Installation method for energy-saving steel-plastic auxiliary frames and doors/windows

An installation method and energy-saving technology, applied in the direction of windows/doors, frame fixing, building components, etc., can solve the problems of damage and pollution of the outer frame of doors and windows, time-consuming labor and materials, labor wages and other problems, saving labor costs, The effect of improving utilization, saving resources and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

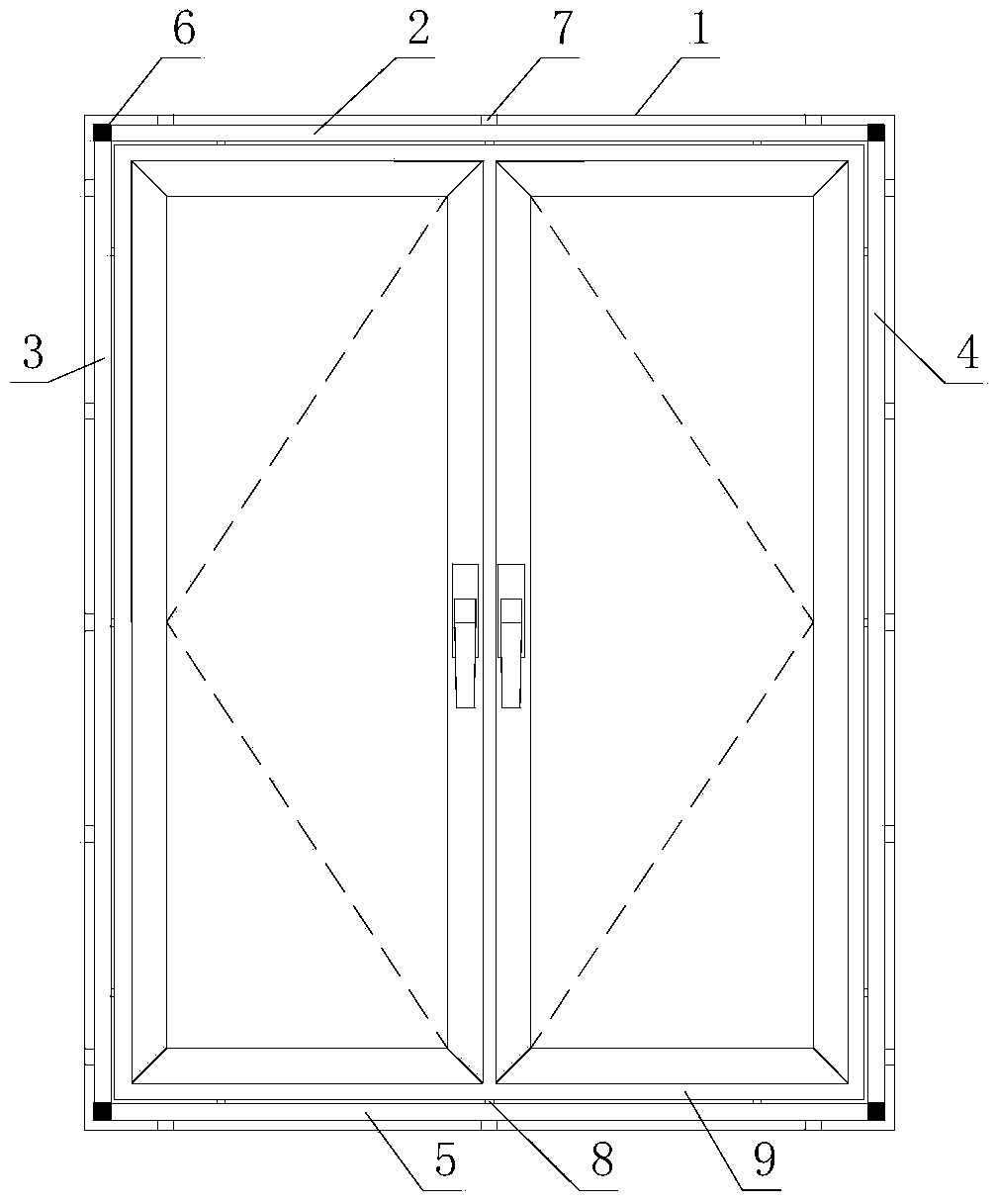

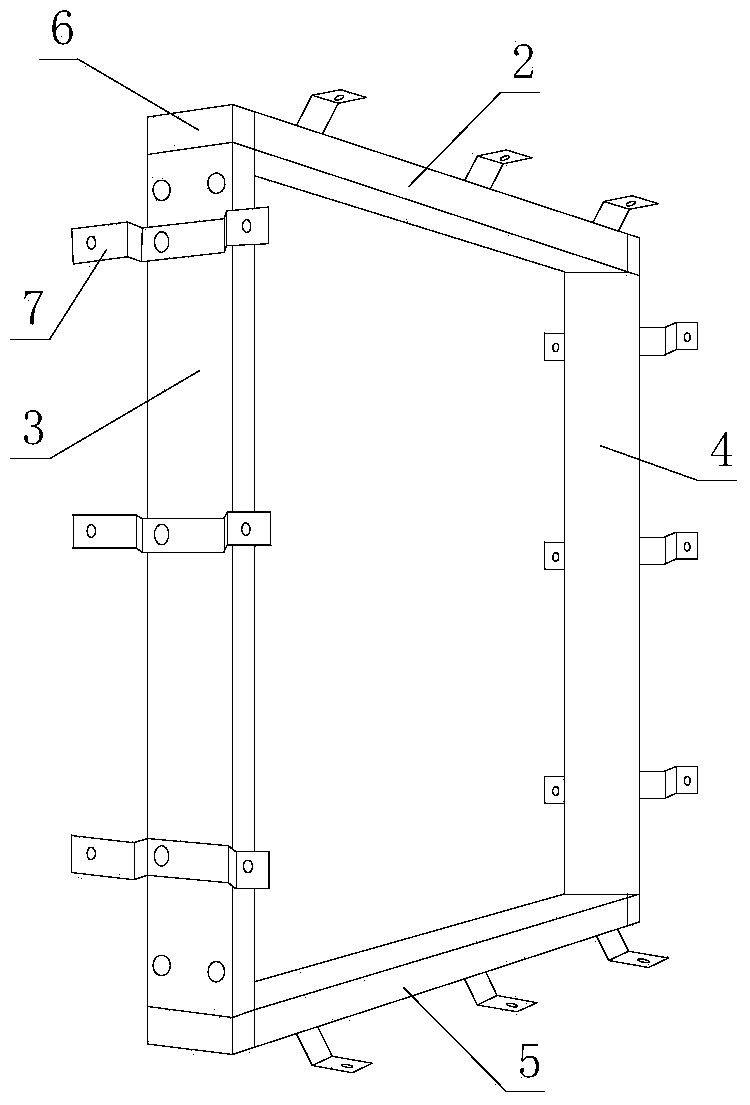

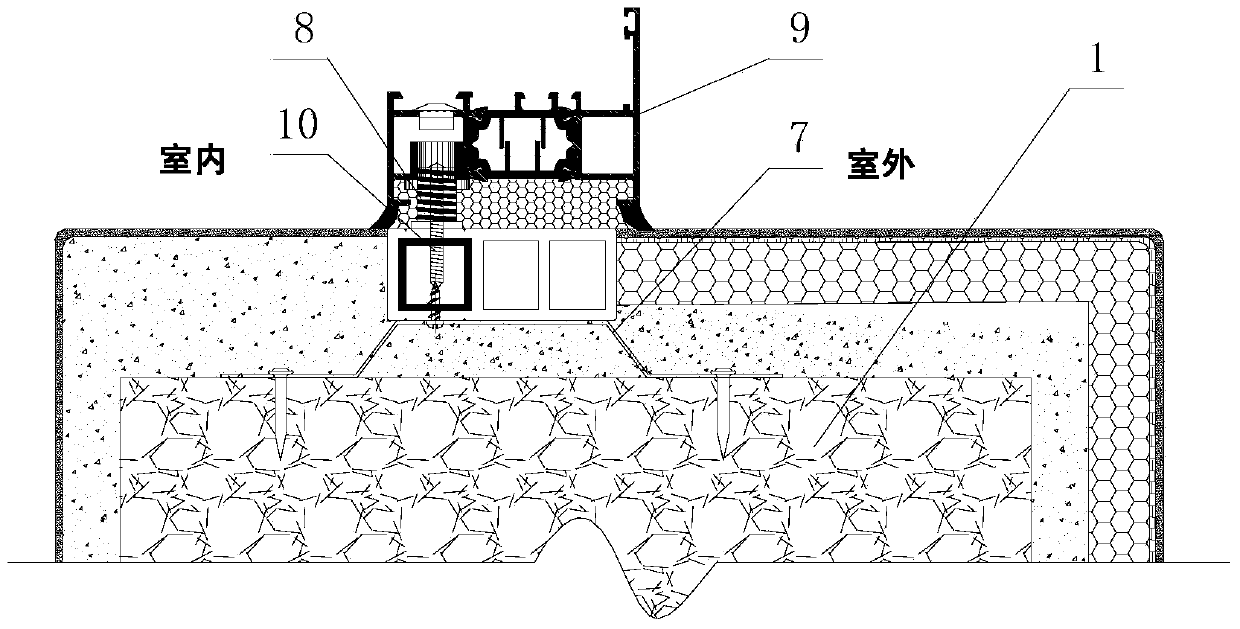

[0041] Such as Figure 5 Shown is an installation method of an energy-saving steel-plastic attached frame and an aluminum alloy sunshade inner casement system door and window. The side of the attached frame with the steel lining faces indoors, and the indoor side of the outer frame 9 of the door and window is flush with the indoor side of the attached frame. The outdoor side of door and window outer frame 9 exceeds the outdoor side of the attached frame;

[0042] Before the door and window outer frame 9 is pushed into the opening of the attached frame, the positioning pressure line 11 is fixedly installed on the additional frame, and the outdoor side of the positioning pressure line 11 is flush with or exceeds the outdoor side of the attached frame, and the positioning pressure line 11 is inboard. Silicone sealant is applied, and the door and window outer frame 9 to be installed is pushed out from the indoor to the installation hole to the positioning pressure line 11, and the s...

Embodiment 2

[0044] Such as Figure 6 As shown in the installation method of an energy-saving steel-plastic attached frame and a plastic-steel sliding door and window, the side of the attached frame with the steel lining faces the outside, and the center of the steel lining of the outer frame 9 of the door and window needs to be flush with the center of the steel lining of the attached frame. Drive into self-tapping screw 10 in door and window outer frame 9 central steel liner positions, and door and window outer frame 9 is fixedly connected with attached frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com