Phase-change energy-storage composite coating material and method for making same

A technology of phase change energy storage and composite coatings, which is applied in chemical instruments and methods, coatings, heat exchange materials, etc., and can solve problems that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

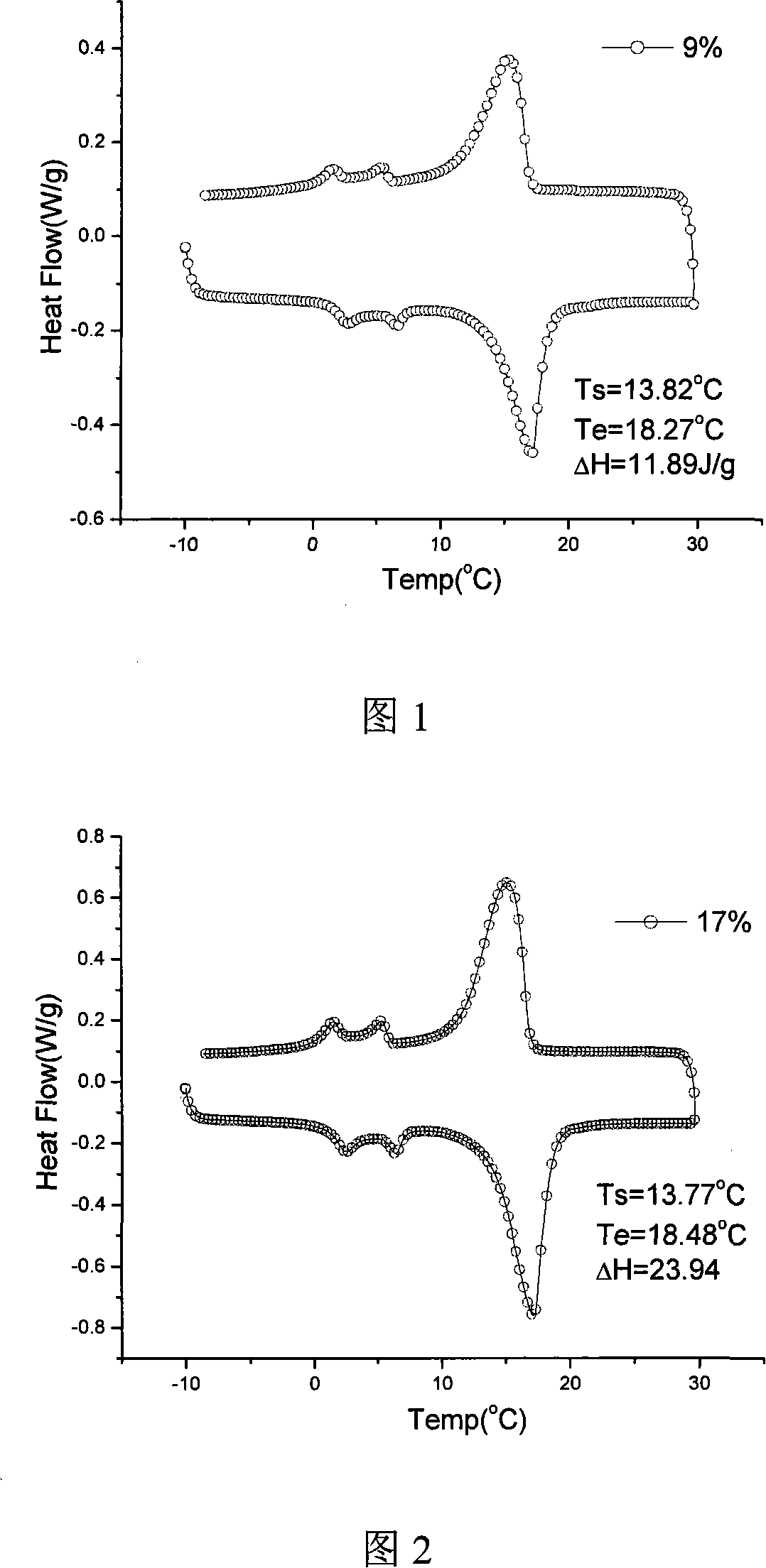

Embodiment 1

[0014] The porous graphite-based phase change energy storage composite material powder is composed of butyl stearate and porous graphite powder with a mass ratio of 5:1, that is, the phase change material accounts for 83% of the total mass of the composite material. The pure acrylic emulsion adopts the anionic pure acrylic emulsion of Qingdao Xingguo Paint Chemical Co., Ltd., and its solid content is 40%. The styrene-acrylic emulsion is Acronal S 716 styrene-acrylic emulsion from BASF, Germany, with a solid content of 50%. According to the above-mentioned preparation method, prepare phase-change energy-storage composite paint, the content of porous graphite-based phase-change energy-storage composite material micropowder in functional layer paint is 9wt%, the formula of overlay paint is: pure acrylic emulsion: styrene-acrylic emulsion: water= 0.4:0.1:0.5. The proportions among the ingredients described in the present invention are all weight ratios. In the preparation proces...

Embodiment 2

[0016] The porous graphite-based phase change energy storage composite material powder is composed of butyl stearate and porous graphite powder with a mass ratio of 5:1, that is, the phase change material accounts for 83% of the total mass of the composite material. The pure acrylic emulsion adopts the anionic pure acrylic emulsion of Qingdao Xingguo Paint Chemical Co., Ltd., and its solid content is 40%. The styrene-acrylic emulsion is Acronal S 716 styrene-acrylic emulsion from BASF, Germany, with a solid content of 50%. According to the above-mentioned preparation method, prepare phase-change energy-storage composite paint, the content of porous graphite-based phase-change energy-storage composite material micropowder in functional layer paint is 17wt%, and the formula of covering layer paint is: pure acrylic emulsion: styrene-acrylic emulsion: water= 0.4:0.1:0.5. In the preparation process of the functional coating and the covering coating, a small-scale high-speed disper...

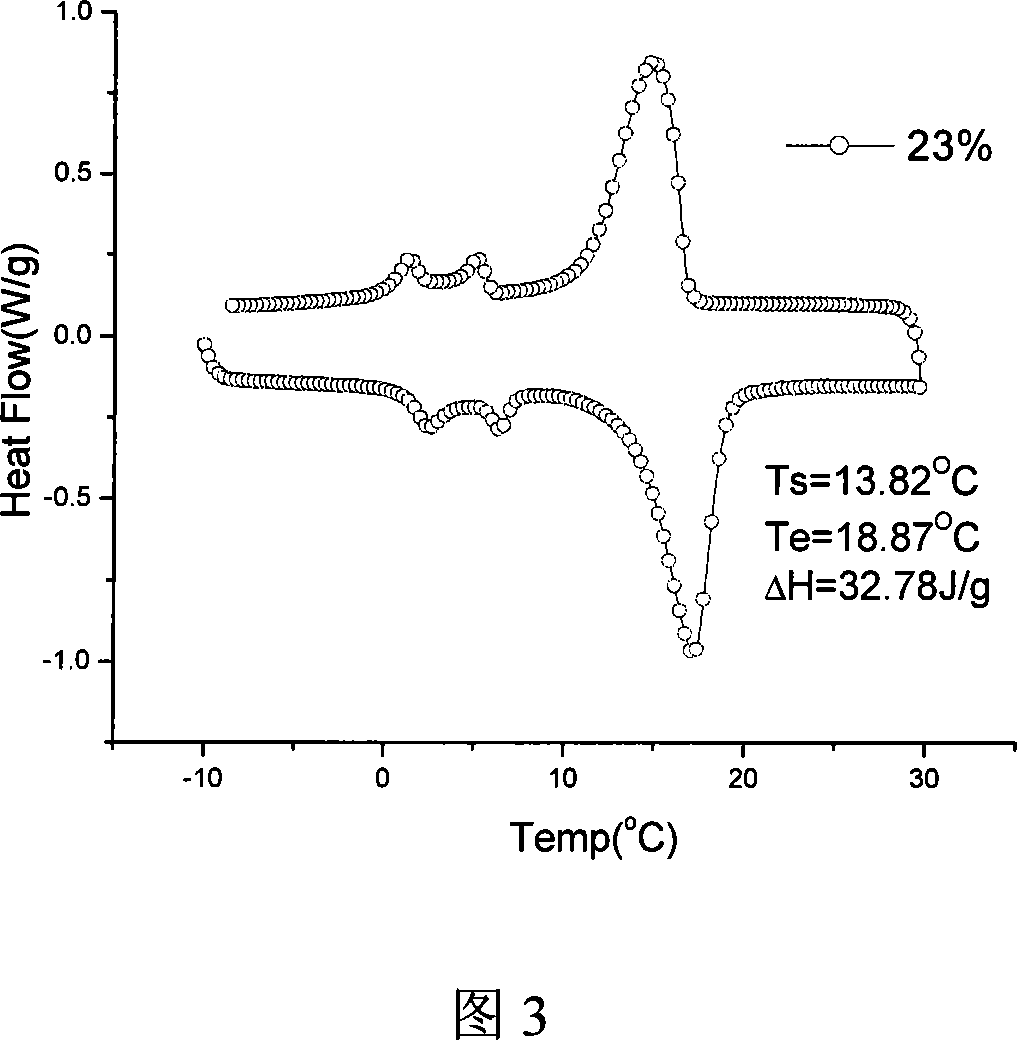

Embodiment 3

[0018] The porous graphite-based phase change energy storage composite material powder is composed of butyl stearate and porous graphite powder with a mass ratio of 5:1, that is, the phase change material accounts for 83% of the total mass of the composite material. The pure acrylic emulsion adopts the anionic pure acrylic emulsion of Qingdao Xingguo Paint Chemical Co., Ltd., and its solid content is 40%. The styrene-acrylic emulsion is Acronal S 716 styrene-acrylic emulsion from BASF, Germany, with a solid content of 50%. According to the above-mentioned preparation method, prepare phase-change energy-storage composite coating, the content of porous graphite-based phase-change energy-storage composite material micropowder in functional layer coating is 23wt%, and the formula of overlay coating is: pure acrylic emulsion: styrene-acrylic emulsion: water= 0.4:0.1:0.5. In the preparation process of functional coatings and covering coatings, a small high-speed disperser made in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com