Butt joint device of expansion joint of drain pipe

A technology of expansion joints and butt joints, applied in the direction of pipes/pipe joints/pipes, adjustable connections, passing elements, etc., can solve the problems of water seepage or leakage of expansion pipes, inability to be relatively fixed, and prolong the progress of the project, so as to reduce the difficulty of installation. , Simple docking, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

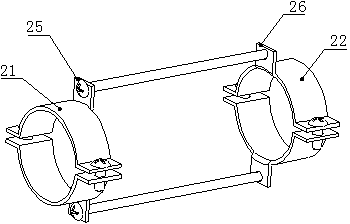

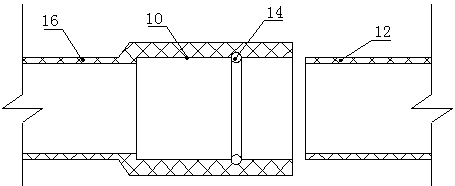

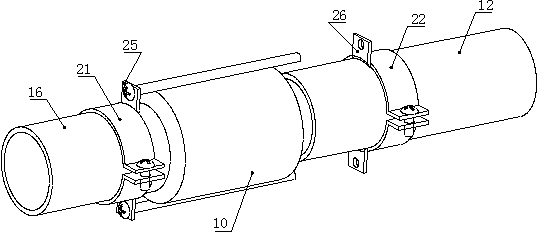

[0015] Such as figure 1 , figure 2 As shown, the present invention is a drainage pipe telescopic joint docking device, which is used to assist the connection pipe end to form a telescopic connection position. The telescopic connection position has an outer sleeve 10, an inner insertion tube 12, and is located between the outer sleeve 10 and the The sealing ring 14 between the inner tubes 12, the inner tube 12 is inserted into the opening of the outer tube 10, the opposite end of the outer tube 10 to the opening is connected with a main body root 16, and the main body root 16 is circumferentially provided with a second A clasp ring 21, the outer circumference of the inner insertion tube 12 is provided with a second clasp ring 22, the first clasp ring 21 has a first spacer 25 perpendicular to the tube axis, the second clasp ring 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com