Patents

Literature

158 results about "Flexural fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measuring device for flexural fatigue property of flexible material

InactiveCN1587967AEffective bending fatigue measurementAccurate Bending Fatigue MeasurementsMaterial strength using steady bending forcesUsing mechanical meansMeasurement deviceCollection system

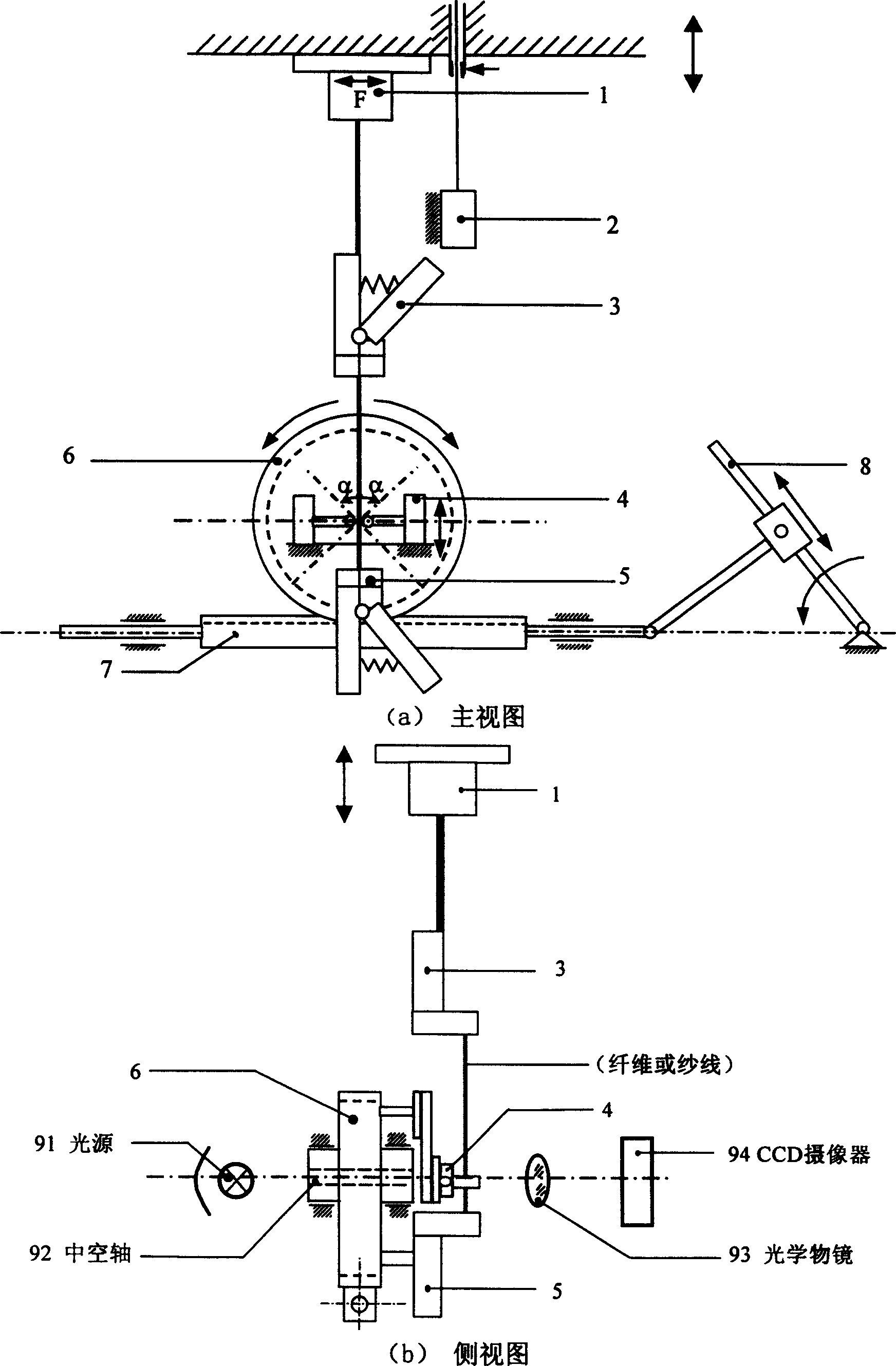

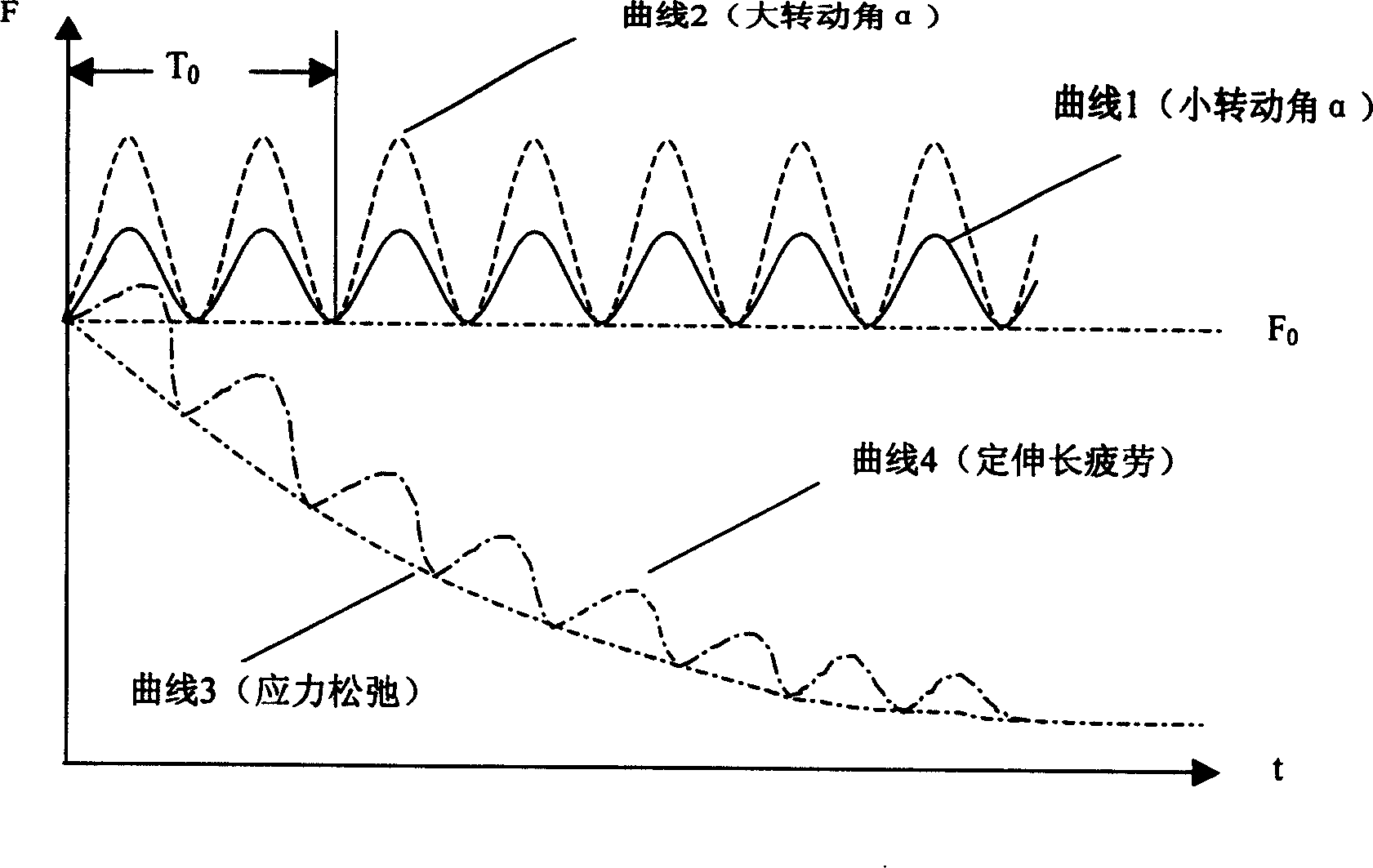

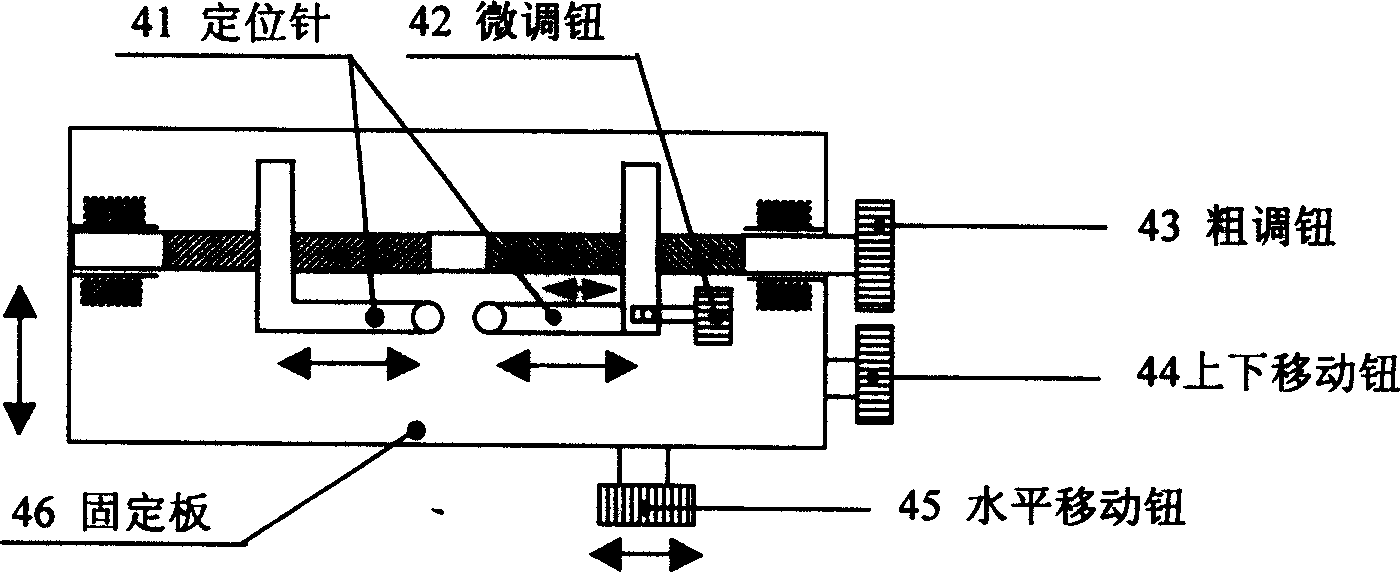

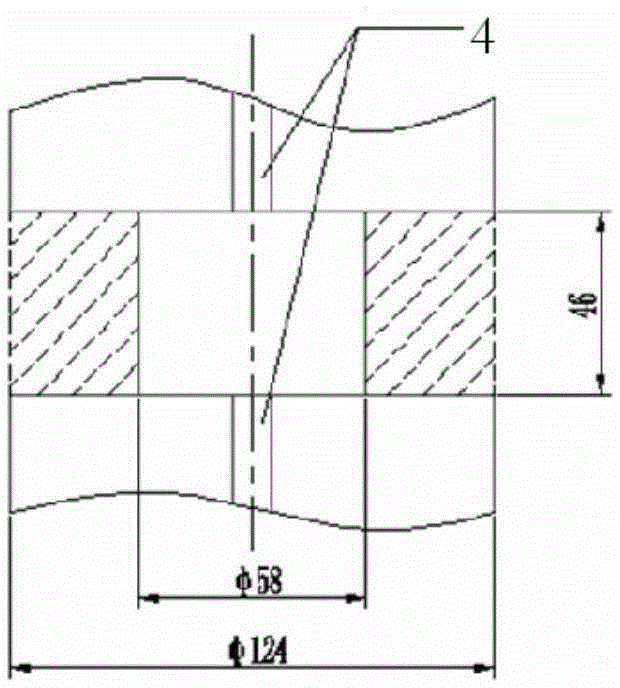

The invention is an apparatus used for measuring flexible material flexural fatigue, with property of being consisted of crank block rack mechanism, force and displacement sensor, upper and lower cartridge, optical plummet centering system, up-and-down and rotation driving system and control circuit, program and signal collection system, finishing measurement of fixed point flexural fatigue and relaxation creep behaviour of flexible material with stationary load and stretch effectively and accurately. The index property measured are endurance failure time, endurance limit strength and limiting strain, relaxation time, sample thickness or diameter. The apparatus has simple but practical structure, convenient installation and replacement, many tunable parameters containing sample length, fixed points position and their distance, bending rotational angle and angular frequency, original load and stretch, accurate measurement, and can avoid influence of move of application point in bending, offset of sample and vibration.

Owner:DONGHUA UNIV

Rubber composition and pneumatic tire using the same

InactiveUS20070167555A1Reduce fuel consumptionReduce consumptionSpecial tyresTyre beadsSilicon dioxidePolybutadiene

A rubber composition containing (i) a conjugated diene-based rubber gel having a toluene swelling index of 16 to 70, (ii) a diene-based rubber such as natural rubber, polyisoprene rubber, aromatic vinyl-conjugated diene copolymer rubber and / or polybutadiene rubber, and (iii) an optional carbon black and / or silica and (a) a pneumatic tire using this composition as a high hardness reinforcing layer extending from a bead along a tire sidewalls, in which the fluidity and dimensional stability at the time of extrusion are improved, while maintaining a sufficient hardness of a high hardness reinforced rubber, (b) a pneumatic tire using this composition as two ends of a tire tread extrudate, maintaining a flex fatigue of the two ends of the tread, in which the extrudability and extrusion dimensional stability are improved and (c) a pneumatic tire using the composition as a 1.5 mm to 6 mm thick undertread, in which a high elasticity and relatively thick gauge undertread, and excellent processability and steering stability are provided.

Owner:THE YOKOHAMA RUBBER CO LTD +1

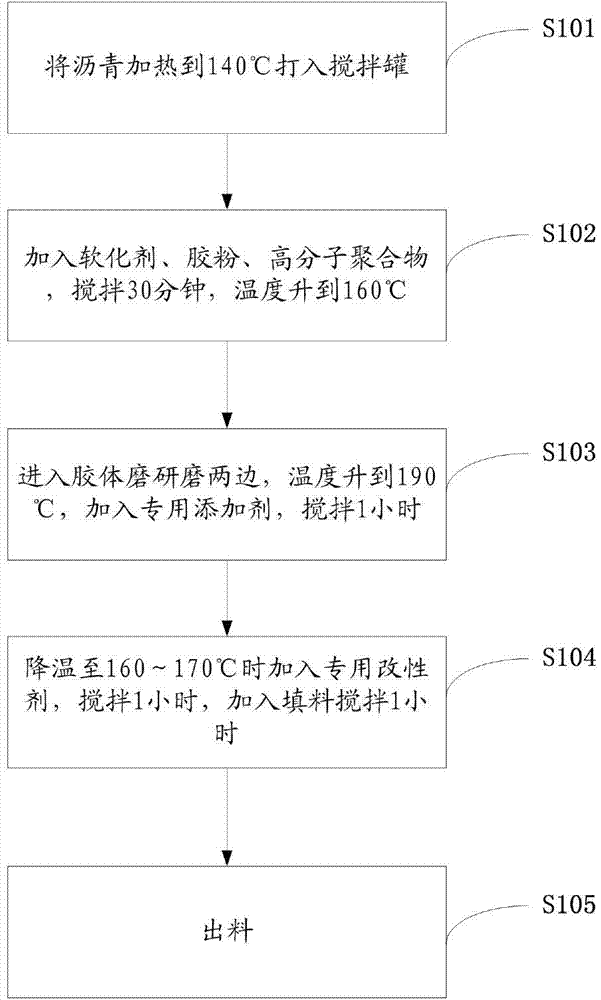

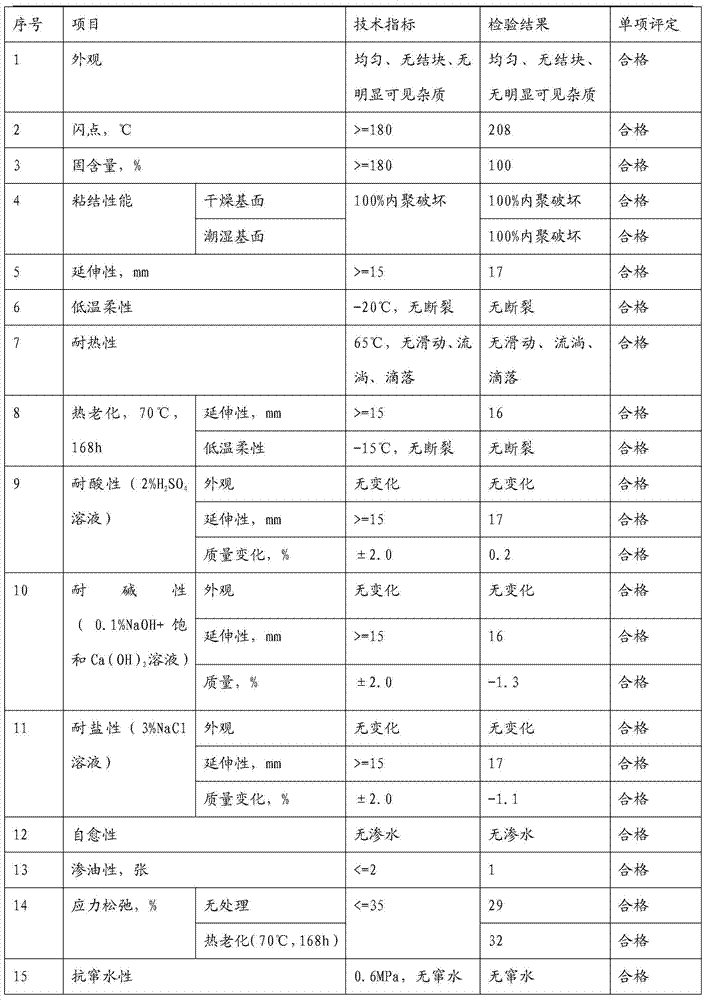

Non-cured rubber asphalt waterproof paint

InactiveCN104119799AWill not harmCompletely sealed and waterproofUnspecified rubber coatingsConjugated diene hydrocarbon coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint. The preparation technology of the paint comprises the following steps: heating the asphalt to 140 DEG C, loading the heated asphalt into a stirring tank, adding a softening agent, rubber powder, and polymer, stirring for 30 minutes, heating to 160 DEG C, delivering the mixture to a colloid mill to grind the two edges, heating to 190 DEG C, adding a special additive, stirring for one hour, cooling to 160 to 170 DEG C, adding an auxiliary agent, stirring for one hour, adding a filling material, stirring for one hour, and finally discharging. The paint solves the problems of waterproof layer fracture due to the cracking stress, which is transferred from the basic layer to the waterproof layer, and the accelerated aging due to the flexural fatigue and high stress state of the waterproof layer. Moreover, because of the cohesiveness of the paint, the capillary pores and cracks in the basic layer can be perfectly sealed by the paint, thus the problem of water leaking in the waterproof layer is solved, and the waterproof reliability is greatly improved.

Owner:徐立

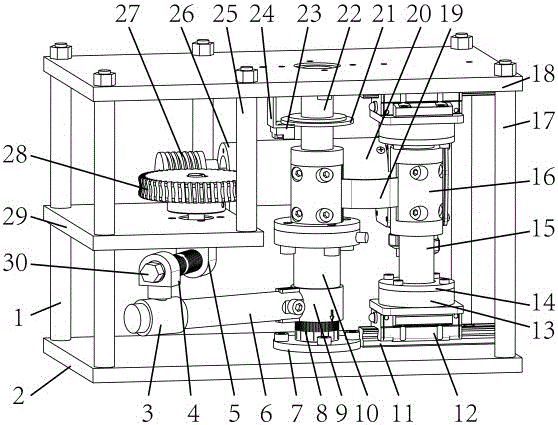

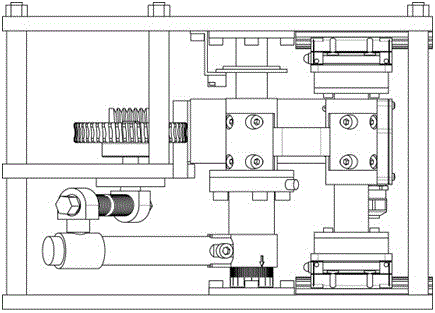

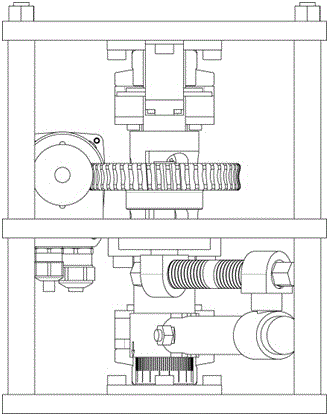

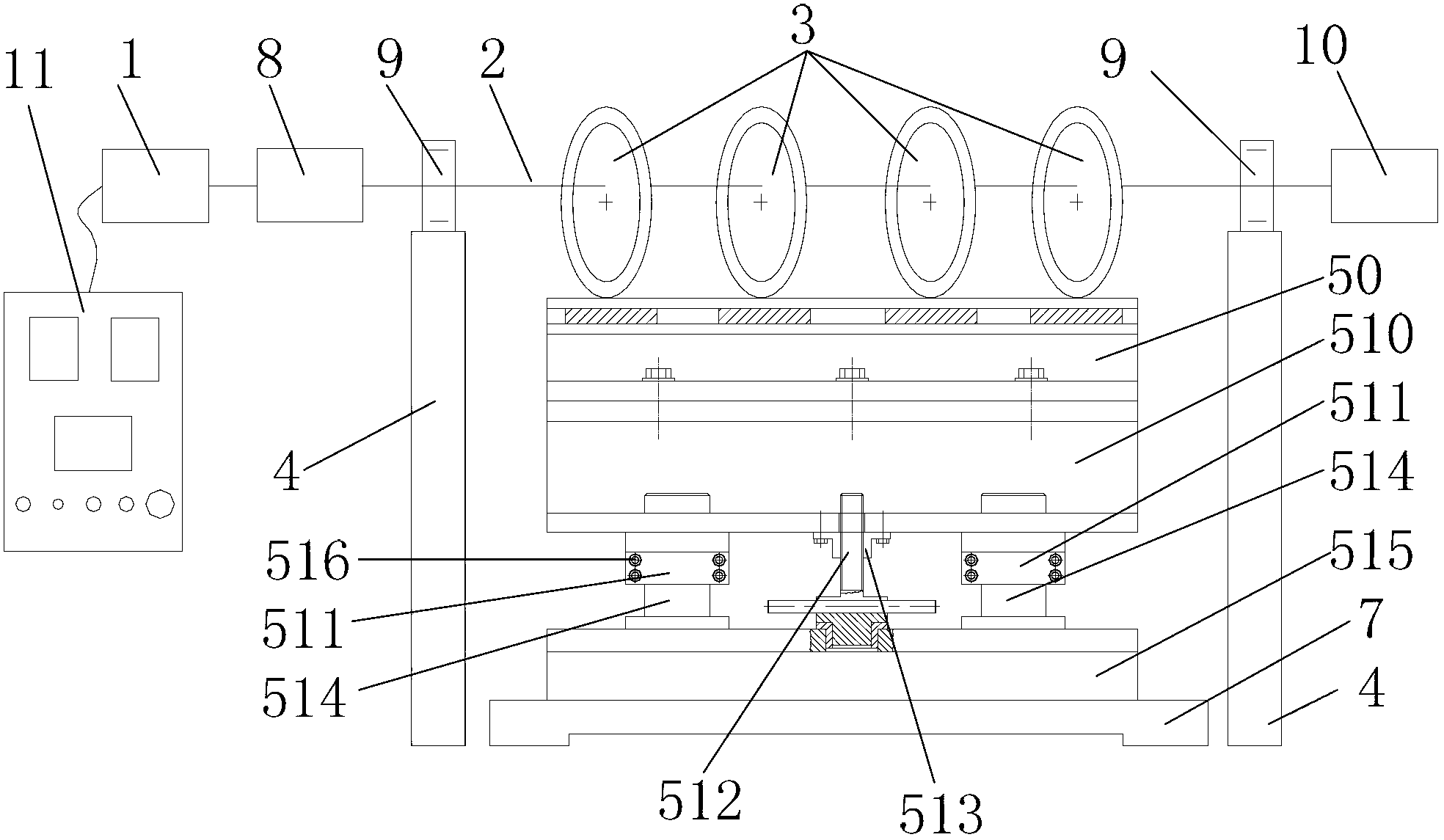

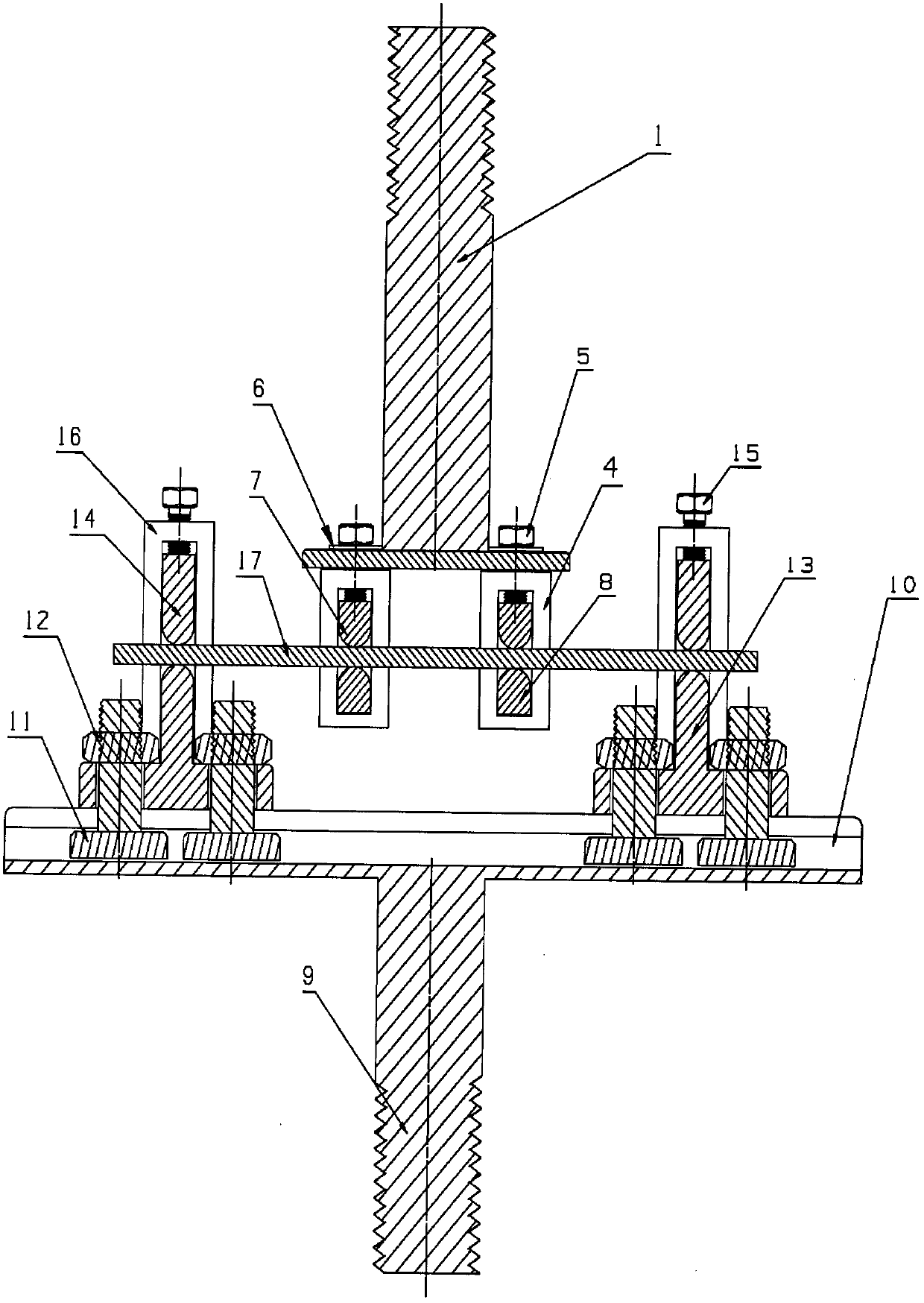

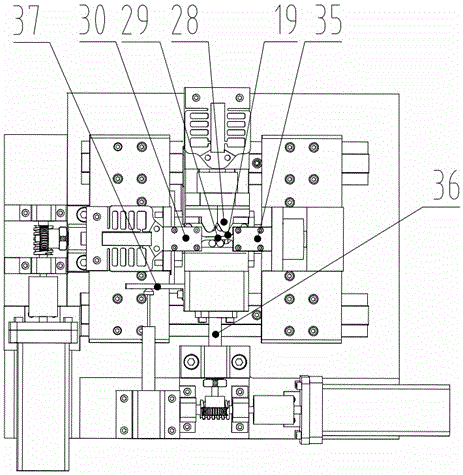

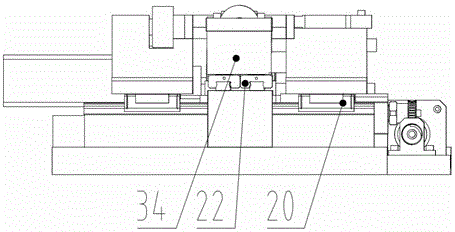

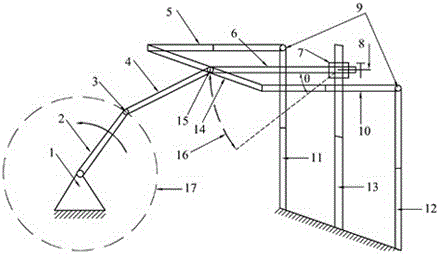

Flexural fatigue mode adjustable tester for testing mechanical properties of materials, and testing method thereof

ActiveCN105758733AAvoid influenceAccurate measurementWork measurementMaterial strength using steady bending forcesAngular degreesEngineering

The invention relates to a flexural fatigue mode adjustable tester for testing mechanical properties of materials, and a testing method thereof, belonging to the field of precision instruments. The tester comprises a flexural fatigue loading unit, a test piece clamping unit, an associated movement unit and a precise detection unit, wherein the flexural fatigue loading unit is powered by a direct current servo motor, a crank and rocker mechanism is driven to realize reciprocating swinging of a rocker by primary worm gear reduction, the rocker drives the clamping unit to realize reciprocating rotation, a bended test sample is repeatedly bent along with the reciprocating rotation of the clamping unit, and the associated movement unit does associated rotation and translation under the driving of the bended test sample. The tester has the advantages that the error of converting bending moment in three-point bending loading is avoided, the influence of the friction force of a support roller on the testing result is avoided, the bending moment and the bending angle can be accurately measured, different fatigue modes can be realized, and fatigue testing with different stress amplitudes and different average stresses can be realized.

Owner:JILIN UNIV

Flexural fatigue testing machine

ActiveCN102706759AShort test cycleImprove work efficiencyMaterial strength using repeated/pulsating forcesHydraulic motorEngineering

The invention provides a flexural fatigue testing machine, which comprises a hydraulic motor and a deceleration machine used as driving devices, a main shaft, a plurality of eccentric wheels, a main shaft supporting seat and a specimen holder, wherein the main shaft is arranged on the main shaft supporting seat in a rotatable mode, the eccentric wheels on the main shaft are driven to rotate by the hydraulic motor, a specimen is fixed on the specimen holder, the height of the specimen holder and the horizontal distance between the specimen holder and the main shaft are adjustable, and periodic load is applied to the specimen by the eccentric wheels so as to enable the specimen to be bended and deformed repeatedly until the specimen is fractured. According to the flexural fatigue testing machine disclosed by the invention, a flexural fatigue test can be carried out on a plurality of specimens simultaneously every time, fatigue performances of the specimens can be contrasted, the test period is short, and the work efficiency is high; and the flexural fatigue testing machine has a simple structure and is low in cost, the flexural fatigue test can be carried out on specimens with different specifications, different loading positions and loading working conditions can be selected, and the scope of application of the machine is wide.

Owner:SANY HEAVY IND CO LTD (CN)

High-strength and high-modulus polyethylene film and continuous solid-state extrusion overstretching production method thereof

InactiveCN101891912AImprove corrosion resistanceHigh strengthTextile cablesLow densityUltimate tensile strength

The invention discloses a high-strength and high- modulus polyethylene film and a continuous solid-state extrusion overstretching production method thereof. The invention is characterized in that the high-strength and high- modulus polyethylene is made from ultra-high molecular weight polyethylene with the viscosity-average molecular weight of 1,000,000-6,000,000, the tensile strength thereof is 6.6-30cN / dtex, the tensile modulus is 220-1350cN / dtex, and the elongation at break is 1.2-3%. The high-strength and high- modulus polyethylene film has the advantages of high strength, high corrosion resistance, low density and good abrasive resistance and flexural fatigue resistance. The continuous solid-state extrusion overstretching production method has the advantages of simple production technology, easy control and continuous production. The polyethylene film cut before and after overstretching can also be produced into high-strength and high-model polyethylene film split fibre or flat filament which is widely used in ropes, netting gears, bullet-proof and stab-proof articles, strengthened cladding materials for pipelines or cables, strengthened materials for buildings, composite materials and other fields.

Owner:SHANDONG ICD HIGH PERFORMANCE FIBRES CO LTD

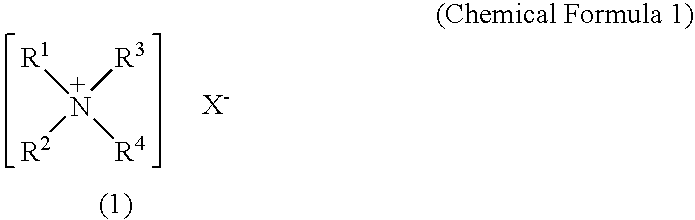

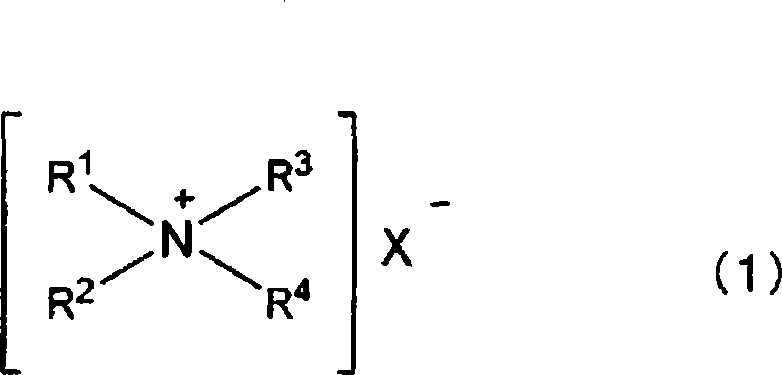

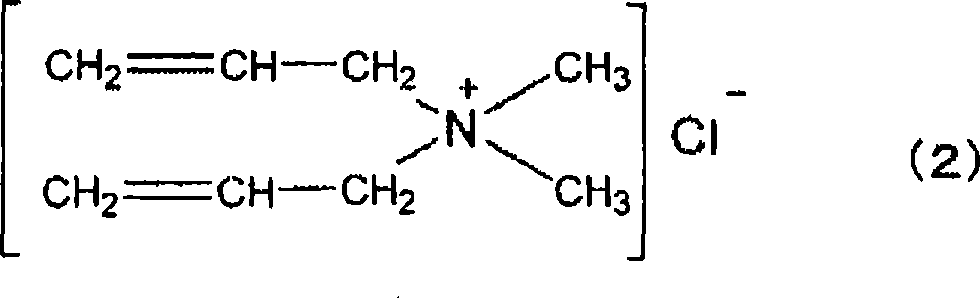

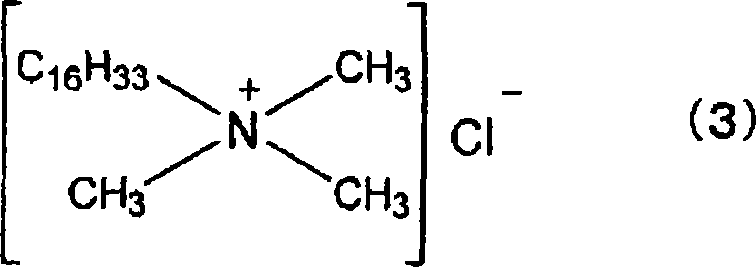

Dip-Forming Composition and Dip-Formed Article

InactiveUS20080051498A1Good flexibilityComfortable fittingnessFibre treatmentCoatingsColloidDibenzoyl Peroxide

A dip-forming composition is provided, which can give a dip-formed article that exhibits good softness of touch and comfortable fittingness, an excellent tensile strength and a high flexural fatigue resistance, and which is less likely to color even when worn and subjected to working for a long time period. The above problem is solved by the dip-forming composition which is obtained by converting an organic peroxide, which is solid at 30° C. under normal pressure, to an aqueous dispersion in the presence of a surfactant and a polymeric protective colloid, adding the dispersion to a conjugated diene rubber latex, and aging the mixture. The organic peroxide is preferably dibenzoyl peroxide or dilauroyl peroxide.

Owner:ZEON CORP

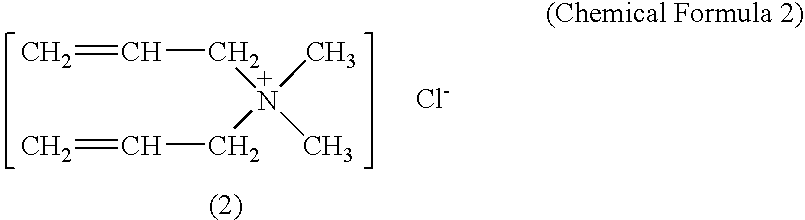

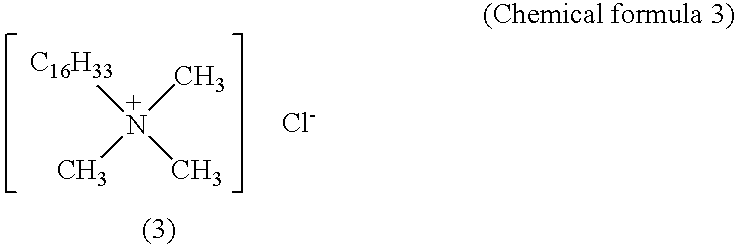

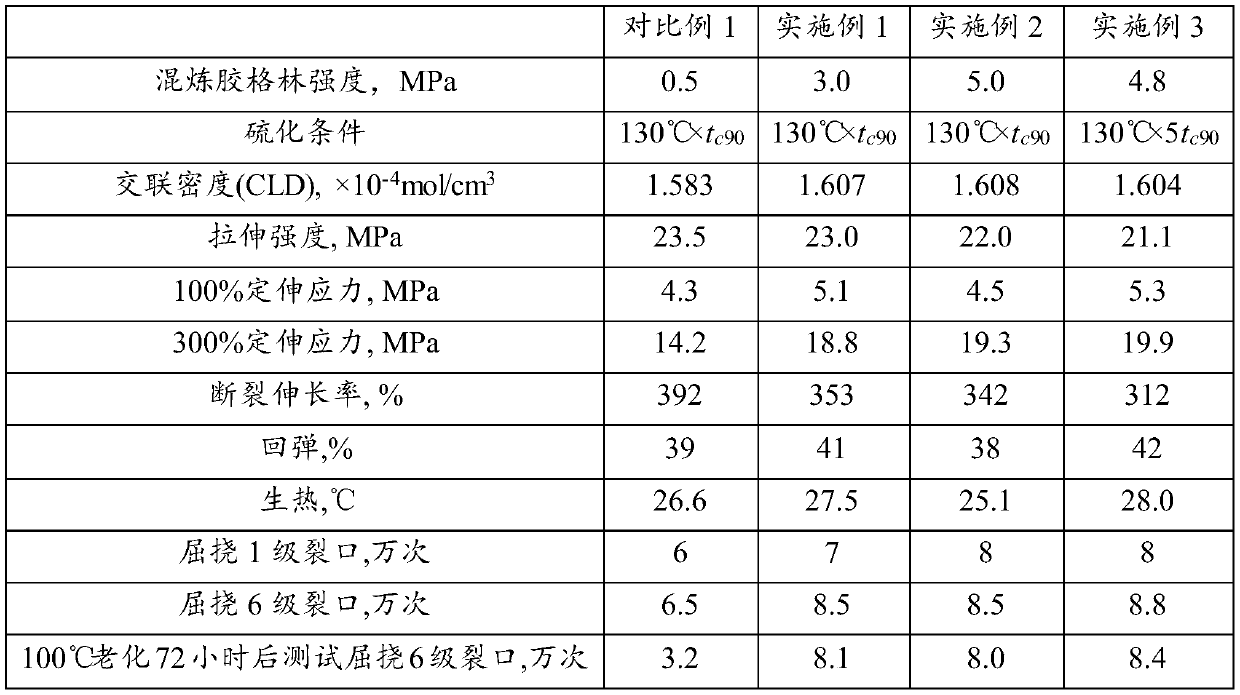

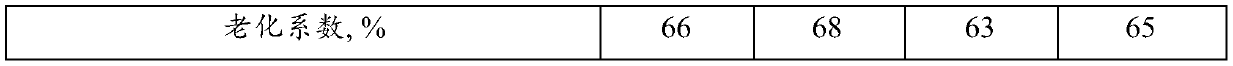

High-flexural-fatigue-life aviation sidewall rubber as well as preparation method and application thereof

The invention relates to a formula of high-flexural-fatigue-life aviation sidewall rubber and particularly relates to application and a preparation method of aviation tire sidewall rubber containing trans-1,4-butadiene-isoprene copolymer rubber. The sidewall rubber contains the following substances in parts by weight: 5-30 parts of trans-1,4-butadiene-isoprene copolymer rubber TBIR, 50-85 parts ofnatural rubber NR, 10-20 parts of butadiene rubber BR, 0-80 parts of carbon black, 0-30 parts of silicon dioxide, 0-5 parts of a silane coupling agent Si690, 0-10 parts of a plasticizer, 0-0.8 part of a scorch retarder, 0.5-3 parts of sulfur, 0.3-5 parts of an accelerant and other aids. The sidewall rubber is prepared by virtue of a three-section banburying and open milling process. The Green strength of the mixed sidewall rubber is more than 3MPa, vulcanized rubber has the stress at definite elongation of 300% of over 18MPa, and the flexure-resistance 6-level cracking number of times is over80000.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

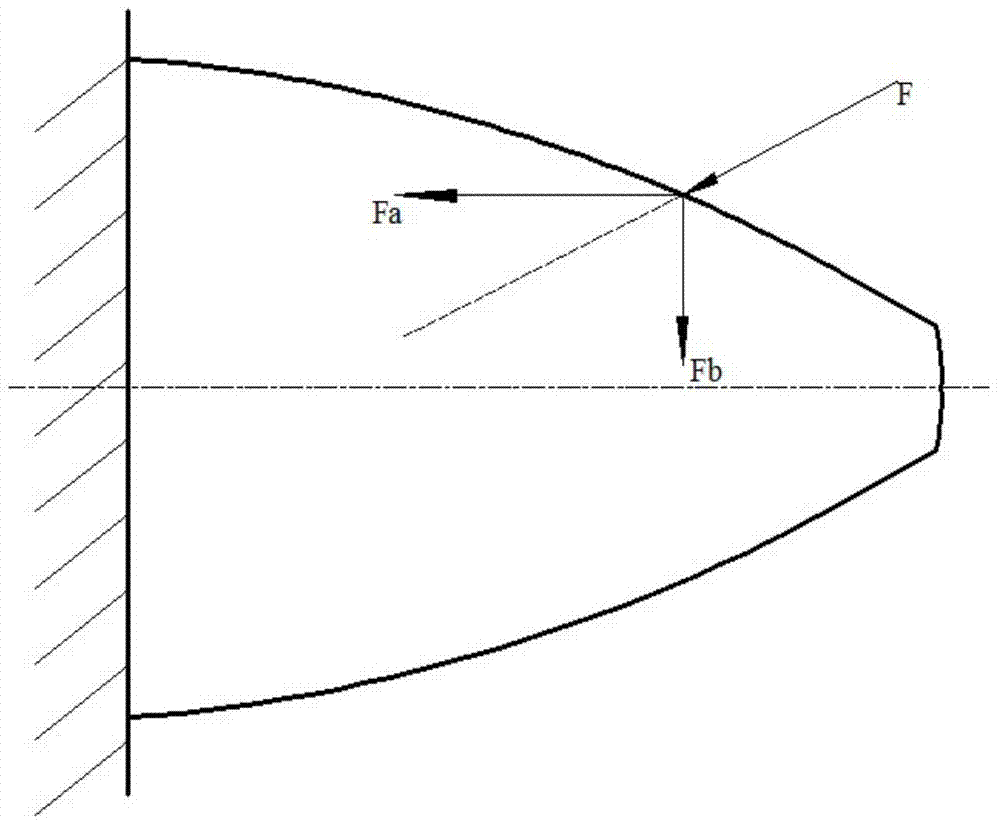

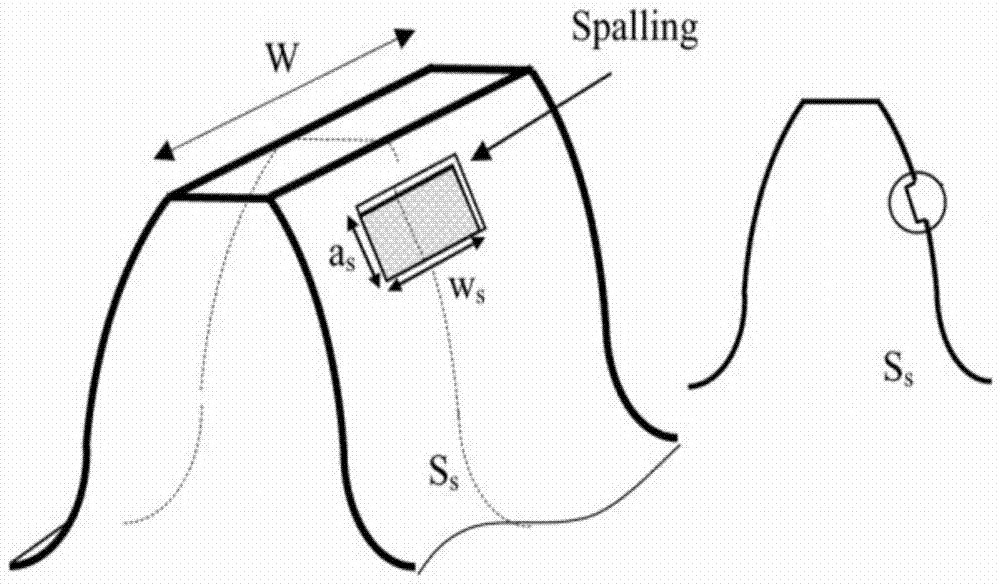

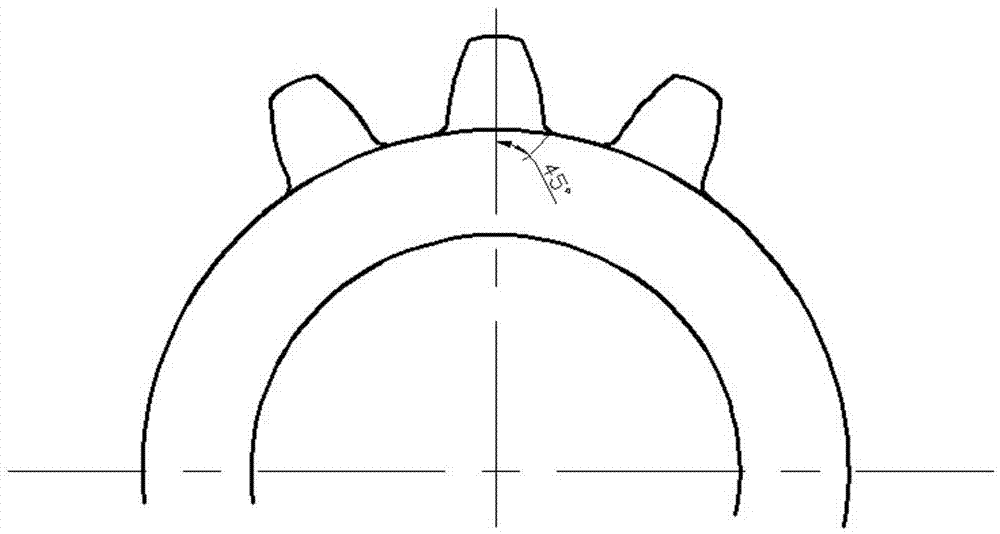

Time-varying characteristic quantitative calculation method for meshing stiffness of gear with minor defect

InactiveCN103577687AReduce complexityReduce the amount of calculationSpecial data processing applicationsRooted toothGear wheel

The invention relates to a quantitative calculation method for the meshing stiffness of a gear with a minor defect. In order to describe the influence of a typical gear fault on the time-varying stiffness characteristic, a meshing stiffness energy method calculation model is firstly introduced, wherein five kinds of elastic strain energy, which refers to bending, shearing, radial compression, contact and base deformation, are respectively considered, and five corresponding stiffnesses are further formed. The quantitative calculation method is based on the energy method, the influences of case crush, tooth root crack and tooth breakage on the stiffness distribution are discussed one after another. Aiming at spalling defects, the influences of spalling length (in the meshing direction) and spalling width (in the tooth width direction) on a stiffness distribution curve is researched, and the quantitative relationship between the spalling size and the stiffnesses degradation is obtained. In the aspect of flexural fatigue crack, the change rule of the stiffness curve along with the crack depth, and the quantitative relationship between the stiffness curve and the crack depth are discussed. In the aspect of broken gear tooth, the influence of missing of a single tooth on the stiffness distribution is discussed. By adopting the quantitative calculation method, the actual meshing situation can be really reflected, the complexity and computation in the process of solving can be lowered.

Owner:BEIJING UNIV OF TECH

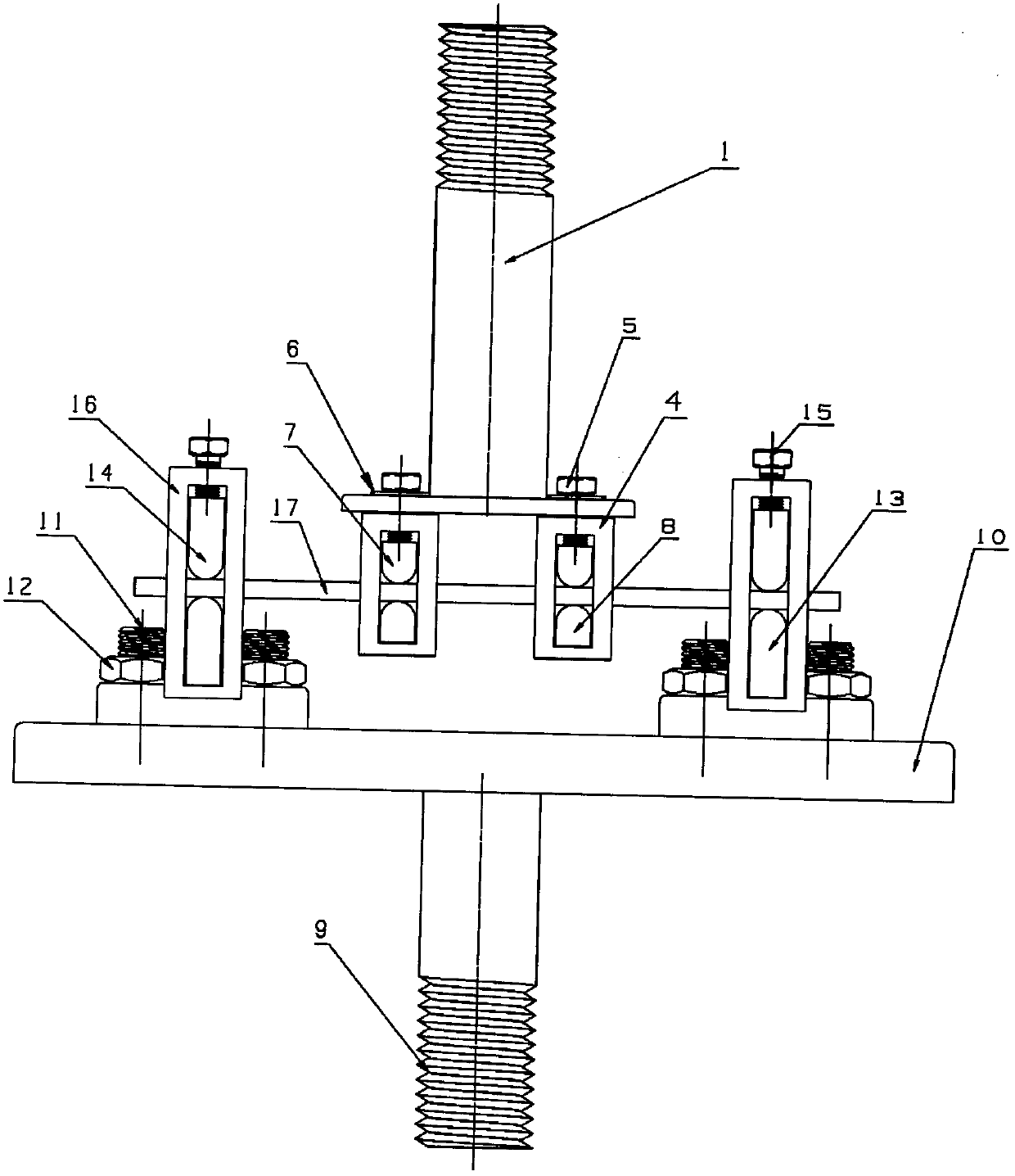

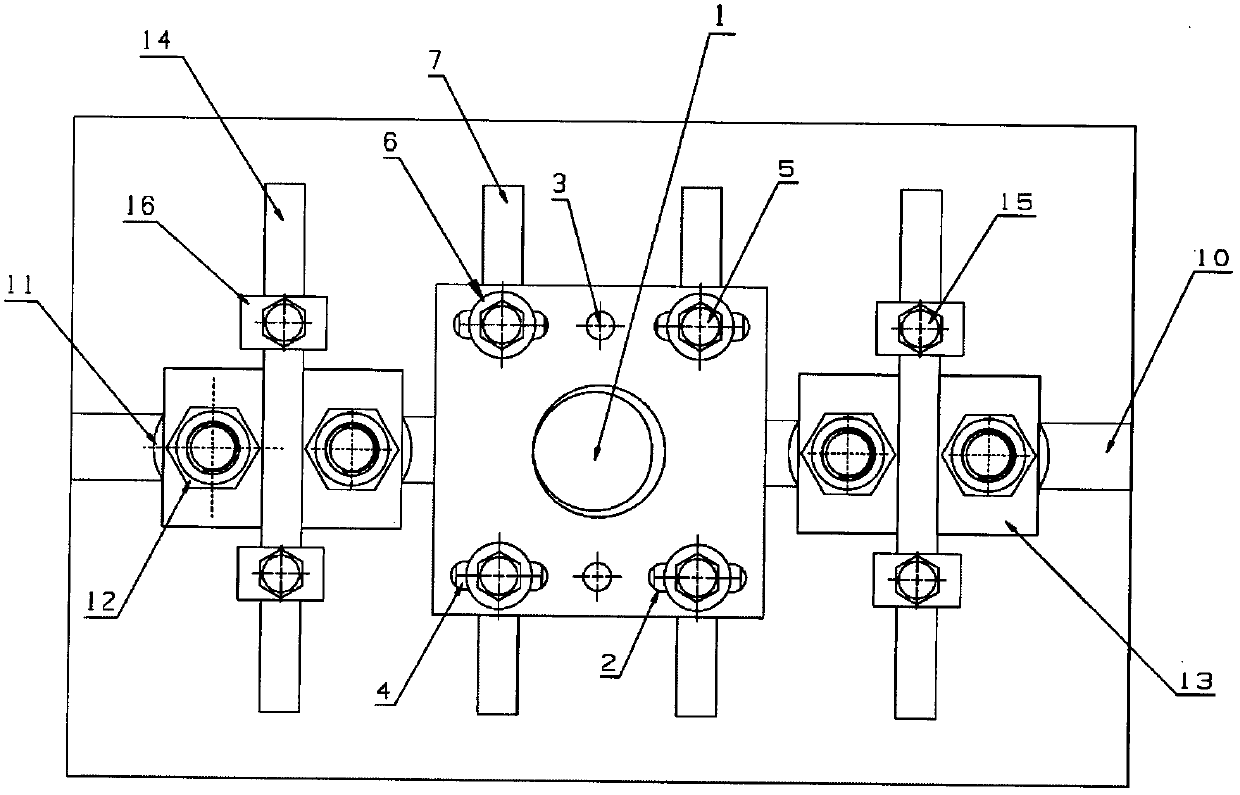

Three-point and four-point flexural fatigue general test fixture for composite material

InactiveCN107917844AMeets bending fatigue test standardsStable clampingStrength propertiesStrength of materialsEngineering

The invention discloses a three-point and four-point flexural fatigue general test fixture for a composite material. The three-point and four-point flexural fatigue general test fixture for the composite material belongs to a fixture used for testing mechanical properties of materials, is detachably arranged on the conventional fatigue test machine and carries out three-point and four-point flexural fatigue test. The fixture is divided into a loading part and a supporting part, and the loading part and the supporting part can be connected with a fatigue testing machine in a thread form. The fixture can regulate clamping size according to the size of a sample, domestic and foreign related flexural fatigue test standards are met, and universality is strong. The fixture can guarantee that thesample can be stably clamped in a flexural fatigue testing process without producing slippage, so that an experiment can be accurately and smoothly carried out.

Owner:TIANJIN POLYTECHNIC UNIV

Polyamide laminated film

InactiveUS6294263B1Excellent gas barrier performanceIncrease resistanceSynthetic resin layered productsDomestic articlesElastomerXylylene

The present invention is to provide a polyamide laminated film comprising a resin layer A and a resin layer B formed on at least one surface of the resin layer A,the resin layer A being composed mainly of a m-xylylene group-containing polyamide polymer (a-1) which is one prepared from monomer components containing a xylylenediamine compound as a main diamine component and an alpha,omega-aliphatic dicarboxylic acid having from 6 to 12 carbon atoms as a main dicarboxylic acid component, the xylylenediamine compound being m-xylylenediamine alone or a mixture of m-xylylenediamine and p-xylylenediamine, andthe resin layer B being mainly composed of a mixed polymer (b-3) which is a mixture of from 99 to 80% by weight of an aliphatic polyamide (b-1) and from 1 to 20% by weight of an elastomer (b-2).The laminated film is good in a gas barrier property and also in a flexural fatigue resistance and a transparency.

Owner:TOYO TOYOBO CO LTD

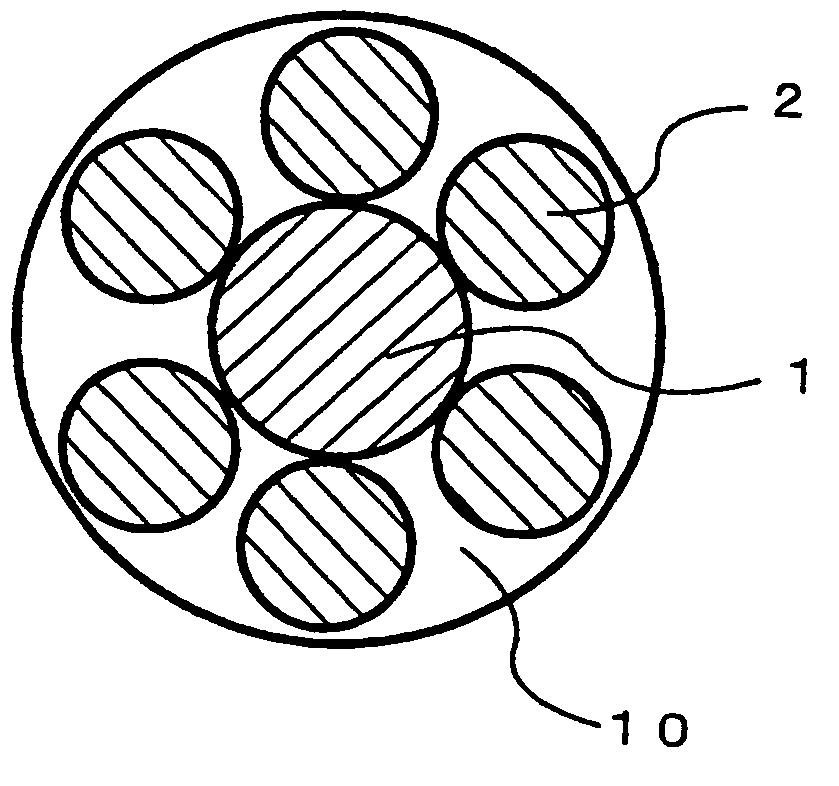

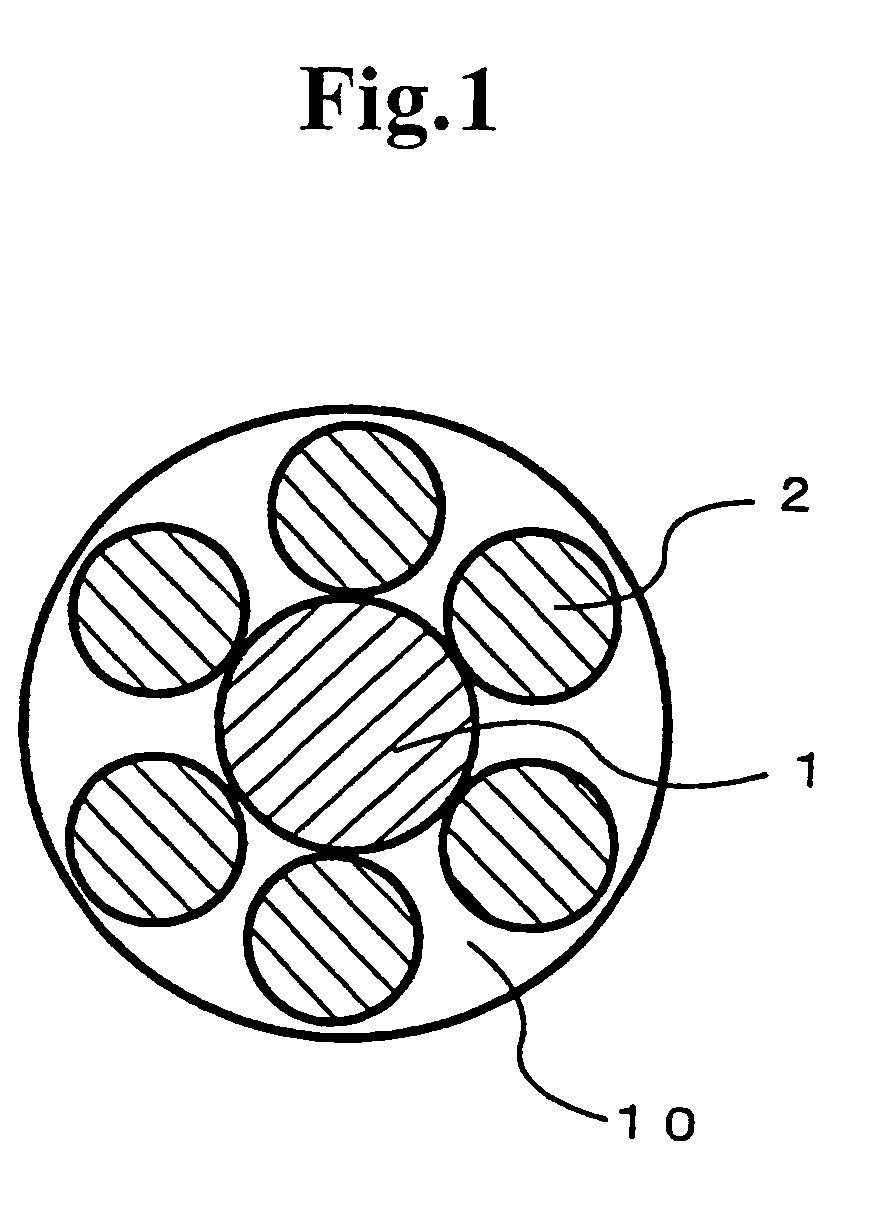

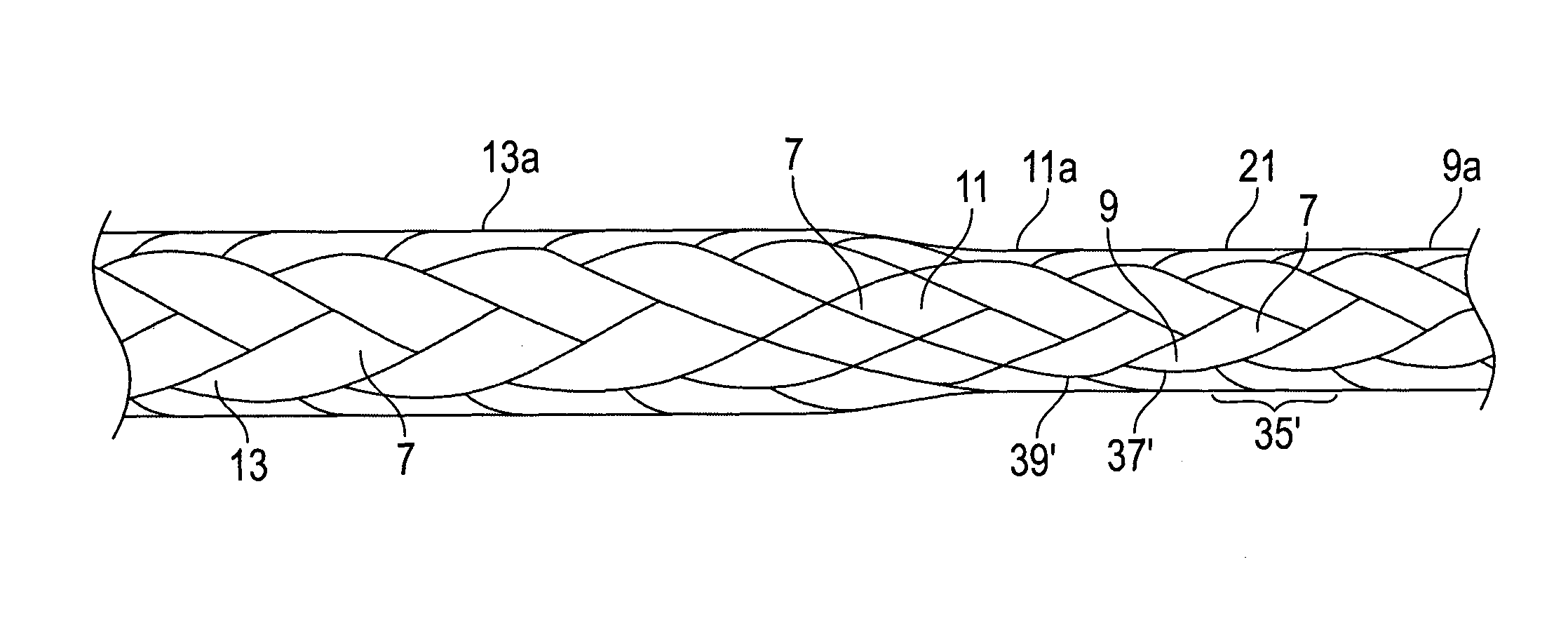

Rubber reinforcing cord and rubber product employing the same

A rubber reinforcing cord having high flexural fatigue resistance and high dimensional stability is provided and a rubber product such as a rubber belt employing the cord is provided. The cord includes a fibrous core and a plurality of subsidiary strands which are disposed around the fibrous core and each of which is twisted by a primary twist, in which the fibrous core and the subsidiary strands are twisted together by a final twist. The direction of the primary twist of the subsidiary strands and the direction of the final twist are the same and the fibrous core is twisted by a primary twist in a direction opposite to the direction of the primary twist of the subsidiary strands. A rubber product is reinforced with the rubber reinforcing cord.

Owner:NIPPON SHEET GLASS CO LTD

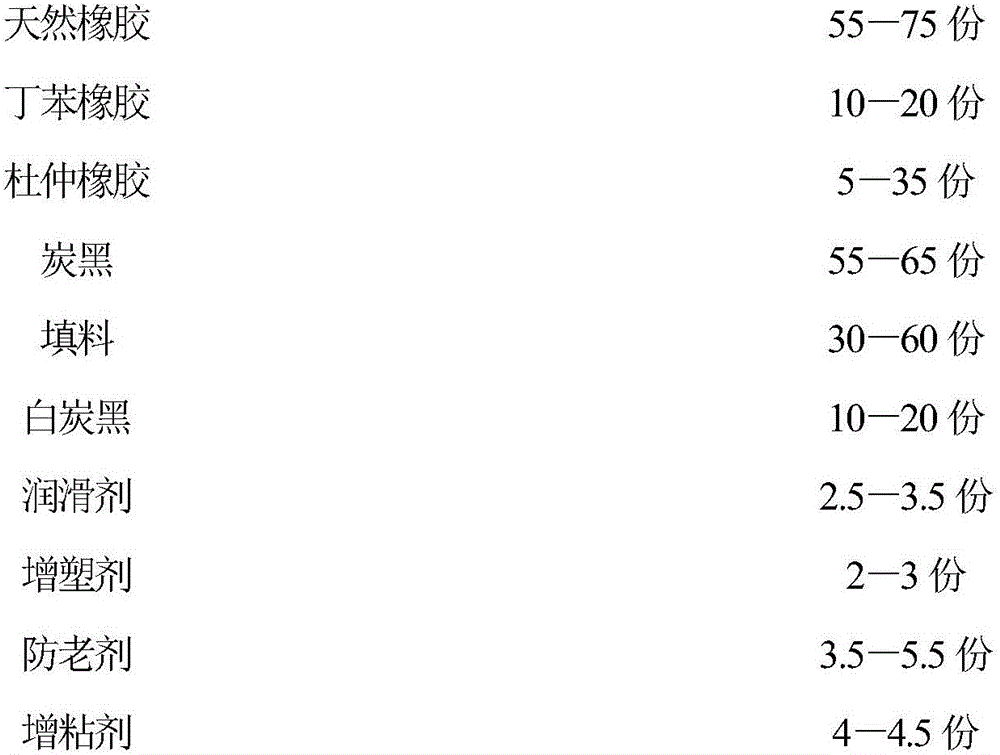

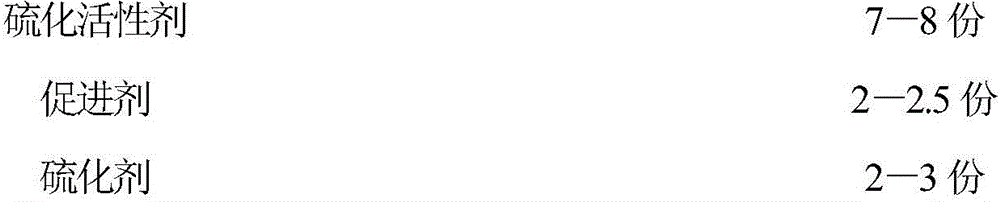

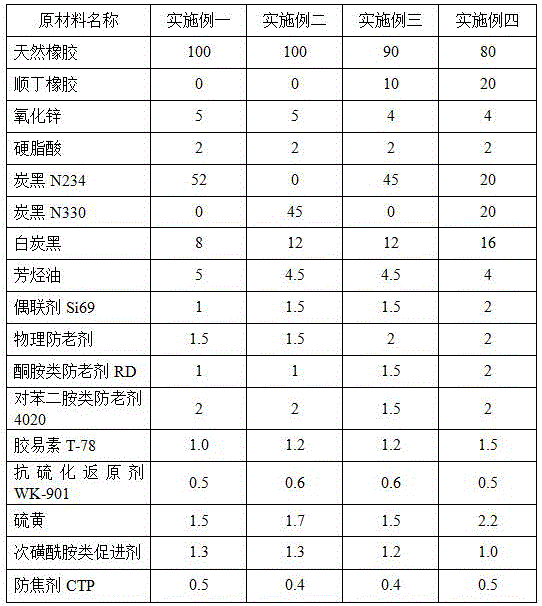

Rubber composition for manufacturing wrapping cloth V-belt compression layer and preparation method of rubber composition

ActiveCN107177057AExcellent compression fatigue resistanceHeat generation is smallBuilding insulationsVulcanizationPolymer science

The invention relates to rubber composition for manufacturing a wrapping cloth V-belt compression layer and a preparation method of the rubber composition. The rubber composition is mainly prepared from components as follows: natural rubber, styrene butadiene rubber, eucommia rubber, a vulcanization activator, a lubricant, an antiaging agent, carbon black, white carbon black, pottery clay, calcium carbonate, a plasticizer, a tackifier, an accelerator and a vulcanizing agent. A natural rubber, styrene butadiene rubber and eucommia rubber compound system is adopted in the rubber composition, the flexural fatigue resistance and heat resistance of the rubber composition are improved, besides, carbon black and white carbon black are combined to serve as a reinforcing agent, dynamic heat dissipation is reduced while the support performance of rubber is guaranteed, and the fatigue life of the rubber is prolonged.

Owner:QINGDAO UNIV OF SCI & TECH +1

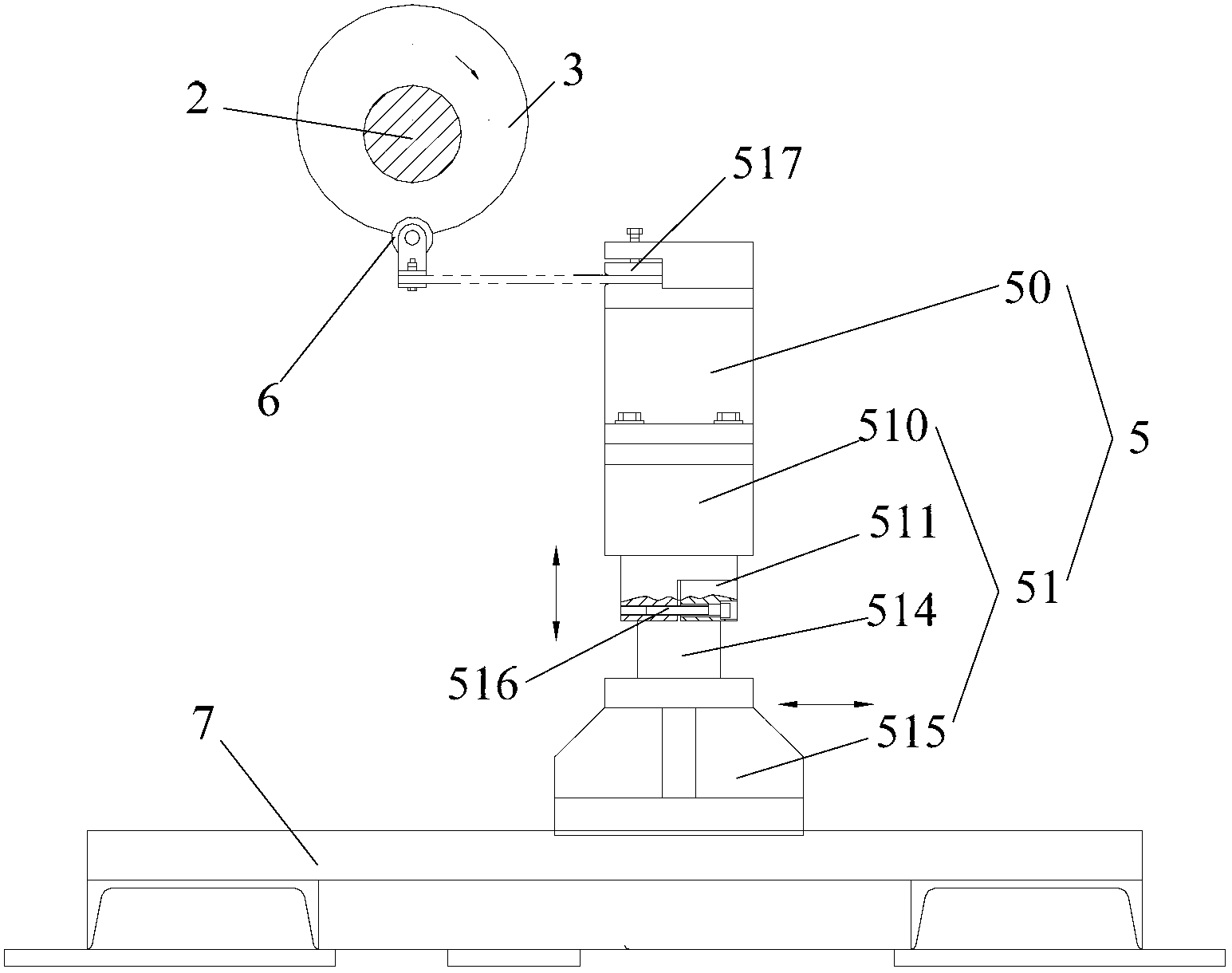

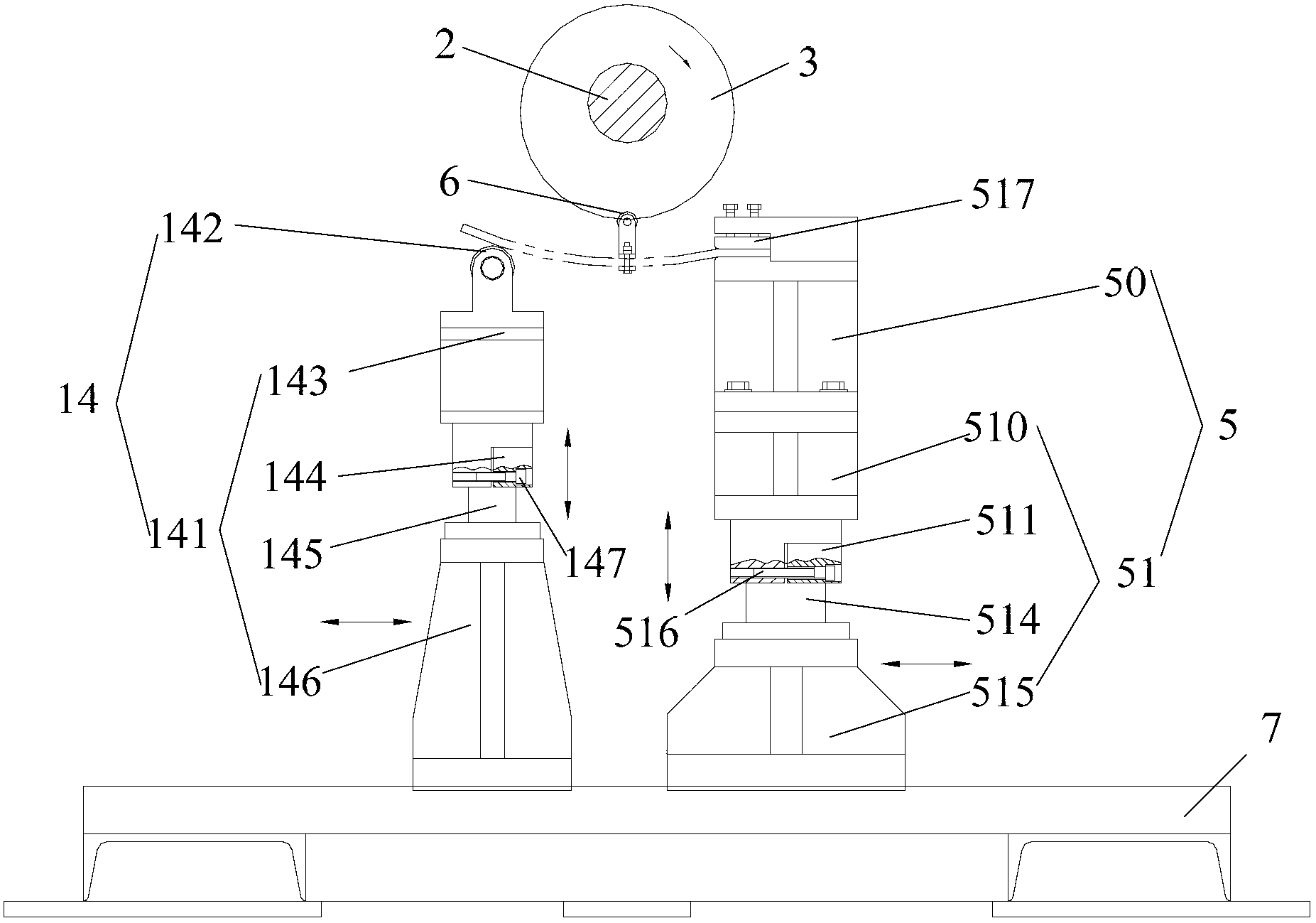

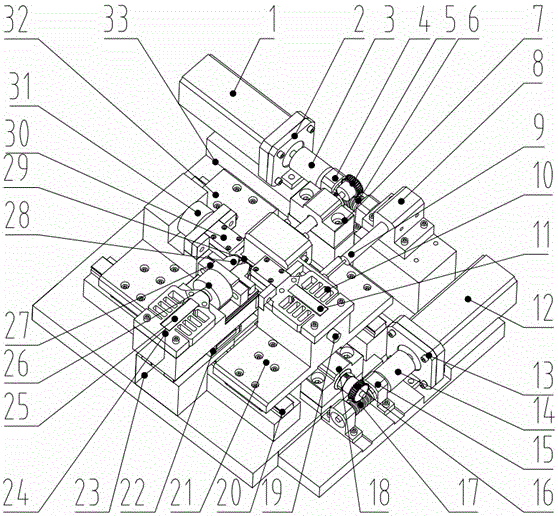

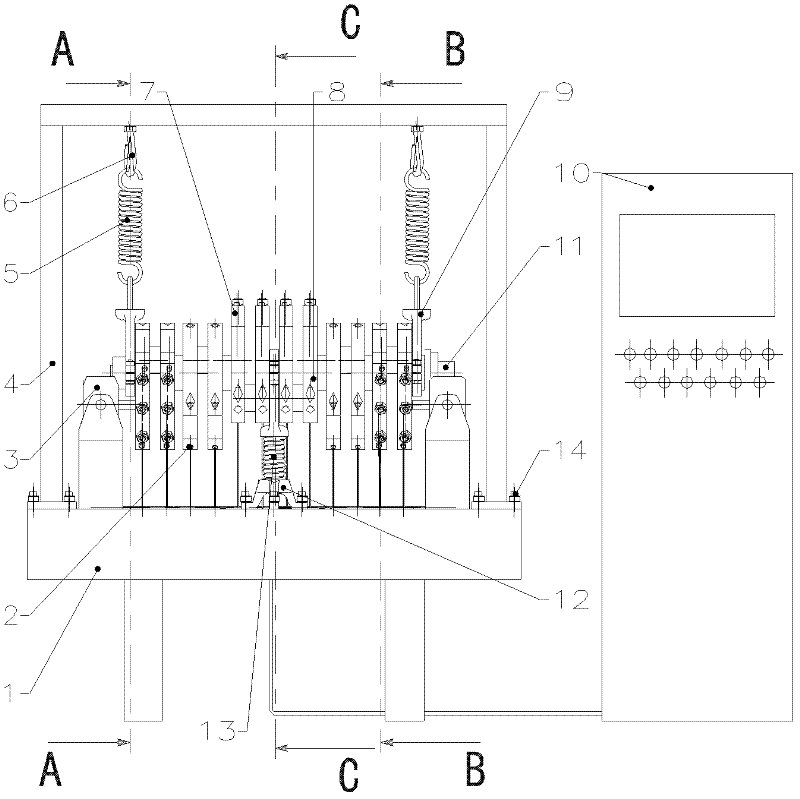

Tensile fatigue-four-point flexural fatigue in-situ mechanical testing device and testing method thereof

PendingCN106769452AReduce volumeCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectricityFatigue loading

Owner:YANCHENG INST OF TECH

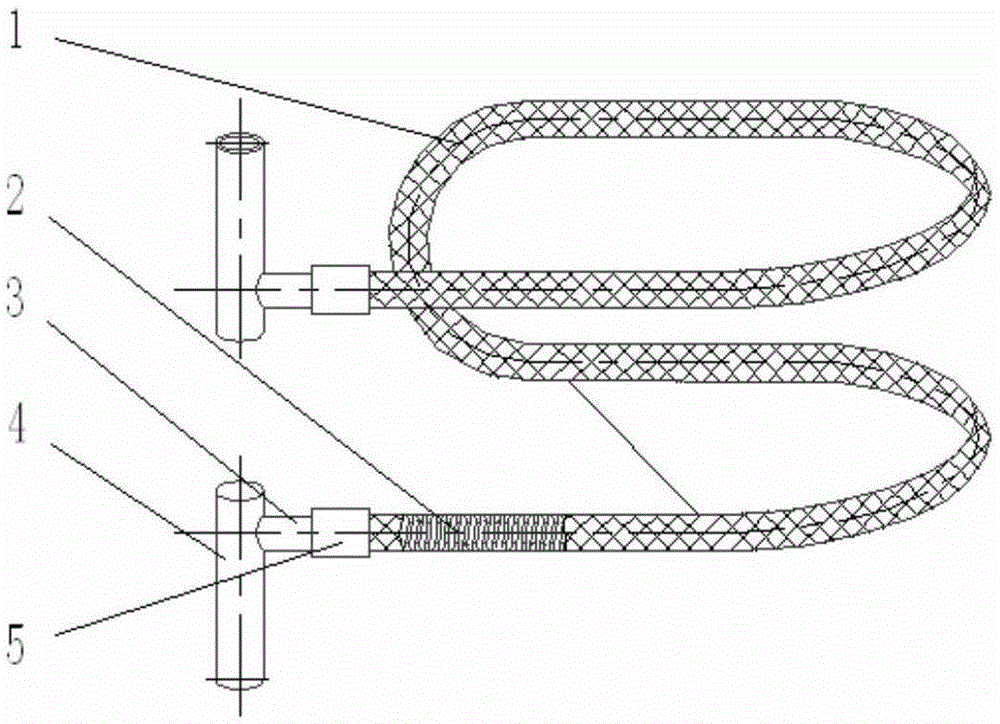

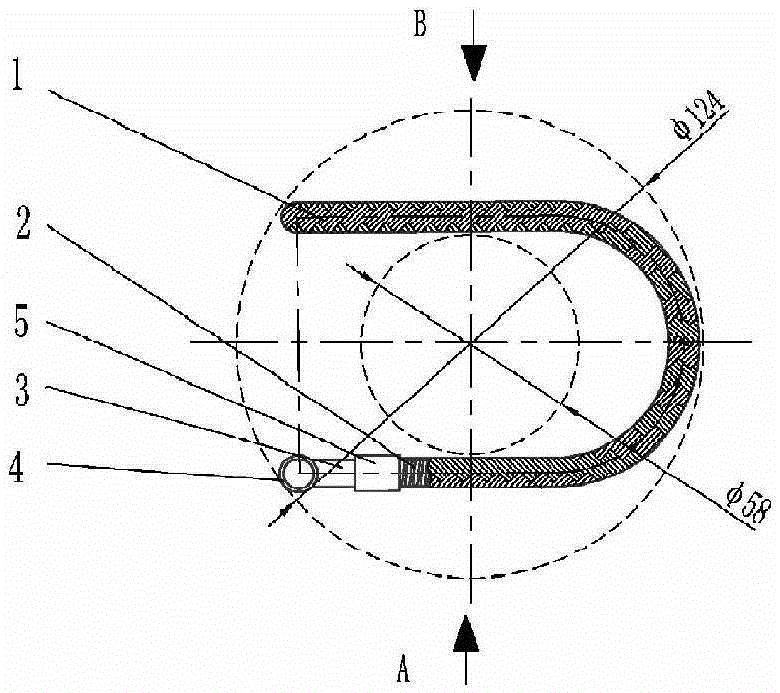

Control rod drive wire displacement compensation device, forming mold and forming method of control rod drive wire displacement compensation device

ActiveCN105240640AImprove displacement compensation abilityImprove fatigue resistancePipeline expansion-compensationStructural engineeringControl theory

The invention discloses a control rod drive wire displacement compensation device which comprises a metal corrugated pipe and a mesh cover wrapping the metal corrugated pipe. The two ends of the metal corrugated pipe are connected with connectors through connecting pipes respectively, and the connectors are perpendicular to the two ends of the metal corrugated pipe. The two ends of the metal corrugated pipe extend in parallel in the horizontal direction from the corresponding connecting pipes and then are bent to form a vertical U-shaped bend through vertical semi-arc bends and oppositely closed to form a horizontal bend through horizontal arcs. The vertical U-shaped bend is organically combined with the horizontal arc bend, and therefore compensation of displacement in the three-dimensional direction can be achieved, the corrugated structure is combined with the deformation degree of the U-shaped bend, so that the displacement compensation capacity is obviously improved, and the telescopic resistance and flexural fatigue performance are greatly improved; and therefore the service life of the displacement compensation device exceeds millions of times, and is obviously longer than that of an existing displacement compensation device. Meanwhile, the structure can be mounted in narrow space such as an annular column, the requirement for mounting precision is low, enough inner pressure and outer pressure resisting capacity is achieved, and medium leakage cannot happen within the life period.

Owner:AEROSUN CORP

Composition for dip forming and dip-formed molding

A composition for dip forming which can give a dip-formed molding which has a satisfactory texture, is excellent in tensile strength and flexural fatigue resistance, and is less apt to color even when worn and used in working for long. The composition for dip forming is obtained by converting an organic peroxide which is solid at ordinary pressure and 30 DEG C to an aqueous dispersion in the presence of a surfactant and a polymeric protective colloid, adding the dispersion to a conjugated diene rubber latex, and aging the mixture. The organic peroxide preferably is dibenzoyl peroxide or dilauroyl peroxide.

Owner:ZEON CORP

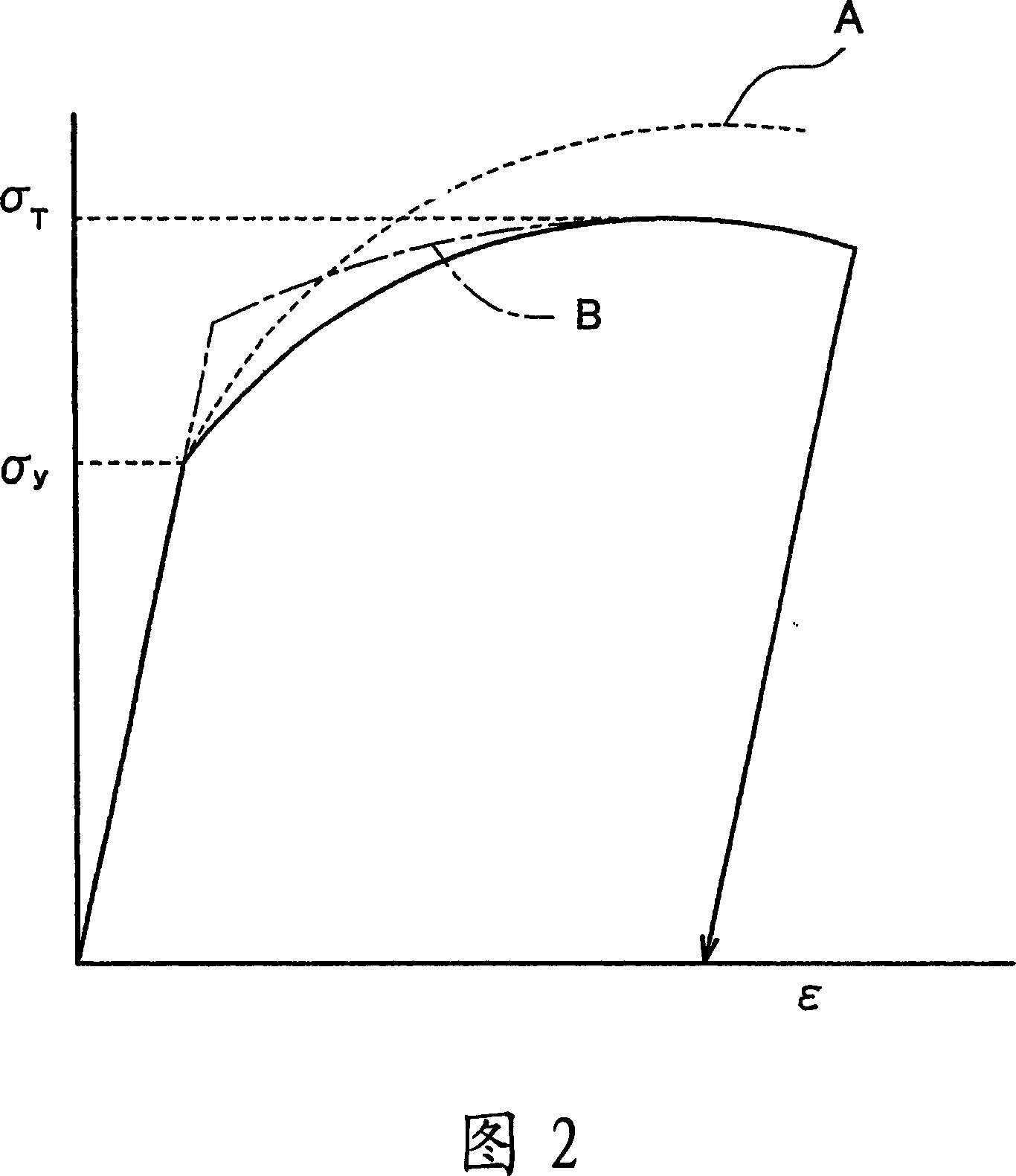

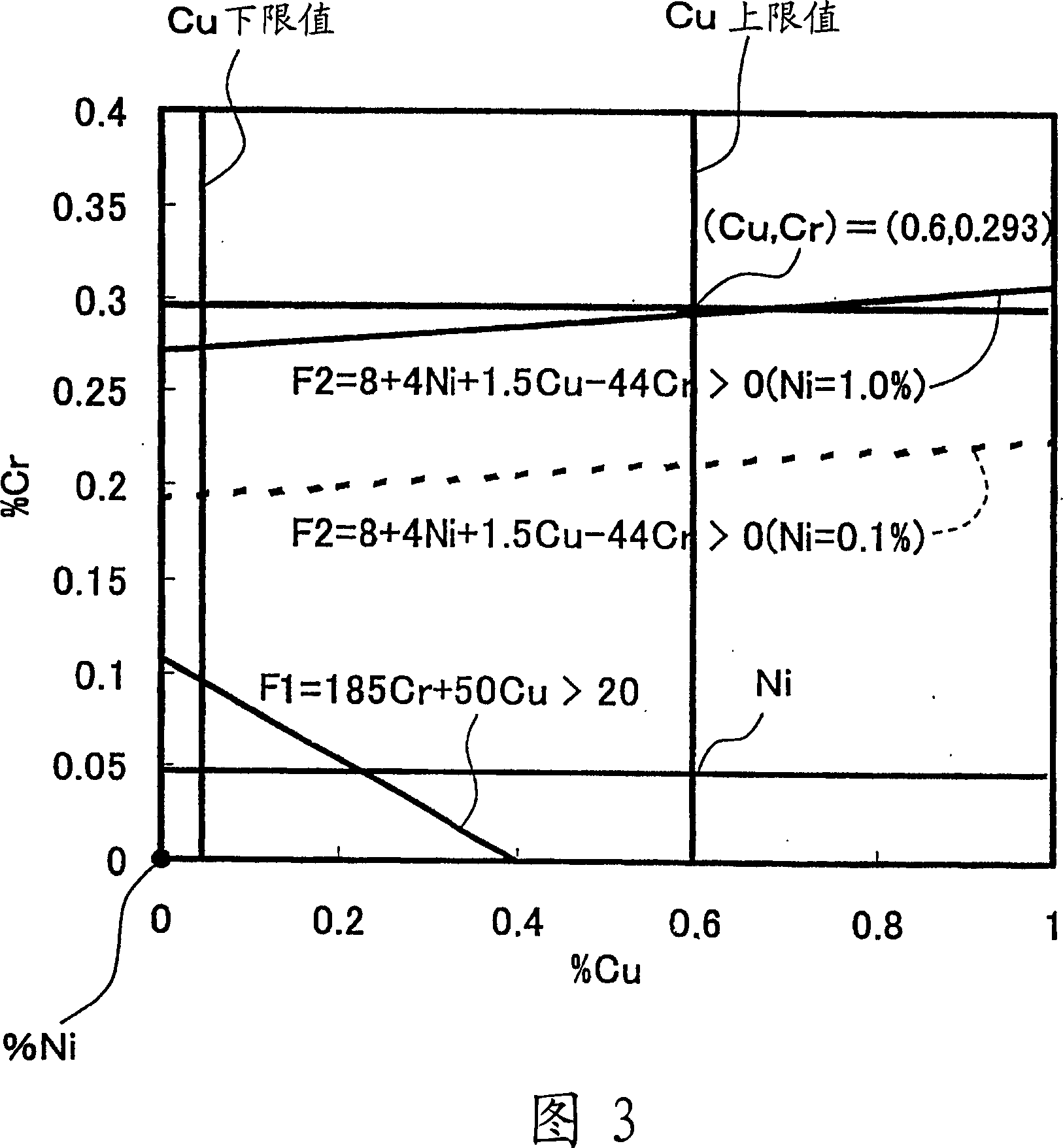

Nitrocarburized microalloyed steel member

InactiveCN101008069AImprove curvature correctionCrankshaftsSolid state diffusion coatingHardnessPearlite

A nitrocarburized microalloyed steel member consists of a microalloyed steel that includes a nitrocarburized layer on a surface, a cross-sectional structure of which steel except for the nitrocarburized layer includes a ferrite and pearlite structure. The microalloyed steel mainly consists of Fe and has a composition: C; Si; Mn; S; Cu; Ni; and Cr having fitting content ranges. If the contents of the Cu, the Ni, and the Cr are represented by WCu, WNi, and WCr mass %, respectively, and composition parameters F1 and F2 are 185WCr+50WCu and 8+4WNi+1.5WCu-44WCr, respectively, then the composition parameters F1 and F2 satisfy F1>20 and F2>0.

Owner:HONDA MOTOR CO LTD +1

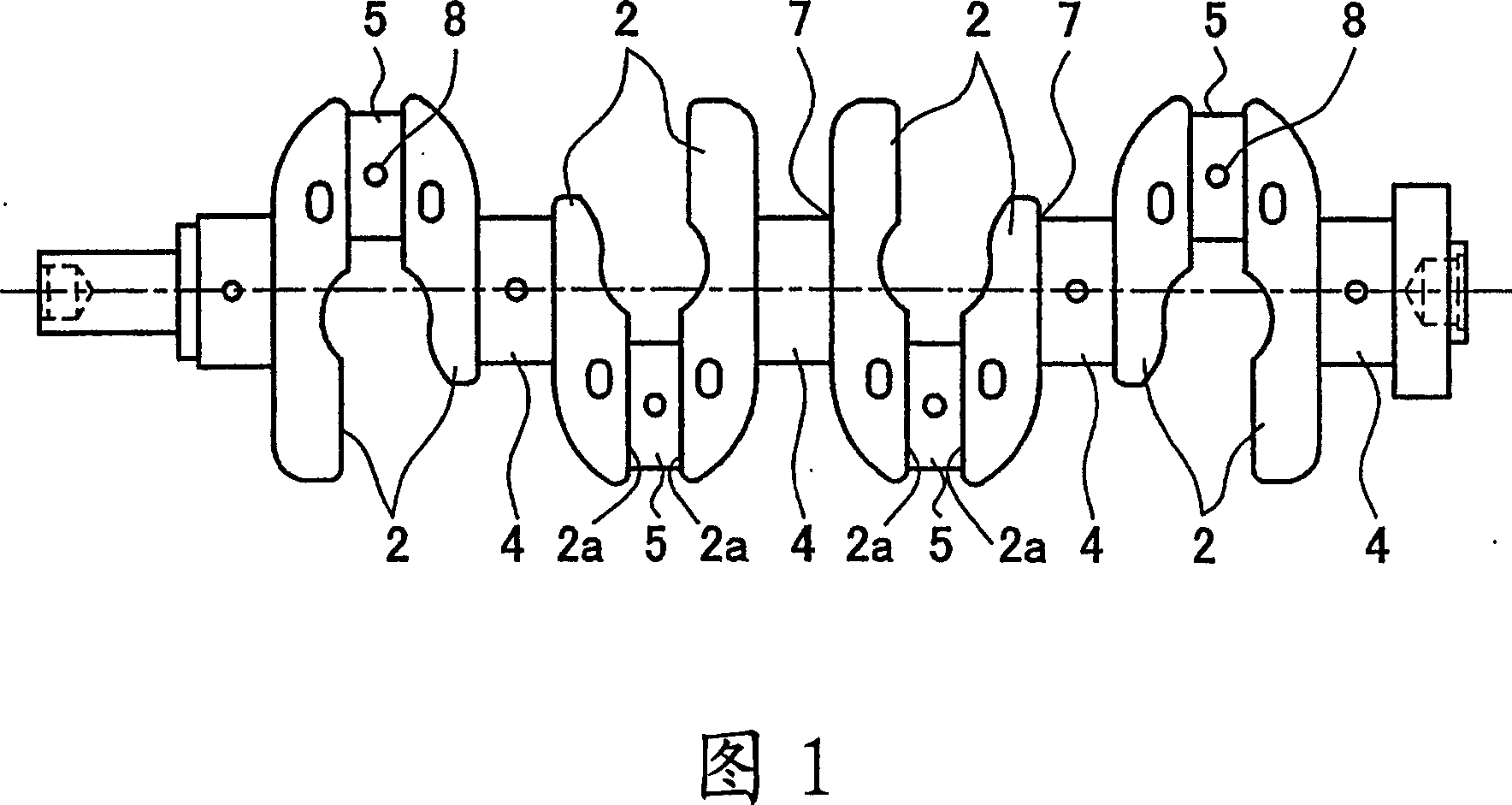

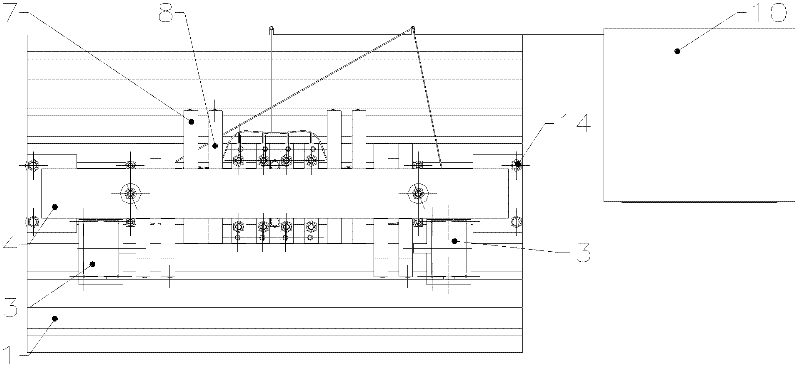

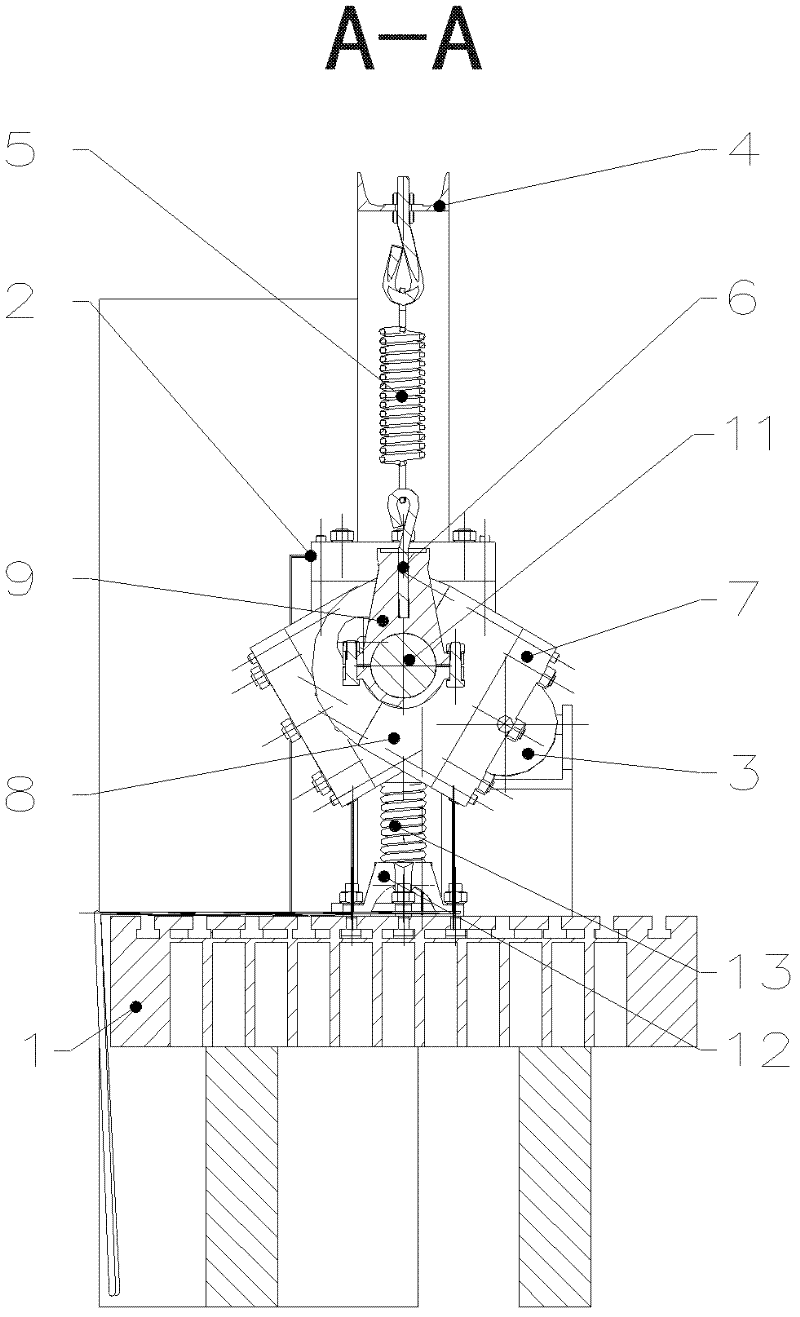

Flexural fatigue testing machine for multi-throw crank shaft

InactiveCN102353537AImprove rigidityHigh precisionMachine gearing/transmission testingHandling systemControl theory

The invention relates to a flexural fatigue testing machine for a multi-throw crank shaft, which comprises a working platform, displacement sensors, electromagnetic vibration exciters, a portal frame, counterweight blocks, a signal controlling and processing system and the like. The portal frame, a spring supporting seat and the electromagnetic vibration exciters are fixedly arranged on the working platform; the portal frame is connected with two ends of the multi-throw crank shaft through two tension springs; a main shaft in the middle section of the multi-throw crank shaft is connected withthe spring supporting seat through a compression spring; each crank shaft arm of the multi-throw crank shaft is respectively and fixedly provided with a crank shaft arm clamp body; the counterweight blocks are respectively and fixedly arranged on each crank shaft arm clamp body; two electromagnetic vibration exciters are symmetrically arranged at the two ends of the multi-throw crank shaft, further, armatures of the two electromagnetic vibration exciters are fixed with two counterweight blocks at the outermost ends of the multi-throw crank shaft; the displacement sensors are fixedly arranged on the counterweight blocks; and the two electromagnetic vibration exciters and the displacement sensors are synchronously connected with the signal controlling and processing system through conducting wires. The flexural fatigue testing machine for the multi-throw crank shaft has a simple structure, convenience in operation, high precision and small error, and is applicable to the flexural fatigue testes of crank shafts of different models.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

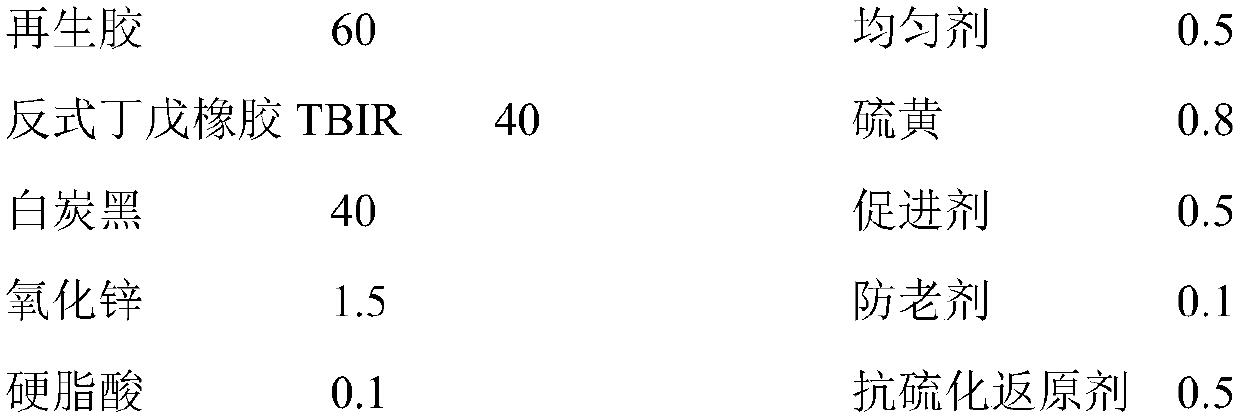

Trans-butadiene-isoprene rubber modified regenerated rubber as well as preparation method and purpose thereof

ActiveCN107814994AGuaranteed physical and mechanical propertiesImproved dynamic fatigue performanceSpecial tyresDispersityPolymer science

The invention relates to regenerated rubber modified by utilizing trans-butadiene-isoprene rubber as well as a preparation method and application thereof. The trans-butadiene-isoprene rubber modifiedregenerated rubber is prepared from the following components in parts by weight: 95 to 50 parts of regenerated rubber, 5 to 50 parts of the trans-butadiene-isoprene rubber TBIR, 2.5 to 50 parts of filling, 1.5 to 4 parts of zinc oxide, 0.1 to 0.6 part of stearic acid, 0 to 5 parts of homogenizing agent, 0.8 to 5 parts of sulfur, 0.5 to 3.5 parts of accelerant, 0.1 to 3 parts of anti-aging agent and 0 to 2.0 parts of anti-reversion agent. According to the preparation method, the regenerated rubber is modified by adopting the trans-butadiene-isoprene rubber TBIR; the dispersity of the filling can be improved; vulcanized rubber is increased by 30 to 70 percent in tensile strength, by 40 to 100 percent in 300-percent stress at definite elongation, by 10 to 20 percent in abrasion performance and by 100 to 700 percent in flexural fatigue performance. The regenerated rubber can be used for a tire tread, a tire side, a tire body, a belted layer and an airtight layer of a tire, a highway pavement and a runway and the dynamic fatigue performance is improved.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD +1

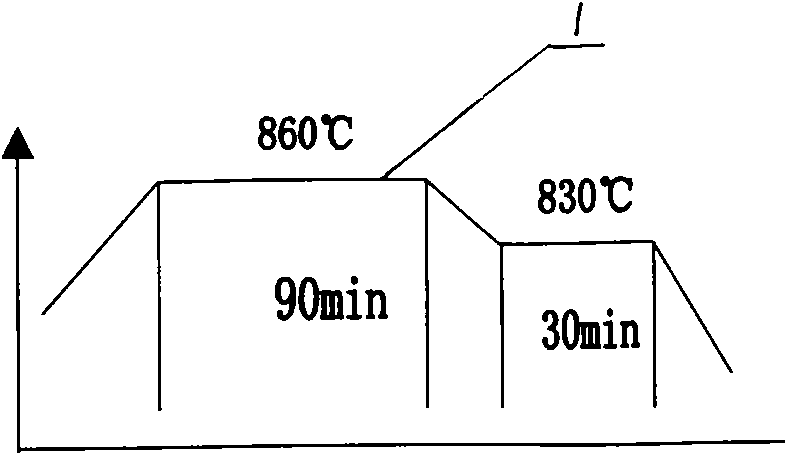

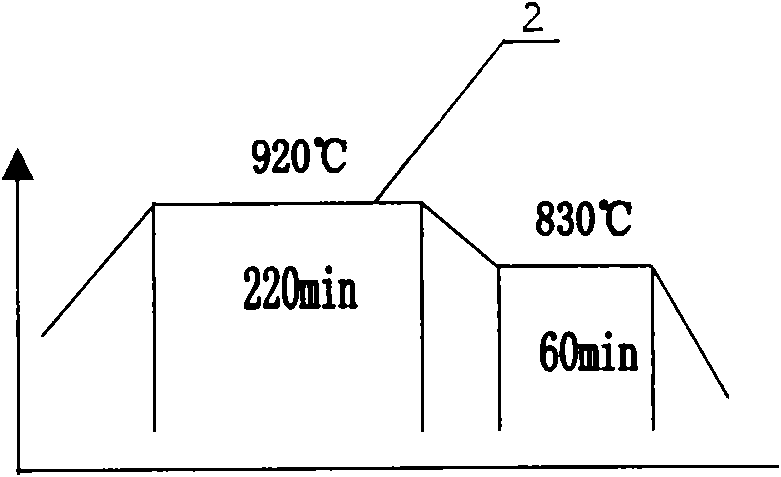

Organic rare-earth energizer for chemical heat treatment

ActiveCN101560637ASimple recipeImprove wear resistanceSolid state diffusion coatingChemical treatmentRare earth

The invention relates to an organic rare-earth energizer for chemical heat treatment and provides a surface chemical heat treatment energizer for a metal product. The energizer has the advantages of high activity, low cracking temperature, simple prescription, no pipeline blockage, and the like. The energizer not only can improve the catalysis speed and reduce the catalysis temperature, but also can obviously improve the brittleness, the wearing resistance and the contact fatigue and the flexural fatigue life of a catalyzing layer, has safety, reliability and stable product quality, greatly reduces the energy consumption in the heat treatment process, increases the heat treatment speed by 25 percent to 50 percent and reduces the energy consumption by 30 percent to 55 percent by the cooperation of rare-earth metallocene and ferrocene. By using a mixture of the rare-earth metallocene and the ferrocene as a main component of the energizerm, and the energizer has low the cracking temperature, can solve the problem of blocking a pipeline in the heat treatment process and can be used in the solid catalyzing and liquid catalyzing fields.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

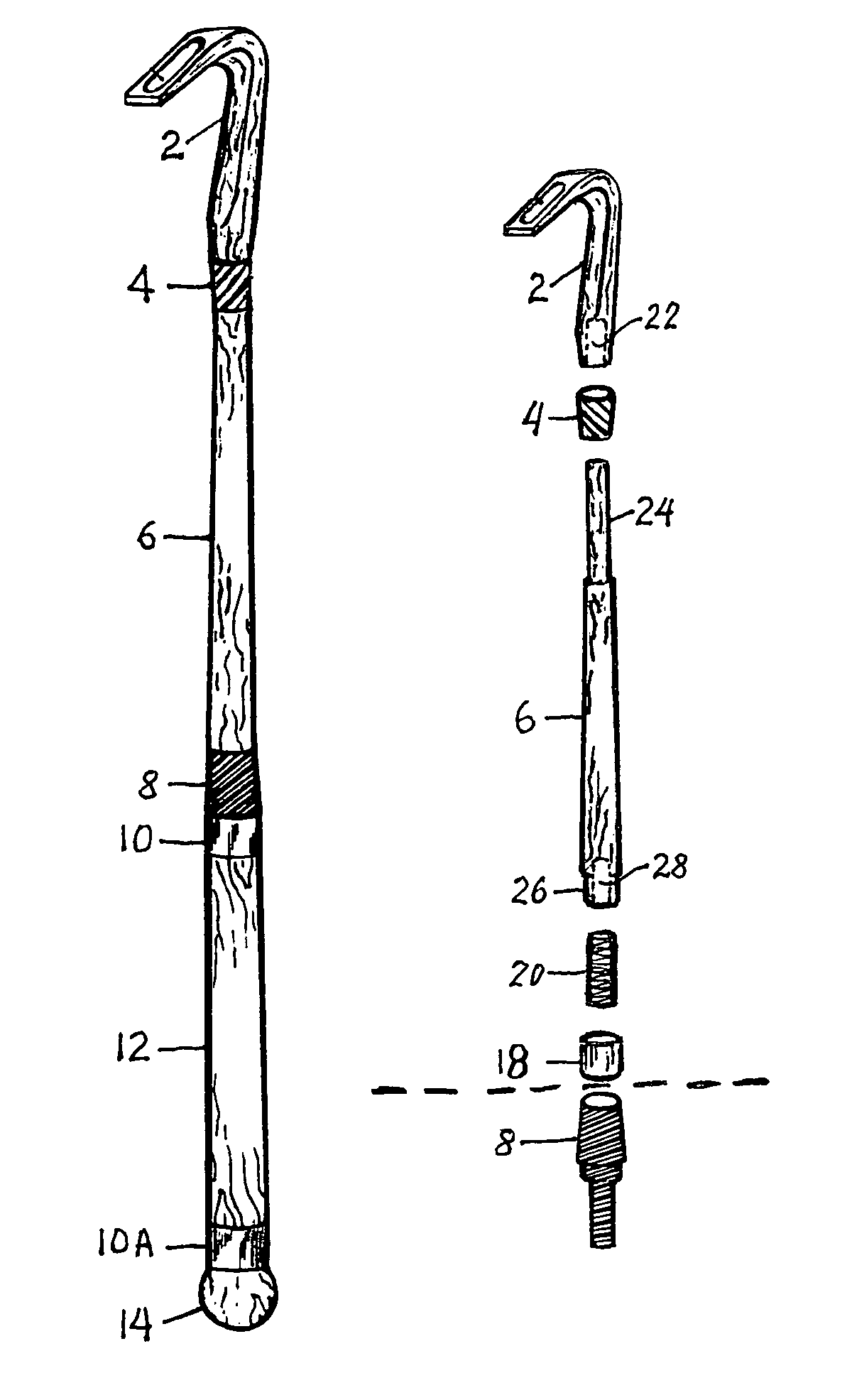

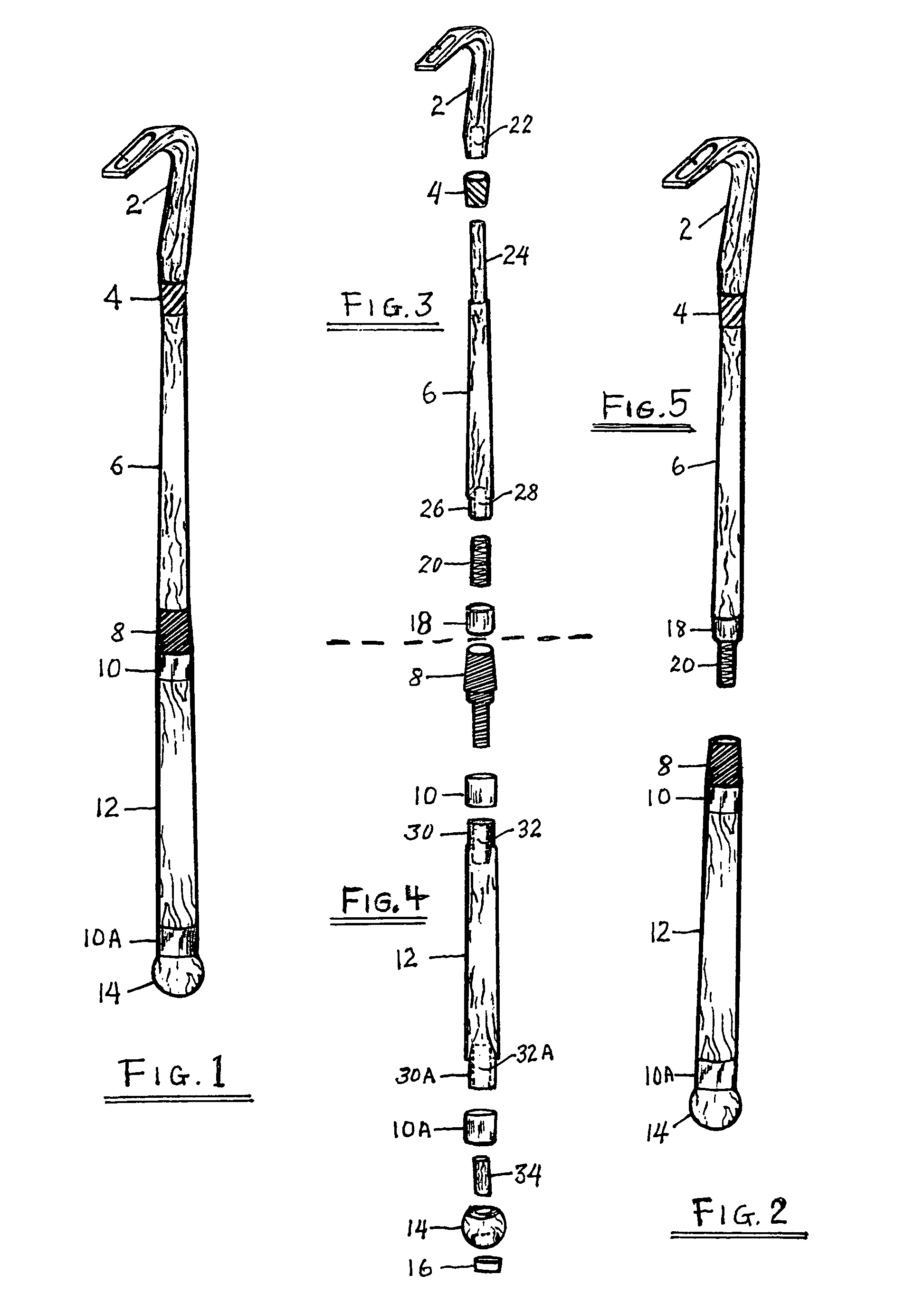

Component craps stick

InactiveUS7090217B1Eliminates and delays typeEasy to removeBoard gamesFlexural fatigueBiomedical engineering

This invention is a component craps stick for manipulating dice in a gaming casino, formed as a three-component detachable assembly of a rattan hook, a rattan shaft and a pinewood handle. The rattan components may be removed and replaced when they deteriorate or break due to flexural fatigue in extensive casino use. The three-component configuration is a distinct improvement over currently used single-piece rattan craps sticks which must be totally replaced when any part deteriorates or breaks.

Owner:SIRON JOHN R

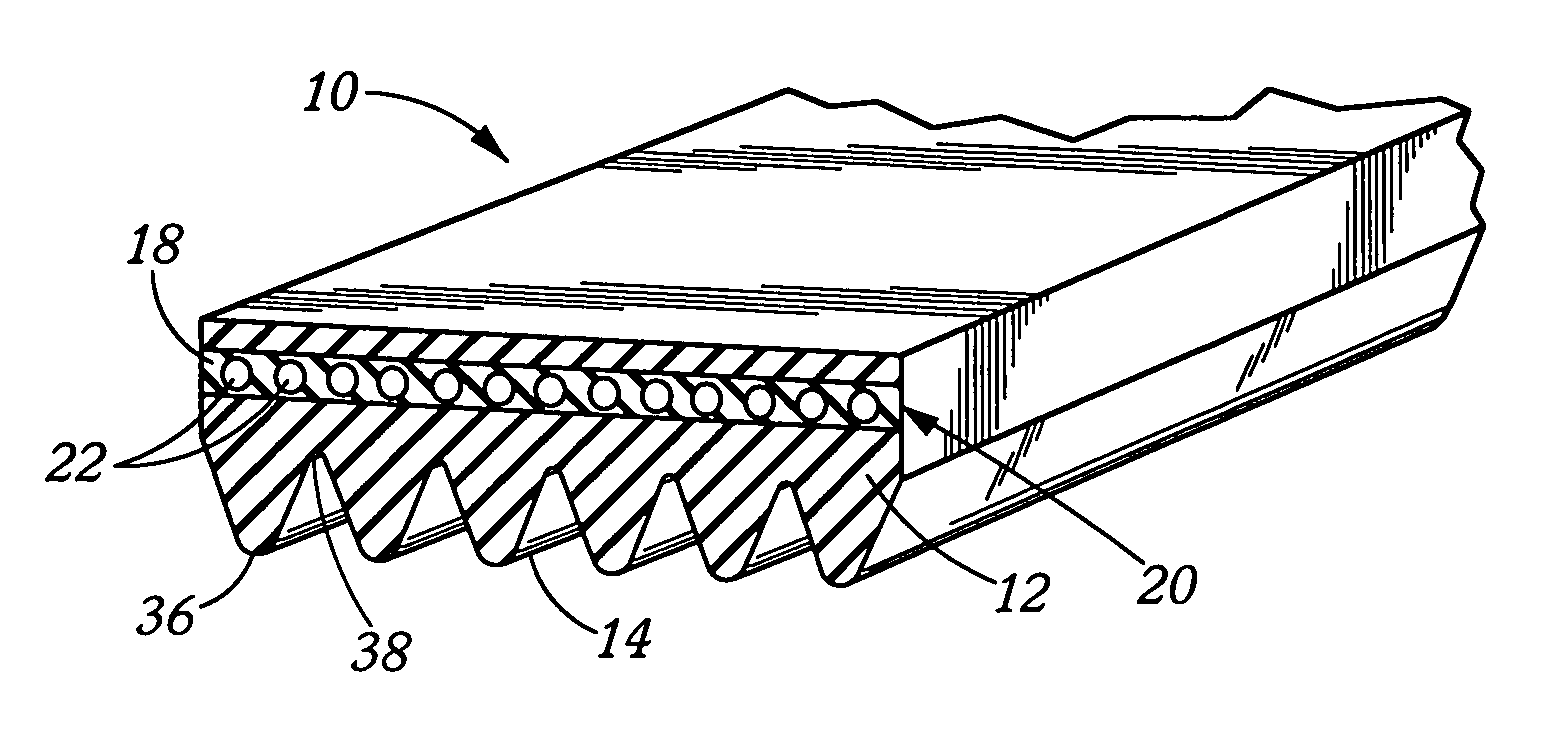

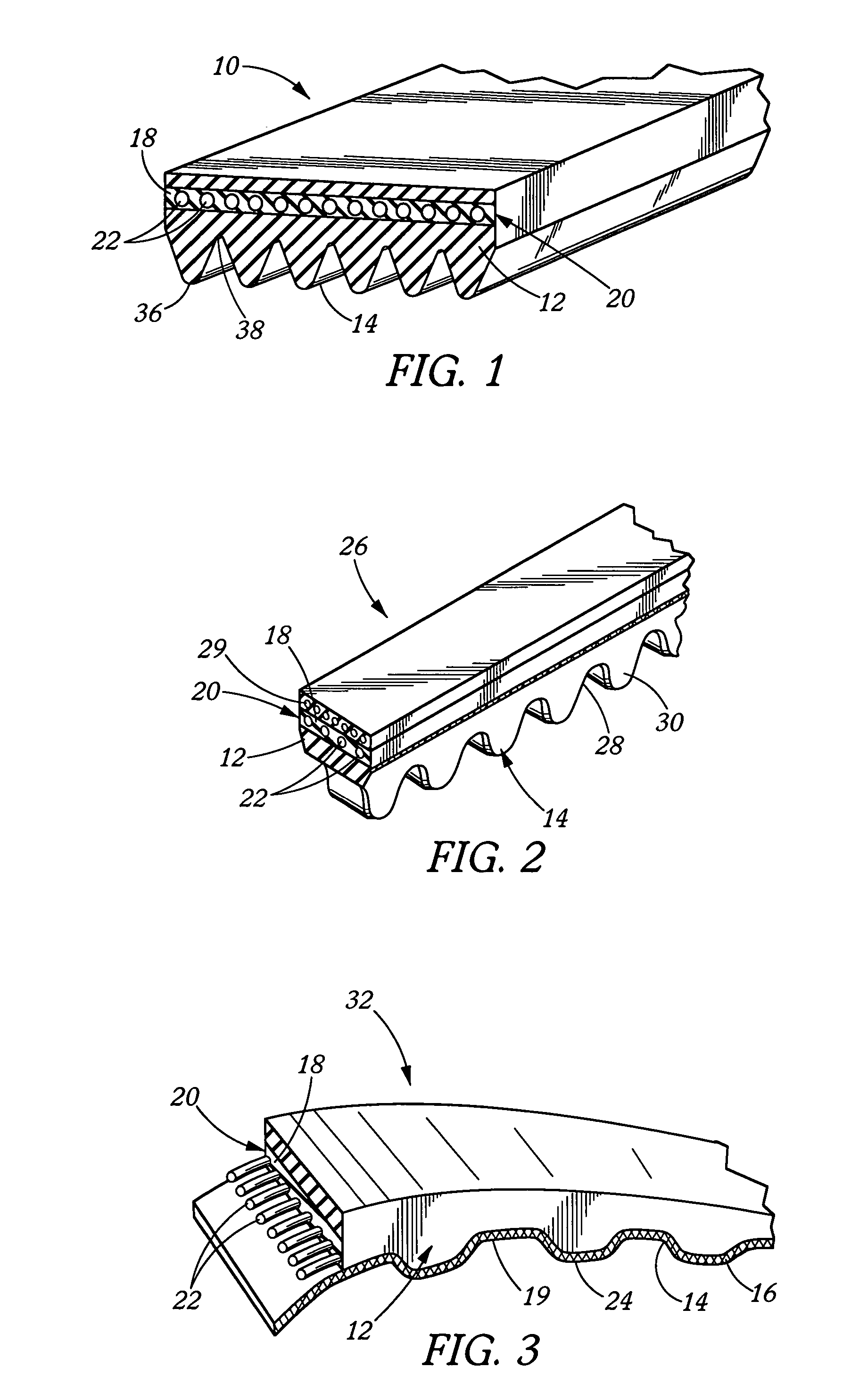

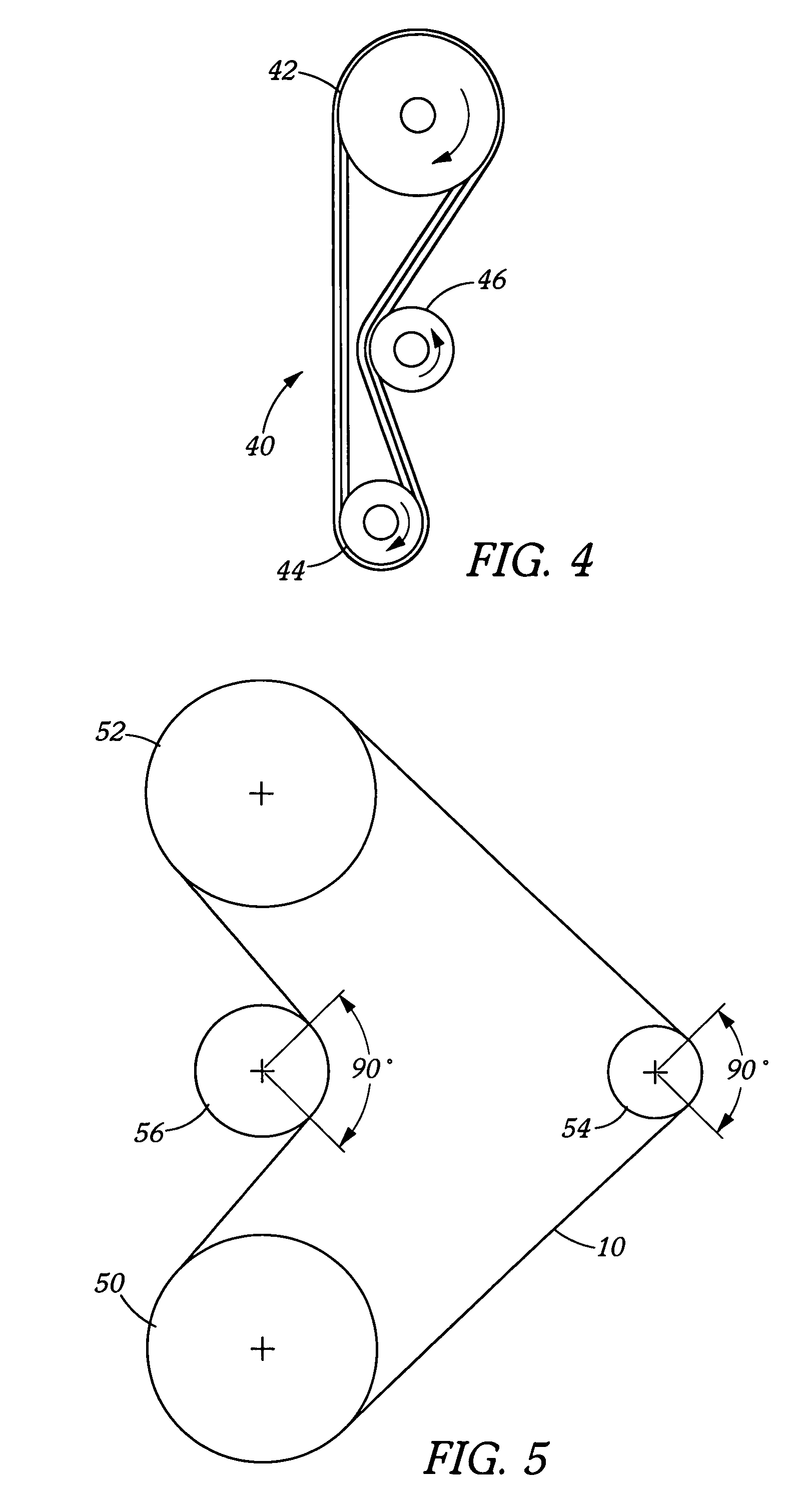

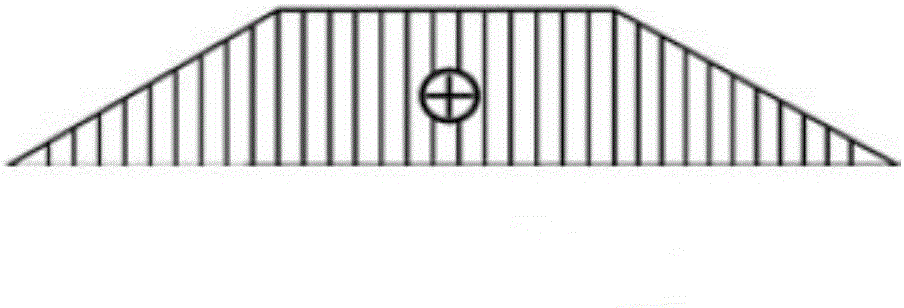

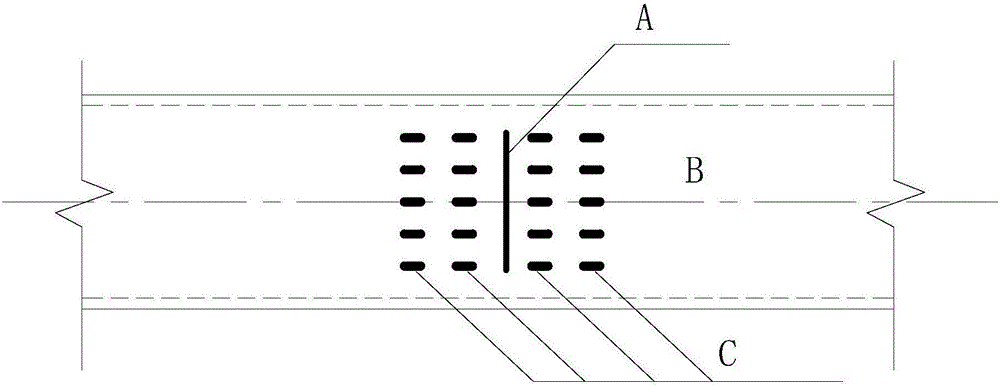

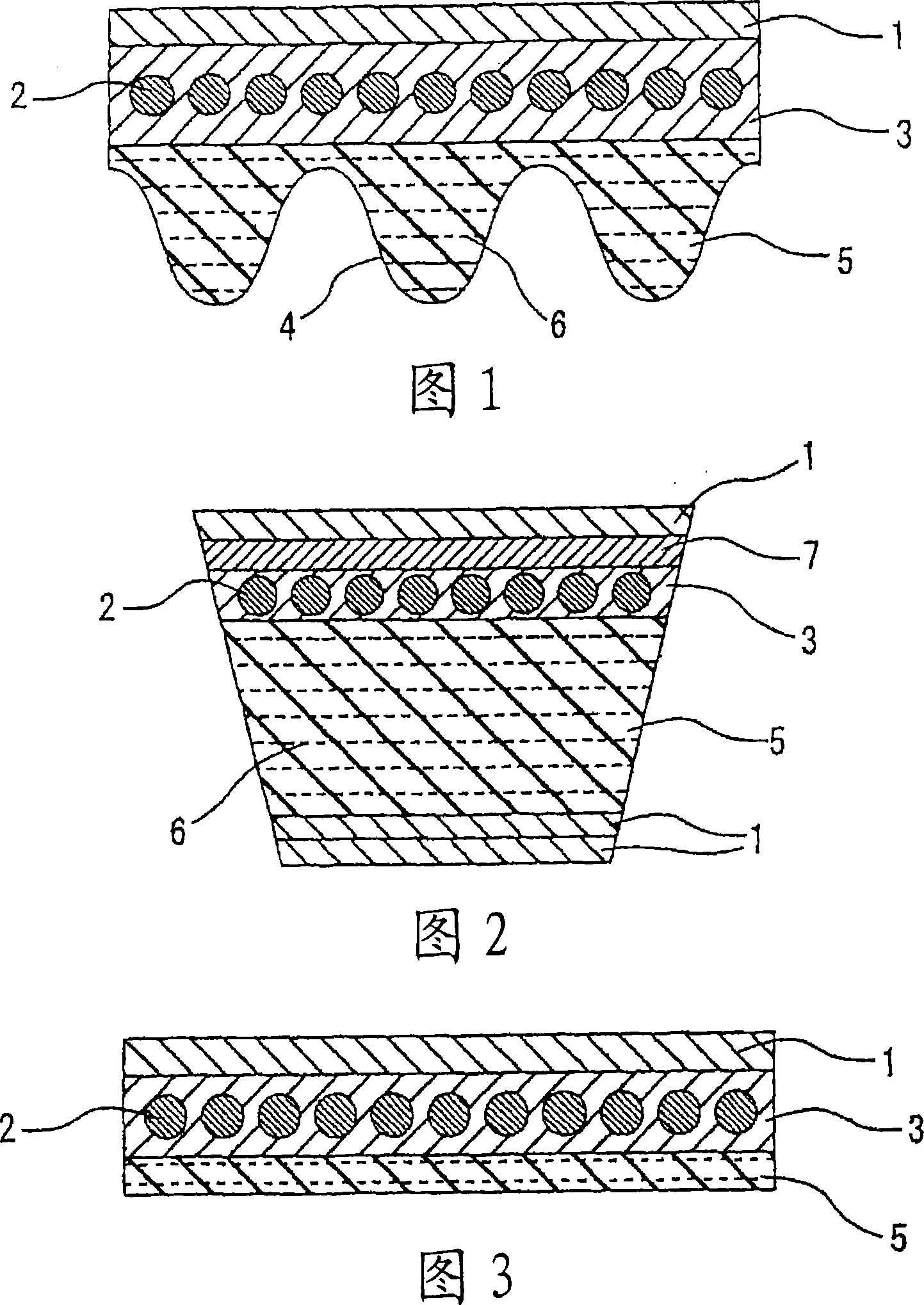

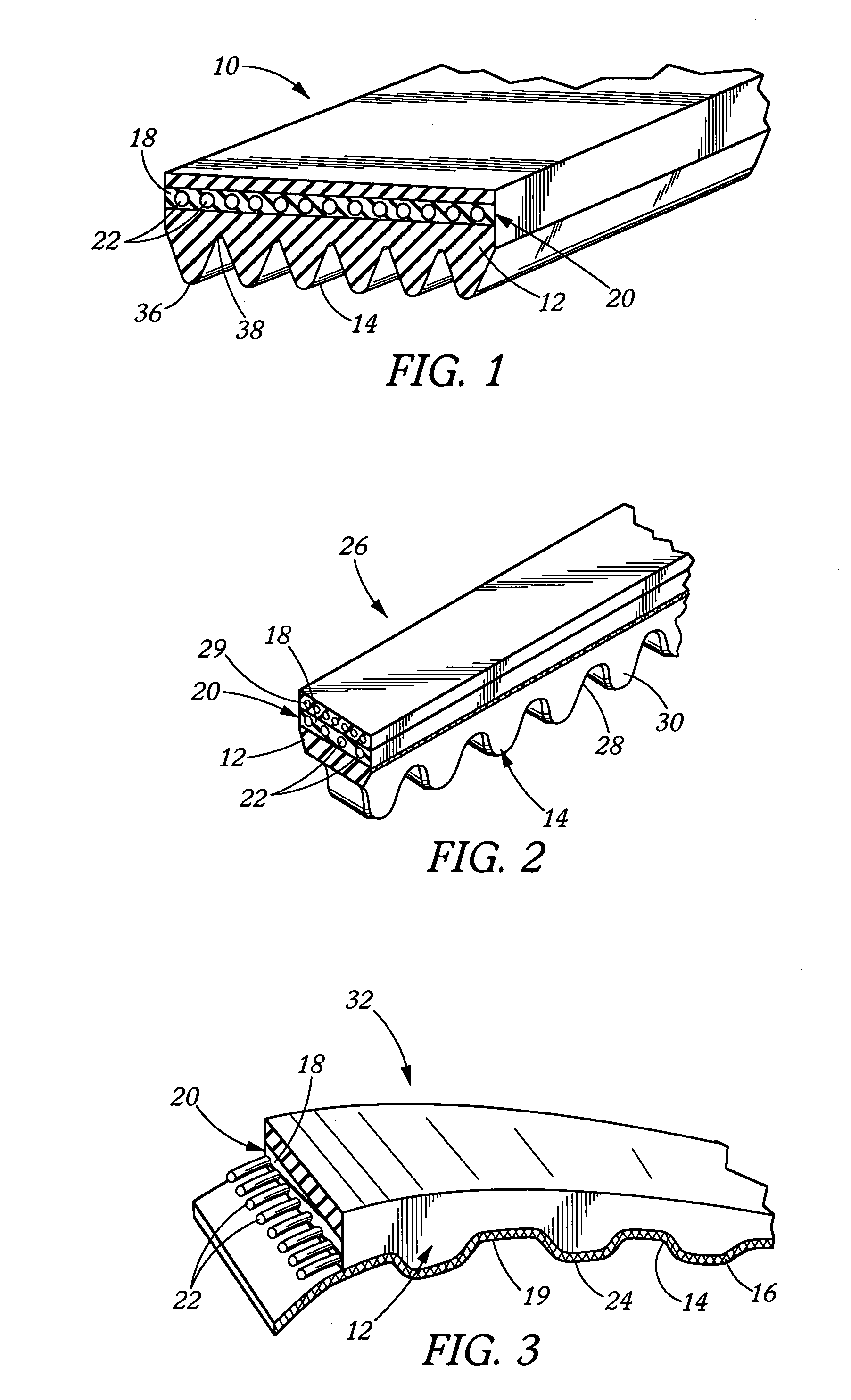

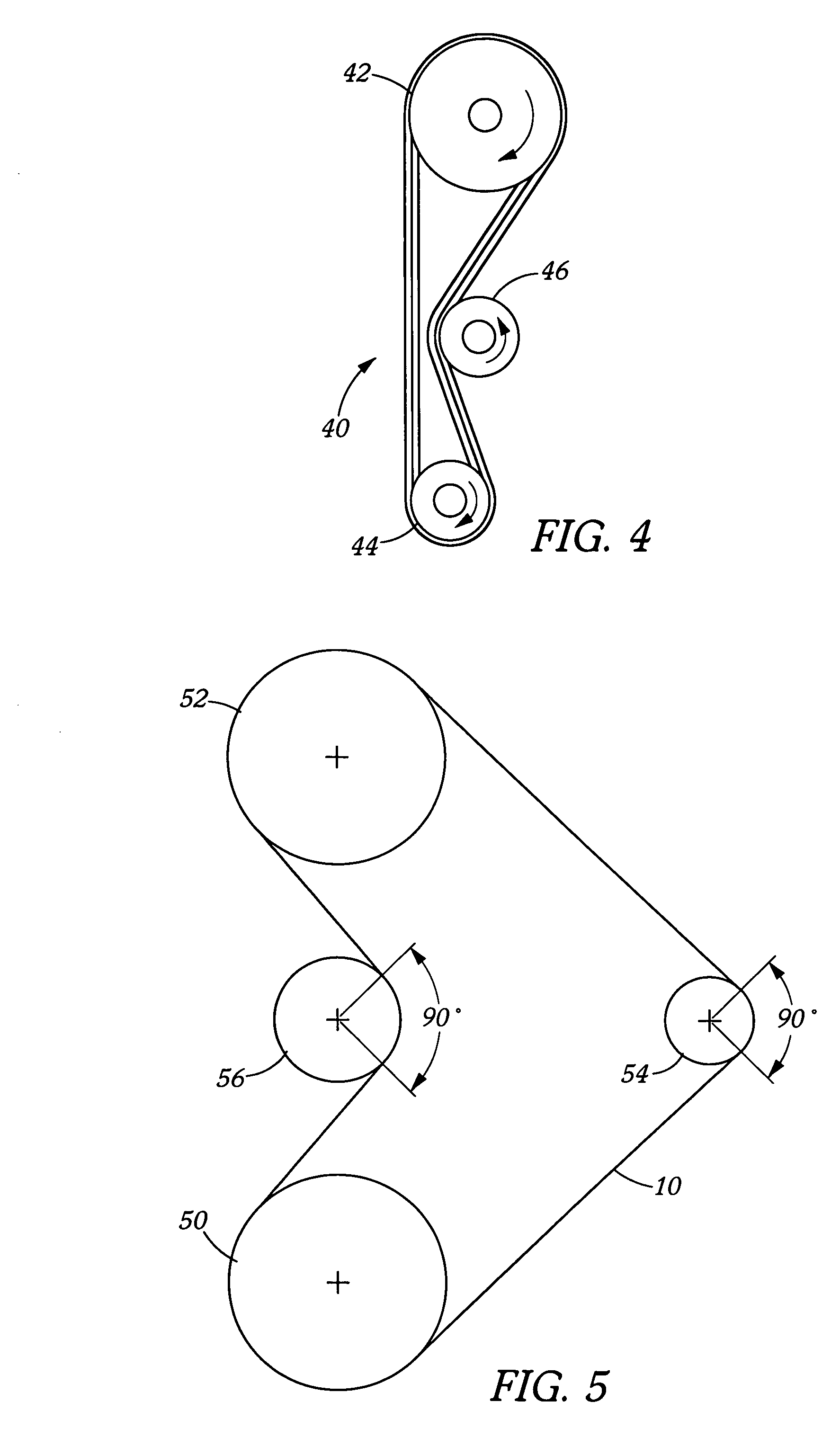

Power transmission belt

ActiveUS7201688B2Increased durabilityIncrease resistanceV-beltsRopes and cables for vehicles/pulleyYarnPolyamide

An endless power transmission belt comprising load carrier cord comprising a cord formed from a plurality of strands, wherein the strands comprise fibers of para-aramid and polyvinylpyrrolidone (PVP); and a method for increasing the flexural fatigue resistance and durability of an endless belt, comprising the step of selecting for the belt's load carrier cord a yarn comprising a fiber of para-aramid and PVP.

Owner:THE GATES CORP

Detecting method for flexural fatigue crack initiation process of submarine pipeline

ActiveCN107179250AThe detection method is accurateAccurate measurement structureMaterial strength using steady shearing forcesSupport pointStrain gauge

The invention discloses a detecting method and device for a flexural fatigue crack initiation process of a submarine pipeline. The detecting method comprises: arranging a strain gage in the middle of a pipeline test piece; placing the pipeline test piece on a fatigue pressure application mechanism platform; taking two ends of the pipeline test piece as supporting points and enabling the middle of the pipeline test piece to be suspended; applying a downward cyclic load to two positions symmetric along the middle of the pipeline test piece by a fatigue pressure application mechanism; and detecting whether fatigue cracks are initiated on the pipeline through a strain difference measured by the strain gage arranged on the pipeline test piece, and determining extension length of cracks according to strain values measured by different strain gages in the circumferential direction to further obtain a relationship between the cyclic load times of the pipeline test piece and the length of the fatigue cracks. The detecting method has the advantages that the crack initiation condition of the submarine pipeline can be predicted by detection on the pipeline test piece, the detecting method is simple and accurate, a submarine pipeline which is not mounted can be detected, and whether the submarine pipeline meets requirements of submarine services can be judged.

Owner:CHINA PETROLEUM & CHEM CORP +1

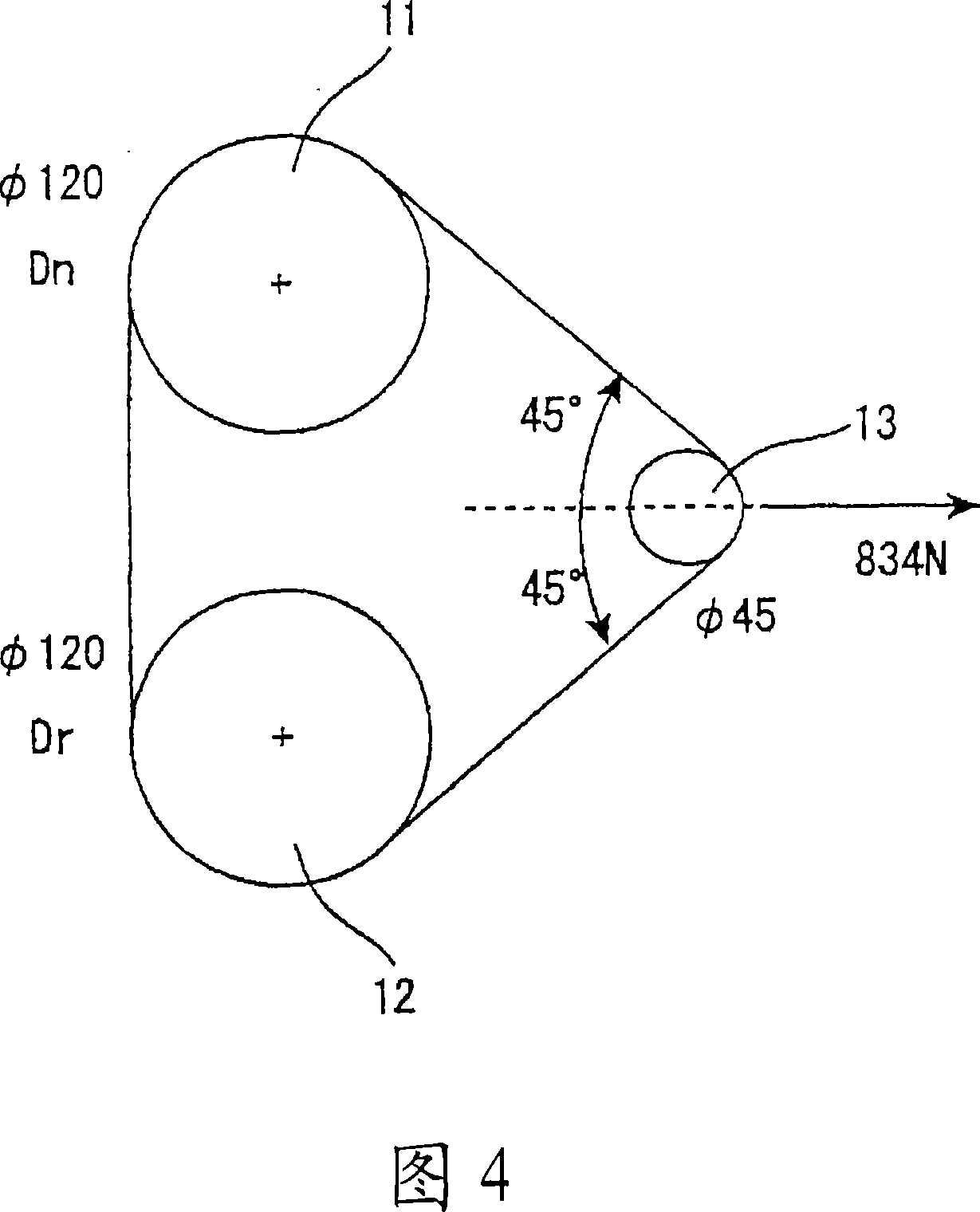

Test device for flexible life of coiled tubing

InactiveCN105823629AAccurately Obtain Bending Fatigue LifeMachine part testingMaterial strength using repeated/pulsating forcesInternal pressureReciprocating motion

The present invention provides a test device for the flexible life of a coiled tubing. The device comprises a motor, a crank, a first rotating hinge, a connecting rod, a first hydraulic rod, second rotating hinges, a coiled tubing, a clamp, an air inlet, a second hydraulic rod, a first support, a second support, a third support, a crossbeam and a connection shaft. The crank, the connecting rod and the coiled tubing form a crank and rocker mechanism; the first hydraulic rod and the second hydraulic rod which are configured to apply tension load to the coiled tubing are able to rotate around the second rotating hinges and drive the coiled tubing to rotate back and forth along the swing locus; the air inlet is configured to apply internal pressure to the coiled tubing; the motor is started, the crank is configured to drive the coiled tubing under the action of internal pressure and the tension load to do reciprocating motion along the swing locus, and the degree of crook and the angle of the swing locus of the coiled tubing are changed by changing the length of the crank, so that the flexural fatigue characteristic test of the coiled tubing in different conditions are realized. The test device for the flexible life of a coiled tubing is suitable for the field of the petroleum and natural gas drilling and production engineering technology.

Owner:SOUTHWEST PETROLEUM UNIV

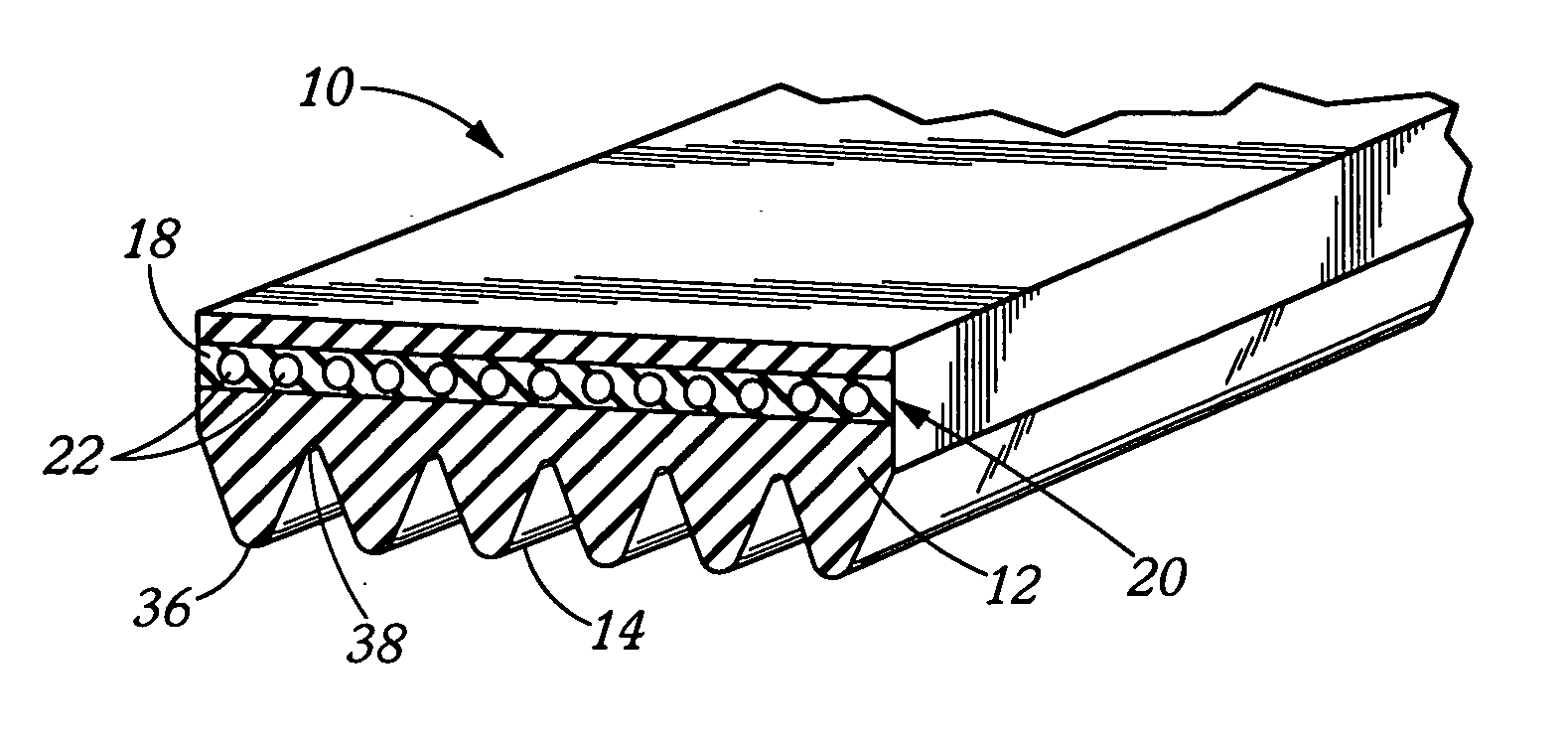

Friction transmission belt

A friction transmission belt, which comprises a compressed rubber layer containing an ethylene-a-olefin elastomer, a short fiber and silica and having a single-layer structure. The friction transmission belt can inhibit a noise owing to the slip caused when the friction drive section of the belt is covered with water and has excellent flexural fatigue characteristics, and further can be manufactured by a simple and easy working process.

Owner:BANDO CHEM IND LTD

Power transmission belt

ActiveUS20050202916A1Increased durabilityIncreasing flexural fatigue resistanceV-beltsRopes and cables for vehicles/pulleyYarnAramid

An endless power transmission belt comprising load carrier cord comprising a cord formed from a plurality of strands, wherein the strands comprise fibers of para-aramid and polyvinylpyrrolidone (PVP); and a method for increasing the flexural fatigue resistance and durability of an endless belt, comprising the step of selecting for the belt's load carrier cord a yarn comprising a fiber of para-aramid and PVP.

Owner:THE GATES CORP

Pre-vulcanized tread rubber for retreaded tire and manufacturing process of pre-vulcanized tread rubber

InactiveCN105860156AImprove tensile propertiesImprove wear resistanceSpecial tyresEngineeringMechanical property

The invention discloses a prevulcanized tread rubber for retreading tires and a manufacturing process thereof. Natural rubber is used as the main matrix material, and reinforcing agent, anti-aging agent, active agent, vulcanizing agent, accelerator, dispersing agent are added in a certain proportion. A variety of fillers such as anti-scorch agent, anti-scorch agent and anti-reversion agent. The sizing material of the invention is characterized in that the sizing material is mainly used for the retreading of truck tires, and has excellent physical and mechanical properties, wear resistance, flexural fatigue resistance, aging resistance and reversion resistance. When the tire is retreaded, the pre-vulcanized tread compound is used in combination with the pre-vulcanized buffer compound, which can reduce or even avoid the delamination problem between the old carcass and the tread, improve the safety of the retreaded tire, and prolong the service life of the retreaded tire.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Cross-linkable rubber composition and cross-linked product

A cross-linkable rubber composition comprised of a mixture of a carboxyl group-containing nitrile copolymer rubber (A) with a carboxyl group content per 100 g of 2×10−3 to 1×10−1 equivalents and a carboxyl group-containing acryl-based polymer (B) with a carboxyl group content per 100 g of 4×10−4 to 1×10−1 equivalents in a weight ratio A:B=40:60 to 90:10 into which a cross-linking agent (C) able to cross-link the carboxyl groups of both the nitrile copolymer rubber (A) and the acryl-based polymer (B) is blended, the amount blended of the cross-linking agent (C), converted to equivalents of functional groups able to react with carboxyl groups in the cross-linking agent, being 0.3 to 3 times equivalents of the total content of both the carboxyl groups of the nitrile copolymer rubber (A) and the acryl-based polymer (B) is used. According to the present invention, a cross-linkable rubber composition giving a cross-linked product superior in not only mechanical property, such as tensile strength and low compression set, and oil resistance, but also high weathering resistance, such as dynamic ozone resistance, and high mechanical property, such as flexural fatigue resistance can be provided.

Owner:ZEON CORP

Braided rope, suitable to be used as a towing warp, comprising changing properties in the length direction thereof

Disclosed is a tow warp construction and a process for forming such tow warp construction where such tow warp construction has a longer life span, that is retains its useful dimensions and characteristics longer than known tow warp constructions and consequently has a longer useful life span than known tow warp constructions. Most broadly the construction of the tow warp construction of the present disclosure and process for forming such includes gradually and progressively introducing fibers from a second group of fibers (or “second group of linear elements”) into an otherwise conventional stranding process where fibers from a first group of fibers (or “first group of linear elements”) are being stranded to form strands (or “third group of linear elements”), so as to either or both increase the diameter of the strands and / or substitute the first group of fibers by fibers from the second group of fibers, so as to: a) in the first instance, increase the diameter of the formed strands and subsequently of a strength member formed of the strands, especially for increasing the diameter and strength of the tow warp's strength member in and about the splice braid zone where it connects to a towed object such as a paravane; and b) in the second instance, substitute in a predetermined region on the long dimension of the strands and subsequently in a predetermined region on a long dimension of a strength member formed of the strands fibers of higher creep and / or lower melting points by fibers of lower creep and / or higher melting points, especially for increasing the resistance of the tow warps strength member to bending fatigue.

Owner:HAMPIDJAN

Crosslinkabel rubber composition and crosslinked object

InactiveCN1860171AExcellent mechanical propertiesExcellent dynamic ozone resistancePolymer scienceCompression set

A crosslinkable rubber composition which comprises a mixture consisting of a nitrile copolymer rubber (A) having a carboxy content of 2x10<-3> to 1x10<-1> eq / 100 g and an acrylic polymer (B) having a carboxy content of 4x10<-4> to 1x10<-1> eq / 100 g in a proportion of from 40 / 60 to 90 / 10 by weight and, incorporated in the mixture, a crosslinking agent (C) capable of forming crosslinks with carboxy groups of each of the nitrile copolymer rubber (A) and the acrylic polymer (B), wherein the amount of the crosslinking agent (C) incorporated, in terms of the amount of that functional group of the crosslinking agent which is reactive with carboxy groups, is 0.3 to 3 equivalents to the sum of the carboxy groups of each of the nitrile copolymer rubber (A) and the acrylic polymer (B). The crosslinkable rubber composition gives a crosslinked object which is excellent not only in mechanical properties including tensile strength and reduced compression set and oil resistance but in a high degree of weatherability including dynamic ozone resistance and a high degree of mechanical properties including flexural fatigue resistance.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com