Control rod drive wire displacement compensation device, forming mold and forming method of control rod drive wire displacement compensation device

A technology for displacement compensation and forming molds, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, mechanical equipment, etc., and can solve the problems of inability to perform three-dimensional displacement at the same time, complex bellows structure, and large volume. Achieve the effect of improving displacement compensation ability and anti-fatigue performance, improving anti-expansion and bending fatigue performance, and requiring low installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

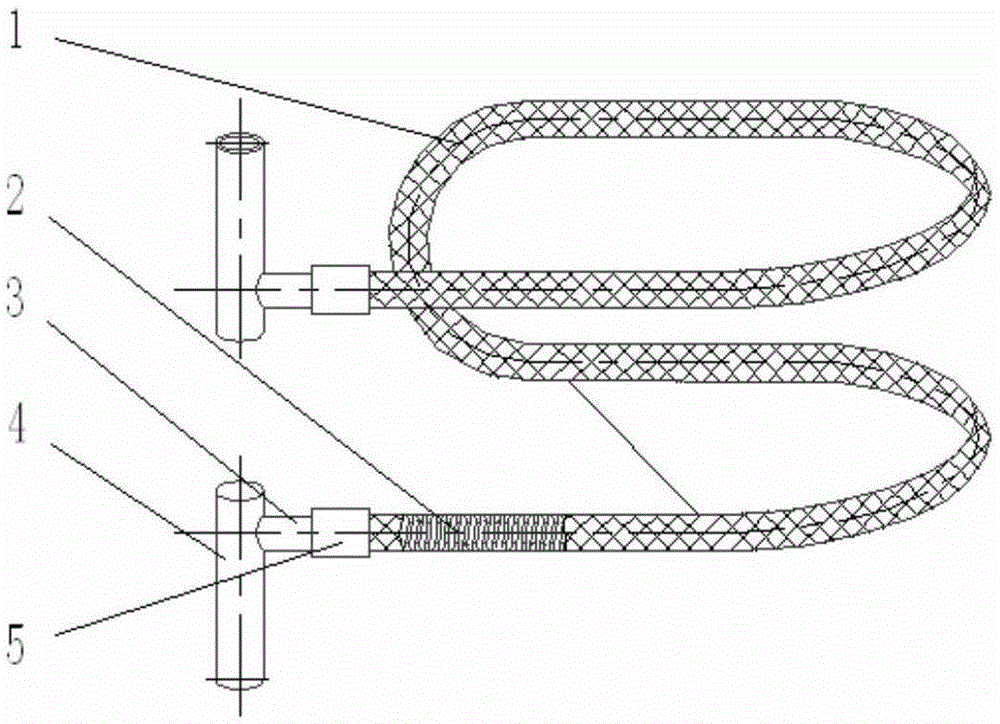

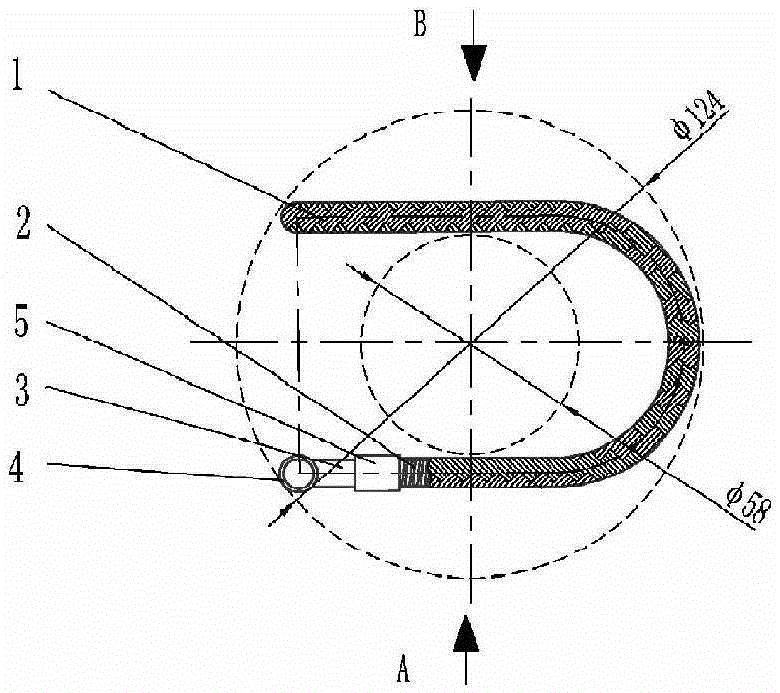

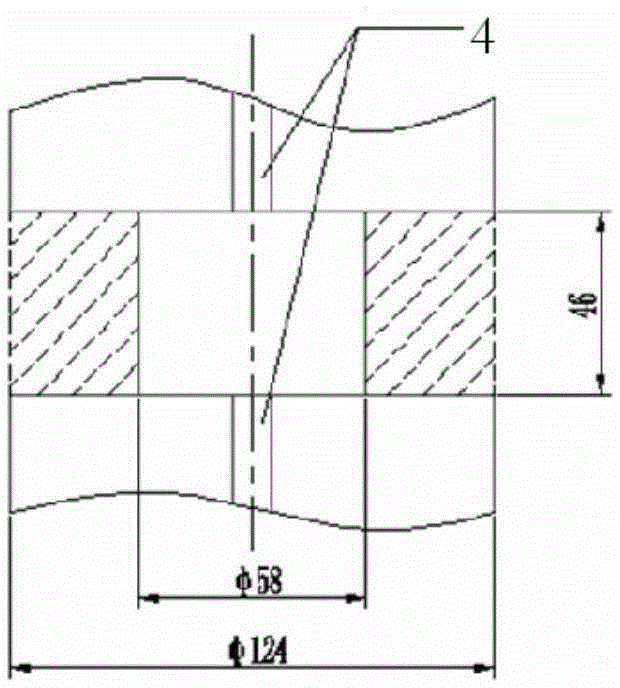

[0045] A control rod drive line displacement compensation device of this embodiment, such as Figure 1-6 As shown, it is installed in a circular column space with an outer diameter of φ124mm, an inner diameter of φ58mm, and a height of 46mm. It includes a metal corrugated pipe 2 and a steel mesh sleeve 1 and a metal corrugated pipe 2 wrapped around the metal corrugated pipe 2. The two ends of the metal bellows are respectively connected to the vertical ferrule joint 4 through seamless joints, and the two ends of the metal bellows 2 respectively extend from the corresponding seamless joints 3 in the horizontal direction, and are bent by a vertical semicircular arc to form a vertical U-shaped bends 2-1, 2-3; and then align with each other through horizontal semi-circular arc bending to form a horizontal U-shaped bend 2-2; the ferrule joint 4 is welded to the control rod pipeline. The position and direction of the ferrule joint 4 are allowed to have a certain amount of deviation, w...

Embodiment 2

[0070] This embodiment provides a control rod drive line displacement compensation device, such as Figure 7-9 As shown, among the three continuous curved shapes of the metal bellows in the control rod drive line displacement compensation device of this embodiment, the second curved shape 2-4 is an Ω shape. The other structure, forming mold, and heating method are basically the same as those of the first embodiment. It is installed in a circular column space with an outer diameter of φ150mm, an inner diameter of φ60mm, and a height of 50mm.

[0071] The second curved Ω-shaped bend is composed of a 210°~240° big arc and two 15°~30° small arcs connected to the two ends of the arc. The bending radius of the small arcs at both ends is larger than the center of the big circle. 1.5 times the angle arc, because the Ω-shaped bend has a longer arc segment with a large central angle under the same bending radius, the compensation device with the Ω-shaped bend has a larger compensation dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com