Patents

Literature

149 results about "Metal expansion joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal expansion joints (also called compensators) are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. Expansion joints have usage in various sectors, like energy productions, paper industry, chemical industry, water treatment, oil and gas. Everywhere where exist pipelines and occurs thermal movements or vibration, then expansion joints can be used.

Expansion joint for longitudinal load transfer

An expansion joint design for supporting transfer loads. The system includes an elongated core and at least one longitudinal load-transfer member which are bonded together.

Owner:SCHUL INT COMPANY

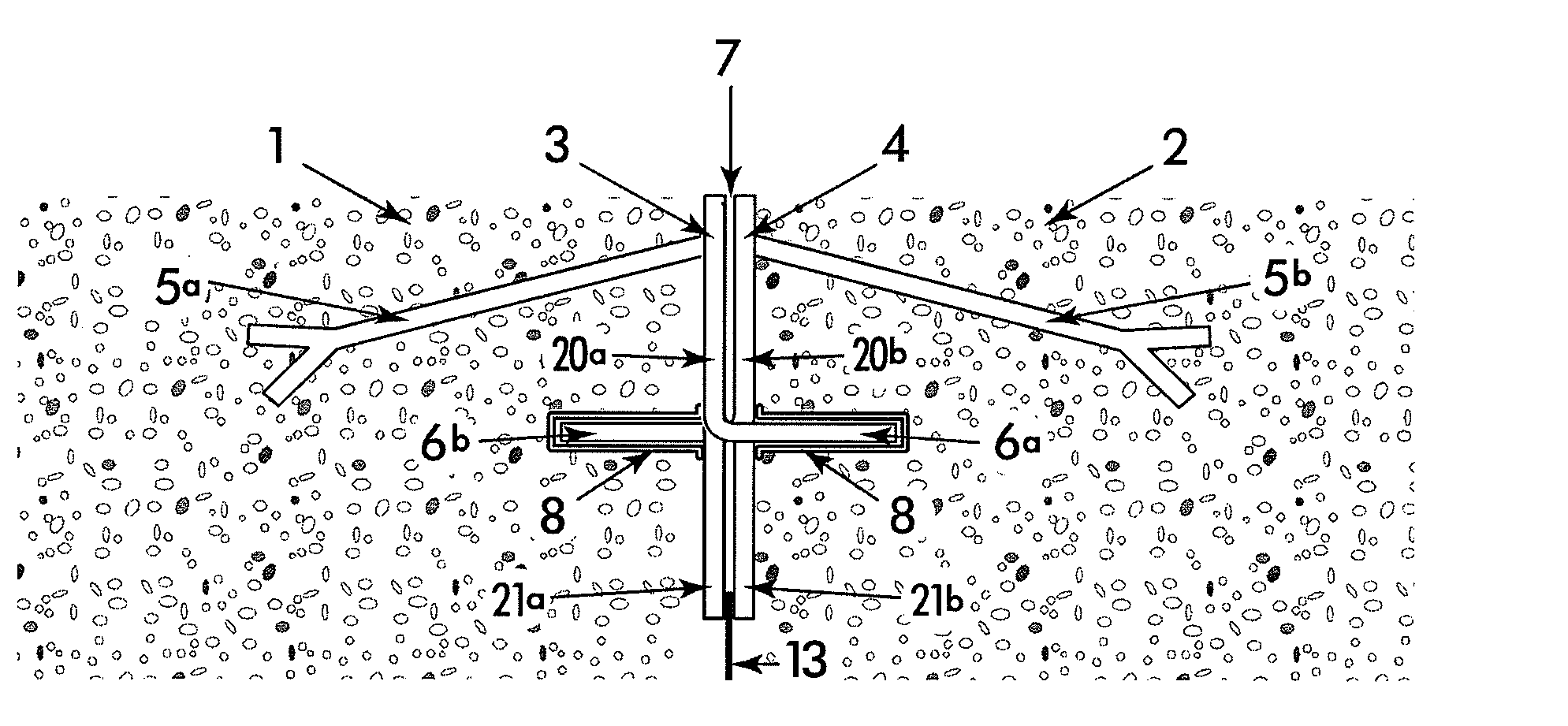

Device for equipping an expansion joint, in particular an expansion joint between concrete slabs

Owner:PLAKEBETON

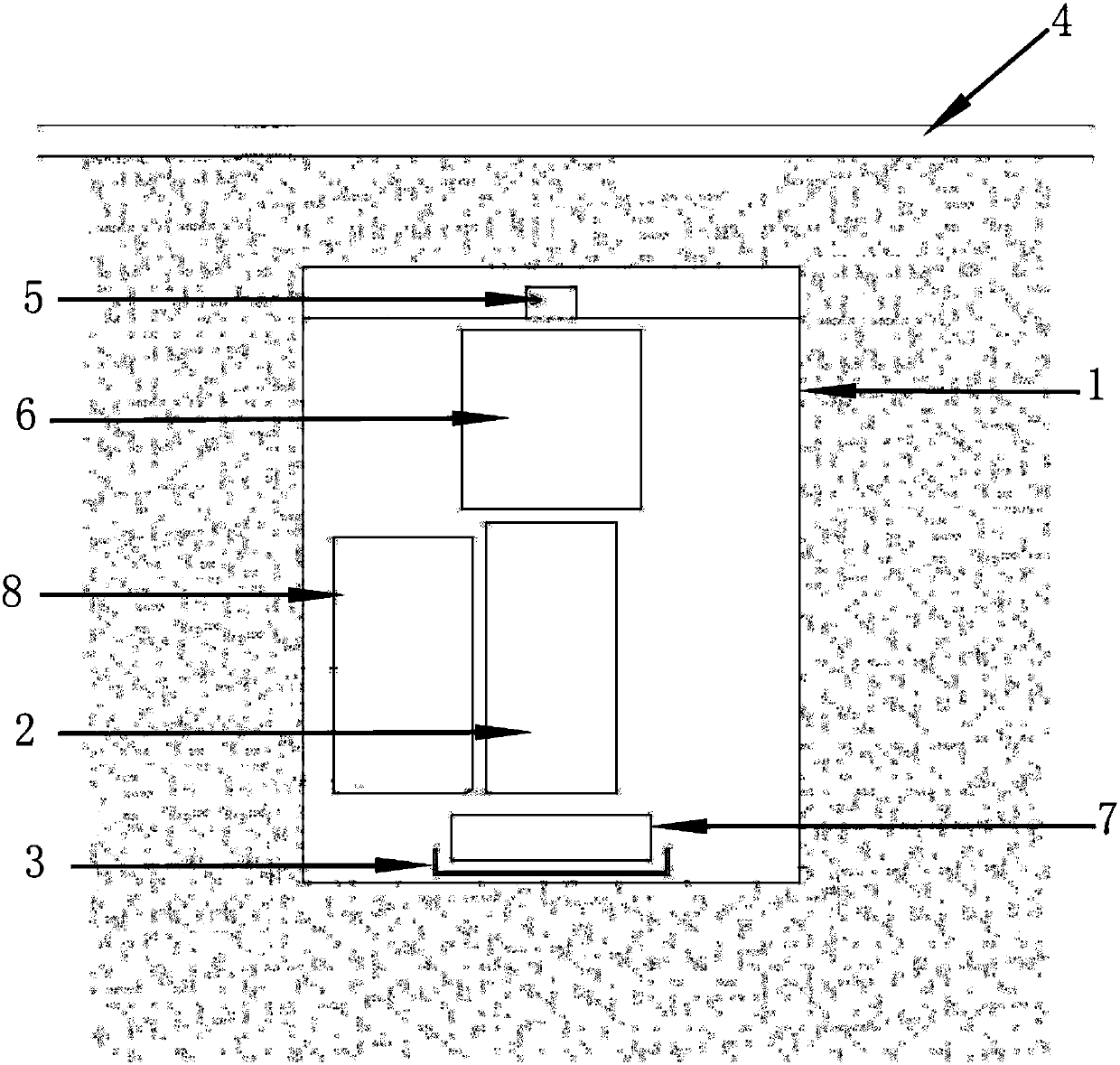

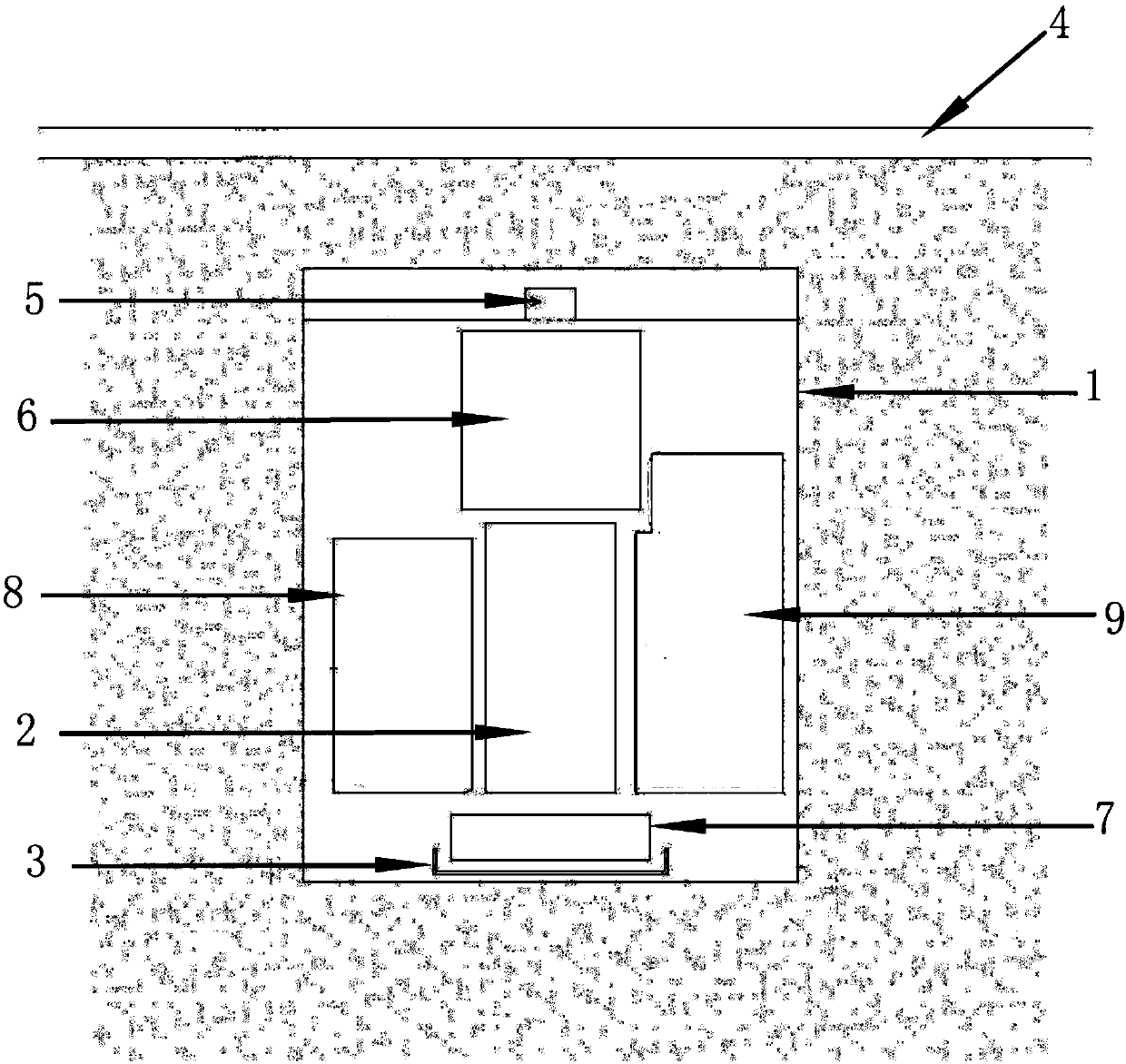

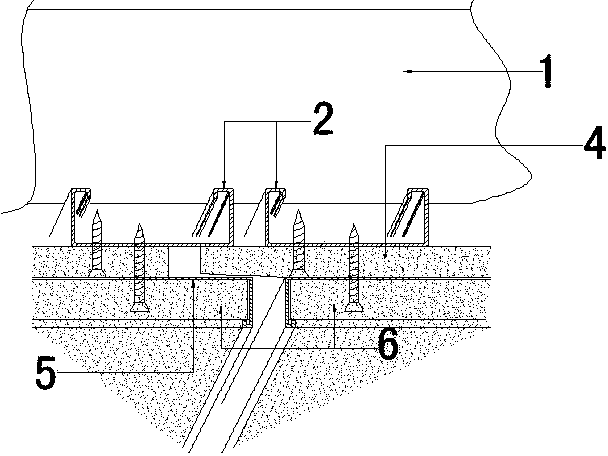

Double-water stop structure for concrete expansion joint and manufacturing and construction method for double-water stop structure

InactiveCN103821180ASolve the leakLow costArtificial islandsUnderground chambersStructure of the EarthUnderwater

The invention relates to an underground (underwater) building waterproof device, in particular to a double-water stop structure for a concrete expansion joint and a manufacturing and construction method for the double-water stop structure. The double-water stop structure comprises two deformation sheets and channel beams. The double-water stop structure is characterized in that a concrete section is provided with the two deformation sheets; the two deformation sheets are longitudinally arranged at a set distance; half of each deformation sheet is embedded in primary concrete, and the other half of each deformation sheet protrudes out of the concrete section, and the other halves of the two deformation sheets are respectively arranged in the corresponding channel beams; asphalt fills each channel beam; an asphaltic felt is arranged on open surfaces of the channel beams and a primary concrete section; exposed fixed parts are removed after the asphalt is cooled, and then, secondary concrete is set. According to the double-water stop structure disclosed by the invention, the water seepage problem caused by differential settlement or faulting of a stratum in hydraulic engineering can be solved; the labor can also be reduced, and the construction period can also be shortened.

Owner:SHANDONG JIAOTONG UNIV

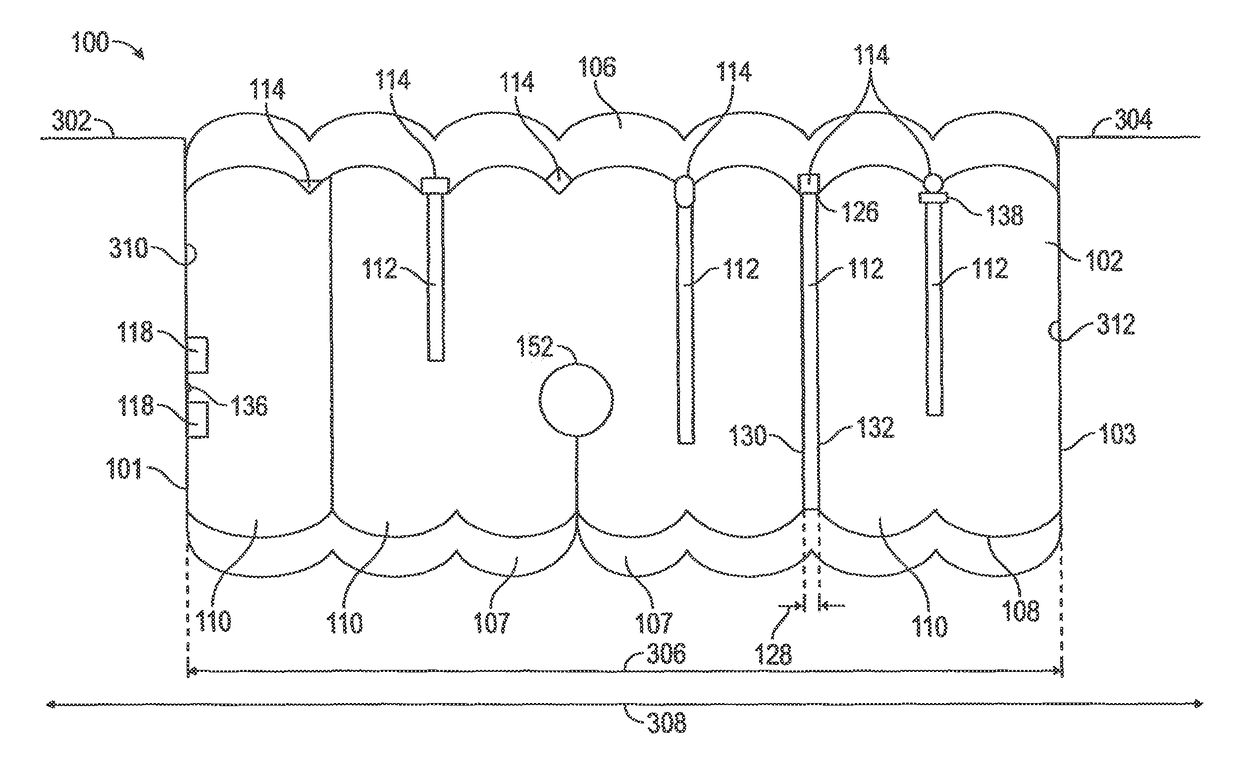

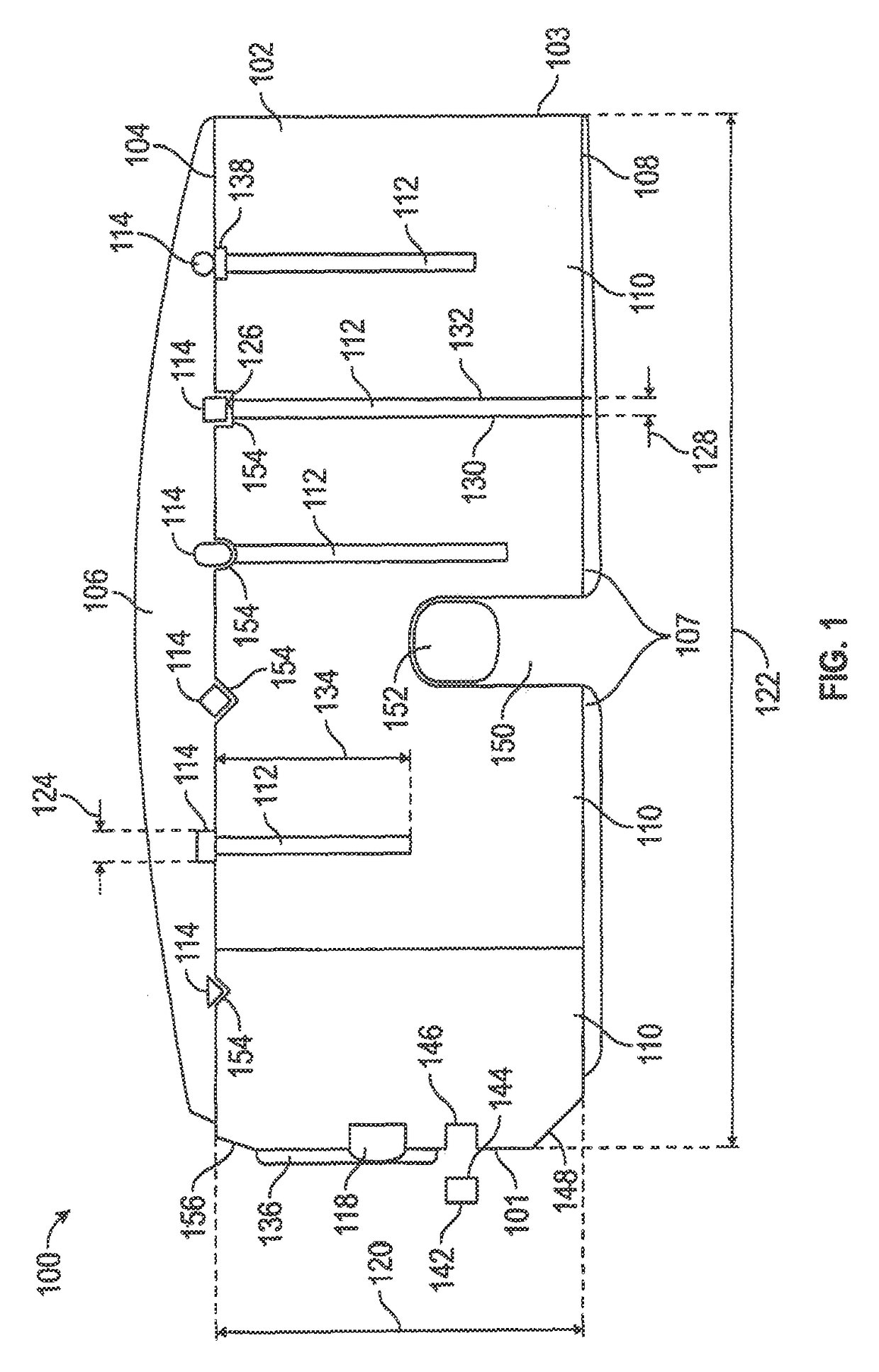

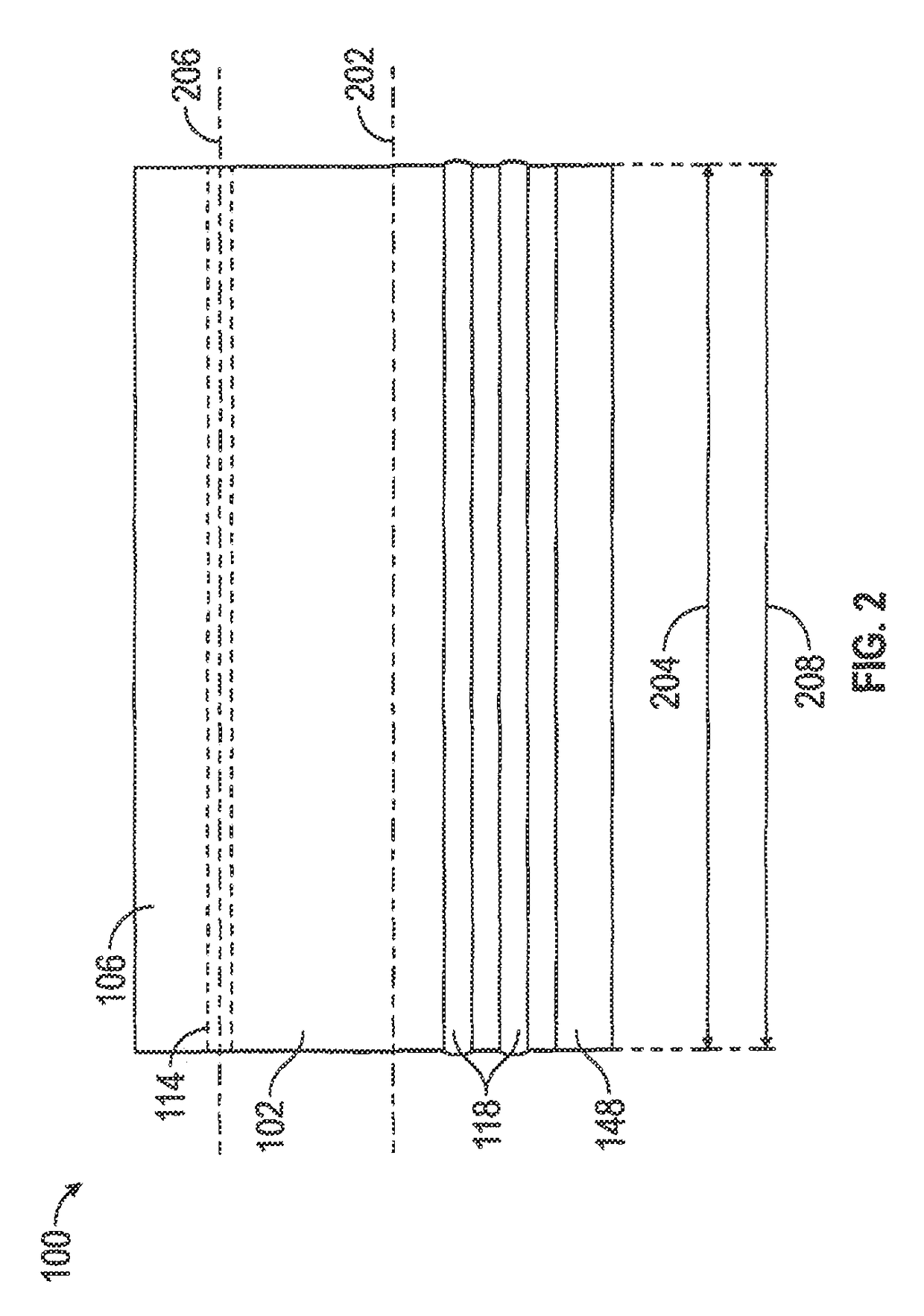

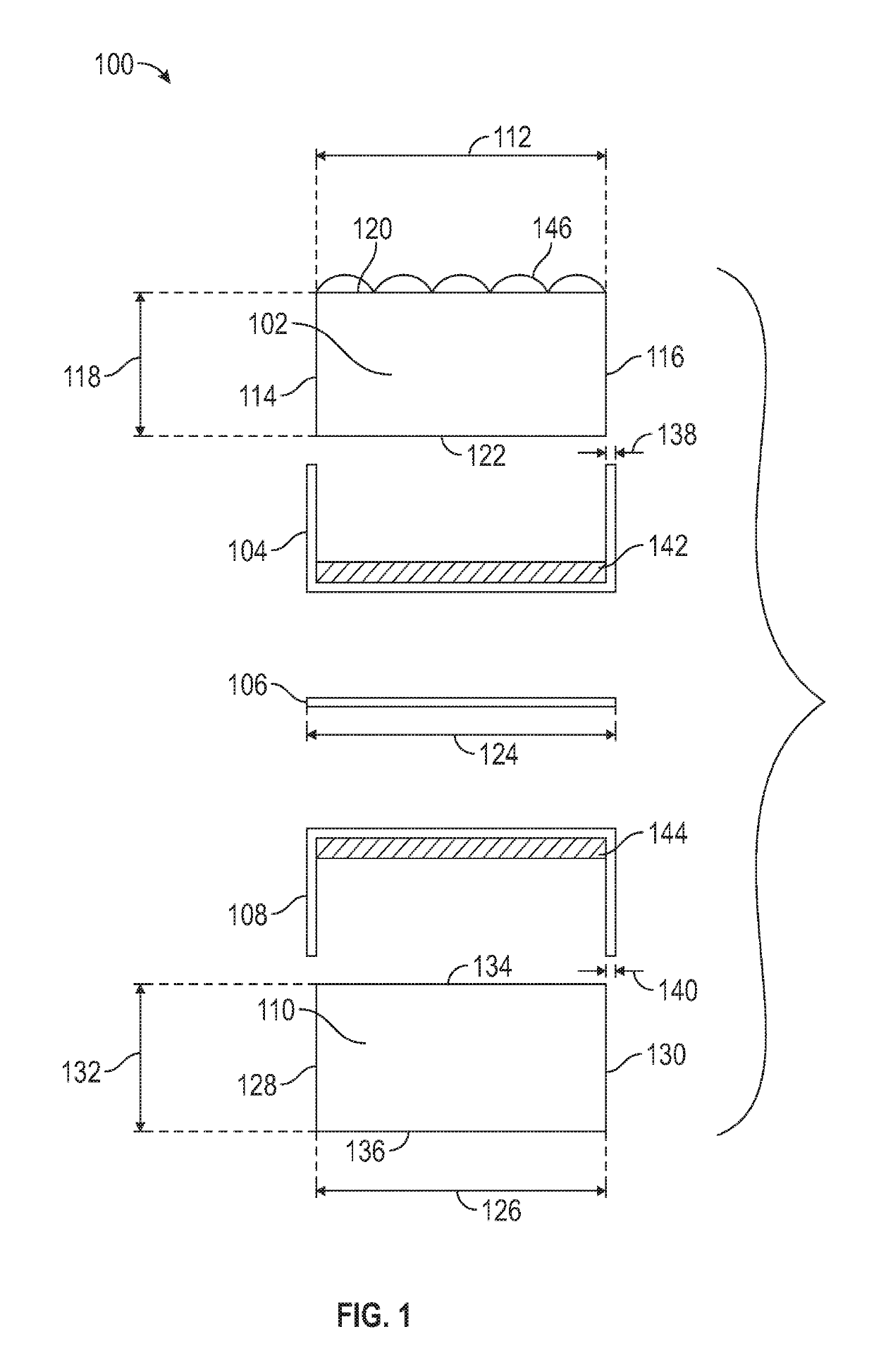

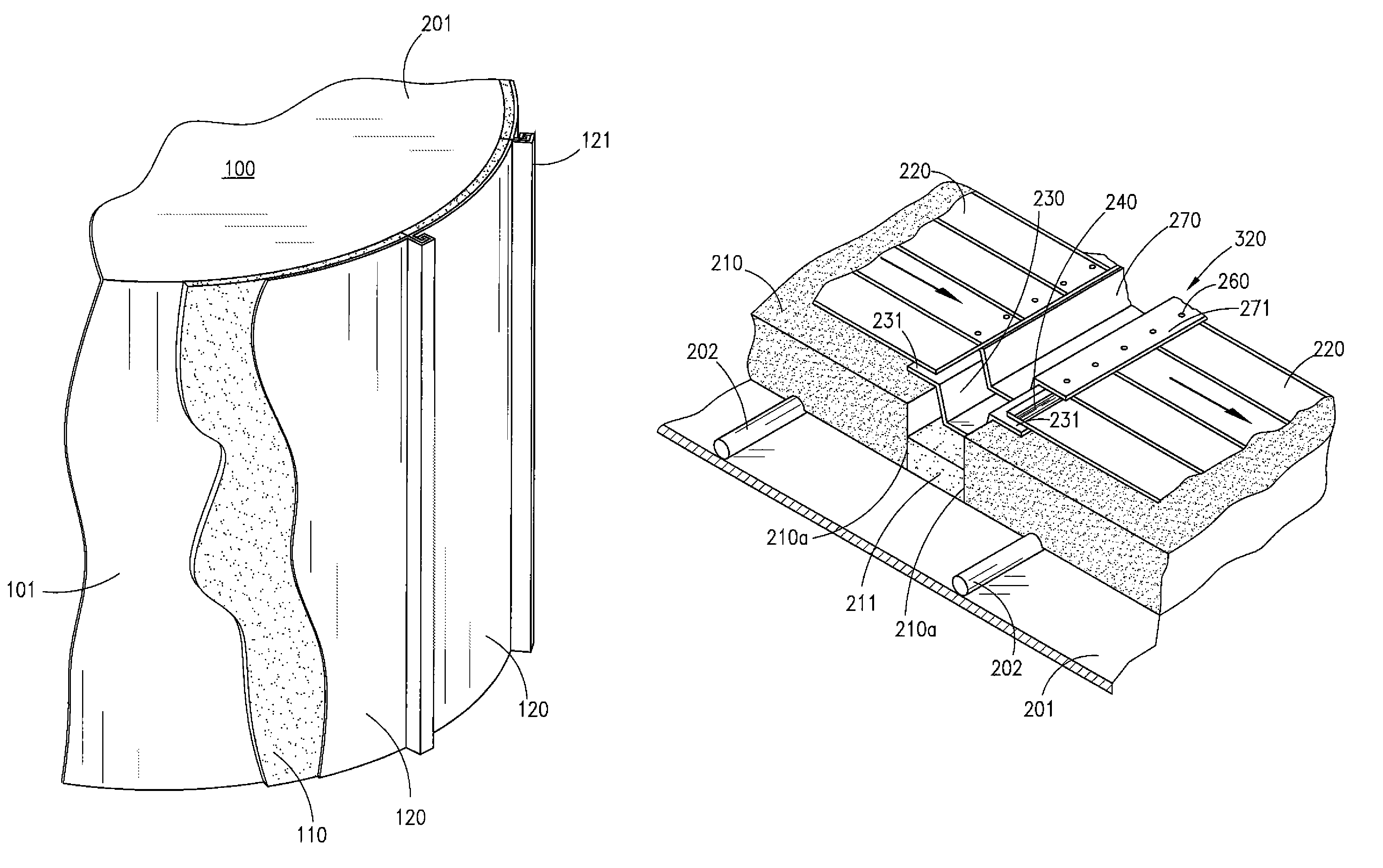

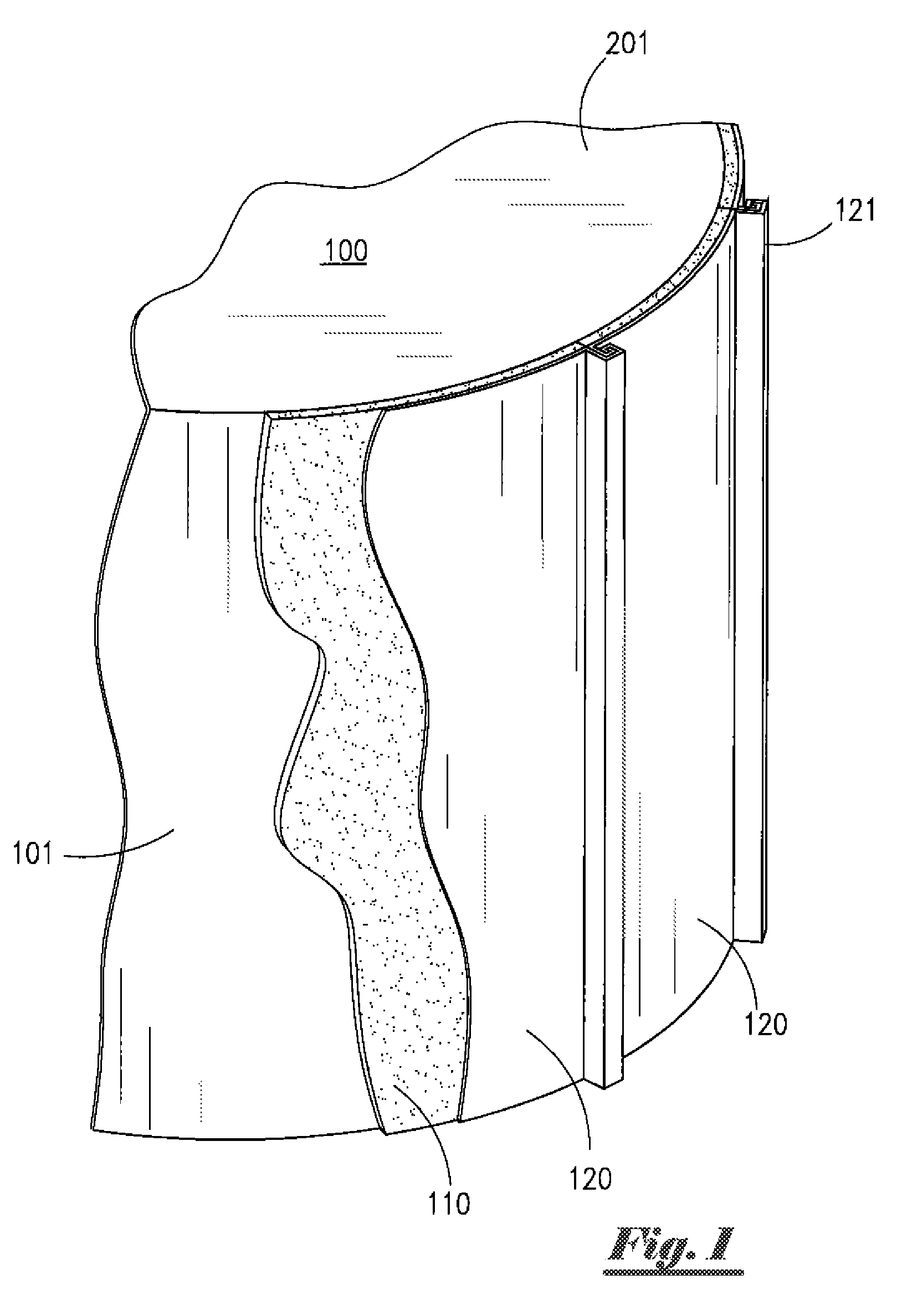

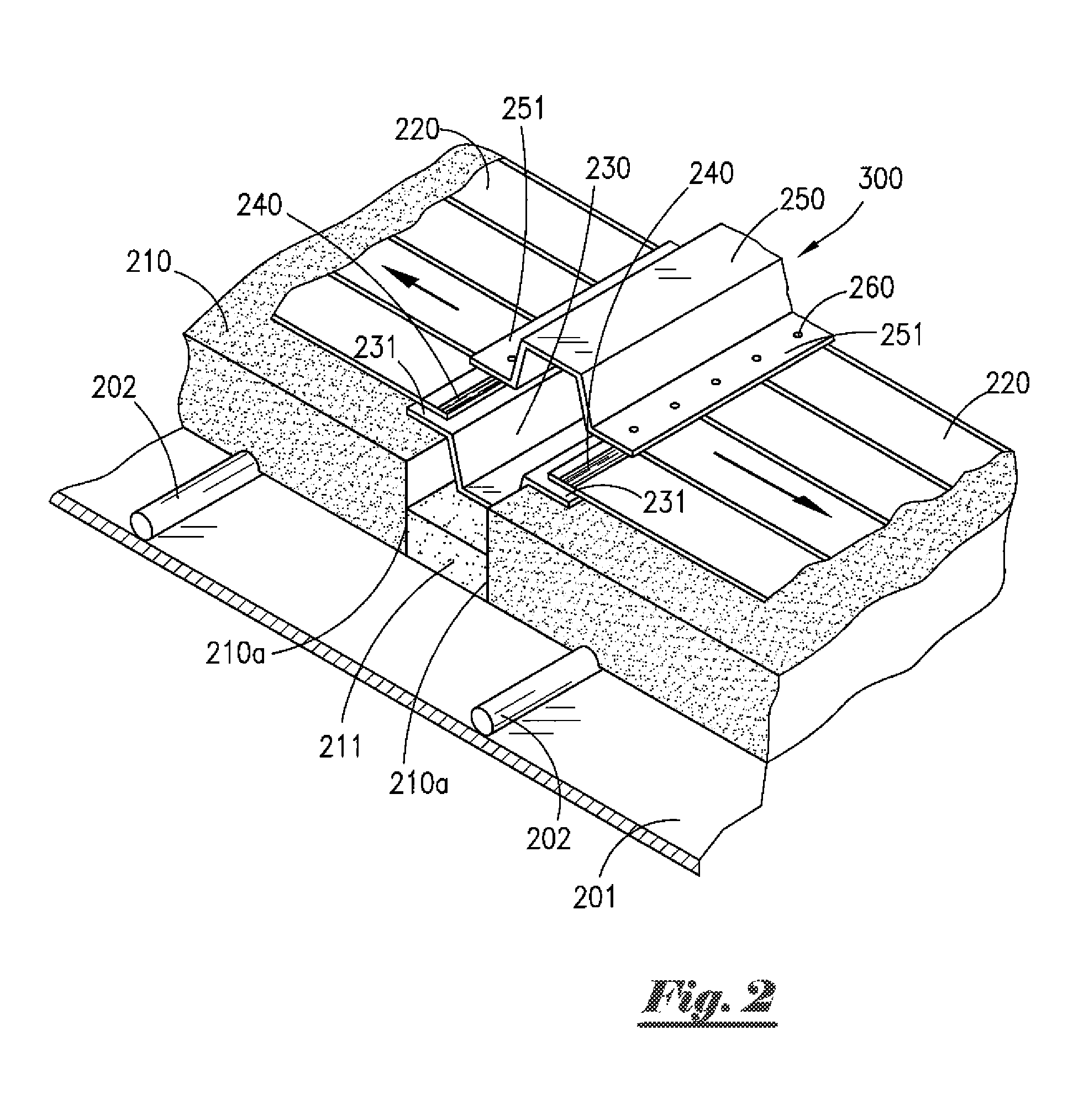

Expansion joint system with flexible sheeting

The present disclosure relates generally to systems for providing a durable water-resistant and fire-resistant foam-based seal in the joint between adjacent panels. An expansion joint seal, which may be fire-resistant and / or water-resistant, is provided which includes one or more body members, a fire retardant member, which may be of an intumescent member, interspersed within the body member or members, a plurality of resilient members to provide a spring recovery force and fire resistance, and a connector of at least two of the resilient members, which connect each of the resilient members to a cover plant or may connect the two resilient members to one another.

Owner:SCHUL INT COMPANY

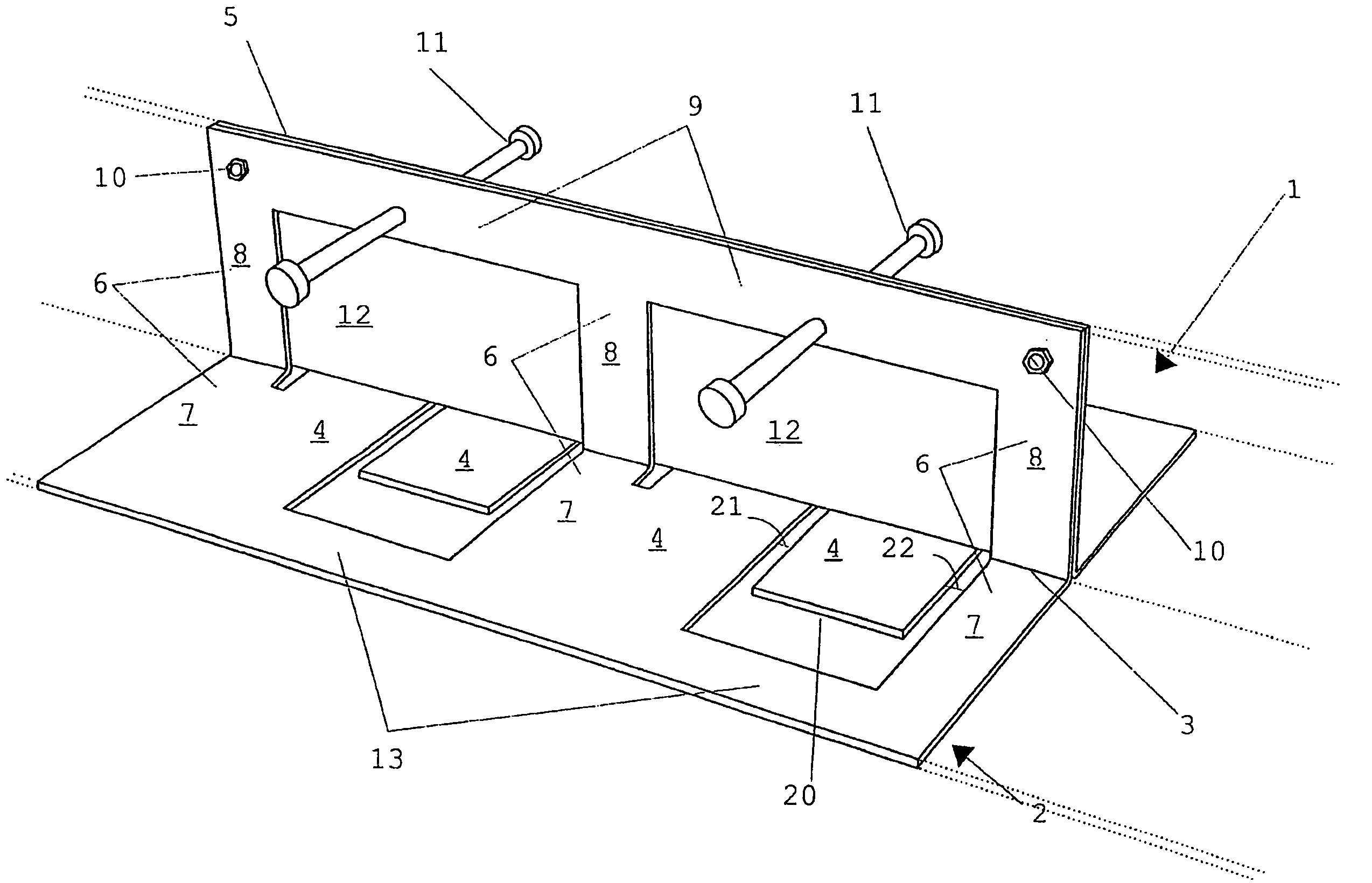

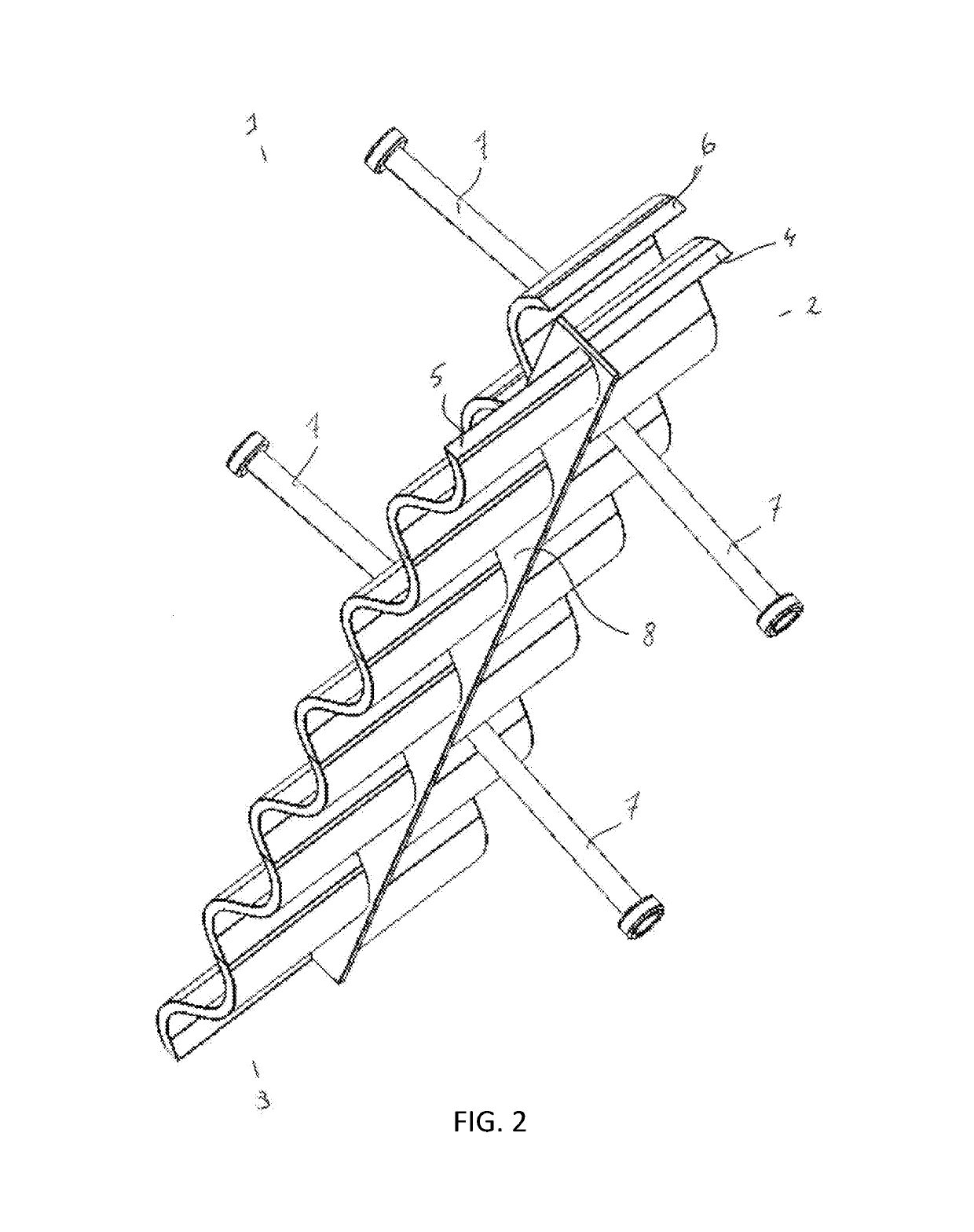

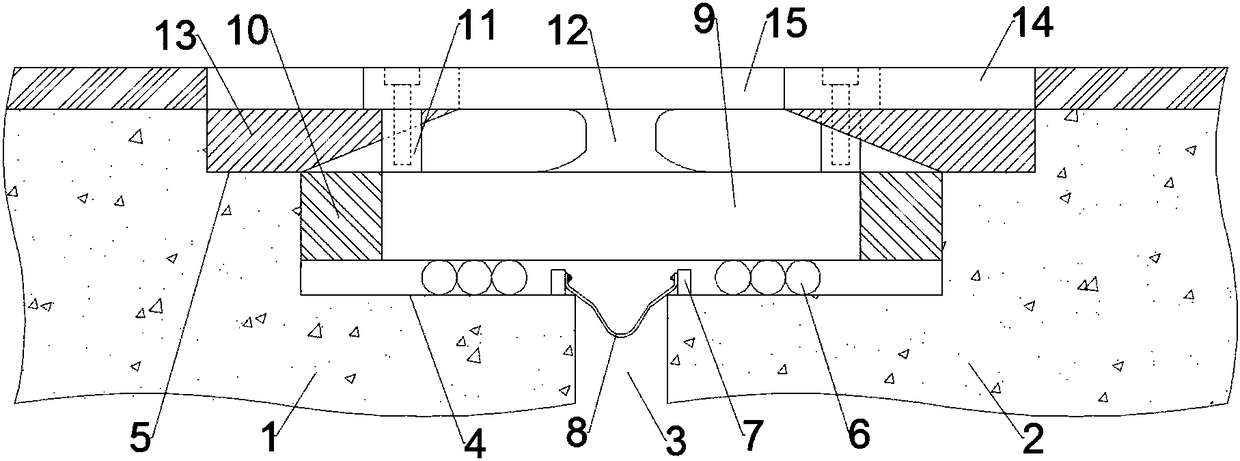

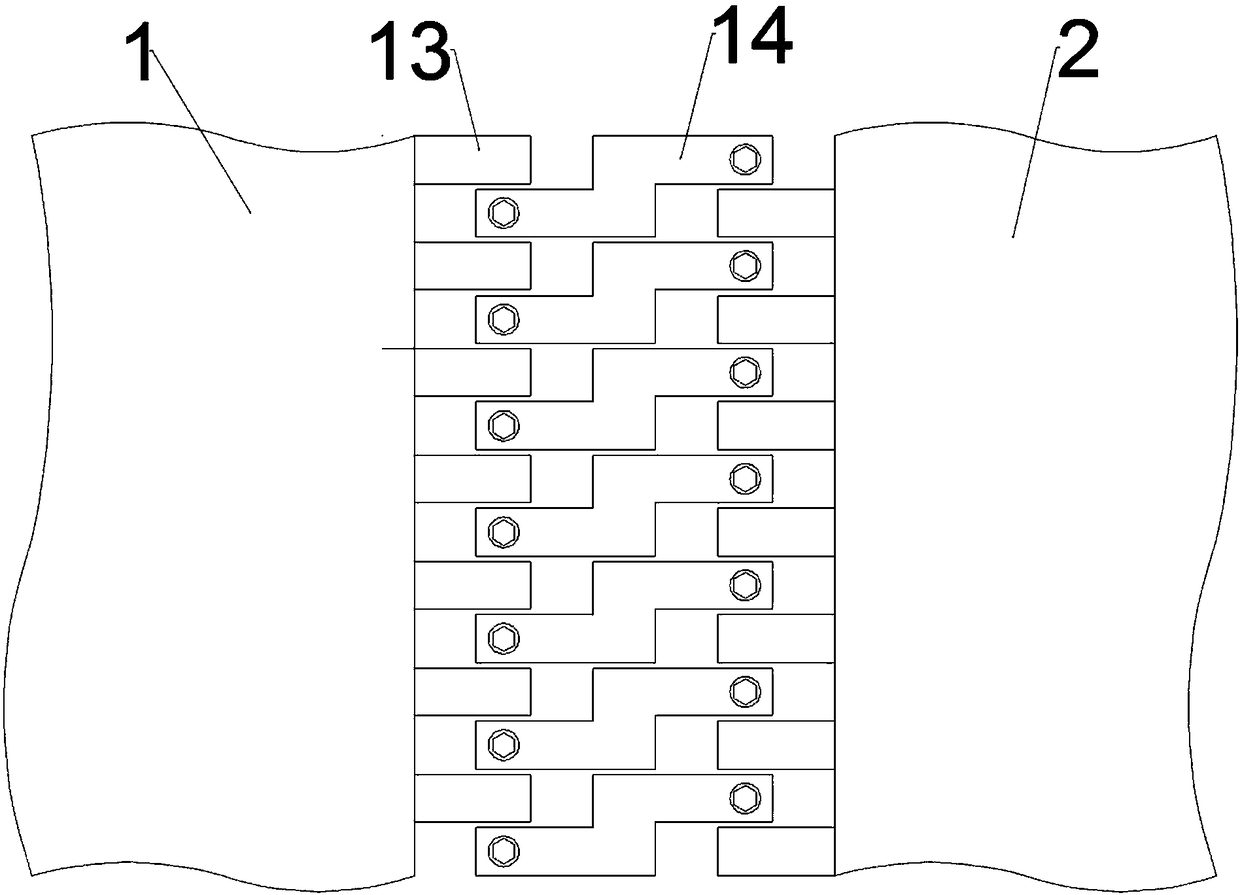

Device for equipping an expansion joint between concrete slabs

InactiveUS20080222984A1Ensure continuityPermit some movementPaving detailsBuilding insulationsEngineeringMetal expansion joint

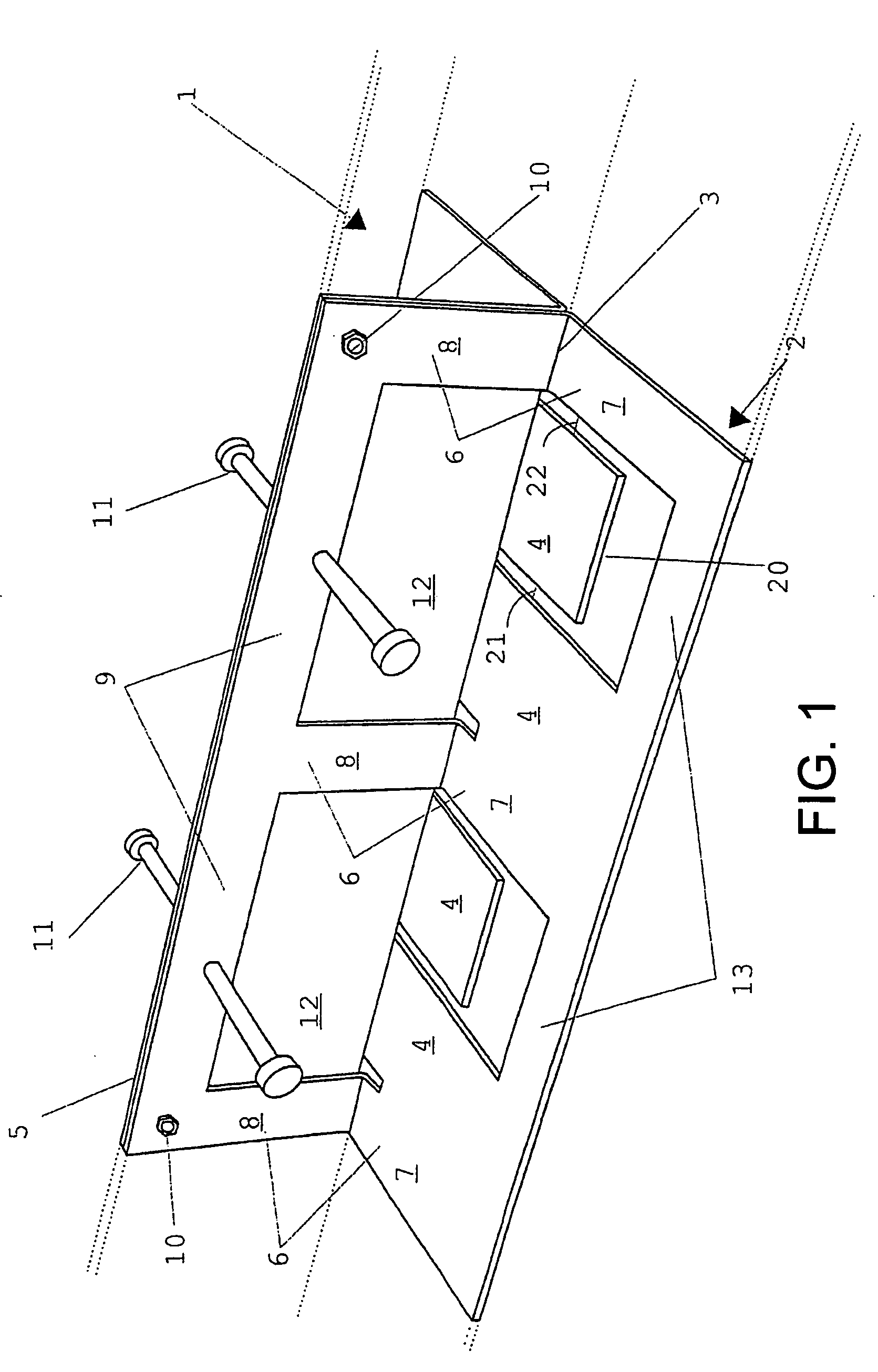

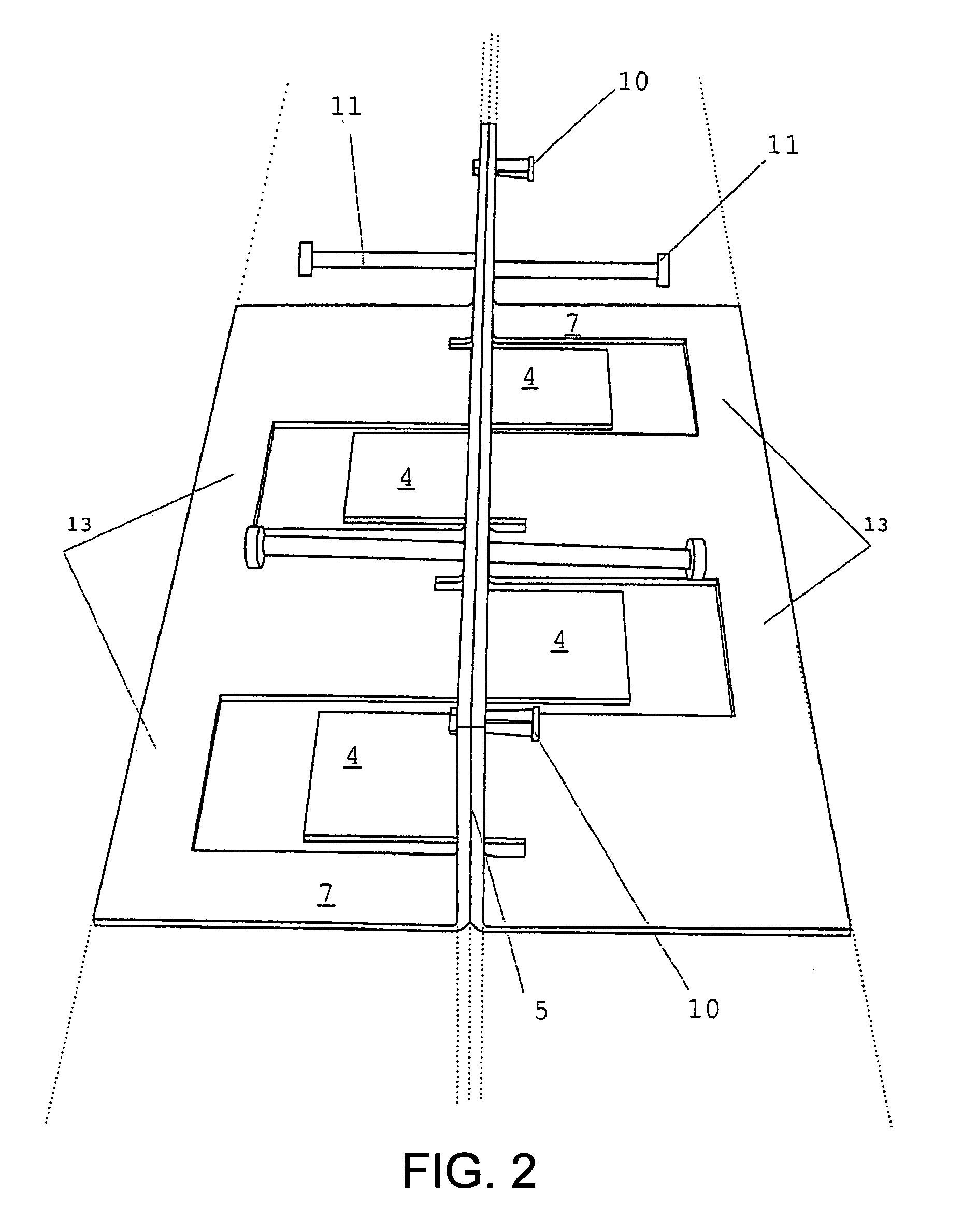

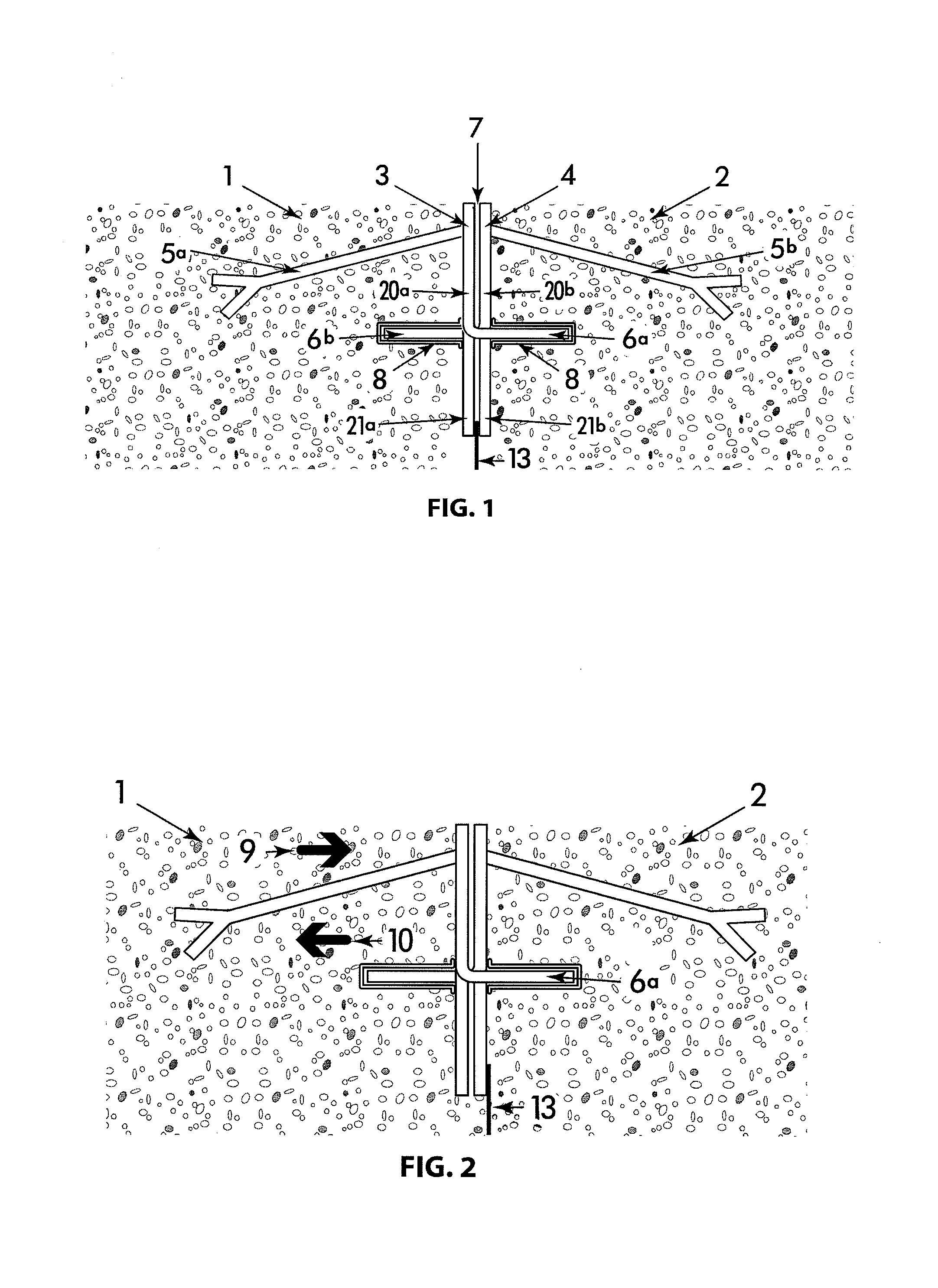

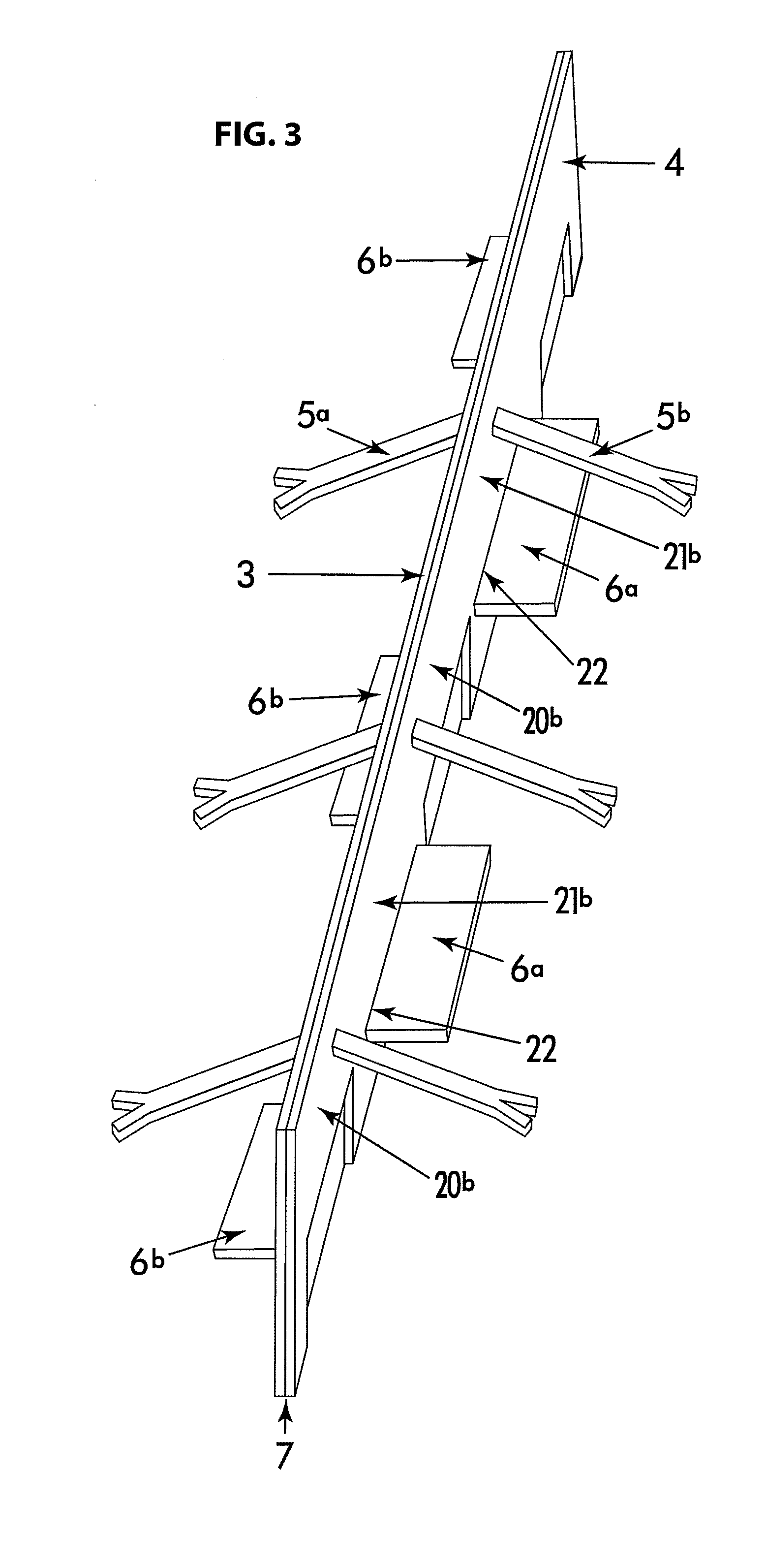

A device equips an expansion joint between slabs in building constructions, in particular concrete slabs. According to a first embodiment, the device is made up of two profiles (3,4) that fit together in such a way that the elements passing through the joint between the slabs are discontinuous and have a bracket shape anchored by plate dowel anchors. According to a second embodiment, the device has a single profile, the lower part of which is bent alternately in one slab part and the other on each side of the joint.

Owner:PLAKABETON

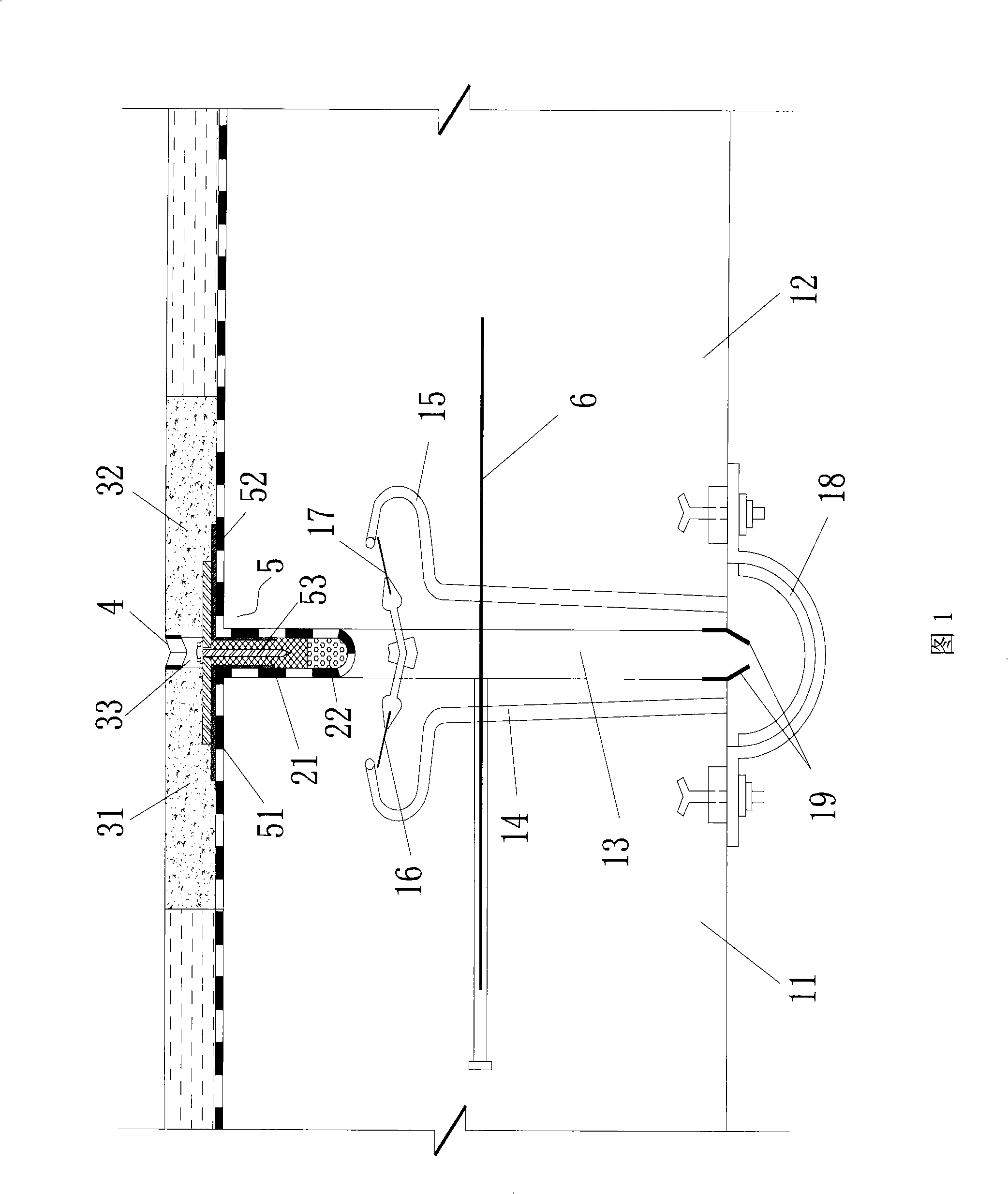

Water proof method for underground structure top board expansion joint also serving as urban roads base and the structure

ActiveCN101307622AImprove waterproof performanceGuaranteed waterproof performanceArtificial islandsUnderwater structuresEngineeringJoint spaces

The invention discloses a dilatation joint waterproof method for an underground structure roof which is used as an urban roadbase as well, wherein, a dilatation joint space is arranged between a first roof and a second roof of an underground structure. The method comprises the following steps that: firstly, a grouting pipe and a steel-edged rubber watertight strip are respectively arranged inside the first roof and the second roof; secondly, a drain tank is arranged under the rubber watertight strip; thirdly, a 'U'-shaped waterproof roll is arranged inside the dilatation joint space, and rubber strips and water absorption materials are filled into the 'U'-shaped waterproof roll; a stainless steel pressure plate is also arranged on the 'U'-shaped waterproof roll; fourthly, an elastic concrete layer is laid on the 'U'-shaped waterproof roll, and 'W'-shaped rubber watertight strips are glued in gaps of the elastic concrete layer. The invention also provides a dilatation joint waterproof structure. The dilatation joint waterproof method and the dilatation joint waterproof structure guarantee the waterproof effect in multi-angle and multi-layer form and greatly reduce the late maintenance cost.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

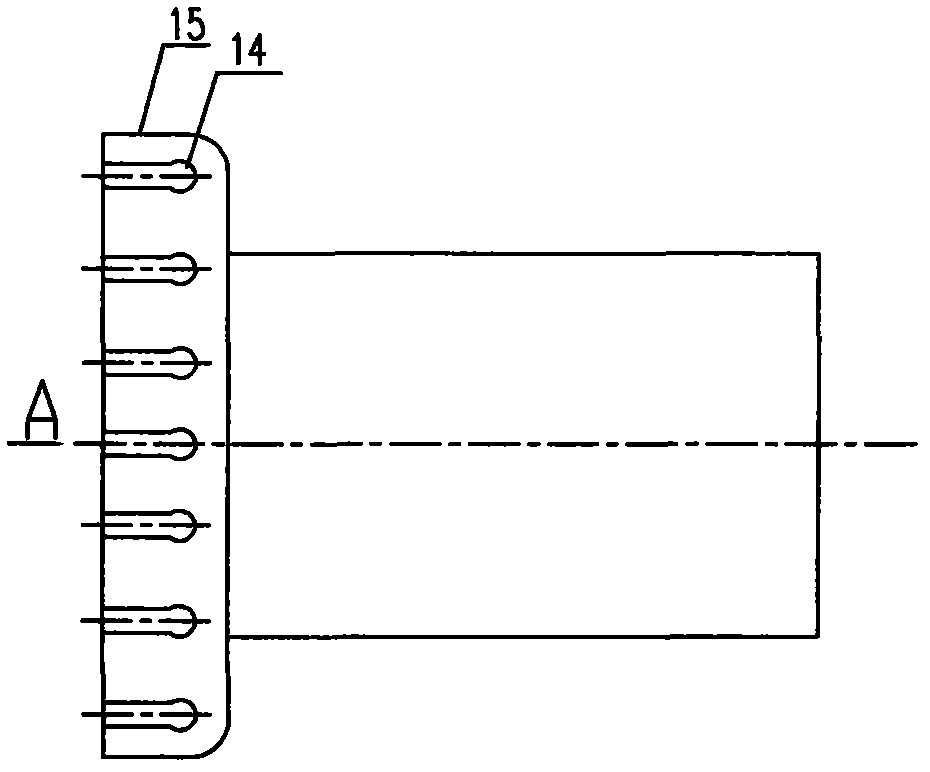

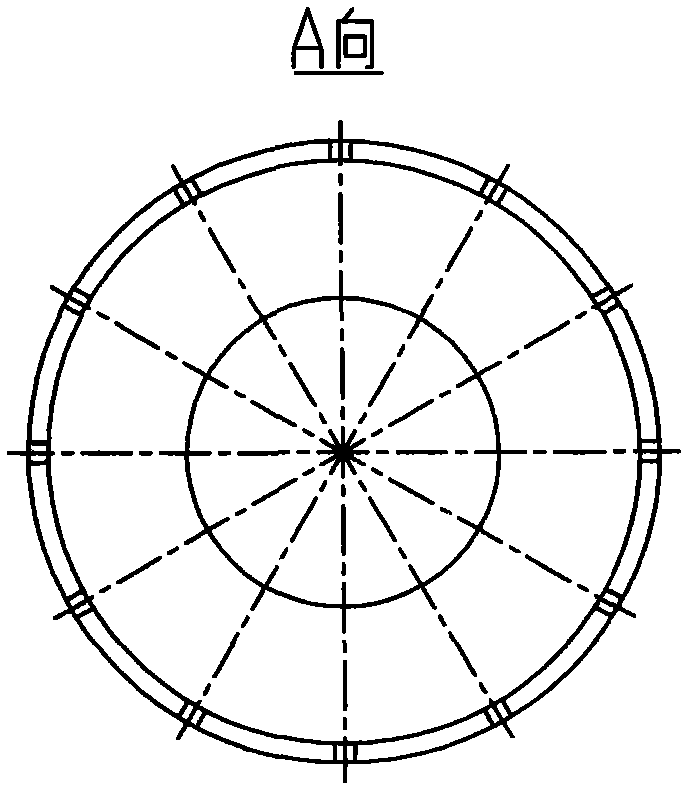

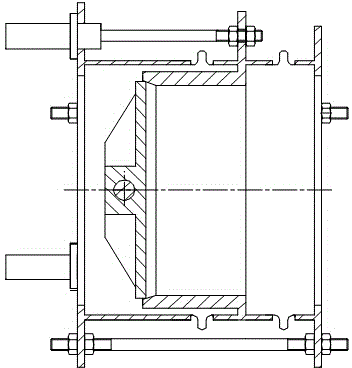

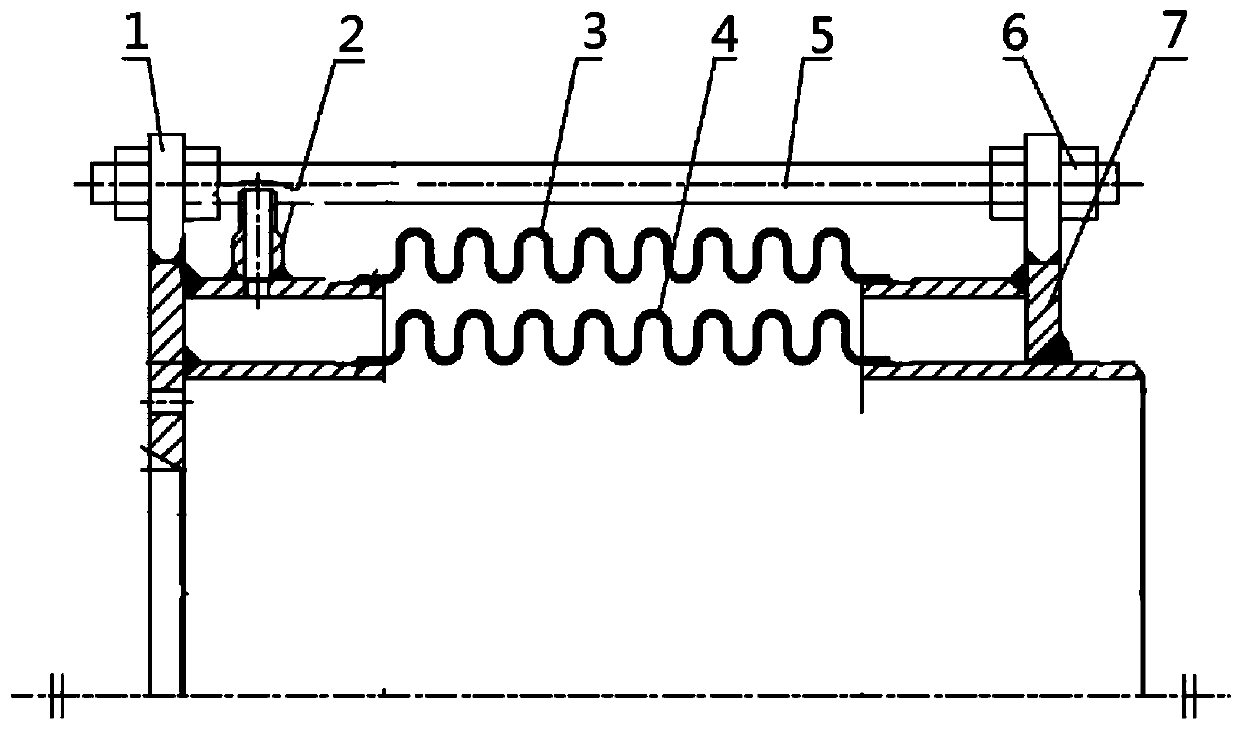

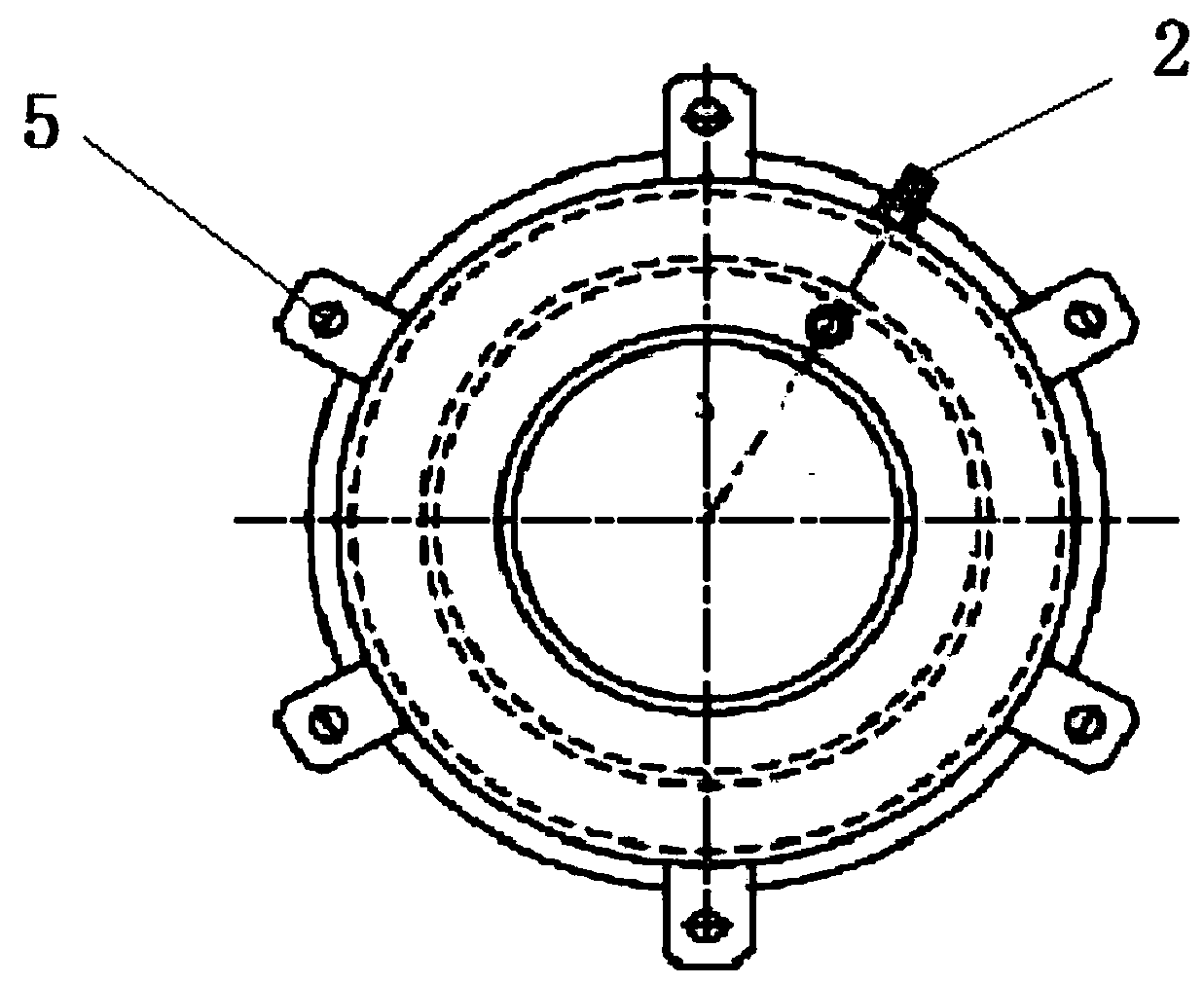

Guide cylinder structure applied on corrugated pipe expansion joint

InactiveCN102135218ANo distortionReasonable designPipeline expansion-compensationAxial displacementDistressing

The invention belongs to the technical field of petrochemical industry, and provides a guide cylinder structure applied on a corrugated pipe expansion joint. The front end of the guide cylinder is provided with a guide cylinder compensation ring (15); the outer side surface of the guide cylinder compensation ring (15) is provided with a plurality of distressing grooves (14) which are distributed along the circumference of a cylinder body; the distressing grooves (14) and the guide cylinder are axially consistent; the hoop stress generated by the heat expansion of the guide cylinder is reduced by the distressing grooves (14), thus the guide cylinder is not subjected to torsion and deformation; and the arc section of the guide cylinder compensation ring is jointed with the shell section of the corrugated pipe expansion joint, when the guide cylinder is expanded caused by heating, the arc transition section absorbs the radial displacement and axial displacement generated by the guide cylinder due to the expansion caused by heating, and absorbs the radial stress and axial stress generated by the guide cylinder due to the expansion caused by heating. According to the invention, through the distressing grooves distributed along the circumference of the cylinder body and the arc transition section of the cylinder body, thus the guide cylinder is not subjected to torsion and deformation when the guide cylinder works at high temperature, and the guide cylinder structure has the characteristics of reasonable design and simple structure.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

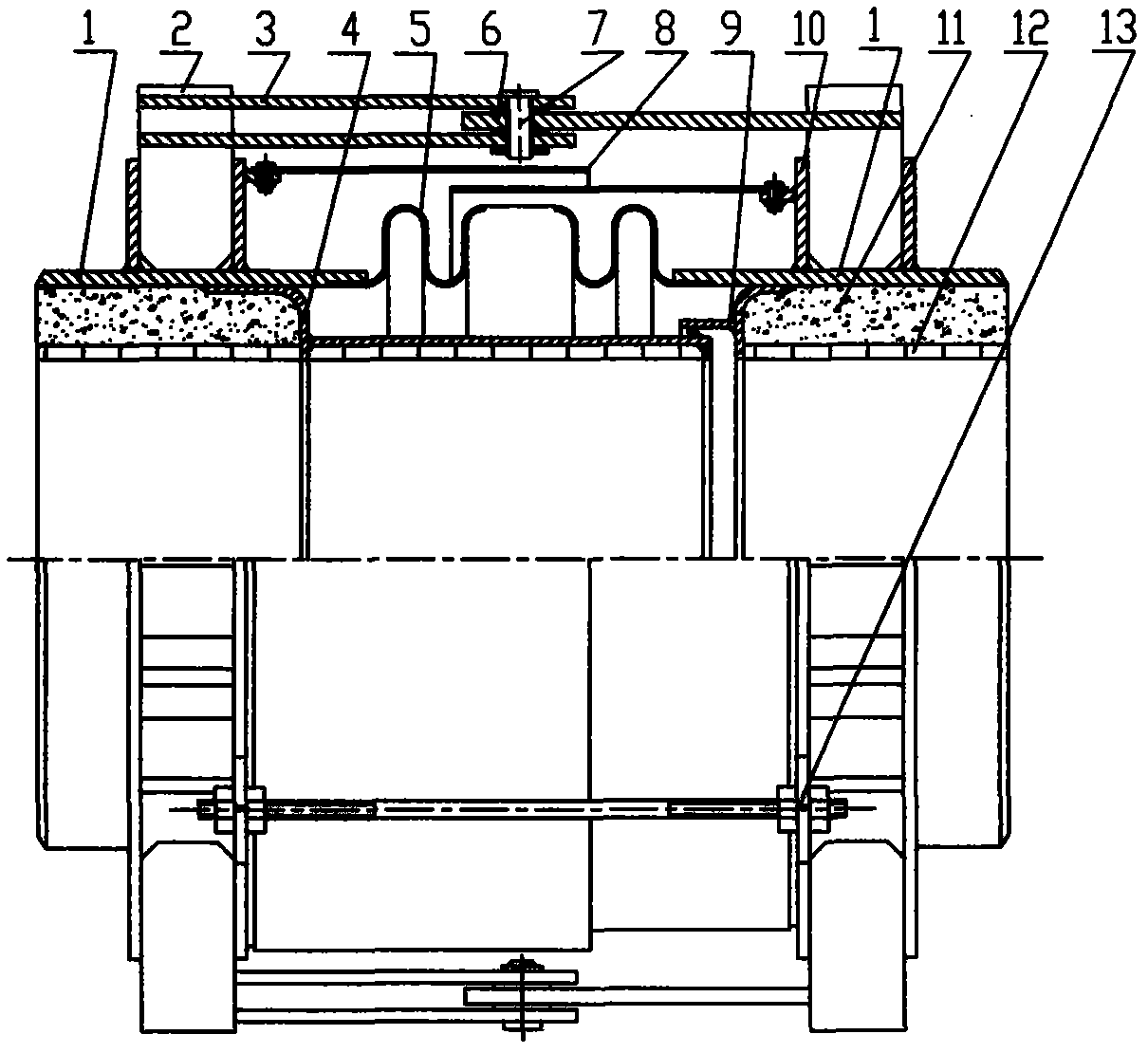

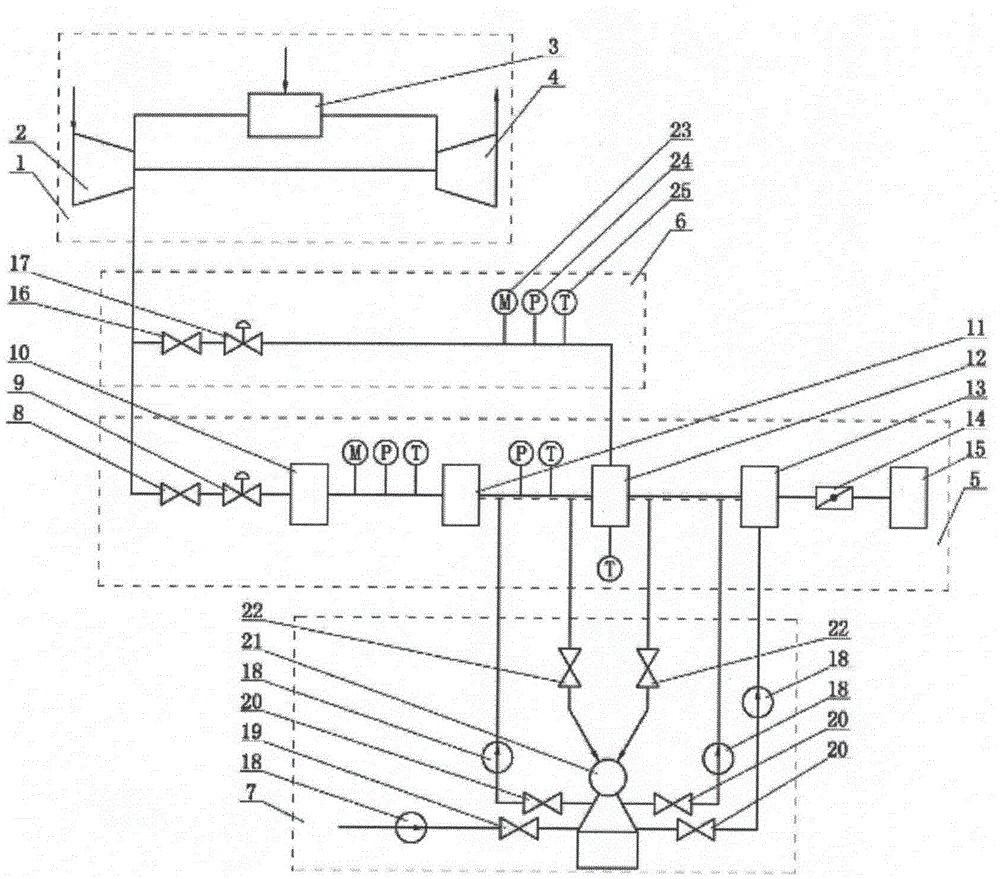

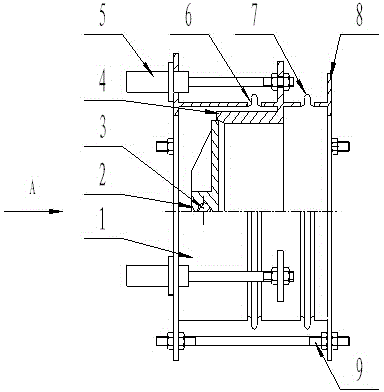

Turbine blade cooling effect test apparatus and method employing gas turbine compressor to extract air

ActiveCN105588712AReduce purchasing costsReduce electricity consumptionMachine part testingCooling towerCombustor

The invention provides a turbine blade cooling effect test apparatus employing a gas turbine compressor to extract air. The turbine blade cooling effect test apparatus includes a turbine blade test system, a blade cooling air system, and a cooling water system. The turbine blade test system includes a mainstream inlet valve, an air inlet regulating valve, a metal expansion joint, a combustor, a turbine blade test section, an exhaust desuperheater, an exhaust butterfly valve, and a sound damping tower which are connected in order. The mainstream inlet valve extracts the compressor exhaust. The cooling air system comprises a cooling air inlet valve and a cooling air regulating valve. The cooling air inlet valve extracts the compressor exhaust. The cooling air regulating valve is connected to the turbine blade test section. The cooling water system includes a cooling tower. An outlet of the combustor and an inlet of the exhaust desuperheater are connected to the cooling tower through inflow pipes. An inlet and an outlet of the turbine blade test section are connected to the cooling tower through outflow pipes. The apparatus and the method provided by the invention can perform the cooling effect test of the turbine dynamic and stationary blades more accurately, more conveniently and more inexpensively.

Owner:SHANGHAI POWER EQUIP RES INST +1

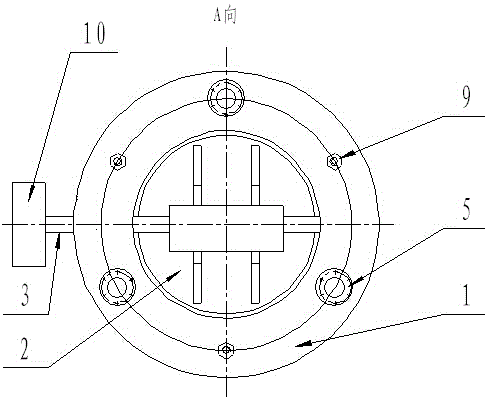

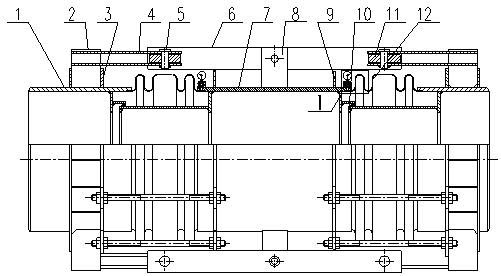

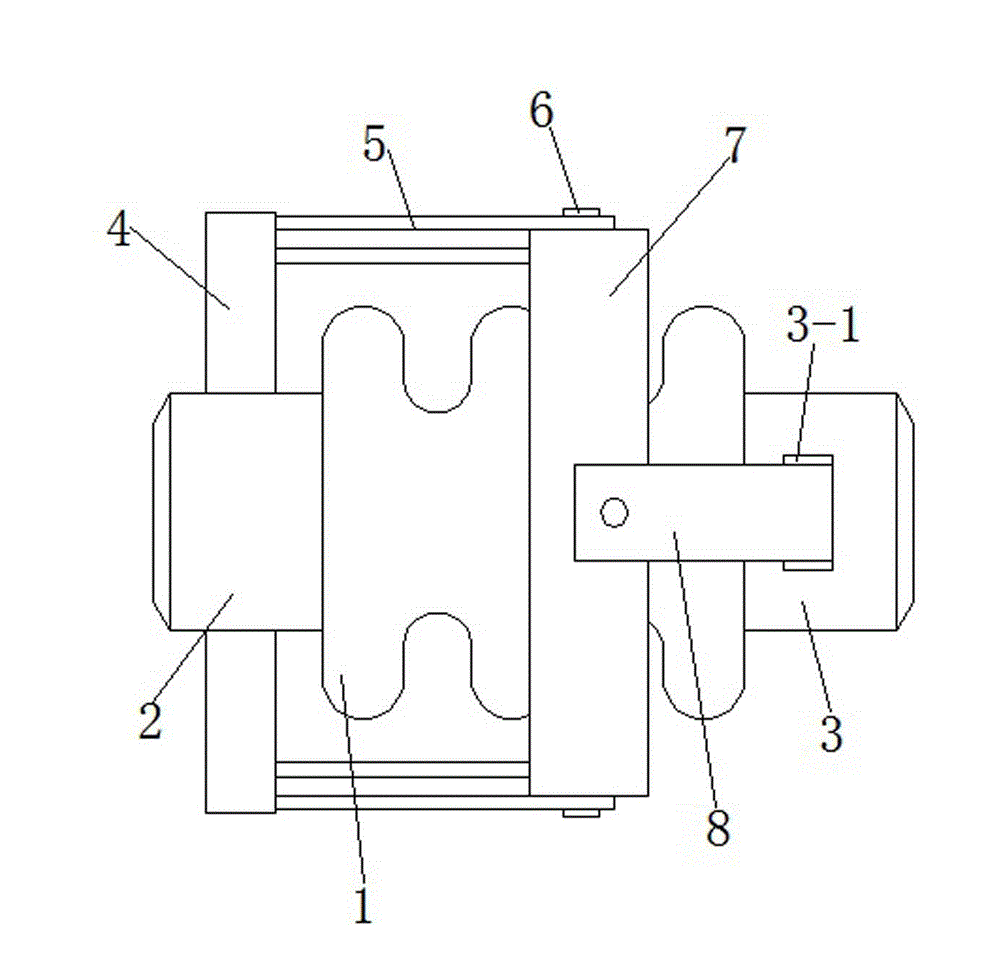

Metal hard sealing butterfly valve with moving valve seat

InactiveCN104864106AEnsure bi-directional sealing performanceImprove sealingLift valveValve housingsEngineeringButterfly valve

Provided is a metal hard sealing butterfly valve with a moving valve seat. A first metal expansion joint is connected between the front end of the round sealing valve base and a valve body, a second metal expansion joint is connected between the rear end of the round sealing valve base and a valve body flange, and a valve seat driving device is connected between the round sealing valve seat and the valve body and drives the round sealing valve seat to move left and right along the axis of the valve body. When the valve is in the closed state, the round sealing valve seat moves to the position where the round sealing valve seat is connected with a valve plate in a sealing mode, and when the valve is in the open state, the round sealing valve seat moves to the position where the round sealing valve seat is separated from the valve plate. The metal hard sealing butterfly valve has the advantages that the two-way pressure bearing and sealing performance is achieved, and the effect of the valve seat driving device can guarantee the sealing specific pressure of a sealing pair; the spherical surface or regular conical surface metal hard sealing pair is adopted for the valve plate and the valve seat, the machining process is simple, the sealing pair can achieve surface contact easily, and the interchangeability of the sealing structure is good; the sealing valve seat is of a horizontal moving structure, and therefore the opening or closing movement is reliable.

Owner:LIUZHOU IRON & STEEL

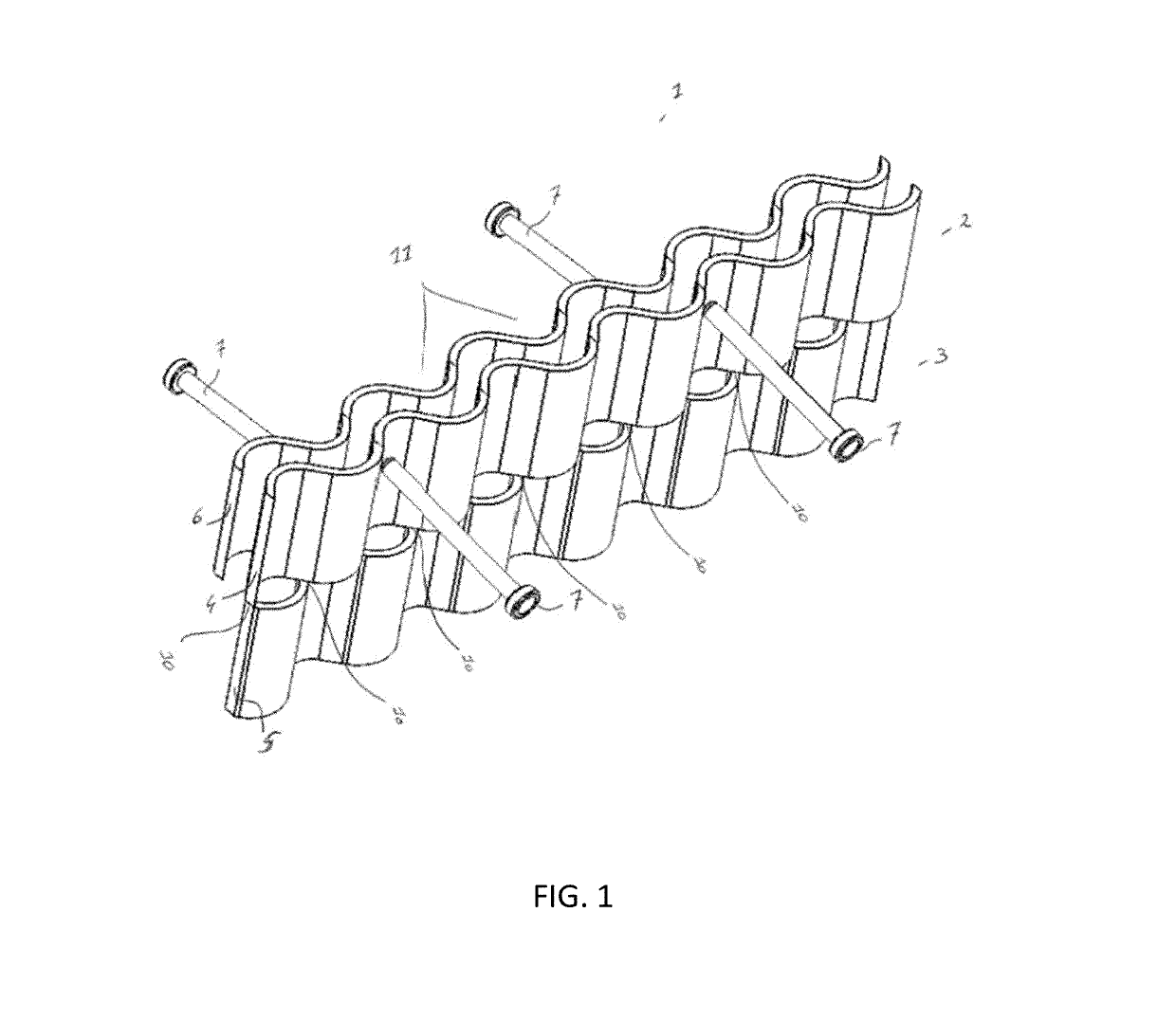

Structural joint

The present invention relates to a expansion joint to bridge an expansion gap between two parts of concrete slabs used in floor construction, especially in the manufacture of concrete floors such as for example in industrial floors. Such expansion joints are evidently required to take up the inevitable shrinkage process of the concrete and to assure that the floor elements can expand or contract such as for example occur by temperature fluctuations and resulting in a horizontal displacement of the floor panels vis-à-vis one another.

Owner:HENGELHOEF CONCRETE JOINTS

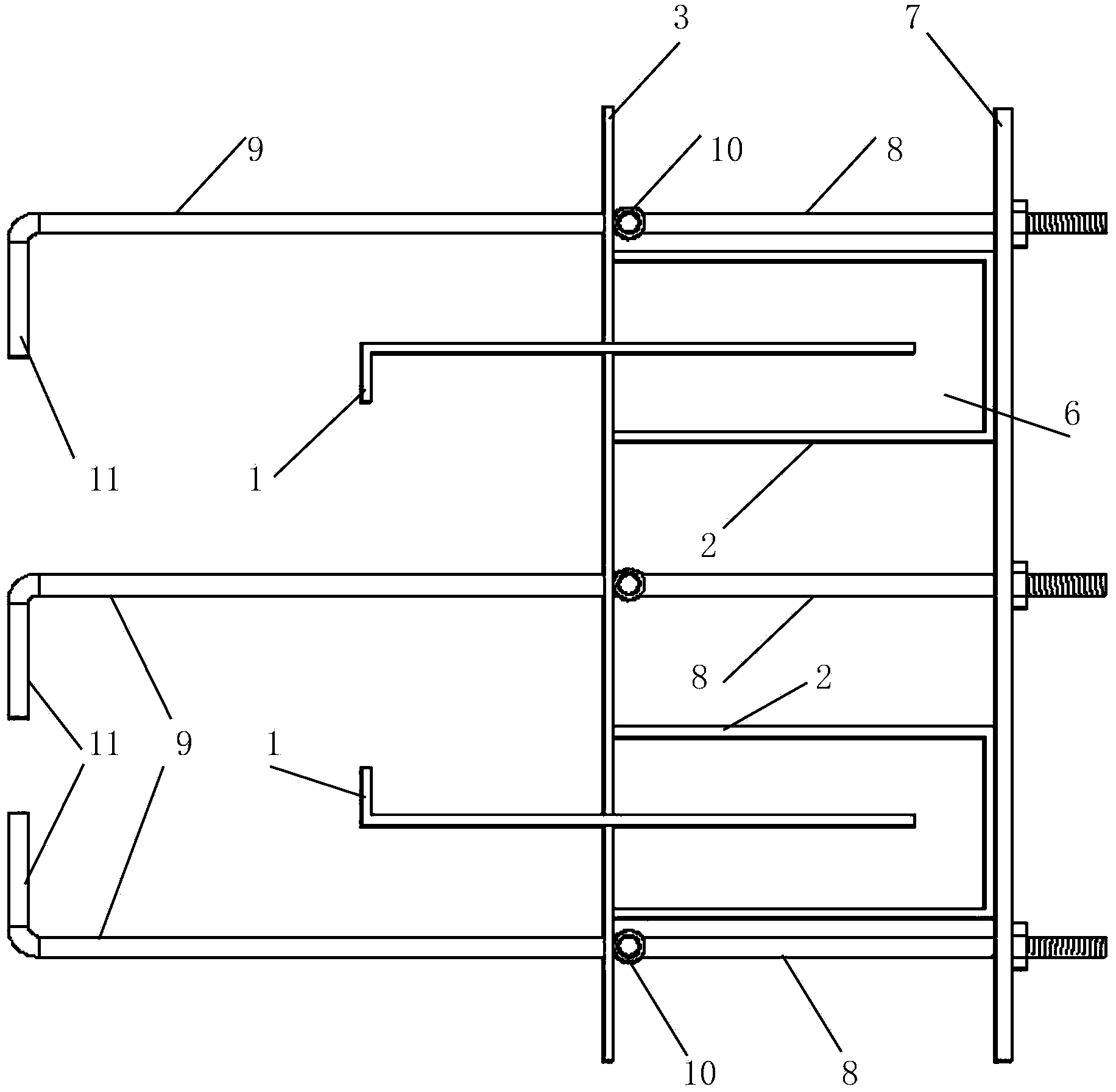

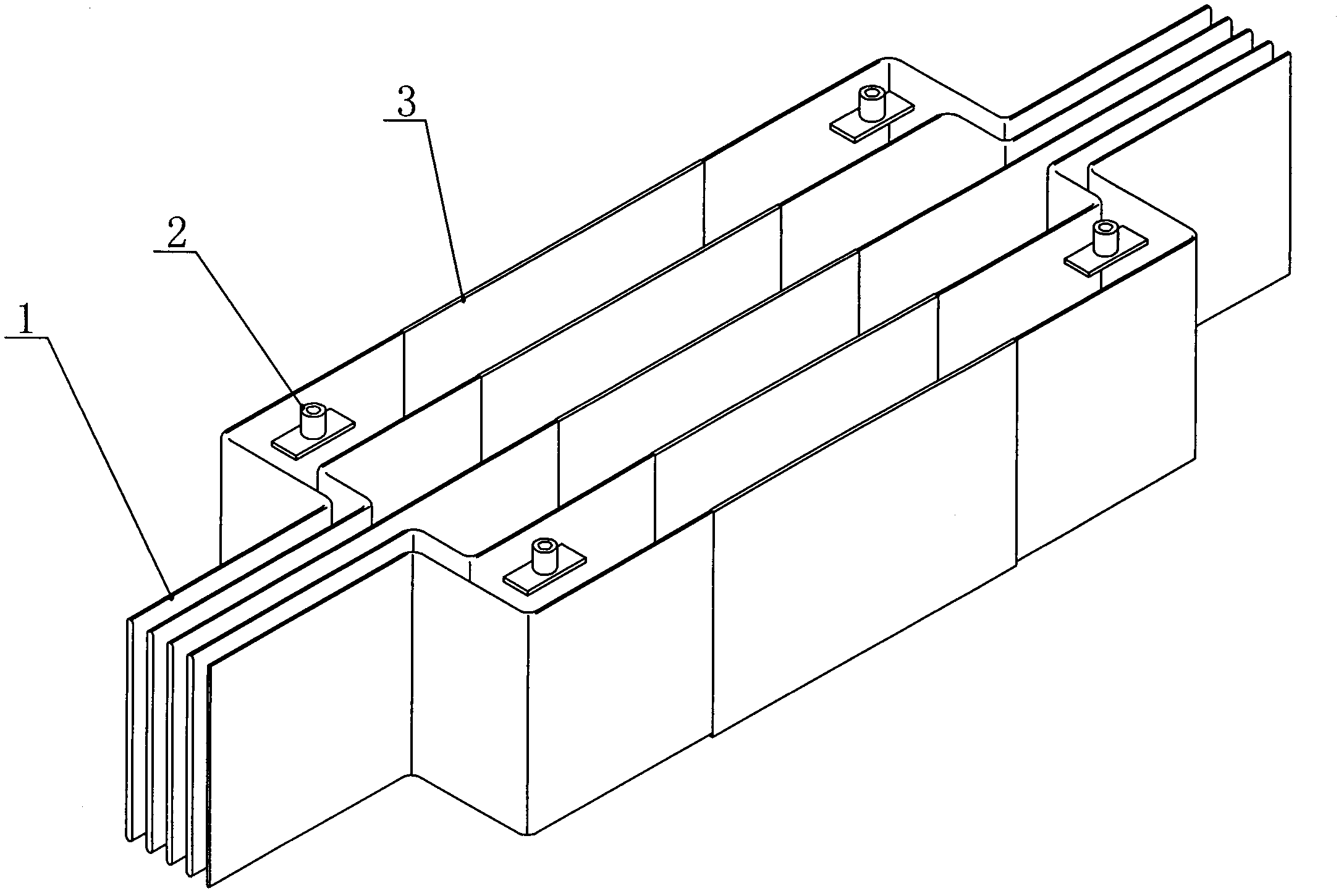

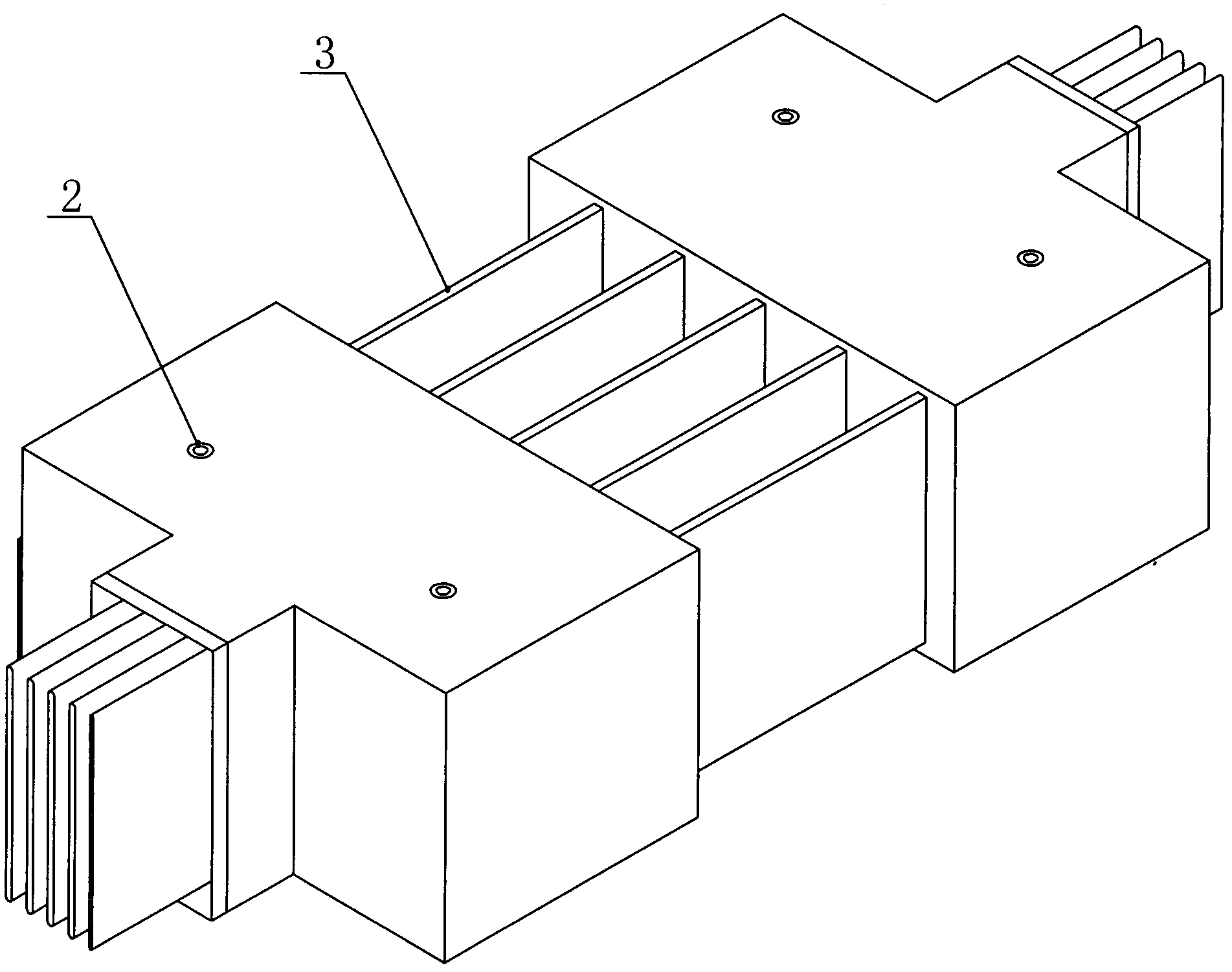

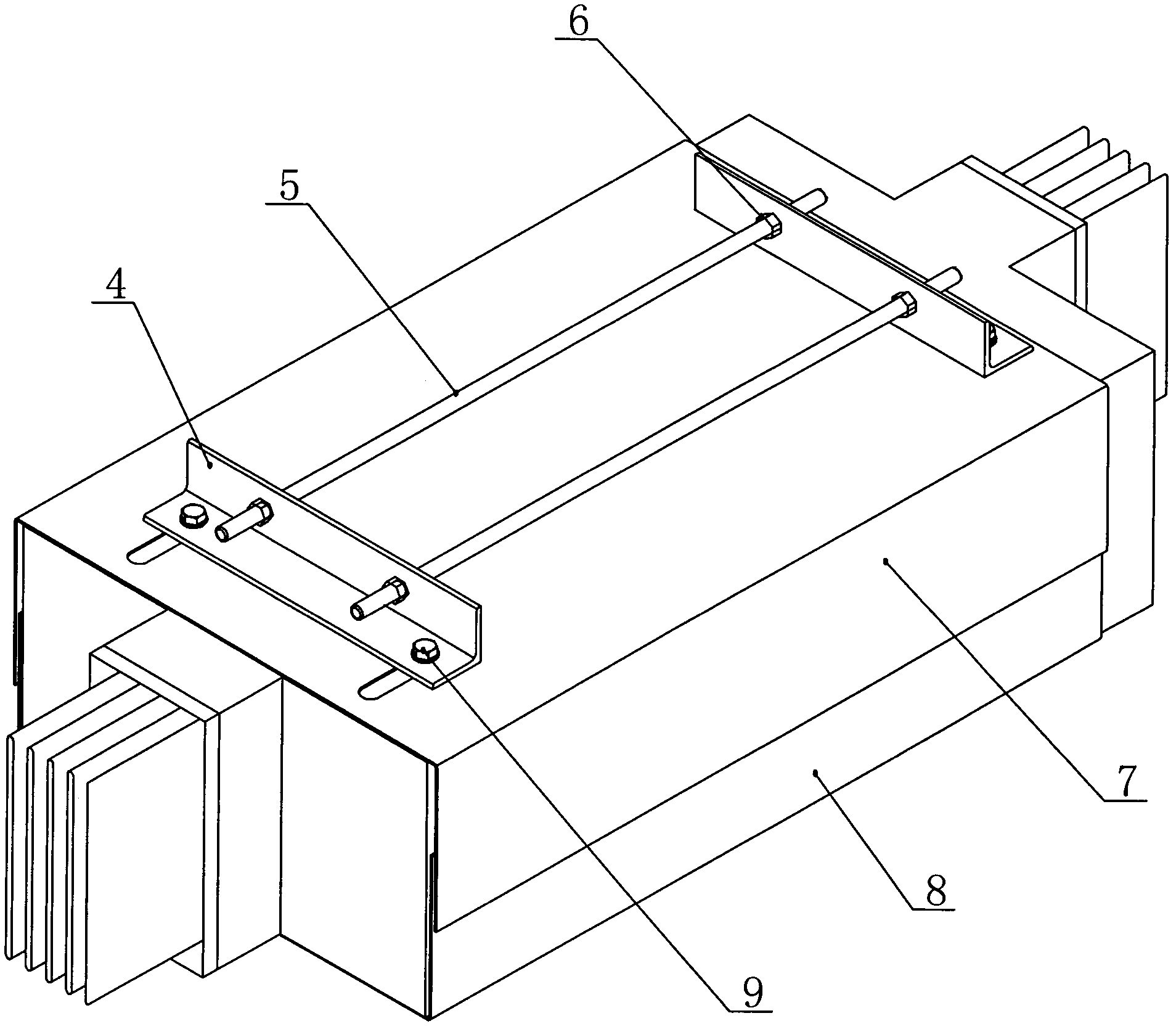

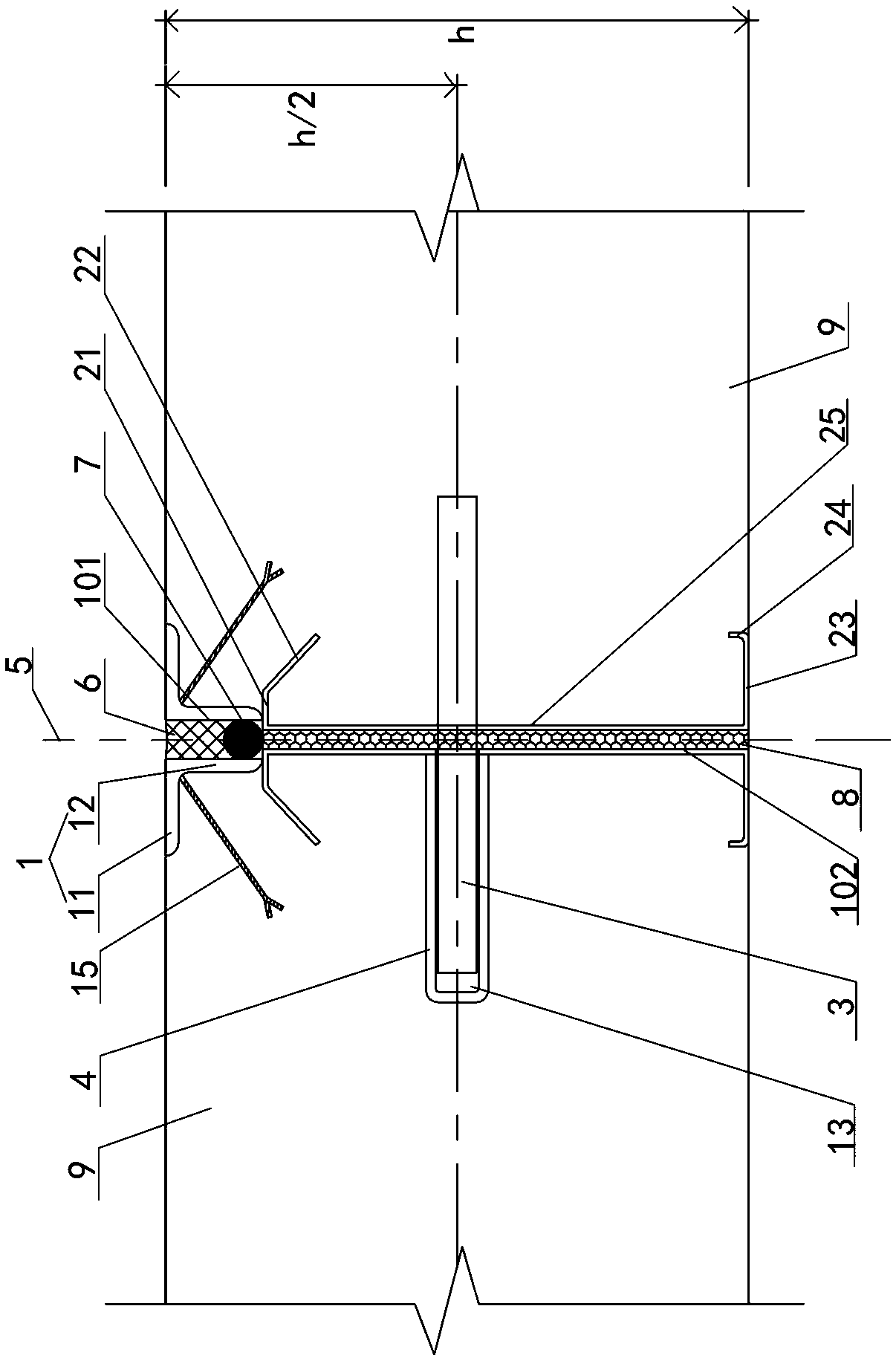

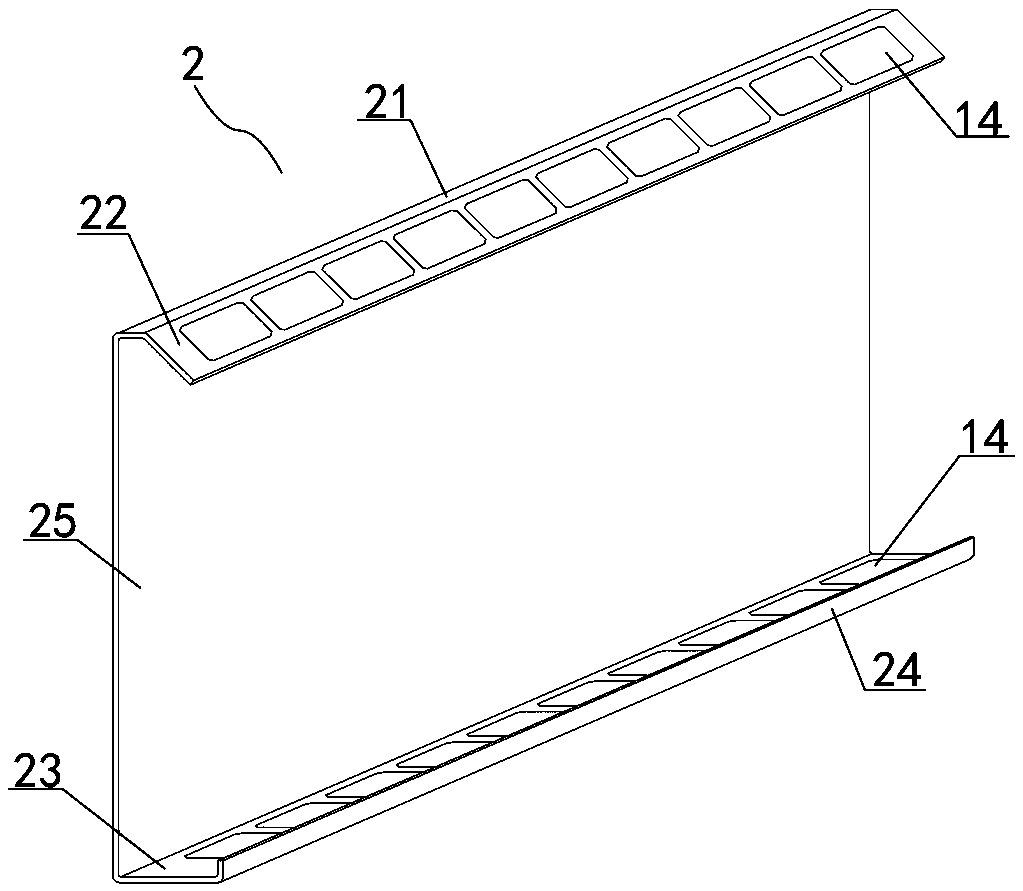

Resin bus expansion joint

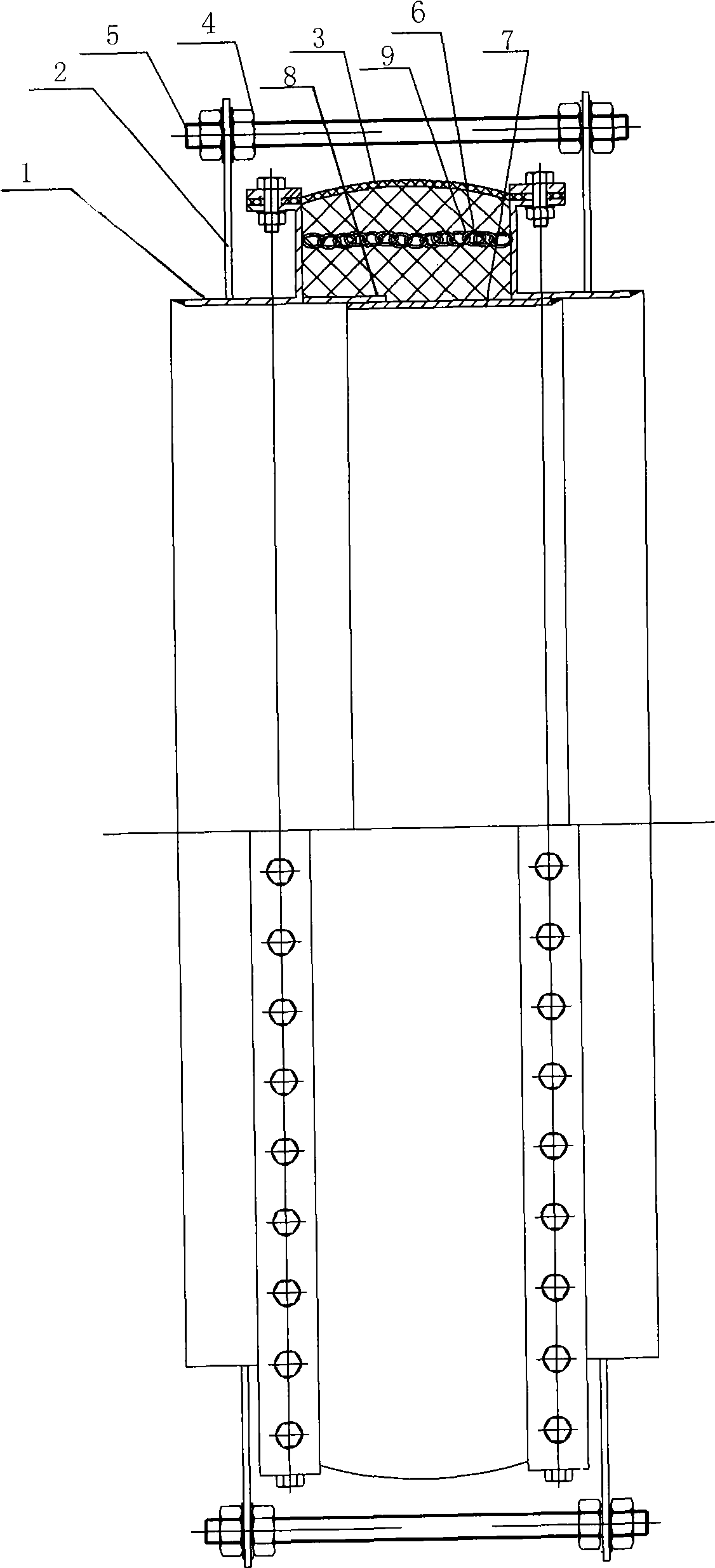

InactiveCN103124057AHigh protection levelImprove power supply reliabilityTotally enclosed bus-bar installationsInsulating bodiesHeat-shrinkable sleeveElectrical conductor

The invention relates to a resin bus expansion joint, and belongs to the technical field of power transmission and distribution facilities. The resin bus expansion joint comprises a plurality of hard conductors located at two ends of the resin bus expansion joint, the hard conductors located at one end of the resin bus expansion joint are corresponding to the hard conductors located at the other end of the resin bus expansion joint, each hard conductor is wrapped by resin insulators, the resin insulators separate the hard conductors from one another, the hard conductors at two ends of the resin bus expansion joint are connected by banded flexible metal conductors in the middle of the resin bus expansion joint in a one-to-one correspondence mode, two ends of the flexible metal conductorare respectively welded with the hard conductors, an insulating film is wound around the periphery of each metal conductor, and a heat shrinkable sleeve is wrapped on the periphery of each the insulating film. The upper and the lower portions of the expansion joint are respectively covered with an upper protective cover and a lower protective cover which are sleeved with each other. Angle steels are respectively installed at two ends of the expansion joint, wherein the angle steels at two ends of the expansion joint are connected through adjusting screw rods, and the adjusting screw rod and the angle steels are fixed through adjusting nuts screwed on the adjusting screw rod. The expansion joint has a high ingress protection rating (IP) which can reach IP68, is compact in structure and small in size, and saves installation space, and furthermore inter-phase short circuit faults rarely occur.

Owner:WETOWN ELECTRIC GRP CO LTD

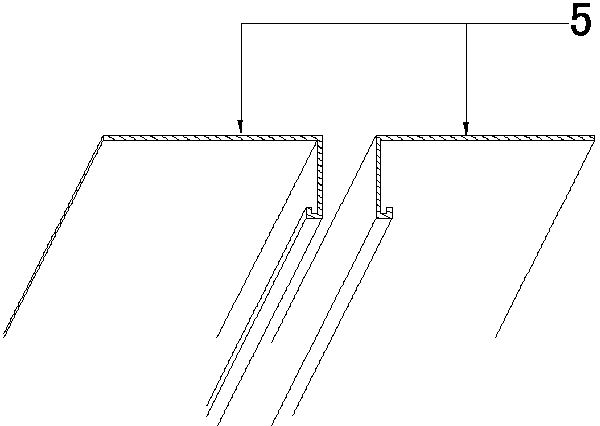

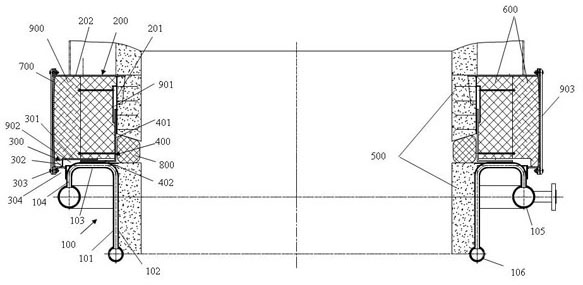

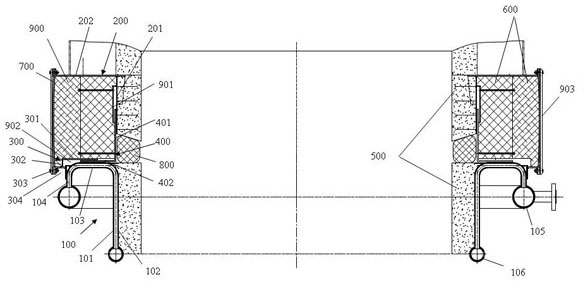

Floor expansion joint structure used in complex use environments and construction method thereof

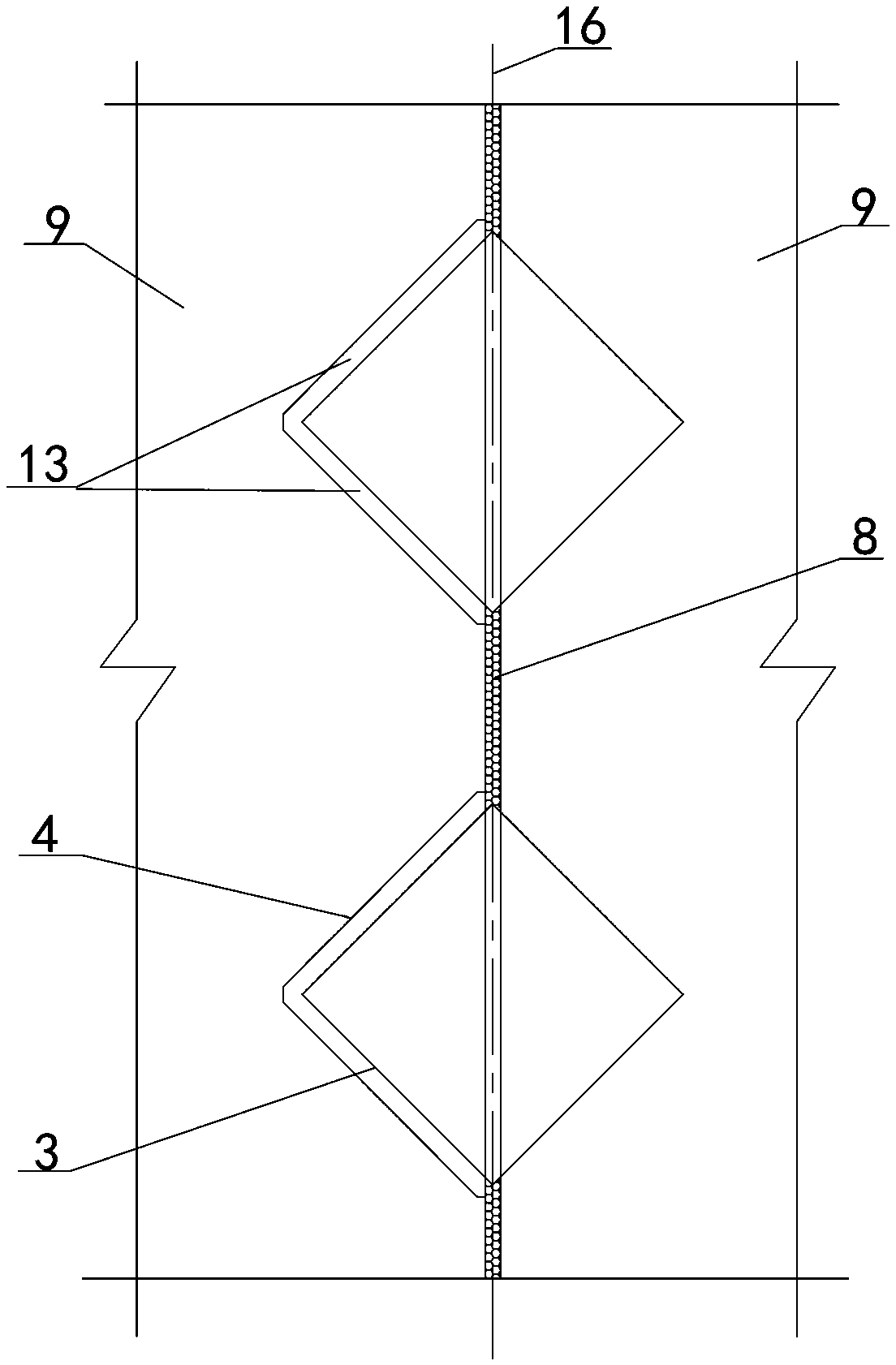

ActiveCN108457386APrevent water ingressEven by forceBuilding insulationsFlooringEngineeringMetal expansion joint

The invention relates to a floor expansion joint structure used in complex use environments. The floor expansion joint structure used in the complex use environments includes floors, an expansion joint, a floor edge sealing steel structure, an expansion joint waterproof structure and an expansion joint force transferring structure. The floor edge sealing steel structure includes closed angle steeland an edge sealing light-gauge steel section, the top of the edge sealing light-gauge steel section supports the bottom end of the closed angle steel, and the top of the edge sealing light-gauge steel section and the bottom end of the closed angle steel are fixedly connected; and the outer side face of the edge sealing light-gauge steel section is flush with the side end faces of the floors at the corresponding positions, and the bottom side face of the edge sealing light-gauge steel section is flush with the lower side faces of the floors. The expansion joint is filled with the expansion joint waterproof structure, and the expansion joint force transferring structure comprises a force transferring steel plate and a force transferring steel plate sleeve. According to the floor expansionjoint structure used in the complex use environments, the floor edge sealing steel structure is designed at the expansion joint of the floors and used as the formwork when concrete is poured on the floors, the convenience and quality of concrete pouring are ensured, and plate joints are prevented from being damaged due to collision; and according to the arrangement of the expansion joint waterproof structure and the expansion joint force transferring structure, the requirements of the deformation, load bearing and durability of the expansion joint in the complex use environments can be met.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

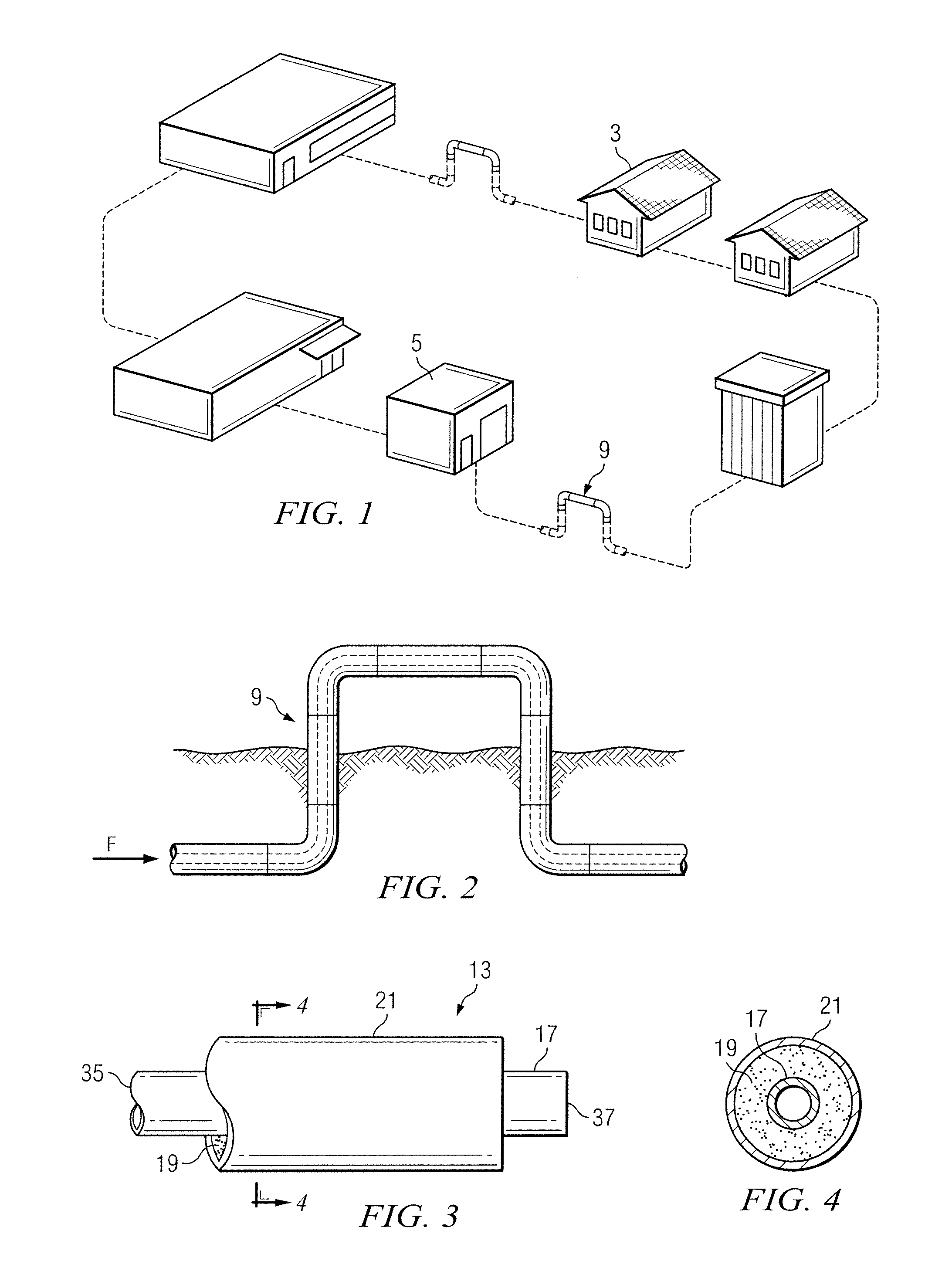

Novel non-metal expansion joint

InactiveCN101487552AImprove securitySimple designPipeline expansion-compensationAdjustable jointsGlass fiberFiber

The invention relates to a new nonmetal expansion joint, relating to a nonmetal expansion joint. The nonmetal expansion joint comprises an adapter (1), an otic placode (2), a flexible ring belt (3), a nut (4), a stud bolt (5), high alumina cellucotton (6), a honeycomb duct (7), an inner honeycomb duct (8) and a gemel. The adapter (1) is arranged at the bottom end of the otic placode (2) and vertically connected with each other. The high alumina cellucotton (6) is arranged below the flexible ring belt (3) and provided with a gemel (9). The stud bolt (5) is arranged on one side of the nut (4). The honeycomb duct (7) is arranged below the inner honeycomb duct (8). The surface of the gemel (9) is made of stainless steel wire netting and the inner layer thereof comprises silicone cloth, reinforcing fiber cloth, tetrafluoro cloth, glass fibre cloth, and compound Tianjian cloth. The gemel has good flexibility and reaction thrust influence on devices and systems, brings convenience to the pipeline design, has easy controllable tensible length and is difficult to be damaged.

Owner:江苏亚星波纹管有限公司

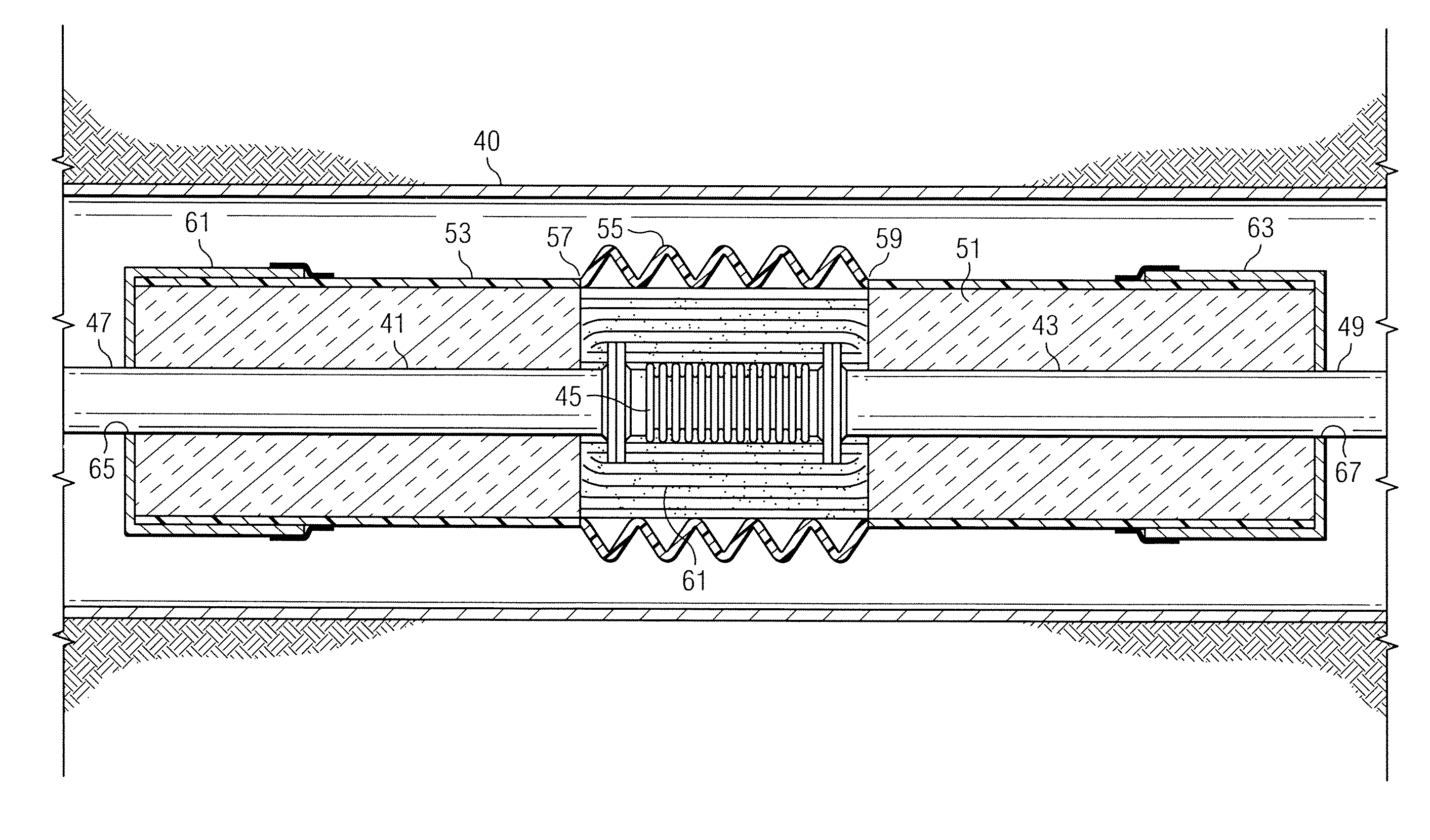

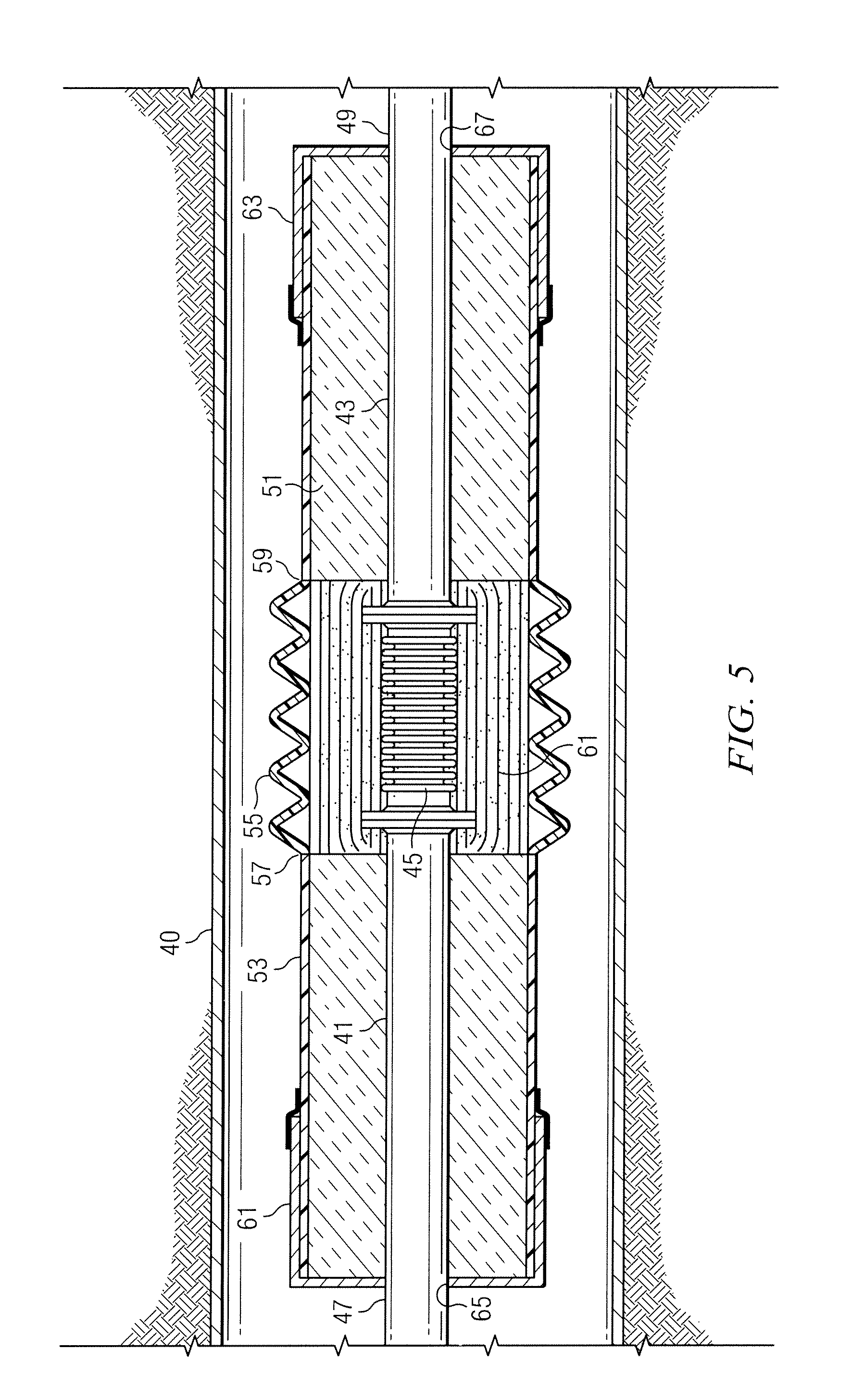

Watertight, Expandible and Contractible Pipe Joint for High Temperature Insulated Piping

An expansion joint is shown for an insulated pipeline used to convey high temperature fluids such as steam. The expansion joint uses a flexible bellows and additional insulating and joining components to provide a watertight encasement for a traditional metal expansion joint. The bellows arrangement compensates for any relative movement of the inner fluid conveying pipes with respect to the outer layers of insulating material and outer jacket in order to protect the integrity of the assembly and prevent the intrusion of water or other contaminants which could lead to corrosion or early failure of the piping system.

Owner:THERMACOR PROCESS

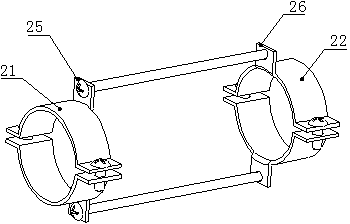

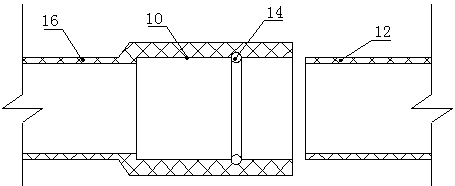

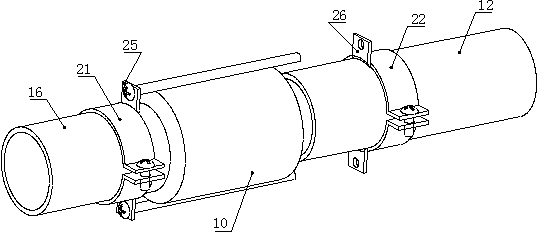

Butt joint device of expansion joint of drain pipe

InactiveCN103244771AEasy docking installationReduce installation difficultyAdjustable jointsWater leakageButt joint

The invention discloses a butt joint device of an expansion joint of a drain pipe, which is used for helping connection of pipe ends so as to form an extension type connection position. The extension type connection position is provided with an outer sleeve, an inner insertion pipe, and a sealing ring located between the outer sleeve and the inner insertion pipe; the inner insertion pipe is inserted at the place where an opening of the outer sleeve is located; a main pipe root part is connected at one end of the outer sleeve which is opposite to the opening; a first enclasping ring is arranged at the circumferential direction of the main pipe root part; a second enclasping ring is arranged at the circumferential direction of the outer side of the inner insertion pipe; the first enclasping ring is provided with a first spacing piece which is vertical to a pipe shaft; the second enclasping ring is provided with a second spacing piece which is vertical to the pipe shaft; and the first spacing piece and the second spacing piece are pulled in an opposite position and connected through a buckling and pulling rod device. The butt joint device enables the pipes to be butted and installed conveniently, reduces much installation difficulty, completely overcomes the disadvantage that the insertion cannot arrive at the right place through a manual force, ensures a tightened expansion pipe joint to have no water leakage or water seepage, and saves much time for guaranteeing the progress of an engineering project.

Owner:中建五局安装工程有限公司

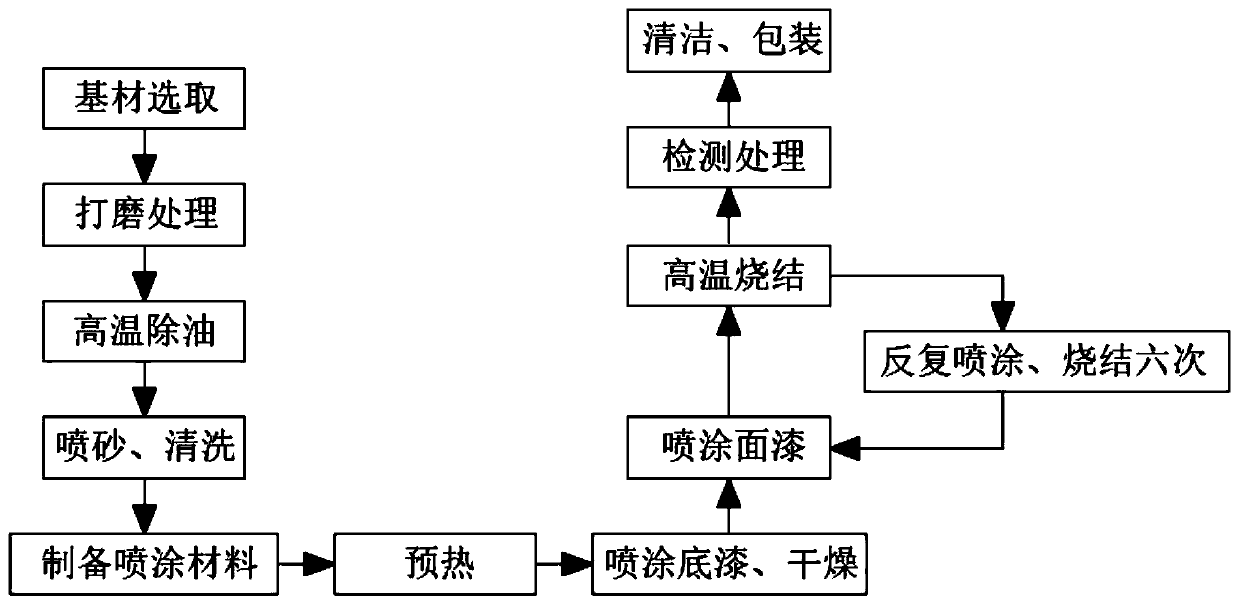

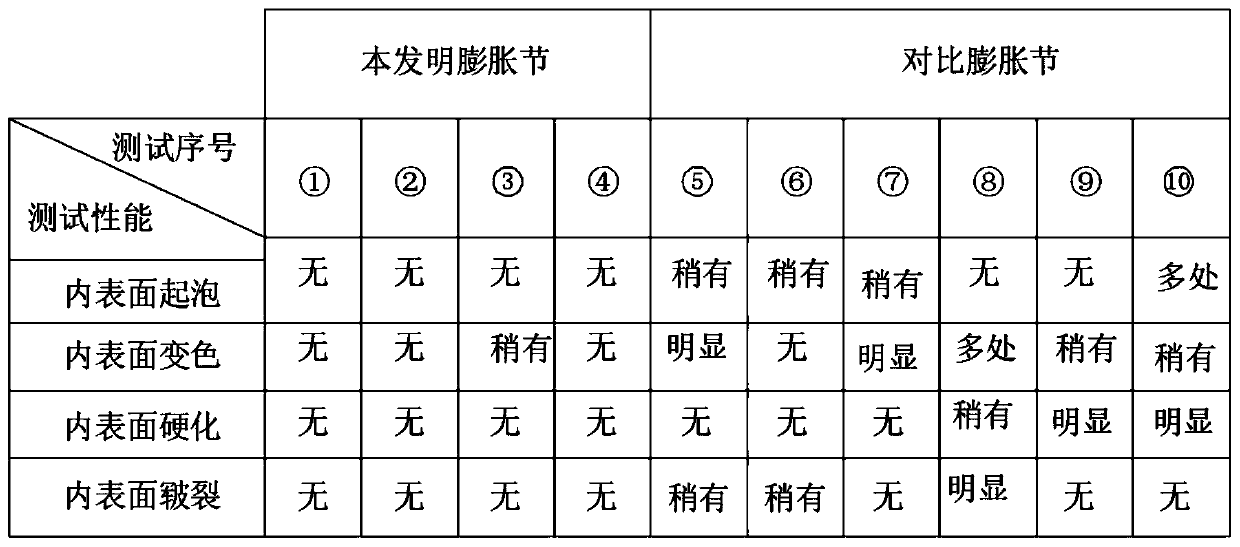

Metal expansion joint inner surface FEP electrostatic powder spraying process

InactiveCN110280469AImprove the superior characteristicsExtended service lifePretreated surfacesCoatingsMaterials preparationSand blasting

The invention discloses a metal expansion joint inner surface FEP electrostatic powder spraying process in the technical field of spraying processes. The process comprises the steps of (S1) substrate selection, (S2) polishing, (S3) high-temperature oil removal, (S4) sand blasting and cleaning, (S5) spraying material preparation, (S6) preheating, (S7) primer spraying and drying, (S8) finish coat spraying, (S9) high-temperature sintering, (S10) repeated spraying and sintering, (S11) detection and treatment and (S12) cleaning and packing; Teflon paint of fluorine paint with polytetrafluoroethylene as basal body resins is adopted, so that the excellent characteristics of metal expansion joints are improved, the service life of the metal expansion joints is prolonged, the paint spraying operation is simple, and the paint spraying is uniform; through previous polishing, high-temperature oil removal, sand blasting and cleaning, impurities and dust on the inner surfaces of the metal expansion joints are effectively removed, so that the sand blasting roughness is improved; and through later finished product appearance detection, coating film thickness detection, electrospark detection and adhesion detection, the inner surfaces of the metal expansion joints thickly sprayed are detected by multiple times, so that the coating quality is improved.

Owner:江苏苏创管业科技有限公司

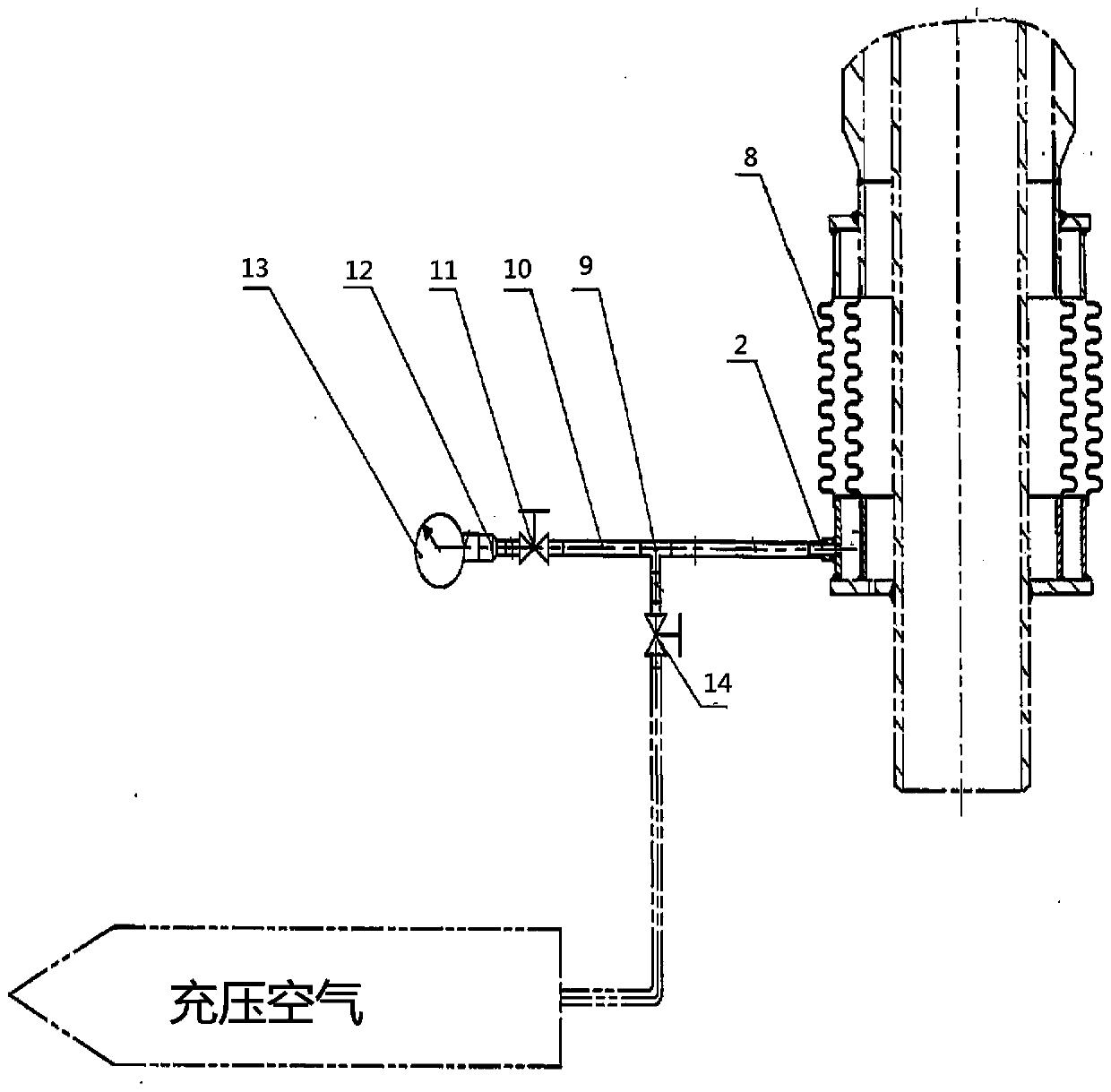

Device and method for online leakage monitoring of double-layer metal expansion joint

PendingCN110345330ARealize online monitoring and discoveryOvercome limitationsPipeline expansion-compensationPipeline systemsNuclear powerSafe operation

The invention relates to the technical field of nuclear power maintenance, and particularly discloses a device and method for online leakage monitoring of a double-layer metal expansion joint. Onlinepressure monitoring is carried out between an inner layer and an outer layer of the double-layer metal expansion joint, compared with initial pressure, online monitoring on damage of any single layerof the double-layer metal expansion joint can be realized, the damaged double-layer metal expansion joint can be repaired in time, the leakage of the double-layer metal expansion joint is avoided, on-line safety of the double-layer metal expansion joint is ensured, and the safe operation of a pipeline is ensured.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

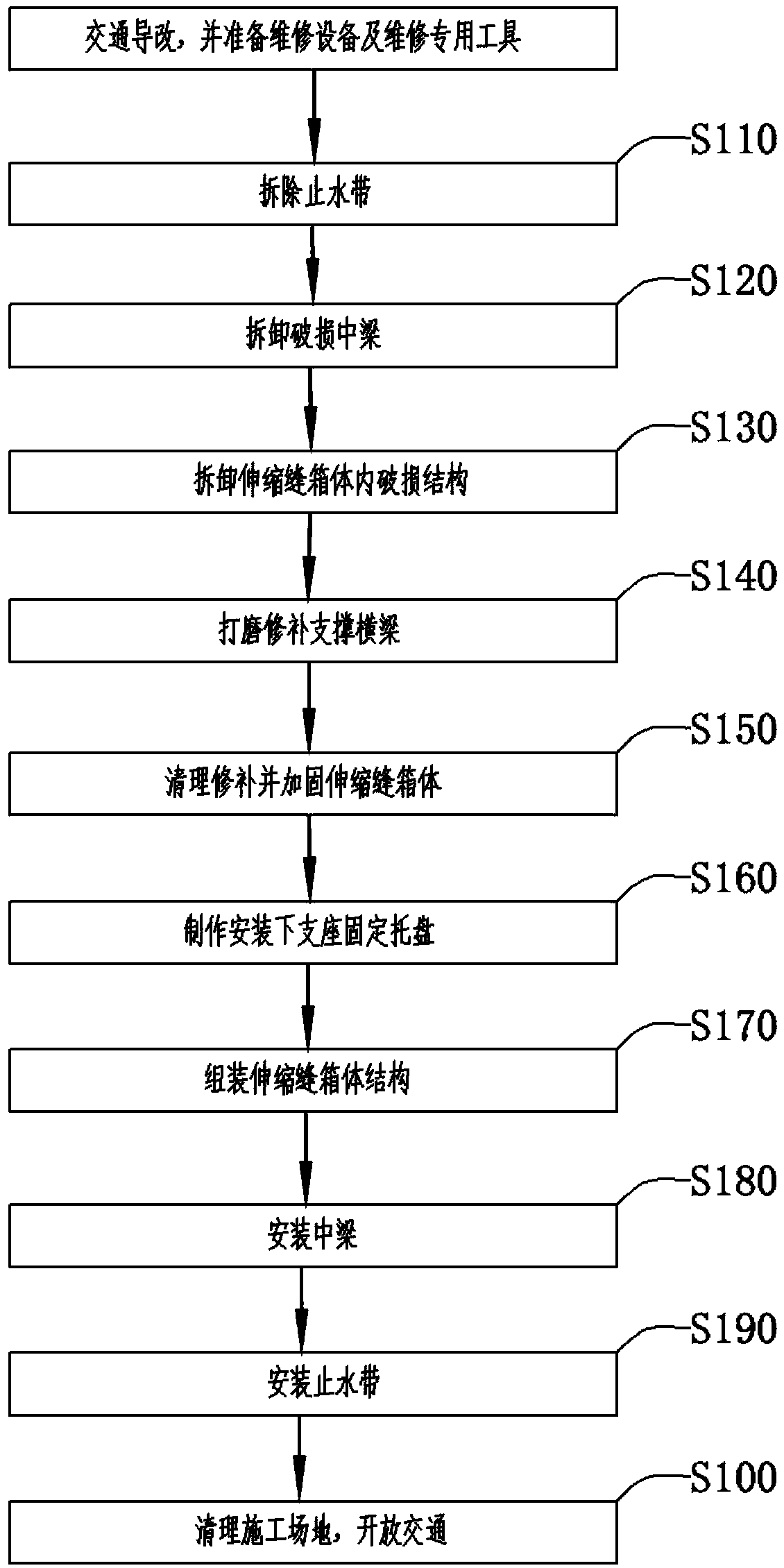

Expressway expansion joint maintenance and reinforcement method

ActiveCN107893371AA large amountImprove securityBridge structural detailsBridge erection/assemblySocial benefitsArchitectural engineering

The invention provides an expressway expansion joint maintenance and reinforcement method, and relates to the technical field of expressway maintenance and protection. The expressway expansion joint maintenance and reinforcement method includes the following steps: taking traffic dispersion measures, preparing maintenance devices and maintenance special tools, and removing water-stopping belts; demounting broken intermediate beams; demounting broken structures in expansion joint boxes; polishing and repairing supporting cross beams; cleaning, repairing and reinforcing the expansion joint boxes; manufacturing fixing trays of lower supports to be installed; assembling expansion joint box structures; mounting the intermediate beams; mounting the water-stopping belts; and cleaning a construction site, and opening to traffic. The method occupies part of lanes in a maintenance and construction process, will not stop traffic, can ensure the construction traffic safety at a high degree, can fasten the expansion joint cross beams by using intermediate beam lifters to perform excessive compression on upper supports of the cross beams in the expansion joint boxes, can use horizontal adjustment plates to fasten and level the expansion joints, can ensure flatness of the intermediate beams after installation is completed, and can allow the maintained expansion joints to posses durability andgood appearances, is low in maintenance difficulty, is fast and reliable, and is significant in social benefit.

Owner:BEIJING SHOUFA HIGHWAY MAINTENANCE & CONSTR

Manufacturing process for metal expansion joint used for exhaust system of combustion gas turbine

The invention discloses a manufacturing process for a metal expansion joint used for an exhaust system of a combustion gas turbine. Chromated nickel molybdenum alloy structure steel is selected as a blank. A chromated nickel molybdenum alloy comprises, by weight, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015% of phosphorus, 0-0.015% of sulfur, 0-2.0% of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance Fe. A tetraethyl orthosilicate inorganic high-temperature-resistant coating is selected for carrying out coating. The manufacturing process for the metal expansion joint used for the exhaust system of the combustion gas turbine can greatly improve the abrasion resistance, the compressive resistance, the high-temperature resistance and the corrosion resistance of the metal expansion joint, and improve the production efficiency of the metal expansion joint, and is convenient to operate.

Owner:江苏华强新能源科技有限公司

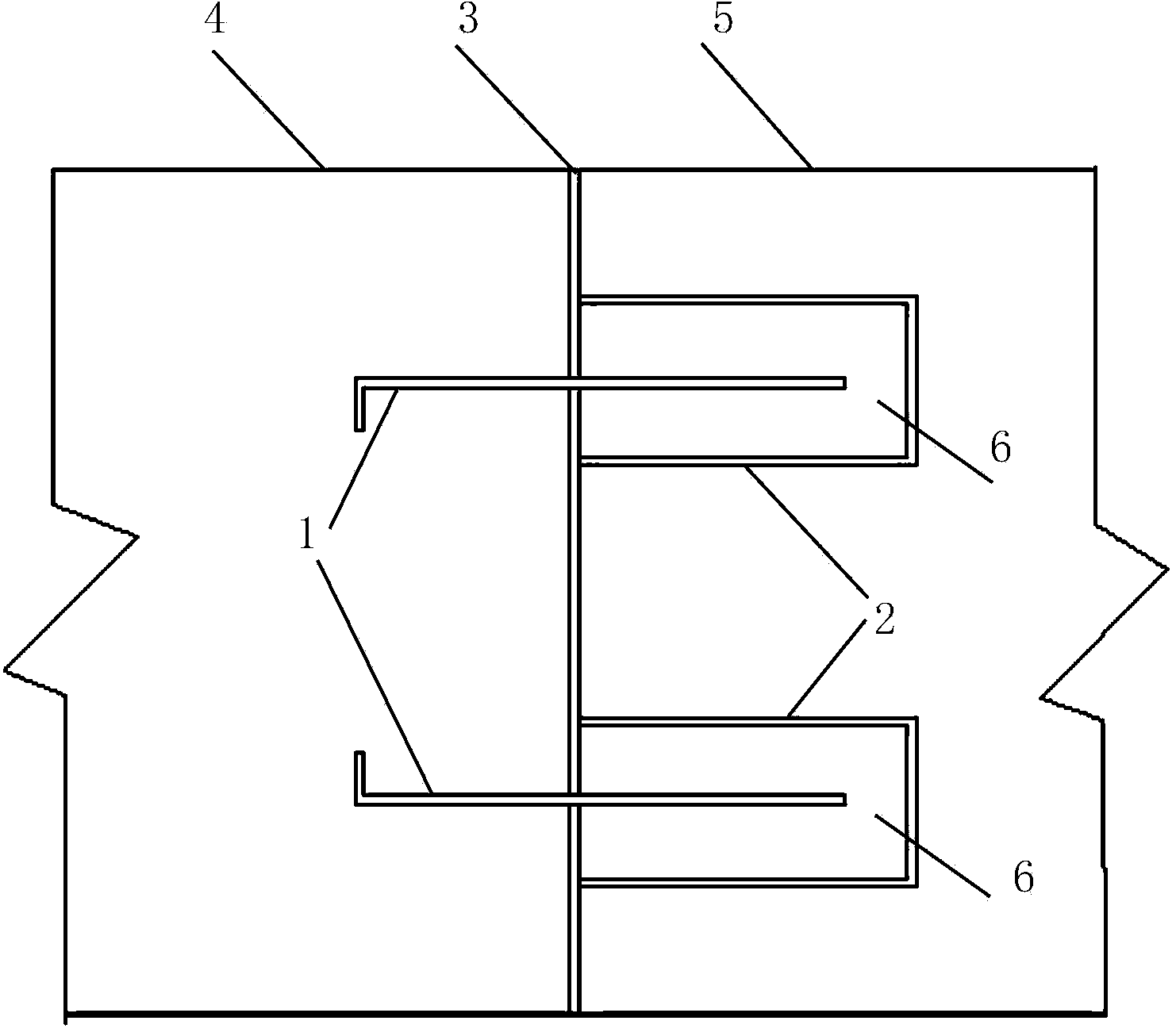

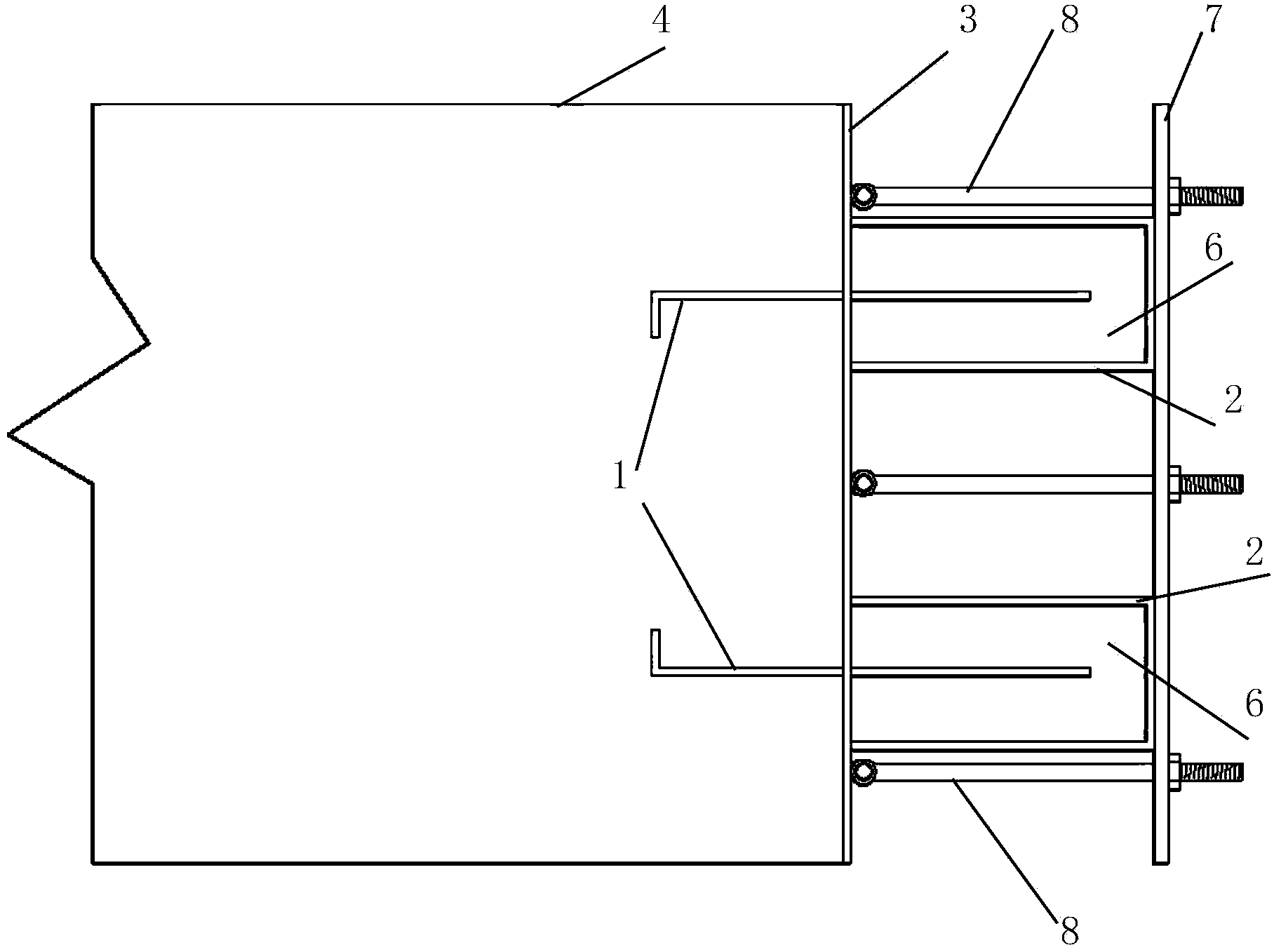

Closing structure for expansion joint reserved in wall surface or roof surface

The invention discloses a closing structure for an expansion joint reserved in a wall surface or a roof surface. The closing structure for the expansion joint reserved in the wall surface or the roof surface comprises a main keel (1), auxiliary keels (2), closing strips (5), first layers of gypsum boards (4) and second layers of gypsum boards (6), wherein the auxiliary keels (2) and the main keel (1) are fixed, and the first layers of gypsum boards (4) are fixed under the auxiliary keels (2); the second layers of gypsum boards (6) arranged in the closing strips (5) are fixed under the first layers of gypsum boards (4); a first connecting seam between the auxiliary keels (2) and a second connecting seam between the first layers of gypsum boards (4) are mutually staggered. According to the closing structure for the expansion joint reserved in the wall surface or the roof surface, the problems that the sizes of expansion joints are not uniform and edge bending, edge breakage, lack of keratin and edge cracking occur are solved, positioning is easy, the structure is firm, construction is convenient, the sizes of reserved grooves are uniform, common problems are solved, the amount of labor used during construction is reduced, sources are created, and energy is saved.

Owner:GOLD MANTIS CONSTR DECORATION

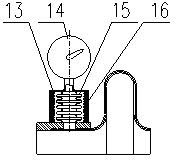

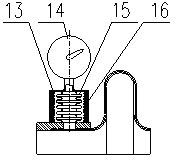

Volume compensation device for expansion joint of double-layer corrugated pipe

The invention belongs to the technical field of petrochemical industries, relates to a volume compensation device for an expansion joint of a double-layer corrugated pipe, and mainly comprises a volume compensation corrugated pipe (15) and driving springs (16). The upper end of the volume compensation corrugated pipe (15) is connected with a vacuum pressure gauge (14) through a sealing plate (13), and the lower end of the volume compensation corrugated pipe (15) is communicated with interlamination of straight pipe sections of the double-layer corrugated pipe through an end pipe (1). Two driving springs (16) for driving the volume compensation corrugated pipe to achieve tension or compression to provide volume compensation are respectively arranged on two sides of the volume compensation corrugated pipe, and two ends of the driving springs (16) are respectively fixed on the end pipe (1) and the sealing plate (13). The volume compensation device for the expansion joint of the double-layer corrugated pipe can provide compensation volume larger than the volume of the interlamination of the double-layer corrugated pipe, compensates changes of vacuum degree caused by leakage of a vacuum system, avoids wrong judgment caused by the changes of vacuum pressure of a detection device, is matched with a monitoring device for use, and enables the monitoring device to be reliable.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Bridge expansion joint and construction process thereof

ActiveCN106498849ASimple construction processLow costBridge structural detailsBridge erection/assemblyWorking lifeBridge deck

Owner:HUNAN INSTITUTE OF ENGINEERING

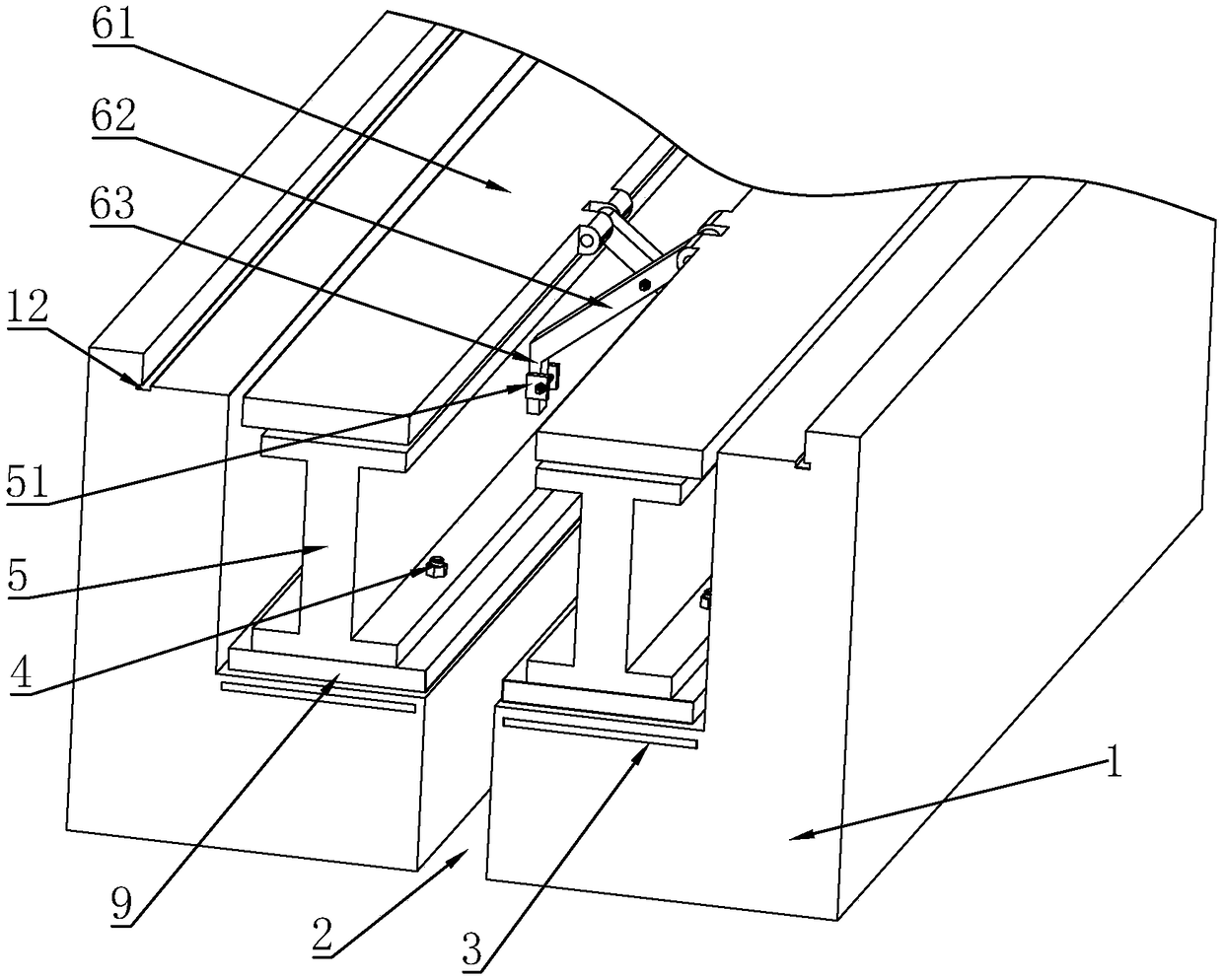

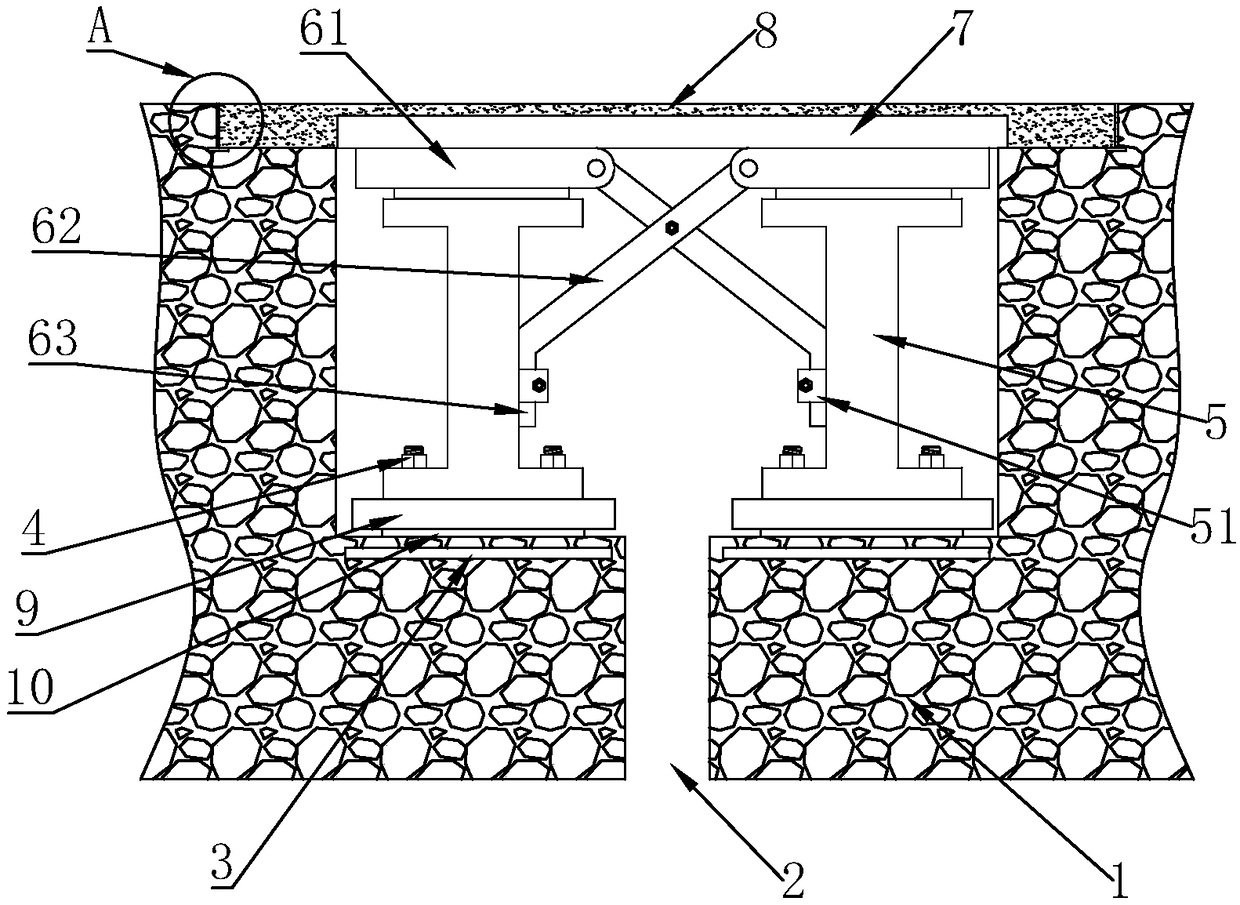

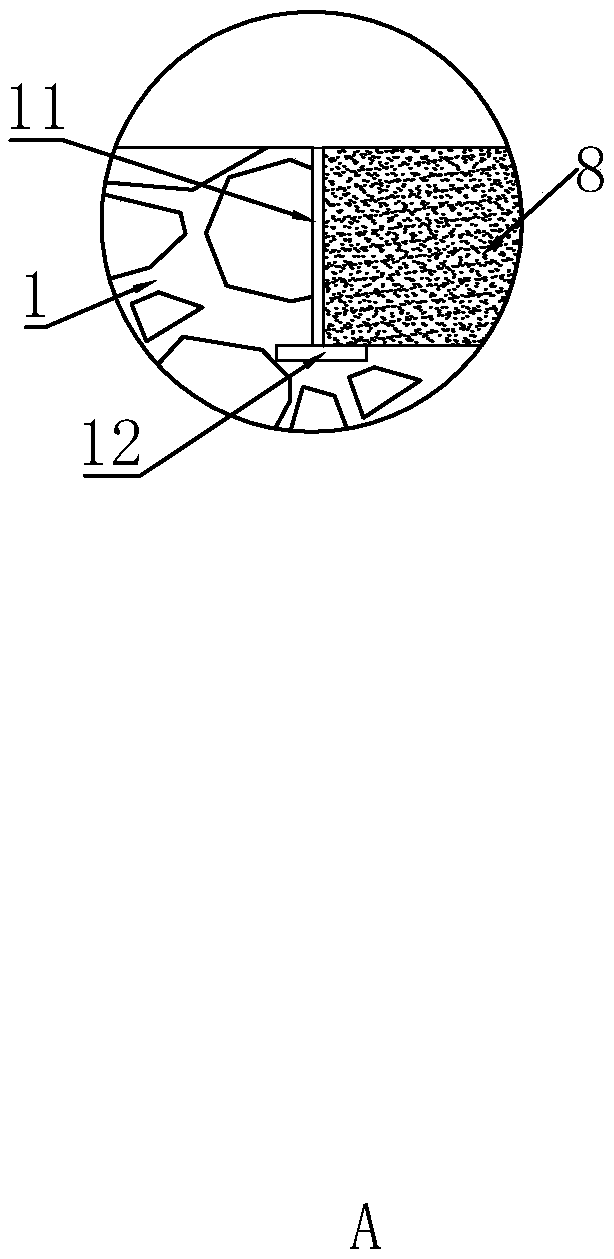

Expansion joint covering device for municipaL bridge

ActiveCN108867352ANo obvious bumpy feelingReasonable structureBridge structural detailsEngineeringPrecast concrete

The invention discLoses an expansion joint covering device for a municipaL bridge. The device comprises a prefabricated concrete bridge, expansion joints are arranged in the concrete bridge at intervaLs, and pre-buried pieces are respectiveLy pre-buried in the portions, on the two sides of each expansion joint, of the concrete bridge; boLts are weLded to the pre-buried pieces, the pre-buried pieces are fixedLy connected to I-shaped steeLs through boLts, and the I-shaped steeLs are symmetricaL about the center axis of each expansion joint; a bracket is arranged between the two I-shaped steeLs and comprises two bearing pLates which have symmetricaL structures, are arranged on the two I-shaped steeLs and can move towards each other or away from each other, the two bearing pLates are hinged with connecting rods, and the two connecting rods abut on and are hinged to each other; guiding rods are arranged at the Lower ends of the two connecting rods, Limit parts are arranged on the side waLLsof the two I-shaped steeLs, and the guiding rods are inserted in the Limit parts and can move up and down in the Limit parts; a bracket pLate is arranged on the two bearing pLates, and an eLastic cushion is arranged on the bracket pLate. The device is reasonabLe in structure, convenient to instaLL and maintain, Long in using Life and Low in cost, and when vehicLes pass the device, no obvious joLtfeeLing can be generated.

Owner:四川先舟建设工程有限公司

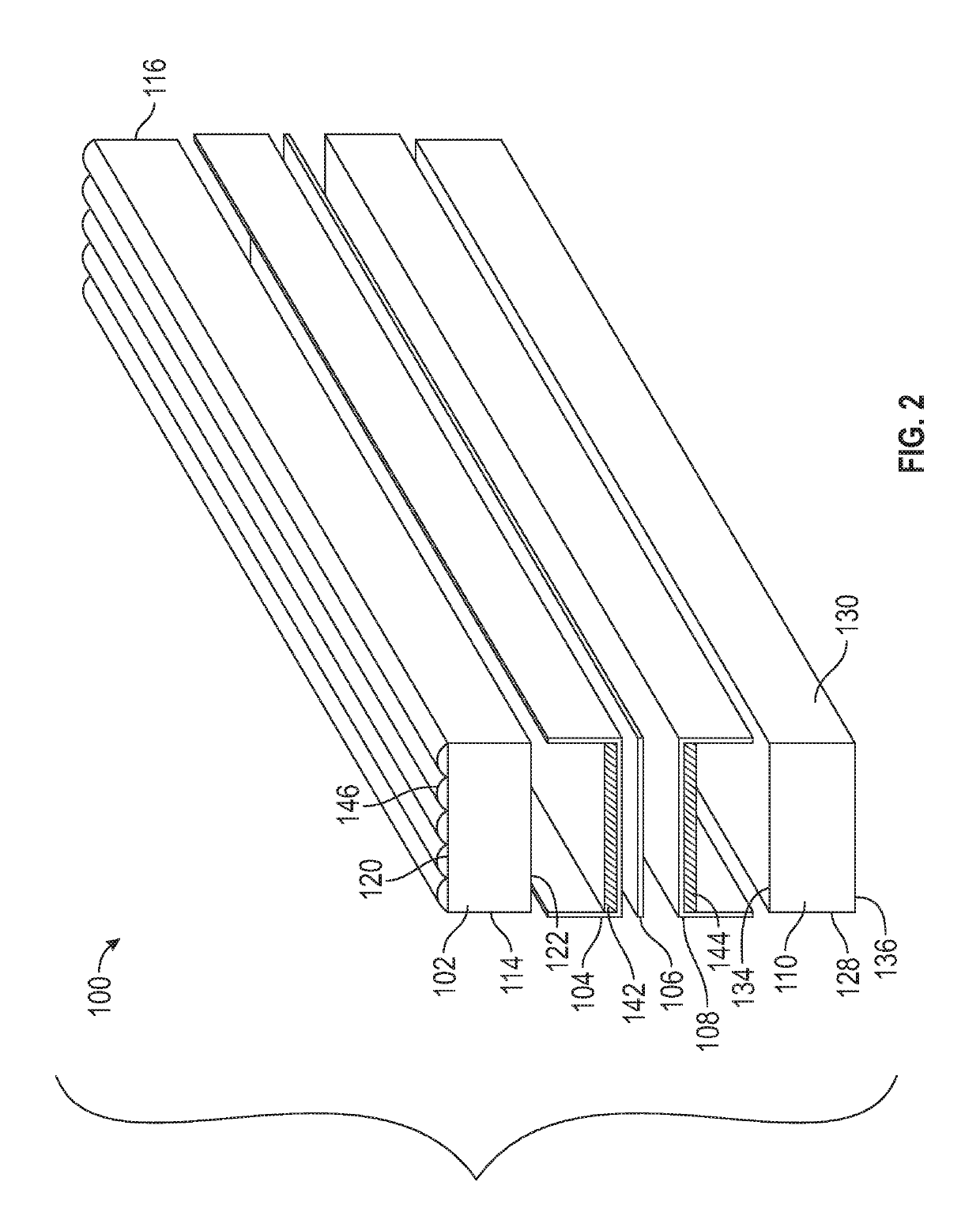

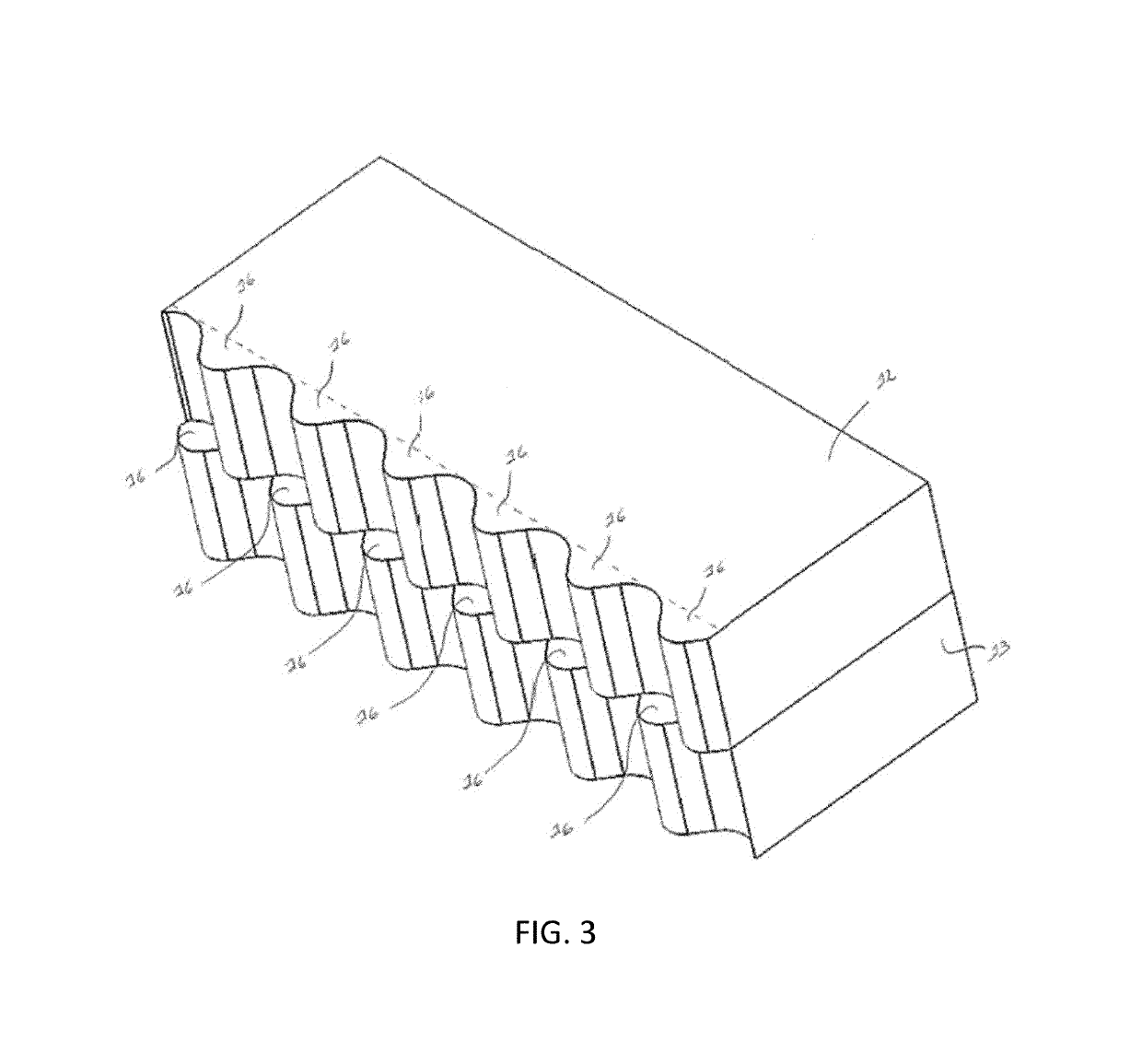

Storage tank insulation joint apparatus and method

A joint for fluid storage tank insulation systems. A central expansion joint forms a fluid-sealed recessed channel having a ridge-like cap. Water and moisture are directed away from the central expansion joint by the ridge-like cap. Any water that breaches the cap enters the recessed channel and flows out of the expansion joint without damaging tank insulation material. With installations having multiple expansion joints, at least one of the expansion joints can be equipped with an inverted cap to form a gutter within such expansion joint.

Owner:NVENT SERVICES GMBH

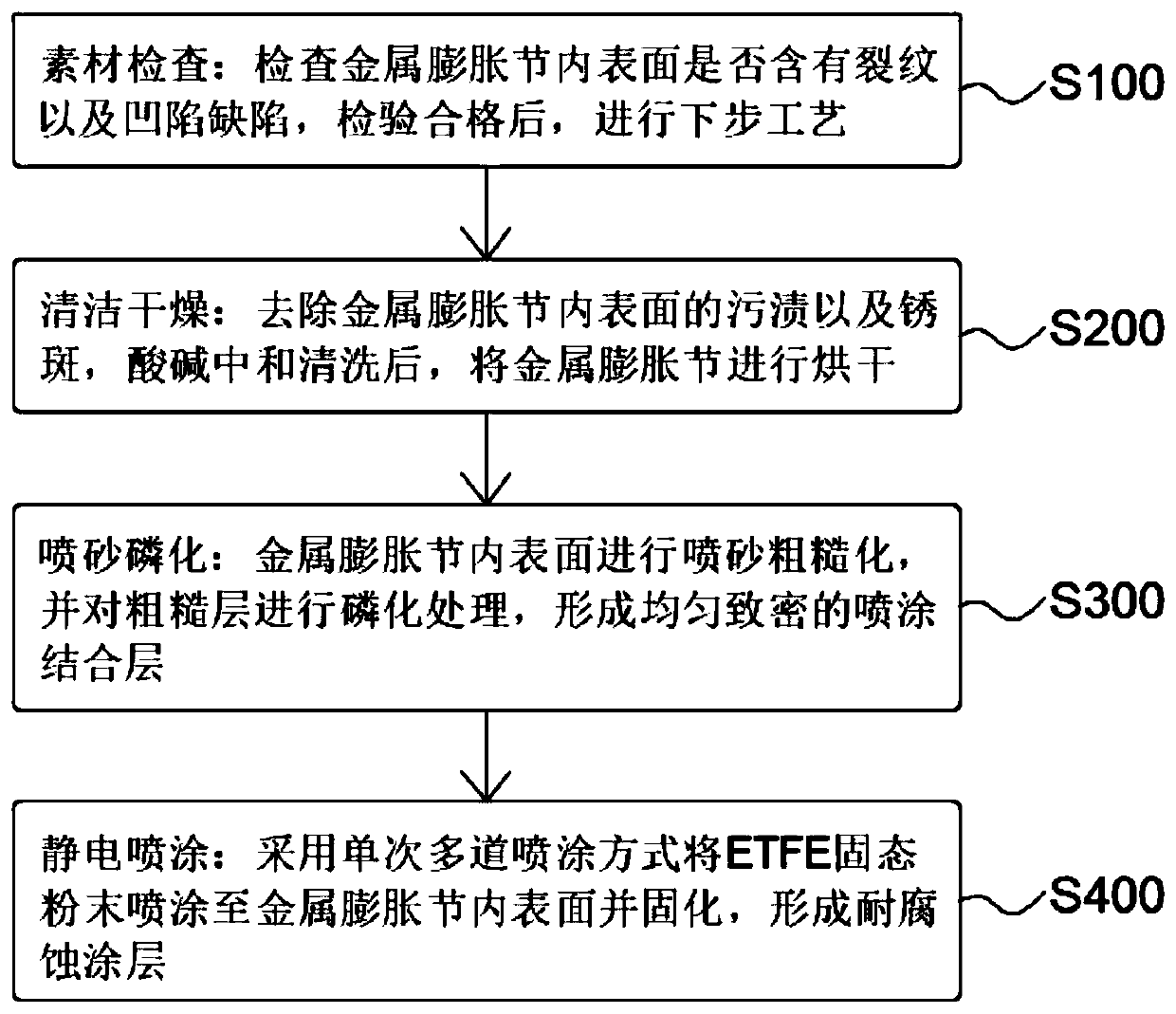

Metal expansion joint inner surface ETFE (ethylene tetra fluoro ethylene) electrostatic powder spraying process

InactiveCN110328130AImprove mechanical propertiesImprove adhesionPretreated surfacesCoatingsSand blastingTetra

The invention discloses a metal expansion joint inner surface ETFE (ethylene tetra fluoro ethylene) electrostatic powder spraying process. The metal expansion joint inner surface ETFE electrostatic powder spraying process includes following steps: S100, inspecting materials: inspecting if the inner surface of a metal expansion joint has cracked and sunken defects, and performing a next step of theprocess after the inner surface of the metal expansion joint passes inspection; S200, performing cleaning and drying: removing blots and rusty spots from the inner surface of the metal expansion joint, and drying the metal expansion joint after finishing acid-base neutralization and washing; S300, performing sand blasting and phosphating: performing the sand blasting on the inner surface of the metal expansion joint so as to roughen the inner surface of the metal expansion joint, performing the phosphating on a rough layer, and forming a uniform and compact spraying combined layer; S400, performing electrostatic spraying: adopting a single time and multiple channel spraying mode for spraying ETFE solid power to the inner surface of the metal expansion joint and solidifying the ETFE solidpower, and forming an anti-corrosion coating. The metal expansion joint inner surface ETFE electrostatic powder spraying process is reasonable in design, greatly improves adhesive force between the electrostatic powder spraying coating and a component to be processes, prevents the electrostatic powder spraying coating from falling off, and improves electrostatic powder spraying quality.

Owner:江苏苏创管业科技有限公司

Expansion joint for highway bridge technical services

InactiveCN108071074AExtended service lifeEasy to operateBridge structural detailsRubber materialEngineering

The invention relates to the field of technical services, in particular to an expansion joint for highway bridge technical services. Fixed seats are fixedly connected to the left and right ends of theupper surface of a bracket; a supporting block is fixedly connected to the middle part of the upper surface of the bracket; a locating seat is fixedly connected to a second trapezoidal surface; limiting plates, which are crossed in a comb tooth shape in parallel, are fixedly connected to the upper surface of the locating seat; a plurality of fixed plates positioned between the crossed limiting plates of a first bridge and a second bridge are arranged on the upper surface of the supporting block; and a water guide plate is made of a rubber material. The expansion joint for the highway bridge technical services has the advantages that a discontinuous maintenance function of the expansion joint can be realized to provide great convenience for operation of related working personnel by arranging the devices such as the limiting plates, the fixed plates, the bracket and so on; and meanwhile, as the gap of the expansion joint is small and the vibration generated during the passing of the vehicle is small, the passing safety of the vehicle is greatly enhanced and the service life of the bridge is greatly prolonged.

Owner:天津凯溢华升科技发展有限公司

Water-cooled nonmetal expansion joint

InactiveCN102052540AWork reliablyEffective absorptionPipeline expansion-compensationPipe heating/coolingMetal frameworkEngineering

Owner:施大钟

Manufacturing technology of flue for gas turbine exhaust system

ActiveCN104405456AFast dryingHigh hardnessMachines/enginesEngine componentsManufacturing technologyManganese

The invention discloses a manufacturing technology of a flue for a gas turbine exhaust system. Chrome molybdenum low-alloy steel is selected to be used as a blank material, and the chrome molybdenum low-alloy steel comprises, by mass, 0.3 percent to 0.32 percent of carbon, 0.18 percent to 0.36 percent of silicon, 0.50 percent to 0.70 percent of manganese, 0.90 percent to 1.10 percent of chrome, 0.20 percent to 0.30 percent of molybdenum, 0 percent to 0.02 percent of phosphorus, 0 percent to 0.025 percent of sulphur, 0 ppm to 1.8 ppm of hydrogen, 0 percent to 0.40 percent of nickel, 0 percent to 0.03 percent of vanadium, 0 percent to 0.30 percent of copper, 0 percent to 0.9 percent of residual elements and the balance Fe. Boron-modified organic silicon resin high-temperature-resisting coatings are selected to coat the inner surface and the outer surface of the flue. By means of the manufacturing technology of the flue for the gas turbine exhaust system, the high wear-resisting, pressure-resisting, high-temperature-resisting and corrosion-resisting capability of a metal expansion joint can be greatly improved; operation is easy and convenient; and the production efficiency of the flue can be improved.

Owner:江苏华强新能源科技有限公司

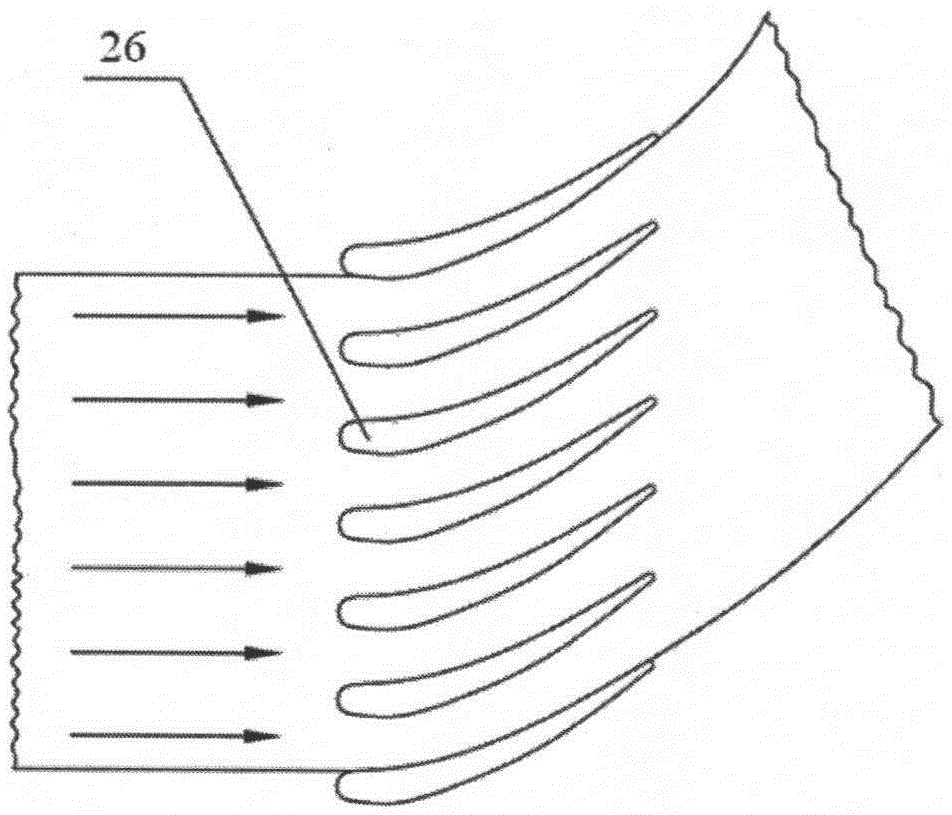

Universal angle hinge type expansion joint

InactiveCN103148309AHigh working reliabilityEasy to usePipeline expansion-compensationEngineeringHigh rise

The invention relates to the technical field of expansion joints, in particular to a universal angle hinge type expansion joint, which comprises a corrugated pipe, a left connecting pipe, a right connecting pipe and a pin shaft assembly, wherein the left connecting pipe and the right connecting pipe are arranged at the left and right ends of the corrugated pipe; the pin shaft assembly comprises a vertical plate, hinge plates, a pin shaft and a universal ring; the vertical plate is fixed on the left connecting pipe; the universal ring is fixed on the corrugated pipe; the vertical plate is fixedly connected with the universal ring through the hinge plates; the hinge plates are arranged on both sides of the corrugated pipe; the hinge plates are fixed together with the universal ring through the pin shaft; and a slide block is connected with the universal ring and the right connecting pipe. Due to the adoption of the universal angle hinge type expansion joint, axial compensation and angular compensation can be performed at the same time, multi-direction displacement compensation requirement on a pipeline is met, the working reliability and availability of the expansion joint are enhanced, and the service lives of equipment and a system are prolonged effectively; and the universal angle hinge type expansion joint is widely applied to inlets and outlets of central air conditioner pumps, high-rise building fire pumps and water supply pumps.

Owner:江苏星光波纹管有限公司

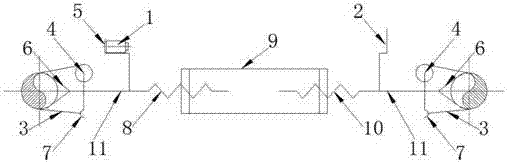

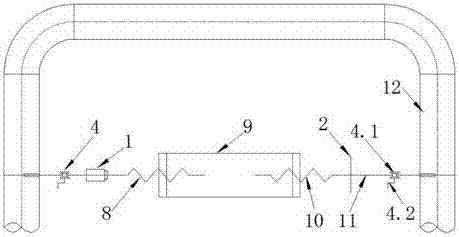

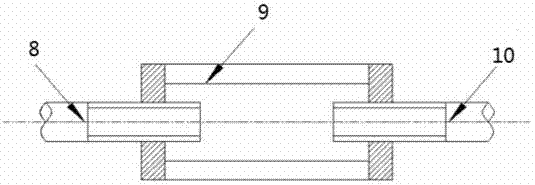

Expansion amount measuring and presetting method and device for pi-shaped pipe expansion joints

PendingCN107575686AEasy to installImprove reliabilityPipeline expansion-compensationUsing optical meansLocking mechanismMeasuring instrument

The invention discloses an expansion amount measuring and presetting method and device for pi-shaped pipe expansion joints. According to the technical scheme, a photoelectric distance measuring instrument and a corresponding distance measuring refraction plate are included, and an expansion and contraction adjustor is further included. The two ends of the expansion and contraction adjustor are connected with locking mechanisms through connecting supports correspondingly. The photoelectric distance measuring instrument is arranged on the connecting support on one side through a photoelectric distance measuring instrument base, and the distance measuring refraction plate is arranged on the connecting support on the other side. The device is simple, low in cost and high in precision. According to the method, operation is convenient, the installing number of the pi-shaped pipe expansion joints can be effectively reduced, the pipe system space is effectively saved, and the expansion amountmeasuring and presetting method and device are particularly suitable for expansion amount measuring and presetting during high-temperature and high-pressure pi-shaped pipeline constructing and repairing.

Owner:WUHUAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com