Novel high-strength low-rigidity metal expansion joint

A metal expansion and high-strength technology, applied in the field of expansion joints, can solve the problems of reduced elastic properties of bellows, reduced strength of bellows under extrusion stress, increased stiffness, etc., and achieves the effect of improving displacement compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

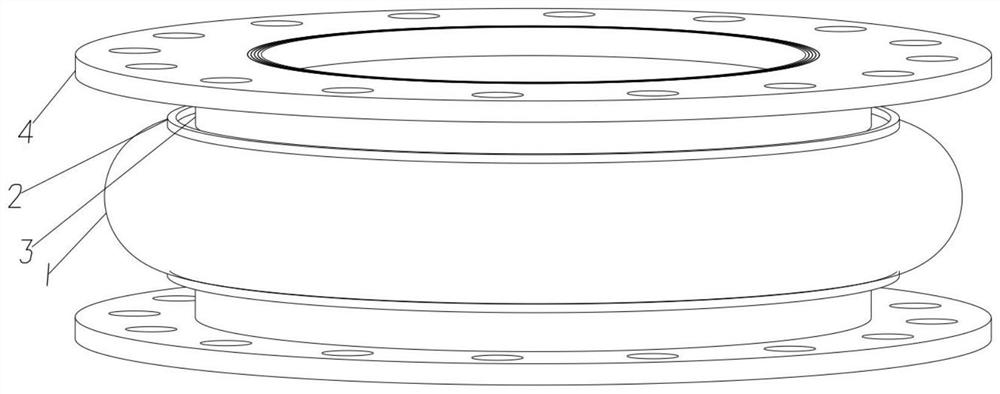

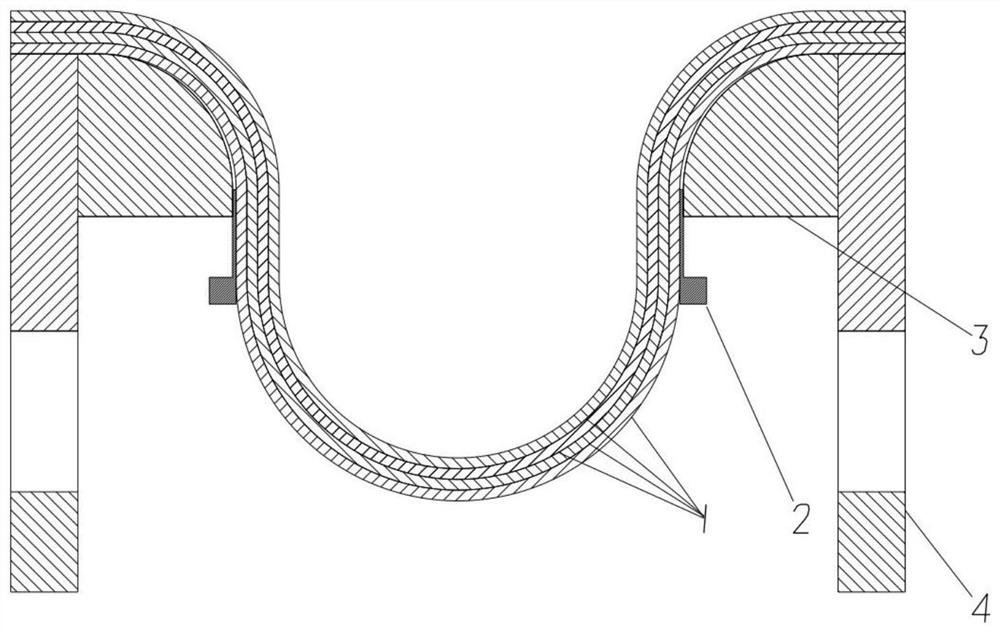

[0017] Specific embodiments of the present invention such as figure 1 and figure 2 As shown, a new type of high-strength and low-rigidity metal expansion joint includes multilayer bellows, flanges, gaskets and reinforcing rings. The multilayer bellows includes four layers of corrugated plates, and each layer of corrugated plates is tightly connected; The end face of the flange is fixedly connected with the end face of the multi-layer corrugated pipe, and the reinforcing ring is arranged at the joint between the flange and the multi-layer corrugated pipe. During processing and assembly, it is controlled by the pads.

[0018] The reinforcing ring 3 and the flange 4 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com