Double-water stop structure for concrete expansion joint and manufacturing and construction method for double-water stop structure

A technology of concrete and expansion joints, which is applied in underwater structures, infrastructure engineering, earthwork drilling and mining, etc. It can solve the problems of irregular deformation of concrete tanks, prolonging the construction period, and difficult cleaning, so as to save installation procedures, reduce construction period, The effect of preventing cross-sectional interface misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

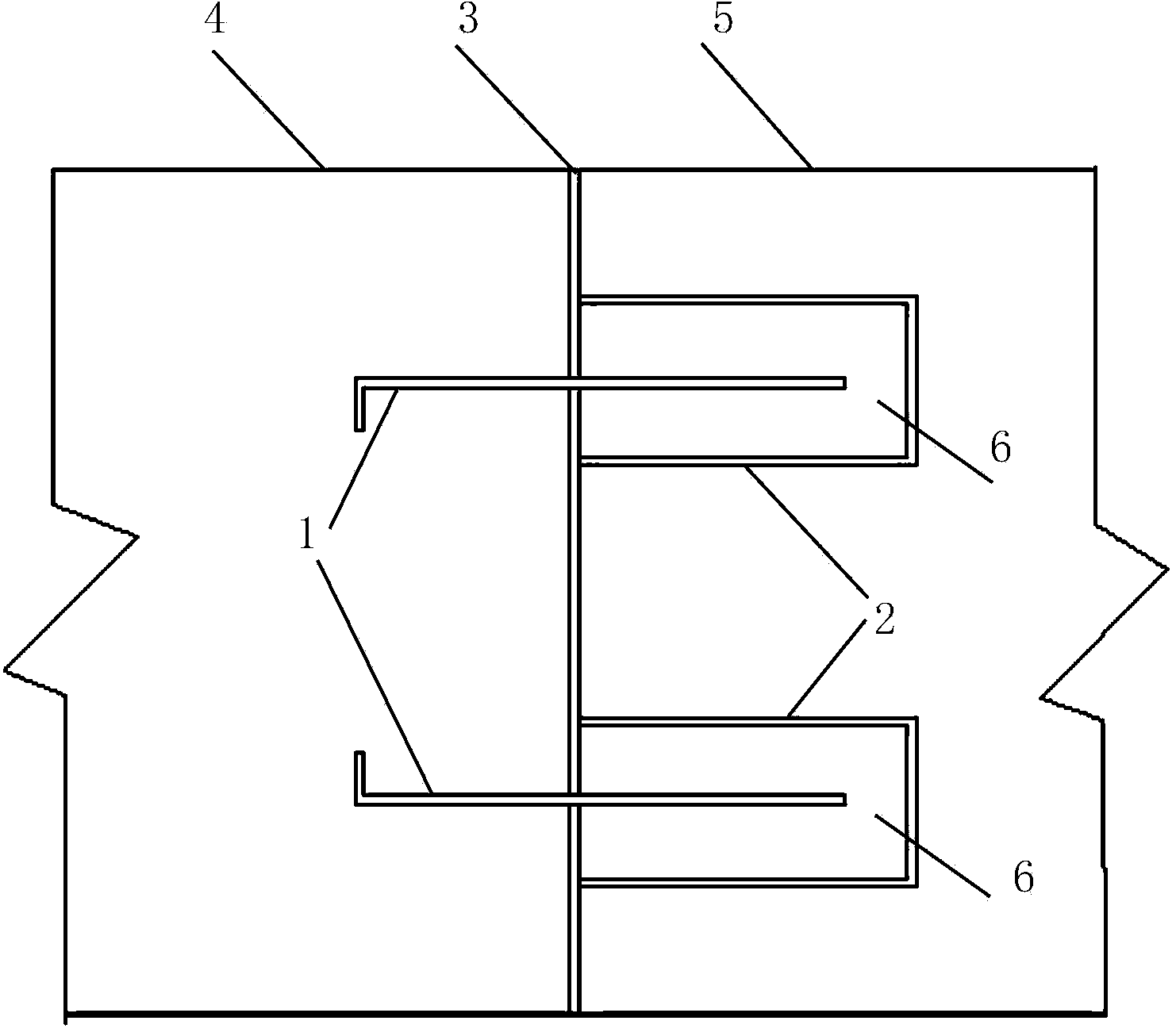

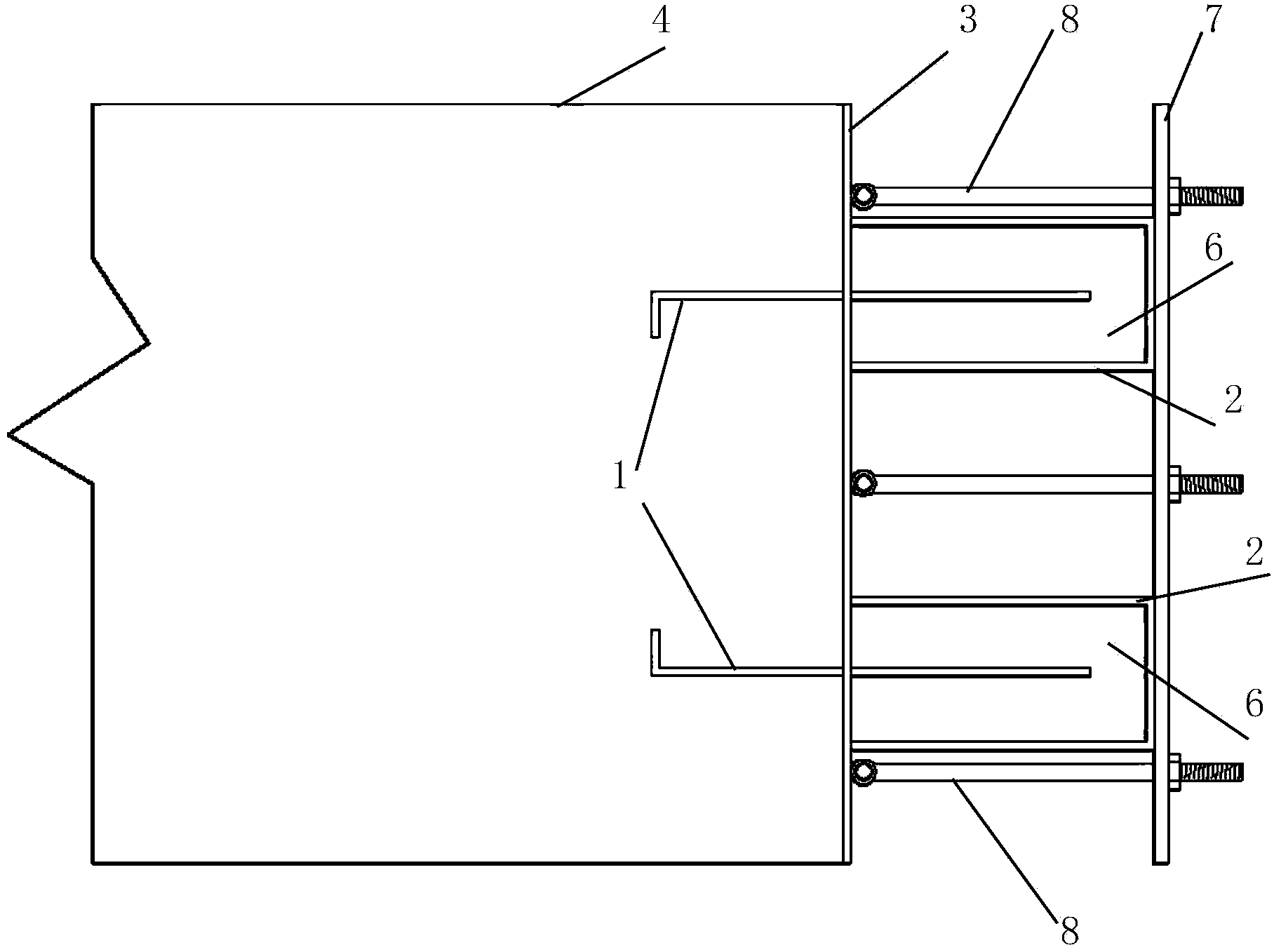

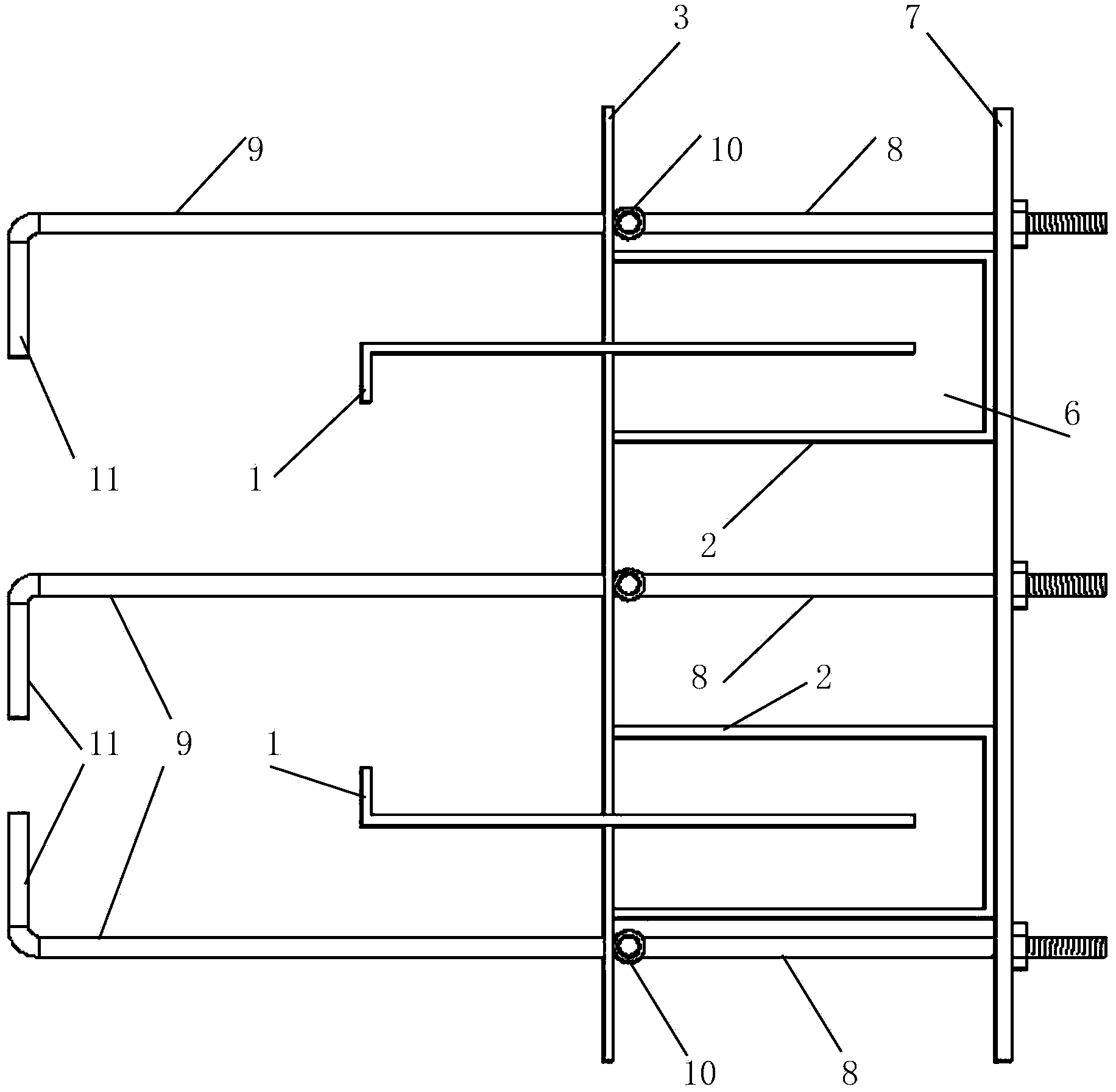

[0044] Embodiment, referring to the accompanying drawings: a concrete expansion joint double water-stop structure, including a deformation piece 1, a channel steel 2, two deformation pieces 1 are provided on the concrete section, and the two deformation pieces 1 are vertically arranged at a predetermined distance , half of which is pre-embedded in the first-stage concrete 4, and the other half protrudes from the concrete section and is respectively arranged in the corresponding channel steel 2, and the channel steel 2 is provided with asphalt 6; the channel steel 2 Linoleum 3 is provided on the opening surface and the section of the first-stage concrete 4 .

[0045]Further, the deformable sheet 1 is in the form of a rectangular plate with a width of 30-60 cm and a length equal to the height of the concrete section. The side poured into the concrete is bent at 90° with a bending height of 2-5 cm. Two deformable sheets 1 are respectively arranged on The distance between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com