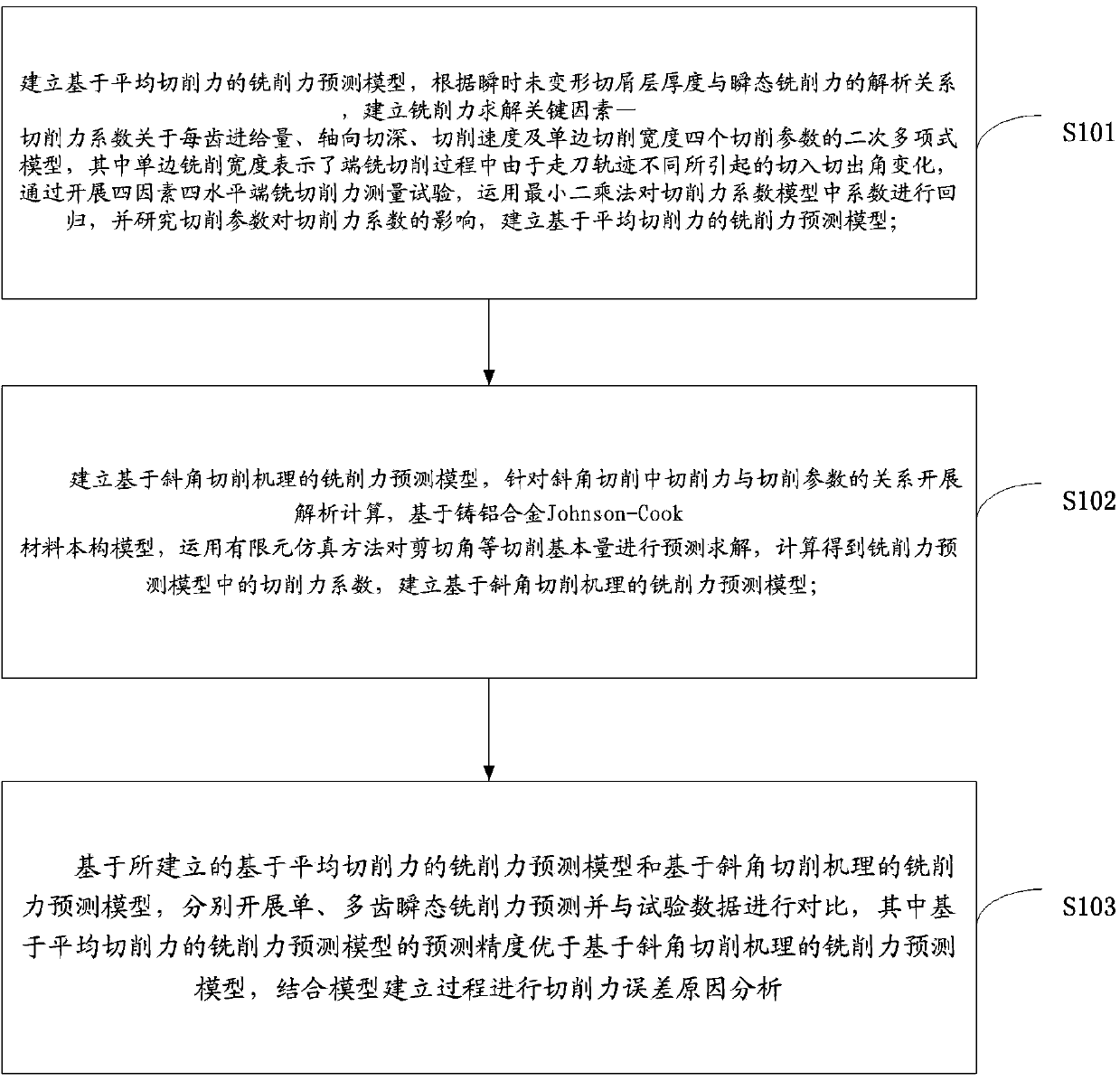

Construction method of aluminium alloy material end milling-cutting force and cutting processing deformation model

The invention discloses a construction method of an aluminium alloy material end milling-cutting force and cutting processing deformation model. According to the construction method, a milling-cutting force prediction model on the basis of an average cutting force is established; a milling-cutting force prediction model on the basis of an inclined cutting mechanism is established; on the basis of the established milling-cutting force prediction model on the basis of the average cutting force and the established milling-cutting force prediction model on the basis of the inclined cutting mechanism, single-tooth and multi-tooth transient milling-cutting force predictions are respectively carried out and obtained data is compared with testing data; an aluminum alloy material milling-cutting processing deformation model is established; on the basis of a real number encoded adaptive genetic algorithm, a flatness error of an end milled surface is predicted; the construction method has the important research significance for researching the processing deformation mechanism.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Orthodontic appliance with snap fitted, non-sliding archwire

An orthodontic appliance may include an archwire and multiple orthodontic brackets. The archwire may fit within a human mouth and contain multiple male connectors. Each orthodontic bracket may have a configuration that facilitates attaching the orthodontic bracket to a single tooth. Each orthodontic bracket may allow one of the male connectors to be locked into the orthodontic bracket with a snapping action. The male connector may be unable to slide with respect to the orthodontic bracket after being locked in the orthodontic bracket. A manual unlocking action may allow the male connector to disengage from the orthodontic bracket.

Owner:UNIV OF SOUTHERN CALIFORNIA

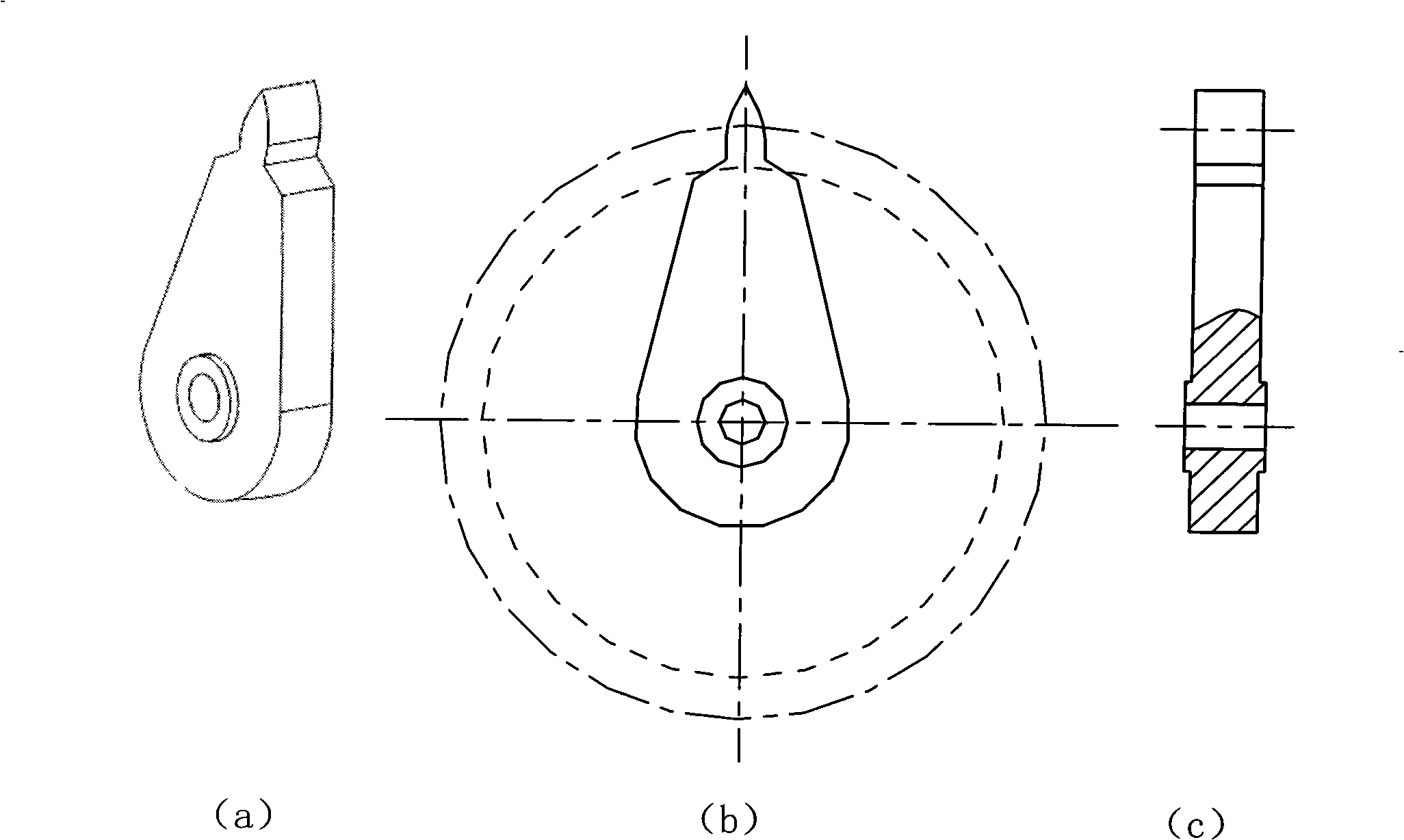

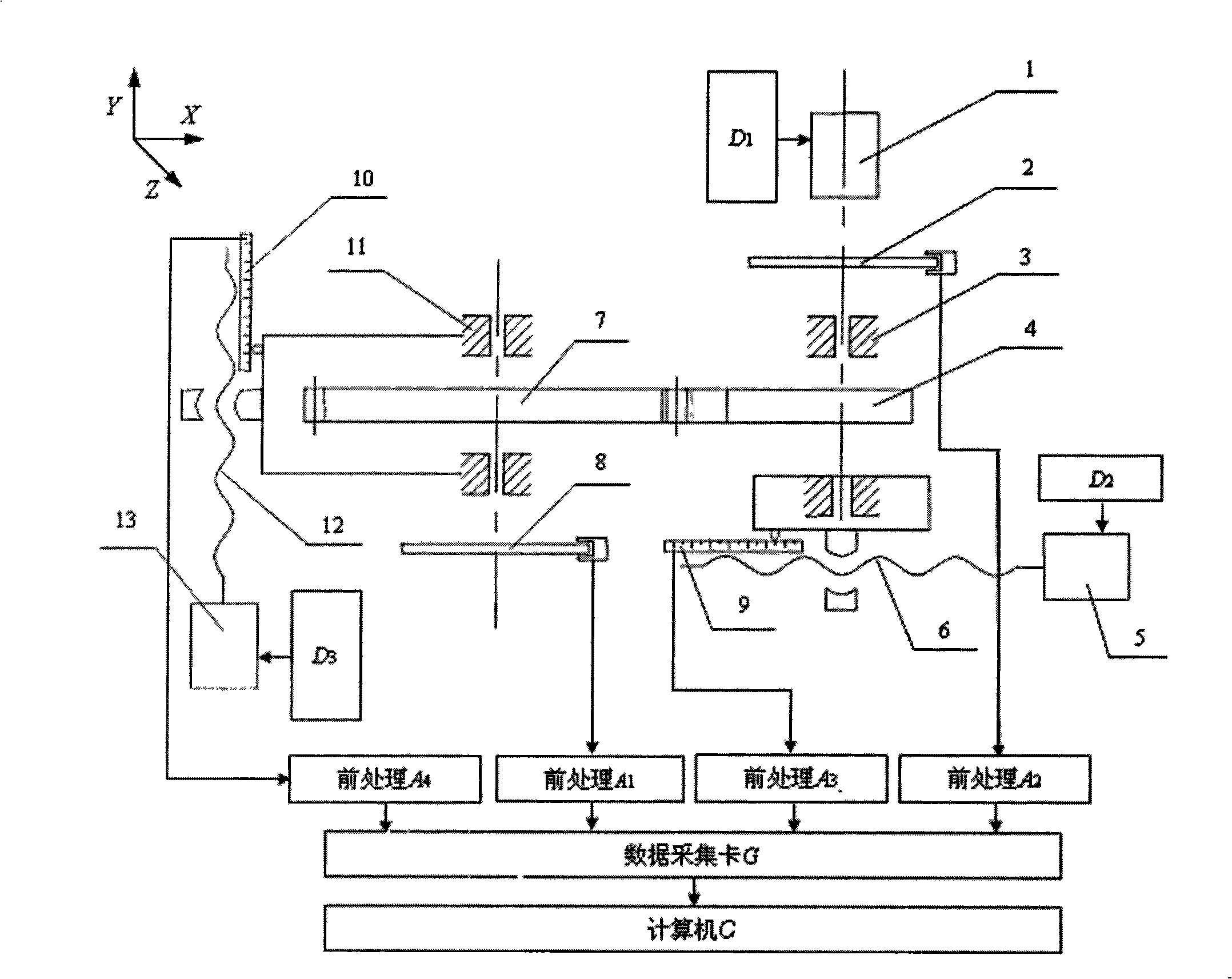

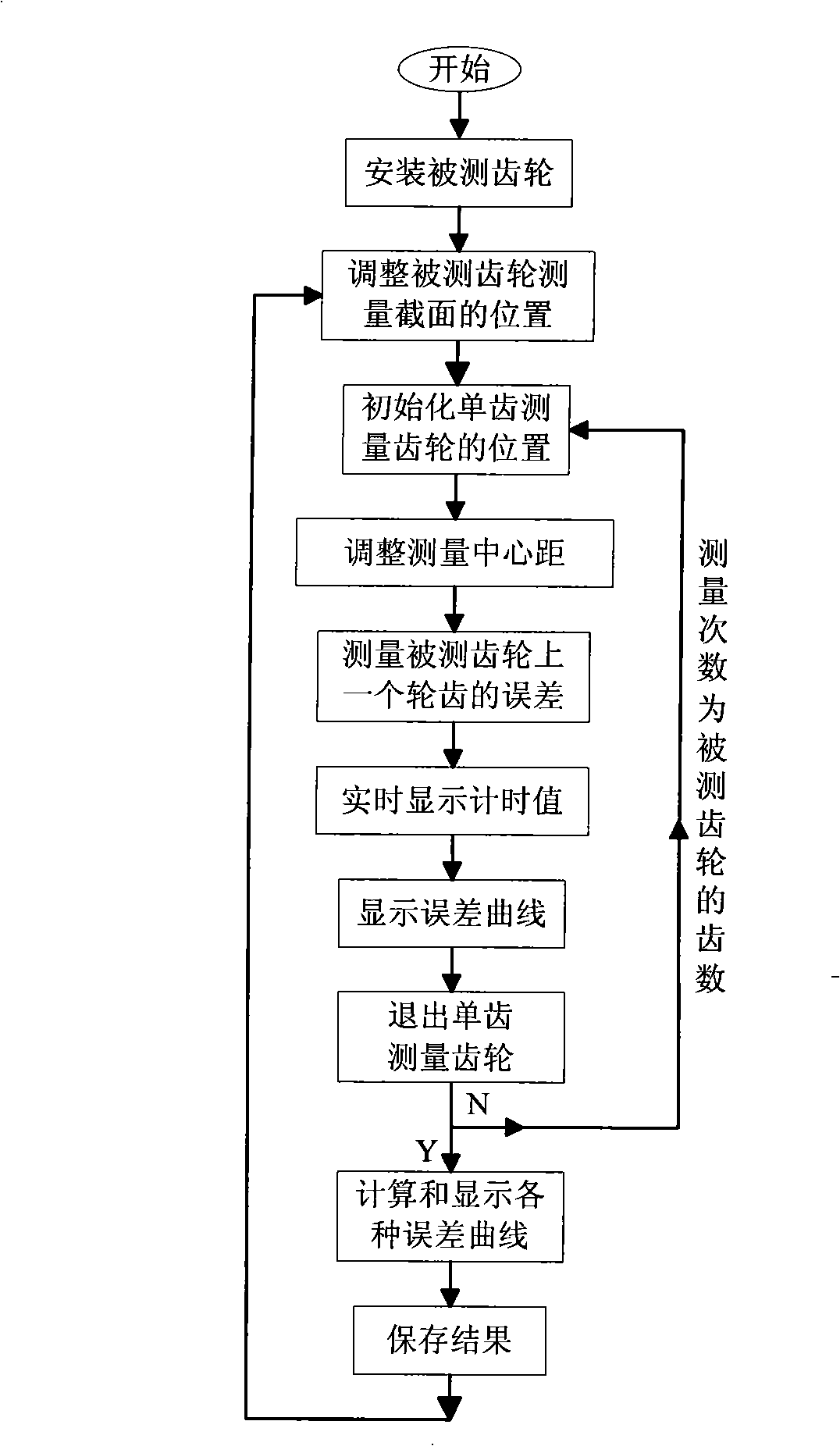

Single tooth type gear global error measuring apparatus and method

ActiveCN101294868AEasy to manufactureLow costMachine gearing/transmission testingGear wheelData acquisition

The invention relates to a single-tooth type gear integrated error measuring device and a method thereof, and belongs to the precision measuring technology and the technology field of mechanical transmission. The method uses a single-tooth measuring gear as a measuring element to realize the rolling point scanning measurement of all gear teeth of gears of different specifications to be measured. Angular displacement signals generated in the transmission process of the sing-tooth measuring gear and the gears to be measured are converted into electrical signals through a sensor; the signals are input into a computer after passing through a pre-processing circuit and a data acquisition board; four types of integrated error curves, the geometrical deviation of each item, the three-dimensional tooth surface typological deviation and the contact zone aspect graph of the gears to be measured are obtained through analysis and data processing; and the error result and the error curve can be shown and printed. According to the method, one measuring gear completes the measurement of the gears of different specifications to be measured and realizes flexible measurement of the gear integrated error. The single-tooth measuring gear has the advantages of convenient manufacture, low cost, high precision, wide application range, ensured measurement precision and extended measuring range.

Owner:BEIJING UNIV OF TECH

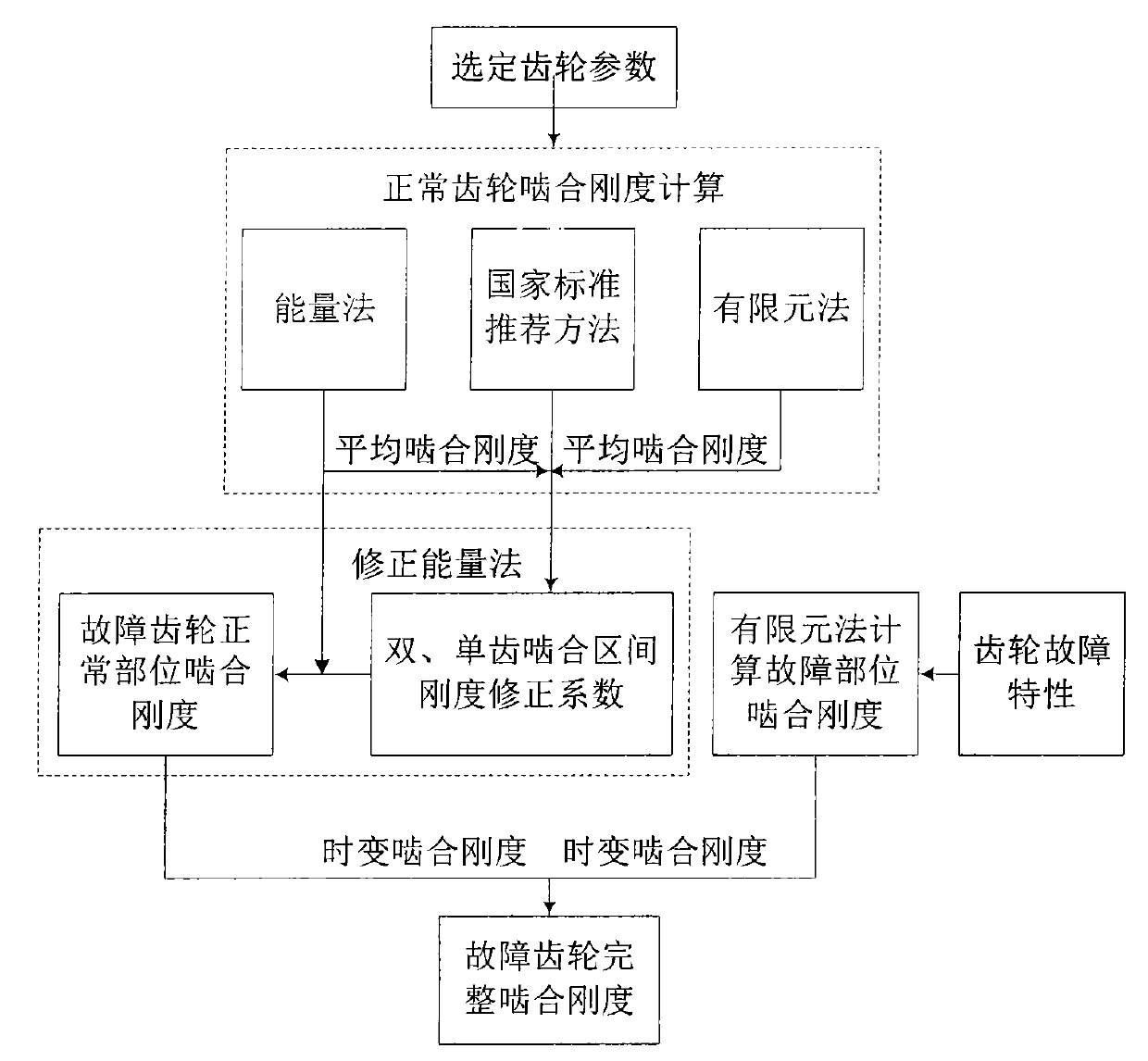

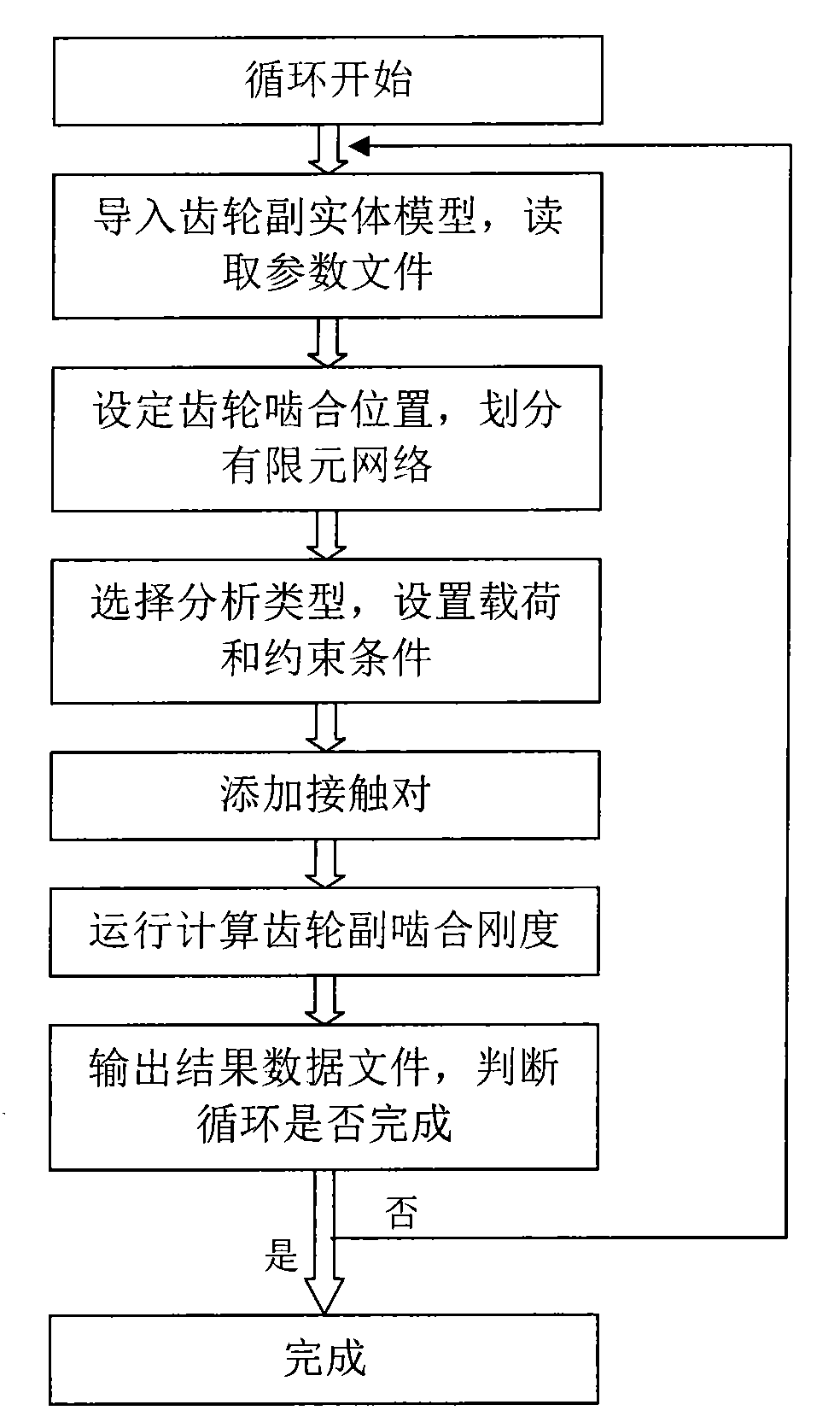

Method for simulation analysis on meshing stiffness of cylindrical spur gear undergoing damaged single-tooth failure

InactiveCN101770538AIncrease stiffnessReliable theoretical basisMachine gearing/transmission testingSpecial data processing applicationsElement modelSimulation

The invention relates to a method for the simulation analysis on the meshing stiffness of a cylindrical spur gear undergoing damaged single-tooth failure. The method comprises the following steps: firstly, setting the correction coefficient of the meshing stiffness of single-tooth and double-tooth meshing section on the basis of the calculation results of the average stiffness according to the finite element method and the national standard method, so as to improve the calculation accuracy of the meshing stiffness of a normal gear according to the energy method; secondly, establishing a finite element model of the spur gear undergoing damaged failure targeting on the failure location of the spur gear by combining the three-dimensional modeling software and the finite-element analysis software, and compiling a simulation calculation program by using the computer language, so as to calculate the time-varying meshing stiffness; and finally, integrating the calculation results of the two steps to obtain the integrated meshing stiffness of the spur gear. By fully integrating the advantages of the corrected energy method and the finite element method, the invention can not only guarantee the calculation accuracy, but also improve the calculation efficiency. The method of the invention for the simulation calculation of the meshing stiffness of the gear undergoing damaged single-tooth failure is effectively applicable in the research on the vibration response mechanism of a gear system.

Owner:BEIJING UNIV OF TECH

System and Method for Controlling an Electronic Device

InactiveUS20140364967A1Effectively and discretely control many operationComputer controlDetails for portable computersCanine toothVibration detection

For use with a head-worn computer, such as Google's Glass device, a user-generated tooth-tapping based input is used to control various and select computer operations during its use. The user simply opens and closes their jaw slightly so that they tap their right side pair of canine teeth, their left side pair of canine teeth, or all their teeth together to generate a sound and a vibration. This sound and vibration generated by a single tooth tap or any combination thereof is detected by at least one microphone located on the head-worn computer, and according to other embodiments of this invention two or more microphones and / or vibration-detection sensors. The computer receives the tapping sound signals from the microphone and uses controlling circuitry and / an algorithm to determine the exact tap-sequence and time between taps to establish a “command signature”, specific to each particular tap-sequence. From this, the computer compares the command signature with a corresponding command or action stored in the onboard memory and then performs that command or action, as required. The user can effectively and discretely control many operations of the head-worn computer merely through tooth tapping.

Owner:SULLIVAN SCOTT

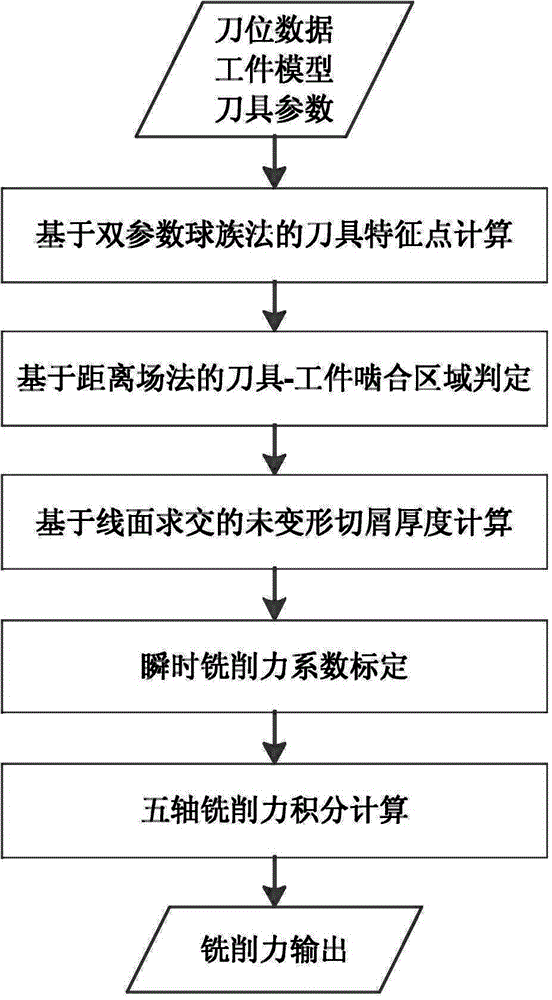

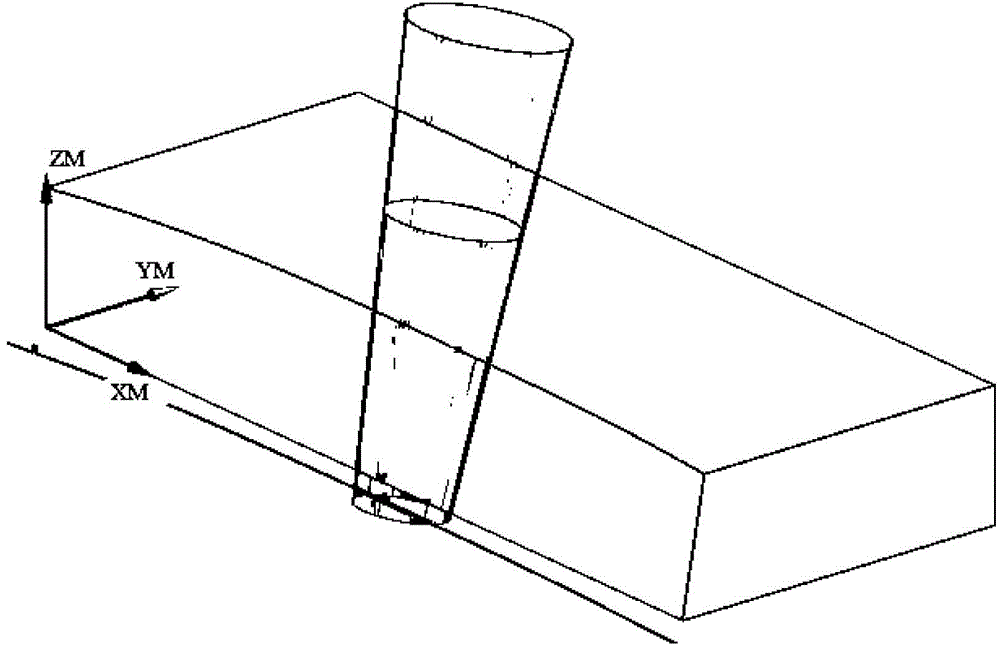

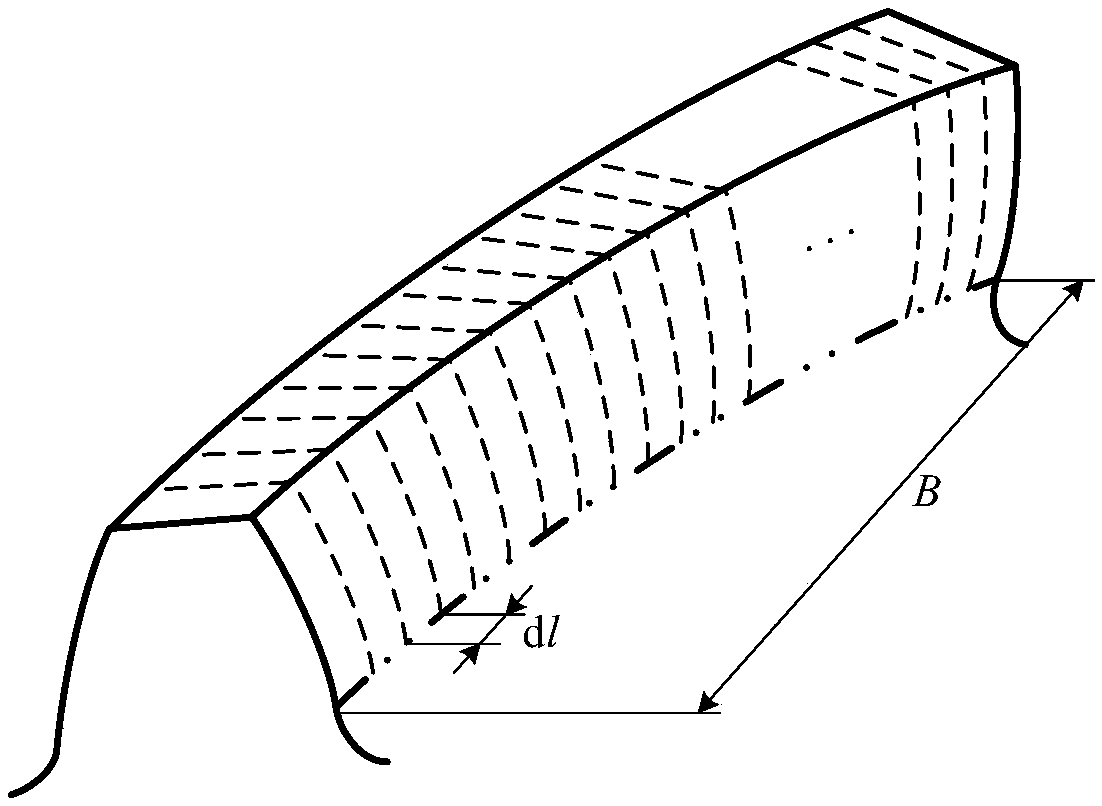

Method for predicting milling force of five-axis numerical control side milling

ActiveCN103955169AImprove accuracyEfficiencyProgramme controlComputer controlNumerical controlField methods

The invention provides a method for predicting milling force of five-axis numerical control side milling. The method comprises the steps that firstly, the current cutter spacing cutter-workpiece meshing area is acquired based on the distance field method, points and normal directions on a cutting edge of the current cutter spacing are converted to a previous cutter spacing cutter coordinate system, the analytical expression of a non-transformation cuttings thickness is obtained according to the line and face intersection method, and milling force coefficients are acquired through three-axis single-tooth milling experiment calibration; secondly, the cutter is dispersed into a plurality of slice infinitesimals in the axial direction, and the tangential milling force, the radial milling force and the axial milling force of the slice infinitesimals are obtained through calculation according to cutter geometrical parameter information, cutter-workpiece meshing area information, non-transformation cutting thicknesses calculated value and the milling force coefficients; lastly, the force coordinates are converted into the X-axis direction, the Y-axis direction and the Z-axis direction, and integration is carried out on the slice infinitesimals in the axial direction to obtain the five-axis side milling force predicting value at current time. By means of the method, the accuracy and efficiency of prediction and calculation on the milling force of five-axis side milling are improved.

Owner:SHANGHAI JIAO TONG UNIV

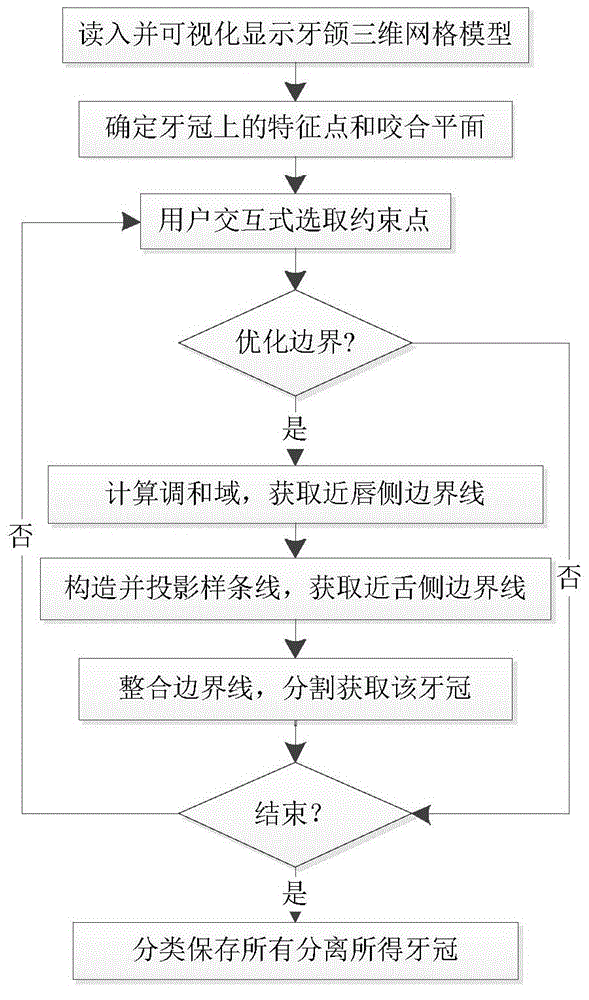

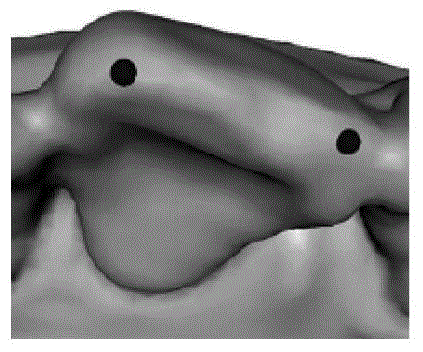

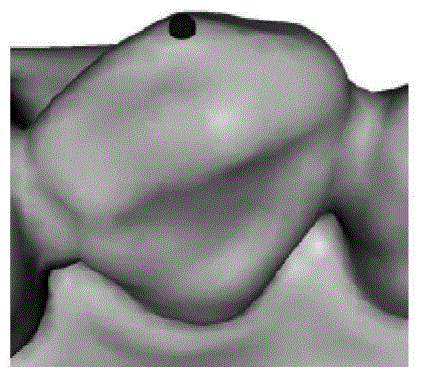

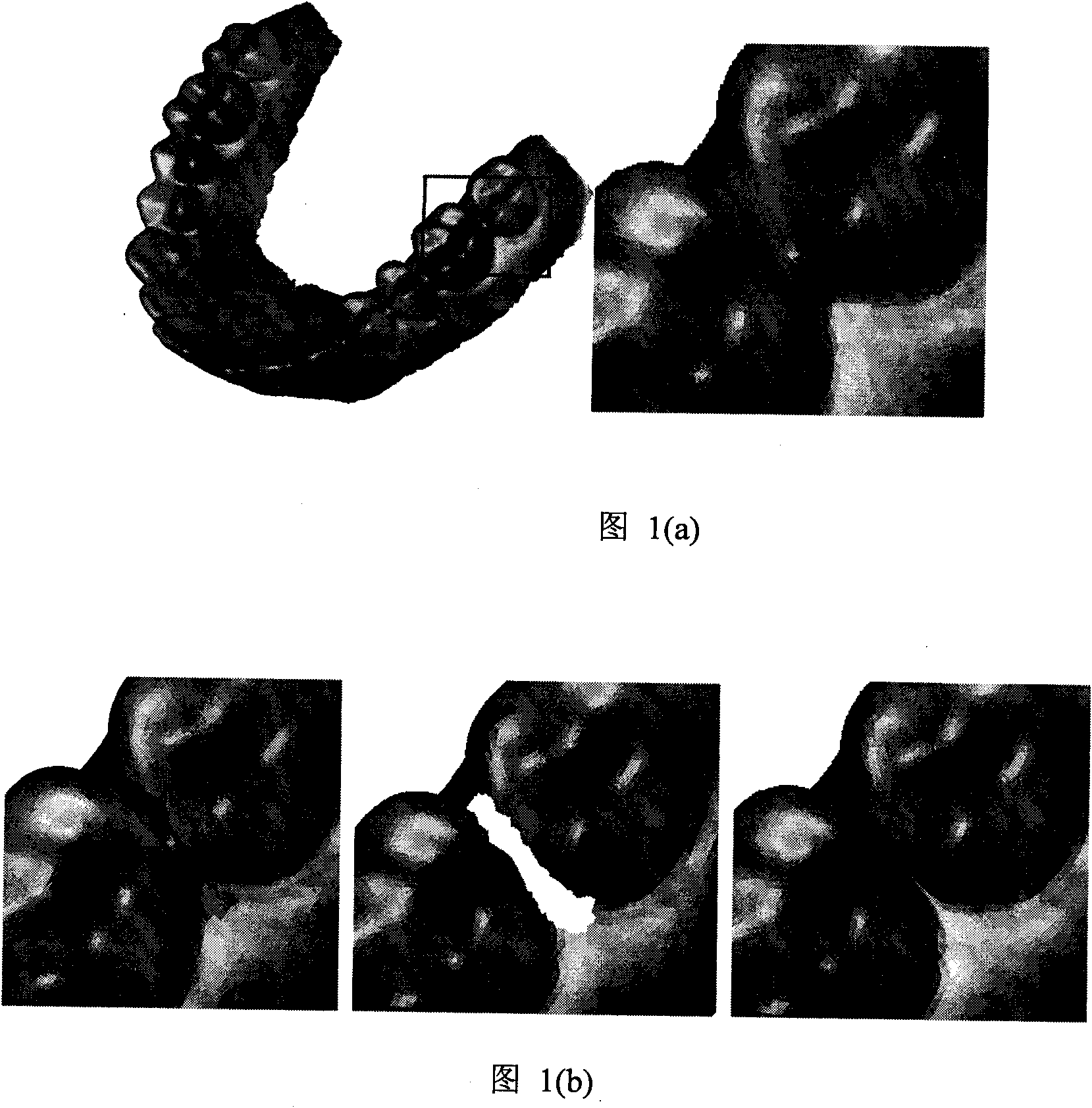

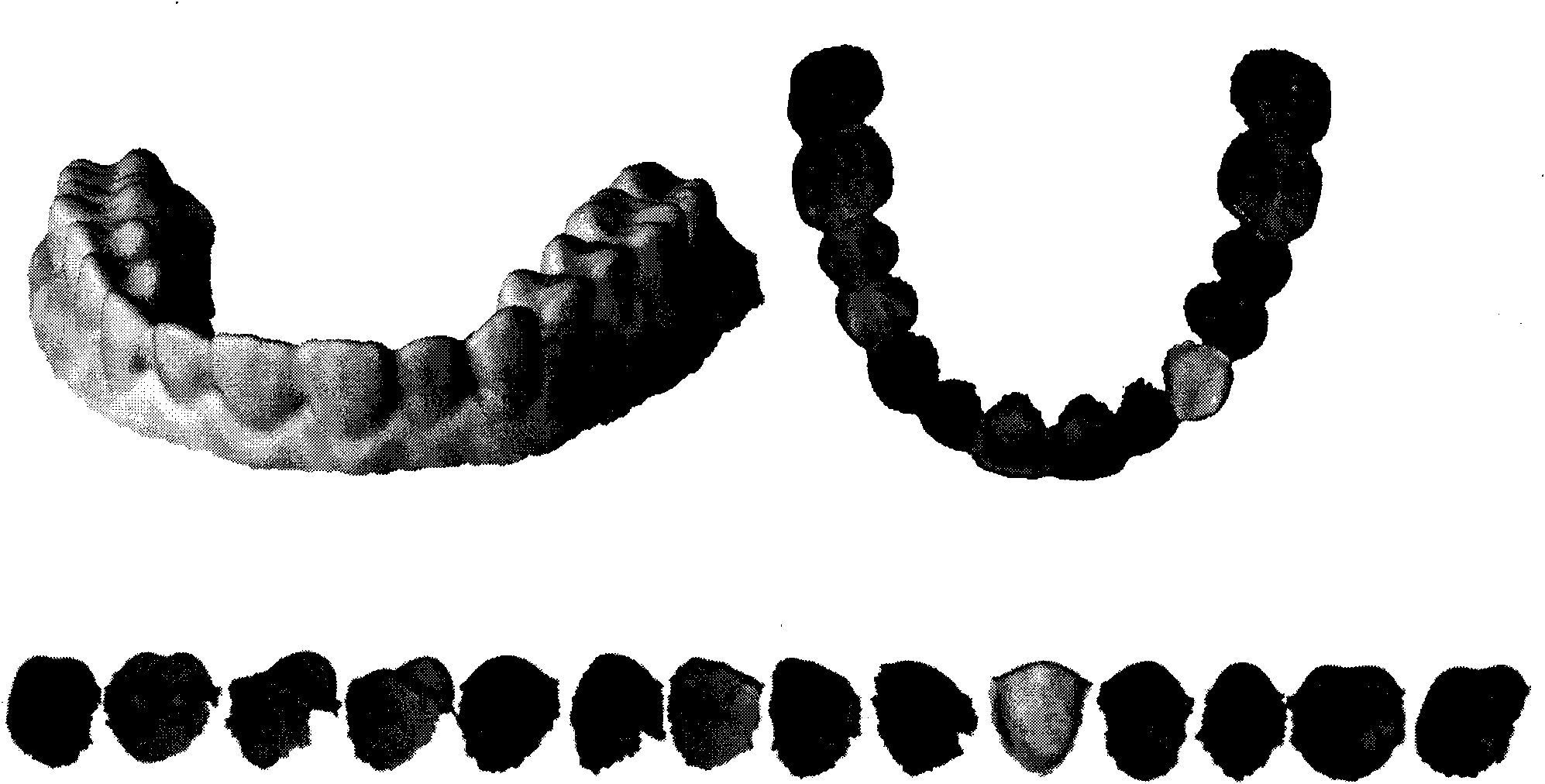

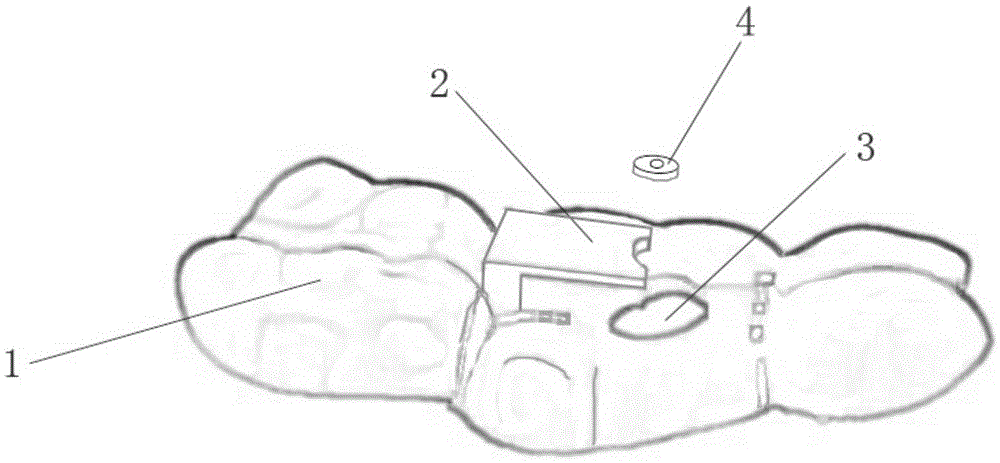

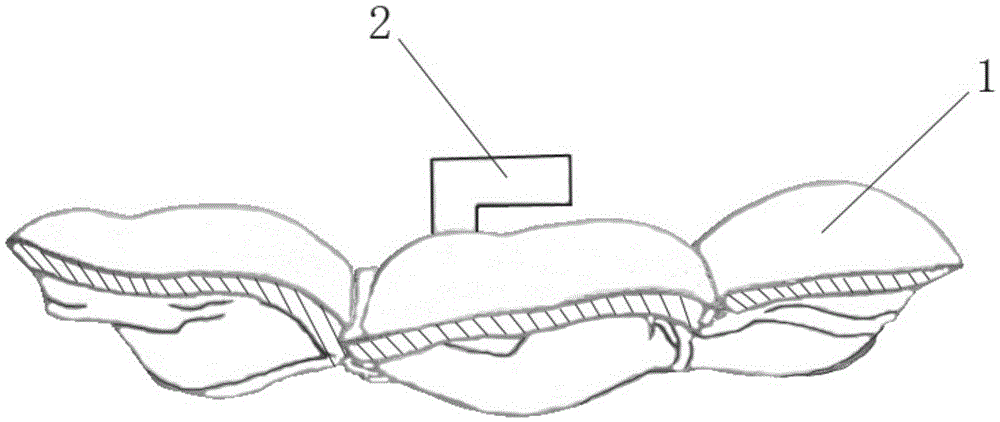

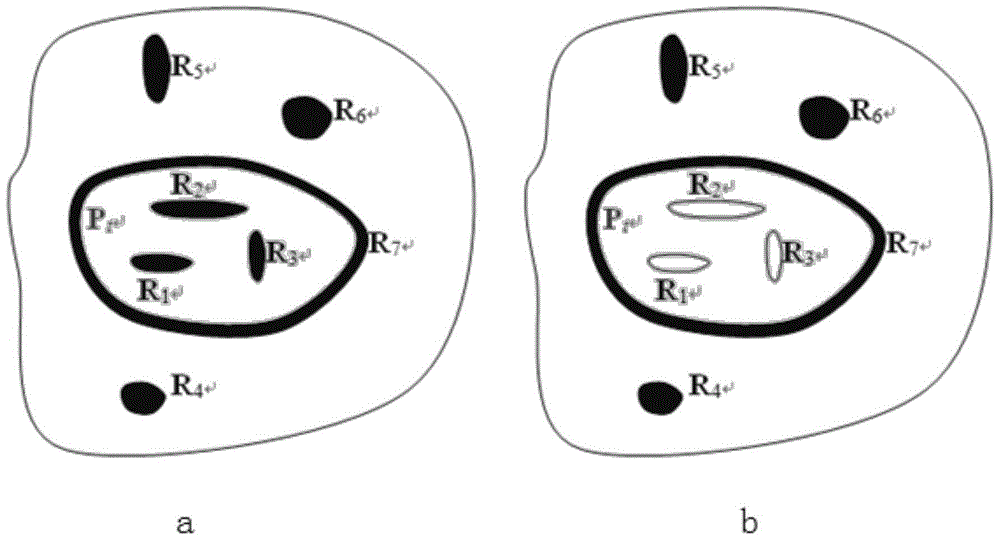

Computer interaction type method for segmenting single tooth crown from three-dimensional jaw model

InactiveCN104392492AImprove robustnessEasy to useImage data processingSpecial data processing applicationsUpper toothBorder line

The invention discloses a computer interaction type method for segmenting a single tooth crown from a three-dimensional jaw model. The method includes the steps: reading and visually displaying the three-dimensional jaw grid model; detecting anatomic characteristic points and an occlusion plane of upper teeth of a jaw in the three-dimensional jaw grid model; assigning constraint points of harmonic fields of the three-dimensional jaw grid model; calculating the harmonic fields according to constraint conditions to obtain a tooth crown segmenting border line; performing grid cutting according to the obtained tooth crown segmenting border line to obtain a tooth crown model. By the method, a tooth segmenting border can be accurately obtained, the method is simple to use, and a user interactively determines two border points on a visual view of the jaw model for a single tooth to be separated, so that the tooth crown grid model of the tooth can be accurately obtained. The method has important significance for dental orthodontics, virtual jaw surgery simulation and the like.

Owner:CENT SOUTH UNIV

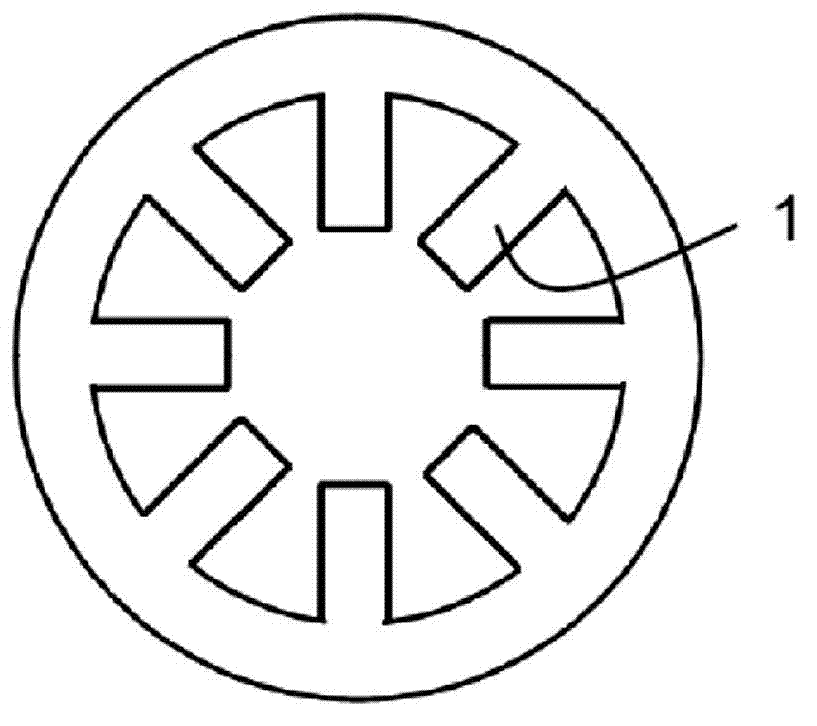

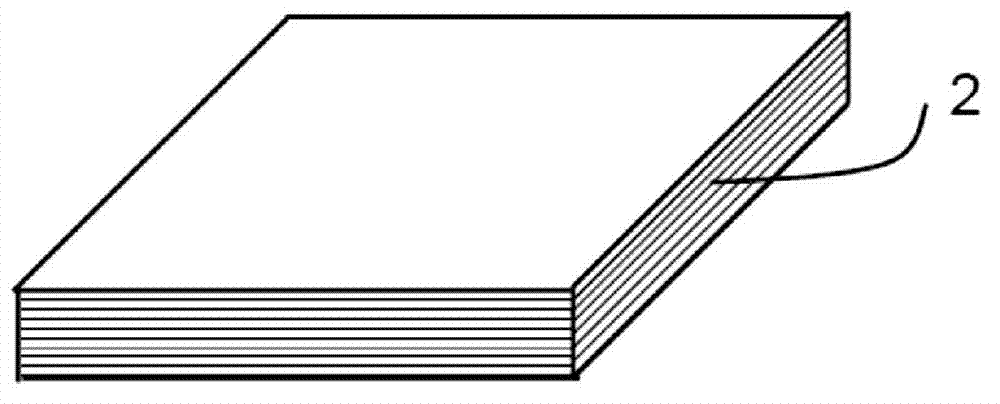

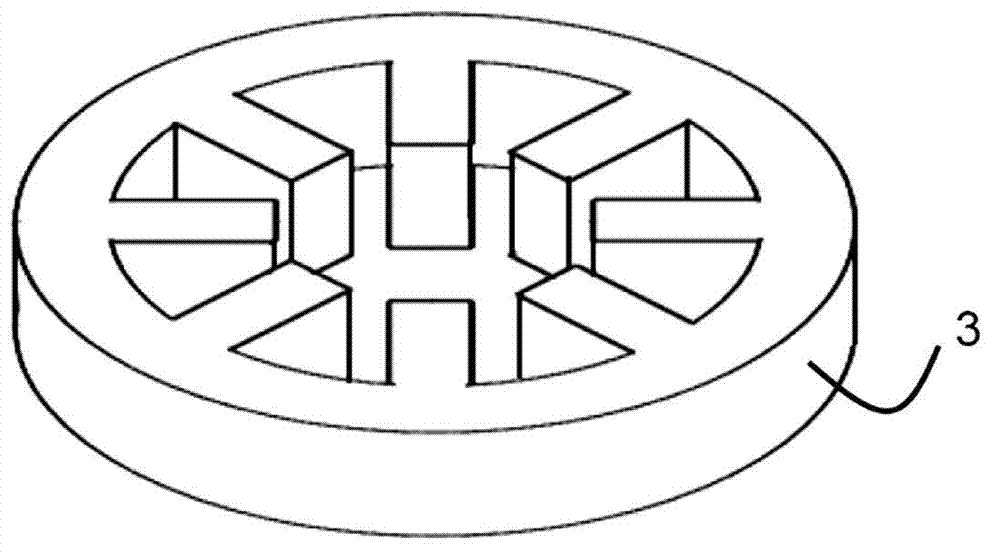

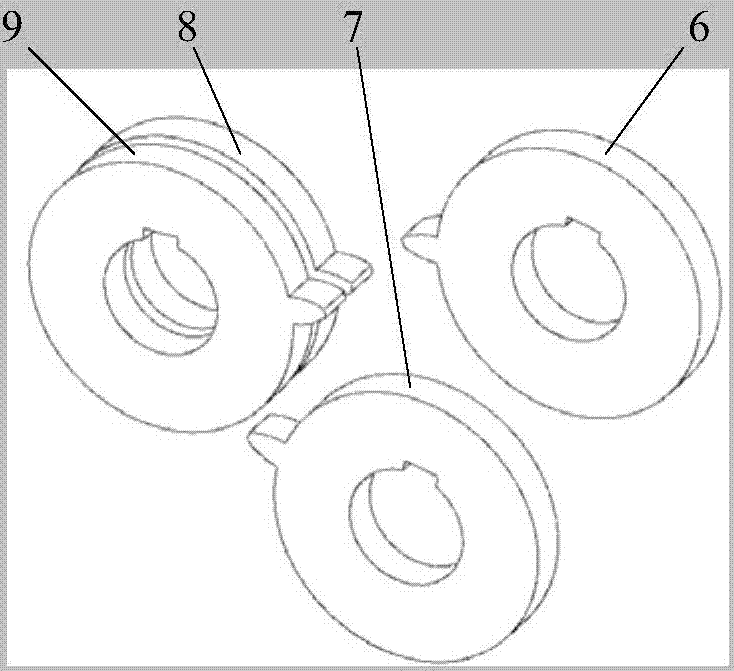

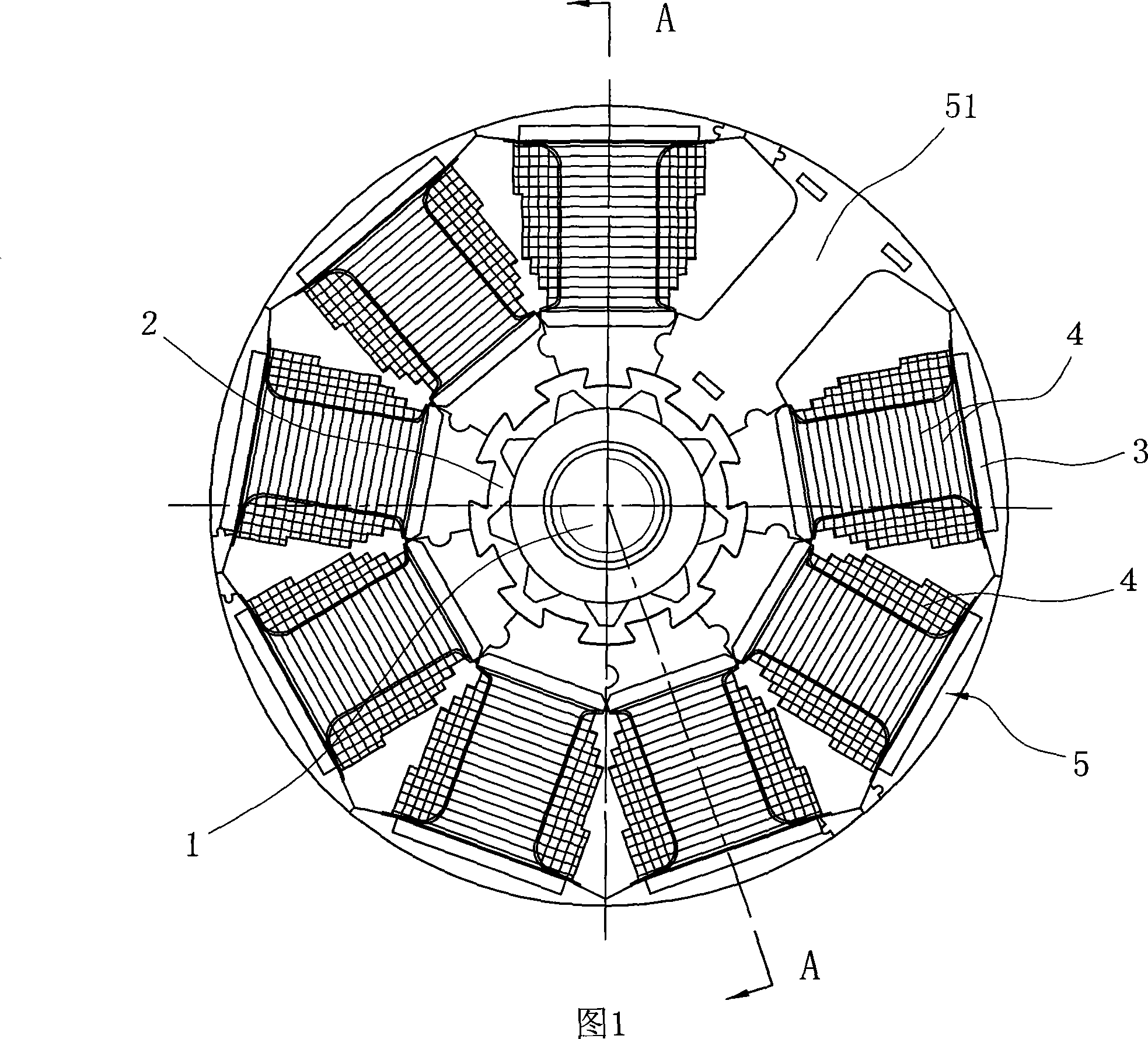

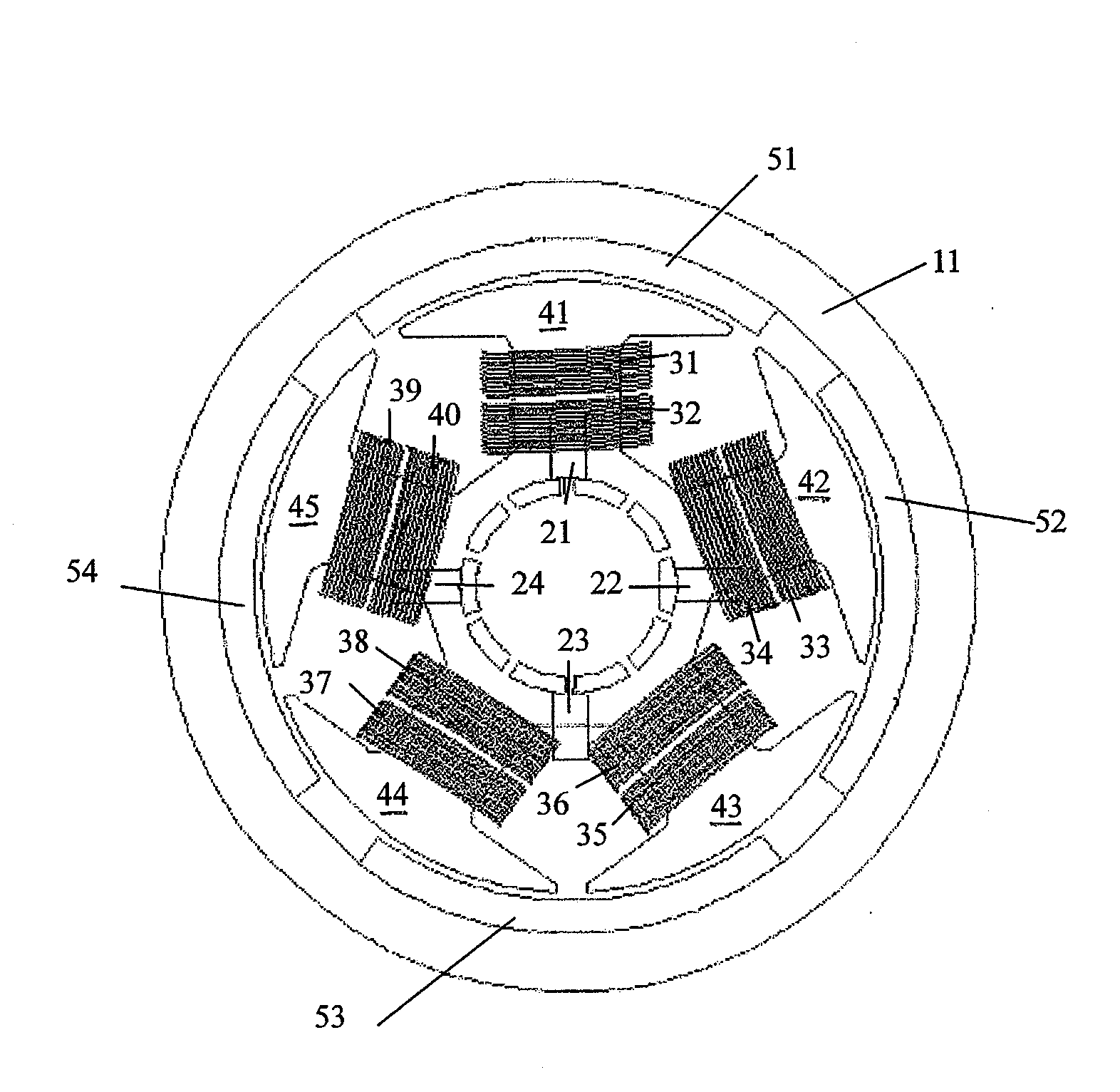

Amorphous, microcrystal or nanocrystalline alloy stator core and method for producing same

ActiveCN102820743AImprove permeabilityReduce lossNanotechnologyManufacturing stator/rotor bodiesEtchingLaser cutting

The invention provides an amorphous, microcrystal or nanocrystalline alloy stator core and a method for producing the same. The method for producing the stator core comprises the following steps that an amorphous, microcrystal or nanocrystalline alloy strip is laterally cut into a plurality of rectangular sheets with the same shape and size; the alloy sheets which are obtained through lateral cutting are subjected to annealing treatment; a plurality of alloy sheets which are obtained through annealing treatment are subjected to resin solidification treatment to obtain amorphous, microcrystal or nanocrystalline alloy sheets with the preset thickness; any one mode of laser cutting, plasma cutting, water cutting, wire cut electrical discharge machining, flame cutting and chemical etching is used to cut the alloy sheets with the preset thickness to obtain annular amorphous, microcrystal or nanocrystalline alloy splicing modules or at least one single-tooth circular arc splicing module; and the annular amorphous, microcrystal or nanocrystalline alloy splicing modules or at least one single-tooth circular arc splicing module are laminated or spliced to form the stator core. According to the method for producing the stator core, the production efficiency can be increased, and the cost can be lowered.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Orthodontic appliance with snap fitted, non-sliding archwire

An orthodontic appliance may include an archwire and multiple orthodontic brackets. The archwire may fit within a human mouth and contain multiple male connectors. Each orthodontic bracket may have a configuration that facilitates attaching the orthodontic bracket to a single tooth. Each orthodontic bracket may allow one of the male connectors to be locked into the orthodontic bracket with a snapping action. The male connector may be unable to slide with respect to the orthodontic bracket after being locked in the orthodontic bracket. A manual unlocking action may allow the male connector to disengage from the orthodontic bracket.

Owner:UNIV OF SOUTHERN CALIFORNIA

Method for accurately recovering single tooth form on three-dimensional tooth-mandible model

InactiveCN101604354APromote recoveryAutomatic recoverySpecial data processing applicationsComputer-aidedComputer aid

The invention discloses a method for accurately recovering a single tooth form on a three-dimensional tooth-mandible model, and belongs to the field of computer-aided biomedical engineering. The method mainly comprises the following steps: (1) identifying and deleting a fusion part between teeth; and (2) according to hole boundary information generated after deleting the fusion part, constructing a curved surface sheet which accords with a practical spatial position relation between the teeth and can synchronously reflect local characteristics of corresponding tooth parts. The method of the invention only comprises simple human-computer interaction operation, has high automation degree, mainly carries out linear computation, can quickly, stably and accurately recover the form of a deletion part of the single tooth on the three-dimensional tooth-mandible model, and has important application value in the field of computer-aided oral orthodontics.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

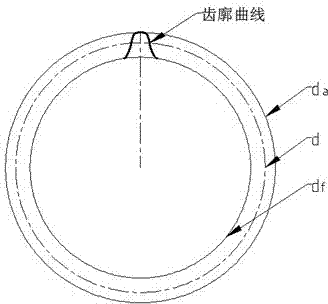

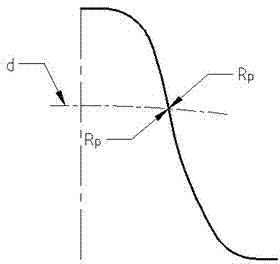

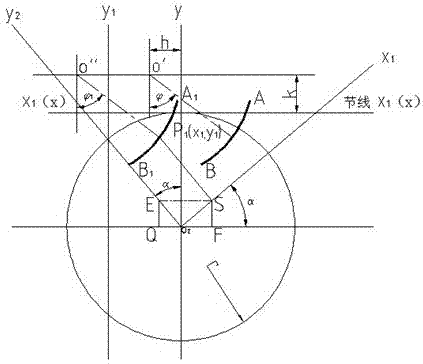

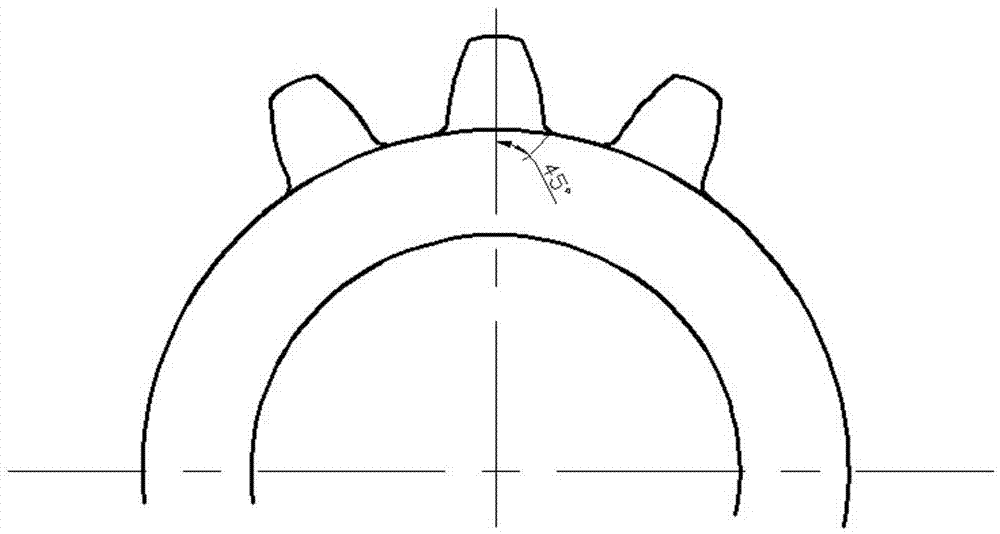

Precise modeling method for biarc correction cycloidal gear

ActiveCN103678818AHigh precisionSave programming calculationsPortable liftingSpecial data processing applicationsGear wheelMachining

The invention relates to a precise modeling method for a biarc correction cycloidal gear and belongs to the technical field of gear modeling. The method concretely includes the steps that basic parameters are determined, the reference circle, the addendum circle and the dedendum circle of the gear are drawn, a biarc correction cycloid is calculated according to the basic parameters in the biarc correction cycloid and interior and exterior tooth profile equations, a single tooth profile and a single tooth blank are established, the single tooth profile and the tooth blank are imported into professional software so that the solid body can be stretched and Boolean operation can be carried out, modeling of the single tooth is completed, and then modeling of the whole gear is completed by applying array. The precise modeling method for the biarc correction cycloidal gear is an important modeling method for actual machining and simulation operation of the biarc correction cycloidal gear and has the advantages of being high in modeling precision and efficiency, and simple and convenient in calculation, design and manufacturing process and ensuring the design precision and the manufacturing precision of the biarc correction cycloidal gear.

Owner:KUNMING UNIV OF SCI & TECH

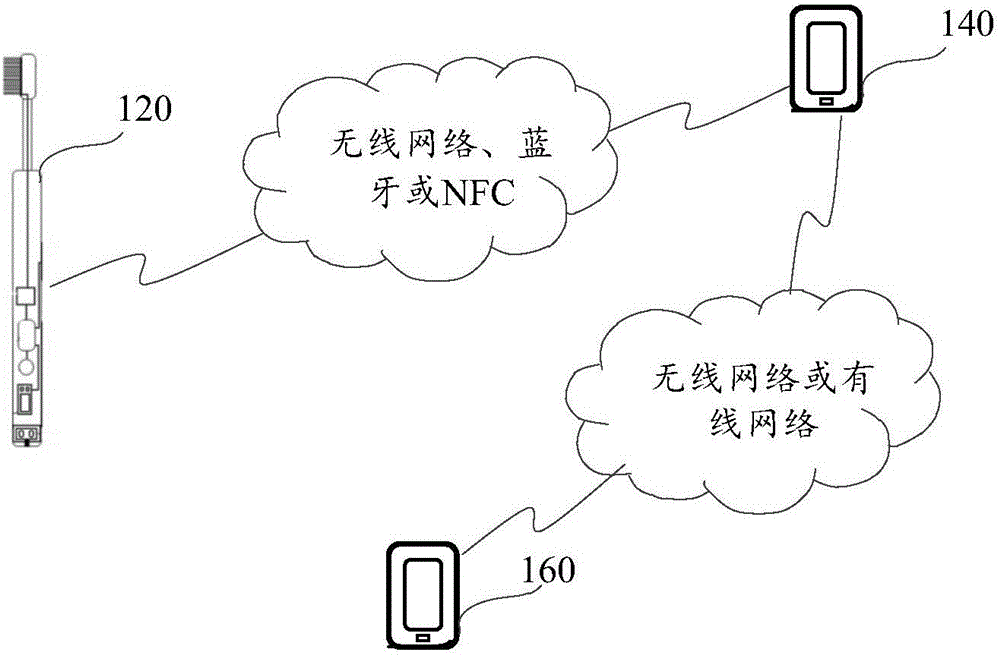

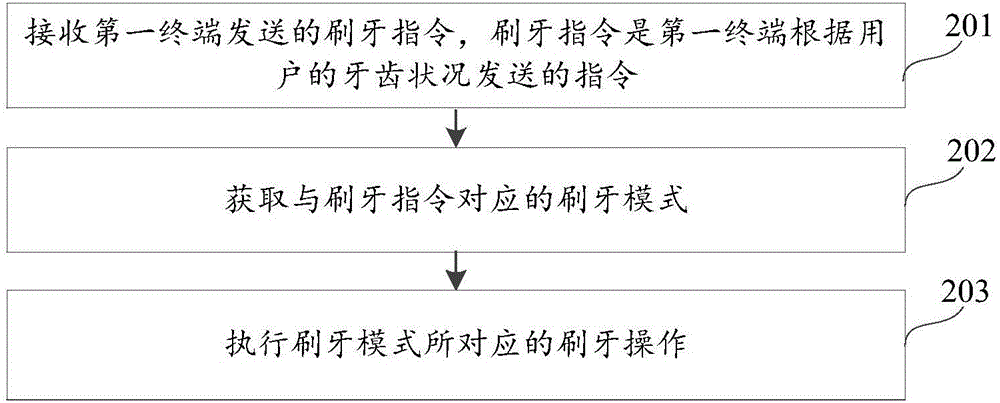

Intelligent tooth brushing method and device

InactiveCN106200460AMeet real needsImprove applicabilityProgramme controlComputer controlComputer scienceTooth brushing

The disclosure provides an intelligent tooth brushing method and device and belongs to the intelligent household field. The intelligent tooth brushing method comprises steps of receiving a tooth brushing instruction sent by a terminal, wherein the tooth brushing instruction is an instruction sent by the terminal according to the tooth condition of a user; obtaining a tooth brushing mode corresponding to the tooth brushing instruction; and executing a tooth brushing operation corresponding to the tooth brushing mode. The problems in the prior art that the tooth brushing mode is single, and the single tooth brushing mode cannot meet demands of each user as each user has a different tooth condition, and thus an intelligent toothbrush is poor in applicability are solved. The effect of setting a tooth brushing mode corresponding to the tooth condition of the user can be achieved, different brushing operations can be executed for different tooth conditions, real demands of the user can be met, and the applicability of the intelligent toothbrush is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

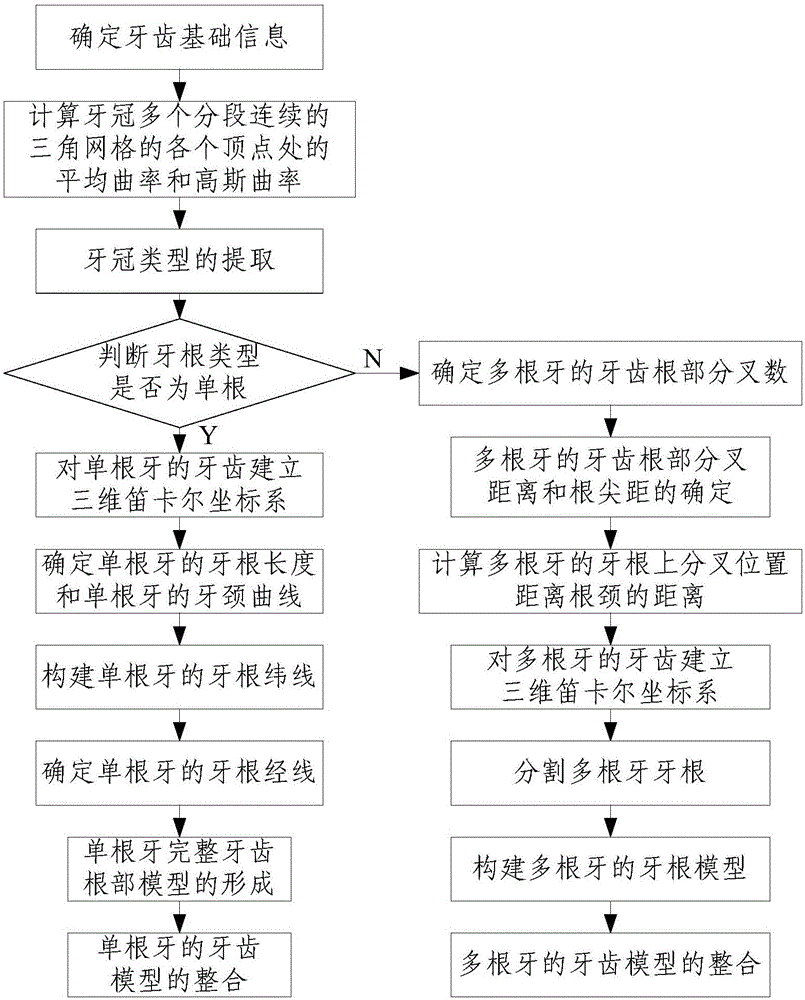

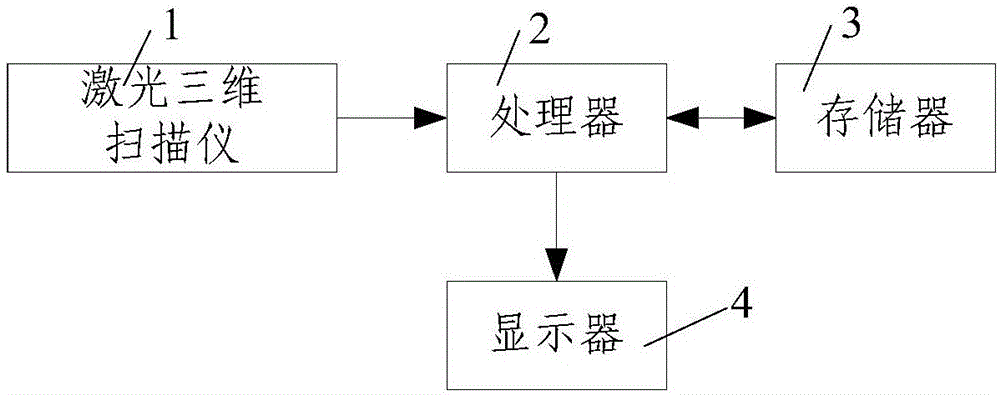

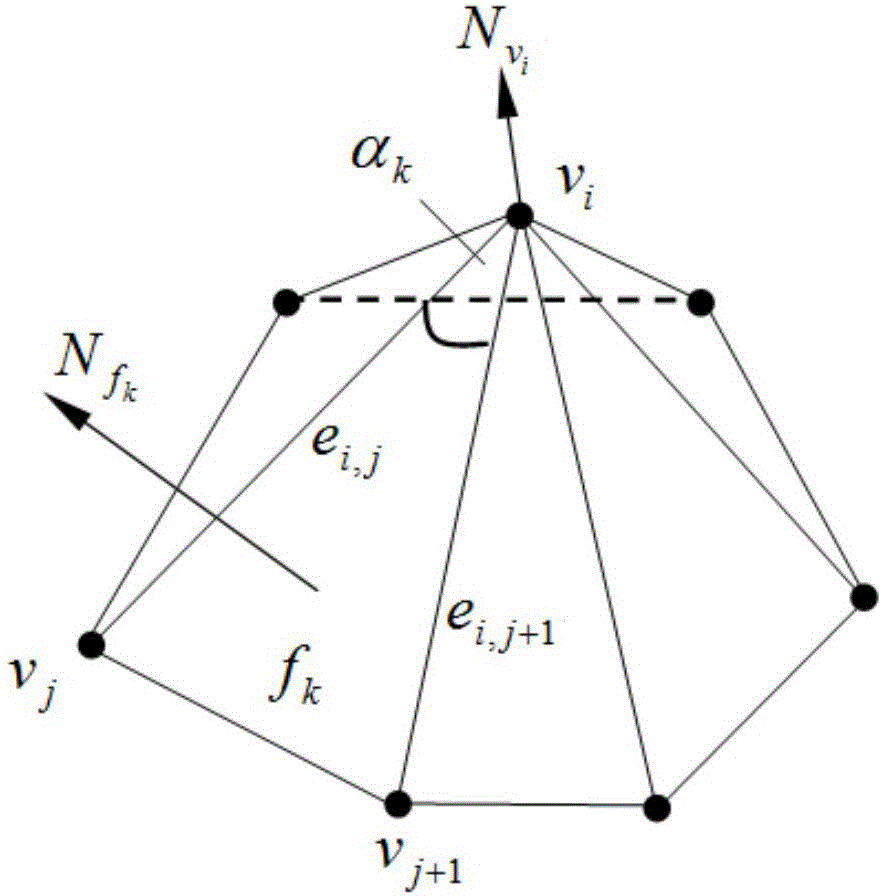

Tooth modeling method based on dental crown and tooth root characteristics

ActiveCN106295170AGet data fastHigh precisionMedical simulationSpecial data processing applicationsRooted toothSingle tooth

The invention discloses a tooth modeling method based on dental crown and tooth root characteristics. The tooth modeling method includes the following steps that 1, tooth basis information is determined; 2, the average curvature and the gaussian curvature at a top point of a triangular mesh are determined; 3, the computational processes of the average curvatures and the gaussian curvatures at all the top points of continuous triangular meshes of multiple segmentations of a dental crown are completed; 4, the type of the dental crown is extracted; 5, whether the tooth type is single or not is judged; 6, a tooth model of the single-root tooth is established; 7, the tooth model of the multi-root tooth is established. According to the tooth modeling method, a dental crown model of a single tooth is obtained through a laser three-dimensional scanner, the dental crown and tooth roots are separated, the type of the tooth is determined according to the characteristics of the dental crown, the corresponding tooth root model is established, and the tooth modeling method is high in accuracy, small in calculation quantity, visible, rapid, effective and low in cost.

Owner:北京赢冠口腔医疗科技股份有限公司

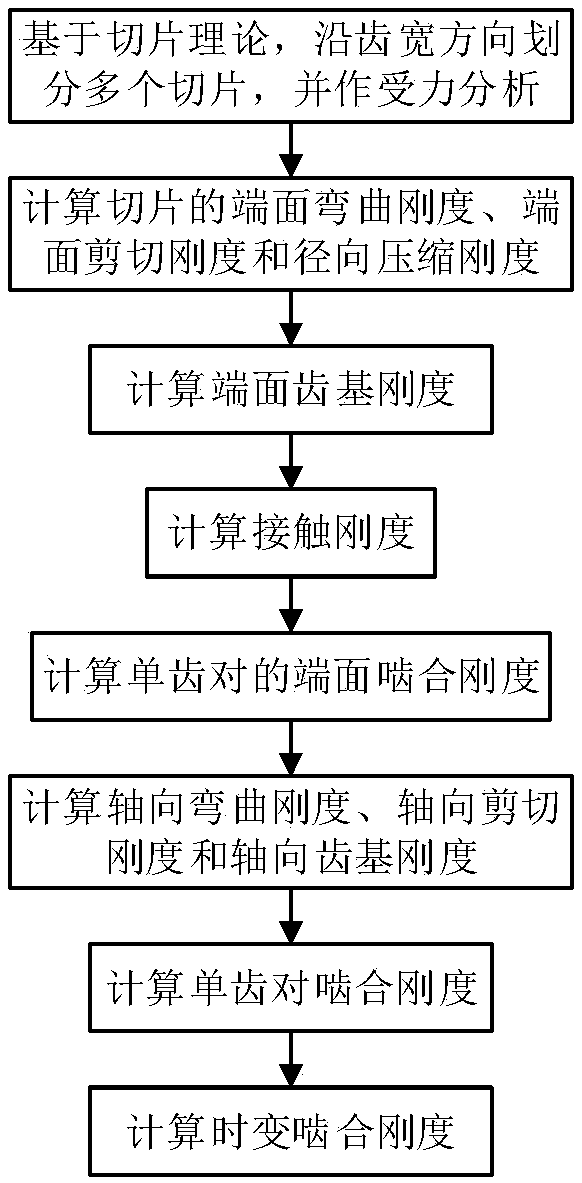

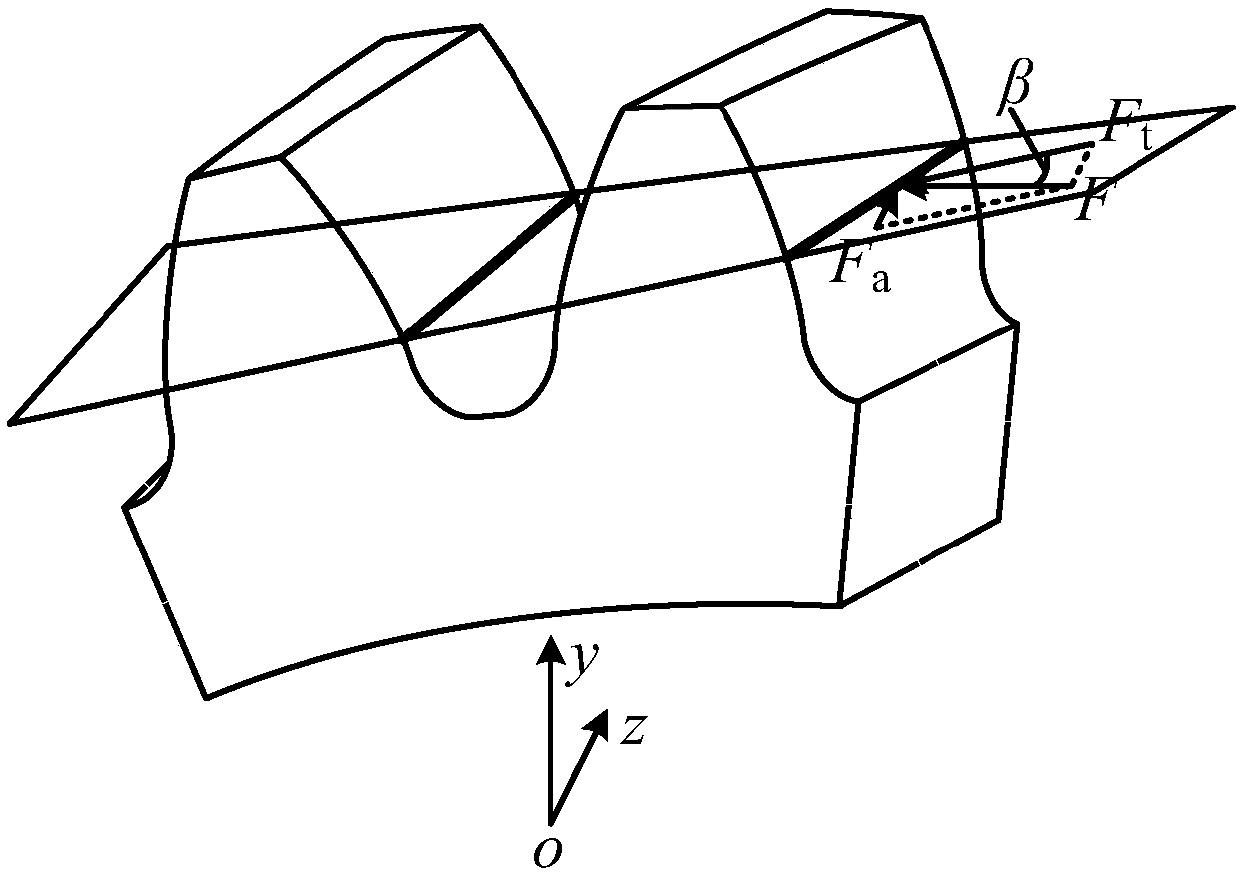

Method considering axial deformation for calculating time-varying meshing stiffness of helical gear

ActiveCN107798200AHigh precisionGeometric CADDesign optimisation/simulationRadial compressionEngineering

The invention proposes a method considering axial deformation for calculating time-varying meshing stiffness of a helical gear. The method aims at improving the accuracy of calculating the meshing stiffness of the helical gear. The method comprises the implementation steps of calculating the end surface bending stiffness, end surface shearing stiffness, radial compression stiffness and end surfacetooth base stiffness of the helical gear; calculating contact stiffness; calculating the end surface meshing stiffness of a single tooth pair; deducing and calculating axial bending stiffness, axialshearing stiffness and axial tooth base stiffness; calculating the meshing stiffness of the single tooth pair; calculating the time-varying meshing stiffness. According to the method, the influence ofaxial meshing force on the time-varying meshing stiffness of the helical gear is considered, a calculation expression for the quantitative calculation of the axial bending stiffness, axial shearing stiffness and axial tooth base stiffness of the helical gear is deduced, the time-varying meshing stiffness of the helical gear is calculated by combining all the stiffness in the end surface direction, the calculation accuracy is improved, and the method can be used for the dynamic performance analysis and optimization design of the helical gear.

Owner:XIDIAN UNIV

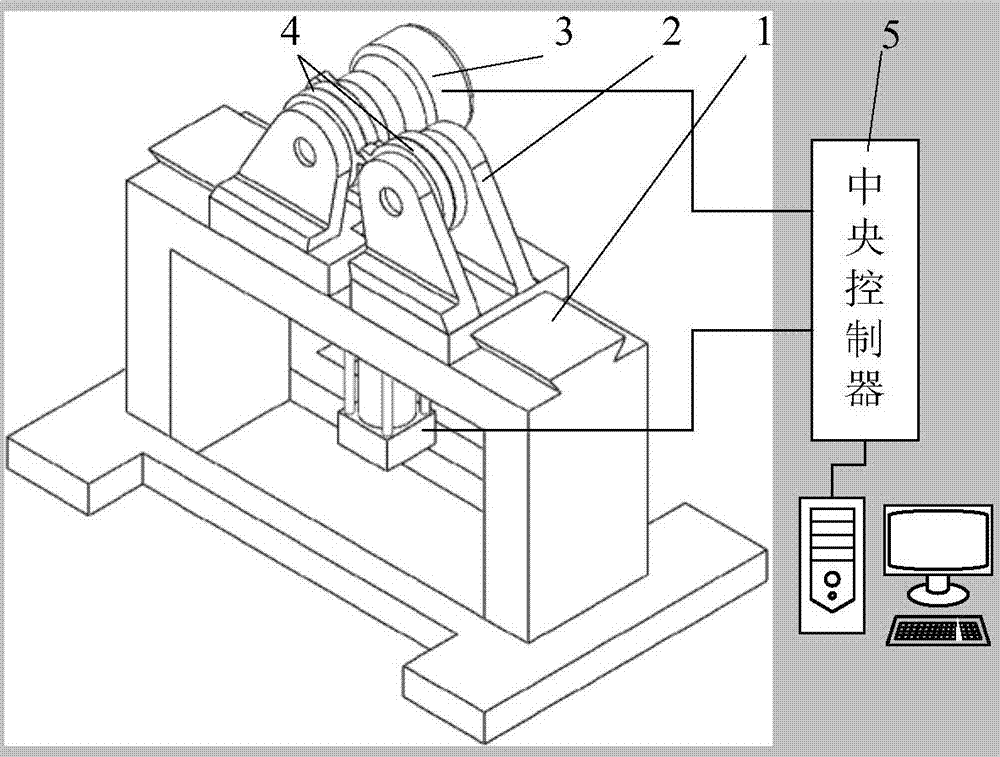

Gear engagement fatigue testing device and method

ActiveCN106959211AImprove real-time performanceImprove accuracyMachine gearing/transmission testingSmall amplitudeLoad time

The invention discloses a gear engagement fatigue testing device, and the device comprises a drive apparatus fixed on a foundation table, a simulation load apparatus, and a test gear apparatus. The drive apparatus and the simulation load apparatus respectively cooperate with the test gear apparatus, and are respectively connected with a central controller. The central controller controls the drive apparatus through outputting a displacement time curve signal, and controls the simulation load apparatus through outputting a load time curve signal. A brand-new loading process is employed to convert the meshing in a rotation process of a gear pair into the meshing in a reciprocating swinging process. The actual process of gear transmission is simulated, and a high-frequency big-period test can be carried out for a single tooth. The small-amplitude movement facilitates the building of the test apparatus, and the real-time performance and accuracy of stress and strain data collection in a gear failure process. The device is high in automation degree, is good in testing quality, is novel in testing loading method, and is suitable for the measurement of the related data in the gear transmission process.

Owner:TSINGHUA UNIV

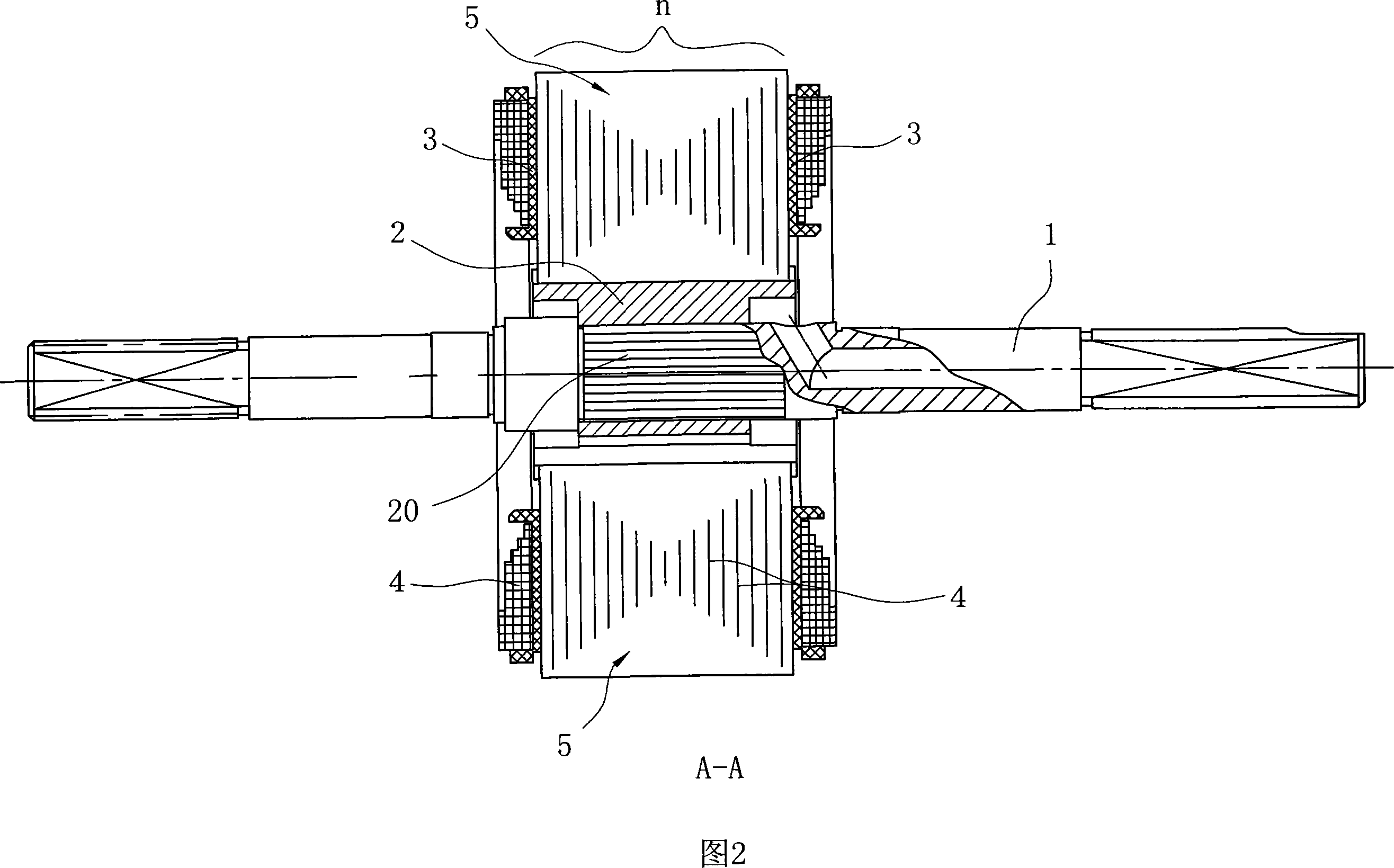

Winding support of single tooth winding for insulation motor

Owner:ROBERT BOSCH GMBH

High-strength gear processing process

ActiveCN103737334AImprove single tooth strengthDense grain structureGear wheelsOther manufacturing equipments/toolsHardnessHigh intensity

The invention relates to a high-strength gear processing process which is characterized by comprising the following steps: (1) selecting a 20CrMnTi alloy steel round blank as a raw material; (2) performing external grinding on the round blank to remove fine cracks on the surface; (3) annealing the round blank and performing shot blasting; (4) processing the round blank in a phosphating solution and a saponifying solution respectively; (5) performing plastic deformation on the round blank through an extrusion material to obtain a blank with an involute tooth profile at one end and a smooth cylindrical body at the other end; (6) performing plastic deformation on the blank obtained from the step (5) through the extrusion material to obtain a blank with an involute tooth profile at one end and an annular convex edge at the other end; (7) lathing an inner hole in the center of the blank; (8) performing carburizing and quenching treatment on a workpiece; (9) performing tempering treatment on the workpiece; (10) performing shot blasting. A gear obtained by the process is high in hardness of surface and good in flexibility of a core part, and the single-tooth strength of the gear (2module) is improved.

Owner:无锡市神力齿轮冷挤有限公司 +1

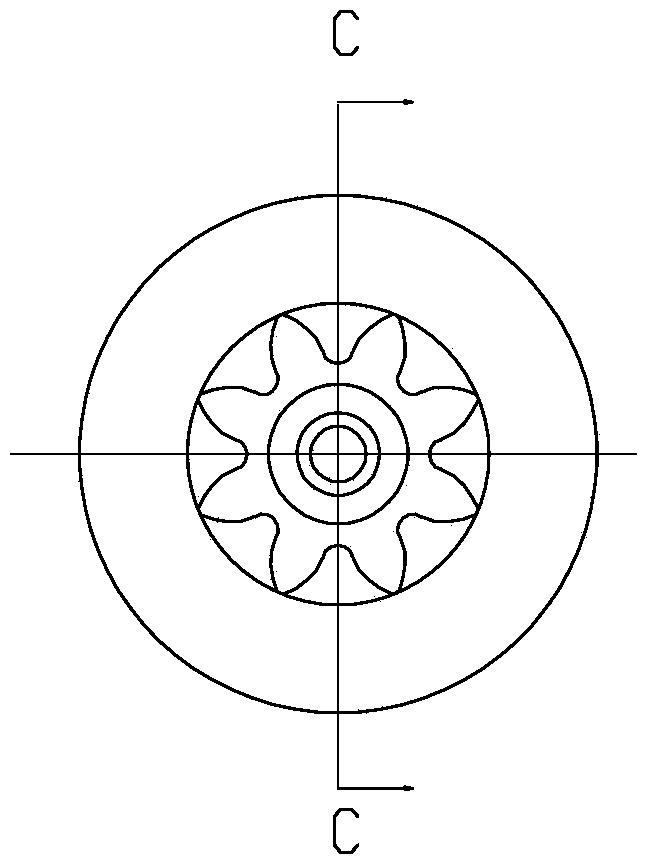

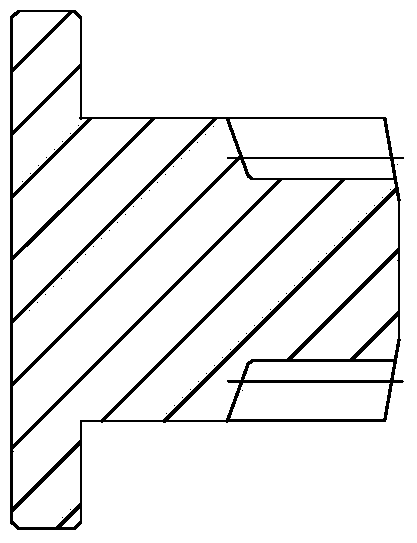

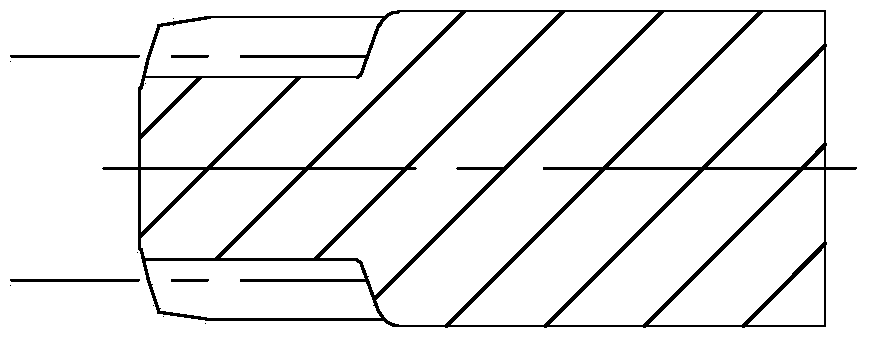

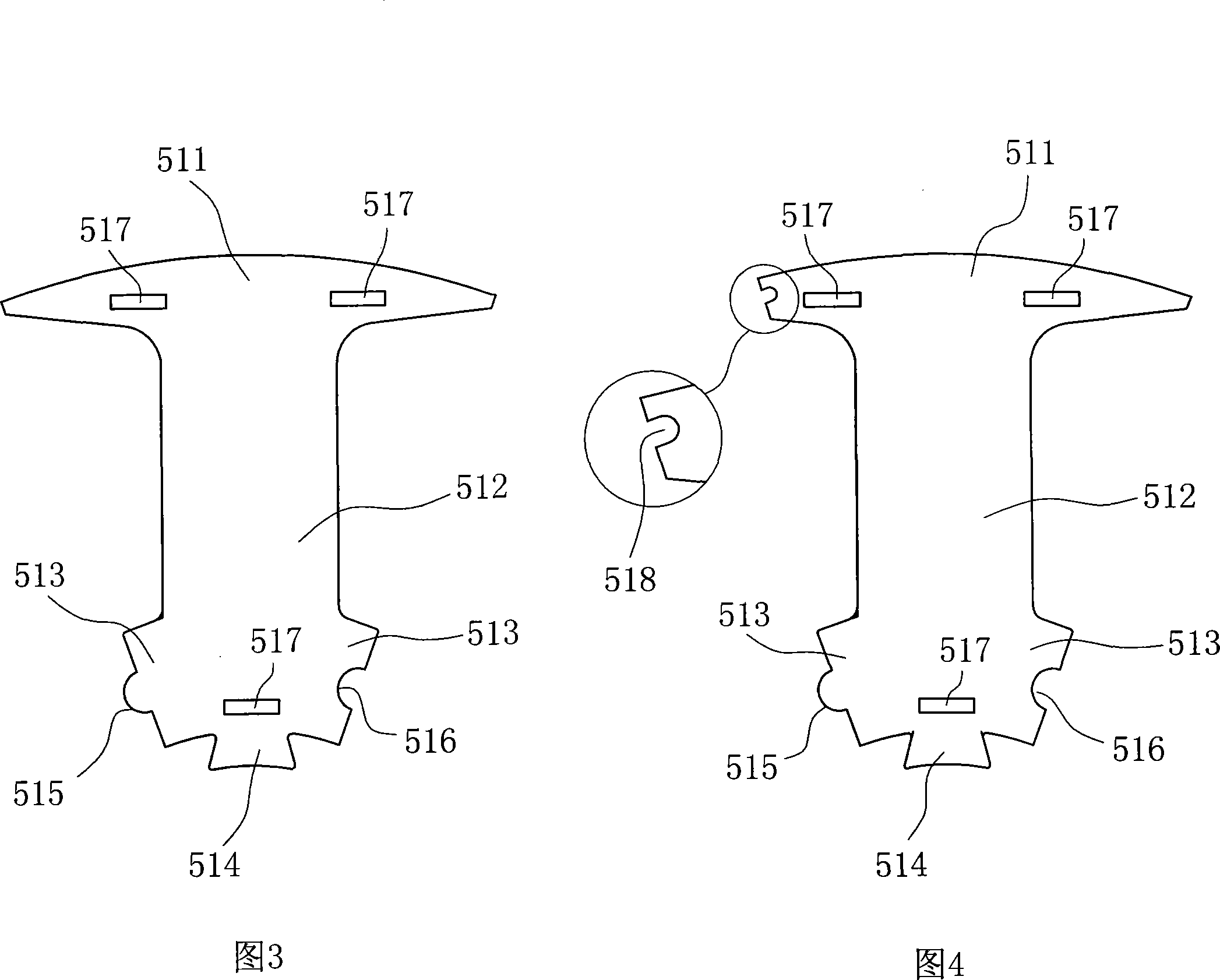

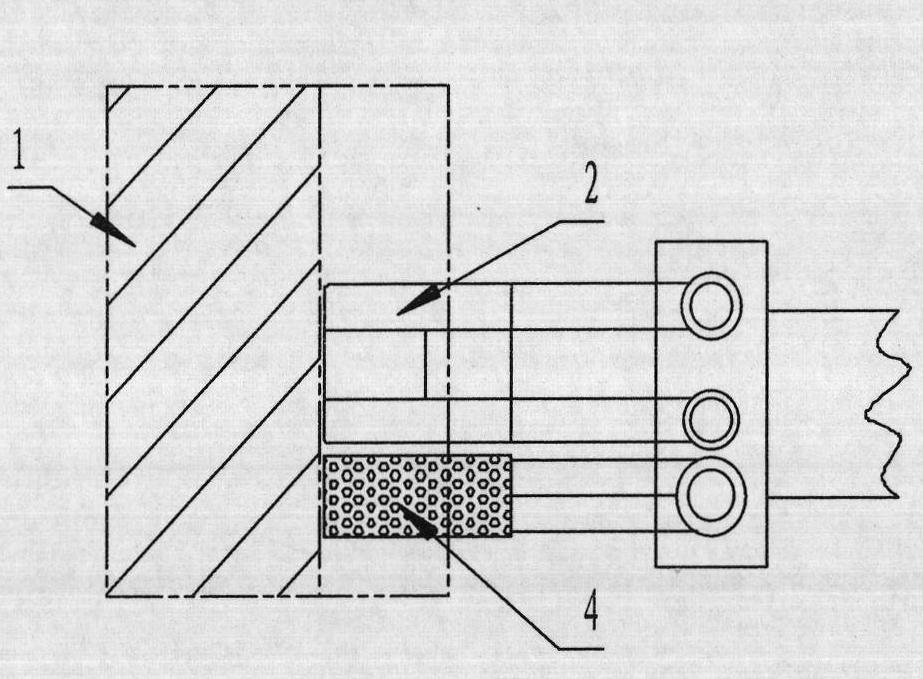

Blocking type electric engine iron core and manufacturing method thereof

InactiveCN101232206AIncrease profitSave silicon steel materialSalient polesManufacturing stator/rotor bodiesPunchingEngineering

A separated iron core comprises a plurality of sector-shaped tooth block groups spliced with each other, wherein windings can be wound on the sector-shaped tooth block; and each sector-shaped tooth block group consists of a plurality of sector-shaped punching sheets stacked on each other. The iron core is characterized in that each sector-shaped punching sheet is a single-tooth sheet including a tooth crown, a tooth body and a yoke portion with an engagement section; each sector-shaped punching sheet further comprises a dovetail protrusion portion with a narrow upper portion and a wide lower portion extending on the bottom of the tooth body; and a dovetail groove section with wide bottom and narrow opening can be formed between the protrusion portions of two sector-shaped punching sheets correspondingly engaged with each other. The invention can improve the material utilization rate by stamping individually and stacking together; the dovetail protrusion portion is designed on the bottom of the tooth body of single sector-shaped punching sheet and the dovetail groove is formed between two engaged sector-shaped punching sheets; and the sector-shaped tooth block can be clamped on a positioning stand with matched tooth socket structure through the groove structure without fixing of bolts and via-holes, thus achieving simple structure, convenient assembly and high positioning accuracy.

Owner:NINGBO POLARIS TECH

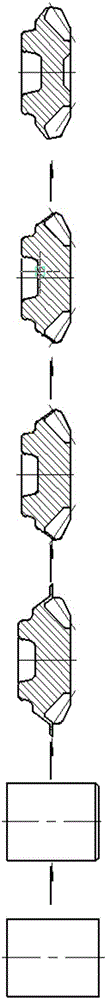

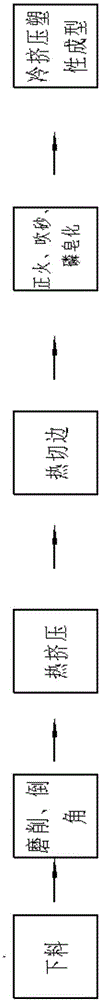

Molding process for straight bevel gear

The invention relates to a processing technique for a straight bevel gear and aims to provide a molding process for a straight bevel gear in order to improve the forging processing precision and processing efficiency of the bevel gear. The molding process comprises the following steps: (1) tooth die modeling includes rough forging tooth die modeling and finishing tooth die modeling; the pitch circle chordal tooth thickness of the rough forging tooth die is slightly smaller than that of the finishing tooth die, and the tooth whole depth of the rough forging tooth die is larger than the tooth whole depth of the finishing tooth die; the single tooth profile volume of a 0.992 rough forging tooth equals to the product of the single tooth profile volume of the finishing tooth die and 1.008; (2) the warm forging plastic forming is carried out; (3) hot forging edge cutting is carried out; (4) rough forged pieces are subjected to normalization, surface grit blasting and phosphorous saponification; (5) cold accurate alignment plastic forming is carried out. The processing technique for the straight bevel gear has the advantages that the quantity of raw materials is saved, the technological requirements on blank processing are lowered; the production cycle is reduced, and the cost is reduced; the product quality is stable, the product precision is high, the mechanical performance is good, the tonnage of required equipment is small, and the cost is low.

Owner:SICHUAN ZHONGYOU MACHINERY

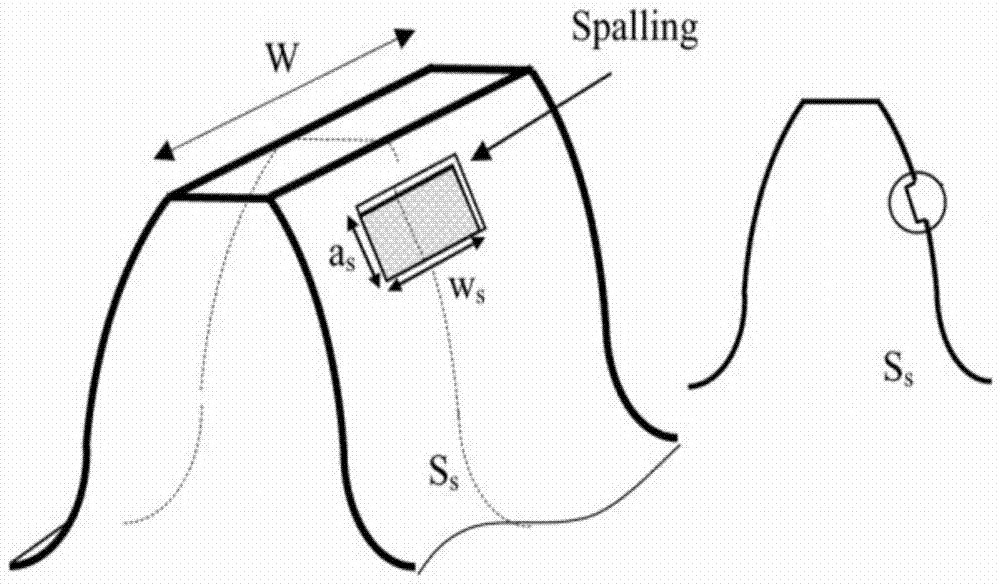

Time-varying characteristic quantitative calculation method for meshing stiffness of gear with minor defect

InactiveCN103577687AReduce complexityReduce the amount of calculationSpecial data processing applicationsRooted toothGear wheel

The invention relates to a quantitative calculation method for the meshing stiffness of a gear with a minor defect. In order to describe the influence of a typical gear fault on the time-varying stiffness characteristic, a meshing stiffness energy method calculation model is firstly introduced, wherein five kinds of elastic strain energy, which refers to bending, shearing, radial compression, contact and base deformation, are respectively considered, and five corresponding stiffnesses are further formed. The quantitative calculation method is based on the energy method, the influences of case crush, tooth root crack and tooth breakage on the stiffness distribution are discussed one after another. Aiming at spalling defects, the influences of spalling length (in the meshing direction) and spalling width (in the tooth width direction) on a stiffness distribution curve is researched, and the quantitative relationship between the spalling size and the stiffnesses degradation is obtained. In the aspect of flexural fatigue crack, the change rule of the stiffness curve along with the crack depth, and the quantitative relationship between the stiffness curve and the crack depth are discussed. In the aspect of broken gear tooth, the influence of missing of a single tooth on the stiffness distribution is discussed. By adopting the quantitative calculation method, the actual meshing situation can be really reflected, the complexity and computation in the process of solving can be lowered.

Owner:BEIJING UNIV OF TECH

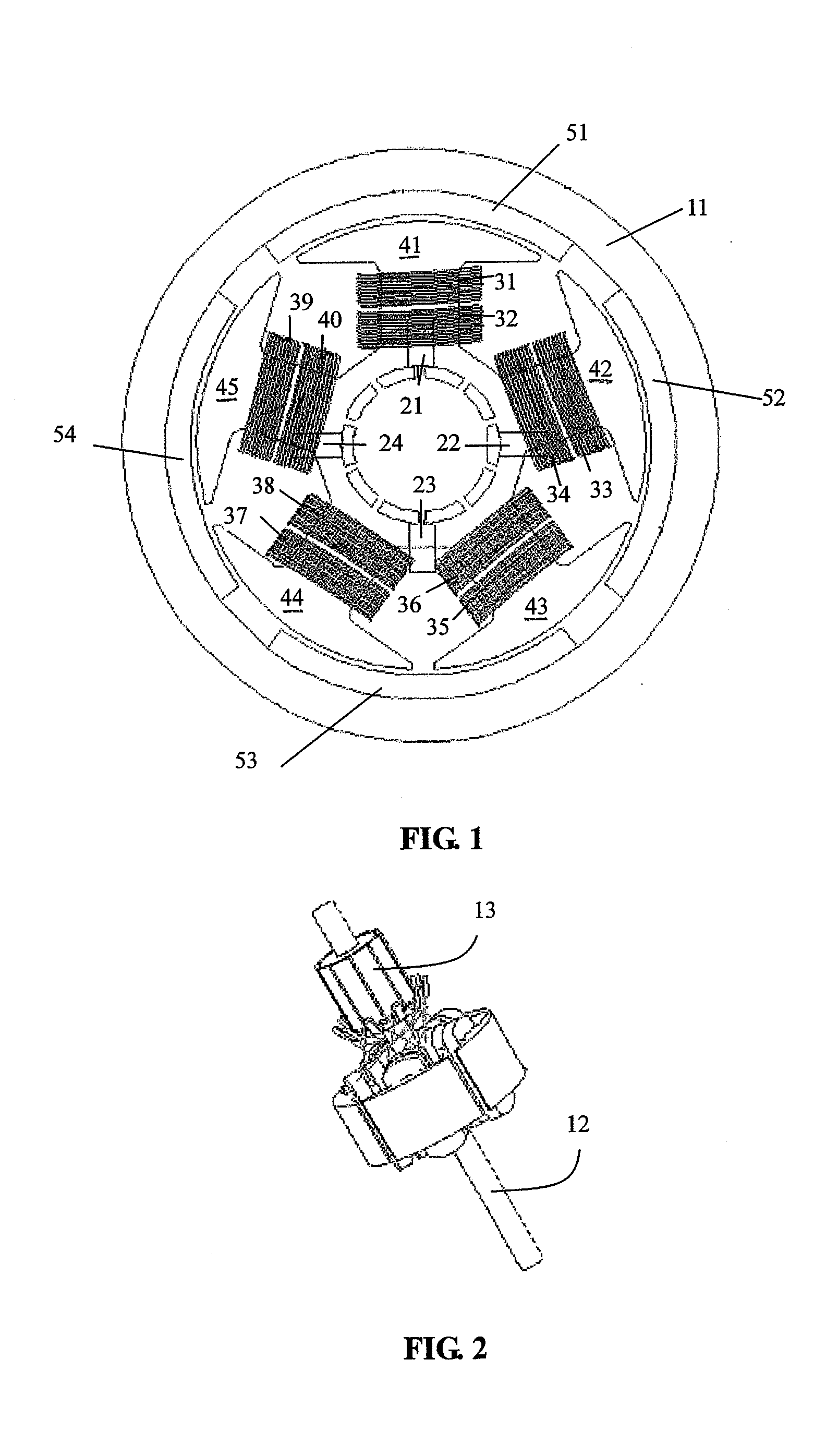

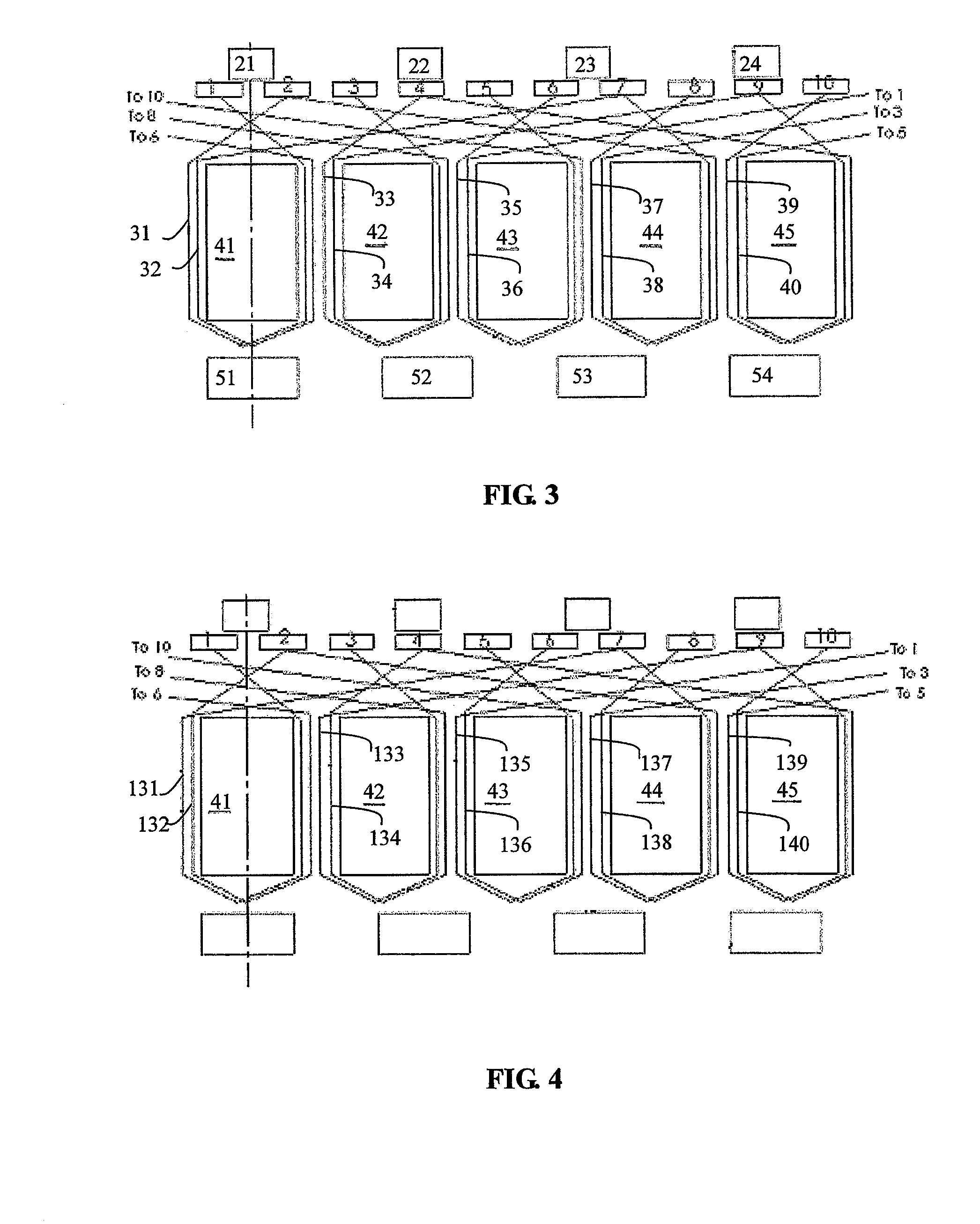

Electric motor and rotor therefor

An electric motor comprises: a rotor; a stator; and brush gear. The rotor has a shaft, a rotor core and a commutator fitted to the shaft. The rotor core has 5n teeth, n being a positive integer. Two coils are wound in each tooth with each coil being wound about a single tooth and having two ends. The commutator has 10n bars forming a brush contact surface. The stator comprises a yoke and a plurality of permanent magnets installed at an inner surface of the yoke and facing the rotor core. The brush gear has a plurality of carbon brushes arranged to make sliding contact with the brush contact surface of the commutator. The ends of the two coils wound in each tooth are respectively connected to two pairs of adjacent bars and the center line between one pair of the two pairs of adjacent bars and the center line between the other pair of the two pairs of adjacent bars are diametrically opposed.

Owner:JOHNSON ELECTRIC SA

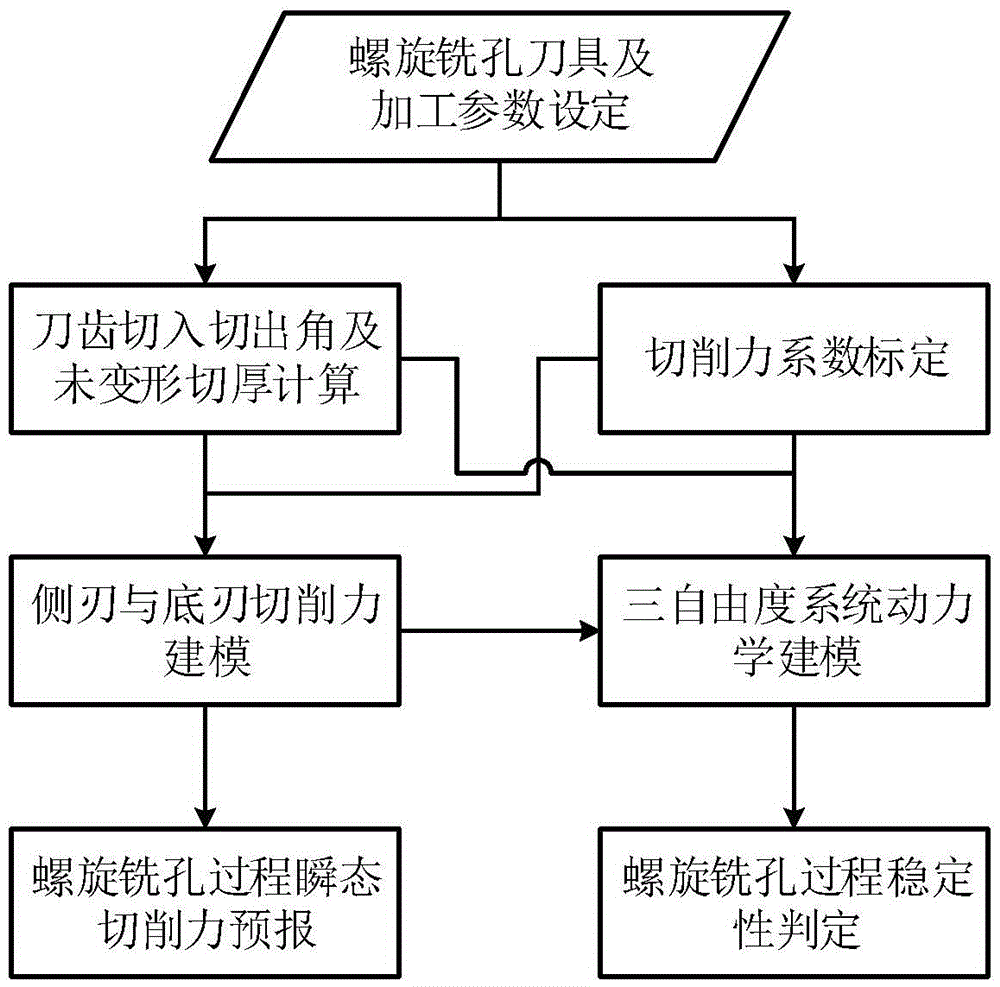

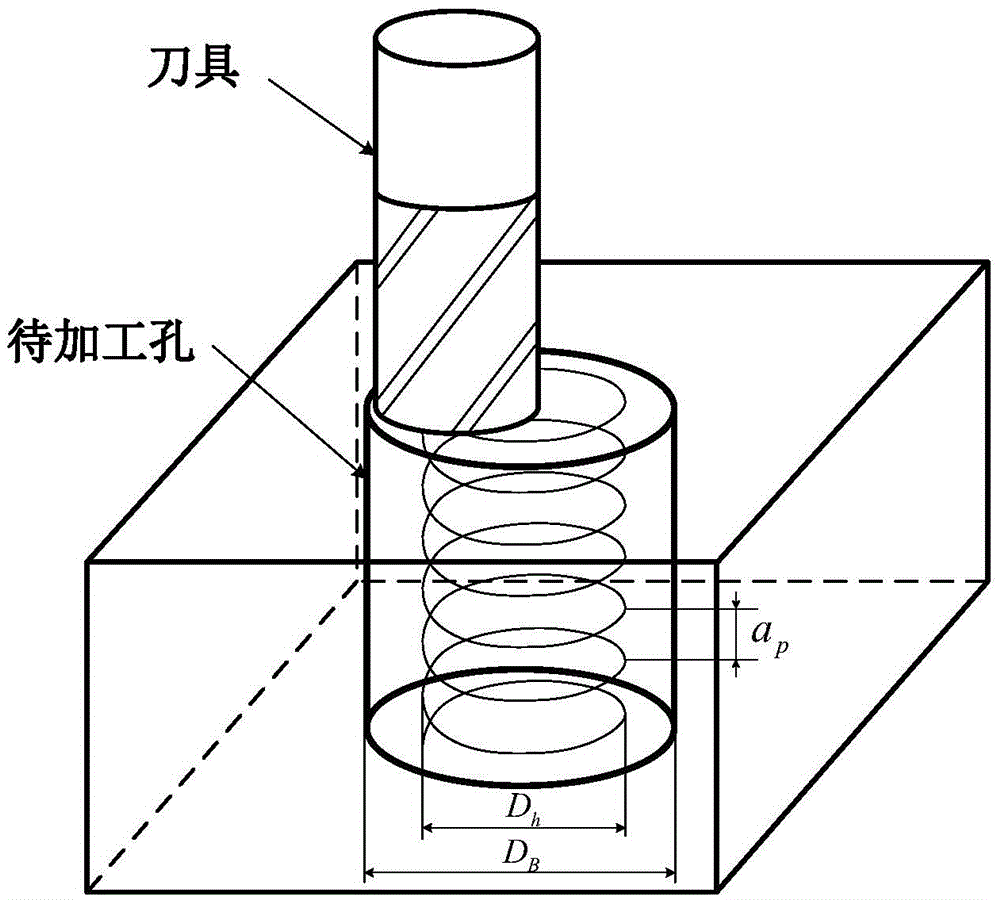

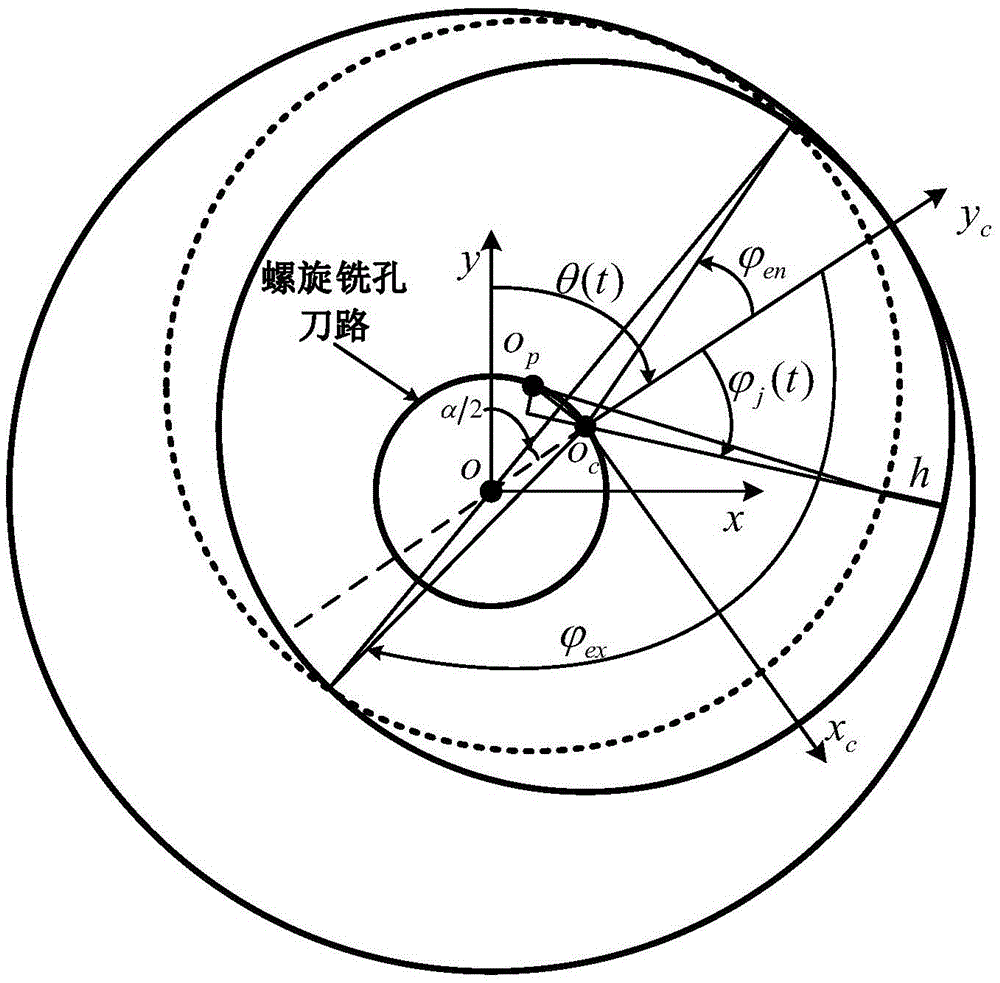

Method for cutting force forecasting and stability judging in spiral hole milling process

The invention provides a method for cutting force forecasting and stability judging in the spiral hole milling process. The method comprises the following steps that a tool and machining parameters are selected according to the size of a hole to be machined, and a spiral milling tool path is generated; assumption is carried out based on a tool tooth track arc, and the analytic calculation expression of the tool tooth cut-in and cut-out angle and non-deformation cutting thickness is obtained according to the tool geometric position relation between adjacent tool positions; side edge and bottom edge cutting force coefficients are obtained through triaxis single-tooth milling experiment calibration and triaxis inserting milling experiment calibration; the obtained parameters are substituted into a binary cutting force model to obtain side edge cutting force and bottom edge cutting force through calculation, and the side edge cutting force and the bottom edge cutting force are added to achieve precise forecasting of instant cutting force in the spiral hole milling process; and a three-freedom-degree milling kinetic equation comprehensively considering the milling tool structure mode coupling effect and the dynamic cutting thickness regeneration effect is built, and the stability of the machining process is judged based on a numerical integration method. The accuracy of cutting force forecasting and stability judging in the spiral hole milling process is improved.

Owner:SHANGHAI JIAO TONG UNIV

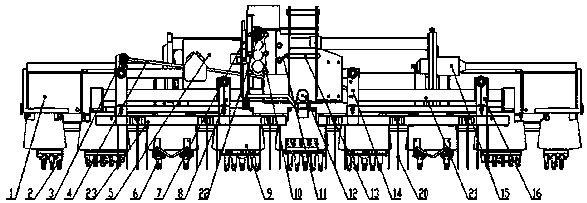

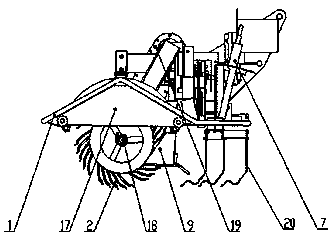

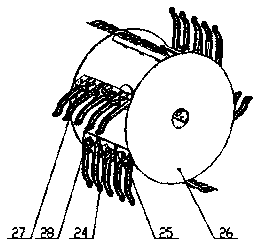

Interrow and interplant weeding device for paddy field seedling

The invention discloses an interrow and interplant weeding device for paddy field seedlings, which comprises: a box body connecting plate arranged on a rack; a main transmission box and a suspension rack arranged on the box body connecting plate; a power transmission shaft is connected with the main transmission box; the rack at one side of the box body connecting plate is sequentially provided with a weeding depth adjusting rod, a spring wire transmission rod a and an eccentric wheel transmission box; a spring wire transmission rod b, a clutch and a transmission swing rod are sequentially connected with the rack on the other side of the box body connecting plate through bearings; a cover plate is fixed on the other side of the rack; a seedling separator and a weeding cage transmission shaft are arranged on the lower side of the cover plate, and a weeding cage and a single-tooth weeding cage are distributed on the weeding cage transmission shaft. According to the interrow and interplant weeding device for the paddy field seedlings, the interrow and interplant weeding can be carried out simultaneously, thereby improving the efficiency of mechanical weeding, loosening the root systemsoil of the seedlings, improving the production and the quality of the seedlings, and being environment-friendly and pollution-free.

Owner:JILIN ACAD OF AGRI MACHINERY

Navigation device for root canal treatment and making method thereof

ActiveCN105596091AProcess stabilityReduce adverse effectsTeeth fillingSurgical navigation systemsDental crownsTooth Fracture

The invention discloses a navigation device for root canal treatment. The navigation device is composed of plywood, a guide post and a working length marking plate, the plywood is a sleeve plate which is matched with the dental crown shape of an offending tooth or the offending tooth and a partial tooth or a whole tooth of an adjacent single tooth, and an exposure opening is formed in the portion corresponding to an offending tooth root canal; the cross section of the guide post is shaped like an inverted L, the guide post is connected with the plywood into a whole through the end of a vertical section, a notch is formed in the end of a horizontal section, the edge in the notch corresponds to an offending tooth root canal approach, and the distance between the lower surface of the horizontal section and the upper surface of the plywood is at least 1.5 mm; the working length marking plate is a disc with a hole formed in the middle and is movably fixed on a fissure drill or expansion or file, and matching and limiting of the working length marking plate and the upper surface of the notch of the guide post are achieved through the lower surface of working length marking plate. The invention further discloses a making method of the navigation device for root canal treatment. The navigation device has better compactness with a tooth body, accurate positioning can be achieved without relying on a doctor, tooth body tissue cutting is reduced, the probability of a tooth fracture of a patient is reduced, and it is guaranteed that root canal treatment is conducted smoothly.

Owner:SICHUAN UNIV

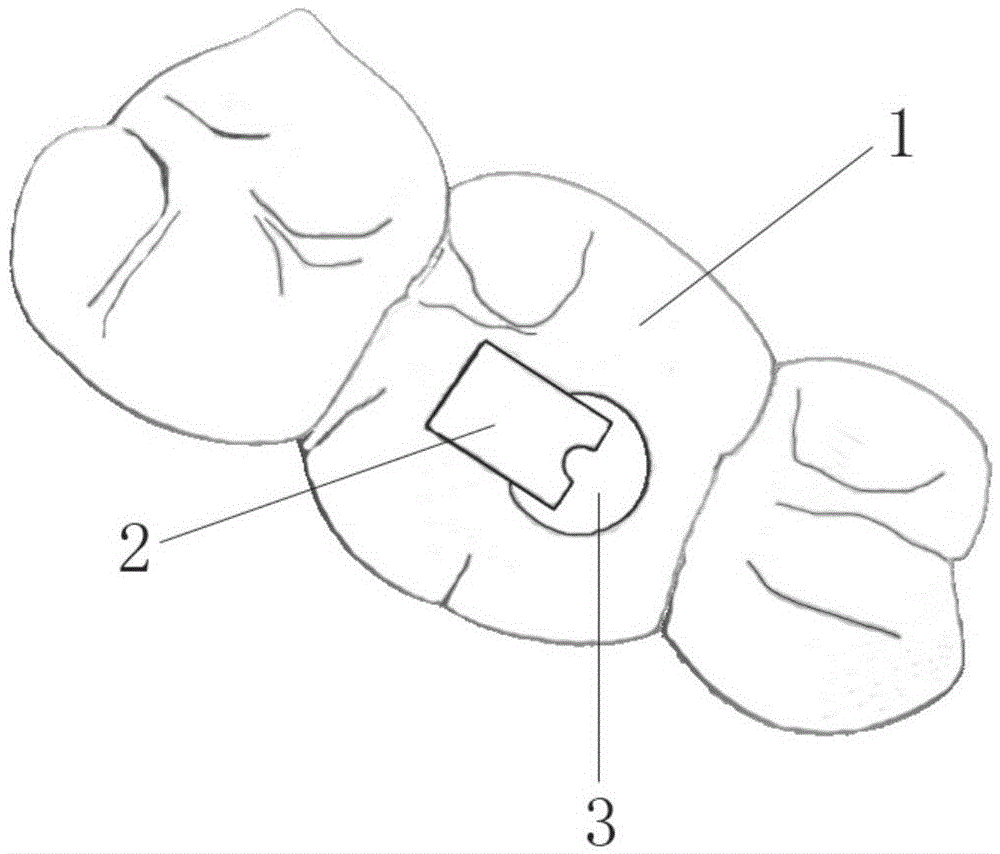

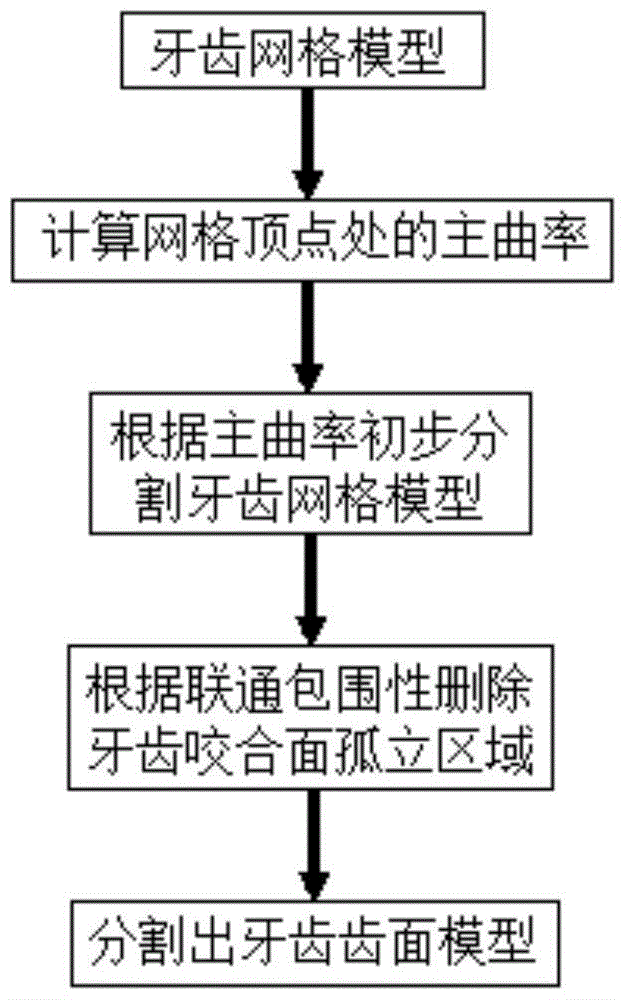

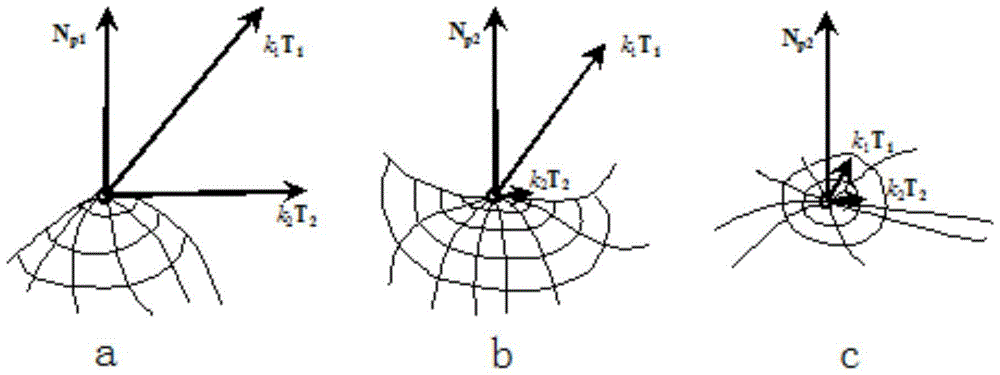

Tooth mesh model automatic segmentation method based on principal curvature

ActiveCN105678747AEasy to operateAvoid fuzzy clusteringImage enhancementImage analysisAutomatic segmentationImaging processing

The invention belongs to the technical field of three dimensional image processing, and specifically relates to a tooth mesh model automatic segmentation method based on a principal curvature. The tooth mesh model automatic segmentation method takes a tooth triangular mesh model as a curved surface to calculate the principal curvature of the mesh, and utilizes the principal curvature and a region growing method to segment the tooth curved surface for single tooth. The tooth mesh model automatic segmentation method based on a principal curvature can keep away from complicated fuzzy clustering, and can take a tooth triangular mesh model as a curved surface to calculate the principal curvature of the mesh, and utilizes the principal curvature and a region growing method to segment the tooth curved surface for single tooth. The tooth mesh model automatic segmentation method based on a principal curvature can simplify operation of a doctor and clearly show single tooth model so as to help comprehensive inspection and rectification of teeth.

Owner:QINGDAO LANXIN MEDICAL TECH CO LTD

Cold induction quenching process for single tooth back of large-modulus gear ring

InactiveCN101914669AReduce cooling rateSolve the technical problem of high quenching crack sensitivityIncreasing energy efficiencyFurnace typesSprayerInduction heater

The invention discloses a cold induction quenching process for the single tooth back of a large-modulus gear ring, which comprises the steps of: adjusting the concentration of a quenching medium to 4-6 percent; inputting quenching parameters into a control program according to technological requirements; adjusting the position of a sensing heater: delivering the sensing heater into workpiece teeth, enabling the lower end of the sensing heater to be aligned to the lower end surface of the workpiece teeth part, adjusting the coupling gap between the sensing heater and a teeth root to be 1-2mm, adjusting the gasp between two teeth faces to be consistent, and starting a back cooling sprayer to carrying out spraying cooling on heated workpieces; and electrifying a machine tool to ensure that the sensing heater begins to carry out sensing and heating on the workpiece, wherein quenching temperature is 940-960 DEG C, after the sensing heater is preheated for 6-8 seconds, moving the sensing heater along the tooth width direction of the workpiece at 180mm / min, stopping heating when the sensing heater moves to the other end of the tooth, simultaneously stopping moving the sensing heater, cooling for 20-22 seconds, closing the back cooling sprayer to terminating the quenching process; and rotating the workpiece along a circumferential direction by a tooth position according a preset program, and automatically carrying out heating quen ching on the next tooth by the sensing heater.

Owner:LUOYANG LYC BEARING

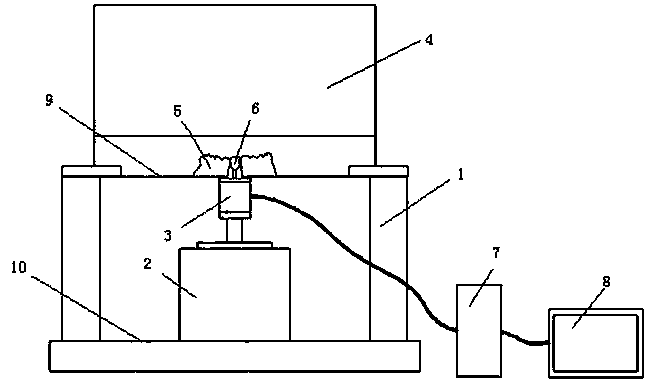

Three-dimensional force measure system of non-trace rectification device as well as measure method

The invention relates to a measure problem of dentistry no-orthodontic bracket no-trace rectification force in three dimensional coordinate, and provides a three-dimensional force measure system of non-trace rectification device as well as a measure method. The measure system and the measure method are characterized in that a single tooth to be straightened is separated from an integral jaw gypsum model, a six-dimensional force transducer is fixedly connected to the single tooth to be straightened, X, Y and R shafts displacement can be used for finely tuning a platform to simulate a straightening process, so that the position change of the single tooth to be straightened can be controlled, deformation of the non-trace rectification device is generated, deformation restoring force is generated, so that orthodontic force of non-trace rectification on the three dimensional coordinate can be determined. By researching the active force system and effect of the non-trace rectification device on the three dimensional coordinate, the orthodontic doctors can make a more reasonable and effective treatment scheme, and design staff can design a better customized non-trace rectification device. The method has the advantages of high measure precision, good real-time capability, simple and easy measure process.

Owner:FUZHOU UNIV

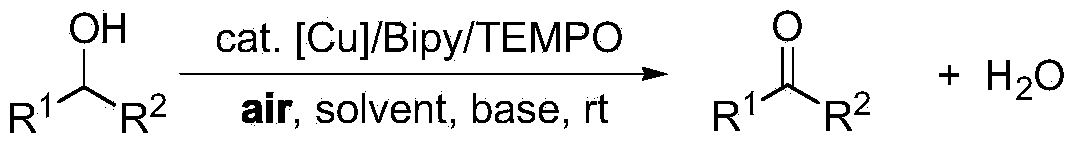

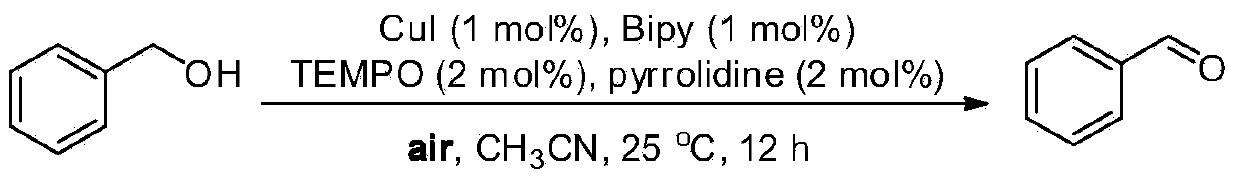

Greening method for preparing aldehydes and ketones through alcohol oxidation of copper catalyst

InactiveCN103420748ALow toxicityReduce pollutionOrganic compound preparationCarbonyl group formation/introductionOrganic solventDouble teeth

The invention provides a greening method for preparing aldehydes and ketones through the alcohol oxidation of a copper catalyst. The greening method comprises the following steps: taking copper salt as the catalyst, a single-tooth or double-teeth N ligand as the ligand and an organic nitric oxide compound as a co-catalyst, and performing the alcohol aerobic oxidation reaction in water-phase or organic solvent under the existence of alkali and air to prepare an aldehyde and Ketone compound. A copper catalyst system, which is low in cost, easy to obtain, low in toxicity and high in activity, is adopted in the greening method, air is used as an economic, safe and green oxidant, and under the mild condition of the indoor temperature air, the aldehyde and ketone compound is prepared through effective alcohol oxidation. The reaction condition is simple and mild, the operation is easy, the reaction conversion rate is high, the product separation and purification are simple, and the recovery rate is high. The requirement on the reaction condition is relatively low, and the greening method has a good research and industrial application prospect.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com