Patents

Literature

95results about How to "Reduce installation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

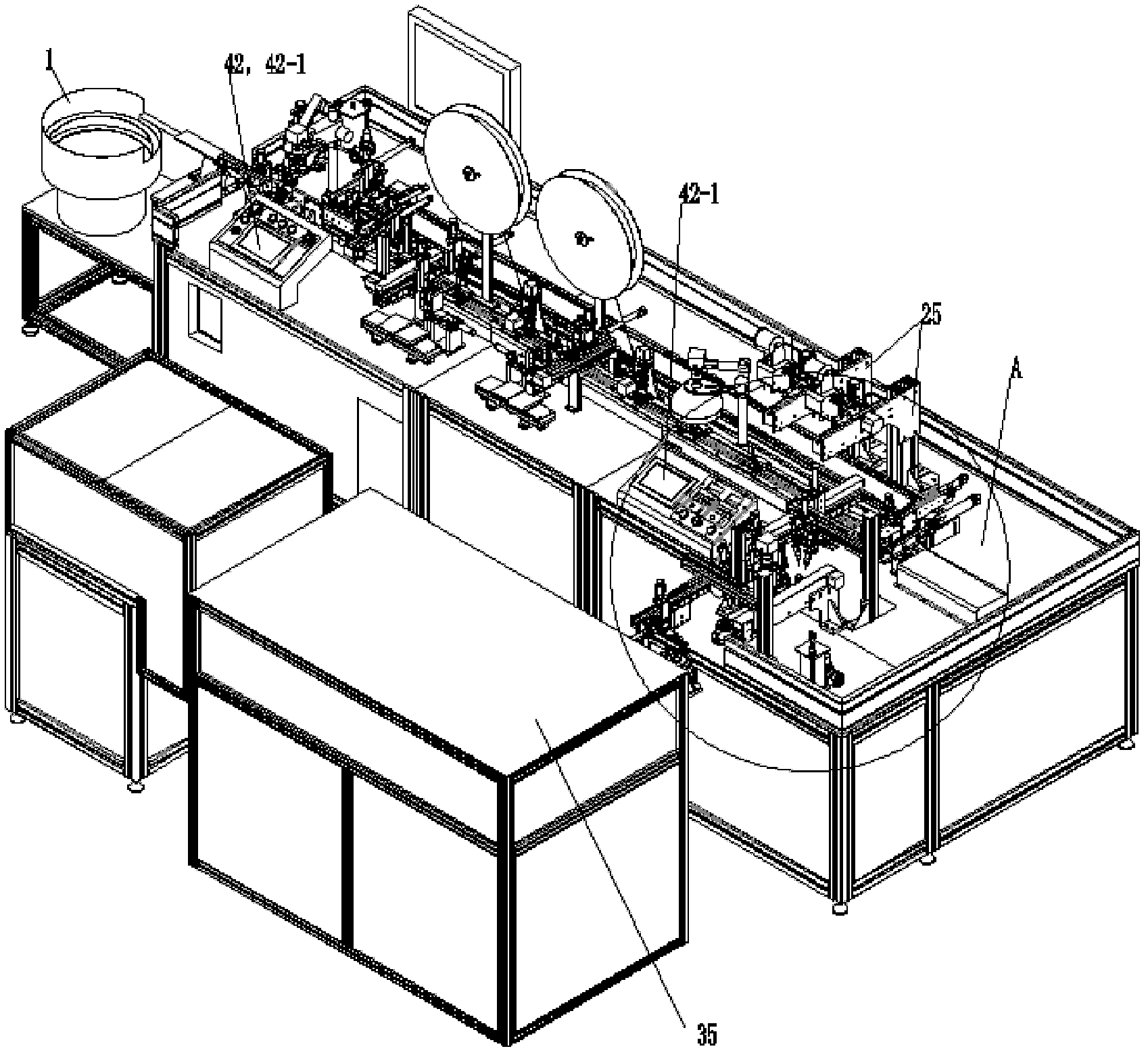

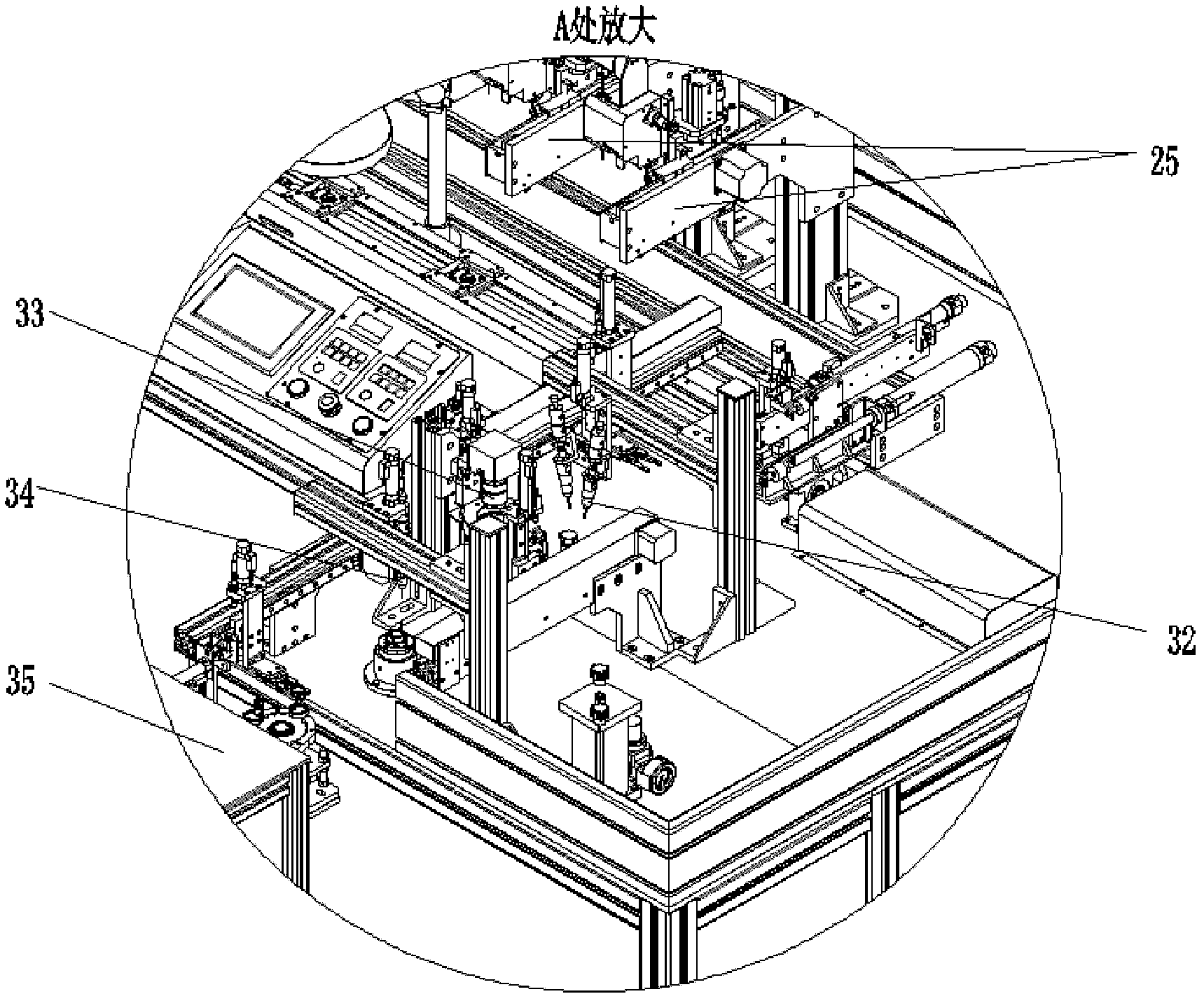

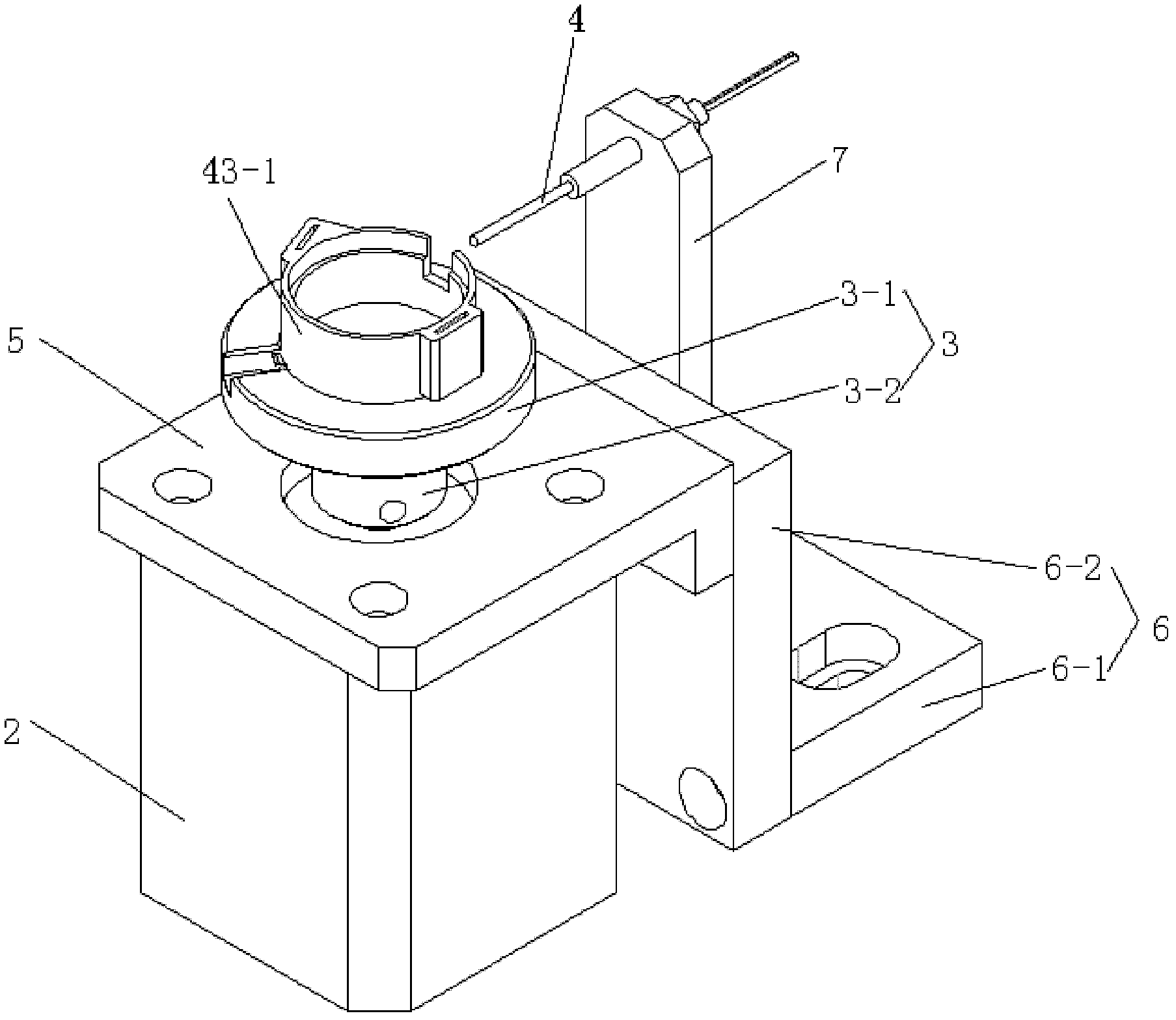

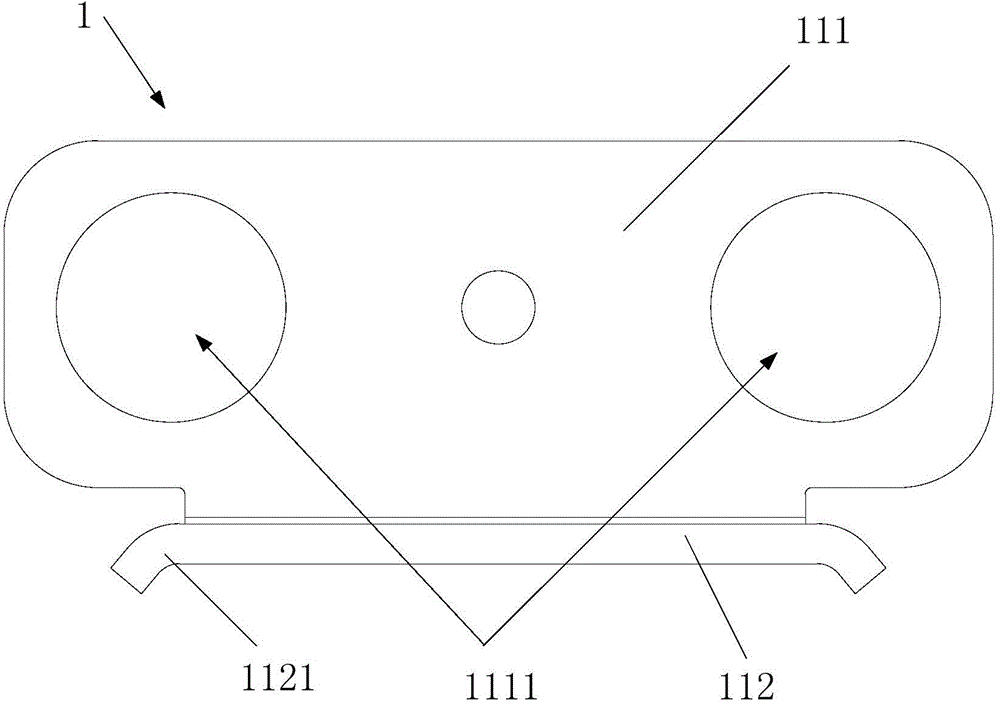

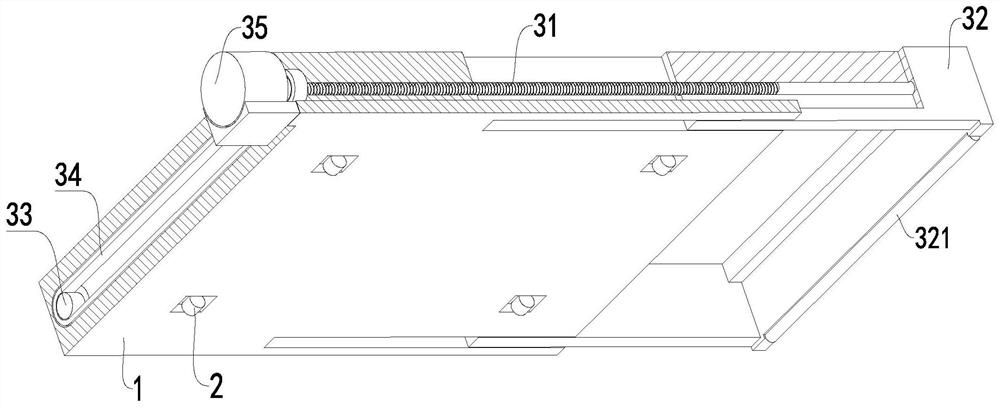

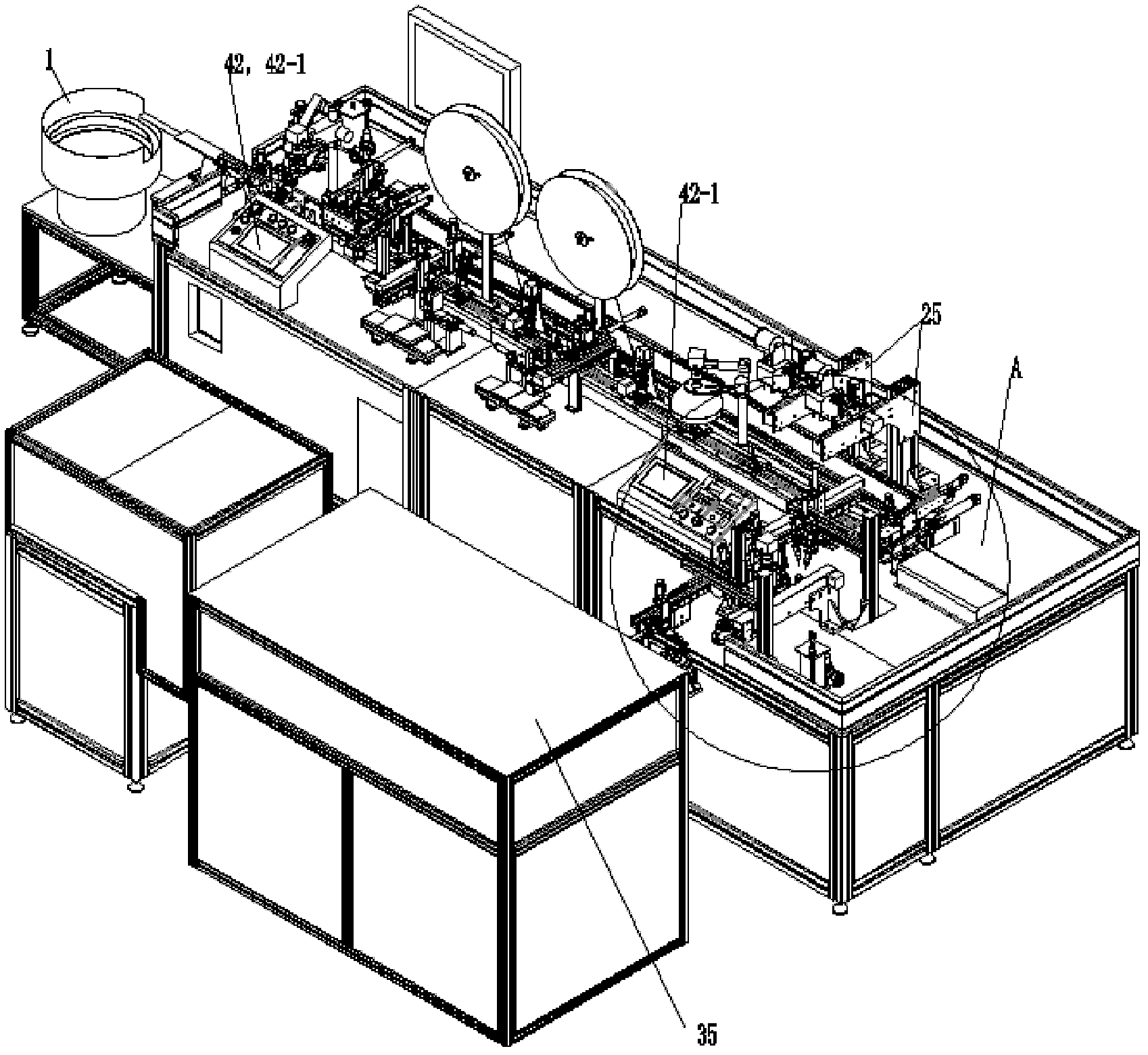

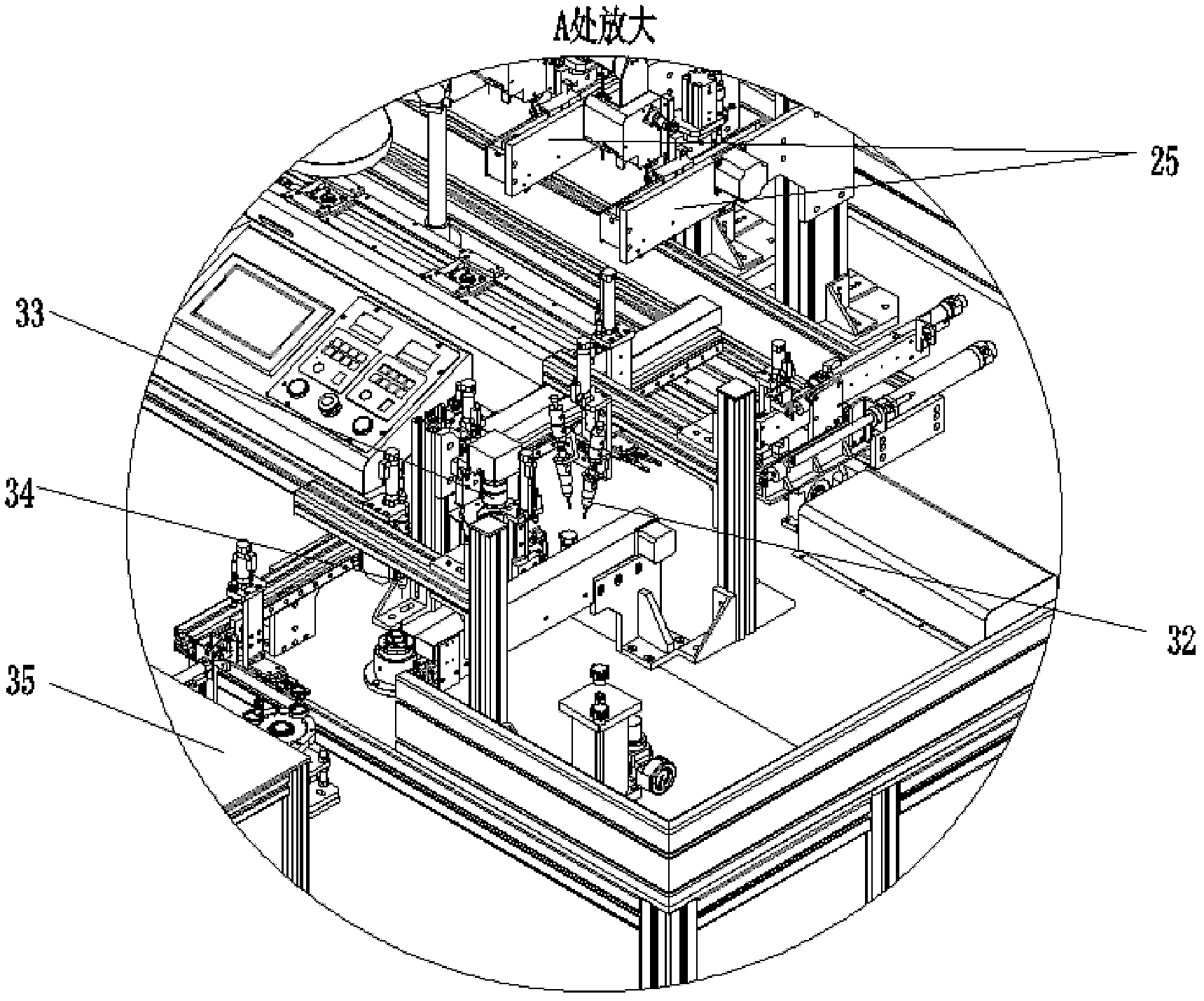

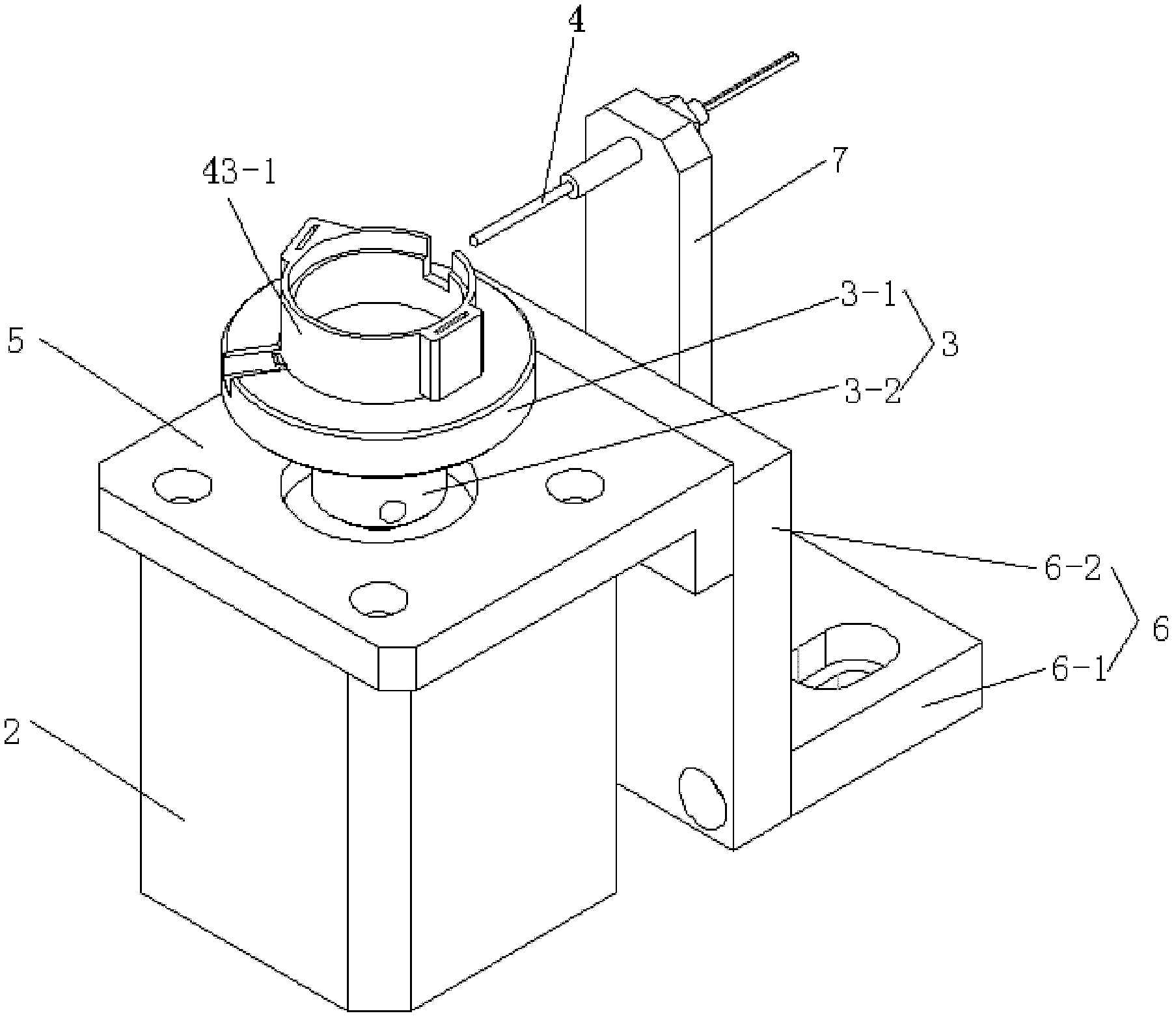

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

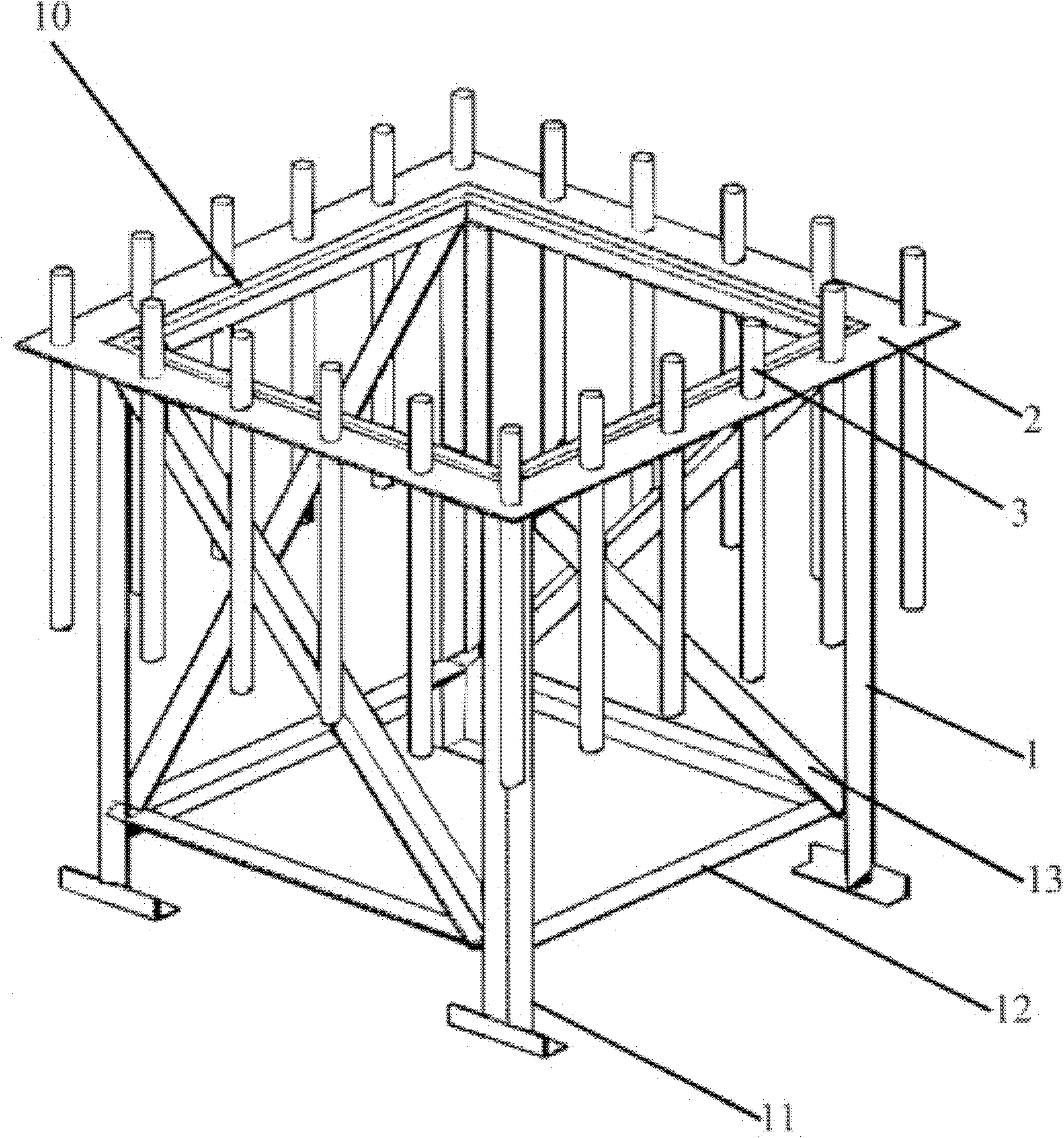

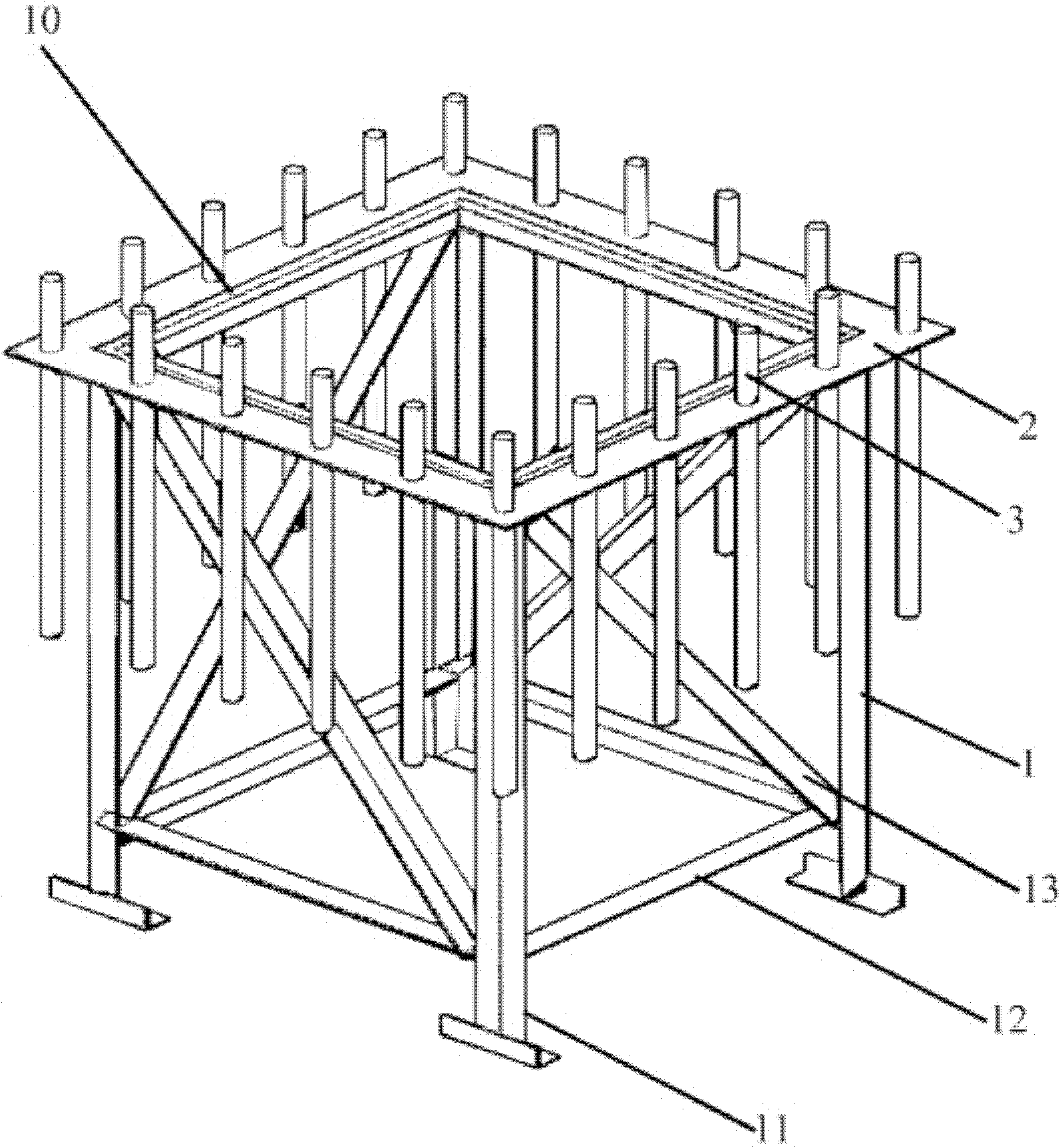

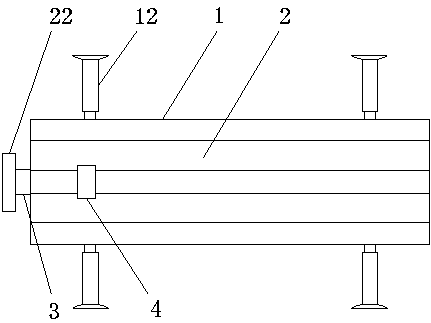

Foundation bolt stock and manufacture method thereof

The invention discloses a foundation bolt stock and a manufacture method thereof, belonging to the field of steel structure construction. The foundation bolt stock comprises a support frame and a location plate frame, wherein the upper end of the support frame is provided with a support surface, a location frame is arranged on the support surface, the location plate frame is of a rectangular-ambulatory plate frame structure and is sleeved on the location frame on the support surface of the support frame, and a plate body of the location plate frame is uniformly provided with a plurality of location holes for installing foundation bolts. Compared with the traditional foundation bolt stock, the foundation bolt stock has the advantages that: 1, due to size control of a location plate and a column bottom plate of the foundation bolt stock, the problem of interference of concrete vertical joint bars and the location plate is reduced; and 2, the consumption of materials is reduced, and the material waste is decreased.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

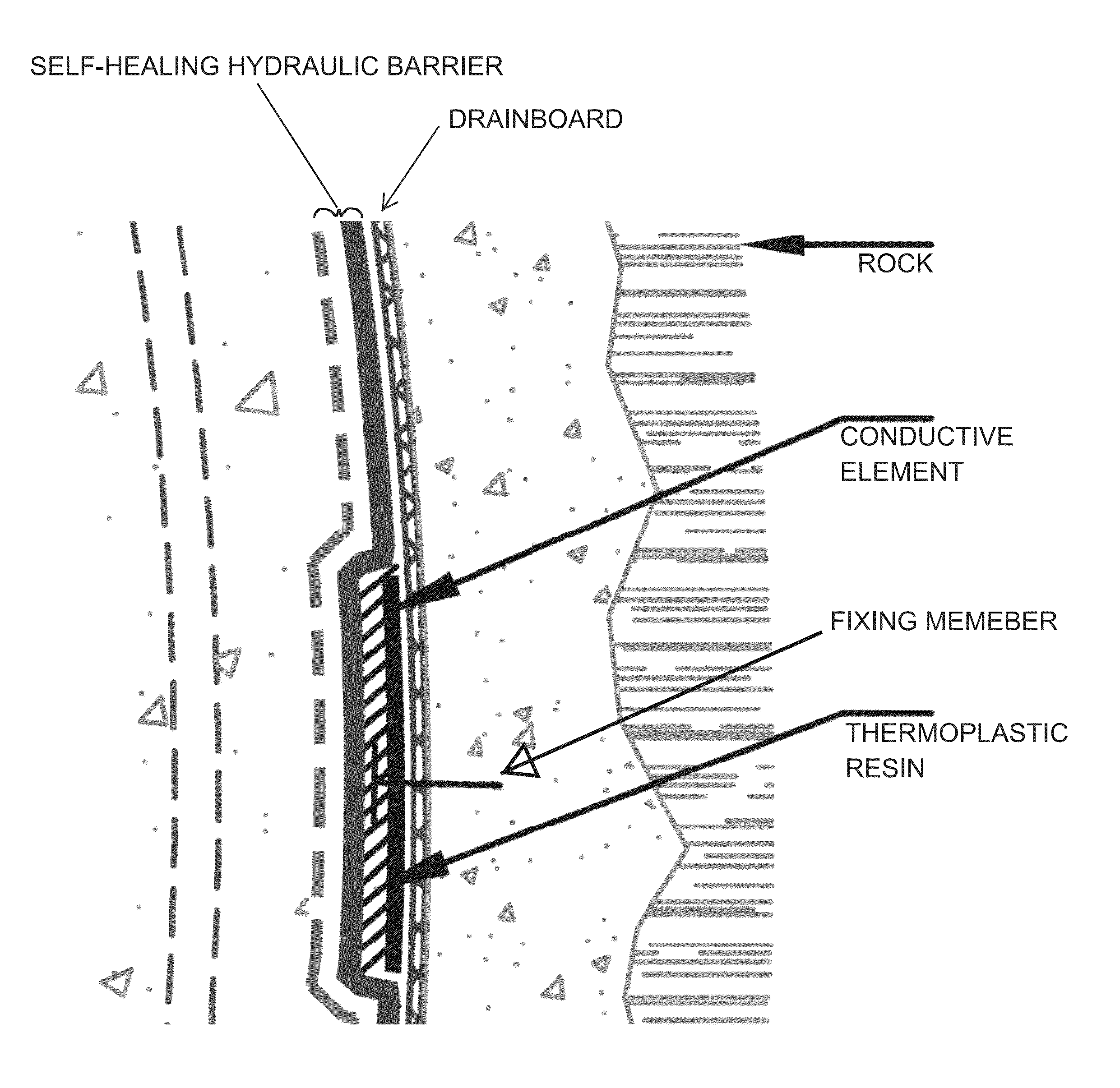

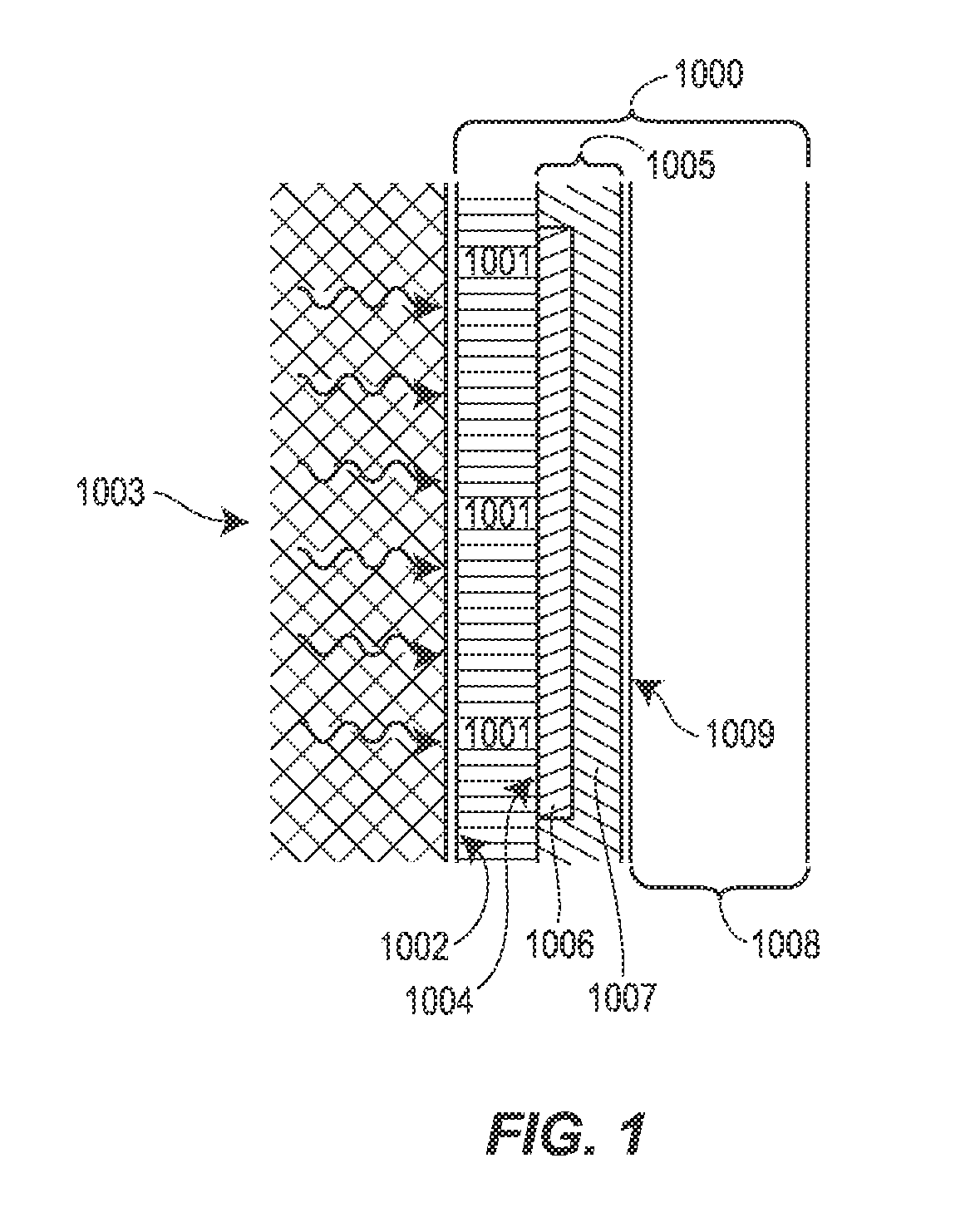

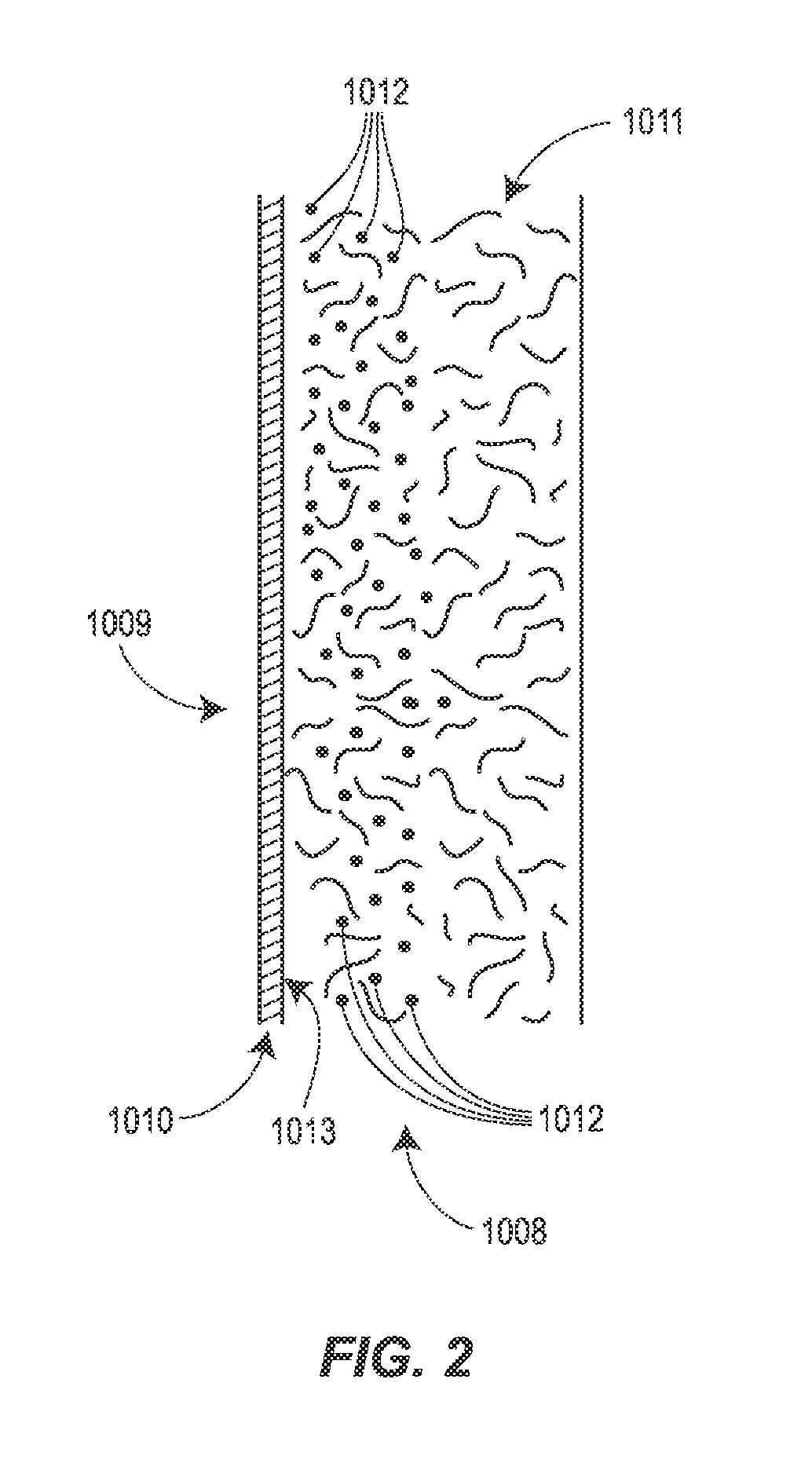

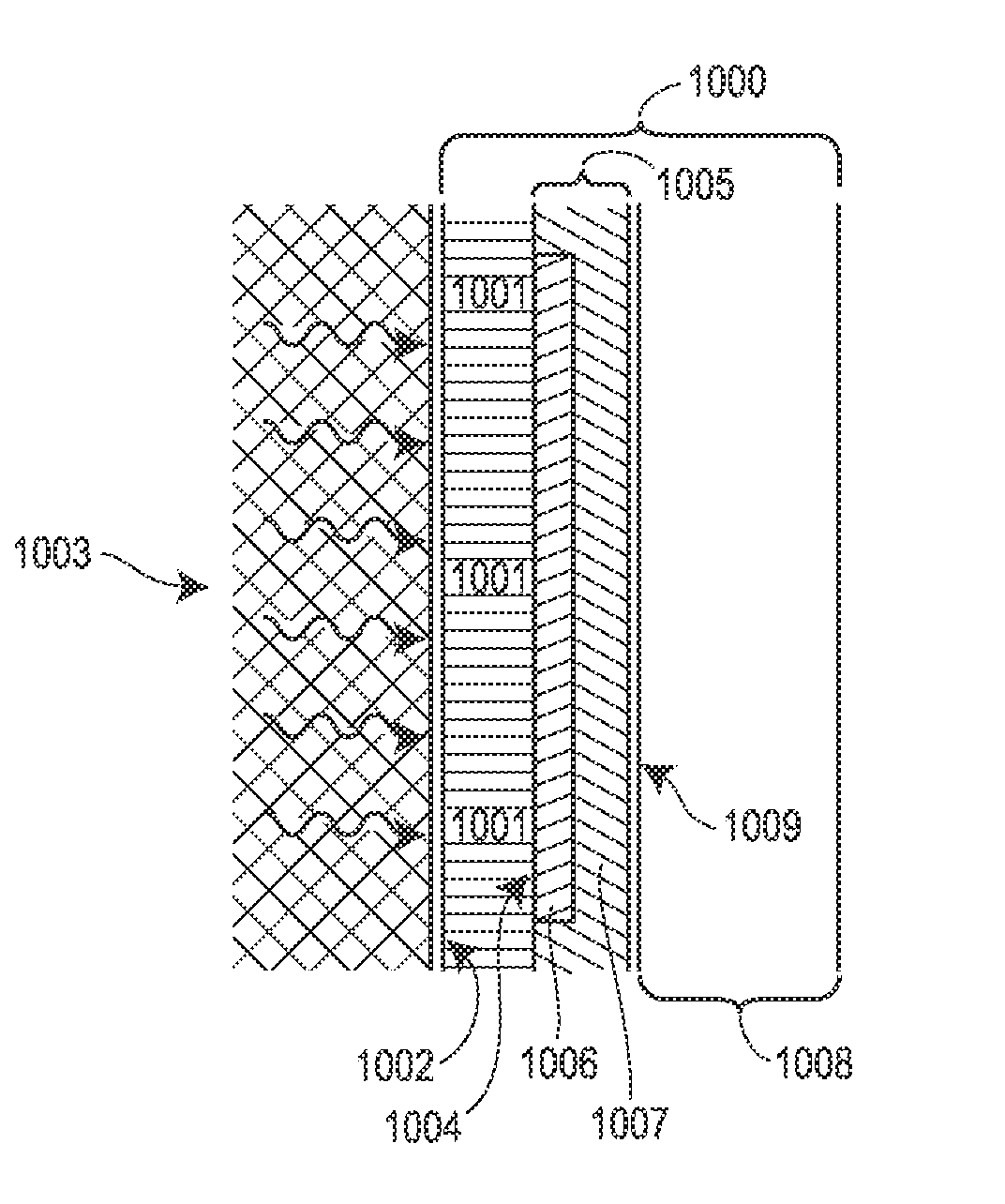

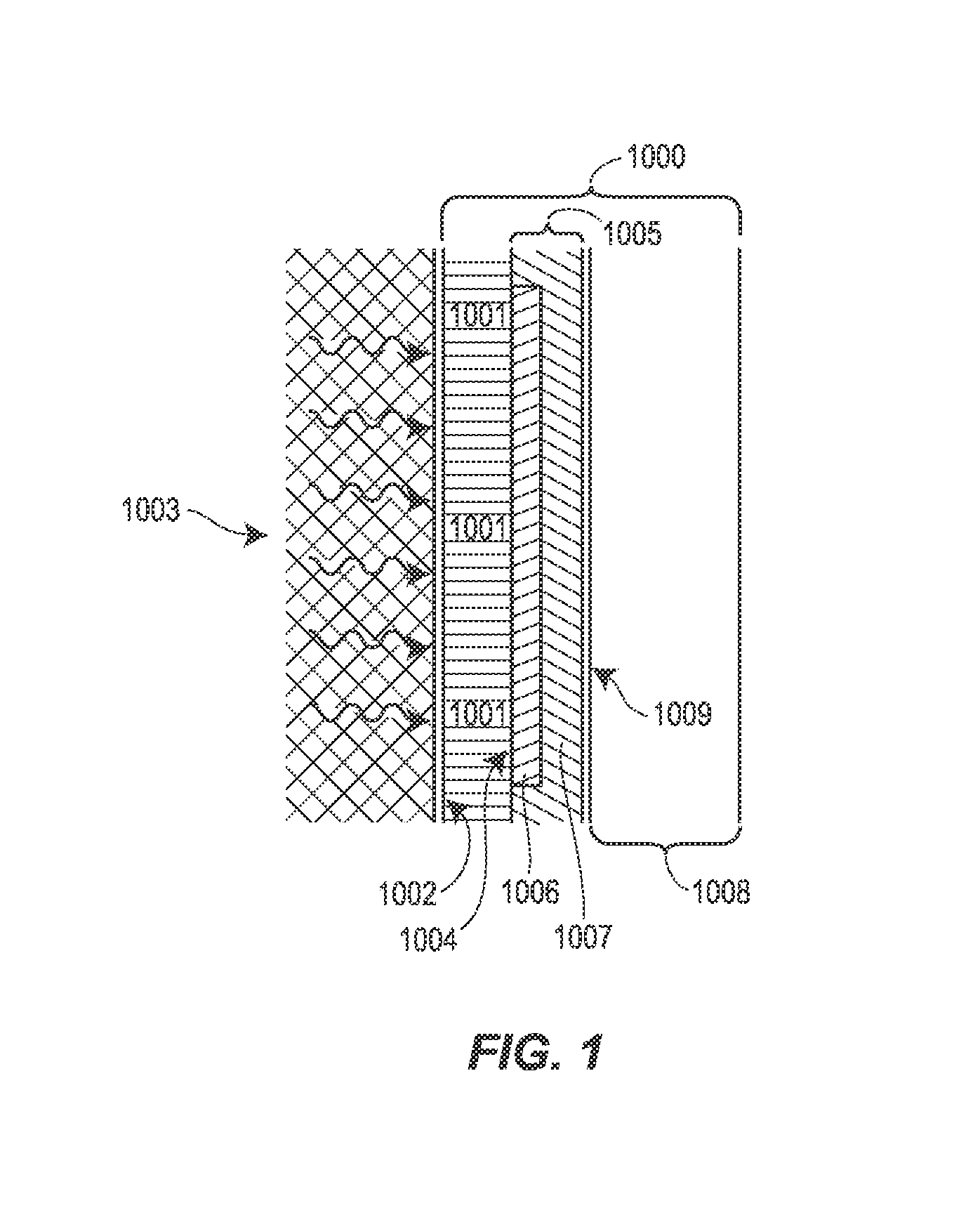

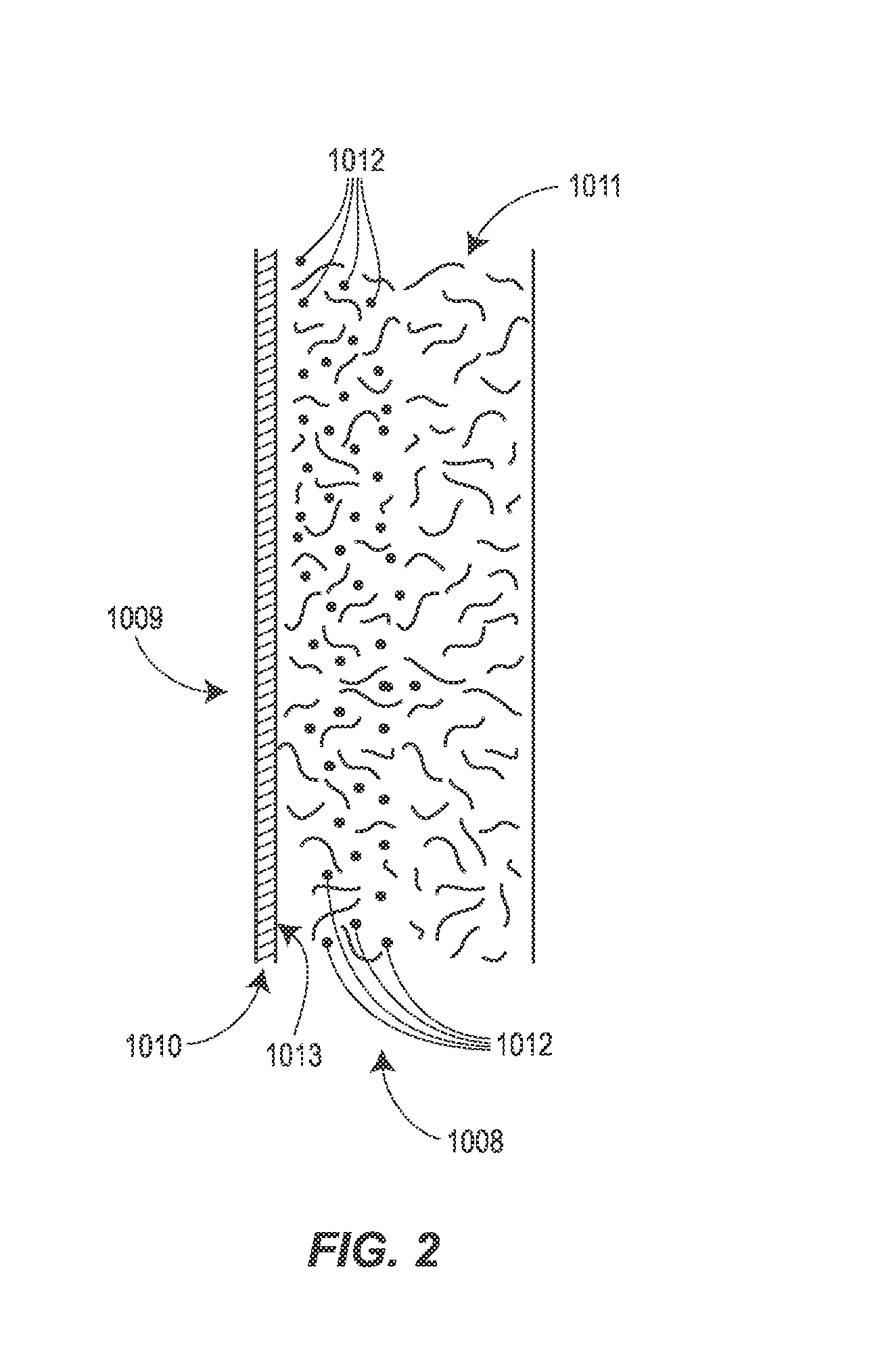

Induction welded waterproofing

InactiveUS8454773B2Reduce installation efficiencyExtension of timeCovering/liningsWallsAbsorbent materialGeotextile

Owner:AMCOL INTERNATIONAL CORPORATION

Induction Welded Waterproofing

InactiveUS20120152437A1Reduce installation efficiencyIncrease installation costCovering/liningsWallsAbsorbent materialEngineering

In accordance with an embodiment of the disclosure, A water-proofing laminate includes a drainboard having a first surface positioned against a hydraulic source and a second surface opposed to the first surface, a fastener plate positioned against the second surface of the drainboard securing the drainboard to the hydraulic surface, the fastener plate comprising a conductive element and a thermoplastic resin, and a self-healing hydraulic barrier comprising a thermoplastic surface adjoined to a geotextile and carrying a water-absorbent material, the thermoplastic surface inductively welded to the fastener plate.

Owner:AMCOL INTERNATIONAL CORPORATION

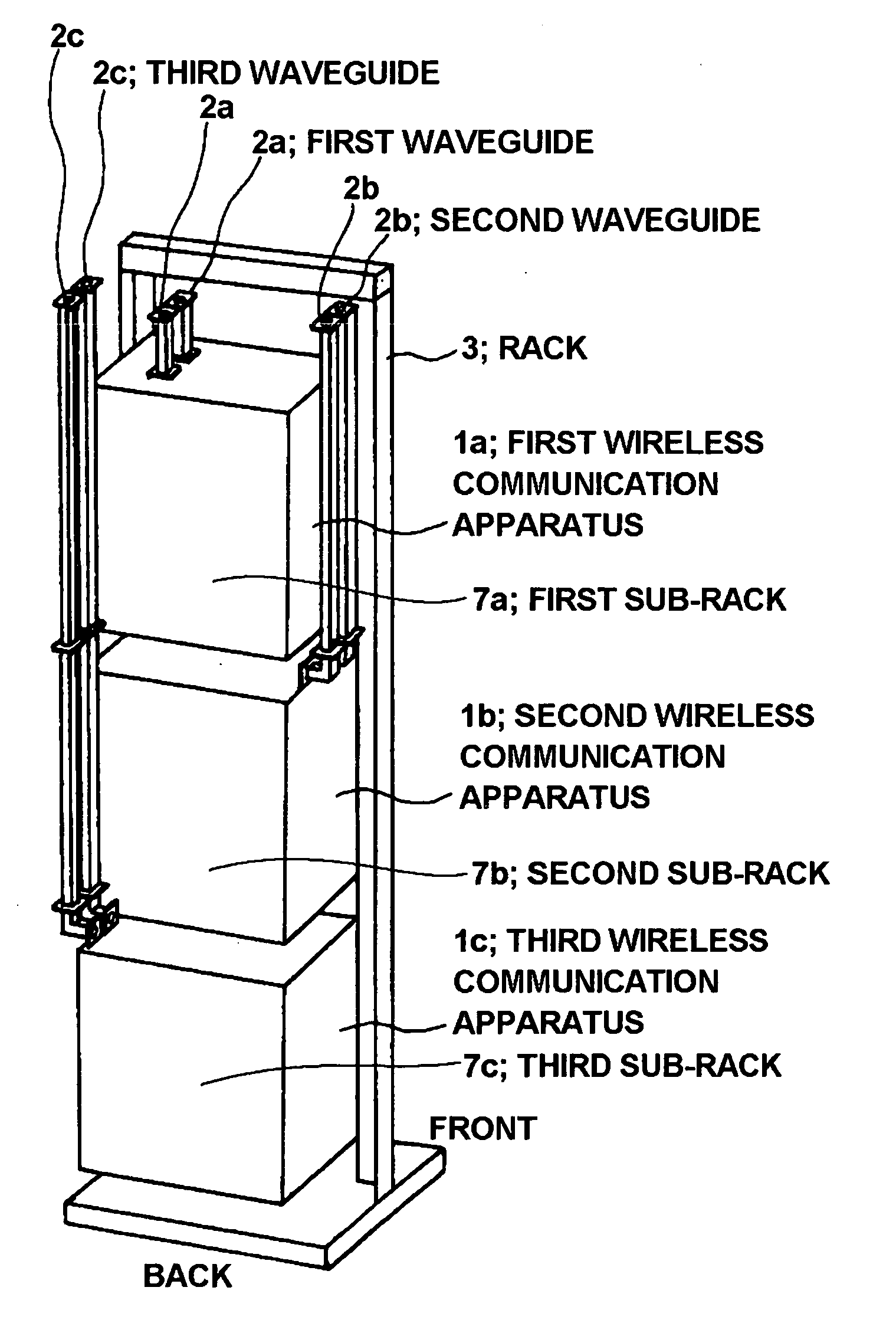

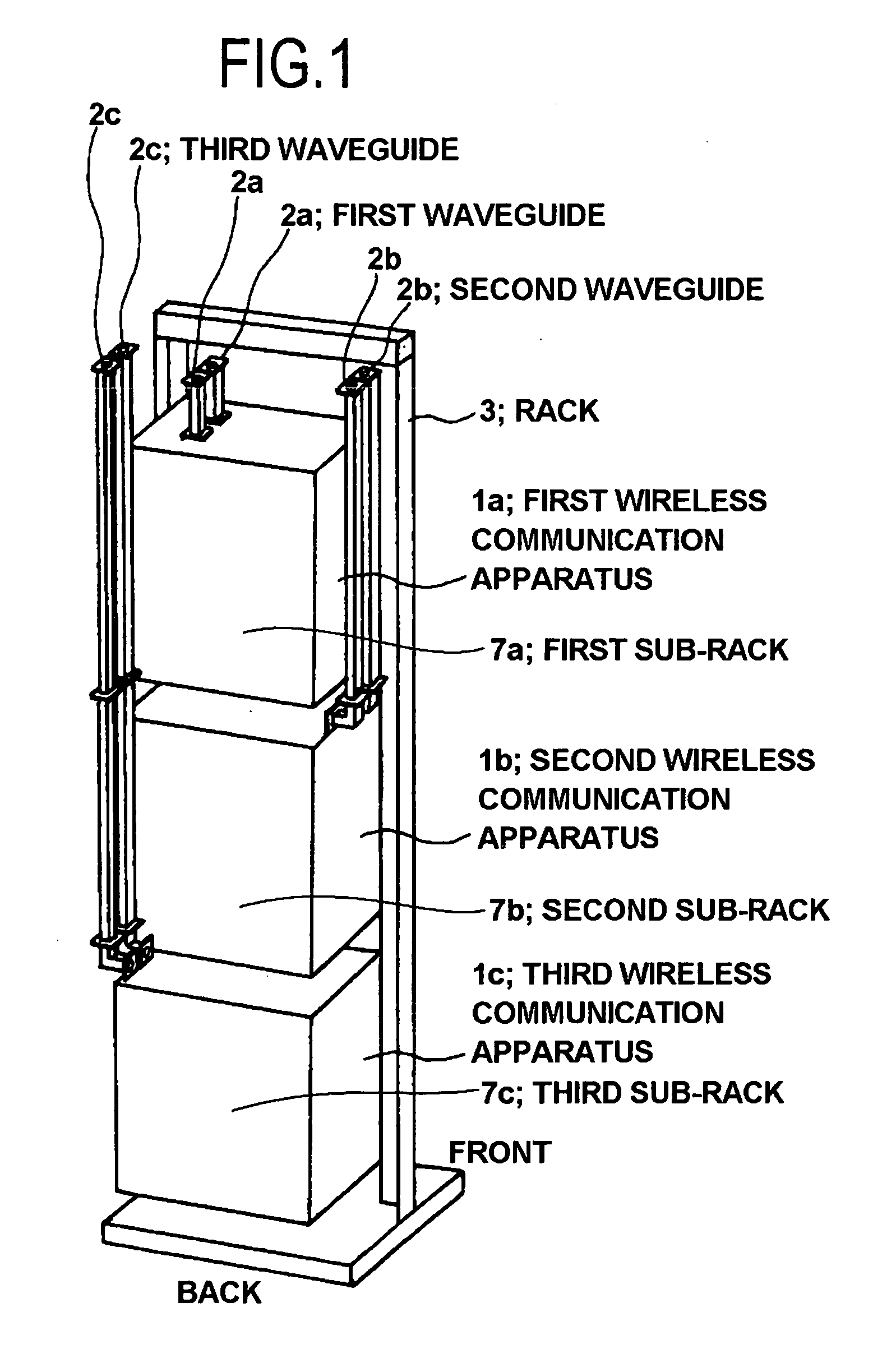

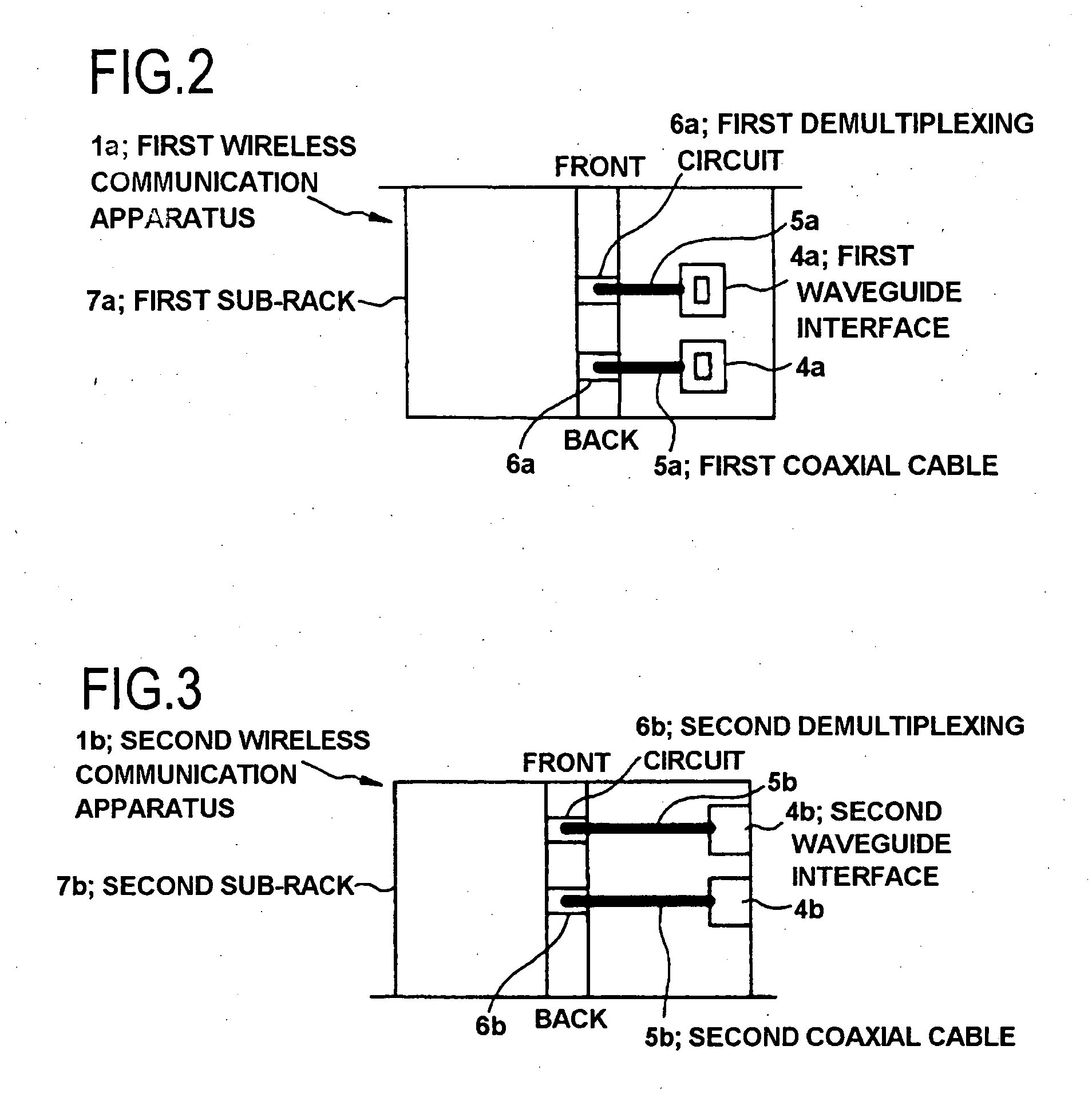

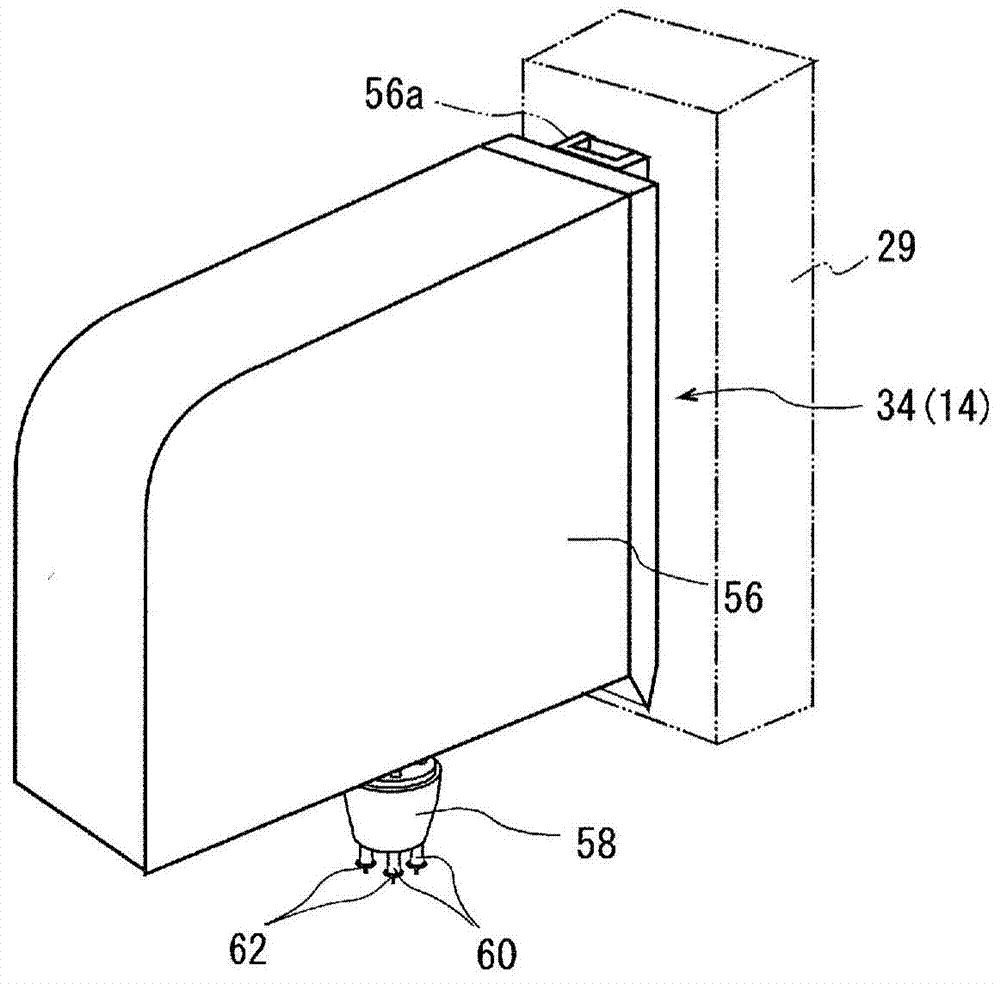

Wireless communication system and apparatus

InactiveUS20050196126A1Reduce installation efficiencyImprove efficiencyRack/frame constructionOptical light guidesCommunications systemWaveguide

A wireless communication system comprises a plurality of wireless communication apparatus, a plurality of sub-racks, and a rack. The wireless communication apparatus comprises a demultiplexing circuit, a cable to be connected to the demultiplexing circuit, a waveguide interface to be connected to the cable, and a waveguide to connect the waveguide interface and the antenna. A plurality of sub-racks for each housing the wireless communication apparatus to be connected to an antenna are installed in the rack. Among a plurality of the wireless communication apparatus which are different from one another, a pair of the waveguide interface and waveguide is disposed at a different position from other pair / pairs of waveguide interface and waveguide on a predetermined projectional plane. The waveguide assigned to each of the wireless communication apparatus extends along an outside of the sub-rack.

Owner:NEC CORP

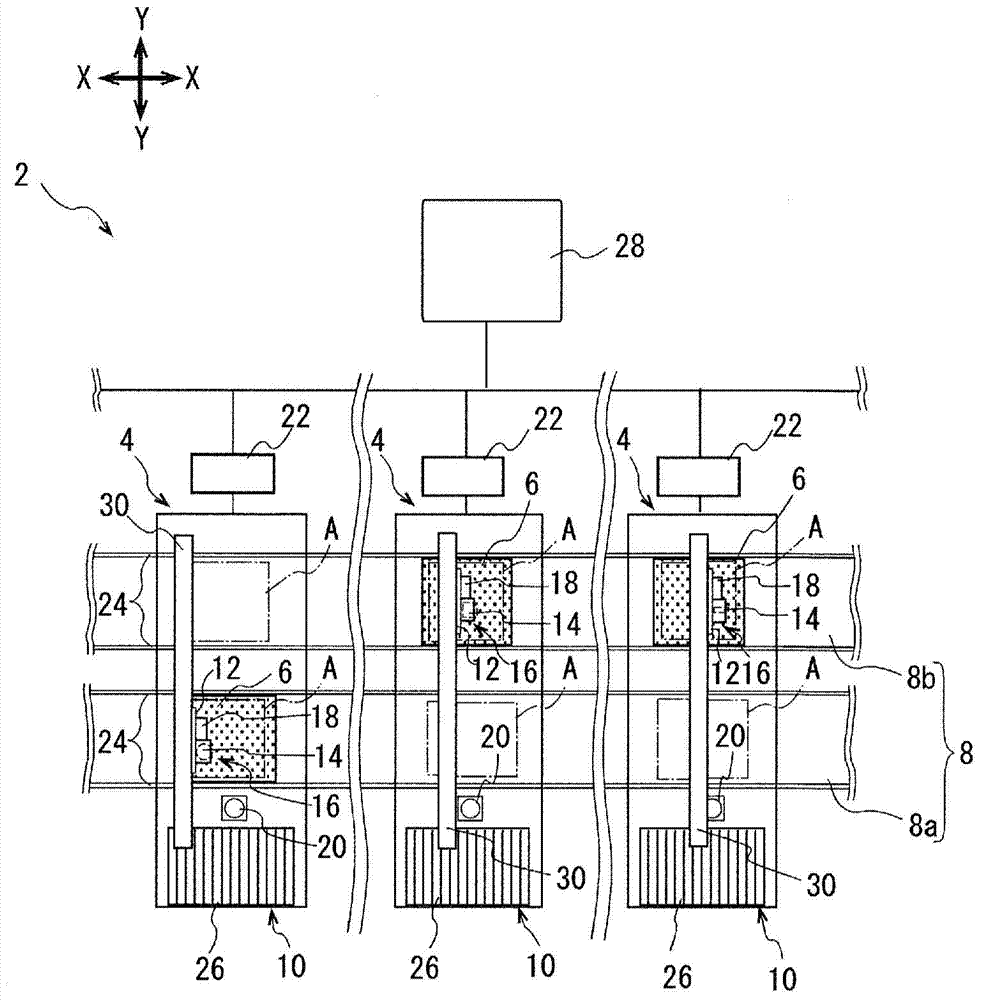

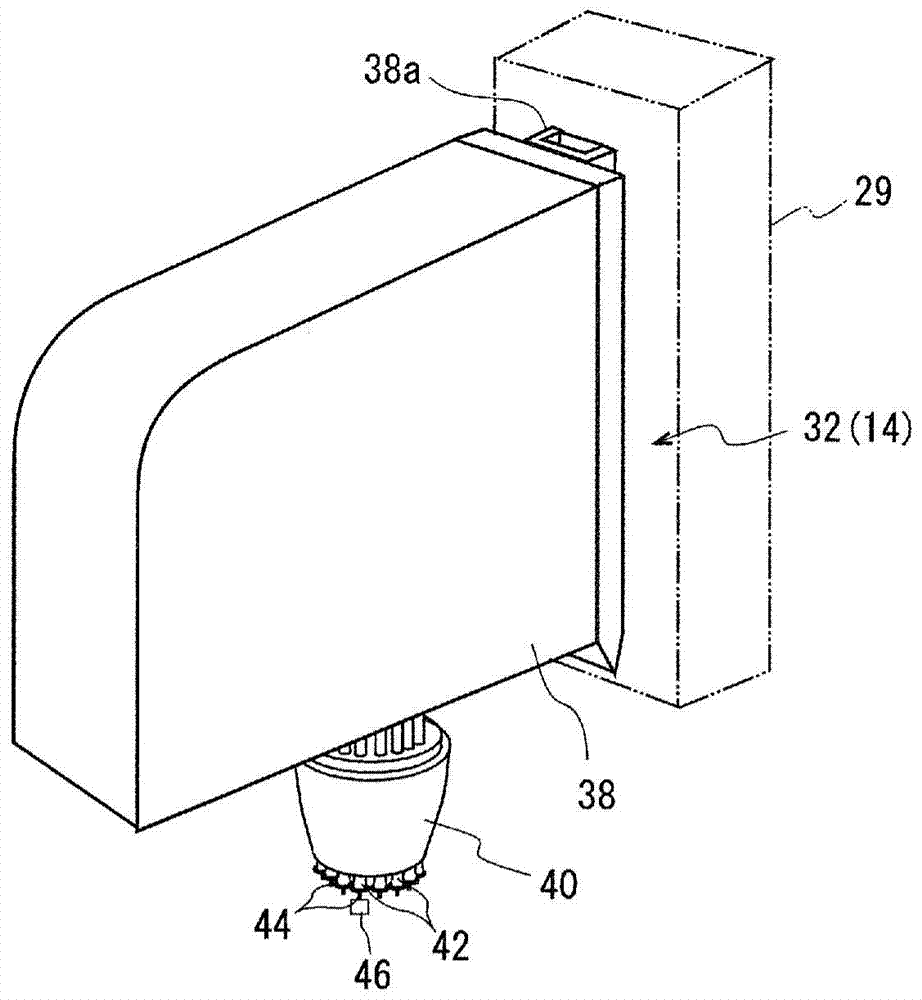

Component mounting line

ActiveCN103947310AAchieve equalizationIncrease productivityElectrical componentsEngineeringCycle time

Provided is a component mounting line that enables optimization of production efficiency by using a plurality of modular component mounting devices that are connected in series and that each have two parallel substrate transport devices. In the plurality of modular component mounting devices which are connected in series and each of which has two parallel substrate transport devices, one pair of substrate transport devices positions two mutually different types of substrates at a component mounting position on each component mounting device and transports the substrates to and from the mounting positions, the component mounting devices being provided with the following: a total cycle time computation unit for finding total cycle time by computing for each component mounting device one cycle time for mounting a component onto one of the two types of substrate and another cycle time for mounting a component onto the other of the two types of substrates; and an equal component distribution unit for distributing to every component mounting device the components to be mounted onto the pair of substrates so that the total cycle times are equalized.

Owner:FUJI KK

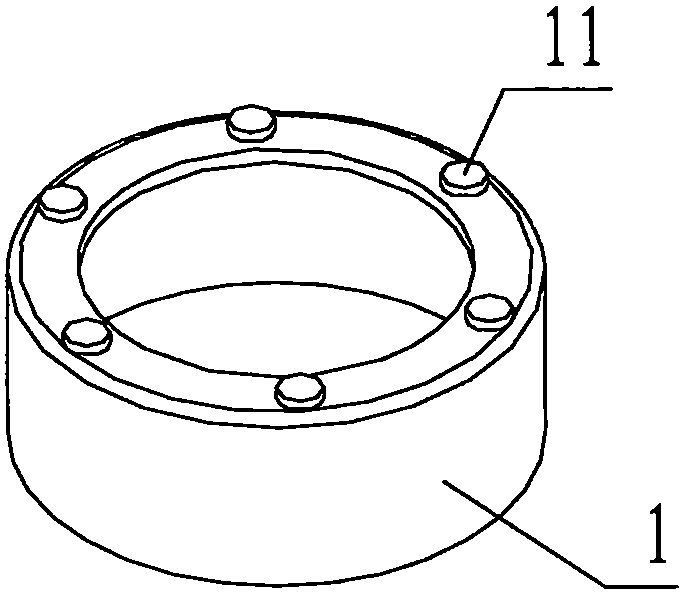

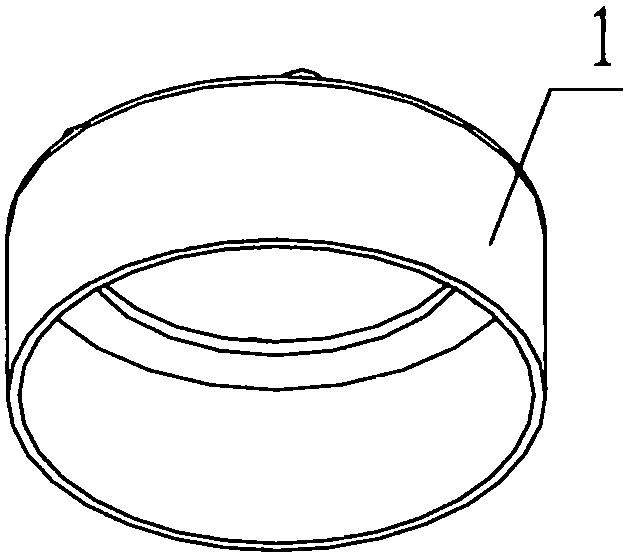

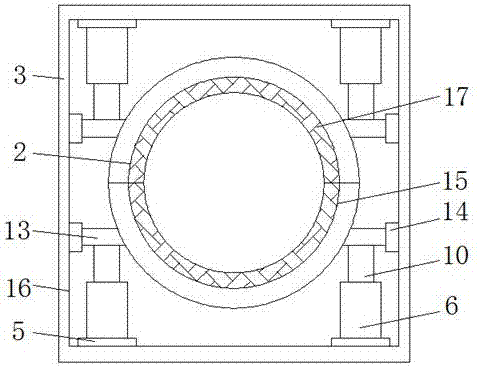

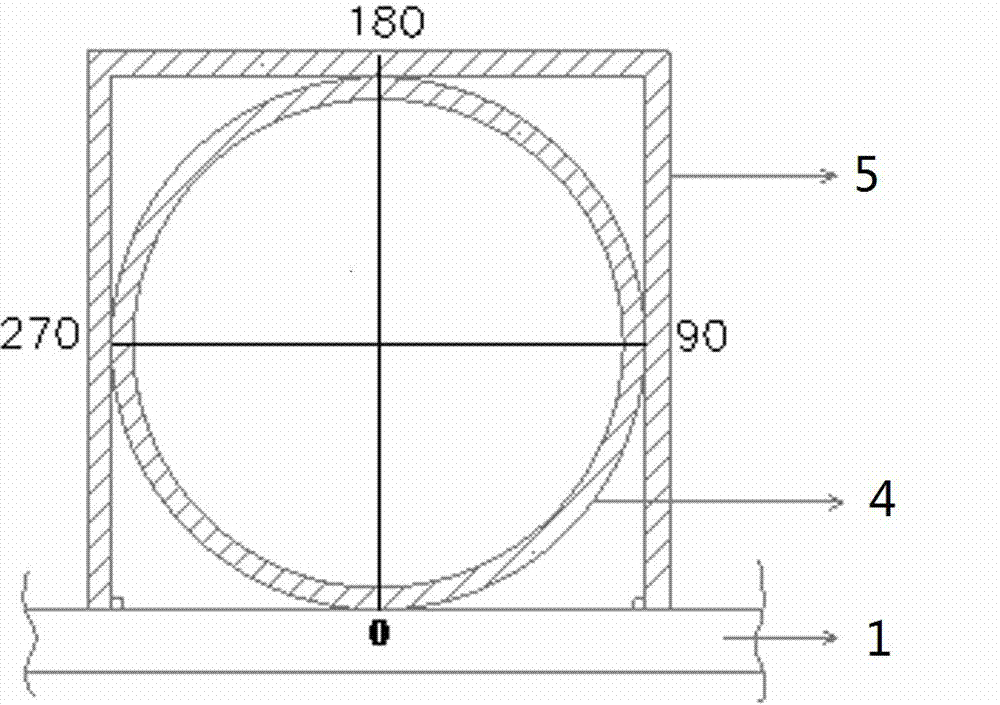

Automobile power-assisted steering motor rotor bearing lining

InactiveCN105186762AExtended service lifeAvoid rigid contactSupports/enclosures/casingsBearing unit rigid supportEthylene propylene rubberFlange

The invention discloses an automobile power-assisted steering motor rotor bearing lining. An elastic lining is arranged between a rotor bearing and the inner wall of the bearing seat of a stator housing. The lining is in an annular shape and is a thin-wall ethylene propylene rubber member the top of which is provided with flanges. In virtue of the elastic lining of the lining, the axis of the rotor and the axis of the inner chamber of a stator magnetic shoe are subjected to flexible rectification in order to be coaxial. A technical scheme of adjusting the axial pretightening force of the rotor bearing on the bearing seat by using the flanges achieves purposes of prolonging the service life of the rotor bearing, eliminating the axial floating of the rotor bearing, increasing installation efficiency, and reducing cost.

Owner:NINGBO HONGLING MOTOR

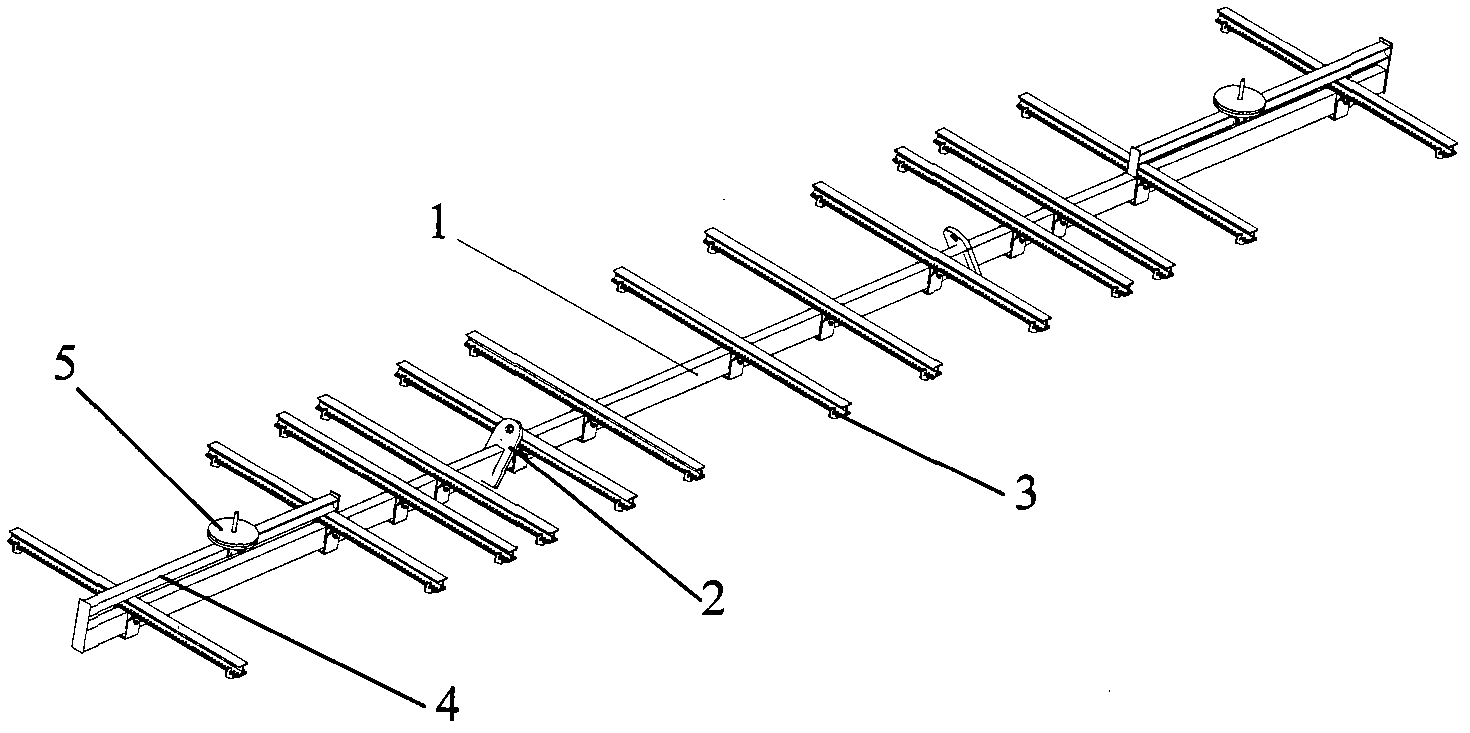

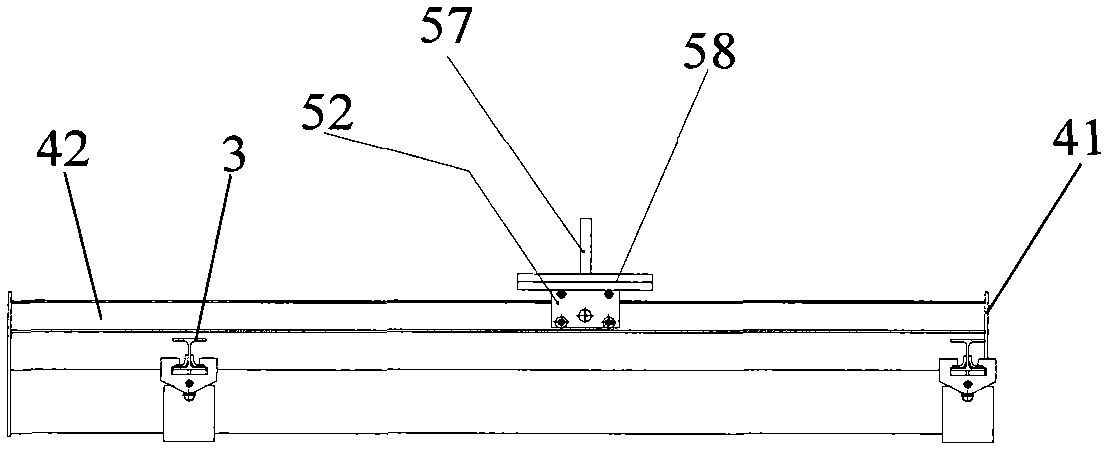

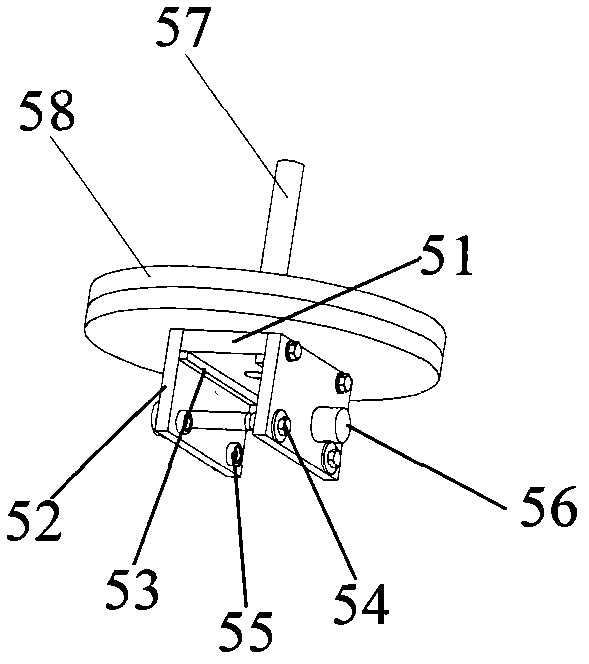

Hoisting device of center tube bundle of railway locomotive

InactiveCN102464262AImprove installation efficiencyReduce labor costsLoad-engaging elementsMain bearingEngineering

The invention discloses a hoisting device of a center tube bundle of a railway locomotive. The hoisting device comprises a main bearing beam, wherein more than two fixed hoisting lugs used for being hung on a crane are arranged on the main bearing beam; and a plurality of movable cross beams used for hoisting a center tube bundle are arranged on the main bearing beam. The hoisting device of the center tube bundle of the railway locomotive, provided by the invention, can be used for hoisting the center tube bundle to the bottom of the locomotive, thus the installation efficiency of the center tube bundle is increased, the labor cost is saved, and the labor intensity is reduced.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Block bar of refrigerator and refrigerator

ActiveCN104132499AImprove assembly efficiencyReduce manufacturing costDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention provides a block bar of a refrigerator and the refrigerator. The block bar is installed on a door of the refrigerator and used for limiting the maximum starting angle of the door. The block bar comprises a body and two matching portions, wherein installation portions are symmetrically arranged on the body, the body is connected with the door through the installation portions, and the two matching portions are symmetrically arranged on the body. Due to the fact that the two matching portions are symmetrically arranged on the block bar, the block bar can be universally used on a left door and a right door of the refrigerator, the problem that rework occurs when an existing block bar is installed wrongly can be solved, and installation efficiency of the block bar can be effectively improved; the block bar can be universally used on the left door and the right door of the refrigerator, and therefore the block bar can be manufactured only through one mold; compared with the existing block bar, the block bar has the advantages that less types of molds are needed when the block bar is manufactured, expense input for the molds is reduced, and manufacturing cost of the block bar is reduced.

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR

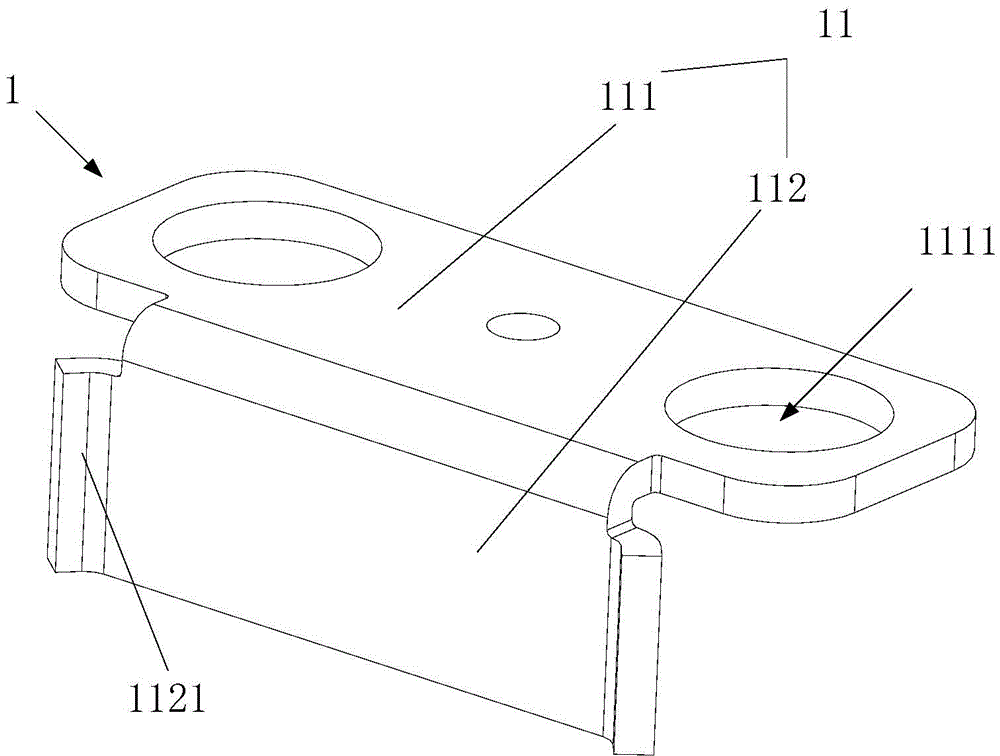

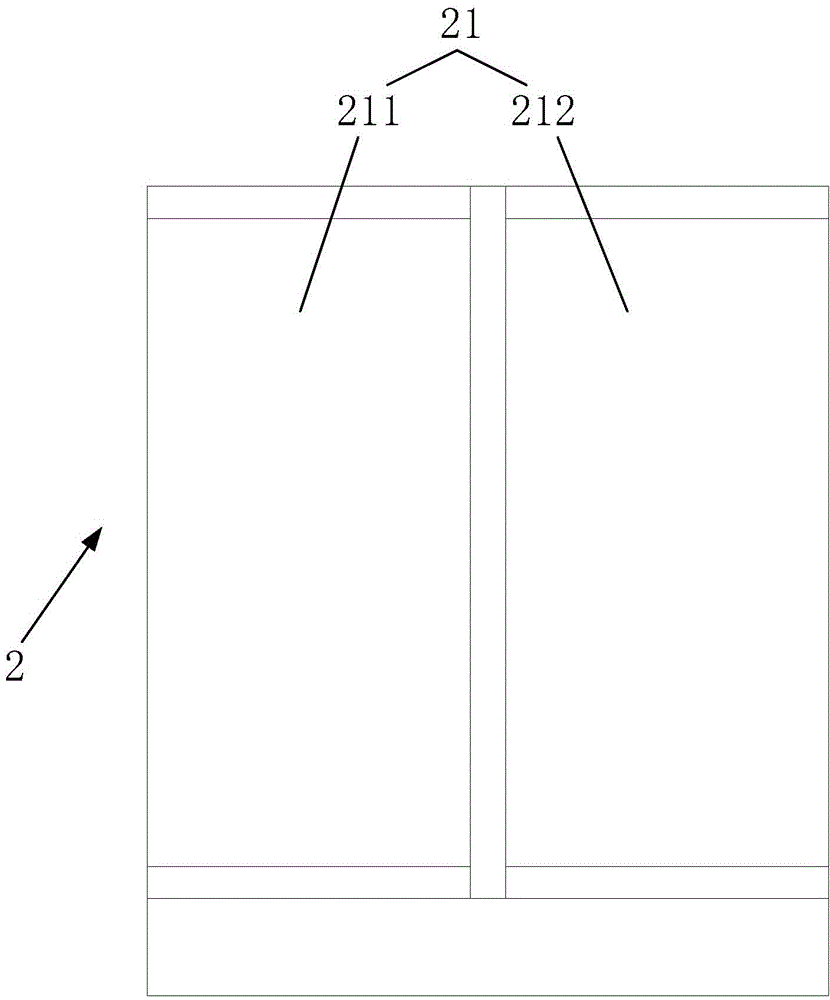

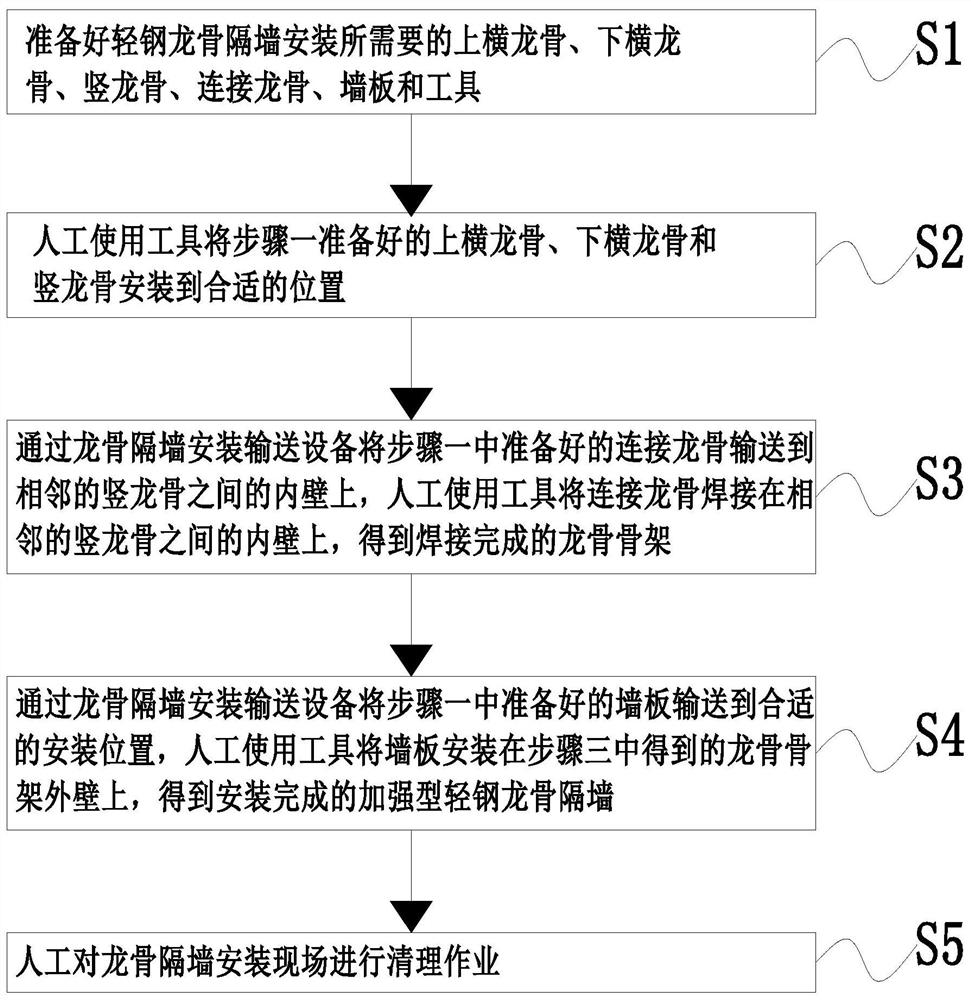

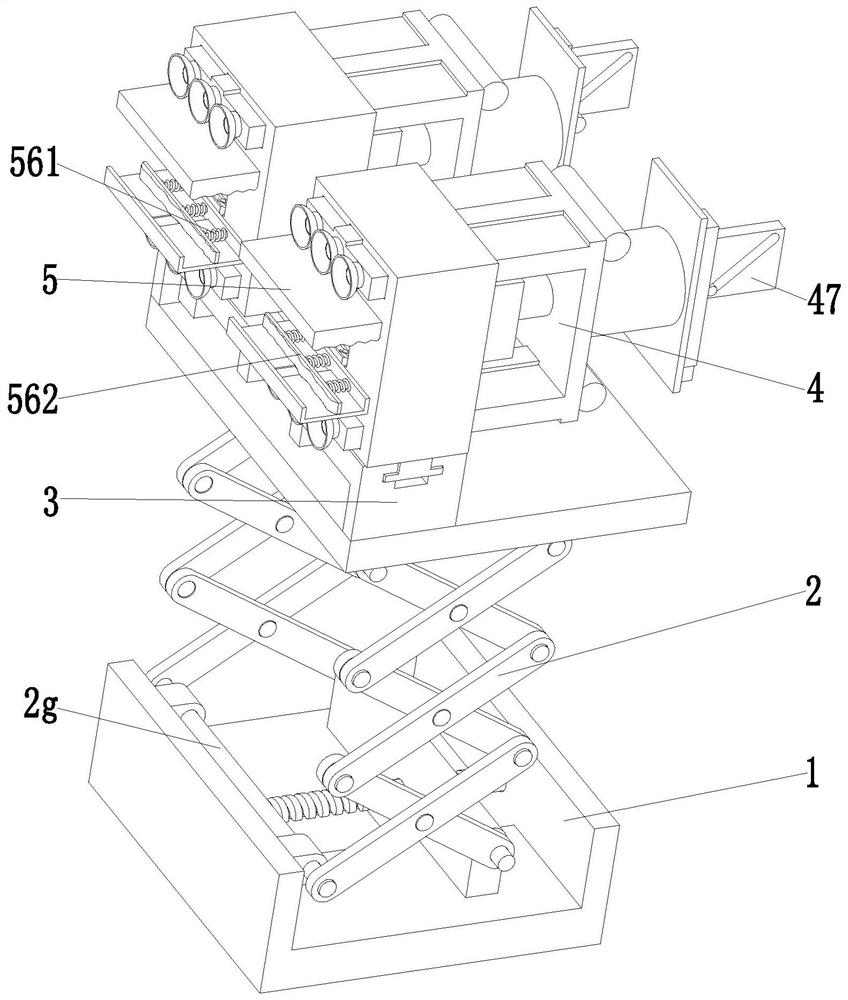

Reinforced light steel keel partition wall installation and construction method

ActiveCN113047639AReduce installation efficiencyIncreased riskWallsBuilding material handlingMaterials preparationKeel

The invention relates to a reinforced light steel keel partition wall installation and construction method. The reinforced light steel keel partition wall installation and construction method mainly comprises the following steps of material preparation, installation operation, material conveying, wallboard installation, cleaning operation and other procedures; used keel partition wall installation conveying equipment comprises a U-shaped bottom plate, a lifting device, an adjusting device, an adsorption device and a clamping device. The following problems existing during the installation of an existing connecting keel and a wallboard are solved, a, when a traditional connecting keel and the wallboard are installed, because the installation height of the connecting keel and the wallboard is higher, a worker needs to stand on a ladder to position and install the connecting keel and the wallboard, and the installation method is higher in danger and lower in installation efficiency; and b, when an existing wallboard is installed, stable positioning operation cannot be carried out on the wallboard, so that the phenomenon of dislocation exists when the wallboard is installed, installation operation needs to be carried out again, and the installation quality and efficiency of the wallboard are reduced.

Owner:中际城市建设有限公司

Heat exchanger

ActiveCN110530173AReduce installation efficiencyQuick connectionHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerEngineering

The invention relates to a heat exchanger which comprises a heat exchange tube, a heat exchange device and a connecting device, the heat exchange tube is Z-shaped, the heat exchange device is installed in the heat exchange tube, and the end of the heat exchange tube is connected with the connecting device through threads. The problems that in the heat exchange process of an existing heat exchanger, an adopted connecting device is complex in mounting and dismounting process and multiple in operation step, and when a plurality of heat exchange pipes are connected, consumed time is too long, andmounting efficiency is low can be solved; meanwhile, the problems that in the heat exchange process of existing equipment, a heat exchanger matched with the existing equipment is needed to achieve different heat exchange temperatures, temperature adjustment cannot be achieved on the same heat exchanger, and therefore the production cost is increased, and the working efficiency is low are solved.

Owner:ANHUI GALAXYLA PURIFICATION ENG

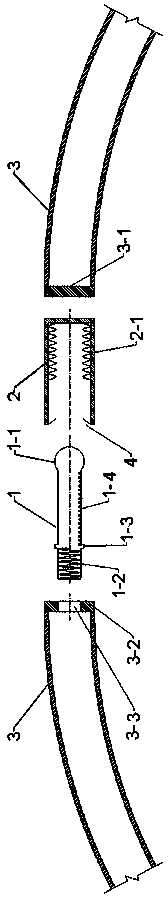

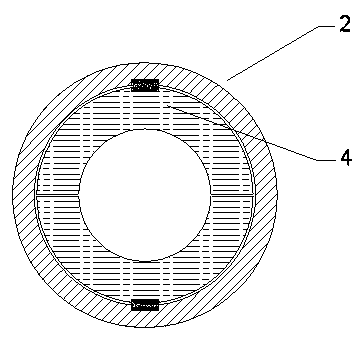

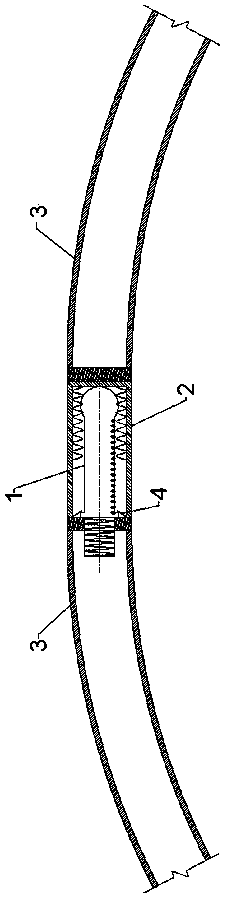

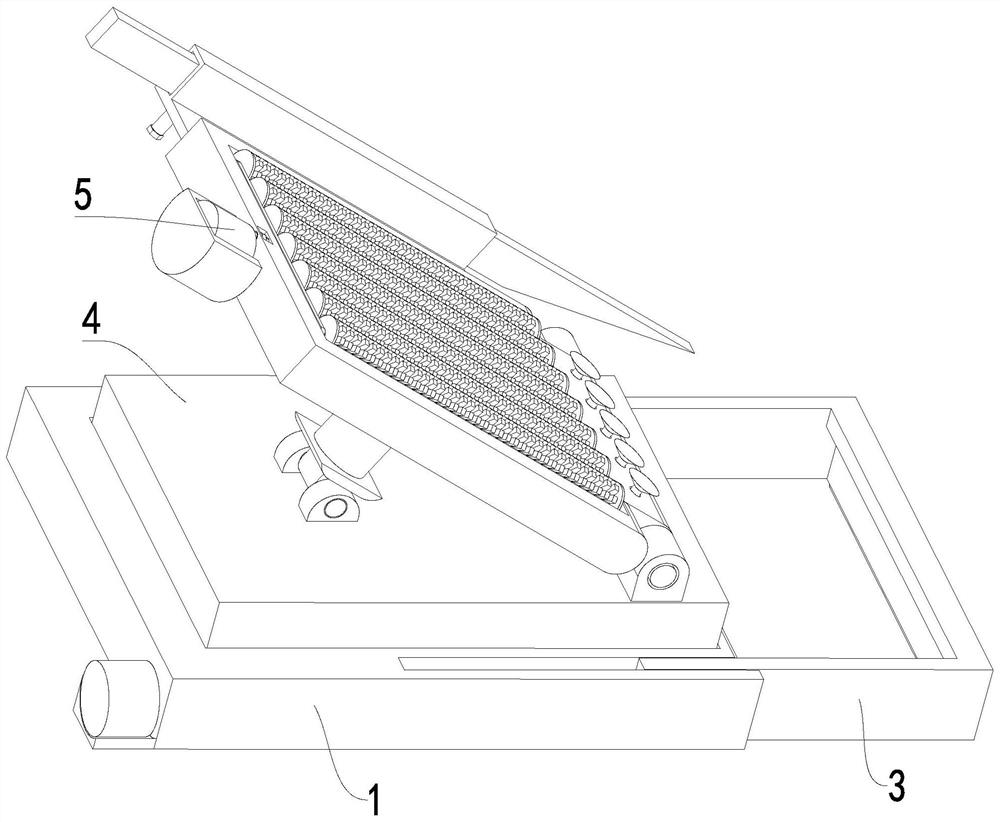

Instant-plug spherical hinge-type quantifiable-yield steel arch connecting component and using method

ActiveCN110608055ASimplify the assembly processIncrease laborUnderground chambersTunnel liningSheet steelScrew thread

The invention discloses an instant-plug spherical hinge-type quantifiable-yield steel arch connecting component and a using method. The connecting component is arranged between two steel arches and comprises a connecting rod and a sleeve. The connecting rod comprises a spherical tip at one end, a threaded tip at the other end, and a rod body in the middle. An annular protruding part is arranged atthe joint of the threaded tip and the rod body. The sleeve is of a structure with one end sealed and the other end open. An internal threaded part is arranged at a position, close to the sealed end,of the inner wall of the sleeve, and a one-way clamping part is arranged on the inner wall of the open end of the sleeve. A perforated steel plate is welded to the end of the steel arch on one side ofthe connecting component, and a sealed steel plate is welded to the end of the steel arch on the other side of the connecting component. A threaded hole matched with the threaded tip is formed in thecenter of the perforated steel plate, and the sealed end of the sleeve and the sealed steel plate are welded together. The instant-plug spherical hinge-type quantifiable-yield steel arch connecting component is exquisite in structure, easy to operate and capable of achieving efficient support, the assembling procedure of the steel arches is greatly simplified, the number of workers is reduced, and the work time is shortened.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

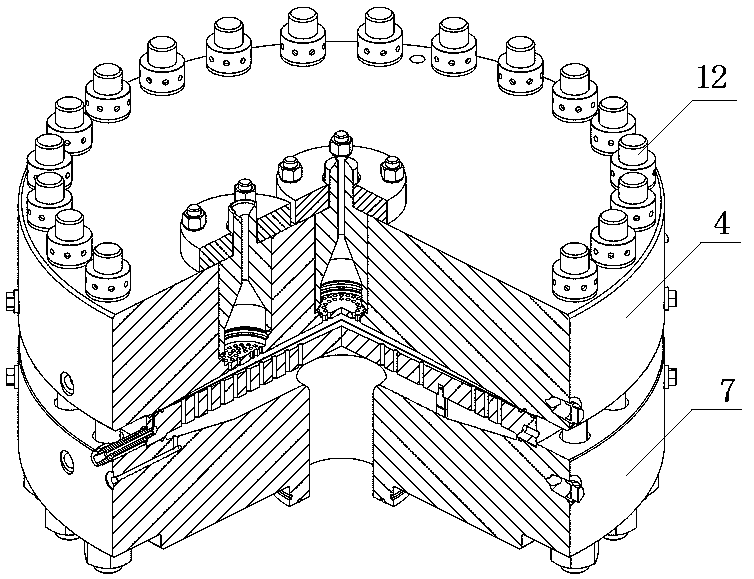

EHV diaphragm compressor hydraulic leading seal diaphragm head

PendingCN109538451AFlexible controlReduce space occupationPositive displacement pump componentsFlexible member pumpsFlueCylinder block

The invention discloses an EHV diaphragm compressor hydraulic leading seal diaphragm head, which comprises a cylinder cap, a diaphragm, an oil distribution disk, and a cylinder body, and also comprises a stuffing box and a main nut matched with the stuffing box. The cylinder body is shaped like an inverted Chinese character 'tu', and is matched with the lower part of the stuffing box; an accommodation oil distribution disk and a groove of the diaphragm are arranged at the upper part of the cylinder body, and depth of the groove is less than the total height of the oil distribution disk and thediaphragm; an oil duct is arranged in the middle part of the cylinder body, a piston is arranged in the oil duct, and the piston is connected with a crankshaft of the compressor; an air flue is arranged on the cylinder cap, which is communicated with an air suction inlet and an air vent respectively, the lower end opening of the air flue is positioned under the cylinder cap; a pressure oil inletis also arranged at the side of the cylinder cap, a pressure oil outlet is arranged at a joint gap between the cylinder cap and the main nut above the cylinder cap, and the pressure oil inlet is communicated with the pressure oil outlet; a seal ring is arranged at a joint gap between the cylinder cap and the main nut. The EHV diaphragm compressor hydraulic leading seal diaphragm head solves the problem of difficult bolt arrangement, uneven force and complicated assembly in the prior art.

Owner:SHENYANG YUANDA COMPRESSOR

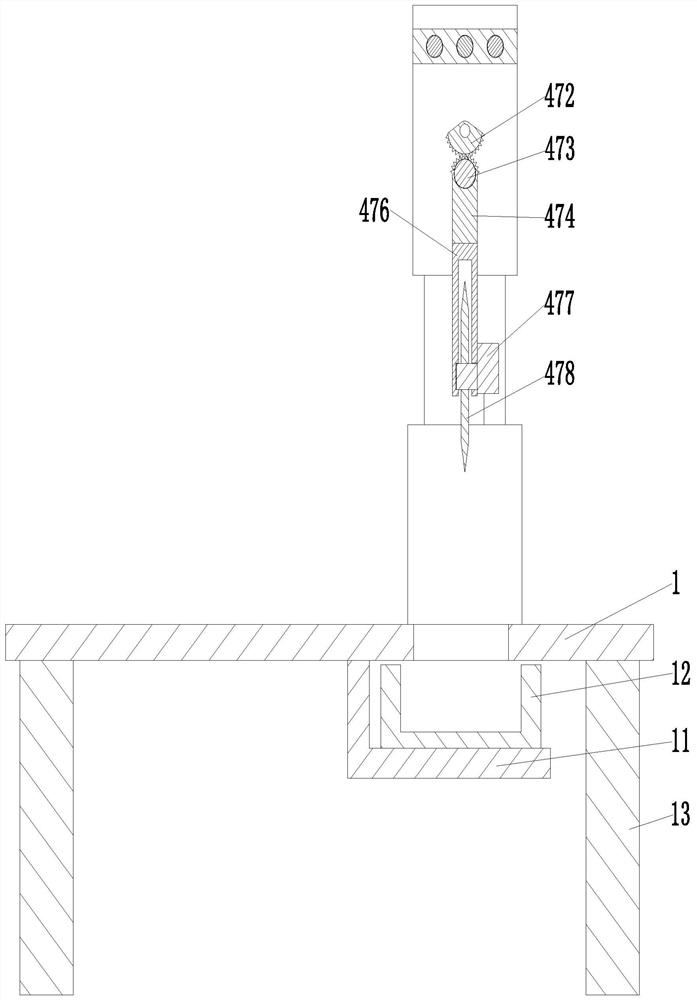

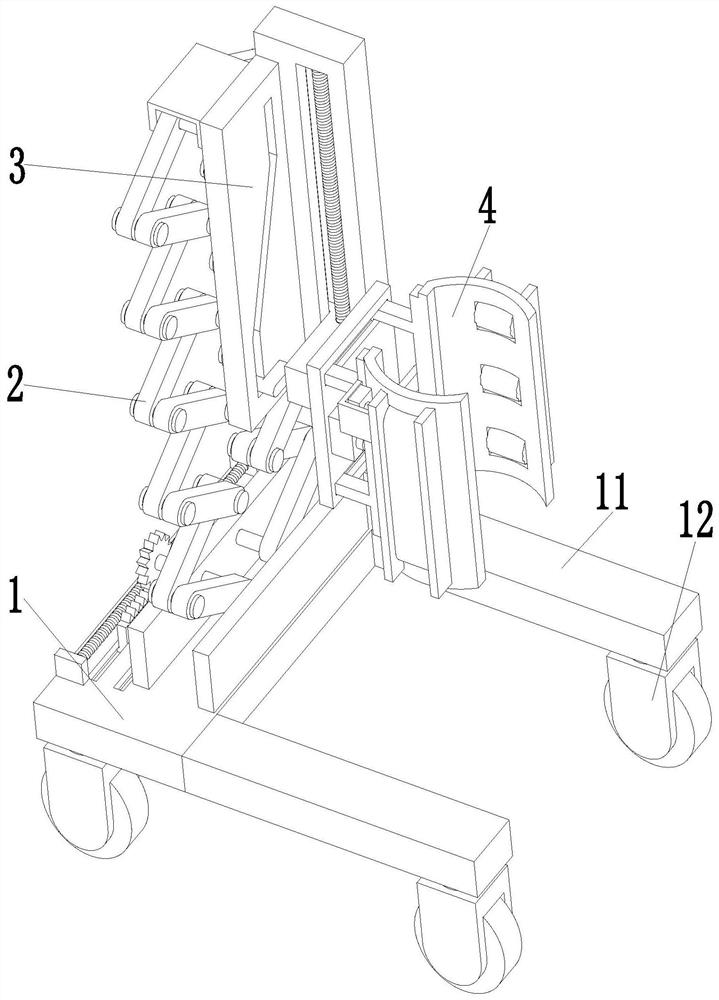

Auxiliary mounting device for sulfur hexafluoride switch in electrical cabinet

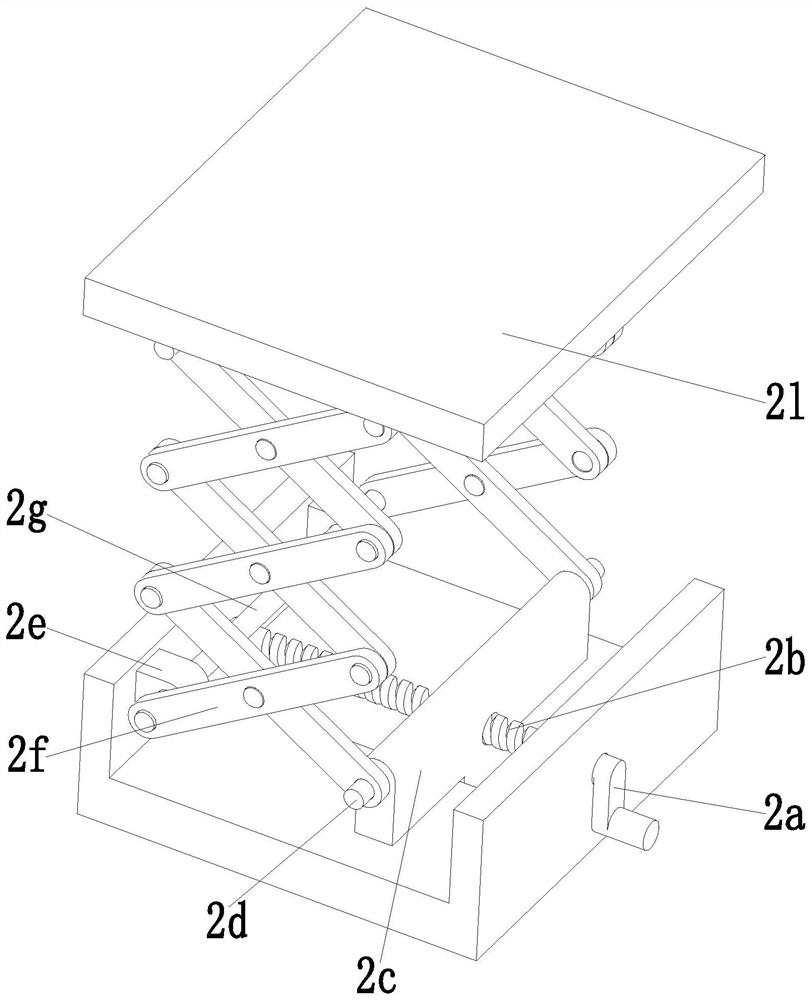

ActiveCN111085974AEasy to installReduce installation efficiencyWork holdersWork benchesHydraulic cylinderSulfur hexafluoride

The invention relates to an auxiliary mounting device for a sulfur hexafluoride switch in an electrical cabinet. The auxiliary mounting device comprises a device body, a moving block is arranged at the upper part of the device body, a hydraulic cylinder placing groove is arranged in the middle of the device body, and a penetrating screw rod is arranged in the middle of the moving block; the two ends of the screw rod are rotationally fixed to the moving block through bearings, a nut is arranged on the screw rod, and a supporting column is connected with the upper end of the nut; a fixing ring is hinged to the upper part of the supporting column through a rotary locking button, clamping parts are arranged at the two ends of the fixing ring, and a hand drill motor is fixed to the position, behind the baffle, of the fixing ring; the hand drill motor is connected with the control switch through a wire, the control switch is connected with a lithium battery through a wire, and a hydraulic cylinder is arranged in the hydraulic cylinder placing groove; and the power end of the hydraulic cylinder is fixedly connected with the bottom of the moving block, a supporting screw is horizontally and fixedly arranged at the upper end of the device body, a supporting nut is rotationally arranged outside the supporting screw, and a supporting disc is arranged at one end outside the supporting nut.The auxiliary mounting device has the advantages of being convenient to use, good in auxiliary mounting effect and reasonable in structure.

Owner:STATE GRID CORP OF CHINA +1

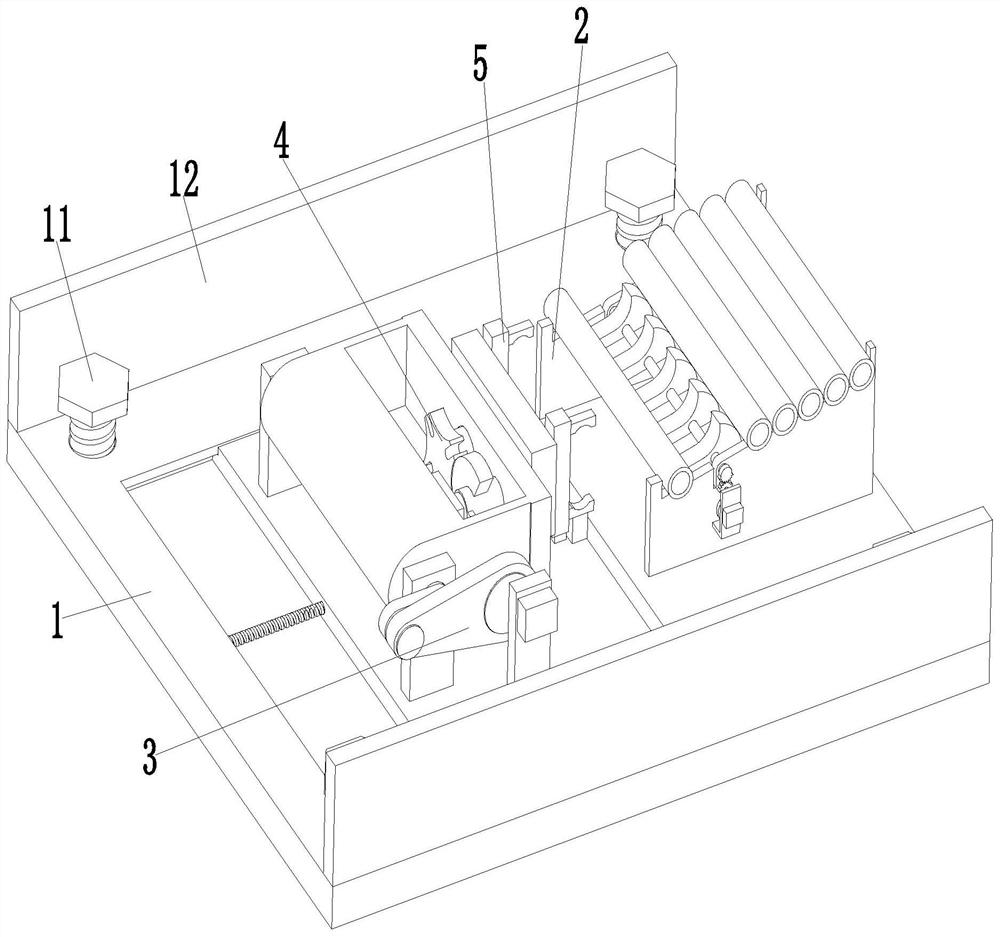

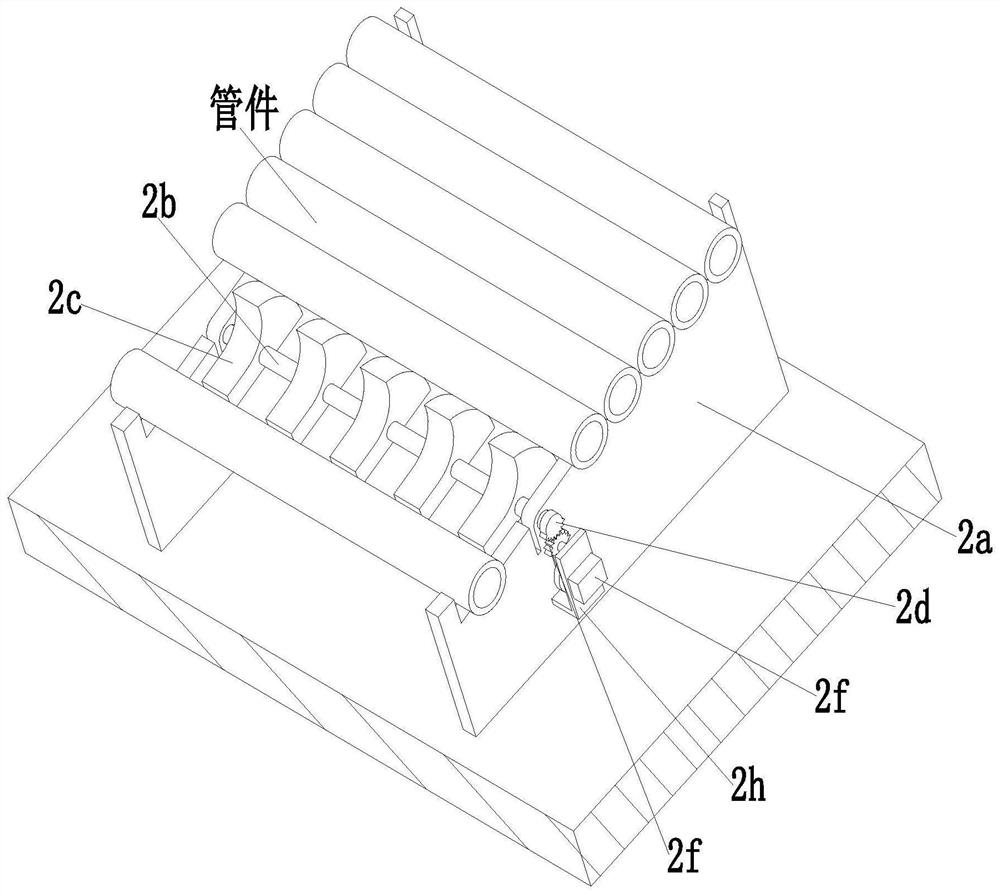

Municipal engineering pipe fitting mounting construction method

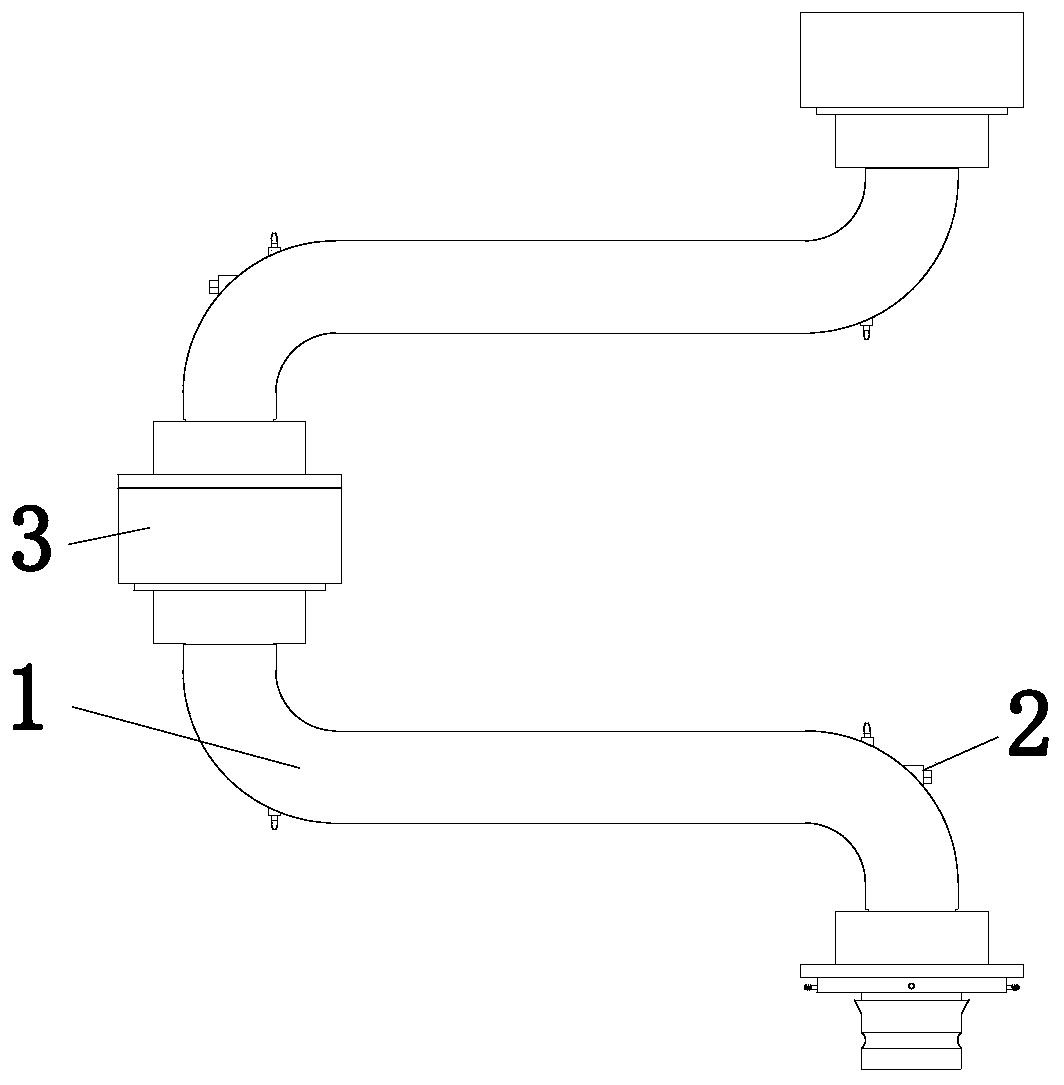

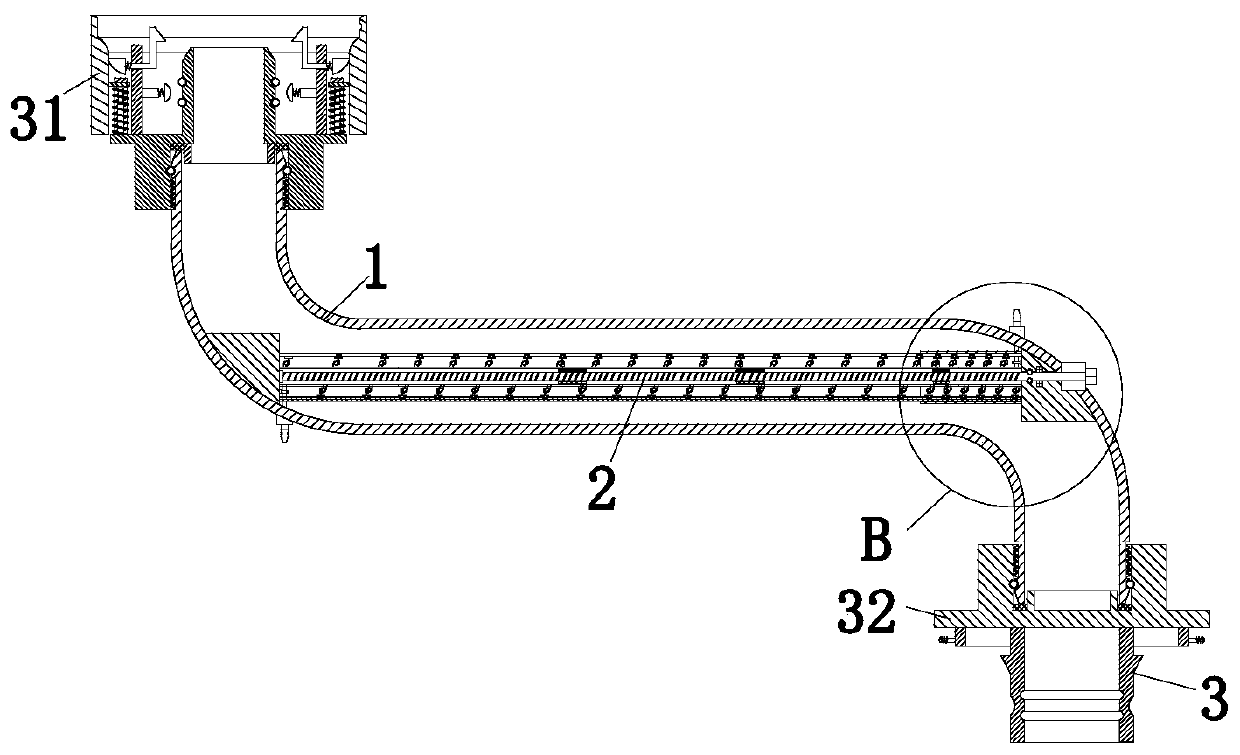

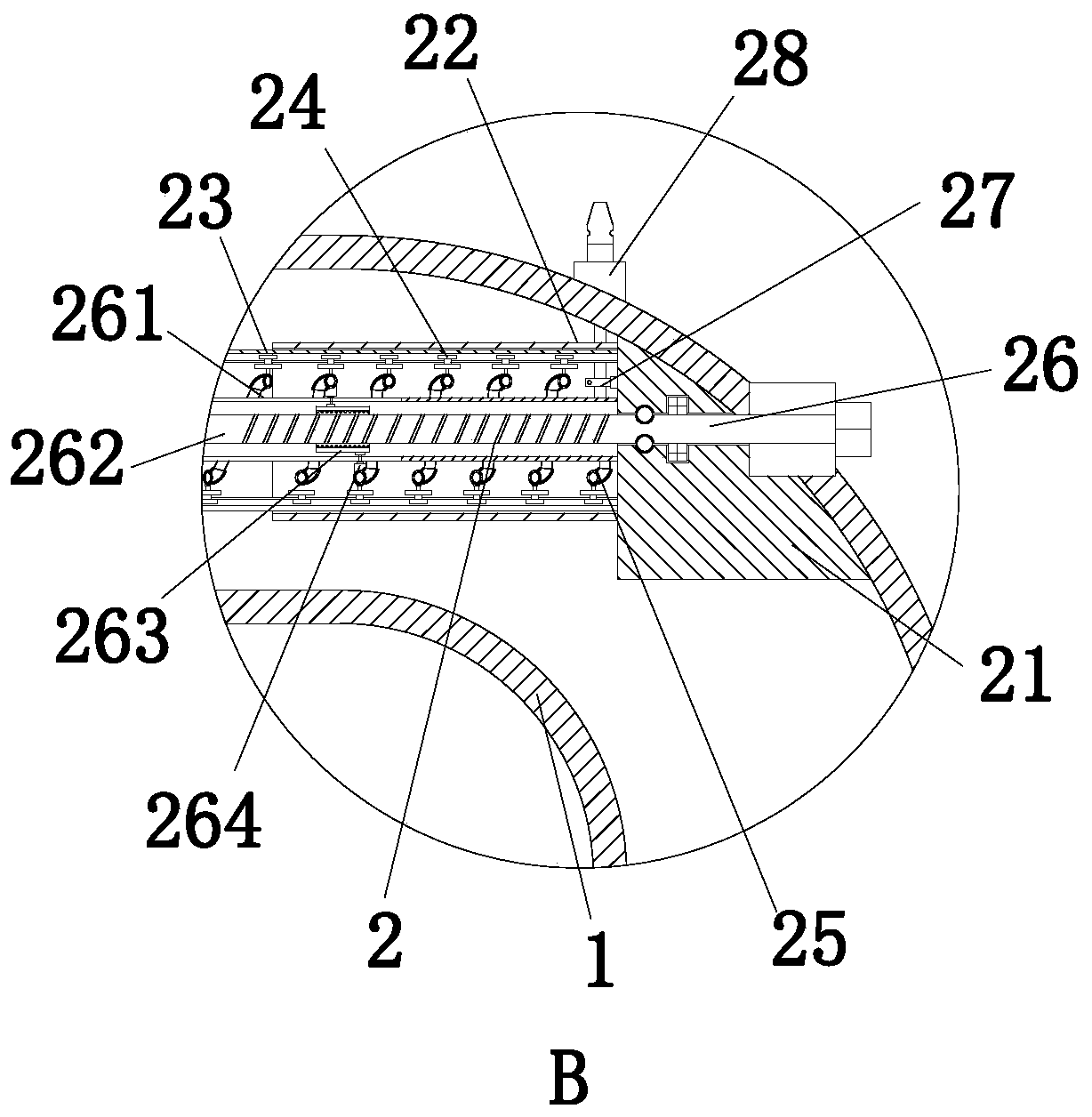

InactiveCN112922938AReduce installation efficiencyReduced installation qualityMaterial gluingMaterials preparationPipe fitting

The invention relates to a municipal engineering pipe fitting mounting construction method. The method mainly comprises the following steps and various working procedures of material preparation, a mounting operation, a butt joint operation, a gluing operation and the like. Used pipe fitting mounting equipment comprises a bottom plate, a feeding device, a turnover device, an adjusting device and a clamping device. According to the municipal engineering pipe fitting mounting construction method, the following problems existing in an existing pipeline mounting and conveying operation can be solved: a, during traditional pipeline conveying and mounting, the pipelines need to be manually held by hands to perform a connection operation between the pipelines, and the danger is large when the pipelines are manually held by hands at high altitude for connection; and b, existing pipeline mounting equipment cannot perform a stable feeding operation on pipelines and cannot perform a stable butt joint operation on the pipelines, so that the mounting efficiency and quality of the pipelines are reduced.

Owner:邓耀华

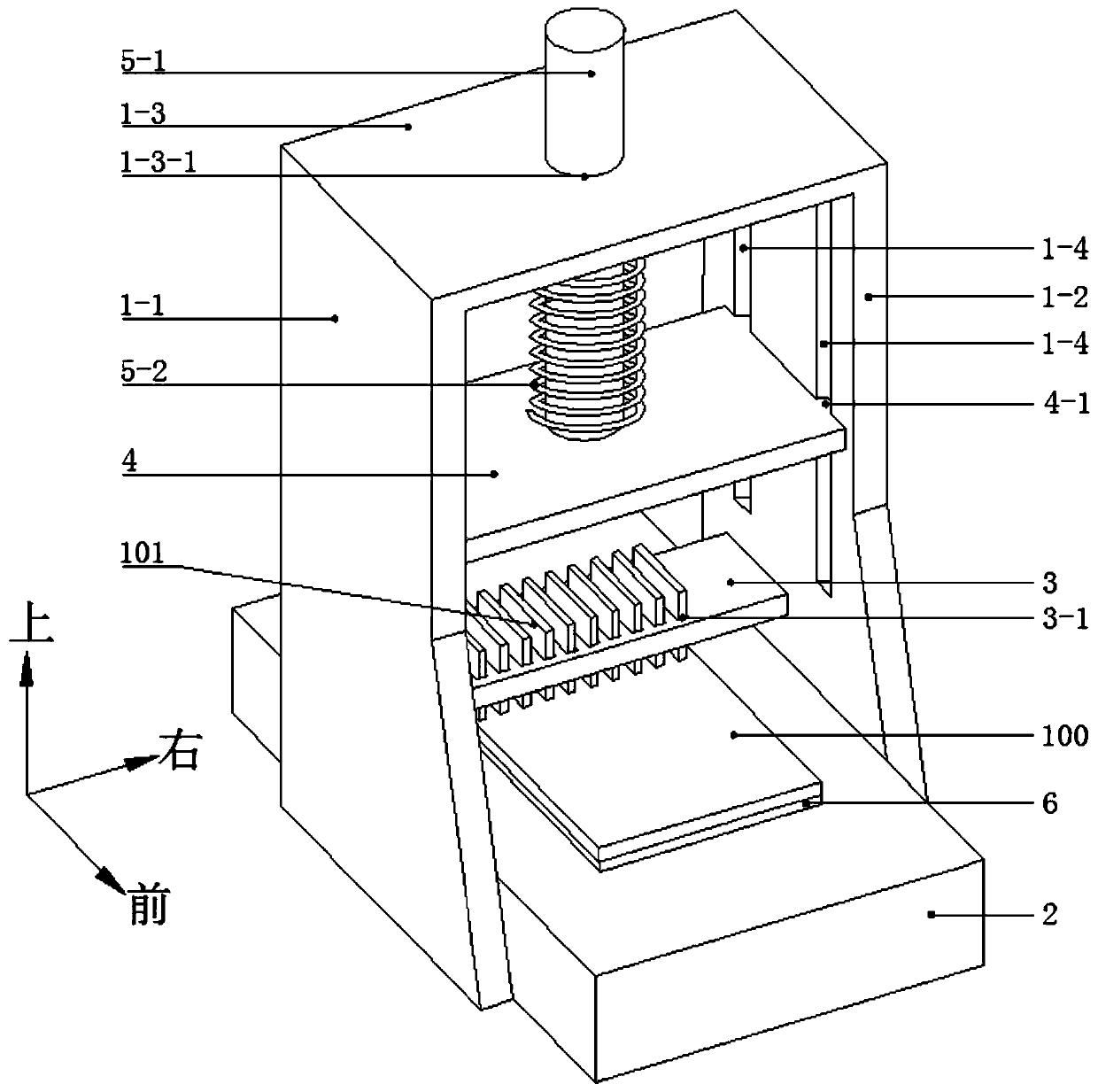

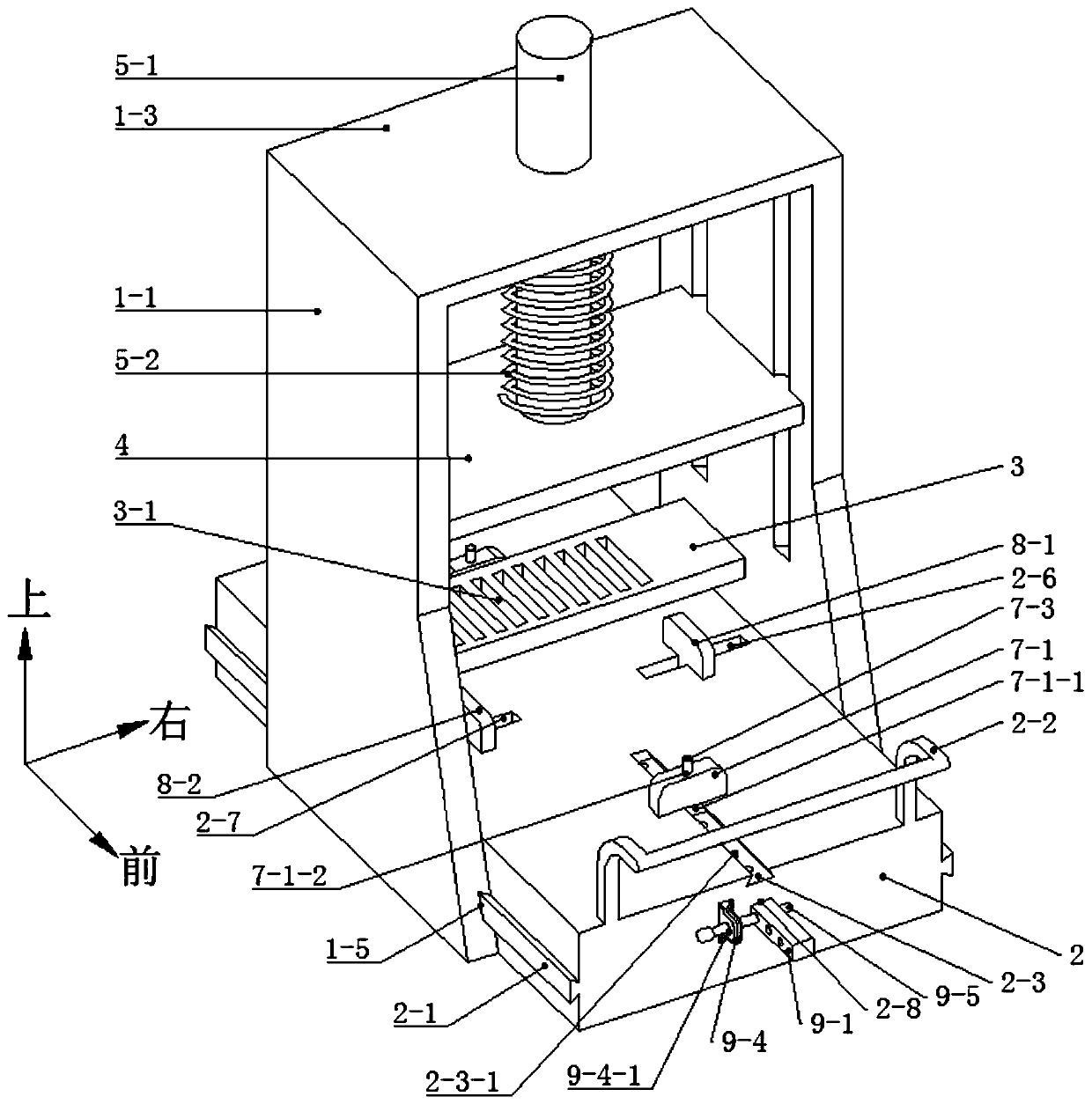

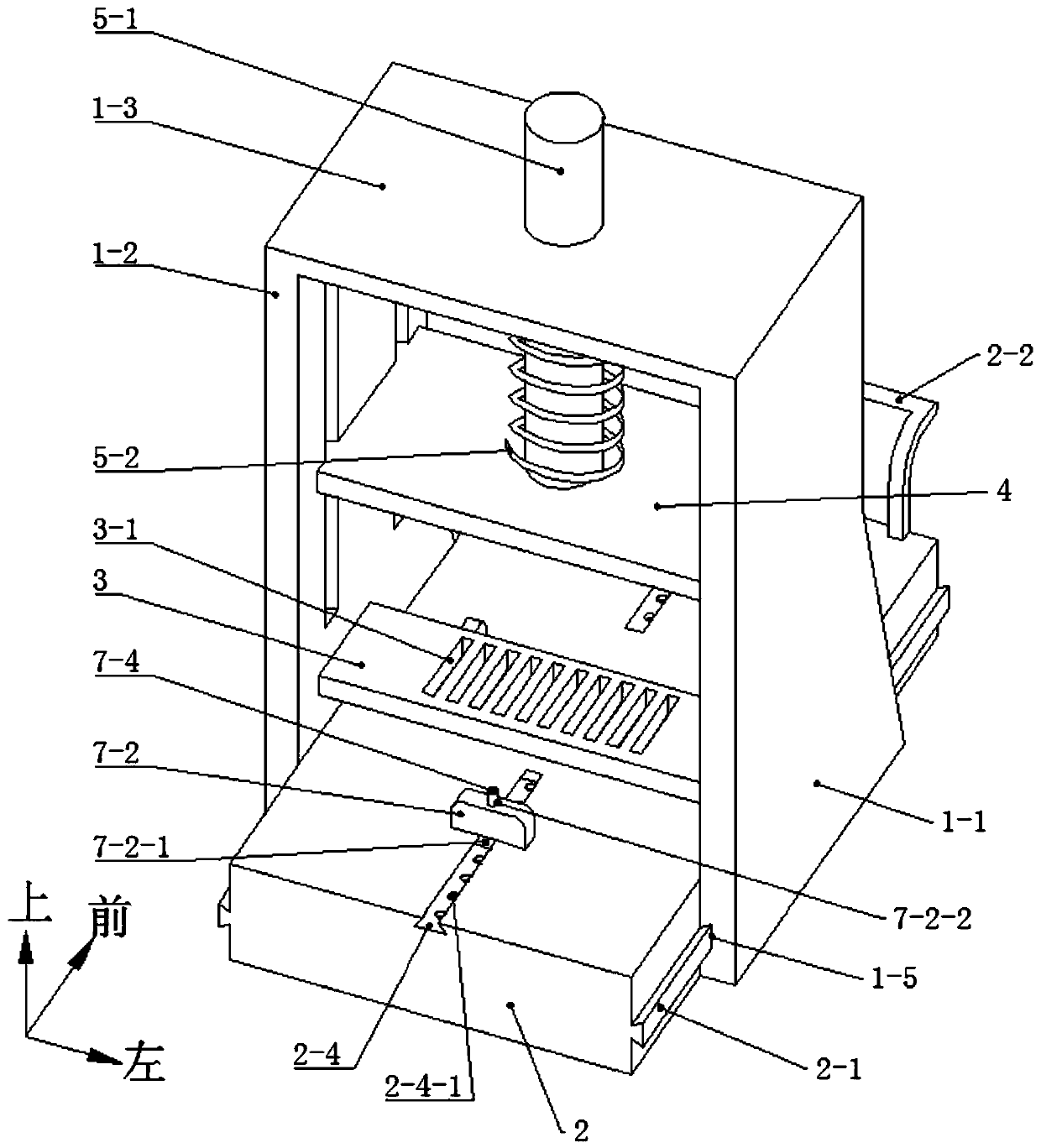

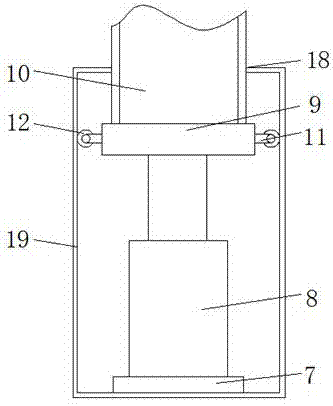

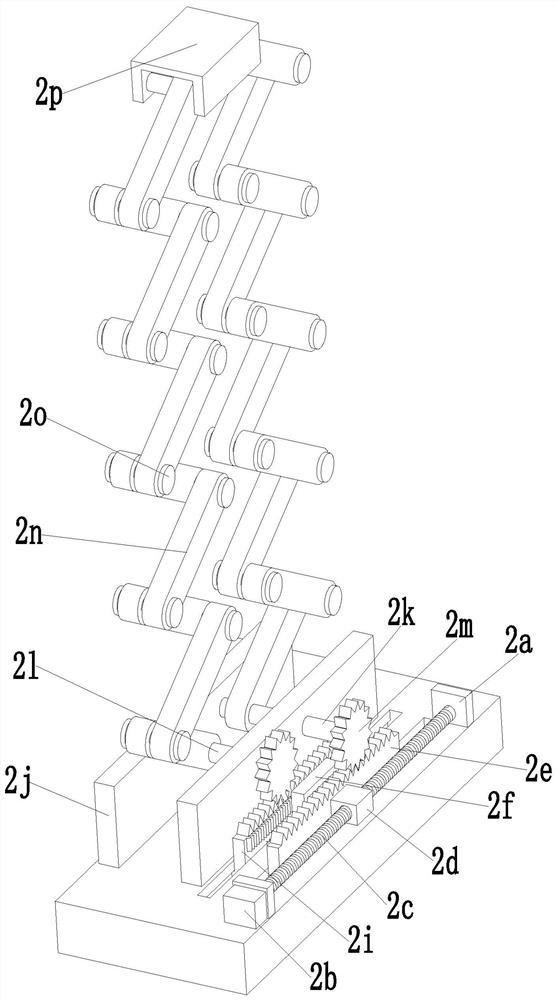

Batch installation device for memory banks of server mainboard

ActiveCN111258387AImprove installation efficiencyReduce labor intensityDigital processing power distributionComputer hardwareMemory bank

The invention discloses a batch installation device for memory banks of a server mainboard, and relates to the technical field of memory bank installation. The device comprises a support, a base, a memory bank loading plate and a mounting plate, the support comprises a first supporting plate, a second supporting plate and a top plate. The upper end of the first supporting plate and the upper end of the second supporting plate are connected with the top plate. The lower end of the first supporting plate and the lower end of the second supporting plate are both connected with the base, the installation plate and the memory bank loading plate are sequentially arranged between the top plate and the base from top to bottom, the installation plate is connected with the support through the lifting mechanism, the memory bank loading plate is connected with the support, and the memory bank loading plate is provided with a plurality of memory bank loading holes. Memory banks can be installed onthe server mainboard in batches, so that the labor intensity of operators is reduced, and the installation efficiency of the memory banks is improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

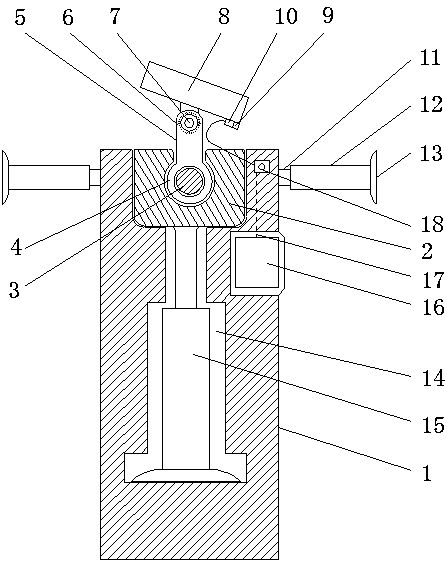

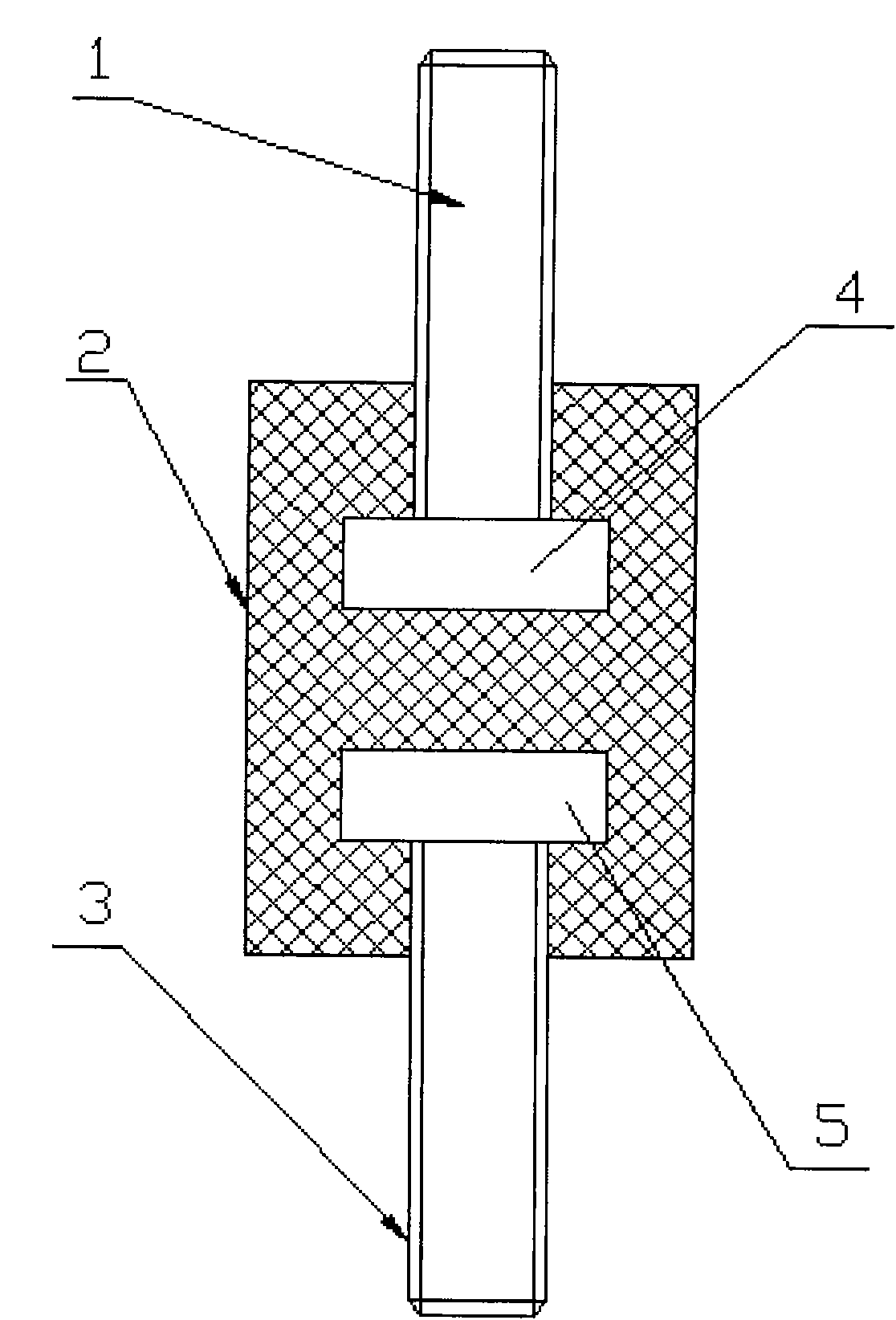

Shockproof insulation bolt structure of machine tool

InactiveCN102312892AReduce installation efficiencyIncrease costScrewsShock absorbersEngineeringMachine tool

The invention relates to a shockproof insulation bolt of a machine tool. The shockproof insulation bolt comprises an upper bolt, a connecting body, a lower bolt, an upper flange and a lower flange. The shockproof insulation bolt structure of the machine tool is provided with the upper bolt and the lower bolt, an upper flange and a lower flange are respectively arranged at one end of the upper bolt and one end of the lower bolt, one end of the upper bolt and one end of the lower bolt, which are provided with the flanges, are arranged oppositely, and the axial lines of one end of the upper bolt and one end of the lower bolt are coaxially fixed; and a connection body is made of elastic insulation rubber, and the upper bolt and the lower bolt are wrapped together by the connection body.

Owner:曹培娟

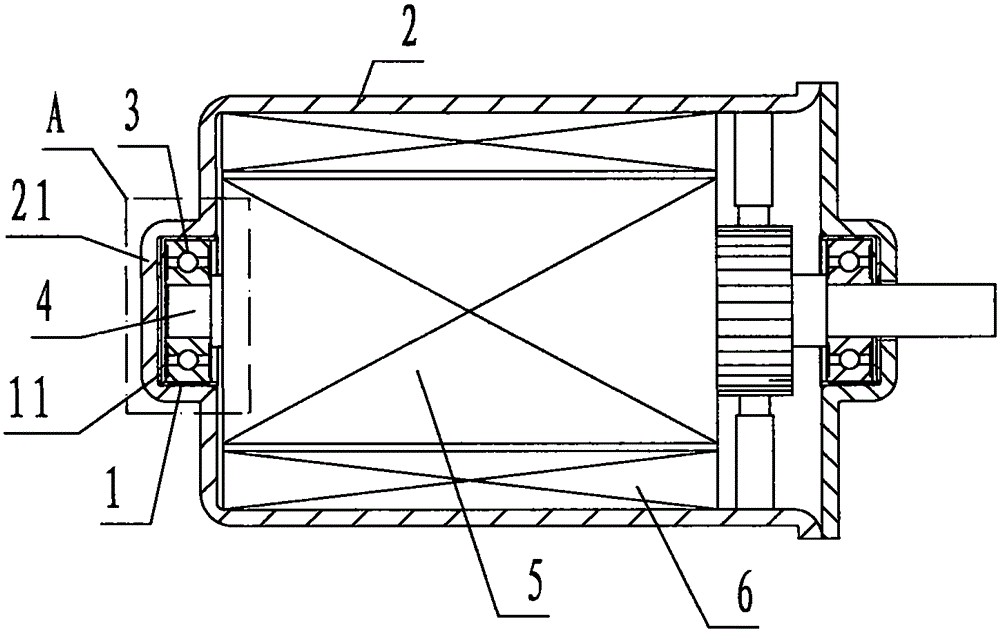

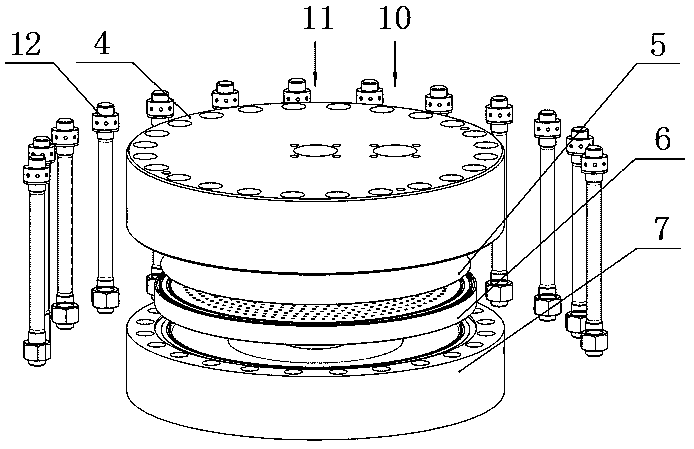

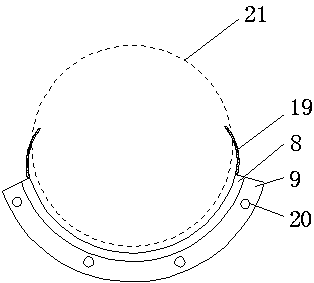

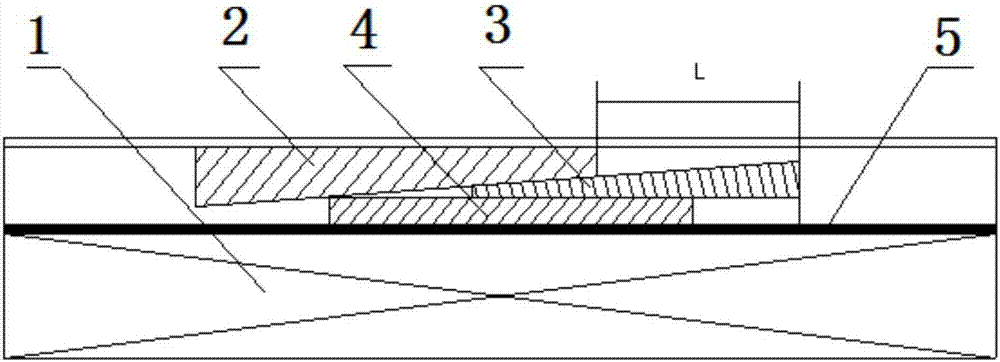

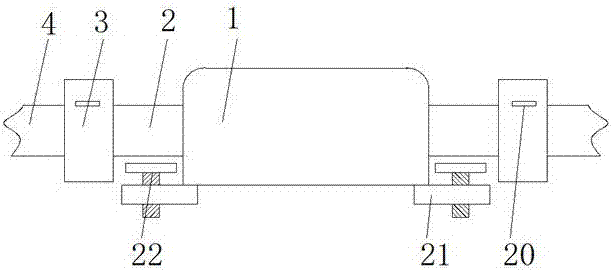

Technical method for checking corrugated plate tightness of hydro-generator stator

InactiveCN107346927AHigh measurement accuracyEasy to operateManufacturing dynamo-electric machinesCushionEngineering

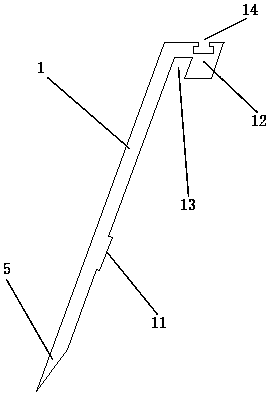

The invention is composed of a stator bar (1), a main slot wedge (2), a secondary slot wedge (3), a corrugated plate tightness check sample (4) and a cushion strip under wedge (5), wherein the cushion strip under wedge in proper thickness is placed on a linear section of the stator bar (1); the main slot wedge (2), the secondary slot wedge (3) and the corrugated plate tightness check sample (4) are placed into a slot; the secondary slot wedge (3) is located between the corrugated plate tightness check sample (4) and the main slot wedge (2); a slot wedge processing tool is used for tightening the secondary slot wedge (3), the exposing length of the secondary slot wedge (3) is measured as L=100-125mm and a vernier caliper is used for measuring the practical thickness of the cushion strip under wedge (5), and meanwhile, the cushion strip under wedge (5) in the slot meets a mounting requirement, a depth meter is used for measuring the compression amount of a corrugated plate and the radial height of the corrugated plate (6) is 1.25-1.40mm. According to the invention, the measurement accuracy of the compression amount of the corrugated plate is greatly increased, the operation is simple and convenient and the efficiency is high, so that the mounting period is saved.

Owner:HARBIN ELECTRIC MASCH CO LTD

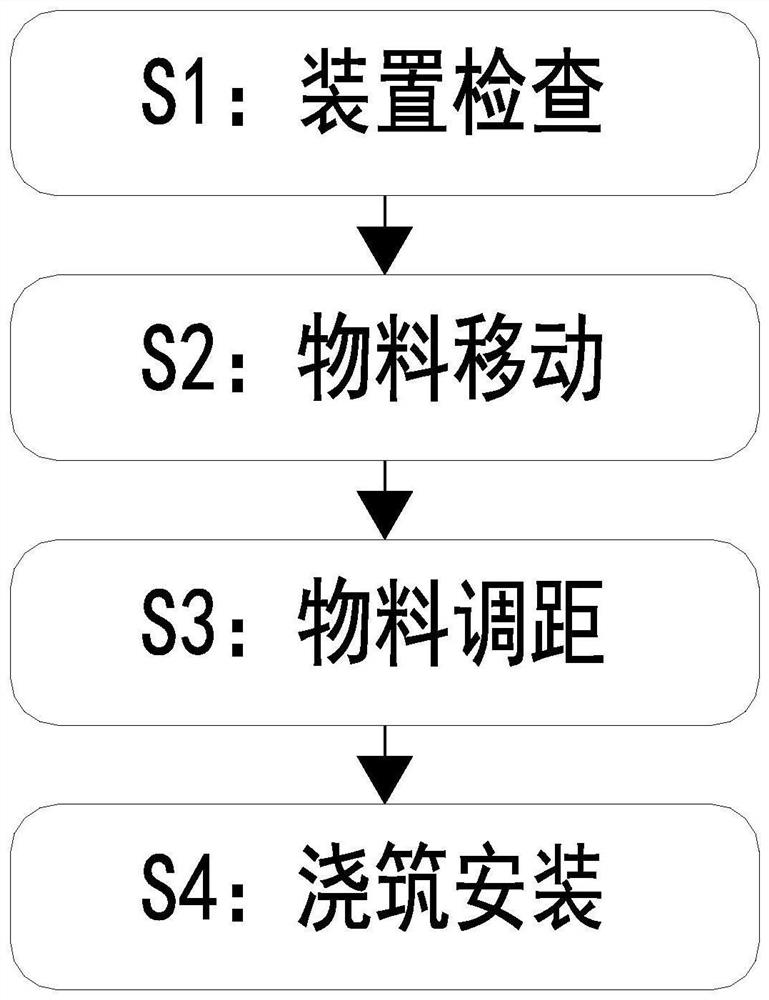

Prefabricated concrete part mounting and reinforcing method

ActiveCN113123611AReduce installation efficiencyEasily damagedBuilding material handlingStairwaysArchitectural engineeringMachine

The invention relates to a prefabricated concrete part mounting and reinforcing method. The prefabricated concrete part mounting and reinforcing method adopts a prefabricated concrete part mounting and reinforcing device as follows. The prefabricated concrete part mounting and reinforcing device comprises a base, walking wheels, an extending mechanism, an adjusting mechanism and a transmission mechanism. The walking wheels are arranged on the inner sides of corners of the lower end of the base, the extending mechanism is arranged on the right side of the base, the adjusting mechanism is arranged on the upper end face of the base, and the transmission mechanism is arranged at the upper end of the adjusting mechanism. According to the method, the problems that in the process of supporting and follow-up pouring installation of a concrete prefabricated staircase by putting up a bearing bracket, the time consumed in the putting up and disassembling process of the bearing bracket is usually long, and therefore the installation efficiency of the concrete prefabricated staircase is reduced; and in the process that the concrete prefabricated staircase is placed on the bearing bracket through a hoisting machine, the concrete prefabricated staircase easily collides with a wall and the bearing bracket can be solved.

Owner:泸州发展华西绿色建材有限公司

Water pump convenient for pipe installation

InactiveCN107575419ASolve the inconvenience of installationEasy to installPump componentsPumpsEngineeringWater body

The invention provides a water pump convenient for pipe installation and relates to the field of water pumps. The water pump convenient for pipe installation comprises a water pump body, wherein two sides of the water pump body are communicated with a connecting pipe; a fixed box is connected to one end, which is far away from the water pump body, of the connecting pipe in a sleeving manner; and acommunicating pipeline is overlapped at one end, which is far away from the water pump body, of the connecting pipe and positioned inside the fixed box. According to the water pump convenient for pipe installation, due to the fixed box arranged on one side of the connecting pipe, an effect of driving a movable rod to move is achieved under match of rollers, a fixed block and a movable block by virtue of retraction of an electric telescopic rod inside the fixed box, and the effect of driving a clamping ring to clamp and fixedly mount the connecting pipe and communicating pipeline inside the fixed box is achieved by matching a movable column and a slide block in case of movement of the movable rod. Therefore, pipe installation on the water pump is realized, and the problem that the conventional water pump is inconvenient for pipe installation during use is solved.

Owner:于浩

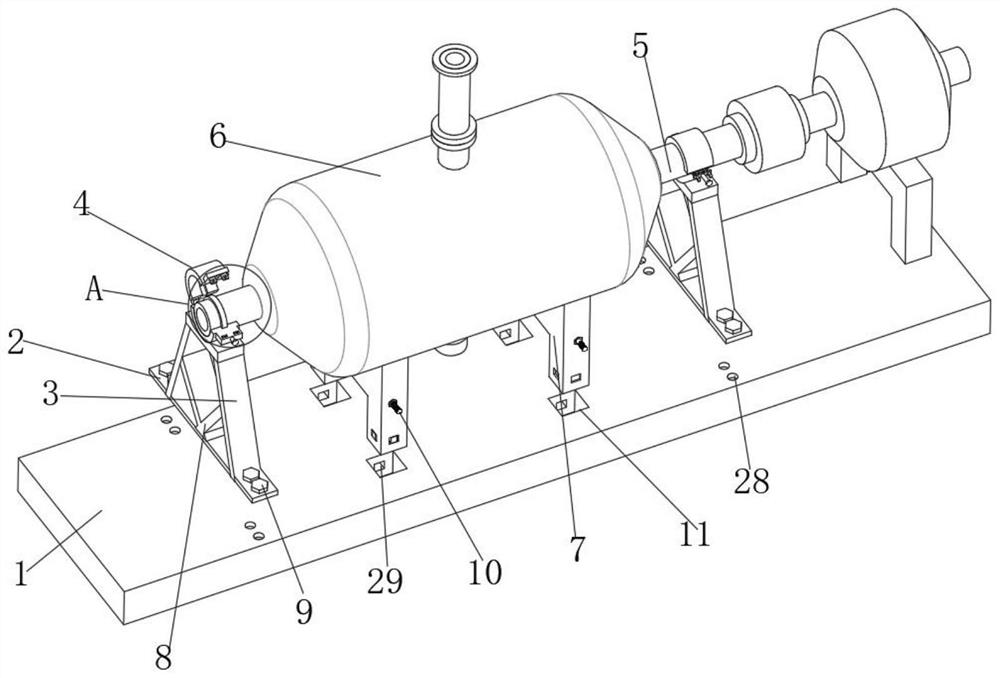

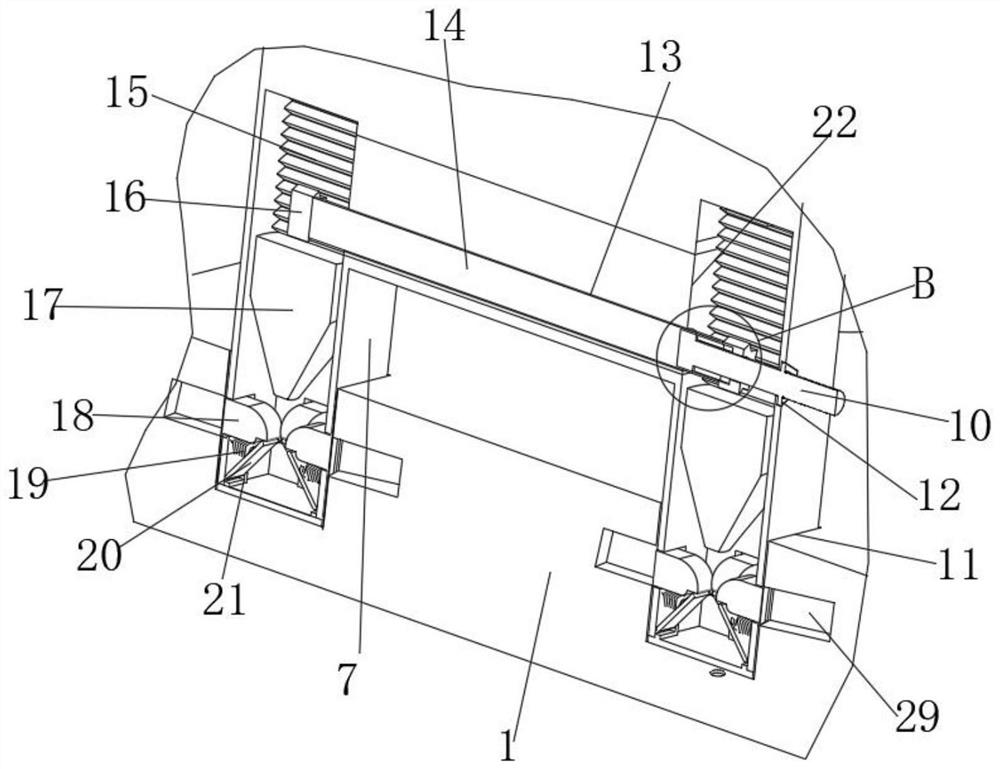

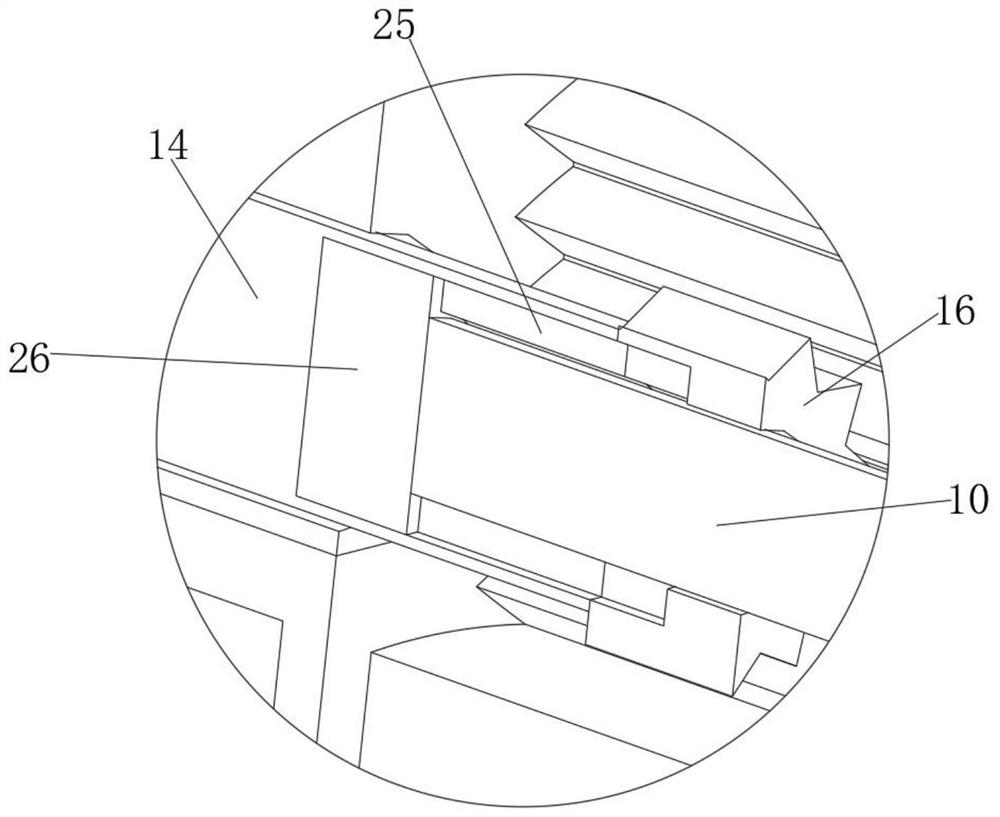

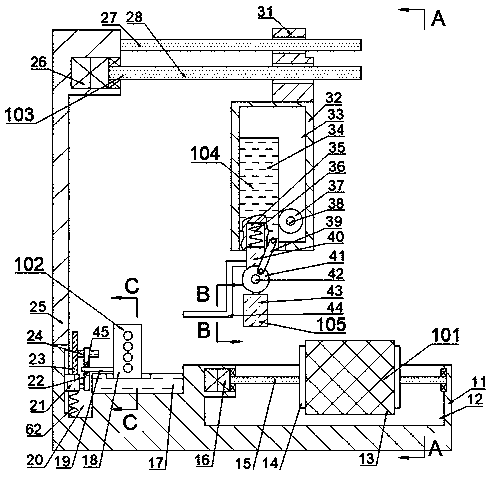

Multifunctional chemical equipment for preparing chemical raw material

InactiveCN113294655AStable installation and removalRelieve pressureStands/trestlesRaw materialSupport plane

The invention belongs to the technical field of chemical equipment, and particularly relates to multifunctional chemical equipment for preparing a chemical raw material. The multifunctional chemical equipment comprises a bottom plate, wherein the bottom plate is in screwed connection with a mounting plate through a bolt, the upper surface of the mounting plate is fixedly connected with a supporting frame, the interior of the supporting frame is fixedly connected with an auxiliary support, a bearing seat connected with a rotating bearing in a clamped mode is arranged at the upper end of the supporting frame, and the rotating bearing is arranged inside the bearing seat. The effects of strengthening the structural stability and sharing pressure are achieved through the arranged auxiliary support, the pressure of a main body on the supporting frame is reduced, the service life of the supporting frame is prolonged, and practicability is improved; an annular clamping block is clamped to an annular groove, connection between the rotating bearing and the bearing seat is convenient and fast, time is saved, the position is accurate, rotation is safer and stabler; and the main body and the bottom plate are more convenient to mount and dismount through rectangular clamping blocks and limiting grooves, the limiting effect is good, the labor amount is reduced, time is saved, and the mounting efficiency is improved.

Owner:YANCHENG INST OF IND TECH

GPU factory-leaving testing automatic installation device

InactiveCN110238625AAutomatic dockingRealize automatic wiring functionMetal working apparatusEngineeringTest platform

The invention discloses a GPU factory-leaving testing automatic installation device comprising a machine base. The machine base is internally provided with a conveying cavity with an upward opening, the conveying cavity is internally provided with a conveying device for conveying a GPU, a wiring device for wiring of the to-be-tested GPU is located on the left side of the conveying device and arranged on the end face of the upper side of the machine base, the end surface of the upper side of the machine base is provided with a plurality of stand columns located on the left side of the conveying device in an arrayed manner from front and back, the stand columns are provided with transverse movement devices used for achieving left-right transverse movement motion needed by installing the GPU, the transverse movement devices are internally provided with lifting devices, and the end face of the lower side of a rotating wheel is fixedly provided with a GPU clamp. By means of the GPU factory-leaving testing automatic installation device, the GPU is automatically inserted on a test platform, automatic wiring of the GPU is achieved, manual installation can be replaced, the installation efficiency is low, and the labor intensity of operators is reduced.

Owner:南京溧水高新产业股权投资有限公司

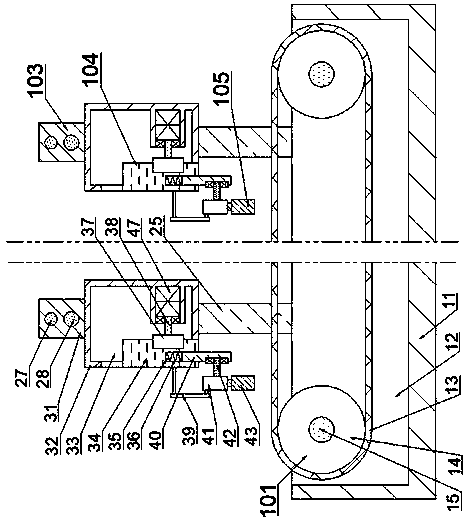

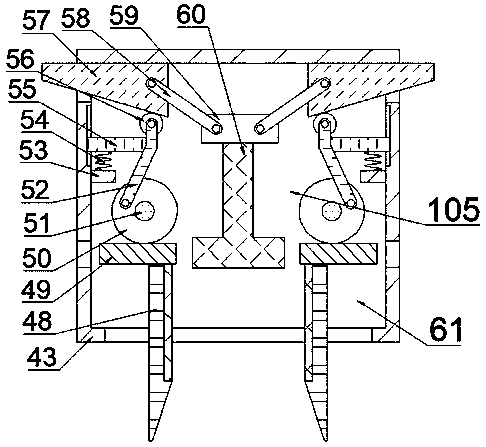

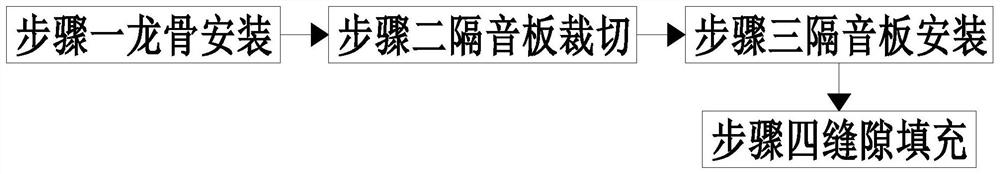

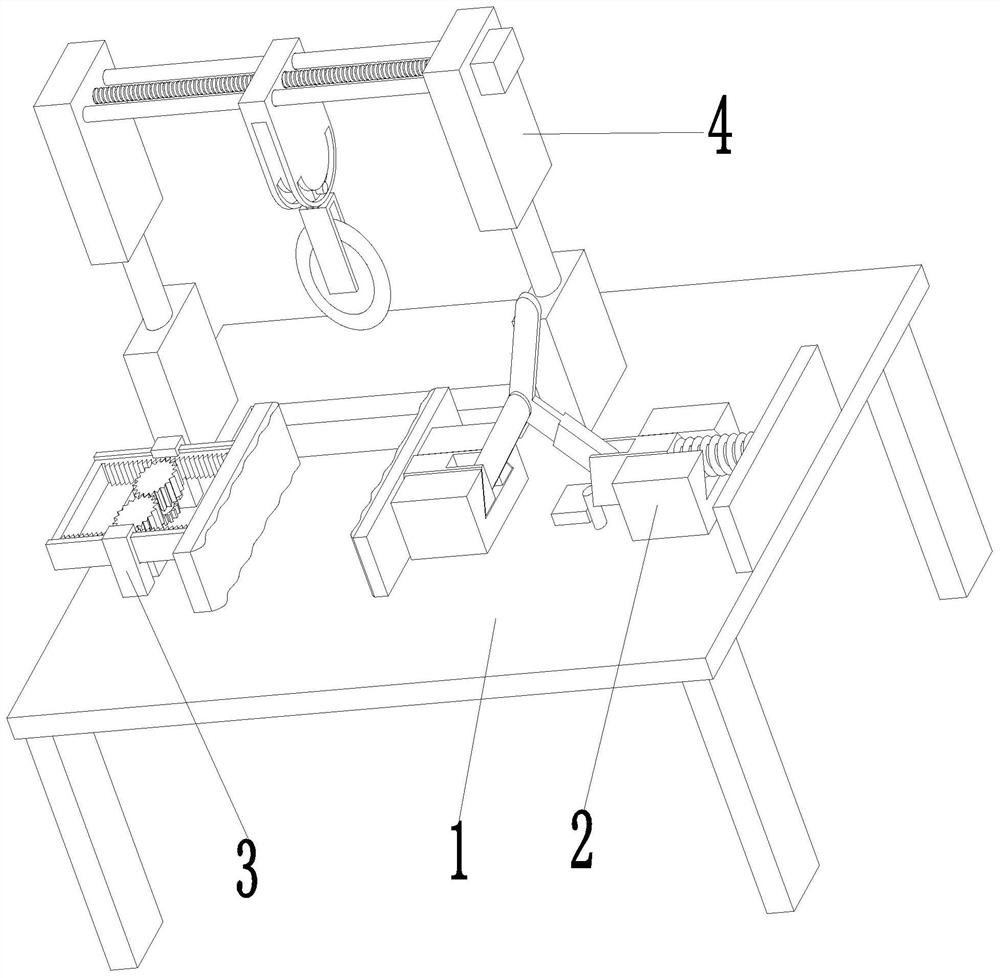

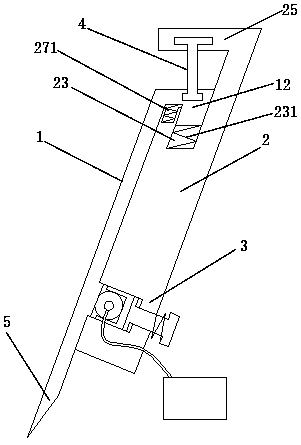

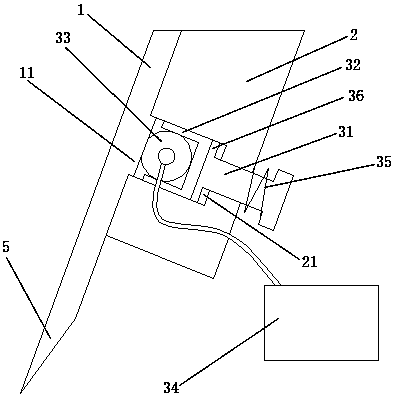

A cutting device for building sound insulation panels

InactiveCN111997213BReduce installation efficiencyImprove crop qualitySound proofingClassical mechanicsEngineering

The present invention relates to a cutting device for building sound insulation panels. The method for installing the sound insulation panels using the cutting equipment for building sound insulation panels mainly includes the following steps: keel installation, sound insulation panel cutting, and sound insulation panel installation As well as various processes such as gap filling, the sound insulation panel cutting equipment used includes a bottom plate, a positioning device, a pressing device and a cutting device. The present invention can solve the following problems existing in the existing sound insulation panel cutting, a. Traditional When cutting the sound insulation board, it is necessary to manually hold the cutting tool to cut the sound insulation board. The safety hazard of manual cutting of the sound insulation board is relatively large, and the labor intensity of manual cutting is high, and the cutting efficiency is low, which reduces the quality of the sound insulation board. For the efficiency of installation, the manually cut sound insulation panels often have burrs, which affects the use of the sound insulation panels.

Owner:安徽中南天开建设集团有限公司

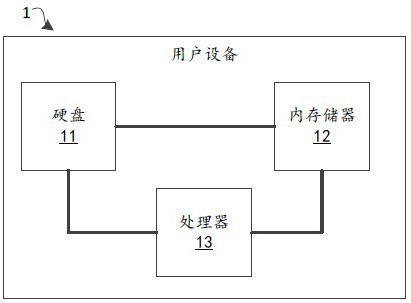

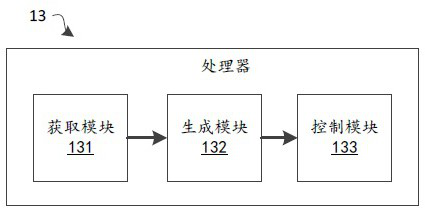

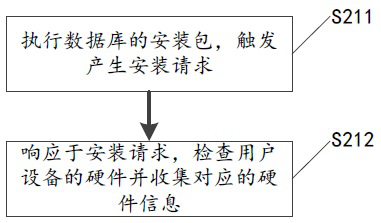

Database installation method based on AI configuration, user equipment and storage medium

PendingCN111949281AImprove stabilitySave applicabilitySpecial data processing applicationsSoftware deploymentUser deviceEngineering

The invention discloses a database installation method based on AI configuration, user equipment and a storage medium, and the method comprises the steps: responding to an installation request of a database on the user equipment to acquire hardware information of the user equipment; processing the hardware information through a preset AI configuration model, and generating and obtaining configuration parameters of a database; and performing installation control on the database according to the configuration parameters. According to the technical scheme, configuration information can be flexibly generated in the database installation process, and the installation process is automatically set, so that storage resources are better saved, the system installation efficiency is improved, the high stability of the database is ensured, and the application performance of the database can be improved; and meanwhile, the error rate of manual operation can be reduced, the labor cost required by later operation and maintenance of the database is saved, and the exception caused in the database tuning process is effectively avoided, so that the installation and use experience of a user on the database is improved.

Owner:深圳市广通软件有限公司

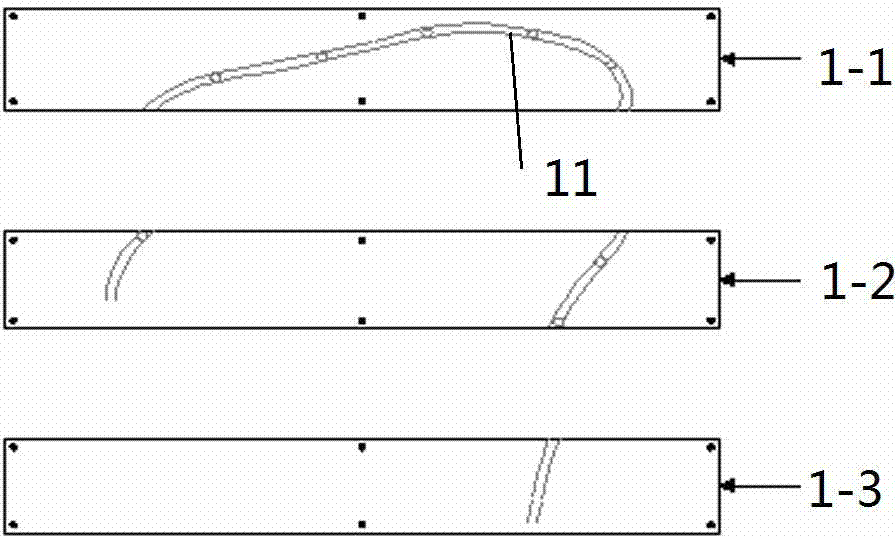

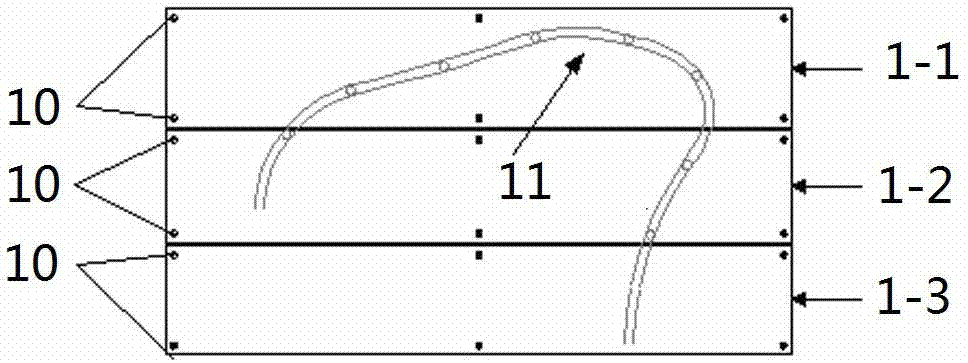

Multi-radian special steel reticulated shell structure manufacture method

The invention discloses a multi-radian special steel reticulated shell structure manufacture method. The multi-radian special steel reticulated shell structure manufacture method comprises the steps of first performing simmer bending on steel tubes to make into multi-radian bent tubes, next performing sample plate manufacture on the multi-radian bent tubes, then performing radian checking and fine adjustment on the multi-radian bent tubes, performing assembling on the multi-radian bent tubes when the radians of the multi-radian bent tubes are qualified, wherein the assembling method is that the a tiled horizontal type circulation reverse assembling method is adopted to perform grouping assembling and pre-assembling between groups on the multi-radian bent tubes through an assembling jig frame of a multi-radian special steel reticulated shell structure, removing the pre-assembling between the groups, performing vertical type installation on each group of the multi-radian bent tubes, performing connection on the groups, accomplishing the manufacture of the whole multi-radian special steel reticulated shell structure. The multi-radian special steel reticulated shell structure manufacture method can enable the manufacture of the multi-radian special steel reticulated shell structure to be rapid, accurate and safe.

Owner:WUHAN YIYE STEEL STRUCTURE

Automatic assembly production line of buzzers

ActiveCN102848187BGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Baking oven convenient for carbon discharge

InactiveCN105747903AReduce installation efficiencyEasy to installRoasters/grillsCooking & bakingEngineering

The invention discloses a baking oven convenient for carbon discharge. The baking oven comprises an oven body, an oven cover and support columns, wherein the oven cover is arranged at the upper end of the oven body; the support columns are arranged at the lower end of the oven body; a smoke outlet pipe and an air inlet are respectively formed in the two sides of the oven body; an object carrying plate, a carbon plate and a carbon discharge channel are arranged in the oven body; the object carrying plate, the carbon plate and the carbon discharge channel are of an integral fixing structure; the object carrying plate is fixed with the carbon plate through fixing columns; the carbon discharge channel is of a big-end-up conical structure and is fixedly arranged under the carbon plate; a carbon accommodating tank is arranged between the two support columns. According to the baking oven disclosed by the invention, carbon dust falling from the carbon plate can be directly collected in the carbon accommodating tank; then, the carbon accommodating tank can be taken out in sliding and pulling manners for carbon dust cleaning, so that convenience and quickness are realized.

Owner:JIANGSU FEINIDI METAL PROD

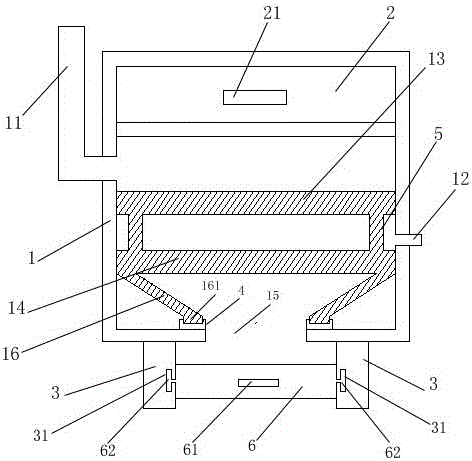

Pipeline installation construction method for water supply and drainage engineering of building

InactiveCN112249962AIncrease costImprove efficiencyPipe laying and repairConveyorsEnvironmental geologyWater supply

The invention relates to a pipeline installation construction method for water supply and drainage engineering of a building. The pipeline installation construction method for the water supply and drainage engineering of the building mainly comprises the following steps: design preparation, installation working, detection working and the like, wherein used water drainage pipeline installation equipment comprises a bottom plate, a lifting device, an adjusting device and a clamping device. According to the invention the following problems in existing water drainage pipeline installation can be solved: a, when a traditional water drainage pipeline is installed, a plurality of workers need to cooperate to convey a water drainage pipeline to a proper installation position, the installation method consumes labor and time, and is high in difficulty and cost, the workers are prone to fatigue during installation process, and when the pipeline inclines and topples over, even the workers can be injured; and b, the existing water drainage pipeline installation equipment cannot carry out stable clamping working on the water drainage pipeline and cannot carry out adjustment working during pipeline connection, so that the installation efficiency for the water drainage pipeline is reduced, and the conveying efficiency for the water drainage pipeline can be increased.

Owner:汪美霞

Pneumatic roller scraping mechanism

The invention discloses a pneumatic roller scraping mechanism. The mechanism comprises a fixed plate, a scraping plate, a trimming mechanism, wherein the scraping plate is arranged on one side of thefixed plate; a mounting groove is arranged under the fixed plate; a threaded channel is formed in one side of the mounting groove, and is communicated with the mounting groove; the trimming mechanismcomprises a trimming screw, a movable sleeve, an air pipe, an air pump and an elastomer; the movable sleeve has a U-shaped structure with one opening side; the movable sleeve is arranged in the mounting groove; the air pipe is arranged in the movable sleeve; the air pump is connected with the air pipe; the trimming screw is connected in the threaded channel in a threaded running-through manner, penetrates through the threaded channel and extends into the mounting groove; the trimming screw is used for pushing the movable sleeve to move, and the movable sleeve is used for driving the air pipe to move; the elastomer is connected to the outside of the trimming screw in a sleeving manner; and elastomer is elastically compressed between the end part of the trimming screw and the outer side of the fixed plate. The pneumatic roller scraping mechanism realizes multiple trimming for the scraping plate.

Owner:江苏海特尔机械有限公司

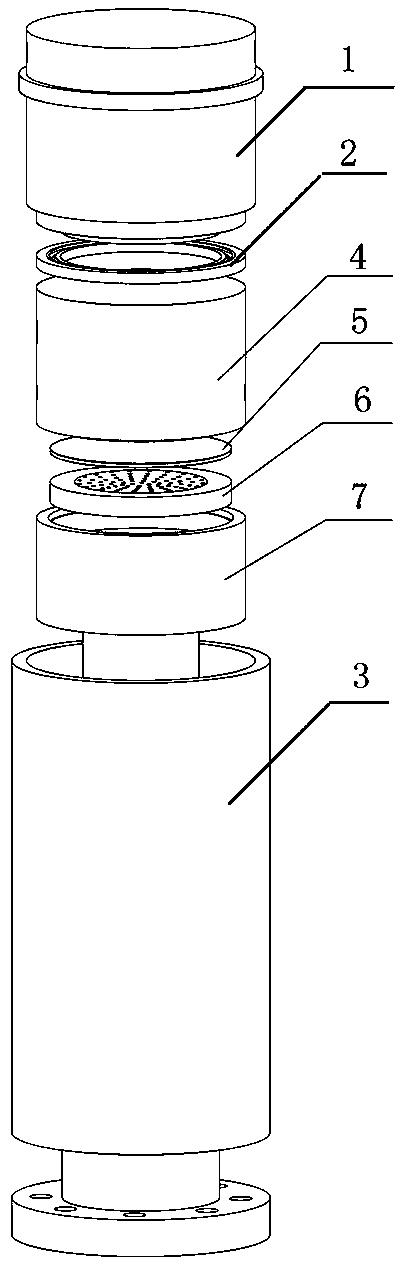

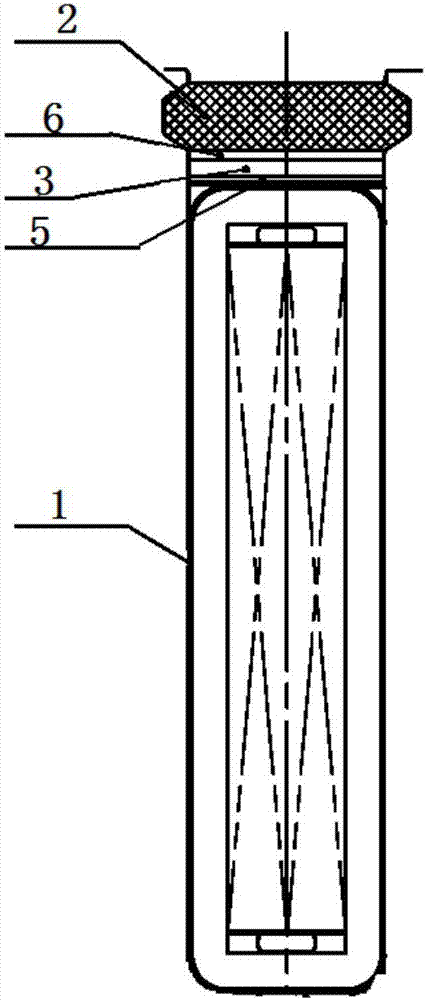

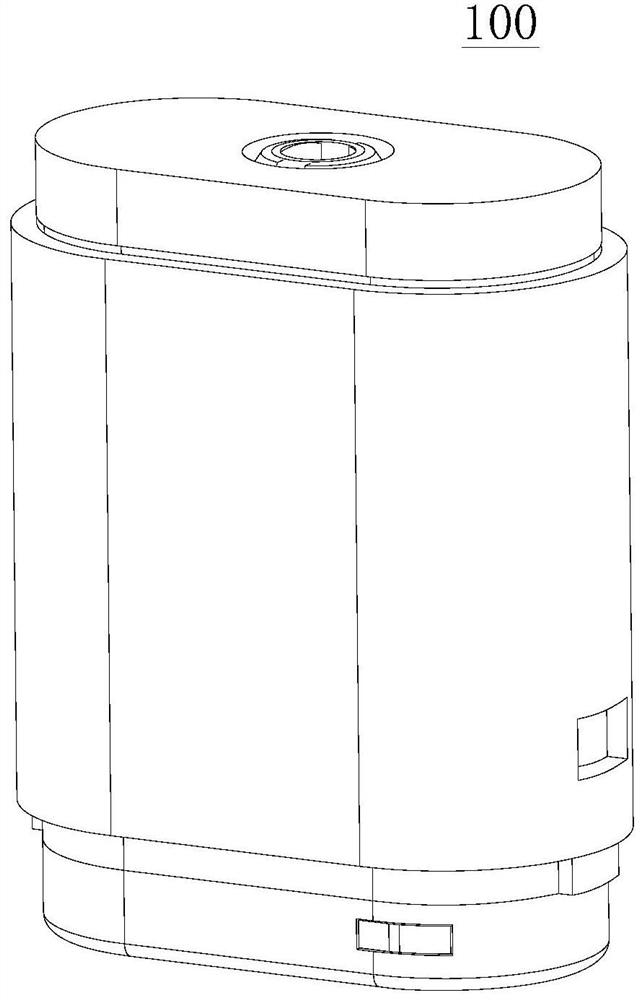

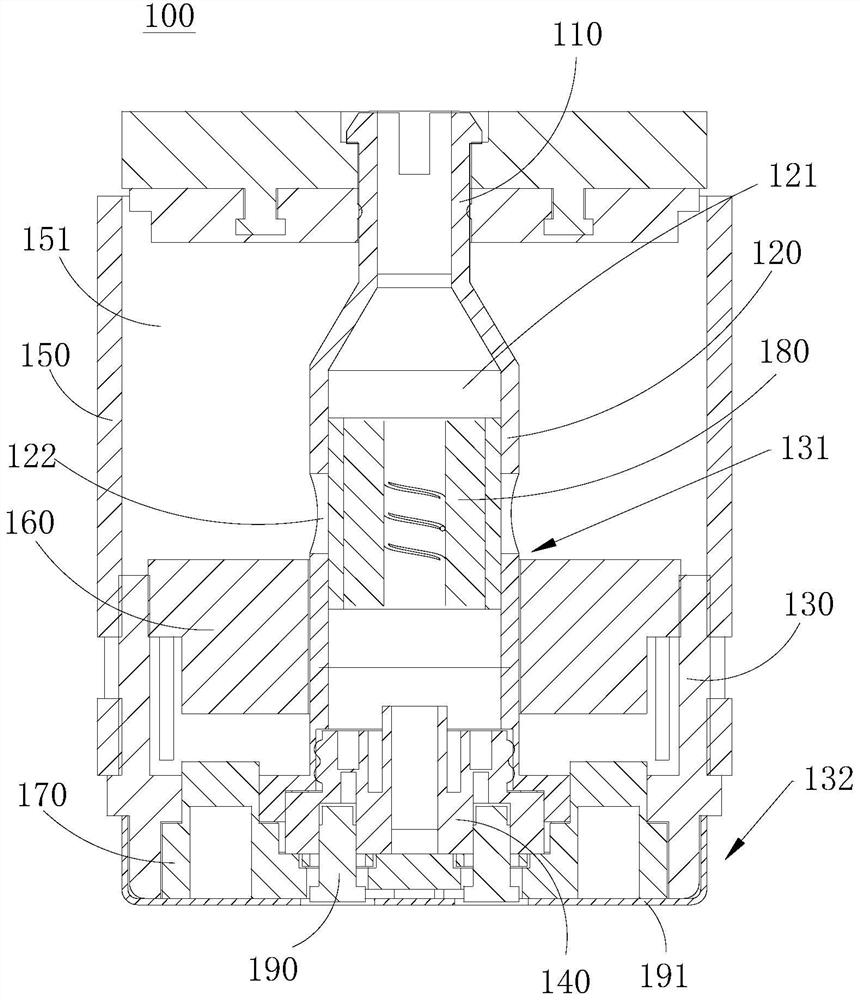

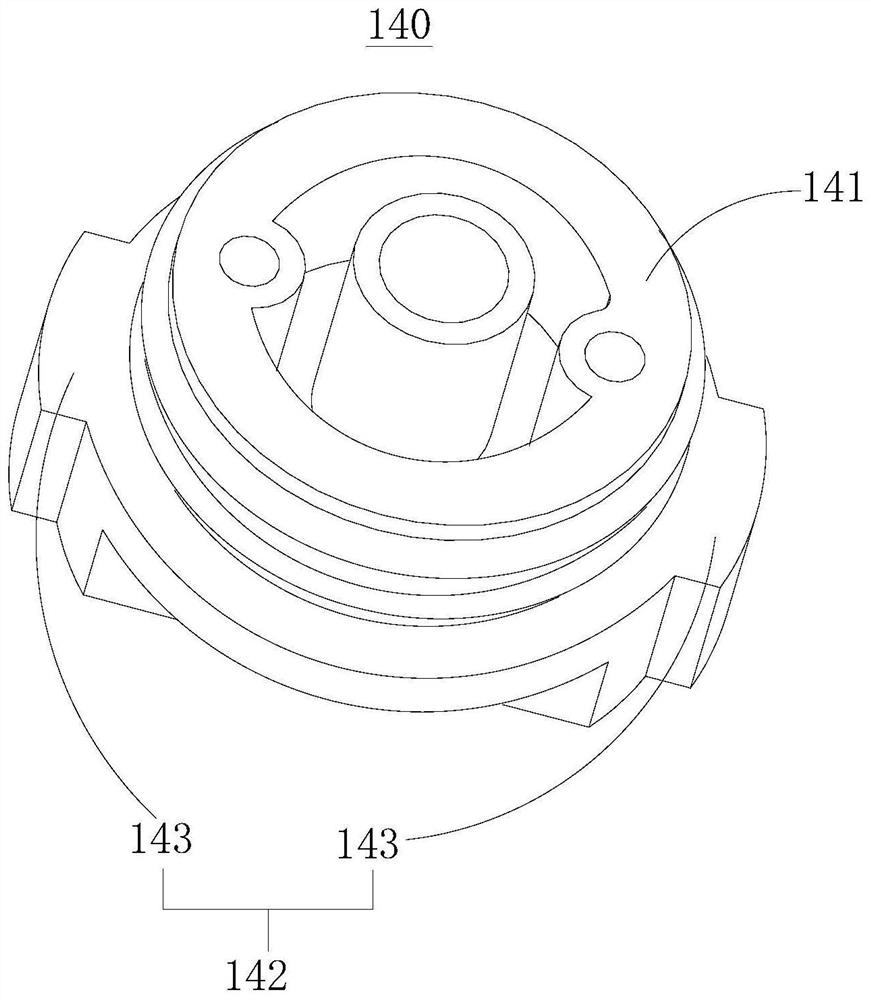

Atomizer and electronic atomization device

Owner:JIANGMEN MOORE TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com